E.H. Wachs Company

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.wachsco.com

Goliath Guillotine Pipe Saw

User’s Manual

E.H. Wachs Company Part No. 06-150-520-MAN

Rev. 0-0607, June 2007

Revision History:

Version 1 June 2007

Copyright © 2007 E.H. Wachs Company. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs Company.

Goliath Guillotine Pipe Saw

Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Table of Contents

Chapter 1: About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

How to Use The Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Symbols and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operator Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 3: Introduction to the Goliath Guillotine . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Usage and Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Machine Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Chapter 4: Assembly, Disassembly, and Storage. . . . . . . . . . . . . . . . . . . . . . . . . 17

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Long-Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Chapter 5: Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lifting the Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installing the Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Using the Autofeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Mechanical Autofeed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Hydraulic Autofeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Operating the Standard Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Connecting the Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Clamping the Saw to the Workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Operating the Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Removing the Saw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Operating the Machine with the Topside Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connecting the Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connecting Hoses to the TCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connecting Hoses to the Goliath. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Clamping the Saw to the Workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Operating the Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Mechanical Autofeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Hydraulic Autofeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Removing the Saw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Goliath Guillotine Pipe Saw

Chapter 6: Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Grease Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Autoclamp Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Chapter 7: Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Chapter 8: Parts List and Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . 63

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Autofeed Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Return Goods Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 1

About This Manual

Chapter 1, About This Manual

In This Chapter

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain the Goliath Guillotine pipe saw. It includes instructions for set-up,

operation, and maintenance. It also contains parts lists and

diagrams, and troubleshooting instructions to help you

order replacement parts and perform user-serviceable

repairs.

Before operating the Goliath, you should read through this

manual and become familiar with all instructions. At a minimum, make sure you read and understand the following

chapters:

• Chapter 1, About This Manual

• Chapter 2, Safety

• Chapter 3, Introduction to the Goliath Guillotine

• Chapter 5, Operating Instructions

• Chapter 9, Accessories

PURPOSE OF THIS MANUAL

HOW TO USE THE MANUAL

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

EVISION TRACKING

R

If you will be performing service or repairs, make sure you

read and understand these chapters:

• Chapter 1, About This Manual

• Chapter 4, Assembly and Disassembly

• Chapter 6, Routine Maintenance

• Chapter 7, Troubleshooting and Repair.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 1

Goliath Guillotine Pipe Saw

You will also want to refer to Chapter 8, Parts Lists and

Drawings.

HOW TO USE THE MANUAL

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining the equipment.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

equipment.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions.

Refer to it for safety notes and other information.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special alerts and notes. They appear in the outside

column of the page, next to the section they refer to. Make

sure you understand what each symbol means, and follow

all instructions for cautions and warnings.

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

NOTE

This symbol indicates a user notice.

Notices provide additional information to

supplement the instructions, or tips for

easier operation.

2 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 1, About This Manual: Manual Updates and Revision Tracking

MANUAL UPDATES AND REVISION TRACKING

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. Revised chapters will be available for customers. If

you receive revised chapters for your manual, remove the

old chapters from your binder and replace them with the

new chapters.

When a manual is revised, we will update the revision history on the title page and at the bottom of the pages in the

revised chapters. It is important to put the current title page

with the revision history in your manual. This will help you

make sure you have all current information.

You may have factory service or upgrades performed on the

equipment. If this service changes any technical data or

operation and maintenance procedures, we will include

revised sections of the manual when we return the equipment to you. Remove the old chapters from your manual

and replace them with the revised chapters.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@wachsco.com

.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 3

Goliath Guillotine Pipe Saw

4 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 2

Safety

Chapter 2, Safety

The E.H. Wachs Company takes great pride in designing

and manufacturing safe, high-quality products. We make

user safety a top priority in the design of all our products.

WARNING

Read this chapter carefully before operating your Goliath

Guillotine pipe saw. Serious injury or death could result

from improper operation or repair of this equipment.

Repair and/or service to this equipment must only be done

by an authorized and certified dealer.

OPERATOR SAFETY

Follow these guidelines for safe operation of the equipment.

• READ THE OPERA TING MANUAL. Make sure you

understand all setup and operating instructions before

you begin.

• INSPECT MACHINE AND ACCESSORIES. Before

starting the machine, look for loose bolts or nuts, leaking lubricant, rusted components, and any other physical

conditions that may affect operation. Properly maintaining the machine can greatly decrease the chances for

injury.

• ALWAYS READ PLACARDS AND LABELS.

sure all placards, labels, and stickers are clearly legible

Make

In This Chapter

OPERATOR SAFETY

SAFETY LABELS

MACHINE SAFETY

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 5

Goliath Guillotine Pipe Saw

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

• KEEP CLEAR OF MOVING PARTS. Keep hands,

arms, and fingers clear of all rotating or moving parts.

Always turn machine off before doing any adjustments

or service.

• SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry , and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

• KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

NOTICE

This alert indicates a situation that, if not avoided, will

result in damage to the equipment.

IMPORTANT

This alert indicates a situation that, if not avoided, may

result in damage to the equipment.

6 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

SAFETY LABELS

There are two safety labels on the Goliath Guillotine saw.

These are illustrated in Figure 2-1 and Figure 2-2.

Figure 2-1. Observe the warning label for moving

parts hazards.

Chapter 2, Safety: Safety Labels

Figure 2-2. Observe the warning label for blade hazard.

MACHINE SAFETY

Observe the following guidelines for reliable machine operation and care.

• Make sure all hydraulic couplers are wiped clean before

connection.

• Make sure all pressure and return hoses are connected to

the correct couplings.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 7

NOTICE

Failure to follow the instructions for machine safety

could result in damage to the

equipment.

Goliath Guillotine Pipe Saw

• Always replace blades, hydraulic components, and other

parts with replacement parts recommended by the E.H.

Wachs Company.

• Keep the machine lubricated according to the instructions in Chapter 6.

• Make sure the blade is tight before cutting.

• Do not exceed the rated hydraulic flow (see Specifications in Chapter 3).

• Always keep critical tool markings, such as warning

stickers and tags, legible.

• Do not use the saw for applications for which it is not

intended.

• Service and repair should be performed by experienced

personnel only.

8 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 3

Introduction to the

Goliath Guillotine

Chapter 3, Introduction to the Goliath

Read this chapter carefully to become familiar with the

components and features of your Goliath Guillotine pipe

saw.

USAGE AND APPLICATIONS

The Goliath Guillotine is designed to cold-cut pipes, solids,

and multi-stranded casing strings from 16” to 32” (41 to 81

cm) in diameter. The Goliath is easy to set up, even sub-sea,

and is available with an autoclamp option and topside controls for remote operation.

The Goliath Guillotine operates on hydraulic power, with

two heavy-duty hydraulic motors requiring a power source

with 15 gpm flow at 1500 psi (standard) or 15 gpm @ 2000

psi (autoclamp).

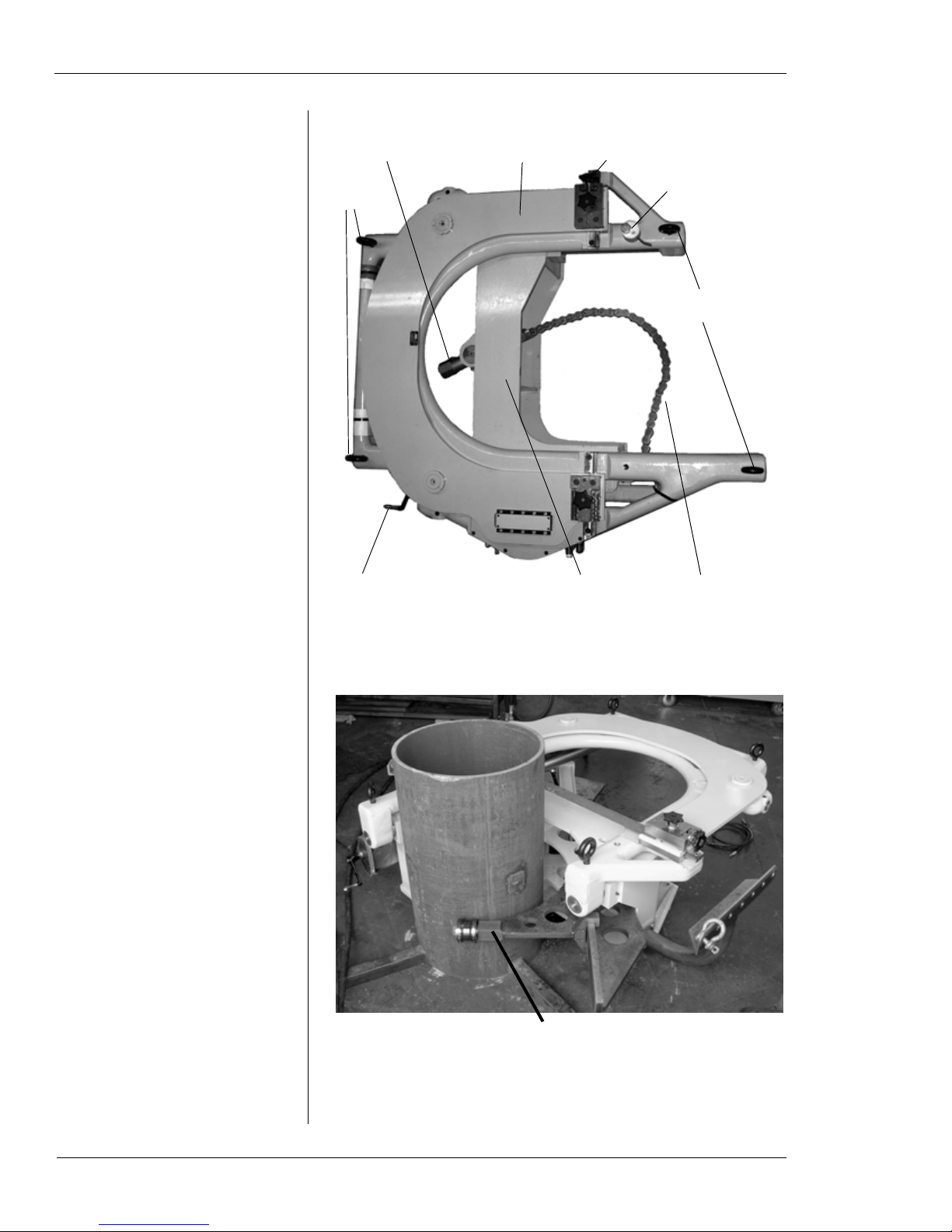

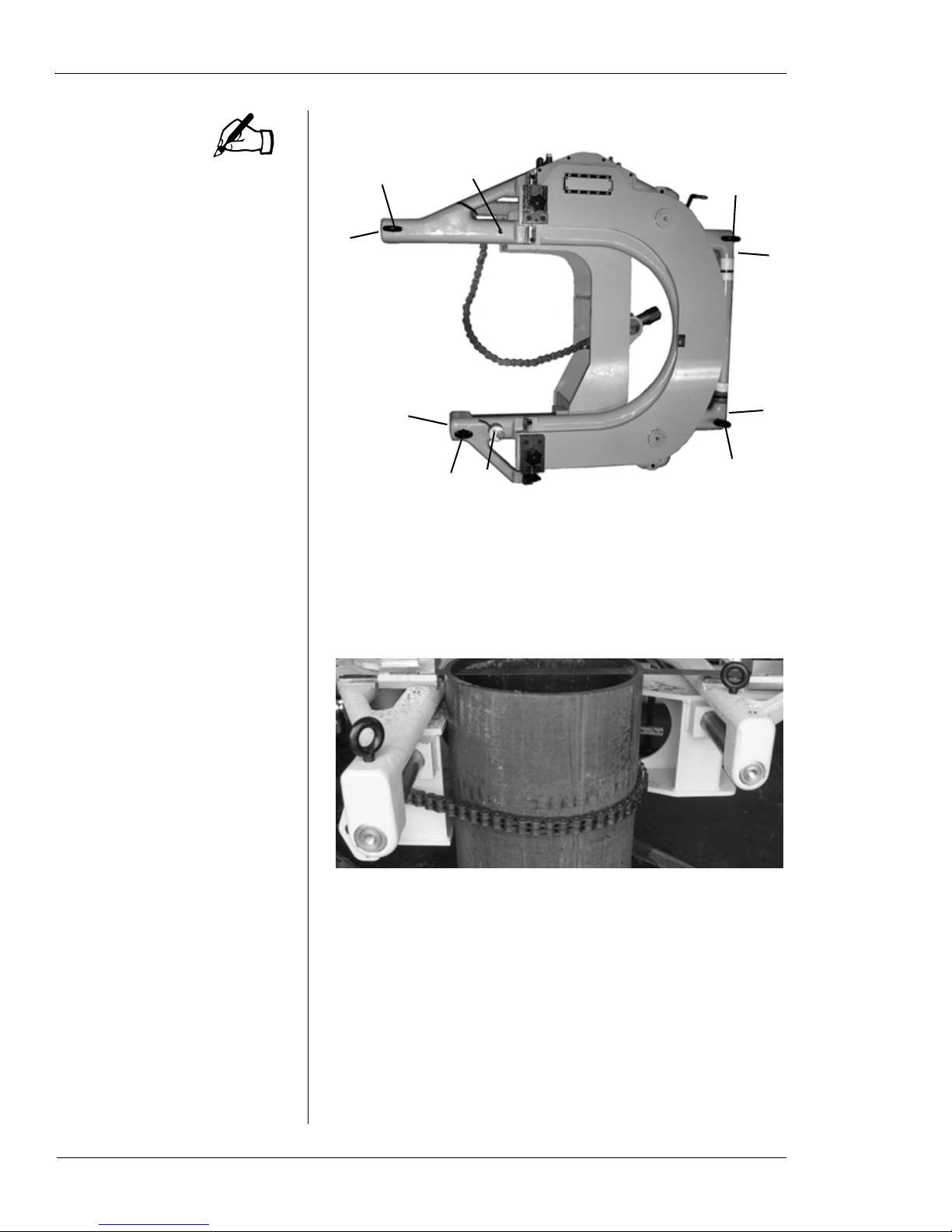

Figure 3-1 illustrates the components of the standard Goliath Guillotine. Figure 3-2 shows the saw with the optional

autoclamp. The autoclamp arm closes under hydraulic

power and holds the pipe in the pipe saddle during cutting.

In This Chapter

USAGE AND APPLICATIONS

MACHINE CONTROL

SPECIFICATIONS

OPERATING ENVELOPE

ACCESSORIES

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 9

Goliath Guillotine Pipe Saw

Chain tension nut

Lift

hooks

Feed handle Pipe saddle Clamping chain

Blade tensionerSaw bow

Coolant nozzle

Lift hooks

Figure 3-1. Components of the standar d Goliath Guillotine are illustrated.

Autoclamp arm

Figure 3-2. Goliath with autoclamp accessory.

10 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 3, Introduction to the Goliath: Machine Control

MACHINE CONTROL

The topside control unit (TCU) provides remote controls for

up to three hydraulic drives. On the Goliath Guillotine, one

drive controls the saw motion, and two are used for options:

the autoclamp mechanism and the hydraulic autofeed.

Instructions for operating the saw using the TCU are in

Chapter 5.

Figure 3-3. The topside control unit (TCU) has controls for the cutting and optional clamping and feed

drives on the Goliath Guillotine. It has inputs for

hydraulic power and separate outputs and controls for

up to three drives.

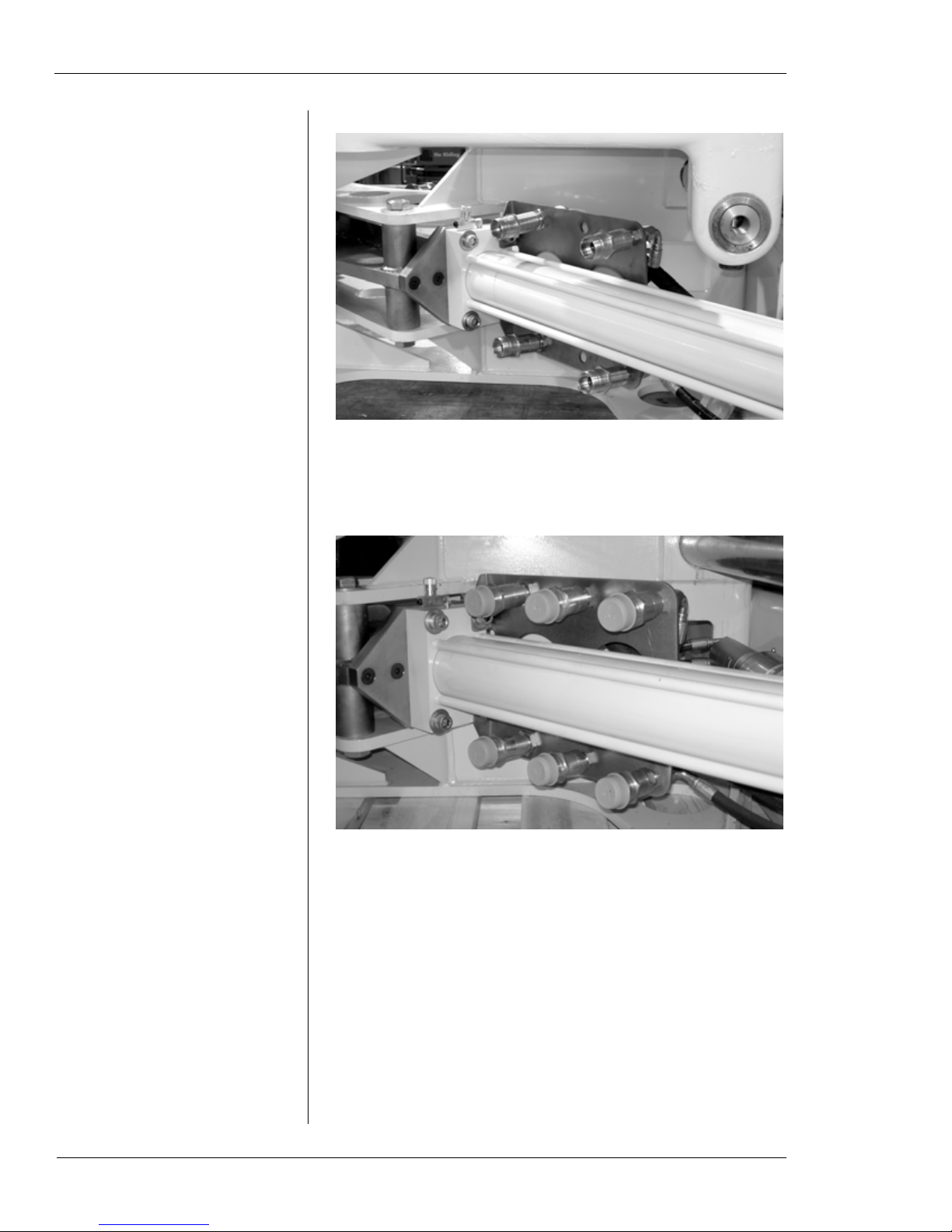

For use with the TCU, the Goliath is fitted with a hydraulic

connector bulkhead, as shown in Figure 3-4 and Figure 3-5.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 11

Goliath Guillotine Pipe Saw

Figure 3-4. A hydraulic fitting bulkhead on the Goliath Guillotine has connectors for operating the autoclamp and cutting drives remotely from the TCU.

12 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 3-5. For Goliath Guillotines with hydraulic

autofeed, the hydraulic fitting bulkhead has connectors for three drives.

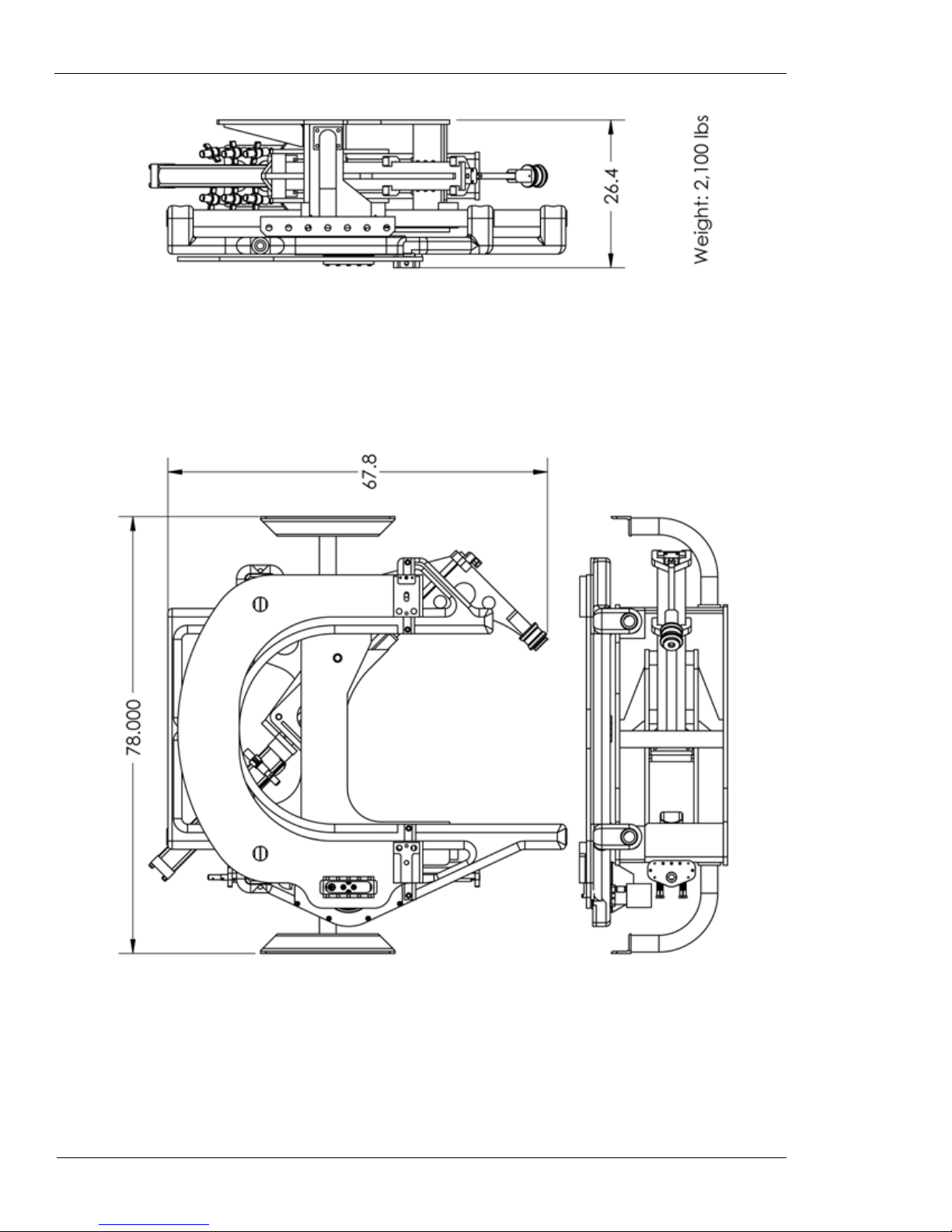

SPECIFICATIONS

Capacity 16-32” (41-82 cm) diameter pipe

Hydraulic Standard: 15 gpm @ 1500 psi

requirements (57 l/m @ 103 bar)

Autoclamp: 15 gpm @ 2000 psi

(57 l/m @ 138 bar)

Feed system Manual or mechanical autofeed

(selectable by operator)

Autofeed rate Low speed: 0.008” (0.020 cm)

(per cycle) High speed: 0.016” (0.041 cm)

Dimensions Length: 76.5” (194 cm)

(standard) Width: 66” (168 cm)

Height: 25” (63.5 cm)

Dimensions Length: 82.5” (210 cm)

(with autoclamp) Width: 78” (198 cm)

Height: 25.9” (65.8 cm)

Chapter 3, Introduction to the Goliath: Specifications

Weight Standard: 1800 lbs (818 kg)

Autoclamp: 2100 lbs (955 kg)

Finish Painted cast surfaces; chrome-plated rods;

other components zinc-nickel iridescent

chromated.

OPERATING ENVELOPE

The drawing in Figure 3-6 shows the operating envelope for

the Goliath Guillotine saw.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 13

Goliath Guillotine Pipe Saw

14 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 3-6. The drawing shows the operating envelope for the Goliath.

Chapter 3, Introduction to the Goliath: Accessories

ACCESSORIES

• Auto-clamp mechanism for easy, remote set-up and

operation.

• Remote control system with topside control unit (TCU)

and hose reel.

• Machine-mounted control panel with hose connector

bulkhead and control levers.

• Hydraulic autofeed drive (controlled using the TCU).

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 15

Goliath Guillotine Pipe Saw

16 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 4

Assembly,

Disassembly, and

Storage

Chapter 4, Assembly, Disassembly, and Storage

In This Chapter

The Goliath Guillotine pipe saw is shipped fully assembled

from the factory, except for the blade and the clamping

chain. It is ready to operate as soon as you remove it from

its shipping pallet.

ENVIRONMENTAL REQUIREMENTS

The Goliath Guillotine can be used in any environment,

including underwater and undersea.

Be sure to follow the environmental guidelines for the

hydraulic power unit you are using with the saw.

LONG-TERM STORAGE

If the saw has been used in salt water, spray it thoroughly

with fresh water to remove salt residue. Grease all grease

fittings before storage, and apply machine oil to the rods,

screw, and gears.

ENVIRONMENTAL

EQUIREMENTS

R

LONG-TERM STORAGE

Strap the saw securely to its shipping pallet. If possible,

store the saw in a dry, non-corrosive environment.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 17

Goliath Guillotine Pipe Saw

18 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5

Operating

Instructions

Chapter 5, Operating Instructions

This chapter includes instructions for three Goliath configurations:

• standard machine

• autoclamp machine with bulkhead for topside control

• autoclamp machine with hydraulic autofeed and bulkhead for topside control.

You should lubricate the Goliath saw before every cut. See

lubrication instructions in Chapter 6.

LIFTING THE SAW

The Goliath is provided with four eye hooks for lifting it

with a crane. There are ten threaded holes in the frame for

mounting eye hooks; put the hooks into the appropriate

holes for the way you are mounting the saw on the workpiece. Specific lifting instructions are included in each section of this chapter.

In This Chapter

LIFTING THE SAW

INSTALLING THE BLADE

USING THE AUTOFEED

OPERATING THE STANDARD

ACHINE

M

OPERATING THE MACHINE WITH

THE TOPSIDE CONTROL UNIT

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 19

Goliath Guillotine Pipe Saw

IMPORTANT

Always leave the

chains and lift

attached to the saw while cutting.

A

G

E

C

I

H

F

B

D

Figure 5-1. Eyebolt locations on the Goliath Guillotine. (Hooks are shown installed in locations A, B, C,

and D.) Location F is also used for the optional coolant nozzle, as shown. Locations G, H, I, and J are on

the ends of the frame, as shown in Figure 5-2 and

Figure 5-3.

G

J

H

20 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 5-2. The eyebolts can be screwed into the

threaded holes G and H on the end of the frame.

Chapter 5, Operating Instructions: Lifting the Saw

J

I

Figure 5-3. Eyebolts can be scr ewed in to the thr eaded

holes I and J in the end of the frame.

To mount the saw on top of a horizontal pipe—

• Connect chains to eyebolts installed in frame locations I

and J and lift the saw in a vertical orientation.

Figure 5-4. Use eyebolt locations I and J to lift the

saw vertically onto a horizontal pipe.

To mount the saw on the side of a horizontal pipe—

• Connect chains to eyebolts installed in frame locations

G and I and lift the saw on its side.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 21

Goliath Guillotine Pipe Saw

Figure 5-5. Use eyebolt locations G and I to mount

the saw on the side of a horizontal pipe.

To mount the saw on a vertical pipe—

• Connect chains to eyebolts installed in frame locations

A, C, and D, and lift the saw in a horizontal orientation.

Figure 5-6. Use eyebolt locations A, C, and D to

mount the saw on a vertical pipe.

22 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Installing the Blade

INSTALLING THE BLADE

Installing the blade on the saw is the same for all configurations of the Goliath. There are two different blades available:

• a coarse blade used for heavy wall or multi-strand pipe

• a fine blade used for thin-wall, single-strand pipe.

Figure 5-7. Goliath Guillotine blade. The mounting

holes at each end are held by the dowel pins in the

clamp blocks.

Mount the saw onto the workpiece before installing the

blade.

CAUTION

Use gloves when

handling blades to

prevent cuts.

There are two blade clamp blocks that hold the blade in

place, one on each end of the saw bow. The block on the

right side (when facing the saddle) has a knob for tensioning

the blade, as shown in Figure 5-8.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 23

Goliath Guillotine Pipe Saw

Clamping knobs

Blade tensioning knob

Figure 5-8. The photos show the clamp blocks on the

Goliath saw bow . The right block (bottom photo) has a

blade tensioning knob.

Unscrew the clamp knob on the left clamp block

1.

almost to the top of the screw. You will need to lift the

block high enough to raise the dowel pins out of the

bow.

24 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Installing the Blade

Figure 5-9. Loosen the clamp knob on the left clamp

block so that you can raise the dowel pins out of the

saw bow.

Holding the block up, slide the end of the blade under

2.

the block so that the hole in the blade is lined up

beneath the dowel pin.

Set the clamp block down with the dowel pin through

3.

the hole in the blade. Tighten the clamp knob with

your fingers until it is just snug.

Unscrew the clamp knob on the right block and lift the

4.

block to insert the other end of the blade.

Set the right block back down with the dowel pin

5.

through the hole in the blade and tighten the clamp

knob until it is just snug.

IMPORTANT

Install the blade so that the

teeth point to the left.

teeth point to left

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 25

Goliath Guillotine Pipe Saw

Figure 5-10. Install the right clamp block on the

blade and snug the clamp knob.

Using the 1-3/8” end wrench, turn the blade tension-

6.

ing knob on the right clamp block to tighten the blade.

Figure 5-11. Tighten the tensioning knob to pull the

saw blade tight.

Use the 1-3/8” wrench to tighten the clamp knobs on

7.

both clamp blocks.

26 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Using the Autofeed

Figure 5-12. Tighten the clamp knob on both clamp

blocks to secure the blade for cutting.

USING THE AUTOFEED

There are two types of autofeed provided with the Goliath

Guillotine: mechanical or hydraulic. Mechanical autofeed

machines can be configured either with on-machine controls or the topside control unit (TCU). Machines with

hydraulic autofeed are controlled using the TCU.

Mechanical Autofeed

The mechanical autofeed mechanism works the same for all

configurations of the Goliath Guillotine. Use this procedure

to engage and disengage the autofeed when cutting with the

saw.

The autofeed is driven from the cam wheel that moves the

saw bow for cutting. A trip pin on the underside of the cam

wheel strikes the feed shaft on each revolution, turning the

shaft and rotating the feed worm gear.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 27

Goliath Guillotine Pipe Saw

Cam wheel

Feed screw Feed worm

Trip pin Feed shaft

Feed worm gear

Figure 5-13. The photo shows the mechanical feed

drive components.

When the autofeed is disengaged, the feed screw turns

freely and does not move the bow. Engaging the autofeed

locks the feed screw, allowing the feed worm gear to index

the bow into the workpiece with each revolution of the

wheel cam.

The feed rate is approximately 0.008” per saw cycle. A second trip pin in the wheel cam allows you to double the feed

rate. With the saw off, slide the second pin down out of the

wheel until it locks in place. The wheel motion will then trip

the feed shaft twice during each saw cycle.

28 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Using the Autofeed

Secondary trip pin

Primary trip pin

Figure 5-14. To double the feed rate, use a pliers to

pull the secondary trip pin down until it snaps into

place. Slide it back up into the cam wheel to set the

feed rate back to the standard speed.

Make sure the autofeed is disengaged when starting

1.

the saw motion. The feed lockout pin will be pushed

in to disengage the feed.

Figure 5-15. Push the feed lever up to the disengaged

position and push in the lockout pin.

Engage power to the saw according to the instructions

2.

in the appropriate section below.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 29

Goliath Guillotine Pipe Saw

With the saw running, pull out the lockout pin to

3.

release the feed lever.

Figure 5-16. Pull out the lockout pin and release the

feed lever to engage the autofeed.

The feed screw will turn until the autofeed notch

4.

engages the lockout pin. The pin will hold the feed

screw stationary, allowing the saw bow to advance.

Hydraulic Autofeed

The hydraulic autofeed is operated using the feed controls

on the topside control unit (TCU). A separate hydraulic

motor turns the autofeed drive, with the speed set independently of the cutting speed.

The hydraulic autofeed mechanism is shown in fig. Instructions for operating the hydraulic autofeed are in the section

of this chapter titled “Operating the Machine with the Topside Control Unit”.

30 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Operating the Standard Machine

Figure 5-17. The hydraulic autofeed mechanism is

shown. The feed can be driven using a wrench on the

hex end of the clevis.

OPERATING THE STANDARD MACHINE

Follow the instructions in this section to set up and operate

the standard Goliath Guillotine (configured without autoclamp or topside controls).

Connecting the Hoses

Connect the hydraulic pressure hose to the pressure

1.

side connector (with the flow bypass valve) on the

saw.

Connect the return hose to the return side connector on

2.

the saw.

There is no flow/

speed control on

the standard Goliath. If your HPU does not

have speed control, call E.H.

Wachs Company to request

an optional flow control valve

assembly.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 31

Goliath Guillotine Pipe Saw

Pressure side (from HPU)

Flow valve (in bypass position)

Return side (to HPU)

Figure 5-18. Connect the hydraulic hoses to the connectors on the Goliath. When the flow valve is in the

bypass position (as shown), the saw motion is disabled.

IMPORTANT

It is recommended

that you mount the

saw to the workpiece without

the blade installed. The blade

could be damaged if the saw

strikes the workpiece during

positioning.

Clamping the Saw to the Workpiece

Before mounting the saw on the workpiece, make sure the

bow is fully retracted. If necessary, turn the manual feed

handle clockwise until it tops out.

32 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Operating the Standard Machine

Figure 5-19. If necessary, turn the feed handle clockwise to retract the saw bow before mounting the saw.

Attach the saw to a crane or lift as described in “Lift-

1.

ing the Saw” earlier in this chapter.

Lift the saw and position it so that the saddle is against

2.

the workpiece. Wrap the clamping chain around the

workpiece and pull it snug.

Figure 5-20. With the crane holding the saw in place,

wrap the clamping chain around the workpiece.

Insert the closest cross pin of the chain into the clamp

3.

screw hook.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 33

Goliath Guillotine Pipe Saw

Figure 5-21. Insert the chain cross pin into the screw

hook.

Tighten the clamping chain as tight

as you can get it

with the end wrench.

Using a 2-1/2” end wrench supplied with the saw,

4.

tighten the chain tensioning nut by turning it clockwise until the chain is secure.

Figure 5-22. Turn the chain tensioning nut clockwise

to secure the saw to the workpiece.

34 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Release the crane slightly to allow the clamping chain

5.

to support the weight of the saw. Leave the crane

attached to the saw while cutting.

Operating the Saw

Chapter 5, Operating Instructions: Operating the Standard Machine

Make sure the flow valve on the saw is set to the

1.

bypass (off) position.

Flow valve in bypass (off) position

Figure 5-23. Make sure the flow valve is off before

starting the saw.

Make sure the autofeed lever is disengaged, with the

2.

feed lockout pin pushed in.

WARNING

IMPORTANT

Always support

the workpiece

securely on both sides of the

cutting location. Any unsecured section of the workpiece could shift or fall during

cutting, damaging the equipment or causing injury to an

operator.

NOTICE:

The lifting device

should be attached

to the saw during cutting, but

make sure there is slack in

the chain at all times.

Figure 5-24. The feed lever should be disengaged and

the lockout pin pushed in.

Turn on the hydraulic power unit and ensure that it is

3.

operating at 1500 psi (103 bar).

Slowly open the flow valve on the saw to start the cut-

4.

ting motion. Open the valve all the way.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 35

Goliath Guillotine Pipe Saw

Figure 5-25. Open the flow valve (up position) to

engage the saw cutting motion.

See “Using the

Autofeed” earlier in

this chapter.

To engage the cut, pull out the autofeed lockout pin to

5.

release the feed lever. The feed screw will engage and

the bow will index into the workpiece.

If the saw binds or chatters while cutting, disengage

6.

the autofeed for a few cycles.

When the cut is complete, disengage the autofeed.

7.

Turn off power to the saw by closing the flow valve

8.

(bypass position).

You may need to

remove the blade

before retracting

the bow.

36 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 5-26. Close the flow valve to stop the saw.

Using the feed handle on the end of the feed screw,

9.

retract the saw bow fully from the workpiece.

Chapter 5, Operating Instructions: Operating the Standard Machine

Feed handle

Figure 5-27. T urn the feed handle clockwise to r etract

the saw bow. (Note that the handle can be mounted on

either end of the feed screw. Turn it counter-clockwise

if it is on the saddle end of the screw.)

Removing the Saw

Raise the crane or lift to put tension on the chains

1.

holding the saw.

Using the 2-1/2” end wrench, loosen the chain ten-

2.

sioning nut by turning it counter-clockwise. Turn the

nut all the way back to release the chain.

WARNING

IMPORTANT

Be sure the crane

is supporting the

saw before you loosen the

clamping chain. The saw

could shift or fall, injuring an

operator or damaging the

equipment.

Figure 5-28. Turn the chain tensioning nut counterclockwise to loosen the chain.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 37

Goliath Guillotine Pipe Saw

Remove the chain cross pin from the screw hook and

3.

unwrap the chain from the workpiece.

Carefully move the saw away from the workpiece

4.

with the crane.

OPERATING THE MACHINE WITH THE TOPSIDE

CONTROL UNIT

This section describes how to install and operate the saw

using the topside control unit (TCU).

Brief instructions for operating the TCU are on the instruction label on the top of the unit.

Figure 5-29. Instruction label on the topside control

unit.

Connecting the Hoses

Connecting Hoses to the TCU

Wipe all hose couplers with a clean, lint free cloth

1.

before making connections.

Connect the hoses from the hydraulic power unit

2.

(HPU) to the HPU fittings on the back of the topside

control unit (TCU).

38 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

HPU FITTINGS

PressureReturn

Figure 5-30. HPU hose fittings on the back of the

control unit.

Connect the cutting drive hose set from the machine or

3.

from the hose reel to the cutting drive fittings on the

back of the TCU. The hoses and fittings are color

coded.

Figure 5-31. Connect the cutting drive hoses to the

TCU.

If the machine has a hydraulic clamping mechanism,

4.

connect the clamping drive hose set to the clamping

drive fittings on the back of the TCU. The hoses and

fittings are color coded.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 39

PressureReturn

CUTTER DRIVE

Goliath Guillotine Pipe Saw

CLAMPING DRIVE

Figure 5-32. Connect the clamping drive hoses to the

TCU (for machines with hydraulic clamping mechanism).

If your Goliath Guillotine is equipped with a hydraulic

5.

feed drive, connect the feed drive hose set to the feed

drive fittings on the back of the TCU.

PressureReturn

40 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

PressureReturn

FEED DRIVE

Figure 5-33. Feed drive connectors (for machines

with hydraulic feed drives).

Connecting Hoses to the Goliath

Connect the clamping drive hoses from the TCU or

1.

hose reel to the fittings on the saw bulkhead as shown

in Figure 5-34.

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Clamping drive pressure

Clamping drive return

Figure 5-34. Connect the clamping drive hoses to the

saw as shown.

Connect the cutting drive hoses from the TCU or hose

2.

reel to the fittings on the saw bulkhead as shown in

Figure 5-35.

Cutting drive pressure

Cutting drive return

Figure 5-35. Connect the cutting drive hoses to the

saw as shown.

For machines with hyraulic autofeed, connect the

3.

autofeed drive hoses from the TCU or hose reel to the

fittings on the saw bulkhead as shown in Figure 5-36.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 41

Goliath Guillotine Pipe Saw

Autofeed drive pressure

Autofeed drive return

Figure 5-36. Connect the hydraulic autofeed drive

hoses to the saw as shown.

Clamping the Saw to the Workpiece

Position the saw at the cutting location on the pipe,

1.

with the saddle against the pipe surface.

Start the hydraulic power unit.

2.

Make sure that the clamping drive levers and the cut-

3.

ting drive lever on the TCU are in the closed (up) position, as shown in Figure 5-37.

Set the clamping direction lever on the TCU to the

4.

ENGAGE position.

42 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Figure 5-37. Before clamping, make sure that both

clamping levers and the cutting lever are in the up

position, and that the clamping direction lever is in the

ENGAGE position.

Open both clamping drive levers (down position) at

5.

the same time to engage the autoclamp drive. When

the clamp pressure equalizes with the system pressure,

the clamp is fully engaged against the pipe.

Figure 5-38. Put both clamping levers down at the

same time to engage the clamping drive.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 43

Goliath Guillotine Pipe Saw

Close both clamping drive levers (up position) at the

6.

same time. The valves will hold pressure on the

clamping drive to keep the saw clamped on the pipe.

Figure 5-39. When the clamping drive is fully

engaged (clamping pressure equals system pressure),

return both clamping levers to the up position.

WARNING

IMPORTANT

Always support

the workpiece

securely on both sides of the

cutting location. Any unsecured section of the workpiece could shift or fall during

cutting, damaging the equipment or causing injury to an

operator.

Slightly lower the crane holding the saw to allow the

7.

clamp to hold the saw’s weight. Leave the crane

attached to the saw.

Operating the Saw

Make sure the cutting drive speed control lever is set

1.

to 0.

Figure 5-40. Set the cutting drive speed lever to 0

before starting the saw.

44 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Open the cutting drive lever (down position).

2.

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Figure 5-41. Push the cutting drive lever down to

open it.

Move the cutting drive speed lever up gradually.

3.

When sufficient flow reaches the saw, the saw bow

will begin the cutting motion.

Figure 5-42. Push the cutting speed lever up slowly

until the saw motion begins.

Mechanical Autofeed

Egage the autofeed mechanism, or feed the saw manu-

1.

ally into the pipe.

Set the cutting drive lever for the speed you want.

2.

Typically, you can set it to the maximum.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 45

Goliath Guillotine Pipe Saw

Figure 5-43. Set the cutting speed lever to the desired

cutting speed.

If the saw begins to chatter or bind, slow the cutting

3.

speed lever.

When the cut is complete, set the cutting speed lever

4.

back to 0. Close the cutting drive lever by moving it to

the up position.

46 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 5-44. When the cut is complete, set the cutting

speed lever back to 0. Then return the cutting drive

lever to the off (up) position.

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Using the feed handle on the end of the feed screw,

5.

retract the saw bow fully from the workpiece.

Feed handle

Figure 5-45. T urn the feed handle clockwise to r etract

the saw bow. (Note that the handle can be mounted on

either end of the feed screw. Turn it counter-clockwise

if it is on the saddle end of the screw.)

You may need to

remove the blade

before retracting

the bow.

Hydraulic Autofeed

Set the feed direction lever to the FORWARD posi-

1.

tion, as shown in Figure 5-46.

Open the feed drive lever by pushing it down.

2.

Adjust the feed speed lever until the feed motion

3.

starts. Set the lever to the desired speed.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 47

Goliath Guillotine Pipe Saw

Figure 5-46. With the feed direction lever in the FORW ARD position, move the feed drive lever (shown her e

in the up position) down to start the drive. Then move

the feed speed lever to start flow to the feed drive.

Set the cutting drive lever for the speed you want.

4.

Typically, you can set it to the maximum.

Figure 5-47. Set the cutting speed lever to the desired

cutting speed.

48 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Allow the saw to operate at a slow feed rate until the

5.

blade has parted through the near wall of the pipe.

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Oscillating bow

Blade

Frame

Pipe

Figure 5-48. Cut at a slow feed rate until the blade

parts through the wall of the pipe.

After the blade has parted the near wall, you can speed

6.

up the feed rate by adjusting the feed speed lever . You

may need to slow the rate down if you are cutting an

internal casing. Reduce the feed speed if the machine

starts to bind or chatter, or if you see the blade deflecting as it cuts.

As the blade approaches the far wall of the pipe, slow

7.

the feed rate to the setting used at the start. Finish the

cut at this feed rate.

When the cut is complete, move the feed speed lever

8.

back to 0 to stop the feed motion.

Figure 5-49. Stop the feed motion by setting the feed

speed lever back to 0.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 49

Goliath Guillotine Pipe Saw

Move the feed drive lever back to the up position.

9.

Figure 5-50. Move the feed drive lever up to stop the

feed motion.

Set the cutting speed lever back to 0, and pull the cut-

10.

ting drive lever back up to the off (up) position.

50 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Figure 5-51. When the cut is complete, set the cutting

speed lever back to 0. Then return the cutting drive

lever to the off (up) position.

To reverse the feed and move the saw bow back to the

11.

start position, set the feed direction lever to the

REVERSE position and use the feed drive lever to

operate the drive. You may have to remove the blade

first to prevent it from binding on the pipe.

Removing the Saw

Slowly raise the lift holding the saw until there is just

1.

enough tension to hold the saw in place.

Set the clamping direction lever to the RETRACT

2.

position.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 51

Goliath Guillotine Pipe Saw

Figure 5-52. Set the clamping direction lever to the

RETRACT position.

Open both clamping drive levers (down position) at

3.

the same time to retract the autoclamp drive. When the

clamp pressure equalizes with the system pressure, the

clamp is fully retracted.

52 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 5-53. Put both clamping levers down at the

same time to retract the clamping drive.

Close both clamping drive levers (up position) at the

4.

same time.

Chapter 5, Operating Instructions: Operating the Machine with the Topside Control Un it

Figure 5-54. When the clamping drive is fully

retracted (clamping pressure equals system pressure),

return both clamping levers to the up position.

Set the clamping direction lever back to the ENGAGE

5.

position for the next operation.

Figure 5-55. When the clamp has been retracted,

move the clamping direction lever back to the

ENGAGE position.

Use the crane to remove the saw from the workpiece.

6.

If you are finished with the saw , turn off the HPU. Set

7.

the saw in its storage location and disconnect the

hoses.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 53

Goliath Guillotine Pipe Saw

54 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 6

Routine Maintenance

Chapter 6, Routine Maintenance

Grease all grease points on the Goliath Guillotine every

time you use the machine.

GREASE POINTS

Grease the fittings in the following locations on the Goliath:

• Two on top of the saw bow (one on each side)—

Figure 6-1.

In This Chapter

GREASE POINTS

Figure 6-1. Ther e are two gr ease fittings on the top of

the saw bow.

• Two on the feed drive side of the frame for the frame

guide shaft—Figure 6-2.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 55

Goliath Guillotine Pipe Saw

Figure 6-2. Fittings on the feed drive side of the

frame. (The saw bow is fed all the way forward.)

• Two on the open side of the frame for the frame guide

shaft—Figure 6-3.

56 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 6-3. Grease fittings for the frame guide shaft

on the open side of the frame.

• One on the gear shaft housing—Figure 6-4.

Figure 6-4. Fitting on the gear shaft housing.

• Nine on the feed drive assembly—Figure 6-5:

—two on the feed frame for the feed screw (one each

end)

—one on the feed slide housing for the feed screw

—six on the feed shaft mount.

Chapter 6, Routine Maintenance: Grease Points

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 57

Goliath Guillotine Pipe Saw

Figure 6-5. There are two fittings on the ends of the

feed frame (top photo), and six fittings on the feed

shaft mount and one on the feed slide housing (bottom

photo).

58 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Figure 6-6. There are two grease fittings on the

optional hydraulic autofeed motor.

Also apply grease to the bow guide plate at the ends of the

frame. Use a brush or a clean, dry cloth to wipe grease onto

the plates.

Figure 6-7. Gr ease the bow guide plates on both sides

of the frame (one side shown).

Autoclamp Lubrication

Chapter 6, Routine Maintenance: Grease Points

• Grease the clamp wheel fitting on the autoclamp arm.

• Apply grease to the autoclamp rail with a brush or clean

cloth.

Grease the autoclamp rail

Figure 6-8. Grease the fitting for the clamping wheel

and apply grease to the autoclamp rail.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 59

Goliath Guillotine Pipe Saw

60 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 7

Service and Repair

Chapter 7, Service and Repair

The Goliath Guillotine does not have any user-serviceable

parts. If the machine is not operating correctly, contact E.H.

Wachs Company service for repair.

TROUBLESHOOTING

Refer to the troubleshooting procedures in Table 1.

In This Chapter

TROUBLESHOOTING

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 61

Goliath Guillotine Pipe Saw

Symptom Potential Cause Solution

Table 1: Goliath Troubleshooting

Machine Loose on Pipe

(Chain Clamp)

Clamp nut not tight Re-torque chain tension nut

Chain tensioner at max travel Loosen tensioner and relocate

chain hook to next tighter pin

Machine Loose on Pipe

(Autoclamp)

Low clamp pressure With machine stopped, re-

energize clamp valve

Low HPU pressure Make sure system pressure

from HPU is at least 2,000 psi

Cut Not Flat Blade is dull or damaged Replace with new blade

Wrong blade Replace with correct blade

Blade is not tight Tension blade and lock in

place

Feed rate too fast Lower feed rate to one trip

pin or slower speed on TCU

Feed overload improper Reduce spring pressure on

feed lock pin

Machine Stalling Cutter blade is binding See procedures under “Cut

Not Flat” above

Low hydraulic system pressure

Make sure system pressure

from HPU is at least 2,000 psi

Slide ways are damaged Inspect guide rods and ways

for damage, debris, or lack of

lubrication

62 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 8

Parts List and

Ordering Information

Chapter 8, Parts List and Ordering

In This Chapter

PARTS LIST

Refer to parts lists on the following pages for ordering

spare and replacement parts.

PARTS LIST

AUTOFEED DRAWING

ORDERING INFORMATION

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 63

Goliath Guillotine Pipe Saw

BASE MACHINE

Qty. Part No. Description

1 04-045-00 HANDLE, FEED (MODEL "D")

1 05-011-002 FEED HOUSING

1 05-011-013 FEED TOWER

2 05-011-014 PLATE, FEED TOWER REAR END

1 05-011-015 PLATE, FEED TOWER FRONT END

2 05-011-016 GIB, FEMALE FEED

1 06-052-015 PLATE, BULKHEAD MOUNTING

1 06-052-048 SCREW, FEED

1 06-052-049 SADDLE

1 06-052-050 WELDMENT, SADDLE

1 06-052-051 SLIDE, CLAMP

1 06-052-052 WELDMENT, CLAMP SLIDE

1 06-052-053 SLIDE

1 06-052-054 WELDMENT, SLIDE

1 06-052-055 PLATE, CLAMP MOTOR MOUNT

1 06-052-056 WHEEL, CLAMP

1 06-052-057 WASHER, CLAMP WHEEL

2 06-052-058 WELDMENT, LIFTING ARM

1 06-052-059 ADAPTER, HANDLE

1 06-052-060 BLOCK, RAIL LOCKDOWN

1 06-052-350 PLATE, SADDLE FRONT

2 06-052-351 PLATE, SADDLE MID RIB

1 06-052-352 PLATE, SADDLE REAR

1 06-052-353 PLATE, SADDLE SPREADER 1

1 06-052-354 PLATE, SADDLE SPREADER 2

1 06-052-355 PLATE, SADDLE SPREADER 3

1 06-052-356 PLATE, SADDLE SPREADER 4

1 06-052-357 PLATE, SADDLE SPREADER 5

1 06-052-358 PLATE, SADDLE SPREADER 6

1 06-052-359 BLOCK, SADDLE GUIDE - LARGE

1 06-052-360 BLOCK, SADDLE GUIDE - SMALL

1 06-052-361 PLATE, CLAMP WELDMENT SLIDE

1 06-052-362 PLATE, CLAMP WELDMENT STIFF BACK

2 06-052-363 POST, CLAMP WELDMENT

1 06-052-364 PLATE, SLIDE BOW

2 06-052-365 PLATE, SLIDE END

1 06-052-366 SHAFT, CLAMP SLIDE

1 06-052-367 BLOCK, CYLINDER SPACER

1 060-52-368 PLATE, SADDLE GUSSET

64 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 8, Parts List and Ordering: Parts List

1 06-052-369 PLATE, LIFTING ARM

1 06-052-370 TUBE, LIFTING ARM

1 06-052-371 BRACKET, LIFTING ARM

2 97-009-07 RETAINER, PINION GEAR

1 98-037-011A FRAME, MAIN

1 98-037-012 FRAME, BOW

1 05-011-018 CLAMP, BLADE PULL

2 98-037-014 BOLT, BLADE CLAMP

1 98-037-015 KNOB, BLADE TENSION

1 05-011-019 CLAMP, BLADE TENSION

2 05-011-020 ADAPTER, BLADE

1 98-037-017 GUIDE, TENSION CLAMP

1 98-037-020 SHAFT-S, FRAME GUIDE

1 98-037-021 SHAFT-L, FRAME GUIDE

2 98-037-023 BLOCK, BOW SLIDE

2 06-150-053 NUT, TRUNION

2 98-037-024 SHAFT, BOW SLIDE

1 98-037-025 YOKE, BOW FEED

1 98-037-026 COVER, FEED YOKE

1 98-037-027 SHAFT, GEAR

1 98-037-028 GEAR

2 98-037-029 GEAR, PINION

1 98-037-030B WHEEL, CAM

1 98-037-031 HOUSING, GEAR SHAFT

1 98-037-032 COVER, GEAR

2 98-037-034 LUG, LIFTING

1 98-037-038 RETAINER, FEED SCREW

1 98-037-039 BUSHING, FEED SCREW

2 98-037-042 RETAINER, WORM GEAR

1 98-037-045 HOUSING, FEED SLIDE

1 98-037-047 MOUNT, FEED SHAFT

2 98-037-049 PLATE, MALE GUIDE

2 98-037-050 GUIDE, BOW - FEMALE

1 98-037-056 SPACER, CAM FOLLOWER - BOW

1 98-037-057 STICKER, LIFTING HARNESS

4 98-037-058 BUSHING, GUIDE ROD

2 98-037-059 KNOB, BLADE CLAMP

1 98-037-61 CHIP REMOVER

3 1/4" DIA X 2" LONG BRASS TUBING BENT AT 45 DEG

1 98-037-65 STICKER, LUBRICATION

1 98-037-070 WASHER, THRUST

2 MOTOR,146cm/r x 1"Shaft x 7/8-14Port x 2Blt

1 BEARING, 1" x 1-1/8" x 3/4" LG. SLEEVE

4 BEARING, 2" x 2-3/16" x 1-1/2" LG. SLEEVE

1 BEARING, 1.9685 x 3.5433 BALL

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 65

Goliath Guillotine Pipe Saw

1 BEARING, 2.3622 x 4.3307 BALL

2 BEARING, 2.0 x 1.25 x 1-1/8-12 THD. CAM

1 SEAL, 8.0 x 9.0 x .625

1 SEAL, 1.938 x 3.543 x .313

2 REF. NUT, 5/8 W. x 2.548-18 THD. LOCK

1 RING, 3.0 x .061 EXTERNAL RETAINING

1 RI NG, 3. 543 x .061 INTERNAL RETAINING

1 RING, 1.969 x .062 EXTERNAL RETAINING

1 RING, 2.375 x .078 EXTERNAL RETAINING

4 O-RING 3-1/4 ID x 3/32 STD.

1 O-RING 3-3/4 ID x 1/8 STD.

1 O-RING 7-1/2 ID x 1/8 STD.

6 EYE-BOLT, 1"-8 THD. X 1-3/4 ID

2 K NOB, BLADE CLAMP

1 K NOB, BLA DE TENSIONER

11 FITTING, 1/4-28 MALE GREASE (STAIGHT)

1 FITTING, 90 DEG. 3/4-14 NPT (M) x 1 1/16-12 JIC (M)

1 FITTING, TEE-MALE 3/4-14 NPT (M) x (M) x (M)

2 FITTING, STR. 7/8-14 ORB (M) x 3/4-14 NPT (F)

2 FITTING, STR. 1 1/16-12 JIC (M) x 7/8-14 ORB (M)

2 FITTING, SWIVEL 90 DEG. 1 1/16-12 JIC (M) x (F)

1 F ITTING, TEE-M ALE 3/4-14 NPT (M) x (M) x 3/4-14 NPT (F)

1 FITTING, 3/4-14 NPT (M) x 1 1/16-12 JIC (M)

1 HIGH PRESSURE BALL VALVE 3/4 NPT

1 98-037-63 HOSE, 3/4" H.P. HYD. -12 JIC (F) x (F) x 17" OA LG.

1 98-037-64 HOSE, 3/4" H.P. HYD. -12 JIC (F) x (F) x 30" OA LG.

1 90 DEG STREET ELBOW 3/8" PIPE SIZE STAINLESS STEEL

2 GALVANIZED PIPE 3/8" X 3" LONG STAINLESS STEEL

2 EYE-BOLT, 1/2-13 X 1-3/16 LG" ID

1 OBLONG SLING LINK 1/2" STOCK DIAMETER

5 ANCHOR SHACKLES 3/8" STOCK Diameter

1 FLAT PROFILE GRAB HOOKS 5/16" CHAIN SIZE

15 CHAIN 5/16" (SOLD IN FOOT LENGTH)

1 1/8" NPT BRASS DRAIN COCK

1 HYDRAULIC CYLINDER 26" STROKE

2 FITTING, BULKHEAD -8 JIC(M) x -8 NPT (M)

2 FITTING, BULKHEAD -12 JIC(M) x -12 NPT(M)

2 NUT, BULKHEAD -8

2 NUT, BULKHEAD -12

2 QUICK DISCONNECT, 1/2" NPT(F) x 3/4" BODY MALE W/ FLANGE

2 QUICK DISCONNECT, 3/4" NPT(F) x 3/4" BODY MALE W/FLANGE

2 NEEDLE VALVE, 1/8" NPT

2 FITTING, ADAPTER 1/8" NPT(M) x 1/8" NPT(M) -90 DEG

4 ZINC ANODE

4 S HOULDER SCREW,1" x 4" LG. (18-8 STAINLESS STEEL)

66 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 8, Parts List and Ordering: Parts List

2 PIN, 1/4 x 5/8 LG DOWEL

4 PIN, 5/16" x 1-1/4" LG. DOWEL

2 PIN, 5/16" x 1-1/2" LG. DOWEL

4 PIN, 3/8" x 1-1/2" LG. DOWEL

1 PIN, 1/2" x 1" LG. DOWEL

3 PIN, 1/2" x 1-1/4" LG. DOWEL

8 P IN, 1/2 x 1-1/2" LG. DOWEL

2 PIN, 3/4" x 1" LG. DOWEL

2 PIN, 1" x 2" LG DOWEL

2 PIN, 1" x 2-1/2" LG DOWEL

2 PIN, 1/4" x 1-1/2" LG. ROLL (18-8 STAINLESS STEEL)

4 P IN, 3/4" x 3" LG. RO LL

2 SHCS, 3/8-16 x 2-1/4" LG. (18-8 STAINLESS STEEL)

6 SHCS, 1/2-13 x 1-1/4" LG. (18-8 STAINLESS STEEL)

4 SHCS, 1/2-13 x 1-1/2" LG. (18-8 STAINLESS STEEL)

4 SHCS, 1/2-13 x 3" LNG. (18-8 STAINLESS STEEL)

4 SHCS, 1/2-20 x 1-1/4" LG. (18-8 STAINLESS STEEL)

1 HHCS, 3/4-16 x 2-1/2" LNG - SS

2 FHCS, 1/4-20 x 7/8" LG. (18-8 STAINLESS STEEL)

7 FHCS, 5/16-18 x 1-1/4" LG. (18-8 STAINLESS STEEL)

8 FHCS, 1/2-13 x 1-1/2" LG. (18-8 STAINLESS STEEL)

4 FHCS, 1/2-20 x 1-1/2" LG. (18-8 STAINLESS STEEL)

6 FHCS, 1/2-13 x 1-3/4 (18-8 STAINLESS STEEL)

4 FHCS, 1/2-13 x 2-1/2" LNG. (18-8 STAINLESS STEEL)

2 FHCS, 3/4-10 x 4" LG. (18-8 STAINLESS STEEL)

10 HHCS, 3/8-16 x 1-1/4 (18-8 STAINLESS STEEL)

12 HHCS, 1/2-13 x 2" LNG. (18-8 STAINLESS STEEL)

4 HHCS-SS, 1/2-20 x 2-1/2" LG. (18-8 STAINLESS STEEL)

2 HHCS-SS, 3/4-16 x 3-1/2" LG. (18-8 STAINLESS STEEL)

1 HHCS, 1-8 x 2" LNG. (18-8 STAINLESS STEEL)

4 HHCS, 1-8 x 2-1/2" LNG. (BUMAX 109 MATERIAL)

2 HHCS-SS, 1"-8 x 3-1/2" LG. (18-8 STAINLESS STEEL)

4 HHCS, 1/2-13 x 1-3/4" LNG. (18-8 STAINLESS STEEL)

4 BHCS, 10-24 x 3/8 (18-8 STAINLESS STEEL)

4 WASHER, 1" (18-8 STAINLESS STEEL)

24 WASHER, 1/2" (18-8 STAINLESS STEEL)

8 LOCK WASHER, SPLIT RING 1/2" (18-8 STAINLESS STEEL)

8 NUT, HEX 1/2-13 (18-8 STAINLESS STEEL)

1 NUT, HEX JAM 3/4-16 (316 SS)

Qty. Part No. Description

1 98-037-035 LEVER, FEED CONTROL

1 98-037-036 PIN, FEED LOCK-OUT

1 98-037-037 CAM, FEED OVERLOAD

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 67

MECHANICAL AUTOFEED (DEFAULT)

Goliath Guillotine Pipe Saw

1 98-037-040 WORM, FEED

1 98-037-041B GEAR, WORM FEED

1 98-037-043 PIN, FEED TRIP

1 98-037-044 SHAFT, FEED

1 SPRING, .60 OD x 2.500 LG. x .085

1 SWING-BOLT, 3/8-16 x 3-1/2 LG.

1 KNOB, 1-1/8 x 1-7/16 x 3/8-16 THD. BLACK

1 KNOB, 1" x 1/4-20 THD. BLACK.

1 BEARING, 7/8" x 1" x 1/2" LG. SLEEVE

1 BEARING, 7/8" x 1" x 5/8" LG. SLEEVE

2 BEARING, .875 x 1.5 x .0585 THK. THRUST

1 PIN, 5/16" x 1-1/2" LG. DOWEL

1 PIN, 3/8" x 1-1/2" LG. DOWEL

1 PIN, 1/2" x 1-1/4" LG. DOWEL

1 PIN, 1/2" x 1-3/4" LG. DOWEL

1 PIN, 3/16" x 1-1/4" LG. ROLL (18-8 STAINLESS STEEL)

1 SSS, 3/8-16 x 1-1/4" LG. (18-8 STAINLESS STEEL)

1 NUT, 3/8-16 NYLOCK (18-8 STAINLESS STEEL)

1 WASHER, 1/4" STD. (18-8 STAINLESS STEEL)

HYDRAULIC AUTOFEED (OPTIONAL)

Qty. Part No. Description

1 P06-150-023 NUT, FEED

1 P06-150-024 SPROCKET, FEED SCREW

1 P06-150-025 SPROCKET, MOTOR

1 P06-150-026 HUB, FEED SCREW DRIVE

1 P06-150-027 YOKE, FEED DRIVE

1 P06-150-028 RING, THRUST

1 P06-150-029 COLLAR, FEED SCREW

1 P06-150-030 SHAFT, GEARBOX OUTPUT

1 P06-150-031 PLATE, FEED MOTOR MOUNT

1 P06-150-032 COVER, FEED CHAIN

1 P06-150-033 HUB, FEED SCREW OVERRIDE

6 P06-150-034 SPRING, BELLVILLE

2 P06-150-035 BEARING, BALL (.75 X 1.625 X.438)

2 P06-150-036 GEARBOX, PRIMARY

2 P06-150-037 SPACER, GEARBOX

1 11-103-00 GEARBOX, PLANETARY OUTPUT

1 P06-150-038 MOTOR, FEED

1 P06-052-155 COUPLER, MOTOR INPUT

0 P06-052-156 COUPLER, MATEX (HYD FEED )

0 P06-052-157 COUPLER, MOTOR (HYD FEED)

1 P06-052-159 HOUSING, FEED BOX INPUT

1 P06-052-150 HOUSING, FEED BOX OUTPUT

3 P06-150-039 SPACER, FEED CHAIN COVER

68 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 8, Parts List and Ordering: Autofeed Drawing

2 P06-150-040 SPACER, FEED DRIVE POSITIONING

1 P06-052-333 ADAPTER, FEED MOTOR

39 #40 SS ROLLER CHAIN (SOLD BY LINKS)

1 #40 SS CONNECTING LINK

2 PIN, DOWEL 5/16 DIA x 2-1/2 LG

1 PIN, DOWEL 5/16 DIA x 1-3/4 LG

1 PIN, DOWEL 1/4 DIA x 1-3/4 LG

1 SHCS, 1/4-28 x 5/8 (18-8 STAINLESS STEEL)

7 SHCS, 8-32 x 3" LNG. (18-8 STAINLESS STEEL)

4 SHCS, 1/4-20 x 1-1/2" LNG. (18-8 STAINLESS STEEL)

1 KEY, 3/16 x 3/16 x 5/8 LG

1 WASHER, FLAT 3/8 TYPE A WIDE (18-8 STAINLESS STEEL)

1 HHCS, 3/8-16 x 1 LG. (18-8 STAINLESS STEEL)

5 SHCS, M6-1.0 x 20 (18-8 STAINLESS STEEL)

3 HHCS, 1/4-20 x 1-7/8 LNG. (18-8 STAINLESS STEEL)

4 BHCS, 1/4-20 x 1-1/4 LG (18-8 STAINLESS STEEL)

2 NUT, HEX JAM 1/4-20 (18-8 STAINLESS STEEL)

2 SSS, 1/4-28 x 1-1/4 LNG. (18-8 STAINLESS STEEL)

4 HHCS, 5/16-18 x 3/4" LNG. (18-8 STAINLESS STEEL)

TOOLING

Qty. Part No. Description

98-037-414 BLADE, 32" GUILLOTINE 2/3 PITCH

98-037-415 BLADE, 32" GUILLOTINE 3/4 PITCH

AUTOFEED DRAWING

The following drawing illustrates the components of the

hydraulic autofeed mechanism.

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 69

Goliath Guillotine Pipe Saw

70 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

Chapter 8, Parts List and Ordering: Ordering Information

ORDERING INFORMATION

Ordering Replacement Parts

When ordering parts, refer to the parts lists in Chapter 8.

Please provide the part description and part number for all

parts you are ordering.

Repair Information

Please call us for an authorization number before returning

any equipment for repair or factory service. We will advise

you of shipping and handling. When you send the equipment, please include the following information:

• Your name/company name

• Your address

• Your phone number

• A brief description of the problem or the work to be

done.

Before we perform any repair, we will estimate the work

and inform you of the cost and the time required to complete it.

Warranty Information

Enclosed with the manual is a warranty card. Please fill out

the registration card and return to E.H. Wachs Company.

Retain the owner’s registration record and warranty card for

your information.

Return Goods Address

Return equipment for repair to the following address.

E.H. Wachs Company

600 Knightsbridge Parkway

Lincolnshire, Illinois 60069 USA

E.H. Wachs Company Part No. 06-150-520-MAN, Rev. 0-0607 71

Goliath Guillotine Pipe Saw

72 Part No. 06-150-520-MAN, Rev. 0-0607 E.H. Wachs Company

E.H. Wachs Company

600 Knightsbridge Parkway • Lincolnshire, IL 60069

847-537-8800 • www.wachsco.com

Loading...

Loading...