E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

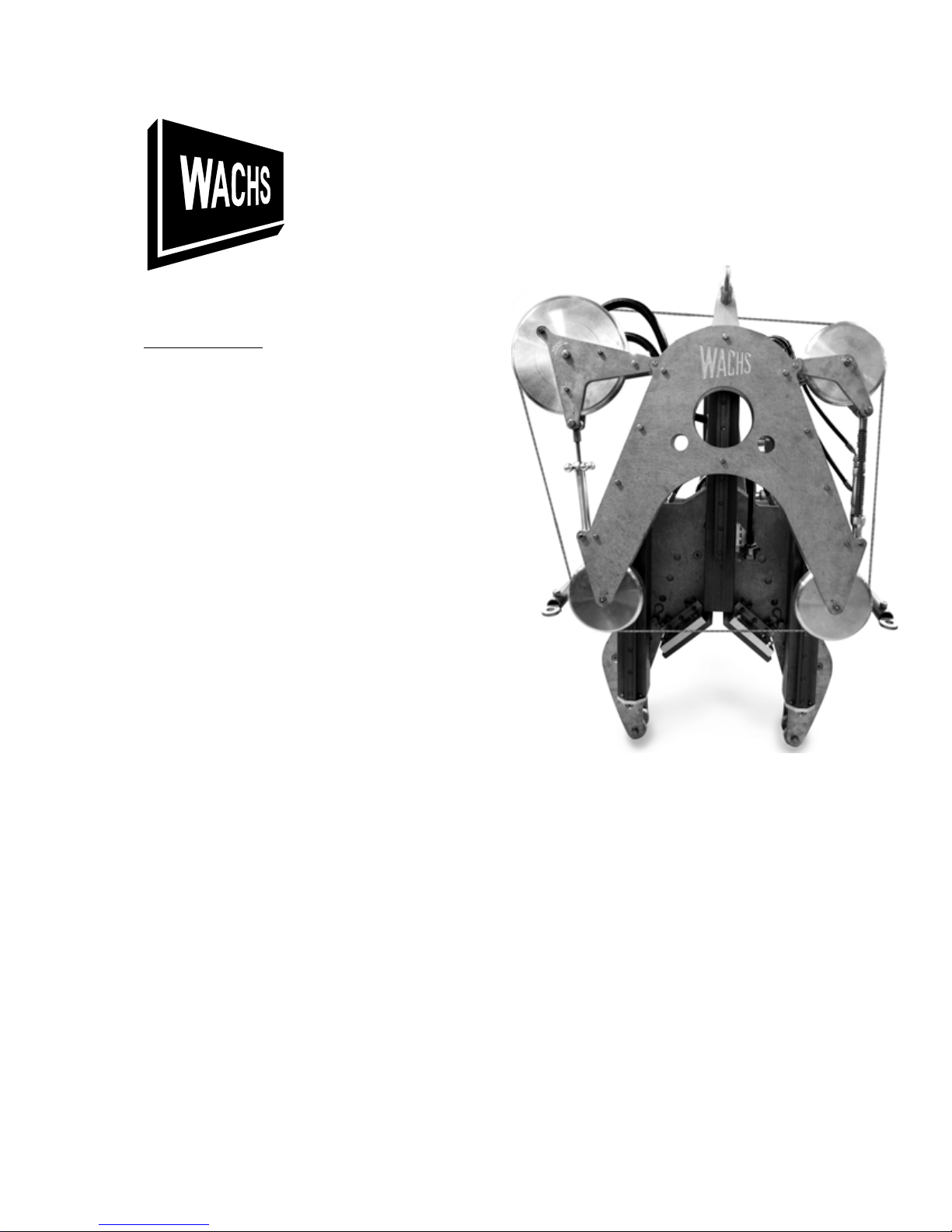

Diamond Wire Saw

User’s Manual

E.H. Wachs Part No. 10-010-MAN

Rev. 1-0310, March 2010

Revision History:

Original March 2010

Copyright © 2010 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

Diamond Wire Saw User’s Manual

Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: About the Diamond Wire Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Diamond Wire Saw Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cutting Wire Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clamping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Topside Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rigging the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lifting for Vertical Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lifting for Horizontal Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rigging the WS-8460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Protective Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3: Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tensioning the Cutting Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjusting Clamp Arms for the Pipe Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WS-164 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WS-3012 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

WS-3616 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

WS-5230 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

WS-8460 Pipe Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Positioning the Clamp Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the Machine on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performing the Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Removing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 i

Diamond Wire Saw User’s Manual

Chapter 4: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replacing the Cutting Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mounting the Wire on the WS-8460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the Mounting Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing the Wheel Liners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Tension and Idler Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Bleeding the Feed Tension Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5: Parts List and Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ii Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1

About the Diamond

Wire Saw

Chapter 1, About the Diamond Wire Saw

In This Chapter

PURPOSE OF THIS MANUAL

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain the diamond wire saw. It includes instructions for set-up, operation, and maintenance. It also contains parts lists, diagrams,

and service information to help you order replacement parts

and perform user-serviceable repairs.

Before operating the diamond wire saw, you should read

through this manual and become familiar with all instructions.

HOW TO USE THE MANUAL

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining your equipment.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

equipment.

HOW TO USE THE MANUAL

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

EVISION TRACKING

R

EQUIPMENT DESCRIPTION

OPERATING ENVELOPE

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions. Refer to it for safety notes and other information.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 1

Diamond Wire Saw User’s Manual

WARNING

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

CAUTION

CAUTION

This is the equipment damage alert

symbol. It is used to alert you to potential equipment damage situations.

Obey all messages that follow this symbol to avoid damaging the equipment or

workpiece on which it is operating.

IMPORTANT

A WARNING alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in seri-

ous injury or death.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special notes and warnings. They appear in the outside column of the page, next to the section they refer to.

Make sure you understand what each symbol means, and

follow all instructions for cautions and warnings.

A CAUTION alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in

minor or moderate injury.

A CAUTION alert with the

damage alert symbol indicates a situation that will

result in damage to the

equipment.

An IMPORTANT alert with

the damage alert symbol indicates a situation that may

result in damage to the

equipment.

2 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Manual Updates and Revision Tracking

NOTE

NOTE

This symbol indicates a user note. Notes

provide additional information to supplement the instructions, or tips for easier

operation.

MANUAL UPDATES AND REVISION TRACKING

A NOTE provides supplementary information or operating tips.

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. When a manual is revised, we will update the

revision history on the title page.

You may have factory service or upgrades performed on the

equipment. If this service changes any technical data or

operation and maintenance procedures, we will include a

revised manual when we return the equipment to you.

EQUIPMENT DESCRIPTION

The diamond wire saw is designed to cut submerged pipe of

varying materials and thicknesses. The machine operates on

hydraulic power, and is controlled remotely using the

Wachs topside control panel (TCP).

The saw uses a continuous-loop diamond cutting wire and a

hydraulic feed system that advances the cutting wire

through the pipe. Using a wire rather than a blade provides

more reliable cutting on varied pipe materials, and helps

avoid binding of the cutting mechanism if the pipe bends

and pinches while the saw is engaged.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@ehwachs.com

.

The diamond wire saw required constant cooling of the wire

during cutting. The machine is specifically designed for

subsea or other underwater cutting applications, but it can

be used for non-submerged uses if adequate coolant is

applied to the wire. The machine can be supplied with customized cooling spray attachments that use tap water or

other available coolant.

The diamond wire saw has three hydraulic drive circuits:

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 3

Diamond Wire Saw User’s Manual

NOTE

The model name indicates

the pipe size capacity. The

first two digits are the largest

pipe, and the second pair of

digits is the smallest. For

example, the WS-3616 saw

will cut pipes from 16” to 36”

(406 to 914 mm) O.D.

• Cutting drive: operates the drive wheel that drives the

cutting wire.

• Feed drive: operates the bow holding the wire drive system, to feed the wire through the pipe and retract the

bow when finished cutting.

• Clamp drive: operates the clamping arms that secure the

machine to the pipe during cutting.

Separate controls and gauges for each circuit are provided

on the TCP, described later in this chapter.

Diamond Wire Saw Models

Various wire saw models are available, each designed to cut

a range of pipe sizes. All models operate in a similar manner. However, the WS-8460 model has some different features, which are highlighted throughout this manual.

The following table lists the models and capacities.

Table 1: Diamond Wire Saw Models

Model

Min. Pipe

Capacity

Max. Pipe

Capacity

WS-164 4” (102 mm) 16” (406 mm)

WS-3012 12” (305 mm) 30” (762 mm)

WS-3616 16” (406 mm) 36” (914 mm)

WS-5230 30” (762 mm) 52” (1321 mm)

WS-8460 60” (1524 mm) 84” (2134 mm)

Cutting Wire Drive System

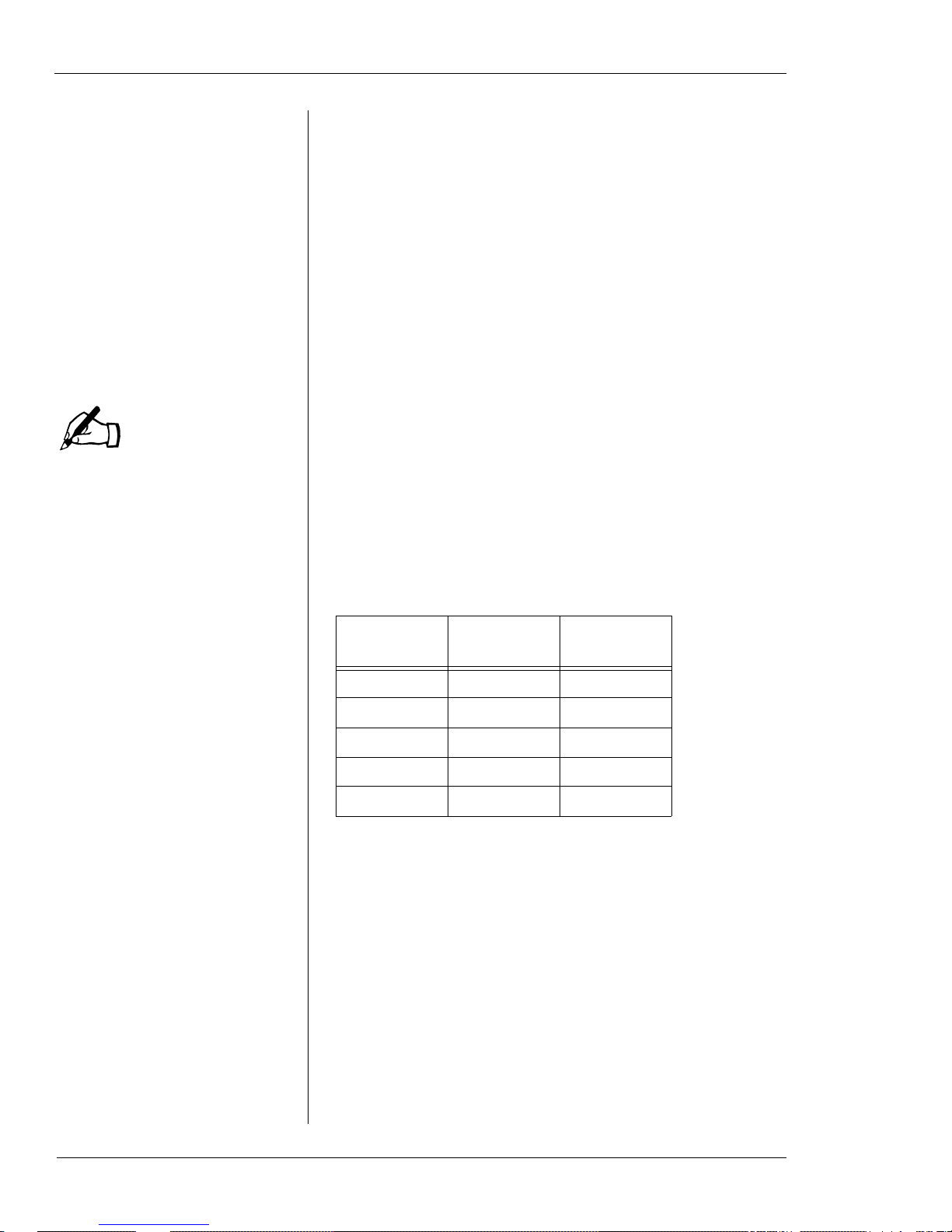

The cutting wire drive system consists of four wheels

mounted on the bow of the machine. Figure 1-1 illustrates

the drive system components.

4 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Equipment Description

NOTE

Drive wheel Idler wheel

Idler wheels Drive wheel

Tension wheelDiamond wire

Tensioning knob

Tension spring

Figure 1-1. The photo shows the cutting wire drive

system components.

The WS-8460 has an additional idler wheel next to the

drive wheel.

The drive wheel is operated by the hydraulic drive motor to

turn the wire around the cutting system loop. It is mounted

on a pivoting fixture used to adjust the tension of the wire.

The tension is set using a knob on the fixture, which also

positions the wheel for installing and removing the cutting

wire.

The tension wheel is on a pivoting, spring-loaded fixture

that maintains wire tension. The other two idler wheels are

fixed at the bottom of the bow where the cutting wire

engages the pipe.

The wire is a custom-made loop for the size of the saw.

Spare wires can be ordered from E.H. Wachs.

Feed System

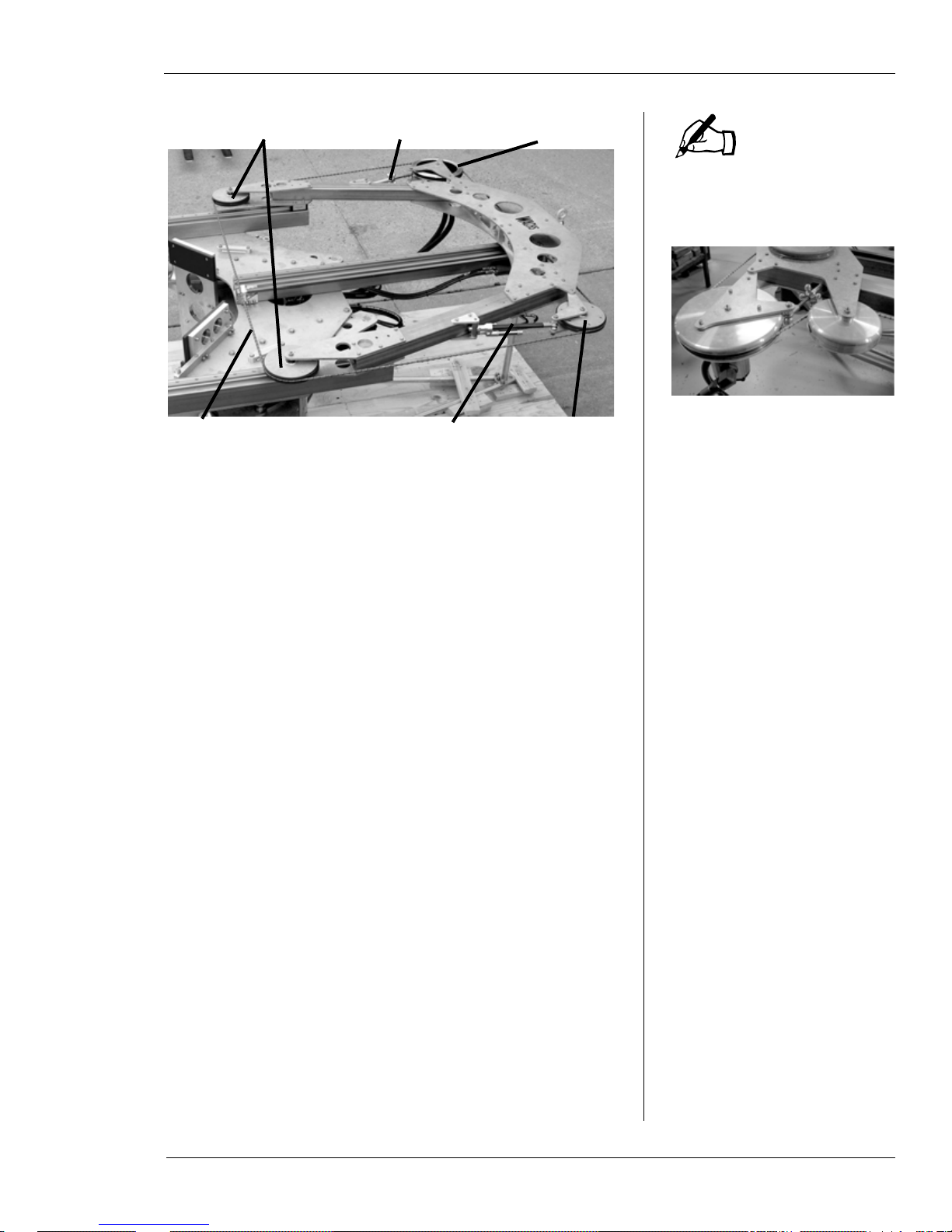

A feed drive mechanism on the main frame of the machine

drives the bow and cutting system up and down to perform

the cut and retract the bow after cutting. The bow rides on

feed rails and is driven by a feed screw in the center of the

frame. Figure 1-2 and Figure 1-3 show the main feed system components.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 5

Diamond Wire Saw User’s Manual

NOTE

Feed rails

Feed rails

Saw bow

Feed screw

Feed block Feed screw

Feed motor Driv e chain

Manual feed nut

The WS-8460 has four feed

rails, as shown below. The

other models have three rails.

Figure 1-2. The saw bow moves on thr e e feed rails on

the frame. The feed screw along the center rail drives

the bow.

6 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

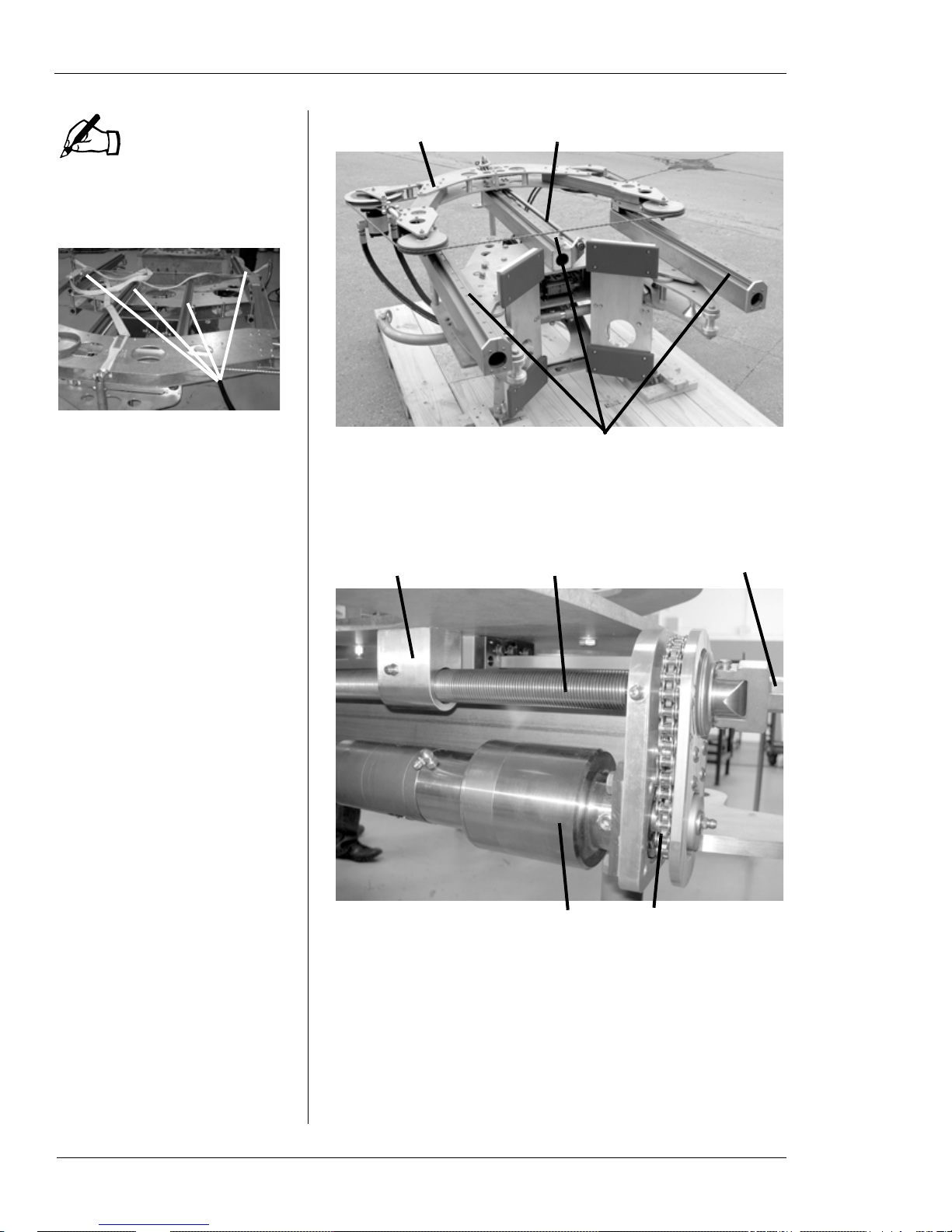

Figure 1-3. The feed system components are shown.

The feed block is attached to the saw bow.

The top of the feed screw has a drive nut to allow the feed to

be operated manually, and a clutch in the top coupling disengages the feed screw if the feed drive jams or reaches the

end of travel.

Chapter 1, About the Diamond Wire Saw: Equipment Description

Manual

feed nut

Feed control actuator Tension wheelTension spring

Figure 1-4. Use the manual feed nut to move the saw

bow if it cannot be operated using hydraulic power.

T urn the nut clockwise to retract the bow away from

the workpiece.

The feed system has a self-adjusting speed control feature.

A hydraulic actuator on the tension wheel fixture measures

the deflection of the wire as it cuts. If the feed speed is too

fast, the increased wire deflection trips the actuator, which

slows down the feed rate. This allows the cutting action of

the wire to catch up. At maximum deflection of the wire, the

actuator will stop the feed motion for as long as necessary.

Figure 1-5. The actuator controls the feed rate by

measuring the deflection of the cutting wire.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 7

Diamond Wire Saw User’s Manual

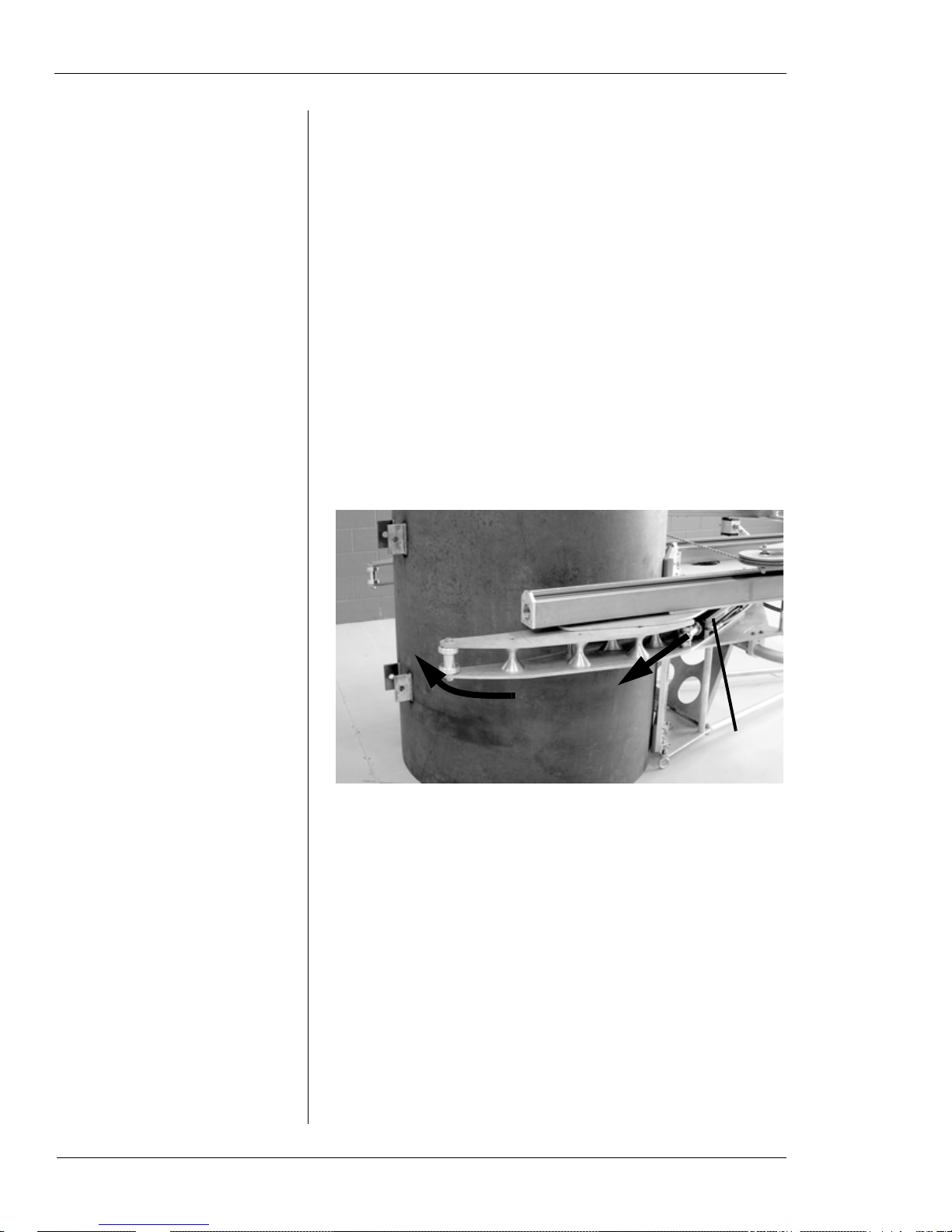

Clamping

cylinder

Clamping

motion

Clamping arm

pivots to contact pipe

Clamping System

An adjustable clamping system allows you to configure the

machine for pipe sizes within each model’s range. The two

clamping arms are attached to the main frame with twopronged forked pins that are removable to reposition the

arms.

The clamping arms are engaged by hydraulic cylinders

mounted to the frame. When the cylinder rods are extended,

the clamps pivot inward to grip the underside of the pipe

and hold the machine securely to it. Figure 1-6 illustrates

the clamping operation.

See “Adjusting Clamp Arms for the Pipe Size” later in this

chapter for information on the clamp position settings for

each wire saw model.

8 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 1-6. The photo shows the wire saw in position

for clamping on a test workpiece. When the hydraulic

cylinder is extended, the clamp arm pivots and closes

on the pipe. Both clamping arms operate together.

Chapter 1, About the Diamond Wire Saw: Equipment Description

Figure 1-7. The photo shows the clamping cylinder

extended and the clamp arm secured against the pipe.

The frame of the machine has clamp shoes attached that the

machine rests upon when installed on the pipe. These shoes

are made of a compressible composite material that deforms

slightly under pressure to create a secure, slip-free grip on

the pipe when the machine is clamped.

Figure 1-8. The front mounting shoes are shown.

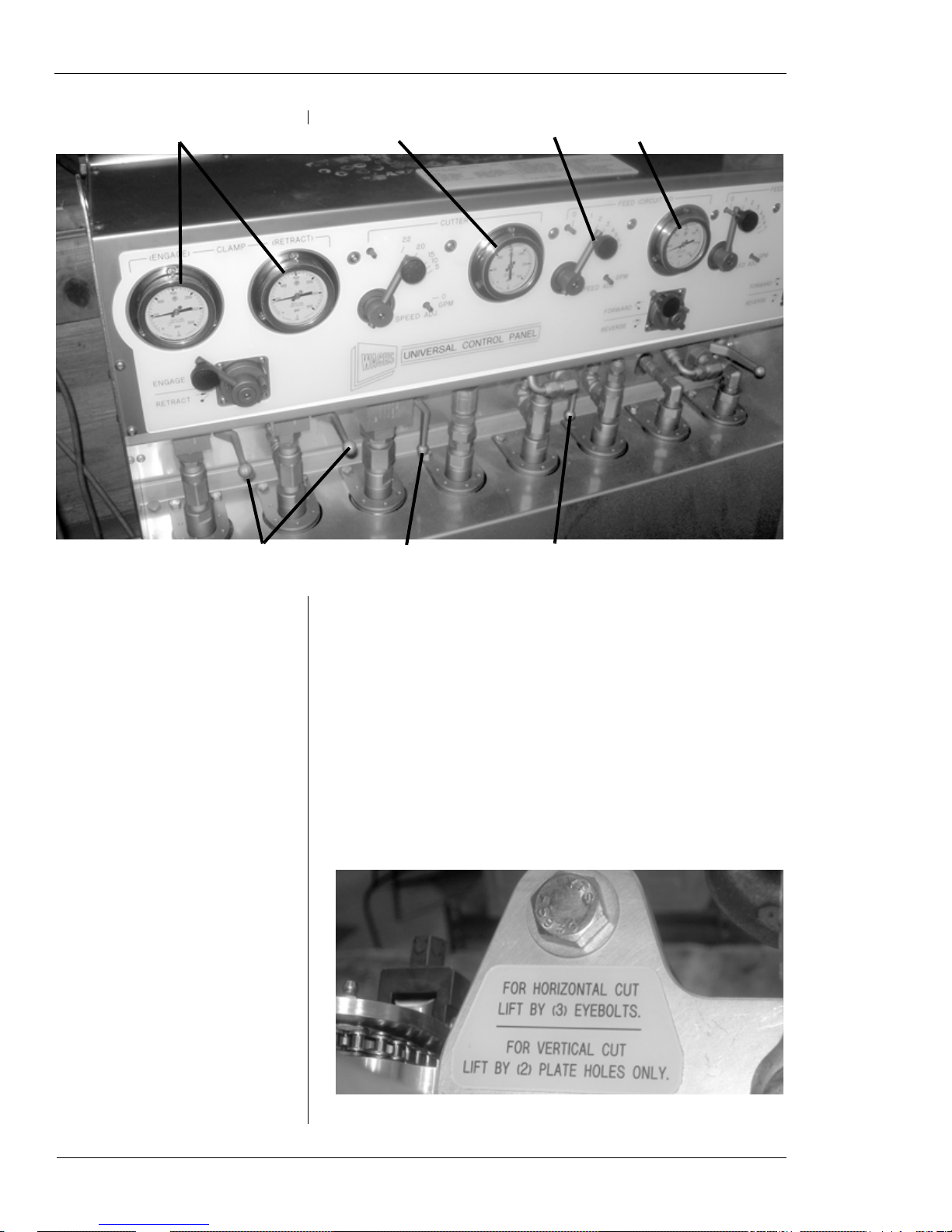

Topside Control Panel

Figure 1-9 illustrates the controls used to operate the subsea

wire saw. Chapter 3 includes detailed instructions.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 9

Diamond Wire Saw User’s Manual

Clamp pressure gauges

Clamp

direction

Cutter

speed

Cutter pressure gauge

Feed speed Feed pressure gauge

Feed

direction

Clamping flow levers (engage

both at once—shown closed

under pressure)

Feed flow lever

(shown open)

Cutter flow lever

(shown open)

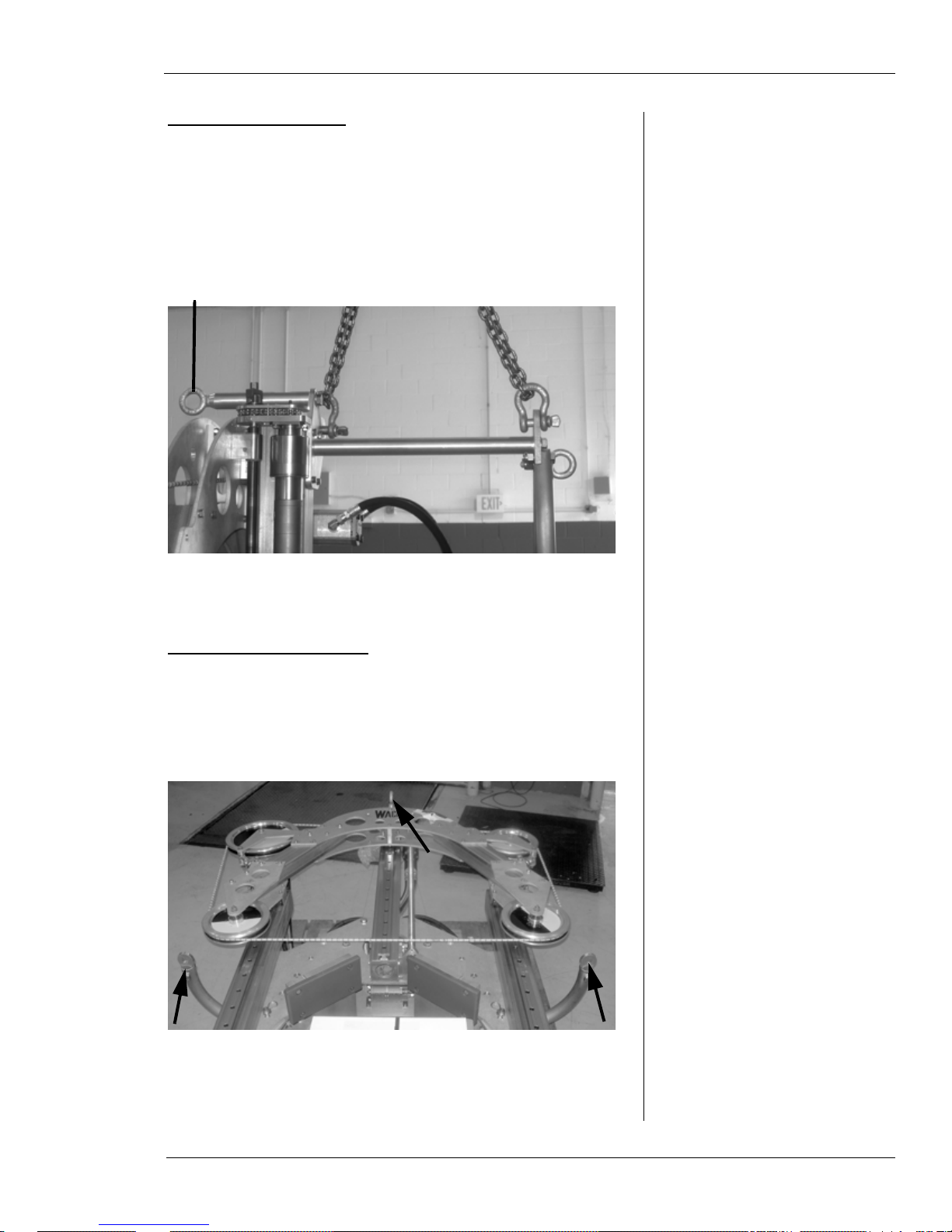

Rigging the Machine

A rigging instruction label is attached to the top of the

machine frame on WS-164 through WS-5230 models. See

the end of this section for information on rigging the WS8460 model.

Figure 1-9. The photo shows the controls on the topside control unit. (The fourth cir cuit, to the far right, is

not used with the subsea wire saw.)

10 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 1-10. The rigging label is on top of the frame.

Chapter 1, About the Diamond Wire Saw: Equipment Description

IMPORTANT: Do not attach to this hook

when lifting the machine vertically!

Lifting for Vertical Cut

Attach the machine to the lifting device using chains on the

top lift hooks. Tip the machine up to a vertical position, then

pick it up. Make sure the chains are the appropriate length to

hold the machine reasonably straight.

Figure 1-11. To position the machine vertically on the

pipe, attach to the two top lift hooks.

Lifting for Horizontal Cut

With the machine positio ned horizontal on the floor or deck,

attach a lift to the two hooks on the lift bar and the front

hook on top of the frame.

Figure 1-12. To position the machine horizontally on

the pipe, attach to the two lift bar hooks and the front

hook on the top.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 11

Diamond Wire Saw User’s Manual

Lift vertically from this point only

Lift horizontally from these three points

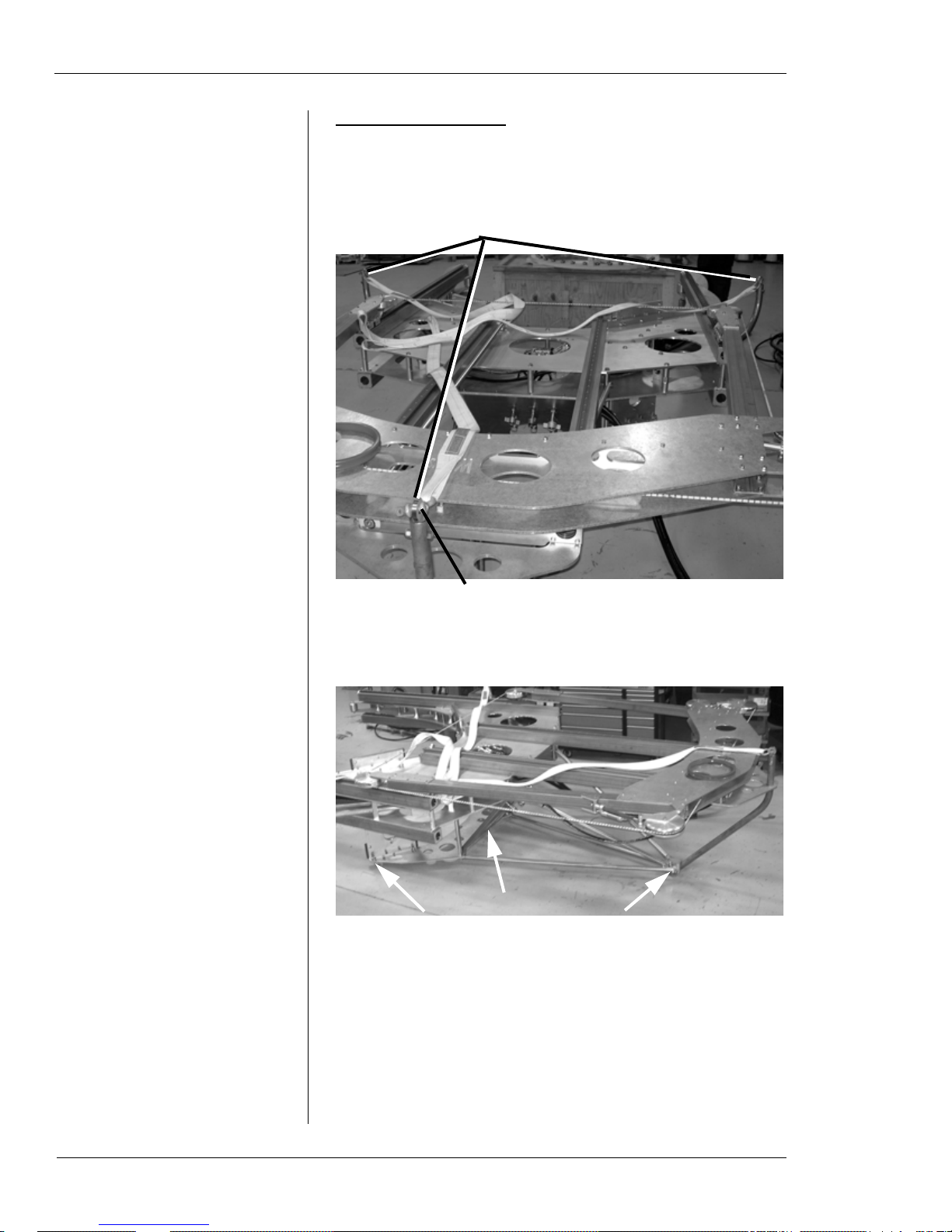

Rigging the WS-8460

You can lift the WS-8460 saw vertically, or in either horizontal orientation. See the following figures for lift points.

Figure 1-13. Use the lift points indicated to lift the

machine horizontally or vertically.

Figure 1-14. To lift the machine horizontally from the

other side, use the three points indicated in the photo

(third point is out of view under frame).

Storing the Machine

Store the machine sitting horizontal with the front of it (the

side with the Wachs logo) facing up. For long-term storage,

12 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 1, About the Diamond Wire Saw: Operating Envelope

clean and dry the machine thoroughly, then cover it with a

waterproof cover.

You can leave the wire installed on the machine during storage. Keep normal tension on the wire to hold it in place.

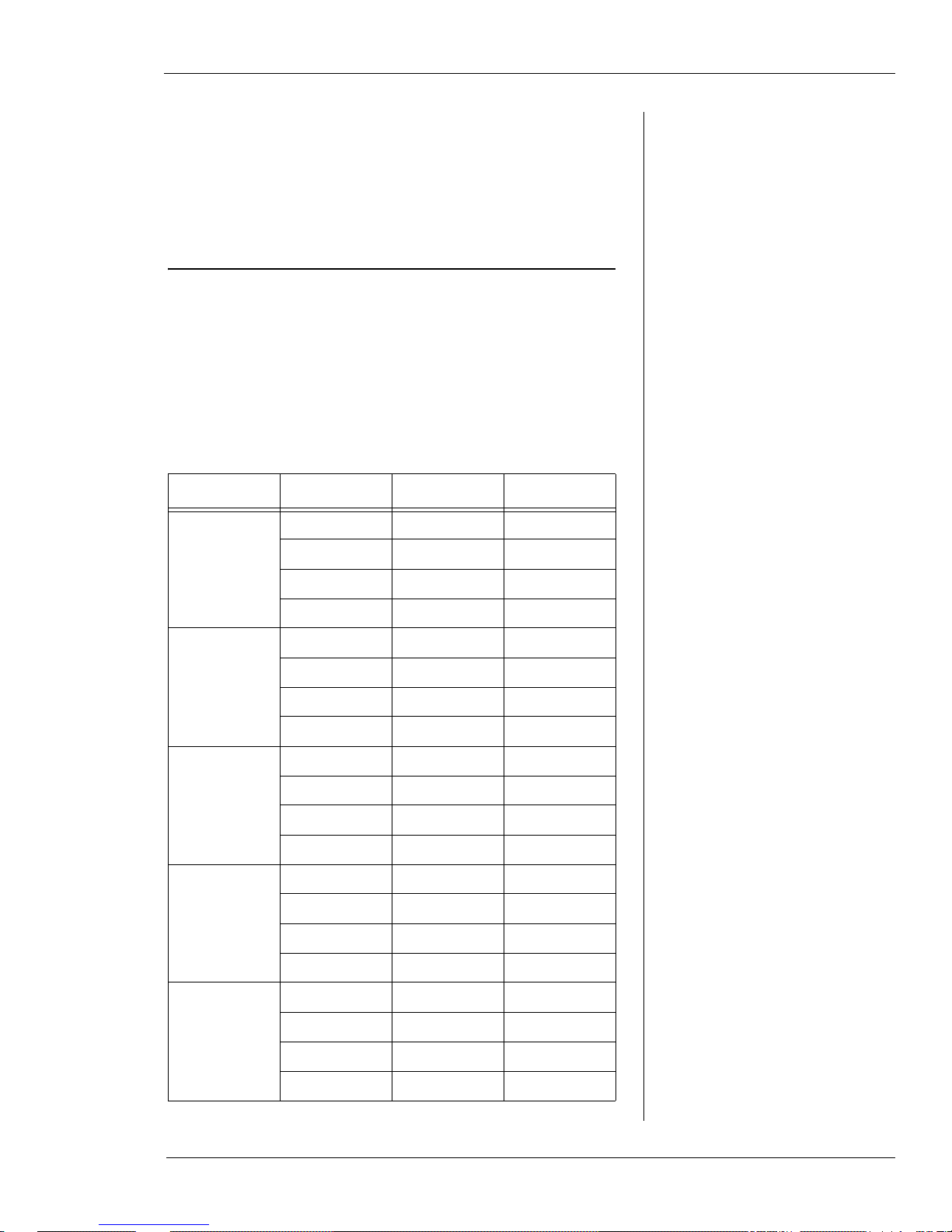

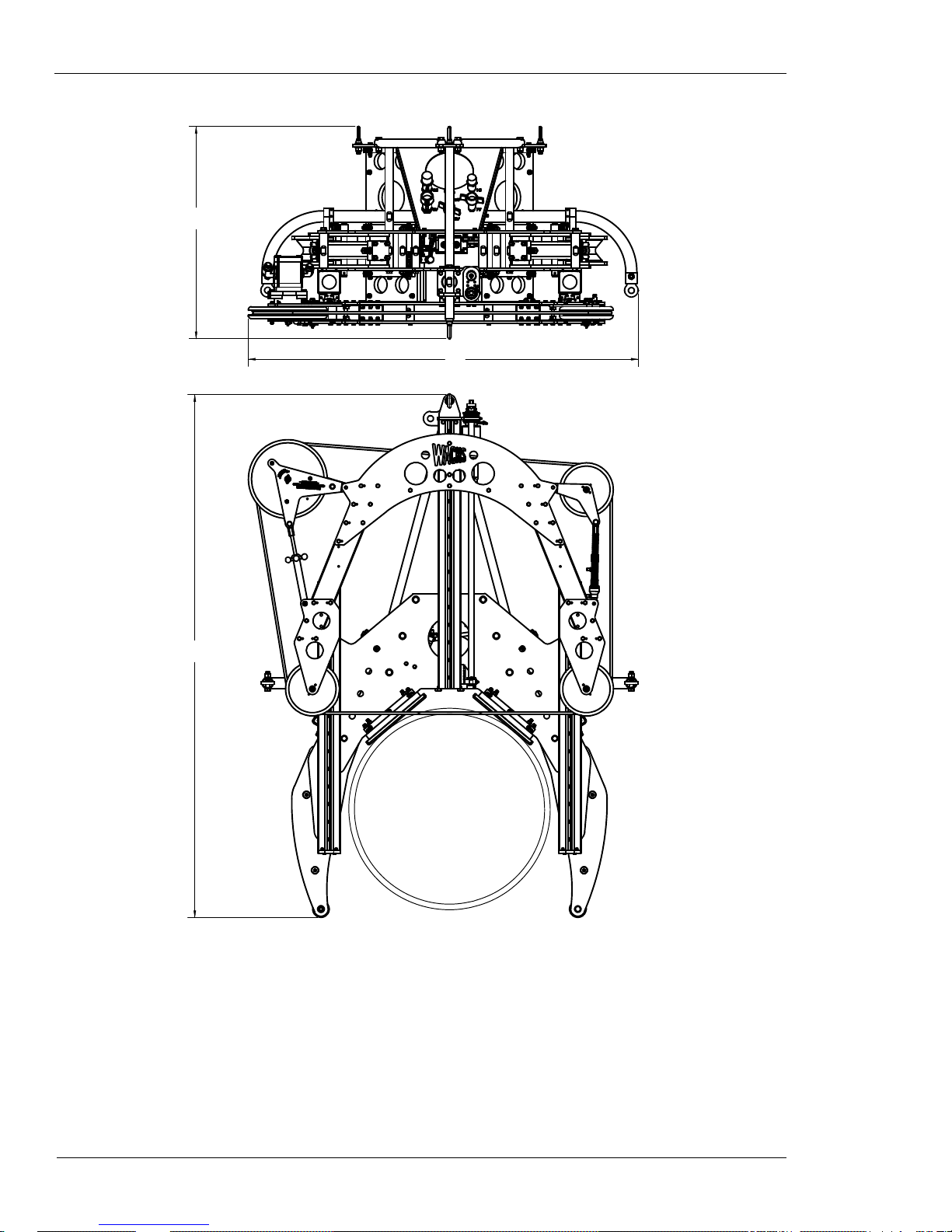

OPERATING ENVELOPE

The table below and the drawing on the next page describe

the operating envelope for all four diamond wire saw models. The “DIM” column in the table refers to the labeled

dimensions on the drawing. “Stroke” is the feed distance of

the saw bow.

Table 2: Operating Envelope Dimensions

Model DIM Inches MM

WS-164

WS-3012

WS-3616

WS-5230

A 48.5 1232

B28.0711

C 63.8 1621

Stroke 22.9 582

A 63.8 1621

B 34.9 886

C 82.6 2098

Stroke 39.0 991

A 69.6 1768

B 38.0 965

C 93.5 2375

Stroke 43.9 1115

A 87.4 2220

B 48.9 1242

C 131.0 3327

Stroke 61.9 1572

WS-8460

Stroke 97.8 2484

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 13

A 119.0 3023

B46.51181

C 205.25 5213

Diamond Wire Saw User’s Manual

A

B

C

14 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 2

Safety

The E.H. Wachs Company takes great pride in designing

and manufacturing safe, high-quality products. We make

user safety a top priority in the design of all our products.

Chapter 2, Safety

In This Chapter

OPERATOR SAFETY

SAFETY LABELS

Read this chapter carefully before operating the subsea wire

saw. It contains important safety instructions and recommendations.

OPERATOR SAFETY

WARNING: The cutting wire spins at very high speed. If

the wire breaks, segments of the wire can fragment and be

thrown from the machine at dangerous speeds. When operating the machine topside, stay a safe distance from the

machine, or behind a protective barrier. Divers should stay

a safe distance from the machine when it is running. Seri-

ous injury or death could result from contact with the

wire or as a result of the wire breaking.

Follow these guidelines for safe operation of the equipment.

• READ THE OPERATING MANUAL. Make sure

you understand all setup and operating instructions

before you begin.

• INSPECT MACHINE AND ACCESSORIES.

Before starting the machine, look for loose bolts or

nuts, leaking lubricant, rusted components, and any

other physical conditions that may affect operation.

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 15

Diamond Wire Saw User’s Manual

Properly maintaining the machine can greatly decrease

the chances for injury.

• ALWAYS READ PLACARDS AND LABELS. Make

sure all placards, labels, and stickers are clearly legible

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

• KEEP CLEAR OF MOVING PARTS. Keep hands,

arms, and fingers clear of all rotating or moving parts.

Always turn machine off before doing any adjustments

or service.

• SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry , and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

• KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

16 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Protective Equipment Requirements

Always wear impact resistant eye protection while operating or working near

this equipment.

WARNING

CAUTION

Personal hearing protection is recommended when operating or working near

this tool.

For additional information on eye and face protection, refer

to Federal OSHA regulations, 29 Code of Federal Regulations, Section 1910.133., Eye and Face Protection and

American National Standards Institute, ANSI Z87.1, Occupational and Educational Eye and Face Protection. Z87.1 is

available from the American National Standards Institute,

Inc., 1430 Broadway, New York, NY 10018.

Chapter 2, Safety: Safety Labels

Hearing protectors are required in high noise areas, 85 dBA

or greater . The operation of other tools and equipment in the

area, reflective surfaces, process noises, and resonant structures can increase the noise level in the area. For additional

information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section

1910.95, Occupational Noise Exposure and ANSI S12.6

Hearing Protectors.

SAFETY LABELS

There is no safety labeling on the subsea wire saw.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 17

Diamond Wire Saw User’s Manual

18 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 3

Operating

Instructions

TENSIONING THE CUTTING WIRE

You should have the wire installed according to the maintenance instructions in Chapter 4.

At the tension wheel fixture, check the start lines on

1.

the feed control actuator. When there is no tension on

the wire, the actuator rod will be retracted and the

start lines will be offset.

Chapter 3, Operating Instructions

In This Chapter

TENSIONING THE CUTTING

IRE

W

ADJUSTING CLAMP ARMS FOR

THE PIPE SIZE

CONNECTING THE HYDRAULIC

OSES

H

MOUNTING THE MACHINE ON

THE PIPE

PERFORMING THE CUT

REMOVING THE MACHINE

Figure 3-1. With no tension on the wire, the feed

actuator start lines will be offset.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 19

Diamond Wire Saw User’s Manual

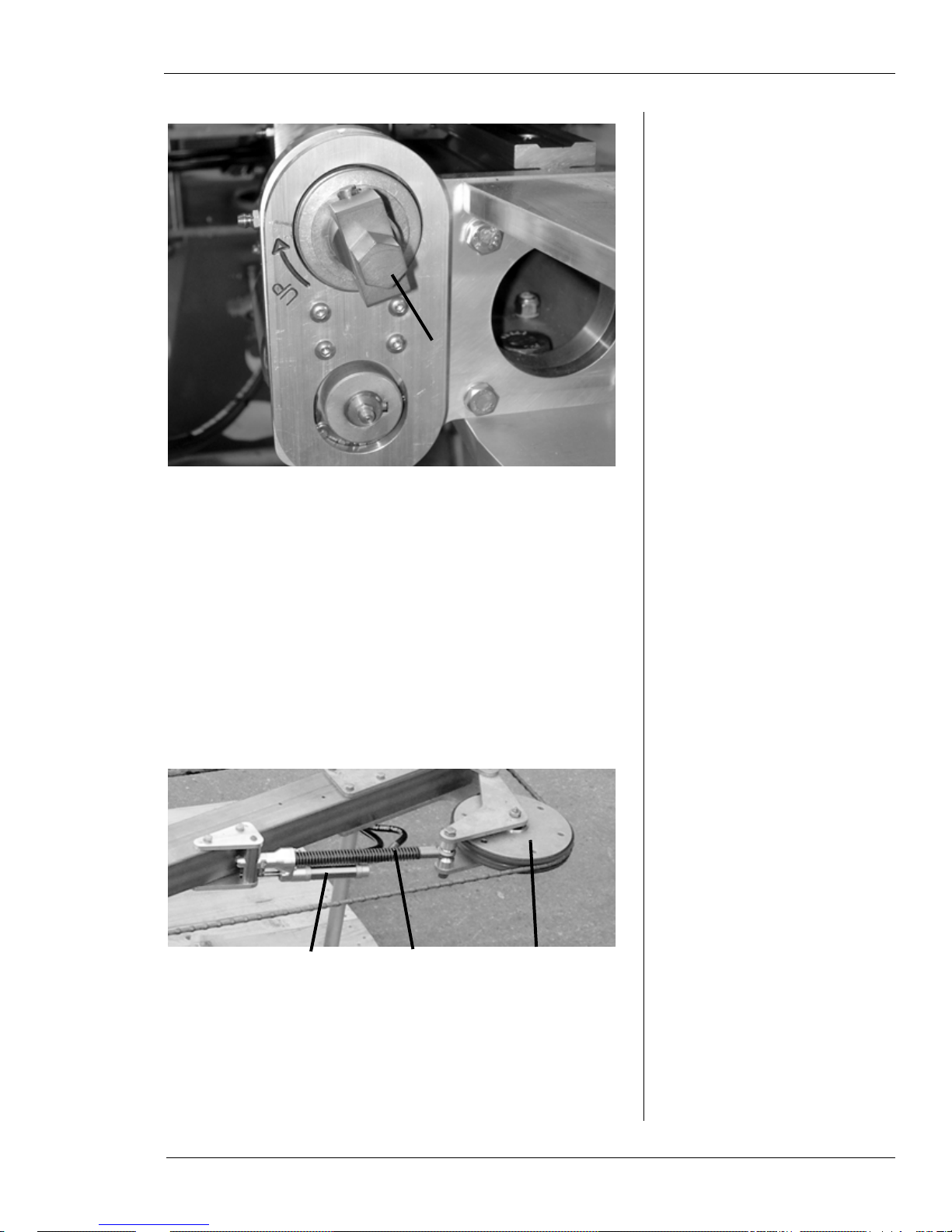

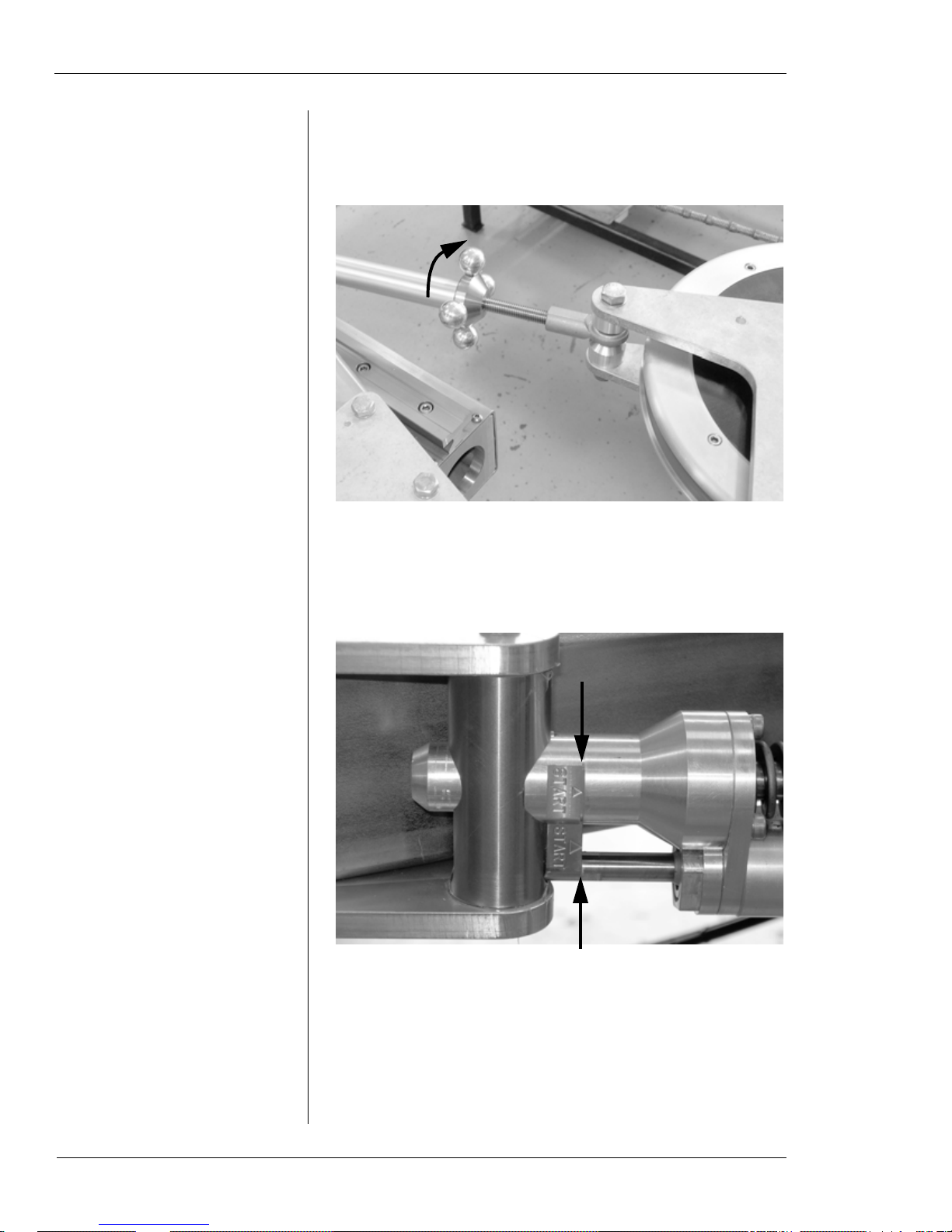

Tighten the drive wheel tensioning knob, as shown in

2.

Figure 3-2, until you can see the line on the springloaded driver wheel, Figure 3-3.

Figure 3-2. Turn the tension knob on the drive wheel

fixture to incr ease the tension on the wire. (Depending

on the exact length of the wire, about 3-4” of the scr ew

will be visible when the tension is set correctly.)

Figure 3-3. When the wire is properly tensioned, the

start lines will be lined up together.

20 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

You should be able to deflect the wire fairly easily by

3.

pushing it up between the idler wheels. Push it in far

enough to compress the tension spring, and make sure

the actuator rod extends into the slot in the shaft.

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

Figure 3-4. When you push the wire to deflect it, the

actuator rod will extend.

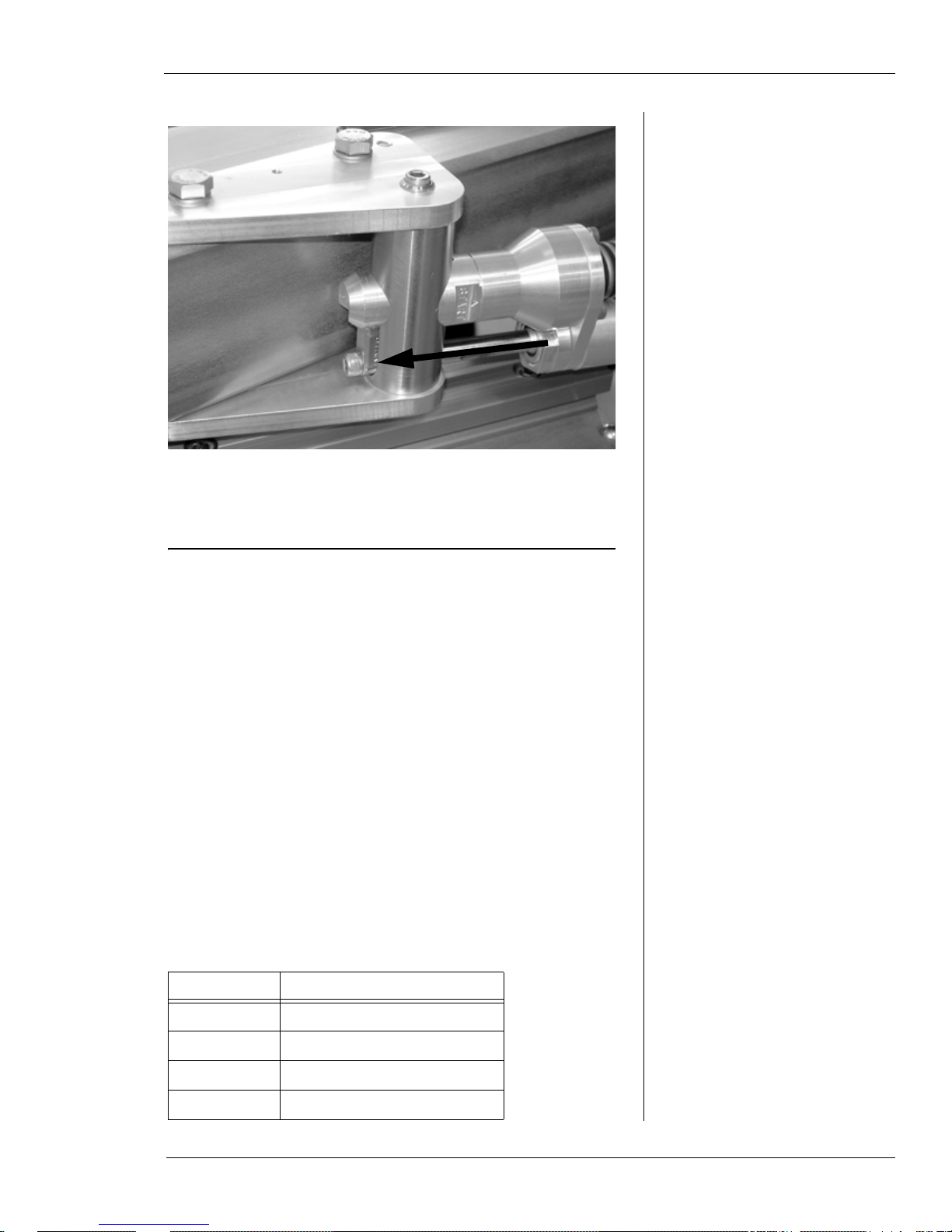

ADJUSTING CLAMP ARMS FOR THE PIPE SIZE

The clamp arms are attached to the main frame using forked

pins that go through two holes in the frame. Multiple sets of

holes allow the arms to be mounted in various positions.

The hole pairs for each position are stamped with the size of

the largest pipe for that position. Refer to the following sections for the pipe size settings for each saw model.

WS-164 Pipe Size Settings

Table 1 describes the pipe size settings for the WS-164

model.

Table 1: Pipe Size Ranges for Clamping

Arm Positions—WS-164

Size Stamp Pipe Diameter Range

7 4” to 7” (102-178 mm)

10 7” to 10” (178-254 mm)

13 10” to 13” (254-330 mm)

16 13” to 16” (330-406 mm)

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 21

Diamond Wire Saw User’s Manual

WS-3012 Pipe Size Settings

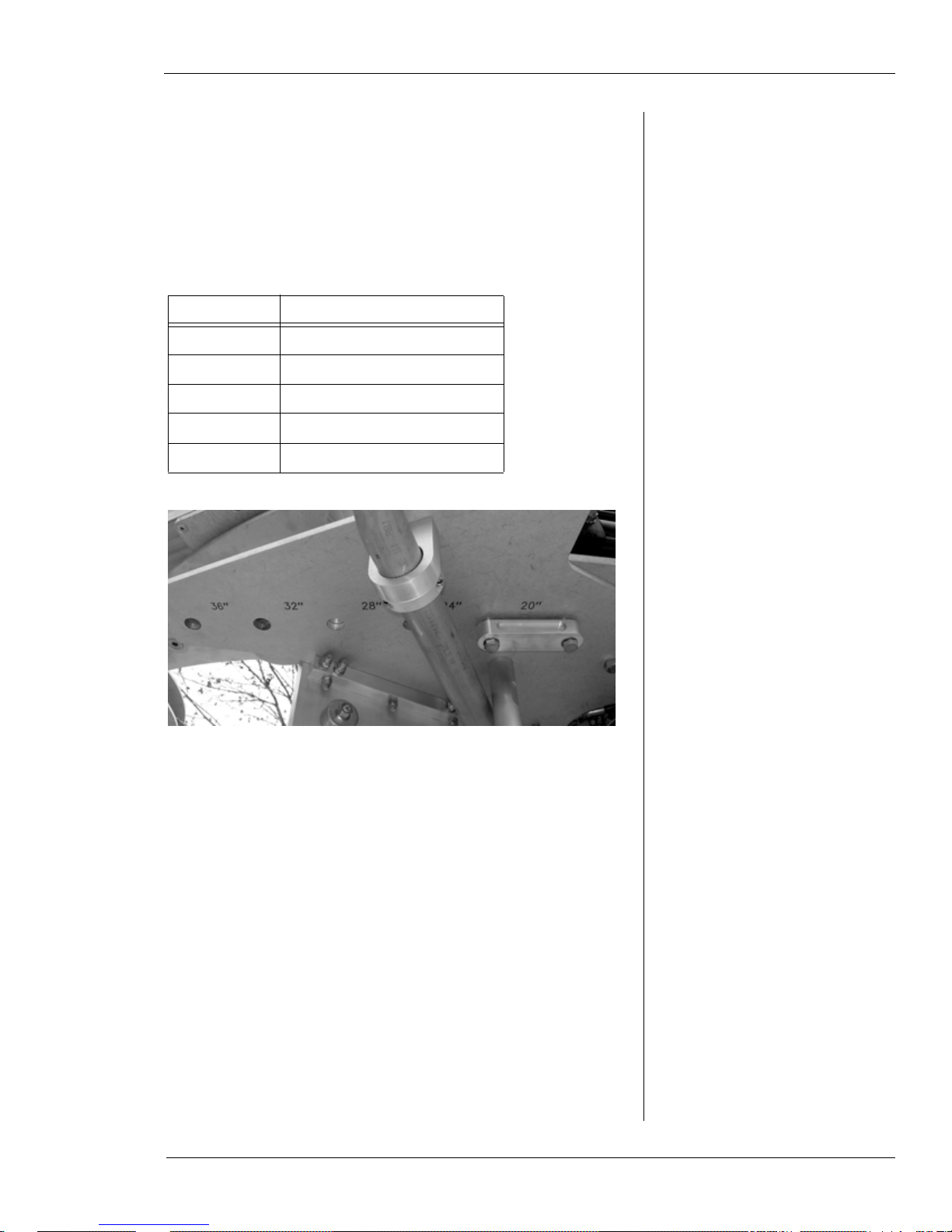

T able 2 and Figure 3-5 describe the pipe size settings for the

WS-3012 model.

Table 2: Pipe Size Ranges for Clamping

Arm Positions—WS-3012

Size Stamp Pipe Diameter Range

14 12” to 14” (305-356 mm)

18 14” to 18” (356-457 mm)

22 18” to 22” (457-559 mm)

26 22” to 26” (559-660 mm)

30 26” to 30” (660-762 mm)

22 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 3-5. The photo shows the size stamps on the

WS-3012 model. The pin is in the 26-30” position.

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

WS-3616 Pipe Size Settings

T able 3 and Figure 3-6 describe the pipe size settings for the

WS-3616 model.

Table 3: Pipe Size Ranges for Clamping

Arm Positions—WS-3616

Size Stamp Pipe Diameter Range

20 16” to 20” (406-508 mm)

24 20” to 24” (508-610 mm)

28 24” to 28” (610-711 mm)

32 28” to 32” (711-813 mm)

36 32” to 36” (813-914 mm)

Figure 3-6. The photo shows the size stamps on the

WS-3616 model. The pin is in the 16-20” position.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 23

Diamond Wire Saw User’s Manual

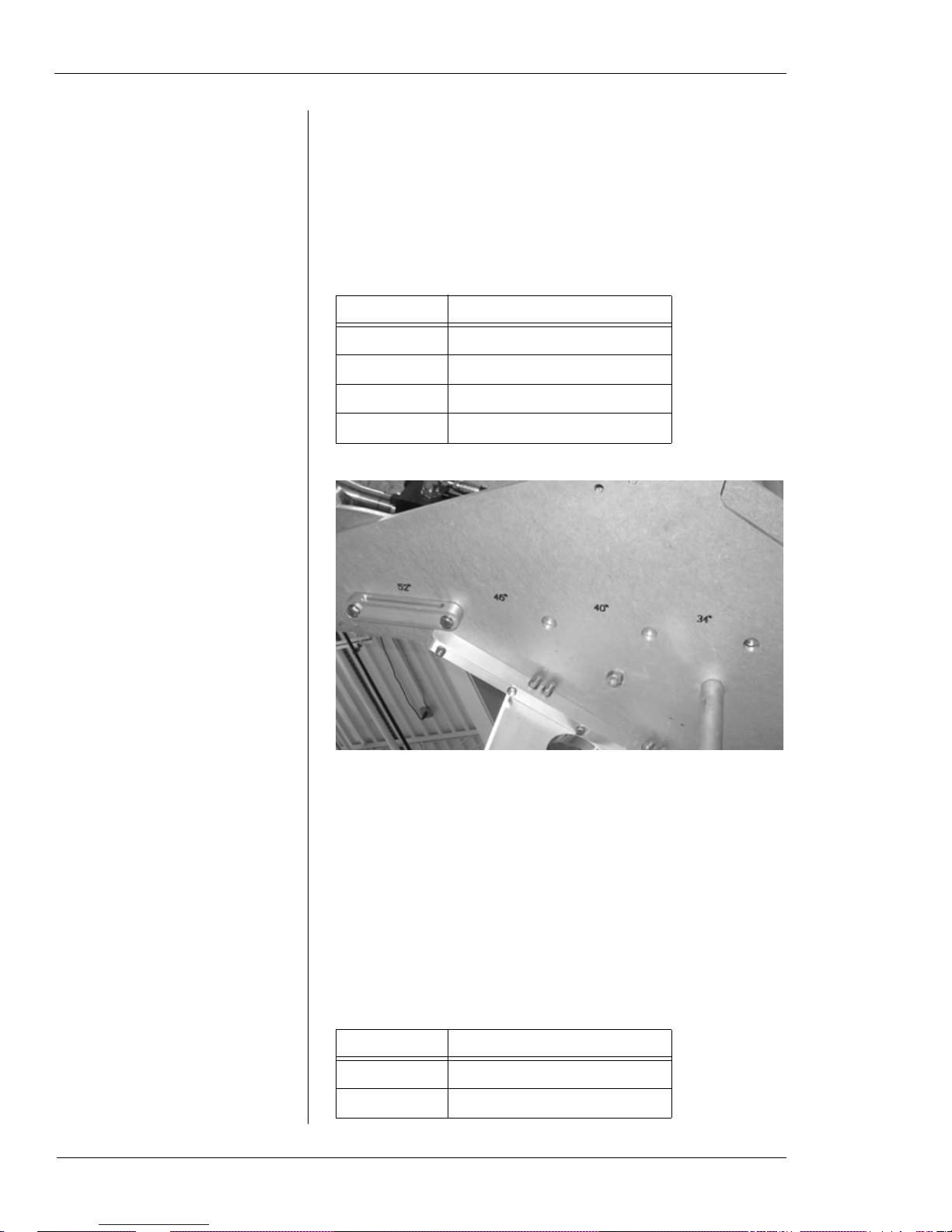

WS-5230 Pipe Size Settings

T able 4 and Figure 3-7 describe the pipe size settings for the

WS-5230 model.

Table 4: Pipe Size Ranges for Clamping

Arm Positions—WS-5230

Size Stamp Pipe Diameter Range

34 30” to 34” (762-864 mm)

40 34” to 40” (864-1016 mm)

46 40” to 46” (1016-1168 mm)

52 46” to 52” (1168-1321 mm)

24 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 3-7. The photo shows the size stamps on the

WS-5230 model. The pin is in the 46-52” position.

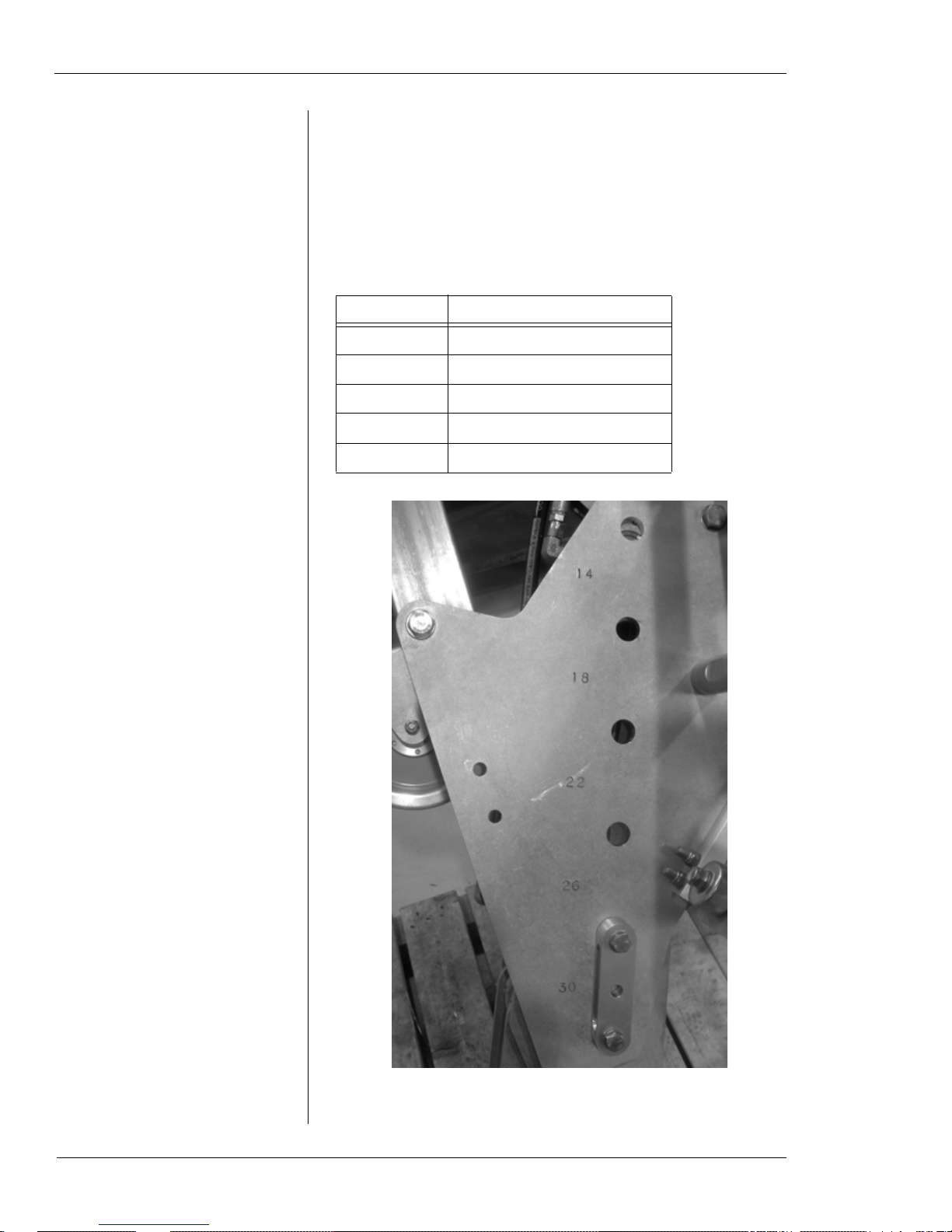

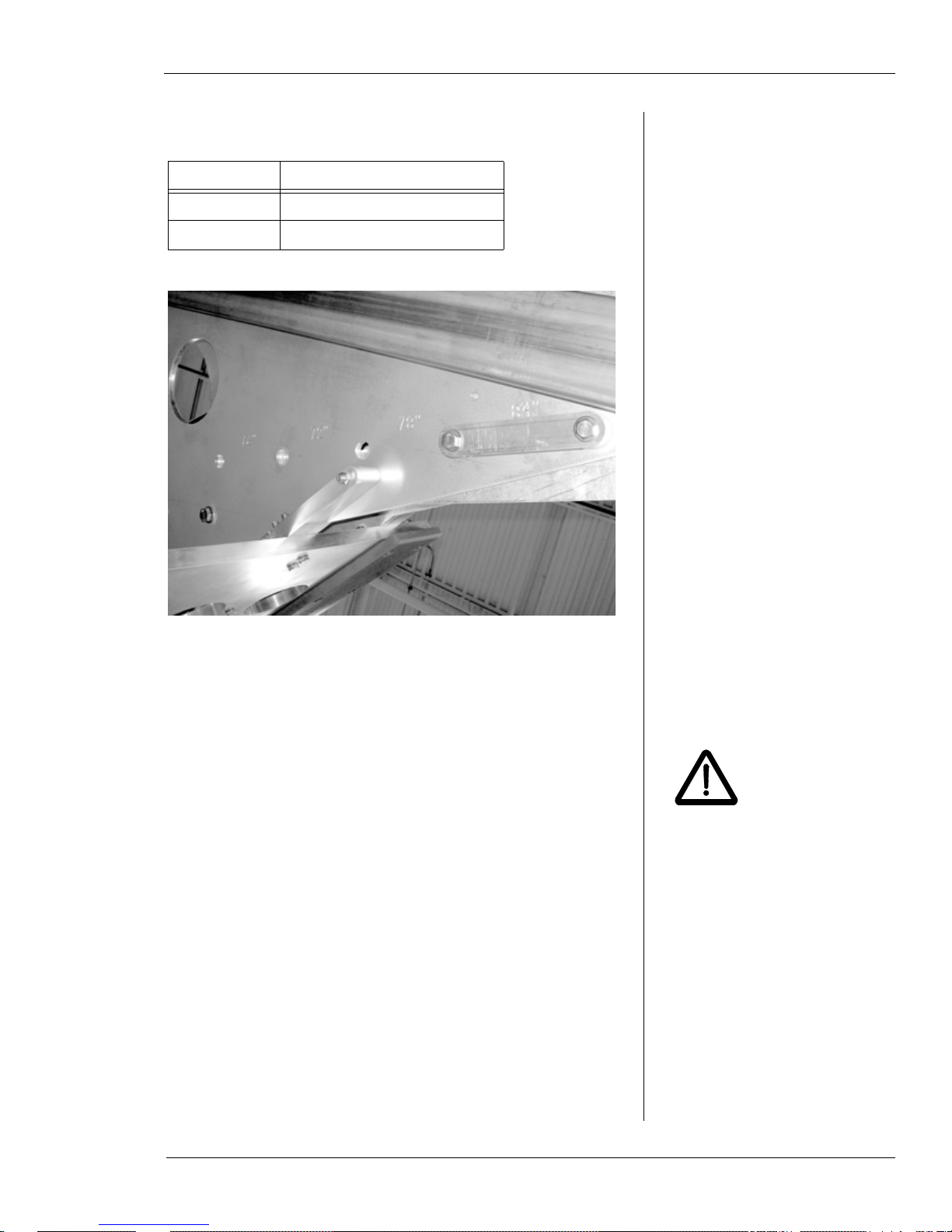

WS-8460 Pipe Size Settings

T able 5 and Figure 3-8 describe the pipe size settings for the

WS-8460 model.

Table 5: Pipe Size Ranges for Clamping

Arm Positions—WS-8460

Size Stamp Pipe Diameter Range

66 60” to 66” (152 4-1676 mm)

72 66” to 72” (167 6-1829 mm)

Chapter 3, Operating Instructions: Adjusting Clamp Arms for the Pipe Size

WARNING

Table 5: Pipe Size Ranges for Clamping

Arm Positions—WS-8460

Size Stamp Pipe Diameter Range

78 72” to 78” (1829 -1981 mm)

84 78” to 84” (1981 -2134 mm)

Figure 3-8. The photo shows the size stamps on the

WS-8460 model. The pin is in the 78-84” position.

Positioning the Clamp Arms

Make sure the saw is sitting horizontally on a level surface

before you adjust the clamp arms.

Remove the spring clips from both pin ends of the

1.

forked pin, then pull the forked pin out of the frame.

Do not attempt to change the

clamp arm positions while the

saw is in a vertical position.

The clamp arms may fall

when the pins are removed,

resulting in personal injury

and equipment damage.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 25

Diamond Wire Saw User’s Manual

Figure 3-9. Remove the spring clips fr om both ends of

the forked pin, then pull the pin out from the other

side.

Slide the clamp arm assembly so that the mounting

2.

holes line up with the appropriate hole pair for the

pipe size you are cutting.

Insert the forked pin through the back of the machine.

3.

Figure 3-10. Insert the forked pin through the hole

pair for the pipe size range (in this case, 46-52”) you

are cutting.

Insert the spring clips in the forked pin on the front of

4.

the machine.

26 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 3, Operating Instructions: Connecting the Hydraulic Hoses

CAUTION

WARNING

Clamp circuit

pressure

Feed circuit

pressure

Cutting drive

circuit pressure

Clamp circuit

return

Feed circuit

return

Cutting drive

circuit return

Set the position of the other clamp arm to the same

5.

location.

CONNECTING THE HYDRAULIC HOSES

Connect the hydraulic hoses from the topside control panel

(TCP) to the hydraulic bulkhead on the machine, as indicated in Figure 3-11.

Before lowering the machine subsea, test all three drive circuits to make sure they are working.

Make sure both clamping

arms are set at the same

position. If they are not the

same, the machine may not

clamp securely on the pipe.

Damage to the machine

could result.

The cutting wire spins at very

high speed. If the wire

breaks, segments of the wire

can fragment and be thrown

from the machine at dangerous speeds. Stay a safe distance from the machine, or

behind a protective barrier,

when operating it topside.

Serious injury or death

could result from contact

with the wire or as a result

of the wire breaking.

The ports marked “A” are pressure lines from the

TCP; the ports marked “B” are return lines to the

TCP.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 27

Figure 3-11. Attach the hydraulic hoses as shown.

Diamond Wire Saw User’s Manual

CAUTION

NOTE

CAUTION

Lift the machine ONLY on the

lifting eyes provided. Lifting

on any other component

could damage the machine.

The flow on the clamp circuit

is set internally at 4 gpm.

MOUNTING THE MACHINE ON THE PIPE

See “Rigging the Machine” in Chapter 1 for instructions on

lifting the machine to position it for horizontal or vertical

cuts.

• Attach lifting shackles to the appropriate lift eyes for the

orientation of the machine.

• Before lowering the machine subsea to the cutting location, make sure the clamping arms are fully open.

Set the controls on the TCP as follows:

• All flow levers up (flow off).

• Cutter speed knob to 17.5 gpm

• Feed speed knob to 1.5 gpm

• (Clamp flow is preset to 4 gpm)

• Clamp direction to ENGAGE

• Feed direction to FORWARD

• (Cutter direction is preset to forward).

As you operate the machine,

check the clamping pressure

frequently to make sure it

stays above 1700 psi. If it

gets too low, stop the

machine and reclamp it to the

pipe.

Align the machine at the desired cut line, perpendicu-

1.

lar to the center axis of the pipe. The clamping arms

should extend around the pipe and the mounting shoes

should be against the pipe, or close to it.

Start the hydraulic power unit. Set it to provide 22

2.

gpm flow at 3000 psi.

Push both clamping flow levers down simultaneously.

3.

Watch the clamping pressure gauges to ensure that the

pressure is within 1900-2200 psi.

When the clamping arms are fully clamped and the

4.

pressure is within 1900-2200 psi, pull both clamping

flow levers up to lock the holding pressure. The pressure will drop quickly to 1850 psi and then slowly to

about 1600 psi.

Repeat the clamp sequence three times. The pressure

5.

should hold above 1700 psi.

28 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

PERFORMING THE CUT

WARNING

Push the feed flow lever down to open the feed circuit.

1.

Chapter 3, Operating Instructions: Performing the Cut

The cutting wire spins at very

high speed. If the wire

breaks, segments of the wire

can fragment and be thrown

from the machine at dangerous speeds. Make sure all

personnel are at a safe distance before starting the cutting drive. Serious injury or

death could result from

contact with the wire or as

a result of the wire breaking.

Figure 3-12. Push the feed flow lever down to supply

power to the feed drive.

Set the feed speed knob to 2.5 gpm.

2.

Figure 3-13. Push the feed speed knob down to

2.5 gpm.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 29

Diamond Wire Saw User’s Manual

NOTE

NOTE

The larger the pipe size, the

longer it will take to feed the

cutting wire close to the pipe.

This is because smaller pipes

fit closer between the mounting shoes.

V isually monitor the position of the cutting wire as the

3.

bow feeds toward the pipe. When the wire is within

1/4” of the pipe surface, pull the feed flow lever up to

turn off the feed drive.

Push the cutting drive flow lever down to open the

4.

cutting drive circuit.

At the minimum operating

speed, the drive wheel will be

spinning at about 1500 RPM.

Figure 3-14. Push the cutting flow lever down to supply power to the cutting drive.

Start with the cutting speed knob at 18 gpm. Visually

5.

ensure that the wheels are spinning.

30 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 3, Operating Instructions: Performing the Cut

NOTE

Figure 3-15. Push the cutting speed knob up to

increase the drive wheel speed.

Push the feed flow lever down to start feeding the wire

6.

into the pipe. The feed speed knob should be at 2.5

gpm.

As the wire enters the cut, increase the cutting speed

7.

by moving the cutting speed knob. Do not go above 19

gpm.

During cutting, the feed control actuator on the ten-

8.

sion wheel fixture adjusts the feed rate to keep the saw

from overfeeding. It should not be necessary to adjust

the feed rate at the TCP.

Continue until the wire has completely severed the

9.

pipe.

Pull the feed flow lever up to turn off the feed drive.

10.

The feed drive will travel

about 2 inches beyond the

bottom of the largest pipe

size.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 31

Diamond Wire Saw User’s Manual

Figure 3-16. Push the feed flow lever up to 0 and pull

the feed flow lever up to turn off the feed drive.

Pull the cutter flow lever up to turn off the cutter drive.

11.

Figure 3-17. Pull the cutter flow lever up to turn off

the cutter.

32 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

REMOVING THE MACHINE

Set the feed direction knob on the TCP to REVERSE.

1.

Chapter 3, Operating Instructions: Performing the Cut

Figure 3-18. Set the feed direction knob to REVERSE.

Push the feed flow lever down to open the feed circuit.

2.

Figure 3-19. Push the feed flow lever down to supply

power to the feed drive.

Push the feed speed knob down to 6.5 gpm (maximum

3.

flow).

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 33

Diamond Wire Saw User’s Manual

NOTE

It will take about 30 minutes

to retract the feed drive on a

36 inch pipe.

Figure 3-20. Push the feed speed knob down to the

maximum setting.

When the saw bow is back at its home position, pull

4.

the feed flow lever up to stop the feed drive.

34 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 3-21. Pull the feed flow lever up to turn off the

feed drive.

Rig the shackles to the overhead lift. Lift just enough

5.

to put tension on the chains and secure the machine.

Push the clamping direction knob to the RETRACT

6.

position.

Chapter 3, Operating Instructions: Performing the Cut

Figure 3-22. Set the clamping direction knob to

RETRACT.

Push both clamping flow levers down simultaneously

7.

until the clamp arms are fully open. The right (return

pressure) gauge reading will equal the system pressure. Pull the clamping flow levers back up.

Lift the machine off the pipe. Move it to the next cut-

8.

ting location or bring it topside if you are finished.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 35

Diamond Wire Saw User’s Manual

36 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 4

CAUTION

Maintenance

Chapter 4, Maintenance

In This Chapter

LUBRICATION

LUBRICATION

Every time you use the machine, lubricate the following

components.

Slowly pump multi-purpose No. 2 EP marine grease

1.

into the grease fittings on each of the 4 wheel hubs.

(Do NOT use AquaLube on the wheel hubs.)

REPLACING THE CUTTING WIRE

REPLACING THE MOUNTING

S

HOES

REPLACING THE WHEEL LINERS

BLEEDING THE FEED TENSION

ONTROL

C

Figure 4-1. Each wheel hub has a grease fitting.

Pump AquaLube into the grease fittings on the feed

2.

gears, feed motor, and feed block (4 fittings).

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 37

Do not directly apply lubricant

to the feed screw.

Diamond Wire Saw User’s Manual

Feed block Feed motor Feed gears

Figure 4-2. Grease the feed components shown at the

top of the feed system.

Pump AquaLube into the grease fitting on the feed

3.

screw mount at the bottom of the screw.

Figure 4-3. Gr ease the fitting at the bottom of the feed

screw.

4.

38 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Pump AquaLube into the grease fittings on the cylinder rod ends until grease is visible.

Chapter 4, Maintenance: Replacing the Cutting Wire

CAUTION

Figure 4-4. Both clamping cylinders have a gr ease fitting on the rod end.

REPLACING THE CUTTING WIRE

Start with the saw bow retracted all the way to the top of the

frame. See special instructions at the end of this section for

the WS-8460 model.

Turn the tension knob on the drive wheel fixture all

1.

the way down to release the tension on the wire.

Wear gloves when handling

the wire. The abrasive surfaces are sharp and could cut

your hands.

Figure 4-5. Turn the tensioning knob all the way

down on the screw to loosen the wire.

Slip the wire off the drive wheel, then remove it from

2.

the other wheels.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 39

Diamond Wire Saw User’s Manual

Cutting direction

Arrowhead

Shoulders

Cutting direction

NOTE

Different brands of wire have different markings to

3.

indicate cutting direction. Look at the new wire

closely to determine direction.

Figure 4-6. This wire has molded arrows indicating

the cutting direction.

The drive wheel fixture is

stamped with an arrow showing the direction of rotation.

Figure 4-7. This type of wire has arrowheads molded

into the plastic coating. The dark “shoulder” of the

cutting bead should trail the bead as the wire cuts.

Place the new wire over the wheels, in reverse order of

4.

removing the wire. Be sure to mount it so that the

arrows are in the direction of travel.

Figure 4-8. Install the wir e so that the arrows point in

the direction of travel, as shown.

40 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 4, Maintenance: Replacing the Cutting Wire

Remove nut

and shaft

Pull wheel

out of frame

Turn the drive wheel tension knob until the wire starts

5.

to tighten and stays on the wheels.

To prepare the machine for a new cut, set the wire ten-

6.

sion as described in the operating instructions in

Chapter 3.

Mounting the Wire on the WS-8460

The WS-8460 has an additional idler wheel next to the drive

wheel. This idler wheel needs to be removed to replace the

cutting wire.

If there is a wire on the saw, turn the drive wheel ten-

1.

sion knob to fully release the tension on the wire.

Remove the nut from the idler wheel shaft, and pull

2.

out the shaft.

Pull the wheel in its housing out of the frame. Keep

3.

the wheel and housing assembled; the housing can

come off once the shaft is removed.

Figure 4-9. Remove the wheel shaft nut and pull the

shaft out from the bottom, then remove the wheel

assembly from the frame.

You can now remove the wire from the saw. Install a

4.

new wire as described above, then replace the idler

wheel and re-install the shaft and nut.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 41

Diamond Wire Saw User’s Manual

REPLACING THE MOUNTING SHOES

You may have to replace the mounting shoes if they are

damaged or worn. Four screws attach each shoe to the

frame.

Figure 4-10. The four screws indicated hold the shoe

to the machine frame.

Remove the nuts on the four screws holding the shoe

1.

in place.

Remove the shoe.

2.

Put the new shoe in place and replace the screws.

3.

Replace the nuts and tighten them securely.

4.

REPLACING THE WHEEL LINERS

The liners on the cutting wire wheels are durable and longlasting. They may wear out after extensive use, or be damaged if the saw malfunctions. If necessary, replace them

using the following procedure.

The tension wheel and 2 idler wheels are identical. The

drive wheel is assembled differently than the others.

42 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Tension and Idler Wheels

NOTE

NOTE

Remove the cutting wire before taking off any of the

wheels.

Remove the nut on the end of the hub bolt and pull the

1.

bolt out of the wheel mounting fixture.

Chapter 4, Maintenance: Replacing the Wheel Liners

Some models have covers

over the wheels. You can

separate and remove the

cover after you take the

wheel out of the wheel

mounting fixture.

Figure 4-11. Remove the hub bolt to take off the

wheel. The bolt head is on top in this view , with the nut

on the bottom of the fixture.

Remove the wheel from its mounting fixture and set it

2.

on a work surface. You can work on either side of the

wheel.

Remove the 12 screws holding the side plate in place.

3.

You only need to remove one side plate.

It may be easier to work on

the wheel if you set it on

something that supports the

side plate, with a gap for the

hub shaft to keep it from sitting on the shaft.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 43

Diamond Wire Saw User’s Manual

Figure 4-12. Remove the scr ews from the side plate to

take it off.

Remove the side plate.

4.

Remove the old wheel liner. You may have to pry it

5.

loose with a screwdriver.

44 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 4-13. Pull the liner off the wheel. You may

have to pry it with a screwdriver to get it loose.

Place the new liner on the wheel and press it down

6.

into place.

Chapter 4, Maintenance: Replacing the Wheel Liners

Figure 4-14. Put the new wheel liner on the wheel.

If you removed the shaft, replace it through the center

7.

of the wheel.

Figure 4-15. Replace the shaft through the center of

the wheel.

Replace the side plate. Line up the holes in the plate

8.

with the holes in the wheel.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 45

Diamond Wire Saw User’s Manual

Fasten the side plate with the 12 screws. Snug each

9.

screw, then tighten them in a criss-cross pattern to

secure the wheel evenly.

Figure 4-16. Replace the screws in the side plate.

Replace the wheel into its mounting fixture. Put the

10.

bolt through the top of the fixture, and install the nut

on the bottom. Tighten the nut securely.

Drive Wheel

Remove the cutting wire before taking off any of the

wheels.

To replace the drive wheel liner, you must first remove the

wheel and motor assembly from the saw bow using the following procedure.

Hold or support the drive wheel and hydraulic motor

1.

assembly , so that it does not fall when you remove the

fasteners holding it to the saw bow.

Loosen the set screws in the stop collars on the pivot

2.

pin and remove the pin from the frame. Be careful not

to lose the stop collars.

46 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 4, Maintenance: Replacing the Wheel Liners

Pivot pin

Stop collars

Set screw

Tension rod

mounting bolt

Hub boltSpacer bolt Top plate

Figure 4-17. Loosen the set screws in the stop collars

to remove the pivot pin.

Remove the nut from the bolt holding the wheel

3.

assembly to the tension rod, then remove the bolt. The

wheel and motor assembly will be free from the saw

bow.

Figure 4-18. Remove the nut (on the bottom) of the

tension rod mounting bolt, and remove the bolt.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 47

Diamond Wire Saw User’s Manual

Remove the hub bolt and spacer bolt from the wheel

4.

assembly, as shown in Figure 4-18. Be careful not to

lose the spacer.

Pull the top plate off the wheel.

5.

Pull the wheel up off the motor shaft. Note the side of

6.

the wheel that mounts onto the motor; the wheel is not

reversible.

Disassemble the wheel and replace the liner as

7.

described in the previous section, “Tension and Idler

Wheels”.

Replace the wheel on the motor shaft, making sure the

8.

correct side is toward the motor.

Replace the top plate. Insert the spacer bolt through

9.

the spacer and snug it down.

Replace the hub bolt and snug it.

10.

Replace the tension rod mounting bolt through the

11.

plates and tension rod end. Put the nut on the end of

the bolt and tighten it securely.

Tighten the spacer bolt and hub bolt securely.

12.

Slide the wheel and motor assembly plates into place

13.

in the saw bow and line up the pivot pin holes.

Set the stop collars in place between the plates. Insert

14.

the pivot pin through the top plate, the stop collars,

and the bottom plate.

Holding the pivot pin in place, position the stop col-

15.

lars against the mounting plates and tighten the set

screws.

48 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 4, Maintenance: Bleeding the Feed Tension Control

Pivot pin

Stop collars

Set screw

Figure 4-19. Make sure the pivot pin is through both

plates, then position the stop collars and tighten the

set screws.

BLEEDING THE FEED TENSION CONTROL

If the feed tension control mechanism is not working properly, you will need to bleed the system. Typically, the problem will be that the system overfeeds, putting too much

tension on the wire and potentially breaking it.

For this procedure, you will need to access the tension control mechanism assembly and the spring tension assembly.

Figure 4-20 shows the location of these assemblies on the

saw.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 49

Diamond Wire Saw User’s Manual

Spring tension

assembly

(10-010-00-435)

Tension control

mechanism assembly

(10-010-00-418)

NOTE

cross-section

Figure 4-20. The photo shows the locations of the tension control system components on the WS5230 saw

model. The assemblies are in the same location on all

models of the diamond wire saw.

The full assembly drawings

with parts lists are included in

Chapter 5.

Position the saw so that the bow is face down (oppo-

1.

site the way shown in Figure 4-20). Use blocks underneath it to avoid damaging the grease fittings.

Remove the cylinder from the spring assembly by

2.

removing ¼-28 SHCS and 1-1/4" nut. T emporarily put

the fasteners back on the cylinder . Note: SHCS is Item

14 and Nut is Item 9 on drawing 10-010-00-435,

shown in Figure 4-21.

50 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Figure 4-21. The drawing illustrates the components

of the spring assembly. Item 2 is the spring assembly

cylinder.

Chapter 4, Maintenance: Bleeding the Feed Tension Control

Sight tube

End plug

Remove the rod end from the tension control mecha-

3.

nism cylinder by removing ¼-28 SHCS. Temporarily

put the SCHS back on the cylinder. Note: SHCS is

Item 20 and Rod End is Item 7 on drawing 10-010-00418, shown in Figure 4-22.

4.

5.

6.

7.

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 51

Figure 4-22. The drawing illustrates the components

of the tension control mechanism. Item 1 is the tension

control mechanism cylinder.

If sight tube has no green fluid visible, remove end

plug and fill with 50/50 antifreeze. (Water may be

used if antifreeze is unavailable).

Open the frame bypass ball valve (Item 10 in

Figure 4-22) and the sight tube bypass ball valve (Item

11 in Figure 4-22).

Slowly cycle the tension control assembly cylinder

(Figure 4-22) back and forth 10 times.

Close the frame bypass ball valve (Item 10 in

Figure 4-22).

Diamond Wire Saw User’s Manual

Slowly cycle the tension control assembly cylinder

8.

(Figure 4-22) back and forth 10 times.

Open the frame bypass ball valve (Item 10 in

9.

Figure 4-22).

Slowly cycle the spring assembly cylinder (Figure 4-

10.

21) back and forth 10 times.

Close the frame bypass ball valve (Item 10 in

11.

Figure 4-22).

Slowly cycle the spring assembly cylinder (Figure 4-

12.

21) back and forth 10 times.

If required, fill the sight tube with 50/50 antifreeze.

13.

Open the frame bypass ball valve (Item 10 in

14.

Figure 4-22).

Close the sight tube ball valve (Item 11 in Figure 4-

15.

22).

Fully extend the spring assembly cylinder (Figure 4-

16.

21) and fully retract the tension control assembly cylinder (Figure 4-22).

Close the frame bypass ball valve (Item 10 in

17.

Figure 4-22).

Cycle either cylinder once; there should be no delayed

18.

movement of the other cylinder. If some “sponge”

exists, repeat steps 5 through 16.

Re-install both cylinders by reversing steps 2 and 3.

19.

52 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 5

Parts List and

Ordering Information

Chapter 5, Parts List and Ordering Information

In This Chapter

ORDERING INFORMATION

ORDERING INFORMATION

To place an order, request service, or get more detailed

information on any E.H. Wachs products, call us at one of

the following numbers:

U.S. 800-323-8185

International: 847-537-8800

You can also visit our Web site at:

www.ehwachs.com

Ordering Replacement Parts

When ordering parts, refer to the parts lists in this chapter.

Please provide the part description and part number for all

parts you are ordering.

Repair Information

DRAWINGS AND PARTS LISTS

Please call us for an authorization number before returning

any equipment for repair or factory service. We will advise

you of shipping and handling. When you send the equipment, please include the following information:

• Your name/company name

• Your address

• Your phone number

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 53

Diamond Wire Saw User’s Manual

• A description of the problem or the work to be done.

Before we perform any repair, we will estimate the work

and inform you of the cost and the time to complete it.

Warranty Information

Enclosed with the manual is a warranty card. Please fill out

the registration card and return to E.H. Wachs. Retain the

owner’s registration record and warranty card for your

information.

Return Goods Address

Return equipment for repair to the following address.

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, Illinois 60069 USA

DRAWINGS AND PARTS LISTS

The drawings on the following pages illustrate the WS-164,

WS-3012, WS-3616, and WS-5230 diamond wire saws.

Each assembly drawing includes a parts list; use the part

numbers to order spare or replacement parts.

The following tables list the drawings provided for each

diamond wire saw model.

54 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

Chapter 5, Parts List and Ordering Information: Drawings and Parts Lists

Table 1: Common Assemblies—All WS Models

Drawing Number Description

10-010-00-412 Planetary Gear Motor

10-010-00-418 Tension Control Mechanism

10-010-00-419 Flow Divider Assembly

10-010-00-431 Frame Drive Arm

10-010-00-432 Frame Drive Wheel

10-010-00-433 Tensioning Wheel Assembly

10-010-00-434 Idler Wheel Assembly

10-010-00-435 Spring Tension Assembly

Table 2: WS-164 Assembly Drawings

Drawing Number Description

10-010-16-411 Feed Frame

10-010-16-413 Lifting Tube

10-010-16-418 Tension Control Mechanism

10-010-16-419 Flow Divider Assembly

10-010-16-224B Bulkhead Plate

Table 3: WS-3012 Assembly Drawings

Drawing Number Description

10-010-30-410 Frame Assembly

10-010-30-411 Feed Frame

10-010-30-413 Lifting Tube

10-010-30-420 Clamp Assembly

10-010-30-421 Adjustable Clamp with Actuator

10-010-30-430 Bow Frame

10-010-30-224B Bulkhead Plate

E.H. Wachs Part No. 10-010-MAN, Rev. 1-0310 55

Diamond Wire Saw User’s Manual

Table 4: WS-3616 Assembly Drawings

Drawing Number Description

10-010-36-410 Frame Assembly

10-010-36-411 Feed Frame

10-010-36-413 Lifting Tube

10-010-36-420 Clamp Assembly

10-010-36-421 Adjustable Clamp with Actuator

10-010-36-430 Bow Frame

10-010-36-224B Bulkhead Plate

Table 5: WS-5230 Assembly Drawings

Drawing Number Description

10-010-52-410 Frame Assembly

10-010-52-411 Feed Frame

10-010-52-413 Lifting Tube

10-010-52-420 Clamp Assembly

10-010-52-421 Adjustable Clamp with Actuator

10-010-52-430 Bow Frame

10-010-52-224B Bulkhead Plate

Table 6: WS-8460 Drawings

Drawing Number Description

08-031, p. 1 General Arrangement

08-031, p. 2 Clamp Configuration

56 Part No. 10-010-MAN, Rev. 1-0310 E.H. Wachs

10 1/4"

A

A

16

3

2

7

3"

SQ.

.10

2.00

SECTION A-A

18

8

1

15

14 12

11

5

9

13

17

10

6

?

1

PRODUCTION RELEASE

11/12/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

11-103-00

GEARBOX, PLANETARY OUTPUT

1

2

1293K21

1/4-28 TAPERED GREASE FITTING; SS

1

3

90-500-04

GREASE FITTING, 1/8 NPT X 30 DEG.

1

4

92196A209

SHCS #8-32 x 3" LG.

7

5

92196A319

SHCS 1/4"-28 x 5/8" LG, SS

5

6

92949A560

BSCHS 1/4"-28x3/8" LG, SS

1

7

brennan #6400-06-06-O

MJ-MORB STRAIGHT CONNECTOR

2

8

P06-052-150

HOUSING, FEEDBOX OUTPUT

1

9

P06-052-155

COUPLER, MOTOR INPUT

1

10

P06-052-158

COUPLER, DRIVE

1

11

P06-052-159

HOUSING, FEEDBOX INPUT

1

12

P06-052-333

ADAPTER, FEED MOTOR

1

13

P06-150-035

BEARING, BALL (.75 x 1.625 x .438)

1

14

P06-150-036

GEARBOX, PRIMARY

2

15

P06-150-037

SPACER, GEARBOX

2

16

P06-150-038

MOTOR, FEED

1

17

Truarc 5100-75 -H

RETAINING RING, SS

1

18

Truarc N5000-162-H

RETAINING RING, SS

1

SIZE

B

REV.

DWG. NO.

10-010-00-412

DRAWN BY

APPROVED BY

DATE

DATE

SCALE

SHEET

1:2

1 OF 1

TITLE

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF E.H. WACHS IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

ANGULAR

15 MIN.

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

PLANETARY GEAR MOTOR

.

10/27/09

.

1

ALL DIMENSIONS ARE IN INCHES.

A

A

19

15

30

18

17

11

23 19

1

4

36720

21

14

13

14

10

12

9

5

8

25

SECTION A-A

22

16

22726 31

24

29

26

28

1

PRODUCTION RELEASE

11/25/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

10-010-00-006

CYLINDER

1

2

10-010-00-007

DIRECTIONAL VALVE

1

3

10-010-00-273

NUT, 273

1

4

10-010-00-274

BLOCK, 274

1

5

10-010-00-274B

BLOCK, 274B

1

6

10-010-00-275B

BLOCK, 275B

1

7

10-010-00-276

ROD END, 276

1

8

10-010-00-277

BLOCK, 277

1

9

1293K21

1/4-28 TAPERED GREASE FITTING; SS

1

10

4912K54

BALL VALVE

1

11

4912K96

BALL VALVE

1

12

50785K75

PIPE TEE FITTING

2

13

50915K413

TUBE RUN TEE FITTING

2

14

5272K721

COMPRESSION TUBE FITTING

4

15

8339K19

ULTRA CLEAR PVC TUBING

1

16

90145A512

DOWEL PIN 3/16" x 1.25" LG, SS

1

17

91465K15

HOSE FITTING, PUSH-ON

1

18

91465K331

HOSE FITTING, PUSH-ON

1

19

92196A196

SHCS #8-32 x 5/8" LG, SS

8

20

92196A319

SHCS 1/4"-28 x 5/8" LG, SS

1

21

92196A542 SHCS 1/4"-20 x 1" LG, SS

2

22

92311A535

SET SCREW 1/4"-20 x 3/8" LG, SS

1

23

9595K34

COMPRESSION SPRING

1

24

Brennan 2404-04-02-SS

FITTING, 1/8 NPT TO 1/4 JIC

2

25

Brennan 5408-04-O

PLUG

1

26

Brennan 6565-06-06

FJS-FJS STRAIGHT

2

27

Brennan 6801-06-04-NWO

MJ-MAORB 90-CONNECTOR

1

28

Brennan 6803-06-06-04-NWO

BRANCH TEE

1

29

Brennan 6804-06-04-06-NWO

RUN TEE 1

30

EATON #705

AIR VENT

2

31

Parker #CV-370-MFMF-65

CHECK VALVE

2

A

A

B

B

C

C

D

D

E

E

F

F

8

8 6

6

5

5

4

4

3

3

2

2

1

17

7

SIZE

D

REV.

DWG. NO.

10-010-00-418

DRAWN BY

APPROVED BY

DATE

DATE

SCALE

SHEET

1:1

1 OF 1

TITLE

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF E.H. WACHS IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

ANGULAR

15 MIN.

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

TENSION CONTROL MECHANISM

.

11/24/09

.

1

ALL DIMENSIONS ARE IN INCHES.

1 2

2

2

3 4

2

4

1

PRODUCTION RELEASE

11/25/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

10-010-00-004

FLOW DIVIDER

1

2

brennan #6400-06-06-O

MJ-MORB STRAIGHT CONNECTOR

4

3

brennan #6602-06-06-06

MJ-FJS-MJ TEE

1

4

brennan #6500-06-06

MJ-FJS 90-CONNECTOR

2

SIZE

B

REV.

DWG. NO.

10-010-00-419

DRAWN BY

APPROVED BY

DATE

DATE

SCALE

SHEET

1:1

1 OF 1

TITLE

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF E.H. WACHS IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

ANGULAR

15 MIN.

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

FLOW DIVIDER ASSEMBLY

.

11/24/09

.

1

ALL DIMENSIONS ARE IN INCHES.

A

A

C

11

2825

30

3

32 331

15

E

E

31

B

D

SECTION A-A

SCALE 1 : 2

16

6

5

74

12

13

914 17

38

35

37

8

22

27

20

DETAIL B

SCALE 2 : 1

2

34

DETAIL C

SCALE 1 : 1

26

21

24

DETAIL D

SCALE 2 : 1

19

1036

39

38

SECTION E-E

SCALE 1 : 2

18

6

4

28

25

29

21

26

23

7

1

PRODUCTION RELEASE

11/12/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

10-010-00-001

HYDRAULIC MOTOR

1

2

10-010-00-002

ROTARY SEAL

1

3

10-010-00-025

ROD, 025

1

4 10-010-00-037A

BLOCK, MOTOR ADAPTER

1

5

10-010-00-043C

PLATE, 033B

1

6

10-010-00-043E

MOTOR SIDE PLATE, 043E

1

7

10-010-00-050

ASSY, HUB, DRIVE WHEEL

1

8

10-010-00-051

MOUNT, BEARING

1

9

10-010-00-059

SCREW, 059 WHEEL

1

10

10-010-00-064

RETAINER, DRIVE WHEEL SEAL

1

11

10-010-00-076

ROD, 044

1

12

10-010-00-280B

WHEEL COVER 280B

2

13

10-010-00-432

FRAME DRIVE WHEEL

1

14

1293K21

1/4-28 TAPERED GREASE FITTING; SS

1

15

3088K7

45 Degree Grease Fitting, 1/4-28

1

16

4207_ATN9

DOUBLE ROW BALL BEARING

1

17

90145A539

1/4 x 5/8 LG. DOWEL PIN

3

18

90585A581

FHCS, 5/16-18 X 3/4" (316 SS)

6

19

91650A570

External Spiral Retaining Ring

2

20

9171K251

1/8" NPT HEX PIPE PLUG

1

21

91831A030

LOCKNUT 5/16"-18, SS

6

22

91950A033

1/2 WASHER, SS

1

23

92196A580

SHCS 5/16"-18 x 5/8" LG, SS

6

24

92210A582

FSHCS 5/16"-18 x 1.125" LG, SS

6

25

92240A714

HHCS 1/2"-13 x 1.25" LG

4

26

93286A030

5/16" WASHER, AL.

6

27

9452K134

-45 O-RING BUNA N 70

1

28

98017A209

1/2 WASHER, SS

4

29

98017A689

5/16" WASHER, SS 6

30

9943K21

CLAMP COLLAR, 1/2" ID (316 SS)

2

31

Garlock 08FDU06

BUSHING

2

32

Parker 16-20_c5ox-s

ORB TO JIC ELBOW

1

33

Parker 16_C5OX-SS

ORB TO JIC ELBOW

1

34

Smalley EH_50

RETAINING RING FOR 50MM BORE

1

35

Smalley EH_72

RETAINING RING FOR 72 MM BORE

1

36

Smalley RRT-185

RETAINING RING

1

37

Smalley WS_137

RETAINING RING FOR 35MM SHAFT

1

38

SS-6204-1RS

BALL BEARING, SS

1

39

Truarc 5108-78-H

RETAINING RING

1

A

A

B

B

C

C

D

D

E

E

F

F

8

8776

6

5

5

4

4

3

3

2

21

1

SIZE

C

REV.

DWG. NO.

10-010-00-431

DRAWN BY

APPROVED BY

DATE

DATE

SCALE

SHEET

1:4

1 OF 1

TITLE

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF E.H. WACHS IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

ANGULAR

15 MIN.

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

FRAME DRIVE ARM

.

11/02/09

.

1

ALL DIMENSIONS ARE IN INCHES.

C C

12.98

1.50

SECTION C-C

2

623

1

4

D

D

SECTION D-D

7

1

PRODUCTION RELEASE

11/12/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1 10-010-00-053A

WHEEL, PLATE 053A

1

2

10-010-00-053 blank

WHEEL, 053

2

3

10-010-00-053D

WHEEL, PLATE 053D

1

4

10-010-00-053E

WHEEL, PLATE 053E

1

5

10-010-00-720

LINER, WHEEL

1

6

92196A543

SHCS 1/4"-20 x 1.125" LG, SS

8

7

92196A539

SHCS 1/4"-20 x 5/8" LG, SS

4

A

A

B

B

C

C

D

D

E

E

F

F

8

8776

6

5

5

4

4

3

3

2

21

1

SIZE

C

REV.

DWG. NO.

10-010-00-432

DRAWN BY

APPROVED BY

DATE

DATE

SCALE

SHEET

1:2

1 OF 1

TITLE

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF E.H. WACHS IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

ANGULAR

15 MIN.

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

FRAME DRIVE WHEEL

.

11/03/09

.

1

ALL DIMENSIONS ARE IN INCHES.

A

A

C

C

D

D

B

SECTION A-A

3

14

8

18

13

11 5 1012415

2

6

DETAIL B

SCALE 2 : 1

202219 9721

SECTION C-C

15

SECTION D-D

1

17

16

1

PRODUCTION RELEASE

11/12/2009

KRP

REV.

DESCRIPTION

DATE

APR.

REVISION HISTORY

PART NUMBER

DESCRIPTION

QTY.

1

10-010-00-025

1

2

10-010-00-032

PLATE, 032

1

3

10-010-00-032B

PLATE, 032B

1

4

10-010-00-052

HUB, WHEEL

1

5 10-010-00-054A

PLATE 054A

2

6

10-010-00-054B

PLATE 054B

1

7

10-010-00-055B

TUBE, 055B

1

8

10-010-00-057

HHCS, 1/2-13 X 3-3/4" (316 SS)

1

9

10-010-00-063

RETAINER, GUIDE WHEEL SEAL

2

10

10-010-00-281

COVER, GUIDE WHEEL

2

11

10-010-00-730

GRIP, WHEEL IDLER

1

12

10-010-00-730B

PLATE, 730B

1

13

91831A137

LOCKNUT 1/2"-13, SS

1

14

91950A033

1/2 WASHER, SS

2

15

92210A539

FHSCS 1/4"-20x5/8"LG, SS

30

16

CLAMP COLLAR, 1/2" ID (316 SS)

2

17

GARLOCK #08FDU06

2

18

P08-018-123

1/4-28 GREASE ZERK; SS

1

19

Spirolox RRT-185

RETAINING RING

2

20

SS-6204-1RS

BALL BEARING, SS

2

21

TIMKEN #FTRA-3047

WASHER, THRUST

1

22

Truarc 5108-78-H

RETAINING RING

2

A

A

B

B

C

C

D

D

E

E

F

F

8

8776

6

5

5

4

4

3

3

2

21

1

SIZE

C

REV.

10-010-00-433

APPROVED BY

DATE

DATE

2:3

PROPRIETARY AND CONFIDENTIAL: THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF E.H. WACHS. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE

UNLESS OTHERWISE SPECIFIED:

TOLERANCES:

FRACTIONS

1/32

ONE PLACE DECIMAL

.015

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

DO NOT SCALE DRAWING.

E.H. WACHS WORKMANSHIP STANDARDS (WI 17-01)

SHALL APPLY TO ALL ITEMS NOT SPECIFIED ON DRAWING.

E.H. WACHS

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

AG

ASSY, TENSIONING WHEEL

.

.

1

ALL DIMENSIONS ARE IN INCHES.

A

A