Precision | Economy | Safety

Operating Manual

Hygrovision BL

Dew point analyzer

www.vympel.de

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

"!

!"#$%&'(&)'*!%*!+&

,-! .%*%/"$&0%+)/12!1'*& 3!

,-,-! 24/2'+%&"*0&(1%$0&'(&"22$1)"!1'*& 3!

"#$"%&'! (!

)*'+,!%)!-""+*.-/*%0! (!

/1"'&!%)!*0&/-++-/*%0&! (!

*0&/-++-/*%0!-0,!%"'$-/*02!$'3#*$'4'0/&! (!

,-5-! %62$'+1'*&2/'!%)!1'*& 7!

,-8-! 9%"+4/%9%*!&2/1*)12$%& ,:!

,-;-! "*"$<=%/&)'*+!/4)!1'*& ,5!

5-//'$1!"-.6! 78!

,->-! "*"$<=%/&2'?%/&+422$<& ,8!

,-@-! "001!1'*"$&)'92'*%*!+&"*0&"))%++'/1%+& ,;!

4*.$%&.%"'! 79!

2:;!<=>?!@!A:;!BCD;;ECD!F>GHC>=!;I;HDJ!K4>LD=!MM7N! 79!

2-&!,'+*O'$1!&1&/'4! ! 4%,'+!MM7! 7P!

"-$/*.+'!)*+/'$! 7P!

2+1.%+&!-0,!Q'-O1!Q1,$%.-$5%0&!)*+/'$! 7P!

'R/'$0-+!"%S'$!&#""+1!.-5+'! 7T!

*$!-,-"/'$! 7T!

&#""+'4'0/-+!.%%+*02!&1&/'4! 7(!

/$*"%,! 7(!

&-4"+'!2-&!'R/$-./*%0!&1&/'4! 7(!

Q*2QU"$'&&#$'! ! O'0/*02!4%,#+'! 7V!

2-&!"$'"-$-/*%0!&1&/'4! ! &2-UMM8! 7V!

,-3-! )'*!/'$&"*0&01+2$"<&%$%9%*!+& 5:!

,-A-! !B%&"*"$<=%/C+&9%*4& 5:!

/#$0*02!%0!/Q'!-0-+1W'$! XM!

,*&"+-1',!*0)%$4-/*%0! XX!

"$%"'$/*'&! XX!

-0-+1W'$!.Q'.6! XY!

-#/%4-/*.!,'S!"%*0/!4'-&#$'4'0/!4%,'! XY!

/#$0*02!%))!/Q'!-0-+1W'$! X9!

,-7-! )'**%)!1*.& & 2%/12B%/"$&0%D1)%+& 5@!

,-,:-! +2%)1(1)"!1'*+& 5A!

,-,,-! B<./'D1+1'*&#$&+!"*0"/0&%E4129%*!& 8:!

,-,5-! %62$'+1'*&+"(%!<&2/'D1+1'*+& 85!

5-! +"(%&'2%/"!1'*&'(&!B%&B<./'D1+1'*&#$& 8;!

5-,-! .%*%/"$&+"(%!<&9%"+4/%+& 8;!

5-5-! %62$'+1'*F+"(%&1*+!"$$"!1'*&"*0&'2%/"!1'*& 8;!

8-! 2/%2"/1*.&!B%&"*"$<=%/& & ('/&'2%/"!1'*& 8@!

8-,-! .%*%/"$&/%E41/%9%*!+& 8@!

#0"-.6*02!-0,!O*&#-+!*0&"'./*%0! 8P!

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

#!

%"'$-/*02!$'&/$*./*%0&! 8P!

"$'"-$*02!/Q'!$'.Q-$2'-5+'!5-//'$1!)%$!-0-+1W'$!%"'$-/*%0! 8P!

&-4"+'!'R/$-./*%0! 8T!

8-5-! )'**%)!1*.&!B%&"*"$<=%/& 83!

/'&/*02!&'-+!*0/'2$*/1! 8(!

8-8-! (4*)!1'*"$&!%+!& 87!

&S*/.Q*02!%0!/Q'!-0-+1W'$! 8V!

.Q'.6*02!/Q'!4*.$%&.%"'!+*2Q/*02! 8V!

.Q'.6*02!/Q'!.%0,'0&-/*%0!4*$$%$!-0,!/Q'!/Q'$4%'+'./$*.!5-//'$1! YM!

,-/'!-0,!/*4'! YM!

5-//'$1!"-.6!.Q-$2'!&/-/#&! YM!

&S*/.Q*02!%))!/Q'!-0-+1W'$! YM!

;-! '2%/"!1*.&!B%&B<./'D1+1'*&#$& ;,!

;-,-! 2/%)"4!1'*"/<&9%"+4/%+& ;,!

;-5-! B"*0$1*.&!B%&B<./'D1+1'*&#$& ;,!

"$'"-$*02!/%!/-6'!4'-&#$'4'0/&! Y7!

Q'-/*02!/Q'!.%0,'0&-/*%0!4*$$%$! YX!

.+'-0*02!/Q'!4*$$%$! YX!

-,Z#&/*02!/Q'!+*2Q/*02!*0/'0&*/1! YX!

4*$$%$!&.-0!@! Y8!

&.-00*02!4%,'! Y8!

/-6*02!,'S!"%*0/!4'-&#$'4'0/&! YY!

;-8-! B)&0%?&2'1*!&9%"+4/%9%*!&4+1*.&!B%&2/%2/'./"99%0&/"!%&'(&)''$1*.&G&B%"!1*.&!B%&

)'*0%*+"!1'*&91//'/& ;>!

;-;-! B)&0%?&2'1*!&9%"+4/%9%*!&)''$1*.&!B%&91//'/&+!%2&#<&+!%2& ;@!

;->-! ?"!%/&0%?&2'1*!&9%"+4/%9%*!&4+1*.&!B%&2/%2/'./"99%0&/"!%&'(&)''$1*.&G&B%"!1*.&!B%&

)'*0%*+"!1'*&91//'/& ;3!

;-@-! ?"!%/&0%?&2'1*!&9%"+4/%9%*!&)''$1*.&!B%&91//'/&+!%2&#<&+!%2& ;A!

;-3-! B)&0%?&2'1*!&9%"+4/%9%*!&1*&"4!'9"!1)&9'0%& ;7!

;-A-! ?"!%/&0%?&2'1*!&9%"+4/%9%*!&1*&"4!'9"!1)&9'0%& >:!

;-7-! +2%)1"$&)'*+10%/"!1'*+&?B%*&9%"+4/1*.&0%?&2'1*!&"!&D%/<&$ '?&!%92%/"!4/%+& >5!

4'-&#$*02!,'S!"%*0/!-/!O'$1!+%S!/'4"'$-/#$'&! 9X!

&#""+'4'0/-+!.%%+*02!&1&/'4! 98!

*0&/-++-/*%0!%)!/Q'!&#""+'4'0/-+!.%%+*02!&1&/'4! 9Y!

#&*02!/Q'!&#""+'4'0/-+!.%%+*02!&1&/'4! 9Y!

;-,:-! 4*1*+!"$$1*.&!B%&B<./'D1+1'*&#$& >@!

#0*0&/-++*02!/Q'!-0-+1W'$! 9P!

>-! !%)B*1)"$&9"1*!%*"*)%& >3!

>-,-! .%*%/"$&1*+!/4)!1'*+& >3!

>-5-! 9"1*!%*"*)%&2/')%04/%+& >3!

4-*0/'0-0.'!%)!/Q'!"%S'$!&#""+1!#0*/! 9T!

.+'-0*02!/Q'!.%0,'0&-/*%0!4*$$%$! 9(!

.+'-0*02!/Q'!.%0,'0&-/*%0!4*$$%$! PM!

/'&/*02!/Q'!/Q'$4%'+'./$*.!5-//'$1!K/'5N! PX!

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

$!

.-+*5$-/*02!)%$!Q1,$%.-$5%0&! PX!

>-8-! $1+!&'(&2'++1#$%&%//'/&9%++".%+& @8!

@-! 9"/H1*.+& @>!

3-! 2")H".1*.& @>!

A-! +!'/".%& @@!

7-! !/"*+2'/!& @3!

/$-0&"%$/!.%0,*/*%0&! PT!

,:-! 0%)'991++1'*1*.&"*&0&01+2'+"$& @3!

,,-! "22%*016&I& @A!

,,-,-! B<./'D1+1'*F#$&"*"$<=%/J&9"1*&)'92' * % * !+& @A!

,5-! "22%*016&#& 3:!

,5-,-! B<./'D1+1'*F#$&%62$'+1'*&2/'!% ) ! 1 ' *& 3:!

,8-! "22%*016&)& 35!

,8-,-! ($'?&)'*!/'$&+<+!%9&9'0%$F::,&D<92>-,A8-::,-& 35!

,;-! "22%*016&0& 38!

,;-,-! ."+&0%$1D%/<&+<+!%9&9'0%$F::,&D<92$@-;>:-::,-& 38!

,>-! "22%*016&%& 3>!

,>-,-! )''$1*.&9'04$%&D<92>-AA:-::8-& 3>!

)'*+!/4)!1'*&0/"?1*.& 3>!

,@-! "22%*016&(& 33!

,@-,-! 2/%++4/%&/%04)!1'*&9'04$%&D92$5-A;A-::>-& 33!

,3-! "22%*016&.& 37!

,3-,-! B1.BF2/%++4/%&."+&/%$%"+%&9'04$%& 37!

,A-! "22%*016&B& A,!

,A-,-! %$%)!/1)"$&2"/"9%!%/+&'(&!B%&B<./'D1+1'*&#$C+&2$4.+& A,!

,7-! "22%*016&1& A5!

,7-,-! +%!!1*.+&9%*4& A5!

4'0#!,'&.$*"/*%0! (X!

*0,*O*,#-+!)#0./*%0!"-$-4'/'$!4'0#&! (Y!

5:-! "22%*016&K& A3!

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

%!

5:-,-! !B%&9'0#4+&/%.1+!%/& A3!

5,-! "22%*016&H& A7!

5,-,-! 4*1D%/+"$&!%/91*"$&2/'./"9J&B<./'D1+1'*-%6%& A7!

55-! "22%*016&$& 7;!

55-,-! 0%+)/12!1'*&'(&!B%&)"$1#/"!1'*&2/')%04/%&('/&B<0/')"/#'*+& 7;!

58-& 7@!

58-! "22%*016&9& 7@!

58-,-! %6"92$%+&'(&B)&"*0&?&)'*0%*+"!1'*& 7@!

5;-! "22%*016&*& 77!

5;-,-! 0')49%*!"!1'*&)B"/!& 77!

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

&!

–

VYMPEL GmbH

Bahnstraße 17

40212 Düsseldorf

Deutschland

Tel: +49211 210 77 391

Fax: +49211 210 77 399

email: info@vympel.de

www.vympel.de

–

Responsible for manufacturing:

143530, Russia, Mossbauer Area, Istrinsky District,

Dedowsk, Shkolny Passage, No.11

Tel.: 8 (495) 992-38-60 (ext. 219)

Fax: 8 (495) 992-38-60 (ext.217)

e-mail: vympelm100@aha.ru

Internet: www.npovympel.ru

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

'!

1. GENERAL DESCRIPTION

1.1. PURPOSE AND FIELD OF

APPLICATION

This manual provides a description of the construction and function of the Hygrovision BL dew point analyzer, model number

KRAY2.844.007 (also called HV BL, Hygrovision, device, instrument, and analyzer in the text).

The Hygrovision BL is a compact portable analyzer used to establish the dew point temperature of water and hydrocarbons.

This portable hygrometer (hereinafter analyzer) functions according to the principal of direct measurement. It employs a

temperature-controlled mirror upon which condensation forms to

establish dew point.

The Hygrovision is one of a series of revolutionary new highprecision chilled-mirror analyzers that are characterized by the

inclusion of a supplemental visualization system. This system

makes it possible to physically observe the condensation (dew

point) process. In addition, this system has two different illumination options, which makes it possible to easily distinguish between water condensation and the formation of hydrocarbon

condensates.

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

(!

PURPOSE

FIELD OF APPLICATION

TYPES OF INSTALLATIONS

The analyzer is designed to measure the dew point of water

(hereinafter also: W dew point, WDP, dpW) and the dew point of

hydrocarbons (hereinafter also HC dew point, HCDP, dpHC) in

natural gas and other gaseous media at operating pressures. It

is also intended for the visual monitoring of the condensation

process.

Hygrovision BL dew point analyzer are designed to be used for:

Spot checking in the field

Checking the functionality of permanently installed dew point

analyzers

Corroborating the accuracy of the measurements made by permanently installed units

Regular direct measurement of water and carbohydrate dew

points in locations that are not equipped with automatic throughflow analyzers are where such analyzers cannot be installed

Checking the results of various manufacturing and working

processes (such as the drying and vacuuming of equipment and

systems, damp presses, processes involving the use of steam,

regeneration, evacuation, etc.)

The BL can be employed by a variety of sectors, including the

gas, oil, and chemical industries, metallurgy, the power industry,

equipment manufacturing, and many other branches where the

quality of manufacturing and operating process can be evaluated through the control of water and hydrocarbon dew points.

INSTALLATION AND OPERATING

REQUIREMENTS

Only by qualified personnel may carry out the installation and

maintenance of the analyzer.

Operating personnel must be familiar with the requirements and

instructions contained in this manual and must be trained in the

operation of explosion-protected equipment.

It is strongly recommended that this training be provided by the

Vympel company.

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

)!

1.2. EXPLOSION PROTECTION

The analyzer consists of an electronics module and a measurement module. (see point 1.4).

The electronics module conforms to all of the requirements for

explosion-protected equipment in accordance with GOST R

52350.0-2005. The explosion Protection categories "flameproof

enclosure (d)" according to GOST R 52350.1-2005 and "Intrinsically safe circuit (i)“ according to GOST R 52350.11-2005

identify the instrument as safe for use in explosion hazard zones

both inside closed facilities and outside in the field according to

GOST R 52350.14-2006.

Electronic Components of the HV BL

Ex protection markings

Electronics module

1 Ex d[ib] IIA T5 Х

Electrical devices associated with the electronics

module (thermoelectric battery, temperature sensor, photo diodes)

These are located with the flameproof enclosure and therefore do not have Ex protection

Light diode

As a simple electrical apparatus according to

GOST R 52350.11 it has no Ex protection

markings.

Attention!

To ensure that the Hygrovision BL is safe with regard to explosions, it is important to

regularly purge the analyzer with air and to always fill the measurement chamber with

sample gas before switching the device on.

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

*+!

=11>?@34@=AB& & CD&@,E"%&+FG+"HE., #

=11>?@34@=AB& & 6D&I%F"#&J.++, +&/$ +G "HF &$#KF+&

/.KF&%.*LE.#*&

=11>?@34@=AB& & MD&I%F"#&J.++, +&/$ +G "H F &$# K F+ &

J.H+,/H,NF&O-F+E.H"%P&%.*LE.#*&

=11>?@34@=AB& & 9D&?H"EEF+.#*&,G&%.*L E&+" )/ &K$ F &

E,&Q"EF+&H,#KF#/"E.,#&

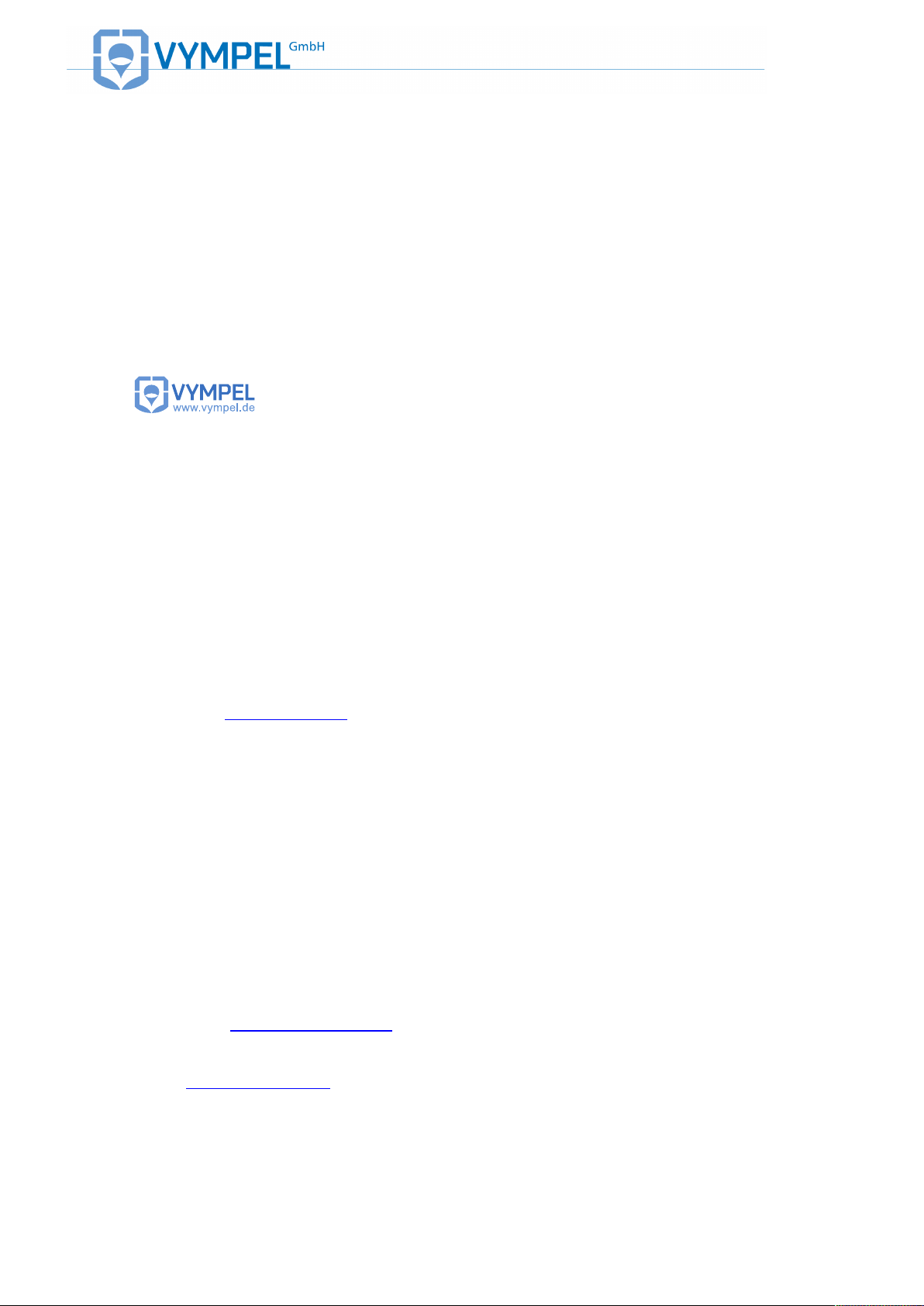

1.3. MEASUREMENT PRINCIPLE

The Hygrovision BL is a compact, portable analyzer used for taking automatic and manual measurements of the dew point temperature of water and/or hydrocarbons.

This portable chilled-mirror automatic hygrometer operates according to the principle of direct measurement and employs a

temperature-controlled mirror to establish the dew point. During

the measurement process the reflectivity of the mirror is measured. As the temperature of the mirror is lowered, its reflectivity

begins to go down when the dew point is reached and condensation begins to form. In this process condensates are deposited on

the mirror (reflective surface).

A special system uses optical properties to register the formation

of this condensate film.

This system utilizes the phenomenon of total refraction to register

dew point.

A laser emitting vertically polarized light illuminates the interface

of a heterogeneous media (gas) 1 and a reflective dielectric surface (temperature controlled mirror) 2 at a specific angle. This

angle is known as Brewster’s Angle.

When the dew point mirror (dielectric surface) is clean, in other

words, when no condensate has formed, the polarized light rays

falling on the interface between the gas and the mirror’s surface

are completely refracted. As a result no light is reflected onto either of the photo detectors (F1 and F2). This results in a null signal from the sensors (ILLUSTRATION 1). With the microscope

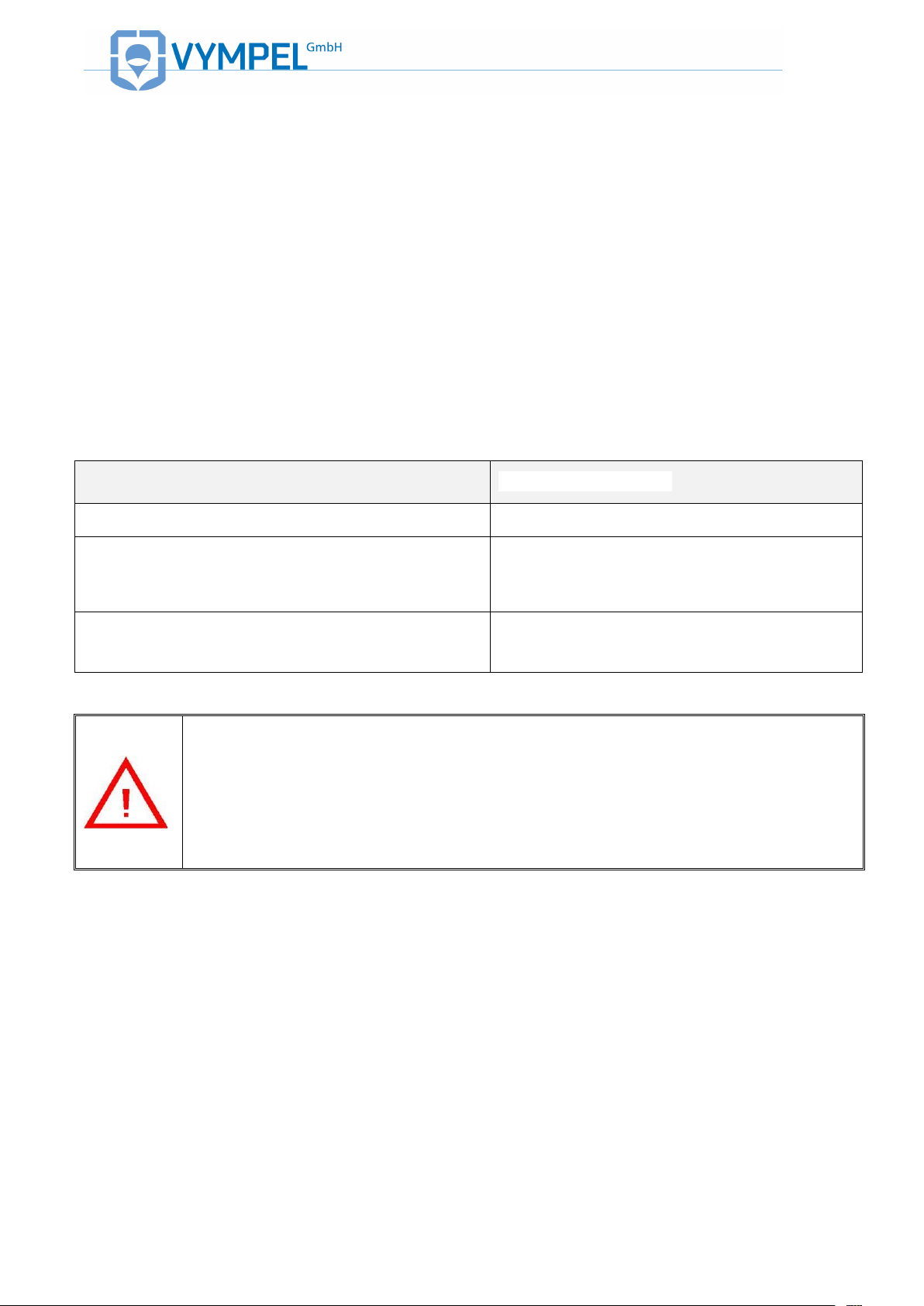

attached, total refraction can be observed visually under both side

lighting and vertical lighting. Under side lighting*, the surface of

the dielectric mirror appears black (illustration 2). Under microscope (vertical) lighting the mirror’s surface appears light blue

(ILLUSTRATION 3).

*Please note: the side-lighting unit and the laser are not the same

component.

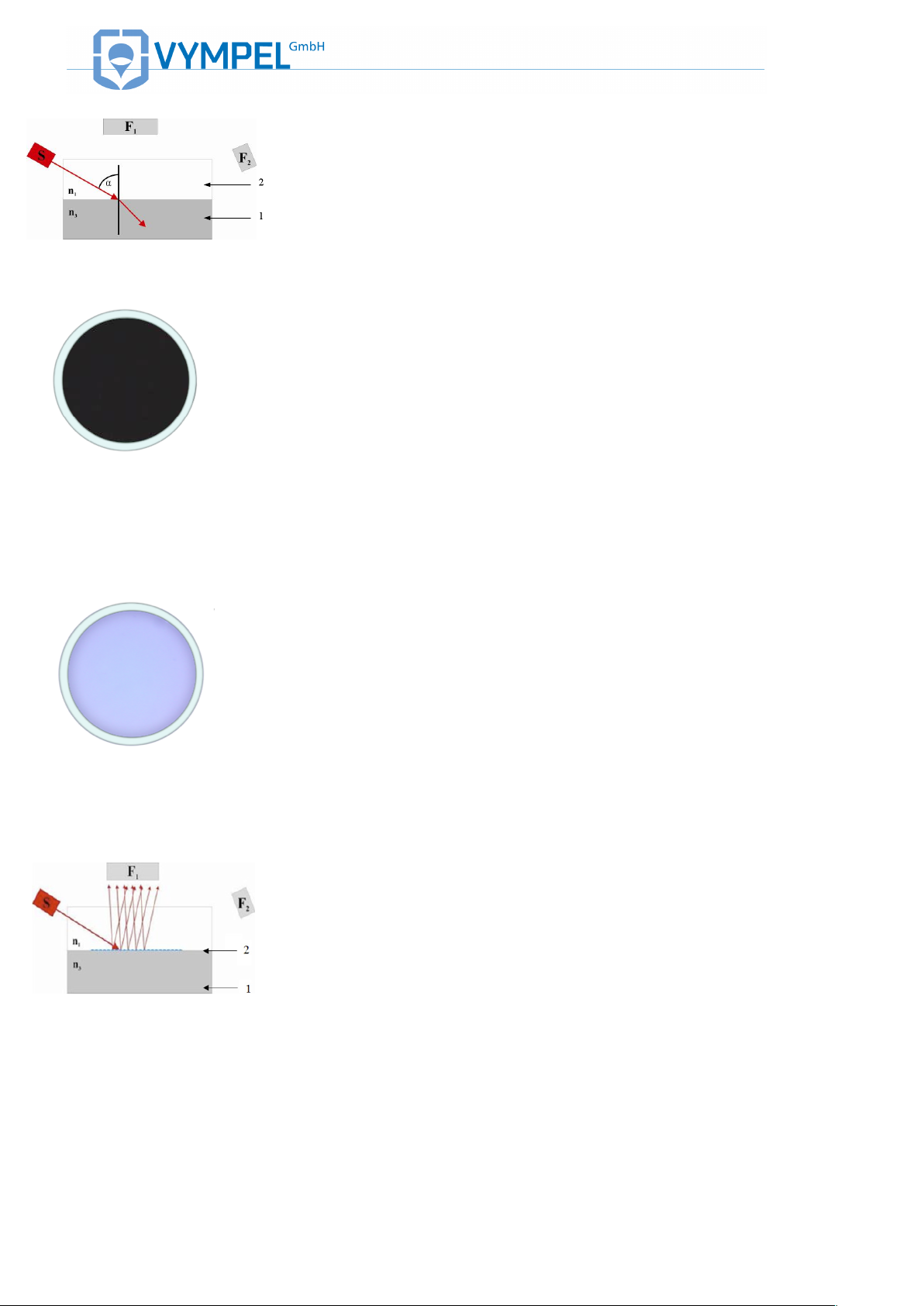

In the case of water vapor, as the temperature of the mirror is

lowered and condensation droplets begin to form, the angle at

which the polarized light strikes the surface changes with the result that refraction no longer occurs. Instead, the light rays are

reflected and scattered. The photoelectric registration system records an increase in the intensity of the light detected by the

photo detector located in position F1 (ILLUSTRATION 4). The

signal intensity (aka signal level) is dependent on the amount of

water condensation.

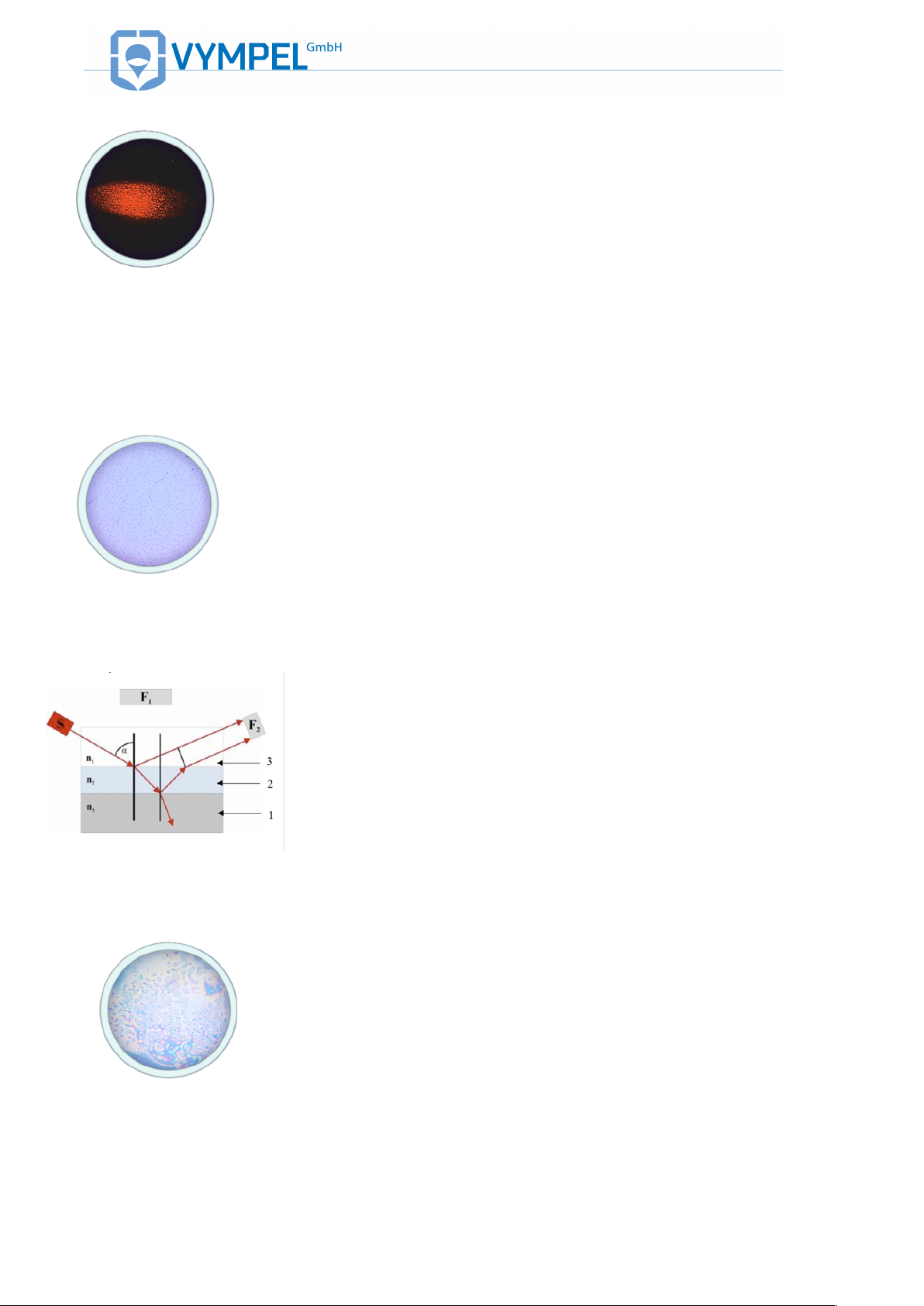

Under side lighting, water condensation appears in the form of an

accumulation of luminous, somewhat similarly sized red droplets

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

**!

=11>?@34@=AB& & RD&S&H,#KF# /" E., #&" /&/F F # &

$#KF+&/.KF&%.*LE.#*&

=11>?@34@=AB& & TD&S&H,#KF# /" E., #&" /&/F F # &

$#KF+&-F+E.H"%&%.*LE.#*&

=11>?@34@=AB& & ;D&1.*LE&+")&K.GG+"HE .,# &"# K&

+FG%FHE.,#&K$F&E,&(I&H,#KF#/"E.,#&

=11>?@34@=AB& & 8D&(I&H,#KF# /" E., #&O.#H %$ KU

.#*&LFNE"#F/P&

in the middle of the mirror’s surface (ILLUSTRATION 5). Under

vertical lighting this condensation appears as an accumulation of

little round black spots evenly distributed over the entire surface

of the condensation mirror (ILLUSTRATION 6).

In the case of hydrocarbons, precipitated condensates accumulate in the form of a thin film on the surface of the mirror (Illustration 7). The building of a contiguous condensate layer (2) on the

mirrors surface (1) results in a change in the angle at which the

polarized light strikes the surface of the dielectric mirror.

The beam of light emitted by the laser is partially reflected as it

encounters the gas/condensate interface (3/2). This set of light

rays is then registered by the photo detector at position F2.

At the same time, due to the condensate film’s high degree of

transparency, a set of slightly refracted light rays, passes through

the gas/condensate interface and is reflected as it strikes the

condensate/mirror interface (2/1). These light rays are then also

registered by the photo detector at position F2. This second set of

rays is now slightly out of phase with the first set.

As a result, the registration system records two distinct light signals detected by the F2 sensor. These two light signals create an

interference pattern due to the slight phase difference.

The intensity of the light signal detected by the sensor is directly

dependent on the quantity of hydrocarbon condensates in the

condensation film.

The hydrocarbon condensation process can only be observed

visually under vertical illumination. In contrast to water vapor condensation, the process of HC condensation cannot be made visible under side lighting, so even though the sidelight is activated,

the mirror remains dark (ILLUSTRATION 2).

Hydrocarbons up to and including Heptanes form rainbow colored

spots. These spread out until they link up to form one continuous

thin iridescent film. (ILLUSTRATION 8). If the mirror continues

to be cooled further, this thin iridescent film becomes a colorless

plastic layer covering the entire condensation mirror’s surface.

Octane and heavier hydrocarbons condense onto the mirror in

the form of small dark semi-transparent dots. With further cooling,

these dots grow to become small droplets and spots

(ILLUSTRATION 9).

Continuation of the cooling process causes these small droplets

to continue to grow, eventually forming large colorless drops of

condensate on an iridescent background.

For further images of water and hydrocarbon condensation refer

to Appendix N.

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

*"!

=11>?@34@=AB& & VD&(I&H,#KF# /" E., #&O, HE "# F &

"#K&LF"-.F+P&

1.4. ANALYZER CONSTRUCTION

The analyzer’s cold-body housing (see ILLUSTRATION 10 and

ILLUSTRATION 11) consists of the high-pressure chamber (1)

a sample sized receptacle (hereafter in the text the measurement

cell (2)) a removable visualization system with 40 power magnification (hereafter in the text microscope (16) and an electronic

module with an integrated touch screen display (10). The analyzer’s high-pressure chamber is designed for a working pressure

of up to 300 bar, and serves to supply and remove the sample

gas that passes over the condensation mirror. In order to observe

the condensation process, the high-pressure chamber is fitted

with a small window upon which the visualization system can be

mounted.

The microscope is mounted directly onto the Hygrovision’s highpressure chamber.

The electronic module controls the analyzer’s processes (cooling/heating); records the mirror temperature and regulates the

photoelectric registration system.

The Hygrovision BL is operated by means of control buttons and

the touch screen display.

Recorded dew point values can be downloaded by means of an

IR port and an RS 485 interface.

In order for the analyzer to operate independent of an external

power supply, a slot for a storage battery is integrated into the

Hygrovision‘s housing, as is a socket for connecting the unit to an

external power supply (12–32V, 15W).

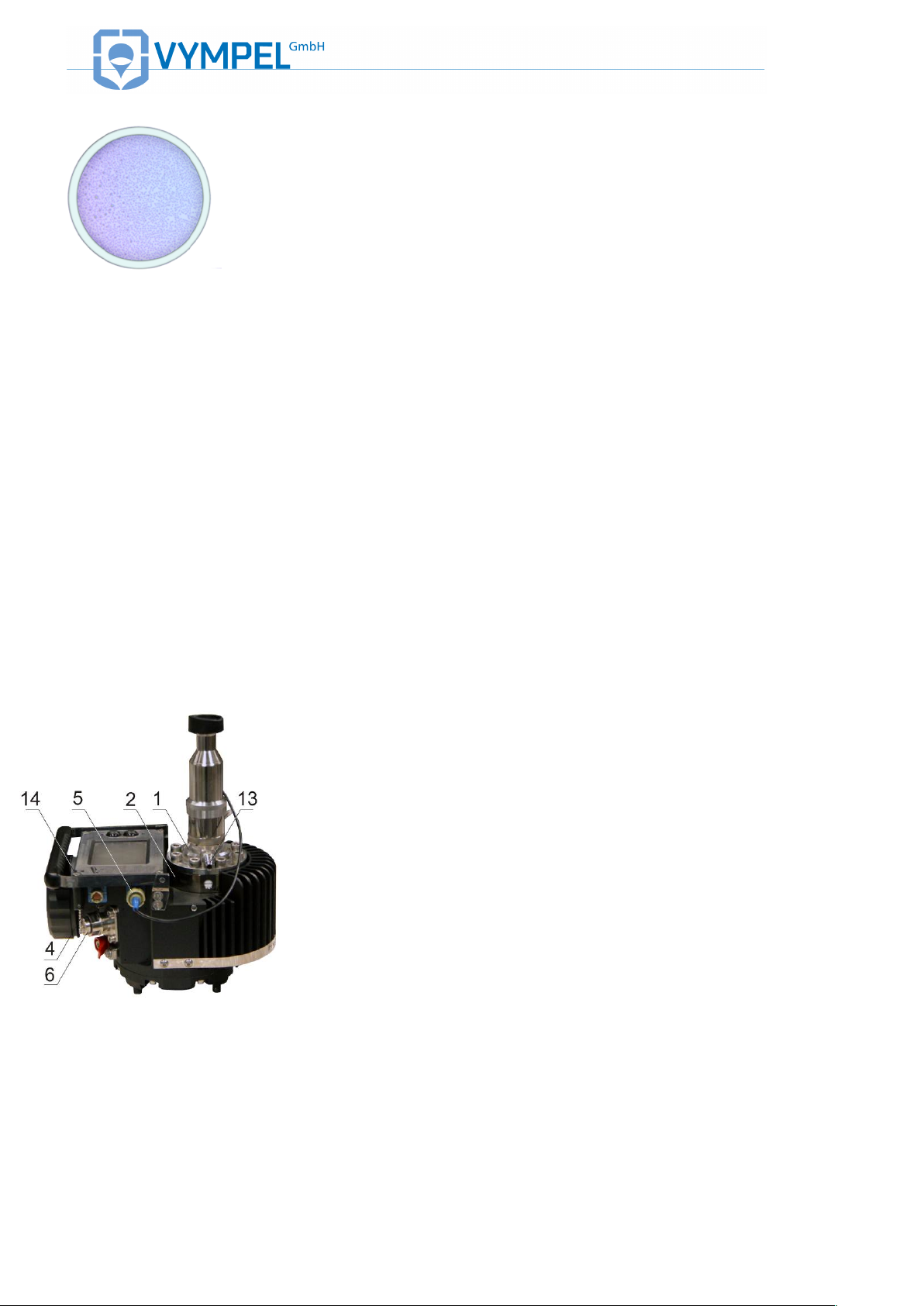

=11>?@34@=AB& & C:D&!".#&H,JN, #F # E/&, G&EL F & &

()*+,-./.,#&01&OCP&

Main components

(see ILLUSTRATION 10 and ILLUSTRATION 11)

• Gas delivery block (Pos.1);

• Measurement cell (PIP) (Pos.2);

• Battery compartment cap (Pos.3);

• Connection for the pressure sensor (Pos.4);

• Plug connector for the light emitting diode (Pos.5);

• RS 485 Modbus interface (Pos.6);

• Ventilation channel for supplementary cooling (Pos.7);

• IR port (Pos.8);

• On/off button (Pos.9)

• Touch screen (Pos.10);

• Control buttons (Pos.11);

• Sample gas inlet nozzle (Pos.12);

• Sample gas outlet nozzle (Pos.13);

• Stylus for use with the touch screen (Pos.14);

• Battery cap securing device (Pos.15).

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

*#!

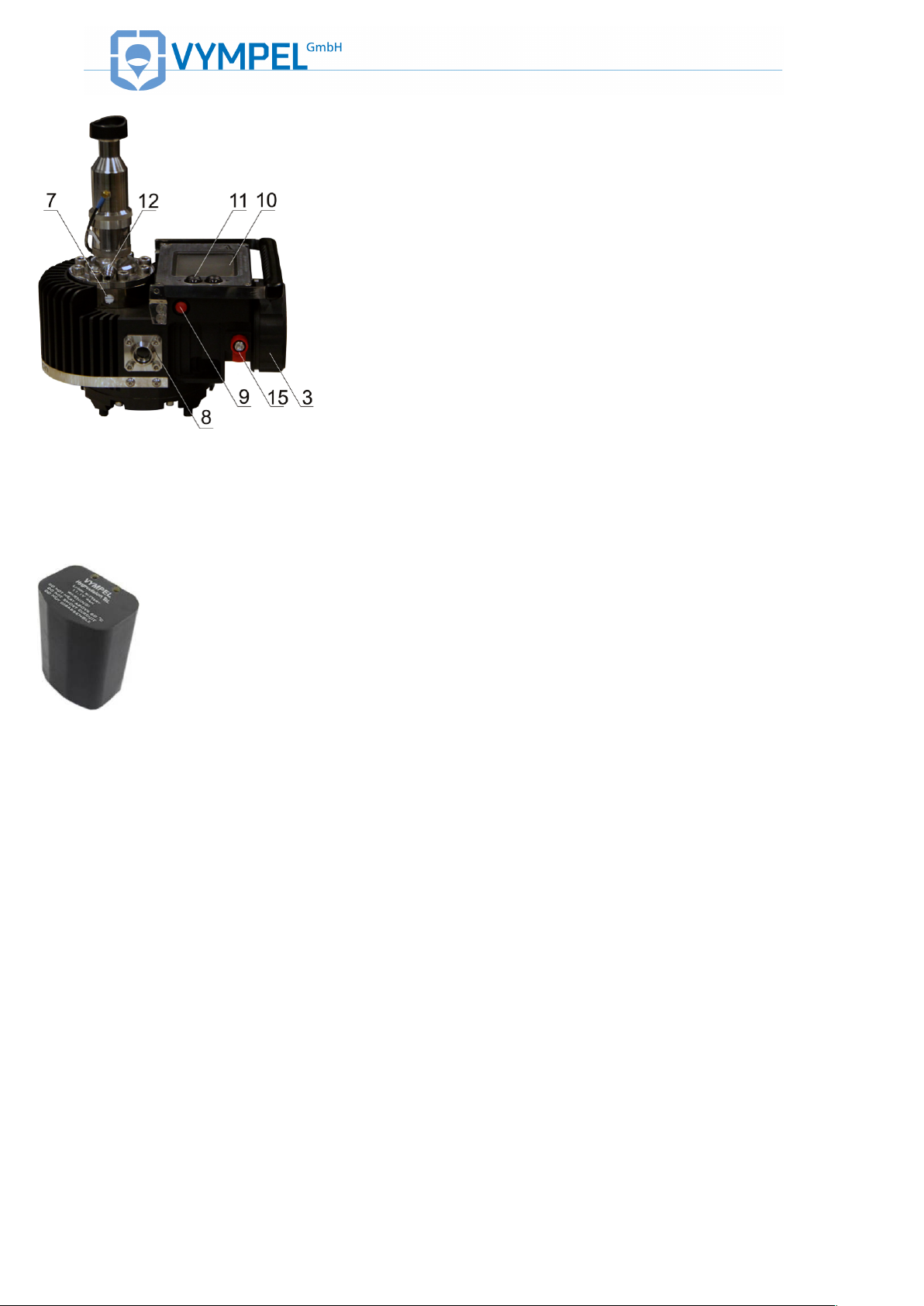

=11>?@34@=AB& & CCD&!".#&H,JN, #F # E/&, G&EL F & &

()*+,-./.,#&01&O6P&

The measurement cell, the electronic module with integrated touch

screen and the power supply module (storage battery) are enclosed within the analyzer’s metal housing (see Appendix A). The

housing is made up of three chambers.

Two of the three chambers (chambers 1 and 2) are pressure resistant encapsulations. These chambers house the circuit boards for

the electronic module (chamber 1) and the storage battery (chamber 2). The connection points for the external power supply and the

IR data port are located on the side of chamber 1.

The third chamber (chamber 3) houses all of the electronic module’s control and display elements. The touch screen display is integrated into the top of chamber 3. Connection points for an external pressure sensor and the microscope’s side-lighting element are

located on the side of this chamber. All of the electrical circuits

housed in chamber three meet the requirements for intrinsic safety.

BATTERY PACK

=11>?@34@=AB& & C6D&3FHL"+*F"W %F&W "EEF +)&

N"HX&

1.5. ANALYZER POWER SUPPLY

Hygrovision series analyzers have an independent onboard power

supply, the BP-06 power supply unit (hereinafter also referred to as

the rechargeable battery, battery, BP)

Important technical data for the BP:

Battery type

LIR18650 (Li-Ion);

Number of elements

6

Rated voltage

11.1 V

Max. discharge current

≤ 3 А

Electrical capacity

4 А h

Service life

300 recharging cycles

(max. 2 years)

Operating conditions

-20 °C – + 60 °С

!

!

A detailed description of the BP unit’s operating requirements can

be found in the manual (KRAY5.549.006 ET) (included in delivery).

It is strongly recommended that only the (KRAY4.841.082) connection cable be used to connect the Hygrovision BL to an external

power source (12 – 32V DC). This cable is designed specifically for

this purpose (ILLUSTRATION 13).

Refer to ILLUSTRATION 35 when connecting the analyzer to an

external power supply.

The Hygrovision’s battery pack should only be recharged using the

specially designed battery charger (KRAY5.122.007) included with

delivery. Information about the use of the charger can be found on

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3 <&

*$!

!

!

=11>?@34@=AB& & CMD&0"EEF+)&HL"+*F +&

O"HHF//,+)P

the label (KRAY5.122.007ET).

1.6. ADDITIONAL COMPONENTS AND

ACCESSORIES

Additional components include those systems and accessories that

ensure the optimal performance of desired analyzer functions.

Additional components fall into one of two categories:

• Additional components included as part of the Hygrovision

BL’s standard equipment;

• Additional components supplied at the customer’s request.

Standard equipment

Included with delivery as standard equipment:

• Microscope (KRAY3.821.003);

• Gas flow and gas pressure control system Model 001

(VMPL5.183.001);

• Gas delivery system Model 001

(VMPL6.450.001)Model -001 VMPL6.450.001;

• Filter for the control of glycols and heavy

hydrocarbons;

• Accessories used for the installation and maintenance

of the measuring system and for individual analyzer

modules.

!

!"#$"%&'&()*+,-./.,#&01&'&234567899::;3<&

*%!

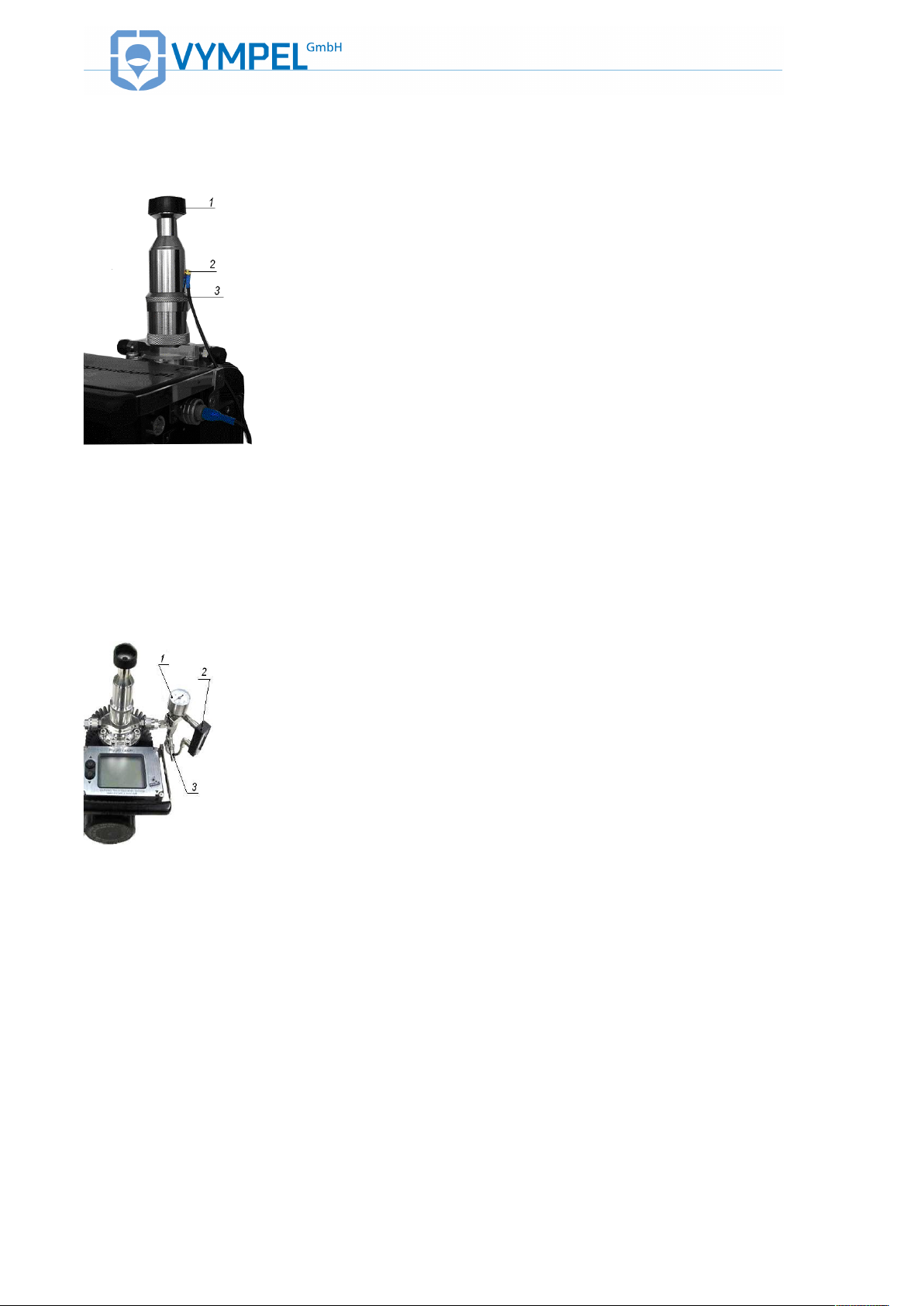

MICROSCOPE

!

=11>?@34@=AB& & C9D&!.H+,/H,NF&

ILLUSTRATION 14 is an exterior view of the microscope

(KRAY3.821.003).

The optical system is positioned immediately above the high-pressure

chamber. Equipped with 40X magnification, this system makes it possible to directly monitor processes taking place on the mirror’s surface

inside the measurement chamber to visually evaluate the compositional quality of the gas (see also 1.3).

The microscope is mounted onto the analyzer by way of a threaded

coupling integrated into the housing for this purpose.

Important components:

• Eyepiece (Pos.1);

• Electrical socket for the lighting system LED (Pos.2);

• Focusing ring (Pos.3)

Gas flow / gas pressure

control system (Model

001)

!

=11>?@34@=AB& & CRD&Y"/&G%,Q&"#K&

*"/&N+F//$+F&H,#E+,%&/)/EFJ&

The gas flow / gas pressure control system Model 001

(VMPL5.183.001) (ILLUSTRATION 15) displays information about

the operating pressure within the analyzer’s measurement chamber.

This system also provides a means to not only adjust the pressure

but also regulate the gas flow rate during the measurement process

(0.5 – 1NL/min).

Included in delivery of the gas flow / gas pressure control system are:

• Manometer (Pos.1);

• Float flow meter with metal housing (Pos.2);

• Flow rate fine adjustment valve (Pos.3);

• Mounting and connecting elements

Refer to Appendix C for a mounting diagram of the gas flow and gas

pressure control system.

Please note:

Most of the systems and system modules are attached to the analyzer by

means of quick-coupling connectors. The advantage such connectors provide is

that no tools or special skills are needed for the installation of various modules

and installation can be accomplished in the shortest mount of time.

!

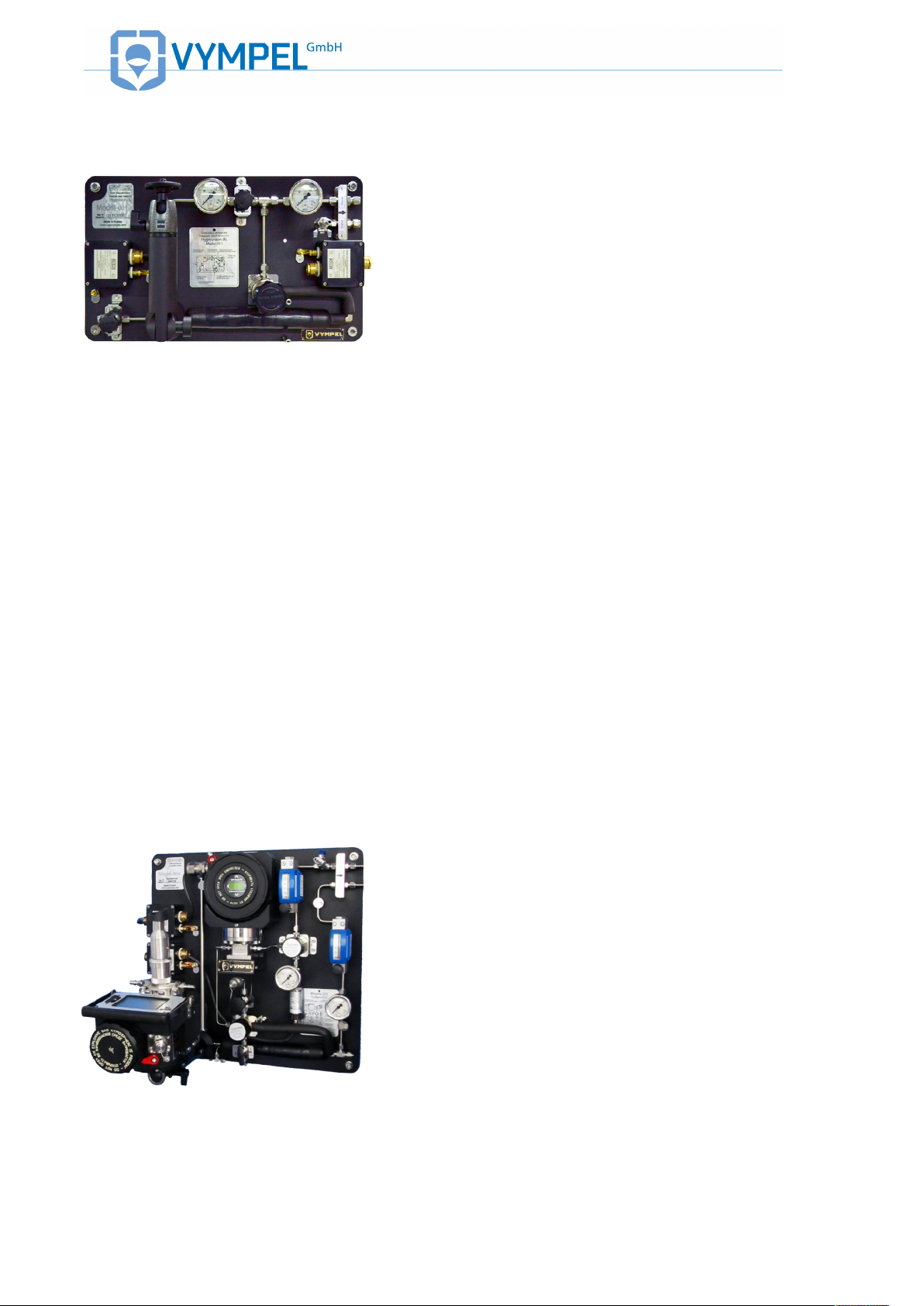

GAS DELIVERY SYSTEM

MODEL 001

!

=11>?@34@=AB& & CTD&Y"/&KF%.-F+)&/)/EF J&

The gas delivery system provides a hermitically sealed

connection between the analyzer and the sample extraction

site. In addition, this system makes it possible to evenly

regulate delivery of the sample gas to the Hygrovision’s

measurement chamber.

Included in delivery of the gas delivery system are:

• Flexible high pressure hose (Pos.1;

ILLUSTRATION 16);

• Fine control valve (Pos.2; ILLUSTRATION 16)

Refer to Appendix D for gas delivery system assembly

instructions..

Please note:

The fittings included in delivery make it possible to connect the analyzer with various measurement equipment, devices, and systems in

the shortest amount of time and do not require additional tools or specialized skills.

PARTICLE FILTER

!

=11>?@34@=AB& & C;D&Z,/.E.,#&,G&ELF&N"+E .H%F &G.%EF+ &

The analyzer is also equipped with an integrated particle filter

in order to remove solid particulates and other mechanical

contaminates from the sample gas. This filter (FE73A-15) is

positioned in the inlet side of the gas delivery housing (Pos.

1; ILLUSTRATION 17) and protects the condensation mirror from possible damage from solid particulates and contaminates in the gas mixture.

The particle filter is included with delivery of the analyzer and

is preinstalled in the analyzer’s housing prior to initial delivery.

A replacement filter cartridge is included with the additional

components delivered with the analyzer as standard equipment.

Please note:

There is a replacement filter cartridge included with the analyzer as

standard equipment. Additional replacement cartridges can be ordered

from Vympel at any time.

GLYCOLS AND HEAVY

HYDROCARBONS FILTER

When taking measurements to determine the dew point of

water, it is common for a variety of gas mixtures to have high

levels of glycol and heavy hydrocarbons. A specially designed filter (KRAY6.451.017) is used for the taking of measurements under these conditions. This filter is included as a

standard additional component with the Hygrovision BL.

(ILLUSTRATION 18).

The filter is installed directly in front of the fine control valve

!

!

=11>?@34@=AB& & C8D&Y%)H,%/&"#K&LF"- )&( I &G.%EF + &

at the end of the flexible high-pressure hose of the gas delivery system (VMPL6.450.001).

In terms of active filtering, the average service life of the filter

cartridge is eight hours. Therefore, the replacement interval

depends in large measure on the type and composition of

heavy hydrocarbons.

Usage requirements as well as detailed information about the

filter can be found in the manual (KRAY6.451.017ET), which

is included with delivery.

The glycol and heavy hydrocarbon filter is delivered with the

analyzer as standard equipment.

EXTERNAL POWER SUPPLY CABLE

!

=11>?@34@=AB& & CVD&Z,QF+&/$NN%)&H"W%F&

The external power supply cable (Illustration 20) is included

with the analyzer as standard equipment. It serves not only to

provide the device with electricity but also to transmit measurement data by way of the RS 485 interface using the standard Modbus/RTU protocol.

Please refer to Table 5 for instructions concerning electrical

configuration and connection..

IR ADAPTER

!

=11>?@34@=AB& & 6:D&=3&4K"NEF+&

The analyzer’s integrated infrared (IR) port can be connected

to a computer by means of the IR adaptor (KRAY5.999.005).

The position of the IR port is shown in Pos.8;

ILLUSTRATION 11.

Additional components that are available for order as optional

accessories include:

• Supplemental cooling system VMPL5.880.003;

• Tripod (Libec TH-650DV);

• Sample extraction system KRAY4.078.091(- 01);

• Pressure reduction system VMPL2.848.005;

• High-pressure outflow module VMPL4.078.025;

• For a detailed list of the Hygrovision BL’s standard

and optional components, please refer to Table 3,

Point 1.12.

!

SUPPLEMENTAL COOLING SYSTEM

!

=11>?@34@=AB& & 6CD&?$NN%FJF#E"%&H,,%.#*& &

/)/EFJ&

The supplemental cooling system (VMPL5.880.003) should

be used when measuring dew point values below -30°C at

ambient temperatures above +30°C and at pressures over

100 bar (ILLUSTRATION 21).

The cooling system consists of a container filled with carbon

dioxide, two connector fittings, and a regulator valve to control the flow of refrigerant.

The system is connected to the outlet nozzle of the venting

channel (Pos.7; ILLUSTRATION 11).

Please refer to Appendix E for mounting instructions.

For a detailed description of the supplemental cooling system

please refer to “Special considerations when measuring dew

point at very low temperatures ”

TRIPOD

In order to make operating the analyzer more convenient

when in the field, the Hygrovision can be mounted on a Libec

TH-650DV tripod.

A tripod attachment point is integrated into the underside of

the Hygrovision’s housing. When mounted, the analyzer can

be oriented in the desired position.

SAMPLE GAS EXTRACTION SYSTEM

The optional sample extraction system (KRAY4.078.091 or

KRAY4.078.091-01) can be installed to create a stationary

sample gas extraction site. The system set consists of the

sample extraction apparatus (or a bypass valve) and a membrane filter for the removal of liquids and particulates from the

gas sample.

Information regarding mounting and operating this system as

well as ordering replacement filter elements can be found in

the manual delivered with the set (KRАY4.078.091EТ or

KRAY4.078.091-01ET).

!

PRESSURE REDUCTION SYSTEM

=11>?@34@=AB& & 66&

The pressure reduction system (VMPL2.848.005) provides

for the reduction of the sample gas pressure from the working pressure (max. inflow pressure is 250 bar) to a pressure

within the range 0.30 – 35 bar.

The module includes a heating element to pre-warm the gas

sample in order to prevent premature condensation due to

the Joule-Thomson effect (a drop in temperature that is a

consequence of a drop in pressure in the gas mixture).

ILLUSTRATION 22 shows an overall view of the Pressure

Reduction System (PRS). For a schematic drawing, please

refer to Appendix F.

Detailed mounting and operating information can be found in

the manual (VYMP2.848.005RE) delivered with the PRS.

HIGH-PRESSURE

VENTING MODULE

The venting module (VMPL4.078.025) is used to channel the

sample gases flowing out of the Hygrovision’s measurement

chamber into the main venting line, in those situations where

the Hygrovision is used as a reference analyzer (Appendix

G).

GAS PREPARATION SYSTEM

SGA-003

!

=11>?@34@=AB& & 6MD&?Y4&::M&.#H%7&( )* + , - ./., # &0 1 &

The SGA 003 gas preparation system, or simply SGA,

(ILLUSTRATION 23) provides for the removal of various

aerosol and mechanical contaminants from the sample gas at

a working pressure of up to 160 bar.

The SGA is designed to accommodate the optional use of a

Hygrovision BL as a temporary reference analyzer. To that

end, a foldout mounting arm, and supplemental sample gas

connection points are integrated into the SGA’s construction.

In addition, the SGA is also fitted with a supplemental access

point on the explosion-proof terminal box in order to connect

the Hygrovision BL to an external power supply and link it to

the data transfer system.

!

1.7. CONTROL AND DISPLAY ELEMENTS

The analyzer has the following control elements:

On / off button (Pos.9; ILLUSTRATION 11);

Control buttons (Pоs.11; ILLUSTRATION 11) for regulating

the temperature of the condensation mirror.

The touch screen display (Pos.10; ILLUSTRATION 11) is

used to set and adjust the analyzer’s operating parameters.

The display presents information in the form of text and

graphics.

The touch screen stylus can be used to operate the display

(Pos. 14; ILLUSTRATION 10).

1.8. THE ANALYZER’S MENU

TURNING ON THE ANALYZER

=11>?@34@=AB& & 69&

To turn on the Hygrovision BL press and hold the on/off button for several seconds (Illustration 24).

After the analyzer has been switched on, the touch screen

will display the software version information for two to three

seconds. (Illustration 25)

The BL is ready to begin measurement operations when the

software message is no longer displayed. The analyzer will

automatically revert to the operation at which it was set

when turned off (Illustration 26, 27).

The following control “icons” are displayed on the analyzer’s

screen:

!

=11>?@34@=AB& & 6R&

!

=11>?@34@=AB& & 6T&

!

=11>?@34@=AB& & 6;&

!

!

Operating mode

Shows the currently selected operating mode (Pos.1

ILLUSTRATION 26; ILLUSTRATION 27);

Mode selection

Used to select the desired operating mode (Pos.12,

ILLUSTRATION 26; ILLUSTRATION 27);

Properties

Used to select and access the analyzer’s basic operating parameters in order to make adjustments (Pos.2, ILLUSTRATION

26; ILLUSTRATION 27) A description of the properties menu is

included in Appendix I.

Measurement channel

Used to select the desired measurement type:

• Dew point of water (channel W) or

• Dew point of hydrocarbons (channel HC)

(Pos.11, ILLUSTRATION 26, ILLUSTRATION 27);

Mirror-cooling modality

a

Used to select the mirror-cooling mode when taking measurements manually:

• a) Cooling of the condensation mirror at a continuous

preprogrammed rate (Pos.10, ILLUSTRATION 26;

ILLUSTRATION 27);

b

• b) Stepwise cooling of the condensation mirror by prepro-

grammed temperature intervals (Pos.10, ILLUSTRATION

26; ILLUSTRATION 27).

Laser activation icon

Used to switch the laser on and off (Pos.9, ILLUSTRATION 26;

ILLUSTRATION 27).

This icon only appears when the microscope lighting button has

been activated. The laser is preset in the on position.

Rough DP – Scan

This button activates a scanning process that finds a preliminary

dew point value in order to establish the basic temperature range

within which an accurate dew point value can be measured

(Pos.7, ILLUSTRATION 26, ILLUSTRATION 27).

Microscope lighting

Used to switch the microscope (vertical) lighting on and off

(Pos.8, ILLUSTRATION 26; ILLUSTRATION 27)

Mirror-cleaning mode

Used to activate the mirror-cleaning mode. In this mode the condensation mirror is heated to a specific temperature in order to

free the mirror surface of condensate residue by means of evaporation (Pos. 6, ILLUSTRATION 26; ILLUSTRATION 27).

!

Measurement scale

Used to change the measurement scale during the measurement

process (Pos. 5, ILLUSTRATION 26; ILLUSTRATION 27)

DISPLAYED INFORMATION

• Battery charge status – Pos.3 (ILLUSTRATION 26;

ILLUSTRATION 27);

• Timer – Pos.4 (ILLUSTRATION 26; ILLUSTRATION

27);

• Current temperature of the condensation mirror – Т;

• Housing temperature – Tb;

• Condensation temperature – Tc;

• Evaporation temperature – Te;

• Temperature interval during mirror cooling - ;

• Signal level of the photodiode - U;

• Dew point temperature – DР.

In stepwise cooling mode an automatic timer is activated

which displays the time spent at each temperature level.

The battery status display consists of nine segments — each

segment represents 10 percent of the battery’s charge.

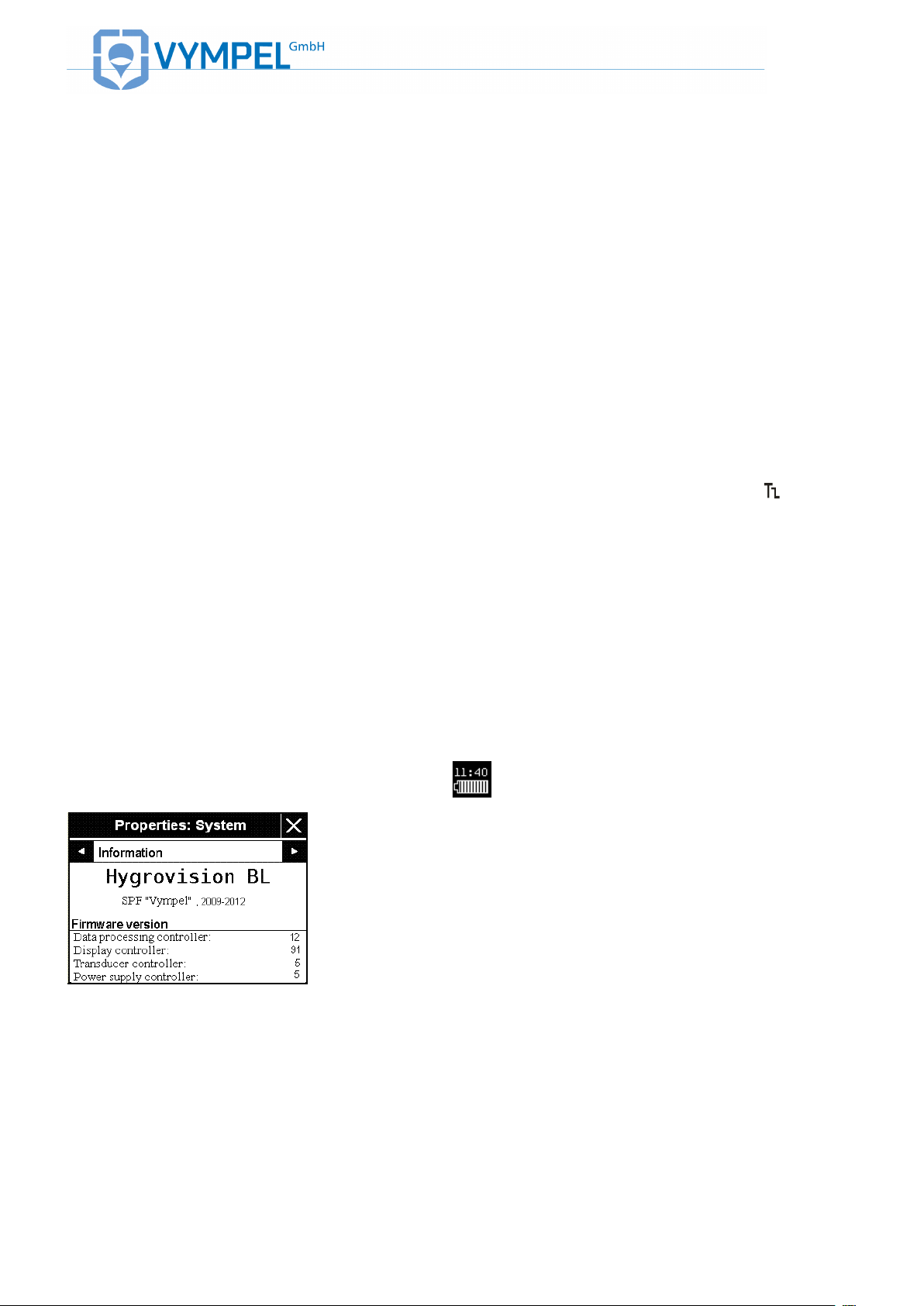

PROPERTIES

!

=11>?@34@=AB& & 68D&Z+,NF+E.F/D&?)/EFJ&'&

ANF+"E.#*&/)/EFJ&

When the icon is tapped, additional information is displayed.

The window that opens when the properties icon is tapped

displays information about the operating system

(ILLUSTRATION 28), the time and date (ILLUSTRATION

29), and the battery status (ILLUSTRATION 30).

!

!

=11>?@34@=AB& & 6VD&Z+,NF+E.F/D&?)/EF J&'&["EF&

"#K&E.JF&

Use the < and > icons to navigate between individual menu

points.

Please note that the date and time are set using the Settings

menu (see also Appendix I).

!

=11>?@34@=AB& & M:D&Z+,NF+E.F/D&?)/EF J&'&Z,QF+&

/$NN%)&

The Hygrovision’s battery should be fully recharged as described in the manual (KRAY5.122.007 ET) when the charge

falls below 20%.

!

ANALYZER CHECK

!

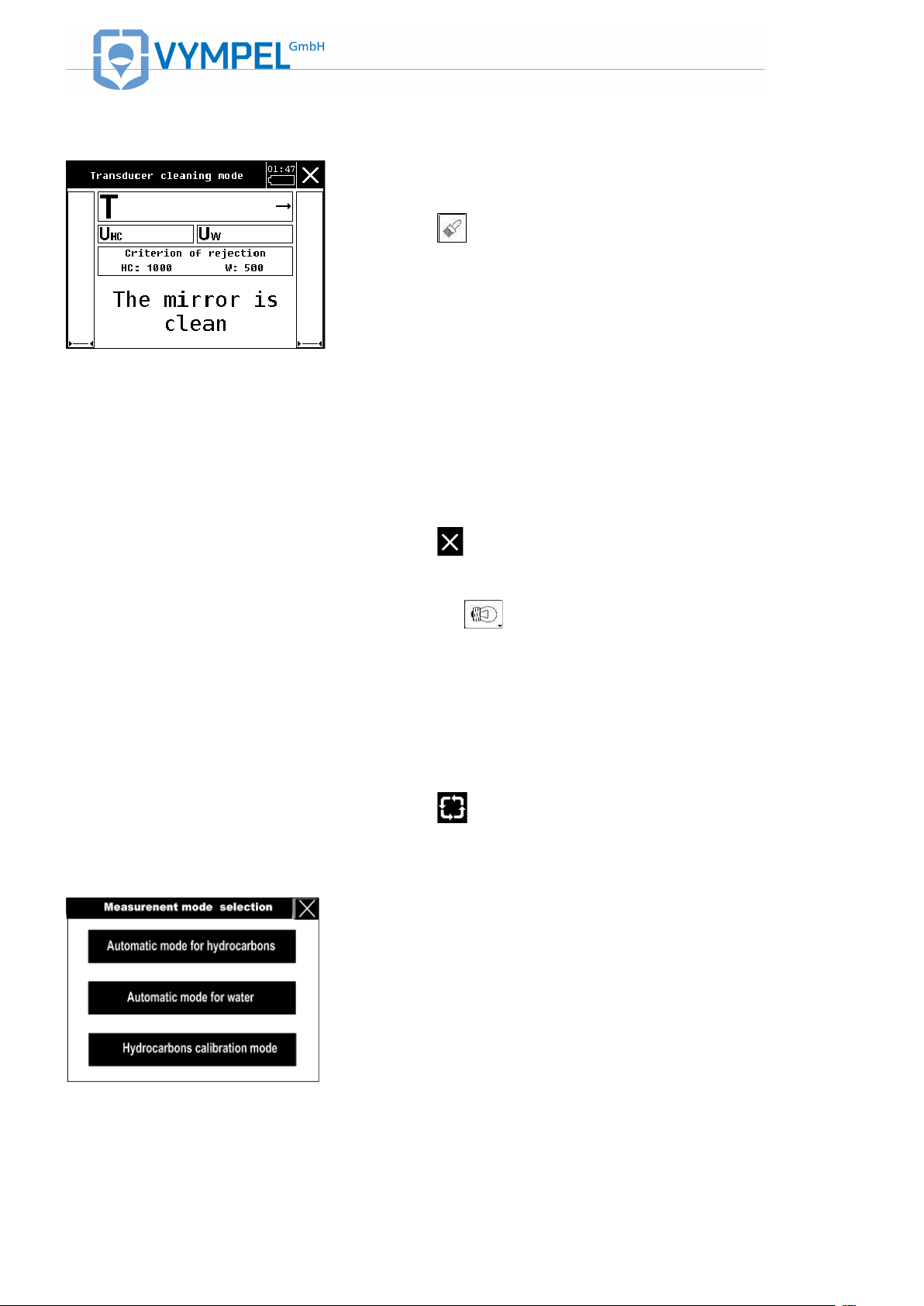

=11>?@34@=AB& & MCD&@+"#/K$HF+&H%F "# .#* &J,KF&

In order to check the functionality of the analyzer follow these

steps:

Tap the icon to switch to the mirror-cleaning mode

(Pos.6, ILLUSTRATION 26; ILLUSTRATION 27)

The analyzer’s display will show the “Transducer cleaning

mode” window (ILLUSTRATION 31)

If the device is operating normally, the condensation mirror

should heat to temperature of +50° ± 0.1° C (Т value).

Please note:

Should there continue to be residue on the surface of the mirror after

the mirror-cleaning cycle has been completed, the error message “The

mirror is dirty” will be displayed. In this case it is necessary to repeat

mirror cleaning as described in Point 5.2 .

Tap the icon to switch to the main menu.

Check that the microscope lighting is working properly by

tapping the icon.

When the microscope lighting is switched on, the symbol appears as a black drawing on a light background.

When this lighting is switched off, the symbol, appears as a

light drawing on a dark background.

AUTOMATIC DEW POINT

MEASUREMENT MODE

Tap the icon (Pos12, ILLUSTRATION 26;

ILLUSTRATION 27) to switch to automatic dew point

measurement mode.

!

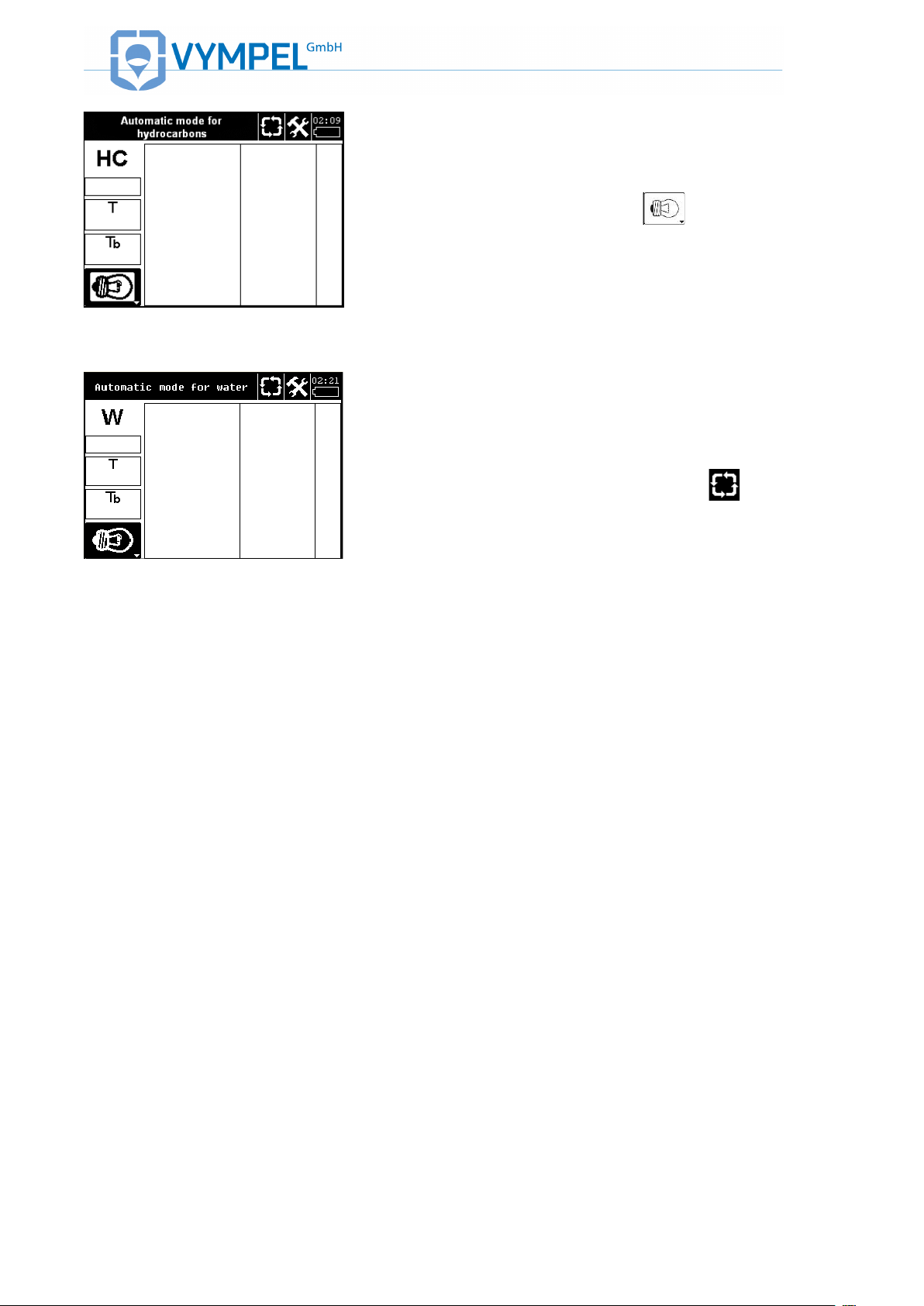

=11>?@34@=AB& & M6&

Select one of the three modes that displayed in the window

that opens (ILLUSTRATION 32):

• Automatic mode for hydrocarbons

• Automatic mode for water

• Hydrocarbons calibration mode

To activate the desired mode, simply tap the related field.

!

!

=11>?@34@=AB& & MM&

In order to visually observe the measurement process in

automatic mode for hydrocarbons, the microscope lighting

must be activated by tapping the icon.

(ILLUSTRATION 33).

!

=11>?@34@=AB& & M9&

In the automatic mode for water, the microscope lighting is

switched off (,--./0120,34! ! #$). Visual monitoring of the

measurement process in this mode is carried out with the

microscope lighting turned off.

In order to switch between modes tap the icon again

(Pos.12, ,--./0120,3 4! ! "&5!,--./01 2 0 ,3 4! ! "') and select the

desired operation by tapping the related field 6,--./0120,34! !

#"78

TURNING OFF THE ANALYZER

To turn off the analyzer, press the red button on the left side of

the touch screen housing (Pos. 9, ,--./ 0 1 2 0 ,3 4! ! **7!and hold it

down until the display switches off (about five seconds).

!

1.9. CONNECTING

PERIPHERAL DEVICES

The following connection points are located on the right side of

the analyzer’s housing:

• ХР2 – used for maintenance purposes

• ХР3 – microscope lighting connection socket (Pos.5 ;

,--./0120,34! ! *+)

• XР1 – socket for connecting the analyzer to an external

power supply and for transferring measurement data

over a RS-485 interface using the Modbus/RTU – Protocol (Pos.6; ,--./ 01 2 0 ,34! ! *+)

A description of the Modbus register is included in 299:;<=>!?.

Attention!

The sockets (Pos. 4, 5) are intrinsically safe devices.

Sockets ХР2 and ХР3 have light blue caps.

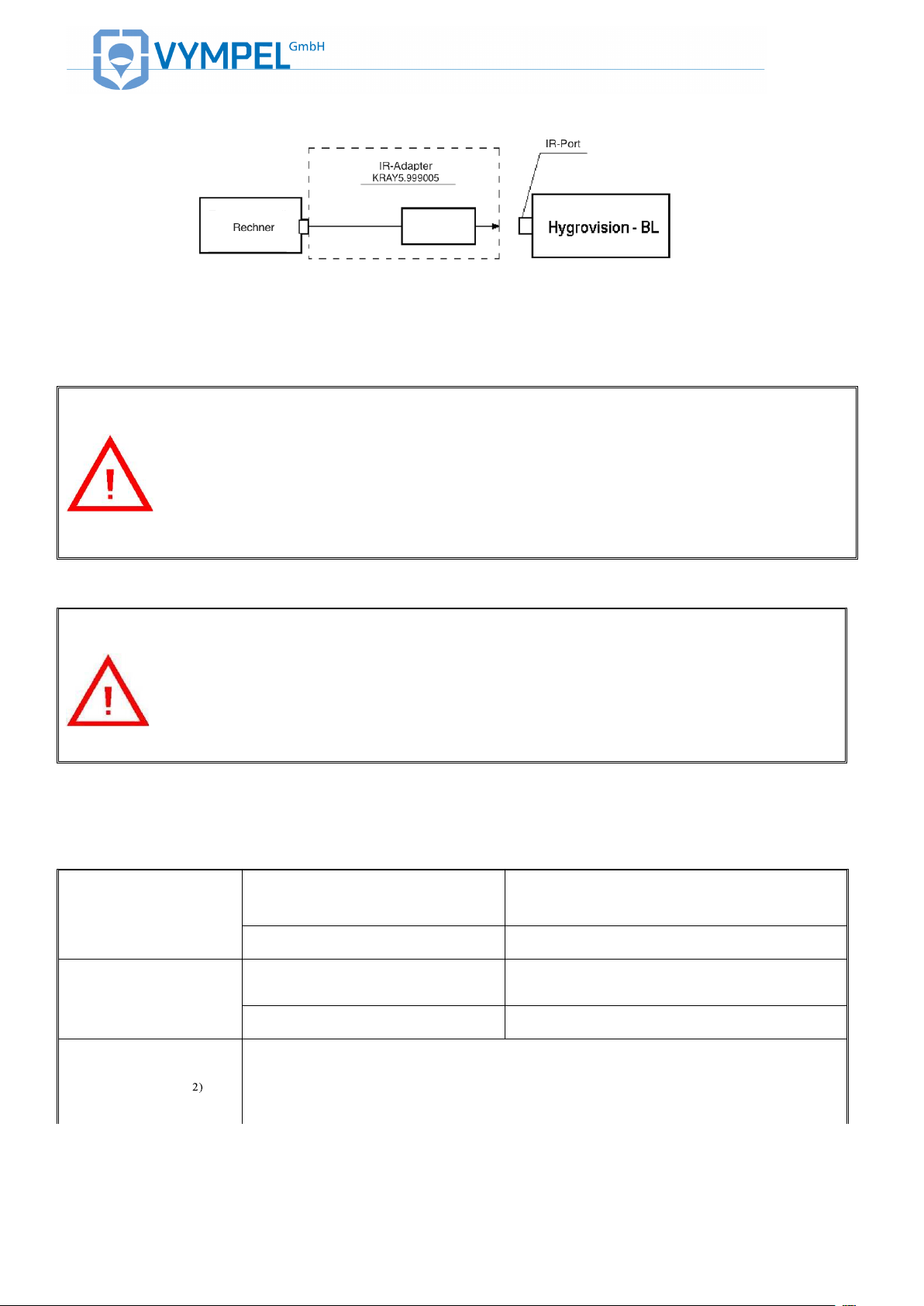

The IR port is located on the left side of the analyzer’s housing (Pos.8; ILLUSTRATION 11). This connection port

makes it possible to connect the Hygrovision to an terminal

module or computer in order to transfer measurement data

via the IR adapter (KRAY5.999.005), which is included with

delivery as a standard component.

Measurement data is transferred using the standard terminal

programs Hygrovision.exe (299:;<=>!@).

!

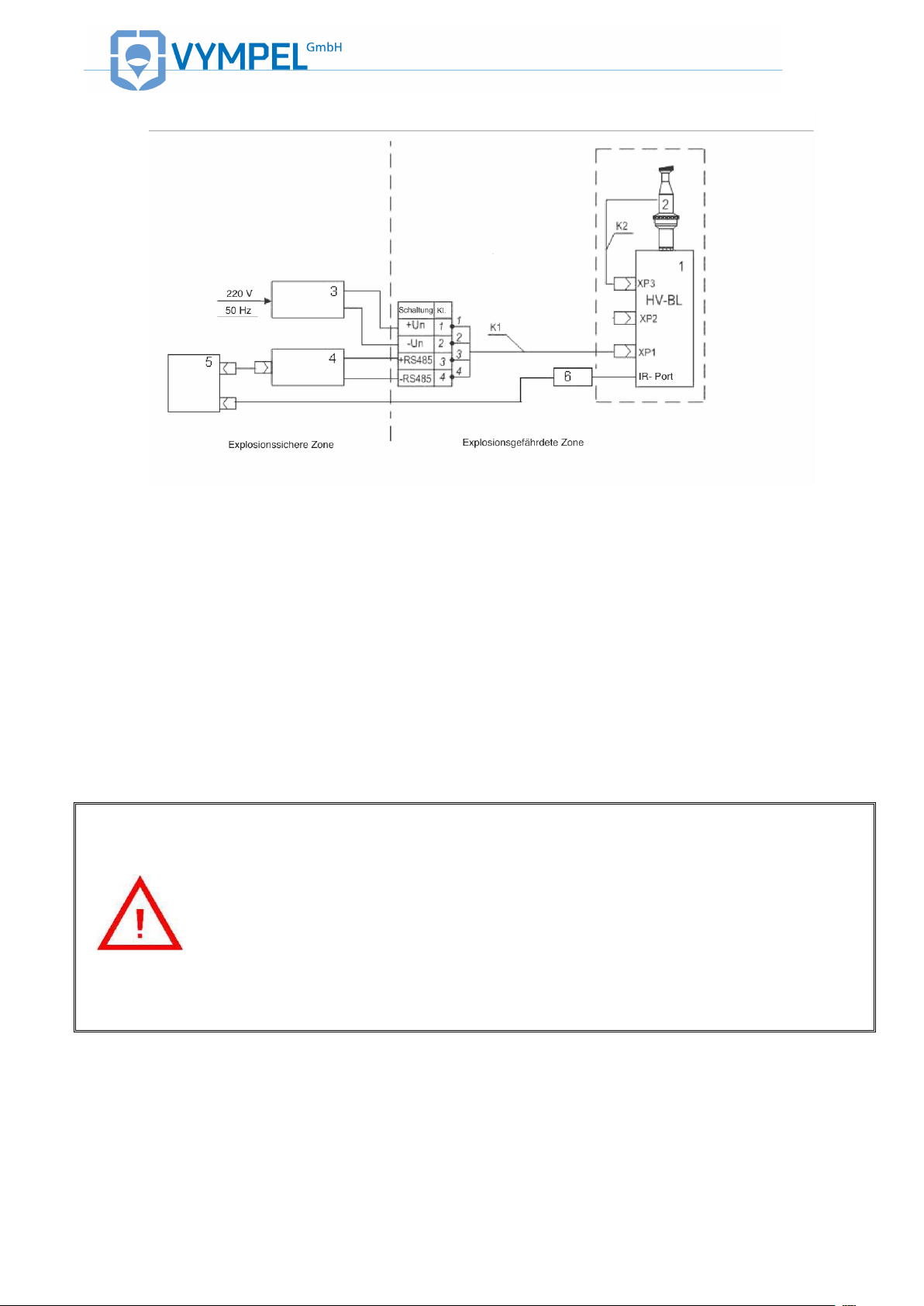

=11>?@34@=AB& & MRD&?HLFJ"E.H&K+" Q .# *&G, +&EL F &H, # #F H E.,#&,G&NF+.NLF+"%&KF-.HF/&

Position of elements in illustration 35:

1 – Hygrovision BL dew point analyzer

2 – Microscope (KRAY3.821.003)

3 – AC power adapter (12- 32) V / 15 W

4 – Interface connector RS – 232 / 485

5 – Computer terminal

6 – IR Adapter (KRAY5.999.005)

К1 – Cable (KRAY4.841.082)

К2 – Cable (VMPL4.841.007)

Attention!

The AC power cable is connected to the analyzer via a supplemental junction box.

Within the junction box, connection of the intrinsically safe and not intrinsically safe

electrical circuits must be carried out separately, in accordance with GOST

R52350.11-2005 and Point 6 of this manual.

&

!

&&&

=11>?@34@=AB& & MTD&I,##FHE.,#&,G&"&H ,JN$EF+&EF+J.#"%&-."&ELF&=3&N,+E

Attention!

The terminal computer and the IR adapter (KRAY5.999.005) are not explosion-proof

devices.

For this reason, connection of these devices to the analyzer may only be carried out

in explosion-proof zone.

1.10. SPECIFICATIONS

@"W%F&C&

Water

-30 ºС – TH

Measurement range

Hydrocarbons

-30 ºС – TH

Water

±0.5 °С

Measurement error

Hydrocarbons

±0.5 °С

Recommended

gas-flow volume

0.5 – 1 Nl/min

Attention!

To ensure the analyzer’s explosion safety, unused socket connections must be secured with the caps included with delivery.

!

Battery-powered operation

= (8.4 – 12.6) V, 4 mА / 15 W

Electrical supply

(Voltage / Power)

External power supply

= (12 – 32) V / 15 W

Battery-powered operation

4 h

Operating time

External power supply

Unlimited

Ambient

Temperature

-10 – +50 0С

Working pressure

≤ 250 bar (dependent on BL version)

Level of housing

protection

IP66

Dimensions

(without micro-

165х204х257 mm

Weight

(without accesso-

7.5 kg

Installation

Suitable for enclosed indoor spaces and open outdoor areas

(hazardous zones)

Sample extraction

connection

Pipe connection module (Dk-Lok connection pipe with an outer diameter of

ø 6mm)

Service life:

Analyzer

Measurement cell

Rechargeable

battery

10 years

3 years

300 charge/ discharge cycles (max. two years)

!

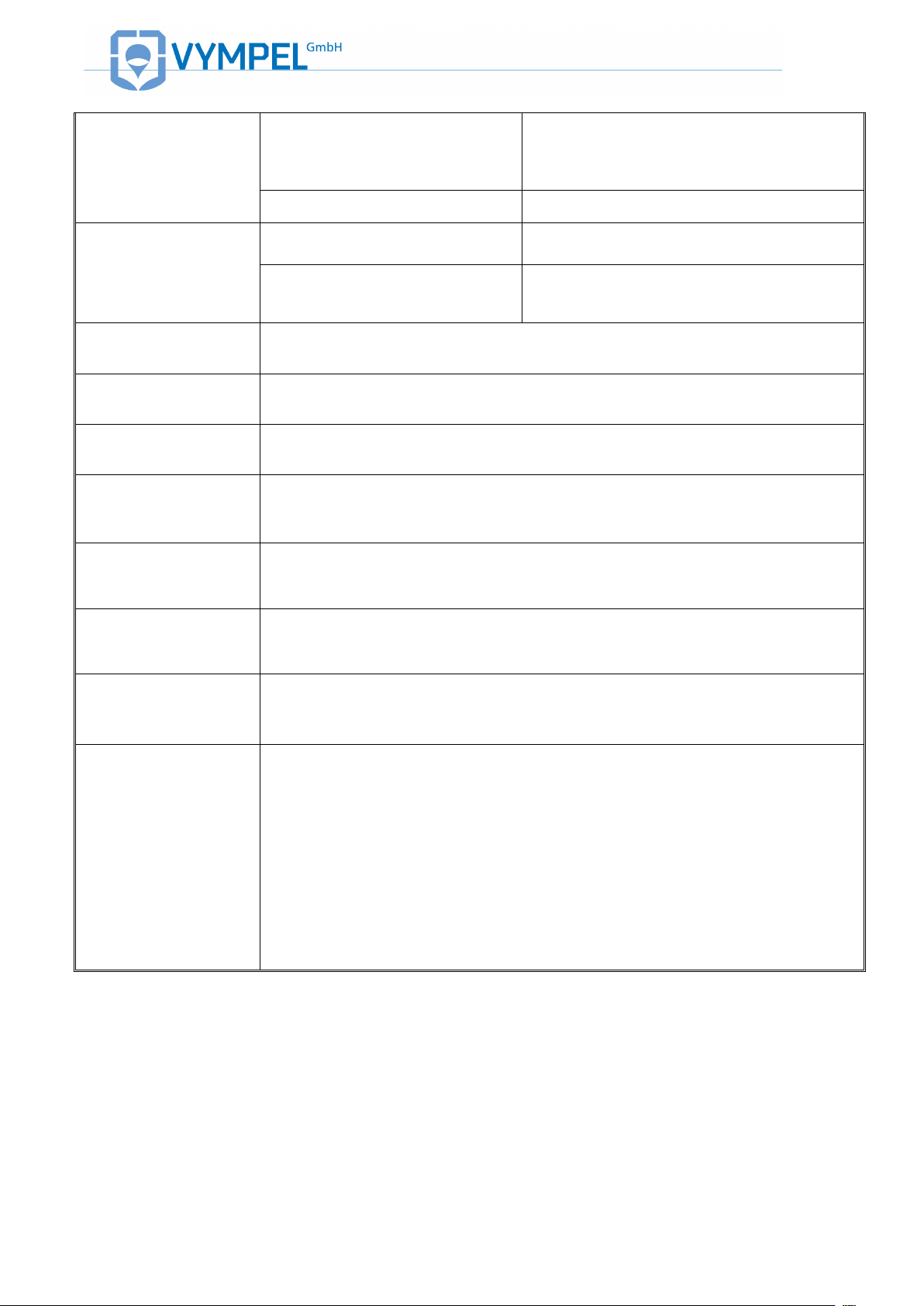

1.11. HYGROVISION BL STANDARD EQUIPMENT

&

&

Table 2 gives an overview of the important standard components delivered with the Hygrovision BL.

@LF&N,/.E.,#/&.#&=11>?@34@=AB& & M;\&=11>?@34@=AB& & M8\&=11>?@ 3 4 @ =AB& & MV&H,++F/N,#K&E,&ELF&#$JW F +.# * &.# &E" W %F &6 7& &

&

Table 2.

!

=11>?@34@=AB& & M;&

!

=11>?@34@=AB& & M8&

!

=11>?@34@=AB& & MV&

&

&

@"W%F&6&

Pos.

Article Number

Description

No.

Main components:

1

VMPL 4.161.003

Transport case

1

2

KRAY 2.844.007

Hygrovision BL dew point analyzer set (including the

following accessories)

1

3

KRAY 3.821.003

Microscope

1

4

VMPL.841.007

Cable

5

VMPL 5. 183.001

Gas flow and gas pressure control system Model 001

1

6

VMPL 6.450.001

Gas delivery system Model 001

1

7

KRAY 6.451.017

Filter for the control of glycols and heavy hydrocarbons

1

!

8 – PVC pipe: inner diameter ø 6х1.5, length= 2500 mm

1

9 – Mounting fittings (set)

1

10

VMPL 4.161.004

Transport case

1

11

KRAY 4.841.082

External power supply cable

1

12

KRAY 5.122.007

Battery charger

1

13

KRAY 5.549.006

AC adapter unit BP-06

1

14

KRAY 5.999.005

IR data connection line

1

15 – Power supply adapter cord IBM 16B; 4.5A ; plug 5.5/2.5

1

16 – Power cord with auto cigarette lighter plug 5.5/2.5

1

17 – Eclipse optics cleaner (59 ml)

1

18 – Cotton swabs (package of 50)

1

19

KRAY 4.160.001

Tube of replacement cartridges for filter KRAY6.451.017

(10 cartridges with adsorbent МАU)

1

20

VMPL 8.392.001

Special disassembly key

1

21

VMPL 8.248.005

Sealing ring

Operating documentation and software

22

KRAY

2.844.007RE

Operating manual

1

23

KRAY2.844.007

FD

Form

1

24

KRAY

2.844.007МL

Verification methodology

1

25

KRAY 2.844.00701 D21

Software

1

Additional equipment*

26

VMPL 5.880.003

Supplemental cooling system

27 – Element made of sintered steel (FE73A-15)

– Libec TH-650DV tripod

KRAY 4.160.001

Tube containing additional replacement filter cartridges

KRAY 5.549.006

Power unit BP-06

KRAY 4.078.091

(- 01)

Sample extraction module

130-502

Membrane filter replacement membranes (5 pcs.)

KRAY6.457.022(-01)

VMPL 2.848.005

Reduction unit model 001

VMPL4.078.025

High pressure venting module

* quantity dependent on customer order

Please note:

Depending on technical developments, the shipment inventory and the design of individual elementss may be

different than what is depicted here, however these alterations will have no effect on basic function and intrinsic

safety.

!

!

1.12. EXPLOSION SAFETY PROVISIONS

The analyzer is fitted with a flameproof enclosure and intrinsically safe electrical circuitry to provide safety against explosion (Table 1).

Other design features that ensure the Hygrovision BL is protected against explosion are:

Spark arresting insulation barriers that ensure the intrinsic safety of the electrical connections at

the control buttons.

Bypass diodes and resistors that ensure the intrinsic safety of the electrical circuit connected to

the display unit. These elements reduce the electrical current and voltage to the values allowed

by GOST R 52350.11 for electrical devices in Group II B. This reduction applies for both normal

and emergency operation modes. Electrical sparking is prevented through a combination of resistors and a fuse module.

The sum of the electrical capacity and the inductivity of the electrical circuit that connects the Hygrovision BL to external components via their individual intrinsically safe plugs conform to the

values required by GOST R 52350.11.

Optoelectronic coupling provides galvanic separation of the signal and the internal circuitry of the

Hygrovision BL.

Electrical clearances and seepage, and the stability of the electrical insulation of the intrinsically

safe circuitry are in accordance with the requirements of GOST R 52350.11

The electrical load does not exceed two thirds of the nominal capacity of components that ensure

intrinsic safety.

The construction and electrical properties of the LED conform to the specifications stated in

GOST R 52350.0 and GOST R 52350.1.

The maximal temperatures generated through internal heating, to which the electrical components

and the housing of the Hygrovision BL are exposed do not exceed those allowed in GOST R

52350.0 for temperature class T5.

The HV BL’s electronics unit connection points through the flameproof enclosure meet the requirements of GOST R 523 50.1 for electrical apparatus of subgroup II B.

Lock nuts and adhesives are used to protect against the loosening of the screws, bolts, and nuts

that secure the various elements of the flameproof enclosure as well as the conductor and

grounding terminals. Similarly, locking devices are used to secure self-threading connectors. The

heads of external fixing screws are recessed and can only be accessed using a special tool.

Cable entry points ensure that conductors have a stable and durable connection. Fasteners comply with the requirements of the GOST R 52350.1 – 2005 directive.

The mechanical strength of the flameproof enclosure meets the requirements of GOST R

52350.0-2005 for electrical apparatus of Group II that are exposed to a strong risk for mechanically inflicted damage. The surface areas of the LCD display and the IR interface are limited to

!

prevent the buildup of static electricity.

Integration of electrical ports into the flameproof enclosure complies with the requirements of

GOST R 52350.0 und GOST R 52350.1.

The construction of the HV BL conforms to the general requirements of GOST R 52350.0-2005

for electrical equipment designed to be operated in explosion-hazard areas. The seals and connectors used for structural elements provide an IP 66 level of protection in accordance with GOST

14254.

All applicable explosion protection information is displayed on the housing of the Hygrovision BL

as required by regulation.

!

2. SAFE OPERATION OF THE HYGROVISION BL

2.1. GENERAL SAFETY MEASURES

The Hygrovision analyzer is a class 0I electrical device (as defined by GOST Standards 12.2.007.0

SSBT), in terms of protection against electrical shock.

Do NOT use the HV BL to take measurements in situations where the analyzer will be exposed to corrosive media or an aggressive.

The charging unit must be plugged into a grounded socket (GOST Norm 12.1.030 SSB). Resistance

in the grounding circuit must not exceed 4 ohms.

Installation and removal of the analyzer should be done only after the valve on the sampling device

has been closed and the pressure within the sampling equipment has been adjusted to atmospheric

pressure using the fine adjustment valve.

2.2. EXPLOSION-SAFE INSTALLATION AND OPERATION

Installation and maintenance of the analyzer may only be carried out by qualified personnel. The device should only be operated by individuals who are familiar with the unit’s documentation and the

guidelines for working in explosion-hazard areas. It is strongly recommended that users of the Hygrovision BL receive training and/or instruction provided by Vympel GmbH in order to fully comply with

the above stated requirements.

The analyzer can be operated in both indoor and outdoor explosion-hazard areas in accordance with

GOST R 52350.14-2006 and other normative standards that regulate the operation of electrical devices in explosion-hazard areas (see 1.2).

A visual inspection of the analyzer must be carried out before the unit is installed to ensure that the

device is in accordance with the information presented in Appendix B. Specific points to check include

but are not limited to the ignition-proof markings, the mechanical integrity of the housing, the state of

the Hygrovision’s various components, and the proper connection of the external intrinsically safe

equipment (the microscope).

Make all necessary electrical connection in accordance with the schematic drawing in section 1.9. After the unit has been installed, check that it is properly grounded and that the grounding resistance

does not exceed 4 ohms.

During installation, it is essential to avoid any friction or shocks that could lead to the creation of

sparks.

Please observe the following guidelines during installation:

• Properly plug in all detachable connection;

• Make sure that all of the housing screw-connector coverings are fully in place, as are all of the

lids and locking mechanisms.

!

When in operation, the analyzer should undergo a regular visual inspection that includes the following

points:

• Check the integrity of all the seals;

• Check that all of the lids and caps are properly in place;

• Check the integrity of the insulation of all the wiring (power supply and data transfer);

• Check the integrity and connection of the grounding wire;

• Check for the presence of dents or other visible mechanical damage, dust, or contamination

that could interfere with the analyzer’s operation.

• Use of an analyzer that is damaged or defective is strictly prohibited.

!

3. PREPARING THE ANALYZER

FOR OPERATION

3.1. GENERAL REQUIREMENTS

UNPACKING AND VISUAL

INSPECTION

Upon receipt, please confirm that the packing in which the analyzer

is delivered is in good condition. Should the packing show signs of

damage, please document this, and contact customer services at

Vympel GmbH.

Carefully unpack the analyzer and its accessories. Refer to the

packing list to ensure that the delivery is complete.

Confirm that there has been no damage during transportation.

OPERATING RESTRICTIONS

Please refer to the restrictions that pertain to analyzer operation

which are listed under point 2.2 of this manual.

Attention!

Completely charge the rechargeable battery of a new Hygrovision before putting the

analyzer into operation for the first time.

PREPARING THE

RECHARGEABLE

BATTERY FOR ANALYZER

OPERATION

A battery charger (KRAY5.122.007), specially designed for charging

the Hygrovision’s battery pack is included with delivery.

The battery can be charged by connecting it to either:

• a 220 V A/C power supply

or

• a 12 V D/C power source

Instructions for using the battery charger can be found on the

charger’s label (KPAY5.122.007 EТ).

!

Attention!

The Hygrovision’s battery must be charged/recharged only in an explosion-proof zone.

SAMPLE EXTRACTION

When selecting a sample extraction site, the following points should be

considered:

! The ambient temperature and the relative humidity lie within the pa-

rameters listed in table 1, point 1.1;

! The temperature of the sample gas as it enters the measurement

chamber must not be lower than temperature of the gas at the extraction site.

If the temperature of the sample supply line (the ambient temperature) is

below the temperature of the sample gas at the point of extraction, the

sample supply line must be heated by means of an electric heating element.

3.2. CONNECTING THE ANALYZER

Place the analyzer on a level surface or mount it on the tripod near

the extraction site. Take care that the bearing surface provides sufficient support for the analyzer.

Attach the gas delivery system (VYMP6.450.001; Pos.1,

ILLUSTRATION 40) to the inlet port of the analyzer’s measuring

chamber. Confirm that the high-pressure valve is closed.

Next, attach the gas flow and gas pressure control system

(VYMP5.183.001; Pos. 3, ILLUSTRATION 40) to the outlet port of

the measuring chamber (Pos. 2). Confirm that the fine adjustment

valve of the gas flow / gas pressure control system is closed.

!

!

=11>?@34@=AB& & 9:&

Both of these systems use quick-connect couplers to attach to the

analyzer’s inlet and outlet ports in order to not only reduce the time

required for (de)installation but also to ensure an airtight seal at

each of these points.

The analyzer connects to the gas supply by means of a flexible

high-pressure hose equipped with a fine adjustment valve (Pos.2).

Connect the end of the hose to outlet port of the extraction system’s shut-off valve. (Dk-Lok connector with an outer diameter of ø

6mm).

Gas that has passed through the measuring chamber is vented

through a PVC hose (included with delivery) that is connected to

the outlet nozzle (Pos.5) of the gas flow / gas pressure control system.

The gas flow can be altered as desired by means of the fine adjustment control valve on the gas flow / gas pressure control system. The manufacturer recommends an optimal volume flow of 0.5

– 1.0 Nl/min.

If the gas composition includes a large number of early-condensing

hydrocarbons that interfere with the clear visual detection of the

formation of water condensation, the user should install the supplemental filter for the control of heavy hydrocarbons

(KRAY6.451.017; included with delivery).

This filter should be mounted between the high-pressure hose and

the gas delivery system (VYMP6.450.001).

Attention!

When (de)installing pressurized devices in the sample gas extraction system or the

gas preparation system (SGA), it is necessary to reduce the operating pressure to

atmospheric pressure.

TESTING SEAL INTEGRITY

After the analyzer has been installed it is necessary to check that

integrity of the sample delivery system connections using the following procedure:

1. Close the valve on the gas flow / pressure control system;

2. Slowly open the sample extraction system shutoff valve

and the valve at the inlet port of the analyzer’s measuring

chamber;

3. Apply a soapy emulsion to the points of connection be-

tween the gas delivery system, the measuring chamber,

and the gas flow and pressure control system, including

between the locknut and connecting sleeve at each joint.

!

4. If bubbles are seen forming in the soapy emulsion it is a

sign that the corresponding connection is not properly

sealed. The connection seal must be reseated to ensure

air tightness.

Attention!

In situations where the dew point of inflammable gases is being measured, it is

necessary to ventilate the analyzer’s measuring chamber and the sample gas delivery lines for 10 to 20 minutes before connecting the device to the power supply.

3.3. FUNCTIONAL TEST

When carrying out a functional test, use the following procedures (as

described in detail below):

1. Switch on the analyzer;

2. Check the microscope lighting;

3. Check the condition of the condensation mirror;

4. Confirm that the thermoelectric battery is working properly;

5. Check that the date and time are correct;

6. Check the charge status of the rechargeable battery pack

7. Switch the analyzer off

SWITCHING ON THE

ANALYZER

!

=11>?@34@=AB& & 9C&

Press the red button on the left side of the analyzer to switch the device on (ILLUSTRATION 41).

The operating program (OP) requires one or two seconds to load.

When the program has completed the startup sequence, the touch

screen will display the last operating mode to which the device was

set (ILLUSTRATION 26; ILLUSTRATION 27; ILLUSTRATION

33; ILLUSTRATION 34).

When the analyzer is switched on, the temperature of the condensation mirror (T) should largely correspond to the temperature of the

housing (Tb), with a maximum deviation of ≈ ± 0.5°C.

CHECKING THE MICROSCOPE

Confirm that the microscope lighting is operating properly by tapping

the “microscope lighting” icon (Pos.8, ILLUSTRATION 26;

!

LIGHTING

ILLUSTRATION 27). Look through the microscope to visually confirm that the lighting switches on and off.

Make sure that the microscope is optimally adjusted for viewing the

surface of the condensation mirror.

Use the focusing ring to adjustment the sharpness of the image.

CHECKING THE

CONDENSATION MIRROR AND

THE THERMOELECTRIC

BATTERY

Activate the “Transducer Cleaning Mode” as described in Point 4.2.

It should only take a few minutes for the condensation mirror to heat

up to a “cleaning” temperature of about +50 °C ± 0.1 °C.

If there are no problems during this process, it can be assumed that

the thermoelectric element is functioning properly.

Check that the signal levels for UHC und UW are within tolerance.

If the system message “The mirror is dirty” is displayed, carry out

technical maintenance as described in Point 5.2.

DATE AND TIME

Open the “Properties: System” menu window for “Date and Time” as

described in Point 1.8 (ILLUSTRATION 29).

Should these parameters require correcting, go the “Properties”

menu and follow the procedure as described in Appendix I.

BATTERY PACK CHARGE

STATUS

Open the “Properties: System” menu window for “Power supply” as

described in Point 1.8 (ILLUSTRATION 30).

If the rechargeable battery pack (BP) is in good condition, the parameters that are displayed will be within the ranges depicted here.

@"W%F&M&

Parameter

Unit

Acceptable

value

Charge status

Qa

10 – 100%

Voltage

Ua

9.0 – 12.6 V

Operating current

Ia

0.01 – 2.5 A

Temperature

Ta

-20 °C – + 60 °C

If the charge status of the BP is below 20%, fully recharge it according

to the instructions provided on the recharging unit label

(KRAY5.122.007ET).

SWITCHING OFF THE

ANALYZER

Switch the analyzer off by pressing and holding the red button until

the touch screen goes off. (ILLUSTRATION 41).

!

4. OPERATING THE HYGROVISION BL

4.1. PRECAUTIONARY MEASURES

The analyzer may be operated in both indoor and outdoor explosion

hazard areas in accordance with GOST R 52350.14-2006 and other

normative documents that regulate the use of electrical devices in explosion hazard areas.

Only fully qualified personnel are to install and operate this device.

Further, this device may only be used by persons who are completely

familiar with the guidelines and normative documents pertaining to

working in explosion hazard areas. It is therefore strongly recommended that the relevant personnel receive instruction and training

from Vympel GmbH.

During installation of the analyzer it is essential to avoid any friction or

shocks that could generate sparks.

Before the analyzer may be (de)installed the shut-off valve on the

sample extraction system and the shutoff valve on the gas delivery

system must both be in the closed position and the pressure within the

analyzer’s measurement chamber must be reduced to the ambient

atmospheric pressure.

4.2. HANDLING THE HYGROVISION BL

PREPARING TO TAKE

MEASUREMENTS

Before taking any measurements, please make sure that the analyzer and its accessory parts are all in proper working order.

When preparing the Hygrovision BL for operation:

• Affix the analyzer to a tripod or place it on a level surface;

• Carefully mount the microscope and plug ends of the micro-

scope lighting cord into the appropriate sockets;

• Connect additional accessories (computer terminal, pressure

transmitter, etc.) to the analyzer at the appropriate points;

• Before switching on the analyzer make sure that all of the

components are mounted in accordance with the requirements of Point 2.2;

• Carry out a functional test of the analyzer immediately before

beginning to take measurements. Also check the power

source as described in point 1.8 of this manual.

!

HEATING THE

CONDENSATION MIRROR

!

=11>?@34@=AB& & 96&

Always clean the mirror before taking measurements by activating

the “Transducer cleaning mode”.

Tap the icon to activate this mode (Pos.6; ILLUSTRATION

26; ILLUSTRATION 27).

When the icon is tapped the “Transducer cleaning mode” menu

window is opened. The information displayed in this mode includes

values for the mirror temperature (T), the signal levels for hydrocarbons (UHC) and water (UW), and signal level rejection criteria, as well

as a text message confirming that the mirror is either clean or “dirty”.

The process of heating the mirror to 50 °C is depicted as a changing

value for T (,--./0120,34! ! $").

CLEANING THE MIRROR

If the message “The mirror is dirty” is displayed after the “Transducer

cleaning mode” cycle is complete (,--./0120,34! ! $#), it will be necessary to clean the condensation mirror according to the instructions

found under Point 5.2.

!

=11>?@34@=AB& & 9M&

When the desired measurement pressure has been reached, ensure

that the microscope and the microscope lighting are adjusted to provide optimal viewing of the surface of the condensation mirror.

Adjust the sharpness of the mirror’s image using the focus ring on the

microscope (Pos.3 ,--./0120,34! ! *$)

ADJUSTING THE LIGHTING

INTENSITY

When working out-of-doors it may be desirable to adjust the intensity

of the condensation mirror illumination in response to various environmental factors and personal preference.

When taking dew point measurements, the process of condensation

can be directly observed visually by means of the microscope

(,--./0120,34! ! *; ,--./0120,3 4! ! ") alternatively, condensation can

be monitored on the display by means of the optical-electric registration system (measurement scale – Pos.5, ,--./0120,3 4 ! ! "&5!

,--./0120,34! ! "'7

!

MIRROR SCAN /

SCANNING MODE

!

=11>?@34@=AB& & 99&

Scanning serves to simplify the process of registering the dew point

manually. In scanning mode, the analyzer establishes an approximate dew point range within which lies the actually dew point.

Tap the function icon (Pos.7; ILLUSTRATION 26;

ILLUSTRATION 27) to begin the scanning process. In this mode

the condensation mirror is cooled at a rate of 0.5 °C per second until

reaching a temperature at which a condensation film of water or hydrocarbons begins to form. When this point is reached the mirror is

automatically reheated to a temperature exactly 10 °C above that at

which the formation of condensation was initially registered.

The signal strengths corresponding to water and/or hydrocarbons

condensation are displayed in the UW and U

HC

menu windows.

In the “Level of fixation” window a value limit for the signal strength

of the UHC and UW channels is displayed. When one of these values

is exceeded the temperature of the mirror will stabilize at the corresponding level. The analyzer will determine whether the condensate

is made of water or hydrocarbons based on which value is exceeded.

When the scanning process is completed, the letters HC will be displayed if the analyzer registers hydrocarbon condensation whereas

the letter W will be shown for water condensation.

To end the scanning process, tap the icon (ILLUSTRATION

44). The analyzer will then be set to standby mode and the mirror

will be maintained at the approximation temperature established in

scanning mode (condensation temperature +10 °C).

At this point, select the desired dew point measurement mode by

tapping the corresponding icon (Pos.10, ILLUSTRATION 26;

ILLUSTRATION 27) to begin the DP measurement process.

!

TAKING DEW POINT

MEASUREMENTS

The Hygrovision BL is designed to provide two methods of dew point

registration:

• Manually controlled dew point registration

• Automatic dew point registration

There are four options for manually controlled dew point registration:

• Hydrocarbon dew point measurement while cooling and

heating the condensation mirror at a preprogrammed rate

• Hydrocarbon dew point measurement while cooling the con-

densation mirror step by step

• Water dew point measurement while cooling and heating the

condensation mirror at a preprogrammed rate

• Water dew point measurement while cooling the condensa-

tion mirror step by step

There are two options for automatic dew point registration:

• Automatic measurement of the hydrocarbon dew point

• Automatic measurement of the water dew point

Dew point results registered in automatic mode are saved in the

analyzers non-volatile memory and can be displayed at any time.

The Hygrovision BL is equipped with an IR-Port and an RS 485 interface for data transfer purposes. The corresponding computer

software (Appendix K) is also included in delivery.

Attention!

When taking measurements for the dew point of water, if a significant amount of

early-condensing hydrocarbons are observed (the formation of non-water drop like

condensation), it will be absolutely necessary to install the filter (KRAY6.451.017)

used for the control of heavy hydrocarbons.

!

!

=11>?@34@=AB& & 9R&

!

=11>?@34@=AB& & 9T&

4.3. HC DEW POINT MEASUREMENT USING

THE PREPROGRAMMED RATE OF COOLING /

HEATING THE CONDENSATION MIRROR

!

1. Select the hydrocarbon measurement channel by activating the

icon (Pos.11, ILLUSTRATION 45). Set the analyzer to the

preprogrammed rate of cooling / heating (per ISO) mode by choos-

ing the icon (Pos.10). Tap the icon to activate the microscope lighting (Pos.8).

2. Push the “down” button (Pos.14, ILLUSTRATION 46) to begin

cooling the condensation mirror at the preprogrammed rate (the factory default setting is 1 °C per minute).

3. As soon as a visually observable film of condensation begins to

form, fix the temperature of the condensation mirror by once again

pushing the “down” button (Pos.14, ILLUSTRATION 46). This fixed

temperature value is shown in the Tc field of the display and the mirror temperature is maintained at this level.

4. Now push the “up” button (Pos.13, ILLUSTRATION 46) to begin

heating the mirror at the preprogrammed rate. As soon as the condensate is observed to begin evaporating push the “up” button again

to fix this temperature. This second fixed temperature value is

shown in the Te field of the display.

In the case of hydrocarbons, the Tc value is, in fact, equivalent to the

Te value. In other words, condensation temperature and evaporation

temperature are the same for hydrocarbons. The fixed Tc and Te

values may not diverge by more than 0.2 °C.

5. The measured dew point temperature is now shown in the DP

field of the display and is stored in the analyzer’s memory.

6. To complete the measurement cycle, tap the icon (Pos.6,

ILLUSTRATION 45) to switch the analyzer to mirror cleaning

mode. At this point the condensation mirror will automatically be

heated to 50 °C and the signal level will be reset to the starting

value.

Pleas note:

Should concurrent condensation of water vapor impair the observation of hydrocarbon condensation, the laser diode can be switched off by tapping the

icon.

!

4.4. HC DEW POINT MEASUREMENT

COOLING THE MIRROR STEP BY STEP

!

=11>?@34@=AB& & 9;&

1. Select the hydrocarbon measurement channel by activat-

ing the icon (Pos.11, ILLUSTRATION 47). Set the

analyzer to step by step cooling mode by choosing the

icon (Pos.10). Tap the icon to activate the microscope

lighting (Pos.8).

2. Begin cooling the mirror by pushing the “down” button

(Pos.14, ILLUSTRATION 46). When the “down” button is

pushed the temperature of the condensation mirror is lowered by 1 °C (factory default setting). The current mirror temperature is shown in the T field of the display. A timer also

appears on the display, which shows how long the mirror has

been at its current temperature.

A newly entered temperature, in other words the next step to

which the mirror will be further cooled, is shown in the

field of the display.

3. Each time the “down” button (Pos. 14, ILLUSTRATION

46) is pushed the newly entered temperature will be lowered

by 1 °C and the timer will be reset to start over.

4. As soon as a visually observable condensation film begins

to form, fix the HC condensation temperature by pushing the

“up” button (Pos.13, ILLUSTRATION 46). The condensation mirror will also be raised by 1 °C and the timer will be

reset.

5. Fixation of the evaporation temperature is analogous to

the process described under point 4.3.

6. To complete the measurement cycle, tap the icon

(Pos.6, ILLUSTRATION 47) to switch the analyzer to mirror

cleaning mode.

Please note:

Should concurrent condensation of water vapor impair the observation

of hydrocarbon condensation, the laser diode can be switched off by

tapping the icon.

!

4.5. WATER DEW POINT MEASUREMENT

USING THE PREPROGRAMMED RATE OF

COOLING / HEATING THE CONDENSATION

MIRROR

!

=11>?@34@=AB& & 98&

1. Select the water measurement channel by activating the

icon (Pos.11, ILLUSTRATION 48). Set the analyzer

to the preprogrammed rate of cooling / heating (per ISO)

mode by choosing the icon (Pos.10). Tap the

icon to deactivate the microscope lighting (Pos.8).

2. Push the “down” button (Pos.14, ILLUSTRATION 46) to

begin cooling the condensation mirror at the preprogrammed

rate (the factory default setting is 1 °C per minute).

3. As soon as a visually observable film of condensation begins to form, fix the temperature of the condensation mirror

by once again pushing the “down” button (Pos.14,

ILLUSTRATION 46). This fixed temperature value is shown

in the Tc field of the display and the mirror temperature is

maintained at this level.

4. Now push the “up” button (Pos.13, ILLUSTRATION 46)

to begin heating the mirror at the preprogrammed rate. As

soon as the condensate is observed to begin evaporating

push the “up” button again to fix this temperature. This second fixed temperature value is shown in the Te field of the

display.

The measured dew point temperature for water is now shown

in the DP field of the display and is stored in the analyzer’s

memory. The condensation mirror is maintained at the

evaporation temperature. Stored dew point values can be

accessed and displayed on the screen at any time.

5. To complete the measurement cycle, tap the icon

(Pos.6, ILLUSTRATION 48). to switch the analyzer to mirror cleaning mode.

!

4.6. WATER DEW POINT MEASUREMENT

COOLING THE MIRROR STEP BY STEP

&

=11>?@34@=AB& & 9V& &

C7&?F%FHE&ELF&Q"EF+&JF"/$+FJF#E&HL"##F%&W)&"HE.-"E.#*&ELF& &.H,#&OZ,/7CC\& &

ILLUSTRATION 49). Set the analyzer to step by step cool-

ing mode by choosing the icon (Pos.10). Tap the

icon to deactivate the microscope lighting (Pos.8).

2. Begin cooling the mirror by pushing the “down” button

(Pos.14, ILLUSTRATION 46).

When the “down” button is pushed the temperature of the

condensation mirror will be lowered by 1 °C (factory default

setting). The current mirror temperature is shown in the T

field of the display. A timer also appears on the display,

which shows how long the mirror has been at its current temperature. A newly entered temperature, in other words the

next step to which the mirror will be further cooled, is shown

in the field of the display.

3. Each time the “down” button (Pos. 14, ILLUSTRATION

46) is pushed the newly entered temperature will be lowered

by 1 °C and the timer will be reset to start over.

4. As soon as a visually observable condensation film begins

to form, fix the W condensation temperature by pushing the

“up” button (Pos.13, ILLUSTRATION 46). The condensation mirror will also be raised by 1 °C and the timer will be

reset.

5. Fixation of the evaporation and dew point temperatures is

analogous to the process described under point 4.5.

T7&@,&H,JN%FEF&ELF&JF"/$+FJF#E&H)H%F\&E"N&ELF& & .H,#&OZ,/7T\J& &

ILLUSTRATION 49) to switch the analyzer to mirror cleaning mode..

Please note:

The manufacturer recommends that during step by step heating and

cooling, the mirror remain at each temperature for about 1 minute.

!

4.7. HC DEW POINT MEASUREMENT IN

AUTOMATIC MODE

!

=11>?@34@=AB& & R:&

Tap the icon to set the analyzer to automatic mode for

haydrocarbons. Refer to point 1.8.

When measuring the hydrocarbon dew point in automatic

mode the following information will be shown on the left side

of the display (see ILLUSTRATION 50):

• Current measurement mode HC;