Page 1

XMC™ digital power explorer kit

with XMC4200 and XMC1300

Quick Start Guide

The XMC™ digital power explorer kit is an evaluation board that introduces the user into digital power

control with Infineon’s XMC4000 and XMC1000 families of ARM® Cortex®-M microcontrollers. It is comprised

of a power board featuring a synchronous buck converter. Two dierent control cards can be connected to

the power board:

XMC4200 control card with HRPWM peripheral and ARM® Cortex®-M4 core for high performance

›

applications

XMC1300 control card with XMC™ peripherals and ARM® Cortex®-M0 core for cost optimized solution

›

Both control cards contain an isolated On-Board Debugger (OBD), so no external debugger is needed to

flash and debug the main controller on the control card.

XMC™ digital power explorer kit is designed to support voltage control mode and current control mode

(peak current control with slope compensation). By using the master and slave connectors, it is also possi-

ble to control a second XMC™ digital power explorer with a single control card.

High resolution PWM (150 ps PWM resolution) peripheral in XMC4200 MCU series is a dedicated peripheral to

cover the most demanding requirements in digital power control applications. Additionally, this series inte-

grates 3 analog comparators with automatic slope generation (10-bits resolution) and smart post-process-

ing that permits extremely accurate and flexible control with minimum CPU load and lowest system cost.

XMC1300 MCU features most of the peripherals included in XMC4200 like CCU timers, ADC and serial commu-

nication, and also adds analog comparators and a MATH co-processor unit which are tailored to fulfill more

cost sensitive applications.

Soware examples for this kit are available for download on DAVE™ website (www.infineon.com/dave).

These examples demonstrate the capabilities of XMC4000 and XMC1000 MCU series in digital power control

applications and ease-of-use and flexibility of DAVE™ soware.

User Manuals including detailed hardware description and schematics for all 3 boards and their design files

can be found on www.infineon.com/xmc_dp_exp

Page 2

Step by step installation guide for XMC™ digital power explorer kit

STEP 1

Install DAVE™

DAVE™ is a free and powerful eclipse-based development platform for XMC™ soware development.

DAVE™ includes GCC compiler from GNU, DAVE™ code engine for automatic code generation and GDB

debugger from GNU. DAVE™ oers pre-defined and tested SW components -DAVE™ APPs- and XMC™

Lib - Low Level Drivers (LLDs)- that accelerate the application soware creation.

To install DAVE™ follow these steps:

Download and execute the latest version of DAVE™ installation file from www.infineon.com/DAVE

›

Follow the installation guidelines that are included in the download package

›

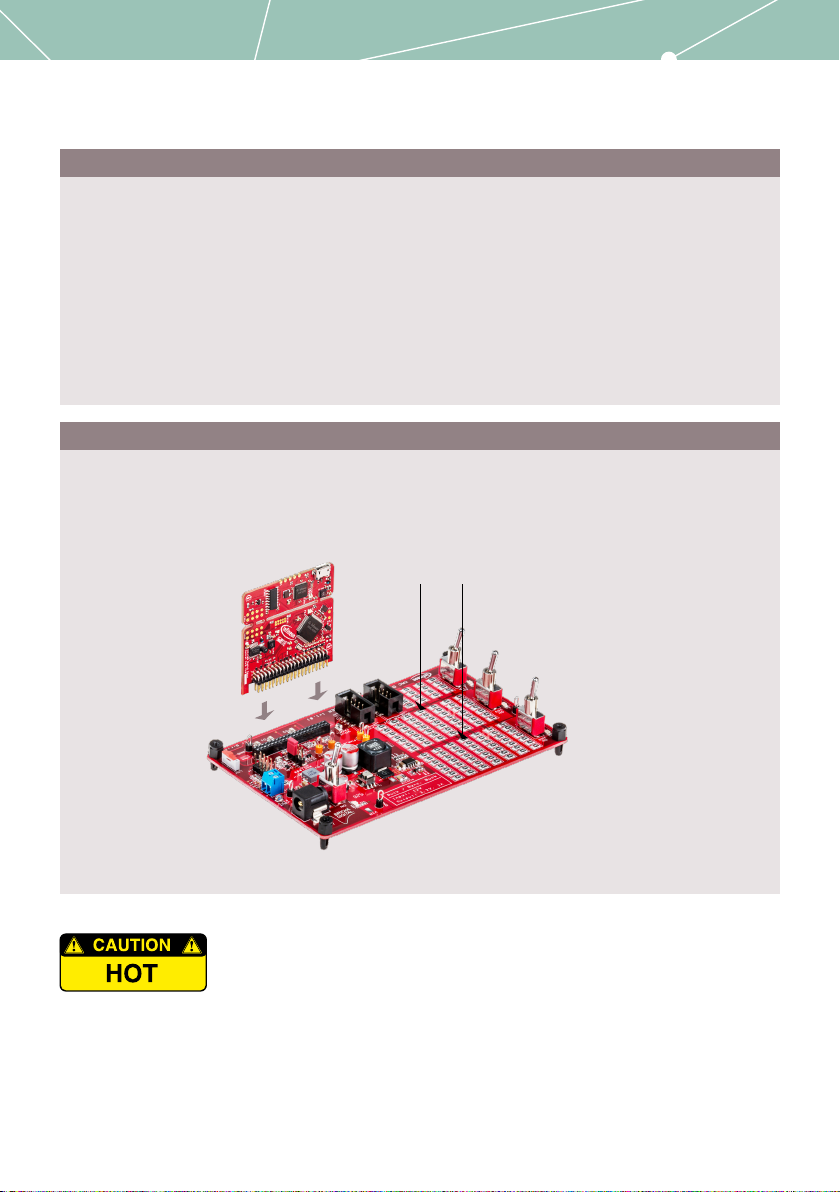

STEP 2

Plug in a control card

Plug one of the control cards into the power board in such way that the control card "noses" goes

›

through the drillings on the power board (see Figure 1)

Load banks

Figure 1

IMPORTANT NOTE: The power board contains resistive load banks (Figure 1).

These loads are purely resistive and during operation may become hot. To prevent

injuries, special care is advised when touching the on-board resistor banks during

the operation. Any other kind of load, including other resistors, can be connected to the connector "V

the purpose of further test or evaluation (blue connector). Using this kit without taking necessary measures

for cooling and isolating external loads may cause personal injuries. This evaluation board is intended for

use only by qualified and skilled technical sta for laboratory usage. Please read disclaimer page carefully

before using this kit.

out

" for

Page 3

STEP 3

Connect the control card to the computer and the power supply to the power board

Connect the USB cable to your computer and to the control card. Debugger part of the control card is

›

galvanically isolated from the power board. Place the jumper (Figure 3) into XMC1000 only if external

slope is needed (i.e. peak current control with XMC1000 set up). Otherwise use XMC4000 position.

Figure 2

Make sure the "power on" switch (SW4) is in "OFF" position. Plug in the power adapter supplied with

›

the kit (12 V, 2 A), into the input jack (J2) on the power board. "Power on" switch can now be moved to

the "ON" position

Figure 4

STEP 4

Load an example project into DAVE™

Start DAVE™ 4 IDE. You can find the DAVE™ icon on your desktop once you complete the installation

›

described in STEP 1.

Define a new workspace or use existing one

›

Download a XMC™ digital power explorer kit project to your workspace by one of these 2 means:

›

– Download the example directly from DAVE™ 4 through the

"Help" menu → "Install Dave App/Example Library"

Select "Work with: Dave Project Library Manager" and choose the right example form the list

•

Click "Next". Accept terms of license agreement and click "Finish"

•

Import the project into workspace by clicking on "Finish"

•

– You can alternatively download projects from www.infineon.com/DAVE

Extract .zip file into your new or existing workspace directory

•

Import the project into DAVE™ through the "File" → "Import",

•

select "Infineon" → "Dave Project" and browse the workspace directory

Figure 3

Page 4

STEP 5

Compile and run the examples on XMC™ microcontroller

1 Compile the project by clicking icon

2 Click icon to open "Debug Configuration" dialog

Step 3 – 4 must be done only when starting a new project.

3 To create a new debug configuration click on

4 Start debug session by clicking "Debug"

Make sure at this point that the "power on" switch in the power board - SW4 - is in the "ON" position.

The debugger starts code download and switches from "DAVE CE" perspective to the

"Debug" perspective.

5 Click "Resume" to restart the code execution

6 The buck converter is now running

Product summary

Type Description Ordering code (OPN)

XMC4200-F64X256 80 MHz ARM® Cortex®-M4F with DSP instructions

and Floating Point Unit (FPU), 256 kB flash,

40 kB RAM, 1kB cash, rich analog mixed signal,

advanced timer/HRPWM unit and communica-

tion peripherals in PG-LQFP-64 package

XMC1302-T038X0200

XMC4200-Q48X256 XMC4200 with 256 kB flash, 40 kB RAM, 1 kB

BSC0924NDI Dual N-channel (high-side and low-side)

IRS2011SPBF High-side and low-side MOSFETs gate driver IC IRS2011SPBF

IFX1763XEJ V33 Wide range input voltage, low dropout voltage

32 MHz ARM® Cortex®-M0 with MATH co-processor,

200 kB flash, 16 kB RAM, rich analog mixed sig-

nal, timer/PWM and communication peripherals

in PG-TSSOP-38 package

cash in PG-VQFN-48 package, used as on-board

debugger controller

OptiMOS™ MOSFET

regulator supplying up to 500mA

XMC4200F64K256ABXQSA1

XMC1302T038X0200AAXUMA1

XMC4200Q48K256ABXUMA1

BSC0924NDI

IFX1763XEJV33XUMA1

Page 5

Features

Input voltage 12 V DC and max output current 2A.

›

Target output voltage: 3.3V.

Power board comprised of a synchronous buck

›

converter (12 V to 3.3 V max 2 A), controlled by

either XMC1300 or XMC4200 microcontroller

Switchable loads on board for easy performance

›

test including option for network analyzers test

Supports voltage control mode and peak current

›

control mode (with slope compensation)

Optional PMBus™ connection

›

Applications

Switched mode power supplies

›

Lighting power supplies

›

Benefits

Fast prototyping of SMPS in synchronous buck

›

topology with dierent control modes

Full BOM list, design files and easy-to-use refer-

›

ence soware available

Useful links

www.infineon.com/dave

www.infineon.com/xmc

www.infineon.com/xmc-dev

www.infineon.com/xmc_dp_exp

Page 6

Dear Customer,

Evaluation boards are provided "as is". Infineon Technologies disclaims any and all warranties, express or

implied, including but not limited to any warranties of non-compliance with any specification, non infringe-

ment of third party rights and implied warranties of fitness for any purpose or for merchantability.

Evaluation boards are not commercial products and are solely intended to be used for evaluation and test-

ing purposes. They shall not to be used for reliability testing or production. The customer shall ensure that

each evaluation board is handled in a way which is compliant with all relevant requirements and standards

in the country in which it is operated.

The evaluation board is intended for use only by qualified and skilled technical sta for laboratory usage

and shall be used and managed according to the terms and conditions set forth in the related documenta-

tion provided with the evaluation board.

The customer accepts the entire risk arising out of the use of the evaluation board for any purpose for which

the evaluation board is not intended, including but not limited to any further processing or distribution of

the evaluation board. Infineon will not accept any liability or product warranty for these evaluation boards.

The customer undertakes to indemnify and hold Infineon Technologies harmless from any third party claims

in connection with or arising out of the use and/or handling of the evaluation boards by the customer.

In case of any questions, please contact your local sales partner.

Published by

Infineon Technologies AG

85579 Neubiberg, Germany

© 2015 Infineon Technologies AG.

All Rights Reserved.

Visit us:

www.infineon.com

Order Number: KIT_XMC_DP_EXP_01

SP001343072

Date: 10 / 2015

Disclaimer

The information given in this document shall in no

eventbe regarded as a guarantee of conditions or characteristics ("Beschaenheitsgarantie").

With respect to any examples or hints given herein,

any typical values stated herein and/or any information regarding the application of the device, Infineon

Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation

warranties of non-infringement of intellectual property

rights of any third party.

Information

or further information on technology, delivery terms

and conditions and prices please contact your nearest

Infineon Technologies Oice (www.infineon.com)

Warnings

Due to technical requirements components may contain dangerous substances. For information on the

types inquestion please contact your nearest Infineon

Technologies oice.

Infineon Technologies components may only be used in

life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such

components can reasonably be expected to cause the

failure of that life-support device or system, or to aect

the safety or eectiveness of that device or system. Life

support devices or systems are intended to be implanted in the human body, or to support and/or maintain

andsustain and/or protect human life. If they fail, it is

reason-able to assume that the health of the user or

other persons may be endangered.

Loading...

Loading...