Wachs WS-8460, WS-164, WS-3012, WS-3616, WS-5230 User Manual

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

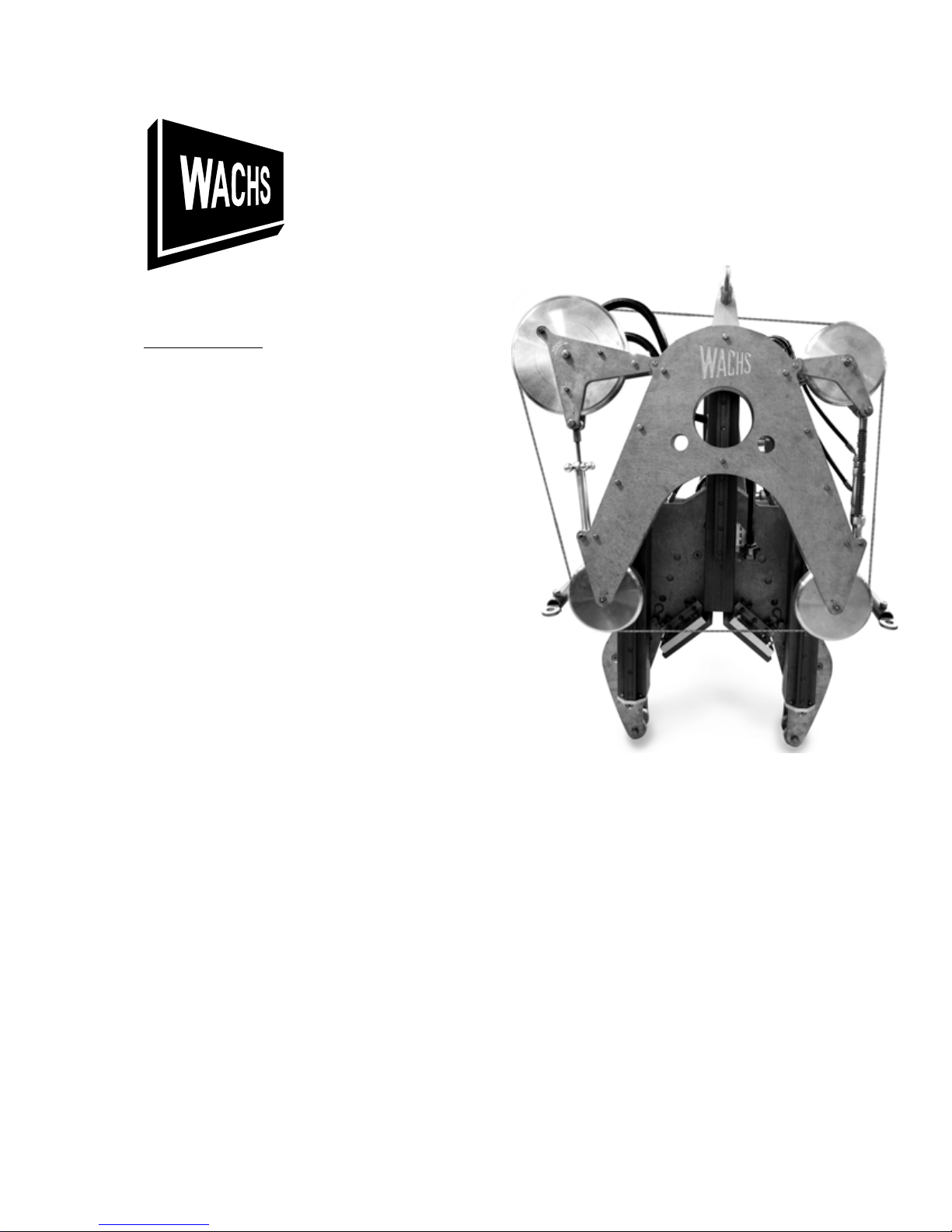

Diamond Wire Saw

User’s Manual

E.H. Wachs Part No. 10-010-MAN

Rev. 1-0310, March 2010

Revision History:

Original March 2010

Copyright © 2010 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

Diamond Wire Saw User’s Manual

Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: About the Diamond Wire Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Diamond Wire Saw Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cutting Wire Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clamping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Topside Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rigging the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lifting for Vertical Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lifting for Horizontal Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rigging the WS-8460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Protective Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3: Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tensioning the Cutting Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjusting Clamp Arms for the Pipe Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WS-164 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WS-3012 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

WS-3616 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

WS-5230 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

WS-8460 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Positioning the Clamp Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the Machine on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performing the Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Removing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 i

Diamond Wire Saw User’s Manual

Chapter 4: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replacing the Cutting Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mounting the Wire on the WS-8460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the Mounting Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing the Wheel Liners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Tension and Idler Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Bleeding the Feed Tension Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5: Parts List and Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ii Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1

About the Diamond

Wire Saw

Chapter 1, About the Diamond Wire Saw

In This Chapter

PURPOSE OF THIS MANUAL

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain the diamond wire saw. It includes instructions for set-up, operation, and maintenance. It also contains parts lists, diagrams,

and service information to help you order replacement parts

and perform user-serviceable repairs.

Before operating the diamond wire saw, you should read

through this manual and become familiar with all instructions.

HOW TO USE THE MANUAL

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining your equipment.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

equipment.

HOW TO USE THE MANUAL

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

EVISION TRACKING

R

EQUIPMENT DESCRIPTION

OPERATING ENVELOPE

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions. Refer to it for safety notes and other information.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 1

Diamond Wire Saw User’s Manual

WARNING

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

CAUTION

CAUTION

This is the equipment damage alert

symbol. It is used to alert you to potential equipment damage situations.

Obey all messages that follow this symbol to avoid damaging the equipment or

workpiece on which it is operating.

IMPORTANT

A WARNING alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in seri-

ous injury or death.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special notes and warnings. They appear in the outside column of the page, next to the section they refer to.

Make sure you understand what each symbol means, and

follow all instructions for cautions and warnings.

A CAUTION alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in

minor or moderate injury.

A CAUTION alert with the

damage alert symbol indicates a situation that will

result in damage to the

equipment.

An IMPORTANT alert with

the damage alert symbol indicates a situation that may

result in damage to the

equipment.

2 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Manual Updates and Revision Tracking

NOTE

NOTE

This symbol indicates a user note. Notes

provide additional information to supplement the instructions, or tips for easier

operation.

MANUAL UPDATES AND REVISION TRACKING

A NOTE provides supplementary information or operating tips.

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. When a manual is revised, we will update the

revision history on the title page.

You may have factory service or upgrades performed on the

equipment. If this service changes any technical data or

operation and maintenance procedures, we will include a

revised manual when we return the equipment to you.

EQUIPMENT DESCRIPTION

The diamond wire saw is designed to cut submerged pipe of

varying materials and thicknesses. The machine operates on

hydraulic power, and is controlled remotely using the

Wachs topside control panel (TCP).

The saw uses a continuous-loop diamond cutting wire and a

hydraulic feed system that advances the cutting wire

through the pipe. Using a wire rather than a blade provides

more reliable cutting on varied pipe materials, and helps

avoid binding of the cutting mechanism if the pipe bends

and pinches while the saw is engaged.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@ehwachs.com

.

The diamond wire saw required constant cooling of the wire

during cutting. The machine is specifically designed for

subsea or other underwater cutting applications, but it can

be used for non-submerged uses if adequate coolant is

applied to the wire. The machine can be supplied with customized cooling spray attachments that use tap water or

other available coolant.

The diamond wire saw has three hydraulic drive circuits:

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 3

Diamond Wire Saw User’s Manual

NOTE

The model name indicates

the pipe size capacity. The

first two digits are the largest

pipe, and the second pair of

digits is the smallest. For

example, the WS-3616 saw

will cut pipes from 16” to 36”

(406 to 914 mm) O.D.

• Cutting drive: operates the drive wheel that drives the

cutting wire.

• Feed drive: operates the bow holding the wire drive system, to feed the wire through the pipe and retract the

bow when finished cutting.

• Clamp drive: operates the clamping arms that secure the

machine to the pipe during cutting.

Separate controls and gauges for each circuit are provided

on the TCP, described later in this chapter.

Diamond Wire Saw Models

Various wire saw models are available, each designed to cut

a range of pipe sizes. All models operate in a similar manner. However, the WS-8460 model has some different features, which are highlighted throughout this manual.

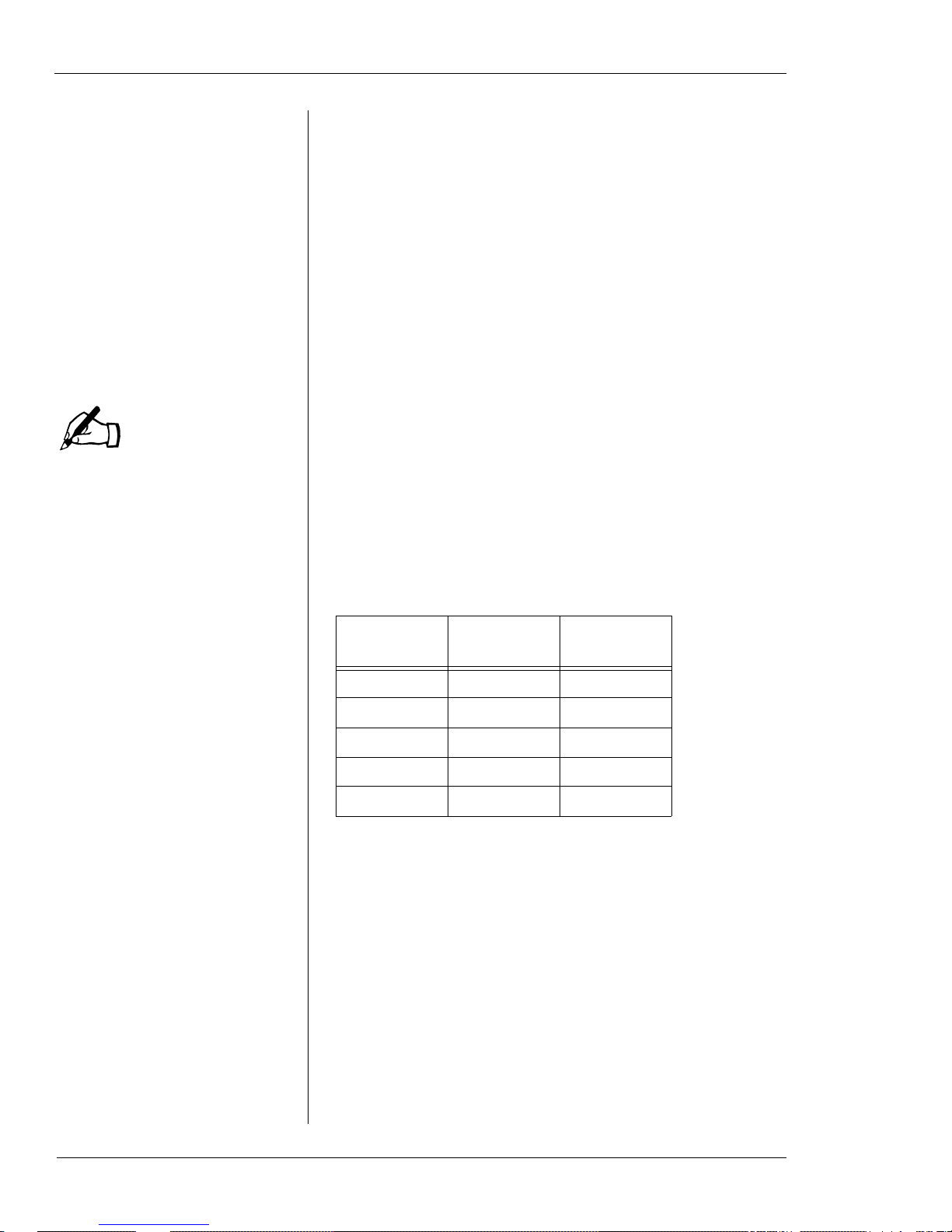

The following table lists the models and capacities.

Table 1: Diamond Wire Saw Models

Model

Min. Pipe

Capacity

Max. Pipe

Capacity

WS-164 4” (102 mm) 16” (406 mm)

WS-3012 12” (305 mm) 30” (762 mm)

WS-3616 16” (406 mm) 36” (914 mm)

WS-5230 30” (762 mm) 52” (1321 mm)

WS-8460 60” (1524 mm) 84” (2134 mm)

Cutting Wire Drive System

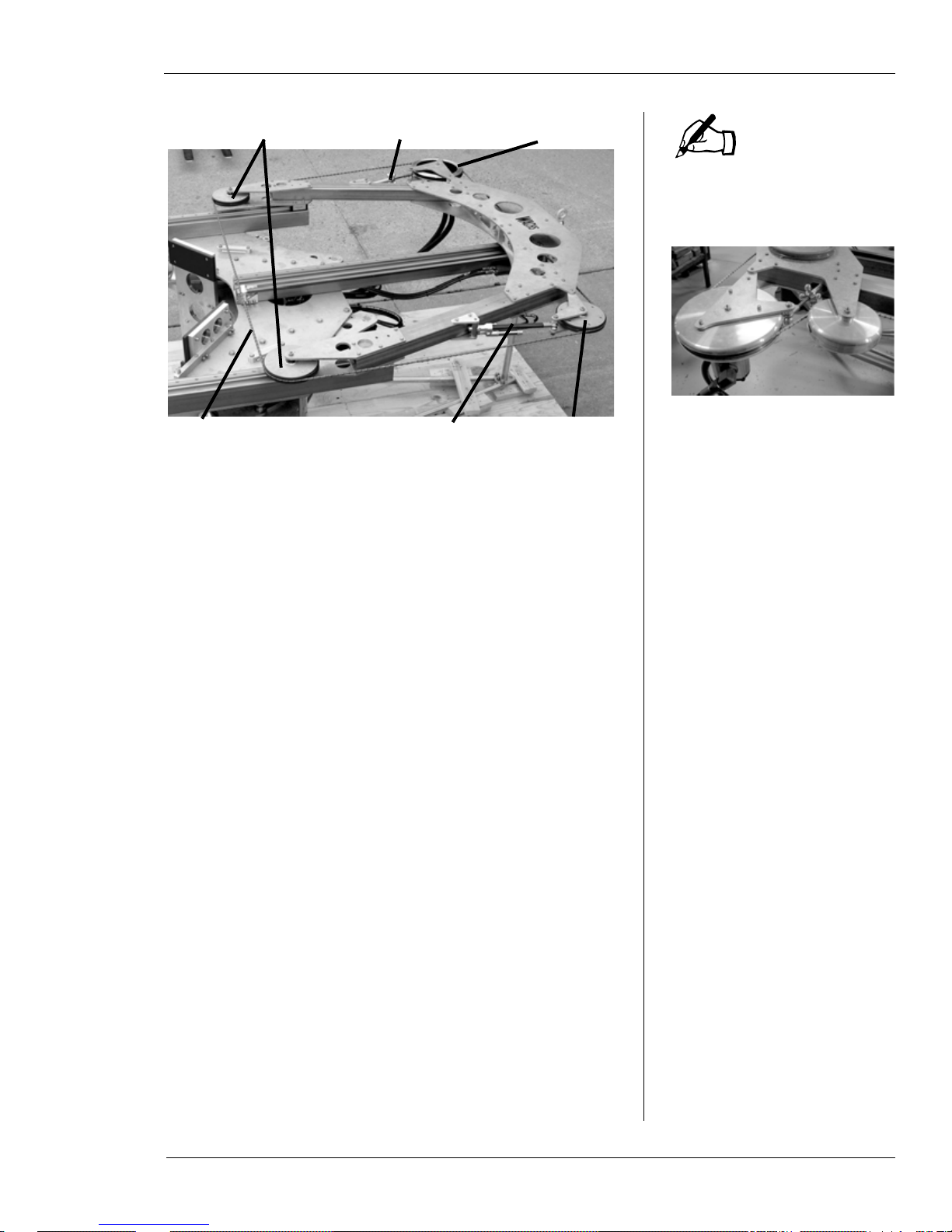

The cutting wire drive system consists of four wheels

mounted on the bow of the machine. Figure 1-1 illustrates

the drive system components.

4 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Equipment Description

NOTE

Drive wheel Idler wheel

Idler wheels Drive wheel

Tension wheelDiamond wire

Tensioning knob

Tension spring

Figure 1-1. The photo shows the cutting wire drive

system components.

The WS-8460 has an additional idler wheel next to the

drive wheel.

The drive wheel is operated by the hydraulic drive motor to

turn the wire around the cutting system loop. It is mounted

on a pivoting fixture used to adjust the tension of the wire.

The tension is set using a knob on the fixture, which also

positions the wheel for installing and removing the cutting

wire.

The tension wheel is on a pivoting, spring-loaded fixture

that maintains wire tension. The other two idler wheels are

fixed at the bottom of the bow where the cutting wire

engages the pipe.

The wire is a custom-made loop for the size of the saw.

Spare wires can be ordered from E.H. Wachs.

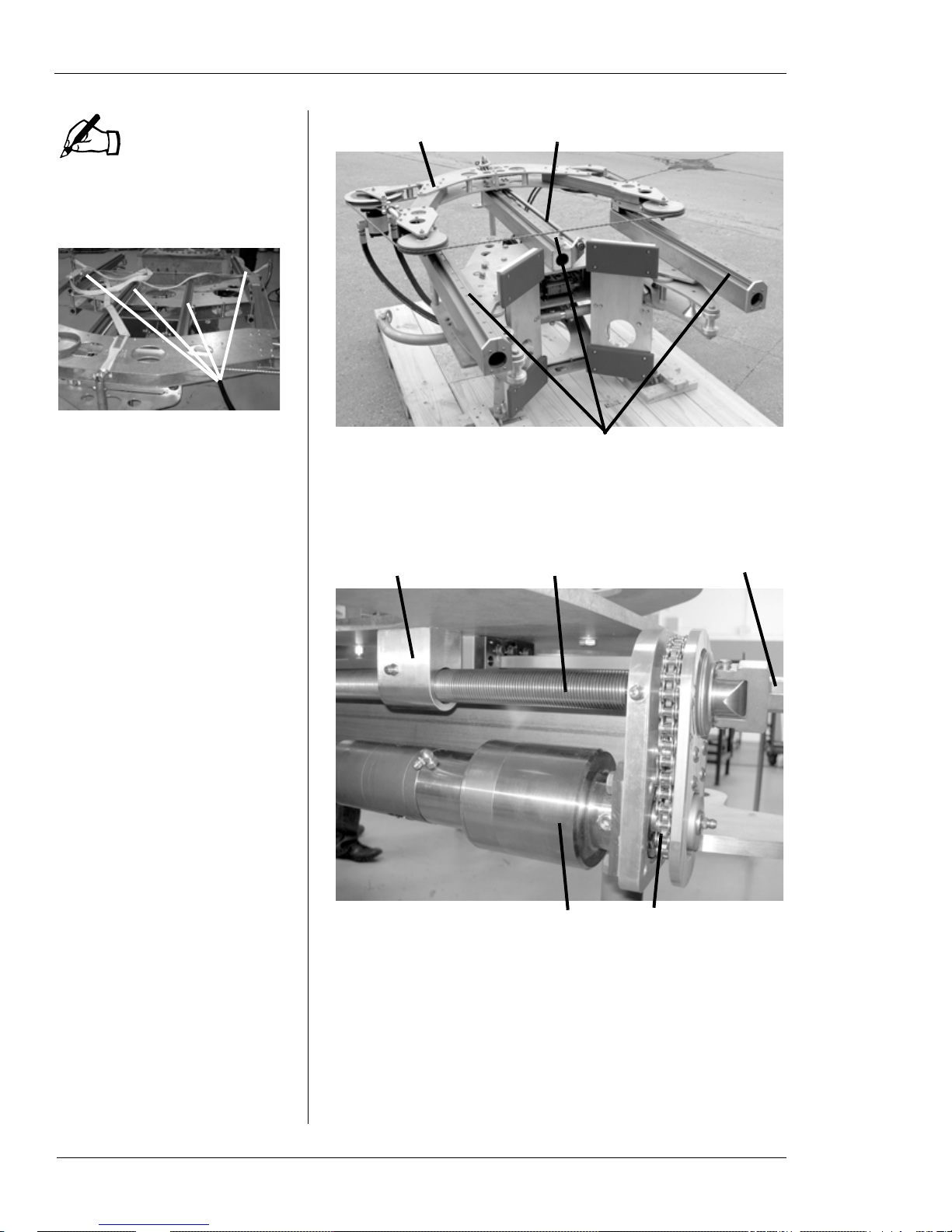

Feed System

A feed drive mechanism on the main frame of the machine

drives the bow and cutting system up and down to perform

the cut and retract the bow after cutting. The bow rides on

feed rails and is driven by a feed screw in the center of the

frame. Figure 1-2 and Figure 1-3 show the main feed system components.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 5

Diamond Wire Saw User’s Manual

NOTE

Feed rails

Feed rails

Saw bow

Feed screw

Feed block Feed screw

Feed motor Driv e chain

Manual feed nut

The WS-8460 has four feed

rails, as shown below. The

other models have three rails.

Figure 1-2. The saw bow moves on thr e e feed rails on

the frame. The feed screw along the center rail drives

the bow.

6 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 1-3. The feed system components are shown.

The feed block is attached to the saw bow.

The top of the feed screw has a drive nut to allow the feed to

be operated manually, and a clutch in the top coupling disengages the feed screw if the feed drive jams or reaches the

end of travel.

Chapter 1, About the Diamond Wire Saw: Equipment Description

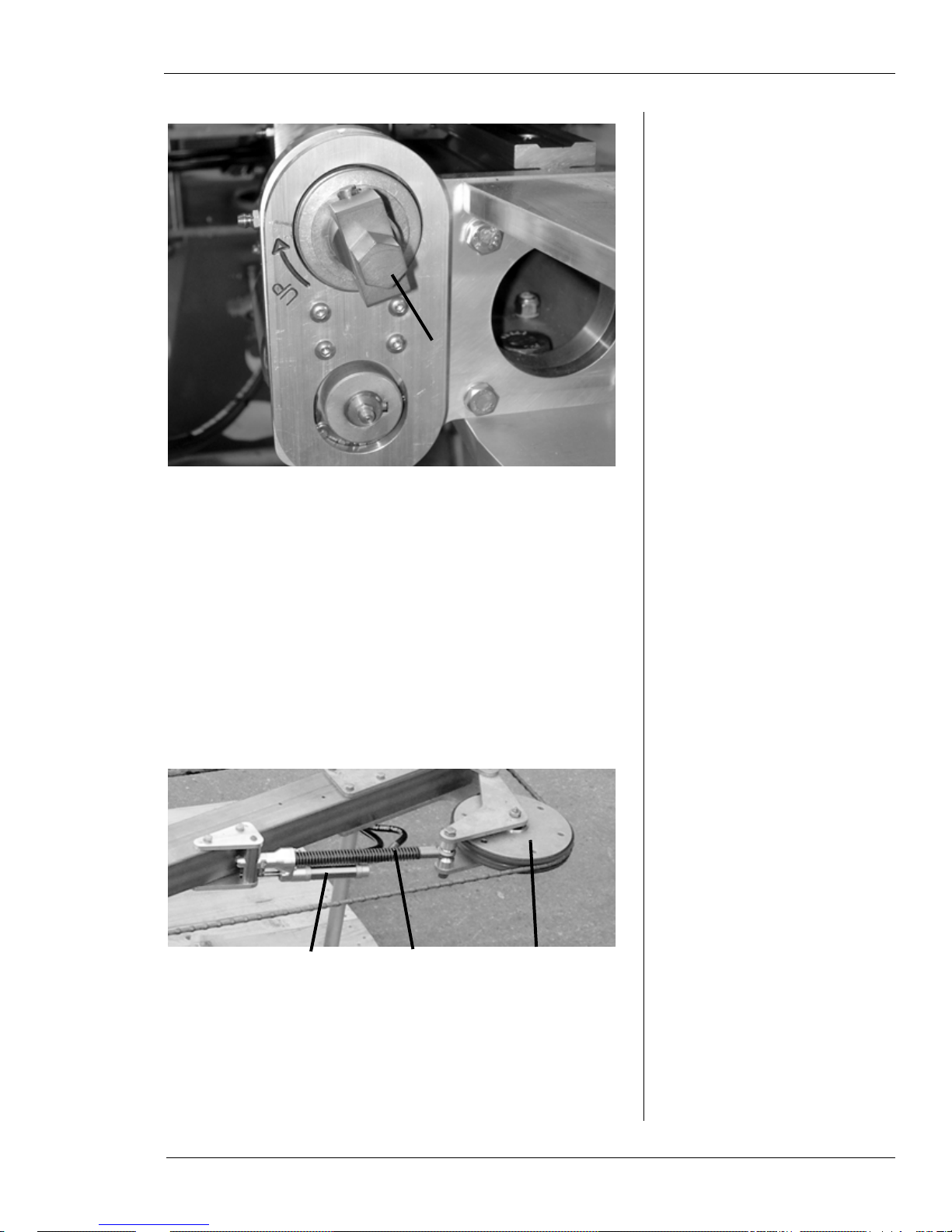

Manual

feed nut

Feed control actuator Tension wheelTension spring

Figure 1-4. Use the manual feed nut to move the saw

bow if it cannot be operated using hydraulic power.

T urn the nut clockwise to retract the bow away from

the workpiece.

The feed system has a self-adjusting speed control feature.

A hydraulic actuator on the tension wheel fixture measures

the deflection of the wire as it cuts. If the feed speed is too

fast, the increased wire deflection trips the actuator, which

slows down the feed rate. This allows the cutting action of

the wire to catch up. At maximum deflection of the wire, the

actuator will stop the feed motion for as long as necessary.

Figure 1-5. The actuator controls the feed rate by

measuring the deflection of the cutting wire.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 7

Diamond Wire Saw User’s Manual

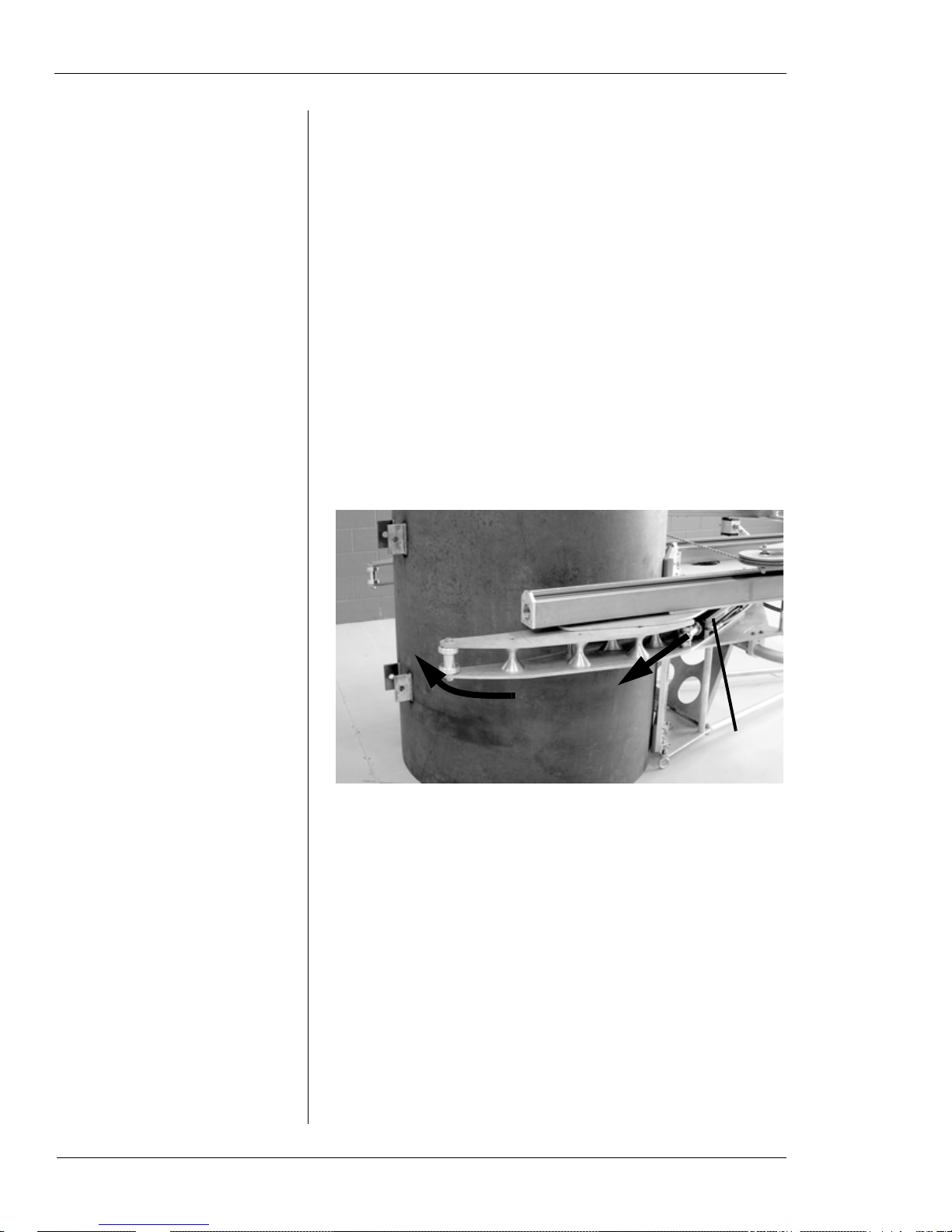

Clamping

cylinder

Clamping

motion

Clamping arm

pivots to contact pipe

Clamping System

An adjustable clamping system allows you to configure the

machine for pipe sizes within each model’s range. The two

clamping arms are attached to the main frame with twopronged forked pins that are removable to reposition the

arms.

The clamping arms are engaged by hydraulic cylinders

mounted to the frame. When the cylinder rods are extended,

the clamps pivot inward to grip the underside of the pipe

and hold the machine securely to it. Figure 1-6 illustrates

the clamping operation.

See “Adjusting Clamp Arms for the Pipe Size” later in this

chapter for information on the clamp position settings for

each wire saw model.

8 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 1-6. The photo shows the wire saw in position

for clamping on a test workpiece. When the hydraulic

cylinder is extended, the clamp arm pivots and closes

on the pipe. Both clamping arms operate together.

Chapter 1, About the Diamond Wire Saw: Equipment Description

Figure 1-7. The photo shows the clamping cylinder

extended and the clamp arm secured against the pipe.

The frame of the machine has clamp shoes attached that the

machine rests upon when installed on the pipe. These shoes

are made of a compressible composite material that deforms

slightly under pressure to create a secure, slip-free grip on

the pipe when the machine is clamped.

Figure 1-8. The front mounting shoes are shown.

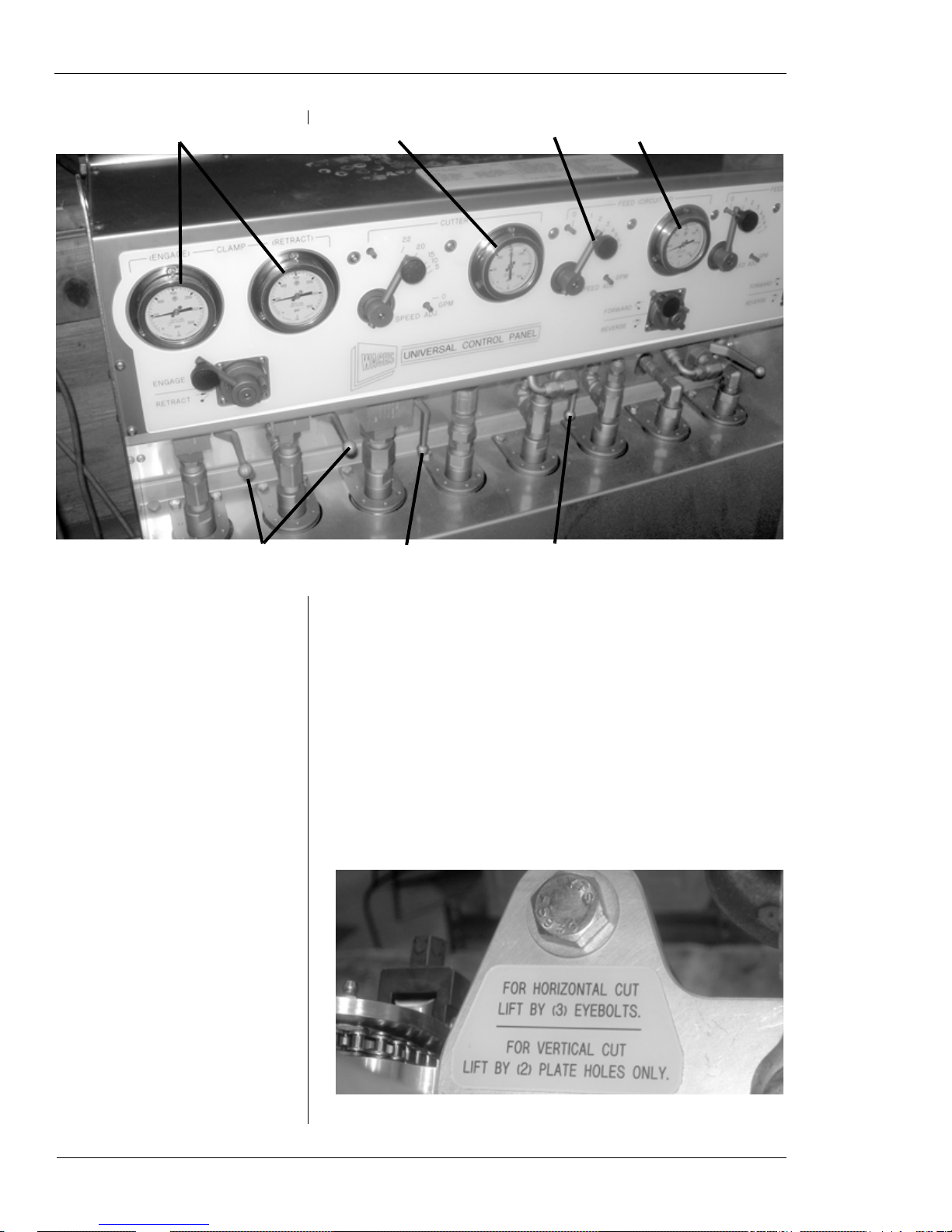

Topside Control Panel

Figure 1-9 illustrates the controls used to operate the subsea

wire saw. Chapter 3 includes detailed instructions.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 9

Diamond Wire Saw User’s Manual

Clamp pressure gauges

Clamp

direction

Cutter

speed

Cutter pressure gauge

Feed speed Feed pressure gauge

Feed

direction

Clamping flow levers (engage

both at once—shown closed

under pressure)

Feed flow lever

(shown open)

Cutter flow lever

(shown open)

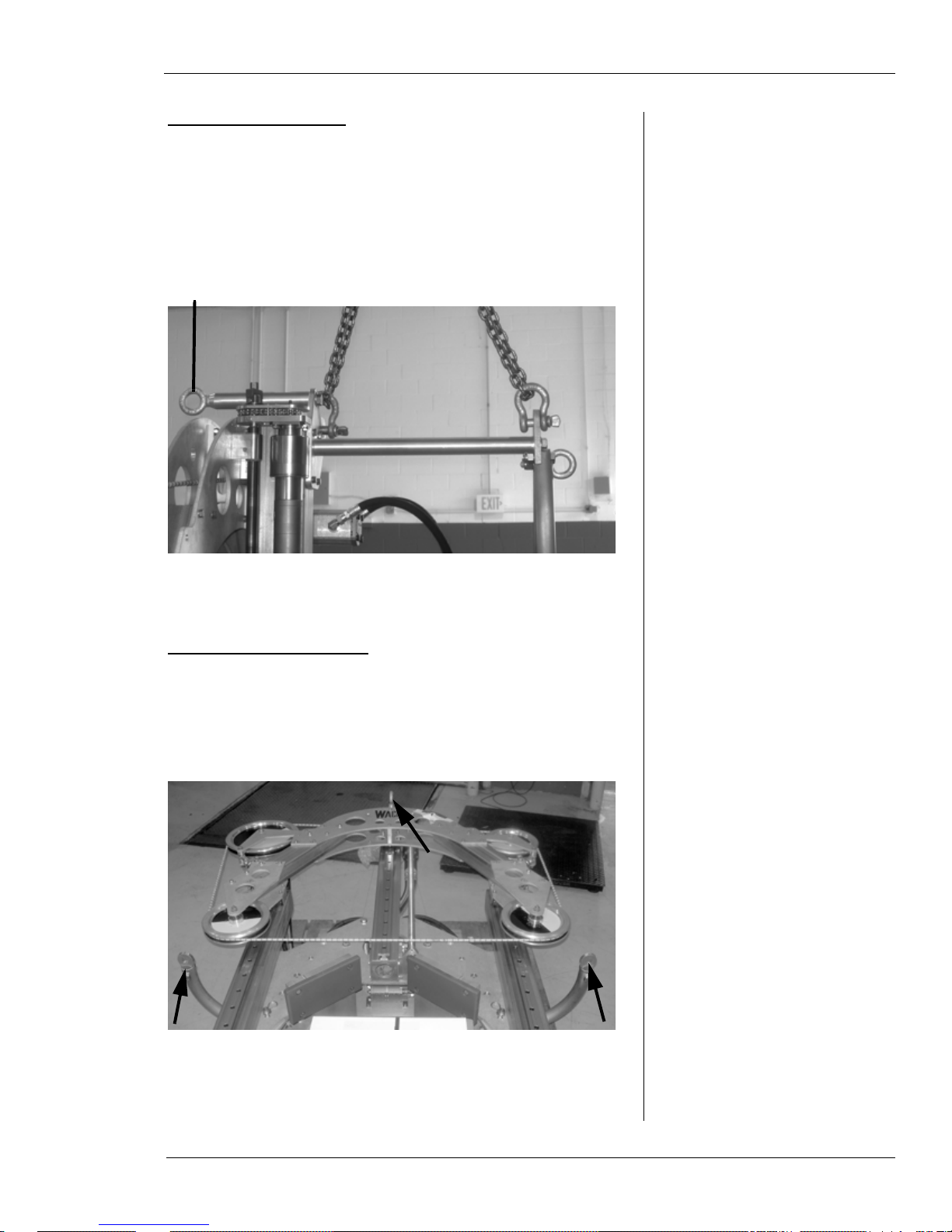

Rigging the Machine

A rigging instruction label is attached to the top of the

machine frame on WS-164 through WS-5230 models. See

the end of this section for information on rigging the WS8460 model.

Figure 1-9. The photo shows the controls on the topside control unit. (The fourth cir cuit, to the far right, is

not used with the subsea wire saw.)

10 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 1-10. The rigging label is on top of the frame.

Chapter 1, About the Diamond Wire Saw: Equipment Description

IMPORTANT: Do not attach to this hook

when lifting the machine vertically!

Lifting for Vertical Cut

Attach the machine to the lifting device using chains on the

top lift hooks. Tip the machine up to a vertical position, then

pick it up. Make sure the chains are the appropriate length to

hold the machine reasonably straight.

Figure 1-11. To position the machine vertically on the

pipe, attach to the two top lift hooks.

Lifting for Horizontal Cut

With the machine positio ned horizontal on the floor or deck,

attach a lift to the two hooks on the lift bar and the front

hook on top of the frame.

Figure 1-12. To position the machine horizontally on

the pipe, attach to the two lift bar hooks and the front

hook on the top.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 11

Diamond Wire Saw User’s Manual

Lift vertically from this point only

Lift horizontally from these three points

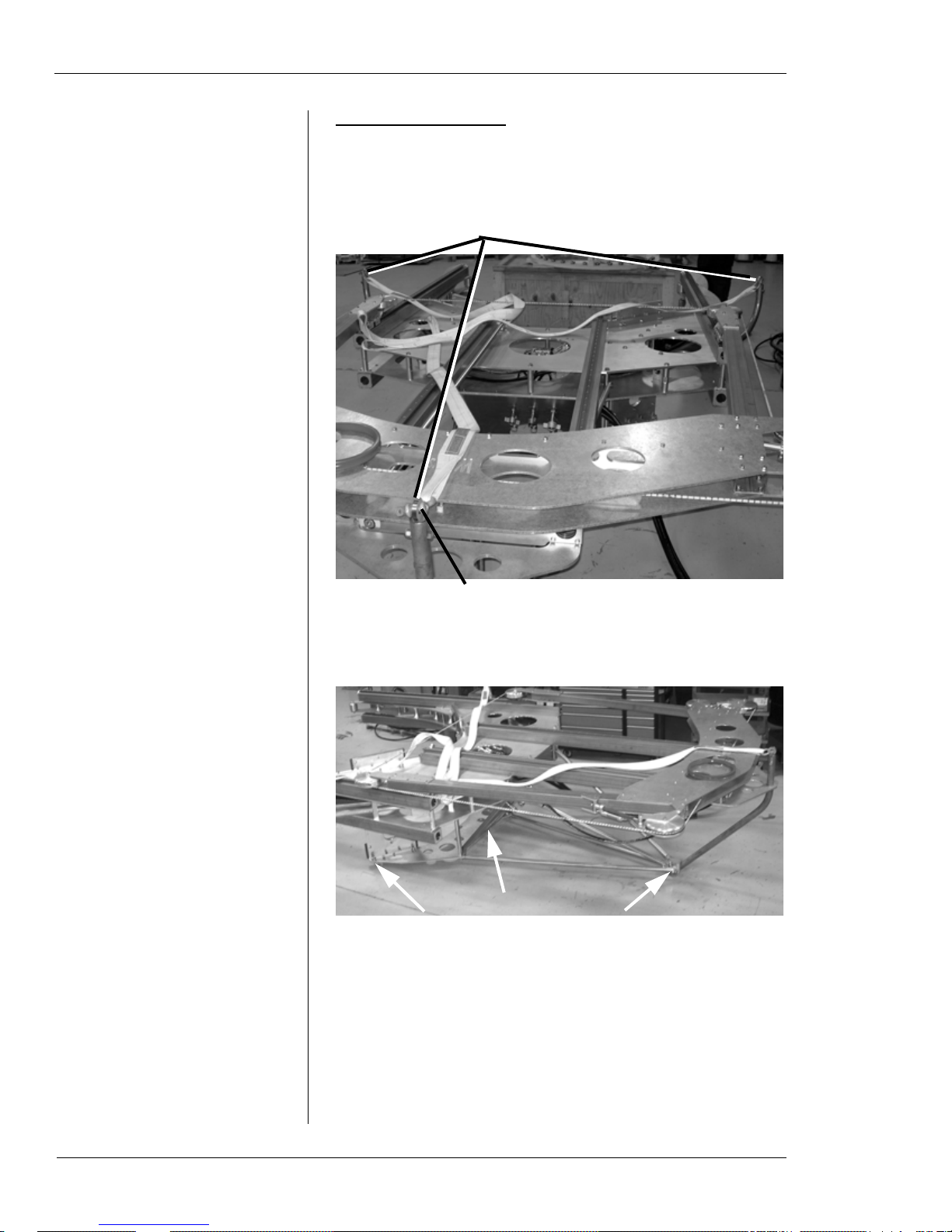

Rigging the WS-8460

You can lift the WS-8460 saw vertically, or in either horizontal orientation. See the following figures for lift points.

Figure 1-13. Use the lift points indicated to lift the

machine horizontally or vertically.

Figure 1-14. To lift the machine horizontally from the

other side, use the three points indicated in the photo

(third point is out of view under frame).

Storing the Machine

Store the machine sitting horizontal with the front of it (the

side with the Wachs logo) facing up. For long-term storage,

12 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Operating Envelope

clean and dry the machine thoroughly, then cover it with a

waterproof cover.

You can leave the wire installed on the machine during storage. Keep normal tension on the wire to hold it in place.

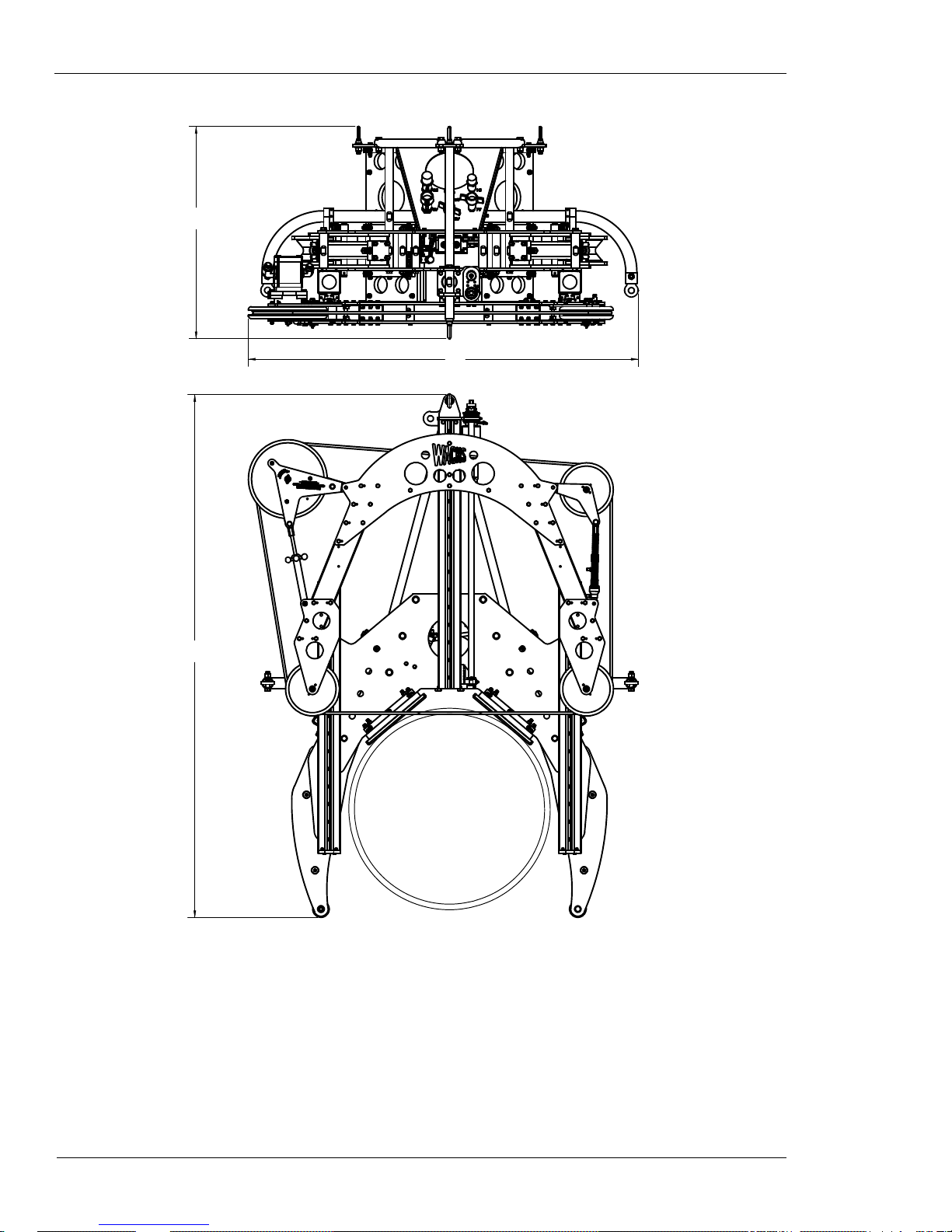

OPERATING ENVELOPE

The table below and the drawing on the next page describe

the operating envelope for all four diamond wire saw models. The “DIM” column in the table refers to the labeled

dimensions on the drawing. “Stroke” is the feed distance of

the saw bow.

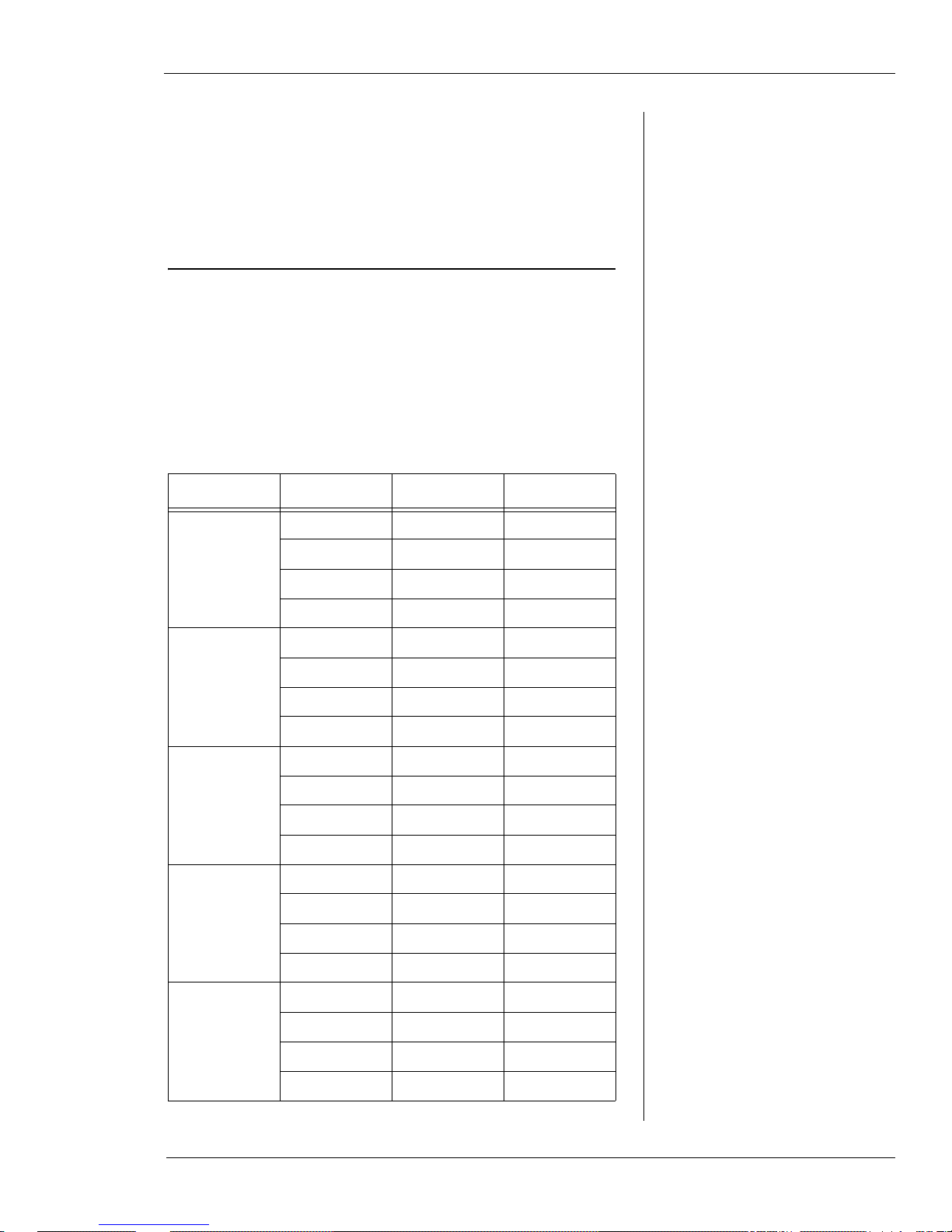

Table 2: Operating Envelope Dimensions

Model DIM Inches MM

WS-164

WS-3012

WS-3616

WS-5230

A 48.5 1232

B28.0711

C 63.8 1621

Stroke 22.9 582

A 63.8 1621

B 34.9 886

C 82.6 2098

Stroke 39.0 991

A 69.6 1768

B 38.0 965

C 93.5 2375

Stroke 43.9 1115

A 87.4 2220

B 48.9 1242

C 131.0 3327

Stroke 61.9 1572

WS-8460

Stroke 97.8 2484

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 13

A 119.0 3023

B46.51181

C 205.25 5213

Diamond Wire Saw User’s Manual

A

B

C

14 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 2

Safety

The E.H. Wachs Company takes great pride in designing

and manufacturing safe, high-quality products. We make

user safety a top priority in the design of all our products.

Chapter 2, Safety

In This Chapter

OPERATOR SAFETY

SAFETY LABELS

Read this chapter carefully before operating the subsea wire

saw. It contains important safety instructions and recommendations.

OPERATOR SAFETY

WARNING: The cutting wire spins at very high speed. If

the wire breaks, segments of the wire can fragment and be

thrown from the machine at dangerous speeds. When operating the machine topside, stay a safe distance from the

machine, or behind a protective barrier. Divers should stay

a safe distance from the machine when it is running. Seri-

ous injury or death could result from contact with the

wire or as a result of the wire breaking.

Follow these guidelines for safe operation of the equipment.

• READ THE OPERATING MANUAL. Make sure

you understand all setup and operating instructions

before you begin.

• INSPECT MACHINE AND ACCESSORIES.

Before starting the machine, look for loose bolts or

nuts, leaking lubricant, rusted components, and any

other physical conditions that may affect operation.

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 15

Diamond Wire Saw User’s Manual

Properly maintaining the machine can greatly decrease

the chances for injury.

• ALWAYS READ PLACARDS AND LABELS. Make

sure all placards, labels, and stickers are clearly legible

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

• KEEP CLEAR OF MOVING PARTS. Keep hands,

arms, and fingers clear of all rotating or moving parts.

Always turn machine off before doing any adjustments

or service.

• SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry , and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

• KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

16 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

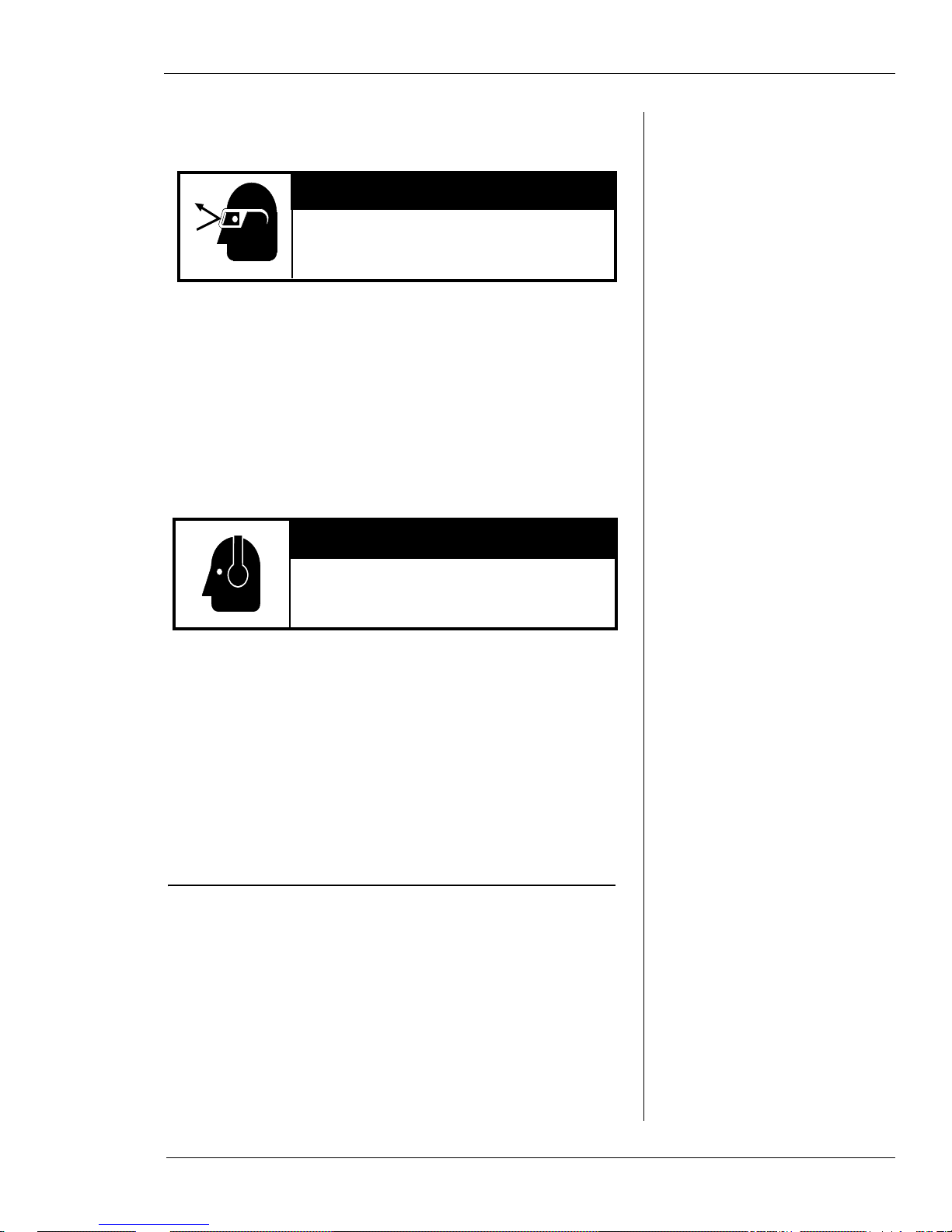

Protective Equipment Requirements

Always wear impact resistant eye protection while operating or working near

this equipment.

WARNING

CAUTION

Personal hearing protection is recommended when operating or working near

this tool.

For additional information on eye and face protection, refer

to Federal OSHA regulations, 29 Code of Federal Regulations, Section 1910.133., Eye and Face Protection and

American National Standards Institute, ANSI Z87.1, Occupational and Educational Eye and Face Protection. Z87.1 is

available from the American National Standards Institute,

Inc., 1430 Broadway, New York, NY 10018.

Chapter 2, Safety: Safety Labels

Hearing protectors are required in high noise areas, 85 dBA

or greater . The operation of other tools and equipment in the

area, reflective surfaces, process noises, and resonant structures can increase the noise level in the area. For additional

information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section

1910.95, Occupational Noise Exposure and ANSI S12.6

Hearing Protectors.

SAFETY LABELS

There is no safety labeling on the subsea wire saw.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 17

Diamond Wire Saw User’s Manual

18 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 3

Operating

Instructions

TENSIONING THE CUTTING WIRE

You should have the wire installed according to the maintenance instructions in Chapter 4.

At the tension wheel fixture, check the start lines on

1.

the feed control actuator. When there is no tension on

the wire, the actuator rod will be retracted and the

start lines will be offset.

Chapter 3, Operating Instructions

In This Chapter

TENSIONING THE CUTTING

IRE

W

ADJUSTING CLAMP ARMS FOR

THE PIPE SIZE

CONNECTING THE HYDRAULIC

OSES

H

MOUNTING THE MACHINE ON

THE PIPE

PERFORMING THE CUT

REMOVING THE MACHINE

Figure 3-1. With no tension on the wire, the feed

actuator start lines will be offset.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 19

Diamond Wire Saw User’s Manual

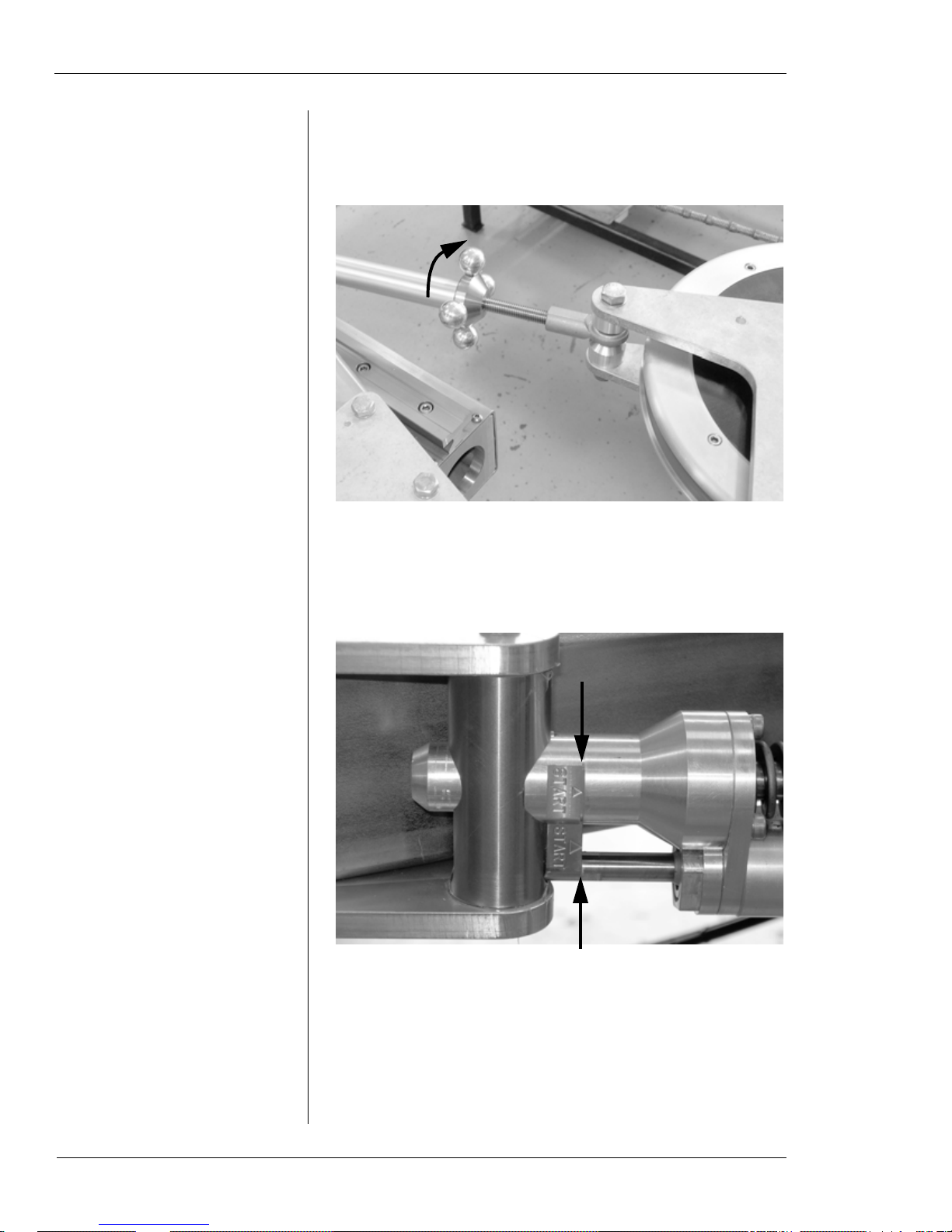

Tighten the drive wheel tensioning knob, as shown in

2.

Figure 3-2, until you can see the line on the springloaded driver wheel, Figure 3-3.

Figure 3-2. Turn the tension knob on the drive wheel

fixture to incr ease the tension on the wire. (Depending

on the exact length of the wire, about 3-4” of the scr ew

will be visible when the tension is set correctly.)

Figure 3-3. When the wire is properly tensioned, the

start lines will be lined up together.

20 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

You should be able to deflect the wire fairly easily by

3.

pushing it up between the idler wheels. Push it in far

enough to compress the tension spring, and make sure

the actuator rod extends into the slot in the shaft.

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

Figure 3-4. When you push the wire to deflect it, the

actuator rod will extend.

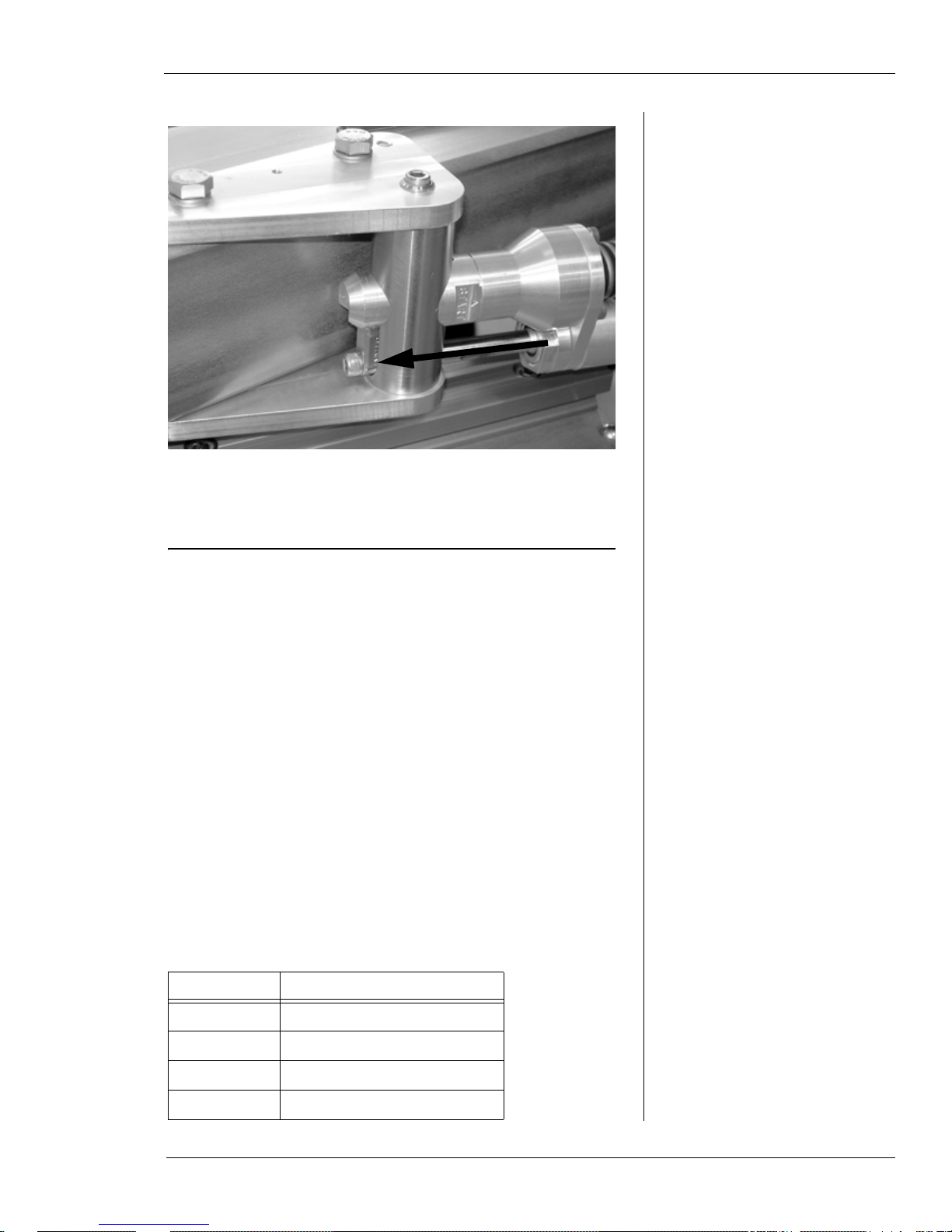

ADJUSTING CLAMP ARMS FOR THE PIPE SIZE

The clamp arms are attached to the main frame using forked

pins that go through two holes in the frame. Multiple sets of

holes allow the arms to be mounted in various positions.

The hole pairs for each position are stamped with the size of

the largest pipe for that position. Refer to the following sections for the pipe size settings for each saw model.

WS-164 Pipe Size Settings

Table 1 describes the pipe size settings for the WS-164

model.

Table 1: Pipe Size Ranges for Clamping

Arm Positions—WS-164

Size Stamp Pipe Diameter Range

7 4” to 7” (102-178 mm)

10 7” to 10” (178-254 mm)

13 10” to 13” (254-330 mm)

16 13” to 16” (330-406 mm)

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 21

Diamond Wire Saw User’s Manual

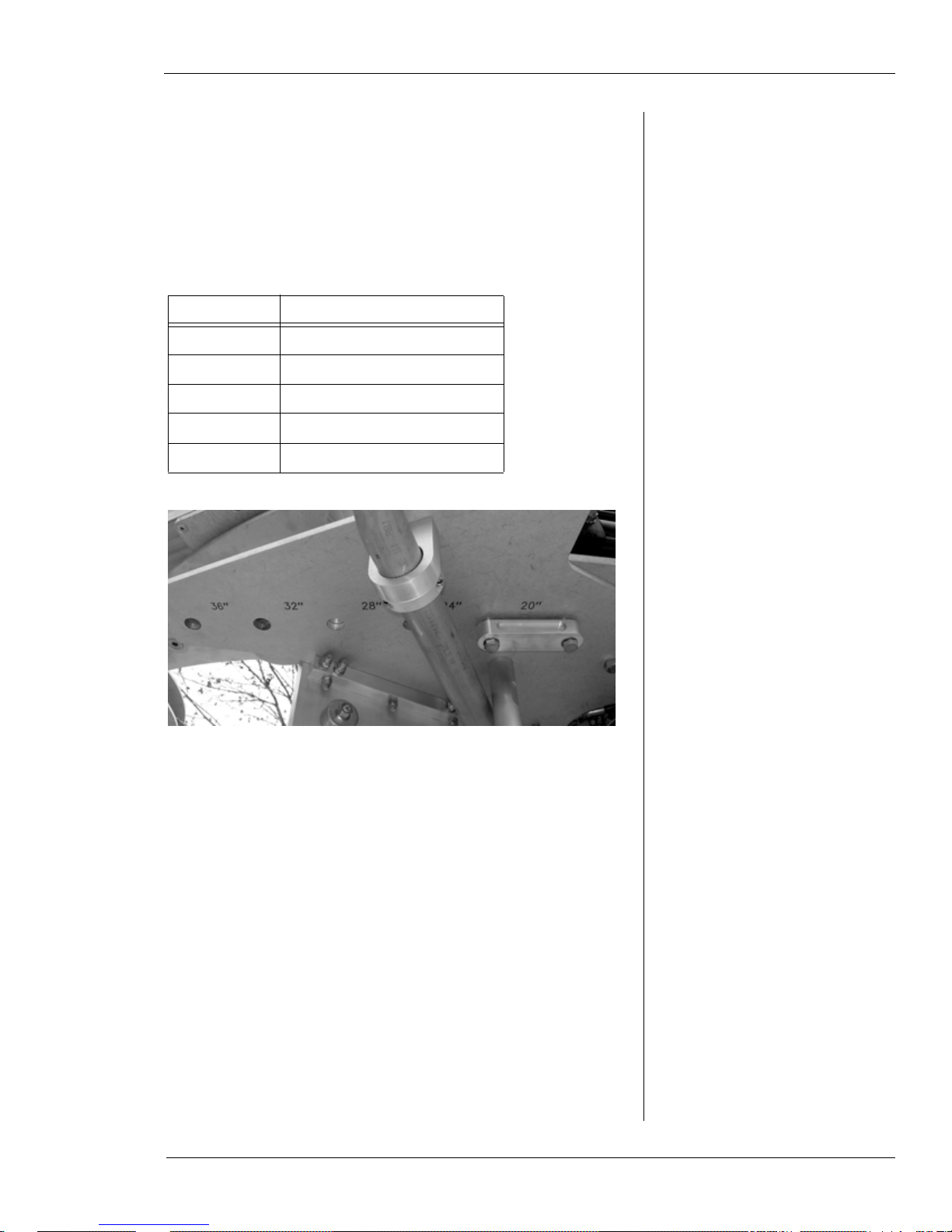

WS-3012 Pipe Size Settings

T able 2 and Figure 3-5 describe the pipe size settings for the

WS-3012 model.

Table 2: Pipe Size Ranges for Clamping

Arm Positions—WS-3012

Size Stamp Pipe Diameter Range

14 12” to 14” (305-356 mm)

18 14” to 18” (356-457 mm)

22 18” to 22” (457-559 mm)

26 22” to 26” (559-660 mm)

30 26” to 30” (660-762 mm)

22 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 3-5. The photo shows the size stamps on the

WS-3012 model. The pin is in the 26-30” position.

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

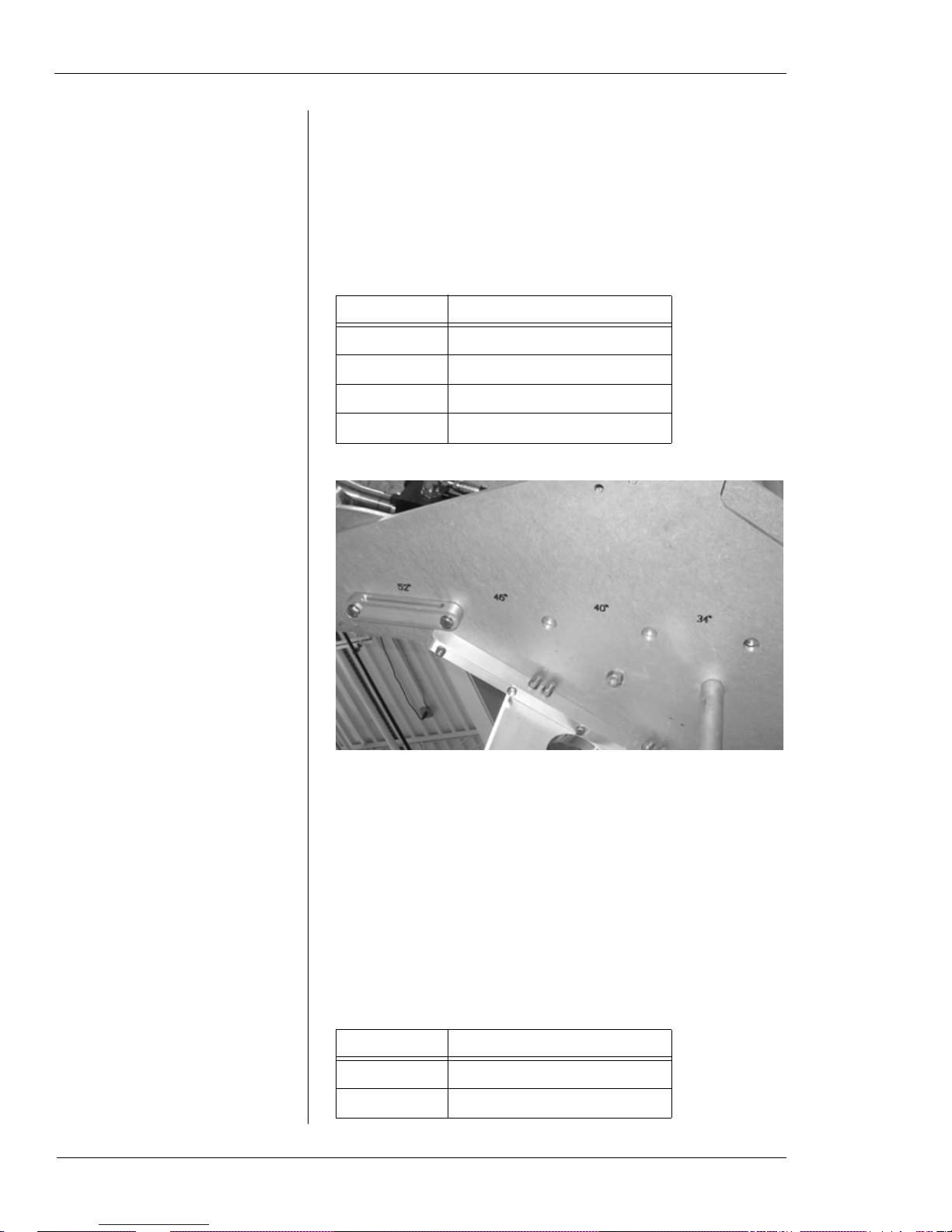

WS-3616 Pipe Size Settings

T able 3 and Figure 3-6 describe the pipe size settings for the

WS-3616 model.

Table 3: Pipe Size Ranges for Clamping

Arm Positions—WS-3616

Size Stamp Pipe Diameter Range

20 16” to 20” (406-508 mm)

24 20” to 24” (508-610 mm)

28 24” to 28” (610-711 mm)

32 28” to 32” (711-813 mm)

36 32” to 36” (813-914 mm)

Figure 3-6. The photo shows the size stamps on the

WS-3616 model. The pin is in the 16-20” position.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 23

Diamond Wire Saw User’s Manual

WS-5230 Pipe Size Settings

T able 4 and Figure 3-7 describe the pipe size settings for the

WS-5230 model.

Table 4: Pipe Size Ranges for Clamping

Arm Positions—WS-5230

Size Stamp Pipe Diameter Range

34 30” to 34” (762-864 mm)

40 34” to 40” (864-1016 mm)

46 40” to 46” (1016-1168 mm)

52 46” to 52” (1168-1321 mm)

24 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 3-7. The photo shows the size stamps on the

WS-5230 model. The pin is in the 46-52” position.

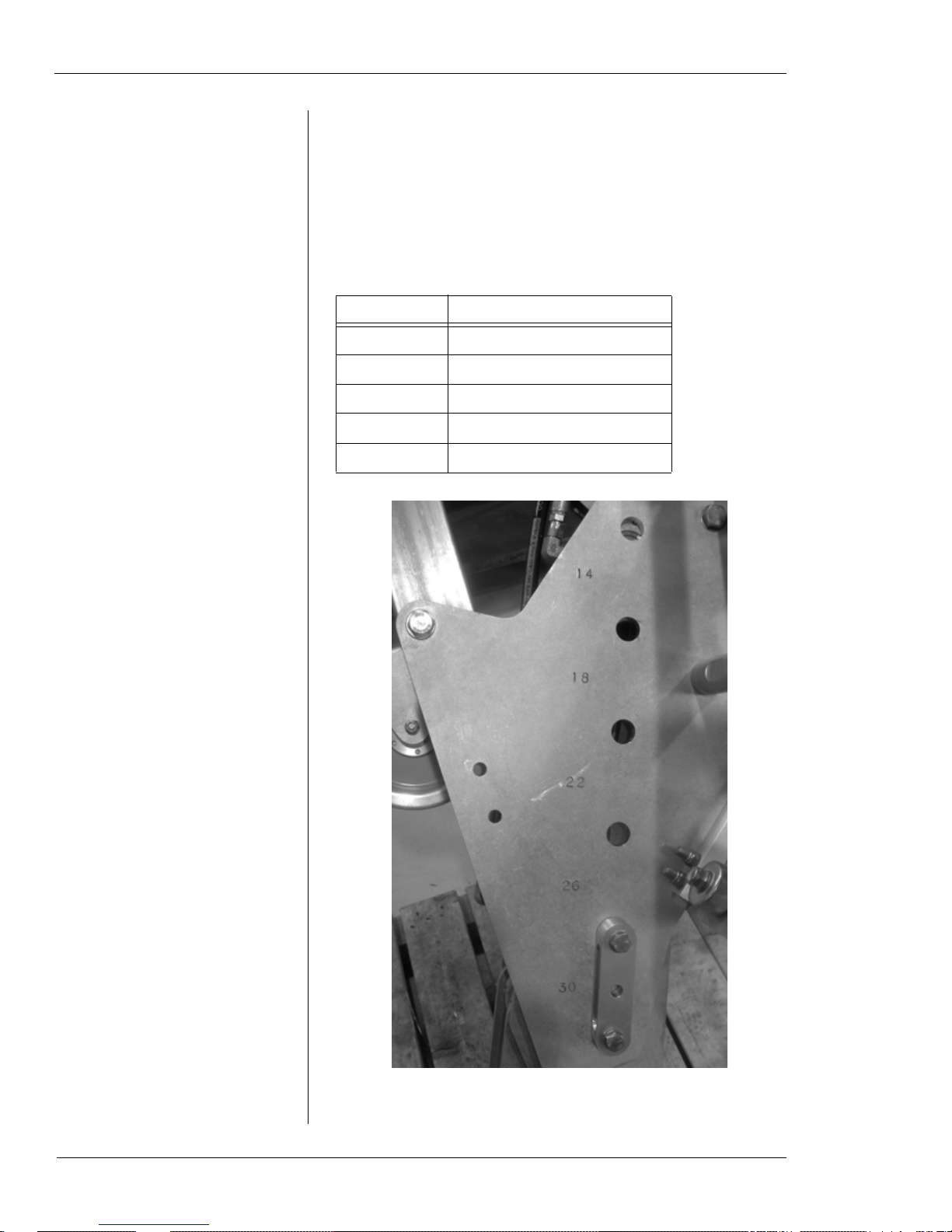

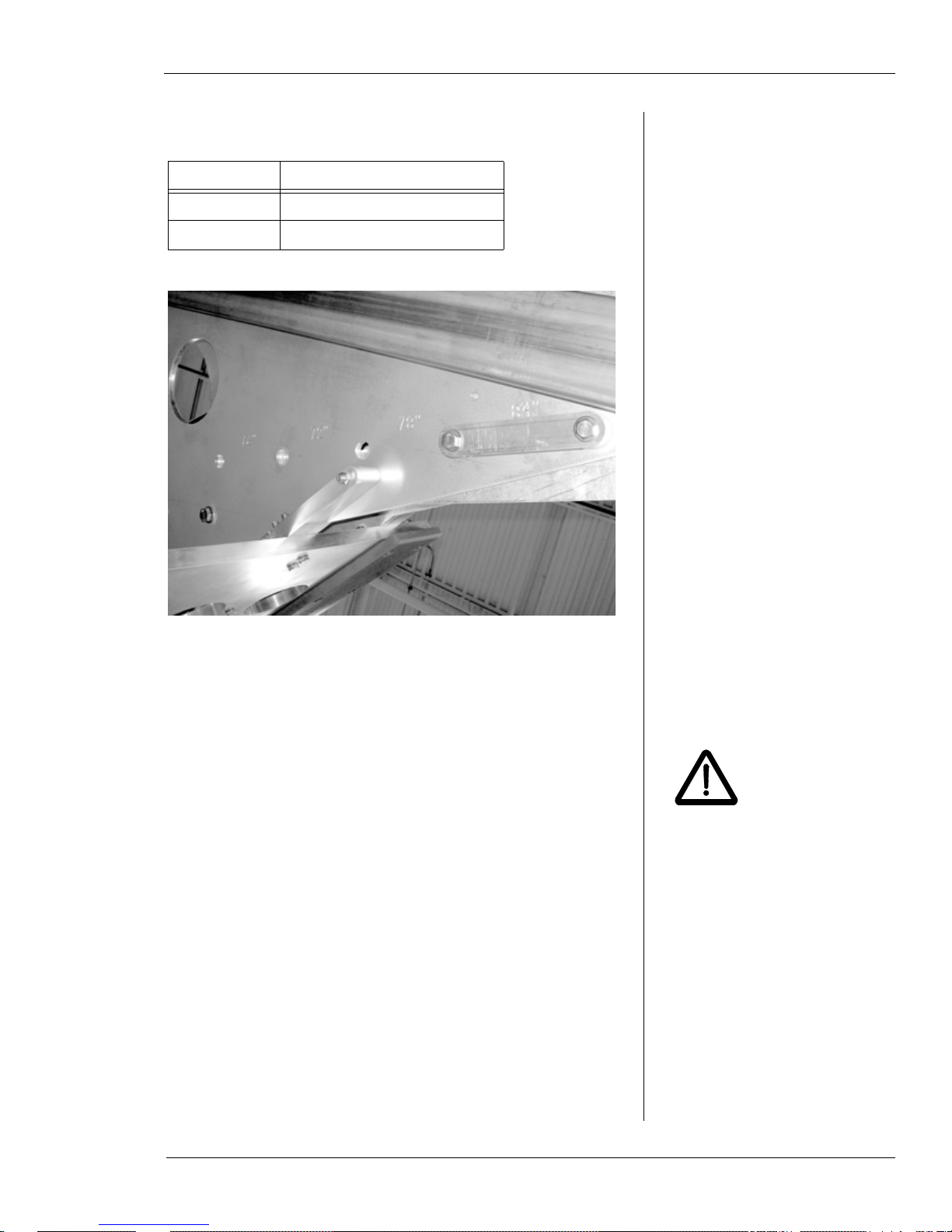

WS-8460 Pipe Size Settings

T able 5 and Figure 3-8 describe the pipe size settings for the

WS-8460 model.

Table 5: Pipe Size Ranges for Clamping

Arm Positions—WS-8460

Size Stamp Pipe Diameter Range

66 60” to 66” (152 4-1676 mm)

72 66” to 72” (167 6-1829 mm)

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

WARNING

Table 5: Pipe Size Ranges for Clamping

Arm Positions—WS-8460

Size Stamp Pipe Diameter Range

78 72” to 78” (1829 -1981 mm)

84 78” to 84” (1981 -2134 mm)

Figure 3-8. The photo shows the size stamps on the

WS-8460 model. The pin is in the 78-84” position.

Positioning the Clamp Arms

Make sure the saw is sitting horizontally on a level surface

before you adjust the clamp arms.

Remove the spring clips from both pin ends of the

1.

forked pin, then pull the forked pin out of the frame.

Do not attempt to change the

clamp arm positions while the

saw is in a vertical position.

The clamp arms may fall

when the pins are removed,

resulting in personal injury

and equipment damage.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 25

Loading...

Loading...