E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

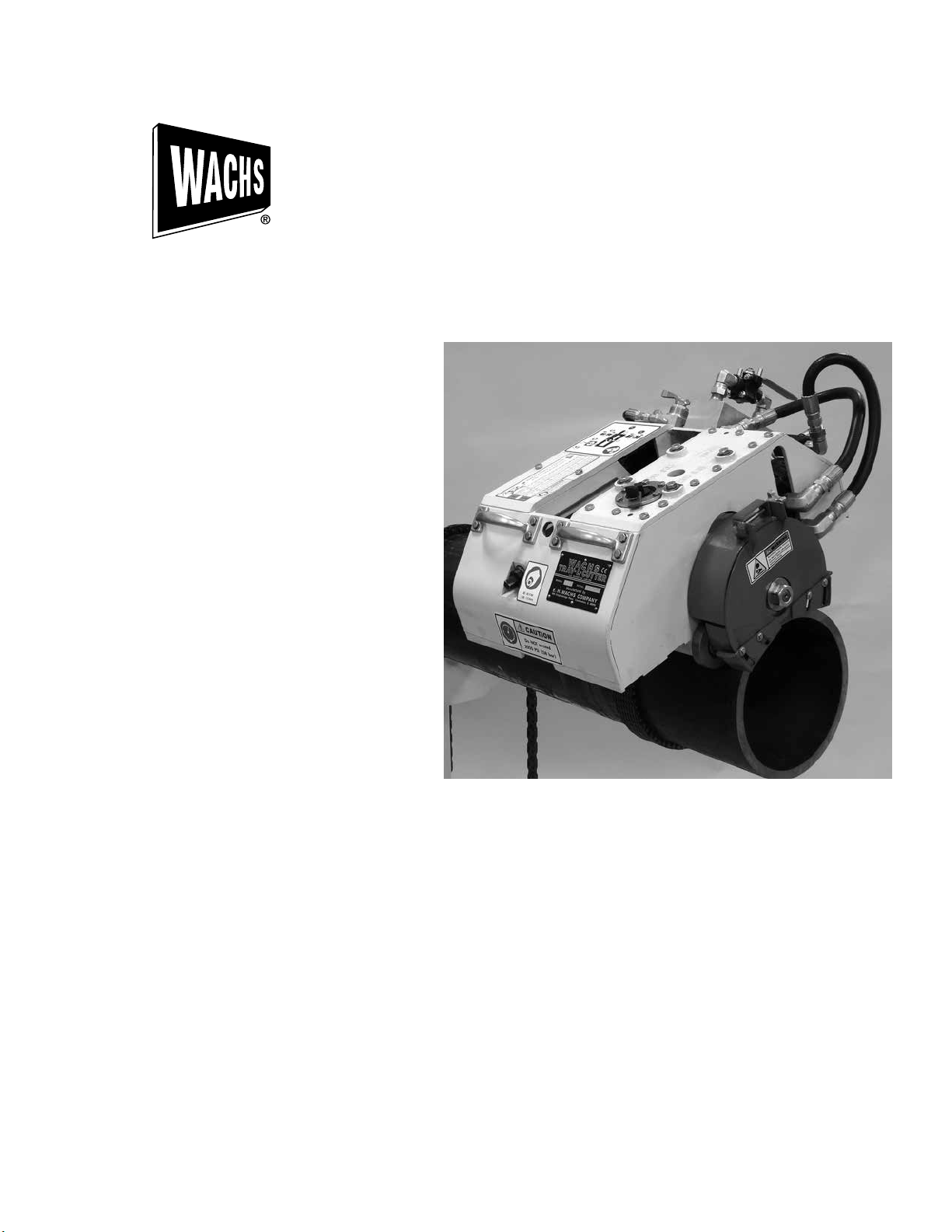

TRAV-L-CUTTER

MODEL E & H/E

STANDARD & ATMOSPHERIC

02-000-01,-02,-03,-04

E.H. Wachs Part No. 02-MAN-01

Rev. A, March 2014

Copyright © 2014 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

EU DECLARATION OF CONFORMITY

WITH

COUNCIL DIRECTIVE 2006/42/EC

Issue Details: DATE:

1/1/2011

Directives: Machinery Safety Directive 2006/42/EC

Conforming Machinery:

Model Number: 02-000-01, 02-000-02

Serial Number:

Manufacturer: E.H. Wachs

Responsible Representative: Orbitalum Tools GmbH

Harmonised Standards &

Other Technical

Standards/Specications

Applied or Referenced:

Provisions with which

Conformity is Declared:

We hereby certify that the machinery descrived above conforms to the provisions of

Council Directive 2006/42/EC on the approximation of the laws of the Member States

relating to the safety of machinery.

Signed:

Trav-L-Cutter:

600 Knightsbridge Parkway

Lincolnshire

IL 60069

USA

Josef-Schüttler-Str. 17, 78224 Singen

Germany

Tel. +49 (0) 7731 - 792 872

Fax +49 (0) 7731 - 792 566

EN ISO 12100-1:2003 + A1:2009

EN ISO 12100-2:2003 + A1:2009

EN 60201-1:2006 (for electric machines)

EN ISO 13857:2008

EN 982:1996 + A1:2008 (E) (for hydrailic machines)

EN 983:1996 (for pneumatic machines)

EN 13732-1:2006

EN ISO 14121-1:2007

EN ISO 13850:2008 (for pneumatic machines)

Essential Health and Safety Requirements of Annex 1 of the

Machinery Directive

Place:

E.H.Wachs, Lincolnshire, IL USA

Signatory: Pete Mullally

Quality Manager

E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: Introduction to the Equipment .........................................1

Purpose of This Manual .........................................................1

How to Use The Manual .........................................................1

Symbols and Warnings ..........................................................2

Manual Updates and Revision Tracking .............................................3

Equipment Description ..........................................................3

Compact Design, Easy Set-up ...............................................3

Standard Weld Prep Capability ..............................................3

Grooved, Mechanical Joint Preparation........................................3

Offshore or Pipe Line Maintenance ...........................................3

Corrosion Resistant .......................................................4

Operates Anywhere .......................................................4

Safe, Cold Cutting ........................................................4

Fast, Reliable ............................................................4

Chapter 2: Safety ..............................................................5

Safe Operating Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safe Operating Environment ...................................................6

Operating and Maintenance Safety ..............................................6

Safety Alerts in This Manual ...................................................6

Protective Equipment Requirements .............................................7

Protective Clothing .......................................................7

Eye Protection ...........................................................7

Hearing Protection........................................................7

Chapter 3: Machine Specications ...............................................9

Chapter 4: Setup and Operating Procedures ......................................15

Wheel Settings ...............................................................15

Chain Lengths ................................................................16

Wheel Settings and Chain Length .................................................17

Chain Length Calculations ...................................................17

Machine Installation ...........................................................18

Operating the Machine .........................................................20

Special Instructions for Assembling 2” Wide Drive Chain ...........................21

Operating Hints .........................................................22

Chapter 5: Maintenance .......................................................23

Lubrication Instructions ........................................................23

E.H. Wachs Part No. 02-MAN-01, Rev. A i

Trav-L-Cutter

Chapter 6: Consumable Select Chart ............................................25

Data on Cutter Size ............................................................25

Cutters ......................................................................27

Chapter 7: Troubleshooting Problems ............................................29

Chapter 8: Parts Lists & Exploded View Drawings .................................31

ii Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 1, Introduction to the Equipment

Chapter 1

Introduction to the Equipment

PurPose of This Manual

This manual explains how to operate and maintain the Trav-L-Cutter. It includes instructions for

set-up, operation, and maintenance. It also contains parts lists and diagrams, and troubleshooting

instructions to help you order replacement parts and perform user-service able repairs.

how To use The Manual

This manual is organized to help you quickly nd the infor mation you need. Each chapter de-

scribes a specic topic on using or maintaining your equipment.

Use these instructions to operate and maintain the equipment.

E.H. Wachs Part No. 02-MAN-01, Rev. A 1

Trav-L-Cutter

syMbols and warnings

The following symbols are used throughout this manual to indicate special notes and warnings.

They appear in the out side column of the page, next to the section they refer to. Make sure you

understand what each symbol means, and follow all instructions for cautions and warnings.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

WARNING

A WARNING alert with the safety alert symbol indicates a potentially hazardous situa tion that could

result in seri ous injury or death.

CAUTION

A CAUTION alert with the safety alert symbol indicates a potentially hazardous situa tion that could result

in minor or moderate injury.

A CAUTION alert with the damage alert symbol indicates a situation that will result in

damage to the equipment.

This is the equipment damage alert symbol. It is used to alert you to poten tial

equipment damage situations. Obey all messages that follow this sym bol to

avoid damaging the equipment or workpiece on which it is operating.

IMPORTANT

An IMPORTANT alert with the damage alert symbol indi cates a situation that may result in

damage to the equipment.

NOTE

This symbol indicates a user note. Notes provide additional information to

supple ment the instructions, or tips for easier operation.

2 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 1, Introduction to the Equipment: Manual Updates and Revision Tracking

Manual uPdaTes and revision Tracking

Occasionally, we will update manuals with improved opera tion or maintenance procedures, or

with corrections if nec essary. When a manual is revised, we will update the revision history on the

title page.

Current versions of E.H. Wachs Company manuals are also available in PDF for mat. You can

request an electronic copy of this manual by emailing customer service at sales@ehwachs.com.

You may have factory service or upgrades performed on the equipment. If this service changes any

technical data or operation and maintenance procedures, we will include a revised manual when

we return the equipment to you.

equiPMenT descriPTion

Compact Design, Easy Set-up

Lightweight, low prole design needs only 10” to 12” of clearance and set up time is ten minutes or

less. Once the adjustable drive chain is pinned together and tensioned around the pipe the machine

is ready to operate.

Standard Weld Prep Capability

Weld preparation detail can be achieved from common 30º and 37-1/2º bevel on standard wall

carbon steel.

Grooved, Mechanical Joint Preparation

The Trav-L-Cutter can simultaneously cut off and groove pipe in one cut. Cutters are available for

Victaulic and other grooved coupling systems.

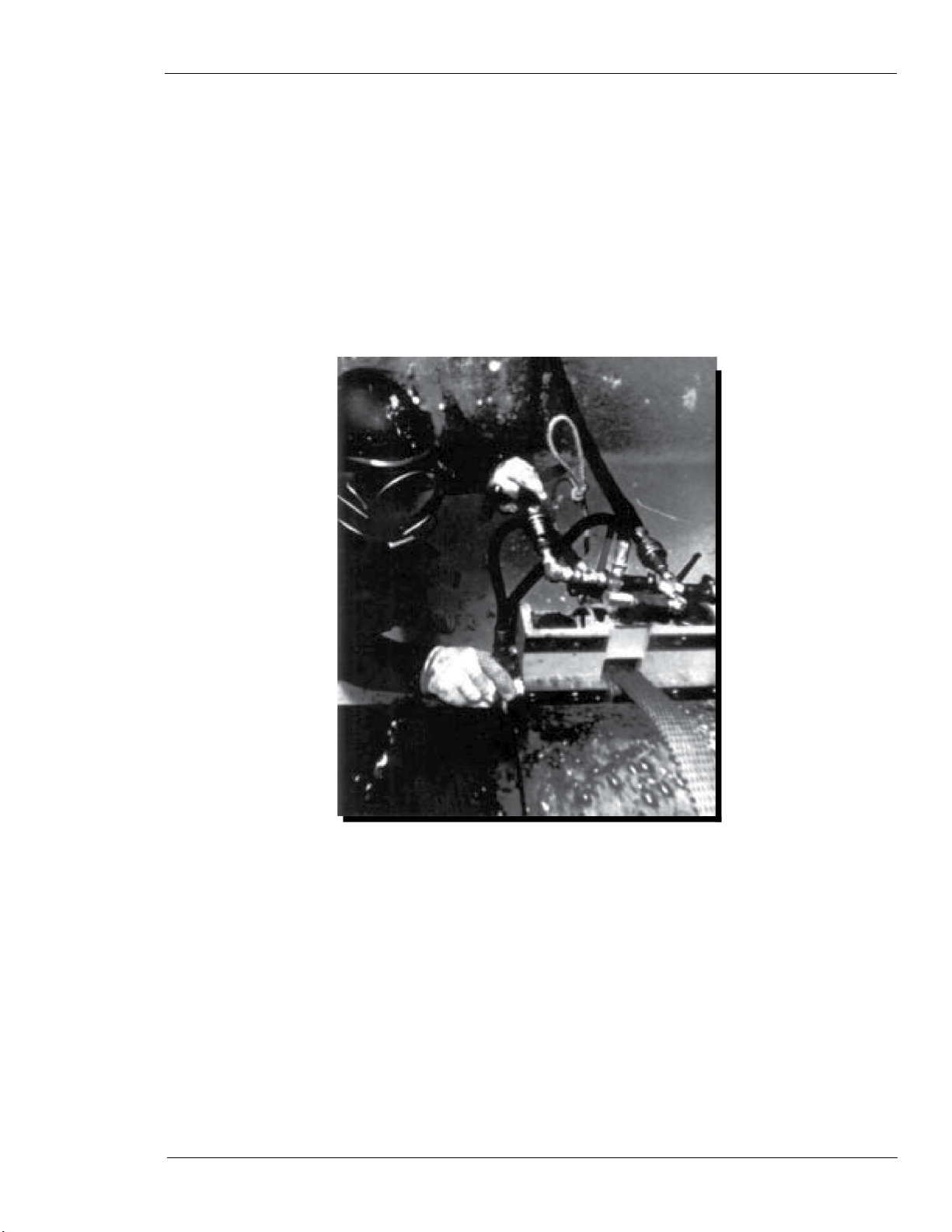

Offshore or Pipe Line Maintenance

The Wachs Hydraulic Trav-L-Cutter offers the inherent advantages of a completely sealed and

self-lubricating closed loop system. The Model HE is particularly suited to eld machining operations under the type of hostile conditions often found in pipe line maintenance and construction

such as dirt, sand and water. It is a portable pipe cutting machine that can be used conveniently on

offshore drilling rigs, pipe lines and on construction work in rivers and harbors.

E.H. Wachs Part No. 02-MAN-01, Rev. A 3

Trav-L-Cutter

Corrosion Resistant

Corrosion from constant exposure to salt water can be minimized with an accessory package that

includes extensive use of stainless steel fasteners, special bearings and seals and high zinc coating.

Operates Anywhere

With air or hydraulic power, the Trav-L-Cutter will operate on horizontal or vertical pipe, in the

eld or in the shop. It cuts and bevels in a mud lled ditch or under water, where it has been used in

chambers and free diving to depths of 600 feet.

Safe, Cold Cutting

The Trav-L-Cutter can be used in explosive conditions, onnatural gas, crude, product and fuel

lines. It has even been used to cut missile fuel cells.

Fast, Reliable

A standard wall pipe can be cut and beveled with a cutting speed of approximately 2 minutes per 1”

of pipe diameter. Cutting time varies for heavier walls and harder alloys. Due to its rugged con-

struction, it is not unusual to nd machines still operating after 10 or 20 years of severe service.

Included with your TRAV-L-CUTTER:

• Operating Manual and Isometric Parts List, Operating Tools, and spare Chain Connecting Pins.

• Basic Mounting Chain for 6” dia. pipe

• Steel Storage Case

• 6-ft. Hose Whip with oiler (air only)

4 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 2, Safety

Chapter 2

Safety

E.H. Wachs takes great pride in designing and manufactur ing safe, high-quality products. We

make user safety a top priority in the design of all our products.

Read this chapter carefully before operating the bridge slide. It contains important safety instructions and recom mendations.

FULL SAFETY INSTRUCTIONS AND GUIDELINES ARE IN THE MANUAL FOR

YOUR TRAV-L-CUTTER MACHINE. Make sure you read and understand these safety recom-

mendations and operating instructions before operating.

safe oPeraTing guidelines

Follow these guidelines for safe operation of all E.H. Wachs equipment.

Look for this sym bol throughout the manual. It indicates a personal injury

hazard.

• READ THE OPERATING MANUAL. Make sure you under stand all setup and operating instructions

before you begin. Keep this manual with the machine.

INSPECT MACHINE AND ACCESSORIES BEFORE USE. Before starting the machine, look for loose

•

bolts or nuts, leak ing lubricant, rusted components, and any other physi cal conditions that may

affect operation. Properly maintaining the machine can greatly decrease the chances for injury.

ALWAYS READ STICKERS AND LABELS. Make sure all labels and stickers are in place, clearly

•

legible, and in good condition. Refer to “Safety Labels” later in this chapter for label locations

on the machine. Replace any dam aged or missing safety labels; see the ordering informa tion at

the end of this manual.

KEEP CLEAR OF MOVING PARTS. Keep hands, arms, and ngers clear of all rotating or moving

•

parts. Always turn the machine off and disconnect the power source before doing any adjustments or service.

E.H. Wachs Part No. 02-MAN-01, Rev. A 5

Trav-L-Cutter

• SECURE LOOSE CLOTHING AND JEWELRY. Secure or remove loose-tting clothing and jewelry,

and securely bind long hair, to prevent them from getting caught in moving parts of the machine.

FOLLOW SAFE PROCEDURES FOR HANDLING LUBRICANTS. Refer to the manufacturer’s instruc-

•

tions and the Mate rial Safety Data Sheets.

Safe Operating Environment

• Do not use this equipment in a potentially explosive atmosphere. Fire or explosion could result,

with the risk of serious injury or death.

• Provide adequate lighting to use the equipment, in accordance with worksite or local regulations.

KEEP WORK AREA CLEAR. Keep all clutter and nonessen tial materials out of the work area. Only

•

people directly involved with the work being performed should have access to the area.

Operating and Maintenance Safety

• This equipment is to be operated and maintained only by qualied, trained personnel.

• Make sure the equipment is stable when attached to the workpiece for the operation. Ensuring

stability of the installed tool is the responsibility of the operator.

• Make sure the workpiece is supported adequately for installation of the equipment. This

includes supporting any workpiece “fall-off” section when severing the workpiece. Ensuring

support of the workpiece is the responsibility of the operator.

• Tooling on any cutting equipment—including lathe tools, saw blades, milling tools, etc.—may

get very hot. Do not touch tooling until you have made sure it is cool enough to handle.

• Wear gloves when removing or cleaning up chips and cutting debris. Chips can be very sharp

and cause cuts.

• Before performing any service on the equipment, dis connect the power source. Follow all

lock-out/tag-out procedures required at the worksite.

Safety Alerts in This Manual

The following alerts are used throughout this manual to indicate operator safety hazards. In all

cases, these alerts include a notice describing the hazard and the means to avoid or reduce risk.

Carefully read all safety alerts.

This icon is displayed with any safety alert that indicates a personal injury

hazard.

WARNING

This safety alert, with the personal injury hazard symbol, indicates a potentially hazardous

situation that, if not avoided, could result in death or serious injury.

6 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 2, Safety: Safe Operating Guidelines

CAUTION

This safety alert, with the personal injury hazard symbol, indicates a potentially hazardous

situation that, if not avoided, could result in minor or moderate injury.

Protective Equipment Requirements

Protective Clothing

Wear safety shoes when operating or servicing the equip ment. Serious injury could result from

dropping the machine or its components.

Do not wear gloves while operating the machine. Gloves can become entangled in moving parts,

resulting in serious injury. Gloves may be worn when setting up the machine or cleaning up after

the operation, but take them off when operating the machine.

NOTE

Gloves should be worn when cleaning up chips and other cutting debris. Chips can

be very sharp and can cause serious cuts. Do not wear gloves when the machine

is operating.

Eye Protection

Always wear impact-resistant eye protection while operat ing or working near this equipment.

For additional information on eye and face protection, refer to Federal OSHA regulations, 29 Code

of Federal Regula tions, Section 1910.133., Eye and Face Protection and American National

Standards Institute, ANSI Z87.1, Occu pational and Educational Eye and Face Protection.

Hearing Protection

This equipment can produce noise levels above 80 dB. Hearing protection is required when operat-

ing the equip ment. The operation of other tools and equipment in the area, reective surfaces,

process noises, and resonant struc tures can increase the noise level in the area.

For additional information on hearing protection, refer to Federal OSHA regulations, 29 Code of

Federal Regulations, Section 1910.95, Occupational Noise Exposure and ANSI S12.6 Hearing

Protectors.

E.H. Wachs Part No. 02-MAN-01, Rev. A 7

Trav-L-Cutter

8 Part No. 02-MAN-01, Rev. A E.H. Wachs

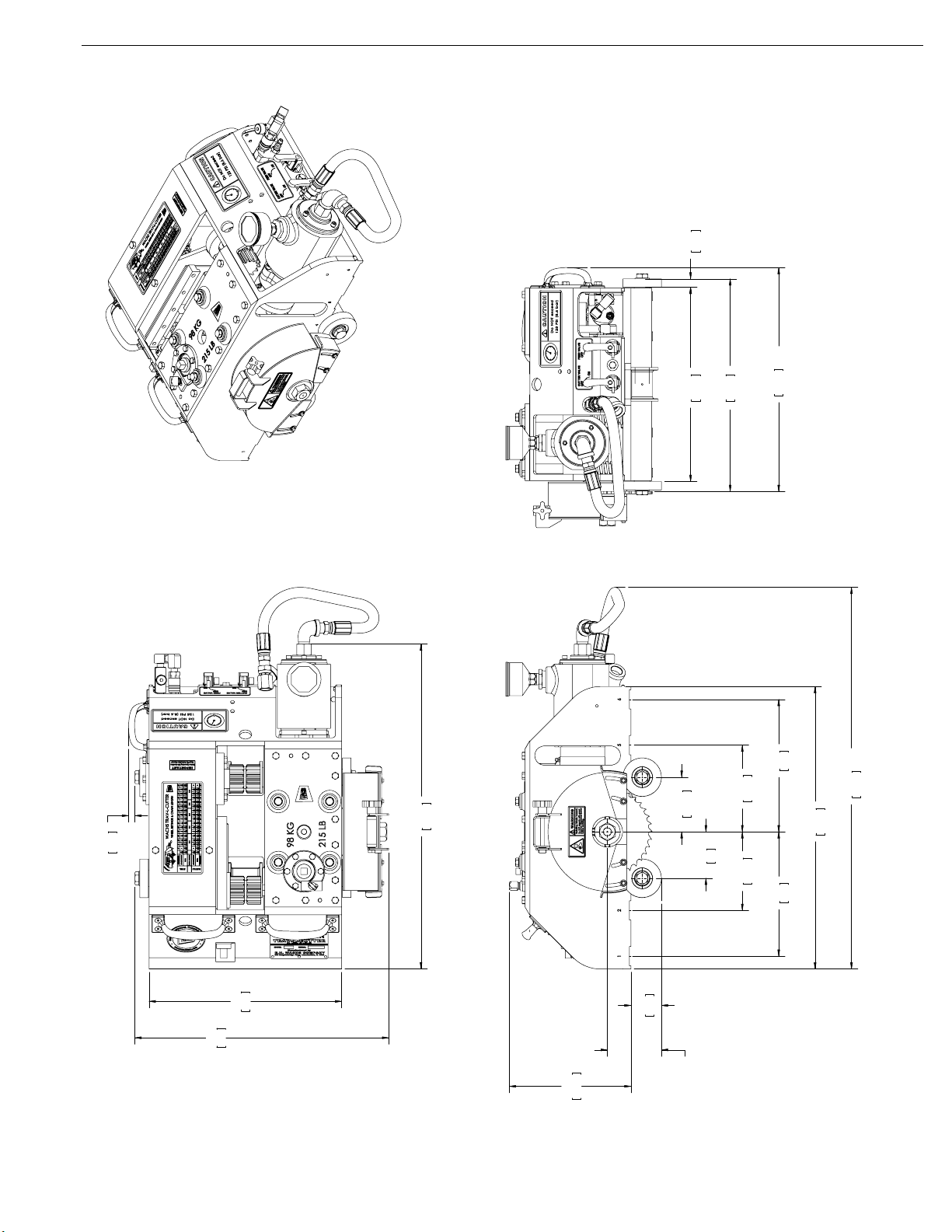

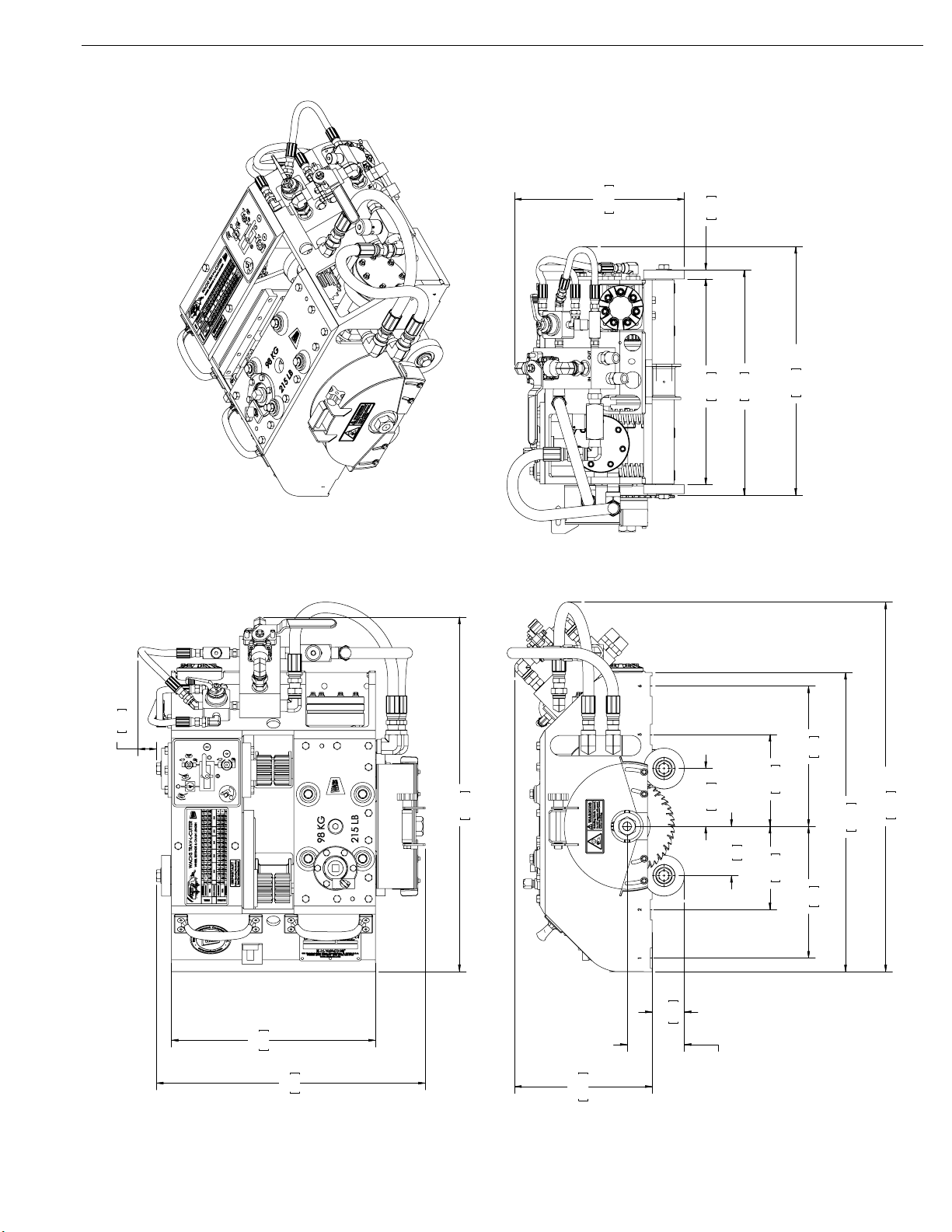

Chapter 3, About This Manual

Chapter 3

Machine Specications

Capacity:

6” through 72” (153 to 1829 mm) pipe, large diameter vessels. All schedules.

Cutter Drive:

Pneumatic: 4 H.P. Governed Air Motor coupled with worm gearbox

Hydraulic:

As above, with hydraulic motor.

Cutter Speed:

Pneumatic: 55 R.P.M. Internally adjustable from 35 to 55 R.P.M. for use on alloys that might

become work hardened. Hydraulic; Adjustable 0-60 R.P.M.

E.H. Wachs Part No. 02-MAN-01, Rev. A 9

Trav-L-Cutter

Feed:

Pneumatic: 3/4 H.P. Air Motor coupled through overload clutch, gearbox and chain reduction to

nal machine drive sprocket. Hydraulic: 4 H.P. Hydraulic Motor.

Feed Method: Positive, non-slip chain drive

Air Requirements: 100 cfm @ 90 psi (2,832 l/min @ 6.3 bar)

Hydraulic Requirements: 15 gpm @ 1500 psi. (57 l/min @ 106 bar)

Clearance:

10” to 12” (254 to 305 mm) radial, depending on pipe diameter. 20” axial (508 mm)

Weight:

Operating - 215 lbs. (97.7 kgs)

Shipping-(typical) - 418 lbs. (190 kg)

Dimensions:

Length: 24” (61 cm)

Width: 20” (51 cm)

Height: 10-3/4” (28 cm)

Controls:

(Pneumatic and Hydraulic):

Cutter on-off, feed on-off, with interlock to prevent machine feed unless cutter is turning. Adjustable Feed Speed Control (Hydraulic Only) Flow Control Valves. Separate controls provide adjustable feed and cutter speed. Forward/Reverse Valve. Permits machine to be backed up.

Shipping and Storage Case:

41” x 25” x 18” (104 x 63.5 x 45.7 cm)

2

10.7 cu. ft. (0.53 m

)

Finish: Paint

Hose Assemblies (Hydraulic):

5/8” hose sets with quick couplers, in 45’ lengths

Hydraulic Power Sources (Model HE):

- Electric, Gasoline or Diesel Engine driven.

Gang of Cutters for Beveling Pipe

1 R.H. Bevel, 1 Slitting Saw, and 1 L.H. Bevel

10 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 3, About This Manual: Machine Specications

TYP

.66

16.8

Operating Envelope

Trav-L-Cutter Assembly, Air Drive

02-000-01

15.12

384.2

16.56

420.5

CUT LINE

REF

17.43

CUT LINE

442.8

ARE MILLIMETERS

DIMENSIONS IN BRACKETS

.50

12.7

15.00

381

25.30

642.6

2.37

60.2

4.25

108.1

3.62

262

10.31

6.75

171.5

92

6.13

155.6

246

9.69

22.00

558.8

REF

29.72

754.9

19.76

502

9.48

240.7

BLADE TRAVEL

3.13 [79.4] MIN.

6.25 [158.8] MAX.

11

Chapter 3, About This Manual: Machine Specications

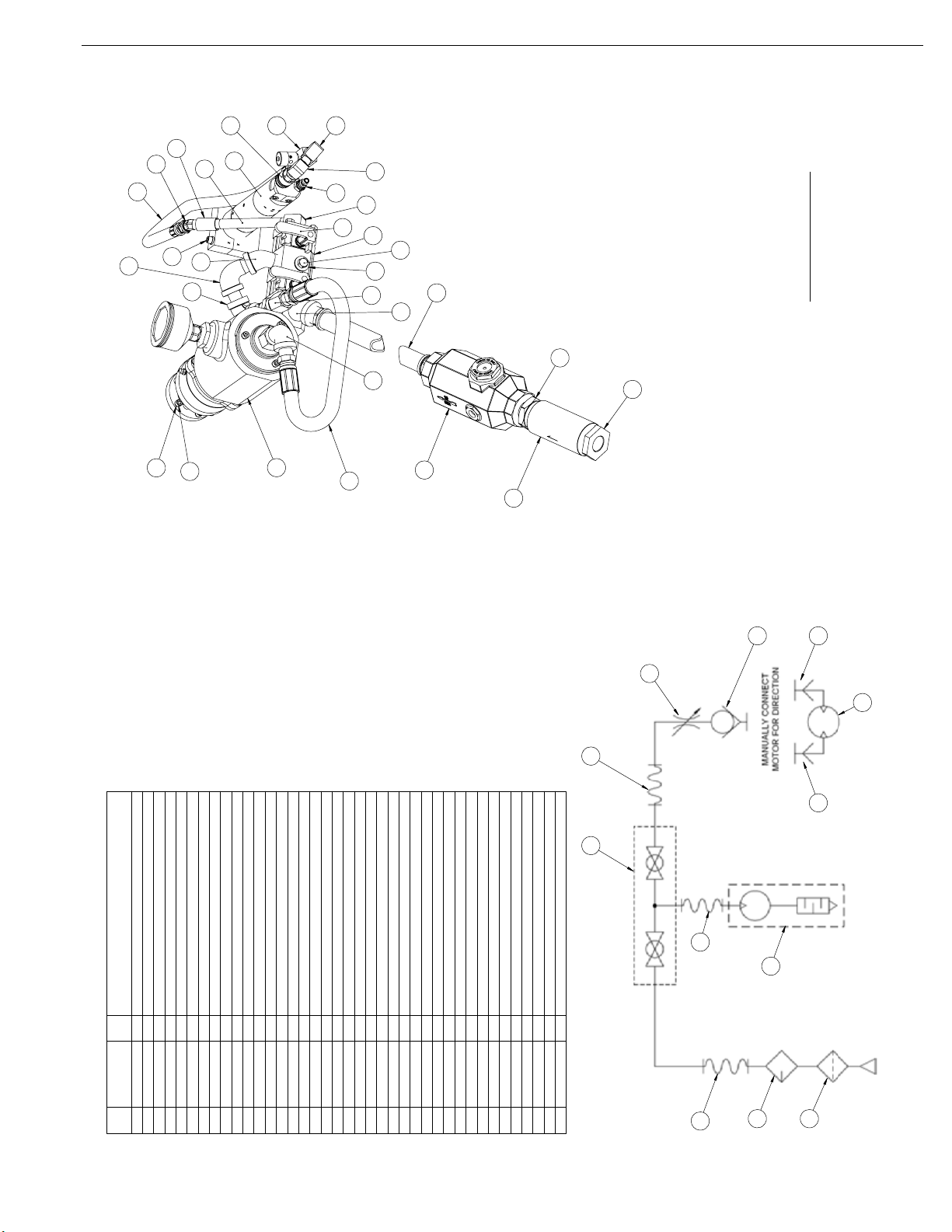

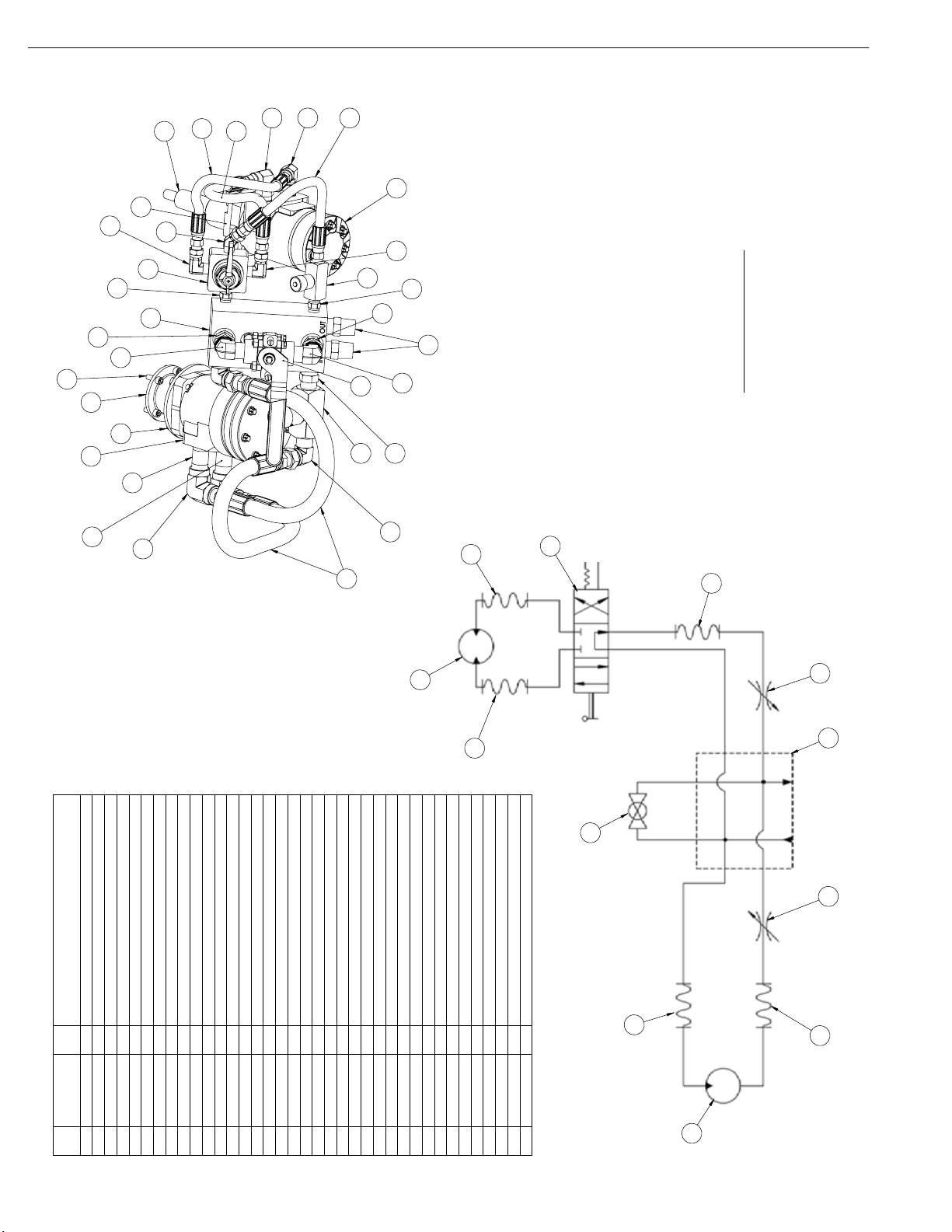

16

22

19

21

4

7

26

33

6

18

25

27

30

3

2023

20

20

8

5

34

36

28

26

2

12

38

15

39

11

9

TRAV-L-CUTTER

AIR SYSTEM COMPONENTS

95 CFM [2690 l/min.]

125 PSI [8.6 bar] MAX.

INPUT REQUIREMENTS

DESCRIPTION

HOSE, 1/2" HP X 30" LONG

MOTOR, TRAVEL-AIR

CLAMP, AIR MOTOR

BODY, AIR FILTER

MANIFOLD, AIR

LABEL, PRESSURE-AIR (NOT SHOWN)

AIR MOTOR SUB-ASSEMBLY

1

1

1

QTY.

02-027-01

02-010-00

02-029-00

PART NUMBER

1

3

2

ITEM

HANDLE, AIR VALVE

HOSE, TRAVEL MOTOR

1

2

1

1

1

1

02-035-00

02-037-00

02-163-00

02-033-00

02-124-00

02-031-00

5

8

4

6

7

9

AIR LINE LUBRICATOR

FILTER ELEMENT (NOT SHOWN)

1

1

02-166-00

02-164-00

10

11

FLOW CONTROL VALVE 1/4"

SHIM, GEAR BOX (NOT SHOWN)

INLET AIR HOSE WHIP, 3/4" X 2"

LABEL, ON-OFF (NOT SHOWN)

1

1

1

02-191-00

02-171-00

02-185-00

12

13

14

COUPLING, 1/4 GALV LP

SSS, 10-32 X 5/16 CP (NOT SHOWN)

END PLUG

1

02-192-00

15

1/4 NPT F X 1/4 NPT M BRASS LP-90

NIPPLE, 1/4 X 5 GALV LP

1

4

3

1

1

02-212-00

90-058-04

90-044-53

90-058-05

90-058-02

17

20

16

18

19

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-45

DISCONNECT, FEMALE 1/4 NPT M

DISCONNECT, MALE 1/4 NPT M

1

2

1

90-058-51

90-059-51

90-059-53

21

22

23

ADAPTER, 1/2 NPT F X 1/2 NPT F SWIVEL-STRAIGHT

NIPPLE, 1/2 CLOSE LP BLACK (NOT SHOWN)

1

90-098-01

24

1/2 HEX HP NIPPLE (NOT SHOWN)

ELBOW, 1/2-90 LP

1

1 ELBOW, 1/2-45 STREET

1

1

5 SHCS, 1/4-20 X 7/8 SS18-8

1 ELBOW, 1/2-90 STREET

90-150-08

90-098-05

90-098-58

90-098-04

90-098-06

90-098-57

29

25

28

30

26

27

HHCS, 5/16-18 X 1 SS18-8 (NOT SHOWN)

FHCS, 1/4-20 X 1 SS18-8 (NOT SHOWN)

WASHER, 1/4" HI COLLAR SS18-8

SSS, 1/4-20 X 3/4 SS18-8 (NOT SHOWN)

1 HHCS, 5/16-18 X 5/8 SS18-8

2

2

4

5

90-161-10

90-153-10

90-155-51

90-161-07

90-154-07

34

32

33

35

31

16

4

5

ELBOW, 3/4-45 LP STREET

WASHER, 5/16 FLAT SS18-8

BUSHING, 1-1/4 X 3/4 GLV REDUCING

NIPPLE, 3/4 CLOSE LP (NOT SHOWN)

1

1

1

1

90-218-03

90-165-52

90-218-10

90-218-01

36

39

37

38

22

2

3

12

11

MOTOR

SPINDLE

2323

6

FEED

MOTOR

INPUT

3/4" FEMALE NPT

9

12

Chapter 3, About This Manual: Machine Specications

ARE MILLIMETERS

DIMENSIONS IN BRACKETS

12.49

317.2

TYP

.66

16.8

15.12

384.2

16.56

420.5

CUT LINE

REF

18.28

CUT LINE

464.4

Operating Envelope

Trav-L-Cutter Assembly, Hydraulic Drive

02-000-02

REF

1.35

34.2

15.00

381

19.76

502

26.07

662.1

10.12

256.9

2.37

60.2

4.25

108.1

92

3.62

BLADE TRAVEL

3.13 [79.4] MIN.

6.25 [158.8] MAX.

6.75

6.13

171.5

155.6

10.31

9.69

262

246

22.00

558.8

REF

27.18

690.2

13

Trav-L-Cutter

8

9

20

23

29

30

6

5

25

19

13

16

26

36

24

28

211421

14

14

4

20

12

23

29

27

26

15

11

27

26

14

2

13

INPUT REQUIREMENTS

2000 PSI [138 bar] MAX.

TRAV-L-CUTTER

HYDRAULIC SYSTEM COMPONENTS

14

15 GPM [57 L/MINUTE]

DESCRIPTION

ADAPTER, CUTTER SPINDLE MOTOR

MOTOR COUPLING, DRIVE PIN

HYDRAULIC MOTOR, CUTTER SPINDLE

HOSE, 1/2" HP X 30" LONG

HYDRAULIC MOTOR, CARRIAGE DRIVE

LABEL, PRESSURE-HYD. (NOT SHOWN)

1

1

2

1

1

QTY.

BRACKET, MOUNTING-DRIVE MOTOR

DRIVE MOTOR ADAPTER

COUPLING, MOTOR (NOT SHOWN)

SHIM, HYDRAULIC GEAR BOX (NOT SHOWN)

1

1

1

1

1

FLOW CONTROL VALVE 1/4"

1/2" FLOW CONTROL VALVE

1/4" HP HOSE ASSEMBLY

1/4" 4-WAY VALVE REVERSING

1

3

1

1

KEY 1/8 X 1/2 #3 WOODRUFF (404) (NOT SHOWN)

1/2" ON/OFF VALVE

LABEL, TRAV-L-CUTTER HYD. (NOT SHOWN)

MANIFOLD

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-45

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-90

1

1

1

1

2

1

FEED

MOTOR

4

14

NIPPLE, 1/2" X 2" SCH 80 A106 B

NIPPLE, 1/4 HEX H.P.

BUSHING, 1/2 X 1/4 HP REDUCING (NOT SHOWN)

ELBOW, 1/4-90 HP STREET

2

2

ADAPTER, 1/2" NPT M X 1/2" NPT F SWIVEL-90

NIPPLE, 1/2" X 2-1/2" SCH 80 A106 B

1/2 HEX HP NIPPLE

2

4

1

3

1

FHCS, 1/4-20 X 1-1/4 SS18-8 (NOT SHOWN)

SHCS, 1/4-20 X 3/4, SS18-8

HHCS, 5/16-18 X 1 SS18-8 (NOT SHOWN)

ADAPTER, 1/2 NPT M X 1/2 ORB M - STRAIGHT

ADAPTER, 1/2" NPT F X 1/2" NPT F-90

2

2

HHCS, 5/16-18 X 2-3/4 SS18-8 (NOT SHOWN)

NUT, 5/16-18 HEX SS18-8 (NOT SHOWN)

WASHER, 5/16 FLAT SS18-8

HHCS, 3/8-16 X 7/8 SS18-8 (NOT SHOWN)

4

4

2

2

2

5

4

4 HHCS, 3/8-16 X 3/4 SS18-8

12

16

15

2

1/2" MALE NPT

INPUT/OUTPUT

11

2

14

02-027-01

02-009-00

02-199-00

PART NUMBER

3

2

1

ITEM

02-200-00

02-202-00

02-201-00

4

5

6

02-204-00

02-203-00

02-205-00

9

8

7

02-206-01

02-212-00

02-211-00

10

11

12

02-214-01

02-213-00

02-215-00

15

14

13

90-029-44

02-298-00

02-218-00

17

16

18

90-058-51

90-058-52

90-058-56

19

20

21

90-098-52

90-058-58

90-058-57

24

23

22

90-098-55

90-098-53

90-098-58

27

26

25

90-150-07

90-098-79

90-098-60

30

29

28

90-153-12

90-161-27

90-161-10

33

32

31

90-165-01

90-171-07

90-165-52

34

35

36

90-171-08

37

5

MOTOR

SPINDLE

Chapter 4, Setup and Operating Procedures

Chapter 4

Setup and Operating Procedures

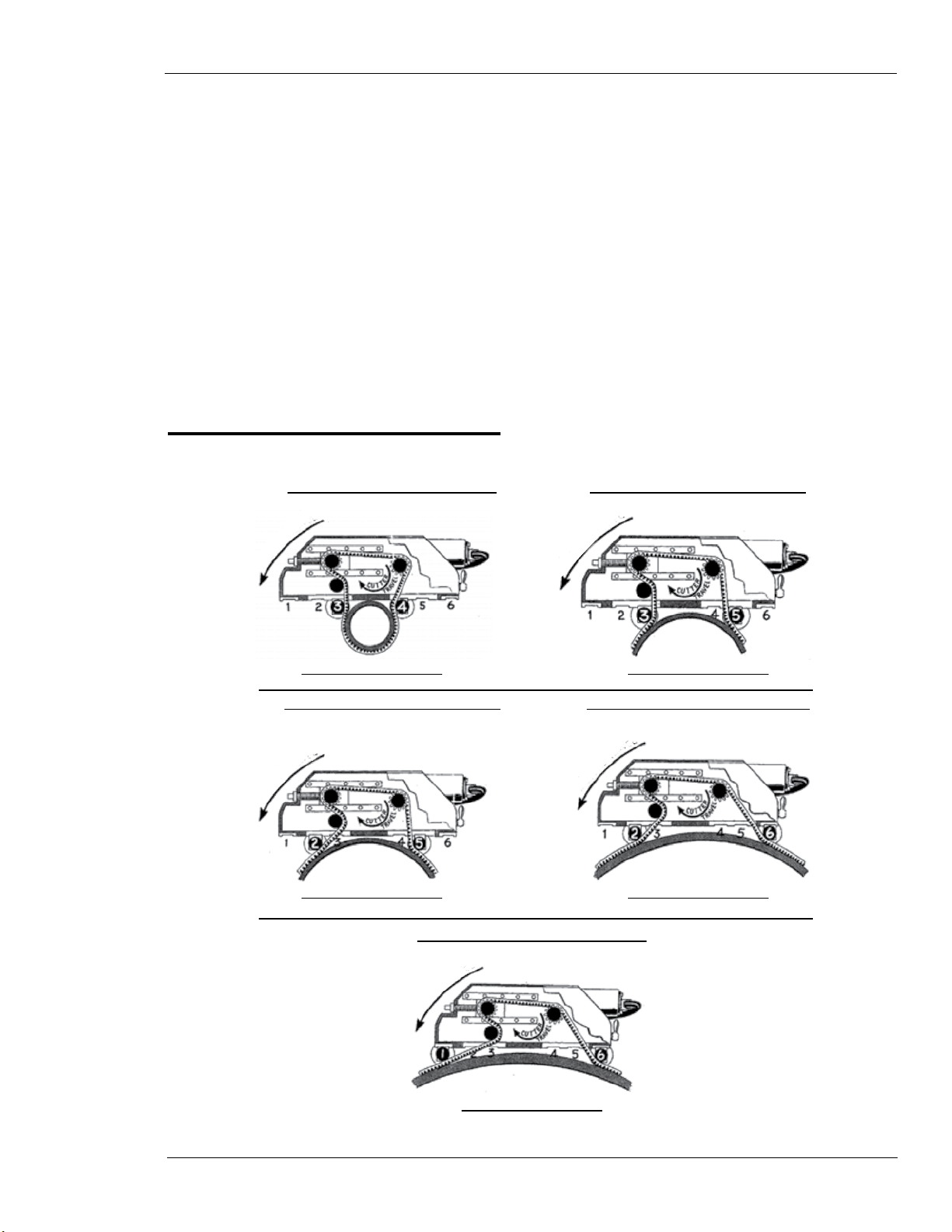

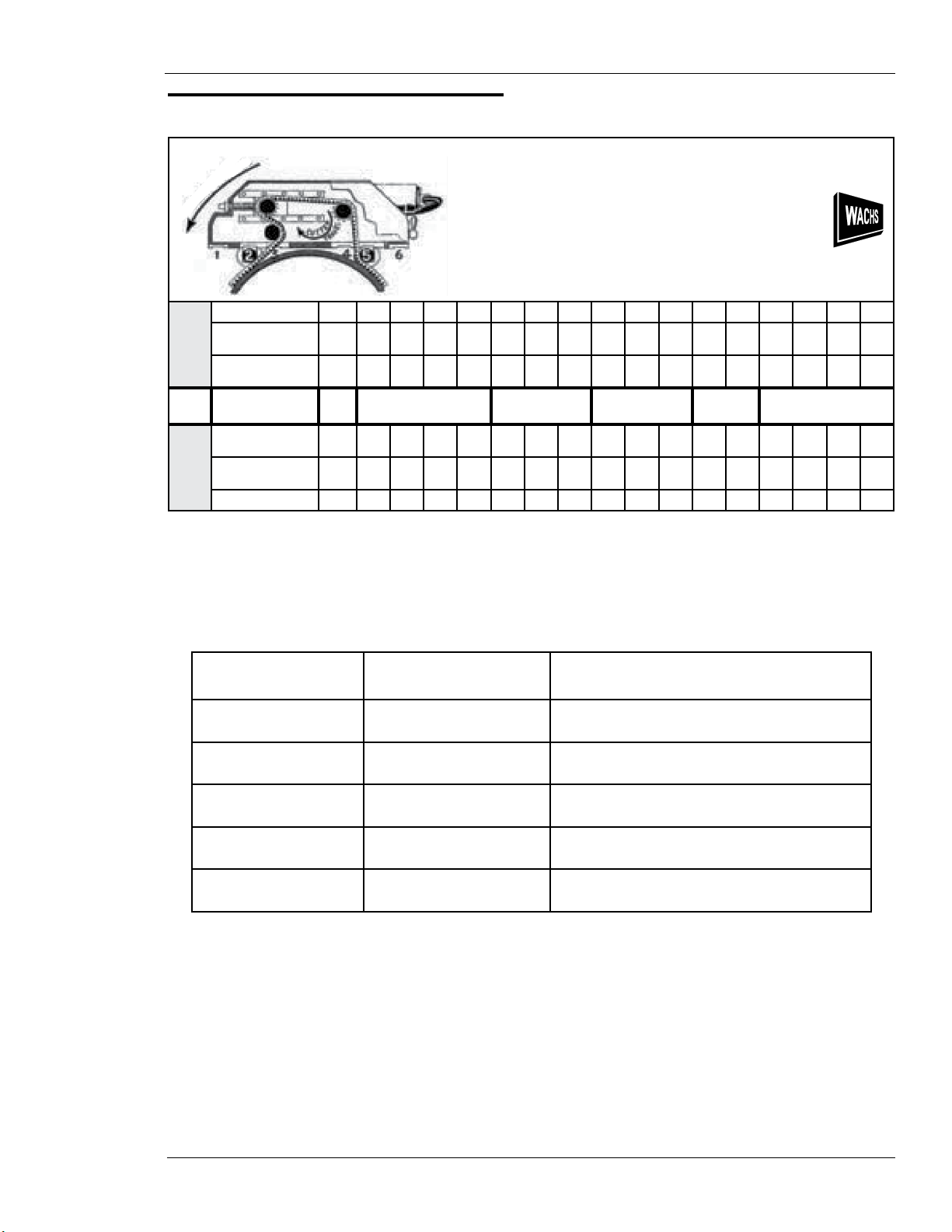

wheel seTTings

PIP E Ø 6.00” – 13.99” (152-355mm)

MACHINE TRAVEL

WHEEL POSITION 3 & 4

PIP E Ø 20.00” – 35.99” (508-914mm)

MACHINE TRAVEL

WHEEL POSITION 2 & 5

PIP E Ø 48.00” – 72.00” (1219-1829mm)

PIP E Ø 14.00” – 19.99” (356-508mm)

MACHINE TRAVEL

WHEEL POSITION 3 & 5

PIP E Ø 36.00” – 47.99” (914-1219mm)

MACHINE TRAVEL

WHEEL POSITION 2 & 6

MACHINE TRAVEL

WHEEL POSITION 1 & 6

E.H. Wachs Part No. 02-MAN-01, Rev. A 15

Trav-L-Cutter

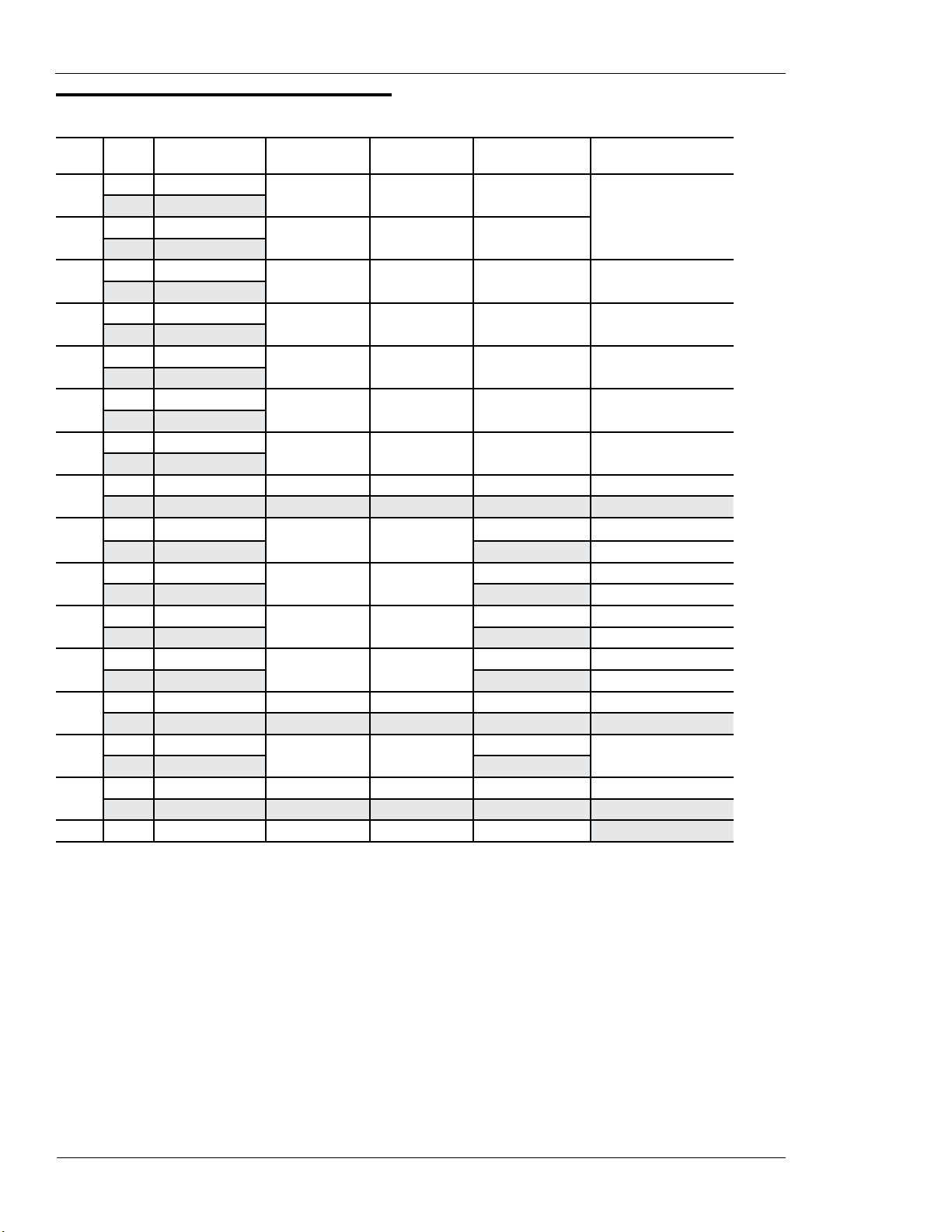

chain lengThs

PIPE

SIZE

TYPE

DI/S¹

6”

8”

10”

12”

14”

16”

18”

20”

24”

30”

36”

42”

48”

54”

60”

72” S 72.00" (1829mm) 38" (965mm) 02-457-72 240" (6096mm) 02-450-72

S 6.625” (168mm)

Di 6.90” (175mm)

S 8.625" (219mm)

Di 9.05" (230mm)

S 10.75" (273mm)

Di 11.10" (282mm)

S 12.75" (324mm)

Di 13.20" (335mm)

S 14.00" (356mm)

Di 15.30" (389mm)

S 16.00" (406mm)

Di 17.40" (442mm)

S 18.00" (457mm)

Di 19.50" (495mm)

S 20.00" (508mm) 2" (51mm) 02-457-20 78" (1981mm) 02-450-20

Di 21.60" (549mm) 7" (179mm) 02-457-20-D 83" (2108mm) 02-450-20-D

S 24.00" (610mm)

Di 25.80" (655mm) 96" (2438mm)

S 30.00" (762mm)

Di 32.00" (813mm) 116" (2946mm)

S 36.00" (915mm)

Di 38.30" (973mm) 133" (3378mm)

S 42.00" (1067mm)

Di 44.50" (1130mm) 152" (3861mm)

S 48.00" (1219mm) 17" (432mm) 02-457-48 164" (4166mm) 02-450-48

Di 50.80" (1290mm) 21" (533mm) 02-457-48-D 173" (4394mm) 02-450-48-D

S 54.00" (1372mm)

Di 57.26" (1454mm) 194" (4928mm)

S 60.00" (1524mm) 18" (458mm) 02-457-60 202" (5131mm) 02-450-60

Di 61.61" (1565mm) 13" (330mm) 02-457-60-D 207" (5258mm) 02-450-60-D

PIPE DIA.

ADD ON

LENGTH²

0 02-457-06 42” (1067mm)

5” (127mm) 02-457-08 47” (1194mm)

8” (203mm) 02-457-10 55” (1397mm) 02-450-10

6” (152mm) 02-457-12 61” (1549mm) 02-450-12

2” (51mm) 02-457-14 63” (1600mm) 02-450-14

6” (152mm) 02-457-16 69” (1752mm) 02-450-16

7” (179mm) 02-457-18 76” (1930mm) 02-450-18

13” (330mm) 02-457-24

20” (508mm) 02-457-30

17” (432mm) 02-457-36

19” (482mm) 02-457-42

20” (508mm) 02-457-54

PART NUMBER TOTAL LENGTH

91" (2312mm) 02-450-24

111" (2819mm) 02-450-30

128"(3251mm) 02-450-36

147" (3734mm) 02-450-42

184" (4674mm)

ACCUMULATED

CHAIN ASSEMBLIES

N/A

02-450-54

¹ S - STEEL PIPE MEASUREMENTS - PER ASME B36.19M-2004

DI- DUCTILE-IRON PIPE MEASUREMENTS - PER ANSI/AWWA C151/A21.51-91

² REQUIRES 42” (1067mm) BASE CHAIN AND ALL PREVIOUS ADD ON LENGTHS

16 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 4, Setup and Operating Procedures: Wheel Settings and Chain Length

wheel seTTings and chain lengTh

MACHINE TRAVEL

WACHS TRAV-L-CUTTER

WHEEL SETTINGS & CHAIN LENGTH

PIPE DIAMETER

ADD ON LENGTH

STEEL

DUCTILE

TOTAL

WHEEL POSITION

ADD ON LENGTH

TOTAL

PIPE DIAMETER

6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36” 42” 48” 54” 60” 72”

IN

MM

IN

MM

IN

MM

IN

MM

5

0

12782036152251615271792511333020508174321948217432205081845838965

42

1067471194551397611549631600691752761930781981912312

3 & 4 3 & 5 2 & 5 2 & 6 1 & 6

5

0

1278203615225161527179717913330205081743219482215332050813330

42

1067471194551397611549631600691752761930832108962438

6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36” 42” 48” 54” 60” 72”

111

2819

116

2946

128

3251

133

3378

147

3734

152

3861

164

4166

173

4394

184

4674

194

4928

Chain Length Calculations

You can calculate the required chain length for any size pipe using the following formulas.

202

5131

207

5258

240

6096

X

X

Pipe O.D. Wheel Positions Chain length Formula

6.0”-13.99”

(168-355 mm)

14”- 19.99”

(356-507 mm)

20”-35.99”

508-914 mm

36”-47.99”

(915-1218 mm)

48”-72”

(1219-1829 mm)

3 and 4 3.235 x (Pipe Diameter in Inches) + 19.06”

3.235 x (Pipe Diameter in mm) + 484 mm

3 and 5 3.204 x (Pipe Diameter in Inches) + 16.33”

3.204 x (Pipe Diameter in mm) + 415 mm

2 and 5 3.175 x (Pipe Diameter in Inches) + 14.98”

3.175 x (Pipe Diameter in mm) + 380 mm

2 and 6 3.162 x (Pipe Diameter in Inches) + 12.82”

3.162 x (Pipe Diameter in mm) + 326 mm

1 and 6 3.149 x (Pipe Diameter in Inches) + 12.61”

3.149 x (Pipe Diameter in mm) + 320 mm

Note that there is some overlap in acceptable wheel positions between size ranges.

E.H. Wachs Part No. 02-MAN-01, Rev. A 17

Trav-L-Cutter

Machine insTallaTion

The Wachs Trav-L-Cutter (TLC) is shipped from the factory completely assembled and lubricat-

ed. It is only necessary to mount the machine, install the cutting wheel and connect the power

supply. Please observe the following warning stickers located on the TLC before proceeding to

operate machine.

Figure 4-1. Machine Installation

1. Refer to the Section on Wheel Setting and Chain Lengths and determine the proper wheel

position for the size of pipe to be cut. If the wheel assemblies are not in the proper slots, the

eight 1/2” socket head cap screws (Part No. 90-090-17) shown in gure 1 should be removed

and the wheel assemblies taken from the carriage.Place the wheel assemblies in the proper

slots in the carriage. Make sure the protruding dowel pins (Part No. 90-076-20) are inserted

in the dowel pin holes. Replace the eight 1/2” socket head cap screws and tighten securely.

2. Check and make sure the cutter spindle is in its uppermost position.

To raise the cutter spindle, loosen the thumbscrew (Part No. 90-059-04) and slide feed screw

lock (Part No. 02-008-00) back. With the aid of the socket wrench turn the feed screw in a

counter clockwise direction until the cutter spindle is raised to its highest position.

3. From the Section on Wheel Setting and Chain Length, select the combination of chain

segments to make up the required length of chain.

Each segment of chain is marked for easy identication.

18 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 4, Setup and Operating Procedures: Machine Installation

Starting with the basic length of chain marked 6 (42” long section) add the necessary chain

segments to make up the proper length. When assembling the segments of chain to the basic

length be sure they are assembled male end to female end. Don’t try to join ends where

numbers come together. The lengths of the chain will engage freely if they are clean.

The chain segments are coupled with special chain connecting pins (Part No. 02-158-00)

furnished with the chain.

When connecting the chain segments it is best that they be placed on a at surface to simplify

the joining of the links. Use the lineup pin (Part No. 02-159-00) to get the joining links in

proper alignment. When the chain links are aligned push the lineup pin out of the chain by

inserting a connecting pin from the opposite side.

4. Turn the chain tension screw (Part No. 02-081-01) counter clockwise to move the chain

tension idler sprocket to its innermost position.

5. Thread the assembled chain through the machine as shown in the section on Wheel Setting

and Chain Length (inside cover). Leave six inches protruding on valve end of machine –

balance of chain on other end.

6. Place the machine on the pipe and join the open ends of the chain with a connecting pin as

shown in sketch for chain assembly (Figure 3, p. 16). To assist in getting chain square on

pipe, rock machine after chain has been connected but before it has been tightened.

CAUTION

During chain connection, one person should hold cutter steady on pipe. Failure to do so could

cause serious injury.

7. Tighten the chain by turning the chain tension screw in a clockwise direction. The chain will

be properly tensioned when the torque wrench is applied to the chain tension screw and it

registers 80 to 85 foot pounds (green line on torque wrench).

8. Recheck chain tension frequently on large diameter or heavy wall pipe cutting.

9. Remove lock nut (Part No. 02-014-00) and driving collar spacer (Part No. 02-022-01) cutter

spindle.

10. Select the proper cutter from Cutter Chart on pages 20-21 and place cutter on cutter spindle.

In as much as the cutter rotates in a clockwise direction as you face it, the cutter should be

placed on the spindle so the at, sharp cutting edges lead into the pipe. Place the driving

collar spacer on the spindle and lock the spacer and cutter tightly to the spindle with the lock

nut.

E.H. Wachs Part No. 02-MAN-01, Rev. A 19

Trav-L-Cutter

Left hand thread in nut turns counter clockwise to tighten. Be sure the cutter drive

collar spacer and lock nut are clean and free of chips and dirt so that the assembly

can be tightened securely.

It is important to use sharp cutters. A dull cutter puts an unnecessary load on the

machine and will result in unsatisfactory cuts. Cutters should be sharpened by a

qualied tool grinder who has equipment to maintain the cutter angles and shape. A

tool grinder who caters to machine shops or tool and die shops is best. Please

contact your E.H. Wachs representative for further details regarding tool sharpening

services.

NOTE

NOTE

oPeraTing The Machine

1. Connect the power supply to hose whip on Pipe Cutter.

CAUTION

Be sure the valves on the machine are off before supplying air to the machine. When the

handles on air valves are up they are in the OFF position.

2. With the power supply turned on the machine is ready to cut the pipe. Turn the valve handle

on Cutter Valve 90° to the right. This will put the cutter spindle motor in operation and rotate

the cutter.

3. Slowly feed the rotating cutter down until it extends through the wall of the pipe by

approximately 1/4”. This is done by turning the feed screw (Part No. 02-001-00) in a

clockwise direction. One complete turn of the feed screw lowers the cutter 1/10”. Lock the

cutter in position by placing the feed screw lock (Part No. 02-008-00) on the shoulder of the

feed screw and lock in place with the thumb screw (Part No. 90-059-04).

4. Turn valve handle on Feed Valve 90° to the right. This will operate the drive motor and make

the machine travel around the pipe and make a complete cut. Speed may be reduced by

adjustment of the feed valve handle (close slowly until proper speed is attained). Machine is

traveling too fast if wheel to right of cutter lifts off pipe or if machine is vibrating excessively.

5. When the cut is completed stop the drive motor by turning Feed Valve to the left until

machine stops. With the cutter still rotating release the elevating screw lock and raise the

cutter to its uppermost position. With the cutter raised, stop the cutter motor by turning Cutter

Valve to the left 90°. Remove the cutter from the machine. Release the tension on the drive

chain by turning the chain tension screw counter clockwise. Remove a connecting pin from

the chain to uncouple it and the machine can now be removed from the pipe.

20 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 4, Setup and Operating Procedures: Operating the Machine

Special Instructions for Assembling 2” Wide Drive Chain

As shown on the right, all sections of the chain have one female end and one male end. One outside

link on the female end of the chain is stamped with the Chain Section Number.

In assembling the chain, always start with the basic length marked 6 (42” long section) and add the

required number of sections of chain, in the proper sequence, until the desired length is obtained.

EXAMPLE: Assemble Chain for 12” pipe. Start with the basic length marked 6 and add to it, in

sequence, the pieces marked 8, 10, & 12. If this chain is correctly assembled it will be the proper

length to be threaded through the Trav-LCutter and wrapped around a 12” pipe as shown in the 1st

picture under Wheel Settings and Chain Lengths on the inside front cover of this manual.

STAMPED WITH CHAIN SECTION No.

FEMALE END MALE END

NOTE: To convert inches to centimeters multiply by 2.54

Figure 4-2. Assembling 2” Wide Drive Chain

NOTE

When cutting medium and large diameter thin wall steel pipe it may be found that the

prescribed length of chain will be too long to be properly tensioned. If this is the case,

remove a section of chain so that the total length will be of a size that can be properly

tensioned.

E.H. Wachs Part No. 02-MAN-01, Rev. A 21

Trav-L-Cutter

WARNING

ALWAYS CONNECT THE MALE END OF ONE SECTION TO THE FEMALE END OF THE

SECTION OF CHAIN THAT PRECEDES IT.

NEVER CONNECT TWO MALE ENDS OR TWO FEMALE ENDS OF CHAIN TOGETHER AS

THIS WILL THROW THE CHAIN OUT OF LINE AND WILL CAUSE MALFUNCTION OF THE

TRAV-LCUTTER AND CHAIN AND SPROCKET BREAKAGE.

Operating Hints

1. It is good practice to drive steel wedges (p/n: 02-175-00) into the saw cut to prevent the pipe

from binding on cutter.

2. Sharp cutters will ensure safe, accurate, dependable cuts. The cutter will stay sharp longer if

cast iron pipe is wire brushed at the point where the cutter is rst fed through the wall of the

pipe.

3. The air motors will operate best with a minimum air pressure of 90 psi. and volume of

approximately 100 cu. ft. per minute.

4. Cut cast iron and ductile iron pipe dry. Use a thread cutting oil or a water soluble cutting oil

on steel and stainless steel pipe to lubricate the cutters and help maintain sharpness.

5. Use a Wachs guide track when cutting in a vertical position or when exact accuracy is

required. See the drawing at the end of this chapter.

6. Adjust the feed rate to reduce or eliminate cutter overload. Feed valve must be opened very

slowly to achieve a slower feed rate. For complete control of feed speed, install needle valve

in feed motor air line.

7. To conrm pipe squareness, use a pipe wrap to establish a square cut line and measure from

this line to the chain in several places on pipe O.D.

8. The maximum effective cutting rate for the Trav-L-Cutter on ductile iron is approximately

one minute per inch of diameter. Some cast iron, steel, heavy wall pipe and beveling will

require a slower feed rate.

22 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 4, Setup and Operating Procedures: Operating the Machine

Setup Using the Guide Track

02-429-00

GUIDE TRACK WHEELS

DIMENSIONS IN BRACKETS ARE MILLIMETERS

APPLICATION

TRACK O.D.

-TABLE-

TRACK I.D.

ASSEMBLY NO.

PART NO.

6.66 [169.0] 8.66 [219.8]

8.66 [219.8] 10.66 [270.6]

10.78 [273.8] 12.78 [324.6]

02-428-06

02-207-06

02-207-08 02-428-08

02-207-10 02-428-10

12.78 [324.6] 14.78 [375.4]

14.03 [356.4] 16.03 [407.2]

16.03 [407.2] 18.03 [458.0]

02-207-12 02-428-12

02-207-14 02-428-14

02-207-16 02-428-16

18.03 [458.0] 20.03 [508.8]

20.03 [508.8] 22.03 [559.6]

22.03 [559.6] 24.03 [610.4]

02-207-18 02-428-18

02-207-20 02-428-20

02-207-22 02-428-22

24.03 [610.4] 26.03 [661.2]

26.03 [661.2] 28.03 [712.0]

28.03 [712.0] 30.03 [762.8]

02-207-24 02-428-24

02-207-26 02-428-26

02-207-28 02-428-28

30" [762] DUCTILE IRON PIPE

30.03 [762.8] 32.03 [813.6]

32.03 [813.6] 34.03 [864.4]

34.03 [864.4] 36.03 [915.2]

36.03 [915.2] 38.03 [966.0]

38.03 [966.0] 40.03 [1016.8]

40.03 [1016.8] 42.03 [1067.6]

02-207-32 02-428-32

02-207-34 02-428-34

02-207-36 02-428-36

02-207-38 02-428-38

02-207-40 02-428-40

02-207-30 02-428-30

42.03 [1067.6] 44.03 [1118.4]

48.03 [1220.0] 50.03 [1270.8]

02-207-42 02-428-42

02-207-48 02-428-48

02-428-XX

GUIDE TRACK ASSEMBLY

(SEE TABLE)

02-207-XX

(SEE TABLE)

90-205-01

(2-PLACES)

02-209-00

(2-PLACES)

E.H. Wachs Part No. 02-MAN-01, Rev. A 23

Trav-L-Cutter

24 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 5, Maintenance

Chapter 5

Maintenance

lubricaTion insTrucTions

All the Ball Bearings in the machine are sealed and require no further lubrication. The bronze

bushings are composed of Sintered Bronze and are oil impregnated and should require no further

lubrication under normal conditions. Under severe conditions, a light coating of oil should be

applied to the bushings in the Chain Guide Rollers and in the Chain Tension Sprocket.

Figure 5-1. Checking the Oil Level

E.H. Wachs Part No. 02-MAN-01, Rev. A 25

Trav-L-Cutter

The Cutter Spindle Gear Box (p/n 02-020-00) and the Carriage Drive Gear Box (p/n 02-02-194-00) are

lled with the required amount of Heavy Duty Worm Gear Oil at the factory. However, the oil in

these gear boxes should be checked before each use and oil added if required.

To check the oil level in the Cutter Spindle Gear Box, (A) stand the saw upright as shown in Figure

5-1. Using an allen wrench, remove the plug (p/n 90-028-01) from the bottom of the gear box. If no

oil is running out of hole, add Heavy Duty Worm Gear Oil (p/n 02-401-00) with an oil can until oil

is running out of hole. Replace plug.

To check oil level in Drive Gear Box (p/n 02-194-00) (B), remove Trav-L-Cutter cover (p/n 02135-00). Set machine on its wheels and remove front plug and top plug. Fill through top hole with

Heavy Duty Worm Gear Oil until oil runs out of front hole. No lubrication is necessary on drive

chain.

The chain will be adequately lubricated when washed clean with kerosene. This is very important

when storing your Trav-L-Cutter for extended periods of time. Place a light coating of oil on Feed

Screw (p/n 02-001-00), Chain Tensioning Screw (p/n 02-081-01) and Guide Rods (p/n 02-019-00

or 02-019-02 for atmospheric models).

26 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 6, Consumable Select Chart

Chapter 6

Consumable Select Chart

daTa on cuTTer size

Use a 6” diameter cutter for up to 1” wall.

Use a 7” diameter cutter for up to 1-1/2” wall.

Use a carbide tipped cutter for cutting cement lined or cast iron pipe. Heavy wall cast iron pipe

may require the use of the next larger size cutter. If the wall thickness of the pipe is unknown, feed

the cutter into the pipe as far as possible and then retract it so that the cut can be inspected to

determine if a larger cutter is needed.

The gang of cutters for beveling pipe is designed for use on steel pipe up to 5/8” wall for making a

weld preparation. The standard bevel is 37.5º.

SPECIAL APPLICATION BLADES CAN BE PRODUCED ON SPECIAL ORDER.

PLEASE CONTACT YOUR WACHS REPRESENTATIVE FOR FURTHER DETAILS.

E.H. Wachs Part No. 02-MAN-01, Rev. A 27

Trav-L-Cutter

5” Left Hand Bevel Cutter 5” Right Hand Bevel Cutter Gang of Cutters for

Beveling Pipe Consists of

One 5” RH Bevel

One 6” Cutter for steel pipe

One 5” LH Bevel

All mounted on drive collars.

8” for Steel Pipe

H.S.S.

8” for Cast Iron and Cement

Lined Pipe; Carbide Tipped

7” for Steel Pipe

7” for Cast Iron and Cement

Lined Pipe; Carbide Tipped

Figure 6-1. Consumable Selection Chart

H.S.S.

6” for Steel Pipe

H.S.S.

6” for Cast Iron and Cement

Lined Pipe; Carbide Tipped

28 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 6, Consumable Select Chart: Data on Cutter Size

cuTTers

SLITTING SAWS

PART NO. SIZE APPLICATION

6” X 3/16”

02-601-00

02-602-00

02-604-00

H.S.S. = HIGH SPEED STEEL

CARBIDE TIPPED SAW

PART NO. SIZE APPLICATION

02-605-00 6” X 3/16” FOR CAST IRON AND CEMENT LINED PIPE UP TO 1” WALL

H.S.S. FOR STEEL PIPE UP TO 1” WALL

7” X 3/16”

H.S.S. FOR STEEL PIPE UP TO 1-1/2” WALL

8” X 3/16”

H.S.S. FOR STEEL PIPE UP TO 2” WALL

02-606-00 7” X 3/16” FOR CAST IRON AND CEMENT LINED PIPE UP TO 1-1/2” WALL

02-607-00 8” X 3/16” FOR CAST IRON AND CEMENT LINED PIPE UP TO 2” WALL

BEVEL CUTTER

PART NO. SIZE APPLICATION

02-608-LH

02-608-RH

02-609-LH

02-609-RH

02-610-LH

02-610-RH

02-611-LH

02-611-RH

5” X 30° MAXIMUM WALL PENETRATION 3/4”

5” X 37-1/2° MAXIMUM WALL PENETRATION 5/8”

6” X 30° MAXIMUM WALL PENETRATION 1”

6” X 37-1/2° MAXIMUM WALL PENETRATION 7/8”

E.H. Wachs Part No. 02-MAN-01, Rev. A 29

Trav-L-Cutter

30 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 7, Troubleshooting

Chapter 7

Troubleshooting Problems

Trouble Possible Cause Remedy

1. Cutter motor and cutter stall 1. Air motor icing Use Wachs special antifreeze oil

2. Dull cutter Replace dull cutter

3. Insufcient air supply Check air supply for 90 psi 100 CFM

4. Dirty air lter element #02-164-00 Replace 02-164-00 (Do not try to clean

5. Saw feeding too fast or too much material being removed in 1 pass

6. Loss of oil in cutter gear box Add oil and check for leaks

7. Dirt, corrosion or broken vanes in air

motor

2. Chain drive sprocket breakage 1. Damaged chain Replace

2. Chain connected incorrectly Check connection points and correct

3. Connection pin not fully inserted Insert completely or replace if damaged

3. Not cutting straight or poor closure 1. Poorly aligned chain Check set up (see Page 2)

2. Dull cutter Change cutter

3. Inclined or vertical pipe Use Wachs guide track

4. Cutter overload Re-adjust feed

4. Machine feed inoperative 1. Dirt and corrosion in drive air motor Flush with alcohol or mineral spirits and

2. Clutch slipping Loosen (2) set screws #90-044-53 &

3. On-off valve failure or obstruction Return machine or valve manifold to

and replace)

Adjust feed and depth of cut

Add oil and check for leaks

reoil. With air on, tap clutch with wood

stick in CCW direction from rear of motor.

tighten hex nut #90-055-02. Retighten

set screws.

E.H. Wachs Co. for repair.

E.H. Wachs Part No. 02-MAN-01, Rev. A 31

Trav-L-Cutter

Trouble Possible Cause Remedy

5. Excessive vibration 1. Feed too fast Slow feed

2. Cutter too deep Raise cutter

3. Dull cutter Replace cutter

4. Drive chain loose Check tension per instructions

5. Cutter installed backwards Replace cutter and install per instructions

6. Excessive wear on cutter gear box

guide rods

Return to E.H. Wachs for repair

32 Part No. 02-MAN-01, Rev. A E.H. Wachs

Chapter 8, Parts Lists & Exploded View Drawings

Chapter 8

Parts Lists & Exploded View

Drawings

E.H. Wachs Part No. 02-MAN-01, Rev. A 33

Trav-L-Cutter

4

3

Trav-L-Cutter Assembly, Air Drive

02-000-01

1

DESCRIPTION

2

34

SILENT CHAIN

PNEUMATIC CARRIAGE ASSEMBLY

OILER ASSEMBLY

CONNECTING PIN FOR CHAIN

1

1

1

QTY.

02-157-00

02-303-00

02-158-00

PART NUMBER

1

3

2

ITEM

STEEL CABLE (NOT SHOWN)

LABEL-SCALE, CHAIN LENGTH (NOT SHOWN)

MANUAL (NOT SHOWN)

1

1

1

1

02-312-00

02-155-00

02-125-00

02-MAN-01

7

6

5

4

STORAGE CASE (NOT SHOWN)

STEEL WEDGE (NOT SHOWN)

WRENCH, TORQUE (NOT SHOWN)

LINE-UP PIN (NOT SHOWN)

1

1

02-162-00

02-159-00

9

8

WHEEL SETTING CHART (NOT SHOWN)

CASE/DIVIDER FOR BLADES (NOT SHOWN)

1

1

3

1

02-176-00

02-287-00

02-175-00

02-177-00

12

11

13

10

WRENCH, 3/8 HEX LONG ARM (NOT SHOWN)

WRENCH, 1/2 DRV. BREAKER BAR (NOT SHOWN)

SOCKET, 1/2 DRV. X 1/2 8PT. IMPACT (NOT SHOWN)

WRENCH, 1-1/4 OPEN END (NOT SHOWN)

CHAIN LENGTHS CHART (NOT SHOWN)

1

1

2

1

1

90-800-10

90-800-05

90-800-11

90-800-01

02-289-00

16

18

15

14

17

Chapter 8, Parts Lists & Exploded View Drawings

7

Air Drive Oiler Assembly

02-303-00

1

2

DESCRIPTION

BODY, AIR FILTER

AIR LINE LUBRICATOR

FILTER ELEMENT

1

1

1

QTY.

5

6

3

INLET AIR HOSE WHIP, 3/4" X 2"

1

BUSHING, 1-1/4 X 3/4 GLV REDUCING

NIPPLE, 3/4 CLOSE LP

END PLUG

1

1

1

02-163-00

02-166-00

02-164-00

PART NUMBER

1

3

2

ITEM

90-218-01

02-192-00

02-171-00

4

6

5

4

90-218-10

7

35

Trav-L-Cutter

26

20

5

7

18.2

28

30

31

29

27

27

1

16

23

4

21

2

21

22

9

14

3

25

18.1

13

18.3

8

24

Pneumatic Carriage Assembly

02-312-00

34

15

28

35

32

12

10

24

24

6

33

35

11

19

17

36

DESCRIPTION

LOCK, FEED SCREW

LABEL, PRESSURE-AIR

LABEL, WARNING-BLADE GUARD

COVER, SPINDLE CARRIAGE

LOCK NUT, DRIVE COLLAR

1

1

1

02-010-00

02-011-00

02-013-00

2

3

4

LABEL, TORQUE

1

1

02-014-00

02-015-00

5

6

1

QTY.

02-008-00

PART NUMBER

1

ITEM

PIN, CUTTER DRIVE

COLLAR, CUTTER DRIVE

HANDLE, AIR VALVE

COVER, DRIVE SIDE

NAME PLATE

WHEEL ASSEMBLY

2

1

02-021-01

02-022-01

7

8

CUTTER GUARD ASSEMBLY

2

1

1

2

1

02-124-00

02-135-00

02-141-00

02-142-00

02-179-00

9

10

11

12

13

LABEL, ON-OFF

MACHINE CHAIN & WHEEL CHART

FEED SCREW ASSEMBLY

AIR MOTOR AND FRAME ASSEMBLY

KIT, CUTTER SPACERS 3/16, 11/16, & 3/4

SPACER, TRAV-L-CUTTER

SPACER, TRAV-L-CUTTER

SPACER, TRAV-L-CUTTER

SCREW, #4 X 1/4 ROUND U-DRIVE SS18-8

1

1

1

02-185-00

02-300-00

02-304-00

14

15

16

1

1

2

02-311-00

02-500-03

02-290-03

17

18

18.1

PIN, 5/16 X 1/2 DOWEL

1

1

6

1 SCREW, 1/4-20 X 1-1/4 THUMB

2

90-048-01

90-059-04

90-066-05

02-290-17

02-290-20

19

20

21

18.2

18.3

SSS, 10-32 X 1/4 SS18-8 CP

FHCS, 1/4-20 X 1/2 SS18-8

WASHER, 1/4 SPLIT RING SS18-8

WASHER, #12 FLAT SS18-8

4

5 HHCS, 1/4-20 X 1/2 SS18-8

2 SSS, 1/4-20 X 3/4 SS18-8

15

90-144-52

90-151-05

90-153-05

90-154-07

22

23

25

24

WASHER, 3/8 FLAT SS18-8

1

2

4 HHCS, 3/8-16 X 5/8 SS18-8

4

12 HHCS, 5/16-18 X 5/8 SS18-8

90-155-52

90-155-56

90-161-07

90-171-06

90-175-51

27

28

29

26

30

LABEL, WACHS CIRCLE LOGO 3.00

LABEL, READ MANUAL .75 DIA.

HANDLE, 6-1/2 X 1-3/4

WASHER, SHOCKPROOF INT. SS18-8

4

8 SHCS, 1/2-13 X 1-3/4 SS18-8

1

1

3

90-175-53

90-190-17

90-400-02

90-900-01

90-900-53

34

35

31

32

33

Chapter 8, Parts Lists & Exploded View Drawings

2

10

6

16

1

14

8

18

11

12

12

Air Motor and Frame Assembly

02-311-00

17

15

9

DESCRIPTION

CONNECTING LINK

OFFSET LINK

DRIVE ROLLER CHAIN 30-1/2" LG.

ROD, GUIDE-STAINLESS

4

QTY.

COMPRESSION SPRING

HOUSING, BEARING-REAR

1

4

1

1

1

WASHER, 5/16 FLAT SS18-8

CARRIAGE DRIVE AND FRAME ASSEMBLY

MANIFOLD ASSEMBLY

ADAPTER, 1/2 NPT F X 1/2 NPT F SWIVEL-STRAIGHT

SPROCKET ASSEMBLY

AIR MOTOR AND SPINDLE ASSEMBLY

1

1

1

1

1

7 HHCS, 5/16-18 X 5/8 SS18-8

WASHER, SHOCKPROOF INT. SS18-8

HHCS, 5/16-18 X 1 SS18-8

WASHER, 3/8 FLAT SS18-8

ELBOW, 3/4-45 LP STREET

5

4

1

1

4

4 HHCS, 3/8-16 X 5/8 SS18-8

5

4

3

7

13

02-169-01

02-019-02

02-102-00

PART NUMBER

3

1

2

ITEM

02-174-00

02-178-01

02-170-00

6

4

5

02-308-00

02-307-00

02-309-00

8

7

9

02-310-00

90-098-57

90-161-07

11

10

12

90-165-52

90-161-10

90-171-06

15

14

13

90-175-51

90-218-03

90-175-53

18

17

16

37

Trav-L-Cutter

10

9

6

8

Air Drive Manifold Assembly

02-308-00

1

DESCRIPTION

MANIFOLD, AIR

NIPPLE, 1/4 X 5 GALV LP

1

1

QTY.

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-45

1/4 NPT F X 1/4 NPT M BRASS LP-90

COUPLING, 1/4 GALV LP

1

1

1

7

2

3

5

NIPPLE, 1/2 CLOSE LP BLACK

1

1 ELBOW, 1/2-45 STREET

1/2 HEX HP NIPPLE

ELBOW, 1/2-90 LP

1

1 ELBOW, 1/2-90 STREET

1

4

38

02-033-00

90-058-04

90-058-02

PART NUMBER

2

1

ITEM

3

90-058-05

90-098-01

90-058-51

5

4

6

90-098-04

90-098-06

90-098-05

7

9

8

90-098-58

10

Chapter 8, Parts Lists & Exploded View Drawings

DESCRIPTION

QTY.

PART NUMBER

ITEM

39

Trav-L-Cutter

14

9

16

5

8

10

13

Carriage Drive and Frame Assembly

02-310-00

68

7

15

11

DESCRIPTION

THRUST WASHER

PLATE, GIB BACKING

NUT, LOCK-CHAIN TEN. SCREW

SCREW, CHAIN TENSION

GIB, CHAIN TENSIONING

SHAFT, GUIDE ROLLER-INSIDE

1

1

2

1

1

1

QTY.

CARRIAGE DRIVE ASSEMBLY

ROLLER, CHAIN GUIDE

SHIM, GEAR BOX

SLIDE AND SPROCKET ASSEMBLY

BUSHING

2

1

FHCS, 1/4-20 X 1" SS18-8

CARRIAGE, UNIVERSAL

1

1

HHCS, 5/16-18 X 1 SS18-8

1

4

2

1

2

1

BHCS, 3/8-16 X 1" SS18-8

1 SSS, 5/16-18 X 3/8 SS18-8

10

4

3

4

12

40

02-082-01

02-083-00

02-081-01

PART NUMBER

1

2

3

ITEM

02-094-01

02-085-01

02-131-00

5

4

6

02-132-01

02-133-00

02-137-02

8

9

7

02-191-00

02-306-00

02-301-00

11

10

12

90-164-03

90-153-10

90-161-10

13

14

15

90-172-10

16

Chapter 8, Parts Lists & Exploded View Drawings

Carriage Drive Assembly

02-301-00

6

8

4

10

9

5

3

(SEE NOTES)

2

1

7

DESCRIPTION

MOTOR, TRAVEL-AIR

OVERLOAD SAFETY COUPLING

CLAMP, AIR MOTOR

HOSE, TRAVEL MOTOR

1

1

QTY.

02-031-00

02-035-00

PART NUMBER

1

2

ITEM

SPROCKET, DRIVE

1

1

1

02-043-00

02-037-00

02-108-00

3

5

4

GEAR BOX, CARRIAGE DRIVE

1

02-194-00

6

SSS, 10-32 X 1/4 CP

KEY, 1/8 SQ X 1-1/4

FLOW CONTROL VALVE 1/4"

1

1

1

90-027-12

02-212-00

90-044-52

8

7

9

DISCONNECT, FEMALE 1/4 NPT M

KEY, 3/16 SQ. X 1/2

1/4 NPT F X 1/4 NPT M BRASS LP-90

DISCONNECT, MALE 1/4 NPT M

1

1

2

2

90-047-05

90-058-05

90-059-51

12

10

11

AIR MOTOR WOODRUFF KEY REPLACEMENT

90-059-53

NOTES:

1.

13

13

13

11

12

PART NO.; 90-029-44

11

41

Trav-L-Cutter

7

1

Air Motor Sub-Assembly

02-029-00

5

8

6

4

9

10

?

3

42

DESCRIPTION

AIR MOTOR

MOTOR COUPLING, DRIVE PIN

1

1

QTY.

02-030-00

02-199-00

PART NUMBER

2

1

ITEM

KEY, 1/4 SQ. X 1-3/8

BUSHING, 1/2 X 1 REDUCING

MUFFLER

ADAPTER, MOTOR-TRV-L-CUTTER(I.R. 4800P)

MOTOR COUPLING CUTTER SPINDLE

1 ELBOW, 1/2-90 STREET

1

1

1

1

1

02-203-00

90-057-13

90-098-75

23-181-00

90-098-05

02-252-00

3

6

5

7

4

8

SHCS, 5/16-18 X 7/8 SS18-8

6

1 SSS, 1/4-20 X 1/4 SS18-8

90-154-02

90-160-08

9

10

Chapter 8, Parts Lists & Exploded View Drawings

DESCRIPTION

QTY

PART NUMBER

ITEM

43

Trav-L-Cutter

Trav-L-Cutter Assembly, Hydraulic Drive

02-000-02

44

DESCRIPTION

QTY.

PART NUMBER

ITEM

Chapter 8, Parts Lists & Exploded View Drawings

6

16.2

26

24

27

25

23

22

23

18

1

20

14

12

13

19

4

19

15

24

30

8

11

3

16.1

21

2

9

5

16.3

7

Hydraulic Carriage Assembly

02-318-00

28

10

DESCRIPTION

LABEL, PRESSURE-HYD.

LOCK, FEED SCREW

1

QTY.

LOCK NUT, DRIVE COLLAR

LABEL, WARNING-BLADE GUARD

PIN, CUTTER DRIVE

COVER, SPINDLE CARRIAGE

2

1

1

1

1

COLLAR, CUTTER DRIVE

WHEEL ASSEMBLY

COVER, DRIVE SIDE

1

1

LABEL, TRAV-L-CUTTER HYD.

MACHINE CHAIN & WHEEL CHART

CUTTER GUARD ASSEMBLY

PLATE, NAME

1

2

FEED SCREW ASSEMBLY

1

1

1

1

21

WASHER, 1/4 SPLIT RING SS18-8

SPACER, TRAV-L-CUTTER

HYD. MOTOR AND FRAME ASSEMBLY

1

SCREW, #4 X 1/4 ROUND U-DRIVE SS18-8

KIT, CUTTER SPACERS 3/16, 11/16, & 3/4

SPACER, TRAV-L-CUTTER

SPACER, TRAV-L-CUTTER

6

1

1

1 SCREW, 1/4-20 X 1-1/4 THUMB

2

1

WASHER, #12 FLAT SS18-8

PIN, 5/16 X 1/2 DOWEL

FHCS, 1/4-20 X 1/2 SS18-8

2

5 HHCS, 1/4-20 X 1/2 SS18-8

1

2

12 HHCS, 5/16-18 X 5/8 SS18-8

11

29

31

LABEL, MANUAL

WASHER, SHOCKPROOF INT. SS18-8

LABEL, WACHS CIRCLE LOGO 3.00

WASHER, 3/8 FLAT SS18-8

4 HHCS, 3/8-16 X 5/8 SS18-8

4

HANDLE, 6-1/2 X 1-3/4

4

2

1

8 SHCS, 1/2-13 X 1-3/4 SS18-8

1

17

02-009-00

02-008-00

02-011-00

PART NUMBER

1

3

2

ITEM

02-014-00

02-021-01

02-013-00

5

6

4

02-022-01

02-135-00

02-141-00

8

7

9

02-142-00

02-298-00

02-179-00

11

10

12

02-300-00

02-317-00

02-304-00

13

14

15

02-500-03

02-290-03

02-290-17

16

16.1

16.2

90-059-04

90-048-01

90-066-05

02-290-20

17

18

19

16.3

90-155-52

90-153-05

90-151-05

20

22

21

90-155-56

90-171-06

90-161-07

24

25

23

90-175-51

90-190-17

90-175-53

28

27

26

90-900-01

90-400-02

90-900-53

31

30

29

45

Trav-L-Cutter

11

2

8

10

6

15

1

5

4

9

7

12

3

14

13

Hydraulic Motor and Frame Assembly

02-317-00

46

DESCRIPTION

HOUSING, BEARING-REAR

OFFSET LINK

ROD, GUIDE-STAINLESS

DRIVE ROLLER CHAIN 30-1/2" LG.

CONNECTING LINK

COMPRESSION SPRING

1

4

1

4

1

1

QTY.

02-102-00

02-174-00

02-019-02

02-169-01

02-170-00

PART NUMBER

1

ITEM

02-178-01

4

6

2

5

3

SPROCKET ASSEMBLY

1

02-307-00

7

HHCS, 5/16-18 X 1 SS18-8

HYD. MOTOR AND SPINDLE ASSEMBLY

HYD. CARRIAGE DRIVE AND FRAME ASSEMBLY

HYD. MANIFOLD ASSEMBLY

1

1

1

02-316-00

02-314-00

02-315-00

9

8

10

WASHER, SHOCKPROOF INT. SS18-8

WASHER, 3/8 FLAT SS18-8

4 HHCS, 3/8-16 X 5/8 SS18-8

4

6 HHCS, 5/16-18 X 5/8 SS18-8

5

4

90-161-10

90-171-06

90-175-53

90-161-07

90-175-51

13

11

14

15

12

Chapter 8, Parts Lists & Exploded View Drawings

14

13

9

16

6

8

5

10

2

12

3

1

4

15

7

8

4

Hydraulic Carriage Drive and Frame Assembly

02-314-00

DESCRIPTION

NUT, LOCK-CHAIN TEN. SCREW

SCREW, CHAIN TENSION

THRUST WASHER

GIB, CHAIN TENSIONING

PLATE, GIB BACKING

1

2

1

1

1

QTY.

02-094-01

02-081-01

02-082-01

02-085-01

02-083-00

PART NUMBER

2

4

3

5

1

ITEM

SHAFT, GUIDE ROLLER-INSIDE

1

02-131-00

6

SLIDE AND SPROCKET ASSEMBLY

ROLLER, CHAIN GUIDE

CARRIAGE, UNIVERSAL

BUSHING

1

1

2

02-132-01

02-137-02

02-133-00

7

9

8

HHCS, 5/16-18 X 1 SS18-8

SHIM, HYDRAULIC GEAR BOX

HYD. CARRIAGE DRIVE ASSEMBLY

FHCS, 1/4-20 X 1-1/4 SS18-8

4

1

1

4

1

02-206-01

90-153-12

02-306-00

90-161-10

02-313-00

11

14

10

12

13

1 SSS, 5/16-18 X 3/8 SS18-8

90-164-03

15

11

BHCS, 3/8-16 X 1" SS18-8

10

90-172-10

16

47

Trav-L-Cutter

4

Hydraulic Manifold Assembly

02-315-00

7

8

3

2

8

14

DESCRIPTION

FLOW CONTROL VALVE 1/4"

1/4" HP HOSE ASSEMBLY

1/2" ON/OFF VALVE

MANIFOLD

1/2" FLOW CONTROL VALVE

1/4" 4-WAY VALVE REVERSING

1

1

QTY.

1

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-45

1

1

1

1

9

15

6

11

10

ADAPTER, 1/2 NPT M X 1/2 ORB M - STRAIGHT

HHCS, 5/16-18 X 2-3/4 SS18-8

ADAPTER, 1/2" NPT M X 1/2" NPT F SWIVEL-90

ADAPTER, 1/4 NPT M X 1/4 NPT F SWIVEL-90

NIPPLE, 1/4 HEX H.P.

4

2

2

NUT, 5/16-18 HEX SS18-8

1/2 HEX HP NIPPLE

3

WASHER, 5/16 SPLIT RING SS18-8

WASHER, 5/16 FLAT SS18-8

2

2

2

2

2

9

11

12

13

12

10

1

5

10

48

02-211-00

02-212-00

1

02-213-00

2

3

PART NUMBER

ITEM

02-214-01

02-218-00

02-215-00

4

5

6

90-058-52

90-058-58

90-058-51

8

9

7

90-098-55

90-098-58

90-098-79

11

12

10

90-161-27

90-165-51

90-165-01

13

14

15

10

90-165-52

16

Chapter 8, Parts Lists & Exploded View Drawings

3

1

6

11

10

9

11

5

10

9

4

DESCRIPTION

CUTTER SPINDLE GEAR ASSEMBLY

HOSE, 1/2" HP X 30" LONG

MOTOR COUPLING, DRIVE PIN

HYDRAULIC MOTOR, CUTTER SPINDLE

ADAPTER, CUTTER SPINDLE MOTOR

ADAPTOR, DRIVE MOTOR

1/2 HEX HP NIPPLE

ADAPTER, 1/2" NPT F X 1/2" NPT F SWIVEL-90

SHCS, 1/4-20 X 3/4, SS18-8

1

2

1

1

1

1

2

2

QTY.

02-020-00

02-027-01

1

02-199-00

2

3

PART NUMBER

ITEM

02-201-00

02-202-00

02-203-00

4

5

6

5

90-098-58

90-098-64

90-150-07

7

8

9

7

8

WASHER, 1/4" HI COLLAR SS18-8

5

4 HHCS, 3/8-16 X 3/4 SS18-8

90-155-51

90-171-07

10

11

HYDRAULIC MOTOR WOODRUFF KEY REPLACEMENT

PART NO.; 90-059-48.

7

8

2

49

Trav-L-Cutter

3

8

1

11

9

15

2

10

6

15

14

6

(SEE NOTES)

4

7

12

13

Hydraulic Carriage Drive Assembly

02-313-00

50

DESCRIPTION

HYDRAULIC MOTOR, CARRIAGE DRIVE

OVERLOAD SAFETY COUPLING

SPROCKET, DRIVE

1

1

QTY.

02-043-00

02-108-00

PART NUMBER

1

2

ITEM

ADAPTER, (DRIVE MOTOR)

GEAR BOX, CARRIAGE DRIVE

1

1

1

02-194-00

02-200-00

02-204-00

4

5

3

KEY, 1/8 SQ X 1-1/4

1/4" HP HOSE ASSEMBLY

BRACKET, MOUNTING-DRIVE MOTOR

1

2

1

02-205-00

90-027-12

02-214-01

8

7

6

KEY, 3/16 SQ. X 1/2

SSS, 10-32 X 1/4 CP

KEY 1/8 X 1/2 #3 WOODRUFF (404)

1

1

1

90-044-52

90-029-44

90-047-05

9

11

10

SSS, 1/4-20 X 1/4 SS18-8

BUSHING, 1/2 X 1/4 HP REDUCING

ELBOW, 1/4-90 HP STREET

2

90-058-56

12

HHCS, 3/8-16 X 7/8 SS18-8

4

1

2

90-058-57

90-171-08

90-154-02

PART NO.; 90-059-48

HYDRAULIC MOTOR WOODRUFF KEY REPLACEMENT

15

14

13

1.

NOTES:

Chapter 8, Parts Lists & Exploded View Drawings

10

11

Wheel Assembly

02-142-00

7

6

1

8

4

3

2

3

5

DESCRIPTION

BUSHING

RING, RETAINING

ROLLER, CHAIN GUIDE

AXLE

2

1

2

02-002-00

02-132-01

02-133-00

1

2

3

1

02-144-00

4

QTY.

PART NUMBER

ITEM

BRACKET, AXLE

BEARING, BALL

WHEEL

PIN, 3/8 X 1-1/2 DOWEL

PIN, 3/8 X 2 DOWEL

2

2

1

02-151-00

02-152-01

90-076-15

7

6

8

1

90-076-20

9

2

02-148-00

5

9

WASHER, 1/2 FLAT SS18-8

HHCS, 1/2-13 X 1.00 SS18-8

2

2

90-195-52

90-191-10

10

11

5

1

6

7

11

10

51

Trav-L-Cutter

5

Feed Screw Assembly

02-304-00

4

3

DESCRIPTION

RING, RETAINING

BEARING, BALL

SCREW, FEED

1

1

1

QTY.

02-002-00

02-003-00

02-001-00

PART NUMBER

2

1

BEARING HOUSING, FEED SCREW

LOCK NUT, FEED SCREW BEARING

1

1

02-005-00

02-006-00

52

ITEM

1

2

3

4

5

Chapter 8, Parts Lists & Exploded View Drawings

1

5

Slide and Sprocket Assembly

02-306-00

4

3

DESCRIPTION

BOLT, MODIFIED 1/2-13 X 1.00 SS

SLIDE, CHAIN TENSION SPROCKET

SPROCKET

WASHER, 1/2 FLAT SS18-8

BUSHING, TENSIONING SPROCKET

1

1

1

1

1

QTY.

02-004-00

02-084-00

PART NUMBER

1

ITEM

2

90-195-52

02-086-00

02-087-00

3

4

5

2

53

Trav-L-Cutter

10

Sprocket Assembly

3

4

02-307-00

DESCRIPTION

5

6

7

9

8

54

LOCKNUT, BEARING

SHAFT, CARRIAGE DRIVE

RING, RETAINING

LOCKWASHER, BEARING

1

QTY.

02-077-00

PART NUMBER

1

ITEM

1

1

1

02-090-00

02-078-00

02-092-00

2

3

4

BEARING, BALL

HOUSING, FRONT BEARING

2

1

02-093-00

02-095-00

5

6

KEY, 5/16 SQ. X 1-1/16

SPACER

SPROCKET, DRIVEN

SPACER

1

1

1

1

02-096-02

02-096-01

90-067-11

02-097-02

7

8

9

10

5

1

2

Chapter 8, Parts Lists & Exploded View Drawings

18

6

2

3

4

24

1

20

5

10

7

8

Cutter Spindle Gear Assembly

02-020-00

DESCRIPTION

BALL BEARING

LOCKWASHER, BEARING

LOCKNUT, BEARING

CAP, BEARING

1

1

1

1

QTY.

WORM SHAFT, HIGH SPEED

SEAL

SPINDLE HOUSING, CUTTER

1

1

LARGE OIL PLUG

BEARING, NEEDLE

SEAL

SPINDLE, CUTTER

1

1

1

1

2

GEAR, WORM-BRONZE

BEARING, BALL

1

2

19

LOCKNUT, BEARING

LOCKWASHER, BEARING

BEARING, BALL

BEARING CAP, CUTTER SPINDLE

1

1

1

1

KEY, 1/4 SQ. X 7/8

GUARD. SEAL

SPP, 1/8 NPT DRYSEAL

BUSHING, BRONZE

1

4

2

1

21

11

KEY, 5/16 SQ. X 2-1/4

SHCS, 1/4-20 X 3/4, SS18-8

SHCS, 1/4-20 X 1 SS18-8

6

1

6

12

9

21

22

13

14

15

16

17

02-057-00

02-059-00

02-058-00

PART NUMBER

1

3

2

ITEM

02-061-00

02-060-00

02-062-00

6

5

4

02-063-00

02-064-00

02-065-00

7

8

9

02-073-01

02-070-00

02-074-00

12

11

10

02-075-00

02-077-00

02-076-00

13

15

14

02-079-00

02-078-00

02-080-00

18

17

16

90-057-08

90-028-01

02-186-00

21

20

19

90-150-07

90-067-22

90-150-10

24

23

22

23

55

Trav-L-Cutter

5

Feed Screw Assembly

02-304-00

4

3

DESCRIPTION

RING, RETAINING

BEARING, BALL

SCREW, FEED

1

1

1

QTY.

2

1

BEARING HOUSING, FEED SCREW

LOCK NUT, FEED SCREW BEARING

1

1

56

02-002-00

02-003-00

02-001-00

PART NUMBER

1

2

ITEM

3

02-005-00

02-006-00

4

5

Chapter 8, Parts Lists & Exploded View Drawings

Guide Track Wheels

02-429-00

1

2

DESCRIPTION

WHEEL, GUIDE TRACK

RING, RETAINING

BEARING, BALL

2

2

2

QTY.

SHCS 1/2-13 X 1.0 SS18-8

WASHER, 1/2 FLAT SS

2

2

5

3

4

02-002-00

02-197-01

02-151-00

PART NUMBER

1

3

ITEM

2

90-190-10

90-195-52

4

5

57

Trav-L-Cutter

bill of MaTerial – sPray MisT cooling sysTeM

(For automatic coolant applications)

PART No. 02-405-00

COOLANT HOSE

REF PART NO QTY DESCRIPTION

031

172

190

1

2

3

4

02-031-00

02-172-00

02-190-00

90-058-51

90-058-57

90-098-01

90-098-12

1

HOSE,TRAVEL MOTOR

1

PLATE,MOUNTING

1

ATTACHMENT,SPRAYMIST

2

ST.EL,1/4-45W/SVL LP

1

BUSHING,1/4 X 1/2 HP

1

NIPPLE-CLOSE 1/2LP

1

ELBOW,SIDE 1/2

58

Chapter 8, Parts Lists & Exploded View Drawings

bill of MaTerial – heavy duTy sPray MisT sysTeM

PART No. 02-430-00

REF PART NO QTY DESCRIPTION

280

281

282

283

071

051

055

02-280-00

02-281-00

02-282-00