INSTALL GUIDE

JACE-700 MOUNTING AND

WIRING GUIDE

The JACE-700 is a compact,

embedded controller/server

platform that allows integrated

control and management of

external devices over the Internet.

It provides support for two

optional communications boards

as well as optional I/O expansion

Part Number 11694 Rev 1.6 | May 2, 2011

modules.

TABLE OF CONTENTS

About This Guide ........................................... 4

Related Documentation ........................................................................................4

Product Description ....................................... 5

Packaging and Features ........................................................................................5

Technical Specifications ........................................................................................7

Equipment Ratings .................................................................................................8

Preparation .................................................... 8

Included in this Package ........................................................................................8

Material and Tools Required .................................................................................8

Precautions .................................................... 9

Safety Precautions ..................................................................................................9

Static Discharge Precautions ...............................................................................10

Battery Precautions ..............................................................................................10

WEEE (Waste of Electrical and Electronic Equipment) ....................................10

Mounting ..................................................... 11

Environmental Requirements ..............................................................................11

Physical Mounting ................................................................................................11

Removing and Replacing the Cover ...................................................................13

Board Layout ........................................................................................................13

About Expansion Options ............................ 14

About Option Cards ............................................................................................15

About Remote I/O Modules ...............................................................................17

About MiniPCI Cards ...........................................................................................18

Wiring Details .............................................. 18

Communications Wiring ......................................................................................18

Grounding ............................................................................................................21

Power Wiring ........................................................................................................21

Contact Inputs ......................................................................................................24

External 12V Backup Battery ...............................................................................24

Wiring to Remote I/O Modules ..........................................................................25

© 2011 Tridium, Inc.

3951 Westerre Parkway, Suite 350

Richmond, Virginia 23233 USA

Information and/or specifications published here are current as of the date of publication of this document. Tridium, Inc.

reserves the right to change or modify specifications without prior notice. The latest product specifications can be found

by contacting our corporate headquarters, Richmond, Virginia. Products or features contained herein are covered by one

or more U.S. or foreign patents. This document may be copied by parties who are authorized to distribute Tridium products in connection with distribution of those products, subject to the contracts that authorize such distribution. It may not

otherwise, in whole or in part, be copied, photocopied, reproduced, translated, or reduced to any electronic medium or

machine-readable form without prior written consent from Tridium, Inc. Complete confidentiality, trademark, copyright

and patent notifications can be found at: http://www.tridium.com/galleries/SignUp/Confidentiality.pdf.

JACE, Niagara Framework, Niagara AX Framework and the Sedona Framework are trademarks of Tridium, Inc.

JACE-700 MOUNTING AND WIRING GUIDE

May 2, 2011

Power Up and Initial Checkout ..................... 25

Apply Power ..........................................................................................................25

Check the Status LED ..........................................................................................26

About the Backup Batteries ................................................................................26

NiMH battery pack ...............................................................................................26

About LEDs .................................................. 27

Status .....................................................................................................................28

Heartbeat ..............................................................................................................28

Debug ...................................................................................................................28

USB ........................................................................................................................28

Ethernet Ports .......................................................................................................28

Maintaining the JACE-700 ........................... 28

Cleaning ................................................................................................................29

Required NiMH Battery Maintenance ................................................................29

Replacement Parts ....................................... 31

Non-replaceable Parts .........................................................................................31

Standard Replacement Parts ...............................................................................31

New Replacement Unit ........................................................................................31

Replacing the JACE-700 ......................................................................................32

Returning a Defective Unit ..................................................................................33

Certifications ................................................ 34

Federal Communications Commission (FCC) ....................................................34

Canadian Department of Communications (DOC) ...........................................34

Declaration of RoHS Compliance ......................................................................34

CE Declaration of Conformity ............................................................................35

Tab Mounting Dimensions ............................ 36

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 3

May 2, 2011 ABOUT THIS GUIDE

Related Documentation

About This Guide

This document covers the mounting and wiring of the Vykon® JACE-700 (J-700)

controller. It assumes that you are an engineer, technician, or service person who is

performing control system installation. Instructions in this document apply to the

following products:

Model Description

J-700 DIN mount JACE-7 series controller, powered by separate plug-in power supply

NPB-PWR-UN 90–263Vac universal input/15Vdc output power supply module, DIN mountable.

WPM-

XXX

Note Not covered in this document is the NiagaraAX software installation and

module or wall mount AC power adapter. Controller supports optional external

I/O expansion modules and internal communications option cards.

Wall-mount universal AC power adapter, with different models available,

where -

XXX

is either: -US, -EUR, or -UK (vary by AC wall plug).

configuration required for a fully functioning unit. Refer to the JACE

Niagara AX Install and Startup Guide for this information.

In addition, the mounting and wiring of JACE expansion options are

covered in separate documents. See the section “A bo u t Ex p an s io n

Options,” page 14.

Related Documentation

For more information on configuring and using the JACE-700 controller, consult the

following documents:

• JACE NiagaraAX Install and Startup Guide

• IO-16-485 Mounting and Wiring Instructions

•NPB-LON Option Install Sheet

• NPB-2X-485 Option Install Sheet

• NPB-232 Option Install Sheet

• NPB-MDM Option Install Sheet

• NPB-GPRS Modem Option Install Sheet

•NPB-ZWAVE Option Card Install Sheet

• NPB-SED-001 Option Card Install Sheet

• NPB-SRAM (Static Ram) Option Install Sheet

• JACE 7 WiFi Option (T7-WIFI) Install Guide

• NiagaraAX Nrio Guide

• NiagaraAX JACE WiFi Option - Engineering Notes

•NiagaraAX User Guide

4 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

PRODUCT DESCRIPTION May 2, 2011

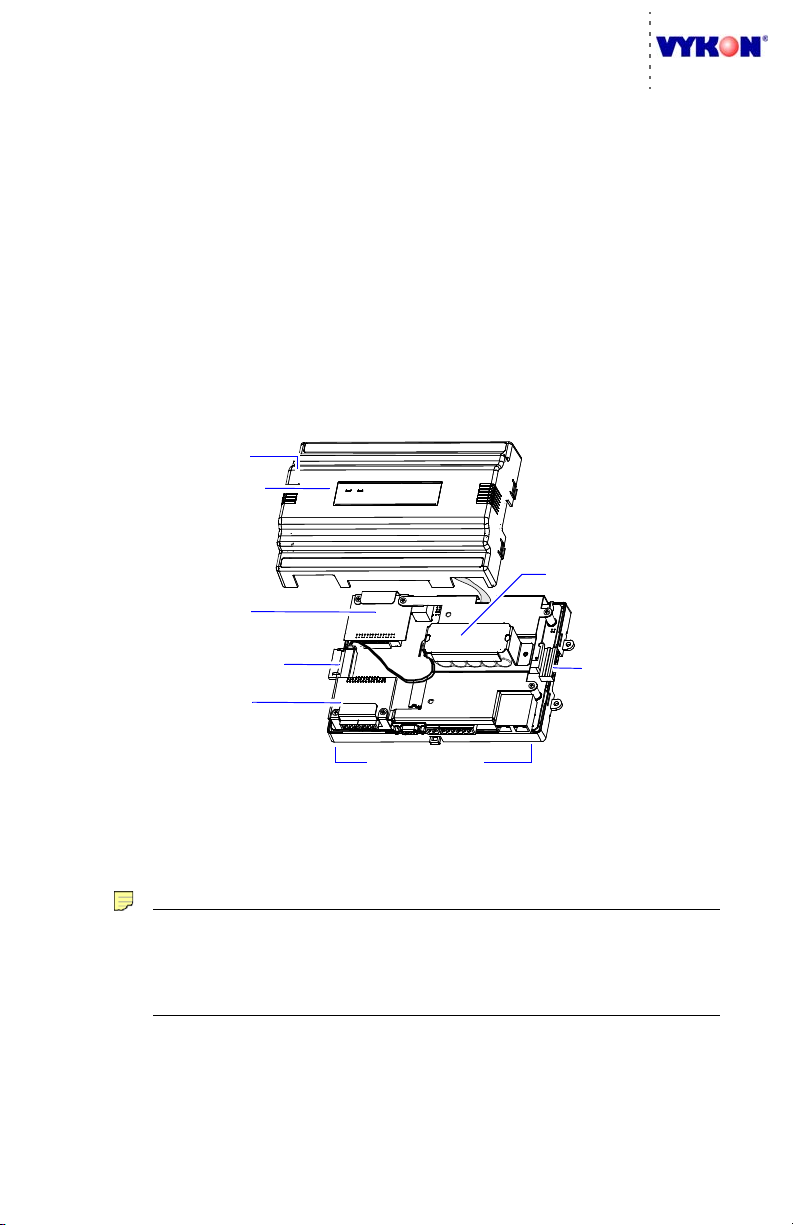

Removable cover

Status and heartbeat LEDs

Option card #2 area

(card shown installed)

Option card #1 area

(card shown installed)

Connector for NPB-PWR-UN

power supply module

NiMH backup

battery pack

RS-485, 15V Power

Output Connector

Connector ports

Packaging and Features

Product Description

The JACE-700 controller is a compact embedded processor platform using on-board

Flash memory for backup, in an expandable DIN-modular package. Designed for use

in commercial environments, the controller runs the NiagaraAX Framework to

provide integrated control, supervision, and network management solutions for wide

variety of networked field devices. NiagaraAX-3.5 or later is required.

Packaging and Features

The JACE-700 features a DIN-mount controller base with mounting tabs for

alternate panel mount. Two available comm option card slots are accessed under the

controller’s removable cover.

Figure 1 and Figure 2 show locations of important features of the controller.

Figure 1 JACE-700 Cover removed with 2 options installed on main board.

Typical installation requires an NPB-PWR-UN universal power supply module

(furnishing 15Vdc) for power, attaching to the controller’s left side. An RS-485 port is

on the controller’s opposite right end connector, along with 15Vdc power for support

of I/O expansion modules, either chained directly and/or wired remotely.

Note Instead of using the NPB-PWR-UN power supply module, you can adapt

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 5

an WPM-XXX wall mount AC power adapter to power the controller.

However, you cannot directly attach I/O expansion modules in this

configuration, nor power remote I/O modules from that WPM-XXX.

May 2, 2011 PRODUCT DESCRIPTION

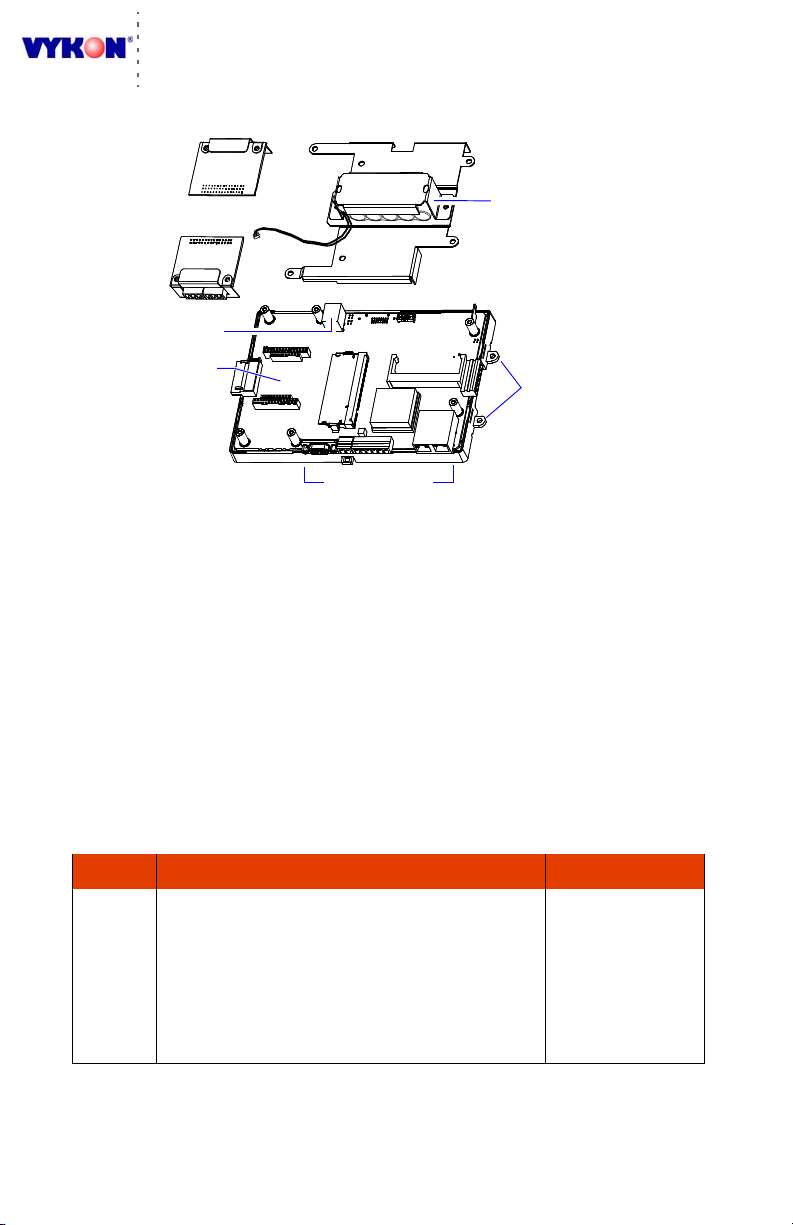

Main controller board

Removed

option cards

DIN-mount base with screw

tabs for panel mount

Connector ports

NiMH battery pack

and shield removed

USB ports (2)

Packaging and Features

Figure 2 JACE-700 main controller board and 2 option cards uninstalled.

As a JACE-7 series controller, the JACE-700 features a PowerPC 440EPx processor,

1GB Flash storage, and 1GB DDR-2 RAM. TCP/IP access is via two standard Gigabit

Ethernet ports, and serial communications ports (RS-232, RS-485) are also standard.

One or two option cards can be added for additional communications, e.g.

LonWorks FTT-10, or another RS-232 port. A MiniPCI slot is also available for WiFi

802.11b/g support. The JACE-700 uses the QNX Neutrino operating system, with

either the Sun Hotspot JVM (in AX-3.6 or later units) or IBM J9 JVM (AX-3.5 units).

Two status LEDs are visible atop the cover. Two USB 2.0 ports are provided, as well

as integral contact inputs to allow system monitoring of UPS power and battery, and

an external enclosure door. A rechargeable NiMH battery pack is included inside the

unit, and a separate connector provides recharging and monitoring of an external

12V sealed lead-acid battery (customer supplied).

The table below provides a summary of features of the controller.

Table 1 JACE-700 controller features and options.

Model Description Ports

JACE-700 DIN-mountable controller. PowerPC 440Epx 652 MHz pro-

.

cessor, 1GB NAND Flash storage, 1GB DDR-2 system RAM.

Includes integral NiMH battery pack, two open enhanced

comm option card slots, one open MiniPCI slot (for WiFi

802.11g option card).

Not furnished is NPB-PWR-UN universal power supply, or

external 12V sealed lead-acid battery and harness.

Two 1GB Ethernet,

RJ-45

One RS-232 Serial,

DB-9 male

One RS-485 Serial, isolated, with 15V/12Vdc

power, 6-position plug

on right side.

Two USB-2.0 ports on

top side of controller.

6 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

PRODUCT DESCRIPTION May 2, 2011

Technical Specifications

Technical Specifications

JACE-7 Platform

• PowerPC 440Epx @ 652MHz processor.

• 1GB on-board NAND Flash storage.

• 1GB DDR-2 333Mhz RAM (maximum Java heap size 384MB).

• Two (2) Gigabit Ethernet ports.

• Two (2) USB-2.0 ports.

• Standard RS-232 port.

• 6-position end connector with isolated RS-485/15Vdc power (usable as a standard non-powered isolated RS-485 port, or to support remote I/O modules).

• MiniPCI slot for optional T7-WIFI 802.11b/g WiFi adapter (AX-3.6 required).

• Two (2) available JACE-7 comm option slots in the JACE-700, for LonWorks,

RS-485 or RS-232, GPRS/Edge Cellular,

• LEDs on front of unit to monitor power and system status.

• Available contact inputs (3) to monitor external UPS AC present, UPS battery

level, external enclosure door status.

Power Supply

• Requires universal AC input (90V – 264V) NPB-PWR-UN power supply module,

supplies 15Vdc, 30VA. Or, a WPM-XXX wall-mount AC adapter can power the

JACE-700 only (requires removal of barrel plug end and wiring to end connector).

• Includes integral rechargeable NiMH backup battery pack, for short duration AC

power fail operation.

• Connection for external, rechargeable, 12V sealed lead-acid battery, for continuous system operation over longer power outages. Provides trickle charge and

monitoring support to customer-supplied battery.

Operating System

• QNX Neutrino Real-Time Operating System.

• Sun Hotspot JVM (Java Virtual Machine) in units with NiagaraAX-3.6 or later;

IBM J9 JVM is used in units with NiagaraAX-3.5.

• JACE NiagaraAX software (AX-3.5 minimum);

AX-3.6 or later required to use the optional T7-WIFI adapter.

Physical

• Plastic DIN-mount backplate with screw tabs for alternate panel mounting.

• Removable snap-on plastic cover with status LEDs and connecting cable.

• Cooling by internal air convection.

• Dimensions: 8.7" (221mm) wide x 5.6" (142mm) high x 2.44" (62mm) deep.

• Weight: Net 1.67 lbs. (0.76 kg), Gross 2.0 lbs. (0.91 kg).

Jennic 802.15.4 wireless,

etc.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 7

May 2, 2011 PREPARATION

Equipment Ratings

Environment

• Operating temperature range: 32°F to 122°F (0°C to 50°C).

• Relative humidity range: 10% to 90% at 77°F (25°C), non-condensing.

• Mechanical ambient conditions are as follows:

— Vibration, in operation: 5 to 9 Hz: 3.5mm amplitude, 9 to 150Hz: 1g.

— Shock resistance, in operation: 15g acceleration, 11 ms duration.

• Storage temperature range: 32°F to 158°F (0°C to 70°C).

• Storage relative humidity range: 5% to 94%, non-condensing.

Equipment Ratings

Electrical

• Input voltage range: 15Vdc (DC only).

Sourced from separate AC power supply, 90Vac to 264Vac, 50/60Hz.

•Power consumption: 20VA maximum.

Preparation

Unpack the controller and inspect the package contents for damaged or missing

components. If damaged, notify the appropriate carrier at once and return any

damaged components for immediate repair or replacement. See “Returning a

Defective Unit” on page 33.

• Included in this Package

• Material and Tools Required

Included in this Package

Included in this package you should find the following items:

• a JACE-700 controller.

•These JACE-700 Mounting and Wiring Instructions, Part Number 11694 Rev 1.6

• a hardware bag containing the following items:

— Two (2) 6-position screw terminal plugs, one for integral contact inputs (door

tamper, UPS battery OK, UPS AC present), one end-mount to wire

RS-485/power to optional remote expansion devices.

— One (1) 2-position screw terminal plug for external sealed lead-acid (SLA)

rechargeable battery (not provided).

— One (1) grounding wire, with quick-disconnect 0.187" female connector.

Material and Tools Required

The following supplies and tools are typically required for installation:

• NPB-PWR-UN universal AC power supply module, 90-263 Vac input, 15Vdc

30W output, DIN-mount capable, with grounding wire.

Alternatively, a WPM-XXX wall-mount AC adapter can power the controller

only. You must cut off the adapter’s barrel plug end, and then wire leads into the

controller’s end connector. A multimeter is needed to check polarity.

8 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

PRECAUTIONS May 2, 2011

Safety Precautions

• DIN rail, type NS35/7.5 (35mm x 7.5mm) and DIN rail end-clips (stop clips),

unless using panel mounting method with screws through mounting tabs.

• Suitable tools and fasteners for mounting unit and accessories.

• #2 phillips screwdriver: used to install and remove an optional option card.

• Small flat-blade screwdriver: used for making wiring connections to removable

screw terminal plugs.

• (Optional) One or two 12V sealed-lead-acid (SLA) rechargeable backup batteries,

with wire harness for connecting to the 2-position connector on the unit. Should

be sized as required by the system. See “External 12V Backup Battery,” page 24.

Precautions

This document uses the following warning and caution conventions:

Caution

Warning Warnings alert the reader to proceed with extreme care in situations

Cautions remind the reader to be careful. They alert readers to situations

where there is a chance that the reader might perform an action that cannot

be undone, might receive unexpected results, or might lose data. Cautions

contain an explanation of why the action is potentially problematic.

where there is a chance that the reader might do something that can

result in personal injury or equipment damage. Warnings contain an

explanation of why the action is potentially dangerous.

Safety Precautions

The following items are warnings of a general nature relating to the installation and

start-up of the JACE-700 controller. Be sure to heed these warnings to prevent

personal injury or equipment damage.

Warning • A 120Vac or 240Vac circuit powers the NPB-PWR-UN power sup-

ply for the controller.

• 15Vdc input (DC only) to controller.

• Disconnect power before installation or servicing to prevent electrical shock or equipment damage.

• Make all connections in accordance with national and local electrical codes. Use copper conductors only.

• To reduce the risk of fire or electrical shock, install in a controlled

environment relatively free of contaminants.

• This device is only intended for use as a monitoring and control

device. To prevent data loss or equipment damage, do not use it for

any other purpose.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 9

May 2, 2011 PRECAUTIONS

Static Discharge Precautions

Static Discharge Precautions

Static charges produce voltages high enough to damage electronic components. The

microprocessors and associated circuitry within a JACE-700 controller are sensitive

to static discharge. Follow these precautions when installing, servicing, or operating

the system:

Caution • Work in a static-free area.

• Discharge any static electricity you may have accumulated. Discharge

static electricity by touching a known, securely grounded object. Do not

handle printed circuit boards (PCBs) without proper protection against

static discharge. Use a wrist strap when handling PCBs. The wrist strap

clamp must be secured to earth ground.

Battery Precautions

Caution • The NiMH battery used in this device may present a risk of fire or

chemical burn if mistreated. Do not disassemble, heat above 122ºF

(50ºC), or incinerate. Replace battery pack with type

10SN-2/3AA60H-W-J1 (NPB-J700-BATT) only. Use of another battery

may present a risk of fire or explosion.

• Dispose of used battery promptly. Keep away from children. Do not disassemble and do not dispose of in fire.

• Replace external backup battery with Listed Power Source Battery Only.

WEEE (Waste of Electrical and Electronic Equipment)

Recycling of Electronic Products: (International Installations)

In 2006 the European Union adopted regulations (WEEE) for the collection and

recycling of all waste electrical and electronic equipment. It is no longer allowable to

simply throw away such equipment. Instead, these products must enter the recycling

process. To properly dispose of this product, please take it to a local recycling center.

If a local recycling center cannot be found, please return it to one of these offices:

Tridium Europe Ltd

1, The Grainstore

Brooks Green Road

Coolham, West Sussex

RH13 8GR United Kingdom

Tridium Asia Pacific Pte Ltd

17 Changi Business Park Central 1

Honeywell Building

Singapore 486073

10 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

Tridium, Inc.

2256 Dabney Road, Suite C

Richmond, VA 23230

MOUNTING May 2, 2011

Environmental Requirements

Mounting

Mount the controller in a location that allows clearance for wiring, servicing, and

module removal.

Note • This product is intended for indoor use only. The unit should not be

exposed to ambient conditions outside of the range of 32ºF (0ºC) to

122ºF (50ºC), or relative humidity outside the range of 10 to 90% at 77ºF

(25ºC), non-condensing. Refer to the “Environment” section on page 8

for further details on mechanical and storage specifications.

• Avoid mounting the controller in a manner that would make it difficult

to operate the disconnect device.

• Before mounting the controller, install any option card(s). See “A b o u t

Option Cards,” page 15.

Additional mounting information applies, as follows:

• Environmental Requirements

• Physical Mounting

Environmental Requirements

Note the following requirements for the controller mounting location:

• If mounting inside an enclosure, that enclosure should be designed to keep the

unit within its required operating range considering a 20-watt dissipation by the

controller, plus dissipation from any other devices installed in the same enclosure.

This is especially important if the controller is mounted inside an enclosure with

other heat producing equipment.

• Do not mount the unit:

— in an area with excessive moisture, corrosive fumes, or explosive vapors.

— where vibration or shock is likely to occur.

— in a location subject to electrical noise. This includes the proximity of large

electrical contractors, electrical machinery, welding equipment, spark igniters,

and variable frequency drives.

Physical Mounting

The following information applies about physically mounting the unit.

• You can mount the controller in any orientation. It it not necessary to remove the

cover before mounting.

• Mounting on a 35mm wide DIN rail is recommended. The JACE-700 unit base

has a molded DIN rail slot and locking clip, as does the NPB-PWR-UN power

supply module and any I/O expansion modules. Mounting on a DIN rail ensures

accurate alignment of connectors between all modules.

• If DIN rail mounting is impractical, you can use screws in mounting tabs on the

NPB-PWR-UN module and the JACE-700, as well as any end-connected accessory. Tab mounting dimensions are on the last page of this document.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 11

May 2, 2011 MOUNTING

4.1" (104)

5.6"

(142)

3.46"

(88)

11.75" (298)

15.125" (384)

Mounting on

DIN rail

Removing from DIN rail

NPB-PWR-UN

DIN rail

end clip

NPB-PWR-UN

IO-16-485

JACE-700

Secure controller or last

directly attached I/O

module using either

screws or DIN rail end

clip (if end clip does not

interfere with 6-position

end connector).

Physical Mounting

Figure 3 and the following procedure provides step-by-step DIN rail mounting

instructions for the controller.

Figure 3 JACE-700 controller and accessory mounting details.

Note Mount the NPB-PWR-UN power supply first, then the controller, then any

directly attached I/O expansion module.

Procedure 1 To mount on DIN rail

Step 1 Securely install the DIN rail with at least two screws, near the two rail ends.

Step 2 Position the NPB-PWR-UN power supply module on the rail, tilting to

hook DIN rail tabs over one edge of the DIN rail (Figure 3).

Step 3 Use a screwdriver to pry down the plastic locking clip, and push down and

in on the module, to force the locking clip to snap over the other edge of the

DIN rail.

Step 4 Mount the controller onto the DIN rail in the same way, such that its left

6-position end connector faces the NPB-PWR-UN power supply.

Step 5 Slide the two devices together along the DIN rail to connect their 6-position

connectors.

12 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

MOUNTING May 2, 2011

Cover

LED ribbon

cable

Connector for LED cable

LED cable left connected

between cover and

controller board

Removing and Replacing the Cover

Step 6 If installing any I/O expansion modules, repeat this for each one, until all

are mounted on the DIN rail and firmly connected into one assembly.

Step 7 To keep the final assembly together, secure at both ends with DIN rail

end-clips provided by the DIN rail vendor. This also prevents the assembly

from sliding on the DIN rail. See Figure 3.

Removing and Replacing the Cover

You must remove the controller’s cover to connect the battery (new unit), and/or to

install any option cards, or replace the NiMH battery. The cover snaps onto the base

with four plastic end tabs–two on each end.

Caution An LED ribbon cable connects the cover to the main board. Be careful

when lifting the cover off. If the controller is on a flat work surface, you can

leave the cable connected, with the cover next to the unit. See Figure 4.

Figure 4 Removing JACE-700 controller cover.

Note If accessory modules are plugged into the controller, you may need to slide

them away from the unit to get to the end cover tabs.

• To remove the cover, press in the tabs on both ends of the unit, and carefully lift it

off (see previous Caution). If necessary, unplug the LED cable from the cover, at

the connector on the back of the cover (see Figure 4).

• To replace the cover, make sure that the LED cable is connected and not folded

outside the base. Orient the cover so the cutout area for comm ports is correct,

then push inwards to snap in place.

Board Layout

Figure 5 shows the location of connectors, option slots, and other features of the

main board in the JACE-700 controller. For side views of communications ports and

other features, see Figure 7 on page 19.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 13

May 2, 2011 ABOUT EXPANSION OPTIONS

PS - OUT

PS + OUT

BB 12V

RS-485

-

RS-485 +

485 GND

PS +

PS

-

NiMH battery connector (keyed)

LEDs for USB hub port activity

Dual USB ports

Earth grounding lug

LED header

Option card 2 area including socket header

MiniPCI

socket

DDR-2

RAM

Option card 1

area including

socket header

RS-232 (DB-9) COM1

External 12V backup battery

GND

GND

GND

RS-485

support of

remote IO

modules

LEDs

LANn

Debug

LED

LAN1

Primary Ethernet

(RJ-45)

LAN2

Secondary

Ethernet

(RJ-45)

From

power

supply

module

Contact Inputs

Door

tamper

UPS battery

OK

UPS AC

present

LEDs

status,

heartbt

Pushbutton

SW1

Serial mode select Jumper

Normal

Serial Shell

Figure 5 JACE-700 controller main board layout details.

Board Layout

A JACE-700 controller ships with both option card slots 1 and 2 open. The DDR-2

RAM socket is populated with a 1GB module. A variety of communications option

cards are available. For details, see the next section “About Expansion Options”.

About Expansion Options

The JACE-700 provides for field-installable expansion using these types of options:

• Option card — Install on connectors inside the controller’s base unit. See “A b o u t

Option Cards,” page 15.

• Remote I/O modules — To wire to the controller’s right-side 6-pin connector.

See “About Remote I/O Modules,” page 17.

• MiniPCI option card — See “A bo u t M in i PC I Ca r ds ,” page 18.

14 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

ABOUT EXPANSION OPTIONS May 2, 2011

About Option Cards

About Option Cards

The JACE-700 controller has two (2) available option slots to accept a custom option

card, compatible with either of these types:

• JACE-2/6 compatible options cards: 30-pin, 2 row connector, or

• Future release JACE-7 option cards: 40-pin, 3 row connector.

To accept either, both option slots on the controller’s base board have a 40-pin

connector. See Figure 5 on page 14. Installing an option card is recommended before

mounting the unit. See “Installing an Option Card,” page 16.

Warning Power to the controller must be OFF when installing or removing

option cards, or damage will occur! Also, you must be very careful to

plug an option card into its connector properly (pins aligned).

Option cards typically provide additional communications features, with the

following available models (with others still in development) listed in Ta b le 2 .

Table 2 JACE-700 controller option cards.

Option Description Notes

NPB-2X-485 Dual, optically-isolated, RS-485

NPB-LON FTT-10A LON (LonWorks) adapter

NPB-232 Single port RS-232 adapter, with a

NPB-GPRS-W GSM cellular modem card using

NPB-ZWAVE

-US

or

-EU

NPB-SRAM Provides “battery-less” operation.

NPB-SED-001 Sedona Framework option card with

adapter with two 3-position removable screw-terminal connector plugs.

with a 2-position removable

screw-terminal connector plug.

DB-9M connector. Supports baud

rates up to 115200.

GPRS (General Packet Radio Service), with onboard socket for SIM

card, and a Wyless SIM. Includes an

SMA antenna.

Z-Wave wireless serial gateway

between the JACE’s NiagaraAX station and an RF wireless Z-Wave

domain. Includes RP-SMA antenna.

Card has static RAM (SRAM) and

integral backup capacitor for data

storage during power lost periods.

both wireless 6LoWPAN and wired

RS-485 port, based on the Jennic

JN5139 wireless microcontroller.

Includes RP-SMA antenna.

30-pin option card.

If installed in option slot 1, ports operate

as COM5 and COM6.

30-pin option card.

Port operates as LON1 if only one LON

option, or LON2 in slot 2 if two LON cards.

30-pin option card.

If installed in option slot 1, port operates

as COM5.

30-pin option card.

Card uses two JACE-700 COM ports, e.g.

COM5 and COM6 if option slot 1.

30-pin option card.

-US model is 908.42 MHz for U.S. usage

-EU model is 868.42 MHz for European

usage. If installed in option slot 1, card

operates as COM5.

30-pin option card.

Does not use/affect COM port operaton.

NOTE: Use requires removing NiMH bat-

tery pack and any external 12V battery.

30-pin option card.

Enables JACE to operate as wireless network coordinator and 6LoWPAN tunnel, to

integrate wireless Sedona-based devices

in the hosted station. Card uses one COM

port, e.g. COM5 if slot 1.

NOTE: COM port used is not available in

the hosted NiagaraAX station, but is

reserved for future MS/TP support.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 15

May 2, 2011 ABOUT EXPANSION OPTIONS

Option Slot 1

Option Slot 2

Option card or

blanking plate in

Slot 1 must be

removed before

shield can be

removed.

Shield tab

Option card in Slot 2 must be

installed under the shield tab.

Shield with NiMH

battery assembly

Shield tab

About Option Cards

Table 2 JACE-700 controller option cards. (Continued)

Option Description Notes

NPB-MDM 56Kbps Auto-dial/Auto-answer

1

Unlike with a JACE-2/6 controller with an NPB-MDM installed in slot 1, the onboard R S-232 COM1 port (DB9)

remains operational. Also, any NPB-MDM option is unaffected by the “mode jumper” position for serial shell

access (jumper in “serial shell” position affects the operation of the onboard RS -232 COM1 port only).

1

Modem

with one RJ-11 connector

for phone line.

30-pin option card.

Does not have own UART (unlike most

other serial cards). Operates as COM5 if

installed in option slot 1, COM6 if in slot 2.

Option card COM port assignments

COM port assignments for option cards installed in the controller start at COM5,

with Slot 1 evaluated first, then Slot 2. (COM1 and COM2 are always assigned to the

onboard RS-232 and RS-485 ports, while COM3 and COM4 are reserved.)

Installing an Option Card

For option-specific details, see the mounting & wiring document that accompanies

the particular option card. The following procedure provides a basic set of steps.

Warning Installing an option card in option Slot 2 requires careful atten-

tion—you must carefully pry up the shield tab to install the option

card under the tab. Do not install an option card in Slot 2 with the

card resting on top of the shield tab! Otherwise, an electrical short or

some other issue from misaligned card header pins may result.

Figure 6 JACE-700 option card and shield removal.

Procedure 2 Mounting an option card in a JACE-700 controller.

Step 1 Remove power from the controller, including any external battery—see

the previous Wa rn in g on page 15.

Step 2 Remove the cover. See “Removing and Replacing the Cover,” page 13.

Step 3 Remove the blanking plate for the option slot, retaining the two screws.

Retain the blanking plate in case the option card must be removed later.

16 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

ABOUT EXPANSION OPTIONS May 2, 2011

About Remote I/O Modules

Step 4 Carefully insert the pins of the option card into the socket headers of the

option card slot.

Note If installing in Slot 2, first carefully pry up the shield tab that goes over the

standoff. Option card 2 must be installed under the shield tab. See

Figure 6 on page 16 for an exploded view.

The mounting holes on the option board should line up with the standoffs

on the base board. If they do not, the connector is not properly aligned.

Press until the option card is completely seated.

Step 5 Place the custom end plate for the option card over the connector(s) of the

option card. With some option cards, the card’s end plate is pre-fastened.

Step 6 With the mounting holes aligned with the standoffs, place the two screws

through the end plate, and into the standoffs on the controller’s base board.

Using a screwdriver, hand tighten these screws.

Step 7 Replace the cover on the controller.

About Remote I/O Modules

The JACE-700 has an integral 6-pin connector to support remote I/O modules. The

connector provides both 15Vdc power and RS-485 communications to modules on

that connected trunk, and is located on the right side of the unit.

Each remote I/O module has a DIN-mount base, and provides two (2) 6-pin

connectors that allow you to “chain” multiple modules together into one assembly.

Tabl e 3 lists the currently available modules.

Table 3 Remote I/O modules compatible with the JACE-700 controller.

Model Description Notes

IO-16-485 Remote I/O RS-485 Module

DIN-mountable RS-485 comm

module that provides 16 points

I/O, with I/O point types as

noted.

Provides the following I/O points:

• 8 - Universal Inputs (UIs).

• 4 - Digital Outputs (DOs), SPST-relay type.

• 4 - Analog Outputs, 0–10Vdc type.

Up to 16 (maximum) IO-16-485 accessory mod-

ules are supported.

Wiring is covered in a

IO-16-485 Installation and Configura-

see the

tion Instructions

separate document,

.

Note A maximum of eight (8) IO-16-485 modules can be powered by the same

NPB-PWR-UN power supply that powers the JACE-700—and this only if

these modules are either directly attached to the JACE and/or located

nearby with little or no “voltage drop” from power cabling.

Higher numbers of IO-16-485 modules may be supported; however, you

must power them separately from the JACE-700. For more details, please

refer to the “System Planning” section in the Remote I/O Module

(IO-16-485) Mounting and Wiring Guide.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 17

May 2, 2011 WIRING DETAILS

About MiniPCI Cards

About MiniPCI Cards

The controller has one (1) available MiniPCI slot—see Figure 5 on page 14. This slot

supports a specific 802.11 wireless (WiFi) adapter option, model T7-WIFI.

Note The JACE-700 requires NiagaraAX 3.6 or later for WiFi support. Please

refer to the JACE 7 WiFi Option (T7-WIFI) Install Guide for mounting

details, and the NiagaraAX JACE WiFi Option - Engineering Notes

document for NiagaraAX platform configuration.

Wiring Details

See Figure 5 on page 14 to locate connectors and other components on the

JACE-700 controller.

Make connections to the controller in the following order.

1 Install any option board (LON, RS-485, RS-232, etc.) in the available option slots.

See “Installing an Option Card,” page 16 for a procedure. For complete details,

refer to the specific documentation that accompanied the option.

2 Connect communications cables. See “Communications Wiring,” page 18 for

ports available on the controller’s base unit. For ports on any installed option

board (485-PWR, LON, RS-485, modem) see the specific mounting and wiring

guide for any additional details.

3 Apply power to the unit. See “Power Up and Initial Checkout,” page 25.

Communications Wiring

Communications ports on the controller are primarily on the bottom side of the

unit, with ports also on the right side and top (Figure 7). Communications port types

include:

• Ethernet

• Serial

Note Prior to connecting cables, provide strain relief for them to prevent

damage to the controller.

18 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

WIRING DETAILS May 2, 2011

Option slot 2 connector area

Option slot 1 connector area

RS-232 (DB-9) COM1

USB ports (2)

RS-485 COM2

15V PS -, + and

12V Backup Battery out

Bottom side

Right side

Top side

LAN 2 Ethernet (RJ-45)

LAN 1 Primary Ethernet (RJ-45)

Communications Wiring

Figure 7 JACE-700 controller communications ports.

Ethernet

Two, female 1-Gigabit Ethernet connections are provided on the controller. These

are RJ-45 connectors labeled LAN1 and LAN2. Use a standard Ethernet patch cable

for connecting to a hub or Ethernet switch.

The factory-default IP address for LAN1 is 192.168.1.12n, where the last

numeral n in the address matches the last digit in the controller’s serial number, and

the subnet mask is 255.255.255.0. By default, LAN2 is disabled.

Refer to the JACE NiagaraAX Install and Startup Guide for details on changing IP

address.

Note Typically, you only use LAN1 (primary port), unless you have a specific

application for the other LAN2 port. For example, isolating a driver’s

network traffic, using LAN2. Do not use LAN2 as the primary port.

Serial

There are two “RS” serial ports on the controller’s base board. Each has a UART

capable of operation up to 115,200 baud. At the bottom of the board (see Figure 7 on

page 19) is an RS-232 port using an DB-9 plug (male) connector. On the right side of

the unit is an isolated RS-485 port, using the bottom three terminals of a 6-position

screw-terminal connector plug.

Note Additional serial ports may be added with option card(s) in Option Slot 1

and Slot 2, such as an NPB-485-PWR card, NPB-232 card, or NPB-2X-485

card (note the last option actually adds two serial ports).

In addition, there are two USB ports—these ports are located on the top side.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 19

May 2, 2011 WIRING DETAILS

PS – (GND)

PS + (15V)

BB (12V Batt)

–

+

S

RS-485

Power

Communications Wiring

RS-232

An RS-232 serial port using a male DB-9 connector always operates as COM1. You

can use standard DB-9 serial cables with this port.

The controller is a serial DTE device, such another DTE device (PC, for example)

requires a “null modem” cable. If connecting to a DCE device (modem, for example),

use a straight-through cable. Tab le 4 provides standard serial DB-9 pinouts..

Note If rebooted with the mode jumper in the “Serial Shell” position (see Figure

5 on page 14), the RS-232 port provides “system shell” access. See the JACE

NiagaraAX Install and Startup Guide for related details.

Table 4 Serial port (RS-232 and RS-485) pinouts.

Base RS-232 DB-9 Port (COM1) Base RS-485 Port (COM2)

Pinout Reference Signal DB-9 Pin Pinouts

DB-9 Plug (male) DCD Data carrier detect 1 6-Position end connector (male)

RXD Receive data 2

TXD Transmit data 3

DTR Data terminal ready 4

GND Ground 5

DSR Data set ready 6

RTS Request to send 7

CTS Clear to send 8

not used on the JACE-7 9

RS-485

An RS-485, optically isolated port is available on 3 pins of the 6-position right-side

connector, and always operates as COM2. As shown in Ta b l e 4, the screw terminals

are minus (–), plus (+), and shield. Wire in a continuous multidrop fashion to other

RS-485 devices, meaning “minus to minus”, “plus to plus,” and “shield to shield.”

Connect the shield to earth ground at one end only, such as at the JACE-700.

USB

Two USB-2.0 ports are standard on the controller. On the JACE-700, these ports are

“stacked” together, located on the top side—see Figure 7 on page 19.

Note Both USB ports are “low current” ports, capable of supplying up to 100 mA

at 5V, maximum.

A typical application for a USB port is to use with a “USB Flash drive” for the transfer

of files. The QNX OS running on the controller can automatically recognize an

inserted Flash drive as a physical disk.

20 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

WIRING DETAILS May 2, 2011

NPB-PWR-UN

(remove cover)

Grounding lug

JACE-700

Grounding lug

Earth Ground

Neutral

Line

L

N

120 or 240Vac

50–60 Hz

Single Phase

Supplied earth

grounding wire

AC Input

20-pin

connector

not used

Grounding

Grounding

An earth ground spade lug (0.187") is provided on the controller for connection to

earth ground. For maximum protection from electrostatic discharge or other forms

of EMI, connect the supplied earth grounding wire to this lug and a nearby earth

ground. Keep this wire as short as possible, see Figure 8.

Figure 8 Grounding and power wiring connections to NPB-PWR-UN module.

Power Wiring

There are two power options for the controller:

• NPB-PWR-UN power supply module (typical), or

• WPM-XXX (Wall Mount AC Adapter)

NPB-PWR-UN

The NPB-PWR-UN module lets you power the controller (and if installed,

connected I/O modules) from AC line power, with a universal input range from

90–263Vac. The NPB-PWR-UN module provides 15V DC ( ) to the controller,

and installs on the left side of the controller. See Figure 8.

Warning • A 120Vac or 240Vac circuit powers the NPB-PWR-UN. Disconnect

• Make all connections in accordance with national and local electrical

• Do not exceed the 30W capacity of NPB-PWR-UN by the powered

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 21

power to this circuit before installation to prevent electrical shock or

equipment damage.

codes. Use copper conductors only.

devices.

May 2, 2011 WIRING DETAILS

Power Wiring

Make power input connections to the terminals on the NPB-PWR-UN circuit board

(cover removal is required). Use the supplied earth grounding wires to make a

connection from a nearby earth ground to the grounding lug on both the

NPB-PWR-UN power supply and the controller. See Figure 8 on page 21.

Procedure 3 Wiring NPB-PWR-UN input power and earth ground.

Step 1 Remove power from the AC circuit being wired to the

NPB-PWR-UN—see previous War ni ng.

Step 2 Remove the NPB-PWR-UN cover.

To do this, press in the four tabs on both ends of the unit, and lift the cover

off. If the JACE-700 controller is plugged into the unit, you may need to

slide it away to get to the cover tabs.

Step 3 Connect the supplied earth grounding wire to a nearby grounding point.

See Figure 8 on page 21.

Step 4 Make AC circuit connections line (mains) and neutral to the terminals

labeled “INPUT PWR.”

Step 5 Replace the cover on the NPB-PWR-UN module.

Make sure all modules in the mounted assembly are firmly connected together

and secured.

Caution Do not energize the AC circuit wired to the NPB-PWR-UN until all other

controller mounting and wiring is completed. See “Power Up and Initial

Checkout,” page 25.

Power and ground is also provided in wiring to remote I/O modules through the

6-position connector. However, note for each remote I/O module, you should

also connect its earth ground spade lug to earth ground at that module’s location.

WPM-XXX (Wall Mount AC Adapter)

You can order and adapt a wall mount AC adapter (model WPM-XXX, where -XXX

is -US, -EU, or -UK) to power only the JACE-700 controller. To use the adapter, you

must cut off its “barrel plug” end, then wire the two leads into the “P-” and “P+”

positions of the 6-position end connector plug, observing proper + and – polarity.

Note • I/O modules cannot be powered by that WPM-XXX adapter.

Note • Newer versions of the WPM-XXX adapter use a “coaxial” type cable

(insulated center conductor is “+”), whereas prior versions have a “twin

lead” type cable, with the “+” conductor marked by a faint white line.

• Before plugging the wired connector plug into the controller, check for

15Vdc at the proper polarity using a multimeter (see Figure 9).

22 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

WIRING DETAILS May 2, 2011

+

-

15.1

VDC

+

P

-

P

+

-

15.1

VDC

+

P

-

P

Prior “twin lead” style adapter cable:

Positive (+) Wire with White Stripe

Cut off barrel plug

WPM-XXX

Check with multimeter before

plugging into controller

Newer “coaxial” style adapter cable:

Positive (+) Wire is Insulated Center Conductor

6-position

end

connector

plug

6-position end

connector plug

-OR-

Detail A:

Coaxial style adapter

cable stripped and

ready for termination

Power Wiring

Figure 9 Adapting a WPM-XXX wall mount AC adapter to power the JACE-700.

After cutting off the WPM-XXX adapter’s end plug:

• If the coaxial type cable, carefully cut back the outer insulation, and gather the

outer shielded conductor (“–”) lead. Cut back about 5/16" (8mm) of the insulation

around the center shielded conductor (“+”) lead. See Detail A above. Terminate

the two leads into the 6-position end connector plug, as shown in Figure 9, top.

• If the twin-lead type cable, carefully cut/separate lengthwise about 1" (25mm)

between the two leads, then strip back 5/16" (8mm) of the insulation around each

lead’s conductor. Terminate the two leads into the 6-position end connector plug,

as shown in Figure 9 bottom.

Before plugging connector into controller, plug the WPM-XXX adapter into an

outlet and use a multimeter (on V DC) to verify correct polarity.

Do not power the controller until all other mounting and wiring is completed. See

“Power Up and Initial Checkout,” page 25.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 23

May 2, 2011 WIRING DETAILS

BB +

UPS AC

UPS BATT

GND

GND

GND

DOOR TMP

BB –

JACE-700

Tamper

switch

UPS Alarm Contacts

Power Fail (if available)

Low Battery (if available)

UPS AC

UPS BATT

GND

GND

GND

DOOR TMP

–

+

BT+

BT–

PS+

PS–

BB

RS-485

JACE-700

12V Sealed

Lead Acid

Backup

Battery(ies)

15Vdc power and

backup battery

passed through

6-position

connector

Contact Inputs

Contact Inputs

Three contact inputs (CIs) are on a 6-position connector next to the 2-position

external battery connector. CIs typically monitor normally-closed (N.C.) alarm

contacts, if available on a UPS and/or the “door tamper” switch of a nearby

enclosure. These CIs are unsupervised—no end-of-line resistors are required.

Figure 10 on page 24 shows example wiring to all three CIs of the controller.

Figure 10 Contact Input wiring to JACE-700 controller.

External 12V Backup Battery

A 2-position connector provides support for an external 12V sealed lead-acid (SLA)

type rechargable battery. For more details, see “About the Backup Batteries,” page 26.

Figure 11 Sealed lead-acid backup battery connection on JACE-700 controller.

Note The minimum wire size for battery connections is 18AWG (1.0mm2) for

up to 4 ft. (1.22m), or 16AWG (1.29mm

24 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

2

) for up to 12 ft. (3.66m).

POWER UP AND INITIAL CHECKOUT May 2, 2011

PS –

PS +

BB

RS-485 RS-485 +

485 GND

JACE-700

IO-16-485

IO-16-485

Power Supply (15V) and 12V Backup Battery

is routed to remote IO modules using a

3-conductor cable. Use the shortest wiring

route possible for power wiring—star, tee,

bus, and loop topologies are all permissible.

RS-485 communications must be

“daisy-chained” to remote IO modules using

a separate shielded twisted-pair cable.

Connect RS-485 shield wire to ground at

one end only

Wiring to Remote I/O Modules

Wiring to Remote I/O Modules

Wiring to remote I/O modules typically provides both 15Vdc power and 12V battery

backup, along with RS-485 communications to the modules. See Figure 12.

Note For limits of supported I/O modules, refer to the Remote I/O Module

(IO-16-485) Mounting and Wiring Guide section “System Planning”.

Figure 12 Power and RS-485 cabling between JACE-700 and remote I/O modules

Power Up and Initial Checkout

Following all mounting and wiring, perform the following:

Procedure 4 Initial power up and checkout.

1 Apply Power.

2 Check the Status LED.

Also see the section “About the Backup Batteries” on page 26.

Apply Power

The JACE-700 controller does not include an on/off switch. To apply power, you

simply energize the AC circuit (90–263 Vac) wired to the attached NPB-PWR-UN

power supply module. If remote I/O modules are wired to the unit, they are also

typically powered by the controller as well.

If powering the JACE-700 controller (only) with a WPM-XXX (Wall Mount AC

Adapter), simply plug the AC adapter into a nearby wall outlet.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 25

May 2, 2011 POWER UP AND INITIAL CHECKOUT

Check the Status LED

Check the Status LED

When power is applied, the front cover STATUS LED will light green. This indicates

that the system is OK and that power is applied. The STATUS LED may be blinking

until the QNX OS has finished loading and the Niagara platform daemon is running.

Once this boot sequence has finished, the STATUS LED should remain lit (steady),

and the BEAT LED should start blinking, at a typical rate of 1Hz. Typically, this is

about 30 seconds after power is applied.

If after applying power, the STATUS LED goes out, or if the BEAT LED comes on

(steady) and stays lit longer than 2 minutes, contact Systems Engineering for

technical assistance. See also the “About LEDs” section on page 27.

About the Backup Batteries

A JACE-7 series controller has two different backup batteries:

•An on-board NiMH battery pack, and

• An optional external, sealed lead-acid, rechargeable backup battery (or batteries)

For continuous system operation during loss of primary power (to the

NPB-PWR-UN module powering the unit), unless power loss is only a few seconds,

both batteries should be installed. Station alarms are generated if either battery is

uncharged or unable to hold a sufficient charge, as well as whenever primary power

is lost. You should always investigate any alarm related to backup batteries.

NiMH battery pack

A custom 10-cell NiMH (nickel metal hydride) battery pack is inside the controller,

mounted atop the shield, and is secured by a metal bracket and two kep nuts. This

battery allows the controller to continue station operation (only) through very short

power bumps, meaning a few seconds in duration. If a longer outage, the NiMH

battery provides enough run time for the unit to backup data and then shutdown.

Typically, this process takes about one minute. Shutdown occurs automatically, after

data is backed up to on-board flash memory.

Upon startup (boot), a test of the NiMH battery is performed. A system alarm is

generated if the NiMH battery voltage level is found to be bad. A charge is also

initiated upon startup, which lasts from 3 hours minimum, and can range up to 18

hours if the battery is completely discharged. During this NiMH battery charge

period, neither the NiMH battery or the external backup battery is tested. After the

startup NiMH charge period, a periodic test of both batteries occurs, and the

appropriate battery alarm is generated is either battery is found to be bad.

Note • If the last NiMH battery test was “bad,” upon loss of primary power the

controller performs an immediate shutdown, backing up data and powering off (including attached expansion modules).

• A NiMH battery characteristic is to lose charge if not left in charge

mode (trickle charge). Leaving the battery unconnected, or in the unit

powered off will cause the battery to fully discharge in a matter of

weeks. Note that in the case of a new controller, it ships from the factory

26 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

ABOUT LEDS May 2, 2011

NiMH battery pack

with a completely discharged battery. Therefore, allow at least 18 hours

for the battery to charge if it has not been in a powered unit.

You should replace the NiMH battery pack approximately every three years, or more

often if the unit is in a high temperature environment. For more information on the

use and replacement of the battery, refer to the “Required NiMH Battery

Maintenance” section on page 29.

Backup Battery

The optional sealed lead-acid backup battery is an external, 12V, rechargeable

battery (or multiple batteries) sized to operate the system during loss of primary

power, for some duration. This includes the controller, as well as power to attached

I/O expansion modules.

You connect the backup battery to the controller using a 2-position connector—see

Figure 11 on page 24. Whenever primary-powered, the controller supplies a

constant “trickle” charge to this battery, at 200mA maximum. At startup (boot), a

test of the backup battery is performed, as well as a periodic test. A system alarm is

generated if a battery test deems the backup battery to be bad.

Providing that the backup battery has tested good, upon loss of primary power the

system operates from this backup battery power until the charge level of the

on-board NiMH battery pack reaches 0. Note that both batteries discharge in

parallel. However, as the sealed lead-acid backup battery capacity is much greater,

the NiMH battery pack discharges much slower than if these backup battery(ies)

were bad or not present.

Note If the backup battery test was “bad,” upon loss of primary power, the

controller performs an immediate shutdown, backing up data and

powering off (including attached expansion modules).

You should replace the sealed lead-acid backup battery(ies) approximately every

three years, or more often if the unit is in a high temperature environment.

About LEDs

The JACE-700 provides a number of LEDs on its main board, of which only the

Status and Heartbeat LEDs are visible on the cover. Checking other LEDs requires

first removing the cover.

LEDs include the following types:

• Status

• Heartbeat

• Debug

• USB

• Ethernet Ports

For the location of LEDs on the main board, see Figure 5 on page 14.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 27

May 2, 2011 MAINTAINING THE JACE-700

Status

Status

The green “STATUS” LED is located on the cover. On the main board, it is also the

green “SYSOK” LED next to the “HBEAT” LED—both are found near the Ethernet

connector housing. The status LED should remain lit whenever the controller is

powered, or else be blinking during the boot sequence. If the status LED does not

light while power is applied, contact System Engineering for technical support.

Heartbeat

The yellow heartbeat “HBEAT” LED is located on the cover, as well as on the main

board next to the “SYSOK” Status LED. The heartbeat LED blinks about once per

second. If the heartbeat LED stays on constantly, does not light, or blinks very

fast (more than once per second), contact System Engineering for technical support.

Debug

The yellow “DEBUG” LED is located on the main board near the Ethernet connector

housing, and remains lit whenever the controller has been rebooted with the “serial

mode select” jumper in the “serial shell” position (see Figure 5 on page 14). This

indicates that the DB-9 RS-232 port is operating in serial shell mode.

USB

Three yellow LEDs “LD1”, “LD2”, and “LD3” are located together on the upper left

area on the main board, in the option slot 2 area. These LEDs indicate USB hub and

port (1 and 2) activity, respectively. These LEDs will not be easily visible if an option

card is installed in the upper (Slot 2) option slot.

Ethernet Ports

Two LEDs for each of the two LAN ports are provided on the back of the metal LAN

connector housing, and operate as follows.

The left-side green “activity” LED indicates activity on that port as follows:

• Off — No Ethernet link is made

• On — Ethernet link is present, but no activity on the LAN

• Blinking — Ethernet link is present with data activity on the LAN.

The right-side yellow “speed” LED indicates Ethernet connection speed, as either:

• Off — “Fast Ethernet” / “Ethernet” (100 Mbps /10Mbps).

• On — “Gigabit Ethernet” speed (1000 Mbps).

Maintaining the JACE-700

This section provides information on the following topics:

• Cleaning

• Required NiMH Battery Maintenance

• Replacement Parts

• Replacing the JACE-700

• Returning a Defective Unit

28 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

MAINTAINING THE JACE-700 May 2, 2011

Cleaning

Cleaning

If dust or metal filings are present inside the unit, clean with vacuum or compressed

air. Otherwise, no cleaning inside the unit is required. Optionally, if the cover

becomes dirty, you can wipe it with a damp cloth and mild detergent.

Required NiMH Battery Maintenance

Battery life expectancy is a function of its discharge cycles (the number of discharges

and their depth) and the ambient temperature of the battery during normal

operation. In most applications, the NiMH battery should see relatively few

discharges. Therefore, ambient temperature has more to do with the life expectancy

of the battery than does any other factor. If the controller is installed in a conditioned

space, this battery should provide dependable service for approximately three years

(average). In an environment where the operating temperature is higher (that is,

50ºC or 122ºF), you should only expect the battery to last approximately one year.

The NiMH battery in the controller is fully discharged when factory shipped.

Additionally, NiMH batteries lose charge over time if not kept trickle-charged (for

more details, see “NiMH battery pack,” page 26). Therefore, even a new unit (or

replacement battery) will require up to 18 hours of powered operation before it can

provide reliable backup power (is at full charge).

The controller monitors the NiMH battery and periodically loads the battery to test

its ability to maintain battery-backed functions. Investigate any battery trouble

message, and check the battery connections to the unit. Replace the battery as

required. To order a new battery, see the “Standard Replacement Parts” section on

page 31. See the next section “Replacing the NiMH Battery” for a replacement

procedure.

Replacing the NiMH Battery

The replacement NiMH battery is an assembly, that is a custom battery pack with an

attached cable and connector plug. See Figure 13. To replace the battery, you must

remove power to the unit and remove its cover.

Caution Use only NiMH battery packs approved for use with the JACE-700.

Procedure 5 Replacing NiMH battery assembly on a JACE-700 controller.

Step 1 Backup the controller’s configuration to your PC using the appropriate

NiagaraAX software tool (for example, Workbench).

Step 2 Remove all power from the controller, including any sealed lead-acid bat-

tery. Wait for LED activity to stop—after a couple of minutes, all LEDs on

the unit should be off.

Step 3 Remove the cover. See “Removing and Replacing the Cover,” page 13.

At this point you have access to the NiMH battery assembly (Figure 13).

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 29

May 2, 2011 MAINTAINING THE JACE-700

Cover removed

NiMH battery

connector on

controller board

NiMH battery pack

(NPB-J700-BATT)

Unplug/plug NiMH battery

from/to connector

1/4" (6mm) Kep nuts

(2) fasten battery

bracket to shield

Battery

bracket

Required NiMH Battery Maintenance

Figure 13 Replacing NiMH battery pack in JACE-700 controller.

Note Dispose of the used NiMH battery properly.

Step 4 Unplug the NiMH battery from the main board connector (see Figure 13).

Step 5 Using a 1/4" (6mm) nutdriver, unfasten and retain the two kep nuts that

secure the metal battery bracket to the shield, and remove the shield and

battery pack.

Step 6 Put the replacement battery into the metal shield, and refasten back into

place on the shield, using the two kep nuts. Hand tighten with a nutdriver.

Step 7 Plug the battery connector plug of the replacement battery into the NiMH

battery connector on the main board of the controller. The connector is

keyed—you cannot plug the battery in reversed.

Step 8 Replace the cover.

Step 9 Restore power to the controller and verify normal operation.

Battery Disposal

Please dispose of the used NiMH battery in accordance with local, state, and federal

regulations.

Warning Do not incinerate or mutilate the battery, as this may cause it to burst or

release toxic materials.

If regulations specify returning the old battery to a recycling center, but no

acceptable recycling center can be found, please return the old NiMH battery pack

to Tridium for proper disposal.

30 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

REPLACEMENT PARTS May 2, 2011

Non-replaceable Parts

Replacement Parts

Servicing the JACE-700 controller may call for replacement parts. There are three

categories of parts:

• Non-replaceable Parts

• Standard Replacement Parts

• New Replacement Unit

Non-replaceable Parts

The controller contains a non-user replaceable 2.5A slow-blow fuse, soldered on the

main circuit board. This fuse provides protection from internal shorts or connection

to incorrect power supplies. If the fuse circuitry is suspect, contact technical

support. See the “Returning a Defective Unit” section on page 33.

Standard Replacement Parts

Standard replacement parts are listed in Ta b le 5 , and can be ordered from stock

without restriction. Standard replacement parts cannot be returned for credit and

should be disposed of in an appropriate manner.

Table 5 Standard replacement parts for a JACE-700 controller.

Part Number Description

NPB-J700-BATT NiMH Battery Pack—see “Required NiMH Battery Maintenance,” page 29

J7-1GB 1 GB DDR-2 333MHz SODIMM RAM memory module (replacement part)

11696 Hardware Bag for JACE-700, containing screw terminal connector plugs (two

6-position, one 2-position, earth grounding wire).

New Replacement Unit

To replace an entire unit, order and install a new JACE-700 controller. If the faulty

controller is still in warranty, you can receive credit by returning it. Be sure to

contact the vendor for a return authorization (RA) number before shipping an item

for return credit. See “Returning a Defective Unit,” page 33, for more details.

Note Before ordering a new controller, it is strongly recommended that you

contact your normal technical support resource to eliminate the possibility

of a software issue or mis-configuration problem.

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 31

May 2, 2011 REPLACEMENT PARTS

Replacing the JACE-700

Replacing the JACE-700

Note Before handling circuit boards, discharge any accumulated static by

touching a nearby earth ground. For details, see the “Static Discharge

Precautions” section on page 10.

To replace a JACE-700 with a new replacement unit, proceed as follows:

Procedure 6 Replacing a JACE-700 controller.

Step 1 If possible, use the appropriate NiagaraAX software tool to back up the con-

troller’s configuration to your PC.

Step 2 Remove power to the controller, including any external 12V battery. The

unit should power down automatically. Wait for all LEDs to remain off.

Step 3 Remove the front cover. See “Removing and Replacing the Cover,” page 13.

Step 4 Note positions of all communications and other wiring cables going to the

controller. If necessary, label connectors and accessory modules to avoid

mis-connection later, after the controller is replaced.

Step 5 Unplug all Ethernet, serial, LON, modem, and I/O connectors from the con-

troller. Note the position of installed option cards, if any. You must transfer

them to the replacement JACE-700 controller.

Step 6 Remove the controller from its mounting (DIN rail, panel mount tabs, etc).

Step 7 Remove any option cards from the old controller and install them into the

replacement JACE-700 controller, if applicable. See “Installing an Option

Card,” page 16 for more details.

Step 8 Mount the replacement controller as it was previously, using the same DIN

rail location and/or screws.

Step 9 Reconnect the earth ground wire to the controller’s grounding lug and any

installed accessory modules.

Step 10 Reconnect any Ethernet, serial, modem, and I/O connectors.

Step 11 If using IO modules, and any of your I/O points have voltage, turn the

devices back on, or reconnect power to them.

Step 12 Replace the cover. See “Removing and Replacing the Cover,” page 13.

Step 13 Restore power to the unit. It should boot up as a new unit (see “Check the

Status LED,” page 26).

Step 14 Using the NiagaraAX platform tools, re-commission the JACE-700 control-

ler, and install the saved station database. For more details, see the JACE

NiagaraAX Install and Startup Guide.

32 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

REPLACEMENT PARTS May 2, 2011

Returning a Defective Unit

Returning a Defective Unit

For proper credit on an in-warranty unit, ship the defective unit per the vendor’s

return material procedures.

Note If the defective unit is under warranty, please follow return instructions

provided in this section.

If the unit is out of warranty, please discard any replaced part.

• Do not return an out-of-warranty JACE-700 controller.

Prior to returning the unit, contact your vendor to obtain a return materials

authorization (RMA) number and other instructions.

Please provide:

• Product model

• Serial number

• Nature of the defect

• PO number to secure the RMA

United States

Phone: 804-254-7086, ext. 11

Email for RMA: rma@tridium.com

Return to:

Tridium, Inc.

2256 Dabney Road, Suite C

Richmond, VA 23230

Attn: Return Department RMA# ____________

Europe

Phone: +44 (0) 1403 740290

Fax: +44 (0) 1403 741804

Email for technical support: supportuk@tridium.com

Email for product orders: ordersuk@tridium.com

Return to:

Tridium Europe Ltd

1, The Grainstore

Brooks Green Road

Coolham, West Sussex

RH13 8GR United Kingdom

Attn: Return Department RMA# ____________

Asia/Pacific

Phone: +65 6887 5154

Fax: +65 6887 5342

Email for technical support: hclim@tridium.com

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 33

May 2, 2011 CERTIFICATIONS

Return to:

Tridium Asia Pacific Pte Ltd

17 Changi Business Park Central 1

Honeywell Building

Attn: Mr Lim Hoon Chat, Engineering Mgr.

Singapore 486073

Attn: Return Department RA# ____________

Australia/Asia Pacific Sales:

Phone: +61 4 1264 4234

Email: mhodder@tridium.com

Federal Communications Commission (FCC)

Certifications

Federal Communications Commission (FCC)

This equipment generates, uses, and can radiate radio frequency energy, and if not

installed and used in accordance with the instruction manual, may cause

interference with radio communications. It has been tested and found to comply

with the limits for a Class A computing device pursuant to Subpart J of Part 15 of

FCC Rules, which are designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation of this

equipment in a residential area may cause interference, in which case, users at their

own expense will be required to take whatever measures may be required to correct

the interference. Any unauthorized modification of this equipment may result in the

revocation of the owner's authority to continue its operation.

Canadian Department of Communications (DOC)

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe A respecte toutes les exigencies du Reglement

sur le material broilleur du Canada.

Declaration of RoHS Compliance

This product meets all requirements of RoHS Directive (EU 202/95/EC). All

components used in this product are RoHS compliant and there have been no leaded

solders used in manufacture.

Related to the RoHS (Restriction of Hazardous Substances) Directive is another

European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE). The WEEE Directive aims to reduce the waste arising from electrical and

electronic equipment, and improve the environmental performance of everything

involved in the life cycle of electrical and electronic equipment.

For related details, see the precaution “WEEE (Waste of Electrical and Electronic

Equipment)” on page 10.

34 Part Number 11694 Rev 1.6 JACE-700 MOUNTING AND WIRING GUIDE |

CERTIFICATIONS May 2, 2011

CE Declaration of Conformity

CE Declaration of Conformity

Date: December, 2009

Application of Council

Manufacturer’s Represen-

Product Model Numbers: JACE-700

Type of Equipment: Electrical Equipment for Measurement, Control and Laboratory Use

EMS Standards Applied: Standard Description Criteria Met

Directive:

Manufacturer: Tridium Inc.

I, Steve Fey, President of Tridium Inc., hereby declare that the equipment specified

above conforms to the above Directives and Standards.

89/336/EEC, 92/31/EEC, 73/23/EEC, 93/68/EEC

3951 Westerre Parkway, Suite 350

Richmond, Virginia 23233

United States of America

Steve Fey, President

tative:

Tridium Inc.

CISPR

16-2-3:2006

IEC 61000-4-2 Electrostatic Discharge

IEC 61000-4-3 Radiated Electromagnetic

IEC 61000-4-4 Electrical Fast Transient / Burst

IEC 61000-4-6 Conducted Radio-Frequency

IEC 61010-1:2001

rev. 9/19/03

Radiated Emissions - Class A Complies

Immunity

Field Immunity

Immunity

Immunity

Safety requirement for electrical equipment

For measurement, control and

laboratory use

PASS

Class B

PAS S

Class A

PASS

Class B

PASS

Class A

PASS

| JACE-700 MOUNTING AND WIRING GUIDE Part Number 11694 Rev 1.6 35

May 2, 2011 TAB MOUNTING DIMENSIONS

0.1590" Dia. (4.04)

0.98" (24.9)

0.334"

Dia. (8.5)

0.35" (8.9)

5.0" (127)

1.72"

(43.7)

0.170" Dia. (4.32)

8.7" (221)

5.6"

(142)

2.50"

(63.5)

NPB-PWR-UN

8.125" (206)