E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

EP 424 End Prep Machine

User’s Manual

E.H. Wachs Part No. 81-MAN-00

Rev. 0-0610, June 2010

Revision History:

Original June 2010

Copyright © 2010 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

EP 424 End Prep Machine

Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protective Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Introduction to the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview of the EP 424 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Form-Tool Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Single-Point Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EP 424 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Drive Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4: Assembly, Disassembly, and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Storage Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 5: Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting the Mandrel on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting the Universal (Standard) Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mounting the Independent Chuck Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using the Drive Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Mounting and Operating the Air Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Mounting and Operating the Hydraulic Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Form Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Planning the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Selecting Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the Tool Holder Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting Up and Mounting the EP 424 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 1

EP 424 End Prep Machine

Assembling the Machine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Removing the Machine from the Workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Single Point Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing the Single-Point Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Planning the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Operating Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Selecting Tool Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Beveling O.D. Set-Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Setting Up and Mounting the EP 424 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Assembling the Machine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Using the Speed Prep Autofeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Compound Bevel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Removing the Machine from the Workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removing the Single-Point Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 6: Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Main Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Felt Wipers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Single-Point Slide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Drive Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Chapter 7: Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adjusting the Single-Point Slide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Tighten the Starwheel Stop Collar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adding/Removing Gib Shims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adjust the Push Plate Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Calibrating the Speed Prep Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Air Motor Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 8: Parts Lists and Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter 9: Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 10: Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2 P art No. 81-MAN-00, Re v. 0-0610 E.H. Wachs

Chapter 1

About This Manual

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain the

EP 424 end prep machine. It includes instructions for setup, operation, and maintenance. It also contains parts lists,

diagrams, and service information to help you order

replacement parts and perform user-serviceable repairs.

Chapter 1, About This Manual

In This Chapter

PURPOSE OF THIS MANUAL

HOW TO USE THE MANUAL

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

EVISION TRACKING

R

Before operating the EP 424, you should read through this

manual and become familiar with all instructions. At a minimum, make sure you read and understand the following

chapters:

• Chapter 1, About This Manual

• Chapter 2, Safety

• Chapter 3, Introduction to the Equipment

• Chapter 5, Operating Instructions

• Chapter 9, Accessories

If you will be performing service or repairs, make sure you

read and understand these chapters:

• Chapter 1, About This Manual

• Chapter 4, Assembly and Disassembly

• Chapter 6, Routine Maintenance

• Chapter 7, Service and Repair.

You will also want to refer to Chapter 8, Parts Lists and

Drawings.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 1

EP 424 End Prep Machine

WARNING

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

CAUTION

HOW TO USE THE MANUAL

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining your equipment.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

equipment.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions.

Refer to it for safety notes and other information.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special notes and warnings. They appear in the outside column of the page, next to the section they refer to.

Make sure you understand what each symbol means, and

follow all instructions for cautions and warnings.

A WARNING alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in seri-

ous injury or death.

A CAUTION alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in

minor or moderate injury.

2 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 1, About This Manual: Manual Updates and Revision Tracking

CAUTION

This is the equipment damage alert

symbol. It is used to alert you to potential equipment damage situations.

Obey all messages that follow this symbol to avoid damaging the equipment or

workpiece on which it is operating.

IMPORTANT

NOTE

NOTE

This symbol indicates a user note. Notes

provide additional information to supplement the instructions, or tips for easier

operation.

A CAUTION alert with the

damage alert symbol indicates a situation that will

result in damage to the

equipment.

An IMPORTANT alert with

the damage alert symbol indicates a situation that may

result in damage to the

equipment.

MANUAL UPDATES AND REVISION TRACKING

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. When a manual is revised, we will update the

revision history on the title page.

You may have factory service or upgrades performed on the

equipment. If this service changes any technical data or

operation and maintenance procedures, we will include a

revised manual when we return the equipment to you.

A NOTE provides supplementary information or operating tips.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@wachsco.com

.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 3

EP 424 End Prep Machine

4 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 2

Safety

E.H. Wachs takes great pride in designing and manufacturing safe, high-quality products. We make user safety a top

priority in the design of all our products.

Chapter 2, Safety

In This Chapter

OPERATOR SAFETY

SAFETY LABELS

Read this chapter carefully before operating the EP 424 end

prep machine. It contains important safety instructions and

recommendations.

OPERATOR SAFETY

Follow these guidelines for safe operation of the equipment.

• READ THE OPERATING MANUAL. Make sure

you understand all setup and operating instructions

before you begin.

• INSPECT MACHINE AND ACCESSORIES.

Before starting the machine, look for loose bolts or

nuts, leaking lubricant, rusted components, and any

other physical conditions that may affect operation.

Properly maintaining the machine can greatly decrease

the chances for injury.

• ALWAYS READ PLACARDS AND LABELS. Make

sure all placards, labels, and stickers are clearly legible

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

• KEEP CLEAR OF MOVING PARTS.

arms, and fingers clear of all rotating or moving parts.

Keep hands,

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 5

EP 424 End Prep Machine

Always turn machine off before doing any adjustments

or service.

• SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry , and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

• KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

6 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

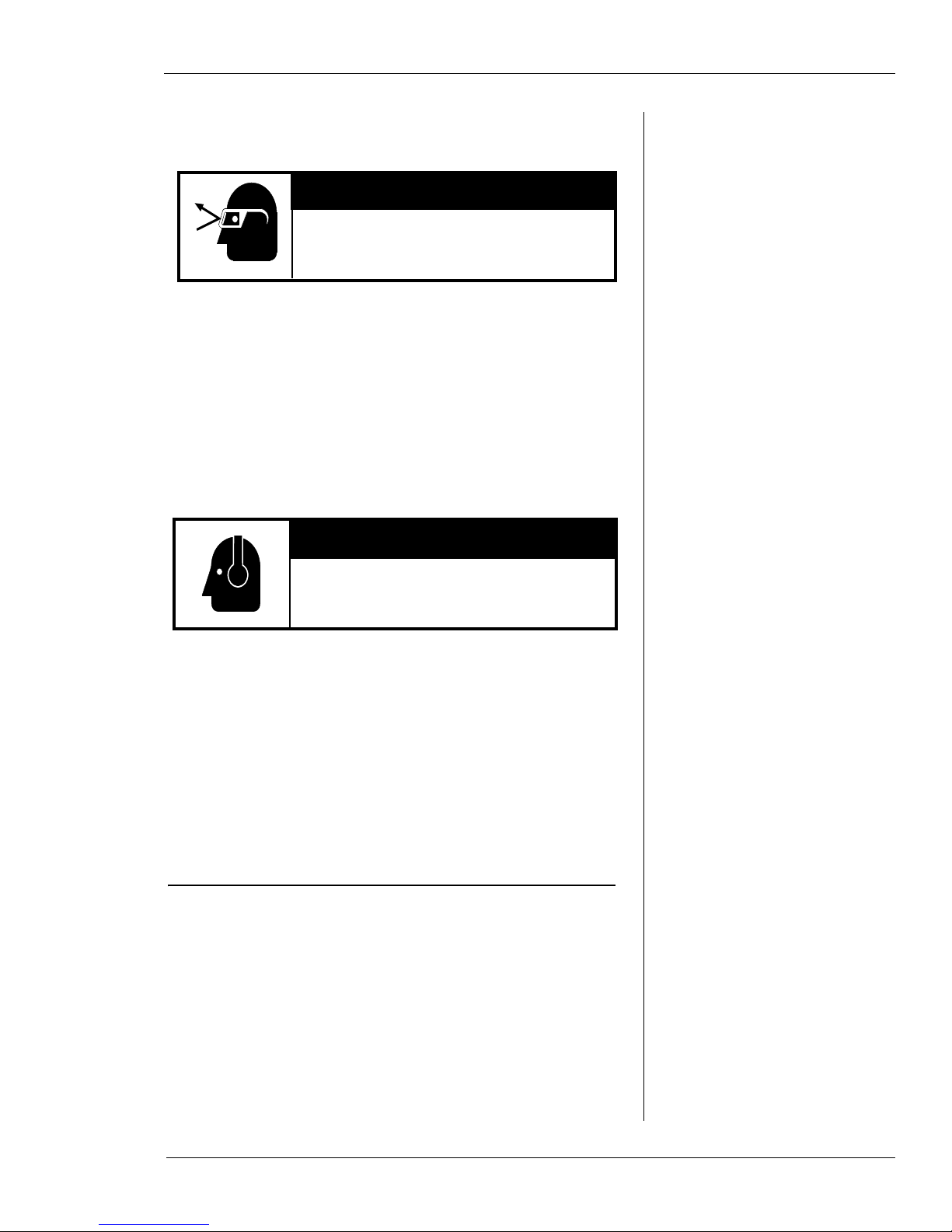

Protective Equipment Requirements

Always wear impact resistant eye protection while operating or working near

this equipment.

WARNING

CAUTION

Personal hearing protection is recommended when operating or working near

this tool.

For additional information on eye and face protection, refer

to Federal OSHA regulations, 29 Code of Federal Regulations, Section 1910.133., Eye and Face Protection and

American National Standards Institute, ANSI Z87.1, Occupational and Educational Eye and Face Protection. Z87.1 is

available from the American National Standards Institute,

Inc., 1430 Broadway, New York, NY 10018.

Chapter 2, Safety: Safety Labels

Hearing protectors are required in high noise areas, 85 dBA

or greater . The operation of other tools and equipment in the

area, reflective surfaces, process noises, and resonant structures can increase the noise level in the area. For additional

information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section

1910.95, Occupational Noise Exposure and ANSI S12.6

Hearing Protectors.

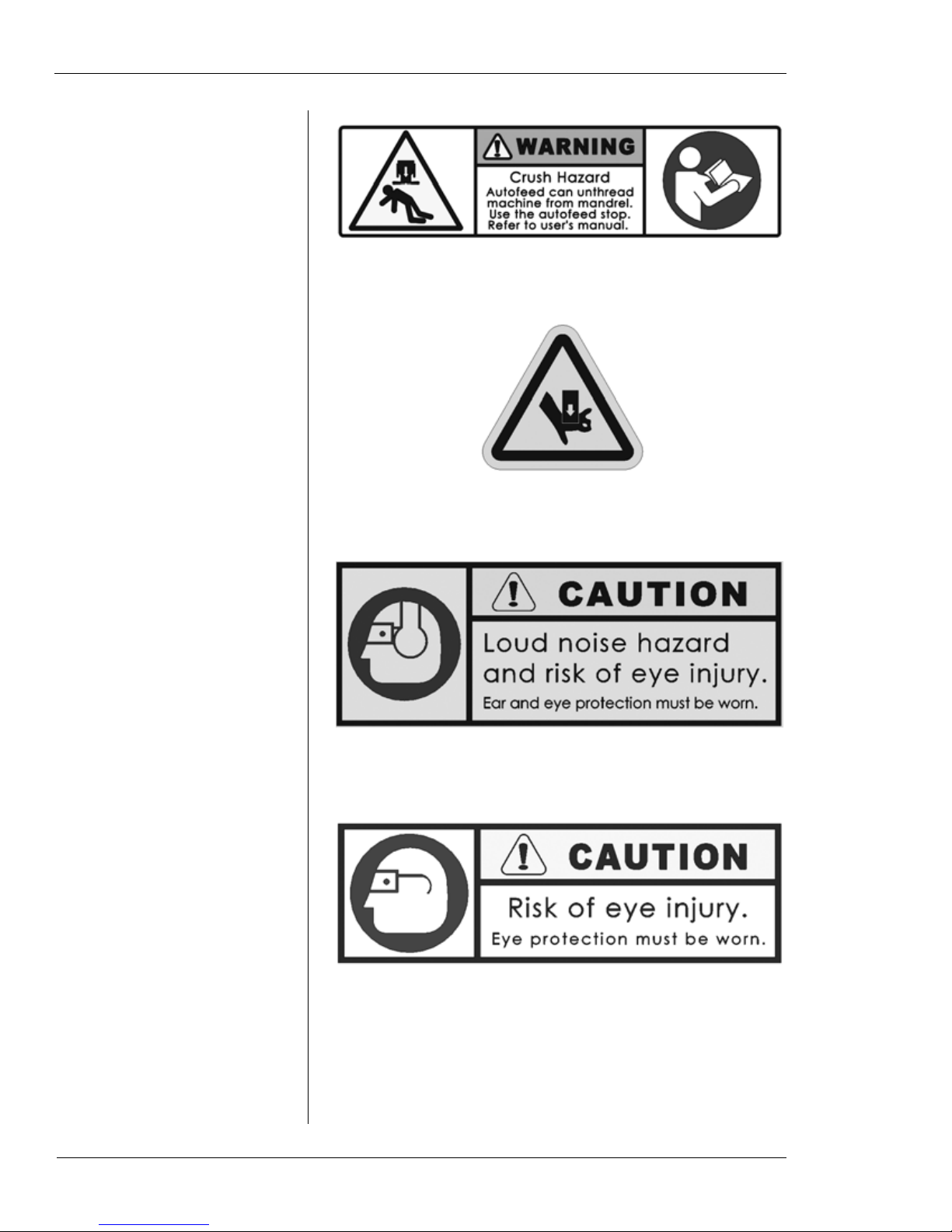

SAFETY LABELS

The following safety labels are on the EP 424 machine. If a

label is lost or unreadable, order and attach a replacement.

See ordering instructions in Chapter 10.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 7

EP 424 End Prep Machine

Figure 2-1. Crush hazard safety label (part no. 81165-00).

Figure 2-2. Crush and cut hazard safety label (part

no. 90-401-04).

Figure 2-3. Loud noise hazard safety label, provided

with air drive configurations (part no. 90-401-03).

Figure 2-4. Eye injury hazard label, provided with

hydraulic drive configurations (part no. 90-401-01).

8 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

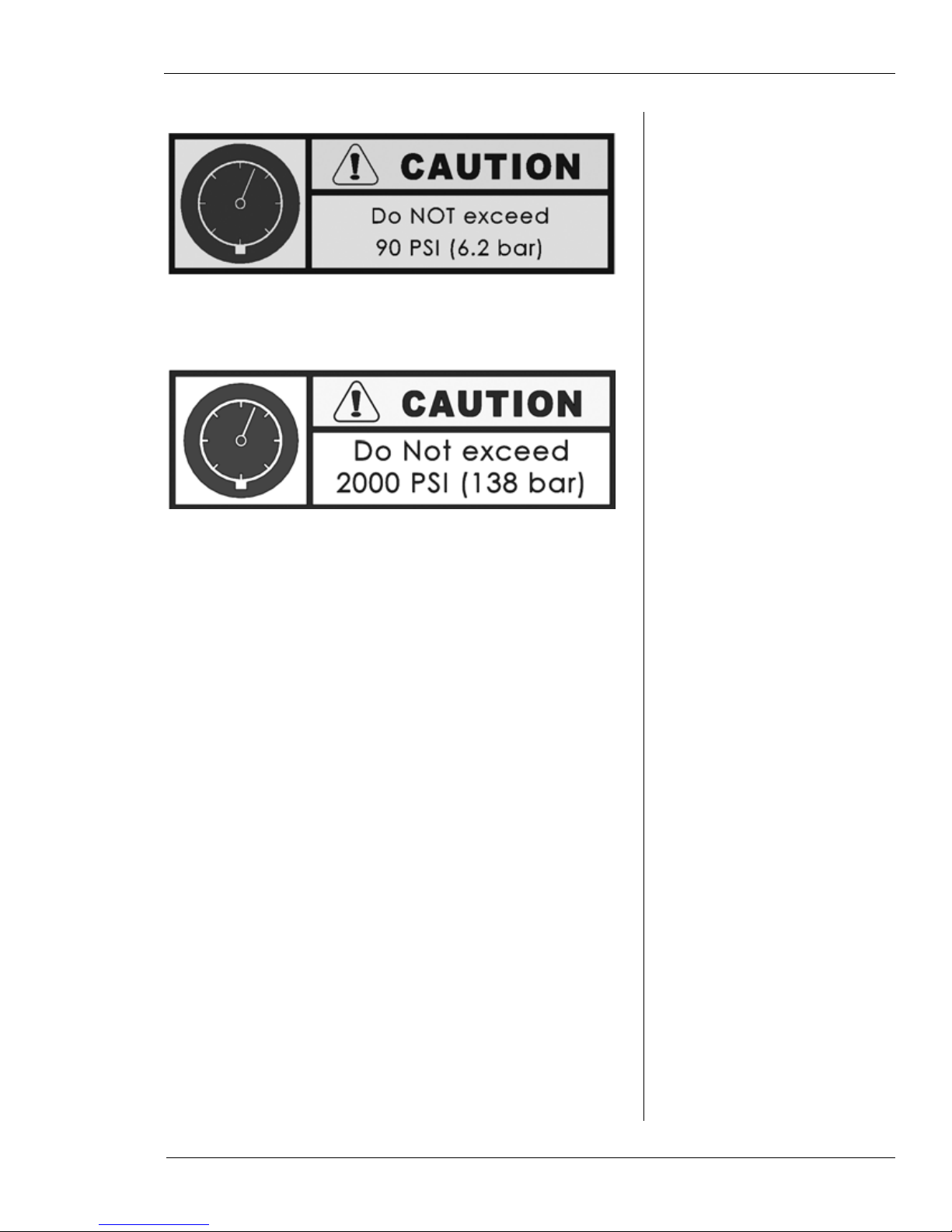

Figure 2-5. Compressed air pressure safety label

(part no. 90-401-02).

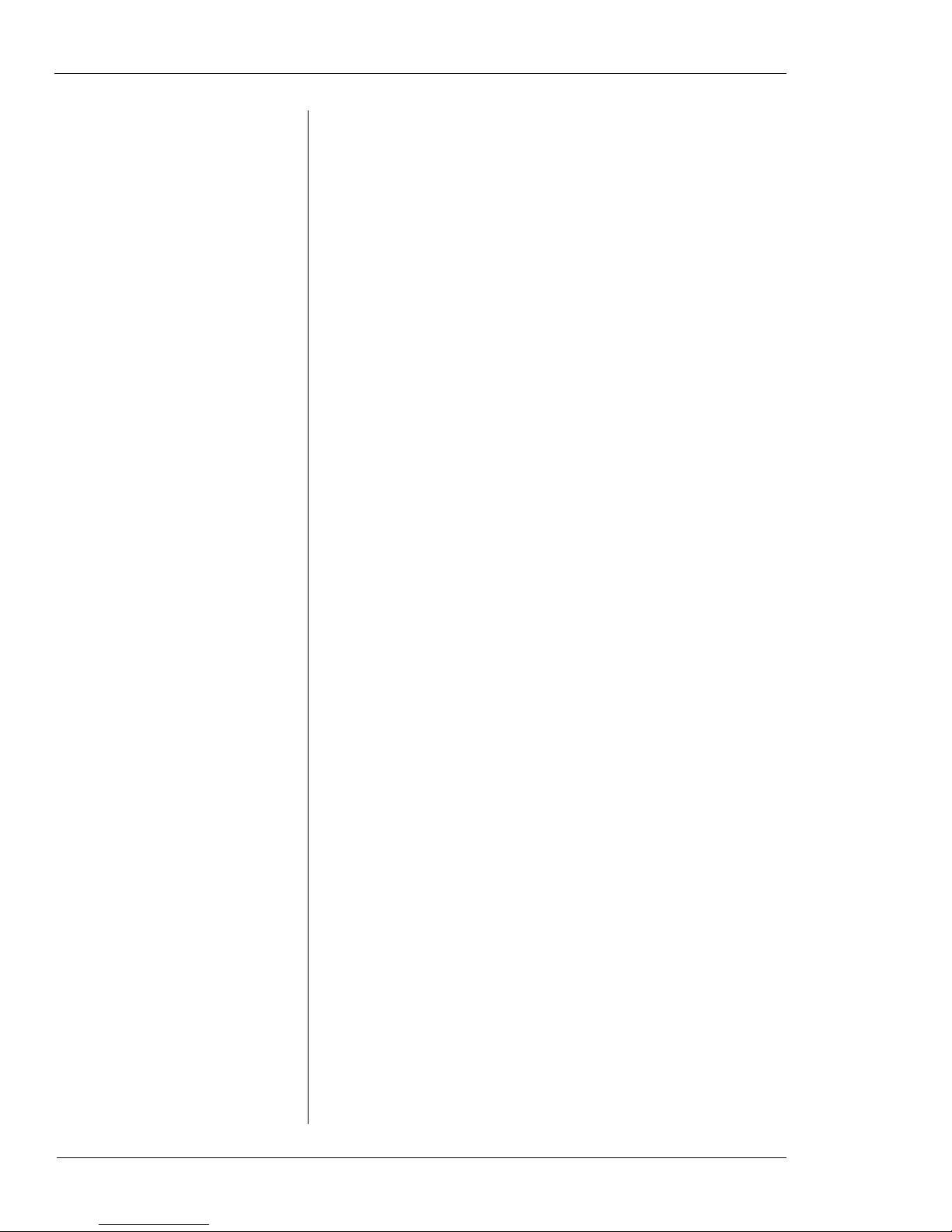

Chapter 2, Safety: Safety Labels

Figure 2-6. Hydraulic pressure safety label (part no.

90-402-01).

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 9

EP 424 End Prep Machine

10 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 3

Introduction to the

Equipment

OVERVIEW OF THE EP 424

Chapter 3, Introduction to the Equipment

In This Chapter

OVERVIEW OF THE EP 424

S

PECIFICATIONS

The EP 424 is an I.D. (inside diameter) mounted end prep

machine for facing, beveling, counterboring, and J-prepping pipes and flanges. It can be used for pipes from 4-24

inches O.D., with wall thicknesses up to 1.6” (41 mm)

using form tools, or 6.5” (165 mm) with single-point operation.

The EP 424 is provided in 4 configurations:

• Form tool machine with air drive, part no. 81-000-01

• Form tool machine with hydraulic drive, part no. 81000-02

• Single-point machine with air drive, part no. 81-000-03

• Single-point machine with hydraulic drive, part no. 81000-04.

Form tool operation is quick to set up and easy to perform

on pipe walls up to schedule 160 (1.6” on 16” pipe). For

heavier wall pipe up to 6.5” wall thickness, the single-point

kit allows you to perform any bevel profile.

OPERATING ENVELOPE

Form-Tool Configuration

The form tool configurations have a rotating tool head with

3 tool holders, for performing up to 3 simultaneous opera-

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 11

EP 424 End Prep Machine

tions. Tooling is available for facing, single-angle beveling,

compound beveling, counterboring,

The form tool configuration will perform end prepping (facing, beveling, J-prepping, and counterboring), with the

operator manually feeding the tool head.

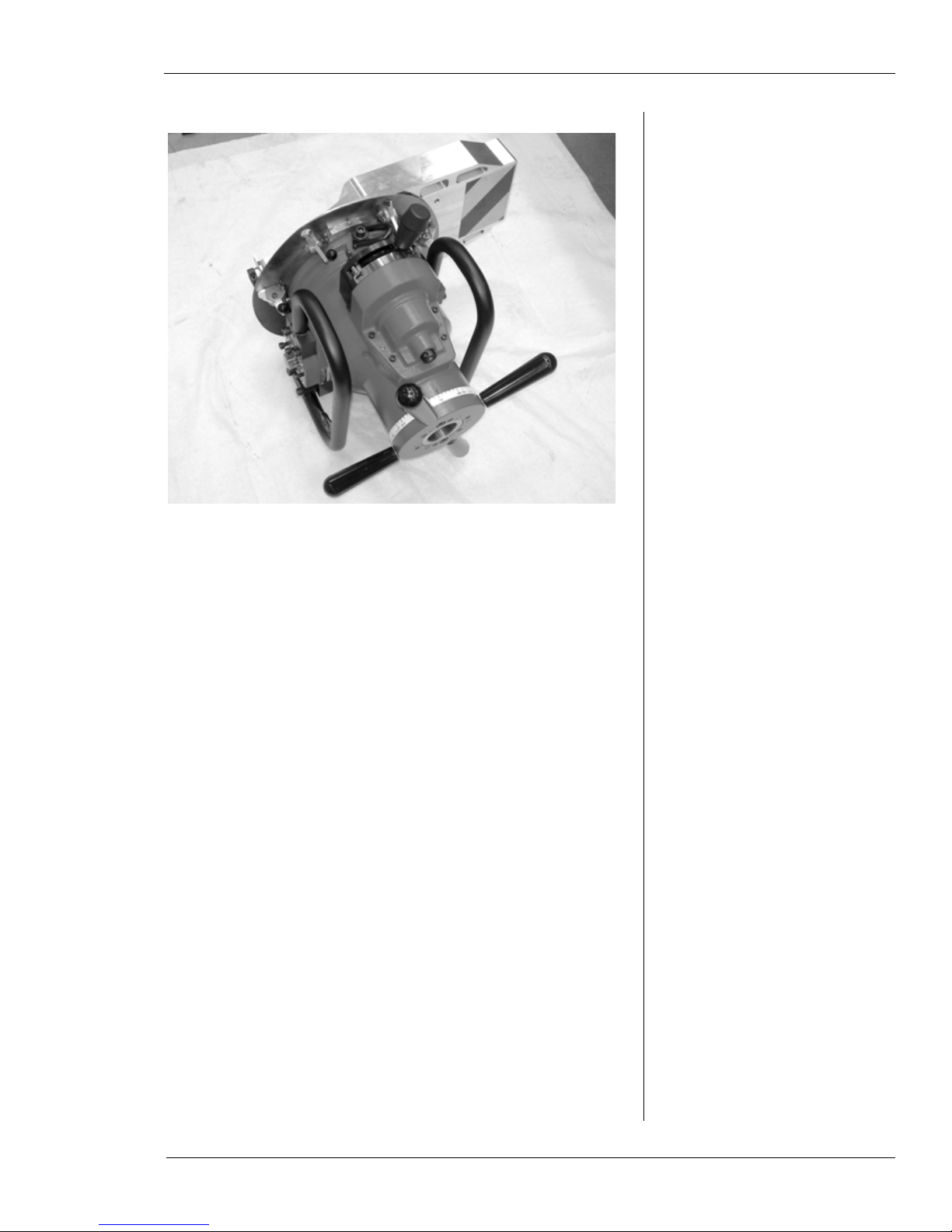

Figure 3-1. The photo shows the form tool configuration of the machine with the standard self-centering

mandrel.

Single-Point Configuration

The single-point machine is provided with a tool slide that

feeds the tool radially across the face of the pipe or flange.

The slide is driven by a starwheel that engages trips on a

ring mounted to the machine housing. Bevels are performed

using the Speed Prep auto-feed system, which automatically

feeds the machine axially as it cuts.

The single-point machine will perform facing or beveling of

thick-walled pipes and flanges.

12 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 3, Introduction to the Equipment: Overview of the EP 424

Figure 3-2. The photo shows the single-point configuration of the EP 424.

EP 424 Components

The following components are provided with the form tool

configuration of the EP 424:

• main drive assembly with lifting attachments

• feed assembly

• rotating tool head

• standard self-centering mandrel

• drive motor (air or hydraulic)

• hand tool set

The single-point configuration includes the following additional components:

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 13

EP 424 End Prep Machine

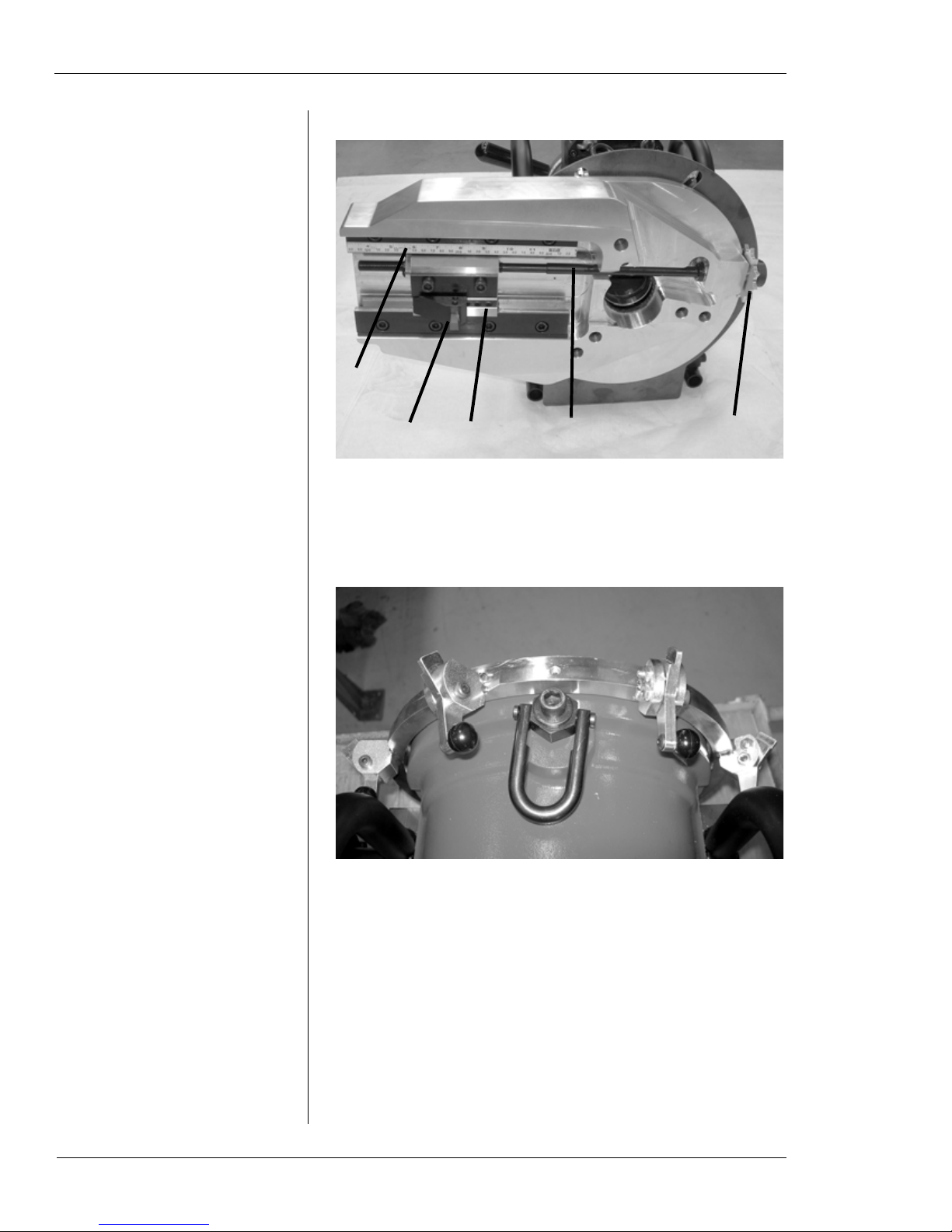

StarwheelFeed screws

Male tool slide

Tool holder

Feed gauge

• single-point slide

Figure 3-3. The single-point slide feeds the tool radially across the pipe face. It is driven along a feed

screw by a starwheel.

• radial feed trip assembly

Figure 3-4. The photo shows the trip assembly

mounted on the main drive housing.

14 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

• Speed Prep autofeed module

WARNING

Speed Prep

module

Chapter 3, Introduction to the Equipment: Overview of the EP 424

The Speed Prep autofeed

can feed the machine until it

comes off the mandrel.

Crushing or other serious

injuries could occur. Use the

autofeed stop plate (81-316-

00) to keep the machine from

feeding too far.

Figure 3-5. The speed prep module is installed on the

main drive to operate the feed mechanism for singlepoint beveling.

• independent chuck mandrel

Figure 3-6. The independent chuck mandrel allows

you to center the machine on the O.D. of the pipe.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 15

EP 424 End Prep Machine

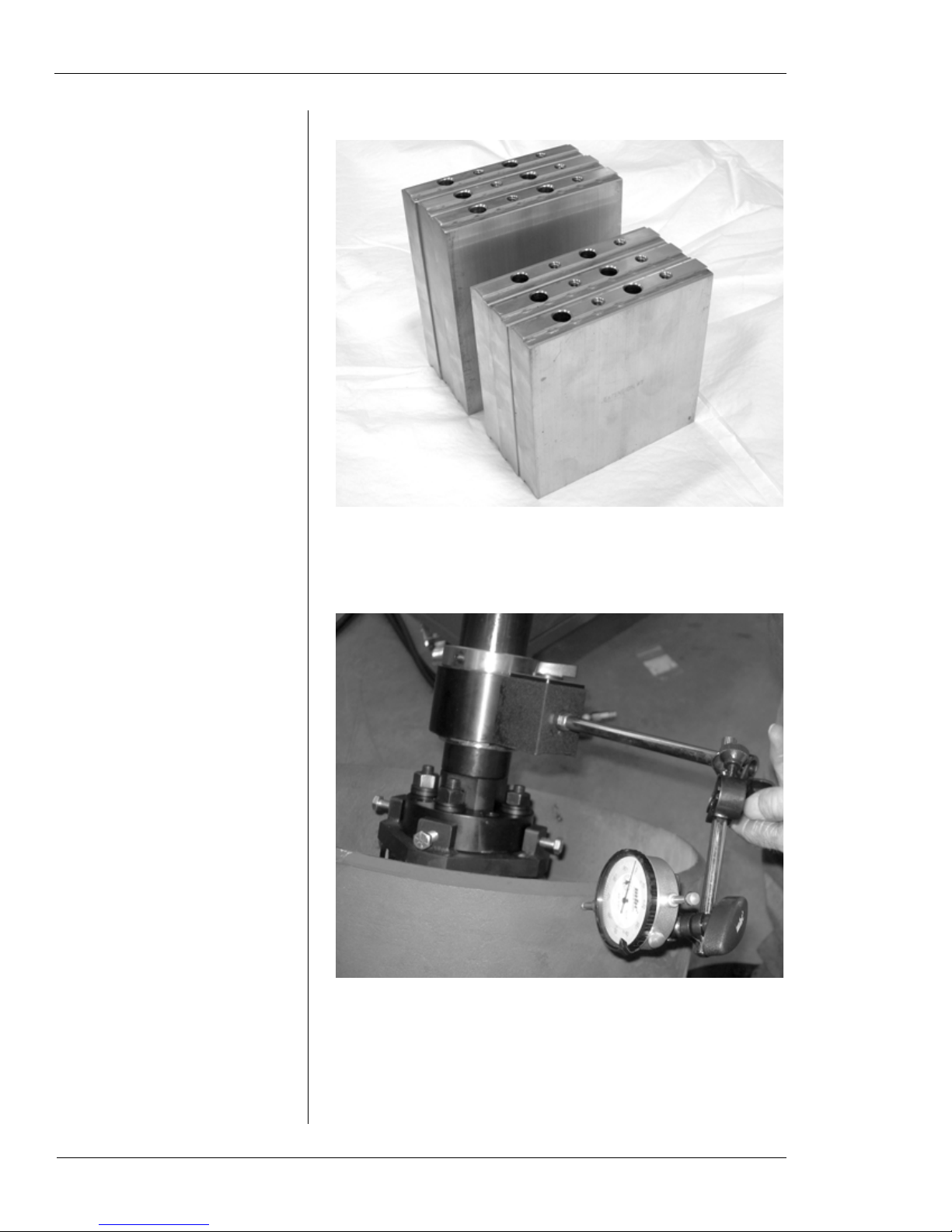

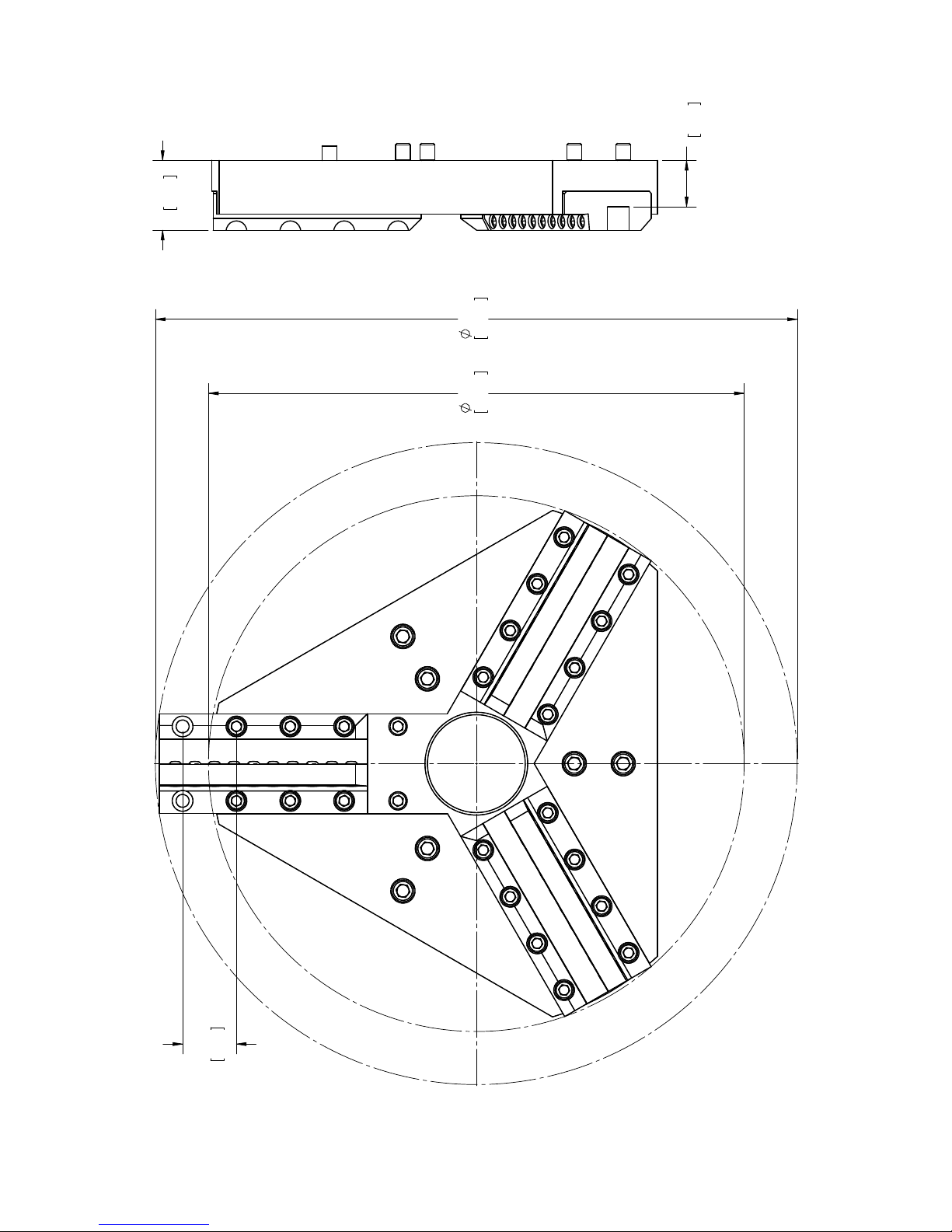

• extension leg kit for standard mandrel

Figure 3-7. Two sets of extension legs allow the standard mandrel to be mounted in pipes up to 23.64” I.D.

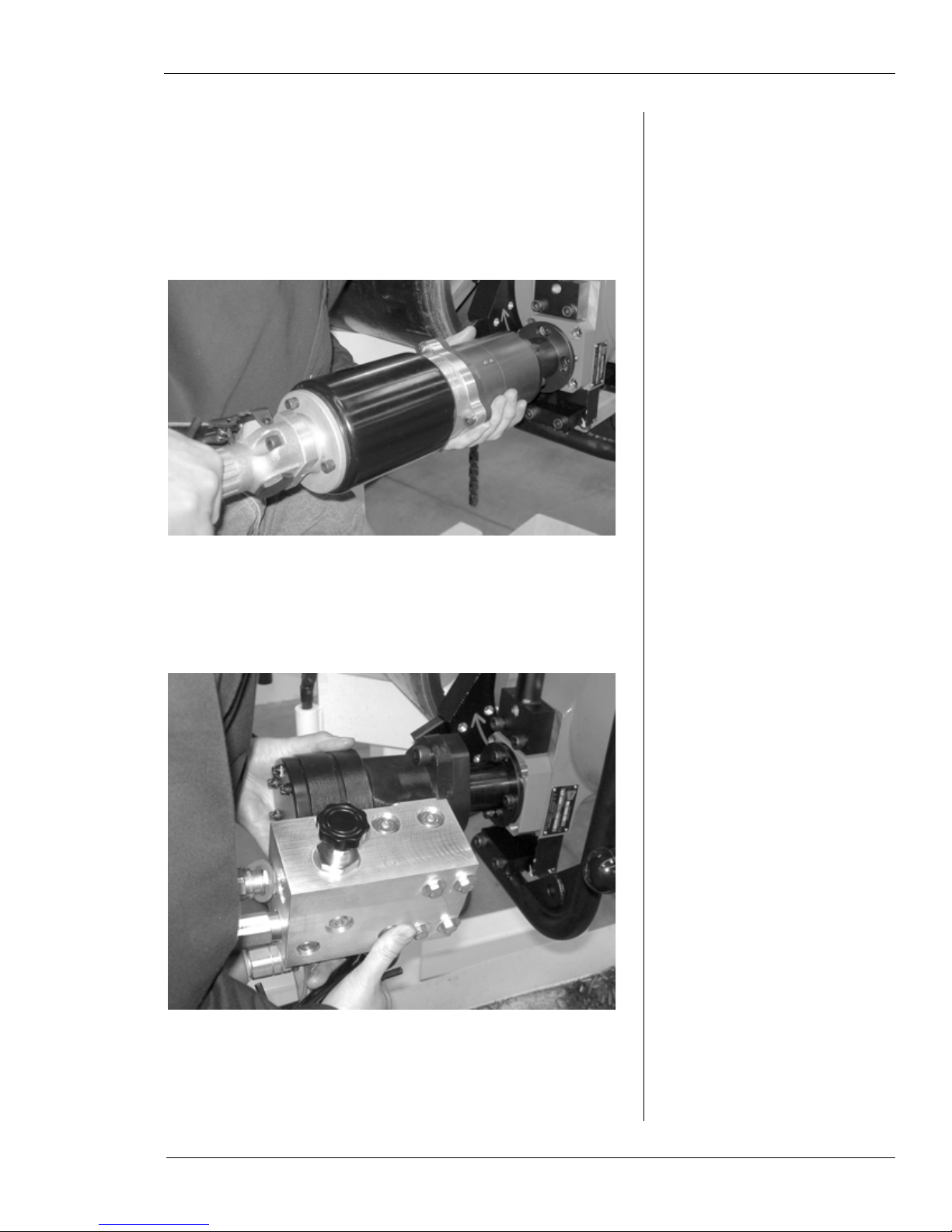

• dial indicator assembly

16 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 3-8. The dial indicator is provided for centering the independent chuck in the pipe.

Chapter 3, Introduction to the Equipment: Overview of the EP 424

Drive Motors

Two drive motors are available for the EP 424:

• a 3.5 HP air motor, part no. 81-311-00. The air motor

requires 95 cfm air flow at 90 psi (2,700 l/min at 6.2

bar).

Figure 3-9. The photo shows the EP 424 air motor.

• a hydraulic motor, part no. 81-310-00. The hydraulic

motor requires 10 gpm flow at 1500 psi (38 l/min @103

bar).

Figure 3-10. The hydraulic motor is interchangeable

with the air motor.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 17

EP 424 End Prep Machine

Both motors include adapters for the EP 424. The motors

are interchangeable, requiring no modifications to the EP

424 machine.

Accessories

The following accessories are available for the EP 424:

• Single-point upgrade kit, part no. 81-400-00 (for formtool machine configuration); includes Speed Prep module, single-point slide, trip ring, and independent chuck.

• Extension leg kit for standard mandrel, part no. 81-303-

01. Extends maximum clamping I.D. to 23.64” (600.5

mm).

• Independent chuck mandrel, part no. 81-305-00. (Provided with single-point machine or kit; available as

option for form tool machine.)

• Short perch mandrel, part no. 81-315-00. Self-centering

mandrel for pipes with bends or limited I.D. access.

• Air treatment module, part no. 26-407-00.

18 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

SPECIFICATIONS

Capacities

Table 1: EP 424 Operating Capacities

Chapter 3, Introduction to the Equipment: Specifications

Air requirements

Hydraulic requirements

Axial feed 0.071” per feed handle revolution

Single-point slide radial feed

Max feed travel 3.50” (88.9 mm)

Max. rotating speed (no

load)

Min. pipe wall thickness Schedule 40

Max. pipe wall thickness

(form tool)

Max pipe wall thickness (sin-

gle-point)

Lift hook capacity 1000 lb (454 kg)

95 cfm at 90 psi

(2690 l/min at 6.2 bar)

Min 10 gpm/max 15 gpm at 2000 psi

(38/57 l/min at 138 bar)

0.0052” (0.132 mm) per engaged trip;

6.5” (165 mm) maximum feed

20 rpm

1.6” (40.5 mm), depending on material

6.5” (165 mm)

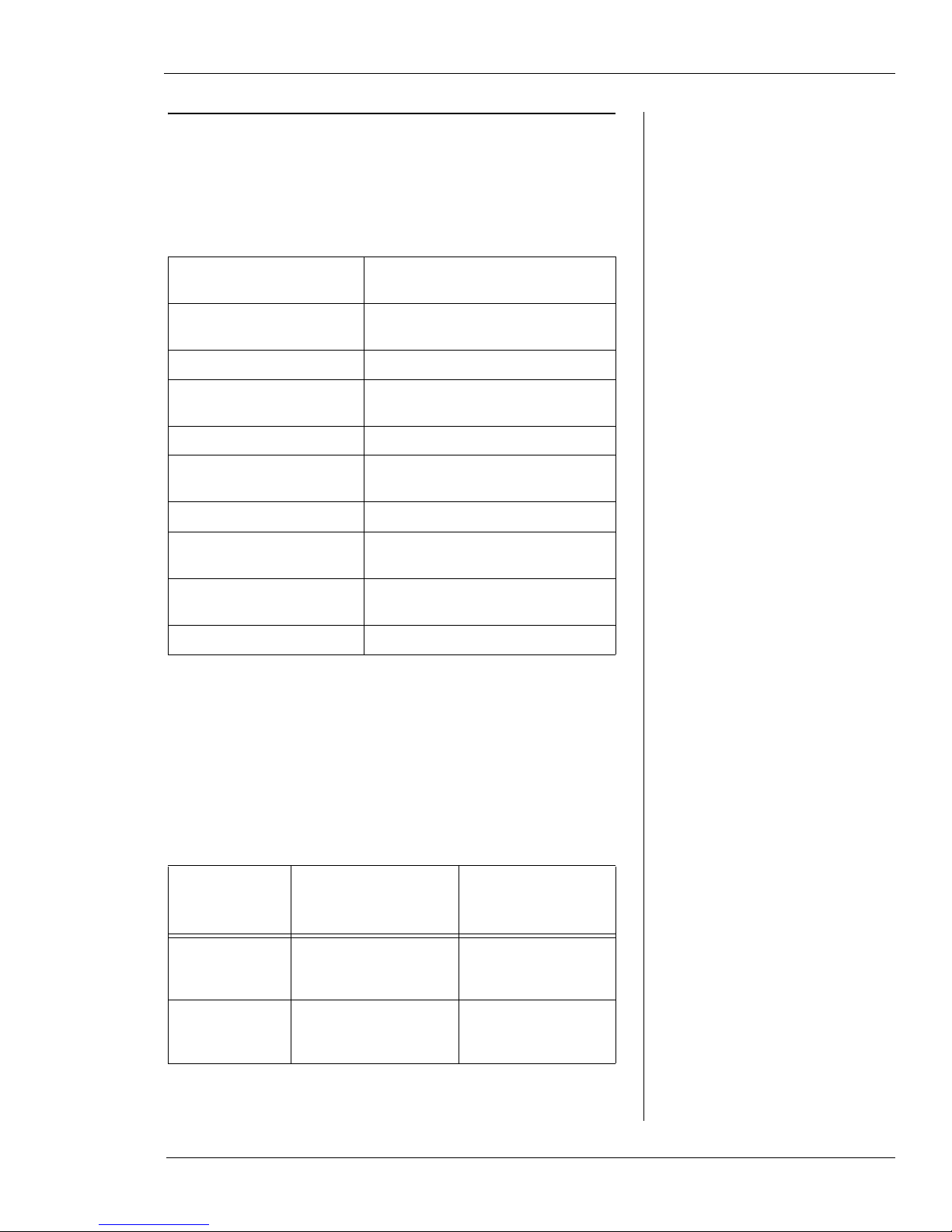

Dimensions and Weights

The envelope drawings in the following section include the

dimensions for each machine configuration, and the weight

for each subassembly. Table 2 below includes overall

dimensions and weights for each configuration.

Table 2: Overall Dimensions and Weights

Configuration

81-000-01

(Form tool/air

drive)

81-000-02

(Form tool/

hydraulic drive)

Dimensions

(L x W x H)

28.8” x 36.2” x 16.1”

(732 x 919 x 408 mm)

28.8” x 25.3” x 16.1”

(732 x 643 x 408 mm)

154.5 lb (70.2 kg)/

172 lb (78.2 kg)

162 lb (73.6 kg)/

179.5 lb/81.6 kg

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 19

Weight

(Std. Mandrel/

Ind. Chuck Mandrel)

EP 424 End Prep Machine

Table 2: Overall Dimensions and Weights

Weight

(Std. Mandrel/

Ind. Chuck Mandrel)

Configuration

81-000-03

(Single-point/air

drive)

81-000-04

(Single-point/

hydraulic drive)

Shipping/

storage case

Dimensions

(L x W x H)

25.5” x 42.3” x 21.2”

(648 x 1075 x 539 mm)

25.4” x 30.4” x 21.2”

(645 x 772 x 539 mm)

37” x 36.3” x 22.3”

(940 x 922 x 566 mm)

176 lb (80 kg)/

193.5 lb (88 kg)

183.5 lb (83.4 kg)/

201 lb (91.4 kg)

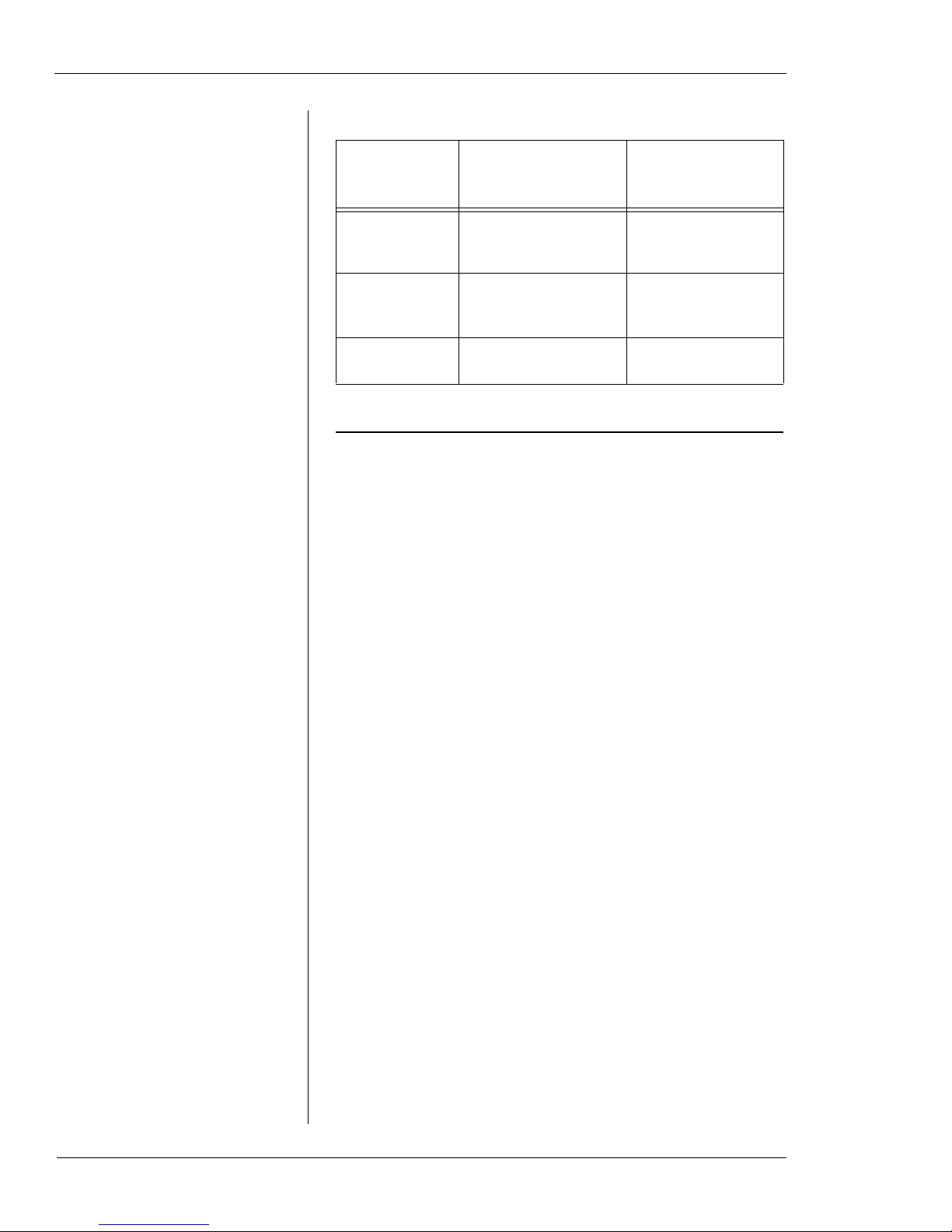

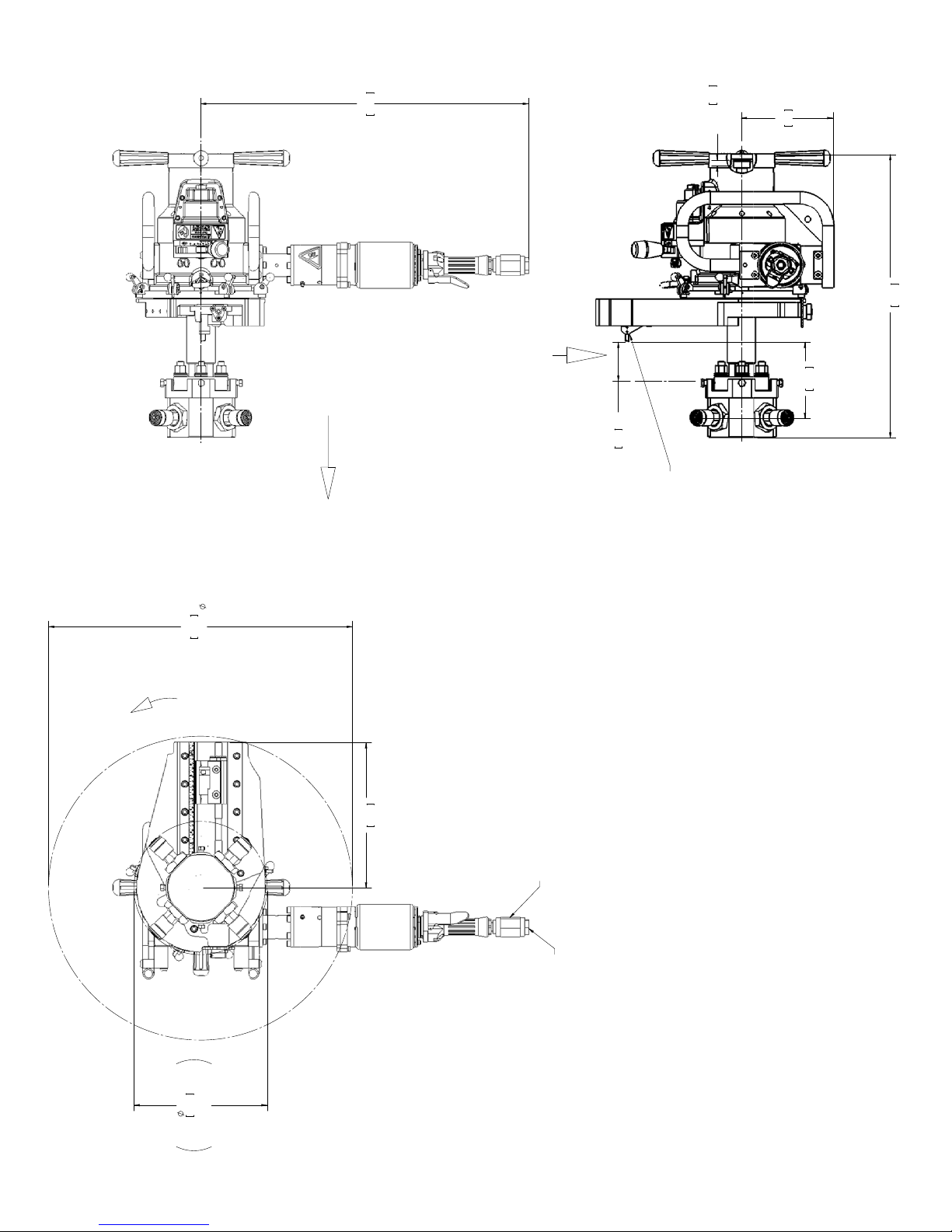

OPERATING ENVELOPE

The drawings on the following pages illustrate the operating

envelope for all configurations of the EP 424:

• Standard machine with air drive (81-000-01)

• Standard machine with hydraulic drive (81-000-02)

• Single-point machine with air drive (81-000-03)

• Single-point machine with hydraulic drive (81-000-04).

There are also dimensional drawings for the following components:

• Standard mandrel with extension legs

• Form tool rotating head

• Independent chuck mandrel with extension legs

• Single-point slide.

20 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

29.31

744.6

AXIAL FEED: .071"[1.80] PER FEED

HANDLE REVOLUTION

(CLOCKWISE)

28.81

731.6

10.47

265.9

1.02

25.9

3.59

91.1

7.5

.29

(SHOWN WITH

ON MANDREL)

.50 [12.7] TREAD ENGAGEMENT

5.38

136.5

208

8.19

&

56-198-02

56-711-01

INSERT HOLDER

3.50

88.9

TOOL

FACING/BEVELING

Operating Envelope

EP 424 Air Drive Conguration

81-000-01

MAX TRAVEL

15.73

13.68

399.5

347.5

20 RPM

MAX FREE SPEED

5.38

136.5

AIR REQUIREMENTS

AIR CONSUMPTION 95 cfm [2690 l/min]

PRESSURE 90 PSI [6.2 BAR]

MAX

MAX

4.20

1/2 NPT

106.6

LEGS SHOWN FULLY EXTENDED

2.72

69.2

MIN

MIN

3.25

82.6

LEGS SHOWN FULLY RETRACTED

NOTE:

SEE 81-303-00 FOR ALL

EXTENSION RANGES

17.41

442.3

.29

7.5

(SHOWN WITH

ON MANDREL)

7.66

AXIAL FEED: .071"[1.80] PER FEED

HANDLE REVOLUTION

(CLOCKWISE)

194.5

28.81

731.6

10.47

265.9

1.52

3.09

38.6

78.4

5.38

.50"[12.7] THREAD ENGAGEMENT

136.5

208

8.19

&

56-711-01

56-198-02

INSERT HOLDER

FACING/BEVELING

TOOL

3.50

88.9

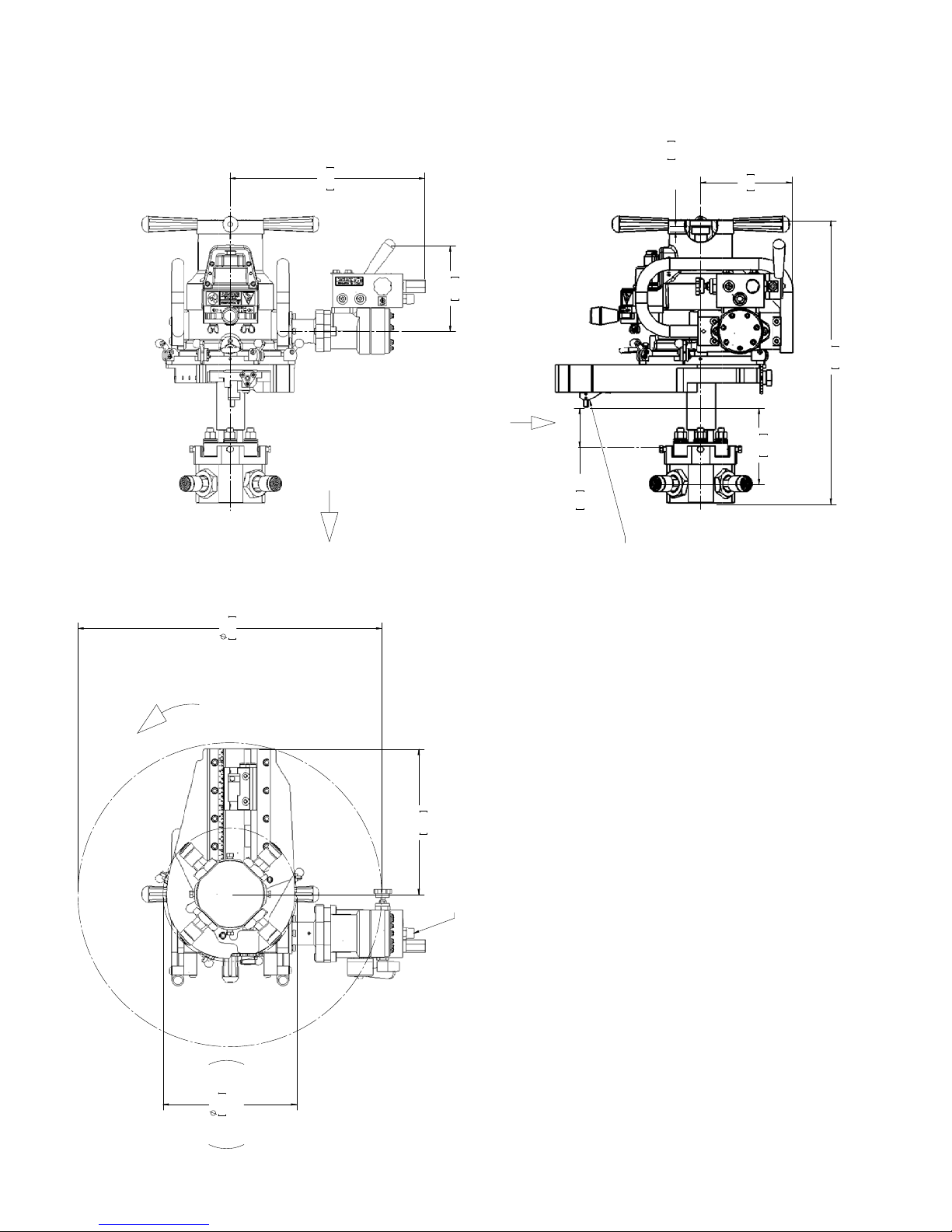

Operating Envelope

MAX TRAVEL

EP 424 Hydraulic Drive Conguration

81-000-02

15.73

13.68

399.5

347.5

20 RPM

MAX FREE SPEED

MAX FLOW 15 GPM [57 LPM]

MAX PRESSURE 2000 PSI [138 BAR]

5.38

136.5

MAX

4.20

MAX

106.7

LEGS SHOWN FULLY EXTENDED

2.72

69.2

MIN

MIN

3.25

82.6

LEGS SHOWN FULLY RETRACTED

NOTE:

SEE 81-303-00 FOR ALL

EXTENSION RANGES

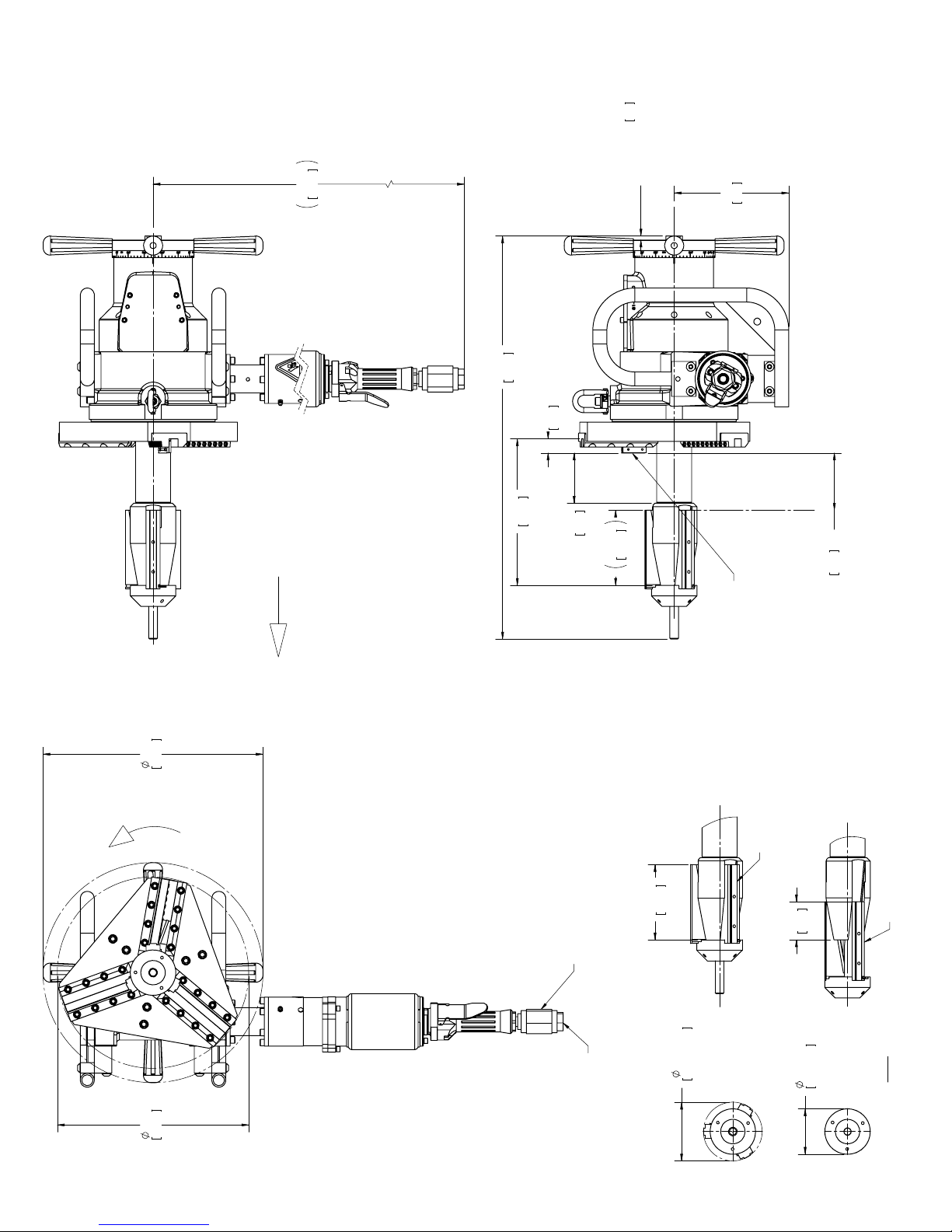

29.31

744.6

.50

12.7

ON MANDREL

THREAD ENGAMENT

8.19

208

25.35

643.8

27.15

689.7

ROTATING

20 RPM

MAX FREE SPEED

AXIAL FEED: .071" [1.80] PER FEED

HANDLE REVOLUTION

(CLOCKWISE)

13.00

330.2

FEED RATE: .0052" [.132]

PER TRIP ENGAGED

TOTAL STROKE: 6.5" [165.1]

3.50

88.9

MAX TRAVEL

&

HOLDER

56-205-01

52-701-01

INSERT TOOL

6.84

173.6

Operating Envelope

EP 424 Air Drive Conguration

Single-Point Operation

81-000-03

11.90

302.3

(SEE 81-305-00

FOR FULL LEG CHART)

AIR REQUIREMENTS

AIR CONSUMPTION 95 cfm [2690 l/min]

PRESSURE 90 PSI (6.2 bar)

1/2 NPT

17.41

442.3

AXIAL FEED: .071" [1.80] PER FEED

HANDLE REVOLUTION

(CLOCKWISE)

7.66

194.5

FEED RATE: .0052" [.132]

PER TRIP ENGAGED

TOTAL STROKE: 6.5" [165.1]

3.50

88.9

MAX TRAVEL

&

HOLDER

56-205-01

.50

12.7

52-701-01

INSERT TOOL

ON MANDREL

THREAD ENGAMENT

8.19

208

25.35

643.8

6.84

173.6

27.15

689.7

20 RPM

MAX FREE SPEED

13.00

330.2

MAX FLOW 15 GPM [57 LPM]

MAX PRESSURE 2000 PSI [138 BAR]

Operating Envelope

EP 424 Hydraulic Drive Conguration

Single-Point Operation

81-000-04

11.94

303.2

SEE 81-305-00

FOR FULL LEG CHART

MIN

3.27

MIN

83.1

MIN I.D. WITH

3.15

80.1

.50

12.7

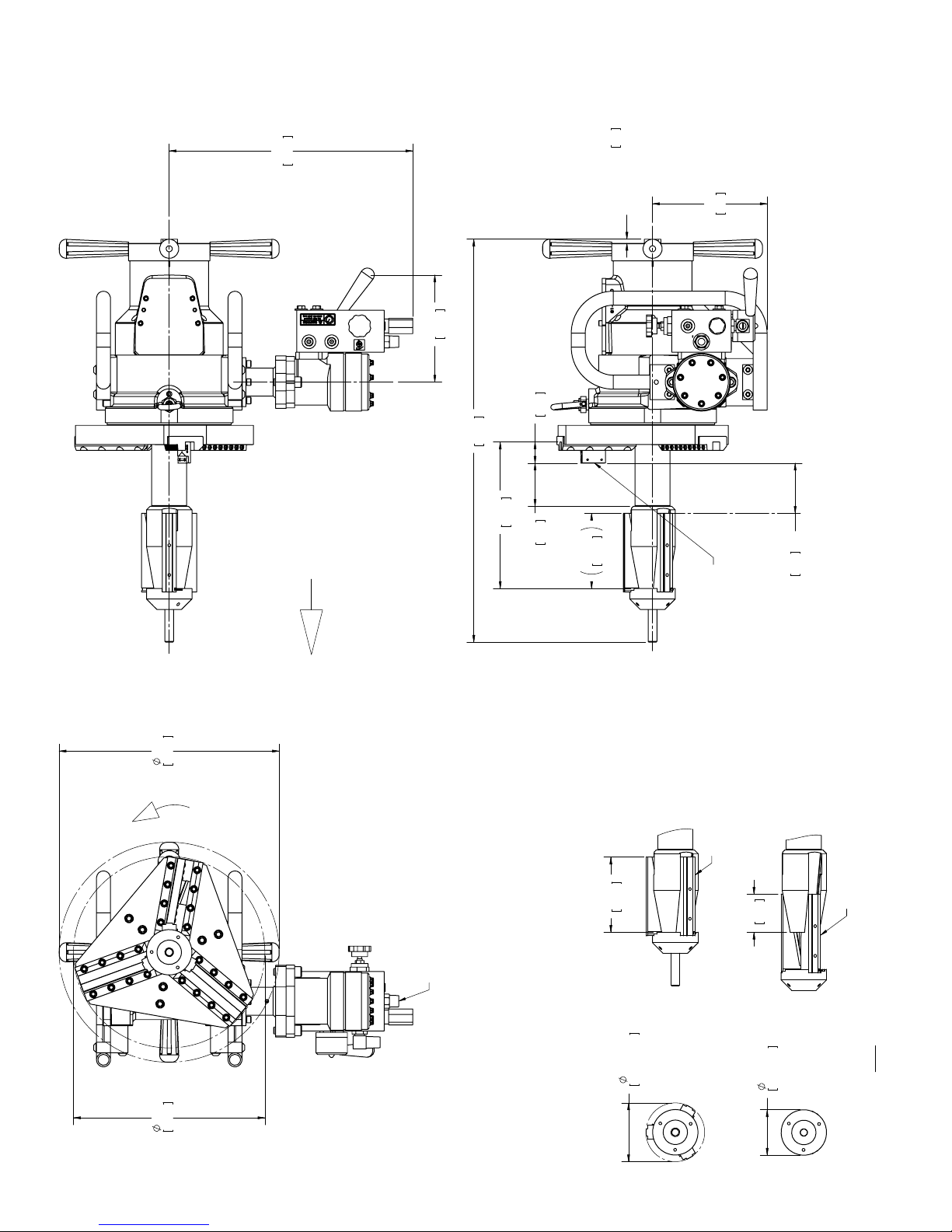

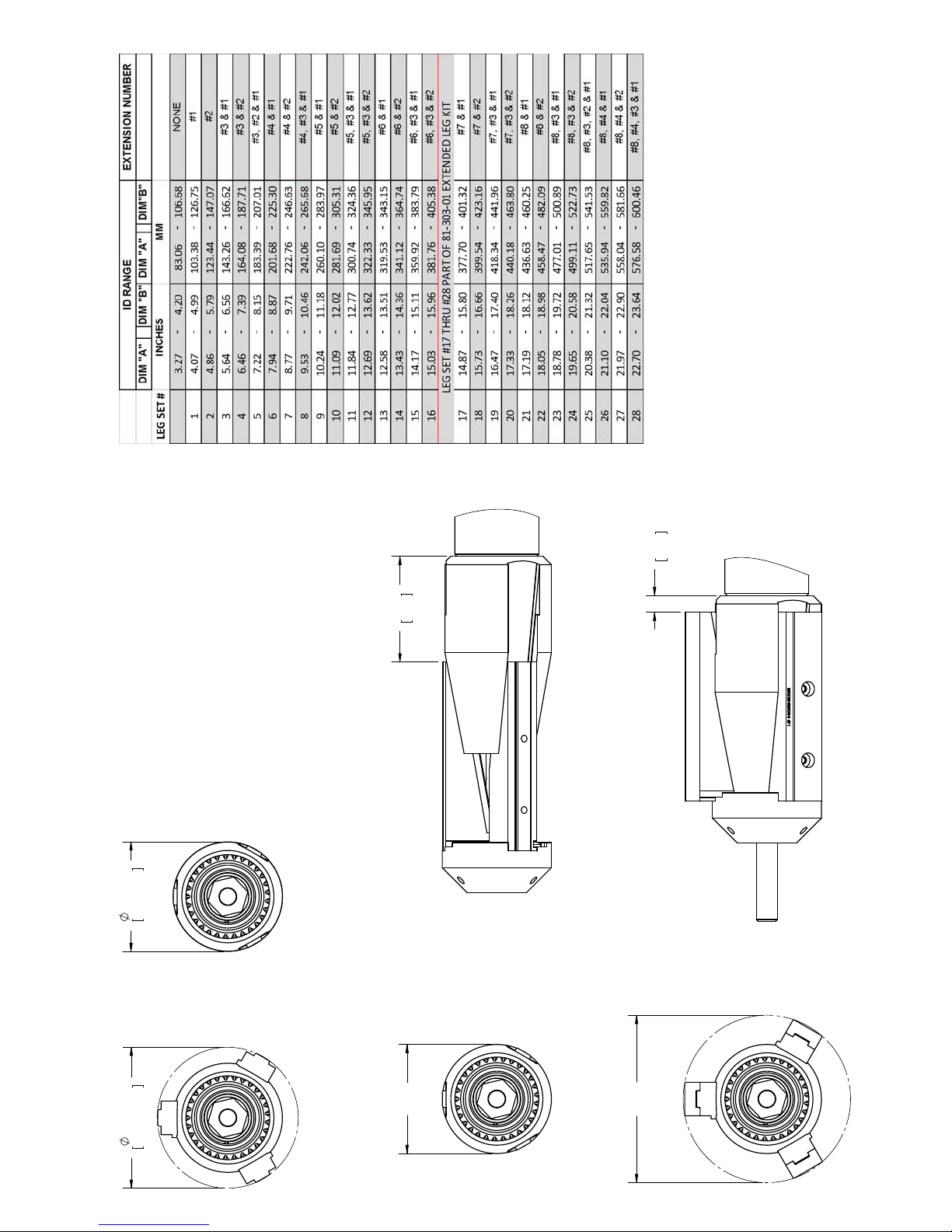

Operating Envelope

EP 424 Standard Mandrel and Extension Legs

81-303-00

MAX

MAX

4.20

MAX I.D. WITH

"A"

MIN

MIN POSITION

"B"

MAX POSITION

MAX

1.79

45.3

16.39

416.2

13.68

347.4

1.19

30.1

Operating Envelope

EP 424 Rotating Tool Head

81-304-00

TOOL HOLDER

SHOWN IN OUTER POSITION

1.38

34.9

MM

ID RANGE

INCHES

8.50 - 10.50 215.9 - 266.7

9.50 - 11.50 241.3 - 292.1

11.18 - 13.15 284.0 - 334.0

INDEPENDENT CHUCK MANDREL

12.18 - 14.15 309.4 - 359.4

14.43 - 16.50 366.5 - 419.1

15.43 - 17.50 391.9 - 444.5

16.87 - 18.81 428.5 - 477.8

17.87 - 19.81 453.9 - 503.2

19.31 - 21.30 490.5 - 541.0

20.31 - 22.30 515.9 - 566.4

22.28 - 24.28 565.9 - 616.7

23.28 - 25.28 591.3 - 642.1

1.75

44.5

24.85

631.1

LEG SET

23-313-00

23-214-01

(23-221-00)

WITH SPACER

23-214-02

(23-221-00)

WITH SPACER

(23-221-00)

WITH SPACER

25.28

23-214-03

642.1

23-214-04

(23-221-00)

WITH SPACER

MAX CLAMPING

23-214-05

(23-221-00)

WITH SPACER

(23-221-00)

WITH SPACER

Operating Envelope

EP 424 Independent Chuck Mandrel

and Extension Legs

81-305-00

8.50

215.9

MIN CLAMPING

26.38

670

MAX TOOL POSTION

TOOL HOLDER 56-205-01

& INSERT TOOL 52-701-01

SHOWN WITH HIGH RANGE

13.58

R

344.8

7.25

184.1

2.55

64.7

Operating Envelope

EP 424 Single-Point Slide

81-306-00

23.62

599.8

MAX TOOL POSTION

TOOL HOLDER 56-205-00

& INSERT TOOL 52-701-01

SHOWN WITH LOW RANGE

SHOWN WITH .50"

THREAD ENGAGMENT

& 3 TOOL HOLDER SCREWS

SLIDE TRAVEL: 6.5"

4.25

107.9

MIN TOOL POSTION

TOOL HOLDER 56-205-01

& INSERT TOOL 52-701-01

SHOWN WITH HIGH RANGE

MIN TOOL POSTION

TOOL HOLDER 56-205-00

& INSERT TOOL 52-701-01

SHOWN WITH LOW RANGE

Chapter 4

Assembly,

Disassembly, and

Storage

Chapter 4, Assembly, Disassembly, and Storage

In This Chapter

PACKAGING

The EP 424 comes in a customized steel shipping/storage

case. The case includes compartments for all standard and

optional components, and is designed to hold all components securely to prevent damage in shipping.

Store the machine in its case at all times when it is not in

use. Figure 4-1 shows the layout of the components in the

case. There are lockdown pins for securing the EP 424

machine, as shown in Figure 4-2.

PACKAGING

STORAGE CHECKLIST

Figure 4-1. The photo shows the EP 424 in its case.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 29

EP 424 End Prep Machine

Figure 4-2. Two lockdown pins are provided to secure

the machine in the storage case. Always insert the pins

through the case brackets and the EP 424 handle

when storing the machine.

STORAGE CHECKLIST

Before storing the EP 424, perform the following maintenance steps. If you are using the machine in an especially

dirty or corrosive environment, perform these steps frequently.

• Clean the machine by wiping off dirt, debris, and accumulated oil or grease.

• Put oil in the air motor oiler, and operate the motor for a

few seconds to lubricate its internal components.

• Lubricate the machine according to the instructions in

Chapter 6.

• Spray or wipe a light coating of anti-corrosion lubricant

on non-finished, non-painted surfaces.

• Put the machine in its storage case, with all components

stored in their compartments.

• If possible, keep the storage case indoors and away from

moisture.

• If you will be storing the machine longer than 30 days,

put desiccant packets in the case to prevent corrosion.

30 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 5

Operating

Instructions

MOUNTING THE MANDREL ON THE PIPE

Typically, you will install the mandrel (either the standard

or independent chuck mandrel) in the pipe before mounting

the EP 424 machine. This makes it easier to align the mandrel and mount the machine.

Chapter 5, Operating Instructions

In This Chapter

MOUNTING THE MANDREL ON

THE PIPE

USING THE DRIVE MOTORS

FORM TOOL OPERATION

SINGLE POINT OPERATION

The standard mandrel is recommended when it can be used

on the pipe. It is self-centering, and is quicker and easier to

mount than the independent chuck mandrel. The standard

mandrel can be mounted in pipes with an I.D. range from

3.27” to 23.64” (83.1 to 600.5 mm).

The workpiece may not be suitable for the standard mandrel, such as in the following situations:

• the I.D. of the pipe is uneven or eroded

• the end of the pipe is on a bend

• the end surface of the pipe is not square

• you need to center the operation on the O.D. of the pipe.

In these cases, you will need to use the independent chuck

mandrel. You can use the independent chuck mandrel for

either form tool or single-point operation. The independent

chuck mandrel can be mounted in pipes with an I.D. range

from 8.50” to 25.28” (215.9 to 642.1 mm).

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 31

EP 424 End Prep Machine

NOTE

NOTE

If the pipe I.D. is larger than

15.96” (405.4 mm), you will

need the extended leg kit.

Mounting the Universal (Standard) Mandrel

Measure the I.D. of the pipe.

1.

See the envelope drawings in

Chapter 3 for an illustration of

the clamp leg configurations.

Figure 5-1. Measure the I.D. of the pipe to determine

which leg set will be required.

Refer to the clamp leg chart in Table 1 to select the

2.

correct combination of clamp legs. Find the I.D. you

measured (inches or mm) in the appropriate column

on the left, then select the leg extensions listed in the

column on the right.

32 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

Table 1: Standard Mandrel Clamping Leg Chart

I.D. Inches I.D. mm

Min Max Min Max

3.27 4.20 83.1 106.7 None

4.07 4.99 103.4 126.8 #1

4.86 5.79 123.4 147.1 #2

5.64 6.56 143.3 166.6 #3 & #1

6.46 7.39 164.1 187.7 #3 & #2

7.22 8.15 183.4 207.1 #3, #2, & #1

7.94 8.87 201.7 225.3 #4 & #1

8.77 9.71 222.8 246.6 #4 & #2

9.53 10.46 242.1 265.7 #4, #3, & #1

10.24 11.18 260.1 284.0 #5 & #1

11.09 12.02 281.7 305.3 #5 & #2

11.84 12.77 300.7 324.4 #5, #3, & #1

12.69 13.62 322.3 346.0 #5, #3, & #2

12.58 1 3.51 319.5 343.2 #6 & #1

13.43 1 4.36 341.1 364.7 #6 & #2

14.17 15.11 359.9 383.8 #6, #3, & #1

15.03 15.96 381.8 405.4 #6, #3, & #2

Leg Extensions Used

With 81-303-01 Extended Leg Kit

14.87 1 5.80 377.7 401.3 #7 & #1

15.73 1 6.66 399.5 423.2 #7 & #2

16.47 17.40 418.3 442.0 #7, #3, & #1

17.33 18.26 440.2 463.8 #7, #3, & #2

17.19 1 8.12 436.6 460.3 #8 & #1

18.05 1 8.98 458.5 482.1 #8 & #2

18.78 19.72 477.0 500.9 #8, #3, & #1

19.65 20.58 499.1 522.7 #8, #3, & #2

20.38 2 1.32 517.7 541.5 #8, #3, #2, & #1

21.10 22.04 535.9 559.8 #8, #4, & #1

21.97 22.90 558.0 581.7 #8, #4, & #2

22.70 2 3.64 576.6 600.5 #8, #4, #3, & #1

Using a 3/16” hex wrench, attach the clamping legs to

3.

the mandrel chuck legs with the captivated screws. If

you are using more than one leg set, install the largest

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 33

EP 424 End Prep Machine

NOTE

Extension leg #1 does not

have threaded holes to install

other legs on top of it.

leg first, then “stack” them in size order. Make sure

the legs seat squarely, then securely tighten the

screws.

Figure 5-2. Screw the captivated scr ews into the mandrel to secure the legs.

Always install extension leg #1 or #2 last, on top of

4.

the others. These legs are steel for greater durability.

34 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-3. Use the steel extension legs (#1 or #2) on

top when installing multiple legs.

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

NOTE

NOTE

Using a 1-1/16” wrench or socket, turn the drawbar

5.

nut counter-clockwise to retract the clamping legs.

Figure 5-4. Turn the drawbar nut counter-clockwise

to retract the clamping legs.

Insert the clamping legs into the I.D. of the pipe. Hold

6.

the mandrel so that the legs are far enough inside the

end of the pipe to be out of the way of the machining

operation.

A socket wrench and 1-1/16”

socket are provided with the

EP 424.

For stability, the clamp legs

should be as close as possible to the end of the pipe.

However, make sure they are

far enough into the pipe to

avoid being damaged during

the operation. This is espe-

cially critical if you are

counterboring.

Figure 5-5. Insert the clamping legs into the pipe.

Turn the drawbar nut clockwise to clamp the legs

7.

inside the pipe until they are snug enough to hold the

mandrel.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 35

EP 424 End Prep Machine

Figure 5-6. Turn the drawbar nut clockwise until the

clamping legs are snug in the I.D. of the pipe.

Check that the legs are square on the pipe I.D., and are

8.

far enough from the pipe end for the operation.

Figure 5-7. Measur e the distance from the pipe end to

the clamping legs to make sure there is enough clearance for the operation.

If necessary, adjust the position of the clamping legs.

9.

Then turn the drawbar nut clockwise to clamp the legs

securely in the pipe.

36 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

NOTE

Mounting the Independent Chuck Mandrel

Start with the chuck body separated from the mandrel.

Measure the I.D. of the pipe.

1.

Figure 5-8. Measure the I.D. of the pipe to determine

which leg set will be required.

Refer to the clamp leg chart in Table 2 to select the

2.

correct clamp legs. Find the I.D. you measured (inches

or mm) in the appropriate column on the left, then

select the leg set listed in the column on the right.

See the envelope drawings in

Chapter 3 for an illustration of

the clamp leg configurations.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 37

EP 424 End Prep Machine

Table 2: Independent Chuck Clamping Leg Chart

I.D. Inches I.D. mm

MinMaxMinMax

8.50 10.50 215.9 266.7 23-313-00 No

9.50 11.50 241.3 292.1 23-313-00 Yes

1 1.18 13.15 284.0 334.0 23-214-01 No

12.18 14.15 309.4 359.4 23-214-01 Yes

14.43 16.50 366.5 419.1 23-214-02 No

15.43 17.50 391.9 444.5 23-214-02 Yes

16.87 18.81 428.5 477.8 23-214-03 No

17.87 19.81 453.9 503.2 23-214-03 Yes

19.31 21.30 490.5 541.0 23-214-04 No

20.31 22.30 515.9 566.4 23-214-04 Yes

22.28 24.28 565.9 616.7 23-214-05 No

23.28 25.28 591.3 642.1 23-214-05 Yes

Screw the 4 chuck legs into the chuck body. Leave

3.

Leg Set Used

Spacer (23-221-

00) Used

about 1/2” of threads exposed for the jam nut.

38 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-9. Screw the chuck legs into the chuck.

Put a jam nut over each leg, with the “shoulder” side

4.

of it toward the chuck body . Thread it a few turns onto

the chuck leg.

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

Shoulder

Figure 5-10. Put on the jam nut as shown, with the

shoulder of the nut toward the chuck.

If chuck leg spacers (23-221-00) are required, install a

5.

spacer over each of the 4 independent chuck buttons.

Figure 5-11. If required, put a chuck leg spacer on

each chuck button end.

Insert a button into the end of each chuck leg. The but-

6.

tons are fitted with o-rings to hold them in the leg.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 39

EP 424 End Prep Machine

Figure 5-12. Put buttons on the end of each chuck leg.

Place the chuck body inside the I.D. of the pipe and

7.

screw the legs out to snug them against the I.D.

40 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-13. Screw the legs out to snug the chuck

inside the pipe.

Remove the nuts from the 4 threaded studs, and put

8.

the interlocking pieces of the alignment gauge over

the studs with the scale sides facing you.

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

Figure 5-14. Mount the alignment gauge to the studs

in the chuck.

Screw the nuts onto the studs to secure the alignment

9.

gauge. The gauge pieces should be tight against the

face plate. You may have to move the chuck out to

tighten the gauge against the face plate.

Figure 5-15. The alignment gauge must be flush

against the face plate surface.

Loosen the clamp legs slightly, and push the chuck

10.

body into the pipe until all four ends of the alignment

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 41

EP 424 End Prep Machine

NOTE

gauge are touching the end of the pipe. Re-tighten the

legs to hold the chuck body in place.

You will roughly center the

chuck body in the pipe (to the

precision of the alignment

gauge scales). You will precisely center the mandrel

later in this procedure.

Figure 5-16. Push the chuck body into the pipe until

all four arms of the alignment gauge are against the

pipe surface.

To center the chuck body, refer to the scales on the

11.

alignment gauges. Using a 1-1/8” end wrench on the

flats of the chuck legs, turn opposite legs in or out

until the scale touches the pipe I.D. at the same distance on both sides.

Figure 5-17. Alternately adjust opposite legs to center

the chuck in the pipe.

42 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

When the chuck body is centered, use a 2-1/4” wrench

12.

to snug the jam nuts against the chuck body.

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

Figure 5-18. When the chuck is rough centered, snug

the jam nuts to hold the clamping legs in place.

Remove the alignment gauge from the studs. Make

13.

sure you have the nut and both washers removed from

each stud.

Figure 5-19. Remove the alignment gauge and the

nuts and washers from the chuck studs.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 43

EP 424 End Prep Machine

NOTE

If the chuck does not need

any further centering adjustment, install a spacer (23203-00) over each stud

before mounting the mandrel.

Mount the mandrel onto the chuck.

14.

Figure 5-20. Mount the mandrel on the independent

chuck.

Replace the 2 washers (female washer first) and the

15.

nut onto each stud to hold the mandrel in place. Snug

the nuts to finger tightness.

Place the indicator mounting collar over the mandrel

16.

and slide it close to the pipe.

44 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-21. Slide the indicator collar over the end of

the mandrel.

Chapter 5, Operating Instructions: Mounting the Mandrel on the Pipe

Tighten the set screws in the indicator collar to hold it

17.

in place on the mandrel.

Figure 5-22. Position the collar near the pipe surface

and tighten the set screws to hold it in place.

Assemble the indicator and set the magnetic mount

18.

onto the indicator mounting collar. T urn the magnet on

to hold the indicator in place.

Figure 5-23. Set the magnetic base of the indicator on

the collar, and turn the switch on to engage the magnet.

Position the tip of the indicator to touch the pipe sur-

19.

face. You can indicate on either the O.D. or the I.D. of

the pipe, depending on where the operation needs to

be centered.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 45

EP 424 End Prep Machine

NOTE

Do not adjust the mandrel

centering screws if stud spacers (23-203-00) are installed.

The mandrel position cannot

be adjusted with the spacers.

Figure 5-24. Set the tip of the indicator to touch the

pipe, perpendicular to the surface.

Move the indicator around the pipe end by rotating the

20.

mounting collar. Check the reading on the indicator

dial to measure how far the mandrel is off center.

46 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-25. Sweep the indicator around the pipe surface to check centering of the mandrel. You can center

on either the O.D. or the I.D. of the pipe, as required

for the operation.

To center the mandrel, adjust the mandrel centering

21.

screws in the face plate.

Chapter 5, Operating Instructions: Using the Drive Motors

Figure 5-26. Turn the mandrel centering screws to

adjust the position of the mandrel.

When you have the mandrel centered, tighten down

22.

the nuts on the mandrel mounting studs.

Remove the indicator and the indicator mounting col-

23.

lar.

USING THE DRIVE MOTORS

Refer to the instructions in this section for the drive motor

(air or hydraulic) provided with your EP 424 machine. The

motors are installed and operated the same way for either

form tool or single-point operation.

Mounting and Operating the Air Drive

T o install the air motor , put the motor flange over the 4

1.

motor mounting screws on the EP 424 motor adapter.

You may have to rotate the motor slightly to engage

the spline in the shaft.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 47

EP 424 End Prep Machine

NOTE

Figure 5-27. Put the air motor flange over the screws

in the motor adapter.

Rotate the air motor to secure the screw heads in the

2.

slotted holes of the flange. Using a 1/4” hex wrench,

tighten the screws securely.

The air supply must provide

95 cfm at 90 psi (2700 l/min

at 6.2 bar).

48 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-28. Turn the flange to seat the screws in the

slots, then tighten the screws.

Make sure the air supply is turned off at the source.

3.

Connect the air line to the connector on the air motor.

Turn on the air supply at the source.

4.

To operate the EP 424, squeeze the trigger on the air

5.

motor. The machine (form tool head or single-point

slide) will start to rotate.

Figure 5-29. Squeeze the air motor trigger to start the

NOTE

machine.

Adjust the motor speed by turning the speed control-

6.

ler.

Chapter 5, Operating Instructions: Using the Drive Motors

Figure 5-30. Turn the speed control collar to adjust

the rotation speed of the machine.

While holding the air motor trigger, operate the

7.

machine as described in the appropriate section below

(form tool or single-point operation).

As the machine cuts, adjust the air motor speed if nec-

8.

essary to reduce chatter and achieve the appropriate

end prep finish.

When the prep is complete, release the air motor trig-

9.

ger to stop the machine.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 49

The use of coolant or cutting

lubricant is recommended.

This will improve the cutting

performance and increase

the life of the tooling.

EP 424 End Prep Machine

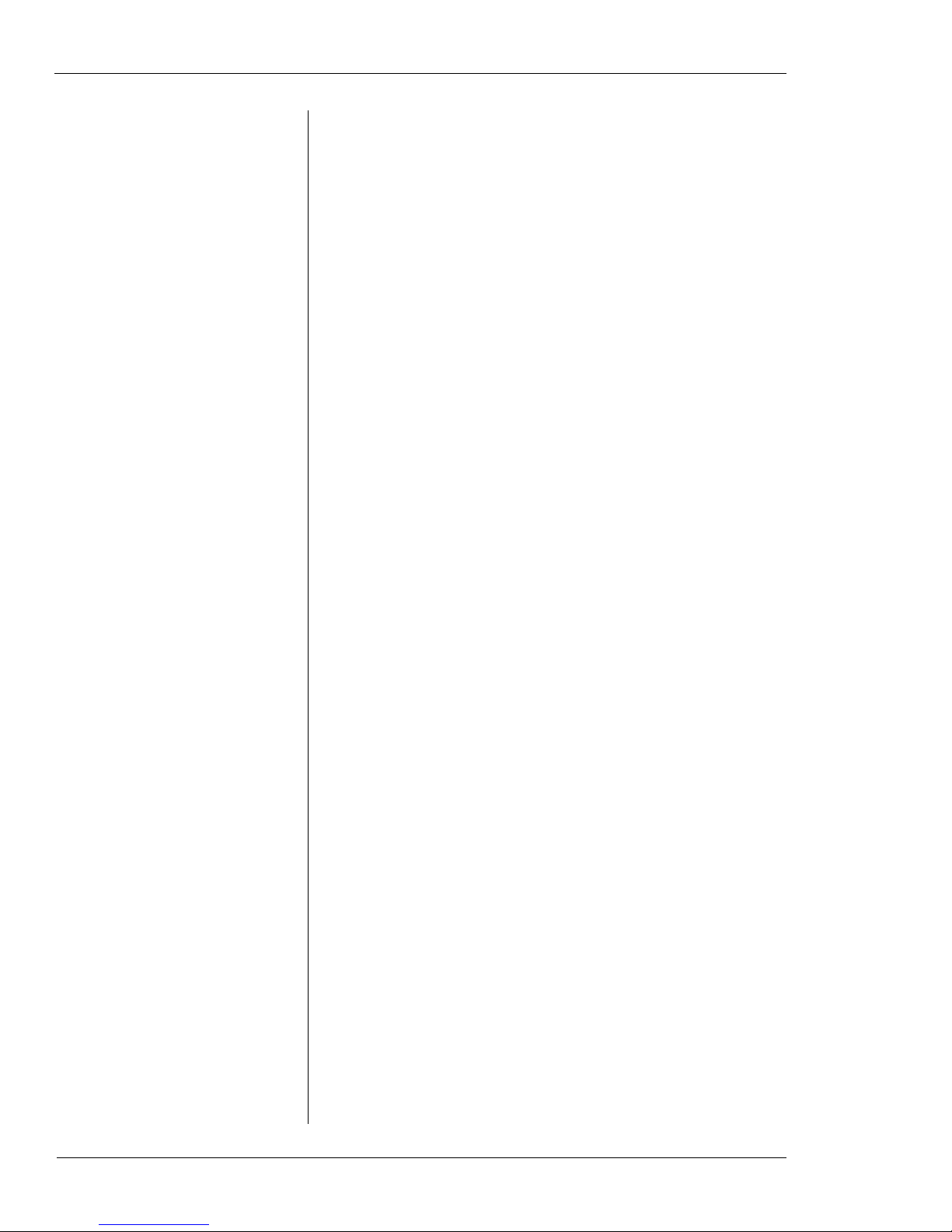

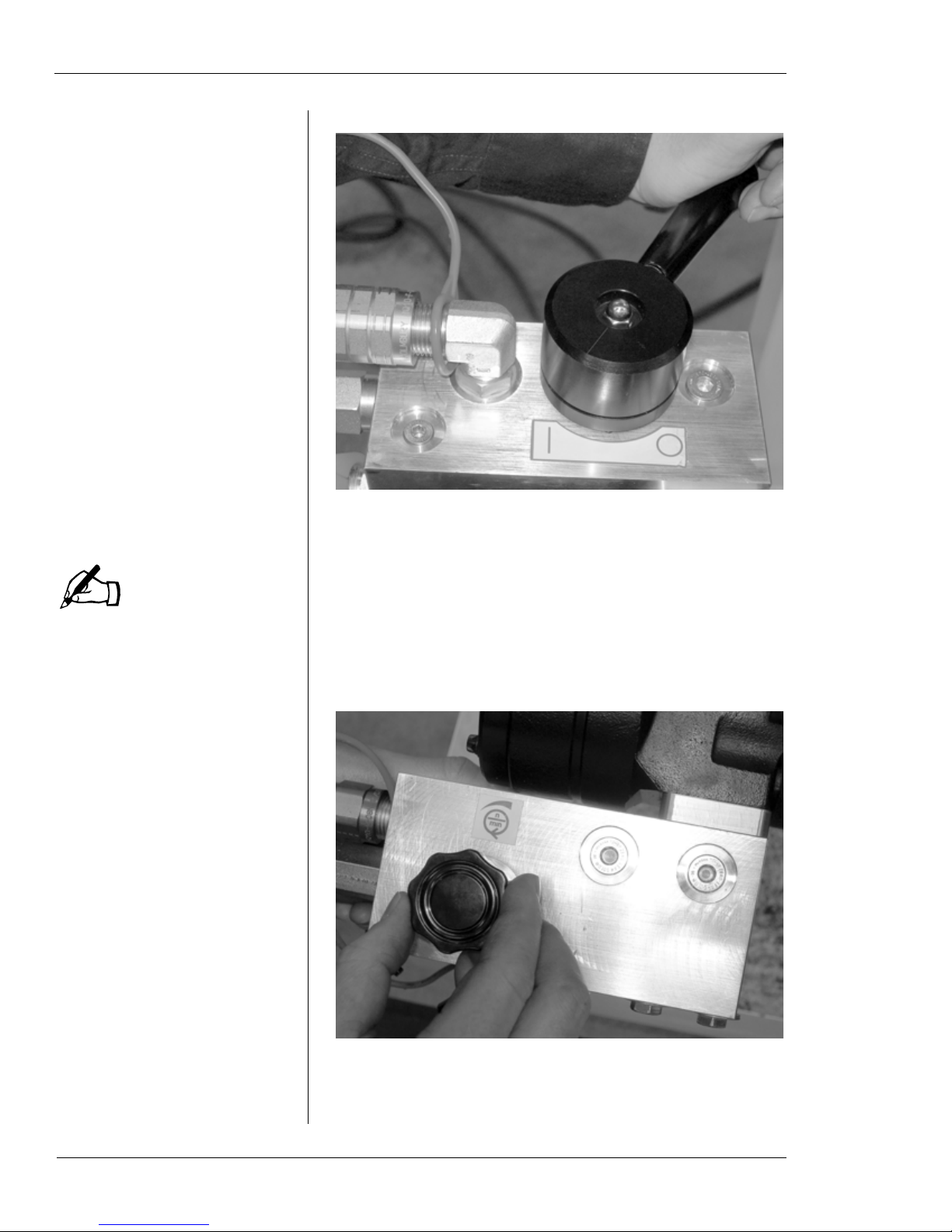

Mounting and Operating the Hydraulic Drive

To install the hydraulic motor, put the motor flange

1.

over the 4 motor mounting screws on the EP 424

motor adapter. You may have to rotate the motor

slightly to engage the spline in the shaft.

Figure 5-31. Mount the hydraulic motor flange onto

the screws in the motor adapter.

Turn the flange to engage the screw heads in the slots,

2.

then tighten the screws using a 1/4” hex wrench.

50 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-32. Turn the flange to seat the screws in the

slots, then tighten the screws.

Connect the hydraulic hoses to the ports on the motor

Tank (return)

connector

Pressure

connector

3.

as described in Figure 5-33.

Chapter 5, Operating Instructions: Using the Drive Motors

Figure 5-33. Connect the hydraulic hoses to the

motor as shown.

Turn on the hydraulic power supply. Set it to 10 gpm

4.

at 1500 psi (38 l/min at 103 bar).

Push the hydraulic drive lever toward the main body

5.

of the machine. The machine will start to rotate.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 51

EP 424 End Prep Machine

NOTE

The form tool head has

arrows indicating the correct

direction of rotation.

Figure 5-34. Turn the hydraulic lever to the ON position as shown.

Make sure the machine is turning clockwise. If it is

6.

turning the wrong way, the hydraulic hoses are

reversed. Turn off the HPU and switch the hoses.

Adjust the drive motor speed by turning the speed dial

7.

on the hydraulic motor.

52 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-35. Use the speed dial on the hydraulic manifold to adjust the machine rotation speed.

Chapter 5, Operating Instructions: Form Tool Operation

NOTE

NOTE

While holding the hydraulic drive lever on, operate

8.

the machine as described in the appropriate section

below (form tool or single-point operation).

As the machine cuts, adjust the hydraulic motor speed

9.

if necessary to reduce chatter and achieve the appropriate end prep finish.

When the prep is complete, release the hydraulic drive

10.

lever to stop the machine.

FORM TOOL OPERATION

The EP 424 has three tool holders, which can each hold a

different tool. This allows you to perform any combination

of facing, beveling, and counterboring simultaneously.

Make sure the EP 424 is set up as follows for form tool

operation:

The use of coolant or cutting

lubricant is recommended.

This will improve the cutting

performance and increase

the life of the tooling.

• Use the standard mandrel, if possible for the workpiece.

• Have the single-point slide removed and the rotating

tool head installed. (See “Removing the Single-Point

Kit” in the next section.)

• If your EP 424 is equipped with the Speed Prep autofeed

module, set the axial feed selector to 0° when doing

form tool operations.

Setting the feed selector to 0°

will reduce wear on the

Speed Prep components

when you are not using the

autofeed.

Figure 5-36. Set the Speed Prep selector to 0° before

doing form tool operations.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 53

EP 424 End Prep Machine

Planning the Operation

Operating Envelope

Make sure you have adequate clearance around the workpiece. See the operating envelope drawings in Chapter 3 for

reference.

Selecting Tooling

Use the following charts to select the appropriate tooling for

the operation.

54 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-37. The chart describes the tooling used for

facing/beveling operations.

Chapter 5, Operating Instructions: Form Tool Operation

Figure 5-38. The chart describes the tooling used for

counterboring.

Figure 5-39. The chart describes the tooling used for

deburring.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 55

EP 424 End Prep Machine

Figure 5-40. The chart describes the tooling used for

J-prep operations.

Adjusting the Tool Holder Positions

You may need to change the positions of the tool holders in

the rotating head, depending on the pipe diameter . Each tool

holder can be set to an “inner” (small diameter) or “outer”

(large diameter) position.

Using a 1/4” hex wrench, remove the 8 screws holding

1.

the tool holder to the rotating head. (Note: if the tool

holder is already in the outer position, it will have 6

screws holding it.)

56 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Chapter 5, Operating Instructions: Form Tool Operation

Figure 5-41. The photo shows the tool holder moved

to the “outer” position for larger diameter pipes.

Move the tool holder to the other position. Line up the

2.

holes and re-insert the screws. Use 6 screws if setting

the holder to the outer position.

Setting Up and Mounting the EP 424

You will probably find it easiest to assemble the main components of the EP 424 as you install the machine. The following is the recommended sequence for installation:

• Configure and mount the mandrel in the workpiece, as

described at the beginning of this chapter.

• Install the machine body onto the mandrel.

• Install the tooling in the rotating tool head.

• Install the drive motor.

If desired, you can assemble the machine and then mount it

on the workpiece. You will need a lifting device to support

the machine as you mount it.

Assembling the Machine Components

The following procedure assumes that the mandrel has been

mounted in the pipe, as described earlier in this chapter.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 57

EP 424 End Prep Machine

NOTE

It is recommended that you

using a lifting device to pick

up the EP 424. If you are lifting it manually, have two

operators lift it.

Attach a crane or other lifting device to the lift hook

1.

on the machine body.

Figure 5-42. Attach the lifting device to the lift hook.

Use the lifting device to pick up the EP 424 and posi-

2.

tion it for mounting on the mandrel. If you do not have

a lifting device, two people can lift the machine into

place using the handles.

58 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-43. Position the machine to mount it on the

mandrel.

Slide the machine forward on the mandrel. Turn the

NOTE

Mandrel

threads

Feed nut

3.

machine back and forth while pushing to engage it all

the way onto the spline.

Chapter 5, Operating Instructions: Form Tool Operation

Figure 5-44. Push the machine forwar d onto the mandrel.

When the machine is fully engaged on the spline,

4.

lower the lifting device slightly to take the tension off

it.

Turn the feed handle clockwise to engage the mandrel

5.

threads in the feed nut.

Push the machine forward

while turning the feed handle

to start the threads.

Figure 5-45. Turn the feed handle clockwise to

engage the mandrel threads in the feed nut.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 59

EP 424 End Prep Machine

Direction of

rotation

Turn the feed handle clockwise until the drawbar nut

6.

emerges from the back of the machine.

Figure 5-46. Engage the mandrel threads fully in the

feed nut for stable operation.

Using a 3/16” hex wrench, loosen the tooling set

7.

screws in the tool holder and put the tool in the holder .

Tighten the set screws.

Figure 5-47. Insert the tool in the tool holder and

tighten the set screws holding it. Make sur e the cutting

edge of the tool is toward the direction of rotation, as

shown.

60 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Install any other tools required for the operation in the

8.

other tool holders. You can perform up to 3 operations

simultaneously—for example, facing, beveling, and

WARNING

NOTE

counterboring.

Turn the feed handle clockwise until the tools are

9.

close to the pipe end. If necessary, loosen the set

screws and adjust the tool positions for the required

operation.

Chapter 5, Operating Instructions: Form Tool Operation

Figure 5-48. T urn the feed handle to position the tools

near the cutting surface. Adjust the tool position if

necessary.

Install and connect the drive motor as described earlier

10.

in this chapter.

Turn on the power source (air or hydraulic).

11.

Turn on the drive motor. The machine will start to

12.

rotate. Adjust the motor speed using the speed controller on the drive.

Turn the feed handle clockwise to feed the tooling into

13.

the pipe face. Check the radial position of the tooling.

Stop the machine if you need to adjust the tool position.

Continue feeding the tooling into the pipe. Adjust the

14.

drive motor speed if necessary to reduce chatter and

achieve the appropriate end prep finish.

You can use the scale on the feed housing to measure

15.

the axial depth of cut. Each line on the the scale is

0.001” (0.025 mm) of feed.

Keep hands clear of the rotating head while the machine is

operating. Contact with the

head or tooling could result in

serious injury.

The use of coolant or cutting

lubricant is recommended.

This will improve the cutting

performance and increase

the life of the tooling.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 61

EP 424 End Prep Machine

Figure 5-49. Use the scale on the feed housing to

measure axial feed distance.

When the prep is complete, turn the feed handle coun-

16.

ter-clockwise to retract the tooling from the pipe end.

Release the air motor trigger to stop the machine.

Removing the Machine from the Workpiece

Turn the feed handle counter-clockwise to retract the

1.

tooling away from the pipe end.

It is recommended that you remove the tooling from

2.

the tool holders before removing the machine. This

prevents accidental damage to the tooling, or damage

or injury caused by the tooling in case of a collision

while moving the machine.

Disconnect the power source (air or hydraulic) from

3.

the drive motor.

Loosen the 4 motor mounting screws and remove the

4.

drive motor.

Connect the lifting device to the lifting eye on the

5.

machine. Raise the lift enough to put slight tension on

the chain or strap.

Turn the feed handle counter-clockwise until the

6.

threads on the mandrel disengage from the feed nut.

Make sure the lift is supporting the machine. Pull the

7.

machine back off the mandrel, and set it on the floor or

a stable work surface.

62 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

If the standard mandrel is installed, use a 1-1/16”

8.

wrench or socket to turn the drawbar nut counterclockwise to loosen the clamp legs.

Chapter 5, Operating Instructions: Single Point Operation

If the independent chuck mandrel is installed, loosen

9.

the jam nuts and then loosen the clamp legs.Pull the

mandrel out of the pipe.

If you are finished with the machine, or are going to

10.

work on a different sized pipe, remove the clamp leg

extensions from the mandrel.

SINGLE POINT OPERATION

Installing the Single-Point Kit

If your EP 424 machine is equipped with the single-point

option kit, it will include the single-point slide, trip ring, and

independent chuck as additional components. Set up the

machine as described below for single-point operation.

Set the machine on a stable work surface that can sup-

1.

port its weight. Use a lifting device to lift the EP 424.

If the mandrel is installed, remove it by turning the

2.

feed handle counter-clockwise until the mandrel is

threaded out of the feed nut.

Figure 5-50. Turn the feed handle counter-clockwise

to thread the mandrel out of the feed nut.

Pull the mandrel out through the front of the machine.

3.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 63

EP 424 End Prep Machine

Figure 5-51. Pull the mandrel out of the machine.

Using a 5/16” hex wrench, remove the 6 screws hold-

4.

ing the rotating head to the main shaft.

Figure 5-52. Remove the 6 screws holding the rotating head to the main shaft.

Remove the rotating head from the main shaft.

5.

64 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-53. Remove the rotating head.

Chapter 5, Operating Instructions: Single Point Operation

Install the trip assembly onto the front of the machine,

6.

with the trip knobs toward the feed handle side. Fit the

ring of the trip assembly around the the rim of the

main housing, with the set screws aligned with the

flats in the housing.

Figure 5-54. Mount the trip assembly on the housing.

Using a 1/8” hex wrench, tighten the 4 set screws in

7.

the trip assembly.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 65

EP 424 End Prep Machine

NOTE

NOTE

The trip assembly screws are

on the back of the ring.

Figure 5-55. Tighten down the 4 set screws while

holding the trip ring assembly in place.

Make sure the felt wiper is in

place on the back of the single-point slide.

Put the single-point slide into place on the main shaft.

8.

Align the 3 dowel pins in the slide with the holes in

the shaft, and press the slide into place.

66 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-56. Ther e are three dowel pins in the back of

the single-point slide to mount it to the main shaft.

Using a 5/16” hex wrench, tighten the 6 captivated

9.

screws in the single-point slide to secure it to the main

shaft.

Chapter 5, Operating Instructions: Single Point Operation

Figure 5-57. Tighten the captivated screws in the 6

holes to attach the single-point slide to the main shaft.

If you want to install the mandrel before mounting the

10.

machine on the workpiece, insert the threaded end of

the mandrel through the single-point slide. You may

have to turn the mandrel slightly while pushing it to

engage the spline.

Figure 5-58. Insert the mandrel through the singlepoint slide.

Turn the feed handle clockwise to engage the threads

11.

of the mandrel into the feed nut. Turn the handle until

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 67

EP 424 End Prep Machine

the threads emerge through the back of the rear feed

assembly.

Figure 5-59. Turn the feed handle clockwise to

engage the mandrel threads in the feed nut.

Planning the Operation

Operating Envelope

Make sure you have adequate clearance around the workpiece. See the operating envelope drawings in Chapter 3 for

reference.

Selecting Tool Holder

Two tool holders are provided with the single-point slide:

• low-range (part no. 56-424-00), for pipe O.D. range

4.24”-23.62” (108-600 mm)

• high-range (part no. 56-424-01), for pipe O.D. range

7.25”-24” (184-610 mm).

For most applications, you can use either tool holder. Make

sure you select one with a range that includes the O.D. of

the pipe you are machining.

68 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Beveling O.D. Set-Back

The O.D. set-back is the distance from the end of the pipe

where you will start the beveling operation. It is determined

Chapter 5, Operating Instructions: Single Point Operation

L

R

R

E

A

W

S = Set-Back

R = Root Radius

L = Land

E = Land Extension

A = Bevel Angle

W = Wall Thickness (After Counterbore)

S

S = R + E + [tan(A) x (W - L - R)]

by the angle(s) of the bevel, the pipe wall thickness, the land

thickness, the land root radius, and the land extension.

For a single-angle bevel, compute the set-back using the following formula:

Figure 5-60. The diagram illustrates how to compute

the O.D. set-back when performing a single-angle

bevel.

SINGLE-ANGLE BEVEL EXAMPLE:

R = 0.125”

L = 0.100”

E = 0.125”

A = 20°

W = 0.800”

S = 0.125” + 0.125” + [tan(20°) x (0.800” - 0.100” - 0.125”]

= 0.250” + [0.364 x 0.575”]

= 0.459”

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 69

EP 424 End Prep Machine

L

R

R

E

A1

W

S = Set-Back

R = Root Radius

L = Land

E = Land Extension

A1 = Inner Bevel Angle

A2 = Outer Bevel Angle

T = Transition (from I.D.)

W = Wall Thickness (After Counterbore)

S = R + E + [tan(A2) x (W - T)] + [tan(A1) x (T - L - R)]

A2

S

T

For a compound bevel, use the following formula:

70 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-61. The diagram illustrates how to compute

the O.D. set-back when performing a compound bevel.

COMPOUND BEVEL EXAMPLE:

R = 0.125”

L = 0.100”

E = 0.125”

A1 = 30°

A2 = 10°

T = 0.750”

W = 1.875”

S = 0.125” + 0.125” + [tan(10°) x (1.875” - 0.750”]

+ [tan(30°) x (0.750” - 0.125” - 0.125”]

= 0.250” + [0.176 x 1.125”] + [0.577 x 0.500]

= 0.250” + 0.198 + 0.289”

= 0.737”

Chapter 5, Operating Instructions: Single Point Operation

NOTE

Setting Up and Mounting the EP 424

You will probably find it easiest to assemble the main components of the EP 424 as you install the machine. The following is the recommended sequence for installation:

• Configure and mount the mandrel in the workpiece, as

described in the previous section.

• Install the machine body onto the mandrel.

• Install the tool holder and tooling in the single-point

slide.

• Install the drive motor.

If desired, you can assemble the machine and then mount it

on the workpiece. You will need a lifting device to support

the machine as you mount it.

Assembling the Machine Components

The following procedure assumes that the mandrel has been

mounted in the pipe, as described earlier in this chapter.

Attach a crane or other lifting device to the lift hook

1.

on the machine body.

It is recommended that you

using a lifting device to pick

up the EP 424. If you are lifting it manually, have two

operators lift it.

Figure 5-62. Attach the lifting device to the lift ring.

Use the lifting device to pick up the EP 424 and posi-

2.

tion it for mounting on the mandrel. If you do not have

a lifting device, two people can lift the machine into

place using the handles.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 71

EP 424 End Prep Machine

Figure 5-63. Position the EP 424 to mount it on the

mandrel.

Slide the machine forward on the mandrel. Turn the

3.

machine back and forth while pushing to engage it all

the way onto the spline.

72 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Figure 5-64. Push the machine forward on the mandrel until you can engage the mandrel threads in the

feed nut.

When the machine is fully engaged on the spline,

NOTE

4.

lower the lifting device slightly to take the tension off

it.

When the machine is as far forward as it will go, turn

5.

the feed handle clockwise to engage the mandrel

threads in the feed nut.

Turn the feed handle clockwise until the end of the

6.

mandrel emerges from the back of the machine. Feed

the machine until at least 1/2” (13 mm) of threads on

the mandrel are visible.

Chapter 5, Operating Instructions: Single Point Operation

Push the machine forward

while turning the feed handle

to start the threads.

Figure 5-65. Engage the mandrel threads fully in the

feed nut for stable operation.

Install the autofeed stop plate on the end of the man-

7.

drel. The stop plate prevents the machine from autofeeding all the way off the mandrel.

Using a 3/16” hex wrench, loosen the tooling set

8.

screws in the male slide and put the tool holder with

the tool in the slide. Tighten the set screws.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 73

EP 424 End Prep Machine

Figure 5-66. Install the tool holder in the slide.

Using a 5/16” hex wrench, turn the starwheel on the

9.

slide to position the tool just beyond the O.D. of the

pipe.

Figure 5-67. Turn the starwheel until the tool bit is

positioned at the required start point.

74 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Turn the feed handle clockwise to advance the tool to

10.

the starting position above the O.D. of the pipe.

Using the Speed Prep Autofeed

WARNING

Loosen the knob on the Speed Prep module, and slide

1.

the gauge to the desired angle on the scale. Refer to

the appropriate scale for using 1 trip or 2 trips. Tighten

the knob.

Engage the required number of trips. For multiple

2.

trips, engage them on opposite sides of the trip assembly.

Start the drive motor to operate the machine. Ensure

3.

that the starwheel is turning when it strikes the

engaged trips.

To engage the Speed Prep autofeed, pull the feed han-

4.

dle back toward you. Y ou will f eel it “snap” into place.

Immediately let go of the feed handle.

As the machine rotates, the autofeed will turn the feed

5.

handle counter-clockwise.

Chapter 5, Operating Instructions: Single Point Operation

The Speed Prep autofeed

can feed the machine until it

comes off the mandrel.

Crushing or other serious

injuries could occur. Use the

autofeed stop plate (81-316-

00) to keep the machine from

feeding too far.

To disengage the autofeed, push the feed handle in.

6.

Compound Bevel

Use the knob stops to set the angles.

Set the Speed Prep knob to the location for the starting

1.

angle (the angle at the O.D. of the pipe). Lock the

knob in place.

Move the left knob stop up against the knob and

2.

tighten it.

E.H. Wachs Part No. 81-MAN-00, Rev. 0-0610 75

EP 424 End Prep Machine

Figure 5-68. Set the left knob stop against the Speed

Prep knob.

Loosen the Speed Prep knob and set it to the location

3.

of the transition angle. Lock the knob in place.

Move the right knob stop up against the knob and

4.

tighten it.

Figure 5-69. Set the right knob stop.

76 Part No. 81-MAN-00, Rev. 0-0610 E.H. Wachs

Set the Speed Prep knob back to the starting angle

5.

position and lock it in place.

Measure and mark the transition point on the pipe face

6.

surface.

Chapter 5, Operating Instructions: Single Point Operation

Start the cutting operation on the O.D. of the pipe. Pull

7.

the feed handle to engage the autofeed when the tool

begins to cut the pipe.

When the tool reaches the transition point, loosen the

8.

Speed Prep knob and move it over against the right

knob stop. Tighten the knob.

Continue until the bevel is complete.

9.

Removing the Machine from the Workpiece

Using a 5/16” hex wrench, turn the starwheel on the

1.

slide clockwise to retract the tool away from the pipe.

Turn the feed handle counter-clockwise to retract the

2.

single-point slide away from the pipe end.

It is recommended that you remove the tool holder

3.

from the slide before removing the machine. This prevents accidental damage to the tooling, or damage or

injury caused by the tooling in case of a collision

while moving the machine.

Disconnect the power source (air or hydraulic) from

4.

the drive motor.