Wachendorff WDGA CANopen Technical Manual

-

Technical Manual

WDGA with CANopen-Interface

© Wachendorff Automation GmbH & Co. KG I Rev.1.24

Imprint

Wachendorff Automation GmbH & Co. KG

Industriestrasse 7

D-65366 Geisenheim

Tel: +49 (0) 67 22 / 99 65 25

Fax: +49 (0) 67 22 / 99 65 70

E-Mail: wdg@wachendorff.de

Homepage: www.wachendorff-automation.de

Wiesbaden District Court HRA 8377, VAT ID: DE 814567094

Managing Director: Robert Wachendorff

Guarantee waiver, right of amendment, copyright protection:

The company Wachendorff Automation assumes no liability and provides no guarantee

for the correctness of this manual's contents or for any resulting direct or indirect

damages. In the interests of continuous innovation and cooperation with our

customers, we reserve the right to change technical data or content at any time.

The company Wachendorff Automation claims copyright protection for this manual. It

may not be modified, extended, reproduced, or forwarded to third parties without our

prior written consent.

Comments:

Should you have any suggested corrections, comments or requests for change, we

invite you to submit them to us. Please send your comments to: wdg@wachendorff.de

Technical Manual

WDGA with CANopen-Interface

Inhaltsverzeichnis

© Wachendorff Automation GmbH & Co. KG

II

Rev.1.24

1 Introduction ..................................................................................... 1

1.1 Encoder types................................................................................................ 1

1.2 About this manual .......................................................................................... 1

1.2.1 Symbols .................................................................................................. 2

1.3 Specifications ................................................................................................ 2

2 Safety information ........................................................................... 3

2.1 General safety information ............................................................................ 3

2.2 Intended use .................................................................................................. 3

2.3 Safe working .................................................................................................. 4

2.4 Disposal ......................................................................................................... 4

3 Device description ........................................................................... 5

3.1 Basic encoder design .................................................................................... 5

3.2 Predefined Connection Settings .................................................................... 5

3.3 LED status indicator and signal codes ........................................................... 6

4 Quick start ........................................................................................ 8

4.1 CAN network integration ................................................................................ 8

4.2 SDO command to set the node ID ................................................................. 8

4.3 Setting-up the encoder .................................................................................. 9

5 General information about CAN ................................................... 11

5.1 CAN physical and transport layer ................................................................ 11

5.2 CANopen ..................................................................................................... 13

5.3 Specifications and profiles ........................................................................... 14

5.3.1 Overview ............................................................................................... 14

5.3.2 Mechanisms of communication ............................................................. 14

5.3.3 Object dictionary ................................................................................... 15

5.4 Network management (NMT) ...................................................................... 16

5.5 Heartbeat and Node-Guarding .................................................................... 17

5.6 Emergency messages ................................................................................. 18

6 WDGA object dictionary ................................................................ 19

6.1 Communication objects ............................................................................... 19

6.2 Device specific objects ................................................................................ 22

6.3 Manufacturer specific objects ...................................................................... 28

7 Object description ......................................................................... 30

7.1 Network management (NMT) commands .................................................... 30

Technical Manual

WDGA with CANopen-Interface

Inhaltsverzeichnis

© Wachendorff Automation GmbH & Co. KG

III

Rev.1.24

7.2 Heartbeat protocol ....................................................................................... 31

7.3 Emergency messages (EMCY) ................................................................... 32

7.4 Error Objects ............................................................................................... 33

7.4.1 Manufacturer status register ................................................................. 33

7.4.2 Alarms ................................................................................................... 34

7.4.3 Warnings ............................................................................................... 34

7.5 Electronic cam switch (CAM) ....................................................................... 34

7.5.1 CAM-state-register ................................................................................ 34

7.5.2 CAM-enable-register ............................................................................. 35

7.5.3 CAM-polarity-register ............................................................................ 35

7.5.4 CAM-Low-Limit ..................................................................................... 35

7.5.5 CAM-High-Limit ..................................................................................... 36

7.5.6 CAM-Hysteresis .................................................................................... 36

7.6 Device profile ............................................................................................... 36

7.7 SYNC .......................................................................................................... 36

7.8 Encoder designation .................................................................................... 36

7.9 Error behaviour ............................................................................................ 37

7.10 NMT start-up behaviour ............................................................................ 37

7.11 Bus-Off Auto-Reset .................................................................................. 37

7.12 Customer Data ......................................................................................... 38

7.13 Temperature ............................................................................................. 38

7.14 Verify Configuration .................................................................................. 38

8 Setting-up the encoder .................................................................. 39

8.1 Mechanical and electrical connection .......................................................... 39

8.2 Configuration via LSS .................................................................................. 41

8.2.1 General settings .................................................................................... 41

8.2.2 LSS configuration by "Switch Mode Global" .......................................... 41

8.2.3 LSS configuration by "Switch Mode Selective" ..................................... 42

8.2.4 End LSS configuration mode ................................................................ 43

8.2.5 Baudrate setting .................................................................................... 43

8.2.6 Node-ID setting ..................................................................................... 44

8.3 Configuration via SDO ................................................................................. 45

8.3.1 SDO access on objects ......................................................................... 45

8.3.2 SDO access on objects larger than 4 bytes .......................................... 47

8.3.3 Baudrate selection ................................................................................ 54

Technical Manual

WDGA with CANopen-Interface

Inhaltsverzeichnis

© Wachendorff Automation GmbH & Co. KG

IV

Rev.1.24

8.3.4 Node-ID selection ................................................................................. 55

8.3.5 Basic NMT commands .......................................................................... 56

8.4 Heartbeat settings ....................................................................................... 57

8.5 PDO Configuration ...................................................................................... 57

8.5.1 PDO parameters ................................................................................... 57

8.5.2 Synchronous PDO ................................................................................ 59

8.5.3 Asynchronous PDO .............................................................................. 59

8.5.4 Variable PDO-mapping ......................................................................... 60

8.6 Changing resolution and direction ............................................................... 63

8.7 Position preset ............................................................................................. 64

8.8 Position value filtering .................................................................................. 65

8.9 Change speed-integration and speed scaling ............................................. 65

8.10 Frequency limit ......................................................................................... 66

8.11 CAM-configuration.................................................................................... 66

8.12 Non-volatilely storage of parameters ........................................................ 68

8.12.1 Saving parameters into EEPROM ..................................................... 68

8.12.2 Restoring default parameters from EEPROM .................................... 69

9 Error diagnosis .............................................................................. 70

9.1 Encoder configurations ................................................................................ 70

10 Support ........................................................................................ 71

Technical Manual

WDGA with CANopen-Interface

List of figures

© Wachendorff Automation GmbH & Co. KG V Rev.1.24

List of figures

Figure 1.1: Encoder label ............................................................................................ 1

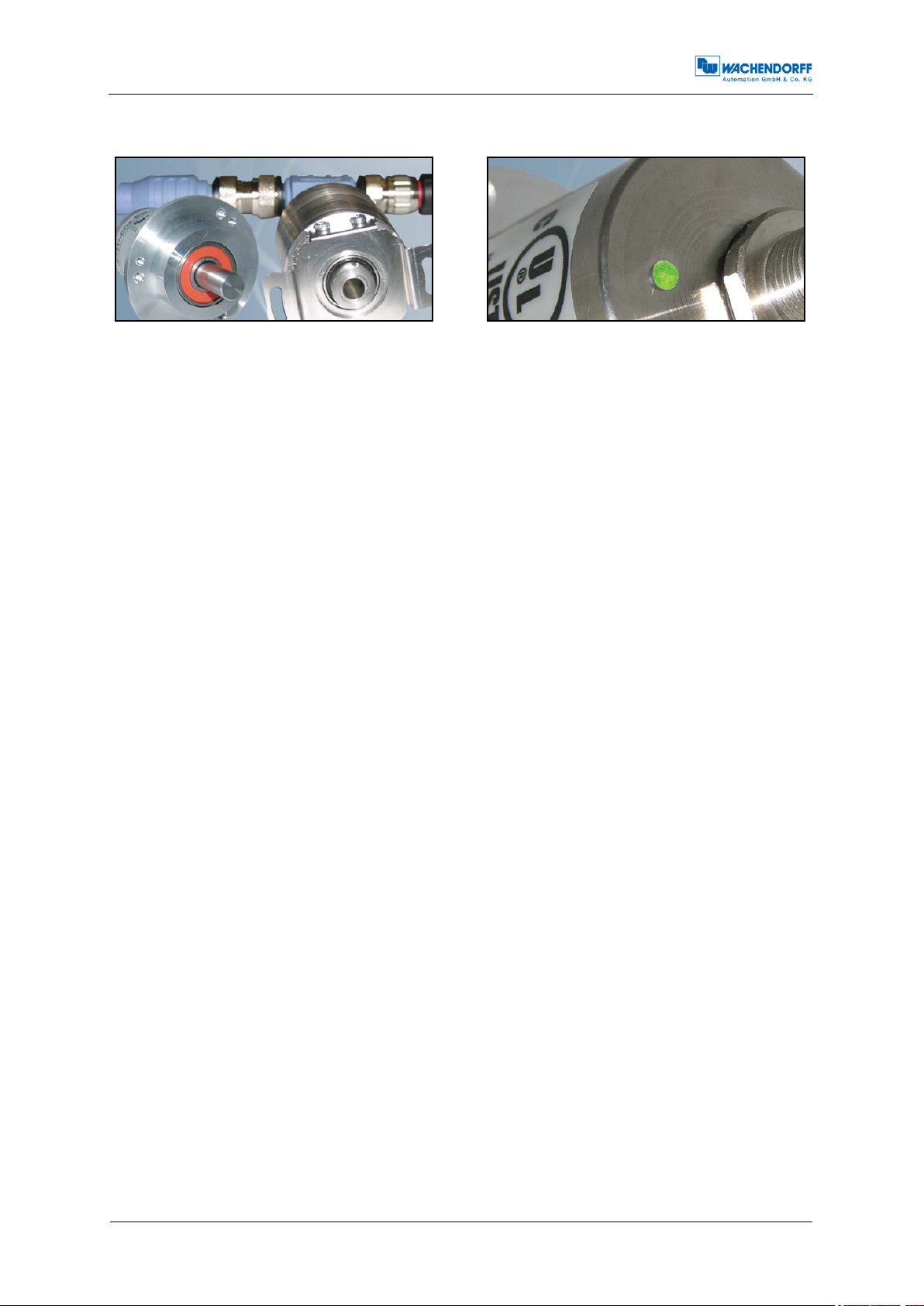

Figure 3.1: Encoder versions, shaft and hollow bore shaft ......................................... 5

Figure 3.2: LED indications 1 ...................................................................................... 6

Figure 3.3: LED indications 2 ...................................................................................... 7

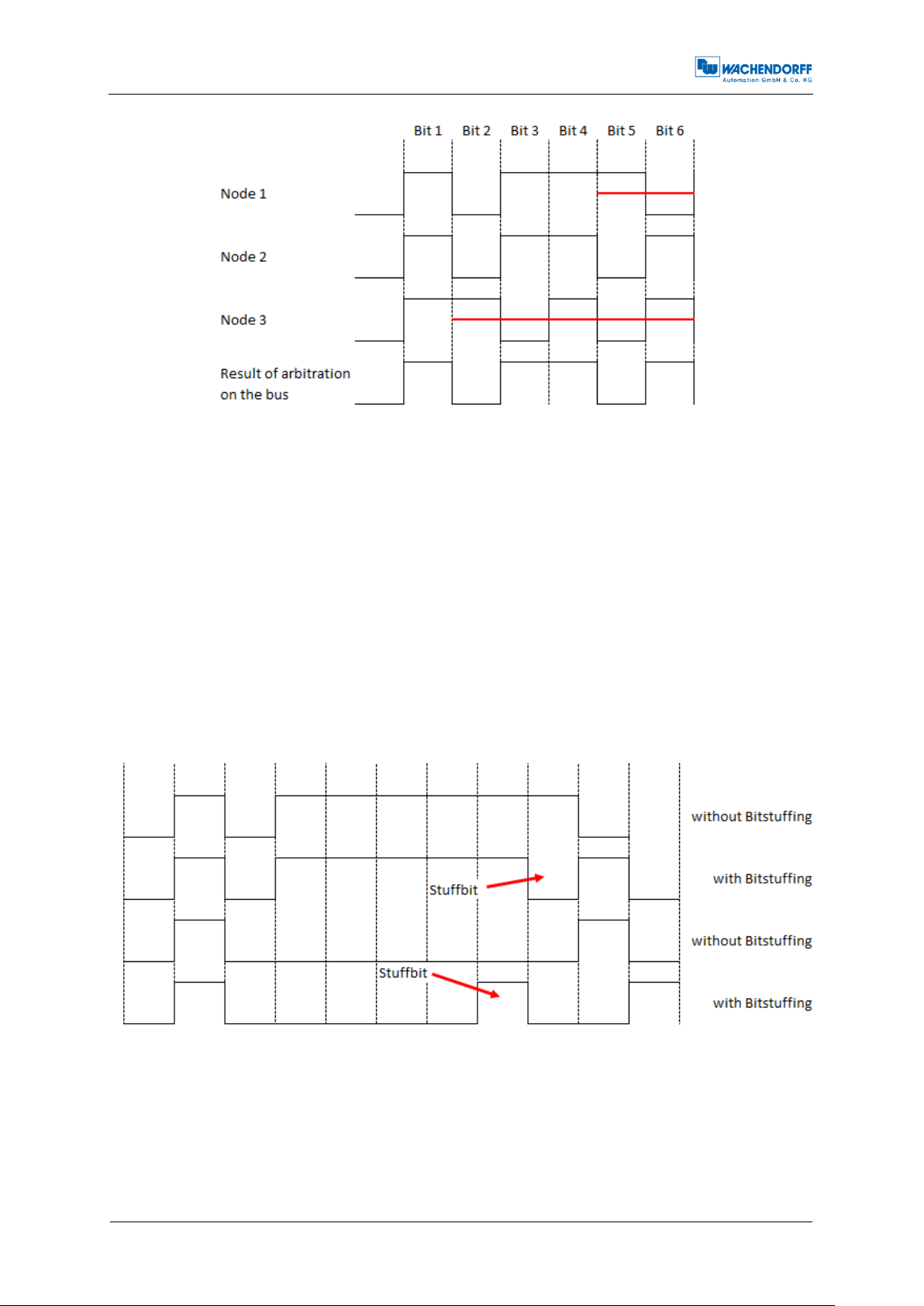

Figure 5.1: Example of the arbitration ....................................................................... 12

Figure 5.2: Bitstuffing ................................................................................................ 12

Figure 5.3: ISO-OSI-Modell ...................................................................................... 13

Figure 8.1: read object .............................................................................................. 45

Figure 8.2: write object ............................................................................................. 46

Figure 8.3: Segmented SDO read access ................................................................ 47

Figure 8.4: Initiate SDO read .................................................................................... 48

Figure 8.5: read SDO segment ................................................................................. 49

Figure 8.6: Segmented-SDO write access ................................................................ 50

Figure 8.7: Initiate SDO write .................................................................................... 51

Figure 8.8: write SDO segment ................................................................................ 53

Technical Manual

WDGA with CANopen-Interface

List of tables

© Wachendorff Automation GmbH & Co. KG

VI

Rev.1.24

List of tables

Table 3.1: CAN-Identifier ............................................................................................ 5

Table 4.1: SYNC-message ......................................................................................... 8

Table 4.2: SDO-write command to set Node-ID ......................................................... 9

Table 4.3: Node-ID in decimal and hexadecimal ........................................................ 9

Table 5.1: CAN baud rates und recommended cable length limits ........................... 13

Table 5.2: Draft Standards ........................................................................................ 14

Table 5.3: Structure of the object dictionary ............................................................. 15

Table 5.4: Available communication – Pre-Operational ............................................ 16

Table 5.5: Available communication – Operational ................................................... 17

Table 5.6: Available communication – Stopped ........................................................ 17

Table 6.1: Object dictionary 1000h – 100Dh ............................................................. 19

Table 6.2: Object dictionary 1010h – 1020h ............................................................. 20

Table 6.3: Object dictionary 1029h – 1A01h ............................................................. 21

Table 6.4: Object dictionary 1A02h – 1F80h ............................................................. 22

Table 6.5: Device specific objects 6000h –6008h ..................................................... 22

Table 6.6: Device specific objects 6009h –6310h ..................................................... 23

Table 6.7: Device specific objects 6311h –6322h ..................................................... 24

Table 6.8: Device specific objects 6323h –6334h ..................................................... 25

Table 6.9: Device specific objects 6335h –6504h ..................................................... 26

Table 6.10: Device specific objects 6505h –6510h ................................................... 27

Table 6.11: manufacturer specific objects 2100h –2500h ........................................ 28

Table 6.12: manufacturer specific objects 2502h –2504h ........................................ 29

Table 7.1: Structure of NMT-command..................................................................... 30

Table 7.2: Commands for NMT-command................................................................ 30

Table 7.3: Node-ID values for NMT-commands ....................................................... 30

Table 7.4: monitor external heartbeat ....................................................................... 31

Table 7.5: Example configuration of a consumer heartbeat...................................... 31

Table 7.6: Basic structure of an EMCY ..................................................................... 32

Table 7.7: Emergency error code list ........................................................................ 32

Table 7.8: Error register ............................................................................................ 32

Table 7.9: Info field list .............................................................................................. 33

Table 7.10: Manufacturer status register .................................................................. 33

Table 7.11: Alarms - Object 6503h ........................................................................... 34

Table 7.12: Warnings – Object 6505h ...................................................................... 34

Table 7.13: CAM-state-register – Value 89h ............................................................. 34

Table 7.14: CAM-state-register – Value 81h ............................................................. 34

Table 7.15: CAM-enable-register – Value 4Ah ......................................................... 35

Table 7.16: Example CAM-polarity-register .............................................................. 35

Table 7.17: Selection of encoder reaction on errors ................................................. 37

Table 7.18: Selection of start-up behaviour .............................................................. 37

Table 8.1: Pin and cable assignment ........................................................................ 40

Table 8.2: LSS-message .......................................................................................... 41

Table 8.3: Command to set encoder “Stopped“-Mode .............................................. 41

Table 8.4: LSS-Selective-Identification-Commands ................................................. 42

Table 8.5: Answer of encoder to LSS-Selective-Identification-Commands ............... 42

Technical Manual

WDGA with CANopen-Interface

List of tables

© Wachendorff Automation GmbH & Co. KG

VII

Rev.1.24

Table 8.6: End LSS configuration mode – Step 1 - store parameters ....................... 43

Table 8.7: End LSS configuration mode – Step 2 - Leave configuration mode......... 43

Table 8.8: set Baudrate ............................................................................................ 43

Table 8.9: Baudrate-Coding ...................................................................................... 43

Table 8.10: Answer of LSS-slave ............................................................................. 44

Table 8.11: set Node-ID............................................................................................ 44

Table 8.12: Example SDO master to encoder .......................................................... 45

Table 8.13: Example SDO answer ........................................................................... 45

Table 8.14: Command definitions ............................................................................. 46

Table 8.15: Example SDO send by master ............................................................... 46

Table 8.16: Example SDO answer ........................................................................... 46

Table 8.17: SDO read request on object 6008h ....................................................... 47

Table 8.18: Declaration of used abbreviations in Figure 8.4 ..................................... 48

Table 8.19: Confirm SDO read access of object 6008h ............................................ 48

Table 8.20: Declaration of used abbreviations in Figure 8.5 ..................................... 49

Table 8.21: read of first segment .............................................................................. 49

Table 8.22: answer with first segment ...................................................................... 49

Table 8.23: Request next segment ........................................................................... 50

Table 8.24: Answer with next segment ..................................................................... 50

Table 8.25: SDO write access of object 6009h ......................................................... 51

Table 8.26: Acknowledgement of write access of object 6009h ............................... 51

Table 8.27: Declaration of used abbreviations in Figure 8.7 ..................................... 52

Table 8.28: send first segment ................................................................................. 52

Table 8.29: Acknowledgement send by the encoder ................................................ 52

Table 8.30: Declaration of used abbreviations in Figure 8.8 ..................................... 53

Table 8.31: send next segment ................................................................................ 53

Table 8.32: Acknowledgement send by the encoder ................................................ 54

Table 8.33: SDO command – set baudrate .............................................................. 54

Table 8.34: Baudrate-coding .................................................................................... 54

Table 8.35: Node-ID selection .................................................................................. 55

Table 8.36: Valid Node-IDs ....................................................................................... 55

Table 8.37: NMT command - Start remote node ...................................................... 56

Table 8.38: NMT command - Stop remote node ....................................................... 56

Table 8.39: NMT command - Enter Pre-Operational-state ....................................... 56

Table 8.40: NMT command - Reset node communication ........................................ 56

Table 8.41: NMT command - Reset remote node ..................................................... 56

Table 8.42: Example of heartbeat setting ................................................................. 57

Table 8.43: Structure of heartbeat message ............................................................. 57

Table 8.44: Heartbeat NMT-state-coding.................................................................. 57

Table 8.45: Default PDO configuration ..................................................................... 57

Table 8.46: Selectable PDO transmission types ....................................................... 58

Table 8.47: PDO-Deactivation .................................................................................. 58

Table 8.48: Example - PDO1 deactivation ................................................................ 58

Table 8.49: Parametrization of PDO1 Sub-Index 2 ................................................... 59

Table 8.50: Parametrization of PDO1 Sub-Index 2 ................................................... 59

Table 8.51: Parametrization of PDO1 Sub-Index 5 to 30ms ..................................... 59

Table 8.52: Parametrization of PDO1 Sub-Index 2 ................................................... 60

Technical Manual

WDGA with CANopen-Interface

List of tables

© Wachendorff Automation GmbH & Co. KG

VIII

Rev.1.24

Table 8.53: Parametrization of PDO1 Sub-Index 5 ................................................... 60

Table 8.54: Example of a mapping-table .................................................................. 60

Table 8.55: Structure of PDO1 (content -> Table 8.54) ............................................ 61

Table 8.56: Mapping parameter ................................................................................ 61

Table 8.57: Mapping position value .......................................................................... 62

Table 8.58: Mapping speed value ............................................................................. 62

Table 8.59: Mapping acceleration value ................................................................... 62

Table 8.60: Mapping parameter – activate new mapping ......................................... 62

Table 8.61: Counting direction and scaling parameters ............................................ 63

Table 8.62: Example setting operating parameters .................................................. 63

Table 8.63: Change of singleturn-resolution by SDO ............................................... 64

Table 8.64: Change of total measuring range by SDO ............................................. 64

Table 8.65: Set position preset ................................................................................. 64

Table 8.66: Check current position ........................................................................... 65

Table 8.67: Example CAM-configuration .................................................................. 66

Table 8.68: Enable first three cams .......................................................................... 66

Table 8.69: CAM-High-Limit 1 .................................................................................. 67

Table 8.70: CAM-High-Limit 2 .................................................................................. 67

Table 8.71: CAM-High-Limit 3 .................................................................................. 67

Table 8.72: CAM-Low-Limit 1 ................................................................................... 67

Table 8.73: CAM-Low-Limit 2 ................................................................................... 67

Table 8.74: CAM-Low-Limit 3 ................................................................................... 67

Table 8.75: Saving parameters ................................................................................. 68

Table 8.76: Example – Save all parameters ............................................................. 68

Table 8.77: Restoring parameters ............................................................................ 69

Table 9.1: Error diagnosis – Encoder configuration .................................................. 70

Technical Manual

WDGA with CANopen-Interface

Glossary

© Wachendorff Automation GmbH & Co. KG

IX

Rev.1.24

autom.

automatic

approx.

approximately

CAN

Controller Area Network

CAN-ID

Main part of the arbitration of a CAN-frame

co

constant: parameter is read-only, doesn’t change

COB-ID

Communication Object identifier, specifying the CAN-ID and

additional parameters for the related communication object

comp.

Compare

DLC

Data Length Code

DS

Draft Standard

DSP

Draft Standard Proposal

dyn

dynamic; information changes depending on encoder features

EDS file

Electronic data sheet, standardised file describing a CANopen

device

EMC

Electromagnetic Compatibility

Encoder

here synonym for absolute rotary encoder

e.g.

for example (exempli gratia)

etc.

et cetera, and so on

GND

Ground

i*

Wildcard character for encoder specific information

i.e.

that is (id est)

Idx

Sub-Index

LED

Light Emitting Diode

LSB

Least Significant Bit/Byte

LSS

Layer Setting Services

MSB

Most Significant Bit/Byte

MT

Multiturn

n.n.

not necessary

NMT

Network management

Node-ID

Part of CAN-ID; number of the encoder in the CAN network

OSI

Open Systems Interconnection Reference Model

p.

Page reference

PDO

Process Data Object. Communication object for transmission

of process data

res.

reserved

Glossary

Technical Manual

WDGA with CANopen-Interface

Glossary

© Wachendorff Automation GmbH & Co. KG X Rev.1.24

ro

Read Only: but not constant

RTR

Remote Transmission Request

rw

Read/Write: parameter can be read and written

SDO

Service Data Object; communication object providing access

to all entries of the object dictionary

ST

Singleturn

SYNC

Synchronisations telegram

wo

Write Only

xxb

Mark that (xx) is a binary representation

xxd

Mark that (xx) is a decimal representation

xxh

Mark that (xx) is a hexadecimal representation

Technical Manual

WDGA with CANopen-Interface

1 - Introduction

© Wachendorff Automation GmbH & Co. KG 1 Rev.1.24

1 Introduction

1.1 Encoder types

This manual is assigned to the following Wachendorff Automation encoders:

WDGA CANopen

It applies to all WDGA CANopen with Revision Number (Software version) 1.18 and

less.

The Wachendorff Automation CANopen vendor id is: 0100 021Fh

The Wachendorff Automation product code is: WDGA= 5744 4741h

The revision number and the serial number vary for each individual encoder and can

be found on the encoder’s label:

Figure 1.1: Encoder label

In the figure 1.1 the revision number is marked blue (here: 1.00). The revision is

combined with a leading 0306 and fixed within the encoder firmware

(e.g. Rev. 1.00 = 0306 0100h; Rev. 1.06 = 0306 0106h).

The serial number is marked green (here: "12345656"). This decimal value transferred

into "hex" is used in the firmware (e.g. "12345656"="00BC 6138"h).

The hardware version is marked red (here: AA). The ASCII value transferred into hex

is the hardware revision coded in the corresponding CANopen object.

1.2 About this manual

This technical manual describes the configuration and mounting possibilities for

absolute-value encoders with a CANopen interface produced by Wachendorff

Automation. It supplements the other publicly available Wachendorff automation

documents, e.g. data sheets, assembly instructions, leaflets, catalogues and flyers.

Ensure that you read the manual before commissioning — check beforehand that you

have the latest version of the manual.

Technical Manual

WDGA with CANopen-Interface

1 - Introduction

© Wachendorff Automation GmbH & Co. KG 2 Rev.1.24

The INFO symbol indicates a section that contains particularly

important information for advanced use of the device.

The IMPORTANT symbol is shown next to a section of text that

describes a method for solving a particular problem.

The WARNING symbol indicates that the adjacent instructions

must be observed to ensure correct use of the device and to

protect the user against hazards.

When reading, pay particular attention to the information, important notices and

warnings that are marked with the corresponding symbols (see 1.2.1).

Section 4 Quick start shows a way how to configure the encoder in a very general

setting with minimal functionality. For optimal usage of the device, it is necessary to

read all the following information. Abbreviations and specific wording is explained at

the beginning of this manual.

This manual is intended for persons with technical knowledge in the handling of

sensors, CANopen interfaces and automation elements. If you do not have any

experience in this field, request the assistance of experienced personnel before

proceeding.

Keep the information provided with our product in a safe place so that you can refer to

it at a later date as necessary.

1.2.1 Symbols

1.3 Specifications

An encoder is a sensor that is designed to detect angular positions (singleturn) and

revolutions (multiturn). The measured data and variables are processed by the

encoder and provided as electrical output signals for the connected peripherals.

The interface and protocol for the communication between encoder and attached

equipment meets the CAN and CANopen specifications. The encoder is capable of

CAN 2.0A and CAN 2.0B. The implemented CANopen protocol meets the CiA 406

encoder profile.

For an easy configuration of the encoder, EDS files (electronic data sheet) are provided

at the download area at www.wachendorff-automation.com.

Technical Manual

WDGA with CANopen-Interface

2 - Safety information

© Wachendorff Automation GmbH & Co. KG 3 Rev.1.24

When commissioning the encoder, ensure that you observe the

assembly instructions, manual and data sheet.

Failure to observe the safety instructions may lead to

malfunctions, property damage and personal injury!

Observe the operating instructions provided by the machine's

manufacturer.

The encoder must not be operated outside the specified limit

parameters (see data sheet).

2 Safety information

2.1 General safety information

2.2 Intended use

Rotary encoders are components that are intended for installation in machines. Before

commissioning (operation in accordance with the intended use), it must be determined

that the machine as a whole corresponds to the EMC and Machine Directive.

A rotary encoder is a sensor that is designed to detect angular positions and

revolutions and must only be used for this purpose! Wachendorff Automation

manufactures and distributes encoders for use in non-safety-relevant industrial

applications.

Technical Manual

WDGA with CANopen-Interface

2 - Safety information

© Wachendorff Automation GmbH & Co. KG 4 Rev.1.24

All electrical connections must be tested before

commissioning.

Appropriate safety measures must be taken to ensure that no

persons are harmed and no damage to the system or operating

equipment occurs in the event of a failure or malfunction.

2.3 Safe working

The installation and mounting of the encoder must only be carried out by a qualified

electrician.

For the construction of electrical installations, all relevant national and international

regulations must be strictly observed.

Failure to commission the encoder correctly may result in malfunction or failure.

2.4 Disposal

Devices that are no longer needed or are defective must be disposed by the user in

proper compliance with the country-specific laws. It must be taken into consideration

that this is a special waste of electronics and that disposal is not permitted via normal

household waste.

There is no obligation by the manufacturer to take the device back. If you have any

questions regarding proper disposal, contact a disposal specialist in your area.

Technical Manual

WDGA with CANopen-Interface

3 - Device description

© Wachendorff Automation GmbH & Co. KG 5 Rev.1.24

Services

COB-ID

NMT

000h

SYNC

080h

EMCY

080h + Node-ID

PDO1(tx)

180h + Node-ID

PDO2(tx)

280h + Node-ID

PDO3(tx)

380h + Node-ID

SDO(rx)

600h + Node-ID

SDO(rx)

580h + Node-ID

3 Device description

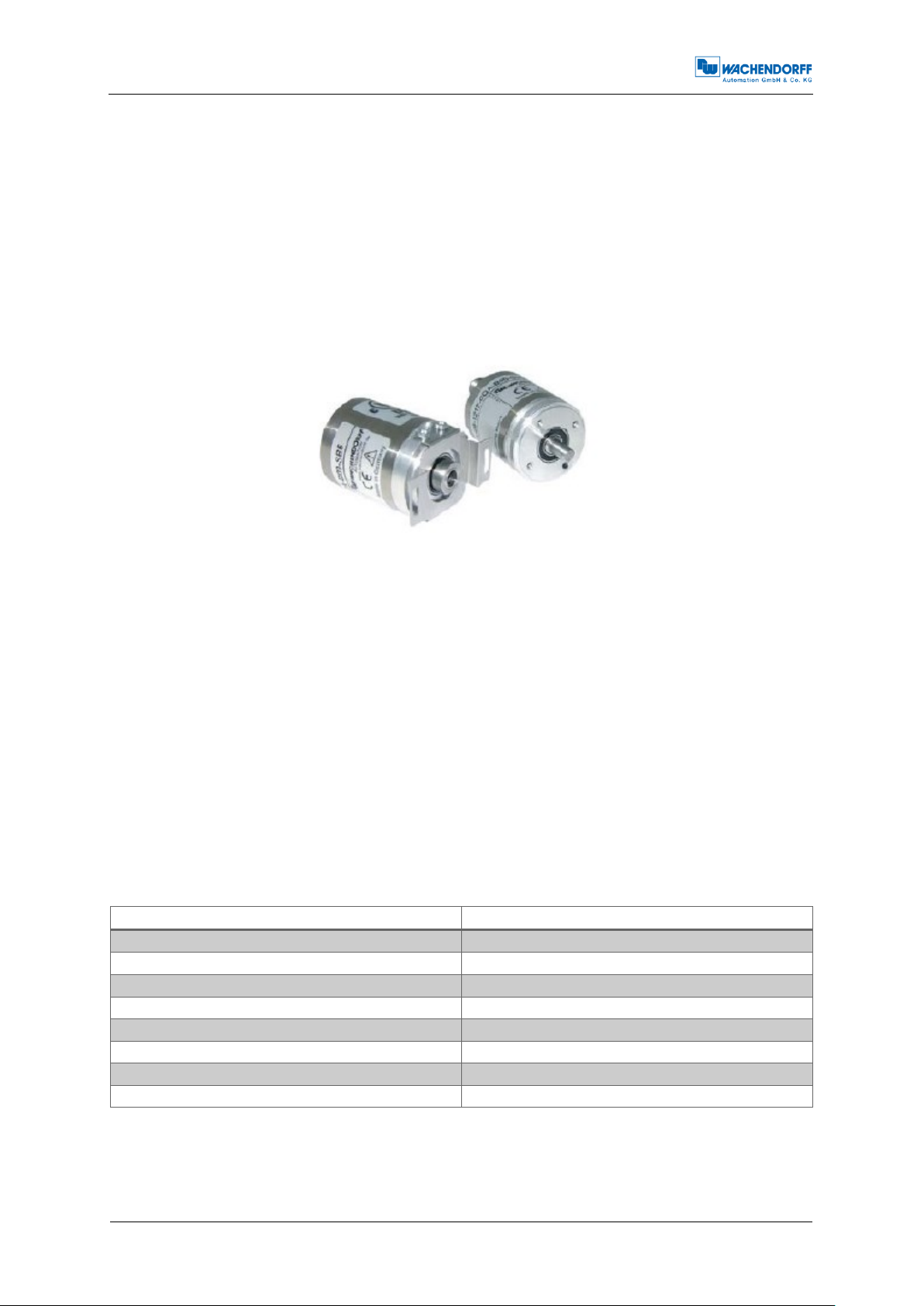

3.1 Basic encoder design

Wachendorff Automation WDGA encoders are available in different mechanical

versions. Key features are size and shape. The standard sizes are 36mm and 58mm

flange diameter. Different types of shapes according to shafts and flanges are

available. Examples of the different versions are shown in Figure 3.1:

Figure 3.1: Encoder versions, shaft and hollow bore shaft

The shaft or the hollow bore shaft will be connected to the rotating part of which the

angular position or rotation you want to measure. The encoder itself is mounted by

several tapped bores or torque supports.

A stub cable or M12 sized connector provides the electrical connection to the CANnetwork.

A bicolour status LED at the top indicates the different states of the encoder during use

and helps with configuration and troubleshooting.

3.2 Predefined Connection Settings

By default all WDGA encoders are set on Node-ID=127h and Baudrate=AutoDetection.

Table 3.1: CAN-Identifier

Technical Manual

WDGA with CANopen-Interface

3 - Device description

© Wachendorff Automation GmbH & Co. KG 6 Rev.1.24

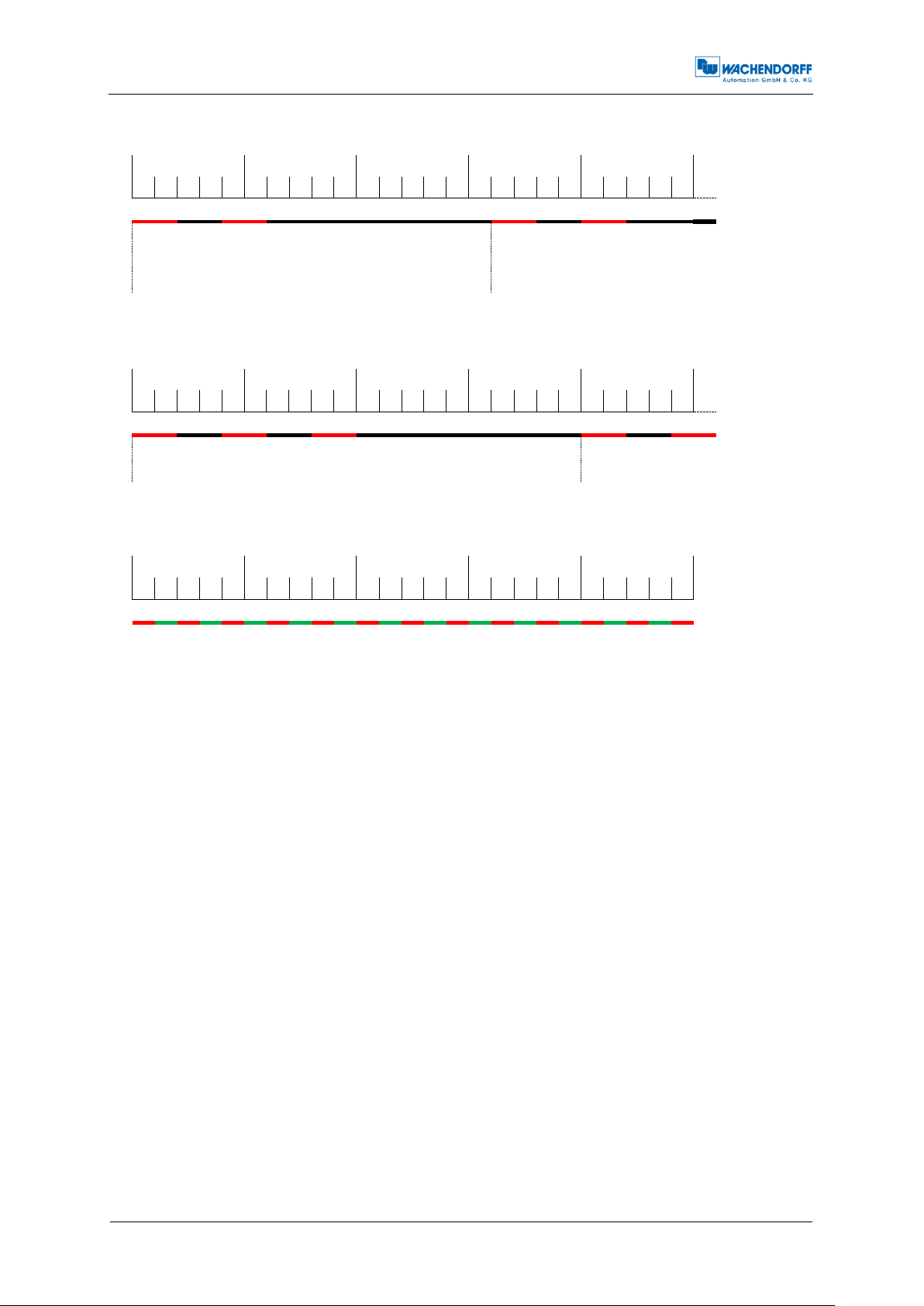

Green ON

Encoder is in

OPERATIONAL

state

0

500

1000

1500

2000

2500

Green blinking

Encoder is in

PREOPERATIONAL

state us

0

500

1000

1500

2000

2500

Green

single flash

Encoder is

in

STOPPED

state

0

500

1000

1500

2000

2500

Red ON

NOT ready /

BUS-OFF

0

500

1000

1500

2000

2500

Red single

flash

Warning,

occurrence

of error

frames

0

500

1000

1500

2000

2500

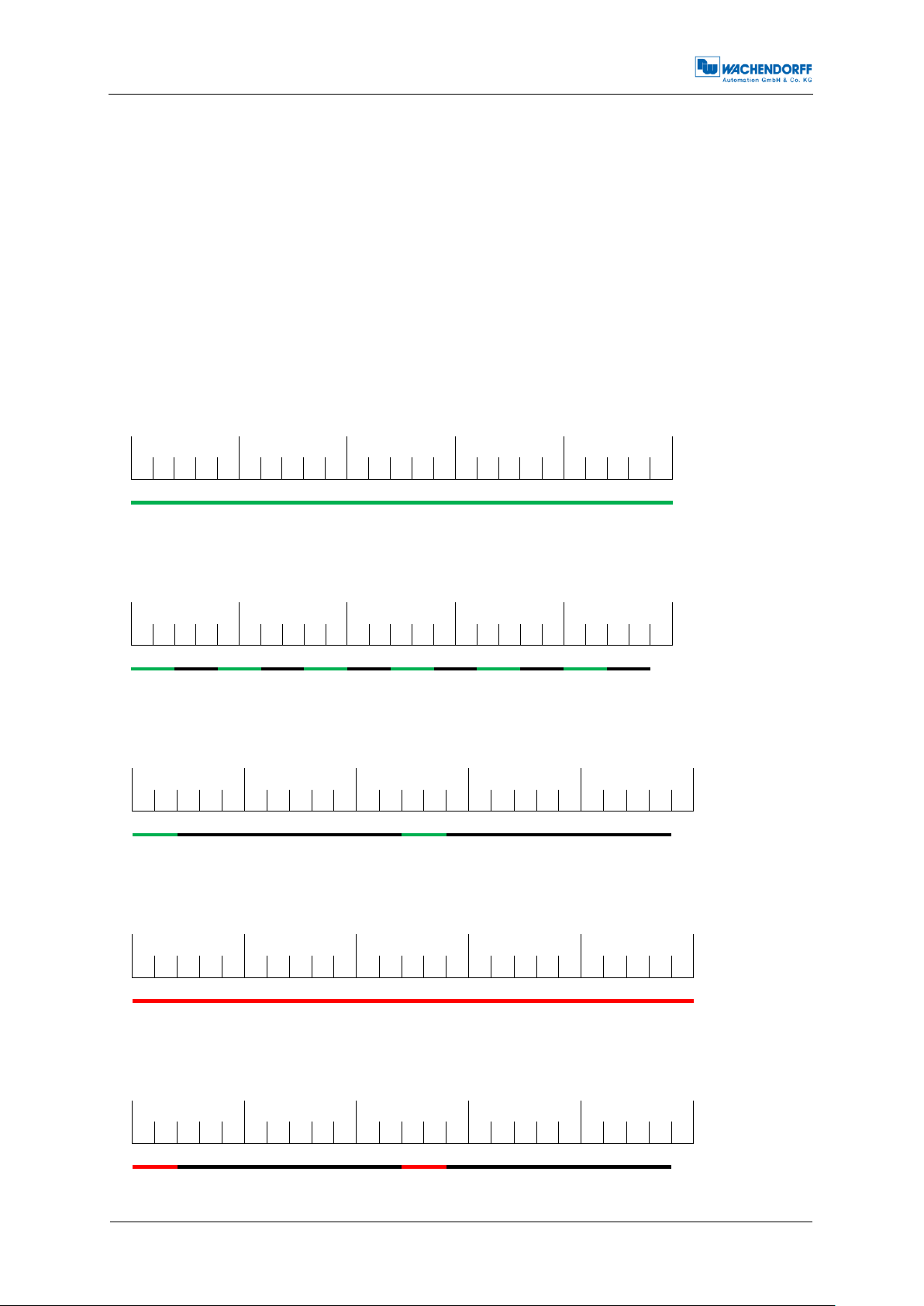

3.3 LED status indicator and signal codes

Definition of LED indication types:

= red LED indications = "Physical Layer" information

= green LED indications = "NMT-Status" information

= LED off

= continue like first cycle

LED-Indications [ms]:

Figure 3.2: LED indications 1

Technical Manual

WDGA with CANopen-Interface

3 - Device description

© Wachendorff Automation GmbH & Co. KG 7 Rev.1.24

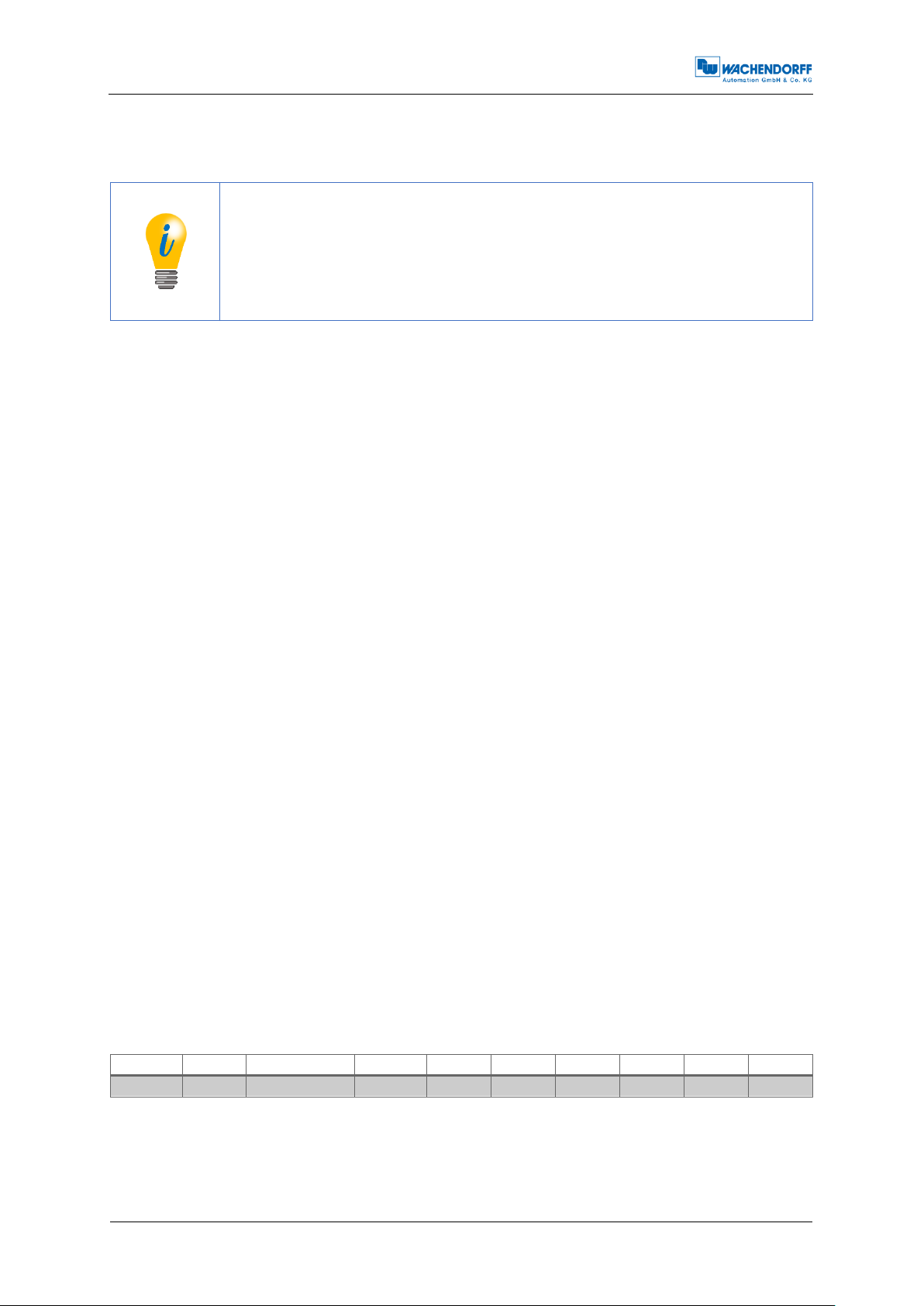

Red double

flash

Error, a

guard event

or a heartbeat event

(heartbeat

consumer)

has

occurred

0

500

1000

1500

2000

2500

Cycle

Red tripple

flash

Encoder is

bus-passive

0

500

1000

1500

2000

2500

Cylce

red-green

flickering

BaudrateAutoDetection in

progress or

LSS config

modus

started

0

500

1000

1500

2000

2500

Figure 3.3: LED indications 2

Technical Manual

WDGA with CANopen-Interface

4 - Quick start

© Wachendorff Automation GmbH & Co. KG 8 Rev.1.24

The encoder indicates every status modification with its status-

LED. See chapter 3.3 "LED status indicator and signal codes".

080h

8

00h

00h

00h

00h

00h

00h

00h

00h

CAN-ID

DLC

Command

Byte0

Byte1

Byte2

Byte3

Byte4

Byte5

Byte6

4 Quick start

4.1 CAN network integration

The default node ID of Wachendorff Automation encoders (Object 2101h sub-Index:

00h) is 7Fh=127d.

For operating in a CAN-Network, the encoder’s baudrate has to be set. The common

ways to set the baudrate is via LSS (CiA DSP-305) or a SDO command.

Wachendorff Automation WDGA encoders have the capability to detect the baudrate

of the network automatically (object 2100h sub-Index: 00h value: 09h - Baudrate-autodetection). So usually the baudrate setup is not necessary. To detect the valid baudrate

the encoder stays passive and scans the communication at the bus. When the

baudrate is detected, the encoder is set to this rate, sends its boot-up message and

switches into pre-operational mode.

To prevent possible collisions in case double assigned node ID it is recommended to

use a 1:1 connection with a bus master for configuration (e.g. a laptop computer with

suitable hard- and software). Set the master on the intended baudrate and use SDO

or LSS services to configure the encoder.

4.2 SDO command to set the node ID

After connecting the encoder WDGA with the CAN bus respectively the master (e.g. a

laptop computer with suitable hard- and software) the LED starts "flickering red and

green" (see Figure 3.3 LED indications 2).

First send one or more SYNC messages, which the encoder can use to detect the

baudrate:

Table 4.1: SYNC-message

The encoder will detect and lock on the used baudrate. It will send its boot-up message

and the LED starts to blink green (see Figure 3.2).

Technical Manual

WDGA with CANopen-Interface

4 - Quick start

© Wachendorff Automation GmbH & Co. KG 9 Rev.1.24

600h+ID

8

2Fh

01h

21h

00h

Node-ID

00h

00h

00h

CAN-ID

DLC

Command

Object

L

Object

H

SubIndex

Byte0

Byte1

Byte2

Byte3

Node-ID (d)

Node-ID (h)

1

01h

2

02h

…

…

4

04h

…

…

127

7Fh

Changing the Node ID automatically adjusts the PDO and

EMCY COB IDs. After the first manual storage, they are frozen

at their current value and no longer automatically adjusted.

Performing the "Restore Defaults" command will re-enable

automatic adjustment.

To set the encoders node ID the object 2101h, Sub-Index 00h has to be accessed.

(Only possible in PRE-OPERATIONAL state!) Send a write-SDO-command with the

intended node ID (in hex):

Table 4.2: SDO-write command to set Node-ID

An example for a node ID might be:

Table 4.3: Node-ID in decimal and hexadecimal

The change of the node ID via SDO will be effective after a reset of the encoder (hard

reset or NMT reset). The new node ID is stored into the EEPROM immediately and

without a further command. The setting of the node ID via LSS is described in chapter

8.

4.3 Setting-up the encoder

Connect the encoder to the bus of application. Please mind the included mounting and

safety advice documents. You can find additional information to this in chapter 8

"Setting-up".

When the encoder is completely integrated into the application you can switch it into

OPERATIONAL mode by the "Start-All-Nodes-Command" (see chapter 7.1).

Technical Manual

WDGA with CANopen-Interface

4 - Quick start

© Wachendorff Automation GmbH & Co. KG

10

Rev.1.24

The encoder is now operational (LED shows green ON) and starts sending its data via

the several process data objects (PDO). The encoders default configuration plans that

the PDO1 is triggered once the position value changes.

The position value (object 6004h) is mapped in PDO1 and transmitted as an

Unsigned32. By default PDO2 transmits the same value but synchronously on the

reception of a SYNC message. Heartbeat is switched off and will not be transmitted by

default. The encoder is now configured and ready for basic applications.

Technical Manual

WDGA with CANopen-Interface

5 - General information about CAN

© Wachendorff Automation GmbH & Co. KG

11

Rev.1.24

5 General information about CAN

5.1 CAN physical and transport layer

CAN is a field bus. It operates with the CSMA/CA (Carrier Sense Multiple Access /

Collision Avoidance) method. It means that collisions during bus access are avoided

by a so called bitwise arbitration. The bits are coded NRZ-L (Non Return to Zero - Low).

A cyclic redundancy check (CRC) and other safety mechanisms provide a secure

transmission. For synchronisation a mechanism called "bit stuffing" is used. CAN is a

multi-master system, i.e. several equal bus nodes can be connected without a bus

master supervising the communication. In principle a CAN bus can be realized with

copper wire or in fibre optic cable.

The common CAN implementation with copper wire operates with differential signals,

transmitted via two wires: CAN

mode rejection ratio.

Data is transmitted with bits that can either be dominant or recessive. The dominant

(0) always overwrites the recessive (1).

HIGH

, CAN

. Therefore CAN has a good common

LOW

The topology of a CAN network is a line, which can be extended by stubs. The

maximum length of a stub is limited to 0,5m.

The network always has to be terminated on both ends with 120Ohms each (between

CAN

und CAN

HIGH

). Other locations or values are not allowed.

LOW

The arbitration mentioned before is used to control the bus access of the nodes by

prioritization of the CAN-Identifier of the different messages. Every node monitors the

bus. If more than on node wants access on the bus, the node with the highest priority

of the messages ID succeeds and the other nodes retreat until there is "silence" on

the bus (see Figure 5.1). Technically the first dominate bit of the ID send overwrites

the corresponding recessive bit of the other IDs. In case that more than one node

uses the same CAN-ID an error occurs only at a collision within the rest of the frame.

On principle a CAN-ID should only be used by a single node!

Technical Manual

WDGA with CANopen-Interface

5 - General information about CAN

© Wachendorff Automation GmbH & Co. KG

12

Rev.1.24

Figure 5.1: Example of the arbitration

Due to the arbitration there is a ranking of the messages. The message with the lowest

ID has the highest priority and therefore it has almost instant access on the bus. The

exception is that an ongoing transmission will not be interrupted. So time critical

messages should be assigned to the high priority CAN-IDs, but even then there is no

determination in the time of transmission (non-deterministic transmission).

For the arbitration all nodes have to be synchronised. Due to the lack of a separate

clock signal, the transmission of many identical bits in line would lead to the loss of

synchronisation. The so called bit-stuffing is used to prevent this case. After five equal

bits a complementary bit will be inserted into the transmission (the application will not

notice). So the nodes can keep up resynchronising on the bit flanks (see Figure 5.2).

Figure 5.2: Bitstuffing

Technical Manual

WDGA with CANopen-Interface

5 - General information about CAN

© Wachendorff Automation GmbH & Co. KG

13

Rev.1.24

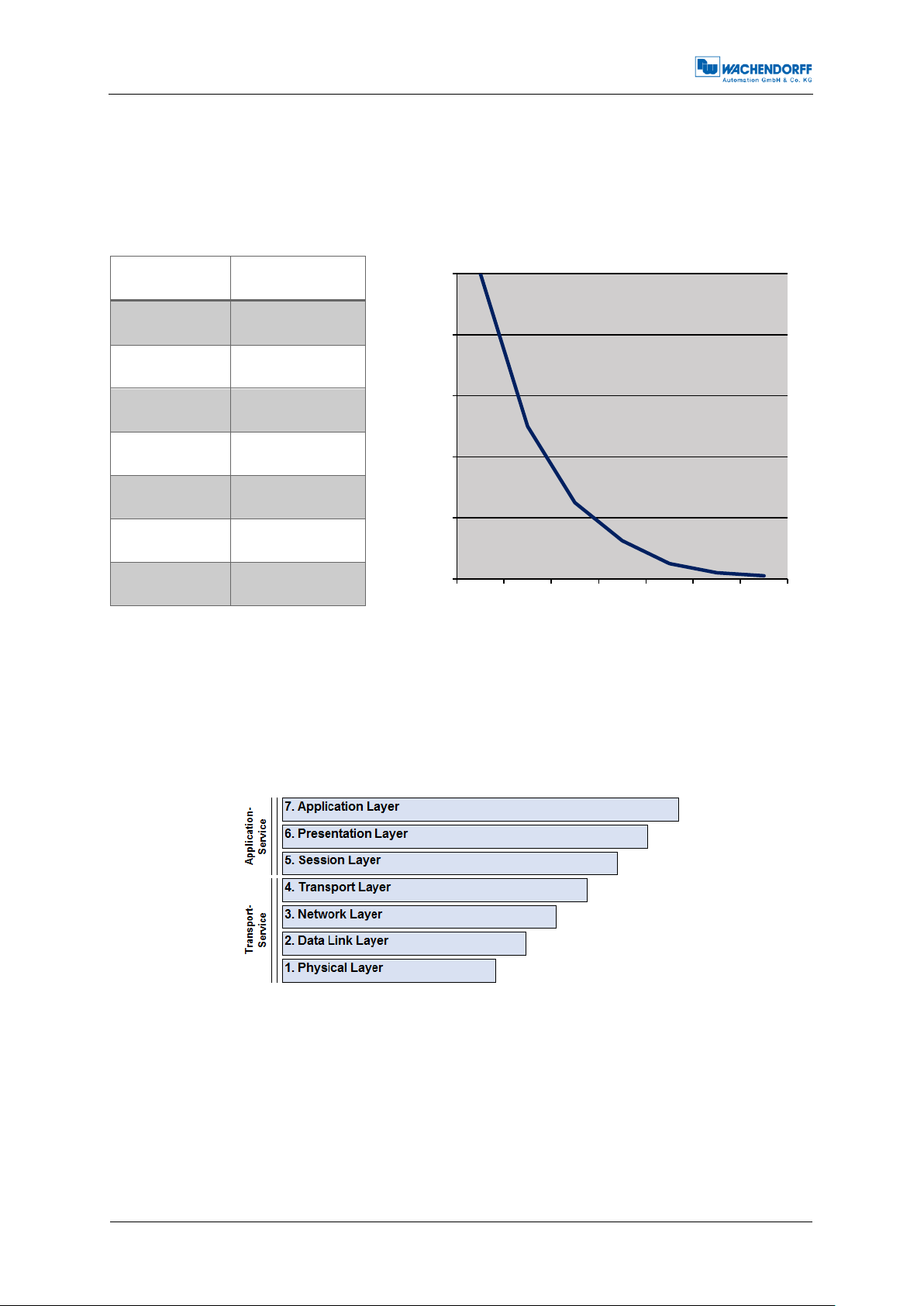

Baud rates

Cable length

10 kBit/s

6,7 km

20 kBit/s

3,3 km

50 kBit/s

1,3 km

125 kBit/s

530 m

250 kBit/s

270 m

500 kBit/s

130 m

1 MBit/s

<40 m

0

200

400

600

800

1000

40 150 270 530 1300 3300 6700

Baudrate [kbits/s]

Cable length [m]

A CAN network can operate with baud rates up to 1 Mbit/s. Due to the necessary

synchronisation of the nodes, the maximum delay caused by the length of the cable

has to be limited. The limitation corresponds with the baudrate. There is a common

recommendation of the maximum cable length at several baud rates.

Table 5.1: CAN baud rates und recommended cable length limits

5.2 CANopen

CANopen is a specified higher protocol (layer 7 protocol) (Figure 5.3).

Figure 5.3: ISO-OSI-Modell

With CANopen it is possible to transfer larger amounts of data, emergency telegrams

and process data. CANopen describes how the communication is performed. That

means that parameters to configure a device are transmitted in a defined form (profile).

A CANopen profile defines objects representing the different functions of a device.

These objects form a table called object dictionary.

Technical Manual

WDGA with CANopen-Interface

5 - General information about CAN

© Wachendorff Automation GmbH & Co. KG

14

Rev.1.24

Specification

Description

CiA 301

Application Layer and Communication Profile

CiA 303

Cabling/pin assignment, Representation of units, Indicator specification

CiA 305

Configuration of baudrate und node ID via LSS

CiA 306

Electronic Data Sheet

CiA 406

Device-/Application-profile

The communication profile defines the basic services and parameters of a CANopen

device (e.g. service data objects SDOs, process data objects PDOs, used CAN-IDs,

etc.).

The device profile defines the specific functions of a device family (e.g. encoders, i/o

devices, ...). For encoders the device profile is the encoder profile CiA 406.

5.3 Specifications and profiles

5.3.1 Overview

The CANopen specifications were defined by the CiA in Draft Standards. Concerning

the WDGA encoders the following specifications are from special importance:

Table 5.2: Draft Standards

5.3.2 Mechanisms of communication

There are several different CANopen communication services:

SDO Service Data Object

Use: for access to the object dictionary. There is one single SDO-channel.

Two identifiers are assigned to the SDO channel, one for each direction of

transmission.

For SDO the 8 byte CAN frame is divided into 1 byte command, a multiplexor of 2 byte

index and 1 byte sub index of the object dictionary, and 4 byte of payload. For bigger

payloads either segmented or block transfer is used.

A SDO transmission will always be acknowledged by the receiver. In case of a failure

an "abort message" is send. The internal delay time of the WDGA encoders is 1

millisecond maximum.

PDO Process Data Object

Use: for transmission of process data. The WDGA encoders provide up to four PDOs.

A PDO uses the full length of the data area of a CAN frame (8 bytes) for the process

data without additional overhead.

Loading...

Loading...