E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

HPU-20 Hydraulic Power Unit

User’s Manual

E.H. Wachs Part No. 14-MAN-35

Revision 0, June 2016

IMPORTANT: Read this manual carefully

before starting and operating the power unit.

Copyright © 2016 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

Table of Contents

Table of Contents

Chapter 1: About the HPU-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Protective Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3: Using the HPU-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting and Moving the HPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Set-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fill the Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hydraulic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 i

HPU-20 Hydraulic Power Unit

ii Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Chapter 1

About the HPU-20

The Wachs HPU-20 hydraulic power unit provides 18 gpm

hydraulic flow at a maximum pressure of 1800 psi (57 l/

min at 124 bar). The unit is powered by a 20 HP electric

motor.

Before operating the unit, read and understand the instructions in this manual.

FEATURES

The HPU-20 hydraulic power unit includes the following

standard features:

• 20 HP electric motor (380-460 V, 50/60 Hz).

• Line reactor to suppress noise.

• Over Temp/Low Oil warning light.

• Pendant with controls for power on/off, speed (flow),

flow direction, and emergency stop.

• Removable mobile base with non-marring casters.

• Five-point lifting system.

• 10 micron hydraulic oil filter.

• Heat exchanger with digital readout.

• Helical cut, ultra quiet hydraulic gear pump.

• Powder coat finish.

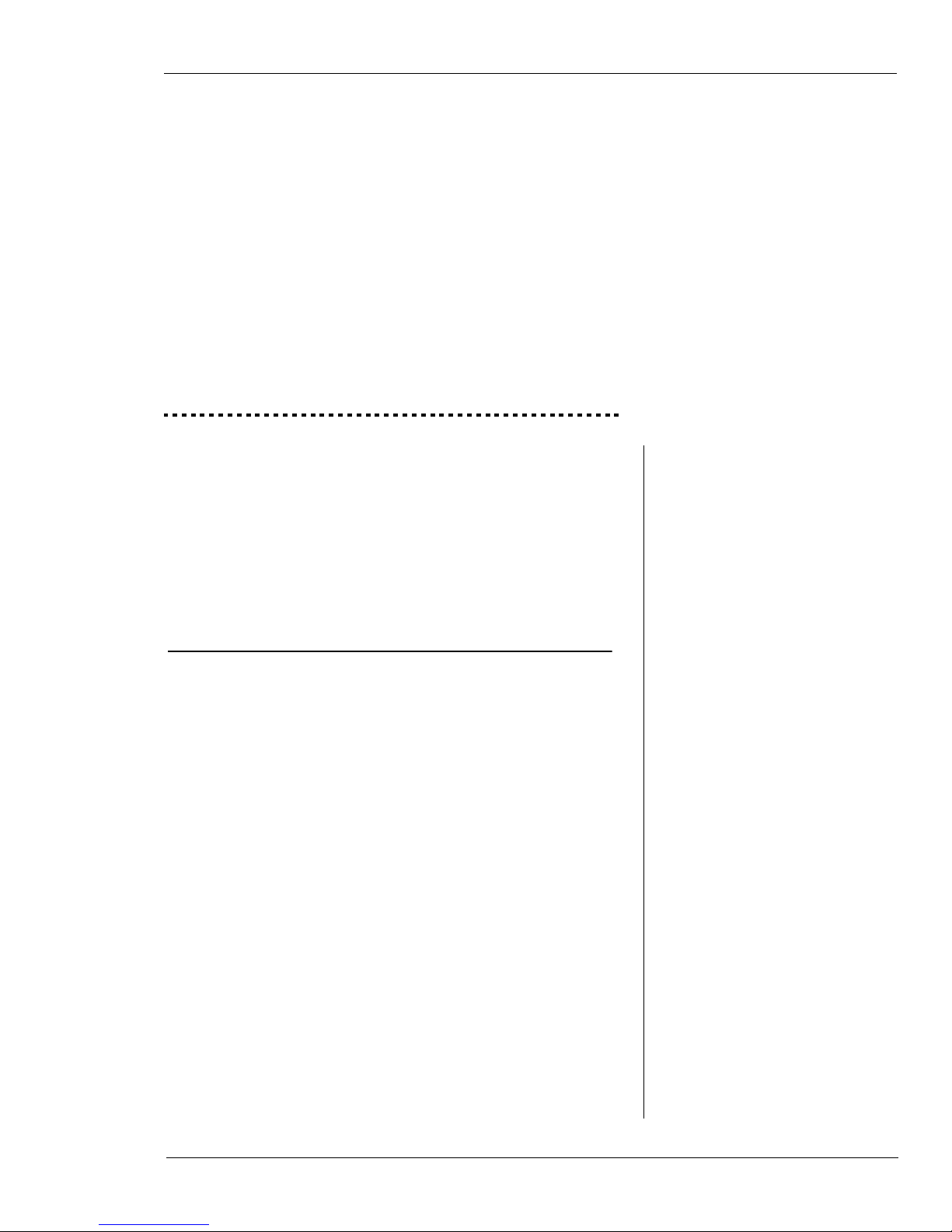

The following figures illustrate the features of the HPU-20

power unit.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 1

HPU-20 Hydraulic Power Unit

Main power/

panel

disconnect

Over temp/

low oil

warning light

Reservoir oil

temperature

and level gauge

Reservoir oil

drain plug

Mobile base

(removable)

Panel lock

fasteners (4)

Figure 1-1. The photo shows the front of the HPU-20.

2 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

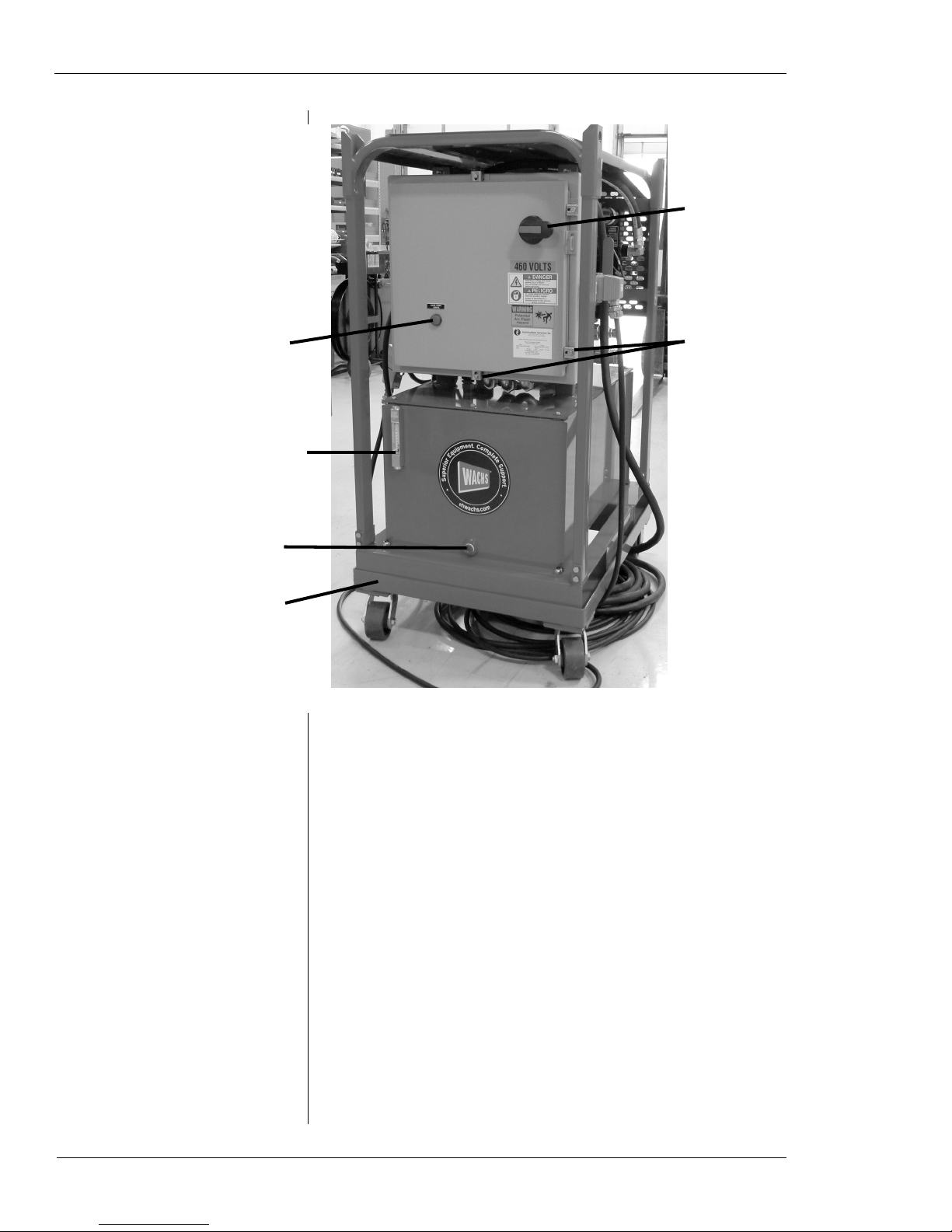

Hydraulic oil

filter

Variable

frequency

drive

Hydraulic oil

cooler

Hydraulic

valve

Oil fill/

breather

Electrical

panel

Operating

pendant

Figure 1-2. The photo shows operating features of the

HPU-20.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 3

HPU-20 Hydraulic Power Unit

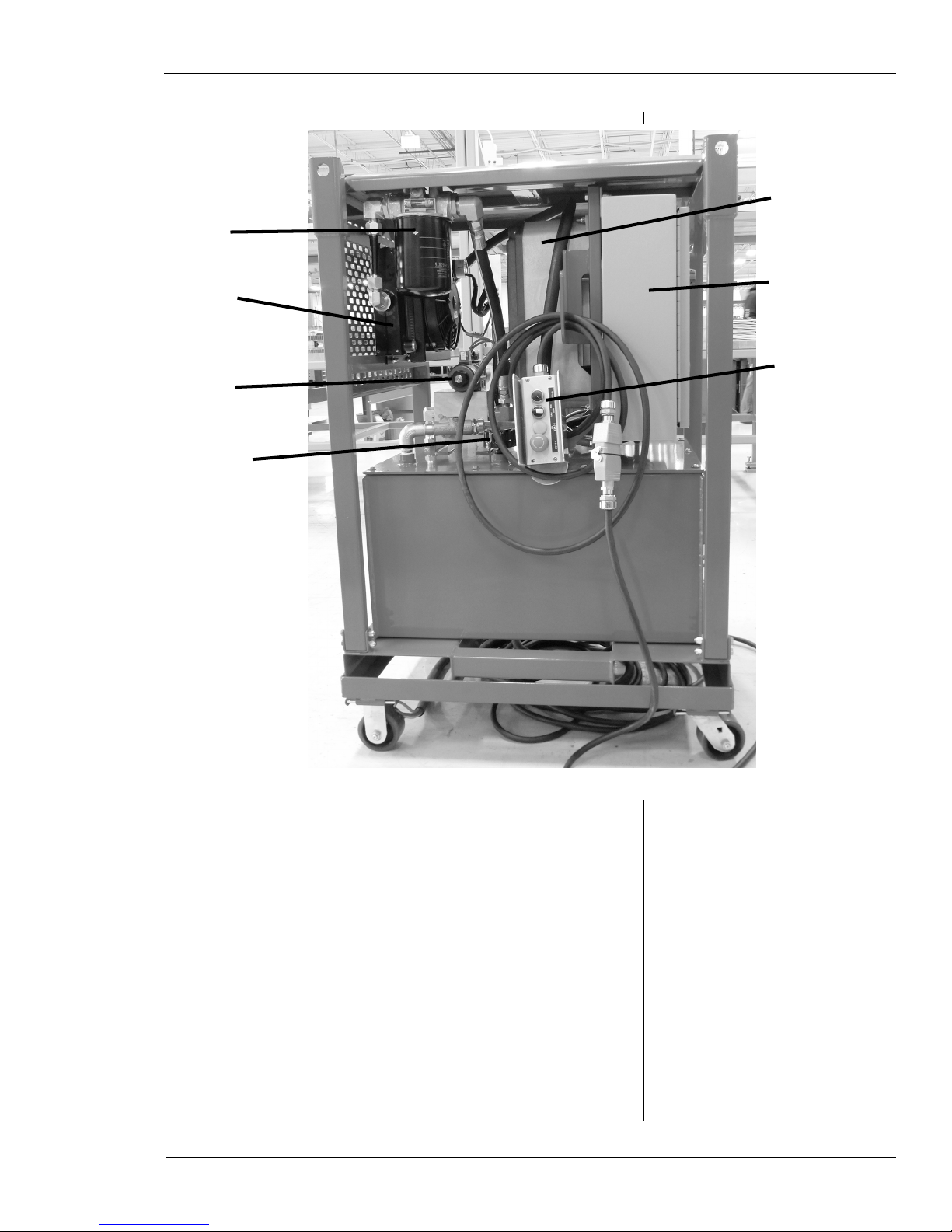

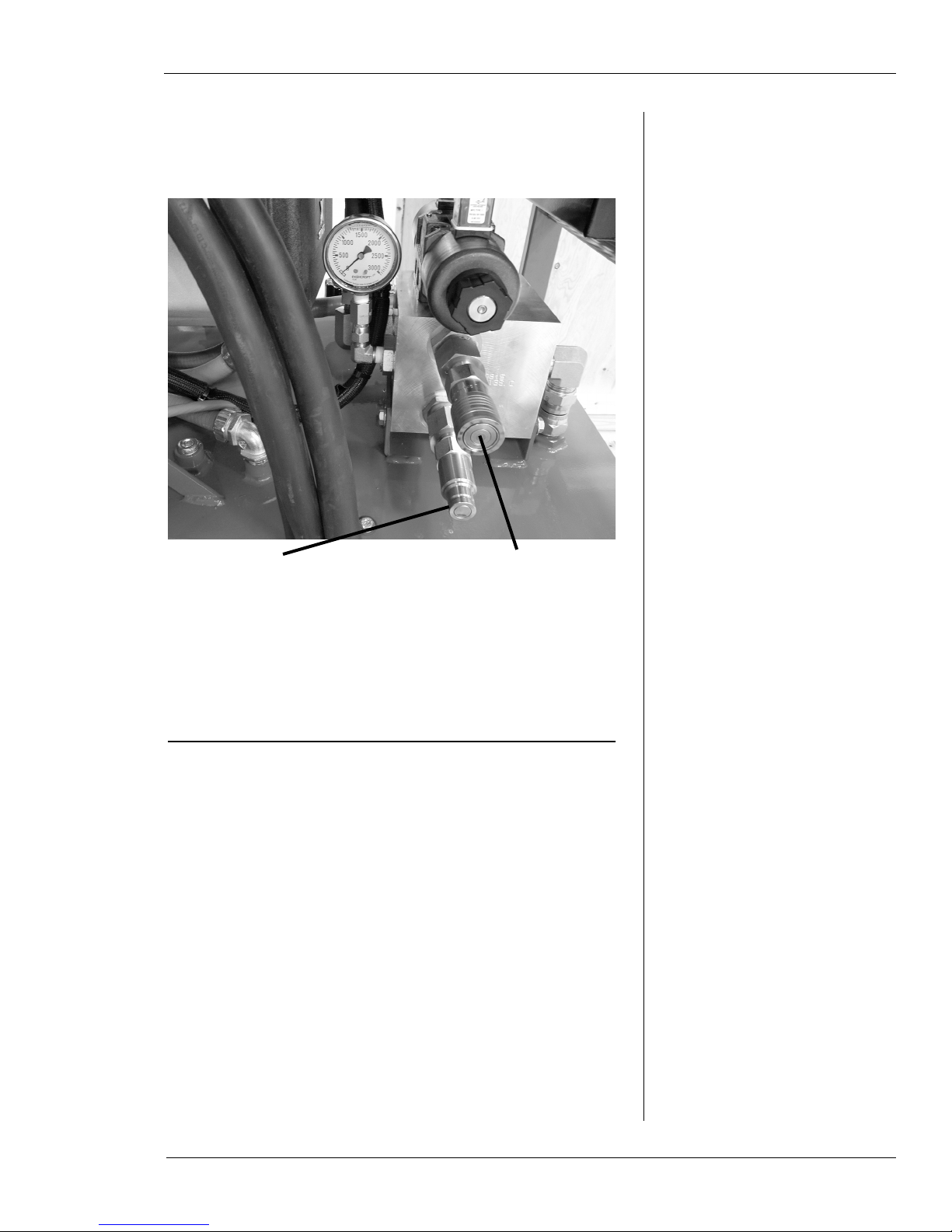

Power

input

Pressure

gauge

Hydraulic

valve

Hydraulic

manifold

Hose

fittings

4 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Figure 1-3. The photo shows operating features of the

HPU-20.

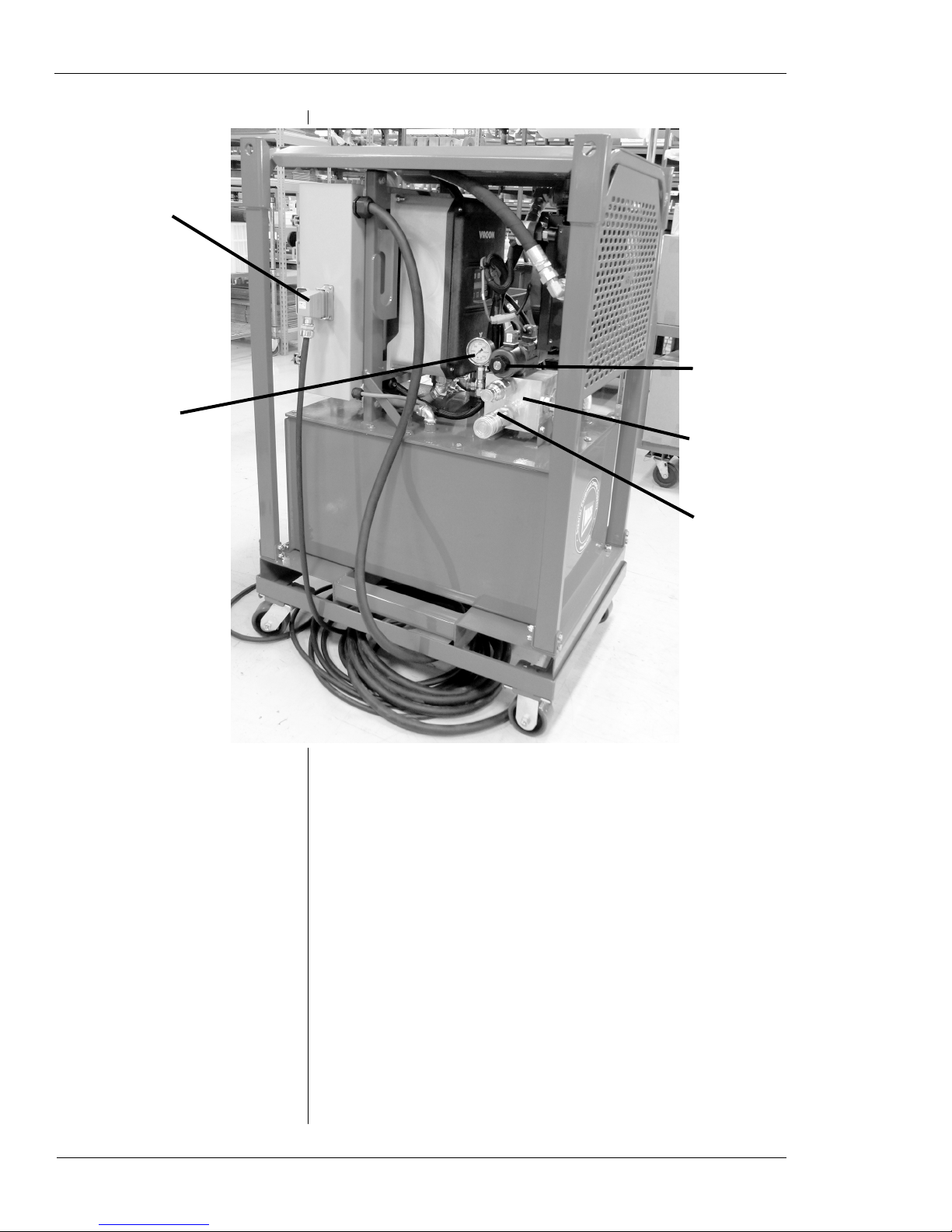

Figure 1-4.

Pressure port:

1/2” NPT adapter (part no. 90058-12) and male quick disconnect (part no. 09-026-00)

Return (tank) port:

1/2” NPT adapter (part no. 90058-12) and female quick disconnect (part no. 09-025-00)

Figure 1-5. The drawing identifies the hydraulic fittings on the HPU-20.

SPECIFICATIONS

• Flow: 4-18 gpm @ 1800 psi (15-68 l/min @ 124 bar)

• Pressure: Factory set at 1800 psi (124 bar)

• Dimensions (with base): 34.5” l x 52.5” h x 26” w

(88 cm x 133 cm x 66 cm)

• Weight: 850 lb (386 kg), including oil and mobile base

• Hydraulic Oil Capacity: 30 gallons (114 liters)

• Hydraulic Relief Pressure: 1800 psi (124 bar)

• Current Draw: 30 amps

• Operating Temperature: 110° F (43° C)

• Noise Level: 62 dB at full flow and operation.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 5

HPU-20 Hydraulic Power Unit

6 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Chapter 2

Safety

Chapter 2, Safety

E.H. Wachs takes great pride in designing and manufacturing safe, high-quality products. We make user safety a top

priority in the design of all our products.

Read this chapter carefully before operating the hydraulic

power unit. It contains important safety instructions and

recommendations.

OPERATOR SAFETY

Follow these guidelines for safe operation of the equipment.

• READ THE OPERATING MANUAL. Make sure

you understand all setup and operating instructions

before you begin.

INSPECT MACHINE AND ACCESSORIES.

•

Before starting the machine, look for loose bolts or

nuts, leaking lubricant, rusted components, and any

other physical conditions that may affect operation.

Properly maintaining the machine can greatly decrease

the chances for injury.

ALWAYS READ PLACARDS AND LABELS. Make

•

sure all placards, labels, and stickers are clearly legible

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

KEEP CLEAR OF MOVING PARTS. Keep hands,

•

arms, and fingers clear of all rotating or moving parts.

In This Chapter

OPERATOR SAFETY

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 7

HPU-20 Hydraulic Power Unit

Always turn machine off before doing any adjustments

or service.

SECURE LOOSE CLOTHING AND JEWELRY.

•

Secure or remove loose-fitting clothing and jewelry, and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

KEEP WORK AREA CLEAR. Keep all clutter and

•

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

NOTICE

8 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

This alert indicates a situation that, if not avoided, will

result in damage to the equipment.

IMPORTANT

This alert indicates a situation that, if not avoided, may

result in damage to the equipment.

Protective Equipment Requirements

WARNING

Always wear impact resistant eye protection while operating or working near

this equipment.

For additional information on eye and face protection, refer

to Federal OSHA regulations, 29 Code of Federal Regulations, Section 1910.133., Eye and Face Protection and

American National Standards Institute, ANSI Z87.1, Occu-

pational and Educational Eye and Face Protection. Z87.1 is

available from the American National Standards Institute,

Inc., 1430 Broadway, New York, NY 10018.

Chapter 2, Safety: Operator Safety

CAUTION

Personal hearing protection is recommended when operating or working near

this equipment.

Hearing protectors are required in high noise areas, 85 dBA

or greater. The operation of other tools and equipment in the

area, reflective surfaces, process noises, and resonant structures can increase the noise level in the area. For additional

information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section

1910.95, Occupational Noise Exposure and ANSI S12.6

Hearing Protectors.

Safety Procedures

All safety requirements listed below are those generally

applicable to hydraulically-powered machinery but are not

intended to be an all-inclusive list. They are intended as

guidelines only and will assist in avoiding risk of injury

when followed by qualified, experienced personnel. These

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 9

HPU-20 Hydraulic Power Unit

precautions should be included in the comprehensive safety

program for the particular machinery, equipment, plant or

process and overseen by personnel capable of analyzing any

hazards associated with operating and maintaining the

equipment.

WARNING

Many types of

machinery have

parts that may

start moving as soon as the

hydraulic circuit is filled and

pressurized. This could result

in injury to personnel or damage to machinery.

WARNING

Make sure all personnel are clear

from the machinery being operated before

shutting down the HPU.

Return all movable parts of the machinery being oper-

1.

ated to their normal startup condition, if possible,

before starting unit.

Be sure all personnel, product, etc. are clear of

2.

machinery before starting hydraulic unit.

Check to make sure any hydraulic connections which

3.

may have been removed, replaced or disconnected

during shut down have been reconnected securely

before starting hydraulic unit.

Before starting the unit, perform all equipment checks

4.

described at the beginning of the operating instructions.

If there are tools or machinery being operated by the

5.

HPU that may move when hydraulic flow or pressure

are turned off or turned on, block or lock these parts in

position before shutting down the hydraulic unit.

Shut down the hydraulic unit and relieve pressure

6.

from all pressurized accumulators, actuators and lines

before removing, tearing down or performing maintenance on any remotely-located actuators, hoses, filters, valves, piping, etc.

Any personnel observing or working on or adjacent to

7.

hydraulically-powered equipment must never place

themselves in a location or position that could produce

an injury in the event of:

10 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

• a hydraulic line failure either with the unit running or

shut down;

• pump or motor failure or;

• pin-hole leaks in hoses or fittings;

• movement of machine components during normal operation or resulting from a component malfunction or failure.

Chapter 2, Safety: Safety Labels

Do not inspect hoses and fittings for leaks using your

8.

bare hands. A pin-hole leak can inject hydraulic fluid

through the skin, with the potential for serious injury.

Avoid locating equipment in any environment for

9.

which it was not designed and which may create a

dangerous operating condition such as an explosive

atmosphere (e.g., gas, dust), high heat (e.g., molten

metal, furnace), chemicals, extreme moisture, etc.

Avoid bodily contact with hydraulic fluids. Some

10.

hydraulic fluids may irritate or injure the eyes and

skin. Check with your fluid suppliers to obtain this

information.

Use only E.H. Wachs parts and materials when servic-

11.

ing the equipment. Substitute parts or materials could

produce a hazardous operating condition.

When piping your equipment, use only materials of

12.

adequate size and strength to suit the flows and pressures of the system. Consider all safety factors when

selecting the strength of materials to allow for shock

and over-pressure conditions which could occur.

WARNING

The injection of

hydraulic fluid

under the skin can

cause serious injury and

even result in death. If an

injection injury occurs, seek

medical treatment immediately.

SAFETY LABELS

Safety labels on the front panel of the unit indicate the electrical hazards.

• Hazardous voltages can cause severe injury or death.

• An arc flash can cause severe injury or death.

Disconnect power from the HPU before opening the cabinet

or performing any service on it.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 11

HPU-20 Hydraulic Power Unit

Figure 2-1. Labels on the front panel warn of electrical hazards.

12 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Chapter 3

Using the HPU-20

LIFTING AND MOVING THE HPU

The HPU-20 is supplied with a mobile base on caster

wheels. The base can be removed from the unit.

The bottom of the HPU-20 frame has channels for lifting

with a fork truck.

There are 5 lift points on top of the HPU-20 frame, one at

each corner and one in the center. Attach to these points

when lifting with an overhead crane.

Figure 3-1. Use the lift points on top of the frame.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 13

HPU-20 Hydraulic Power Unit

SET-UP INSTRUCTIONS

The HPU-20 power unit is completely assembled before

delivery. For safe shipping, it is delivered without hydraulic

fluid.

Fill the Hydraulic Reservoir

NOTE: It is extremely important that the pump is not

started until oil is in the system. Power units are shipped

without oil. Operating a pump

without oil, even for a short

time, will result in damage.

Fill the hydraulic reservoir with hydraulic oil. The HPU-20

holds approximately 30 gallons (114 l). Make sure you fill

the reservoir before starting the power unit.

Use an ISO-AW32 (preferred) or ISO-AW46 oil. Oil should

have anti-wear characteristics, excellent rust protection, and

contain additives to protect against foaming.

Hydraulic reservoir cap

14 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Figure 3-2. Remove the hydraulic reservoir cap and

fill the reservoir with hydraulic oil (approximate

capacity 30 gallons [114 l]).

Figure 3-3. Fill the reservoir to the level indicated on

the oil level/temperature gauge.

Wipe up any spilled oil and replace the cap tightly. Do not

operate the power unit without the cap securely in place.

Connect Power

Connect power to the HPU-20 at the connector on the side

of the electrical panel. The unit can operate on 380-460 V,

50/60 Hz.

The input voltage limit is 380-460 V, +/- 15% (325-530 V).

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 15

HPU-20 Hydraulic Power Unit

Figure 3-4. Attach power to the connector on the

electrical panel of the HPU-20.

NOTE: The power unit is factory-set to operate at 1800

psi (124 bar). It is extremely

important that the hoses used

with this unit are rated for

3000 psi (186 bar) or higher

pressure.

Connect Hydraulic Hoses

Connect the hoses to the quick disconnect fittings as shown.

Return

(tank) port

Pressure

port

Figure 3-5. Connect the hydraulic hoses to the fittings

as shown.

16 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Note: Never connect or disconnect quick couplers when the

HPU is on. Never connect or disconnect quick couplers

when the circuit is under pressure. See the pressure gauge.

OPERATING INSTRUCTIONS

Before starting the power unit, perform the following

checks:

• Make sure the reservoir is filled to the required level

with hydraulic oil.

• Make sure the cabinet door is secured with the panel

lock fasteners.

• Make sure the power cable is securely connected to the

electrical cabinet.

• Make sure the handheld control pendant is connected.

Turn the flow control knob to the OFF position (all the

1.

way counter-clockwise).

Figure 3-6. Turn the main switch on the front of the

cabinet to the ON position.

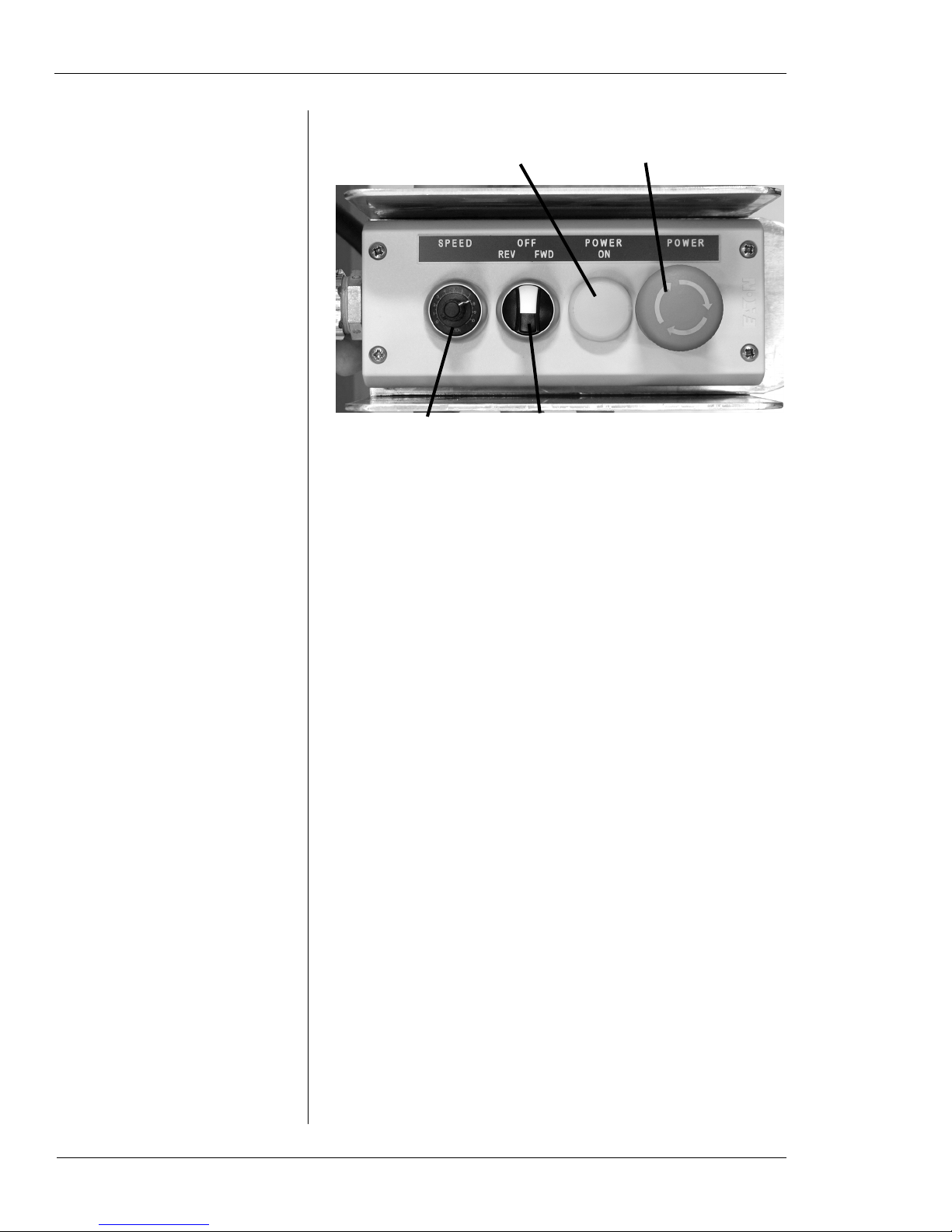

On the handheld pendant, turn the POWER knob

2.

counter-clockwise until the POWER ON indicator

lights up.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 17

HPU-20 Hydraulic Power Unit

POWER ON light indicates

when unit has power.

Turn POWER knob

to start unit.

Turn the SPEED knob

to set the desired flow.

Set the operating direction

to FWD, REV, or OFF.

Figure 3-7. Operate the HPU using the handheld control pendant.

To operate the tool, set the operating direction knob to

3.

the FWD position.

Turn the SPEED knob clockwise to start hydraulic

4.

flow. Adjust the knob for the desired operating speed.

To stop the motor, turn the operating direction knob to

5.

the OFF position. You can leave the SPEED knob at

the same position; this will resume the same speed

when you restart the motor.

Operating the HPU without a hydraulic tool connected

6.

will pump oil over the relief valve, creating heat. If the

unit overheats (above 180° F/82° C), it will shut down

automatically, and the Over Temp/Low Oil indicator

on the panel will light up.

18 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

If the unit gets low on oil, it will shut down automati-

7.

cally, and the Over Temp/Low Oil indicator on the

panel will light up.

Operating Notes

Make sure that the hydraulic circuit is properly plumbed

and appropriate for the available amount of oil from the

unit. A circuit with long hoses or a high-capacity tool could

lower the reservoir level considerably. The power unit must

be plumbed to an open center valve.

If the hydraulic circuit is improperly plumbed, pressure will

build immediately and dump over the relief valve setting,

causing excessive heat.

Cautions

Escaping hydraulic fluid under pressure can have sufficient

force to penetrate skin, causing serious personal injury.

Before disconnecting lines, be sure to relieve all pressure.

Before applying pressure to the system, be sure all connections are tight and that lines and hoses are not damaged.

Fluid escaping from a very small hole can be almost invisible. Use a piece of cardboard or wood rather than hands to

search for suspected leaks.

If injured by escaping fluid, SEE A DOCTOR AT ONCE.

Serious infection or reaction can develop if proper medical

treatment is not administered immediately.

See the safety guidelines in the next chapter.

MAINTENANCE

Every time you use the power unit, inspect all fasteners,

hydraulic hoses, and fittings.

Every time you use the power unit, check the hydraulic oil

level in the reservoir. Check the oil level periodically during

extended use.

Check the condition of the hydraulic fluid, looking for contaminants, dirt, or discoloration. Change the fluid as soon as

it becomes dirty or discolored. It is recommended that you

change the oil every 200 hours of operation.

NOTE: A hydraulic hose failure could be very hazardous;

frequent inspection is important.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 19

HPU-20 Hydraulic Power Unit

The hydraulic system includes a return line filter. Replace

the filter every time you replace the hydraulic fluid. Do not

try to get extended life out of a clogged filter.

Refer to the following chart for hydraulic oil service.

20 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Figure 3-9. The hydraulic oil drain plug is at the bottom of the oil reservoir, on the front of the unit.

Figure 3-10. Replace the hydraulic oil filter every

time you replace the hydraulic oil.

TROUBLESHOOTING

Hydraulic

Refer to the chart below for hydraulic troubleshooting.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 21

HPU-20 Hydraulic Power Unit

Electrical

Electrical system troubleshooting and repair should be performed by trained and certified electrical staff. Electrical

hazards can result in severe injury or death. Always consult

E.H. Wachs if there are problems that are beyond the scope

of available electrical staff.

Refer to the following notes and chart for electrical system

troubleshooting.

• Make sure there are 3 good legs of power, within the

specified power range.

• Make sure all fuses and circuit breakers are not tripped

or blown.

• Check that the disconnect is turned off.

• Check the connect to the handheld pendant.

• Make sure the Stop button on the pendant is in the “Out”

position.

• Make sure the Variable Frequency Drive is in the

“Remote” setting. See the VFD drive manual.

• Make sure the Over Temp/Oil Level indicator is off.

22 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Schematic

Refer to the system schematic on the following page for

troubleshooting and repair.

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 23

Chapter 4

Ordering Information

To place an order, request service, or get more detailed

information on any E.H. Wachs products, call us at one of

the following numbers:

Chapter 4, Ordering Information

In This Chapter

ORDERING REPLACEMENT

PARTS

REPAIR INFORMATION

U.S. 800-323-8185

International: 847-537-8800

You can also visit our Web site at:

www.ehwachs.com

ORDERING REPLACEMENT PARTS

When ordering parts, refer to the drawings and parts lists on

the following pages. Please provide the part description and

part number for all parts you are ordering.

REPAIR INFORMATION

Please call us for an authorization number before returning

any equipment for repair or factory service. We will advise

you of shipping and handling. When you send the equipment, please include the following information:

• Your name/company name

• Your address

• Your phone number

• A description of the problem or the work to be done.

WARRANTY INFORMATION

RETURN GOODS ADDRESS

E.H. Wachs Part No. 14-MAN-35, Rev. 0-0616 25

HPU-20 Hydraulic Power Unit

Before we perform any repair, we will estimate the work

and inform you of the cost and the time to complete it.

WARRANTY INFORMATION

Enclosed with the manual is a warranty card. Please fill out

the registration card and return to E.H. Wachs. Retain the

owner’s registration record and warranty card for your

information.

RETURN GOODS ADDRESS

Return equipment for repair to the following address.

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, Illinois 60069 USA

26 Part No. 14-MAN-35, Rev. 0-0616 E.H. Wachs

Loading...

Loading...