WACKER Group LTC 4 Repair Manual

www.wackergroup.com

Light Tower

LTC 4

REPAIR MANUAL

0160487en 003

0206

0160487EN

LTC Repair Foreword

wc_tx000424gb.fm i

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or repair it. Basic operating and maintenance

procedures are described in the Operator’s Manual supplied with the

machine. Keep a copy of the Operator’s Manual with the machine at all

times. Use the separ ate Parts Book supp lied with the mach ine to order

replacement parts. If you are missing either of the documents, please

contact Wacker Corporation to order a replacement.

Damage caused by misuse or neg lect of the unit should be brough t to

the attention of the operator to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safe ly repair and

maintain the above Wacker model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLIC ATION. WACKER

CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

This manual covers machines with Item Number:

0009375, 0009376, 0620017, 0620018, 0620028

Foreword LTC Repair

wc_tx000424gb.fm ii

CALIFORNIA

Proposition 65 Warning:

Diesel engine exhaust, some of its constituents, and certain vehicle

components contain or em it chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

All rights, especially copying and distribution ri ghts, are reserved.

Copyright 2006 by Wacker Corporation

No part of this pu blication may be rep roduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights, and

violators will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

WARNIN

G

LTC Repair Table of Contents

wc_br0160487en_003TOC.fm 1

1. Safety Information 6

1.1 Laws Pertaining to Spark Arresters ...................................................... 6

1.2 Operating Safety .................................................................................. 7

1.3 Operator Safety while using Internal Combustion Engines .. ..... .... ..... .. 8

1.4 Towing Safety ....................................................................................... 9

1.5 Service Safety ....................................................................................10

1.6 Label Locations .................................................................................. 11

1.7 Safety and Operating Labels .............................................................. 13

2. Technical Data 19

2.1 Engine ................................................................................................ 19

2.2 Generator ........................................................................................... 20

2.3 Machine .............................................................................................. 21

3. Operation 23

3.1 Information Regarding Operation ....................................................... 23

3.2 Locating Trailer ................................................................................... 23

3.3 Leveling Trailer ................................................................................... 24

3.4 Adjusting Lights ..................................................................................24

3.5 Preparing Trailer for Towing or Lifting ................................................25

3.6 Raising Tower (Manual Winch System) ............................................. 26

3.7 Lowering Tower (Manual Winch System) ........................................... 28

3.8 Raising Tower (Power Winch System) ............................................... 30

3.9 Lowering Tower (Power Winch System) ............................................ 32

3.10 Emergency Crank Handle (Power Winch System) ............................. 33

3.11 Control Panels—Lombardini (Manual Winch System) ....................... 34

3.12 Control Panels—Lombardini (Power Winch System) ......................... 35

3.13 Control Panels—CAT (Manual Winch System) .................................. 36

3.14 Control Panel—CAT (Power Winch System) ..................................... 37

3.15 Starting—Lombardini .......................................................................... 38

3.16 Starting—CAT .................................................................................... 39

3.17 Automatic Shutdown ..........................................................................39

3.18 Operating Lights ................................................................................. 40

3.19 Stopping—Lombardini ........................................................................ 40

3.20 Stopping—CAT .................................................................................. 40

3.21 Derating .............................................................................................. 40

Table of Contents LTC Repair

wc_br0160487en_003TOC.fm 2

3.22 Receptacles—60 Hz ............................................................................41

4. Maintenance 42

4.1 Periodic Maintenance Schedule—Lombardini ....................................42

4.2 Periodic Maintenance Schedule—CAT ...............................................43

4.3 Daily Inspection ...................................................................................43

4.4 Installing / Removing Light Fixtures ....................................................44

4.5 Precautions When Replacing / Removing Bulbs .................................45

4.6 Replacing Bulbs ................................... ..... ..... .... .................................46

4.7 Air Cleaner ..........................................................................................47

4.8 Engine Oil ............................................................................................48

4.9 Generator Capacitor Excitation Schematic 60 Hz ...............................49

4.10 Schematic for 60 Hz Metal Halide 4-Light Units ..................................50

4.11 Metal Halide Schematic Components .................................................51

4.12 Engine Wiring—Lombardini 1003 ........................................................52

4.13 Engine Wiring Components—Lombardini 1003 ..................................53

4.14 Engine Control Panel Internal Wiring—Lombardini 1003 ....................54

4.15 Engine Wiring—Lombardini 903 ..........................................................55

4.16 Engine Control Panel Internal Wiring—Lombardini 903 ......................56

4.17 Engine Control Panel Components—Lombardini ................................57

4.18 Engine Wiring—Item Number: 0009376 ..............................................58

4.19 Engine Wiring—Item Number: 0620017, 0620028 ..............................59

4.20 Power Winch Schematic .....................................................................60

4.21 Trailer Wiring .......................................................................................61

5. Lombardini Engin e Troubl eshooting 62

5.1 Troubleshooting Flowcharts ................................................................62

5.2 Engine Does Not Crank—Flowchart 3A ..............................................63

5.3 Checking Keyswitch and Wiring ..........................................................64

5.4 Replacing Keyswitch ...........................................................................66

5.5 Engine Cranks But Does Not Start—Flowchart 4A .............................67

5.6 Checking Fuel System ........................................................................68

5.7 Checking Voltage to Glow Plugs (Lombardini 903 engines) ...............69

5.8 Checking Voltage to Glow Plugs (Lombardini 1003 engines) .............70

5.9 Checking Glow Plug Relay ..................................................................71

5.10 Replacing Glow Plug Relay .................................................................71

5.11 Checking Glow Plugs ..........................................................................72

LTC Repair Table of Contents

wc_br0160487en_003TOC.fm 3

5.12 Engine Shuts Down—Flowchart 5A ................................................... 73

5.13 Checking Oil Pressure and Coolant Temperature Switches .............. 74

5.14 General Engine Troubleshooting ........................................................ 75

6. Caterpillar Engine Troubleshooting 78

6.1 Troubleshooting Flowcharts ..................... ..... .... .................................78

6.2 Engine Does Not Crank—Flowchart 6A ........................................... 79

6.3 Checking Keyswitch and Wiring ......................................................... 80

6.4 Replacing Keyswitch .......................................................................... 81

6.5 Engine Cranks But Does Not Start—Flowchart 7A ............................82

6.6 Checking Fuel Flow ............................................................................ 83

6.7 Checking Glow Plug Wiring ................................................................ 84

6.8 Checking Glow Plugs ......................................................................... 84

6.9 Engine Shuts Down—Flowchart 8A ................................................... 85

6.10 Checking Oil Pressure and Coolant Temperature Switches .............. 86

6.11 General Engine Troubleshooting ........................................................ 87

7. Electrical Troubleshooting Procedures 90

7.1 Troubleshooting Methodology .............................................. ..... .... .....90

7.2 Schematic Components ..................................................................... 90

7.3 Schematic for 60 Hz Metal Halide 4-Light Units ................................. 91

7.4 Checking Continuity ...........................................................................92

7.5 Checking resistance ........................................................................... 92

7.6 Checking voltage ................................................................................ 92

7.7 Troubleshooting Flowcharts ..................... ..... .... .................................92

7.8 Lights do not Illuminate—Flowchart 1A ......................................... .....93

7.9 Lights do not Illuminate—Flowchart 1B ......................................... .....94

7.10 Lights do not Illuminate—Flowchart 1C ..............................................95

7.11 Lights do not Illuminate—Flowchart 1D ............................................. 96

7.12 Checking Engine Speed ..................................................................... 97

7.13 Checking Generator Voltage at Receptacle .......................................98

7.14 Replacing Receptacle ........................................................................99

7.15 Checking Voltage to the Main Circuit Breaker .................................. 100

7.16 Checking Voltage Between Main Circuit Breaker and Terminal Strip 102

7.17 Checking Individual Circuit Breakers ................................................ 104

7.18 Confirming a Malfunctioning Circuit Breaker .................................... 106

7.19 Checking Incoming Voltage to Control Panel Capacitor(s) .............. 107

Table of Contents LTC Repair

wc_br0160487en_003TOC.fm 4

7.20 Checking Outgoing Voltage from Control Panel Capacitor(s) ...........108

7.21 Confirming a Faulty Control Panel Capacitor ....................................109

7.22 Checking Wiring to/from Ballast(s) ....................................................110

7.23 Replacing Ballast ......................... ..... .................................................112

7.24 Restoring Rotor Magnetism (Flashing) / Checking Roto r Winding ....114

7.25 Checking Generator Capacitors ........................................................116

7.26 Alternative Capacitor Check ..............................................................117

7.27 Replacing Generator Capacitor(s) ........................... ..... .... ..... ............118

7.28 Checking Stator Windings .................................................................120

7.29 Removing/Installing Caterpillar Engine with Generator .....................122

7.30 Removing/Installing Lombardini Engine with Generator ...................124

7.31 Separating Stator Assembly from Engine/Rotor Assembly ...............126

7.32 Remounting Stator Assembly to Rotor/Engine Assembly .................128

7.33 Checking Rotor Diodes .....................................................................129

7.34 Checking Rotor Windings ..................................................................130

7.35 Removing/Installing Rotor .................................................................131

7.36 No Voltage at Receptacle—Flowchart 2A .........................................132

7.37 Checking Voltage at Receptacle .......................................................133

7.38 Checking Receptacle’s Circuit Breaker .............................................134

7.39 Troubleshooting the Power Winch ....................................................136

8. Disassembly/Assembly Procedures 139

8.1 Tools ..................................................................................................139

8.2 Ordering Parts ...................................................................................139

8.3 Reference Numbers ( ) ................................................. .... .................139

8.4 Weight Block .....................................................................................139

8.5 Light Assembly ..................................................................................140

8.6 Tower Assembly Exploded View .......................................................142

8.7 Tower Assembly List of Parts ............................................................143

8.8 Upper Mast ........................................................................................143

8.9 Mid Mast ............................................................................................146

8.10 Main Mast ..........................................................................................148

8.11 Replacing Cable and Winch on Power Winch Models ......................152

8.12 Replacing Fuel Tank ............................................... ..... .... .................154

8.13 Replacing Hour Meter ............................................. ..... .... .................156

LTC Repair Table of Contents

wc_br0160487en_003TOC.fm 5

Safety Information LTC Repair

wc_si000164gb.fm 6

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note: Contains additional information important to a procedure.

1.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

DANGER

WARNIN

G

CAUTION

LTC Repair Safety Information

wc_si000164gb.fm 7

1.2 Operating Safety

Familiarity and proper train ing are required for the safe operation of

equipment. Equi p me nt o pe ra te d i m properly or by untr ained personnel

can be dangerous. Read the operating instructions contained in both

this manual and the engine manual and familia rize yourself with the

location and prop er use of al l controls. In experienced op erators should

receive instruction from someone familia r with the equipment before

being allowed to operate the ma chine.

1.2.1 The area immediately surrounding the Light Tower should be clean,

neat, and free of debris.

1.2.2 ALWAYS be sure the machine is o n a firm, level surface and will not

tip, roll, slide, or fall while operating.

1.2.3 NEVER start a unit in need of repair.

1.2.4 Lower the tower when not in use, or if high winds or electrical storms

are expected in the area.

1.2.5 ALWAYS make certain the machine is well-grounded and securely

fastened to a good earthen ground per national and local regulations.

1.2.6 The tower extends up to 9 m (30 ft.). Make sure the area above the

trailer is open and clear of overhead wires and obstructions.

1.2.7 The bulbs become extremely hot in use! Allow the bulb and fixture to

cool 10–15 minutes before handling.

1.2.8 Keep the area behind the trailer clear of people while raising and

lowering the mast! Never raise, lower or turn the mast while unit is

operating!

1.2.9 The trailer must be leveled and the outriggers extended before raising

the tower. The outr iggers mu st remain extend ed while the tower is u p.

1.2.10 If for any reason any part of the mast hangs up or the winch cable

develops slack while raising or lowering the tower, STOP immediately!

Contact an authorized WACKER service representative.

1.2.11 NEVER remove the mast locking pin while the tower is up!

1.2.12 NEVER use the machin e if the insulation on the electrical cord is cut or

worn through.

1.2.13 NEVER operate the l igh ts w it ho ut th e p ro tect i ve le ns co ver i n place or

with a lens cover that is cracked or damaged!

1.2.14 NEVER adjust the mast while the unit is operating.

1.2.15 NEVER raise the mast or operate the Light Tower in high winds.

WARNIN

G

Safety Information LTC Repair

wc_si000164gb.fm 8

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion eng ine s present sp ecial ha zard s during op eratio n

and fueling. Read and follow the warning instructions in the engine

owner’s manual and t he saf ety gu ideli nes belo w. Failu re to follow the

warnings and saf ety guidelines could result in severe injury or death.

1.3.1 NEVER operate the machine indoors unless exhaust fumes can be

adequately ventilated.

1.3.2 DO NOT fill or dr ain the fue l tank ne ar an open flame , wh ile smo kin g,

or while the engine is running.

1.3.3 ALWAYS refill the fuel tank in a well-ventilated area.

1.3.4 DO NOT touch or lean against hot exhaust pipes.

1.3.5 ALWAYS replace the fuel tank cap after refueling.

1.3.6 DO NOT remove radiator cap when the engine is hot . The radiator fluid

is hot and under pressure and may cause severe burns!

1.3.7 DO NOT use gasoline or other type s of fu el s or flam ma bl e so lvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.3.8 ALWAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A hot muffler could ignite the debris and

start a fire.

DANGER

LTC Repair Safety Information

wc_si000164gb.fm 9

1.4 Towing Safety

Towing a large trailer requires special care. Both the trailer and vehicle

must be in good condition and securely fastened to each other to

reduce the possibility of an accident.

1.4.1 ALWAYS check that the hitch and coupling on the vehicle are rated

equal to, or greater than, the trailer's “gross vehicle weight rating”

(GVWR).

1.4.2 ALWAYS inspect the hitch and coupling fo r wear or dam age. DO NOT

tow the trailer using defective parts.

1.4.3 ALWAYS make sure the coupling is securely fastened to the vehicle.

1.4.4 ALWAYS check the tires on the trailer for tread wear, inflation, and

condition. Replace worn tires.

1.4.5 ALWAYS connect the safety chains.

1.4.6 ALWA YS make sure directional and traile r lights are connected and

working proper ly.

1.4.7 ALWAYS check that the l ug nu ts hol d i ng th e w he els ar e tig ht an d that

none are missing.

1.4.8 The maximum recommended speed for highway towing is 72 km/hour

(45 MPH). Recommended off-road towing speed is not to exceed 16

km/hour (10 MPH) or less depending on terrain.

1.4.9 ALWAYS refer to the applicable Department of Transportation

regulations before towing.

WARNIN

G

Safety Information LTC Repair

wc_si000164gb.fm 10

1.5 Service Safety

HIGH VOLTAGE! This unit uses high voltage circuits capable of

causing serious injury or death. Only a qualified electrician should

troubleshoot or repair electrical problems occurring in this equipment.

1.5.1 ALWAYS replace the safety devices and guards after repairs and

maintenance.

1.5.2 Before servicing the Li gh t Tower , m ake sure th e engine start switch is

turned to OFF, the circui t breakers are open (o ff), and the negative

terminal on battery is disconnected. NEVER perform even routine

service (oil/filter changes, cleaning, etc.) unless all electrical

components are shut down.

1.5.3 DO NOT allow water to accumulate around the base of the machine.

If water is present, move the machine and allow the machine to dry

before servicing.

1.5.4 DO NOT service the machine if your clothing or skin is wet.

1.5.5 ALWAYS keep hands, feet, and loose clothing away from the moving

parts on the generator and engine.

1.5.6 ALWAYS keep the machine clean and labels legible. Replace all

missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

1.5.7 ALWAYS make sure slings, chains, hooks, ramps, jacks and other

types of lifting devices are attached securely and have enough weightbearing capacity to lift or hold the machine safely. Always remain

aware of the location of other people around when lifting the machine.

1.5.8 ALWAYS turn off the light circuit breakers and shut down the engine

before disconnecting the light fixtures or changing the light bulbs.

WARNIN

G

LTC Repair Safety Information

wc_si000164gb.fm 11

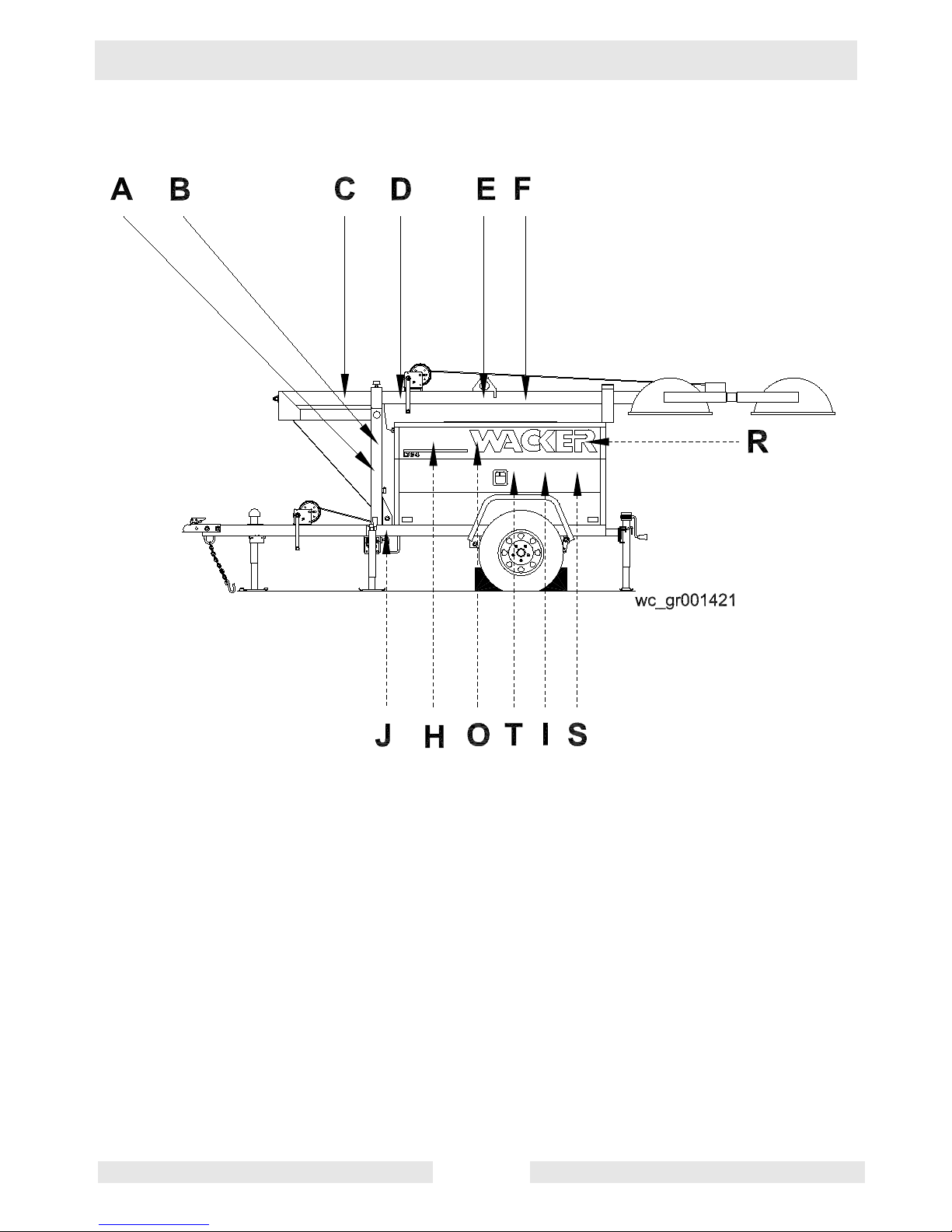

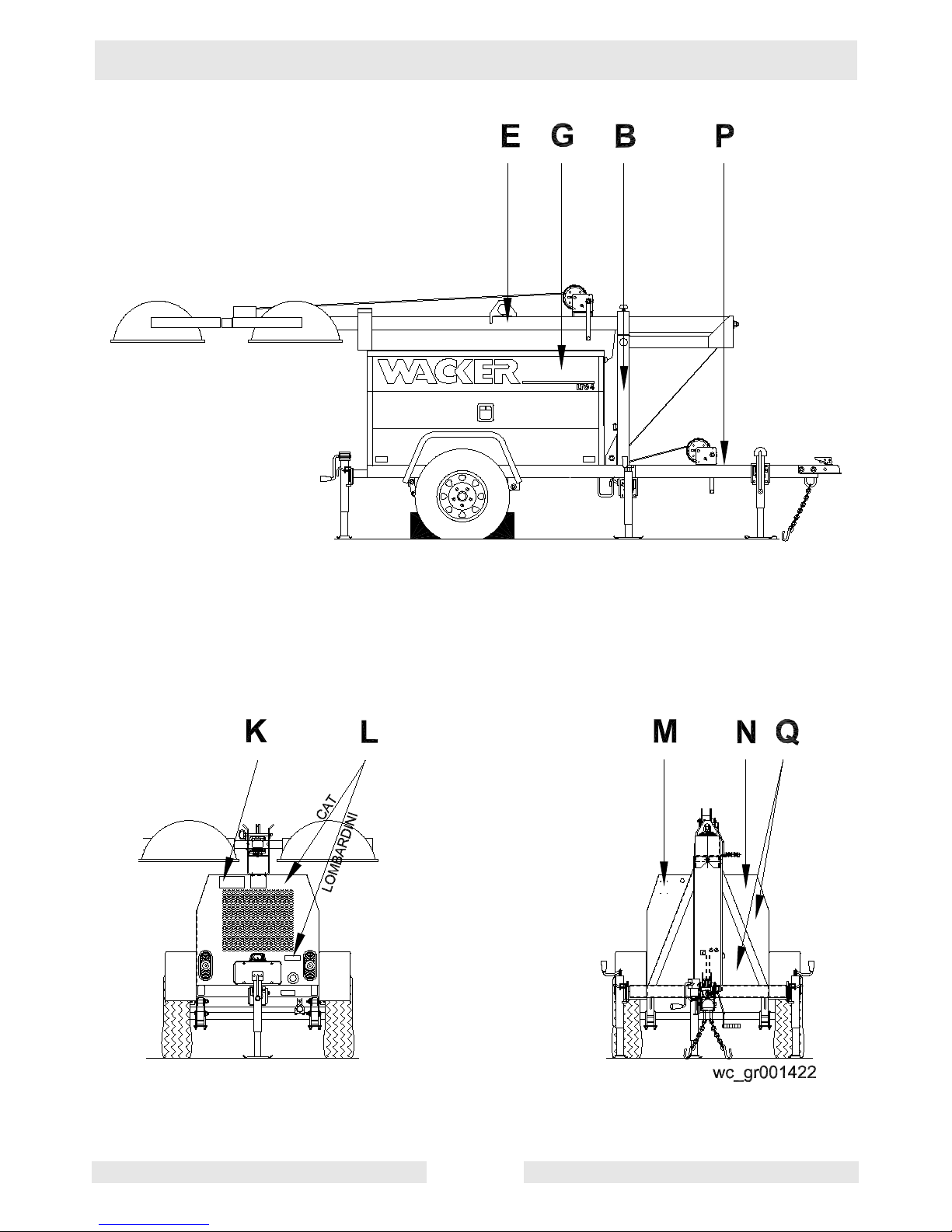

1.6 Label Locations

Safety Information LTC Repair

wc_si000164gb.fm 12

LTC Repair Safety Information

wc_si000164gb.fm 13

1.7 Safety and Operating Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Ref. Label Meaning

A DANGER!

A non-secured, falling mast will cau s e

serious injury or death if a person is hit.

To secure mast, verify automatic locking

pin has engaged to secure tower upright.

B WARNING!

Avoid crushing are a.

C WARNING!

Completely lower tower before tilting

mast. Tilting an extended mast could

cause serious injury or death.

D DANGER!

Contact with overhead electrical power

lines will cause serious inj ury o r death.

Do not position Light Tower under

electrical power lines.

Safety Information LTC Repair

wc_si000164gb.fm 14

E CAUTION!

Lifting point

F WARNING!

Secure mast in transport lock before

lifting or towing. A loose swinging mast

could cause personal injury or machine

damage.

G DANGER!

Asphyxiation hazard. Read the Operator’s Manual for instructions. No sparks,

flames, or burning objects near machine.

Stop the engine before adding fuel. Use

only diesel fuel.

H DANGER!

Asphyxiation hazard. Read the Operator’s Manual for instructions. No sparks,

flames, or burning objects near machine.

Stop the engine before adding fuel. Use

only diesel fuel.

DANGER!

Contact with overhead electrical power

lines will cause serious injury or death.

Do not position Light Tower under

electrical power lines.

WARNING!

Completely lower tower before tilting

mast. Tilting an extended mast could

cause serious injury or death.

I DANGER!

Electrical storage device wit hin. Contact

a qualified electrician for service or to

open electrical box. Electric shock will

cause serious injury or death.

Ref. Label Meaning

LTC Repair Safety Information

wc_si000164gb.fm 15

J Electrical ground

K WARNING!

Stand clear of front and rear of machine

when mast is being tilted up or down.

L WARNING!

Hot surface!

M A nameplate listing the model number,

item number, revision number , and ser ial

number is attached to each unit. Please

record the informa tion found on thi s plate

so it will be available should the

nameplate become lost or damaged.

When ordering parts or requesting

service information, you will always be

asked to specify the model number, item

number, revision number, and serial

number of the unit.

N WARNING!

Ultraviolet radiation from lamp can cause

serious skin and eye irritation. Use only

with provided undamaged l ens cover and

fixture.

Ref. Label Meaning

Safety Information LTC Repair

wc_si000164gb.fm 16

Ref. Label

O

P

I N S T R U C T I O N S D E R E M O R Q U A G E

T O W I N G I N S T R U C T I O N S A B S C H L E P P I N S T R U K T I O N E N I N S T R U C C I O N E S D E R E M O L Q U E

1 . R E A D O P E R A T O R ' S M A N U A L .

2 . U S E H I T C H R A T E D F O R T R A I L E R ' S

" G R O S S V E H I C L E W E I G H T R A T I N G " .

3 . S E C U R E L Y A T T A C H T R A I L E R T O T O W

V E H I C L E .

4 . A T T A C H S A F E T Y C H A I N S U S I N G C R O S S

P A T T E R N .

5 . C H E C K T R A I L E R L I G H T S .

1 .

B E T R I E B S V O R S C H R I F T L E S E N .

2 . A N H A N G E V O R R I C H T U N G V E R W E N D E N ,

D I E D E R G E S A M T B E T R I E B S G E W I C H T S K L A S S E

E N T S P R I C H T .

3 . A N H A N G E R S I C H E R A M Z U G F A H R Z E U G

B E F E S T I G E N .

4 . S I C H E R H E I T S K E T T E N K R E U Z W E I S E A N B R I N G E N .

5 . A N H A N G E R L E U C H T E N P R U F E N .

1 . L E A E L M A N U A L D E L O P E R A R I O .

2 . U T I L I C E U N A C O P L E C O R R E C T A M E N T E

C L A S I F I C A D O P A R A L A " C L A S E D E P E S O B U T O "

D E L V E H I C U L O D E L R E M O L Q U E .

3 . A S E G U R E S E D E A M A R R A R C O R R E C T A M E N T E

E L R E M O L Q U E A L V E H I C U L O D E R E M O L Q U E .

4 . F I J E E N C R U Z L A S C A D E N A S D E S E G U R I D A D .

5 . C O N T R O L E L A S L U C E S D E L R E M O L Q U E .

1 . L I R E L A N O T I C E D ' E M P L O I .

2 . U T I L I S E R U N G R O C H E T D ' A T T E L A G E C O N F O R M E A U

D E B I T N O M I N A L D U P O I D S B R U T D E V E H I C U L E D U

T R A C T E U R .

3 . A T T A C H E R L A R E M O R Q U E F E R M E M E N T A U V E H I C U L E

T R A C T E U R .

4 . A T T A C H E R L E S C H A I N E S D E S U R E T T E E N U T I L I S A N T

U N E M E T H O D E C R O I S E E .

5 . V E R I F I E R L E S L A M P E S D E L A R E M O R Q U E .

1 1 4 8 9 4

LTC Repair Safety Information

wc_si000164gb.fm 17

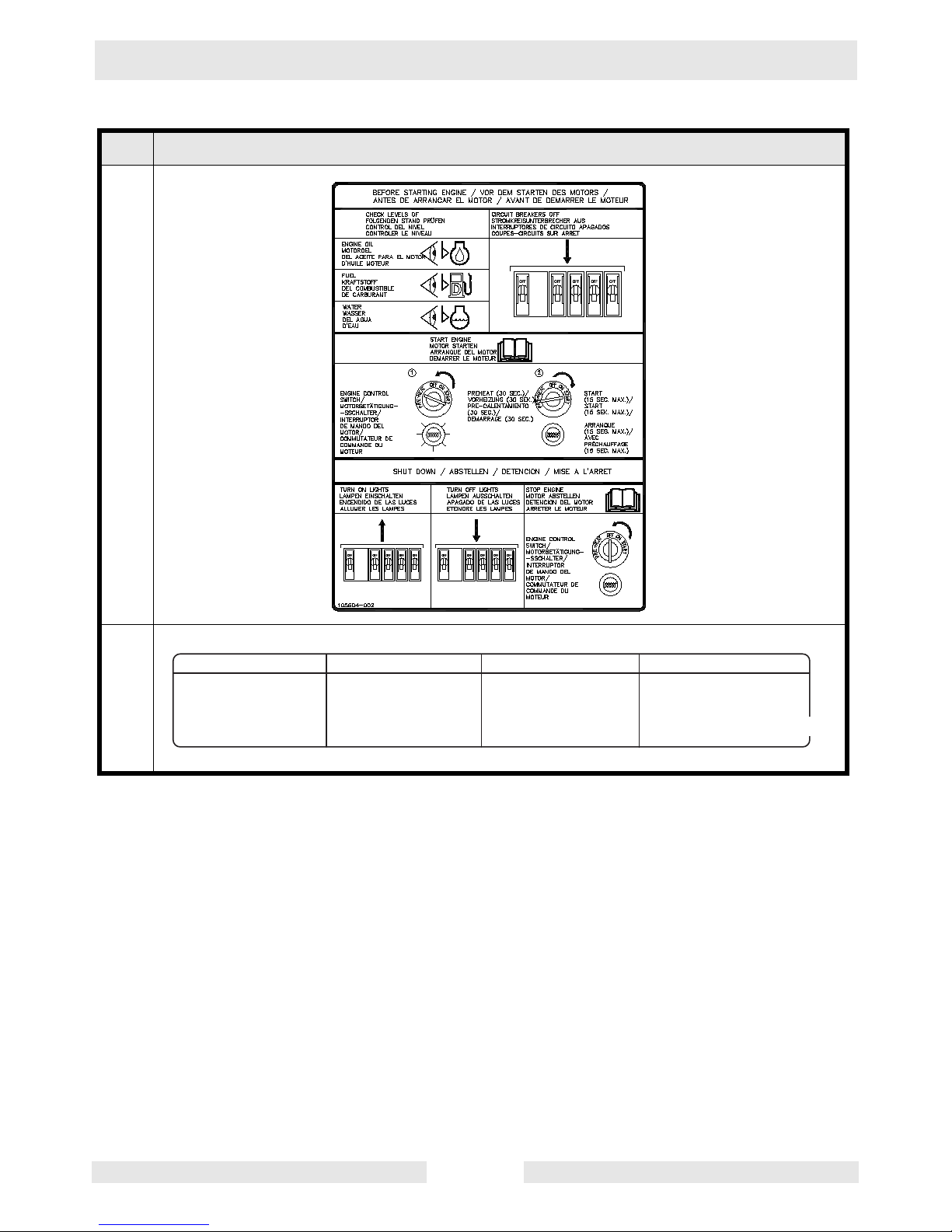

Q

Ref. Label

Safety Information LTC Repair

wc_si000164gb.fm 18

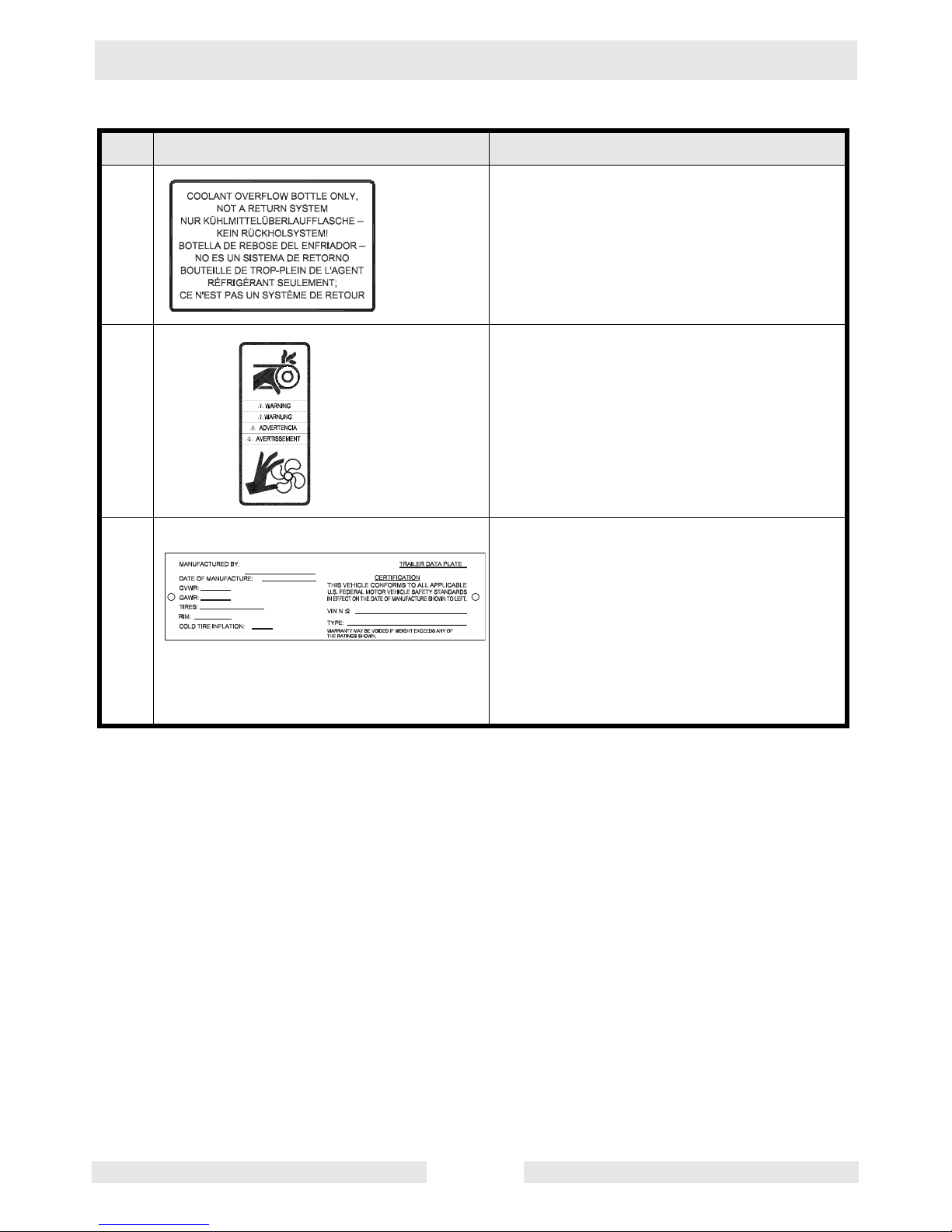

Ref. Label Meaning

R Coolant overflow bottle only, not a return

system.

S WARNING!

Pinching hazard. Rotating machinery.

Certification Label (VIN Number)

Also attached to each unit is a

Certification Label. This label specifies

that the trailer conforms with all Federal

Motor Vehicle Standards in effect at the

time of manufacture. The label includes

the Vehicle Identification Number (VIN)

for the trailer.

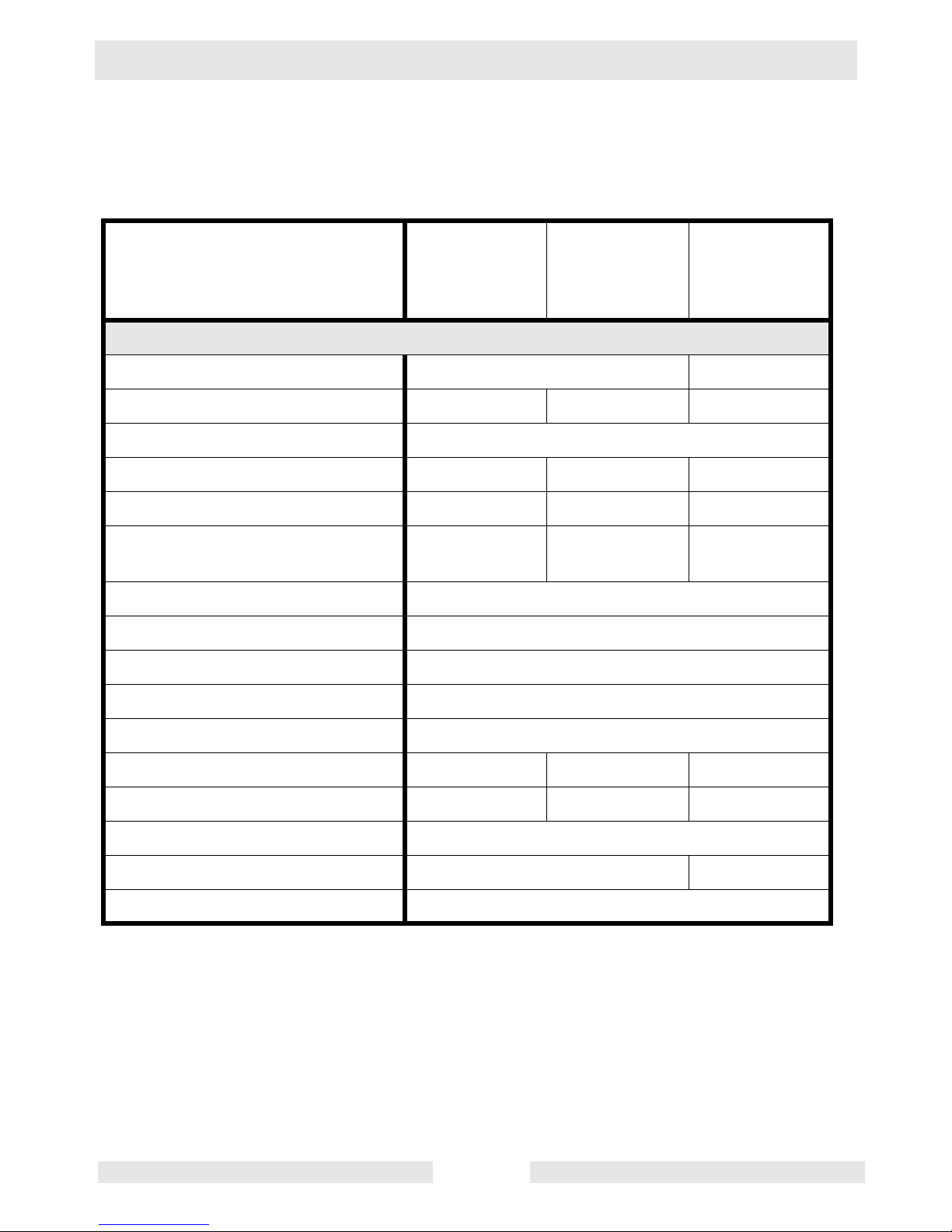

LTC 4 Technical Data

wc_td000157gb.fm 19

2. Technical Data

2.1 Engine

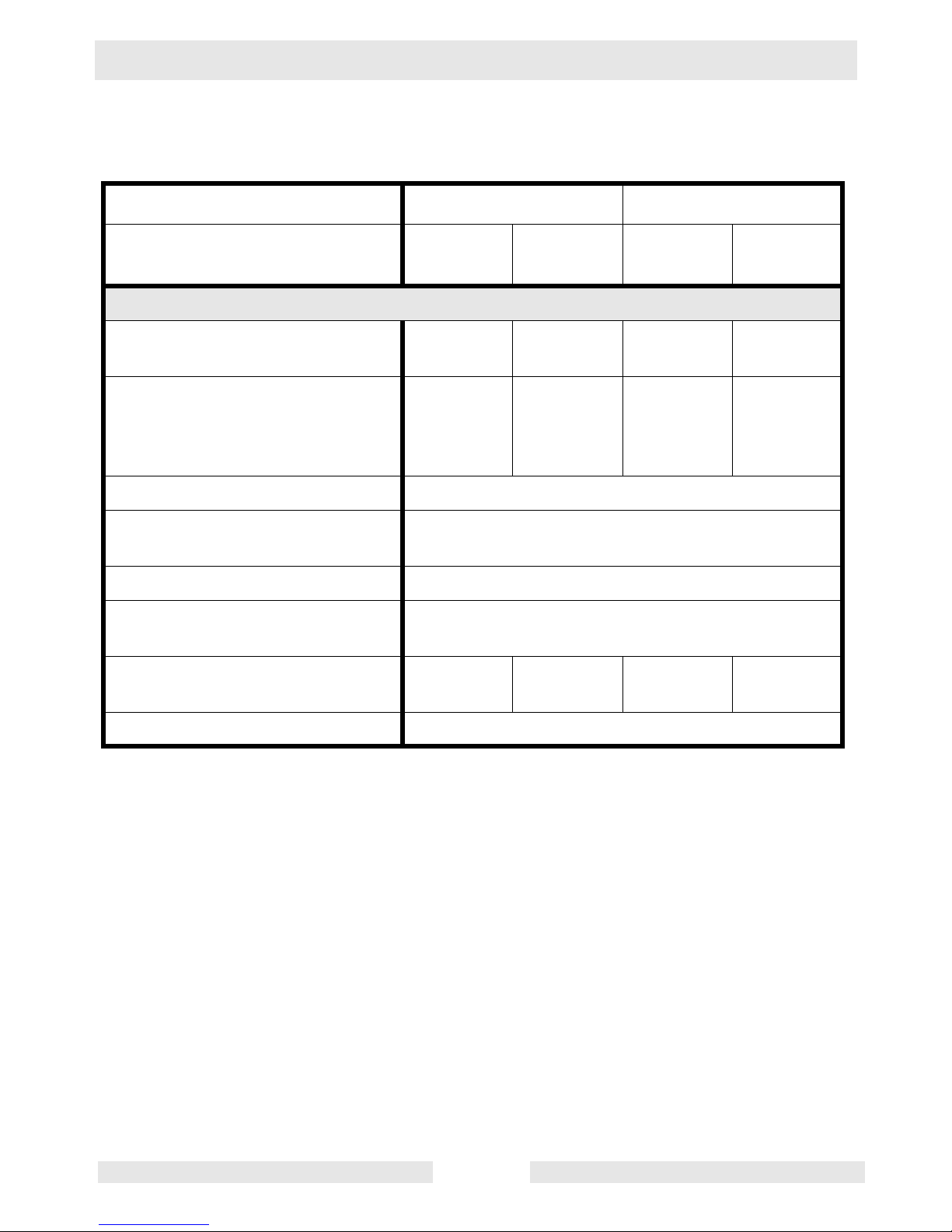

Item Number:

LTC 4L

0009375 Rev.

102 & lower

LTC 4L

0009375 Rev.

103 & above

0620018

LTC 4C

0009376

0620017

0620028

Engine

Make Lombardini Caterpillar

Model LDW903 LDW1003 3003

T ype 3-cylinder , 4-cycle, liquid-cooled diesel

Maximum power rating

kW (Hp)

9.0 (12.1) 10 (13.4) 9.4 (12.6)

Operating power ra ti ng

kW (Hp)

8.1 (10.9) 9.1 (12.2) 8.1 (10.9)

Operating speed

(no-load)

rpm

1850 1850 1850

Alternator

V / A / W

12 / 45 / 540

Battery

V/Ah/CCA

12 / 450

Air cleaner

type

dry-type element

Fuel

type

No. 2 diesel

Fuel tank capacity

l (gal.)

114 (30)

Fuel consumption

l (gal.) / hr.

1.67 (0.44) 1.70 (0.45) 1.70 (0.45)

Running time

hours

68 67 67

Coolant capacity

l (qts.)

4.7 (5.0)

Oil capacity

l (qts.)

2.4 (2.5) 3.5 (3.7)

Oil weight

SAE

15W40 CD or higher

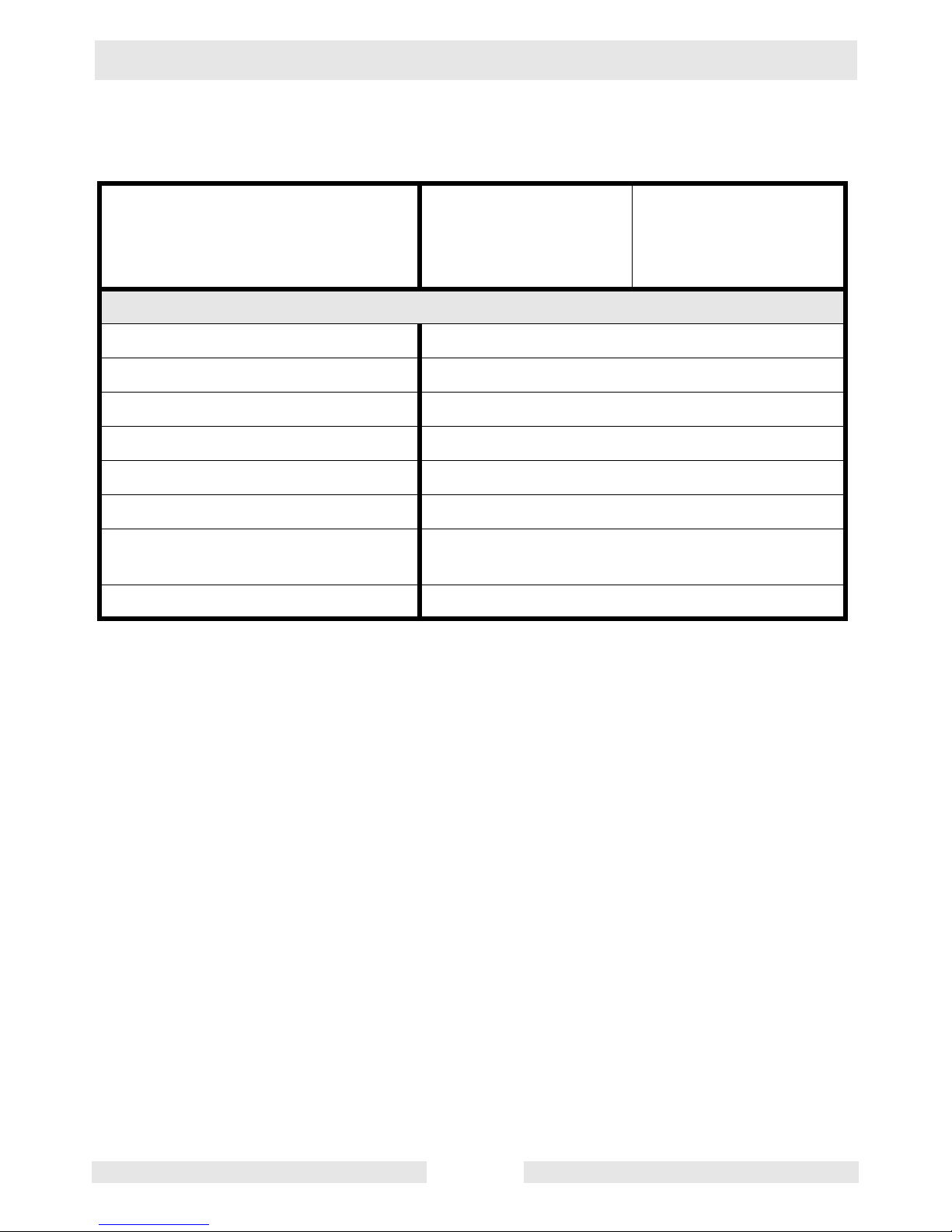

Technical Data LTC 4

wc_td000157gb.fm 20

2.2 Generator

Item Number:

LTC 4L - 60 Hz

0009375

0620018

LTC 4C - 60 Hz

0009376

0620017

0620028

Generator

Frequency

Hz

60 ± 2

Continuous output

kW

6.0

Output

volts/phase

120 / 1Ø

Amps

A

50 / 25

Excitation type Capacitor / Brushless

Power factor 1.0

Voltage regulation - No

load to full load

%

± 5.0

Speed (no-load)

rpm

1850

LTC 4 Technical Data

wc_td000157gb.fm 21

2.3 Machine

LTC 4L LTC 4C

Item Number

0009375 0620018 0009376

0620017

0620028

Machine

Operating wei ght

(GVWR)

kg (lbs.)

815 (1800) 821 (1811) 817 (1802) 832 (1834)

Dimensions

(L x W x H)

cm (in.)

389 x 122

x 160

(153 x 48 x

63)

439 x 162

x 160

(173 x 64 x

63)

389 x 122

x 160

(153 x 48 x

63)

439 x 162

x 160

(173 x 64 x

63)

Height - mast extended

m (ft.)

9 (30)

Lighting system

(1000W)

4

Ballast Coil and core

Max. lighting coverage

@ 0.5 ft. candles

m

2

(acres)

30,400

(7)

Sound level at 7 m

(23 ft.)

dB(A)

71 69 72 71

Tires

size

ST175 / 80D13

Technical Data LTC 4

wc_td000157gb.fm 22

Notes

LTC 4L Operation

wc_tx000543gb.fm 23

3. Operation

3.1 Information Regarding Operation

3.1.1 The information regarding the operation of the machine included in this

manual is condensed. Refer to the Operator’s Manual for complete

operating instructions. Always read, understand, and follow the

procedures in the Operator’s Manual when operating the machine.

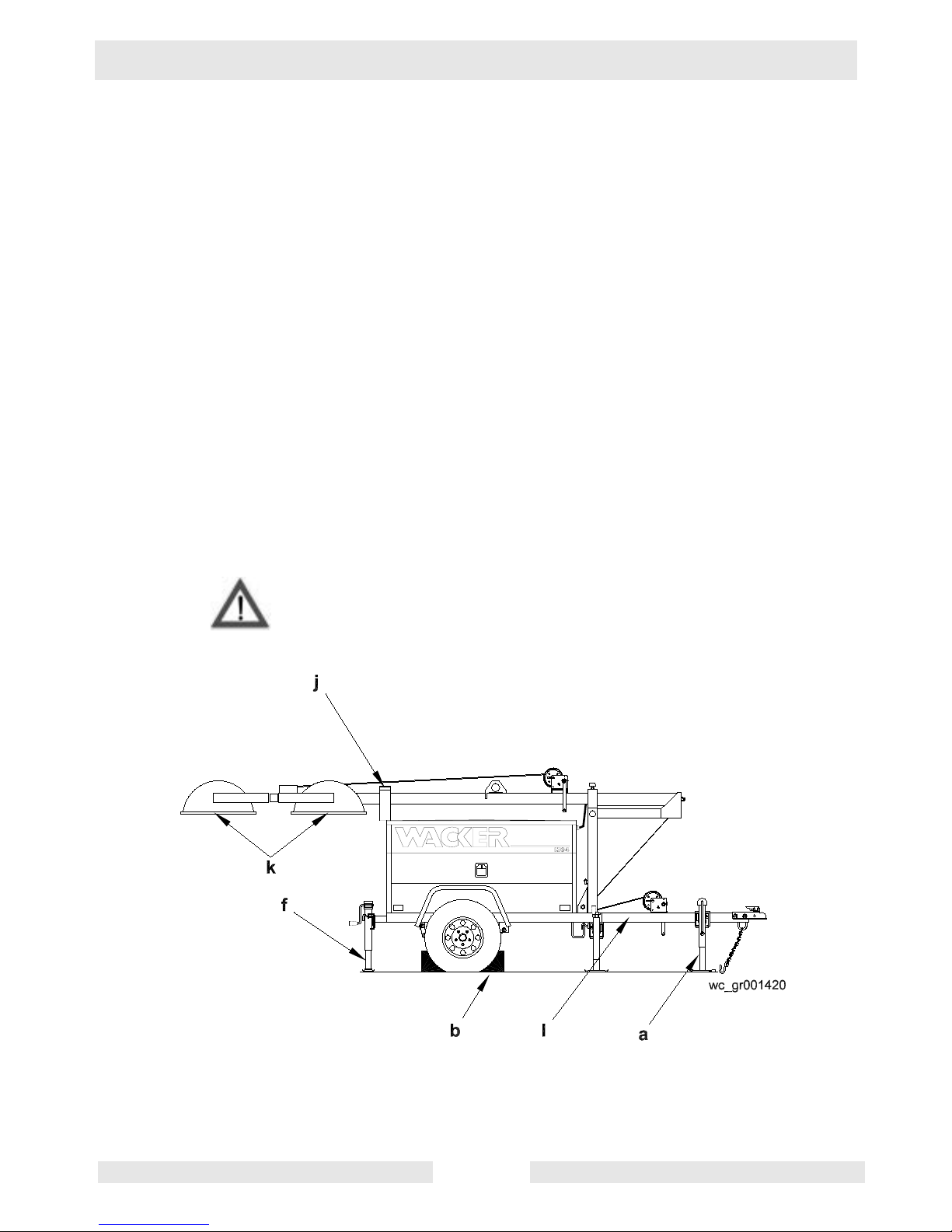

3.2 Locating Trailer

See Graphic : wc_gr0001420

3.2.1 For m ax i mum light coverage locate the Light Tower at ground level or

in a spot higher than the area being lighted.

3.2.2 Posit ion the t railer on a firm, f lat surfac e clear of overhead wires an d

obstructions. Be sure that there is enough area for outrigger

extensions to be fully extended.

3.2.3 Connect the ground stud (l) located on the trailer frame, to a good

earthen ground. Consul t local cod es for prope r grou ndi n g tech ni qu es.

The tower extends up to 9 m (30 ft.). Make sure the area above the

trailer is open and clear of overhead wires and obstructions.

WARNIN

G

Operation LTC 4L

wc_tx000543gb.fm 24

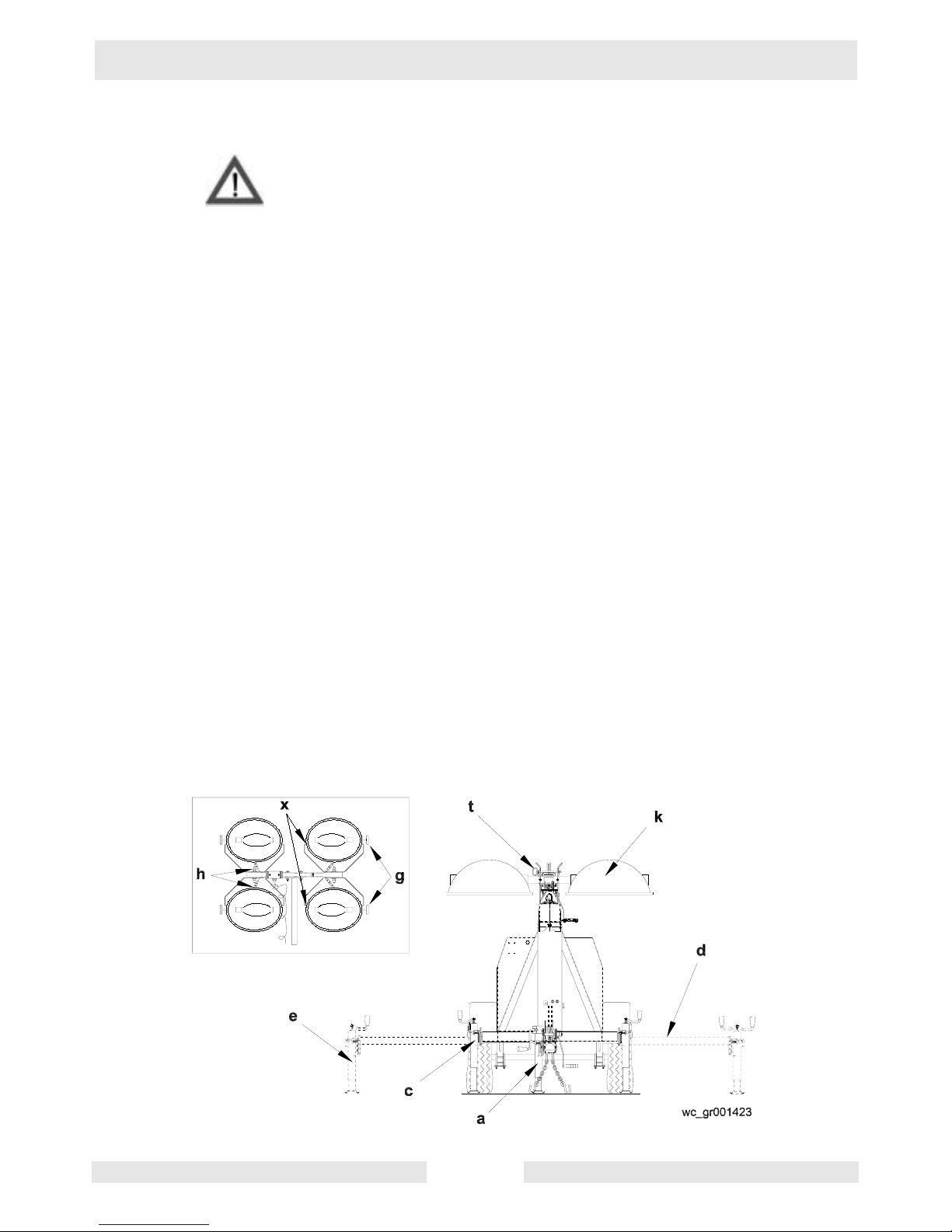

3.3 Leveling Trailer

See Graphic: wc_gr001 42 0, wc_ gr 00 14 23

The trailer must be leveled and t he ou tr i gge r s extended before r a isi n g

the tower. The outriggers must remain extended while the tower is up.

Failure to level the trailer or extend the outriggers will severely reduce

the stability of the unit and could allow the tower to tip and fall.

3.3.1 Pull the locking pin on the tongue jack (a) and rotate the tongue jack

90° as shown. Make sure the tongue jack snaps into position.

Block or chock the trailer wheels (b). Crank the tongue jack down to

raise the trailer tongue off the vehicle.

3.3.2 Pull the outrigger lock pin (c) to release the outrigger. Pull both

outrigger extensio ns (d) out until yo u fe el ou trigge r loc k pin lock ba ck

into place. Rotate jacks (e) down until they snap into position.

3.3.3 Rotate rear jack (f) down, as shown, making sure it snaps into place.

3.3.4 Extend the jack(s) on the highest side(s) of the trailer until they rest

firmly on the ground. Extend the remaining jacks until the trailer is

level.

3.4 Adjusting Lights

See Graphic: wc_gr001 42 3

Each light fixture can be aimed up, down, left or right. Position each

fixture by loose n ing to o lless li ght a dj us ter s (g) and aiming t h e light up

or down. DO NOT loosen the inside nut (x). Loosening this nut could

cause damage to the light fixture. Loosen the nut (h) to turn light

fixtures left o r right. Tighten adjust ers and nuts after posi tioning the

lights.

Always return the light fixtures to aim at the ground when mast is in the

cradle for towing.

WARNIN

G

LTC 4L Operation

wc_tx000543gb.fm 25

3.5 Preparing Trailer for Towing or Lifting

See Graphic: wc_gr001423, wc _gr002166

3.5.1 Check that the mast cr adle lock pi n (j) is in place and secured with the

safety pin.

3.5.2 Ens ur e tha t the t o wer is comp lete ly nes ted ins i de the t ra nsp o rt crad le

and the pin (t) is secure.

3.5.3 Make sure the doors are properly latched.

3.5.4 Return the outriggers to their travel position. Check that the outrigger

bars and jacks are locked in place.

3.5.5 Crank the rear jack (f) all the way in and rotate it 90°.

The the Light Tower is now ready to lift. For towing, continue.

3.5.6 Use the tongue jack (a) to raise the trailer tongue up and then lower it

over hitch on towing vehicle. Lock the hitch to coup l ing and atta ch the

safety chains. Swivel the tongue jack 90° and lock it in place.

3.5.7 Connect the trailer wiring to the towing vehicle. Check the brake, turn,

and tail lights f or proper operation.

3.5.8 Position the light fixtures down (k). For rough, off-road transportation

remove bulbs from fixtures to avoid damage.

3.5.9 Check the tire inflat ion.

3.5.10 Attach a red flag to the end of mast before towing.

CAUTION: Maximum recommended speed for highway towing is 72

km/hour (45 MPH). Recommended off-road towing speed is not to

exceed 16 km/hour (10 MPH) or less depending on terrain.

Operation LTC 4L

wc_tx000543gb.fm 26

3.6 Raising Tower (Manual Winch System)

See Graphic: wc_gr002 16 6

NEVER raise the mast or operate the Light Tower in high winds.

NEVER raise the mast while the engine is running.

HIGH VOLTAGE! DO NOT use the Light Tower if insulation on

electrical cord is cut or worn thro ugh. Repair or re place the cord b efore

using. Bare wires in co ntact wi th the m etal fr ame of the tra iler o r tower

can cause electrocution.

DO NOT position the Light Tower under electrical power lines.

NEVER allow anyone to stand near the r ear of the unit w hile raising th e

mast.

The Light Tower includes two separate winches. One for lifting the

mast to the vertic al position, t he other for raising the tower. Each winch

is an automatic brake-type winch that automatically brakes when the

handle is released. The handle must be rotated to wind in cable as well

as unwind cable.

NEVER touch the winch pawl! Releasing the pawl may cause the

mast or tower to fall.

3.6.1 Check winch cables (n) for wear or damage, and make sure they are

resting properly in pulleys. Do not use the Light Tower if either winch

cable is damaged.

3.6.2 Remove the cradle locking pin (j) from the cradle.

3.6.3 Check the operation of the tongue-mounted winch (o) by rotating the

winch handle 1/4-turn clockwise (“cable in” direction). The winch pawl

must engage winch gear teeth. When operating properly, the winch

pawl will make a “clicking” sound when the winch handle is rotated

clockwise. Do not at tempt to raise the ma st if th e winch is dam aged or

not operating properly.

3.6.4 Continue to rotate the winch handle and raise the mast to the vertical

position until the vertical mast locking pin (p) locks the mast in place.

Be certain the vertical mast locking pin is fully engaged in the locking

position before raising the tower.

WARNING

WARNING

WARNING

WARNING

Loading...

Loading...