Universalanzeige UA964802

User Manual

Version 1.0

Table of contents

1 Safety guide lines ...................................................................................................................6

2 Model ide ntification ..............................................................................................................6

3 Technical Data ........................................................................................................................7

3.1 Genera l data ..................................................................................................................7

4 Hardware data ........................................................................................................................7

4.1 Software d ata ................................................................................................................8

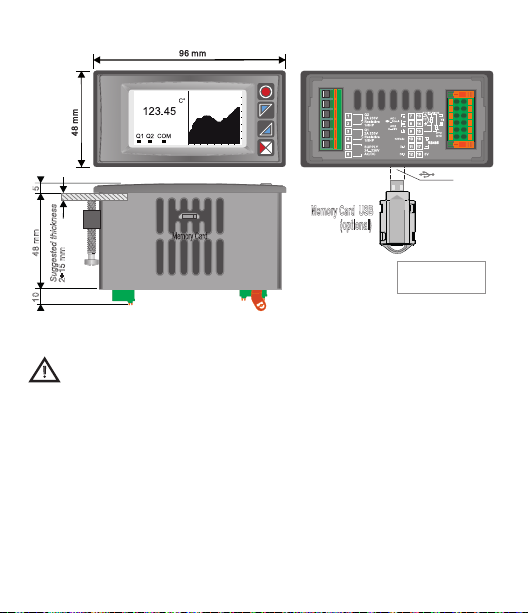

5 Dimensions a nd Installation ...............................................................................................9

6 Electrica l wirings ....................................................................................................................9

6.1 Wiring diagram .......................................................................................................... 10

7 Display and Ke y Functions .................................................................................................14

7.1 Ke y s .................................................................................................................................14

7.2 Display ...........................................................................................................................14

8 Controller Func tions ........................................................................................................... 16

8.1 Memory Card (opt ional) .......................................................................................... 16

8.2 Mo difying alarm thresholds ................................................................................... 16

8.3 Latch on functio n .......................................................................................................17

8.4 Digital input fu nctions ............................................................................................. 18

8.5 Peak values ...................................................................................................................19

8.6 Totalizer function........................................................................................................19

8.7 Sum function .............................................................................................................. 20

8.8 Customizable line ar input ....................................................................................... 20

8.9 Alarm Interve ntion Modes ...................................................................................... 21

8.10 Data logger ................................................................................................................. 23

9 Serial commu nication ....................................................................................................... 24

10 Configuration ....................................................................................................................... 28

10.1 Modifying co nfiguration parameters .................................................................. 28

10.2 Loading default val ues.............................................................................................28

11 Table of configu ration parameters ................................................................................ 29

11.1 Analogue input .......................................................................................................... 29

11.2 V/I custom .................................................................................................................... 33

11.3 Ala rm 1 ......................................................................................................................... 37

11.4 Ala rm 2 .........................................................................................................................39

11.5 Display .......................................................................................................................... 41

11.6 Di gital input 1 ............................................................................................................. 42

11.7 Di gital input 2 ............................................................................................................. 43

11.8 Graphic .........................................................................................................................43

11.9 Ana logue output in mA ........................................................................................... 44

11.10 Analogue output i n Volt .......................................................................................... 45

11.11 Comunication port .................................................................................................... 46

Introduction

Thanks for choosing a Pixsys device.

UA964802 is an indicator/panel meter for acquisition and retransmission of

processes, also with fast transient. It is provided with relay outputs for alarm

purpose, analogue outputs for retransmission of process/setpoints and

programmable digital inputs.

Available in standard format 96x48mm, the device can be configured both for

horizontal and vertical mounting.

Distinctive feature is the intuitive multilingual interface and a

graphical OLED display (monochrome yellow)

Visualization options include bargraph and process trend with programmable

sampling time. Software features include mathematical functions related to

process value like Totalizer and Sum.

Serial connectivity relies on RS485 and Modbus-RTU protocol.

.

128x64 pixel

1 Safety guide lines

Read carefully the safety guidelines and programming instructions contained in

this manual before using/connecting the device. Disconnect power supply

before proceeding to hardware settings or electrical wirings.

Only qualified personnel should be allowed to use the device and/or service it

and in accordance to technical data and environmental conditions listed in this

manual. Do not dispose electric tools together with household waste material.

In observance European Directive 2002/96/EC on waste electrical and electronic

equipment and its implementation in accordance with national law, electric

tools that have reached the end of their life must be collected separately and

returned to an environmentally compatible recycling facility.

2 Model identification

Model 24.. 230 Vac/Vdc +/-15% 50/60 Hz – 8 VA

UA964 802

6 - UA964802 - User man ual

2 relays 2 A + 1 out V + 1 out mA + 2D.I. + RS485 +

OLED + Rfid

3 Technical Data

3.1 General data

Display 2.42” monochrome (yellow) OLED graphical display

Operating

temperature

Sealing IP54 front panel (with gasket) - IP20 box and terminals

Material Box: polycarbonate V0

Weight Approx. 165 g

Temperature 0 -40 °C - Humidity 35..95 uR%

4 Hardware data

Power supply

Analogue input

Relay outputs 2 Relays

Analogue output

Extended power supply

24..230 Vac/Vdc ±15% 50/60 HzConsumption: 8 VA.

AN1 Configurable via

software.

Thermocouple type K, S,

R, J, T, E, N, B. Automatic

compensation of cold

junction from 0..50 °C.

Thermoresistance: PT100,

PT500, PT1000, Ni100, PTC1K,

NTC10K (β 3435K ).

Input V/I (linear): 0-10 V,

0-20, 4-20 mA, 0 -60 mV.

Potentiometer input: 6 K Ω,

150 KΩ.

1 tension

Linear 0..10 Volt.

1 current

Configurable as output

0..20mA or 4..20mA.

Tolerance (25 °C)

+/-0.2% ±1 digit (F.s.) for

thermocouple, thermoresistance and V / mA.

Cold junction accuracy 0.1

°C/°C.

Impedance:

0-10 V: Ri>110 KΩ

0-20 mA: Ri<5 Ω

4-20 mA: Ri<5 Ω

0-60 mV: Ri>1 MΩ

Contacts 2 A - 250 V~.

Resistive charge.

All 16bit +/-0.2% (F.s.)

User manual - UA96 4802 - 7

4.1 Software data

Regulation

algorithms

Alarm mode

Sum Function

Totalizer Function

Trend

visualization

Analogue

retransmission

Digital

transmission

Latch-on function

Data logging

function

Text menus English/Italian/Deutsch/French/Spanish

8 - UA964802 - User man ual

ON/OFF with hysteresis

Absolute / Threshold, Band with instantaneous/delayed/

retentive ac tion/by digital input activation, Sensor failure /

Activation by serial line

By digital input or by keyboard it is possible to sum

different process measurements over time

Visualisation of instant process value and total value since

last reset

Trend visualisation up to 59 samples, with selectable time

basis 1 to 3600s

Process values / Setpoints

Process values / Setpoint / Parameters via RS485

Semi-automatic set ting of limits/ calibration values for

analogue input

Selectable time basis 1s to 3600s, tot. memor y 2.5k words

5 Dimensions and Installation

Suggested thickness

5

48 mm

10

2÷15 mm

Memory Card

Memory Card USB

(optional)

USB

Frontal panel cut-out

45 x 91 mm

6 Electrical wirings

Although t his controller has b een designed to re sist noises in an ind ustrial

environment, please notice the following safety guidelines:

• Separate control lines from the power wires.

• Avoid the proximity of remote control switches, electromagnetic meters,

powerful engines.

• Avoid the proximity of power groups, especially those with phase control.

For permanently connected equipment:

• s upply wiring must b e ≥18 Awg with cables suitab le for temperatur es > 70 ° C;

• for requirements about any external switch or circuit-breaker see EN 61010-1

par. 6.11.3.1 and about external overcurrent protection devices see EN

61010-1 par. 9.6.2; the switch or circuit-breaker must be near the equipment.

User manual - UA96 4802 - 9

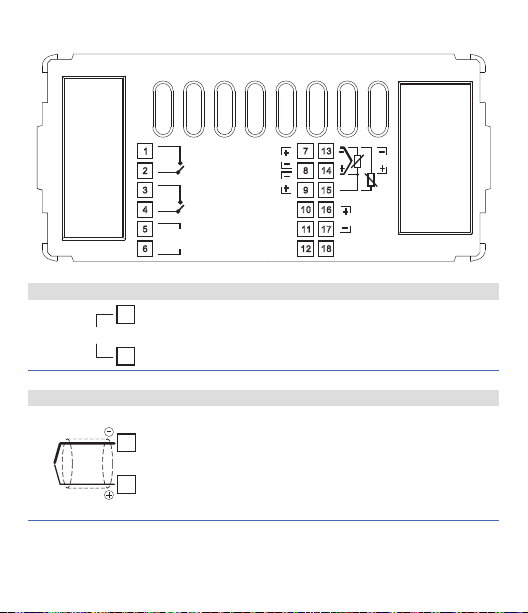

6.1 Wiring diagram

Q2

1

2A 23 0V

R es i s ti ve

2

1/8 HP

Q1

3

2A 23 0V

R es i s ti ve

4

1/8 HP

5

S U PP L Y

24 .. . 230 V

A C /DC

6

6.1.a Power supply

SUPPLY

24..230V

AC/DC

5

Switching supply with ex tended range 24…230 Vac/dc

±15% 50/60Hz – 8 VA (galvanic isolated)

6

AO 1

0/4 .. .2 0m A

AO 2

0. .. 10 V

+24 V dc

P T1 00 -N I1 00

-

TC

0V

+

+

R S 48 5

-

-

V/I

+

P TC

NT C

13

7

+

-

8

14

-

+

159

1610

DI .1

1711

DI .2

18

12

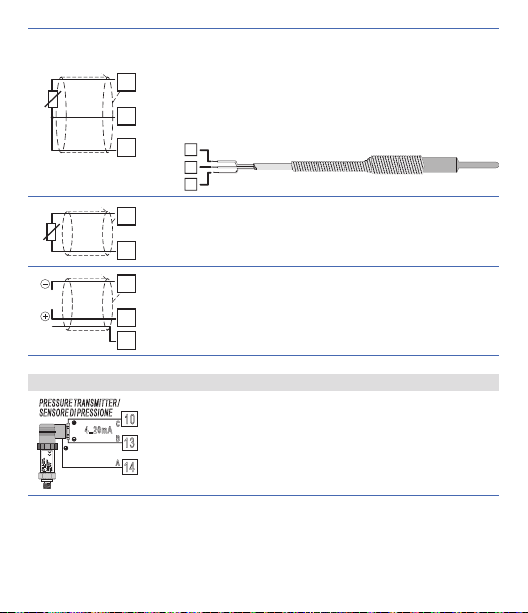

6.1.b AN1 analogue imput

For thermocouples K, S, R, J, T, E, N, B.

• Comply with polarity.

13

AI1 TC

10 - UA964802 - User m anual

• For possible extensions, use a compensated wire

and terminals suitable for the thermocouples used

(comp ensated ).

14

• When shielded cable is used, it should be grounded at

one side only.

PT/Ni100

Shield/Schermo

For thermoresistances PT100, NI100.

PTC/NTC

Shield/Schermo

Shield/Schermo

• For the three-wire connection use wires with the same

AI1

Red/Rosso

Red/Rosso

AI1

V/I

+24Vdc

• For the two-wire connection short-circuit terminals 14

an d 15.

14

• When shielded cable is used, it should be grounded at

one side only.

15

13

15

13

14

10

13

White/Bianco

Red/Rosso

14

15

Red/Rosso

For thermoresistances NTC, PTC, PT50 0, PT1000 and

linear potentiometers.

When shielded cable is used, it should be grounded at

one side only to avoid ground loop currents.

For linear signals V / mA .

• Comply with polarity.

• When shielded cable is used, it should be grounded at

one side only.

section.

13

White/Bianco

6.1.c Example of connection for linear input Volt and mA

PRESSURE TRANSMITTER /

SENSORE DI PRESSIONE

P :0...100mbar

Pmax :3bar

T :0..70°C

OUT : 4...20mA

IN :9...33V DC

For linear signals 0/4..20 mA with three-wire sensor.

10

C

Comply with polarity:

4..20mA

B

13

A= Sensor output (+)

B= Sensor ground (-)

A

14

C= Sensor power supply (+24 Vdc / 35mA)

User manual - UA96 4802 - 11

PRESSURE TRANSMITTER /

10

C

SENSORE DI PRESSIONE

Shield/Schermo

SENSORE DI PRESSIONE

P :0...100mbar

Pmax :3bar

T :0..70°C

OUT : 4...20mA

IN :9...33V DC

B

13

4...20mA

A

14

External supply /

Alimentazione esterna

For linear signals 0/4..20 mA with external power of

sensor.

Comply with polarity:

A= Sensor output (+)

B= Sensor ground (-)

4..20mA

OUT : 4...20mA

IN :9...33V DC

P :0...100mbar

Pmax :3bar

T :0..70°C

PRESSURE TRANSMITTER /

For linear signals 0/4..20 mA with two-wire sensor.

Comply with polarity:

A

14

A= Sensor output

C= Sensor power supply (+24 Vdc / 35mA)

6.1.d Serial input

RS485

16

RS485 Modbus RTU communication

17

18

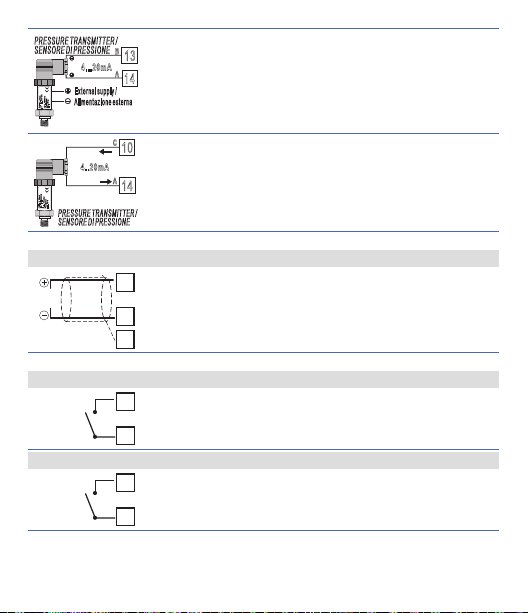

6.1.e Relay Q1 output

3

2A

230V

1/8Hp

Capacity:

Q1

2 A / 250 V~ for resistive loads.

NB: see picture below

4

6.1.f Relay Q2 output

1

2A

230V

1/8Hp

12 - UA964802 - Use r manual

Capacity:

Q2

2A/250 V~ for resistive loads.

NB: see picture below

2

6.1.g mA / Volt output

+24Vdc

AO1

0/4..20mA

AO2

0..10V

7

8

8

9

6.1.h Digital Input 1

10

11

DI1

(PnP)

Electrical endurance Q1 / Q2.

2 A, 250 Vac, resistive load, 10

20/2 A, 250 Vac, cosφ = 0.3, 10

5

operations.

5

operations.

Pin s 7-8: linear output in mA configurable using

parameters as retransmission of process or alarm setpoints

(s ee pa r. 112 -116).

Pins 8-9: linear output in Volt configurable using

parameters as retransmission of process or alarm setpoints

(ve di par. 119-123).

PNP digital input

Digital input according to parameter 95

Short-circuit pins 10 and 11 to activate the digital

input 1

User manual - UA96 4802 - 13

6.1.i Digital input 2

+24Vdc

DI2

(PnP)

10

PNP digital input

Digital input according to parameter 100

Short-circuit pins 10 and 12 to activate the digital

12

input 2

7 Display and Key Functions

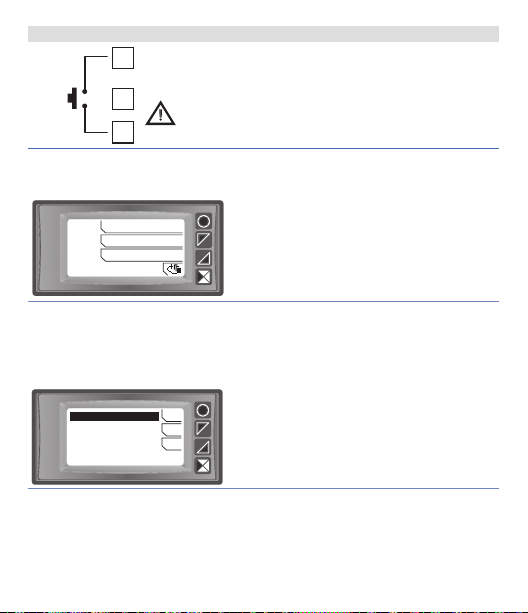

7.1 Keys

Process

Graphic

Peak values

Keys are multifunction: in correspondence

of each key its meaning is displayed.

If no description is showed, press a key

to visualize it. Some menus will be only

displayed, when activated.

7. 2 Display

It visualizes the process, the setpoints and all configuration parameters. The

programming/ operation interface with text menus in 5 languages makes the

navigation intuitive.

English

Italiano

Deutsch

Français

Español

14 - UA964802 - Use r manual

Sel

‹

At first starting, display shows the language

‹

selection.

25.6

Q1 COM

Q2

°C

This page displays the process, the relays

status and the serial communication (if

available).

4.998

4.998

Q1

25.6

Q1

Bar

°C

Q2

Q2

Bar

Q1

This page displays the process, the relays

status and a graph representing the process

trend.

This page displays the process and its

Q2

graphic representation as bargraph.

User manual - UA96 4802 - 15

8 Controller Functions

8.1 Memory Card (optional)

Parameters and setpoint values can be duplicated from one controller to

another using the Memory card.

Insert memory card when the controller is off. On activation, after startup, the

display visualizes “Load data” and “Esc” in correspondence of the relative keys

(only if the correct values are saved in the memory card). Pressing “Load data”

the controller loads the new values. Pressing “Esc” the device keeps the old

values.

Updating Memory Card.

To update the memo ry card values, fo llow the procedure de scribed on

first mod e, pressing “Esc” so as n ot to load the para meters on control ler.

Enter configuration and change at least one parameter. Exit configuration.

Changes are stored automatically.

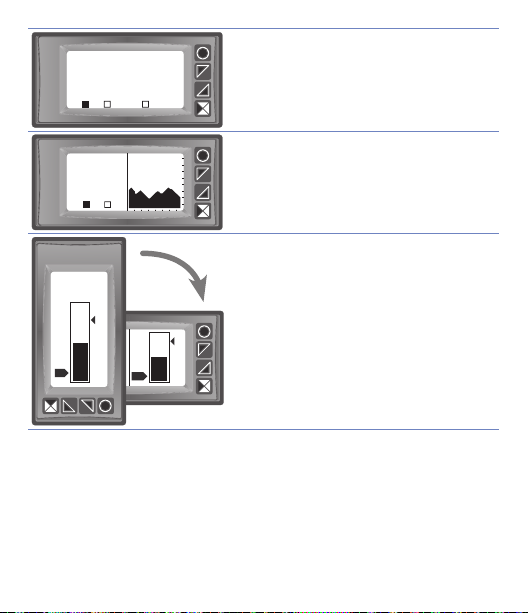

8.2 Modifying alarm thresholds

Selecting one or more absolute/ band alarms, it is possible to modify

the intervention thresholds directly by the user menu, without entering

configuration.

AL . 1

AL . 2

0006.0

100.0

Sel

‹

°C

°C

Press “Setpoint ” to enter the thresholds

‹

modification.

For the modification procedure refer to the following table:

Press Display Do

Press n e m to modify the

“Sel”

1

16 - UA964802 - User m anual

Selects the setpoint to be

modified.

value. Pressing

possible to modify digit per

digit.

it is

Press Display Do

2

“Sel”

“Sel”

3

Selects the nex t setpoint

(if active), otherwise go to

point 3.

n

and m disappear Press “Esc” to exit procedure.

See point 1.

8.3 Latch on function

For the use with input Potentiometers max.6 kohm and Pot.max.150 kohm and

with linear i nput (0..10 V, 0..60 mV, 0/4..20 mA), it is possibl e to associate the star t

value of the scale (par. 4 Lower limit V/I) to the minimum position of the sensor

and the value of end scale (par. 5 Upper limit V/I) to the maximum position of

the sensor.

Latch on

0.000

Input

0.006

mA

For the calibration procedure refer to the following table:

Press Display Do

n

3

1

m

2

“0” Set the vir tual zero value. Press “Esc” to exit procedure.

4

‹

Bar

0

Esc

To use the LATCH ON function: enter

‹

configuration, select Setting on par. 8 Latch

on and press “Sel ” (UA964802 shows the

page in the picture).

Set the value to maximum.

Set the value on minimum.

To exit standard procedure

press “Esc”.

For zero set tings place the

sensor on the zero point

Place the sensor on minimum

operating value (associated

with Lower limit V/I).

Place the sensor on maximum

operating value (associated

with Upper limit V/I).

User manual - UA96 4802 - 17

Max

Min Zero

8.4 Digital input functions

On the UA964802 model, digital inputs can be enabled by confi guring the par.

95 Digital input 1 and the par. 100 Digital Input 2.

• Run: allows the action of relays and linear output.

• Hold: locks the conversion.

• Tare zero (AI): selects to zero the process value (tare function).

• Alarm reset: if one or more alarms are selected with manual reset and alarm

conditions are no longer present, closing the digital input it is possible to

restore the alarm output.

• Totalizer reset: if the totalizer function is active, using the digital input it is

possible to reset the counter.

• Peak s reset: min. peak/max. peak/peak-to-peak values are reset.

• Sum total: if the sum f unction is active, using the digital input it is possible to

increase the “sum” counter as indicated by the process value.

• Sum reset: if the su m function is acti ve, using the digital inp ut it is possible to

reset the “su m” counte r.

• Confi g. lock: if th e digital input i s active it is not p ossible to enter co nfi guration

or to modif y the setpoints.

Selecting Digital input 1 or Digital input 2 on the alarm parameters, the

related relays will activate togheter with the digital inp ut; functions sel ected on

parameters 95 and 100 will continue to work .

To store value in eeprom, see parameter 11 S to re.

18 - UA964802 - User m anual

8.5 Peak values

Maximum

25.6 kg

Minimum

15.7 kg

Peak-Peak

9.9 kg

Rst

Esc

The UA964802 is provided with a page for

the visualization of peak values: max. peak,

min. peak and peak-to-peak of analogue

input. Keeping pressed “Rst” it is possible to

reset the visualized values.

8.6 Totalizer function

The totalizer function, which can be enable by par. 9 Totalizer, performs an

instant me asurement of the pro cess and sums it on a time bas is to the previously

totalized value.

Process

1178.9

Total izer

2301.4

Ex.: if a sensor 4..20mA with F.s. 9000m

select Hour on par. 9 Totalizer. The device will increase the totalized value

considering the m

To store value in eeprom, see parameter 11 S to re.

Rst

m3/h

Esc

3

flowing each second (2.5m3).

On the dedicated page it is possible to see

the instant process value and the totalized

value: keeping pressed “Rst” it is possible to

reset this value.

3

/hour is connected, it is necessary to

User manual - UA96 4802 - 19

8.7 Sum function

The sum function, which can be enabled by par. 10 Sum function, allows to

increase a counter adding the process value on command. It is an application

typical for weighing systems and allows to know the total weighed value.

Process

100.07

Sum

4703.29 kg

Rst

kg

+

Tar

Esc

Press “Sum Func tion” to enter the function

page. Pressing “+” the Process value is

added to the counter. It is possible to reset

the total value keeping pressed “Rst ” and to

fix “tare zero” of the process pressing “ Tar” .

Functions t are, sum and reset can b e managed also by dig ital input if enabl ed on

par. 95 Digital Input 1 and par. 100 Digital Input 2.

To store value in eeprom, see parameter 11 S to re.

8.8 Customizable linear input

Selecting 16 step s on par. 17 V/I custom and connecting a linear sensor it is

possible to customize the linear input for a max. of 16 steps. On parameters

xx-Input value it is necessary to enter the value of the input to which the value

selected on the corresponding parameter xx-Custom value will be related.

Example: sensor 0 -10V.

01-Input value => 0.000V 01-Custom value=>0mBar

02-Input value => 2.000V 02-Custom value=>100mBar

03-Input value => 5.000V 03-Custom value=>500mBar

04-Input value => 10.000V 04-Custom value=>1000mBar

At each value in vo lt (input) it is relate d a value in mBar (custom ized): if the senso r

supplies 2V the device visualizes 100mBar, if it supplies 5V the device visualizes

500mBa r. For interme diate tension values th e value in mBar is calc ulated linearly

between the entered values containing it: 1V = 50mBar, 3.5V=300mBar and

7V=700 mBar.

20 - UA964802 - User ma nual

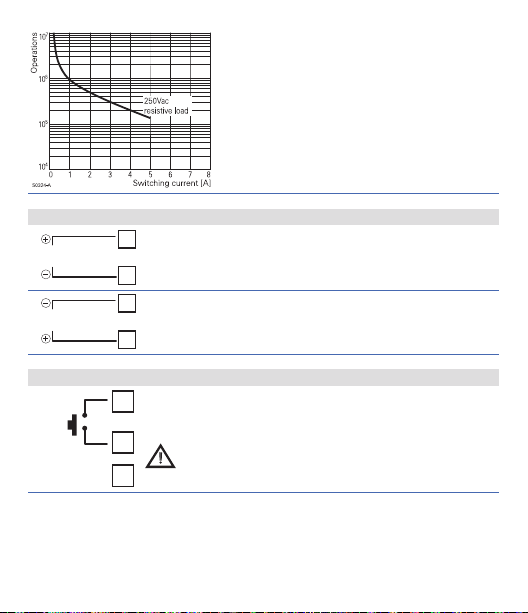

8.9 Alarm Intervention Modes

Alarm Spv

Pv

O

On On

O

Hysteresis

par. > 0

Time

Alarm

output

Pv

Dev. Spv

Dev. Spv

8.9.a Absolute alarm (absolute selection)

1

Hysteresis

par. < 0

Alarm Spv

2

Time

On On

O

O

8.9.b Band alarm (band selection)

1

On On On

O O

Alarm

output

Dev. Spv

Hysteresis

par. > 0

Dev. Spv

Time

Alarm

output

Absolute alarm and hysteresis value

greater than “0” (Par. 58 hysteresis

> 0).

N.B. The example refers to alarm 1;

the function can also be enabled for

alarms 2

Absolute alarm and hysteresis value

less than “0” (Par. 58 hysteresis < 0).

N.B. The example refers to alarm 1;

the function can also be enabled for

alarms 2.

Band alarm and hysteresis value

greater than “0” (Par. 58 hysteresis

> 0).

N.B. The example refers to alarm 1;

the function can also be enabled for

alarms 2.

User manual - UA96 4802 - 21

Pv

Dev. Spv

2

On On On

O O

Alarm Spv

Hysteresis

par. < 0

Band alarm and hysteresis value less

Dev. Spv

than “0” (Par. 58 hysteresis < 0).

N.B. The example refers to alarm 1;

Hysteresis

the function can also be enabled for

alarms 2.

Time

Alarm

output

8.9.c Digital input alarm (sel. “Digital input 1” or “Digital input 2”)

Alarm related to digital input: the relay activates with digital input active.

8.9.d Loop Break Alarm (selection“L.B.A.”)

Sensor alarm breakage: the relay activates in case of sensor breakage or sensor

out of range.

8.9.e Remote control alarm (selection “remote Ctrl ”)

The relay activates writing 1 on word modbus 1015 for the alarm 1 and on word

modbus 1016 for the alarm 2. Writing 0 the relay deactivates.

22 - UA964802 - User ma nual

8.10 Data logger

UA964802 implements a basic Data logger function which can be enabled by

par. 109 Data logger. Right after startup, the device starts storing the process

data on EEPROM memory, the sampling time has to be selected on par. 108

Graphic time. Data can be read via Modbus starting from address 5001 (see

next paragraph)

or via wirel ess reading the RFid mem ory directly from address 0 x600 (1536). The

first data give a reference about the type of saved process values: refer to the

following table for the description of the saved data.

0x600 153 6 Data logger: firmware version

0x6 01 1537 Data logger: sensor type

0x602 1538 Data logger: decimal point

0x603 1539 Data logger: measure unit

0x604 1540 Data logger: sampling time in seconds

1541 Data logger: end memory flag. 0 indicates

0x605

0x 610 15 52 First saved value of analogue input

0x611 15 53 Second saved value of analogue input

... ... ...

0xFFF 4 095 Last saved value of analogue input

The reading of value 0x8000 (-32768) indicates the end of the saved data:

subsequent read data are not valid.

that memor y still available. 1 indicates that

the memor y is exhausted and the device

resumed saving data from address 5017

User manual - UA96 4802 - 23

9 Serial communication

UA964802 equipped with RS485 can receive and broadcast data via serial

communication using MODBUS RTU protocol. The device can be configured

only as a Slave. This function enables the control of multiple controllers

connected to a supervisory system. Each controller responds to a master query

only if the query contains the same address as that in the parameter par. 126

Slave address

The permitted addresses range from 1 to 254 and there must not be controllers

with the same address on the same line.

Address 255 can be used by the master to communicate with all the connected

equipme nt (broadcast mod e), while with 0 a ll the devices receive th e command,

but no response is expected. UA964802 can introduce a delay (in milliseconds)

in the response to the master request. This delay must be set on parameter

129 Serial Delay

memory (100000 writing cycles).

NB: changes made to Words that are different from those reported in the

following table can lead to malfunction.

Baud-rate

Format

24 - UA964802 - User ma nual

.

Each parameter change is saved by the controller on EEPROM

.

Modbus RTU protocol features

Selection on par. 127 Baud Rate:

1.200 baud 28.800 baud

2.400 baud 38.400 baud

4.800 baud 57.600 baud

9.600 baud 115.200 baud

19.20 0 bau d

Selection on par. 128 Serial format:

8, N, 1 (8 bit, no parity, 1 stop)

8, E, 1 (8 bit, even parity, 1 stop)

8, O, 1 (8 bit, odd parity, 1 stop)

8, N, 2 (8 bit, no parity, 2 stop)

8, E, 2(8 bit, even parity, 2 stop)

8, O, 2 (8 bit, odd parity, 2 stop)

Modbus RTU protocol features

Supported

functions

WORD READING (max 20 word) (0x03, 0x04)

SINGLE WORD WRITING (0x06)

MULTIPLE WORDS WRITING (max 20 word) (0x10)

Looking at the table here below it is possible to find all available addresses and

functions:

RO Read Only R/W Read / Write WO Write Only

Modbus

Description

Address

0 Device type RO EEPROM

Read

Only

Reset

value

1 Software version RO EEPROM

5 Slave address R/W EEPROM

6 Boot version RO EEPROM

Process (degrees.tenths for temperature sensors;

1000

digit for linear sensors)

Min. peak (degrees.tenths for temperature

1001

sensors; digit for linear sensors)

Max. peak (degrees.tenths for temperature

1002

sensors; digit for linear sensors)

Peak-to-peak (degrees.tenths for temperature

1003

sensors; digit for linear sensorsati)

RO 0

RO 0

RO 0

RO 0

100 4 Totalizer value (H) RO EEPROM

1005 Totalizer value (L) RO EEPROM

1006 Sum value (H) RO EEPROM

1007 Sum value (L) RO EEPROM

1008 Cold junction temperature (degrees.tenths) RO EEPROM

Relays status (0 = Off, 1 = On):

1009

Bit 0 = Relay Q1

RO 0

Bit 1 = Relay Q2

User manual - UA96 4802 - 25

Modbus

Description

Address

Digital inputs status (0 = Off, 1 = Active):

1010

Bit 0 = D. I.1

Read

Only

RO Bit 1 = D.I.2

Keys status (0 = released, 1 = pressed):

Bit 0 =

1011

Bit 1 =

Bit 2 =

RO 0

Bit 3 =

Error flags

Bit 0 = Cold junc tion error

Bit 1 = Process error (sensor)

Bit 2 = Eeprom writing error

1012

Bit 3 = Eeprom reading error

RO 0

Bit 4 = Missing calibration data error

Bit 5 = Generic error

Bit 6 = Hardware error

Alarms status (0 = None, 1 = Active)

1013

Bit 0 = Alarm 1

RO 0

Bit 1 = Alarm 2

Manual reset: write 0 to reset all alarms.

In reading (0 = Not resettable, 1 = Resettable)

1014

Bit 0 = Alarm 1

R/W 0

Bit 1 = Alarm 2

1015 Alarm 1 status (remote control) R/W 0

1016 Alarm 2 status (remote control) R/W 0

1017 mA analogue output value (remote control) R/W 0

1018 Volt analogue output value (remote control) R/W 0

Run by serial

1019

0 = Inhibited outputs

R/W 1

1 = Active outputs

26 - UA964802 - User man ual

Reset

value

Modbus

Description

Address

Hold by serial

1020

0 = Active analogue input

Read

Only

R/W 0

Reset

value

1 = Analogue input in Hold

1021 Tare zero AI (write 1) R/W 0

1022 Totalizer reset (write 1) R/W 0

1023 Peaks reset (write 1) R/W 0

1024 Sum total (write 1) R/W 0

1025 Total sum reset (write 1) R/W 0

2001 Parameter 1 R/W EEPROM

2002 Parameter 2 R/W EEPROM

2150 Parameter 150 R/W EEPROM

4001 Parameter 1* R/W EEPROM

4002 Parameter 2* R/W EEPROM

4150 Parameter 150* R/W EEPROM

* Paramet ers modified usin g serial address 4 001 to 4150, will be stored o n eeprom only af ter 10s

since last writ ing of one paramete r.

User manual - UA96 4802 - 27

10 Configuration

10.1 Modifying configuration parameters

For configuration parameters see par. 11

Press Display Do

1

“Configuration”

n

and

2

3

“Sel” to confirm

n

and

4

“Sel” to enter

the parameter

5

group

“Sel” to enter

the parameter

6

modification

Shows 0000 with the 1st

digit selected.

Changes the selected digit

m

and moves to the next one

using

Shows the names of the

parameter groups.

Scroll up / down the

m

parameter groups.

Shows the parameters of

the selec ted group.

Shows all parameter

possible selections or the

parameter numeric value.

.

Enter password 1234

Press n and m to select

parameter to be modified.

Press n and m to modify

parameter. For numeric

parameters, pressing

it is possible to modif y

digit-to-digit. Press “Sel” to

confirm modification. Press

“<” to exit without modify.

10.2 Loading default values

Enter password 9999 to restore factory settings of the device.

28 - UA964802 - User ma nual

11 Table of configuration parameters

The following table includes all parameters. Some of them will not be visible on

the models which are not provided with relevant Hardware data.

11.1 Analogue input

Parameters to configure the analogue input.

1 Sensor type

Analogue input configuration/sensor selection

Thermocouple K (Default) -260 °C..1360 °C

Thermocouple S -40 °C ..1760 °C

Thermocouple R -40 °C..1760 °C

Thermocouple J -200 °C..1200 °C

Thermocouple T -260 °C..400 °C

Thermocouple E -260 °C..1000 °C

Thermocouple N -260 °C..1280 °C

Thermocouple B +80 °C..1820 °C

Pt100 -200 °C..600 °C

Ni100 -60 °C..180 °C

NTC 10kOhm -40 °C ..125 °C

PTC 1kOhm -50 °C..150 °C

Pt500 -100 °C..600 °C

Pt1000 -100 °C..600 °C

0. .10 V

0..20 mA

4..20 mA

0..60 mV

Pot. max. 6 kOhm

Pot. max. 150 kOhm

User manual - UA96 4802 - 29

2 Decimal Point

Selects type of the visualized decimal point

0 No decimals. Default

0.0 1 Decimal

0.00 2 Decimals

0.000 3 Decimals

3 Measure unit

Selects the visualized measure unit

°C (Default)

°F

K

V

mV

A

mA

Bar

mBar

psi

Pa

mm

cm

dm

m

km

in

kg

q

t

oz

lb

m/s

m/m

m/h

l/s

l/m

l/h

3

m

3

m

3

m

rpm

%rh

ph

/s

/m

/h

N

kN

%

L

gal

mmHg

atm

mH2O

Nm

kNm

kgf

kgp

kip

lbf

ozf

pcs

g

4 Lower limit V/I

Range AN1 lower limit only for linear input. Ex: with input 4..20 mA this

parameter takes value associated to 4 mA

-32767 + 32767 [digit

30 - UA964802 - User ma nual

1

], Default: 0.

5 Upper limit V/I

Range AN1 upper limit only for linear input. Ex: with input 4..20 mA this

parameter takes value associated to 20 mA

-32767 + 32767 [digit

1

], Default: 1000.

6 Offset calibration

Value added / subtracted to the process visualization (usually correcting

the

value of environmental temperature)

-1000..+1000 [digit

-100.0..+100.0 (degrees.tenths for temperature sensors). Default 0.0.

1

] for linear sensors and potentiometers.

7 Gain calibration

Percentage value that is multiplied for the process value (allows to

calibrated the working point)

-100. 0%..+100 .0%, Default: 0.0

ex: to corre ct the range from 0..1000°C showing 0..1010°C, set the par. to -1.0.

8 Latch On

Automatic setting of limits for linear inputs and potentiometers. (see par. 8.3)

Disabled (Default)

Enabled

Setting

9 Totalizer

Visualizes the total fluid volume considering the sensor signal as unit/time

value (ex. if the connected sensor has an output 4..20mA with F.s. 2000m³/

hour, the param eter 9 Totalizer has to be selec ted as Hour and the display will

visualize th e total fluid volume fro m the last RESET/START signal). (see par. 8.6)

Disabled Display visualizes the process (Default)

Second Display visualizes the flow in unit/s

Minute Display visualizes the flow in unit/min

Hour Display visualizes the flow in unit/hour

User manual - UA96 4802 - 31

10 Sum function

Enables the sum function and its dedicated page. Allows to sum the

process value to a variable.

Disabled (Default)

Enabled

(see par. 8.7)

11 Store

Enables to store in eeprom the values of peak, totalizer, sum function and

tare zero. If disabled, at starting the above-mentioned values star t from 0.

The storing is done automatically every 5 minutes.

Disabled (Default)

Enabled

12 Filter samples

ADC Filter: number of input sensor readings to calculate the mean that

defines process value. NB: when readings increase, control loop speed

slows down.

1..15 means Default: 10.

13 Sampling frequency

Sampling frequency of analogue / digital converter.

NB: Increasing the conversion speed will slow down reading stability

(ex: for fast transients, as pressure, it is advisable to increase sampling

frequency)

242 Hz 4.2ms (Maximum speed conversion)

123 Hz 8.2ms

62 Hz 16.1ms

50 Hz 20ms

39 Hz 25.6ms

33.2 Hz 30.1ms

19.6 Hz 51ms

16.7 Hz (Default) 59.9ms Ideal for filtering noises 50 / 60 Hz

12.5 Hz 80ms

32 - UA964802 - User ma nual

10 Hz 100m s

8.33 Hz 120ms

6.25 Hz 160ms

4.17 Hz 240ms (Minimum speed conversion)

11. 2 V/ I custom

Parameters to configure the customizable linear input. (see p ar. 8.8)

17 V/I custom

Selects the linearization type for the analogue input if selected as linear.

Lower and upper limits. The input will be linearized by parameters 4 and

5 (Default)

16 sp ezza te. The input will be linearized by parameter 18-49

18 01-Input value

Defines the input value to which the 1st customized value is assigned

0..20000 Default: 0.

19 01-Custom value

Defines the 1st customized value assigned to the input

-32767..32767 [Dig it

20 02-Input value

Defines the input value to which the 2nd customized value is assigned

0..20000 Default: 2000.

21 02-Custom value

Defines the 2nd customized value assigned to the input

-32767..32767 [Dig it

22 03-Input value

Defines the input value to which the 3rd customized value is assigned

0..20000 Default: 0.

1

] Default: 0.

1

] Default: 1000.

User manual - UA96 4802 - 33

23 03-Custom value

Defines the 3rd customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

24 04-Input value

Defines the input value to which the 4th customized value is assigned

0..20000 Default: 0.

25 04-Custom value

Defines the 4th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

26 05-Input value

Defines the input value to which the 5th customized value is assigned

0..20000 Default: 0.

27 05-Custom value

Defines the 5th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

28 06-Input value

Defines the input value to which the 6th customized value is assigned

0..20000 Default: 0.

29 06-Custom value

Defines the 6th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

30 07-Input value

Defines the input value to which the 7th customized value is assigned

0..20000 Default: 0.

34 - UA964802 - User m anual

31 07-Custom value

Defines the 7th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

32 08-Input value

Defines the input value to which the 8th customized value is assigned

0..20000 Default: 0.

33 08-Custom value

Defines the 8th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

34 09-Input value

Defines the input value to which the 9th customized value is assigned

0..20000 Default: 0.

35 09-Custom value

Defines the 9th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

36 10-Input value

Defines the input value to which the 10th customized value is assigned

0..20000 Default: 0.

37 10-Custom value

Defines the 10th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

38 11-Input value

Defines the input value to which the 11th customized value is assigned

0..20000 Default: 0.

User manual - UA96 4802 - 35

39 11-Custom value

Defines the 11th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

40 12-Input value

Defines the input value to which the 12th customized value is assigned

0..20000 Default: 0.

41 12-Custom value

Defines the 12th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

42 13-Input value

Defines the input value to which the 13th customized value is assigned

0..20000 Default: 0.

43 13-Custom value

Defines the 13th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

44 14-Input value

Defines the input value to which the 14th customized value is assigned

0..20000 Default: 0.

45 14-Custom value

Defines the 14th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

46 15-Input value

Defines the input value to which the 15th customized value is assigned

0..20000 Default: 0.

36 - UA964802 - User ma nual

47 15-Custom value

Defines the 15th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

48 16-Input value

Defines the input value to which the 16th customized value is assigned

0..20000 Default: 0.

49 16-Custom value

Defines the 16th customized value assigned to the input

-32767..32767 [Dig it

1

] Default: 0.

11. 3 Alarm 1

Parameters to configure the Alarm 1. (see par. 8.9)

54 Alarm type

Alarm 1 selection

Disabled (Default)

Absolute alarm

Band alarm

Digital input 1

Digital input 2

Sensor failure

Remote control by Modbus

55 Contact type

Selects the alarm 1 output contact and intervention type

Normally open (Default)

Normally closed

N.O.-Disabled Power on

N.C.-Disabled Power on

User manual - UA96 4802 - 37

56 Alarm threshold

Selects the alarm 1 setpoint

-32767..+32767 [Digit1] (degrees .tenths for temperat ure sensors), Default: 0.0.

57 Deviation threshold

Selects the deviation from alarm 1 setpoint for the band alarm

0..+32767 [Digit

1

] (degrees.tenths for temperature sensors), Default: 0.0.

58 Hysteresis

Alarm 1 hysteresis

-1000..+1000 [Digit1] (degrees.tenths for temperature sensors), Default: 0.0.

59 Reset type

Alarm 1 contact reset t ype

Automatic: (Default)

Manual: Manual reset by keyboard

Manual stored: Keeps relay status also af ter an eventual power failure

60 Error contact

State of contac t for alarm 1 output in case of error

Open (Default)

Closed

62 Actuation delay

Alarm 1 delay.

-3600..+3600 seconds. Default: 0

Negative: delay in alarm output phase.

Positive: delay in alarm entr y phase.

63 Lower limit

Lower limit for alarm 1 setpoint.

-32767..+32767 [Digit1] (degrees.tenths for temperature sensors). Default: 0.

38 - UA964802 - User ma nual

64 Upper limit

Upper limit for alarm 1 setpoint

-32767..+32767 [Digit

1000.

1

] (degrees.tenths for temperature sensors). Default:

65 Protection

Alarm 1 set protection. Does not allow user to modify setpoint

Free Modification allowed (Default)

Lock Protected

Hide Protected and not visualized

11. 4 Alarm 2

Parameters to configure the Alarm 2

69 Alarm type

Alarm 2 selection

Disabled (Default)

Absolute alarm

Band alarm

Digital input 1

70 Contact type

Selects the alarm 2 output contact and intervention type

Normally open (Default)

Normally closed

N.O.-Disabled Power on

N.C.-Disabled Power on

71 Alarm threshold

Selects the alarm 2 setpoint

-32767..+32767 [Digit1] (degrees .tenths for temperat ure sensors), Default: 0.0.

Digital input 2

Sensor failure

Remote control by Modbus

User manual - UA96 4802 - 39

72 Deviation threshold

Selects the deviation from alarm 2 setpoint for the band alarm

0..+32767 [Digit

1

] (degrees.tenths for temperature sensors), Default: 0.0.

73 Hysteresis

Alarm 2 hysteresis

-1000..+1000 [Digit1] (degrees.tenths for temperature sensors), Default: 0.0.

74 Reset type

Alarm 2 contact reset t ype

Automatic: (Default)

Manual: Manual reset by keyboard

Manual stored: Keeps relay status also af ter an eventual power failure

75 Error contact

State of contac t for alarm 2 output in case of error

Open (Default)

Closed

77 Actuation delay

Alarm 2 delay.

-3600..+3600 seconds. Default: 0

Negative: delay in alarm output phase.

Positive: delay in alarm entr y phase.

78 Lower limit

Lower limit for alarm 2 setpoint.

-32767..+32767 [Digit1] (degrees.tenths for temperature sensors). Default: 0.

79 Upper limit

Upper limit for alarm 2 setpoint

-32767..+32767 [Digit

1

] (degrees.tenths for temperature sensors). Default:

1000.

40 - UA964802 - User m anual

80 Protection

Alarm 2 set protection. Does not allow user to modify setpoint

Free Modification allowed (Default)

Lock Protected

Hide Protected and not visualized

11. 5 Display

84 Language

Selects the language

English (Default)

Italiano

86 Contrast

Selects the contrast value for the display

0%..100%, Default: 80%.

87 Reverse

Enables the display reverse visualiz ation

Disabled (Default)

Enabled

88 Screen timeout

Determines the time af ter which the display switches to standby mode

when no key has been pressed, reducing brightness so as not to be an

inconvenience in environments with little lighting and to extend the

display’s life time.

Always on (Default)

15 seconds

30 seconds

1 minute

Deutsch

Français

2 minutes

5 minutes

10 minutes

Español

30 minutes

1 hour

User manual - UA96 4802 - 41

89 Display direction

Selects the display visualization direction.

Horizontal (Default)

Vert ical

90 Starting page

Selects the page visualized at starting after the initial splash screen

Process (Default)

Graphic

Peak values

Tot aliz er

Sum function

11. 6 Digital input 1

Parameters to configure the digital input 1.

95 Digital input function

Selects the digital input 1 function. (see par. 8.4)

Disabled (Default)

Run

Hold

Tare zero (AI) (impulse functioning)

Alarm reset

Totalizer reset (impulse functioning)

Peaks reset

Sum total (impulse functioning)

Sum reset (impulse functioning)

Config. lock

96 Contact type

Selects the digital input 1 inactive contact.

Normally open (Default) Executes function with closed contact

Normally closed Executes function with open contact

42 - UA964802 - User ma nual

11. 7 Digital input 2

Parameters to configure the digital input 2. (see par. 8.4)

100 Input function

Selects the digital input 2 function

Disabled (Default)

Run

Hold

Tare zero (AI) (impulse functioning)

Alarm reset

Totalizer reset (impulse functioning)

Peaks reset

Sum total (impulse functioning)

Sum reset (impulse functioning)

Config. lock

101 Contact type

Selects the digital input 2 inactive contact.

Normally open (Default) Executes function with closed contact

Normally closed Executes function with open contact

11. 8 Graphic

Parameters to configure the trend and bar graph management.

105 Graphic type

Selects the type of graph to be visualized on the relevant page.

Trend (Default)

Bar graph

106 Lower limit

Trend or bar graph lower limit.

-32767 + 32767 [Digit

1

], Default: 0.

User manual - UA96 4802 - 43

107 Upper limit

Trend or bar graph upper limit.

-32767 + 32767 [Digit

1

], Default: 1000.

108 Trend time

Selects the trend sampling time.

1..3600 seconds, Default: 60s.

109 Data logger

Enables the over time registration of the process in eeprom

The sampling time is equal to the trend upgrading time.

Disabled (Default)

Enabled

110 Data logger time

Selects the data logger sampling time.

1..3600 seconds, Default: 60s.

11. 9 Analogue output in mA

Parameters to configure the analogue output in mA

112 Retransmission

Enables analogue output

Disabled (Default)

Process

Alarm 1

Alarm 2

Remote control by Modbus

113 Signal type

Selects the signal for the analogue output in mA

0..20 mA

4..20 mA (Default)

44 - UA964802 - Use r manual

(see par. 8.10)

114 Lower limit

Analogue output mA lower limit range

-32767..+32767 [ Digi t

1

] (degrees .tenths for temperat ure sensors), Default: 0

115 Upper limit

Analogue output mA upper limit range

-32767..+32767 [Digit

1

] (degrees.tenths for temperature sensors) Default:

1000

116 Error value

Selects the value of the analogue output in mA in case of error

0 mA (Default)

4 mA

20 mA

11.10 Analogue output in Volt

Parameters to configure the analogue output in Volt

119 Retransmission

Enables analogue output

Disabled (Default)

Process

Alarm 1

Alarm 2

Remote control by Modbus

120 Signal type

Selects the signal for the analogue output in Volt

0..10 V (Default)

121 Lower limit

Analogue output Volt lower limit range

-32767..+32767 [ Digi t

1

] (degrees .tenths for temperat ure sensors), Default: 0

User manual - UA96 4802 - 45

122 Upper limit

Analogue output Volt upper limit range

-32767..+32767 [Digit

1

] (degrees.tenths for temperature sensors) Default:

1000

123 Error value

Selects the value of the analogue output in Volt in case of error

0 V (Default)

10 V

11.11 Comunication port

Parameters to configure the serial communication port. (see par. 9)

126 Slave address

Selects the slave address for serial communication

1.. 254. Default: 24 0

127 Baud rate

Selects the baud rate for serial communication

1.200 b aud

2.400 baud

4.800 baud

9.600 baud

19.200 baud (Default)

28.800 baud

39.40 0 baud

57.600 baud

115 .20 0 ba ud

1

The decimal point visualization depends on the “Sensor type” and “Decimal point” selection.

46 - UA964802 - User m anual

128 ComPort setting

Selects the format for the serial communication

8,N,1 8bit, No parity, 1 Stop bit (Default)

8,E,1 8bit, Even parity, 1 Stop bit

8,O,1 8bit, Odd parity, 1 Stop bit

8,N,2 8bit, No parity, 2 Stop bit

8,E,2 8bit, Even parity, 2 Stop bit

8,O,2 8bit, Odd parity, 2 Stop bit

129 Serial delay

Selects the serial delay

0..100 milliseconds. Default: 10

Notes / Updates

User manual - UA96 4802 - 47

Table of configuration parameters

1 Sensor type 29

2 Decimal Point 30

3 Measure unit 30

4 Lower limit V/I 30

5 Upper limit V/I 31

6 Offset calibration 31

7 Gain calibration 31

8 Latch On 31

9 Totalizer 31

10 Sum function 32

11 Store 32

12 Filter samples 32

13 Sampling frequency 32

17 V/I custom 33

18 01-Input value 33

19 01-Custom value 33

20 02-Input value 33

21 02-Custom value 33

22 03-Input value 33

23 03-Custom value 34

24 04-Input value 34

25 04- Custom value 34

26 05-Input value 34

27 05-Custom value 34

28 06-Input value 34

29 06- Custom value 34

30 07-Input value 34

31 07-Custom value 35

32 08-Input value 35

33 08-Custom value 35

34 09-Input value 35

35 09-Custom value 35

36 10-Input value 35

48 - UA964802 - User m anual

37 10-Custom value 35

38 11-Input value 35

39 11-Custom value 36

40 12-Input value 36

41 12-Custom value 36

42 13-Input value 36

43 13-Custom value 36

44 14-Input value 36

45 14-Custom value 36

46 15-Input value 36

47 15-Custom value 37

48 16-Input value 37

49 16-Custom value 37

54 Alarm type 37

55 Contact t ype 37

56 Alarm threshold 38

57 Deviation threshold 38

58 Hysteresis 38

59 Reset type 38

60 Error contact 38

62 Actuation delay 38

63 Lower limit 38

64 Upper limit 39

65 Protection 39

69 Alarm type 39

70 Contact t ype 39

71 Alarm threshold 39

72 Deviation threshold 40

73 Hysteresis 40

74 Reset type 40

75 Error contact 40

77 Actuation delay 40

78 Lower limit 40

79 Upper limit 40

User manual - UA96 4802 - 49

80 Protection 41

84 Language 41

86 Contrast 41

87 Reverse 41

88 Screen timeout 41

89 Display direction 42

90 Starting page 42

95 Digital input function 42

96 Contact t ype 42

100 Input function 43

101 Contact type 43

105 Graphic type 43

106 Lower limit 43

107 Upper limit 44

108 Trend time 44

109 Data logger 44

110 Data logger time 44

112 Retransmission 44

113 Signal type 44

114 Lower limit 45

115 Upper limit 45

116 Error value 45

119 Retransmission 45

120 Signal type 45

121 Lower limit 45

122 Upper limit 46

123 Error value 46

126 Slave address 46

127 Baud rate 46

128 ComPort setting 47

129 Serial delay 47

50 - UA964802 - User ma nual

User manual - UA96 4802 - 51

Wachendorff Prozesstechnik GmbH & Co. KG

Industriestrasse • 65366 Geisenheim

Tel.: +49 (0) 67 22 / 99 65 - 20

Fax: +49 (0) 67 22 / 99 65 - 78

E-Mail: wp@wachendorff.de

www.wachendorff-prozesstechnik.de

© Copyright by Wachendor ff Prozesstechnik GmbH & Co. KG

Loading...

Loading...