RS-2

E.H. Wachs Water Utility Products

600 Knightsbridge Parkway, Lincolnshire, IL 60069

RS-2

i

PIPE & VALVE

MAINTENANCE MACHINERY

Mod. RS-2 S/N:

E.H. WACHS COMPANY

100 Shepard St. Wheeling, IL 60090

PART NUMBER: 78-MAN-01

REVISION NO: R1_1

Patent Pending

Revised:

Jan. 2004

1

RS-2

TABLE OF CONTENTS

SECTION I INTRODUCTION & SPECIFICA TIONS...................................................................3-4

SECTION II SAFETY INSTRUCTIONS............................................................................................5

SECTION III SET UP & OPERA TING PROCEDURES............................................................6-16

SECTION IV CHARTS & SCHEMA TICS..................................................................................17-19

Electric RS-2...............................................................................................................19

Hydraulic RS-2............................................................................................................19

Pneumatic RS-2..........................................................................................................19

SECTION V BILL OF MA TERIALS...........................................................................................20-33

Main Head Assembly............................................................................................21-22

Revolution Counter Assembly ..............................................................................21-22

Hydraulic Drive Assembly.....................................................................................21-22

Pneumatic Drive Assembly..................................................................................23-24

Electric Drive Assembly........................................................................................25-26

ACCESSORIES...................................................................................................27-30

Universal Handwheel............................................................................................27-28

1” Inch Drive Adapter............................................................................................27-28

Handwheel Adaptor Plate....................................................................................27-28

General Accessories............................................................................................29-30

Cleco Air Motor......................................................................................................31-33

SECTION VI ORDERING INFORMA TION......................................................................................34

2

RS-2

SECTION I INTRODUCTION-SPECIFICA TIONS

INTRODUCTION:

The RS-2 Portable V alve Operator for rising

and non-rising stem valves offers reliable

opening and closing of water , wastewater,

pipeline and petroleum valves.

The RS-2 offers these advantages:

! Available in Hydraulic, Pneumatic or

Electric Drive.

! Operate all Rising & Non-Rising Stem

valves. From 6” to 60”.

! 4” Opening for operating Rising Stem

Valves.

! Mount to any Hand Wheel with

“Universal Hand Wheel Adapter”.

! Forward and Reverse operation.

! Variable Speed Control.

! Built in easy view LCD counter.

OPERATE YOUR RS-2 AND OTHER

Universal Handwheel Adaptor

VALVE TURNING AND PIPE

CUTTING EQUIPMENT WITH....

WACHS WACHS

WACHS

WACHS WACHS

HYDRA HYDRA

HYDRA

HYDRA HYDRA

! Cart Mounted / Electric Start

! 9 to 15 H.P. Gas or Diesel Engines

! 8 to15 G.P.M. units Available

ULIC POULIC PO

ULIC PO

ULIC POULIC PO

WER UNITWER UNIT

WER UNITS

WER UNITWER UNIT

Electric Hydraulic Pneumatic

3

RS-2

SECTION I INTRODUCTION-SPECIFICA TIONS

SPECIFICATIONS

CAPACITY: Operate all rising and non-rising stem valves from 6” to 60”, which require mechanized turning.

DRIVE: Lightweight Aluminum gear box. Two stage reduction.

DRIVE HUB: 4” opening for rising stem valve operation.

REVOLUTION

COUNTER: Built in “easy view” LCD Counter. Push button reset counts 1/10 revolution increments, forward and

FINISH: Aluminum gear housing, Zinc plated handle.

DIMENSIONS: 42” length, 4.75” width, 10.3” height

WEIGHT : 40-45 lbs.

POWER

REQUIREMENTS: Air drive, 60 cfm @ 90 psi.

MOTOR Adjustable speed.

CONTROLS: Forward and reverse dial.

OPTIONAL Universal Handwheel Adaptor (pn: 09-405-00) Dedicated Handwheel Adapter Plate (pn: 09-404-00)

ACCESSORIES: 1” Square drive adopter (pn: 09-402-00) 8 ft. Valve Key (pn: 05-402-00)

Planetary motor drive. Steel Ring and Pinion secondary drive.

reverse automatically.

AIR ELECTRIC HYDRAULIC

Electric, 110 volt AC

(15 amps or 3500 watt generator)

2 Speed gear box

Forward and reverse control knob.

Hydraulic, 8 gpm @ 1800 psi

Variable speed.

Adjustable torque control.

Forward and reverse control valve

*NOTE: SEE PAGE 19 FOR PEAK TORQUE AND MAXIMUM RPM OUTPUT

4

RS-2

SECTION II SAFETY INSTRUCTIONS

Read the Following thoroughly before proceeding

Since 1883, EH Wachs has built a reputation for

quality and a commitment to consumer satisfaction.

In accordance with this, Wachs must take on the

added responsibility of doing our best to assure the

safest use of our equipment.

We have assembled a list of safety reminders to

aid in creating the safest possible working environment. We recommend that the precautionary steps

listed there be closely observed.

1. READ THE OPERATING MANUAL!!

Reading the setup and operating instructions prior to

beginning the setup procedures can save valuable time

and help prevent injury to operators or damage to ma-

chines.

2. INSPECT MACHINE & ACCESSORIES!

Prior to machine setup physically inspect the machine

and it's accessories. Look for worn tool slides, loose bolts

or nuts, lubricant leakage, excessive rust, etc. A properly

maintained machine can greatly decrease the chances

for injury.

3. ALWAYS READ PLACARDS & LABELS!

All placards, labels and stickers must be clearly legible

and in good condition. Replacement labels can be pur-

chased from the manufacturer.

ALWAYS WEAR PROTECTIVE EQUIPMENT:

WARNING

Impact resistant eye protection

must be worn while operating or

working near this tool.

For additonal information on eye and face protection, refer to

federal OSHA regulations, 29 Code of Federal Regulations,

Section 1019.133., Eye and Face Protection and American

National Standards Institute, ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Z87.1 is available

from the American National Standards Institute, Inc., 1430

Broadway, New York, NY 10018

CAUTION

Personal hearing protection is required at all times when operating or working near this tool.

Hearing protectors are required in high noise areas, 85dBA

or greater. The operation of other tools and equipment in the

area, reflective surfaces, process noises and resonant

structures can substantionally contribute to and increase

the noise level in the area. For additional information on

hearing protection, refer to federal OSHA regulations , 29

Code of Federal Regulations, section 1910.95, Occupational Noise Exposure and ANSI S12.6 Hearing Protectors.

4. KEEP CLEAR OF ROTATING PARTS!

Keep hands, arms and fingers clear of all rotating or

moving parts. Always turn machine off before attempting

any adjustments requiring contact with the machine or it's

accessories.

5. SECURE LOOSE CLOTHING & JEWELRY!

Loose fitting clothing, jewelry; long, unbound hair can get

caught in the rotating parts on machines. By keeping

these things secure or removing them you can greatly

reduce the chance for injury.

6. KEEP WORK AREA CLEAR!

Be sure to keep the work area free of clutter and nonessential materials. Only allow those personnel directly

associated with the work being performed to have access

to the area if possible.

CAUTION

Some individuals are suseptible to

disorders of the hands and arms

when exposed to tasks which involve repetitive motions and/or vibration. Disorders such as Carpal

Tunnel Syndrome and Tendonitis

can be caused or aggravated by

repetitious, forceful exertions of the

hands and arms.

! Use minimum hand grip force.

! Keep wrists straight

! Avoid prolonged, continuous vibration exposure

! Avoid repeated bending of wrists and hands.

! Keep arms and hands warm and dry.

5

RS-2

Section III

Set Up

&

Operating Procedures

6

RS-2

SECTION III SET-UP AND OPERATION

necessary to start with a nut and stem

jammed against the bonnet, and there will be

no guesswork about which way to turn

the nut because the valve will be free. Also, if

it is inadvertently turned the wrong way , one

or two turns can be made before a positive

stops occurs, and by reversing direction, full

operation of the valve can be effected.

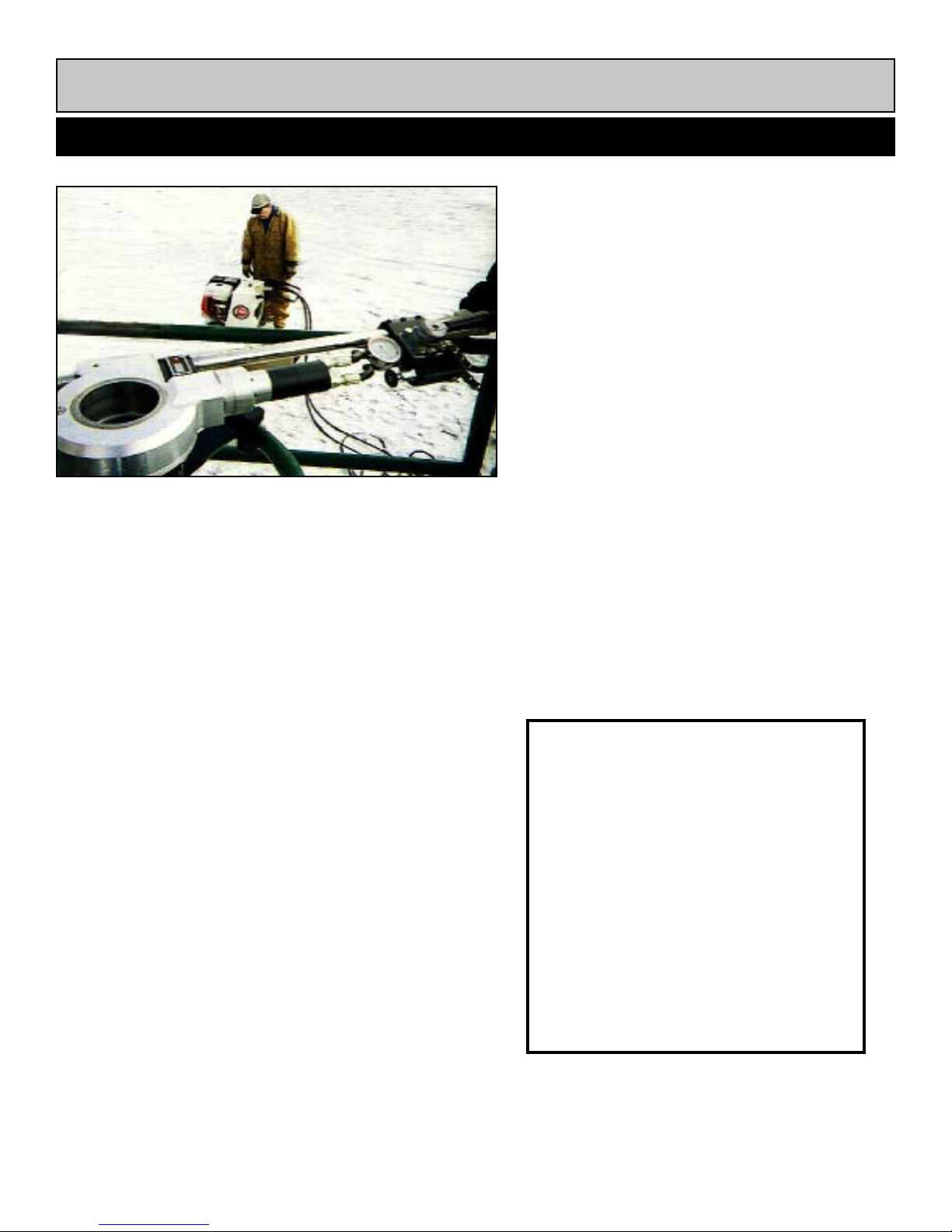

Using the RS-2 machines to operate valves

is easier on the valve because a steady

turning torque is applied rather than jerky

motions. This prevents the stem breakage

that is sometimes caused by turning the

valve by hand. Also, more valves can be

Valve Maintenance Procedure

A valve that has not been operated for a number of

years needs to be closed by using a series of up

and down motions. Occasionally , crews attempting

to close a difficult valve use a T -handle or a cheater

bar, applying a great deal of pressure in one direction simply to force the valve closed. The correct

way to exercise a valve is to begin with a steady

amount of torque in the direction necessary to close

the valve, moving through five to ten rotations, then

the direction should be reversed for two or three

revolutions, followed by five or ten more turns in the

closing direction. This procedure should be repeated until full closure is attained.

The reason for the cautious approach is that

tuberculation and sediment have probably built up

on the gates, stem, and slides. By using the procedure described, water in the system can flush the

debris that has broken away from the gate slide.

The stem is exercised through the series of

up and down motions. Once the valve has been fully

closed, it should be opened a few turns so that the

higher velocity water flowing under the gates can

move the remainder of the sediment downstream.

After the valve is reopened, it should be turned in

the closing direction one or two revolutions. Thus,

the next time the valve is operated, it will not be

turned in less time. A further advantage is that

information about each valve can be generated automatically by the revolution counter

and torque gauges for inclusion on permanent records.

HOW TO DETERMINE AN

UNKNOWN VALVE ROTATION:

When the direction to turn the valve

stem is not known, select a rotation

direction and proceed with caution. If

resistance is felt, immediately reverse

the rotation. Continue this procedure,

reversing direction when resistance is

felt, until a free turning direction is

achieved. Document the direction,

open or closed position, and number

of turns required.

7

RS-2

SECTION III SET-UP AND OPERATION

I. SET UP PROCEDURE (V alve Key & Socket):

1. Insert 1” drive adaptor into RS-2 drive hub, secure

with 1/4 20x5/8” SHCS. (Ref. 1)

1” Square Drive Adaptor

Ref. 1

2. Insert valve key and socket into valve. (Ref. 2)

Valve Operator

Extension Handle

Stop Collar

Valve Key & Socket

II. OPERA TOR POSITIONING

Standing on the wrong side of the machine will allow

the handle to PUSH against the operator and can

knock him off balance or pin him against an obstacle if

torque suddenly increases. When positioned properly,

an increase in torque will PULL the handle and control

out of the operator’s hand and stop the machine (See

illustrations below).

IMPORTANT: Always refer to the manual or the valve

direction decal located on valve handle for correct

operation positions.

Ref. 2

3. Install stop collar at a comfortable operating height

to support the weight of the RS-2.

4. Mount the RS-2 on the valve key and rest on stop

collar. Connect the power source.

5. Zero the counter when valve is ready to be turned

by pressing the red reset button on the counter face.

Always use the counter to determine the number of

rotations the valve has turned.

6. Determine direction of valve rotation and which

side of RS-2 to operate from. The operator should

stand on the side of the machine which allows the

torque to PULL the machine handle away from his

body .

CAUTION: The RS-2 is capable of producing up

to 800 ft./lbs. of torque to turn valves. It is very

!

!

important that proper procedure be exercised

when using the valve operating machine.

Operator should always change sides for opposite rotation

V alve Key Operation

8

RS-2

SECTION III SET-UP AND OPERATION

I. SET UP PROCEDURE

(

Universal Handwheel Adapter)

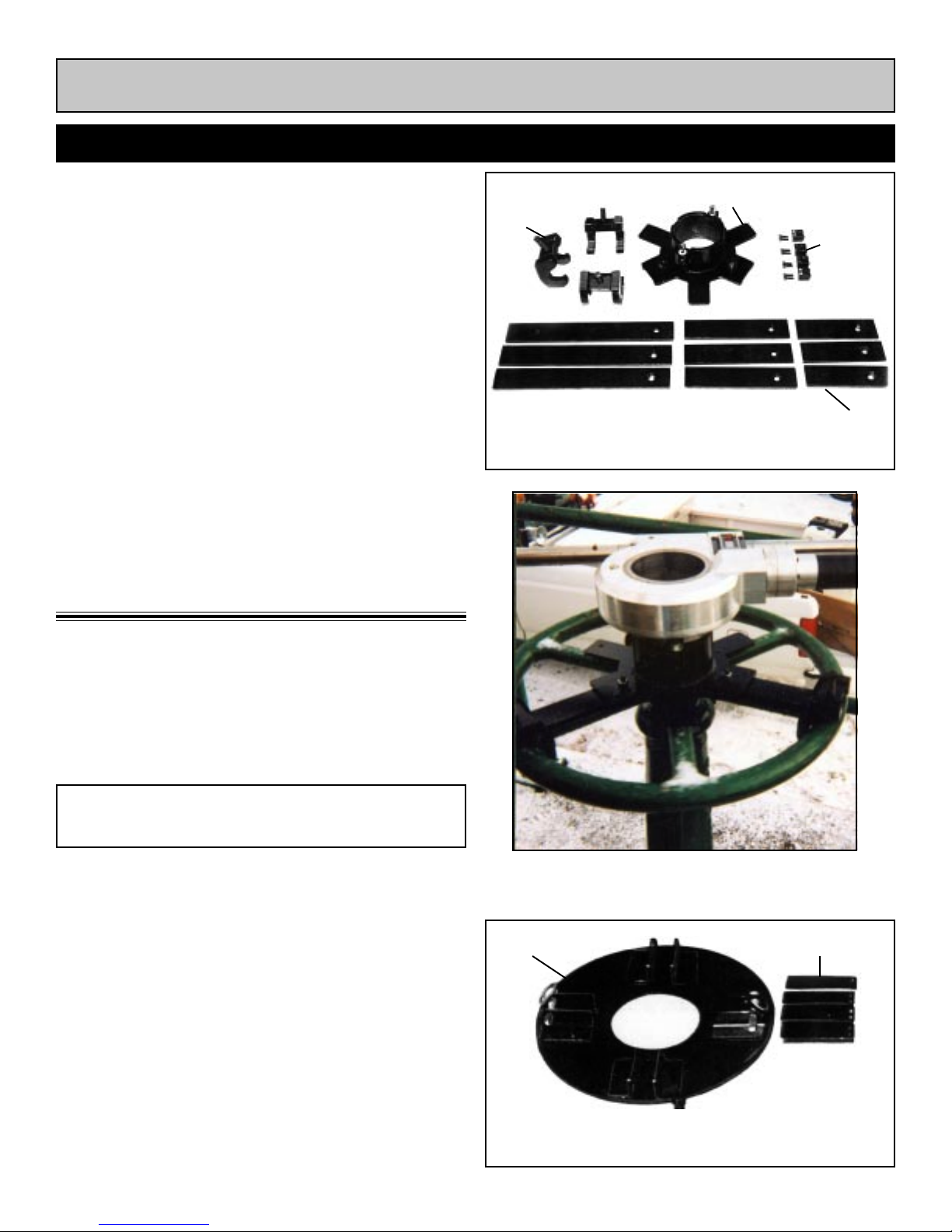

1. Install the 4 handwheel fingers onto the RS-2

rotating drive hub slots with the provided 1/4 20x1”

socket head cap screws.

2. Measure the valve handwheel to determine the

correct length torque arm required to mount to the

universal hand wheel. Install the torque arms using

the provided flat head screws and nuts.

3.Set the assembly over the rising stem valve. Center

the opening of the universal handwheel adapter

over the rising stem screw.

4.Mount the 3 straddle clamps over the torque arms

and under the valve handwheel and secure the

assembly with the 1/2 13x2” square head screws in

the straddle clamps.

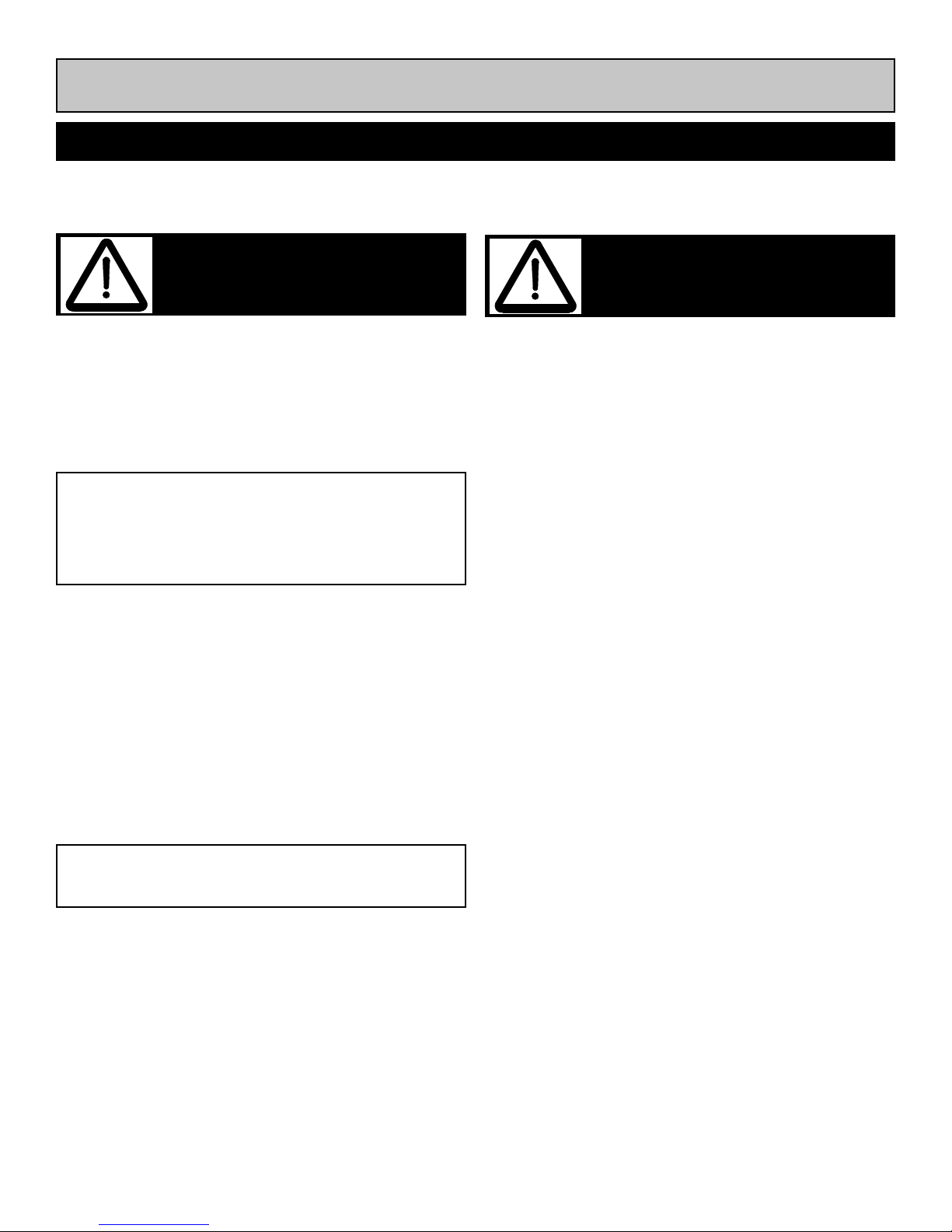

I. SET UP PROCEDURE

(

Mounting Dedicated Handwheel

Adaptor Plate)

1. The dedicated adaptor plate must be mounted to

rising stem valve with U-bolts supplied with your

dedicated adaptor plate. Holes must be drilled into

adapter plate to bolt plate to handwheel spokes.

Universal Handwheel

Straddle Clamps

Drive Fingers

Torque Arms

Universal Handwheel Adapter Assembly

NOTE: Center dedicated handwheel plate

""

"

""

2. After mounting adapter plate, bolt fingers to RS-2

drive hub using the slots provided for this purpose,

located on bottom of actuator , using 1/4 20x5/8”

socket head cap screws.

3. Place RS-2 on adapter dedicated plate so that

fingers rest in adapter plate slots.

4. Insert “fast-pins” in holes provided to lock actuator

on adapter plate.

5. Place the RS-2 onto the Universal hand wheel

adopter by inserting the 4 drive fingers into the 4

mounting slots on the Universal handwheel adopter.

Insert the swing bolt assemblies into the slots and

tighten the nuts to secure the assembly .

hole over center of rising stem screw.

Adapter Plate

9

Universal Handwheel Assembly

Drive Fingers

Dedicated Handwheel Adapter Assembly

RS-2

SECTION III SET-UP AND OPERATION

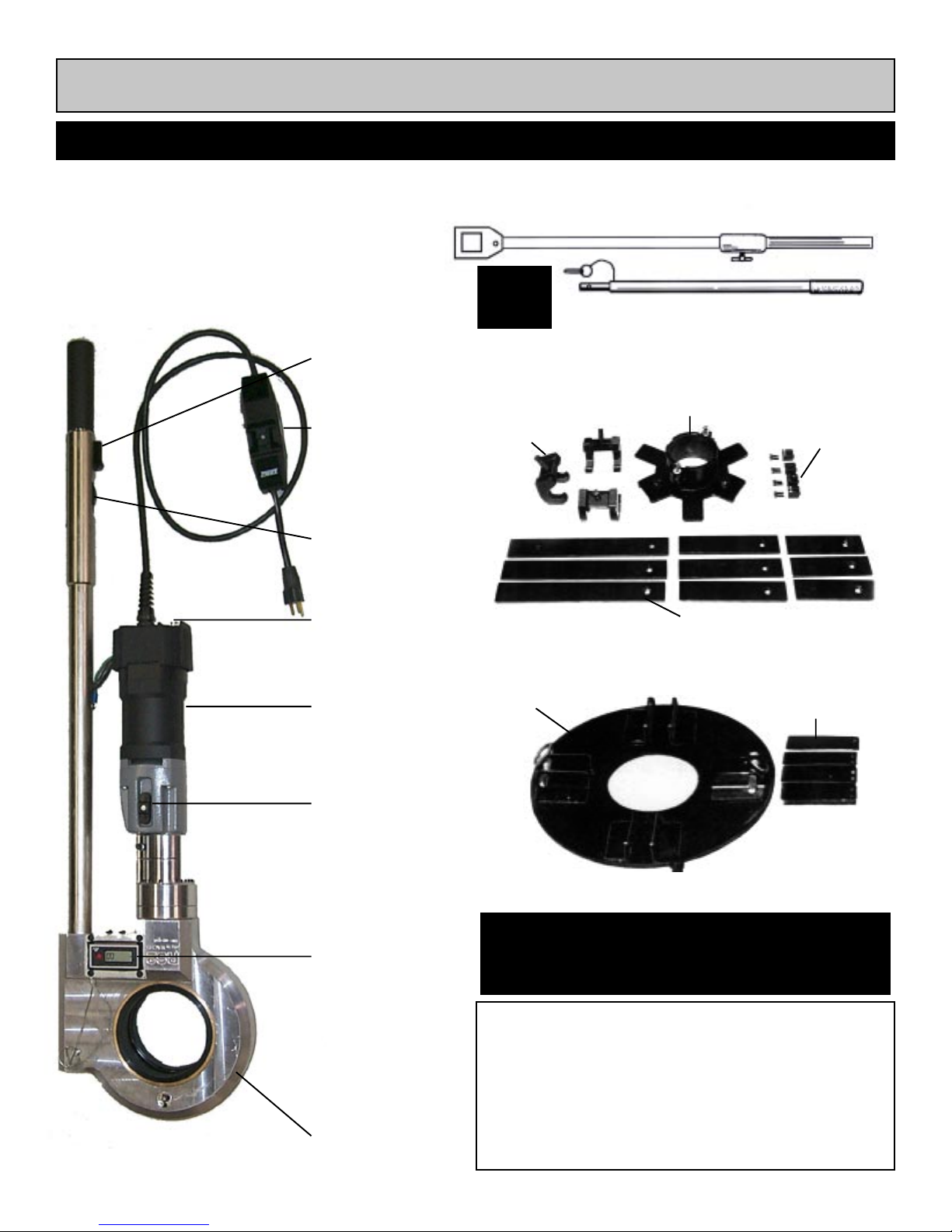

CONTROLS AND COMPONENTS

ELECTRIC RS-2

On/Off

Trigger

GFI

Ground Fault

Interrupter

Forward/Reverse

Switch

Reset Button

Valve Socket

1” Drive Adapter

Straddle Clamps

Valve Key Operation

Stop Collar

Valve Operator

Extension Handle

Universal Handwheel Operation

Universal Handwheel

Drive Fingers

Long, Medium, Short Torque Arms

Electric Motor

High/Low

Torque

Setting

Switch

1/10th Counter

w/Reset Button

Power Head

Dedicated Handwheel Operation

Drive Plate

Lifting Handles

CAUTION: DO NOT connect or disconnect hoses

!

!

INTRODUCTION

It is impossible to determine how much torque a

valve stem can take before breaking. Size, age,

condition, tuberculation, and period of time since

last operation will have an effect to this. The

recommended start-up procedure for operating a

valve is to set the RS-2 to its lowest torque setting.

10

to valve operator or power source while power

source is operating.

Drive Fingers

RS-2

SECTION III SET-UP AND OPERATION

OPERATING PROCEDURE:

ELECTRIC RS-2

CAUTION: Before beginning turning sequence,

know which direction to turn the valve to avoid

breaking the valve stem.

1. Af ter plugging in power cord, push reset button

on GFI to power up unit.

2. Set speed control knob to high speed/low

torque setting (see illustration below).

NOTE: If the motor overload circuit breaker

pops while attempting to free a frozen valve,

reset the circuit breaker by pressing the

""

"

""

3. If the valve does not move in either direction,

switch speed control to low speed/high torque

setting.

Once the valve has started turning, return the

speed control switch to the high speed/low torque

setting. This procedure will assure you that the

machine stops operating as soon as any type of

obstruction is encountered or when the valve is

seated.

reset button and attempt to free the valve

again before switching to the low speed/

high torque setting.

CAUTION: Only use extension cords rated

for 10 AMPS or higher.

NOTE: More torque will be required to seat,

""

"

""

DURING OPERATION:

When operating a valve, a build up of torque can

be felt by the operator. When this occurs, it is a

sign of either build up of material in the valve gate

slides or that the end of travel is approaching. The

operator should change sides and reverse the

valve direction for a few turns, doing this each

time resistance is felt. This method of exercising

cleans out tuberculin and other contaminant build

up. The counter will keep track of how many turns

you have put on the valve.

unseat or clear tuberculin from the valve.

11

Loading...

Loading...