E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

Window Cutter

User’s Manual

E.H. Wachs Part No. 06-030-MAN

Rev. 2-0709, July 2009

Revision History:

Version 1 June 2006

Copyright © 2009 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

Window Cutter

Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operator Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Introduction to the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Usage and Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Window Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hydraulic Power Unit (HPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 4: Assembly, Disassembly, and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Removing the Machine from the Shipping/Storage Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Long-Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 5: Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Configuring the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Tracking Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting the Chain Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mounting on Horizontal Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mounting on Vertical Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting the Guide Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting the Window Cutter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connect Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 1

Window Cutter

Cutting the Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Horizontal Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Vertical Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Machine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Flow Control Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Radial Cut Stabilizing Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rotating the Cutter Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Feeding the Cutter into the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 6: Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 7: Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 8: Parts Lists and Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 9: Accessories and Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 10: Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Ordering Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 1

About This Manual

Chapter 1, About This Manual

In This Chapter

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain your

window cutter system. It includes instructions for set-up,

operation, and routine maintenance. It also contains parts

lists, assembly diagrams, and troubleshooting instructions

to help you order replacement parts and perform user-serviceable repairs.

Before operating the window cutter, you should read

through this manual and become familiar with all instructions. At a minimum, make sure you read and understand

the following chapters:

• Chapter 1, About This Manual

• Chapter 2, Safety

• Chapter 3, Introduction

• Chapter 5, Operating Instructions.

If you will be performing service or repairs, make sure you

read and understand these chapters:

PURPOSE OF THIS MANUAL

HOW TO USE THE MANUAL

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

EVISION TRACKING

R

• Chapter 1, About This Manual

• Chapter 4, Assembly, Disassembly, and Storage

• Chapter 6, Routine Maintenance

• Chapter 7, Service and Repair.

You will also want to refer to Chapter 8, Parts Lists and

Drawings.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 1

Window Cutter

HOW TO USE THE MANUAL

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining the window cutter.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

window cutter.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions.

Refer to it for safety notes and other information.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special notes and warnings. They appear in the outside column of the page, next to the section they refer to.

Make sure you understand what each symbol means, and

follow all instructions for cautions and warnings.

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death. See Chapter 2 for more

detailed safety information.

NOTE

This symbol indicates a user notice.

Notices provide additional information to

supplement the instructions, or tips for

easier operation.

2 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 1, About This Manual: Manual Updates and Revision Tracking

MANUAL UPDATES AND REVISION TRACKING

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. Revised chapters will be available for customers. If

you receive revised chapters for your manual, remove the

old chapters from your binder and replace them with the

new chapters.

When a manual is revised, we will update the revision history on the title page and at the bottom of the pages in the

revised chapters. It is important to put the current title page

with the revision history in your manual. This will help you

make sure you have all current information.

You may have factory service or upgrades performed on

your equipment. If this service changes any technical data

or operation and maintenance procedures, we will include

revised sections of the manual when we return the equipment to you. Remove the old chapters from your manual

and replace them with the revised chapters.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@ehwachs.com

.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 3

Window Cutter

4 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 2

Safety

Chapter 2, Safety

The E.H. Wachs Company takes great pride in designing

and manufacturing safe, high-quality products. We make

user safety a top priority in the design of all our products.

WARNING

Read this chapter carefully before operating the window

cutter system. Serious injury or death could result from

improper repair or service of this equipment.

Repair and/or service to this equipment must only be done

by an authorized and certified dealer.

OPERATOR SAFETY

Follow these guidelines for safe operation of any mechanical equipment associated with the data logger.

• READ THE OPERA TING MANUAL. Make sure you

understand all setup and operating instructions before

you begin.

• INSPECT MACHINE AND ACCESSORIES. Before

starting the machine, look for loose bolts or nuts, leak-

ing lubricant, rusted components, and any other physical

conditions that may affect operation. Properly maintain-

ing the machine can greatly decrease the chances for

injury.

• ALWAYS READ PLACARDS AND LABELS.

sure all placards, labels, and stickers are clearly legible

Make

In This Chapter

OPERATOR SAFETY

SAFETY LABELS

SAFETY PRECAUTIONS

MACHINE SAFETY

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 5

Window Cutter

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

• KEEP CLEAR OF MOVING PARTS. Keep hands,

arms, and fingers clear of all rotating or moving parts.

Always turn machine off before doing any adjustments

or service.

• SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry , and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

• KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

NOTICE

This alert indicates a situation that, if not avoided, will

result in damage to the equipment.

IMPORTANT

This alert indicates a situation that, if not avoided, may

result in damage to the equipment.

6 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

SAFETY LABELS

There is no safety labeling on the window cutter.

SAFETY PRECAUTIONS

Chapter 2, Safety: Safety Labels

• Perform all setup and configuration of the machine with

the power supply disconnected. Connect the power supply when you are ready to start cutting.

MACHINE SAFETY

• Do not feed the cutter into the pipe too quickly. If the

machine chatters, slow down your feed rate.

• Use the auxiliary clamp when feeding the cutter into the

pipe when the cutter head is not at one end of the

machine.

WARNING

Failure to follow the

instructions for

safe operation

could result in operator injury.

NOTICE

Failure to follow the instructions for machine safety

could result in damage to the

equipment.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 7

Window Cutter

8 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 3

Introduction to the Equipment

Chapter 3, Introduction to the Equipment

Read this chapter carefully to become familiar with the

components and features of your window cutter.

USAGE AND APPLICATIONS

The window cutter is designed to cut access windows in

pipes ranging from 6” to 48” diameter, up to 1-1/4” thick.

An adjustable-depth milling mechanism allows you to precisely cut through the thickness of the pipe without damaging any internal structures.

The window cutter is mounted directly on a horizontal pipe.

For a vertical pipe, a guide ring the size of the pipe is

installed on the pipe at the top of the machine. Rings are

available for 16”, 18”, and 20” pipes; other sizes can be

made to order.

The machine can cut windows up to 36” in length axially

and from 10° to a full 360° radially.

In This Chapter

USAGE AND APPLICATIONS

SYSTEM COMPONENTS

REQUIREMENTS

SPECIFICATIONS

ACCESSORIES

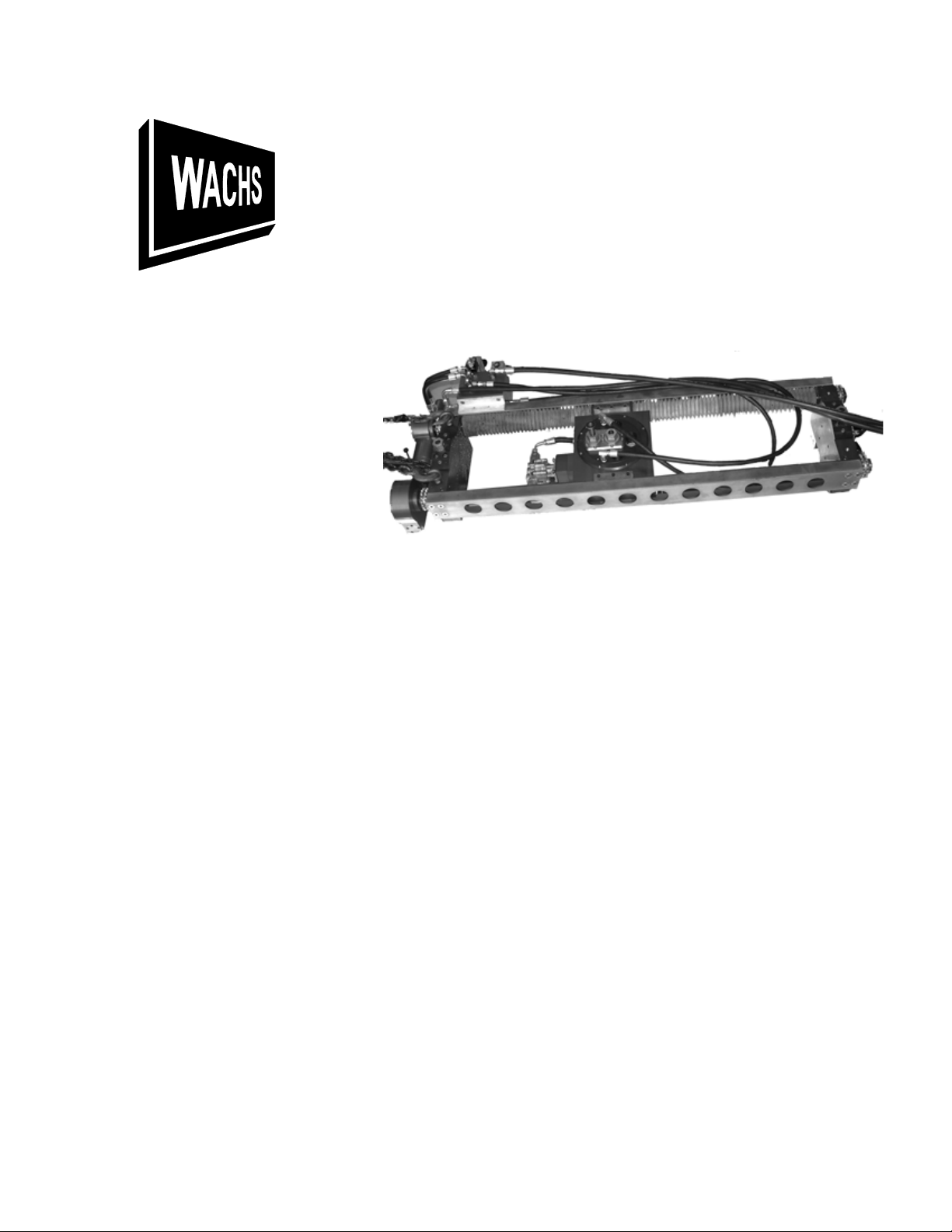

SYSTEM COMPONENTS

Window Cutter

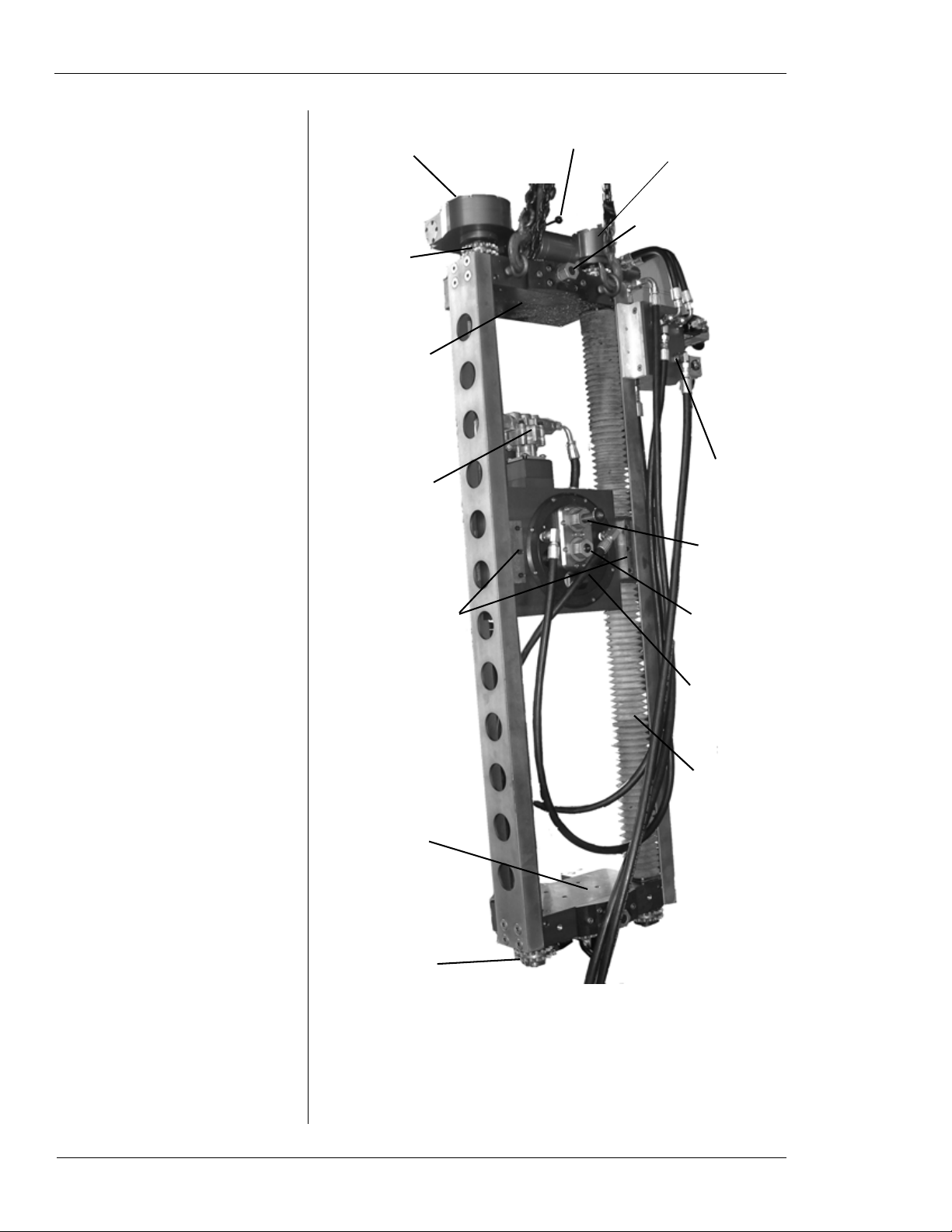

Figure 3-1 illustrates the components of the window cutter.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 9

Window Cutter

Radial gearbox Drive control lever

Chain tensioning

Feed select

gearbox

nut

Spindle

motor

Stabilizing

wedges

Manifold

Cutter

feed nut

Spindle

assembly

Spindle

assembly

Axial

drive

lock nut

screw

End support

plate

Radial drive

sprocket

Radial drive

sprocket

End support

plate

Figure 3-1. Window cutter components

10 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 3, Introduction to the Equipment: Requirements

Starter box

Filter housing

Fluid reservoir Tank heater

Motor

Hydraulic Power Unit (HPU)

Figure 3-2 illustrates the hydraulic power unit (HPU) provided with the window cutter.

Figure 3-2. Hydraulic power unit provided with the

window cutter.

REQUIREMENTS

Handling

The window cutter weighs approximately 400 lbs (182 kg).

You will need a hoist or crane to move it and position it on

the pipe for cutting.

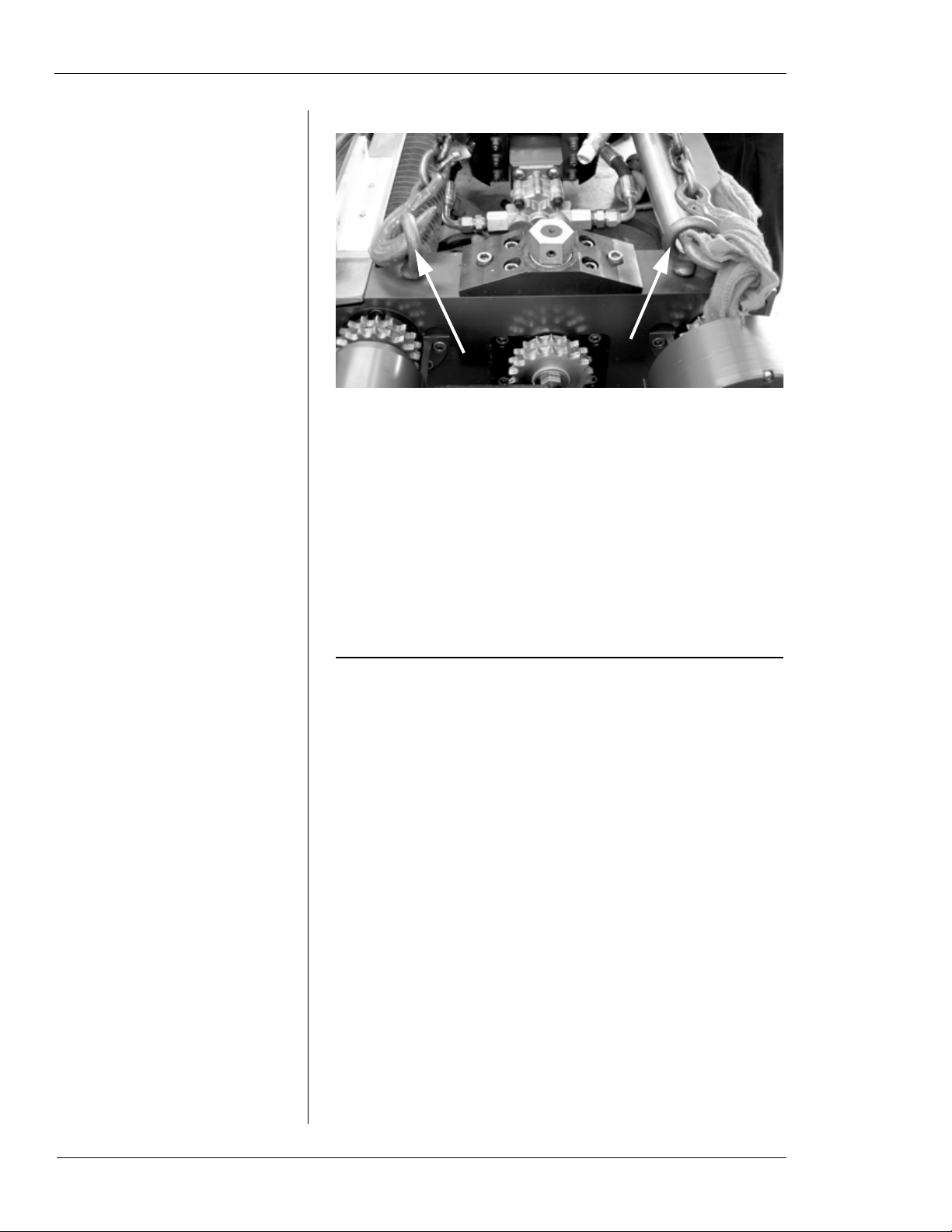

The machine has four removable lift hooks installed on its

frame. To position the machine horizontally, use all four

hooks. T o position the machine vertically, use the two hooks

at the top end of the frame.

CAUTION

Do not attempt to lift or move

the window cutter by hand.

Use a hoist or crane.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 11

Window Cutter

Figure 3-3. Two lift hooks are provided at each end of

the frame for lifting the window cutter. The hooks are

in threaded holes and can be removed.

Power Source

The hydraulic power unit for the window cutter provides 10

gpm (38 lpm) flow at 2,000 psi. The HPU operates on 230

V electric power at 28.4 amps.

SPECIFICATIONS

Length: 63” (160 cm)

Width: 31” (79 cm)

Height: 13” (33 cm)

Radial Clearance: 16.5” (42 cm)

Weight: approx. 400 lbs (180 kg)

Max. Axial Feed: 36”

Axial Feed Rate: 6 inches per minute

Max. Radial Feed:360°

Radial Feed Rate:6 inches per minute

Blade RPM: 40-160 rpm

Tooling: 6” diameter slitting blade

5” diameter beveling blade

12 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

ACCESSORIES

• Guide rings for vertical pipe—16”, 18”, and 20”

Chapter 3, Introduction to the Equipment: Accessories

Figure 3-4. Guide ring for cutting on vertical pipe

• Radial cut support clamp

Figure 3-5. Support clamp for r educing vibration dur ing radial cuts

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 13

Window Cutter

14 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 4

Assembly, Disassembly, and Storage

Chapter 4, Assembly, Disassembly, and Storage

The window cutter is shipped fully assembled from the factory in a shipping/storage crate.

REMOVING THE MACHINE FROM THE SHIPPING/STORAGE CRATE

You will need to use a crane to pick up the window cutter.

Screw the lift hooks into the window cutter frame if

1.

they are not already in place.

Position the crane above the crate.

2.

Attach a chain or cable to each of the four lift hooks

3.

on the machine, and attach the other ends to the crane.

Raise the crane until the cables or chains are taut, then

4.

slowly lift the machine. Make sure that the machine is

fairly level and that it does not catch against the side

of the crate.

In This Chapter

REMOVING THE MACHINE FROM

THE SHIPPING/STORAGE CRATE

ENVIRONMENTAL

R

EQUIREMENTS

LONG-TERM STORAGE

Always lift the machine out of

the case using all four hooks.

If you will be mounting it on a

vertical pipe, set it down on a

flat surface first and lift it from

there with the two top hooks.

Make sure the crane hook is

centered over the window

cutter before lifting it.

You can mount the machine directly on a horizontal

5.

pipe as described in Chapter 5. If you are mounting it

on a vertical pipe, first set it down on a level surface

and detach the hooks from the bottom end of the

machine.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 15

Window Cutter

ENVIRONMENTAL REQUIREMENTS

The window cutter can be operated in any environment,

including undersea. If used underwater, it is especially

important that you keep it well lubricated, and that you

clean and oil it after each use.

The hydraulic power unit can get wet without damage but

should not be operated in standing water.

LONG-TERM STORAGE

Clean the machine thoroughly before storage. If it has been

used undersea, spray it with fresh water to remove salt residue. Remove the cutting blade from the machine.

Oil all machined surfaces and grease the machine according

to the instructions in Chapter 6.

Secure the machine in its crate. If possible, store it in a noncorrosive atmosphere away from salt water.

16 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 5

Operating Instructions

Chapter 5, Operating Instructions

In This Chapter

CONFIGURING THE MACHINE

Install the Tracking Wheels

The window cutter moves radially around the pipe on four

tracking wheels, two on each end of the frame. There are

four positions for the tracking wheels, depending on the

diameter of the pipe you are cutting.

CONFIGURING THE MACHINE

INSTALLING THE MACHINE

CUTTING THE WINDOW

Figure 5-1. There are four mounting positions on the

frame for the tracking wheels. Table 1 describes how

to set the wheels correctly for the size of the pipe you

are cutting. (Note that the 3/16” spacer is required for

some pipe sizes as indicated in Table 1.)

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 17

Window Cutter

Table 1: Tracking Wheel Mounting Positions for Various Pipe Sizes

Pipe Size (inch) 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 42 48

Wheel Position 4 4 3 3 3 3 2 2 2 2 2 1 1 1 1 1 1 1 1

Space Required Y Y Y Y Y Y Y Y

Table 2: Chain Length for Various Pipe Sizes

Pipe Size (inch) 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 42 48

Chain Length (in) 53 58 63 68 71 76 81 87 92 98 103 109 115 120 126 132 150 150 168

Add Links:

2 inch 22 11 211

3 inch 111 2 1

5 inch 1 1 1 1 1 1 1 1 1 1 1

10 inch 1 1 1 1 1 1 1 1

20 inch 11112 1122

50 inch 111111112

Note that the orientation of the wheel

blocks is reversed

for positions 3 and 4.

Attach the tracking wheels at the indicated position using

one 3/8-16 x 1-1/2” socket head cap screw per block.

Tighten the screws with a hex wrench.

Setting the Chain Length

The mounting/drive chains are supplied with links of various sizes to extend them to the length required for the pipe

you are cutting. The standard chains are 53 inches long;

Table 2 describes the links required for each pipe size.

Make sure both

chains are the

same length before

you install them on the

machine.

18 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Attach the required links to each chain using the supplied

master links or pins. Leave the ends of the chains disconnected; you will need the chain open to install it on the window cutter after you have the machine in place on the pipe.

Chapter 5, Operating Instructions: Installing the Machine

Pipe Side

INSTALLING THE MACHINE

Mounting on Horizontal Pipe

Always use a crane or hoist to lift and move the window

cutter.

Before lifting or moving the machine, do the following:

• Disconnect all hoses from the machine.

• Make sure the cutting head is fully retracted.

• Make sure the mounting chains are off the machine.

If necessary, install all four lift hooks by screwing

1.

them into the window cutter’s frame.

Position the crane over the center of the window cut-

2.

ter.

Attach a chain or cable to each lift hook and connect

3.

them to the crane.

Raise the crane slowly to lift the machine. Position the

4.

machine over the pipe at the cutting location and

lower it onto the pipe.

Wrap one of the mounting chains around the pipe at

5.

one end of the window cutter and thread it through the

drive sprockets as shown in Figure 5-10.

Leave the crane

attached to the

machine and supporting its weight until you

have the mounting chains

installed and tightened.

Figure 5-2. Thread the chain over the outside sprockets and between the inside sprocket and the pipe.

Connect the ends of the chain with the supplied pin.

6.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 19

Window Cutter

Have one person

hold the chain

straight while the

other person tightens it.

Make sure the chain is straight around the pipe.

7.

Tighten the chain until it is snug by turning the chain

tensioning nut clockwise, as shown in Figure 5-11.

Figure 5-3. Tighten the tensioning nut until the chain

is snug.

Install the chain at the other end in the same manner.

8.

Tighten the chain by turning the chain tensioning nut

9.

counter-clockwise.

Figure 5-4. Turn the tensioning nut counter-clockwise

to tighten the chain.

20 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Turn the nut until you can see the red indicator line on

Indicator line

10.

the screw, as shown in Figure 5-13.

Chapter 5, Operating Instructions: Installing the Machine

Figure 5-5. The red indicator line is on the screw

inside the tensioner cover plate. Tighten the nut until

you can see the line.

Tighten the first tensioning nut until you can see the

11.

red indicator line on the screw.

Lower the crane and remove the lift chains from the

12.

window cutter frame

Mounting on Vertical Pipe

The window cutter can be installed with either end up on a

vertical pipe. Typically, you will install it with the controls

at the top, to give the most clearance below the machine.

Always use a crane to lift and move the window cutter.

Mounting the Guide Ring

The guide ring mounts on the pipe at the top of the window

cutter to support the machine’ s weight and ensure a straight

radial cut. Mounting the guide ring will require two people.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 21

Window Cutter

You can specialorder guide rings

for other pipe

sizes.

Guide rings for 16”, 18”, and 20” pipes are supplied with

the window cutter.

If necessary, take the two halves of the guide ring

1.

apart by removing the screws.

Put the halves of the guide ring together over the pipe

2.

at the location where the top of the machine will be

located. The support flange (thicker side of the ring)

must be on the bottom, as shown in fig.

Figure 5-6. Hold both halves of the guide ring on the

pipe and insert the screws through the brackets. Put

the nuts on the screws.

Insert the screws on both sides of the ring. Tighten

3.

them securely with a 15/16” wrench or socket.

Figure 5-7. Tighten the nuts on the guide ring screws

securely.

22 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Mounting the Window Cutter

You will only need two lift hooks on the window cut-

1.

ter frame. Install the hooks at the end of the frame that

will be on top.

Position the crane over the window cutter.

2.

Attach a chain or cable to each lift hook and connect

3.

them to the crane.

Lift the window cutter slowly until the entire machine

4.

is off the floor.

Position the window cutter so that the tracking wheels

5.

at the top are just above the guide ring on the pipe.

Chapter 5, Operating Instructions: Installing the Machine

Figure 5-8. Set the top of the machine against the

pipe, with the tracking wheels on against the pipe and

on top of the guide ring.

Lower the machine gently so that the wheels are rest-

6.

ing on top of the guide ring.

Wrap a binding strap around the pipe and the middle

7.

of the window cutter. Tighten the strap to pull the

machine against the pipe.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 23

top of the guide ring.

Make sure the

wheels are against

the pipe and are on

Window Cutter

Pipe Side

Figure 5-9. Use a binding strap around the pipe and

center of the machine to pull it snug against the pipe.

Wrap one of the mounting chains around the pipe at

8.

the top of the window cutter (about six inches above

the guide ring) and thread it through the drive gears as

shown in Figure 5-10.

Figure 5-10. Thread the chain over the outside gears

and between the inside gear and the pipe.

Connect the ends of the chain with the supplied pin.

9.

Have one person

hold the chain

straight while the

other person tightens it.

24 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Make sure the chain is straight and parallel with the

10.

guide ring. Tighten the chain until it is snug by turning

the chain tensioning nut clockwise, as shown in

Figure 5-11.

Figure 5-11. Tighten the tensioning nut on the top

chain until the chain is snug.

Install the bottom chain in the same manner as the top

11.

chain.

Chapter 5, Operating Instructions: Installing the Machine

Tighten the bottom chain by turning the chain tension-

12.

ing nut counter-clockwise.

Figure 5-12. Turn the bottom tensioning nut counterclockwise to tighten the chain.

Turn the nut until you can see the red indicator line on

13.

the screw, as shown in Figure 5-13.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 25

Window Cutter

Indicator line

Figure 5-13. The red indicator line is on the screw

inside the tensioner cover plate. Tighten the nut until

you can see the line.

Tighten the top tensioning nut until you can see the

14.

red indicator line on the screw.

Remove the binding strap.

15.

Lower the crane and remove the lift chains from the

16.

window cutter frame.

Connect Power Supply

Connect the hoses from the power unit to the connec-

1.

tors on the window cutter manifold.

CUTTING THE WINDOW

Horizontal Pipe

To cut the pipe window, you will first make the two axial

cuts along the length of the pipe. Then perform the radial

cuts around the pipe’s circumference. See the diagram in

Figure 5-14.

26 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 5, Operating Instructions: Cutting the Window

CUT 4

CUT 1

CUT 2

CUT 3

.

Figure 5-14. For a horizontal pipe, cut the pipe window as shown in the diagram. Perform both axial cuts

first, then make the radial cuts at the ends.

Vertical Pipe

When window cutting on a vertical pipe, perform the side

and bottom cuts first, then the top cut. This keeps the cutter

above the fall-off piece on the final cut. See the diagram in

Figure 5-16.

Figure 5-15. Perform the illustrated cut sequence

when using the window cutter on a vertical pipe.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 27

Window Cutter

(Center)

Neutral

Radial

Drive

Axial

Drive

Machine Controls

There are three levers that control machine motion:

• The drive control lever at the end of the machine. This

lever has three positions, as shown in Figure 5-16.

Figure 5-16. The photo shows the drive control lever

at the bottom of the machine; directions are reversed

when the controls are at the top.

• The spindle drive lever, which turns the blade spindle on

and off, as shown in Figure 5-17.

• The motion drive lever, which has three positions, as

shown in Figure 5-17.

28 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 5, Operating Instructions: Cutting the Window

On

Up/

Down/

Off

CCW

CW

Figure 5-17. The spindle (cutting) drive is on the top

in this orientation (on the shorter manifold block). The

motion drive lever is on the bottom (on the taller manifold block).

When the spindle drive is engaged, the motion drive is automatically in cutting feed (slow) mode. When the spindle is

disengaged, the motion drive is in rapid feed mode.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 29

Window Cutter

Rapid Feed Control

Cutting Feed Control

Spindle Drive Control

Flow Control Valves

There are flow control valves for the drives on the manifold.

These are illustrated in Fig.

Figure 5-18. Use the knobs to adjust the flow control

valves for the drives.

To adjust the flow control valve, loosen the set nut behind

the valve knob, turn the knob, then tighten the set nuts.

Radial Cut Stabilizing Clamp

A stabilizing clamp is provided to reduce vibration when

making a radial cut with the machine head near the center of

the window cutter frame.

30 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 5, Operating Instructions: Cutting the Window

Center

Nut

Figure 5-19. The stabilizing clamp attaches across

the frame at the cutting head to reduce vibrations during a radial cut.

Rotating the Cutter Head

The entire cutter head rotates to set the cutting direction.

Use the following procedure to rotate the head.

Loosen the center nut on the cutter head.

1.

Figure 5-20. Loosen the center nut (top) to allow the

cutter head to turn.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 31

Window Cutter

Turn the head to the desired cutting direction.

2.

IMPORTANT: Make sure the blade is oriented correctly for the direction you are cutting, as illustrated in

Figure 5-21.

Figure 5-21. Make sure the blade is oriented to cut in

the cutting direction indicated.

Feeding the Cutter into the Pipe

Before engaging either the axial or radial motion drive for

cutting, first feed the cutter blade into the pipe.

Make sure the spindle drive lever is in the OFF posi-

1.

tion, and the motion drive lever is in the NEUTRAL

(center) position.

Turn on the hydraulic power unit and turn on power to

2.

the window cutter with the HPU control pendant.

Use the drive select lever at the end of the machine

3.

and the motion drive lever on the manifold to position

the blade where you want to start cutting.

If necessary, rotate the cutter head to the correct orien-

4.

tation as described in the previous section.

Set the drive select lever for the drive motion (axial or

5.

radial) that you will be cutting.

32 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Put the spindle drive lever into the ON position to start

Spindle

Feed Nut

6.

the spindle drive motion.

Using the supplied 1-3/8” socket, turn the spindle feed

7.

nut on the cutter head counter-clockwise to feed the

blade into the pipe.

Chapter 5, Operating Instructions: Cutting the Window

Figure 5-22. Turn the spindle feed nut counter-clockwise to feed the blade into the pipe.

Feed the blade in slowly. If the blade starts to chatter,

8.

stop for a few seconds, then resume feeding at a

slower rate.

Feed the blade in until you have penetrated the pipe

9.

wall. Continue feeding as far as you can without cutting internal structures in the pipe.

Remove the socket from the spindle feed nut.

10.

With the spindle drive still engaged and the blade turn-

11.

ing, use the motion drive lever to start making the cut.

The motion drive will automatically be in cutting

(low-speed) mode while the spindle drive is running.

Continue until the cut is complete. Move the motion

12.

drive lever to the NEUTRAL position to stop the drive

motion.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 33

Window Cutter

Using the 1-3/8” socket, turn the spindle feed nut

13.

clockwise to retract the blade from the pipe. Be sure to

retract the blade completely.

Turn off the spindle drive motion.

14.

Position the cutter head for the next cut using the drive

15.

select lever and the motion drive lever. If necessary,

rotate the cutter head as described in the previous section.

34 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 6

Routine Maintenance

Grease the machine using Phillips 66 X/C 22CF Aviation

Grease or equivalent.

Chapter 6, Routine Maintenance

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 35

Window Cutter

36 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 7

Service and Repair

Refer to the drawings and parts lists in Chapter 8 for service

and repair information on window cutter components.

Chapter 7, Service and Repair

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 37

Window Cutter

38 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 8

Parts Lists and Drawings

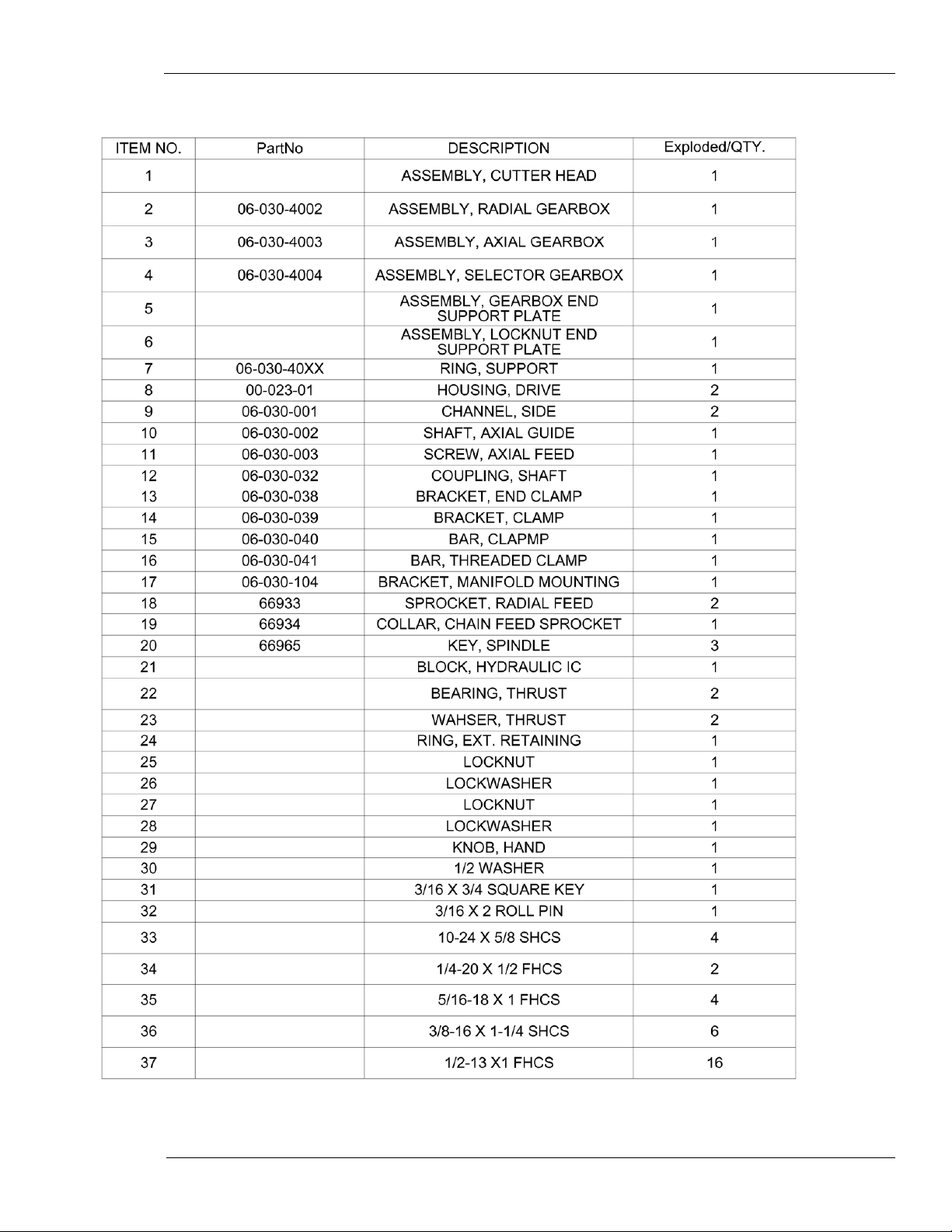

Refer to the drawing and the parts list on the following

pages for ordering spare and replacement parts.

Chapter 8, Parts Lists and Drawings

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 39

Chapter 8: Parts Lists and Drawings Window Cutter

40 06-030-MAN E.H. Wachs Company

Window Cutter Chapter 8: Parts Lists and Drawings

E.H. Wachs Company 06-030-MAN 41

Chapter 8: Parts Lists and Drawings Window Cutter

42 06-030-MAN E.H. Wachs Company

Window Cutter Chapter 8: Parts Lists and Drawings

E.H. Wachs Company 06-030-MAN 43

Chapter 8: Parts Lists and Drawings Window Cutter

44 06-030-MAN E.H. Wachs Company

Window Cutter Chapter 8: Parts Lists and Drawings

E.H. Wachs Company 06-030-MAN 45

Chapter 8: Parts Lists and Drawings Window Cutter

46 06-030-MAN E.H. Wachs Company

Window Cutter Chapter 8: Parts Lists and Drawings

E.H. Wachs Company 06-030-MAN 47

Chapter 8: Parts Lists and Drawings Window Cutter

48 06-030-MAN E.H. Wachs Company

Chapter 9

Accessories and Spare Parts

The following accessories are provided with the window

cutter.

Chapter 9, Accessories and Spare Parts

• Guide rings for vertical pipe—16”, 18”, and 20”

Figure 9-1. Guide ring for cutting on vertical pipe

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 49

Window Cutter

• Radial cut support clamp

Figure 9-2. Support clamp for r e ducing vibration during radial cuts

50 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Chapter 10

Ordering Information

Chapter 10, Ordering Information

To place an order, request service, or get more detailed

information on any E.H. Wachs products, call us at one of

the following numbers:

U.S. 800-323-8185

International: 847-537-8800

You can also visit our Web site at:

www.ehwachs.com

ORDERING REPLACEMENT PARTS

When ordering parts, refer to the parts lists in this chapter.

Please provide the part description and part number for all

parts you are ordering.

REPAIR INFORMATION

In This Chapter

ORDERING REPLACEMENT

ARTS

P

REPAIR INFORMATION

WARRANTY INFORMATION

RETURN GOODS ADDRESS

Please call us for an authorization number before returning

any equipment for repair or factory service. We will advise

you of shipping and handling. When you send the equipment, please include the following information:

• Your name/company name

• Your address

• Your phone number

• A description of the problem or the work to be done.

E.H. Wachs Part No. 06-030-MAN, Rev. 2-0709 51

Window Cutter

Before we perform any repair, we will estimate the work

and inform you of the cost and the time to complete it.

WARRANTY INFORMATION

Enclosed with the manual is a warranty card. Please fill out

the registration card and return to E.H. Wachs. Retain the

owner’s registration record and warranty card for your

information.

RETURN GOODS ADDRESS

Return equipment for repair to the following address.

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, Illinois 60069 USA

52 Part No. 06-030-MAN, Rev. 2-0709 E.H. Wachs

Loading...

Loading...