www.vympel.de

Hygrovision mini

Dew point analyzer

Operating Manual

Precision | Economy | Safety

2

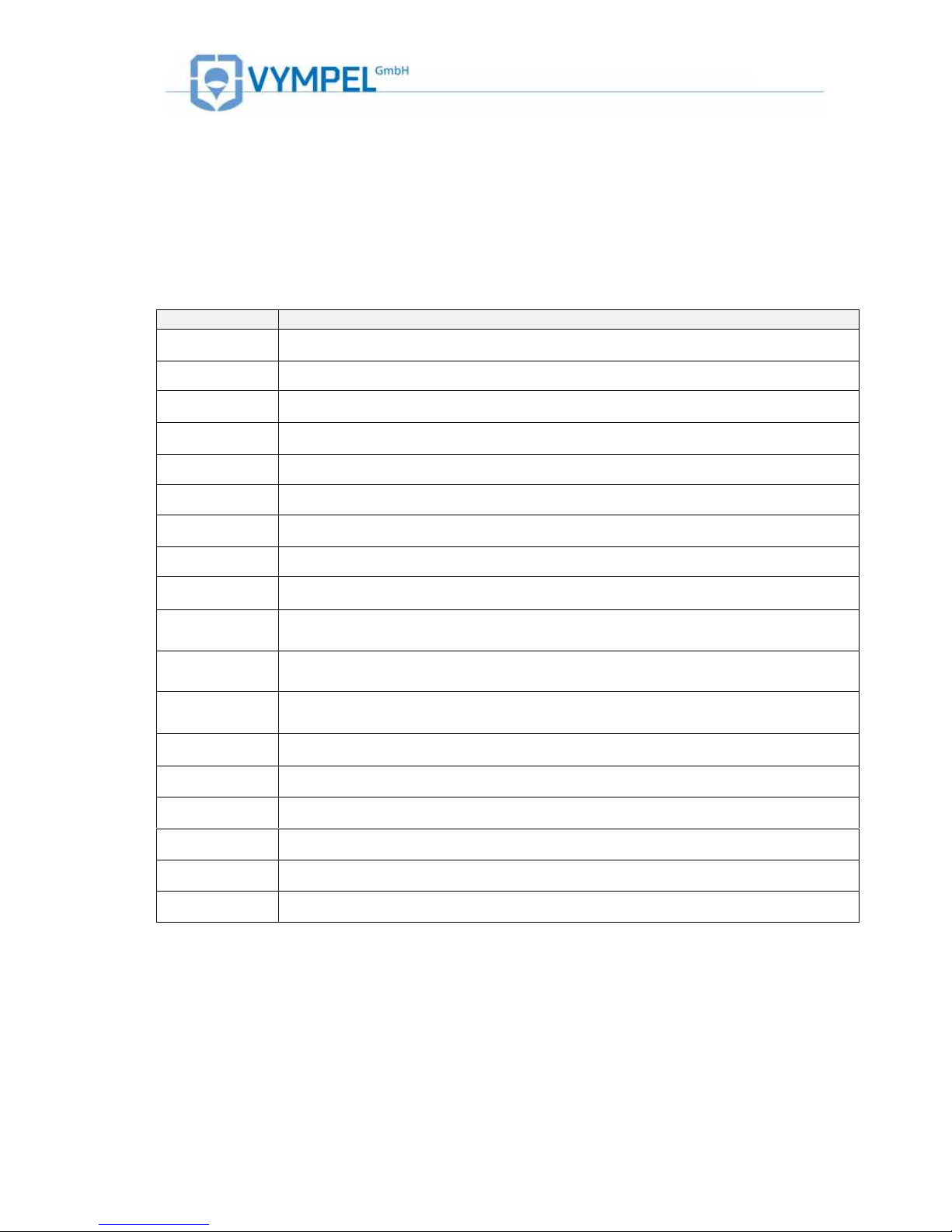

Contents

1! Analyzer description.............................................................. 4!

1.1! Purpose and applications.............................................................. 4!

1.2! Technical characteristics............................................................... 5!

1.3! Measurement principle.................................................................. 6!

1.4! Construction.................................................................................. 6!

1.4.1! The Hygrovision mini’s main components and controls ............................8!

1.4.2! Hygrovision mini power supply..................................................................9!

1.4.3! Control and display elements ..................................................................10!

1.4.4! Turning the Hygrovision mini on and off..................................................11!

1.5! Menu of the Hygrovision mini...................................................... 12!

1.5.1! Menu structure ........................................................................................12!

1.5.2! Main menu...............................................................................................13!

1.5.3! “Mirror cleaning” ......................................................................................13!

1.5.4! “Measuring the dew point: Тdp”................................................................14!

1.5.5! “Settings” .................................................................................................15!

1.5.6! Status of the battery charge ....................................................................16!

1.5.7! Program codes ........................................................................................17!

1.6! Accessories and additional equipment ....................................... 18!

1.6.1! Battery charger........................................................................................18!

1.6.2! Sample gas delivery system....................................................................18!

1.6.3! Through-flow control system ...................................................................19!

1.6.4! Particle filter.............................................................................................19!

1.6.5! Filter for the control of heavy hydrocarbons ............................................20!

1.6.6! Sample extraction set..............................................................................20!

1.6.7! Supplemental cooling system..................................................................20!

1.7! Hygrovision mini set.................................................................... 21!

1.8! Explosion safety provisions......................................................... 23!

1.9! Markings ..................................................................................... 24!

1.10! Packaging ................................................................................. 24!

2! Proper operation of the Hygrovision mini............................ 25!

2.1! General requirements ................................................................. 25!

2.1.1! Unpacking and visual inspection of the device........................................25!

2.1.2! General requirements for the sample extraction site ...............................25!

2.1.3! General safety measures ........................................................................25!

2.2! Connecting the analyzer ............................................................. 26!

2.3! Using the Hygrovision mini ......................................................... 27!

2.3.1! Preparing to take dew point measurements............................................27!

2.3.2! Visual identification of water condensation .............................................28!

2.3.3! Visual identification of hydrocarbon condensation .................................29!

2.3.4! Rough dew point measurement ..............................................................31!

2.3.5! Measuring water and hydrocarbon dew points.......................................33!

2.3.6! Supplemental cooling ..............................................................................37!

2.4! Deinstallation of the Hygrovision mini ........................................ 38!

3

3! Maintenance ........................................................................39!

3.1! Function tests ..............................................................................39!

3.1.1! Check the status of the battery charge ................................................... 39!

3.1.2! Check the condensation mirror............................................................... 40!

3.1.3! Check that the thermoelectric battery – TEB (Peltier element) is

functioning .......................................................................................................... 40!

3.1.4! Check the lighting systems ..................................................................... 40!

3.1.5! Perform a leak test.................................................................................. 41!

3.2! Maintenance procedures .............................................................41!

3.2.1! Servicing the power supply unit IP-01 .................................................... 41!

3.2.2! Cleaning the condensation mirror........................................................... 41!

3.2.3! Checking the efficiency of the thermoelectric battery (TEB).................. 43!

3.2.4! Replacement of the particle filter ............................................................ 44!

3.2.5! Calibrating the Hygrovision mini ............................................................. 44!

3.3! Troubleshooting malfunctions......................................................45!

3.4! Error message codes...................................................................46!

4! Markings ..............................................................................47!

5! Packaging............................................................................47!

6! Storage ................................................................................47!

7! Transportation .....................................................................48!

8! Recycling .............................................................................48!

Anlage А...................................................................................49!

Factory settings ...................................................................................49!

Appendix B ...............................................................................50!

Sample extraction system....................................................................50!

Appendix C...............................................................................51!

Membrane Filter (KRAY6.457.022) .....................................................51!

Function.............................................................................................................. 51!

Description ......................................................................................................... 51!

Membrane .......................................................................................................... 51!

Technical Data ................................................................................................... 52!

Recommended installation and usage ............................................................... 52!

Anlage D...................................................................................54!

Examples of the appearance of water and hydrocarbon

condensation .......................................................................................54!

Appendix E ...............................................................................57!

Appendix F ...............................................................................58!

4

1 Analyzer description

1.1 Purpose and applications

The Hygrovision mini is a compact analyzer designed to measure the dew points of water and hydrocarbons.

This portable hygrometer (hereafter also analyzer) is an instrument that is designed to

directly measure dew point temperatures by means of a temperature-controlled mirror.

Hygrovision mini areas of application:

⇒ Spot check measurements in the field

⇒ Check the operational performance of permanently installed Hygrometers

⇒ Confirm previous measurement results

⇒ Regularly measure water and hydrocarbon dew points directly in locations that are

not equipped with automatic through-flow hygrometers or where no such instruments

can be permanently installed.

⇒ Monitor various products as well as working and manufacturing processes (for exam-

ple, drying and vacuuming of facilities, systems, damp presses, steamers, regenerators, evacuators, etc.)

Hygrovision analyzers can be used in a variety of sectors including the gas, oil and chemical

industries, metallurgy, power generation, instrument engineering and many other fields, in

order to provide quality control of production processes where water and hydrocarbon dew

point values are of relevance.

The analyzer is certified “explosion-proof” as defined by EN 60079-0:2009 and it has a

“flameproof enclosure” in accordance with EN 60079-1:2007. The Hygrovision mini has

an “intrinsically safe power circuit” as per EN 60079-11:2007 and is labelled II 2G

Exd [ib] IIB+H2 Т5. The analyzer can be deployed in designated explosion risk areas of

indoor and outdoor installations in accordance with EN 60079-14:2008 and in other explosive areas where the use of electrical equipment is controlled by regulation.

5

1.2 Technical characteristics

Table 1

Water

≥ -50 °C (T

housing

)

Measurement range:

Hydrocarbons

≥ -50 °C (T

housing

)

Water

±1 °C

Absolute error

Hydrocarbons

±1 °C

Recommended volume of

sample gas stream

0.3 – 0.5 N L/min

9 – 12.6 V

Power supply: voltage

current / power requirement

4 Ah / 15 W

Battery charge life

Min. 12 h

Operating temperature range

-10 °C – +50 °С

Ambient humidity

Max. 98% at < + 35°C

Operating pressure

< 100 bar

Sample gas temperature

-20 °C – +50 °C

Enclosure protection per

IEC 60529

IP 54

Dimensions (without Microscope)

253x120x110 mm

Weight (without replacement

parts and accessories)

4 kg

Suitable installation

In closed rooms or in open areas

(explosion hazard zones)

Connection to the sample

gas delivery piping

Swagelok connector for pipes (tubes) with

an outer diameter of 6 mm

Service life:

- Analyzer*

10 years

- Battery

300 charging cycles

max. of two years

* - with regular maintenance and replacement of parts subject to wear

6

1.3 Measurement principle

The Hygrovision mini analyzer registers the dew point of water or hydrocarbons in a

gaseous mixture according to the principle of direct measurement, utilizing a mirror that

can be heated and cooled.

The measurement process involves monitoring the surface of the mirror and noting the temperature at the moment condensation forms on its surface.

In addition, the observation process is enhanced by the availability of two different lighting systems for illuminating the dielectric condensation mirror.

During the measurement cycle the reflectivity of the mirror is monitored. When the dew

point is reached reflectivity decreases as a condensation film forms. The temperature

(T) at which this happens is the dew point.

The analyzer is equipped with an achromatic 40-power microscope for observing the

surface condition of the mirror. In addition, there are two options for illuminating the

mirror: vertical and side lighting.

• Vertical lighting can be used for the visual registration of the water and hydrocarbon dew points.

• Side lighting is used specifically for the visual registration (confirmation) of the

dew point of water only.

The low angle of this illumination increases the optical intensity created by the scattering of light rays striking water condensation. This effect makes it possible to register

condensation earlier and with absolute clarity.

The mini is outfitted with a button pad that serves as the control interface. For example, it is

used to manually switch between lighting systems during the measurement process and to

regulate the mirror temperature. The temperature at which a clear condensation film forms

on the mirror’s surface is also fixed using this button keypad.

1.4 Construction

The Hygrovision mini analyzer has an explosion-proof design. For more information

about explosion proofing see point 1.8.

The analyzer consists of a cold body housing, a high-pressure gas delivery system,

and an optical system.

The optical system includes a microscope and two lighting elements: one mounted

perpendicular to the mirror and one at a low angle.

The housing body of the analyzer includes an electronics unit and a measurement

cell. In order to support autarkic operations, the body of the mini includes a battery

compartment designed for the mini’s rechargeable battery.

The measurement cell, the gas delivery system, and the microscope, combined form

the measurement chamber. The measurement chamber is designed to accommodate

a working pressure of 100 bar.

7

The measurement cell includes the temperature-controlled condensation mirror, which

has an integrated thermal sensor, a thermoelectric battery, and a light emitting diode

for providing the side illumination.

The gas delivery system guides the sample gas over the temperature-controlled mirror in the measurement cell. This system includes a small observation window for

monitoring the condensation process and a particle filter to protect against contamination.

The microscope is mounted directly onto the gas delivery system. The vertical lighting

system is integrated into the microscope.

The electronics unit is made up of the liquid crystal display, the replaceable power

source (battery), and a four-button control unit (button pad). Via the four-button control

pad, the electronics unit makes it possible for the Hygrovision mini user to control how

rapidly the condensation mirror is cooled and heated. The button pad is also used to

turn the analyzer on and off, select the illumination system, and enter other operating

commands.

Data from the last measurement as well as system information are shown on the Liq-

uid Crystal Display (LCD).

A charging unit is delivered with the analyzer for recharging the battery .

8

1.4.1 The Hygrovision mini’s main components and

controls

Illustration 1

1) Locking lid of the battery compartment

2) Sample gas inlet nozzle

3) Padded eyepiece

4) Mirror illumination cable

5) Sample gas outlet nozzle

6) Ventilation channel for supplemental housing cooling

7) Locking mechanism for the electronics unit cover

8) LCD screen

9) Extendable handle

Illustration 2

10) Control unit

9

11) Housing body

12) Ventilation channel for supplemental mirror cooling

13) Focus control ring

14) Battery compartment lid locking mechanism

1.4.2 Hygrovision mini power supply

The analyzer is equipped with an independent source of electricity:

power supply unit IP-01 (battery).

Attention!

The battery should only be charged using the

specially designed charging unit.

1.4.2.1.1 Important technical data:

Table 2

! Battery type

⇒ LIR18650 (Lithium-Ion Li-Ion);

! Number of cells

⇒ 6

! Nominal voltage

⇒ 11.1 V

! Discharge current

⇒ max. 3A

! Electrical capacity

⇒ 14,400As

! Standard

service life

⇒ min. of 300 charge/recharge cycles; max. 2 years

! Operating

conditions

⇒ -20°C to + 60°C

A charging unit is incuded with the delivery of the Hygrovision for charging the IP-01

battery.

10

1.4.3 Control and display elements

Illustration 3

Refer to the table below for the function(s) of individual buttons

Table 3

The four-button control unit is used to operate and adjust the analyzer. The button pad

is located to the right of the LCD screen (pos. 1 to 4, illus. 3)

The buttons serve different functions depending on the control mode selected.

These functions are listed in table 2.

Pos.

Description

Color

Function

1

“Menu”

Red

Analyzer on/off;

Return to main menu without saving or applying

changes;

Quick access to the main menu

2

“Select”

Yellow

Open the main menu;

Return to the main menu (save / apply changes);

Switch illumination mode

3

“Up”

Black

Scroll through menu sub-points;

Increase the value of the selected parameter;

Raise the mirror temperature;

Mark the evaporation temperature

4

“Down”

Black

Reduce the value of the selected parameter;

Lower the mirror temperature;

Access cooling parameter adjustment mode;

Mark the condensation temperature

11

Information about the current measurement as well as information about the system is

displayed on the LCD screen (pos. 5, illus.3).

1.4.4 Turning the Hygrovision mini on and off

Hold down the menu button (red) for a few seconds to turn the analyzer on

(pos. 1, illus. 3).

After the device has been turned on, the software version is displayed on the LCD

screen for 2–3 seconds.

When this message disappears the analyzer is in the dew point measurement mode

and ready for operation.

To turn the analyzer off, hold down the menu (red) button until the LCD screen goes

off.

12

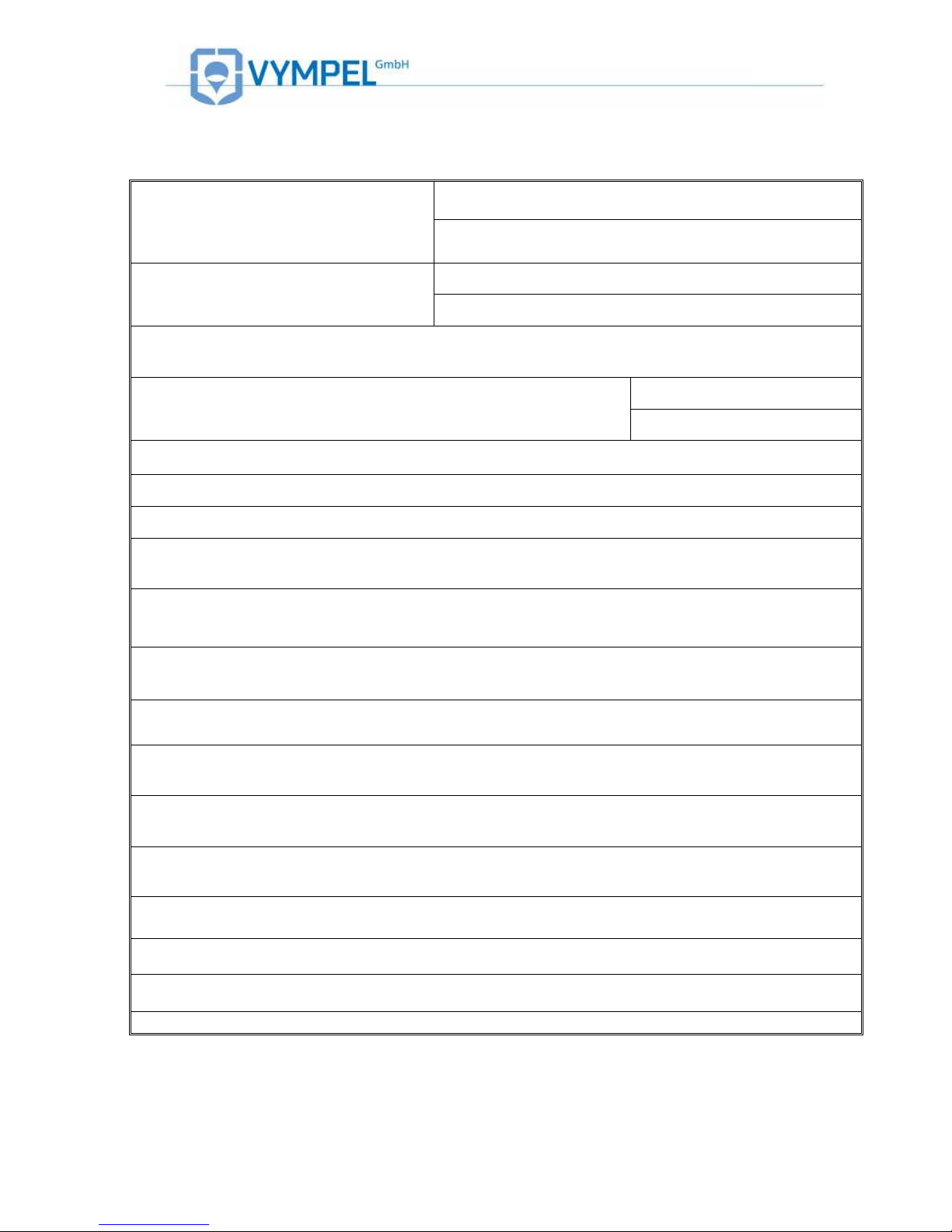

1.5 Menu of the Hygrovision mini

1.5.1 Menu structure

13

1.5.2 Main menu

Illustration 4

Briefly push the menu button to select the main menu.

The main menu consists of the analyzers main functions, which are organized

thematically under these four menu points:

• Mirror cleaning

• Dew point temperature measurement (Тdp)

• Settings

• Battery

1.5.3 “Mirror cleaning”

Illustration 5

In the “Mirror cleaning” mode, the analyzer automatically heats the surface of the condensation mirror to a predetermined temperature. This temperature will be maintained until the

cleaning program is completed. The factory preset mirror-cleaning temperature is +55 °С.

In cleaning mode, the Hygrovision mini displays the following information (illus. 5):

• Program code (M10);

• Pre-programmed mirror temperature (54.9 °C — large number in the display);

• Current housing temperature (Tb= 24.4 °C);

• Current battery charge (100%)

After the cleaning program is complete, visually inspect the condition of the mirror through

the microscope. If contaminants that could interfere with dew point measurement remain, follow the instructions for manually cleaning the mirror as described under point 5.2.

14

To leave the cleaning mode, press the menu button.

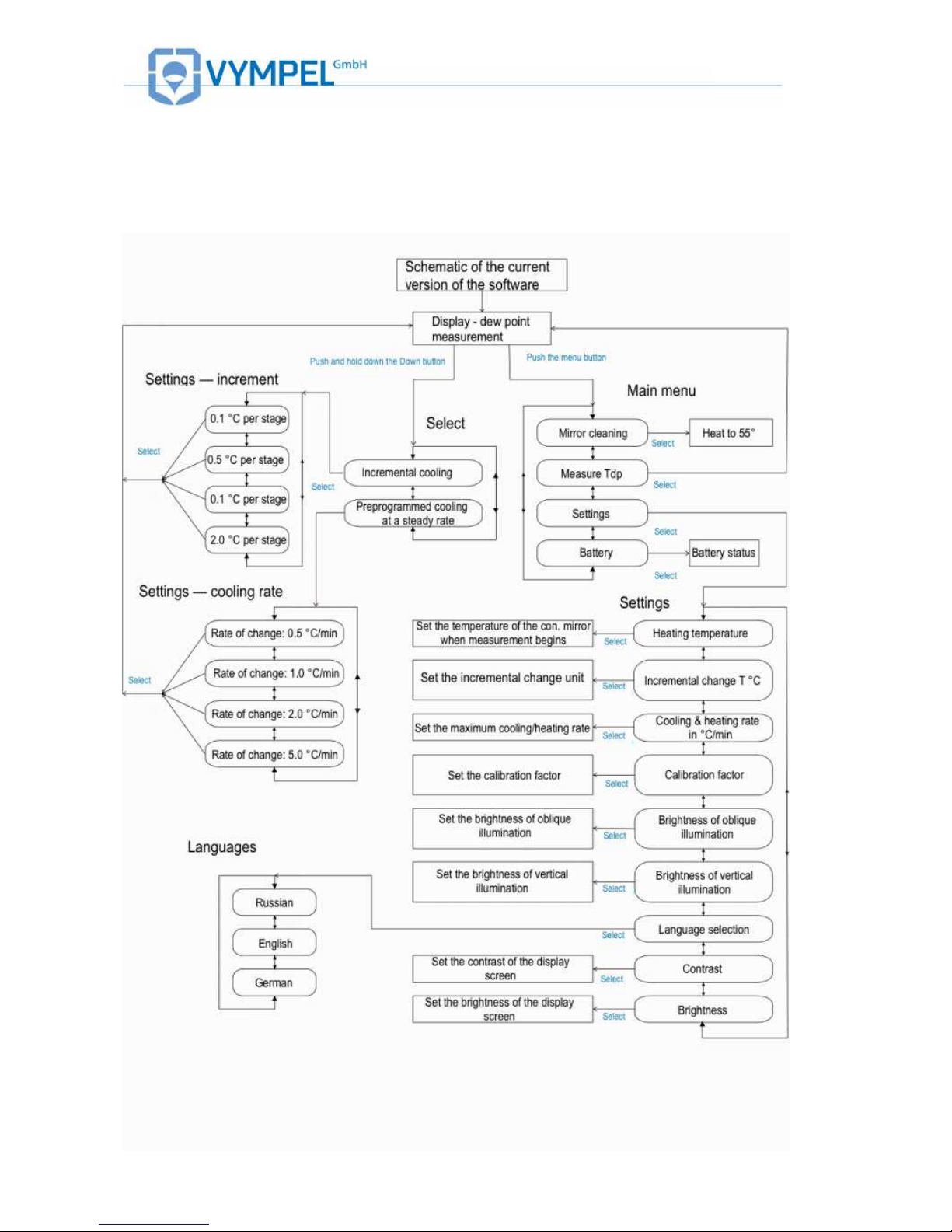

1.5.4 “Measuring the dew point: Тdp”

Illustration 6

Make sure the analyzer is turned on and select the “Dew point measurement” mode.

Use the “up” and “down” buttons to scroll through the menu points and push the “select” (yellow) button to choose the measurement mode.

When in the dew point measurement mode the analyzer will display the following information (illus. 6):

• Program code (М20);

• Current mirror temp. (24.2 °С — large number in the display);

• Pre-programmed mirror temperature: Т (24.2°С);

• Temperature of the housing Тb (24.2°С);

• Battery charge (100%)

In the dew point measurement mode, the mirror’s temperature is determined by the

temperature of the housing (Tb) and the parameter value stipulated under M31, which

specifies the “heating temperature” (see point 1.8.4).

During the dew point measurement process, the analyzer is controlled using the

select, up, and down buttons.

For specific information regarding the measurement of water and hydrocarbon dew

points, refer to points 4.2 to 4.5.

15

1.5.5 “Settings”

Illustration 7

The main operating parameters for the analyzers can be adjusted under the

“Settings” menu (Illustration 7). These parameters are:

• Heating temperature

• Temperature change interval for mirror cooling during the measurement cycle in

°С

• Rate of heating and cooling °C/min

• Calibration factor

• Brightness of side lighting

• Brightness of vertical lighting

• Language

• Contrast

• Display brightness

• Calibration coefficient

Use the Select (yellow) button to choose the corresponding sup-menu point.

Use the Up and Down buttons to make changes to the selected parameter.

Confirm the newly set value(s) by pushing the Select button again.

For the factory default parameter settings see Appendix C.

16

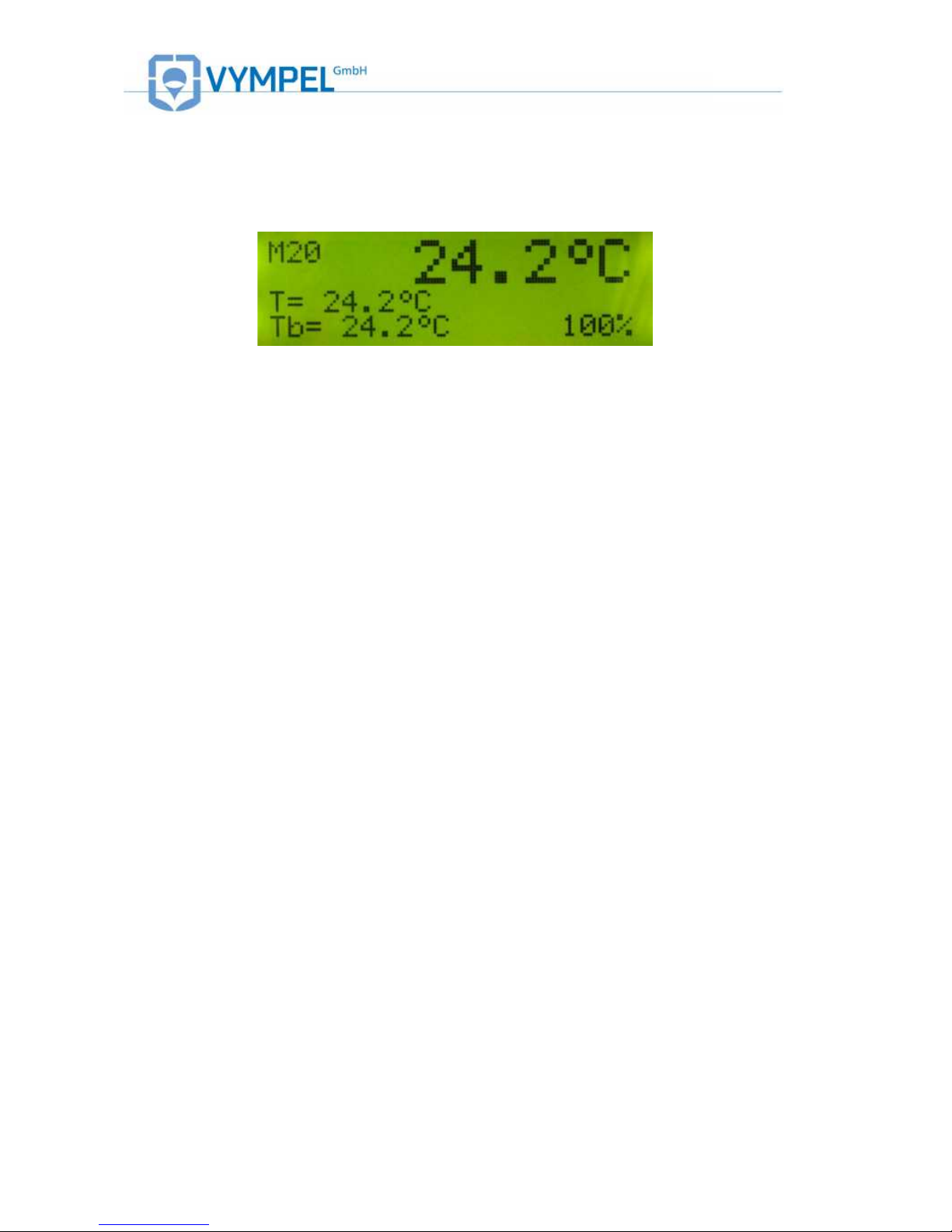

1.5.6 Status of the battery charge

Illustration 8

Under this menu, specific parameters regarding the status of the battery (IP 01) can be

viewed on the analyzer’s display (Illustration 8)

Table lists the most important parameters and the respective minimum and maximum

value tolerances.

Table 4

Parameter

Code

Value range

Voltage

Ua

9.0 – 12.6 V

Operating current

Ia

0.01 – 2.5 A

Charge status

Qa

5 – 100 %

Temperature

Ta

-20°C – + 60°C

If a battery parameter value is outside of the tolerance range listed in Table , the appropriate error message will be displayed. (See point 3.4 / Table 8).

Attention – In the first 5 seconds after this mode has been selected, the maximum op-

erating current detected during analyzer operation is determined and the voltage corresponding to this maximum power demand is displayed.

17

1.5.7 Program codes

Each of the analyzer’s program points has its own code, which is shown in the upper

left hand corner of the display.

Table 5 shows a list of these program codes.

Table 5

Code

Program point

М10

Mirror cleaning

М20

Measurement

М21

Measurement with incremental temperature change

М21М

Cooling parameters adjustment

М22

Measurement with cooling and heating rate

М23

Measurement with cooling and heating rate (when heating the mirror)

М30

Settings

М31

Heating temperature

М32

Change interval setting

М33

Maximum cooling rate setting

М34–A

Calibration factor setting A

М35

Contrast setting (side lighting)

М36

Contrast setting (vertical lighting)

М37

Language selection

М38

Display contrast setting

М39

Display illumination setting

М40

Battery

M34–B

Calibration factor setting B

18

1.6 Accessories and additional equipment

A number of accessories and additional equipment are included with delivery of the

Hygrovision mini.

A list of these items is provided under point 2.6 / Table 5.

1.6.1 Battery charger

Illustration 9

In order to charge the analyzer’s battery (IP 01), a specially designed battery charger is

included with delivery. Instructions for using and handling this charger are listed on the

sticker (KRAY5.122.009EТ) that accompanies it.

1.6.2 Sample gas delivery system

Illustration 10

The sample gas delivery system included with the delivery of the Hygrovison mini consists of: a high-pressure valve (Illustration 10, Pos.2), 2.5 meters of high-pressure

hose (Illustration 10, Pos.1), and a quick-connect coupler (Illustration 10, Pos.3).

This system provides the user with a method for steadily supplying the analyzer’s

measurement chamber with sample gas.

19

1.6.3 Through-flow control system

Illustration 11

The through-flow control system consists of a fine control valve (Illustration 11,

Pos.2), manometer (Pos.3), rotameter with protective housing (Pos.5), and a quickconnect coupler (Pos.4). This system makes it possible to control and regulate the flow

of sample gas into the measurement chamber.

The system includes a 2.5-meter PVC hose to be attached to the rotameter’s outlet

nozzle for the safe release of the sample gas.

1.6.4 Particle filter

Illustration 12

Solid particulate matter with a crass-section of 15µm and larger as well as other mechanical contaminants are removed from the sample gas by means of a particle filter.

The filter cartridge (Pos.1) is inserted into the gas inlet nozzle of the gas delivery unit of

the analyzer’s housing (Pos.2).

The particle filter pre-installed when the analyzer is delivered.

Replacement filter cartridges are included with delivery as additional equipment.

For detailed instructions on replacing the particle filter refer to point 6.2.4.

The analyzer can also be operated without a particle filter.

20

1.6.5 Filter for the control of heavy hydrocarbons

Illustration 13

The filter for the control of heavy hydrocarbons is included with delivery of the analyzer.

It is intended for insertion as an additional control while measuring the dew point of water, when the sample gas contains a large quantity of glycols and heavy hydrocarbons.

The filter has a maximum operational life of 30 minutes at a flow rate of 2Nl/min.

1.6.6 Sample extraction set

In order to install a fixed sampling point, a gas sampling set can be ordered separately.

This set consists of a sample extraction module (see Appendix B) a by-pass valve, and

a membrane filter for removing liquids and particulates from the gas sample (see Appendix C.

1.6.7 Supplemental cooling system

Illustration 14

If very low dew point values (below -30 °C) are to be measured in situations where the

external temperature is high (over +35 °C) and the pressure conditions are over 70 bar,

it is recommended that supplemental cooling be used.

The supplemental cooling system is not included with delivery of the analyzer and must

be order separately. This system consists of two nozzles, and a valve for regulating the

coolant flow (see point 2.3.6).

Note: It is also possible to cool the housing of the analyzer using various liquids, such

as water or alcohol solutions.

21

1.7 Hygrovision mini set

Illustration 15

Table 6

Designation

Description

Pos.

No.

Notes

Included in Delivery

VMPL2.844.001

The «Hygrovision mini» dew point analyzer set

includes the following equipment and accessories:

1 1

KRAY3.821.003

Microscope

2 1

VMPL4.841.001

Microscope cable

3

VMPL4.161.001

Transportation case

4 1

VMPL5.122. 001

Battery charger

5 1

VMPL5.549.001

Rechargeable battery

6 1

VYMP5.183.001

Through-flow meter

7 1

VMPL6.450.001

High-pressure hose for sample gas supply (2.5 meters)

8 1

VMPL6.451.017

Filter for the of removal heavy hydrocarbons

9

KRAY4.160.001

Replacement cartridge set for the VYMP6.451.014

filter (10 replacement cartridges incl. adsorbent

medium)

10

VMPL8.392.001

Special key

11 1

PVC hose w/ inner diameter D6x1.5; Length: 2.48m

12 1

Optics cleaning solution (Eclipse 59 ml)

13 1

Cotton swabs for cleaning the sensor (50 pcs.)

14 1

Adapter (12V)

15 1

22

AC adapter (220V)

16

FE73A-15

Particle filter replacement cartridge (gas delivery system

insert)

17

DGV-2-S

Seal

18

VMPL.248.005

Sealing ring

19

Mounting connector set

DMC6M-20M15SA

Connector with external threads Dk-Lok

DMC6M-8R-SA

Connector with external threads Dk-Lok

DMC6M-8G-SA

Connector with external threads Dk-Lok

DFSA-D-6M-SA

Quick-connect coupler Dk-Lok

Operating documentation

VMPL2.844.001M

P

Testing documentation

VYMP2.844.001R

E

Operating manual

– 1

VYMP2.844.001F

O

Information form

VYMP5.122.001ET

Battery charger instruction manual

VYMP6.451.014ET

Filter instruction manual (VYMP6.451.014 filter)

Additional equipment (available by special order)*

VYMP5.549.001

Replacement battery IP-01

TH-650 DV

Stand (tripod)

VMPL5.880.006

Supplemental cooling set

FE73-15

Replacement particle filter

Accessories for installing a sample extraction point on the Pipeline

KPAY4.078.091

Gas sampling set (consists of a sampling

device (KRAY6.457.013) and a membrane

filter (KRAY6.457.022))

KPAY4.078.091-01

Gas sampling set (consists of a bypass

valve (KRAY6.451.013) and a membrane

filter (KRAY6.457.022-01))

130-502

Replacement membrane set for the

KRAY6.457.022 (-01) membrane filter

* The number of units varies depending on the order

Note: Depending on technical developments, instruments may have slight variations in

construction and delivery packaging, however these variations have no effect on the

fundamental safety and functionality of the analyzer.

23

1.8 Explosion safety provisions

The following features ensure that the Hygrovision mini is protected against explosion.

Spark arresting insulation barriers ensure the intrinsic safety of the electrical circuitry and

connections at the control buttons.

Bypass diodes and resistors ensure the intrinsic safety of the electrical circuit connected to

the control unit. These elements reduce the electrical current and voltage to the values

allowed by GOST R 52350.11 for electrical devices in Group II B. This reduction applies for

both normal and emergency operation modes. Electrical sparking is prevented through a

combination of resistors and a fuse module.

The sum of the electrical capacity and the inductivity of the electrical circuit that connects

the Hygrovision mini to external components via their individual intrinsically safe plugs

conform to the values required by GOST R 52350.11.

The electrical load does not exceed two thirds of the nominal capacity of components

ensuring intrinsic safety.

The construction and electrical properties of the LED conform to the specifications stated in

GOST R 52350.0 and GOST R 52350.1.

The maximal temperatures generated through internal heating, to which the electrical

components and the housing of the Hygrovision mini are exposed do not exceed those

allowed in GOST R 52350.0 for temperature class T5.

The connection points of the flameproof enclosure of the HV mini’s electronics unit conform

to the requirements of GOST R 523 50.1 for electrical apparatus of subgroup II B.

Lock nuts and adhesives are used to protect against the loosening of the screws, bolts, and

nuts that secure the various elements of the flameproof enclosure as well as the conductor

and grounding terminals. Similarly, locking devices are used to secure self-threading

connectors. The heads of external fixing screws are recessed and can only be accessed

using a special tool.

Cable entry points ensure that conductors have a stable and durable connection. Fasteners

comply with the requirements of the GOST R 52350.1 – 2005 directive.

The mechanical strength of the flameproof enclosure meets the requirements of GOST R

52350.0-2005 for electrical devices of Group II that are exposed to a strong risk for

mechanically inflicted damage. The surface area of the LCD display is limited to prevent

the buildup of static electricity.

Integration of electrical ports into the flameproof enclosure complies with the requirements

of GOST R 52350.0 und GOST R 52350.1.

The construction of the HV mini conforms to the general requirements of GOST R 52350.02005 for electrical equipment intended for operation in explosion-hazard areas. The seals

and connectors used for structural elements provide an IP 66 level of protection in

accordance with GOST 14254.

24

All applicable explosion protection information is displayed on the housing of the

Hygrovision mini as required by regulation.

1.9 Markings

Markings on the analyzer’s housing provide the following information:

! Trademark and name of the manufacturer

! Name of the device

! Explosion protection labeling

! Certifying Authority and Certificate Number

! Label regarding protection against the effects of solids and water according to

IEC 60529:1992 (IP54)

! Dew point measurement range

! Operating pressure limit

! Operating temperature of the device

! Serial number

! Country of manufacture

1.10 Packaging

The analyzer’s components must be appropriately protected prior to being

packaged for transportation or storage.

The device is to be packaged in a closed ventilated room with an ambient temperature of +15 °C to +40 °C and a relative humidity no higher than 80%.

The ambient air must not contain any aggressive components.

Proper packaging protects the device against the effects of climatic and mechanical stresses during loading and unloading, transportation, and storage.

The operating documentation is located under the lid of the transport case. The

packing list and accompanying certification is contained in watertight packaging

and is also located in the compartment in the lid of the case.

Illustration 16

25

2 Proper operation of the

Hygrovision mini

2.1 General requirements

2.1.1 Unpacking and visual inspection of the device

Upon delivery, please make sure that the packaging is in good condition. If it is damaged,

document this in writing and contact customer service at Vympel GmbH.

Unpack the analyzer carefully. Check that the delivery includes all of the components listed

on the accompanying inventory sheet.

Also check to make sure that neither the analyzer no any of its components has been

damaged during transportation.

Attention!

Upon receipt of a new analyzer, fully charge the battery (IP 01) of the Hygro-

vision mini before switching it on for the first time.

2.1.2 General requirements for the sample extraction site

Please observe the following criteria when selecting a site where the analyzer will be

connected to the pipeline:

! the location should offer convenient access for the mounting, installation and operation of

the analyzer

! gas samples should be collected at locations that are specially designed for this purpose

! the ambient temperature and the relative humidity should lie within the tolerance range as

listed under point 126.

2.1.3 General safety measures

In terms of protection against electrical shock, the Hygrovision mini is a Class 0I

(GOST norms 12.2.007.0 SSB) electrical device

The Hygrovision mini may not be used to take dew point measurements of aggressive

media or in an aggressive environment.

When in use, the battery charger must be connected to an electrical outlet that is

grounded (GOST norms 12.1.030 SSB).

Resistance in the ground circuit must not exceed 4 Ohms.

26

The valve of the gas sampling system must be closed and the pressure within the

sampling system must be adjusted to match ambient atmospheric pressure using the

needle valve before the analyzer is connected to or disconnected from the sample delivery pipe.

2.2 Connecting the analyzer

Place the analyzer on a level surface or affix it to a stand near the sampling point.

Ensure that the analyzer is positioned in such a way as to have adequate support.

Attach the through-flow meter (pos. 4, illus. 17) to the outflow nozzle of the measurement

chamber (pos. 5, illus 17). Ensure that the through-flow meter’s needle valve (pos.3) is closed.

Connect the PVC hose to the outlet nozzle of the rotameter (pos.1). The hose ensures

proper venting of the sample gas.

Connect the gas delivery system to the inlet nozzle of the analyzer’s measurement chamber

by means of the quick-connect coupling (pos.6). Ensure that the high-pressure valve of the

manometer is closed (pos.2).

Connections at the input and output nozzles of the analyzer are made via quick-connect

couplers that provide both a reduction in the (de)installation time and absolutely tight seals.

Please note: Gas mixtures that contain early-condensing hydrocarbons can make the visual

observation of water condensation difficult. In this situation, the filter for regulating heavy hydrocarbons (included in delivery) should be installed. The filter is installed between the highpressure hose and the gas delivery system.

Illustration 17

1- PVC hose

2- Manometer

3- Needle valve

4- Through-flow control system

5- Rotameter

6- Gas delivery system

7- Supplementary cooling system

27

2.3 Using the Hygrovision mini

2.3.1 Preparing to take dew point measurements

Switch on the Hygrovision mini portable dew point analyzer as described in the handbook above.

Slowly open the gas delivery system valve while watching the associated manometer,

in order to monitor the increase in pressure in the measurement chamber. When the

appropriate pressure is reached, open the needle valve to set the sample gas volume

flow rate of 0.5 Nl/min as indicated by the rotameter.

After the measurement chamber has been ventilated in this way for 10 minutes, reduce

the volume flow to 0.2 – 0.3 Nl/min to begin taking dew point measurements.

After the desired measuring pressure has been reached, ensure that the microscope is

optimally adjusted for observing the surface of the condensation mirror.

Use the focus ring for making fine adjustments to the sharpness of the image.

When working out of doors, the intensity of the mirror surface illumination may need to

be adjusted depending on environmental conditions and personal preferences.

After adjusting the illumination intensity and image sharpness, select the “Dew point

measurement” mode.

Attention!

When measuring the dew point of flammable gases, the

measurement chamber and the sampling connection hose must

be ventilated for 10 – 20 minutes before connecting the analyzer

to the power supply.

When doing maintenance and servicing work on the Hygrovision

mini, the analyzer should always be disconnected from the electrical

supply.

Upon completion of maintenance and servicing work, the

measurement chamber and the gas sampling connection

should be ventilated for 10 – 20 minutes before putting

the analyzer back into operation.

28

2.3.2 Visual identification of water condensation

Illustration 18 Illustration 19

When using the Hygrovision mini, the operator can observe the condensation of water

vapor utilizing either side lighting or vertical lighting.

Under side lighting, the dark surface of the mirror appears to become evenly covered

with red spots as condensation forms (illustration 18).

Under vertical lighting, the light surface of the mirror appears to become evenly

covered with dark spots as condensation forms (illustration 19)

Illustration 20 Illustration 21

In the temperature range between 0 °C and -10 °C, it may occasionally happen

that condensed water vapor on the mirror surface itself, is in a super-cooled

state for a certain period of time.

In the temperature range from -10°C to -50°C, when condensation occurs it can

form on the mirror’s surface in both a liquid and crystalline state simultaneously

(illustrations 20 and 21). In this situation the dew point is also the freezing point.

29

Illustration 22

Illustration 23

Under side lighting, the ice crystals that form appear as clear luminous red patches

when viewed through the microscope (illustration 22).

Under vertical lighting, the ice crystals that form appear as branching dark patches on

a light background when viewed through the microscope (illustration 23).

2.3.3 Visual identification of hydrocarbon

condensation

The condensation of hydrocarbons (HCs) can only be observed under vertical lighting.

In contrast to the observation of the condensation of water vapor, the condensation of

hydrocarbons cannot be observed under side lighting. When illuminated from the side

the surface of the mirror simply remains dark during hydrocar

bon condensation in

the "HC Dew Point” mode (illustration 25).

Illustration 24

Hydrocarbons that condense onto the mirror’s surface appear as a film of rainbow-colored gradients (illustration 20), These hydrocarbons range up to include

heptanes.

As the mirror continues to cool, this rainbow-colored film becomes colorless and

spreads out to cover the entire surface of the mirror.

30

Illustration 25

Illustration 26

Octane and higher hydrocarbons condense on the surface of the mirror in the form of

small, dilute dark spots. As the mirror continues to cool, these small spots slowly form

into droplets (illustration 26).

As the cooling process continues, the small condensation droplets slowly collect to

more completely cover the mirror’s surface, until it becomes noticeably darkened. Finally, larger colorless drops form on a rainbow-colored background (illustration 24).

31

2.3.4 Rough dew point measurement

Rough dew point measurements serve to establish the temperature range within which

the dew point is to be found. Rough dew point measurements are made exclusively using the incremental cooling process (manual mode).

To change the cooling parameter settings select the menu point “Cooling parameters”

" “Change interval”. Each time the “Dew point measurement” mode is started, the

value set for the change interval under the “Cooling parameters” menu will be used for

the measurement process.

The factory default setting for the change interval in the rough dew point measurement

program is 5 °C. This value can be changed as desired.

The size of the cooling interval is key to the accuracy of the rough measurement being

taken.

The size of the absolute error is directly influenced by the choices made in setting the

change interval parameters. For a change interval of 5 °C, the absolute error for the

measurement being taken is ± 2.5 °C.

Please carry out the preliminary dew point measurements according the process outlined in illustration 23.

32

Illustration 27

33

When the device is first switched on, all temperatures shown on the display (mirror

condensation temperature; housing temperature and target temperature) may vary by

up to ± 0.2 °C. The value for the condensation mirror temperature is determined by the

sum of the housing temperature value and the heating/cooling temperature value.

Illustration 28

By using the “down” button, the target temperature can be adjusted to a colder value.

The current temperature of the condensation mirror should reach this value within a

few seconds.

After the Down button is pushed once, a timer appears in the display showing the time

that is passing as the mirror changes to the temperature that has been entered. Each

time the Up or Down button is pushed the timer restarts.

2.3.5 Measuring water and hydrocarbon

dew points

After taking a rough dew point measurement, hold down the Up button for several seconds to select the normal dew point measurement mode.

A menu will appear on the display that offers the choice of either incremental cooling

(illustration 29) or automatic cooling (illustration 30) modes.

Illustration 29 Illustration 30

Please note: incremental cooling set to a temperature interval of 2 °C or automatic

cooling (at a rate of 1 °C per minute) will guarantee a water or hydrocarbon dew point

measurement with an accuracy ±1 °C.

A diagram of the dew point measurement process carried out in the incremental cooling mode is shown in illustration 32.

A diagram of the dew point measurement process carried out in the automatic cooling

34

mode is shown in illustration 31.

When taking water dew point measurements in automatic cooling mode, push the

Down button to fix the temperature at which condensation occurs, and to fix the temperature at which evaporation occurs push the Up button.

The dew point value will be calculated as the mean of these two temperatures (the

condensation and evaporation points) in automatic cooling mode and shown on the

analyzer’s display.

When measuring the dew point of hydrocarbons in automatic cooling mode fix the

condensation temperature as described above. However, unlike when measuring the

dew point for water, no evaporation temperature is registered for hydrocarbons. Instead

to establish the dew point of hydrocarbons push the Up button twice after fixing the

condensation temperature.

In incremental cooling mode the condensation and evaporation temperatures are not

automatically saved.

In order to calculate the dew point temperature of water and/or hydrocarbons in this

mode, use the following formula:

DP

Water

= (Т

C (W)

+ ТV)/2

DP

Hydrocarbons

= Т

C (HC)

Т

C

=

Fixed temperature value of the condensation of

water vapor (W) or hydrocarbon vapor (HC)

Т

V

=

Fixed temperature value of the evaporation of

the water condensate

DP

Hydrocarbons

=

Hydrocarbon dew point temperature

DP

Water

=

Water dew point temperature

Recommendations for determining the duration of the temperature stages in incremental cooling mode can be found under point 4.3.1 (Rough dew point measurements).

In the event that traces of condensate remain on the mirror’s surface after the dew

point measurement procedure has been completed, select the Mirror cleaning mode.

35

Illustration 31

36

Illustration 32

37

2.3.6 Supplemental cooling

Illustration 24

The graph in illustration 29 shows the effectiveness of the supplemental cooling system. The analyzer’s integrated cooling system is directly influenced by the housing

temperature, which in turn is directly influenced by the ambient temperature. In addition, the process of cooling the condensation mirror raises the temperature of the analyzer’s housing by 5 to 7 °C. In some situations, in order to take measurements at very

low temperatures (≤ -50°C) it may be necessary to lower the temperature of the housing by means of supplemental cooling.

A variety of media can be used to cool the housing (water; propane; natural gas, etc.)

The housing has built-in cooling channels that provide for the easy and reliable circulation of liquid and gas as cooling media. The inlet and outlet ports are designed to accept pipe connectors with G1/8 external threads.

The cooling system can withstand pressures of up to 100 bar.

The measurement of very low temperature dew point values under very high operating

pressure requires the introduction of supplemental cooling of the analyzer’s housing.

Please note: The analyzer’s housing temperature (T

housing

/ Tb) must always remain

at least 5 °C above the dew point temperature being measured throughout the supplemental cooling process.

To connect supplemental cooling, remove the caps from the analyzer housing

(Illustration 1, Pos. 7); (Illustration2; Pos.12). Attach the socket DMC3M-2G-NTA SA

(Illustration 34; Pos. 3) to the inlet opening of the cooling channel as well as the hose

connection adapter DHAM 10M-AG-S (Illustration; 34; Pos 5) to the outlet opening.

Connect the hose (Illustration 34; Pos. 1) with flow-line adapter (Illustration; Pos 4) with

the inlet socket (Illustration 34;Pos. 3). To connect the hose to the refrigerant bottle use

!75,0&

!70,0&

!65,0&

!60,0&

!55,0&

!50,0&

!45,0&

!40,0&

!35,0&

0& 5& 10& 15& 20& 25& 30& 35& 40&

Lowest possible T

(mirror)

°C

Housing temperature °C

9.0&MPa&

2.7&Mpa&

0.1&MPa&

33

38

fitting DMC 6M-14M15-SA; DMC 6M-16M15-SA or DMC 6M-18M15-SA (included with

the supplemental cooling accessories).

If necessary, connect a ventilation hose to the connection adapter DHAM 10M-AGS(Item 5) in order to properly vent used gas.

Water or natural gas may also be used as supplemental coolant media.

Illustration34

2.4 Deinstallation of the Hygrovision mini

Use the following procedure to uninstall the analyzer:

1) Switch off the analyzer;

2) Close the high pressure valve of the gas delivery system;

3) Using the needle valve integrated into the through-flow control system, adjust the

pressure in the measurement chamber to match that of the ambient environment;

4) Disconnect the sample gas delivery system and the through-flow control system from

the measurement chamber.

39

3 Maintenance

Analyzer maintenance consists of regular metrological recalibration, checks of the technical

condition and, if necessary, cleaning the condensation mirror and replacing filter elements.

Proper storage, transport, and operational conditions will ensure that the analyzer’s

metrological characteristics continue to conform to the relevant prescribed standards.

3.1 Function tests

When the analyzer is switched on, the following function tests should be carried out:

! Charge status and condition of the battery pack (IP-01)

! Condition of the condensation mirror

! Functionality of the thermoelectric battery

! Status of the lighting system

3.1.1 Check the status of the battery charge

Select “Battery” mode (see point 1.5.6). If the battery (IP-01) is in proper working order, values for parameters displayed will lie within the tolerances listed in Table

If the charge status is below 20%, fully charge the battery. Please, only use the charging unit

delivered with the analyzer the charge the IP-01 battery pack.

The charging unit can use either 220V AC current or 12V DC current to charge the battery.

The battery charging procedure is also illustrated on the sticker (VMPL5.122.001ET ) that is

delivered with the charging unit.

Attention!

The battery (IP-01) should only be (re)charged in an explosion-proof

area. The battery should only be charged using the charging unit delivered with the analyzer!

40

3.1.2 Check the condensation mirror

Perform a visual inspection of the state of the surface of the condensation mirror using

the microscope. Be sure to adjust the focus if necessary.

The condition of a clean condensation mirror surface may differ slightly from the illustrations in Appendix D. These differences are due to the heterogeneity of the mirror’s

dielectric material and the mechanical processing of the condensation surface. It may

therefore be the case that a few red dots or scratches are observed under side lighting

during this check.

Should three fourths of the surface of the mirror be covered with red dots, it will be necessary

to clean the condensation mirror (see point 3.2.2).

3.1.3 Check that the thermoelectric battery – TEB

(Peltier element) is functioning

In dew point “Measurement" mode, press the "down" function key (Illustration 3; Pos. 4)

several times to adjust the temperature of the mirror to between -15 °C and -25 °C. The

“current temperature” of the condensation mirror should not take more than 30 seconds in

order to reach the “input temperature”. This process can be monitored on the display using

the timer.

Now select "Mirror cleaning" mode. The “current temperature” of the condensation mirror

should level off at +55 °C (±0.2 °C) within a minute.

If all the above steps carried out without problems - it can be assumed that the

thermoelectric element is fully functional.

If no problems arise when carrying out the above steps, it can be assumed that the

thermoelectric element is fully functional.

3.1.4 Check the lighting systems

After the analyzer is first switched on (see 1.4.4), it takes two to three seconds for the

operating system to load. The version of the installed OS is displayed on the analyzer’s

LCD screen. When this initial start-up process is complete, the analyzer automatically

switches to measurement mode.

The vertical lighting system is activated during this initial process. Once the OS is

loaded and the analyzer switches to the dew point measurement mode, mirror illumination switches from vertical lighting to side lighting.

In Appendix D, example images of the mirror’s surface under both side and vertical

lighting are shown. These pictures show a clean mirror as well as several different

types of condensate accumulation.

Use the “select” button to switch between lighting modes.

Should the sequence described here proceed as outlined, it can be assumed that the

lighting systems are functioning normally.

Lighting intensity can be adjusted under the “Settings” menu (see point 1.5.5).

41

3.1.5 Perform a leak test

After the device is installed, all gas-sample line connections must be examined for

leaks in the following manner:

• Close the valve of the flow control system

• slowly open the inlet valve of the sampling line and the valve at the inlet of the ana-

lyzer’s measuring chamber

• Apply a soap emulsion to the connection points between the gas supply system, the

measuring chamber and the flow control system; making sure to completely coat over

the space between the lock nuts and the connecting sleeves

If bubbles form in the emulsion it is an indication that there is a leak. If this occurs, it is

necessary to reseal the leaky connection connection and retest it.

3.2 Maintenance procedures

Standard maintenance includes:

! Service the power supply unit (battery)

! Check the condition of the condensation mirror and clean if necessary

! Check the efficiency of mirror cooling (efficiency of the thermoelectric battery)

! Replace the particle filter

! Calibrate the analyzer

! Clear error messages

3.2.1 Servicing the power supply unit IP-01

Observing the following guidelines will ensure that the battery has a long service life:

• If the analyzer is not used for more than ten days, remove the battery to avoid

unnecessary discharging.

• The charge status of all batteries held in storage should be checked at least once

a month and when necessary fully recharged.

3.2.2 Cleaning the condensation mirror

In order to check the condition of the condensation mirror’s surface, set the analyzer to

“Mirror cleaning” mode.

If contamination that could interfere with water and/or hydrocarbon dew point measurements remains on the surface of the mirror after the automatic cleaning process is

completed, the following steps can be taken before manually cleaning the mirror.

1. Select the “Dew Point Measurement” mode.

2. In the incremental cooling mode, press the “down” button repeatedly to lower

the target temperature to between -25 °C and -30 °C.

42

3. After reaching the desired target temperature select “Mirror cleaning” mode

again.

Repeat this process up to three times if necessary.

If there is no improvement in the condition of the mirror’s surface after repeated cycles

in the “Mirror cleaning” mode, it will be necessary to clean the mirror manually.

Everything required for this procedure is included with delivery.

Attention!

Manual cleaning of the condensation mirror is only to be done in an

explosion proof environment!

Please follow these steps when cleaning the mirror manually :

1. Disconnect the illumination cable and remove the microscope.

2. Remove the eight bolts from the measurement chamber and open it. (This

should only be done in a “clean” environment).

3. Dip one of the cotton-swab applicators into the cleaning fluid and gently clean

the surface of the condensation mirror. An absolute minimum of pressure

should be applied to the mirror’s surface during this procedure (illustration 35).

Illustration 35

In certain cases the condensation mirror can alternatively be given a “quick” cleaning.

43

Using the special key provided (VYMP 8.392001), turn the sleeve containing the integrated observation window counter-clockwise and remove it from the gas delivery sys-

tem (illustration 36). Clean the surface of the condensation mirror with an applicator

dipped in the cleaning fluid (illustration 37).

Illustration 36 Illustration 37

Please note: If after cleaning the mirror in the manner described above

contaminants remain on the surface of the mirror, it can also be cleaned using acetone in place of the cleaning fluid delivered with the analyzer.

3.2.3 Checking the efficiency of the

thermoelectric battery (TEB)

Follow these steps to check the thermoelectric battery:

1. Switch on the analyzer;

2. Select the dew point “Measurement” mode and press the “down” button repeatedly to set the temperature T to -60 °C (±1);

3. After three minutes have passed, note the mirror temperature T and the housing temperature T

b

shown on the display. The difference between these two

values must not exceed 65 °C;

4. Select the “Mirror cleaning” mode.

Attention!

Please take the utmost care when cleaning the condensation mirror

manually as damage in the form of scratches or grooves will greatly reduce the performance of the analyzer. Mechanical damage to the condensation mirror caused during cleaning is not covered under the warranty.

44

3.2.4 Replacement of the particle filter

Illustration 38

Optimally, the particle filter cartridge should be replaced at least once a year.

To replace the filter cartridge (illustration 38):

1. Unscrew the inlet nozzle (Pos. 1) and remove it from the sample delivery

unit of the analyzer’s housing

2. Carefully remove the small spring (Pos. 2)

3. Carefully remove the filter cartridge (Pos. 3)

4. Place a new cartridge in the opening (Pos. 4)

5. Carefully replace the spring

6. Screw the inlet nozzle back into the sample delivery unit of the housing

3.2.5 Calibrating the Hygrovision mini

Calibration of the Hygrovision mini involves shifting the analyzer’s standard calibration curve to reflect a set value within the analyzer’s measurement range.

To make the adjustment, reset the calibration factors in the “Settings” mode:

⇒ Under the “Settings” menu, use the Up and Down buttons to select the calibration co-

efficient mode.

⇒ Set the coefficient to the desired value using the Up and Down buttons.

⇒ Press the Select button to confirm the set value.

The value for the calibration coefficient A is calculated as follows:

Т

calib

= A + B * Т

meas

Т

calib

= defined dew point value

Т

meas

= measured dew point value

Т

calib

; Т

meas

– Dew point temperature measured directly using a reference analyzer.

Calibration factor A is determined as Т

calib

= 0°C and calibration factor B =1.

45

3.3 Troubleshooting malfunctions

Possible technical failures as well as the appropriate responses in each case are presented

in Table 7.

Table 7

Failure

Possible cause

Response options

1.

The analyzer won’t switch

on.

The battery charge is too low.

(Re)charge the battery.

a) The battery temperature exceeds tolerable limits

(0 °C – + 45°C).

b) The electrical circuit between

the thermometer and the temperature control unit is defective.

2.

The battery cannot be

(re)charged: the

charging indicator is red.

c) There is no electrical contact

between the battery and the

charging unit.

Check the

appropriate parameters

and elements.

a) The lighting cable electrical circuit is defective.

Check the lighting cable

3.

The lighting for the optical

system is not functioning.

b) The light emitting diode is

defective.

Replace the cable with

the LED.

a) The microscope is not

properly installed.

Ensure that the microscope is properly aligned

and screwed into position

until it is tight.

b) The observation window

lens is dirty.

4.

The sharpness of the

mirror’s image can’t

be adjusted.

c) Condensation has accumulated

in the space between the

observation window and the lens

of the microscope.

Clean the optical

elements using the

cleaning fluid included in

the set for cleaning the

mirror.

a) The thermoelectric battery

is defective.

Replace the

thermoelectric battery.

5.

The mirror does

not reach the set

temperature.

b) The through-flow volume

in the measurement chamber is

too high.

Reduce the through-flow

volume in the measurement chamber to 0.5

Nl/min.

46

c) High operating pressure

or housing temperature

(see point 4,5)

Use supplemental cooling of the analyzer housing

a) From time to time the

analyzer switches off unexpectedly.

6.

b) Led indicator flickers.

The battery is not

properly (securely)

installed.

Ensure that the battery lid

is aligned correctly and

screw it down tight.

3.4 Error message codes

Table 8 presents a list of error codes and their meanings as well as a description of the

appropriate action to take in each case.

Table 8

Error mes-

sage

Diagnostic error message

Response

E 01

Poor battery contact!

Replace the battery!

Check the battery contacts; if necessary replace

the battery.

E 02

T

bat

≥ + 60.1 °C

Cool the battery!

In order for the analyzer to regain functionality,

allow the battery to cool down.

E 03

T

bat

≤ – 20.1°C.

Warm the battery!

In order for the analyzer to regain functionality,

allow the battery to warm up.

E 09

Circuit breaker tripped!

Cooler!

E 10

Circuit breaker tripped!

Requires + 5V.

E 11

Circuit breaker tripped Ia over 2500

mA

Switch the device off and then turn it on again. If

the same error message is displayed contact the

manufacturer.

E 12

Battery is low!

Charge battery!

Recharge the battery.

E 13

Tb ≤ – 45,1 °C!

Warm the device

E 14

Tb ≥ + 65,1 °C!

Cool the device

In order to regain functionality, heat/cool the analyzer so that it is within the temperature range

listed in Table 3.

If your analyzer displays an error code not listed in this table, please contact the

manufacturer.

47

4 Markings

Labeling on the analyzer’s housing provides the following information:

! Trademark and name of the manufacturer

! Name of the device

! Explosion protection labeling

! Certifying Authority and Certificate Number

! Information label about protection against the effects of solids and water according to

IEC 60529:1992 (IP54)

! Dew point measurement range

! Operating pressure limit

! Operating temperature of the device

! Serial number

! Country of manufacture

5 Packaging

The analyzer’s components must be appropriately protected prior to being packaged

for transportation or storage.

The device is to be packaged in a closed ventilated room with an ambient temperature

of +15 °C to +40 °C and a relative humidity of no more than 80%.

The ambient air must not contain any aggressive components.

Proper packaging protects the analyzer against climatic influences and mechanical

stress during (un)loading, transportation, and storage.

Operating documentation is located under the lid of the transport case, as are the packing list and accompanying certification. These are protected by watertight packaging.

6 Storage

Analyzers are to be stored exclusively in containers intended for that purpose supplied by the

manufacturer. These containers are designed to protect the device from mechanical damage, contamination and the effects of aggressive media.

For transportation purposes, analyzers may be held in storage (max. 6 months) in the transport packaging.

48

7 Transportation

Transportation requirements:

Analyzers are to be transported only in climate-controlled, hermetically sealed closed

containers.

When in service, the device must be transported in the carrying case included with delivery.

8 Recycling

The materials and work pieces used in the manufacture of the Hygrovision mini dew

point analyzer are environmentally friendly. During the period the device is in service as

well as after it has been decommissioned, these materials and work pieces can be

classified as non-hazardous to human health. Likewise they present no risk to production and storage spaces.

Hygrovision mini analyzers that are no longer being used may be disposed of in any

way deemed appropriate by the user.

Old disused batteries are to be turned over to companies that are licensed and/or

authorized to dispose of these products.

49

Anlage А

Factory settings

Table 9

Code

Parameter

Unit of

measurement

Measurement

range

Value

M 31

Warming temperature

°C

0 – 60

0.0

M 32

Change interval

°C

0 – 10

5.0

M 33

Cooling rate

°C / min

0 – 10

3.0

M 34

Calibration factor

°C

-10 – 10

0.0

M 35

Oblique illumination brightness

-preset level-

0 – 10

10

M 36

Vertical illumination brightness

-preset level-

0 – 10

5

M 37

Language selection

-

Russian

English

German

Russian

M 38

Display: contrast

-preset level-

0 – 10

6

M 39

Display: brightness

-preset level-

0 – 10

8

M34-B

Calibration coefficient

°C

-10 – +10

0,0

50

Appendix B

Sample extraction system

Illustration 39

The sample extraction system is intended for permanent installation on the main

gas line. This apparatus makes possible the extraction of a gas sample at the existing working pressure.

The sample extraction system is mounted onto the pipe by means of an installation

bushing (Illustration 39, pos. 1) attached to the gas line at the desired sampling

point. The installation bushing is made of 09G2C steel (9MnSi5/ 13Mn6) and is included with delivery of the extraction system.

Gas flow can be controlled or stopped by opening or closing the integrated ball valve. When the valve handle is in the vertical position (parallel to the gas flow) the

valve is open and gas flows into the extraction apparatus. When the handle is in the

horizontal position (perpendicular to the gas flow), the valve is closed and gas is

prevented from entering the sampling system.

The connection nozzles of the sample extraction system is intended to be connected to a pipe made of stainless (DK-Lok, THT-3R60-12-1). No additional rolling

of the pipe end is necessary in order to affix the pipe.

51

Appendix C

Membrane Filter (KRAY6.457.022)

Function

The membrane filter is designed to remove from the gas sample the liquids and particulate matter that could contaminate or damage the analyzer’s measuring chamber or

the components of the sampling unit.

Description

The filter consists of a housing and a membrane.

The filter housing has an inlet opening labeled B and an outlet opening labeled OUT.

(See schematic drawing KRAY4.078.091-01: A [Inlet opening], B [Purge], OUT [outlet

opening]). The gas sample enters the filter housing through the inlet port, passes

through the membrane, and exits through the outlet port. In this process small contaminants and even micro particles are trapped by the membrane and removed from

the gas sample.

Membrane

Illustration 40

The membrane has microscopic pores through which gas and water vapor molecules

can easily pass. Liquids, on the other hand, are comprised of a large number of molecules that are closely bound together. The surface tension inherent in liquids is very

strong. Due to this surface tension bonding, liquid molecules remain too large to pass

through the microscopic pores of the membrane. In this way even the smallest aerosols

and particles are removed from the gas stream (Illustration 40). And because all of the

gas-phase molecules can easily pass through the filter, the gaseous composition of the

sample remains unaltered. The membrane is extremely elastic and is appropriate for

use where a wide range of technological fluids may be present. The low adsorption

properties of the membrane mean that this filter is also appropriate for systems intended to have component concentration levels in the ppm or ppb range. The membrane is also constructed of a robust but soft and flexible material in order to ensure a

long service life.

52

Technical Data

Maximum operating pressure

250 bar

Recommended maximum gas flow volume through

the membrane: 130-502

72,000 cm3 / min

Gas flow volume through the membrane: 130-502

14,400 cm3 / min

Housing material / sealing ring material

Stainless steel / Viton

KRAY6.457.022

Dimensions (mm):

KRAY6.457.022-01

see Illustration 30

see Illustration 31

KRAY6.457.022

(inlet, outlet)

Outer diameter ø12.0 mm

Connection:

KRAY6.457.022-01

(inlet, outlet, purge)

Outer diameter ø 6.0 mm

Illustration 41

Illustration 42

Recommended installation and usage

The filter is available in two versions:

Version 1 – for mounting directly onto the sample extraction device

Version 2 – for installation within a sample delivery system

53

Illustration 43

For version 1, the filter is mounted in such a way that liquids seperated from the gas stream return

to the sample source. In this configuration (

Illustration 43) the filter is mounted vertically, immediately downstream of the

sample extraction point (Pos.2). The gas then flows through the OUT port toward the analyzer.

Illustration 44

Version 2 of the filter is also mounted vertically as shown in Illustration 33.

Pos.1

Filter

A

Sample gas inlet

B

Bypass outlet / purge

OUT

Outlet to analyzer

A minimum flow rate of 5 Nl/min is required to purge the filter through outlet B.

Ordering information:

Filter part number is KRAY6.457.022:

Replacement Membrane Set (5 pieces)

54

Anlage D

Examples of the appearance of

water and hydrocarbon condensation

(Microscope perspective)

Condensation mirror as seen

under side lighting

Condensation mirror as seen

under vertical lighting

Illustration 45

Absence of

condensation

(individual red dots and

scratches are acceptable)

Illustration 46

Illustration 47

Condensation mirror

showing water con-

densation

Illustration 48

55

Illustration

49

Water condensation in both

liquid and crystaline phases

Illustration 50

Illustration 51

Water condensation in

crystaline phase only

Illustration 52

Illustration 53

Hydrocarbon condensation

(inc. heptane)

Illustration 54

56

Illustration 55

Hydrocarbon condensation

(Octane and

higher ranked HCs)

Illustration 56

57

Appendix E

Illustration 57

58

Appendix F

Page:

No.

Adjusted

Replaced

New

Cancelled

Number of

documents

Document

number:

Signature

Date

59

Loading...

Loading...