4211-7, S.7

Operation & Maintenance Instruction

Page 1 of 10

September, 2017

VX™ VENT VALVE PORTION, PART NO.

SEPTEMBER, 2017

Supersedes issue dated December, 2003

NOTE: The following description and

operation

components being new or this device

its components having been repaired,

tested, installed and maintained in

accordance with instructions issued by

this and any other applicable Wabtec

Corporation

replaced in this device, the operation of the

complete device must pass a series of

tests prescribed in the latest issue of the

applicable Wabtec Test Specification. At the

time this device is applied to the brake

equipment arrangement, a stationary

vehicle test must be made to insure that this

device functions properly in the total brake

equipment arrangement. (Consult your

local Wabtec Corporation

Representative for identity of the test

specification, with latest revision date, that

covers this device.)

IMPORTANT: Only Wabtec Corporation

supplied parts are to be used in the repair

of this device in order to obtain satisfactory

operation. Commercially available nonO.E.M. parts are unacceptable.

NOTE: The part numbers and their

associated descriptions are the property of

Wabtec Corporation and may not be

replicated in any manner or form without

the prior sole written consent of an Officer of

Wabtec Corporation.

is

based

on this

device

and its

and

publications.

WARNING: At the time any part is

™ Trademark of Wabtec Corporation

© 2017 Wabtec Corporation. All rights reserved

699505

4211-7, S.7

Operation & Maintenance Instruction

September, 2017

Page 2 of 10

NOTE: The

following description

and

operation

is based on

this device and its components having been repaired, tested,

installed and maintained in accordance with instructions of

this and any other applicable publications issued by the

Wabtec Corporation, or its predecessor, the Westinghouse

Air Brake Company.

1.0 DESCRIPTION

The VX Vent Valve Portion is a double

which, when properly installed and

deplete brake pipe air locally at a rapid rate to assist in

propagating

an

emergency

brake

main line of brake pipe is reduced at an emergency rate.

The VX Vent Valve Portion features increased emergency

venting capacity and jump distance capabilities. A unique

diaphragm

design

incorporated

the need for a separate venting piston and provides a self-

diaphragm

maintained,

application

type valve

functions to

whenever the

within the Portion eliminates

2.1

RELEASE AND

RUNNING

Brake pipe air under

the metal screen filter into cavity b, on the non-spring side of

the vent valve

cavity b1, above the

past the control piston seat of the body and into cavity b2 on

the spring side of the vent valve diaphragm assembly. Brake

pipe air flow continues through the passage in the seated

piston where it is blocked by the exhaust valve. Brake pipe

air under pressure in cavity b1 flows through the charging

choke into the control pressure volume Q.

pressure

entering Port 1 flows through

diaphragm assembly,

control diaphragm

through passage B into

and piston assembly,

purging action. Operation of a VX

Vent Valve Portion at one

location (in a train consist) aids in producing an emergency

rate of brake pipe reduction at the next locomotive unit or car

and action of the Vent Valve

Portion

on each

succeeding

unit

or car assists in a fast transmission of an emergency brake

signal through an open train line pipe.

The VX Vent Valve Portion is designed so that it can be

readily removed from the pipe bracket, laminate, mounting

plate, or branch pipe tee on which it is mounted, for

maintenance or repair. Provision is made for the attachment

of a vent protector arrangement at the exhaust port of the

Portion body.

The VX Vent Valve Portion may be used in equipment

arrangements where the air pressure does not exceed 150

psig. Special installation procedures are required when

installing the VX Vent Valve Portion in specific equipment

arrangements. Consult your Wabtec Corporation

Representative for information on your required applications.

2.0 OPERATION

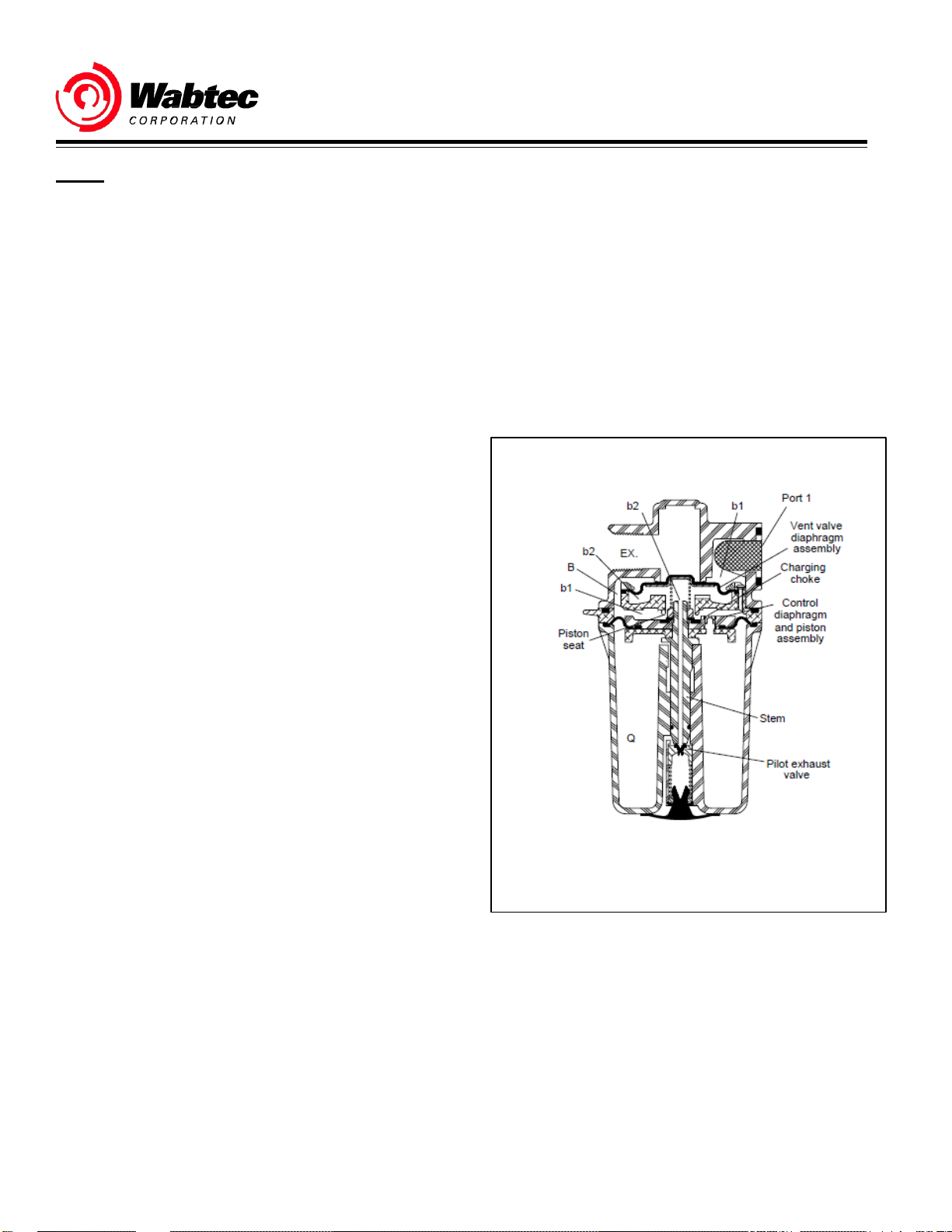

NOTE: The views shown in Figures 1, 2, 3 and 4 are

diagrammatic representations for functional analysis only.

They are not to be used as actual physical representations

of the VX Vent Valve Portion.

Figure 1 - Release and

Diagrammatic View

Running

4211-7, S.7

Operation & Maintenance Instruction

Page 3 of 10

September, 2017

2.2

EMERGENCY - FIRST

STAGE

When an emergency rate of brake pipe reduction occurs,

the brake pipe

rapidly

creating a

in cavities b, b1 and b2 and the air pressure in the control

pressure volume

piston

assembly

seat

on

seat of the body. The

from cavity b1. Air pressure in cavity b2 is then directed to

exhaust through

the exhaust valve. Cavity b2 is

small

volume.

air

pressure

in cavities b, b1

differential between the brake pipe

Q. This

to move,

causes

the

unseating

control diaphragm

the piston stem from its

the exhaust valve and seating the

the

seating

passage

of the piston

in the

unseated

exhausted quickly

and

b2 is reduced

piston on

isolates

piston stem at

pressure

the

piston

cavity b2

due to its

2.3

EMERGENCY - SECOND

STAGE

The rapid exhaust of air pressure from cavity b2 creates a

differential on th e non-spring side

assembly causing

and connects brake pipe

and

to exhaust (Port EX). Air pressure in the control pressure

this

assembly

air from port 1

volume Q then flows to atmosphere through the charging

choke of the control piston, cavity b1, passage B, cavity b

and port EX, when the air pressure in the control pressure

volume

Q is vented, the vent

the control diaphragm and piston

the

Release

Position by the force exerted by the spring.

of

the

vent

valve

to move

away

and

cavities b

valve diaphragm assembly

assembly

are returned to

diaphragm

from its seat

and

b1

and

Figure 2 - Emergency Position - 1st

Diagrammatic View

Stage

Figure 3 - Emergency Position - 2nd

Stage

Diagrammatic View

4211-7, S.7

Operation & Maintenance Instruction

September, 2017

Page 4 of 10

3.0

MAINTENANCE

SCHEDULE

3.1 IMPORTANT: The VX

from the

completely disassembled, the parts cleaned, inspected,

lubricated and then reassembled using NEW Wabtec

Corporation rubber

parts as specified in accordance with the

application schedule,

so indicate. The assembled portion is then to be tested for

correct operation.

equipment arrangement

parts

Vent Valve

and other

or more

Portion is to be removed

and taken to the shop, be

NEW

Wabtec Corporation

following

frequently,

if service conditions

vehicle

Recommended

Type of Application Least Once

Frequency

- At

Every

Freight Cars 120 Months

Locomotives 12 Months

Passenger

Transit 24 Months

(Interstate) 36 Months

4.0

PARTS CATALOG AND REPLACEMENT

PARTS

4.1

PARTS

CATALOG

4.1.1 IMPORTANT: When ordering replacement parts for

the VX Vent Valve Portion,

issue of the Wabtec

Part No. 699505, refer to the

Corporation

Parts

Catalog

current

3211-7, S.7.

NOTE: The reference numbers used in the Parts Catalog

and those used in this

number and the descriptive part name to be sure that the

desired

part is ordered.

publication may

differ.

Check

the part

4.2

REPLACEMENT

PARTS

4.2.1 IMPORTANT: To obtain satisfactory operation and

reliability of the VX Vent Valve Portion, ONLY Wabtec

Corporation replacement parts are to be used in the

maintenance

of this portion.

5.0

SAFETY PROCEDURES AND

WARNINGS:

The following

wherever the symbol appears in the maintenance

procedures. Failure to observe these

result in serious injury to those performing the work

and/or bystanders.

statements

WARNINGS

of warning

apply

all or in part

precautions

may

• The use of an air jet, which must be less than 30

p.s.i.g., to blow parts clean or to blow them dry

after being cleaned with a solvent will cause

particles of dirt and/or droplets of the cleaning

solvent to be airborne. Wire brushing may also

cause particles of dirt, rust, and scale to become

airborne. These conditions may cause skin and/or

eye irritation.

• When using an air jet, do not direct it toward

another

in bodily injury.

person.

Improper

use of air jet could result

• Personal eye protection must be worn when

performing any work on this device or its

components parts to avoid any possible injury to

the eyes.

• The use of

of lubricants can involve health and/or safety

hazards. The manufacturers of the solvents and

lubricants should

as OSHA Form OSHA-20 or its equivalent). The

recommended precautions and procedures of the

manufacturers should be followed.

solvents

be

as

cleaning

contacted

agents and the use

for

safety

data (such

• When performing any test or work on devices or

equipment while they are on the vehicle (on car

test, etc.)

that vehicle movement will not occur which could

result in injury to personnel and/or damage to

equipment.

special precautions must be taken to

insure

• Assembly may be under a spring load. Exercise

caution during disassembly so that no parts "Fly

Out" and cause bodily injury.

• All air supply and/or electric current to this device

and/or to an y components part must be cut-off

before this device and/or any component part is

removed from the equipment arrangement.

• "Bottled" up air under pressure (even though air

supply

of dirt to

level when this device and/or any component part

is removed from the equipment arrangement.

is cut-off)

become airborne

may cause gaskets and/or

and an

increase

particles

in sound

• Personal eye and ear protection must be worn and

care

taken

to

avoid possible injury

any work on this device and/or component part.

when performing

4211-7, S.7

Operation & Maintenance Instruction

Page 5 of 10

September, 2017

• To prevent receiving electrical shock when

performing electrical test, hands must be clear of

electrical components, contacts and housing and

the required "in-lab" grounding procedures must

be

strictly adhered

be used.

in severe injury or death.

Failure

to.

A wooden

to heed this

work

bench

WARNING could

should

result

• An adequate support or lifting device must be

available to support the Device and/or Valve

Portion(s) during removal, installation and

maintenance procedures.

6.0

CLEANING

SPECIAL

SOLVENT,

TOOLS

LUBRICANT, SEALANT

AND

6.1.1 The

Vent Valve Portion

such as mineral spirits or naptha, that will dissolve oil or

grease and that will permit the parts to be cleaned without

abrasion.

solvent

used to

MUST BE an aliphatic hydrocarbon

clean

the

reusable

parts of the VX

solvent,

IMPORTANT: Cleaning solvents are to be used in a well

ventilated

area.

6.2 LUBRICANTS

6.2.1 Number 2 Silicone Grease, Wabtec Corporation

Specification

such as Dow Corning Corporation Dow Corning 55,

for the

o-ring bearing surfaces of the bushing(s) which will be in

contact with the o-rings.

M-7680-2,

lubrication

(Industry Designation

of specified o-rings, o-ring grooves

MIL-G-4343),

is required

and

6.2.2 A

Corporation

913), such as Super Flake Graphite Company - Superfine

Number 597 Joseph Dixon Crucible Company - Microfyne

Graphite or National Carbon Company Number 38 or 39

Graphite, and two parts of SAE-20 oil by weight is required

for

choke plug prior to the installation of this choke plug in the

piston.

compound consisting

Specification M-7695-2, (AAR Specification M-

the lubrication

of

the threads

of

one part

of

the cleaned

of graphite, Wabtec

or

NEW

piston

6.3.1

Locking Sealant,

7499-05,

application to the threads of the piston stem prior to the

installation of the piston jam nut.

such as Loctite

Wabtec

Corporation Specification

Corporation

TL-242, is

required

7.0

MAINTENANCE

PROCEDURES

NOTE: When performing the procedures which

NOT use hard or sharp tools to remove o-rings, gaskets,

seals or the diaphragms. Exercise care so that no damage

is done to

reusable

parts.

WARNING; When

follow, springs within the assembly may be placed

under compression. Exercise care so that no parts are

inadvertently expelled. Inadvertently expelled parts

may cause bodily injury and/or damage to parts.

performing

the

procedures

7.1 DISASSEMBLY

NOTE: The VX Vent Valve Portion

pounds.

weighs approximately

7.1.1 If the mounting gasket is still in its groove in the

mounting face of the body (2), it is to be removed and

SCRAPPED. The

Portion and is not illustrated.

gasket IS

NOT a part of the

VX Vent

7.1.2

its port in the body (2).

Remove

and

SCRAP

the wire mesh strainer (3) from

7.1.3 Remove the four 3/8" x 11/2" hex. head cap screws (1)

which

secure the

together.

housing

(19),

filling

piece (9), and

the

7.1.4

then remove the

clamping plate subassembly (5, 6, 7, 9) from the housing

(19) as a unit.

Carefully

remove the

filling

piece with

body

(2) from the

diaphragm

filling piece

and diaphragm

7.1.4.1

Remove

the spring (8).

7.1.5 Remove the three #8 x 1/2" button head screws (5)

which secure the

(7) and

filling

diaphragm

piece (9) together.

clamping plate (6), diaphragm

7.1.6 Remove the diaphragm clamping plate (6) and

diaphragm (7) from the filling piece (9). SCRAP the

diaphragm

M-

for

7.1.7

groove in the

(7).

Remove

filling

and

SCRAP

piece (9).

the 51/4" O.D. o-ring (4) from its

7.1.13 Remove the piston-diaphragm sub-assembly (13,

14, 15) as a unit from the piston stem (17) and diaphragm

follower

(16).

follow,

which

Valve

body

DO

7

(2)

(9),

4211-7, S.7

Operation & Maintenance Instruction

September, 2017

Page 6 of 10

Figure 4 - VX Vent Valve

Portion

4211-7, S.7

Operation & Maintenance Instruction

Page 7 of 10

September, 2017

7.1.14 Remove and SCRAP the diaphragm (15) from the

piston (13).

7.1.15 Remove the

stem (17).

diaphragm follower

(16) from the piston

7.1.16

Remove and SCRAP

the

washer

has an interference fit with the

7.1.17 WARNING: During the following procedure,

the spring (24) will be compressed. Exercise care

that no parts are inadvertently expelled from the

assembly. Inadvertently expelled parts may cause

bodily injury and/or damage to property.

(26) in the bottom of the housing (19). The seal

the vent protector

washer

and can be

seal

pulled

(27) from

out.

Carefully

housing (19), then, while holding these parts depressed,

remove the retaining ring (26) from its groove in the housing

(19).

(24) permitting the spring (24) to extend its full travel.

depress the washer (25) and spring (24) into the

Slowly release

the

hold

on the

washer

(25) and spring

7.1.18

Remove the washer (25), spring (24)

with seal (21) from the housing (19).

and exhaust

valve

7.1.19

Remove and SCRAP

the

exhaust valve

(23).

the

exhaust valve seal

(22) from

7.2 Cleaning and Inspecting

7.2.1

NON-REUSABLE

PARTS

7.2.1.1 ALL gaskets, o-rings,

and diaphragms

NEW Wabtec

ARE

TO BE

Corporation

seals,

SCRAPPED

parts.

the wire mesh strainer

and

replaced

NOTE: A Kit of

available and may be obtained by ordering Part Number

654716. See Parts

this Kit.

Rubber Parts

Catalog

for the

VX Vent Valve

3211-7, S.7 for parts

Portion is

included

7.2.2

BODY AND

HOUSING

IMPORTANT: Cleaning solvents are to be used in a well

ventilated

area.

7.2.2.1 Using a

with the cleaning solvent,

the interior and exterior

(19).

clean, lint-free

as

described

surfaces

rag tha t has been saturated

in

of the

Section

body

6.1.1, clean

(2) and housing

7.2.2.2 After these parts are cleaned, they MUST BE

completely

blow the parts dry.

dried. Use a low pressure jet of clean, dry air to

7.2.2.3 Inspect the

Pay particular attention to the bushings within the housing.

The bushings should be free of nicks, scratches and pits.

Replace

if they

condition that may result in the unsatisfactory operation of

the VX Vent Valve Portion.

so

7.2.3

the

body and/or housing

show

signs of excessive wear, or if they are in such a

EXHAUST

body

VALVE

(2) and housing (19) for damage.

if found to be

7.2.3.1

cleaning solvent, Section 6.1.1 and promptly wipe it clean

with a clean, lint-free cloth.

Dip the exhaust valve

(23) in a

bath

of

the

7.2.3.2

low pressure jet of clean, dry air.

Blow

the

exhaust

valve (23)

completely

7.2.3.3 Inspect the exhaust valve (23). It is to be replaced

if it is found to be nicked, cut, cracked, broken, or damaged

in any

way,

or if it is in such a condition that

unsatisfactory operation

of the VX Vent Valve Portion.

may

7.2.4

REMAINING REUSABLE

PARTS

7.2.4.1 Wash

solvent as described in Section 6.1.1.

all remaining

reusable parts

using the

7.2.4.2 The springs (8, 24) may be wire brushed to assist

in the removal of any dirt, rust or scale.

with

7.2.4.3 After the parts have been

completely dried. Use a low pressure jet of clean, dry air

blow to the parts dry.

cleaned, they

7.2.4.4 Inspect the piston (13). Replace the piston if it is

in

bent,

broken, damaged, excessively

condition that may result in the unsatisfactory operation of

the VX Vent Valve Portion.

worn, or if it is in such a

7.2.4.4.1 Remove the 1/8" choke plug (14) from the piston

(13) and place it in a bath of the

cleaning

solvent to soak.

7.2.4.4.2 While the choke plug is soaking, inspect the

opening in the piston (13) from which the choke plug (14)

was removed to be sure that it is clean and free of dirt. If

necessary,

clean, dry air.

blow

the

opening clean

with a

low pressure

damaged,

prescribed

dry, using a

result in the

cleaning

MUST BE

jet of

or

4211-7, S.7

Operation & Maintenance Instruction

September, 2017

Page 8 of 10

7.2.4.4.3Remove the choke plug (14) from its solvent and

blow

it

completely

air.

dry, using a

low

pressure jet of clean, dry

7.2.4.5 Inspect the piston (13). Replace the piston if it is

bent,

broken, damaged, excessively

condition that may result in the unsatisfactory operation of

the VX Vent Valve Portion.

worn, or if it is in such a

7.2.4.6

that it is clean and that its size, 1.1mm Drill, has not been

changed. DO NOT use hard or sharp metal tools to clean

the orifice as its size and shape MUST NOT be changed.

Replace

size of the orifice, 1.1mm Drill, has been changed.

Inspect

the choke plug if it is damaged in any way or if the

the orifice of the choke

plug

(14) to be sure

7.2.4.7 Lightly coat the threads of the cleaned and

inspected or NEW choke plug (14) with the oil and graphite

compound as described in Section 6.2.2, then install the

choke

plug

(14) in

to be installed at its full travel in the piston (13).

place

in the piston (13). The choke

plug

7.2.4.8

is found to be bent, cracked, broken, damaged in any way,

or if the size of the passage way of the stem has been

changed, (the size of the passage way MUST BE a 0.156"

Drill) or if the stem is in such a condition that may result in

the unsatisfactory operation of the VX Vent Valve Portion.

Be sure that

stem threads.

Inspect

all

the piston stem (17).

of the old

locking sealant

Replace

is

cleaned

the stem if

from the

7.2.4.9

is

cracked,

or if it has taken a permanent set.

Inspect

the

rusted, pitted,

springs

broken,

(8,24).

bent

Replace any

damaged

spring that

in

any

way,

7.2.4.10

ring (26) if it is not elastic enough to hold securely.

Inspect

the retaining ring (26).

Replace

the retaining

7.2.4.11

is

cracked,

any way, or that is in such a condition that may result in the

unsatisfactory operation

Inspect

cut, bent,

the remaining parts.

broken, excessively

of the VX Vent Valve Portion.

Replace

worn,

any part that

damaged

7.3 ASSEMBLY

7.3.1 Apply Number 2 Silicon Grease, Wabtec Corporation

Specification M-7680-2 to a NEW exhaust valve seal (22)

and press in place in the exhaust valve (23), then install the

exhaust valve with seal (21), seal end first, into the bushing

in the bottom of the

housing

(19).

7.3.2

the housing (19) so that the spring (24) is seated on the

exhaust

on the spring (24).

7.3.3 WARNING: In the procedure which follows,

the

that no parts are inadvertently expelled from the

assembly.

Install

the

exhaust valve

vale (23), then

spring (22) will be compressed. Exercise care so

install

spring (24) into the bottom of

the

washer

(25) so that it seats

Carefully

far

retaining ring groove, then while holding these parts

depressed, install the retaining ring (26) being sure that

"snaps"

(25) and spring (24) permitting the spring (24) to extend its

full

depress and

enough

travel to seat the

into the

into its groove.

hold

the

washer

bushing

washer

in the

housing

Slowly release the hold

(25) on the retaining ring (26).

(25) and spring (24)

(19) to

expose

on

the

7.3.4 Apply Number 2 Silicon Grease, Wabtec Corporation

it

Specification M-7680-2 to a NEW vent protector seal (27)

and press in place in the

have an interference fit in the washer.

it

7.3.5 Install a NEW diaphragm (15) on the piston (13, 14)

and be sure that the inner bead of the diaphragm fits into

the bead groove of the piston (13).

washer

(25). The

seal

Figure 5 – Piston Diaphragm (15)

7.3.6

the threaded end of the piston stem (17), then install the

diaphragm

in

diaphragm

Install

the diaphragm

and piston

(15)

sub-assembly

contacts

follower

the

diaphragm follower

(16), flat side up, onto

(13, 14, 15) so that the

(16).

7.3.7

the piston (13).

Install

a NEW seal seat (12) in place in its groove on

7.3.8

it contacts and seats on the seal - seat (12).

Install

the

washer

(11) on the piston stem (17) so that

7.3.9

Specification

stem (17).

Apply a coating

M-7499-5, to the

of

locking sealant,

exposed threads

Wabtec Corporation

of the piston

the

washer

(27)

will

it

4211-7, S.7

Operation & Maintenance Instruction

Page 9 of 10

September, 2017

IMPORTANT: The

to the instructions of the

locking sealant

locking sealant manufacturer

is to be

applied

according

.

7.3.10

piston stem (17) and snug it against the

a 7/8" open end

hold the sub-assembly, torque the 1/2" jam nut (10) to 30 to

35 foot-pounds.

NOTE: The

assembly

sealant to cure. See locking sealant manufacturer

instructions for proper curing time.

Install

the 1/2" jam nut (10) on the

wrench

diaphragm

(10 to 17)

on the flats of the piston stem (17) to

- piston -

MUST BE

follower

set

threaded

washer

aside

to permit the locking

(11). Using

- piston stem sub-

end of the

7.3.11 Apply a light coating of Number 2 Silicone Grease,

Wabtec

a

piston stem (17) and lightly lubricate the lower bushing of the

housing

lubricant.

Corporation

NEW 11/16" O.D. o-ring (18).

(25), the

Specification M-7680-2, to the surfaces of

bushing which

Also, fill

the o-ring

the o-ring groove on the

will

contact, with the

7.3.12

Install

the NEW lubricated 11/16" O.D. o-ring (18) in its

groove

wiping with a clean, dry, lint-free cloth.

on the piston

stem (17).

Remove any excess

lubricant by

7.3.13 Install the diaphragm - piston - follower- piston stem

sub-assembly (10 to 18) as a unit into the housing (19) so

that the piston stem with o-ring (17, 18) enters the bushing in

the

housing

into the bead groove of the housing (19). Apply finger

pressure

(19) an d the outer bead of the

to

seat

the

bead

of the

diaphragm

diaphragm

(15) in its groove.

(15) fits

7.3.14

Install

the

control

the piston stem (17) so that the spring (8) seats on the top of

the jam nut (10).

spring (8) over the

exposed

threads of

7.3.15

Install a NEW

so that the metal spring cup of the diaphragm faces the

piece (9) and the bead of the

groove of the

bead of the

diaphragm

filling

diaphragm

piece (9).

in its groove.

(7) in

place

diaphragm

Apply

finger

in

the filling

(7) enters the bead

pressure

piece (9)

filling

to seat the

7.3.16 Place the diaphragm clamping ring (6) over the

diaphragm

three screw holes of the clamping plate (6) are

tapped holes in the filling piece (9).

(7) and on the

filling

piece (9) being sure that the

aligned

with the

7.3.17

Install

three #8 x 1/2" button head screws (5) through the

aligned holes

piece (9). Equally tighten the screws to maintain alignment

and secure the sub-assembly. Torque the screws to 20-23

in-lbs.

of the

diaphragm clamping

ring (6) and the filling

7.3.18 Install a NEW 51/4" O.D. o-ring (4) into its groove in

the filling piece (9). Apply Number 2 Silicon Grease,

Wabtec Corporation Specification M-7680-2 to the O-ring

and groove.

7.3.19 Place the filling piece - diaphragm sub-assembly (4

to 9) onto the

spring (8) fits inside the spring cup of the

so that the mounting screw holes of the filling piece (9) are

aligned

7.3.20

exhaust port of the

VX Vent Valve tab on the

x 11/2" hex. head cap screws (1)

of the housing (19) and filling piece (9) and into the body

(2).

Equally

fashion to 20-25 ft-lbs.

housing

with the four

Place

the

body

tighten the screws (1) in an alternating

(19) and over the spring (8) so that the

diaphragm

screw holes

(2) onto the

body

(2) faces the same direction as the

filling

of the housing (19).

filling

piece (9) so that the

piece (9), then

through

install

the

aligned holes

(7) and

four 3/8"

7.3.21 Install a NEW wire mesh strainer (3) in place in the

inlet port #1 of the body.

8.0 TESTING

AND ADDITIONAL

INFORMATION

8.1 IMPORTANT: After the

No.

699505, has been assembled, BUT BEFORE it is

returned to service, it MUST PASS a series of test

following the procedures of the current issue of the

Wabtec Corporation Test

VX

Vent

Specification

Valve

Portion, Part

T-4322-O.

8.2 IMPORTANT: Whenever

No.

699505,

for any reason, and it is reinstalled or replaced with a

NEW or repaired and tested

mounting gasket MUST BE used. This 1" flange fitting

gasket, Part No.

Portion, but it is

654716.

is removed from an

93986,

included

the VX Vent Valve Portion,

equipment arrangement

VX Vent Valve

is not a part of the VX Vent

in the Rubber Parts Kit, Part No.

Portion, a NEW

Part

Valve

8.3 IMPORTANT: Whenever

No. 699505, is removed from an

reason, and it is

repaired and tested

vehicle

Valve

arrangement.

test MUST

Portion functions

reinstalled

VX Vent Valve

BE

the VX Vent Valve Portion,

equipment

or

replaced

Portion, a

made

to be sure that the

properly

in the

Part

for any

with a NEW or

stationary

VX Vent

total equipment

8.4 Consult your Wabtec Corporation Representative

if

additional

information is required.

4211-7, S.7

Operation & Maintenance Instruction

September, 2017

Page 10 of 10

Wabtec Corporation

1001

Air

Brake Avenue

(412)

825-1000

www.wabtec.com

• Wilmerding,

• Fax (412)

PA

825-1019

15148

Loading...

Loading...