АЯ 74

MARK-302Т

DISSOLVED

OXYGEN

METER

Operation Manual

Nizhny Novgorod

2010

2

VZOR will appreciate any suggestions and comments aimed

at product quality improvement.

If you have any trouble with the instrument performance,

please contact us in writing or by phone.

Postal address: 603106, Russia, Nizhny Novgorod, POB 253

Telephone: + 7 (831) 229-65-67, 412-29-40

E-mail: market@vzor.nnov.ru

Website: www.vzornn.com

3

C O N T E N T S

1 DESCRIPTION AND OPERATION ....................................................................... 4

1.1 Purpose ............................................................................................................ 4

1.2 Basic parameters ............................................................................................. 4

1.3 Specifications ................................................................................................... 6

1.4 Product components ........................................................................................ 7

1.5 Description and operation ................................................................................ 7

1.6 Measuring instruments, tools and accessories ................................................ 9

2 INTENDED USE .................................................................................................. 10

2.1 Operating limitations ...................................................................................... 10

2.2 Safety ............................................................................................................. 10

2.3 Pre-starting procedures ................................................................................. 10

2.4 Measurement procedure ................................................................................ 15

2.5 Functional check ............................................................................................ 18

2.6 Troubleshooting ............................................................................................. 19

3 MAINTENANCE ................................................................................................... 26

4 DELIVERY SET ................................................................................................... 26

APPENDIX A. Solubility of 100 % humidity air oxygen in distilled water,

depending on the temperature ............................................................................ 27

4

1 DESCRIPTION AND OPERATION

1.1 Purpose

1.1.1 Product name and designation

MARK-302Т dissolved oxygen analyzer

TU 4215-022-39232169-2008.

1.1.2 The analyzer has been designed to measure the dissolved oxygen

concentration and water temperature.

1.1.3 The analyzer’s scope of application is high-sensitivity measurement of

the mass concentration of dissolved oxygen (in the microgram range). It is used

primarily at heat power facilities for deaerated water monitoring.

1.1.4 The analyzer may also be used to measure the mass concentration of

water-dissolved oxygen and temperature of surface, waste and potable water, and

may be employed by fish farms; chemical, biotechnological and food industries;

educational institutions and ecology branches.

1.1.5 The type of analyzer:

amperometric;

with external poling voltage;

with one sensitive element;

with a digital LCD display;

with automatic temperature compensation;

with flow-type/ dip sensor;

with automatic calibration when the sensor is placed in the oxygen envi-

ronment (air) at temperatures varying between +15 °С and +35 °С;

with automatic adjustment for atmospheric pressure during calibration.

1.2 Basic parameters

1.2.1 By resistance to climatic effects, the analyzer version group is B4 in

accordance with GOST 12997-84.

1.2.2 By resistance to mechanical effects, the analyzer version is L1 in accordance with GOST 12997-84.

1.2.3 The converter unit degree of protection ensured by the casing is IP30

in accordance with GOST 14254-96.

1.2.4 By resistance to atmospheric pressure, the analyzer version group is

Р1 in accordance with GOST 12997-84 (atmospheric pressure between 84 and

106.7 kPa).

5

1.2.5 Analyzed water parameters:

temperature, °С ………………………………………………….…... 0 to +50;

pressure, MPa, max ……...………………………………..….……....… 0.05;

salt content, g/dm3 ……...………………………..………..……..…... 0 to 40;

рН ……………………………………………………….…….….......... 4 to 12;

rate of water flow via flowing vat, cm3/min ............……………. 400 to 800;

rate of water flow relative to sensor membrane, cm/s ….…………...…... 5.

1.2.6 Permissible concentrations of unmeasured components:

dissolved ammonia, mg/dm3, max ….…...…………………..……….... 40.0;

dissolved phenol, mg/dm3, max ….………….………………..…………. 0.2.

1.2.7 Operating conditions:

ambient air temperature, °C ……………………………...………... +1 to +50;

relative air humidity at 35 °С and lower temperatures without moisture

condensation, %, max …………………….………................................................. 80;

atmospheric pressure, kPa (mm hg) ……………..………..…..84.0 to 106.7

(630 to 800).

1.2.8 The analyzer is calibrated by air of 100 % humidity.

Calibration temperature range, °С ………………………………..… +15 to +35.

1.2.9 The analyzer is powered from a 2,2-3,4 V DC self-contained power

supply (two AA-type alkaline batteries).

1.2.10 Power consumption (at a rated voltage of 2,8 V), mW, max ….…... 10.

1.2.11 The analyzer retains its characteristics within the ranges set in the

analyzer specifications after replacement of the sensor’s spare parts, batteries and

calibration.

1.2.12 The overall dimensions and weights of analyzer components are

summarized in Table 1.1 below.

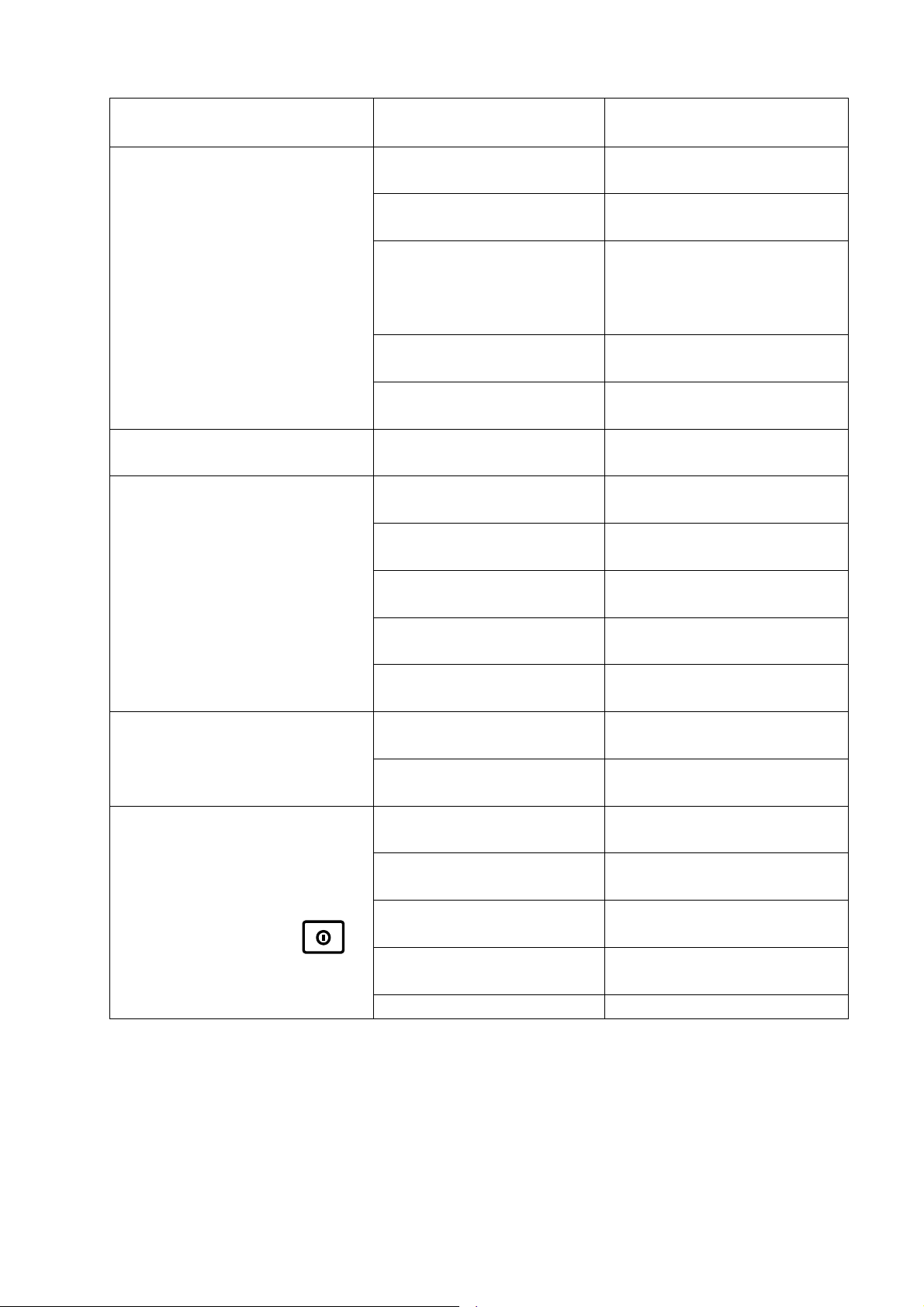

Table 1.1

Name and designation of component versions Overall dimensions,

mm, max

Weight,

kg, max

ВР29.01.000 converter unit 84×160×38 0,30

ВР29.02.000 oxygen sensor (without cable)

16×115

0,12

ВР29.03.000 flowing vat 18×40×121 0,10

1.2.13 GOST 12997-84 conditions for carriage in shipping containers:

temperature, °С ……………………...............…………..….…. – 20 to +50;

relative air humidity at 35 °С, % ............................…….....………...… 95±3;

5-35 Hz sinusoidal vibration with a 0.35 mm shift amplitude in the direction

marked “Top. Do not turn over” on the package.

6

1.3 Specifications

1.3.1 DOC (dissolved oxygen concentration) measuring range at an analyte

temperature of 20 °С, mg/dm3 ..………………………………….……..….. 0 to 10,00.

The upper limits of DOC measuring range, depending on the analyte tem-

perature, are shown in Table 1.2.

Table 1.2

t, °C 0 5 10 15 20 25 30 35 40 45 50

DOC,

mg/dm

ment at an analyte temperature of (20,0±0,2) °С and ambient temperature of

(20±5) °С, mg/dm3 ……………………………….…........................... ±(0,003+0,04С),

measurement due to a change in the ambient temperature, by each ±5 °С from the

normal temperature (20,0±0,2) °С, within the operating temperature range from 0

to +50 °С, mg/dm3 ……………………………………….….…………………. ±0,012C.

measurement due to a change in the ambient temperature by each ±10 °С from

the normal temperature (20±5) °С, within the operating temperature range from +1

to +50 °С, mg/dm3 ….……….............................................................

±(0,001+0,002C).

an analyte temperature coinciding with the calibration temperature which varies between +15 °С and +35 °С, at an ambient temperature of (20±5) °С,

mg/dm3……….…………………………………………...................... ± (0,003+0,04C).

ature measurement at an ambient temperature of (20±5) °С, °C ….……...…... ±0,3.

ature measurement due to a change in the ambient temperature by each ±10 °С

from the normal temperature (20±5) °С, within the operating temperature range

from +1 to +50 °С, °С …….....………………………..…………….…………..….. ±0,1.

DOC measurement, min …………..……….…………………………….…………… 2.

time tу in DOC measurement, min ……….…………......................…………..…… 30.

in analyte temperature measurement, min ……………………….………….………. 1.

analyte temperature measurement, min ………………………………………….….. 3.

17,45 15,29 13,48 12,10 10,00 9,85 8,98 8,30 7,69 7,12 6,59

3

1.3.2 Limits of the analyzer allowable basic absolute error in DOC measure-

where С, here and hereafter, is a measured DOC value in mg/dm3.

1.3.3 Limits of the analyzer allowable additional absolute error in DOC

1.3.4 Limits of the analyzer allowable additional absolute error in DOC

1.3.5 Limits of the analyzer allowable absolute error in DOC measurement at

1.3.6 Analyte temperature measuring range, °С ……...……............. 0 to +50.

1.3.7 Limits of the analyzer allowable basic absolute error in analyte temper-

1.3.8 Limits of the analyzer allowable basic absolute error in analyte temper-

1.3.9 Limit of the permissible value of the analyzer readout setting time t

0.9

in

1.3.10 1.3.10 Limit of the permissible value of the analyzer readout setting

1.3.11 Limit of the permissible value of the analyzer readout setting time t

0.9

1.3.12 Limit of the permissible value of the analyzer readout setting time tу in

7

1.3.13 Analyzer oscillatory readings in DOC measurement for 8 h, mg/dm3,

max ……………………………………………………………..….….. ±(0,0015+0,02C).

1.4 Product components

The analyzer comprises:

converter unit;

oxygen sensor with a 2 m connecting cable;

flowing vat.

1.5 Description and operation

1.5.1 General analyzer data

The MARK-302Т dissolved oxygen analyzer is a small-size microprocessor

device designed to measure the mass concentration of water-dissolved oxygen

(DOC) and the analyte temperature.

The DOC values measured in mg/dm3 or temperature measured in Celsius

degrees (depending on the measuring mode) are displayed on the readout device

– a digital LCD display (“the display”). The minimum value of the least significant

digit for DOC measurement is 0,001 mg/dm3. The least significant digit value for

temperature measurement is 0,1 °С.

The analyzer is calibrated by atmospheric air of 100 % humidity with auto-

matic adjustment for atmospheric pressure during calibration.

Adjustment for atmospheric pressure during the analyzer calibration by at-

mospheric air is provided by a built-in atmospheric pressure sensor.

1.5.2 Analyzer operating principle

The analyzer uses an amperometric sensor operating as a closed-type

polarographic cell. The electrodes are submerged in an internal electrolyte solution

which is separated from the analyte by a membrane penetrable for oxygen but impenetrable for liquid and water vapor. From the analyte, oxygen diffuses through

the membrane into a thin layer of electrolyte between the electrodes and the membrane and undergoes an electrochemical reaction on the surface of the cathode

which is polarized by external voltage applied cross the electrodes. In the process,

the sensor generates a DC signal which is at a fixed temperature proportional to

8

1

3

2

4

5 12

11

13

8

7

16

6

MODE CAL ENTER

DOC in the analyte.

The analyzer features a temperature sensor (platinum thermal resistor) to

measure temperature and to automatically compensate for the temperature dependence of the oxygen sensor signal. The temperature sensor signal is supplied

to the ADC input.

The ADC converts signals of the oxygen sensor and the temperature sensor

into codes incoming the microcontroller.

The microcontroller processes the codes received and shows the information

on the digital LCD display.

1.5.3 Analyzer design

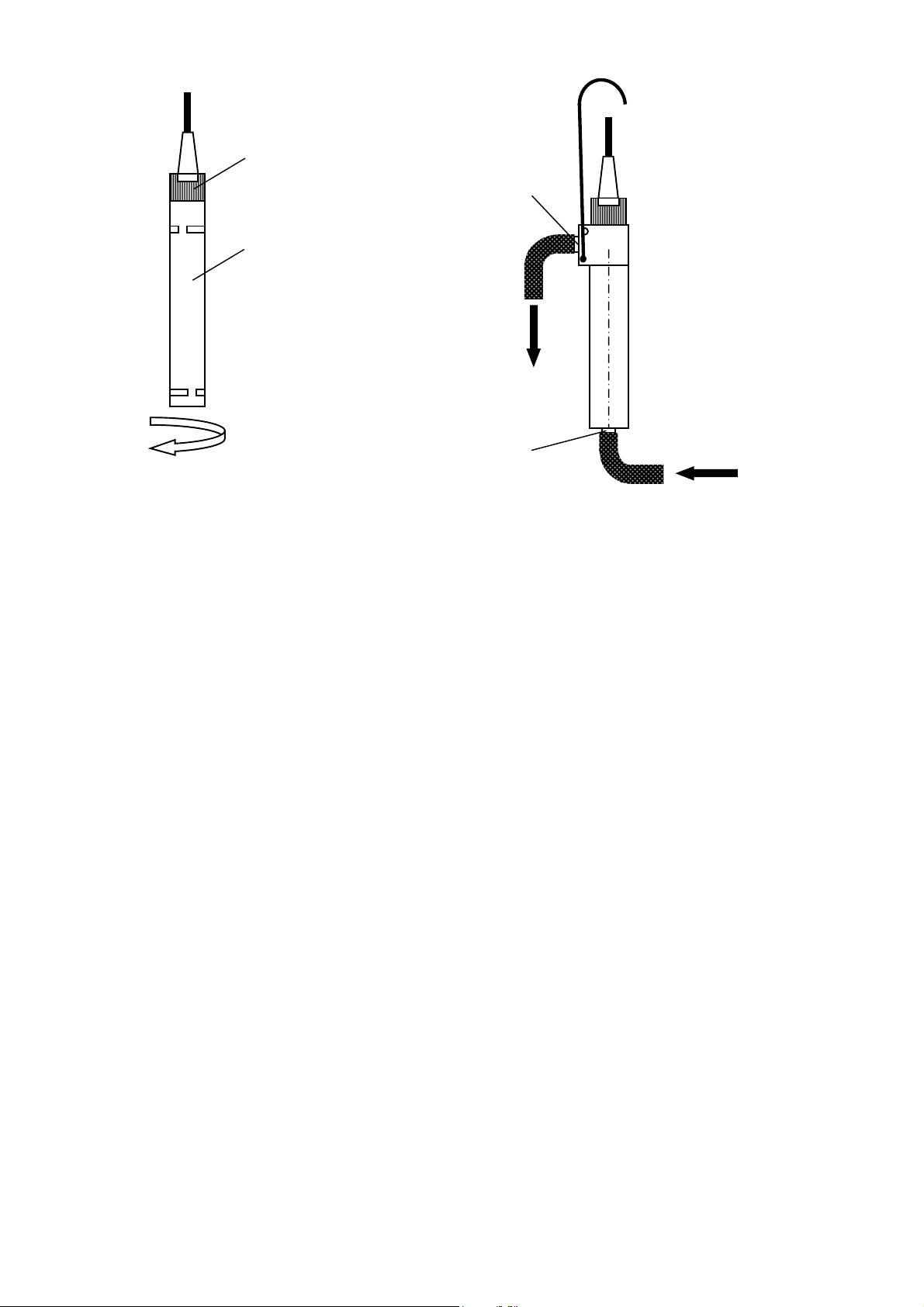

The analyzer is shown in Fig.1.1а.

Converter unit 1 has a sealed plastic housing and is designed to convert signals from oxygen sensor 2 and display measurement data.

The front panel of the converter unit features:

indicator screen 3 designed to display a measured DOC value or temper-

ature (depending on the chosen measuring mode), battery charge and current time

(in off state);

button 4.

The back panel of the converter unit features a battery compartment cover.

Located on top of the converter unit is sealed cable entry 5 for oxygen sensor 2.

а b

17

14

15

10

9

Fig. 1.1

9

Flow measurements use flowing vat 6.

Fig.1.1b shows the oxygen sensor design.

The sensor’s basic functional elements are platinum cathode 7 and silver

anode 8. Secured to cathode 7 with caprone thread 9 is teflon film 10. The membrane and rubber bushing form membrane assembly 11 fitted over bushing 12 and

filled with electrolyte 13. The temperature sensor is enclosed in case 14. Protective

bushing 15 covers the sensor electrode portion and is screwed into cable bushing

16 (Fig.1.1а).

Cable 17 connects the sensor electrode assembly to the converter unit.

Made of a corrosion resistant alloy, flowing vat 6 is a threaded cylinder with

supply and drain connections for controlled water. To install the oxygen sensor in

the flowing vat, replace protection bushing 15 with flowing vat 6.

1.5.4 Functions of buttons on the converter unit front panel

The analyzer front panel features the following buttons as shown in Fig.1.1а:

the button for analyzer power on/off. When the analyzer is energized,

the display shows the measured DOC or temperature value;

the MODE button enables the DOC or temperature measuring mode, with

the display showing the measured DOC or temperature value and mg/dm3 or °С

character, respectively, coming on in the right half of the indicator;

the CAL button selects the analyzer calibration mode. When pressed se-

quentially, the button causes the characters с0 (analyzer reset) and с1 (atmospheric air calibration) to light up on the display;

the ENTER button confirms the selected calibration mode and completes

calibration.

1.6 Measuring instruments, tools and accessories

1.6.1 The following tools and accessories, which are not included in the de-

livery set, will be additionally required for maintenance of the analyzer:

2 mm cross screwdriver;

В-1-250 beaker;

КН-100-19/26 flask;

hydroquinone, chemically pure;

sodium or potassium hydroxide, chemically pure.

10

2 INTENDED USE

2.1 Operating limitations

2.1.1 2.1.1 The MARK-302Т analyzer version is primarily used to measure

DOC in deaerated water.

2.1.2 2.1.2 Para.1.2.5 provides permissible concentrations for a number of

components which affect measuring results.

2.1.3 2.1.3 The analyzer should be positioned so as to prevent water from

getting on the converter unit.

2.1.4 2.1.4 When using the analyzer, avoid hitting or dropping the oxygen

sensor to keep its glass components intact.

2.2 Safety

2.2.1 The analyzer should only be operated by personnel who are familiar

with this manual and chemical handling safety rules in accordance with

GOST 12.1.007-76 and GOST 12.4.021-75.

2.2.2 The analyzer meets the requirements of Safety Class III to

GOST R 52319-2005. The rated supply voltage varies between 2,2 and 3,4 V. No

protective earthing is required.

2.2.3 By electromagnetic compatibility, the analyzer meets the requirements

of GOST R 51522-99 for Class B equipment.

2.3 Pre-starting procedures

On receipt of the analyzer, unpack it, check the set for completeness and

make sure that the packed components are intact.

If kept in cold conditions before delivery, the analyzer should be held at room

temperature for at least one hour before setting-up procedures.

11

2.3.1 Power supply connection

To connect the power supply, remove the battery compartment cover located

on the rear panel of the converter unit. Install two AA-type alkaline batteries observing the polarity marking inside the battery compartment. Replace the battery

compartment cover.

With a power supply installed in the battery compartment, the analyzer can

indicate time, when turned off. The dot between hours and minutes flickers at an

interval of 1 second.

Time indication may be switched off and on again by pressing the MODE

button, with the analyzer off.

Proceed as follows to correct time:

press the CAL button, minutes will start blinking on the display;

use the MODE and ENTER buttons to set the minute value;

press the CAL button, hours will start blinking on the display;

use the MODE and ENTER buttons to set the hour value;

press the CAL button to complete time setting, the analyzer goes into the

time indication mode.

Switch on the analyzer and check if the display shows DOC or temperature

readings in mg/dm3 or °С respectively.

IMPORTANT: ALWAYS OBSERVE polarity when installing batteries.

Failure to meet this condition may damage the analyzer!

When the display shows the sign, replace AA-type alkaline batteries.

2.3.2 Oxygen sensor setting-up procedures

Since the oxygen sensor from the analyzer set is delivered in the “dry” state,

it should be filled with electrolyte included with the delivery set, as described in para.2.6.3, and submerged in distilled water for a minimum of 8 hours.

Make sure two AA-type alkaline batteries are installed in the converter unit.

Regardless of whether the analyzer is on or off, the sensor will receive polarizing

voltage needed to build up an electrode system.

2.3.3 Analyzer functional check

The analyzer functional check includes:

12

analyzer precalibration by atmospheric air oxygen;

check of readings in the null solution.

It is recommended that the analyzer functional check be performed:

after filling the sensor with electrolyte on delivery of the analyzer;

after replacement of the membrane assembly or teflon film;

if there are any doubts as to the analyzer’s serviceability.

2.3.3.1 Analyzer precalibration

Take the sensor out of the vessel with water and place it horizontally (put on

the table).

Press the MODE button to enable the DOC measuring mode in mg/dm3. The

analyzer display will show a figure measured in mg/dm3.

Keep the sensor in the air for 5 min.

Press the CAL button twice. The analyzer display will show the c1 symbol

showing the entry into the outside air calibration mode.

Press the ENTER button. The analyzer display will show DOC readings corresponding to the table of 100 % humidity air oxygen solubility for analyzermeasured temperatures, with allowance for the atmospheric pressure at the time of

calibration, for example, c8.38 mg/dm3.

Wait at least 8 s before pressing the ENTER button once again. The donЕ

caption will appear shortly on the screen and the с symbol will go out. The analyzer

will go into the measuring mode, which means that precalibration is completed.

2.3.3.2 Reading check in the null solution

Prepare an oxygen-free (null) solution, and for this purpose:

prepare an alkali solution (KOH or NaOH), concentration 5 g/dm

pour it into a 0,3-0,5 dm

3

vessel so that its level is 50 to 60 mm;

3

;

add 0,3 to 0,5 g of hydroquinone and stir.

Uptime in air tight vessel is max 1 month.

Submerge the sensor, with its membrane down, in the solution and move it

to slightly agitate the solution in order to prevent air bubbles from amassing on the

membrane. The displayed analyzer reading should decrease slowly.

Take the analyzer readings in 30 min.

They should vary within ±3 mkg/dm3.

13

With the above procedure successfully completed, the analyzer is ready for

normal service. The analyzer calibration by outside air shall then be performed as

per para.2.3.4.

If the readings do not decrease to the specified level, a sensor cycling operation should be carried out as per para.2.3.3.3.

2.3.3.3 Sensor cycling

Proceed as follows to carry out the cycling operation:

switch on the analyzer;

prepare a null solution as per para.2.3.3.2;

submerge the sensor, with its membrane down, in the solution and move

it to slightly agitate the solution in order to prevent air bubbles from amassing on

the membrane;

hold the sensor in the null solution for 5 min, then take it out, shake off the

solution drops from the membrane and hold it in the air for 5 min;

repeat the null solution - air cycle 3 to 4 times;

submerge the sensor in null solution again;

take the analyzer reading in 30 min; it should be within ±3 mkg/dm3.

If the above steps fail to cause the analyzer readings in the null solution to

decrease to the desired values, this suggests either bad quality of the null solution

(bad reagents) or a fault in the analyzer (see section 2.6 Troubleshooting).

Calibration of the analyzer should then be performed subject to para.2.3.4 or

2.3.5.

If any error character (Е3, Е4, Е5, Е6, Е7, Е8, Е9) is displayed during the

analyzer functional check, also refer to section 2.6.

2.3.4 Analyzer calibration by outside air

Outside air calibration of the analyzer should be performed:

when the device is new;

once a shift (8 hr);

after replacement of electrolyte, membrane and teflon film.

Calibration of the analyzer is performed in the outside air at temperatures between +15 °С and +35 °С and a 100 % relative humidity. It is more convenient to

perform calibration at room temperature.

Prior to calibration, the analyzer, with AA-type alkaline batteries installed,

should be held at room temperature for at least 1 hour. The analyzer may be left

14

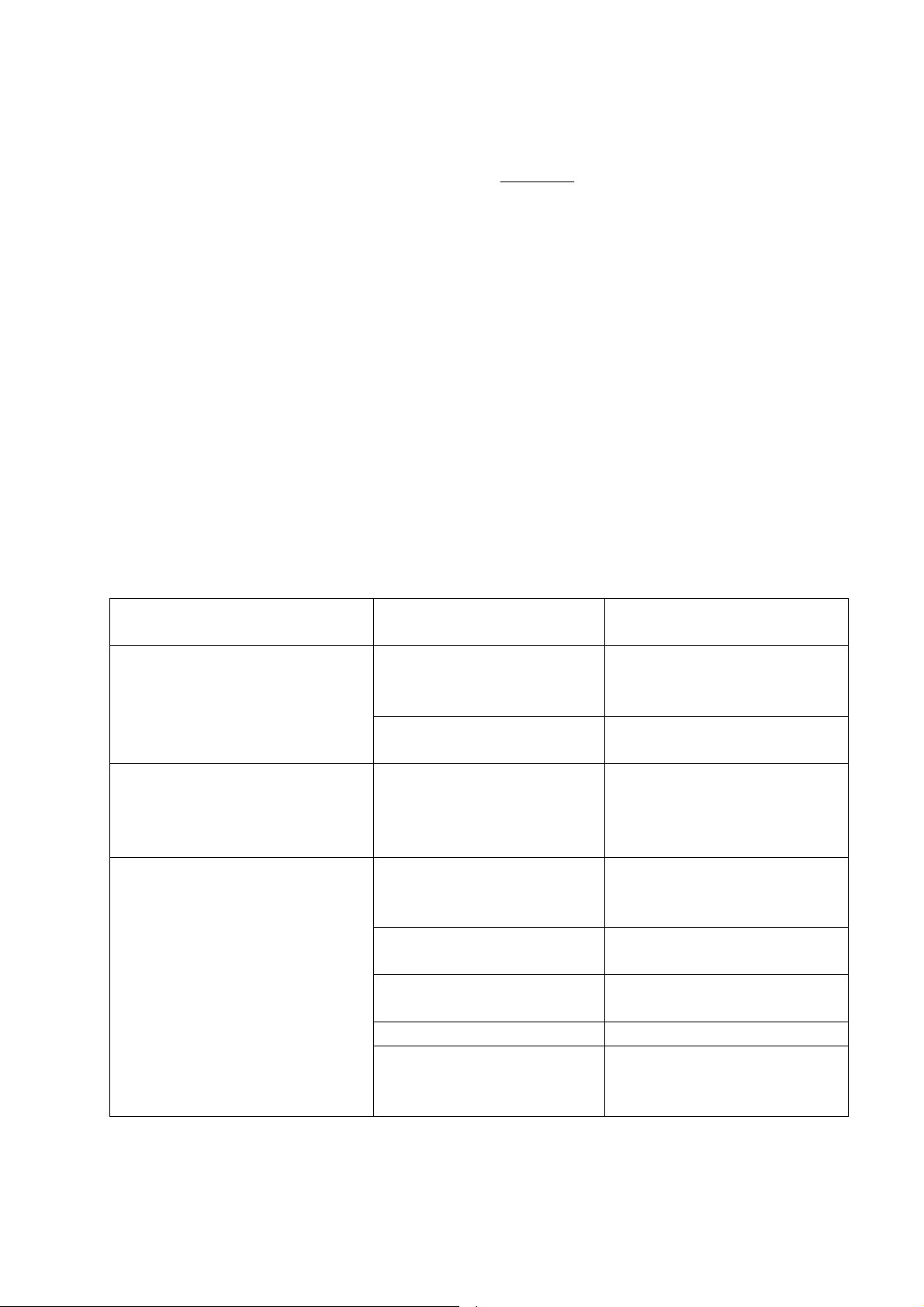

Flask

switched on. Submerge the sensor fully in distilled water of room temperature for a

minimum of 10 min.

Rinse the sensor in distilled water, shake off water drops from the sensor

membrane and put the sensor in the cone flask with a water layer 3 to 5 mm, as

shown in Fig.2.1. Position the flask at an angle of 30 to 45° to the horizontal for the

remaining water to flow off the membrane.

Sensor

Water

Fig. 2.1 − Position of the sensor inside the flask for analyzer calibration

Wait for 10 min before performing the outside air calibration steps which follow.

1 Press the CAL button twice. The c1 character will appear on the display,

showing the entry into the outside air calibration mode.

2 Press the ENTER button. The analyzer will display DOC readings corresponding to the table of 100 % humidity air oxygen solubility for analyzer-measured

temperature, with allowance for the atmospheric pressure at the time of calibration,

e.g. c8.38 mg/dm3.

3 Wait at least 8 s before pressing ENTER once again. The donЕ caption

will briefly appear on the display and the analyzer will go into the measuring mode.

It means the outside air calibration mode is completed and the analyzer is calibrated.

Once calibrated by outside air, the analyzer is ready for use.

Note: Outside air calibration of the analyzer may be cancelled before Step 3

by pressing MODE. The analyzer will go into the DOC measuring mode, retaining

the values of previous calibration coefficients.

2.3.5 Analyzer zero calibration

Analyzer zero calibration allows the sensor residual zero current to be compensated within narrow limits (–3,0 to +3,0 mkg/dm3).

15

Proceeds as follows prior to carrying out this operation:

switch on the analyzer;

prepare a fresh null solution as per para.2.3.3.2;

enable the DOC measuring mode in mg/dm3;

perform cycling operations as per para.2.3.3.3;

hold the sensor in the air for 5 min, submerge the sensor, with its mem-

brane down, in the null solution and move it to slightly agitate the solution in order

to prevent air bubbles from amassing on the membrane;

hold the sensor in the null solution for at least 40 min.

Perform the following steps to set the analyzer zero.

1 Press CAL. The analyzer display will show the с0 caption.

2 Press ENTER. The analyzer display will show DOC Z0 readings in the null

solution without allowance for zero adjustment, e.g. с.002 mg/dm3.

3 Wait at least 8 s before pressing ENTER once again. The donЕ caption

will briefly appear on the display and the analyzer will go into the measuring mode.

The analyzer display will indicate a DOC value in the null solution after analyzer

zero setting:

0,000; if −0,003 mg/dm

Z

−0,003; if Z0 > 0,003 mg/dm3;

0

Z

+0,003; if Z0 < −0,003 mg/dm3.

0

3

≤ Z0 ≤ 0.003 mg/dm3;

Note: Analyzer zero setting may be cancelled before Step 3, by pressing

MODE. The analyzer will go into the DOC measuring mode, retaining the values of

previous calibration coefficients.

2.4 Measurement procedure

2.4.1 Preparation for measurement using a flowing vat

The premesurement procedure as per Fig.2.2 includes the following steps:

remove the hose from the flowing vat outlet connection;

remove the protective bushing from the cable bushing by unscrewing it;

screw in the flowing vat in place of the cable bushing.

16

Cable

bushing

Outlet

connection

Protective

bushing

Drainage

connection

Inlet

From sampler

а b

Fig. 2.2

2.4.1.1 Measurement using a flowing vat

Connect the inlet connection of the flowing vat (with the sensor installed) to

the controlled water line with a flexible hose. Supply controlled water to the flowing

vat and position the vessel with sensor so that the sensor is nearly vertical, its

membrane down. Allow water to freely flow through the vessel for at least 10

minutes, until there are no air bubbles in the water flow. Nor should there be any

air bubbles on the sensor membrane. To remove bubbles from the membrane,

shake the vessel with sensor carefully.

Bubbles amassing in the hose bends, on the sensor membrane or in the water line knee may substantially invalidate the results. One of the signs showing the

presence of air bubbles is that the analyzer oxygen readings will not settle, while

dropping slowly and continuously. Such a process caused by the air oxygen being

washed out from air bubbles may last 1-2 hours.

To eliminate air bubbles in the sampler line, it is recommended:

to sharply increase (by 10-20 s) the water flow through the flowing vat;

reduce the water flow to the normal level (400 to 800 cm3/min).

Switch on the analyzer and take the display readings.

Negative oxygen readings at sampler measurements suggest that the analyzed water contains some electroactive impurities.

17

Measurements may dispense with the flowing vat, if the sensor is placed in a

suitable vessel ensuring a controlled water flow of 5 cm/s in the sensor membrane

area. To protect the membrane from damage, it is recommended to screw in the

protective bushing.

Note: Subject to para.1.3.11, the MARK-302Т analyzer readout setting time

limit tу, when measuring DOC, is 30 min, i.e. after 30 min the analyzer readings in a

fresh null solution should be up to 0,003 mg/dm3.

The real readout setting time for newly released analyzers varies between 1

and 3 min.

When in use for a certain period, the analyzer may have an extended

readout setting time.

To determine the readout setting time of a specific analyzer, prepare a fresh

null solution, submerge the sensor in it, slightly agitating the solution with the sensor, and record the time when the readings of 0,003 mg/dm3 are obtained. It is recommended to perform this operation once a month.

The 0,003 mg/dm3 reading recorded time may be used for measurement, i.e.

take reading when this time expires.

IMPORTANT: while operating the analyzer:

keep the sensor membrane wet. The sensor should be kept in water during intervals between measurements. There is a good reason to store the sensor

installed in the flowing vat filled with controlled water. To prevent water leakage,

the hoses of inlet and outlet connections may be connected with a short pipe;

transport the oxygen sensor in the flowing vat filled with water, at positive

ambient temperatures;

when brought into a warm room from the cold air, prior to enabling, hold

the analyzer at room temperature for at least 1 hour in order for condensed moisture to evaporate.

2.4.2 Water temperature measurement

The temperature measurement mode t °С is enabled by pressing the MODE

button.

Allow for the analyzer readings to be set and record them as a measuring

result.

18

2.4.3 Calculation of dissolved oxygen concentration by analyzer readings,

with allowance for the salt content

When measuring DOC in salty water, use the correction factor α, by which

the analyzer readings should be multiplied. The α value is defined with the formula:

= 1−С

salt

ε,

where С

salt content, g/dm3;

salt

ε factor listed in Table 2.1.

Table 2.1. − Correction factors

t °C ε t °C ε t °C ε t °C ε t °C ε

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

10,0

0,0063

0,0063

0,0062

0,0062

0,0060

0,0060

0,0060

0,0060

0,0058

0,0058

0,0058

11,0

12,0

13,0

14,0

15,0

16,0

17,0

18,0

19,0

20,0

0,0057

0,0057

0,0057

0,0055

0,0055

0,0055

0,0054

0,0054

0,0053

0,0053

21,0

22,0

23,0

24,0

25,0

26,0

27,0

28,0

29,0

30,0

0,0052

0,0052

0,0051

0,0050

0,0050

0,0049

0,0049

0,0049

0,0048

0,0048

31,0

32,0

33,0

34,0

35,0

36,0

37,0

38,0

39,0

40,0

0,0048

0,0047

0,0047

0,0046

0,0046

0,0045

0,0045

0,0044

0,0044

0,0043

41,0

42,0

43,0

44,0

45,0

46,0

47,0

48,0

49,0

50,0

0,0043

0,0042

0,0042

0,0041

0,0041

0,0040

0,0040

0,0039

0,0039

0,0038

Exemplary calculation of correction factor :

Let С

=10 g/dm3, t=20 °C,

salt

thus ε =0,0053,

then =1-10·0,0053=0,947.

Note: This method for salt content correction is based on the International

Standard ISO 5814 Water Quality – Determination Of Dissolved Oxygen – Electrochemical Probe Method.

2.5 Functional check

A serviceable analyzer should meet the following requirements:

with the sensor placed in the null solution, the analyzer readings stay

within ± 3 mkg/dm3;

19

when outside air calibration is accomplished, (para.2.3.4) neither Е3 nor

Е4 is displayed on the screen and readings C

, mg/dm3, are set with an accuracy

cal

±1 % of the calculated value defined with the formula:

Р

cal

)(

tСоС ,

2

atm

325.101

where Со2(t), mg/dm3 solubility of 100 % humidity air oxygen in distilled

water, at temperature t, °С, and normal atmospheric pressure of 101.325 кPa as

per Table A.1;

Р

atmospheric pressure as of the time of calibration, kPa.

atm

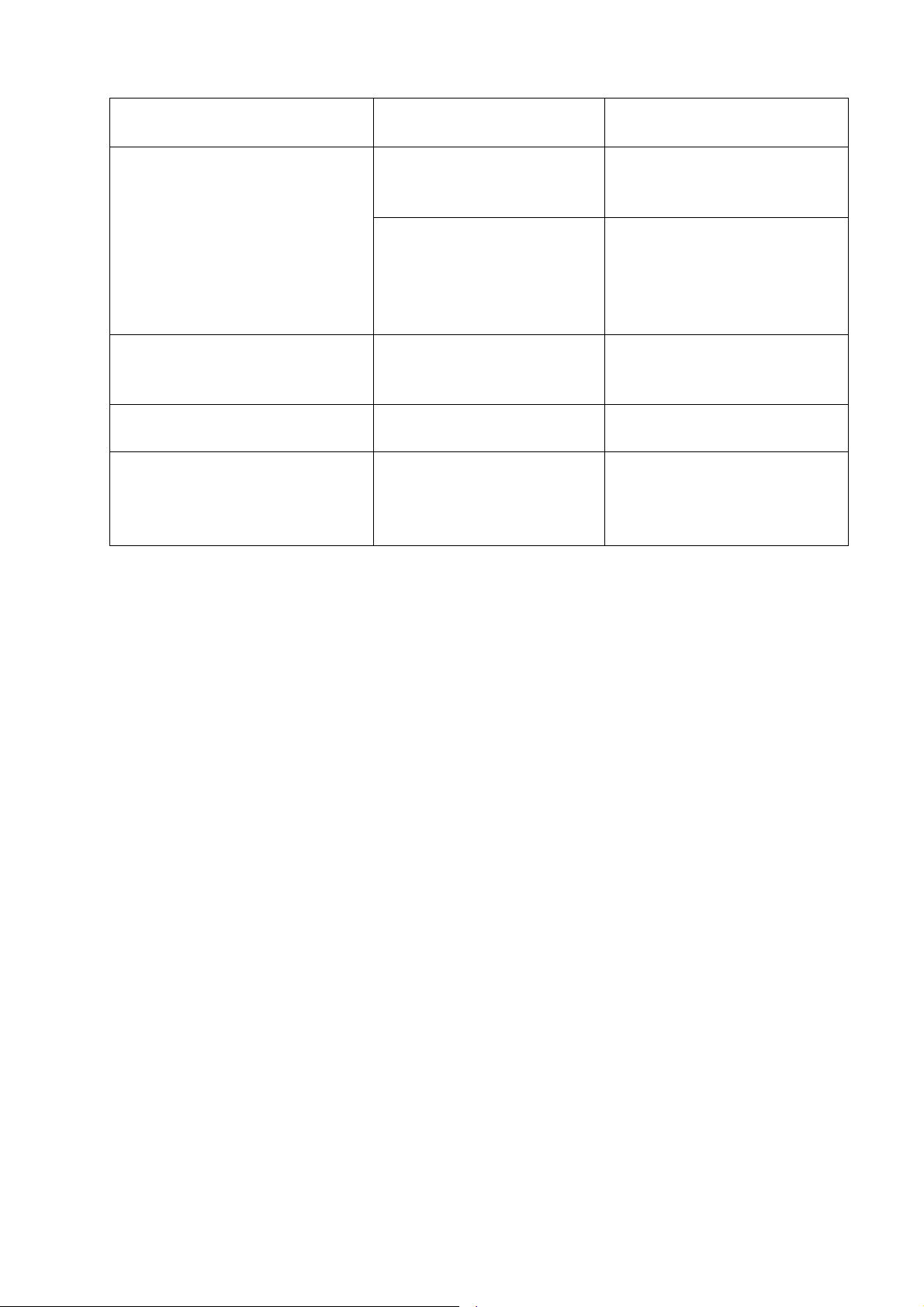

2.6 Troubleshooting

2.6.1 The typical faults of the analyzer and remedial methods are summa-

rized in Table 2.2.

In case of troubles set out in Table 2.2, proceed as recommended in the

Remedy column, in accordance with the clauses given below and Fig.1.1 and 2.4.

Trouble, symptoms Probable cause Remedy

1 With power on, no readings are displayed

2 With power on, all or random segments and characters illuminate on the

screen

3 When the zero point of

measuring range is

checked, analyzer readings

go beyond ±0,003 mg/dm

Poor battery contact Open the battery com-

partment and clean con-

tacts

Supply voltage below

acceptable level

Para.2.3.1 Replace bat-

teries

Dead batteries Para.2.3.1. Replace bat-

teries

Ruptured or punctured

membrane, sensor seal

failure

3

Moisture inside the

converter unit

Overstretched membrane

Para.2.6.3, 2.6.4. Re-

place the membrane and

electrolyte

Dry the converter unit for

3-4 days

Para.2.6.4. Replace the

membrane assembly

Bad null solution Replace the null solution

Broken (cracked) glass

Factory repair

holder of sensor electrodes

Table 2.2

20

Table 2.2 (Continue)

Trouble, symptoms Probable cause Remedy

4 When the analyzer is calibrated by outside air, Е3

(sensor current below rating) is displayed.

5 Electrolyte leaking out

fast

6.1 Sharp change in and

increased instability of analyzer readings.

6.2 During analyzer calibration by outside air, Е4 (excess sensor current) is displayed on the screen.

7 Extended time of response to oxygen concentration variations

8 During measurements,

Е5 (excess measured sensor current) is displayed on

the screen. Analyzer does

not respond to pressed buttons, except button

Electrolyte has leaked

out

Contaminated membrane

Para.2.6.3. Fill in electro-

lyte

Para.2.6.2. Clean the

membrane

Dry membrane Keep the membrane in

water for 2-3 days with-

out dismantling the sen-

sor

Defective membrane Para.2.6.4. Replace the

membrane assembly

Analyzer sensor off the

Position the sensor in air

outside air

Ruptured membrane Para.2.6.4. Replace the

membrane assembly

Ruptured membrane Para.2.6.4. Replace the

membrane assembly

Contaminated electrolyte

Moisture inside the

converter unit

Para.2.6.3. Replace

electrolyte

Dry the converter unit for

3-4 days

Ruptured teflon film Para.2.6.4. Replace tef-

lon film

Analyzer sensor off the

Position the sensor in air

outside air

Contaminated membrane

Contaminated platinum

electrode

Para.2.6.2. Clean the

membrane

Para.2.6.5. Clean the

platinum electrode

Ruptured membrane Para.2.6.4. Replace the

membrane assembly

Contaminated electrolyte

Moisture inside the

converter unit

Para.2.6.3. Replace

electrolyte

Dry the converter unit for

3-4 days

Ruptured teflon film Para.2.6.4. Replace tef-

lon film

Broken down analyzer Factory repair

21

Е

9

Тable 2.2 (Continue)

Trouble, symptoms Probable cause Remedy

9 During measurements,

indication of exceeded display digit capacity appears

on the screen:

Operator’s errors in analyzer calibrations

Para.2.6.6. Perform op-

erations to set initial ana-

lyzer parameters

Broken down analyzer Factory repair

“Е6 mg/dm3” readings

less than 199,9 mg/dm3;

“Е7 mg/dm3” − readings

exceeding 199,9 mg/dm3.

10 During measurements,

Е8 is displayed on the

screen.

11

is displayed on the

screen.

12 Sharp change in and

increased instability of analyzer readings during flow-

Faulty temperature

measuring channel

(heat probe breakage)

Writing error in

ЕЕРRОМ memory

High rate of flow

through the flowing vat

Factory repair

Factory repair

Set the rate of flow

through the flowing vat at

400 to 800 cm3/min

ing vat measurements.

2.6.2 Membrane cleaning

The sensor membrane may be cleaned with a wad of alcohol-soaked cotton.

The sensor membrane may also be submerged in a weak solution (2 %) of

sulfuric acid for about 1 hour, and then wash it in running water.

2.6.3 Filling the sensor with electrolyte, electrolyte replacement

As it is supplied in a dry state (without electrolyte), the sensor needs to be

filled with electrolyte after its receipt from the manufacturer.

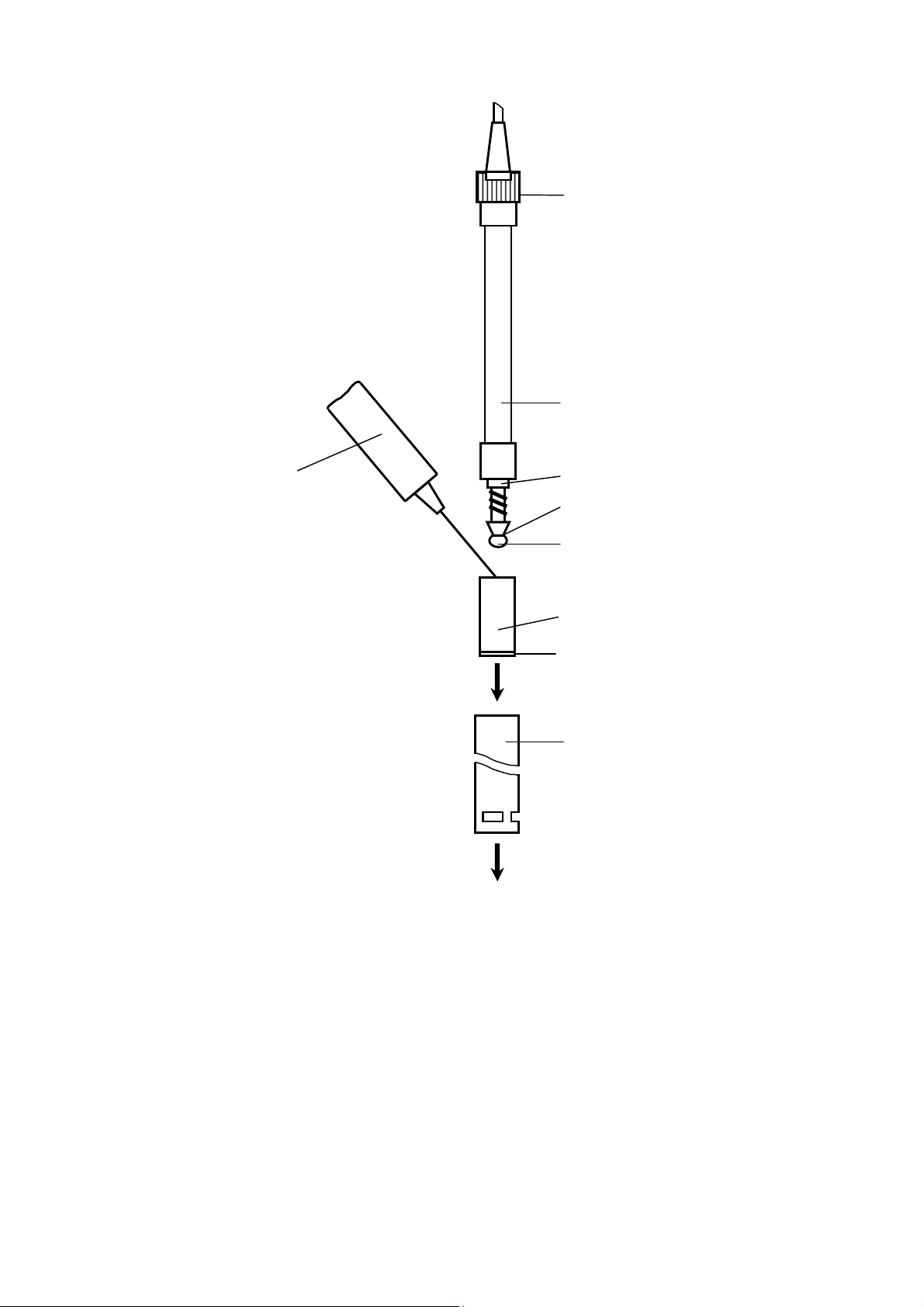

Unscrew and remove the protective bushing from the sensor as per Fig.2.3.

Remove the membrane assembly from the bushing. Draw electrolyte from

SPK into a syringe. Take the membrane assembly and, holding it with the membrane down, inject electrolyte to fill two thirds of the volume, taking care to avoid

damaging the membrane. While continuing to keep vertical the membrane assembly filled with electrolyte, set it on the bushing against the stop. Screw in the protective bushing.

22

Cable bushing

Case

Syringe

filled with

electrolyte

Bushing

Capron thread

Teflon film

Membrane assembly

Membrane

Remove

Protective bushing

Remove

Fig. 2.3 − Dismantling the sensor for filling and replacement of electrolyte,

replacement of teflon film and membrane assembly

IMPORTANT: The membrane should be stretched and pressed firmly

against the sensor platinum cathode. The membrane SHALL NEVER separate

from the cathode!

After a certain period of service, the sensor may have the volume of electrolyte reducing due to leakage through pinholes or ruptures in the membrane, which

necessitates electrolyte replacement.

23

Remove the membrane assembly from bushing 6, drain the remaining electrolyte and wash the assembly with distilled water. Fill the membrane assembly

with new electrolyte.

Electrolyte composition: KCl, chemically pure – 14 g; KOH, chemically pure –

0.2 g; versene – 0.15 g; distilled water – up to 0.1 dm3. Filter the solution.

2.6.4 Replacement of the membrane assembly and teflon film

2.6.4.1 Replacement of the membrane assembly may be necessary in case

of mechanical damage (cracks, ruptures) or overstretching of the membrane. A

faulty membrane manifests itself in analyzer reading instability, high analyzer readings in the null solution and longer time of response during DOC measurement.

Unscrew and remove the protective bushing from the sensor as per Fig.2.3.

Remove the membrane assembly form the inner case and drain the electrolyte.

Check the teflon film for damage.

The film should be firmly pressed against the cathode, in a wrinkle-free man-

ner. Damaged film should be replaced.

Once the teflon film is removed, check the sensor electrode to see if they

look as follows:

platinum cathode 1 (Fig.1.1b) sealed in a glass tube should be clean;

silver anode 2, coiled over the tube should be gray.

If necessary, clean the electrodes with a wad of alcohol-soaked cotton.

IMPORTANT: NEVER use any abrasive for cleaning electrodes!

2.6.4.2 Damaged teflon film should be replaced with new one from spare

parts kit. To do this, place it on the cathode, press the film edges firmly against the

side surface of the glass tube and, holding the edges by hand, wind around 5 to 6

laps of caprone thread making 2 to 3 knots. Cut off with scissors surpluses of teflon

film not closer than 3-5 mm from caprone.

IMPORTANT: NO rupture or hole in teflon film in the platinum cathode

area are permissible!

Take a new membrane assembly from SPK and, holding the assembly vertically, fill electrolyte with it. Then carefully fit the assembly with electrolyte over the

bushing and place the protective bushing.

After membrane assembly/teflon film replacement, perform the steps detailed in para.2.3.3 and 2.3.4.

24

2.6.5 Platinum electrode cleaning

A need for platinum electrode cleaning in a special solution arises in

6-12 months after the first use. It is not recommended to clean the electrode before

this period expires.

To clean the electrode, prepare two solutions.

Solution composition:

Solution1: chlorohydric acid (concentrated) − 50 cm3,

distilled water up to 100 cm3;

Solution 2: acetic acid (80 to 100 %).

Pour the solutions into vessels making sure that the liquid level is up to

3 mm. Then proceed as follows:

remove the teflon film;

wash the sensor with distilled water;

place the sensor into a vessel with Solution 1 and hold it there for 1 hour;

wash the sensor with distilled water;

place the sensor into a vessel with Solution 2 and hold it there also for 1

hour;

IMPORTANT: NEVER PLACE the silver anode in the above solutions!

wash the sensor with distilled water.

Then proceed to para.2.6.4.2.

Note: After cleaning the platinum electrode and performing the steps as per

para.2.6.4.2 and 2.3.3, 2.3.4, the analyzer, when placed in the null solution, can

display low negative values over a period from 24 to 48 hours. For the analyzer to

resume its normal operation as soon as possible, replace the electrolyte after

24 hours.

2.6.6 Analyzer initial parameter setting

The instrument features a mode for setting the analyzer initial parameters of

shift (zero shift) and steepness corresponding to the averaged sensor. This mode

enables calibration to be always performed from the fixed initial conditions.

Use this mode when in doubt as to whether the analyzer has operated cor-

rectly in performing calibration modes.

25

2.6.6.1 Zero shift setting

1 Switch off the analyzer.

2 Press the CAL button and, keeping it pressed, switch on the analyzer. Af-

ter a sound signal release the CAL button. The screen will display с2.

3 Press the ENTER button. The donЕ capture will briefly appear on the

screen and the analyzer will go into the measurement mode. The display will indicate readings in mg/dm3 with zero shift.

2.6.6.2 Average steepness setting

1 Switch off the analyzer.

2 Press the CAL button and keeping it pressed, switch on the analyzer. Af-

ter a sound signal release the CAL button. The screen will display с2. Press the

CAL button again. The screen will display с3.

3 Press the ENTER button. The donЕ capture will briefly appear on the

screen and the analyzer will go into the measurement mode. The display will indicate readings in mg/dm3 corresponding to the average sensor steepness.

Once the analyzer initial parameters are set, proceed to para.2.3.4.

26

3 MAINTENANCE

Maintenance of the analyzer comprises:

analyzer calibration by outside air (para.2.3.4) to be carried out every 8

hours;

analyzer zero calibration (para.2.3.5) to be carried out every three

months;

sensor cycling (para.2.3.3.3) to be carried out when the analyzer has not

been in use for more than 24 hours. This operation ensures the highest response

rate of the instrument in DOC measurements.

When the conditions described in para.2.5 are fulfilled, the analyzer meets

the specifications listed in para.1.3.

4 DELIVERY SET

4.1 The delivery set is shown in Table 4.1.

Table 4.1

Description Quantity

1 MARK-302Т dissolved oxygen analyzer

(with sensor, cable length 2 m)

2 Flowing vat 1

3 Spare parts kit (to oxygen sensor) 1

4 Tool and accessory kit 1

5 Tool and accessory kit 1

6 Operation Manual 1

1

27

APPENDIX A

(reference)

Solubility of 100 % humidity air oxygen in distilled water, depending on the

temperature

Р

=101,325 кPa

atm

Table A.1 mg/dm

t, °С 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9

0 14,62 14,58 14,54 14,50 14,46 14,42 14,38 14,34 14,30 14,26

1 14,22 14,18 14,14 14,10 14,06 14,02 13,98 13,94 13,90 13,87

2 13,83 13,79 13,75 13,72 13,68 13,64 13,60 13,57 13,53 13,49

3 13,46 13,42 13,39 13,35 13,32 13,28 13,24 13,21 13,17 13,14

4 13,11 13,07 13,04 13,00 12,97 12,93 12,90 12,87 12,83 12,80

5 12,77 12,74 12,70 12,67 12,64 12,61 12,57 12,54 12,51 12,48

6 12,45 12,41 12,38 12,35 12,32 12,29 12,26 12,23 12,20 12,17

7 12,14 12,11 12,08 12,05 12,02 11,99 11,96 11,93 11,90 11,87

8 11,84 11,81 11,79 11,76 11,73 11,70 11,67 11,64 11,62 11,59

9 11,56 11,53 11,51 11,48 11,45 11,42 11,40 11,37 11,34 11,32

10 11,29 11,26 11,24 11,21 11,18 11,16 11,13 11,11 11,08 11,06

11 11,03 11,00 10,98 10,95 10,93 10,90 10,88 10,85 10,83 10,81

12 10,78 10,76 10,73 10,71 10,68 10,66 10,64 10,61 10,59 10,56

13 10,54 10,52 10,49 10,47 10,45 10,42 10,40 10,38 10,36 10,33

14 10,31 10,29 10,27 10,24 10,22 10,20 10,18 10,15 10,13 10,11

15 10,08 10,06 10,04 10,02 10,00

16 9,87

17 9,66

18 9,47

19 9,28

20 9,09

21 8,91

22 8,74

23 8,58

24 8,42

25 8,26

26 8,11

27 7,97

28 7,83

29 7,69

30 7,56

31 7,44

32 7,33

33 7,22

34 7,10

35 6,99

36 6,82

37 6,71

38 6,61

39 6,51

9,85

9,64

9,45

9,26

9,08

8,89

8,73

8,56

8,40

8,25

8,10

7,95

7,81

7,67

7,54

7,44

7,32

7,21

7,09

6,98

6,81

6,70

6,60

6,50

9,83

9,62

9,43

9,24

9,06

8,87

8,71

8,55

8,39

8,23

8,08

7,94

7,80

7,66

7,53

7,43

7,31

7,19

7,08

6,97

6,80

6,69

6,59

6,49

9,81

9,60

9,41

9,22

9,04

8,86

8,69

8,53

8,37

8,22

8,07

7,92

7,78

7,65

7,52

7,42

7,30

7,18

7,07

6,96

6,78

6,68

6,58

6,48

9,79

9,58

9,39

9,21

9,02

8,85

8,68

8,51

8,36

8,20

8,05

7,91

7,77

7,63

7,50

7,41

7,29

7,17

7,06

6,95

6,77

6,67

6,57

6,47

9,98

9,77

9,56

9,37

9,19

8,01

8,83

8,66

8,50

8,34

8,19

8,04

7,89

7,76

7,62

7,49

7,39

7,28

7,16

7,05

6,94

6,76

6,66

6,56

6,46

9,96

9,75

9,54

9,36

9,17

8,99

8,81

8,64

8,48

8,32

8,17

8,02

7,88

7,74

7,61

7,48

7,38

7,26

7,15

7,04

6,93

6,75

6,65

6,55

6,45

9,94

9,73

9,52

9,34

9,15

8,97

8,80

8,63

8,47

8,31

8,16

8,01

7,87

7,73

7,59

7,46

7,37

7,25

7,14

7,03

6,92

6,74

6,64

6,54

6,44

9,92

9,71

9,50

9,32

9,13

8,95

8,78

8,61

8,45

8,29

8,14

7,99

7,85

7,71

7,58

7,45

7,36

7,24

7,13

7,01

6,90

6,73

6,63

6,53

6,43

9,90

9,69

9,49

9,30

9,11

8,93

8,76

8,60

8,43

8,28

8,13

7,98

7,84

7,70

7,57

7,44

7,35

7,23

7,11

7,00

6,89

6,72

6,62

6,52

6,42

3

28

Table A.1 (Continue) mg/dm3

t, °С 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9

40 6,41

41 6,31

42 6,21

43 6,12

44 6,03

45 5,93

46 5,84

47 5,75

48 5,66

49 5,58

50 5,49

6,40

6,30

6,20

6,11

6,02

5,92

5,83

5,74

5,66

5,57

5,48

6,39

6,29

6,19

6,10

6,01

5,92

5,82

5,74

5,65

5,56

5,47

6,38

6,28

6,19

6,09

6,00

5,91

5,82

5,73

5,64

5,55

5,47

6,37

6,27

6,18

6,08

5,99

5,90

5,81

5,72

5,63

5,54

5,46

6,36

6,26

6,17

6,07

5,98

5,89

5,80

5,71

5,62

5,53

5,45

6,35

6,25

6,16

6,06

5,97

5,88

5,79

5,70

5,61

5,52

5,44

6,34

6,24

6,15

6,05

5,96

5,87

5,78

5,69

5,60

5,52

5,44

6,33

6,23

6,14

6,04

5,95

5,86

5,77

5,68

5,59

5,51

5,43

6,32

6,22

6,13

6,04

5,94

5,85

5,76

5,67

5,59

5,50

5,42

Loading...

Loading...