WACKER Group CT 36 Series, CT 36ADT, CT 48 Series, CT48AGT-E, CT 48ADT Repair Manual

...

www.wackergroup.com

Walk-Behind

Trowels

CT 30

CT 36

CT 48

REPAIR MANUAL

0112103 001

0600 en

0112103

TROWEL REPAIR FOREWORD

This manual covers machines with Serial Number or Item Number:

0007587, 0007589, 0007590, 0007591, 0007592, 0007594, 0007595, 0007596, 0007597, 0007598, 0007599, 0007601,

0007602, 0007603, 0007697, 0008001, 0008002, 0008003, 0008004, 0008005, 0008006, 0008007, 0008008, 0008011,

0008012, 0008013, 0008014, 0008015, 0008016, 0008019, 0008020, 0008026, 0008027, 0008028, 0008031, 0008032,

0008034, 0008036, 0008040, 0008041, 0008197, 0008198, 0008199, 0008225, 0008226

Operating / Parts Information

You must be familiar with the operation of this machine before you attempt to troubleshoot or make any repairs to it.

Basic operating and maintenance procedures are described in the operator’s / parts manual supplied with the machine.

The operator’s / parts manual should be kept with the machine. Use it to order replacement parts when needed. If this

manual becomes lost, please contact WACKER Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to the attention of the operator, to prevent similar

occurrences from happening in the future.

This manual provides information and procedures to safely repair and maintain this WACKER model. For your own

safety and protection from injury, carefully read, understand and observe the safety instructions described in this

manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION AT

THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

i

FOREWORD

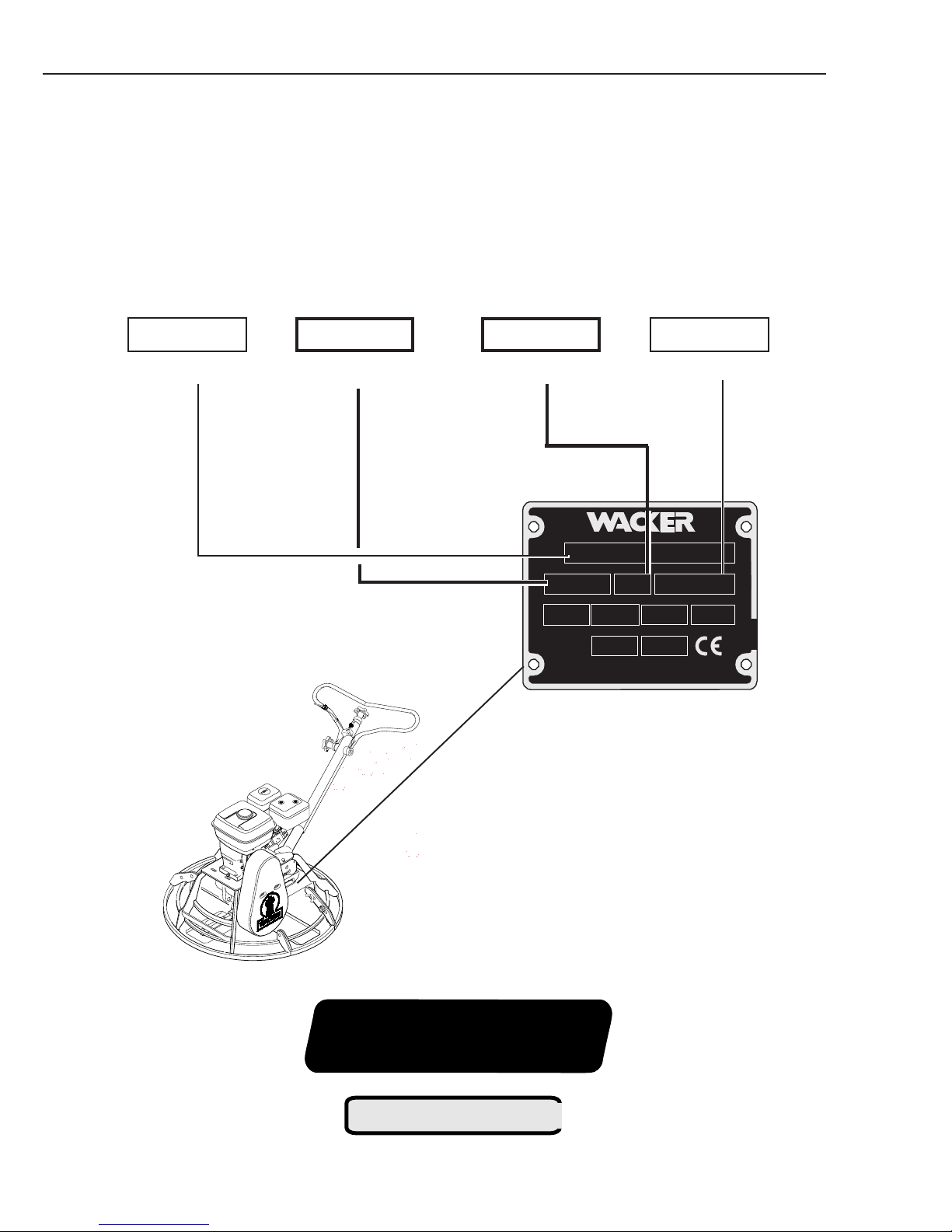

Rev. Serial Number

MENOMONEE FALLS, WI USA 53051

hpkWlbs

dB(A) Manuf. Yr.

Model

kg

MADE

IN USA

Item Number

TROWEL REPAIR

Nameplate

A nameplate listing the Model Number and Serial Number OR the Model Number, Item Number, Revision, and Serial

Number is attached to each unit. Please record the information found on this plate so it will be available should the

nameplate become lost or damaged. When ordering parts or requesting service information, you will always be

asked to specify the model number and serial number OR the model number, item number, revision, and serial

number of the unit.

My machine’s numbers are:

Model number

RevisionItem Number

CT48AGT-ECT48AGT-E

CT48AGT-E

CT48AGT-ECT48AGT-E

00080320008032

0008032 101101

00080320008032

101101

101

Serial Number

0001010100010101

00010101

0001010100010101

88223

Pro-Shift

1022SD42

PATENT PENDING

ii

®

111545

Trowel

Repair Manual

Table of Contents

1 Introduction

1.1 Safety Notes ................................................................................................ 1-2

1.2 Laws Pertaining to Spark Arresters .............................................................. 1-2

1.3 Operating Safety .......................................................................................... 1-3

1.4 Engine Safety...............................................................................................1-3

1.5 Service Safety ............................................................................................. 1-4

1.6 Technical Data ............................................................................................. 1-5

1.7 Application ................................................................................................... 1-6

1.8 General Description ...................................................................................... 1-6

1.9 Periodic Maintenance Schedule ................................................................... 1-6

1.10 Symbols ....................................................................................................... 1-6

2 Guide Handle

2.1 Throttle Control Lever Adjustment ................................................................ 2-1

2.2 Throttle Cable Replacement ......................................................................... 2-1

2.3 Upper Handle - Twist Pitch Control - Exploded View .....................................2-2

2.4 Twist Pitch Control Cable Replacement ........................................................2-4

2.5 Upper Handle -

2.6

Pro-Shift

Pro-Shift

®

Pitch Control Cable Replacement ................................................. 2-8

®

- Exploded View ................................................... 2-6

3 Clutch

3.1 Belt Replacement ......................................................................................... 3-1

3.2 Belt Drive - Exploded View ........................................................................... 3-2

3.3 Clutch Replacement ..................................................................................... 3-3

3.4 Clutch - Exploded View ................................................................................3-4

3.5 Clutch Overhaul ............................................................................................ 3-5

4 Spider

4.1 Trowel Assembly - Exploded View ............................................................... 4-1

4.2 Spider........................................................................................................... 4-2

5 Drivetrain

5.1 Engine Removal - Exploded View ................................................................. 5-1

5.2 Engine ..........................................................................................................5-2

5.3 Gearcase Removal - Exploded View............................................................. 5-3

5.4 Gearcase ..................................................................................................... 5-4

5.5 Gearbox - Exploded View ............................................................................. 5-6

5.6 Gearcase Overhaul ...................................................................................... 5-7

Troubleshooting

1-1

1 INTRODUCTION TROWEL REPAIR

1.1 Safety Notes

This manual contains NOTES, CAUTIONS, and WARNINGS which must be followed to reduce the possibility of

improper service, damage to the equipment, or personal injury. Read and follow all NOTES, CAUTIONS and WARNINGS

included in instructions.

Contains additional

Note:

information important to a procedure.

CAUTION: Provides information important to prevent

errors which could damage machine or components.

WARNING

Warns of conditions or practices which

could lead to personal injury or death!

1.2 Laws Pertaining to Spark Arresters

Notice: Some states require that in certain locations, spark arresters be used on internal combustion engines. A spark

arrester is a device designed to prevent the discharge of sparks or flames from the engine exhaust. It is often required

when operating equipment on forested land to reduce the risk of fires. Consult the engine distributor or local authorities

and make sure you comply with regulations regarding spark arresters.

1-2

TROWEL REPAIR INTRODUCTION 1

1.3 Operating Safety

Familiarity and proper training are required for the safe operation of this equipment! Equipment operated improperly or

by untrained personnel can be dangerous! Read the operating instructions contained in both the operator's manual and

the engine manual and familiarize yourself with the location and proper use of all controls.

WARNING

NEVER allow anyone to operate this equipment

without proper training. People operating this equipment must be familiar with the risks and hazards

associated with it.

NEVER touch engine or muffler while the engine is

on or immediately after it has been turned off. These

areas get hot and may cause burns.

NEVER use accessories or attachments which are

not recommended by WACKER. Damage to equipment and injury to the user may result.

NEVER operate machine with the belt guard missing. Exposed drive belt and pulleys create potentially dangerous hazards that can cause serious

injuries.

NEVER leave machine running unattended.

ALWAYS be sure operator is familiar with proper

safety precautions and operation techniques before using machine.

ALWAYS wear protective clothing when operating

equipment. For instance, goggles or safety glasses

will protect eyes from damage caused by flying

debris.

ALWAYS close fuel valve on engines equipped

with one when machine is not being operated.

ALWAYS store equipment properly when it is not

being used. Equipment should be stored in a

clean, dry location out of the reach of children.

ALWAYS operate machine with all safety devices

and guards in place and in working order.

1.4 Engine Safety

Internal combustion engines present special hazards during operation and fueling! Read and follow warning instructions

in engine owner's manual and safety guidelines below. Failure to follow warnings and safety guidelines could result in

severe injury or death.

WARNING

DO NOT smoke while operating machine.

DO NOT smoke when refueling engine.

DO NOT refuel hot or running engine.

DO NOT refuel engine near open flame.

DO NOT spill fuel when refueling engine.

DO NOT run engine near open flames.

DO NOT run machine indoors or in an enclosed

area such as a deep trench unless adequate

ventilation, through such items as exhaust fans or

hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon monoxide can cause loss of consciousness and may lead to death.

ALWAYS refill fuel tank in well-ventilated area.

ALWAYS replace fuel tank cap after refueling.

1-3

1 INTRODUCTION TROWEL REPAIR

1.5 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over

a long period of time, periodic maintenance and occasional repairs are necessary.

WARNING

DO NOT attempt to clean or service machine

while it is running. Rotating parts can cause

severe injury.

DO NOT crank a flooded engine with the spark

plug removed on gasoline-powered engines. Fuel

trapped in the cylinder will squirt out the spark plug

opening.

DO NOT test for spark on gasoline-powered engines, if engine is flooded or the smell of gasoline

is present. A stray spark could ignite fumes.

DO NOT use gasoline or other types of fuels or

flammable solvents to clean parts, especially in

enclosed areas. Fumes from fuels and solvents

can become explosive.

ALWAYS keep area around muffler free of debris

such as leaves, paper, cartons, etc. A hot muffler

could ignite them, starting a fire.

ALWAYS replace worn or damaged components

with spare parts designed and recommended by

WACKER.

ALWAYS disconnect spark plug on machines

equipped with gasoline engines, before servicing, to

avoid accidental start-up.

ALWAYS keep machine clean and labels legible.

Replace all missing and hard-to-read labels. Labels

provide important operating instructions and warn of

dangers and hazards.

1-4

TROWEL REPAIR INTRODUCTION 1

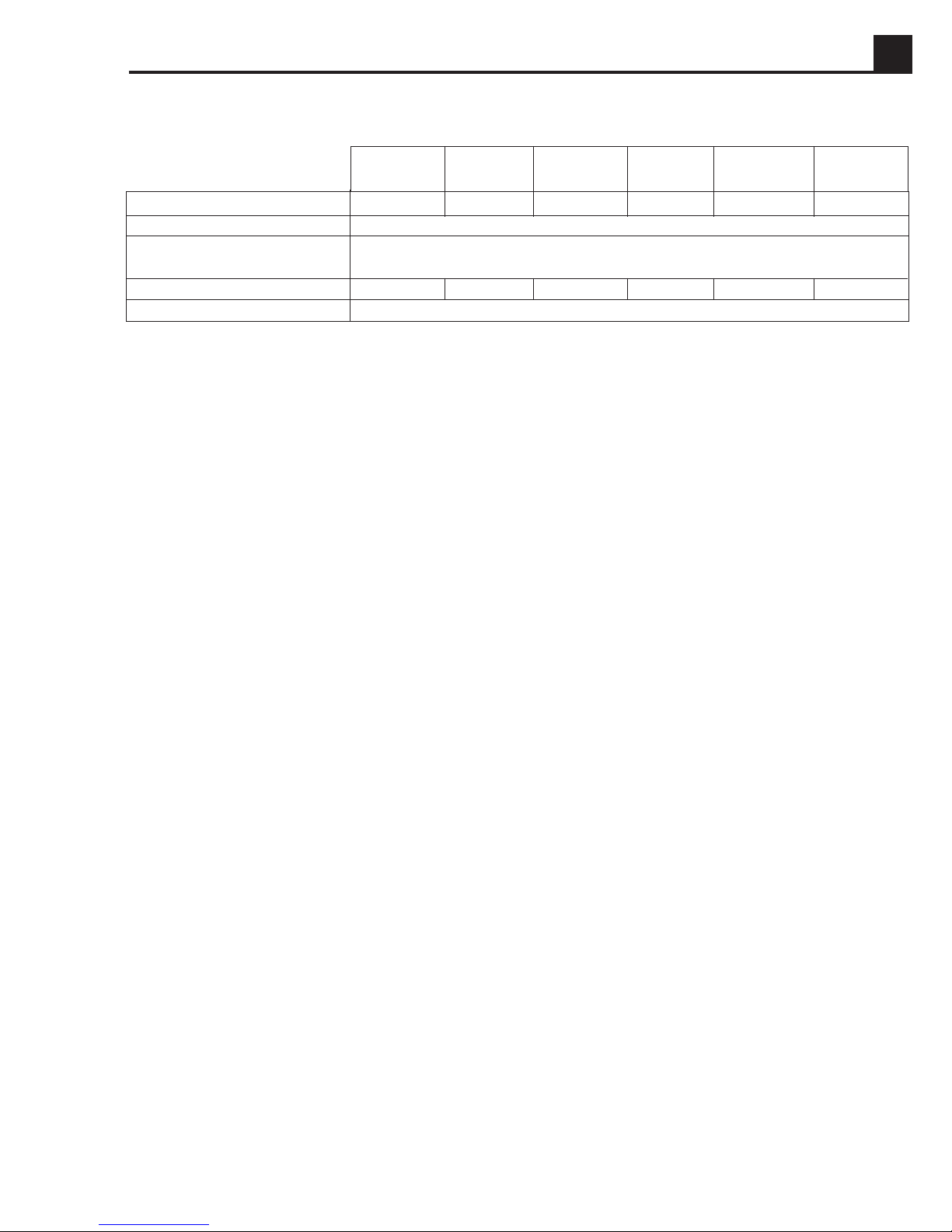

1.6 Technical Data

Trowel

Trowel Diameter in. (mm)

Number of Blades

Gearbox Lubrication type

oz. (ml)

Speed Range rpm

Pitch Range degrees°

CT 36ADT/ CT 48ADT/

CT 30ADT CT 30AGT CT36ADP CT 36AGT CT 48ADP CT 48AGT

30 (762) 30 (762) 36 (914) 36 (914) 48 (1220) 48 (1220)

4

Mobil SHC634

Approx. 45 (1330)

60–100 125–165 60–100 125–165 60–100 125–165

0–15

1-5

1 INTRODUCTION TROWEL REPAIR

1.7 Application

The CT series of trowels are modern, high production

machines intended for floating and finishing freshly poured

concrete slabs. The machine’s good balance, adjustable

handle, and easily accessible controls add to operator

comfort and productivity. An automatic stop switch, or a

combination of an automatic stop switch and an operator

present lever, provide added operator safety. Finishing

rates will depend on operator skill and job conditions.

1.8 General Description

For the CT product line of trowels, engine power is

transferred through a centrifugal clutch and V-belt to the

gearcase and down to the trowel blades. The four trowel

blades are mounted on a spider assembly mounted on the

gearcase output shaft. The spider assembly adjusts the

trowel angle by being raised by the yoke-trowel blade lift.

The trowels can be tilted from 0° - 15 °. The speed

of the trowels ranges from 60-165 rpm, depending on

the model.

1.9 Periodic Maintenance Schedule

The chart below lists basic trowel maintenance. Refer to engine manufacturer’s Operator’s Manual for information on

engine maintenance. A copy of the engine Operator’s Manual was supplied with the machine when it was shipped.

Daily After After Every two Every Every two

before each first weeks or month or years or

starting use 5 hours 50 hrs. 100 hrs. 750 hrs.

Check and tighten external hardware. ●

Grease trowel arms. ●

Check and adjust drive belt. ●●

Grease adjusting yoke. ●

Change gearcase oil. ●

Inspect pitch cable. ●

Change trowel gearcase lubricant. ●

1.10 Symbols

Symbols Used on Repair Pages

L1 Indicates a sealant or threadlocking compound to

be used when assembling part.

[L1] Refer to Sealant Chart at end of manual for

description of sealants.

T1 Indicates the correct torque value for

assembling part.

[T1] Refer to Torque Chart at end of manual for

standard torque measurements.

1-6

TROWEL REPAIR GUIDE HANDLE 2

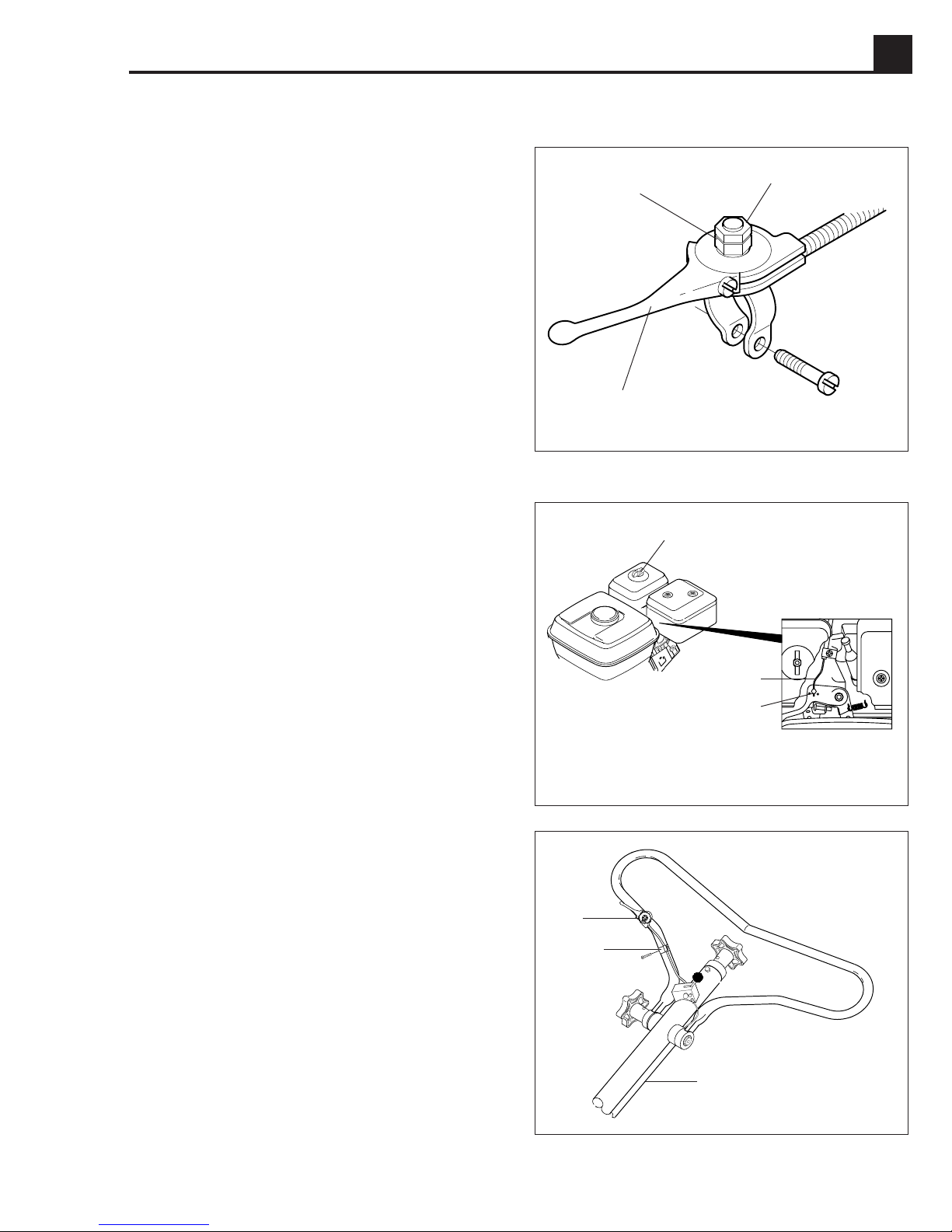

2.1 Throttle Control Lever Adjustment

The throttle control is used to vary the speed of the engine

and to control the rpm of the trowel blades to meet

specific applications and job conditions.

The throttle control uses ratchet action to select and hold

the desired throttle position. If the throttle fails to hold its

selected position, check lever pressure adjustment and

ratchet action.

Adjustment:

1. Tighten hex nut (a) on top of throttle control lever (c)

to increase pressure on throttle control.

2. Lock adjustment in place by tightening jam nut (b).

2.2 Throttle Cable Replacement

Machines are available with various styles of throttle

control. The replacement of this cable is basically the

same for all models.

Disassembly:

a

b

c

1001RM17

d

1. Remove M6 wing nut (d), filter cover, second M6 wing

nut, and filter.

2. Disconnect throttle cable (e) from throttle lever (f).

3. Pull throttle through cable raceway.

4. Disconnect cable clamp (h) from handle. Disconnect

throttle control lever (g) from handle.

5. Disconnect cable (e) from throttle control lever (g).

Assembly:

1. Reconnect cable (e) to throttle control lever (g).

2. Connect throttle control lever to handle.

3. Push throttle cable through cable raceway (j).

4. Connect throttle cable (e) to throttle lever (f).

5. Install cable clamp (h) to take up excess throttle cable.

e

f

1001RM01

g

h

6. Adjust throttle cable so that engine is in idle when throttle

control lever is in the idle position. Tighten cable.

7. Reinstall air filter, wing nut, filter cover and second

wing nut (d).

j

1001RM02

2-1

2 GUIDE HANDLE TROWEL REPAIR

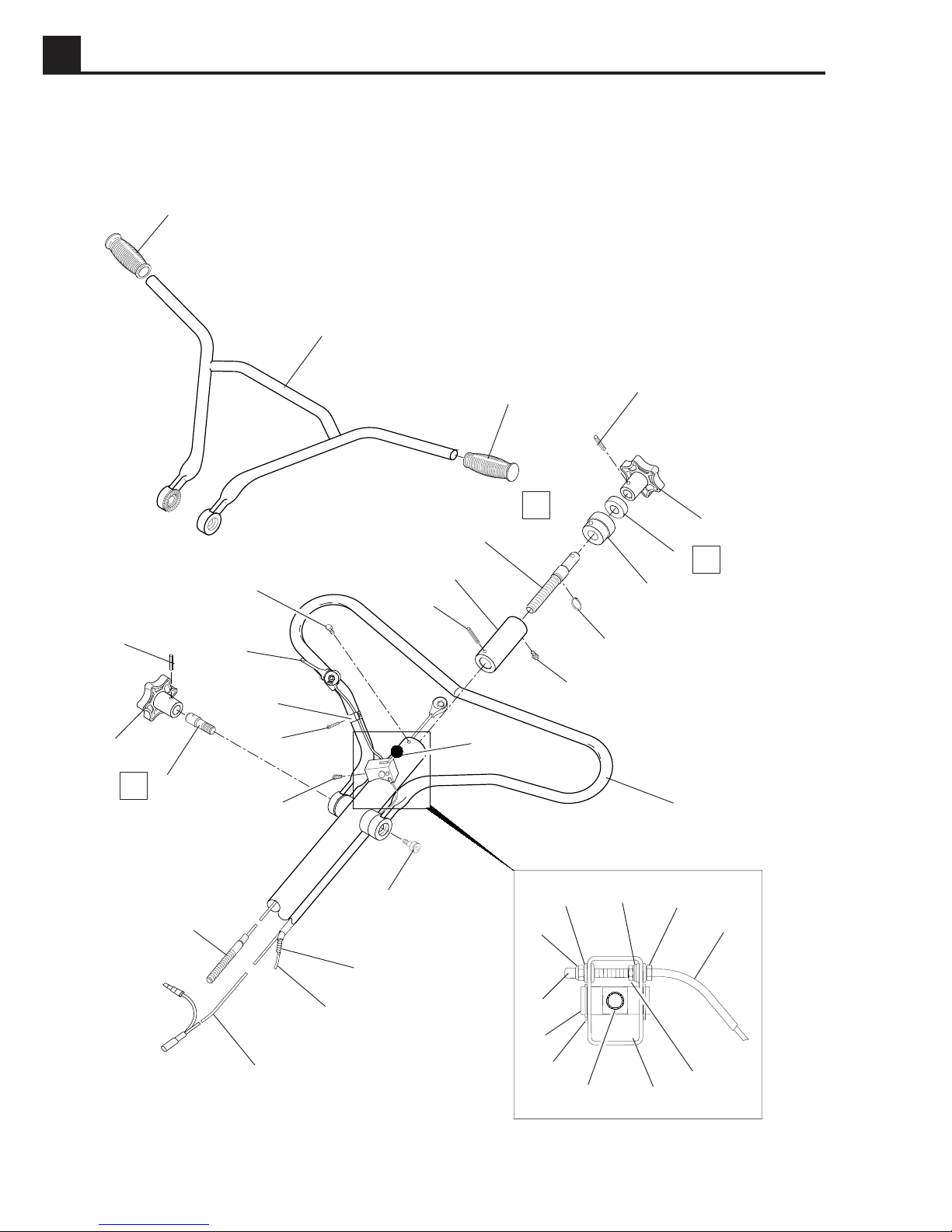

2.3 Upper Handle - Twist Pitch Control - Exploded View

1

2

1

N2

9

12

3

4

23

N2

13

14

15

16

10

11

8

17

3

4

5

N1

6

7

34

22

21

2-2

20

19

18

25

24

33

32

26

31

27

28

21

29

30

1013SD79

TROWEL REPAIR GUIDE HANDLE 2

Ref. Description Qty.

1 Handle-grip 2

2 Handle-bicycle 1

3 Pin-roll style (incl. 1) 2

4 Knob-pitch control 2

5 Bearing-ball 1

6 Holder-handle bearing 1

7 Retaining ring-ext. 1

8 Screw M6x16 1

9 Shaft-pitch control 1

10 Nut 3/4-6 1

11 Pin-roll 1

12 Screw M6x10 1

13 Lever-throttle control 1

14 Clamp 1

15 Screw M5x25 1

16 Screw #8-32x1/4 2

17 Knob 1

Ref. Description Qty.

18 Screw 3/8-16x1-3/8 1

19 Casing-cable 1

20 Cable-throttle 1

21 Wiring harness 1

22 Cable-control, blade 1

23 Rod-handle adjustment 1

24 Cap-screw head 1

25 Nut-lock M5 1

26 Grommet 2

27 Washer B5.3 1

28 Screw M5x45 1

29 Nut BM5 1

30 Cover-switch box 1

31 Handle-switch 1

32 Retaining ring-ext. 1

33 Shaft-handle pivot 1

34 Handle-adjustable 1

N2 - Lubricate threads before assembly.N1 - Fill bearing with grease before assembly.

2-3

2 GUIDE HANDLE TROWEL REPAIR

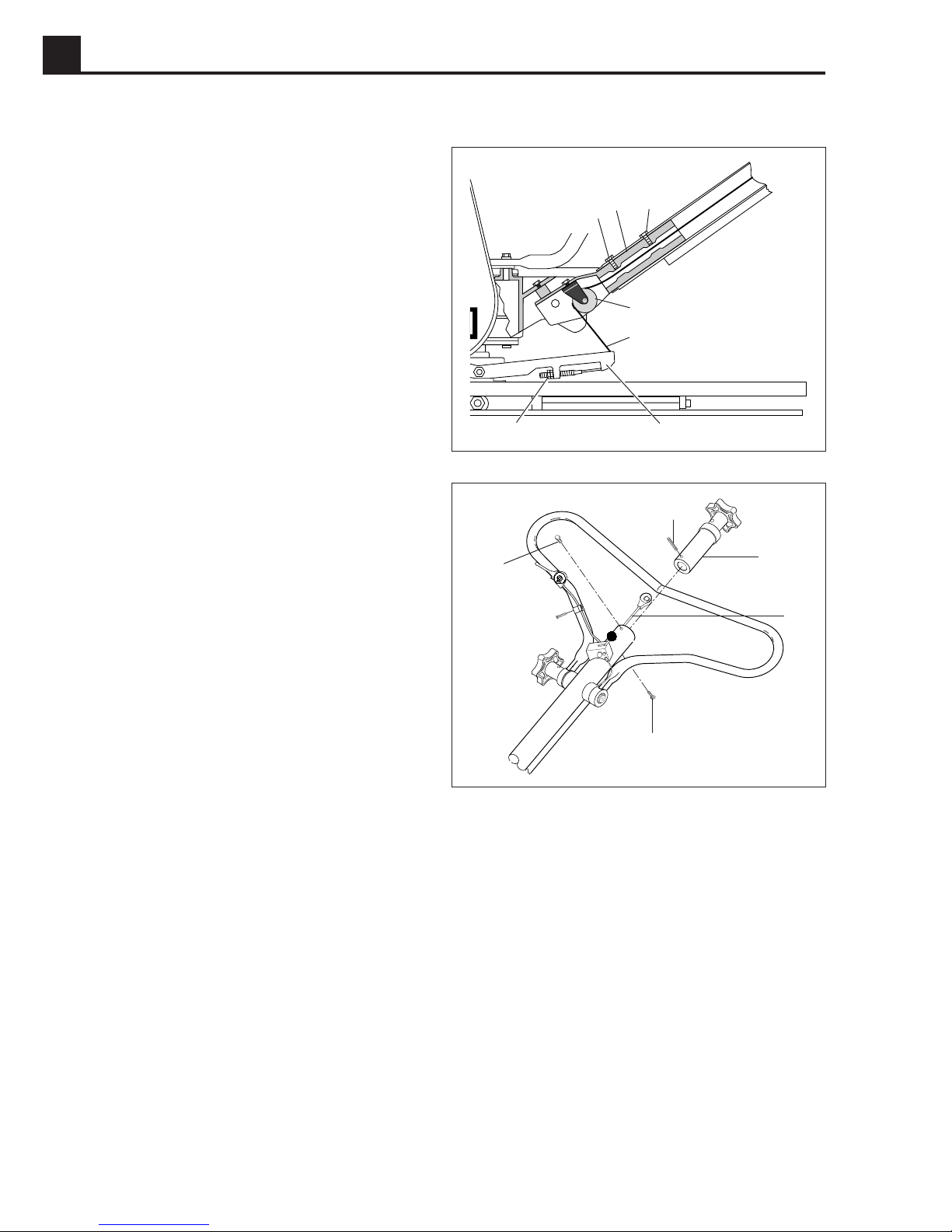

2.4 Twist Pitch Control Cable Replacement

Disassembly:

1. Remove two retaining nuts (f) from the pitch control

cable (d).

2. Disengage cable from fork (e) and slide through

(c).

pulley

3. Remove two M8 screws

base (b). Carefully pull handle and control cable away

from handle base.

4. Remove M6 screw (g) from handle. Remove

M6 screw (m) from underside of handle.

5. Pull Twist Control assembly (j) and pitch control cable

(k) from handle.

6. Drive roll pin (h) from Twist Control assembly.

Remove cable.

(a) holding handle to handle

g

a

b

a

c

d

f

e

1013SD53

h

j

k

2-4

m

1001RM03

Loading...

Loading...