www.wackergroup.com

Operator's manual

Internal vibrator frequency converter

IRFUN

0203511en 003

01.2007

3

Foreword

1. Foreword

For your own safety and protection from bodily injuries, carefully read,

understand and follow the safety information in this manual.

Please operate and maintain your Wacker machine in accordance with

the instructions in this operator's manual. Your Wacker machine will reward you with troublefree operation and a high degree of availability.

Defective components must be replaced immediately.

All rights, especially the right for copying and distribution, are reserved

Copyright 2007 by Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without express permission in writing from Wacker Construction Equipment AG.

Any type of reproduction, distribution or saving on data carriers of any

type or method not authorized by Wacker represents an infringement of

valid copyrights and will be prosecuted. We expressly reserve the right

to make technical modifications - even without special notice - which aim

at further improving our machines or their safety standards.

Table of contents

4

1. Foreword 3

2. Safety information 5

2.1 General instructions ..............................................................................5

2.2 Operation ...............................................................................................5

2.3 Safety checks ........................................................................................6

2.4 Maintenance ..........................................................................................7

2.5 Transport ...............................................................................................8

2.6 Maintenance checks ..............................................................................8

3. Technical data 9

4. Description 17

4.1 Application ...........................................................................................17

4.2 Functional description .........................................................................17

5. Operation 18

5.1 Starting up ...........................................................................................18

5.2 Connection using separate extension cable ........................................19

5.3 Switching off the machine ...................................................................20

6. Description/maintenance 21

6.1 Protection against overheating ............................................................21

6.2 Maintenance schedule ........................................................................21

6.3 Disassembly and assembly .................................................................21

6.4 Maintenance ........................................................................................22

7. Repair instructions 23

7.1 Repair instructions, faults ....................................................................23

8. Wear dimensions 26

9. Disposal 27

9.1 Environmentally friendly recycling .......................................................27

EC Declaration of Conformity 29

DIN EN ISO 9001 Certificate 31

SV00043en.fm 5

Internal vibrators Safety information

2. Safety information

for internal vibrators with integrated frequency converter

2.1 General instructions

2.1.1 The IRFUN may only be worked on independently by persons who

∗ are at least 18 years of age,

∗ are physically and mentally fit for this job,

∗ have been instructed in operating IRFUN and have proved their ability

for the job to the employer and

∗ may be expected to carry out the job they are charged with carefully.

They must have been assigned to work on the IRFUN by the employer.

2.1.2 IRFUN is to be applied only for compacting work. Both the manufactur-

er's operator's manual and this safety information must be observed.

The machine must be immersed in the mass to be compressed.

2.1.3 The persons charged with the operation of IRFUN must be made fa-

miliar with the necessary safety measures relating to the machine. In

case of extraordinary uses, the employer shall give the necessary additional instructions.

2.1.4 Observe the accident prevention regulations set forth by the profes-

sional association for electrical equipment and material and use them

as a basis during all work performed with this machine.

2.2 Operation

2.2.1 Make sure that IRFUN with electric motor drive is only attached to the

voltage and frequency indicated on the nameplate. The nameplate is

located on the inside of the switch box cover. The voltage to which the

machine must be connected is also embossed on the switch housing.

Choose correct cross section for extension cord.

2.2.2 IRFUN may only be connected to electric power supplies with a fault

current protective switch.

Either fault current protective switches of universal sensitivity must be

used or it must be ensured that the IRFUN is connected on its own

without any other consumers to an fault current protective switch designed for non-sinusoidal current consumption.

When connecting the IRFUN to public mains networks, sockets with

15 A fuse must be used.

Safety information Internal vibrators

SV00043en.fm 6

2.2.3 The machine corresponds to class rating 1 (grounded conductor).

2.2.4 Prior to starting IRFUN, make sure that the components are screwed

on securely.

2.2.5 Do not insert or pull out the power plug as a means of turning IRFUN

on or off.

2.2.6 The power cable of IRFUN must not be used to pull out the plug from

the plug receptacle.

2.2.7 Protect electric cable from heat, oil, and sharp edges.

2.2.8 Electrical equipment and material may only be used if they comply with

operational and local safety requirements. They must be in proper condition and this condition is to be maintained.

2.2.9 Activated IRFUNs should not come into contact with any solid objects

over a long period of time, long running times in the air must be avoided.

2.2.10 When taking a break or when leaving IRFUN, the operator must switch

off the machine and park it securely in such a way to ensure that it cannot tip over or fall down.

2.2.11 Do not operate IRFUN in areas where explosions may occur.

2.2.12 Appropriate protective gloves must always be worn when handling

IRFUN. Do not touch the hot vibrator head.

2.2.13 The protective hose must be used to guide the machine during opera-

tion. Using the vibrator head to guide the IRFUN can cause vascular

diseases.

2.2.14 The transmission of vibration oscillations to the material to be com-

pacted can damage or destroy the casing. Casings must be secured

according to regulations before using the machine.

2.3 Safety checks

2.3.1 Before starting operation, the operator has to check that all control and

safety devices are functioning properly.

2.3.2 Prior to connecting the machine, check the electric cable and socket

for damage on a regular basis.

SV00043en.fm 7

Internal vibrators Safety information

2.3.3 Also check the proper functioning of the On/Off switch and the fault

current protective switch.

2.3.4 If defects on the safety devices or other defects impairing the opera-

tional safety of internal vibrators are observed, the supervisor must be

informed immediately. The machine must not be commissioned.

2.3.5 If there are defects jeopardizing operational safety, the machine has to

be switched off immediately.

2.3.6 Check the bottom part of the pipe for cracks, damage or loose screw

connections. The vibration cylinders are not suitable for use if the bottom part of the pipe is missing.

2.3.7 Check the clamps on the connections.

2.3.8 The machine can start to run immediately as soon as it is connected to

the mains depending on the switch setting. This is also possible if the

switch is defective.

2.4 Maintenance

2.4.1 IRFUN must only be opened and repaired by qualified and authorized

personnel.

2.4.2 Only use original spare parts. Alterations to this machine, incl. adjust-

ments of the maximum engine speed set by the manufacturer may only

be carried out with the express permission of WACKER. In case of

non-observance, all liability shall be refused.

2.4.3 Disconnect IRFUN from the electrical power supply system by pulling

out the mains plug before carrying out maintenance and repair work.

2.4.4 Work on the electric parts of the machine may only be carried out by

skilled technicians.

2.4.5 The green-yellow grounded conductor must be longer than the current-

carrying conductors, so that it does not tear off first should the strain

relief fail. If interrupted, it can cause fatal injury. After conducting repairs, check the grounded conductor for continuity.

2.4.6 As soon as maintenance and repair jobs have been completed, all

safety devices must be properly reinstalled. Screws must be tightened

according to the tightening torques specified in the standards.

2.4.7 Clean IRFUN daily. Make sure not to damage the lines when using

high pressure washers.

Safety information Internal vibrators

SV00043en.fm 8

2.5 Transport

2.5.1 Secure IRFUN against falling down during transportation.

2.6 Maintenance checks

2.6.1 According to the conditions and frequency of use, IRFUN must be

checked for safe operation by a technician, for example at a WACKER

service station, at least once every 6 months and repaired if necessary.

Please observe the appropriate rules and regulations valid in your country.

TD00701en.fm 9

Technical data

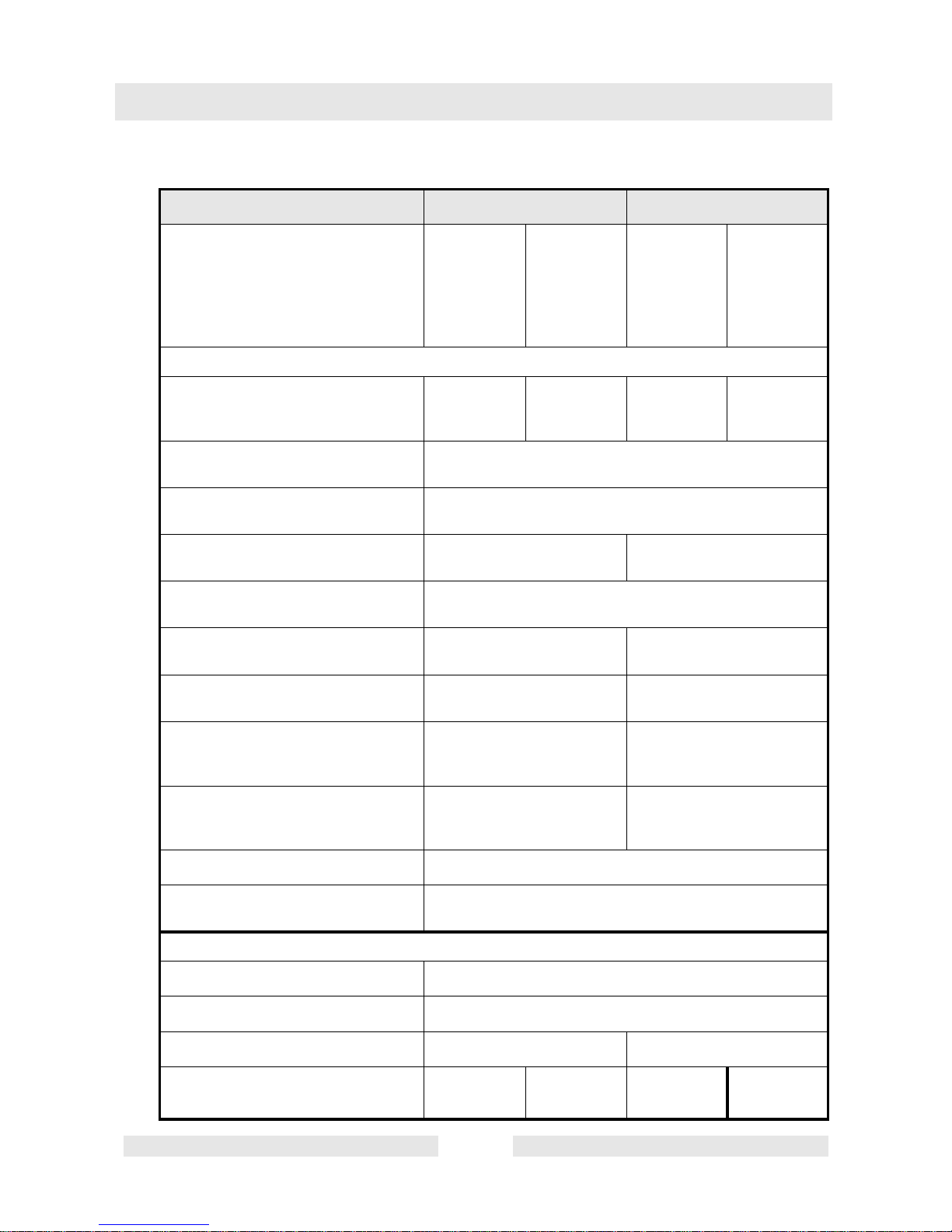

3. Technical data

IRFUN 38/115 IRFUN 45/115

Item no.

8 m

8 m GV

10 m

10 m GV

0008494

0008631

0008495

0008722

0008769

0008771

0008770

0008772

0008496

0008630

0008497

0008723

0008773

0008775

0008774

0008776

Vibrator head

Integrated three-phase

AC motor

kW:

0.41 0.47 0.58 0.68

Voltage

V:

214 3~

Frequency

Hz:

200

Rated current

A:

1.6 2.3

Vibrations

rpm:

12000

Vibrator diameter

mm (in):

38 (1.5) 45 (1.8)

Vibrator length

mm (in):

345 (13.6) 382 (15)

Vibrator weight (mass)

(without hose connection)

kg (lb):

2.2 (4.85) 3.5 (7.72)

Effective diameter in concrete

cm (ft):

up to:

50 (1.6) 60 (2.0)

Oil type

SAE 0W-30

Oil quantity

cm

3

(in3):

8 (0.49)

Inverter / mains connection value

Alternating current V:

110 - 130 1~

Frequency Hz:

50 / 60

Current A:

68

Power kVA:

kW:

0.72

0.85

0.69

0.55

0.96

0.74

0.92

0.74

Technical data

TD00701en.fm 10

Sound pressure level LpA

at operator's station

dB(A):

79

The weighted effective acceleration

value, determined according to

EN ISO 5349

m/s

2

:

2.5

These noise and vibration figures were calculated with the internal vibrator being freely suspended in

air at the nominal speed of the drive motor.

IRFUN 38/115 IRFUN 45/115

TD00701en.fm 11

Technical data

IRFUN 57/115 IRFUN 57k/115

Item no.

8 m

8 m GV

10 m

10 m GV

0008481

0008482

0008628

0008724

0008928, 0008777

0008779

0008778

0008780

0008629

Vibrator head

Integrated three-phase

AC motor

kW:

1.04 0.76

Voltage

V:

214 3~

Frequency

Hz:

200

Rated current

A:

3.5 2.6

Vibrations

rpm:

12000

Vibrator diameter

mm (in):

58 (2.3)

Vibrator length

mm (in):

400 (15.7)

Vibrator weight (mass)

(without hose connection)

kg (lb):

5.8 (12.79) 4.8 (10.59)

Oil type

SAE 0W-30

Oil quantity

cm

3

(in3):

12 (0.73)

Inverter / mains connection value

Alternating current V:

110 - 130 1~

Frequency Hz:

50 / 60

Current A:

12

Power kVA:

kW:

1.38

1.1

1.38

0.92

Technical data

TD00701en.fm 12

Sound pressure level LpA

at operator's station

dB(A):

79

The weighted effective acceleration

value, determined according to

EN ISO 5349

m/s

2

:

2.5 4

These noise and vibration figures were calculated with the internal vibrator being freely suspended

in air at the nominal speed of the drive motor.

IRFUN 57/115 IRFUN 57k/115

TD00701en.fm 13

Technical data

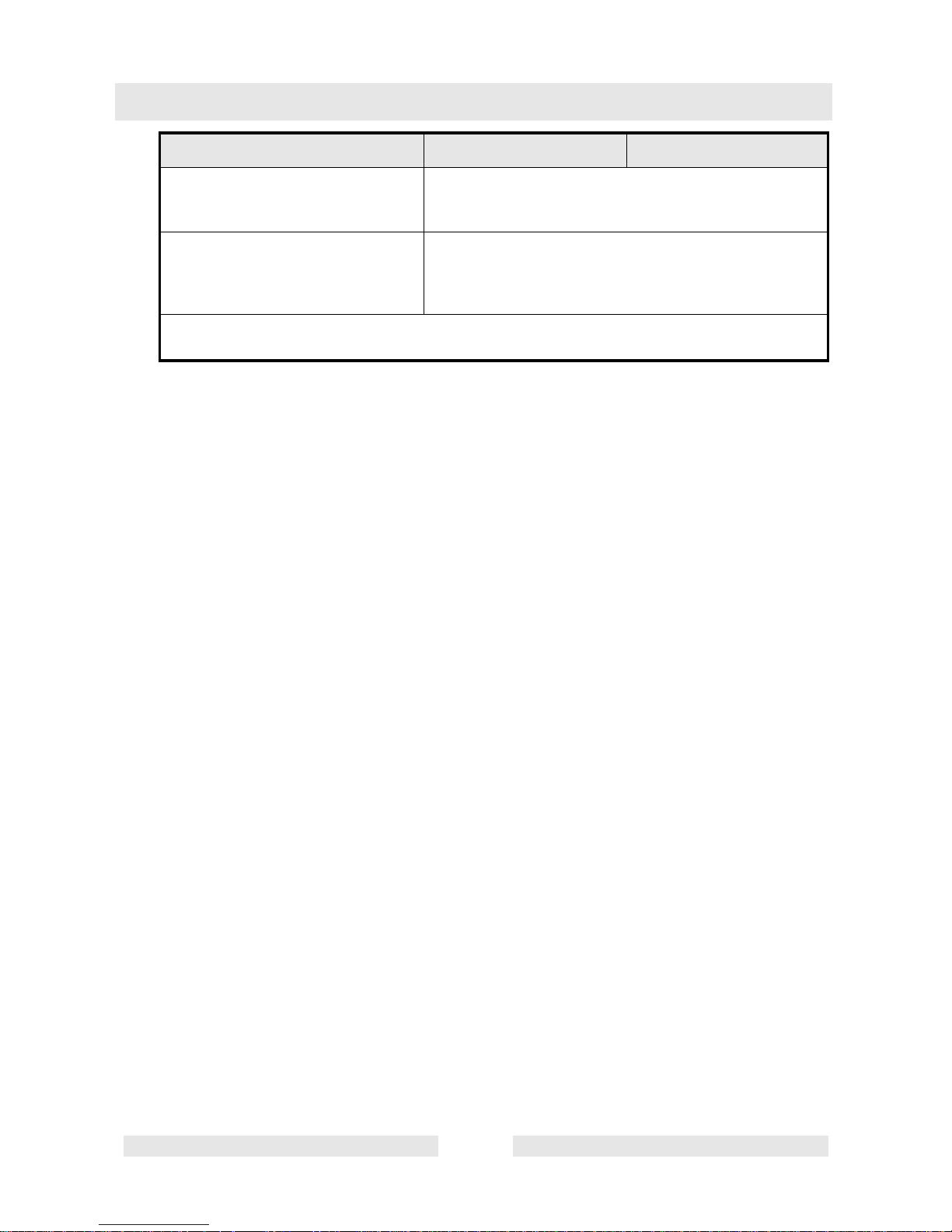

IRFUN 38/230 IRFUN 45/230

Item no.

7 m

8 m

0007956

0008611

0008635

0008640

0007957

0008612

0610109

0610110

0008634

0008639

Vibrator head

Integrated three-phase

AC motor

kW:

0.475 0.682

Voltage

V:

214 3~

Frequency

Hz:

200

Rated current

A:

1.6 2.3

Vibrations

rpm:

12000

Vibrator diameter

mm (in):

38 (1.5) 45 (1.8)

Vibrator length

mm (in):

345 (13.6) 382 (15)

Vibrator weight (mass)

(without hose connection)

kg (lb):

2.2 (4.85) 3.5 (7.72)

Effective diameter in concrete

cm (ft):

up to:

50 (1.6) 60 (2.0)

Oil type

SAE 0W-30

Oil quantity

cm

3

(in3):

8 (0.49)

Inverter / mains connection value

Alternating current V:

220 - 240 1~

Frequency Hz:

50 / 60

Current A:

34

Power kVA:

kW:

0,69

0,55

0,92

0,74

Technical data

TD00701en.fm 14

Sound pressure level LpA

at operator's station

dB(A):

79

The weighted effective acceleration

value, determined according to

EN ISO 5349

m/s

2

:

2.5

These noise and vibration figures were calculated with the internal vibrator being freely suspended in air at the nominal speed of the drive motor.

IRFUN 38/230 IRFUN 45/230

TD00701en.fm 15

Technical data

IRFUN 57/230 IRFUN 57k/230

Item no.

7 m

8 m

0007958

0008613

0610107

0610108

0008632

0008637

0008464

0008636

0008633

0008638

Vibrator head

Integrated three-phase

AC motor

kW:

1.04 0.76

Voltage

V:

214 3~

Frequency

Hz:

200

Rated current

A:

3.5 2.6

Vibrations

rpm:

12000

Vibrator diameter

mm (in):

58 (2.2)

Vibrator length

mm (in):

400 (15.7) 330 (13)

Vibrator weight (mass)

(without hose connection)

kg (lb):

5.8 (12.79) 4.8 (10.59)

Effective diameter in concrete

cm (ft):

up to:

85 (2.8) 65 (2.1)

Oil type

SAE 0W-30

Oil quantity

cm

3

(in3):

12 (0.73)

Inverter / mains connection value

Alternating current V:

220 - 240 1~

Frequency Hz:

50 / 60

Current A:

65

Power kVA:

kW:

1.38

1.1

1.15

0.92

Technical data

TD00701en.fm 16

Sound pressure level LpA

at operator's station

dB(A):

79

The weighted effective acceleration

value, determined according to

EN ISO 5349

m/s

2

:

4

These noise and vibration figures were calculated with the internal vibrator being freely suspended in

air at the nominal speed of the drive motor.

IRFUN 57/230 IRFUN 57k/230

T01036en.fm 17

Description

4. Description

4.1 Application

The machine is run with single phase current, and is a combination of

an internal vibrator and a frequency converter.

4.2 Functional description

The converter in the inverter rectifies the input voltage.

The direct voltage is converted in the d.c.-a.c. converter into 3-phase

alternating current (rotary current) and the frequency increased from

50/60 Hz to 200 Hz.

The d.c.-a.c. converter works in "pulse width modulation" mode which

generates a sinusoidal output current as an average, which ensures

the error-free operation of the connected machines.

The soft start of the connected machines permits the full utilization of

the output capacity of the inverter.

The actuation of the rectifier and inverter is carried out by a control

electronics with microprocessor.

Rectifier 100/115/

230/240V

D.c.-a.c. converter

Electronics

Pulse width modulation

Sinusoidal average

50/60 Hz 200 Hz

Operation

T01036en.fm 18

5. Operation

5.1 Starting up

Connection:

The machine is set to its nominal voltage at factory. Connection to

1-phase-alternating current 50 or 60 Hz.

Assembly instructions for the version without plug receptacle

Danger of electrocution!

Only a qualified electrician is permitted to assemble the plug and per-

form a safety check according to the directives in effect.

Observe the assembly instructions!

Switching on:

Switching on the machine means that the voltage and frequency of the

machine are powered up until the nominal value (soft start) preventing

the generation of critical switch-on current strengths.

The machine is suited for the connection to power generation units if

their operating voltage is between 230/115 V + 15 % for every load

type and the manufacturer of the unit permits operation of consumers

with capacitors. If the machine is operated with power generator units,

a synchronous unit should be selected as far as possible.

Danger to life

T01036en.fm 19

Operation

5.2 Connection using separate extension cable

The cross section required depends on the length of the extension cable:

Type Length L m

Section mm

2

38/115 < 16 1,5

<

27 2,5

<

43 4

<

65 6

38/230 <

66 1,5

<

110 2,5

<

176 4

45/115 <

12 1,5

<

20 2,5

<

32 4

<

49 6

45/230 <

50 1,5

<

83 2,5

<

132 4

57/115 <

13 2,5

<

21 4

<

32 6

<

53 10

57/230 <

33 1,5

<

55 2,5

<

88 4

57k/230 <

40 1,5

<

66 2,5

<

105 4

Operation

T01036en.fm 20

5.3 Switching off the machine

First switch off the machine. Then pull the mains plug from the socket.

T01036en.fm 21

Description/maintenance

6. Description/maintenance

6.1 Protection against overheating

This machine is protected against overheating by means of a thermal

circuit breaker. Every phase is equipped with a separate thermal circuit

breaker.

If the thermal circuit breaker is activated, switch off the machine and

allow it to cool down.

6.2 Maintenance schedule

6.3 Disassembly and assembly

The vibrator head must only be clamped in the lower area of the thick

cap.

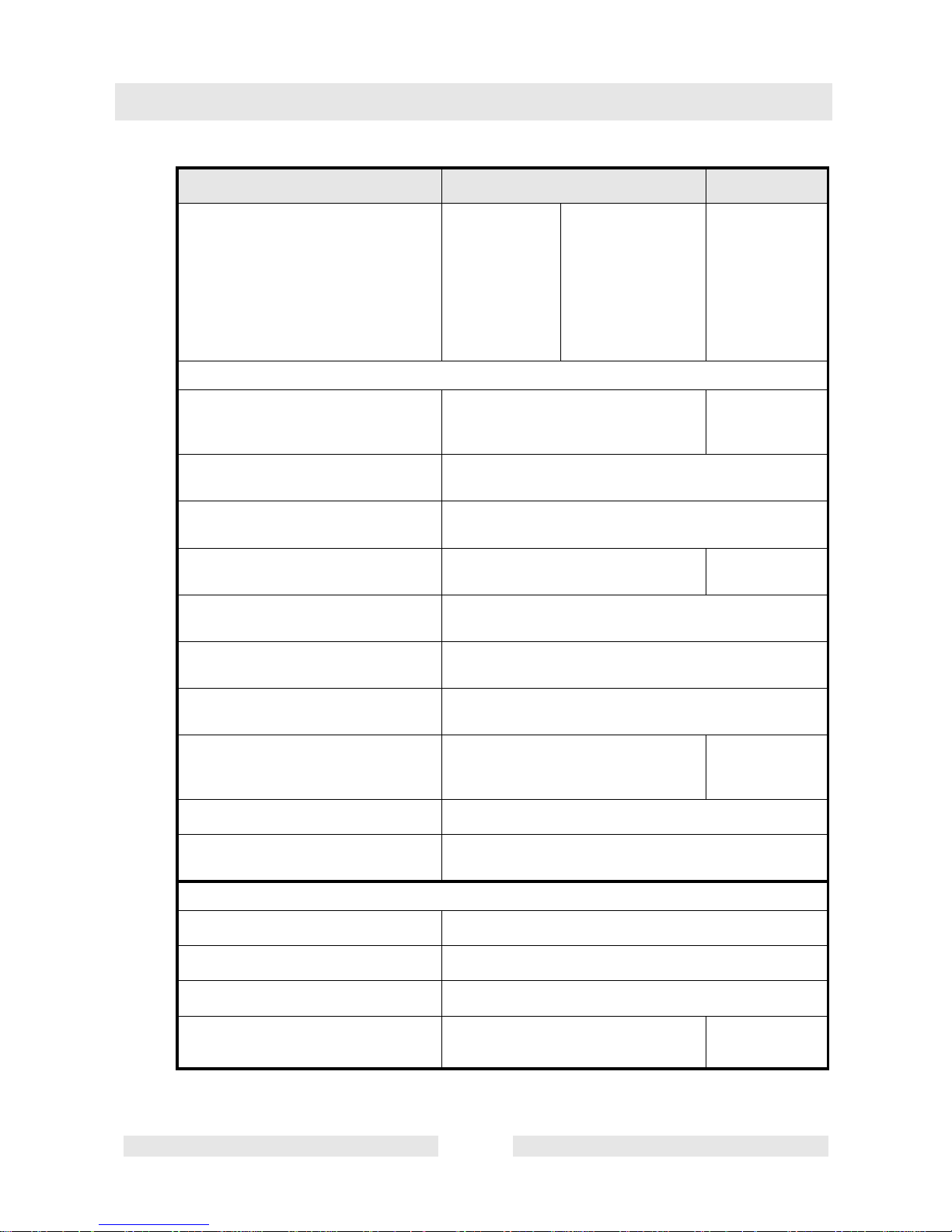

Component Maintenance work Maintenance interval

Feed line

Visual check - cables and switch

box membrane.

Daily

a

Bottle sizes a

38 100

45 120

57 105

57k 80

65 130

65k 105

Description/maintenance

T01036en.fm 22

6.4 Maintenance

6.4.1 When the wear dimension has been reached the corresponding parts

must be replaced. Seal the housing components at the connection with

ergo 4205 and protect against removal by spot welding.

∗ for IR... 30:

Completely replace the vibrator head.

∗ for IR... 38/45/57:

Connecting lines between hose connection and vibrator head:

The closure of the spade connector (1) must be ensured using the

shrink-on tubing (2). See illustration.

∗ for IR... 65:

Connect connecting cables by crimping them to both sides of the butt

connectors.

6.4.2 After opening the vibrator head the correct oil level must be ensured

prior to assembly (see technical data).

T01036en.fm 23

Repair instructions

7. Repair instructions

Work on the electric parts of the machine may only be carried out by

skilled technicians.

7.1 Repair instructions, faults

The machine must not be opened until approx. 5 minutes after pulling

the plug from the socket to allow the integrated capacitors to discharge.

Have maintenance carried out by trained personnel.

Possible errors:

As long as the green LED is lit, the circuit board is electrically charged

- even after you switch off the line voltage. The green LED goes out

when the condensers are discharged.

The diagnostic lamps built into the inverter, five red LEDs and a green

LED, help you troubleshoot any problems you may encounter.

However, this requires, that you open the inverter housing and apply

voltage. This must be carried out by a specialist or a properly

instructed employee.

Interruption of the cable connection

inverter/vibrating cylinder

Insulation fault of the inverter, the

motor cable or the vibrator head

Inverter is overloaded

The output stage of the inverter is

overloaded due to a short-circuit,

ground fault or error in the vibrating

cylinder

Line input voltage too high / too low

Operating control lamp

Repair instructions

T01036en.fm 24

There is a risk of injury should a condenser explode when voltage is

applied and, as a result thereof, potting compound is ejected. This is

why you should always wear eye protection and avoid the area right

above the condensers.

Before you apply voltage, always carry out a visual inspection of the

opened inverter. Condensers with bulged tops or ones that are higher

than the others are already damaged. You must not apply voltage to

this inverter!

If a red LED lights up when you turn on the machine, the machine has

shut down because of a detected error.

(*) - see Technical Data

For additional protection of the machine against excessive input voltage a metal-oxide varistor has been installed in the input circuit.

Malfunction Cause Remedy

Green LED is not lit.

Internal vibrator (IR)

not running.

- Supply cable

interruption.

- Poor contact

transitions.

- Check supply cable.

- Check contact transitions

(switches, connectors) and

rework if necessary.

Green and first red

LEDs illuminate.

IR not running.

- Cable disruption

between frequency

converter (FU) and IR.

- Fault in the FU

electronics.

- Check cables and replace if

faulty.

- Replace FU.

Green and second

red LEDs illuminate.

IR not running.

- Ground contact in the

FU or IR.

- Insulation measurements

at IR and FU, replace faulty

components.

Green and third red

LEDs illuminate.

IR not running.

- Temperature in the FU

housing too high.

- IR runs sluggish.

- Measure the current values

(*) in the output lines.

- Remove fault in the IR.

Green and fourth

red LEDs illuminate.

IR not running.

- Short circuit between

FU and IR.

- Locate the short circuit by

measurements and

remove.

Green and fifth red

LEDs illuminate.

IR not running.

- Incorrect input voltage,

too high or too low.

- Measure voltage at the

switch.

- Check generator.

T01036en.fm 25

Repair instructions

This looks very similar to a small plate capacitor in its design. It is

characterized by a characteristic similar to a Z diode and a very high

load capacity. Its resistance of more than 1 MΩ collapses during

overvoltage in less than 50 nano seconds to less than 1 Ω in extreme

cases.

This protects the electronics against excessive input voltage.

The output frequency is adjusted to 200 Hz using the potentiometer.

Secure the adjustment screw of the potentiometer with locking paint.

Wear dimensions

SK00630en.fm 26

8. Wear dimensions

Measure lengths L and LL at the end of the housing pipe (initial

measurements)

∗ Dimensions in bold are wear dimensions.

∗ Dimensions in brackets are original dimensions of new machines.

∗ Replace vibrator head at the latest when the minimum diameter ø

(measured in the length L) is reached.

∗ The screwed nose caps must be replaced at the latest when the

minimum lengths LL and øLL have been reached.

Machine

type

Dimensions of the vibrator head and screwed

nose caps (mm)

øL

L

L

L

ø

L

L

IR... 30 28 (30) 347 (353) - -

IR... 38 33 (38) 338 (345) 36 (38) 218

IR... 45 38 (45) 372 (382) 42 (45) 333

IR... 57

IR... 57k

50 (58) 390 (400)

320 (330)

54,0 (58)

54,0 (58)

253

213

IR... 65

IR... 65k

52 (65) 475(490)

385(400)

58 (65)

58 (65)

322

258

T01088en.fm 27

Disposal

9. Disposal

9.1 Environmentally friendly recycling

Recycle the machine in an environmentally friendly way observing the

regional regulations and directives, e. g. the European Directive for old

electrical and electronic equipment.

Do not dispose of the machine in household rubbish. It

must be disposed of separately.

Disposal

T01088en.fm 28

C0002324en.fm

Please keep this document in a safe place

EC Declaration of Conformity

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München

certifies that the construction machine:

1. Category:

Internal vibrator with inverter

2. Model:

IRFUN 38

IRFUN 45

IRFUN 57

3. Machine type number:

0007956, 0007957, 0007958, 0008464, 0008481, 0008494, 0008496, 0008611,

0008612, 0008613, 0008628, 0008629, 0008630, 0008631, 0008632, 0008633,

0008634, 0008635, 0008636, 0008637, 0008638, 0008639, 0008640, 0008928,

0610107, 0610108, 0610109, 0610110

was produced in accordance with the following directives:

98/37/EEC

89/336/EEC

73/23/EEC

Dr. Stenzel

Head of Research and Development

Prüf- und Zertifizierungsinstitut

VERBAND DER ELEKTROTECHNIK

ELEKTRONIK INFORMATIONSTECHNIK e.V.

C E R T I F I C A T E

Registration-Number: 6236/QM/06.97

This is to certify that the company

Wacker Construction Equipment AG

Wacker-Werke GmbH & Co. KG

at the following locations

Head Office Munich

Preußenstraße 41

80809 Munich

Production plant Reichertshofen

Karlsfeld logistics centre

Sales regions with all branches all over Germany

has implemented and maintains a

Qality Management System for the following scope:

Machine manufacture

Construction machines

This Q System complies with the requirements of

DIN EN ISO 9001:2000

and the requirements of the German and international Road Traffic Act.

This Certificate is valid until 2009-06-05.

VDE Testing and Certification Institute

Certification

Date: 2006-05-30

63069 Offenbach, Merianstraße 28

Telefon: +49 (0) 69 83 06-0, Telefax: +49 (0) 69 83 06-555

E-Mail: vde-institut@vde.com

, http://www.vde-institut.com

The VDE Testing and Certification Institute is accredited by DAR Accreditation

Bodies according to DIN EN ISO 17020 and DIN EN ISO 45012 and notified in the EU

under ID.No. 0366.

TGA-ZM-09-92-00

KBA-ZM-A 00021-97

DIN EN ISO 9001 Certificate

Wacker Construction Equipment AG – Preußenstraße 41 – 80809 München – Deutschland – Tel.: +49-(0)89-354 02-0 – Fax: +49-(0)89-354 02-390

Wacker Corporation – P.O. Box 9007 – Menomonee Falls, WI 53052-9007 – USA – Tel.: +1(1)262-255-0500 – Fax: +1(1)262-255-0550 – Support: 800-770-0957

Wacker Machinery (HK) Ltd.– Skyline Tower, Suite 2303, 23/F – 39 Wang Kwong Road, Kowloon Bay – Hong Kong – Tel.: +852-3188-5506, Fax: +852-2406-6021

Loading...

Loading...