VM1548C

TTL I/O MODULE

USER’S MANUAL

P/N: 82-0045-000

Released July 31, 2007

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949) 955-1894

bus

2

www.vxitech.com

TABLE OF CONTENTS

INTRODUCTION

Certification..........................................................................................................................................................6

Warranty ...............................................................................................................................................................6

Limitation of Warranty.........................................................................................................................................6

Restricted Rights Legend......................................................................................................................................6

Declaration of Conformity....................................................................................................................................7

Terms and Symbols .............................................................................................................................................. 8

Warnings ..............................................................................................................................................................8

SECTION 1..................................................................................................................................................................11

INTRODUCTION .......................................................................................................................................................11

Introduction ........................................................................................................................................................11

Features...............................................................................................................................................................12

Description .........................................................................................................................................................13

Programming and Data Access...........................................................................................................................13

VM1548 Specifications ......................................................................................................................................15

SECTION 2..................................................................................................................................................................17

PREPARATION FOR USE...........................................................................................................................................17

Installation .......................................................................................................................................................... 17

Calculating System Power and Cooling Requirements ......................................................................................17

Setting the Chassis Backplane Jumpers..............................................................................................................17

Setting the Logical Address................................................................................................................................18

Front Panel Interface Wiring .............................................................................................................................. 19

SECTION 3..................................................................................................................................................................20

PROGRAMMING....................................................................................................................................................... 20

Introduction ........................................................................................................................................................20

Notation ..............................................................................................................................................................22

EXAMPLES OF SCPI COMMANDS ............................................................................................................................23

TTLTRIG Circuit ...............................................................................................................................................23

Interrupt Circuit ..................................................................................................................................................24

Output Register Circuit.......................................................................................................................................25

Input Register Circuit .........................................................................................................................................26

Bi-directional Clock Circuit ...............................................................................................................................27

APPLICATION EXAMPLES ........................................................................................................................................28

Write Mode.........................................................................................................................................................28

Read Mode..........................................................................................................................................................30

Write/Read Mode ...............................................................................................................................................33

REGISTER ACCESS EXAMPLES ................................................................................................................................37

VXIPLUG&PLAY EXAMPLES ...................................................................................................................................39

SECTION 4..................................................................................................................................................................45

COMMAND DICTIONARY......................................................................................................................................... 45

Introduction ........................................................................................................................................................45

Alphabetical Command Listing..........................................................................................................................45

Terminology ....................................................................................................................................................... 46

Command Dictionary..........................................................................................................................................50

IEEE 488.2 COMMON COMMANDS .........................................................................................................................51

*CLS................................................................................................................................................................... 51

*ESE...................................................................................................................................................................52

*ESR?.................................................................................................................................................................53

*IDN? ................................................................................................................................................................. 54

VM1548C Preface 3

VXI Technology, Inc.

*OPC ..................................................................................................................................................................55

*RST................................................................................................................................................................... 56

*STB?.................................................................................................................................................................57

*TRG ..................................................................................................................................................................58

*TST...................................................................................................................................................................59

*WAI ..................................................................................................................................................................60

INSTRUMENT SPECIFIC SCPI COMMANDS...............................................................................................................61

FORMat..............................................................................................................................................................61

INPut:REGister:POLarity................................................................................................................................... 62

INPut:REGister:SOURce ...................................................................................................................................63

INPut:TTLTrig ...................................................................................................................................................64

INPut:TTLTrig:STATE......................................................................................................................................65

OUTPut:CLOCk:ENABle ..................................................................................................................................66

OUTPut:CLOCk:POLarity.................................................................................................................................67

OUTPut:CLOCk:SOURce..................................................................................................................................68

OUTPut:REGister:POLarity............................................................................................................................... 69

OUTPut:REGister:SOURce ...............................................................................................................................70

OUTPut:TTLTrig ...............................................................................................................................................71

OUTPut:TTLTrig:POLarity ...............................................................................................................................72

OUTPut:TTLTrig:SOURce ................................................................................................................................73

OUTPut:TTLTrig:STATE..................................................................................................................................74

READ? ...............................................................................................................................................................75

READ? CLOCks ................................................................................................................................................76

READ? CONTrol ...............................................................................................................................................77

READ? ISENse ..................................................................................................................................................78

RESet:ISENse.....................................................................................................................................................79

SOURce:DATA.................................................................................................................................................. 80

SOURce:DATA:ENABle...................................................................................................................................81

SOURce:DATA:POLarity..................................................................................................................................82

STATus:INTerrupt:ENABle ..............................................................................................................................83

STATus:INTerrupt:NTRansition........................................................................................................................84

STATus:INTerrupt:PTRansition ........................................................................................................................85

TRIGger:SEQuence:IMMediate......................................................................................................................... 86

SCPI REQUIRED COMMANDS..................................................................................................................................87

STATus:OPERation? .........................................................................................................................................87

STATus:OPERation:CONDition?......................................................................................................................88

STATus:OPERation:ENABle.............................................................................................................................89

STATus:PRESet .................................................................................................................................................90

STATus:QUEStionable:CONDition?................................................................................................................. 91

STATus:QUEStionable:ENABle .......................................................................................................................92

STATus:QUEStionable:EVENt?........................................................................................................................93

SYSTem:ERRor? ...............................................................................................................................................94

SYSTem:VERSion? ...........................................................................................................................................95

SECTION 5..................................................................................................................................................................97

THEORY OF OPERATION.......................................................................................................................................... 97

Introduction ........................................................................................................................................................97

VXI INTERFACE......................................................................................................................................................98

Device Transfers (Write Mode).......................................................................................................................... 98

Direction .............................................................................................................................................................98

Clock Enable ......................................................................................................................................................98

Data Load ...........................................................................................................................................................99

Device Triggering (TTL Input Trigger) ...........................................................................................................100

Trigger Decode.................................................................................................................................................100

Trigger Select ...................................................................................................................................................100

Device Transfers (Read Mode).........................................................................................................................102

Direction ...........................................................................................................................................................102

4 VM1548C Preface

www.vxitech.com

Clock Enable ....................................................................................................................................................102

Latch Data ........................................................................................................................................................103

Read Data .........................................................................................................................................................104

INDEX.......................................................................................................................................................................105

VM1548C Preface 5

VXI Technology, Inc.

CERTIFICATION

VXI Technology, Inc. (VTI) certifies that this product met its published specifications at the time of shipment from

the factory. VTI further certifies that its calibration measurements are traceable to the United States National

Institute of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that

organization’s calibration facility, and to the calibration facilities of other International Standards Organization

members.

WARRANTY

The product referred to herein is warranted against defects in material and workmanship for a period of three years

from the receipt date of the product at customer’s facility. The sole and exclusive remedy for breach of any warranty

concerning these goods shall be repair or replacement of defective parts, or a refund of the purchase price, to be

determined at the option of VTI.

For warranty service or repair, this product must be returned to a VXI Technology authorized service center. The

product shall be shipped prepaid to VTI and VTI shall prepay all returns of the product to the buyer. However, the

buyer shall pay all shipping charges, duties, and taxes for products returned to VTI from another country.

VTI warrants that its software and firmware designated by VTI for use with a product will execute its programming

when properly installed on that product. VTI does not however warrant that the operation of the product, or

software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate maintenance by the buyer, buyersupplied products or interfacing, unauthorized modification or misuse, operation outside the environmental

specifications for the product, or improper site preparation or maintenance.

VXI Technology, Inc. shall not be liable for injury to property other than the goods themselves. Other than the

limited warranty stated above, VXI Technology, Inc. makes no other warranties, express or implied, with respect to

the quality of product beyond the description of the goods on the face of the contract. VTI specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

RESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of

the Rights in Technical Data and Computer Software clause in DFARS 252.227-7013.

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509 U.S.A.

6 VM1548C Preface

www.vxitech.com

D ECLARATION OF C ONFORMITY

Declaration of Conformity According to ISO/IEC Guide 22 and EN 45014

ANUFACTURER’S NAME VXI Technology, Inc.

M

ANUFACTURER’S ADDRESS 2031 Main Street

M

Irvine, California 92614-6509

RODUCT NAME TTL I/O Module

P

ODEL NUMBER(S) VM1548C

M

RODUCT OPTIONS All

P

RODUCT CONFIGURATIONS All

P

VXI Technology, Inc. declares that the aforementioned product conforms to the requirements of

the Low Voltage Directive 73/23/EEC and the EMC Directive 89/366/EEC (inclusive 93/68/EEC)

and carries the “CE” mark accordingly. The product has been designed and manufactured

according to the following specifications:

AFETY EN61010 (2001)

S

EMC EN61326 (1997 w/A1:98) Class A

CISPR 22 (1997) Class A

VCCI (April 2000) Class A

ICES-003 Class A (ANSI C63.4 1992)

AS/NZS 3548 (w/A1 & A2:97) Class A

FCC Part 15 Subpart B Class A

EN 61010-1:2001

The product was installed into a C-size VXI mainframe chassis and tested in a typical configuration.

I hereby declare that the aforementioned product has been designed to be in compliance with the relevant sections

of the specifications listed above as well as complying with all essential requirements of the Low Voltage Directive.

July 2007

VM1548C Preface 7

Steve Mauga, QA Manager

Review the following safety precautions to avoid bodily injury and/or damage to the product.

These precautions must be observed during all phases of operation or service of this product.

Failure to comply with these precautions, or with specific warnings elsewhere in this manual,

violates safety standards of design, manufacture, and intended use of the product.

Service should only be performed by qualified personnel.

TERMS AND SYMBOLS

These terms may appear in this manual:

WARNING

CAUTION

These symbols may appear on the product:

VXI Technology, Inc.

GENERAL SAFETY INSTRUCTIONS

Indicates that a procedure or condition may cause bodily injury or death.

Indicates that a procedure or condition could possibly cause damage to

equipment or loss of data.

ATTENTION - Important safety instructions

WARNINGS

Frame or chassis ground

Indicates that the product was manufactured after August 13, 2005. This mark is

placed in accordance with EN 50419, Marking of electrical and electronic

equipment in accordance with Article 11(2) of Directive 2002/96/EC (WEEE).

End-of-life product can be returned to VTI by obtaining an RMA number. Fees

for take-back and recycling will apply if not prohibited by national law.

Follow these precautions to avoid injury or damage to the product:

Use Proper Power Cord

Use Proper Power Source

Use Proper Fuse

To avoid hazard, only use the power cord specified for this product.

To avoid electrical overload, electric shock, or fire hazard, do not

use a power source that applies other than the specified voltage.

To avoid fire hazard, only use the type and rating fuse specified for

this product.

8 VM1548C Preface

www.vxitech.com

WARNINGS (CONT.)

Avoid Electric Shock

Ground the Product

Operating Conditions

Improper Use

To avoid electric shock or fire hazard, do not operate this product

with the covers removed. Do not connect or disconnect any cable,

probes, test leads, etc. while they are connected to a voltage source.

Remove all power and unplug unit before performing any service.

Service should only be performed by qualified personnel.

This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground.

To avoid injury, electric shock or fire hazard:

- Do not operate in wet or damp conditions.

- Do not operate in an explosive atmosphere.

- Operate or store only in specified temperature range.

- Provide proper clearance for product ventilation to prevent

overheating.

- DO NOT operate if any damage to this product is suspected.

Product should be inspected or serviced only by qualified

personnel.

The operator of this instrument is advised that if the equipment is

used in a manner not specified in this manual, the protection

provided by the equipment may be impaired.

Conformity is checked by inspection.

VM1548C Preface 9

VXI Technology, Inc.

SUPPORT RESOURCES

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Instrument Division

5425 Warner Road

Suite 13

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail:

Visit

support@vxitech.com

http://www.vxitech.com for worldwide support sites and service plan information.

10 VM1548C Preface

www.vxitech.com

A

V

V

V

SECTION 1

INTRODUCTION

INTRODUCTION

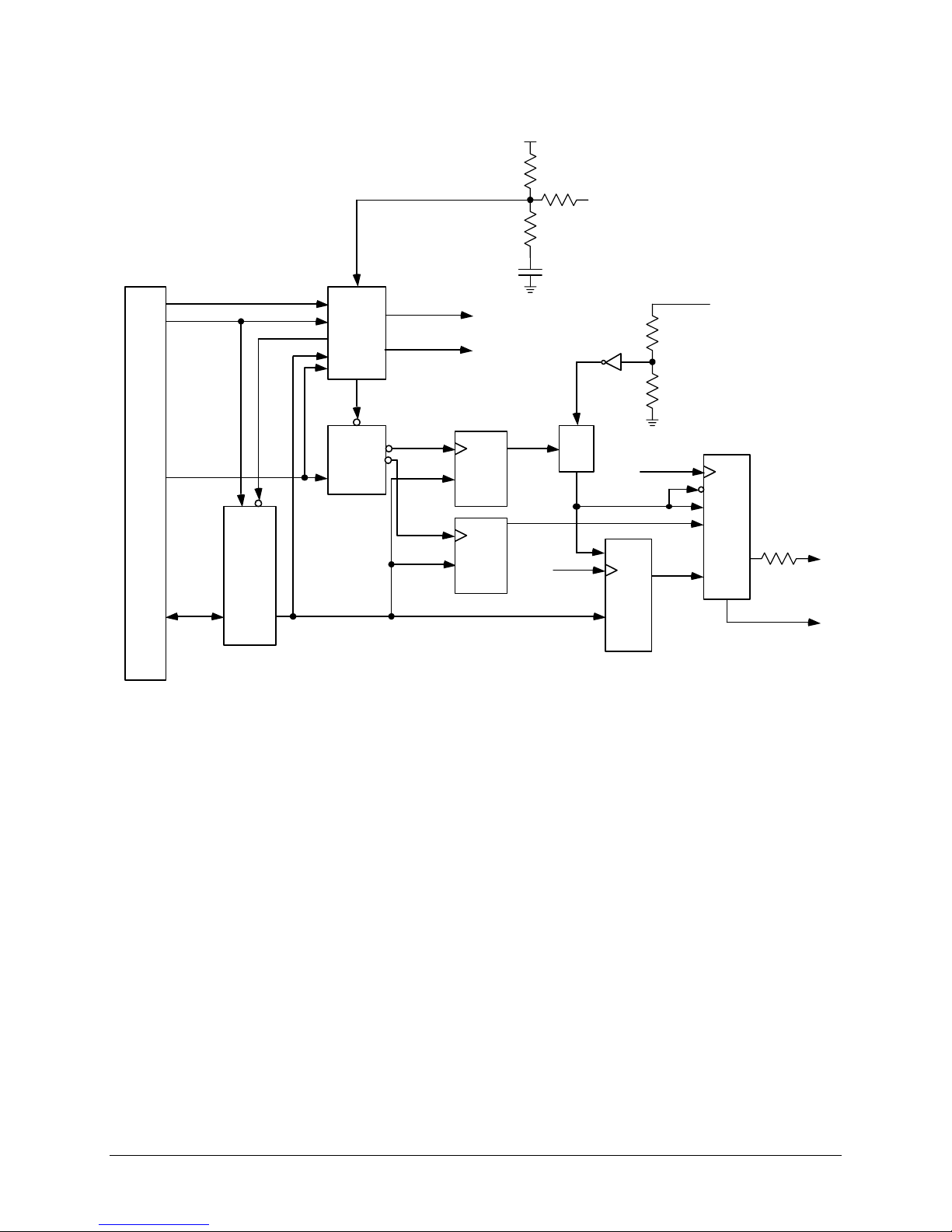

The VM1548C is a high-performance I/O module that has been designed for high data throughput

and flexibility of configuration. The instrument uses the message-based word serial interface for

programming and data movement as well as allowing direct register access for very high-speed

data input and retrieval. The VM1548C command set conforms to the SCPI standard for

consistency and ease of programming.

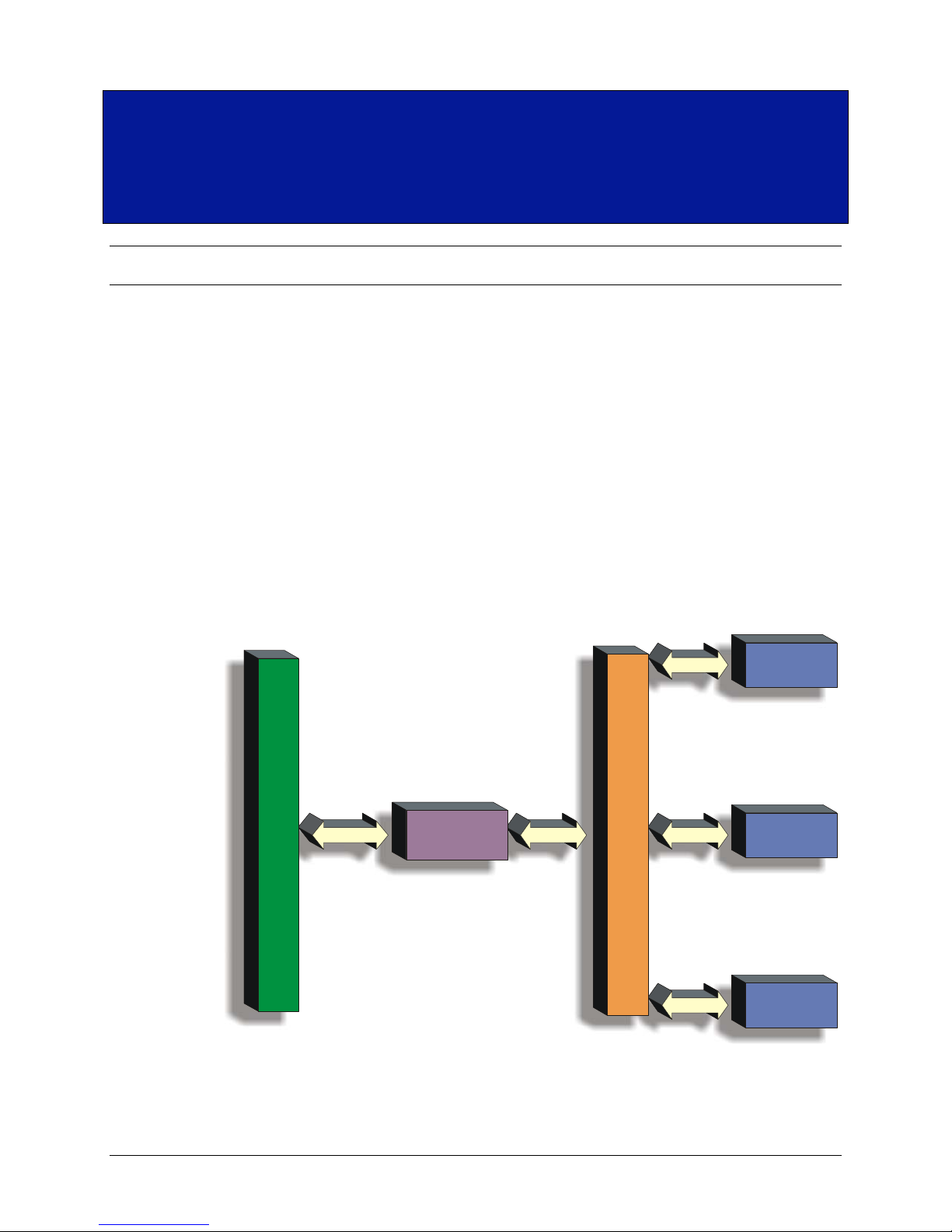

The VM1548C is a member of the VXI Technology VMIP™ (VXI Modular Instrumentation

Platform) family and is available as a 48-, 96-, or 144-channel, singlewide VXIbus instrument.

Figure 1-1 and Figure 1-2 show the 144-channel version of the VM1548C. The 96-channel

version would not have J200 and its associated LED’s and nomenclature while the 48-channel

version would eliminate J202 as well. In addition to these three standard configurations, the

VM1548C may be combined with any of the other members of the VMIP family to form a

customized and highly integrated instrument (see

system size and cost by combining the VM1548C with two other instrument functions in a single

wide, C-size VXIbus module.

Figure 1-1). This allows the user to reduce

V

X

I

B

U

S

MIP

INTERFACE

IGURE 1-1: VMIP™ PLATFORM

F

N

T

E

R

N

L

M

P

B

U

S

MIP

INSTRUMENT

MODULE #1

I

MIP

INSTRUMENT

V

I

MODULE #2

VMIP

INSTRUMENT

MODULE #3

VM1548C Introduction 11

ACC/

ERR

J200

ERR

J201

ERR

J202

bus

FAIL

FAILACC/

FAILACC/

VXI Technology, Inc.

Regardless of whether the VM1548C is configured with other VM1548C modules or

with other VMIP modules, each group of 48 channels is treated as an independent

instrument in the VXIbus chassis and as such, each group has its own FAIL/POWER

and ACCESS/ERROR indicators.

FEATURES

• 48 channels, 6 groups of 8 bits. Up to 144 channels in a single C-size card.

• Group-wise programmable, as an input or an output, through user TTL input or VXI

A16 registers.

• Group-wise programmable polarity through VXI A16 registers as an active high or

low.

• Input: 0 V to 60 V, V

IN(high)

≥ 2.0 V, V

• Output: Open collector (N-DMOS), 0 V to 60 V, up to 300 mA continuous with

over-voltage and over-current protection.

• Data throughput: 5 µs typical system speeds, 200 kilobytes (kB) per second using

D8 access, 400 kB per second using D16 access.

• Data Input/Output Clock Sources: For each group, from Front Panel clock input,

VXI TTL Trigger lines, or word serial event (command).

• Capture clock edge programmable as rising edge or falling edge.

• ASCII, Hex, Octal, and Binary data output types.

• Message or Register based data access.

• SCPI compatible.

≤ 1.5 V, input impedance ≥ 65 kΩ.

IN(low)

IGURE 1-2: FRONT PANEL LAYOUT

F

12 VM1548C Introduction

www.vxitech.com

DESCRIPTION

The VM1548C Open Collector Digital I/O module is a high performance I/O module that has

been designed for high voltage, current, and data throughput. The instrument uses the messagebased word serial interface for programming and data movement as well as allowing direct

register access for very high-speed.

The VM1548C provide 48 open-collector digital I/O line that are configurable as input or output

in six groups of eight channels each. The module can drive up to 60 V with sink current of up to

300 mA per channel. Each group of 8 bits can be configured as an input or an output under

program control. The VM1548C has the flexibility to source the input and output clocks from

either the front panel (one input per group of 8 bits), the backplane TTL Trigger bus or via a word

serial command. By using the appropriate clocking sources, very large numbers of channels may

by synchronized to collect or present data to a UUT (unit under test).

Each clock input is internally pulled to a logic high level and has a RC termination network to

reduce multiple clocking due to line ringing. The RC network consists of a 120 Ω resistor in series

with a 100 pF capacitor, giving a time constant of 12 ns.

The VM1548C can be combined with any member of the VMIP family to form a customized and

highly integrated instrument.

PROGRAMMING AND DATA ACCESS

The data may be read or loaded by one of two different methods:

Word Serial Message-based Data Access: In this mode, the input or output data and all other

functions are accessed via the VXI message-based

interface. Commands are sent to set the I/O ports

as well as to initiate functions such as triggering an

update or to query a port’s input state. This data

access method is very clean from a programming

perspective, but it is also the slowest of the data

access modes.

Register-Based Data Access: This mode offers the fastest throughput. The I/O

ports are directly mapped into the VXI user

definable registers. Data access occurs in

approximately 500 ns, depending on the controller

and software used.

VM1548C Introduction

13

VXI Technology, Inc.

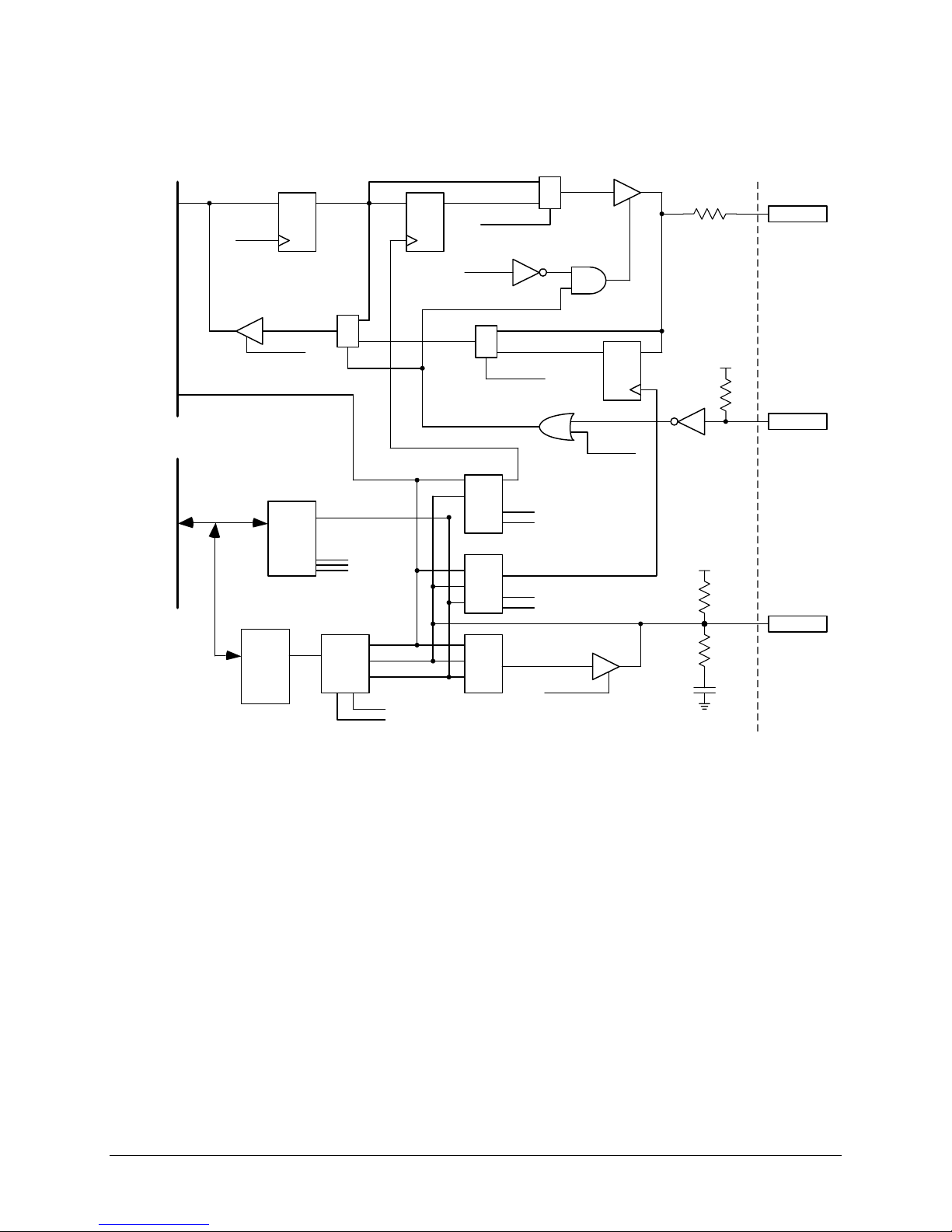

FRONT

PANEL

22

DATA I/O

WRITE

DATA

A

DQDQ

CLKOUTENA

ISENSE

B

DAMPING

RESISTOR

VMIP BUSVXI BACKPLANE

TTL TIGGER 0-7

8:1

SELECT

READ

DATA

8:1

SELECT

A

B

TTL

TRIGGER

SELECT

1:3

SELECT

TTL TRIG

OUT SEL

F

IGURE 1-3: VM1548C MODULE BLOCK DIAGRAM

A

B

3:1

MUX

3:1

MUX

3:1

MUX

CLKINENA

CLK OUT

SEL

CLK IN

SEL

CLKOUTENA

QD

OUTENA

47K

I/O*

47K

CLOCK

120

100pF

14 VM1548C Introduction

www.vxitech.com

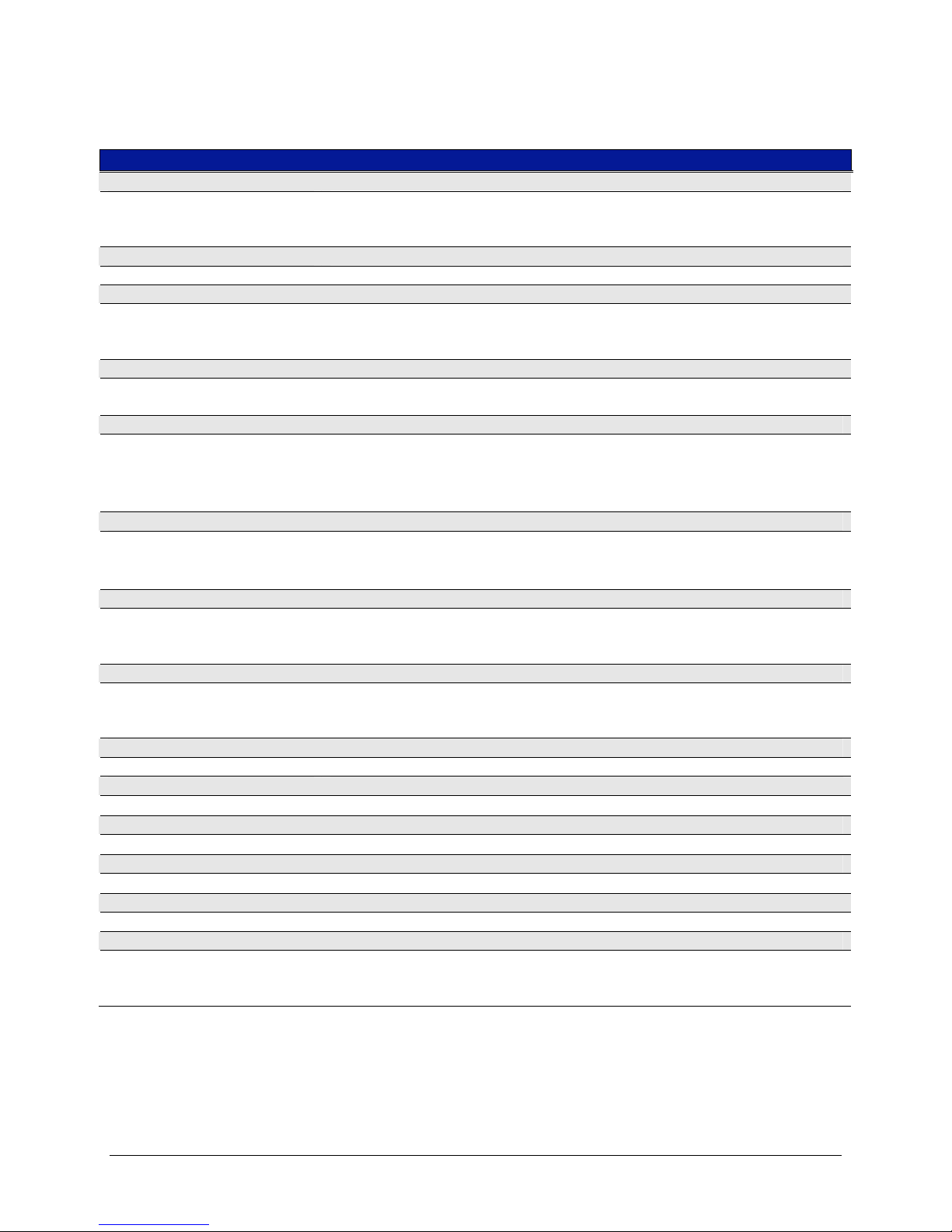

VM1548 SPECIFICATIONS

GENERAL SPECIFICATIONS

NUMBER OF CHANNELS

VM1548C-1

VM1548C-2

VM1548C-3

DIRECTION

DATA THROUGHPUT

48, 6 groups of 8 bits

96, 12 groups of 8 bits

144, 18 groups of 8 bits

bi-directional

5 µs typical system (500 µs register cycle time)

200 kB/s using D8 access

400 kB/s using D16 access

PHYSICAL INTERFACE

N channel DMOS transistor (TPIC2601KTC) with a current protection circuit on

the output side, and a voltage divider and voltage comparator on the input side

CHANNEL INPUT CHARACTERISTICS

V

V

V

Input Impedance

IN(high)

IN(low)

IN(max)

≥ 2.0 V

≤ 1.5 V

≤ 60 V

≥ 65 kΩ

CHANEL OUTPUT CHARACTERISTICS

V

OUT(max)

Current Sink (Max.)

Switch On Time

≤ 60 V

≤ 300 mA

≤ 1 µs

CLOCK AND CONTROL INPUT CHARACTERISTICS

V

V

IN(high)

IN(low)

Current In (VIN = 5.0 V)

> 2.0 V

< 0.8 V

< 10 µA

DATA INPUT CLOCK SOURCES

6 front panel

TTL trigger bus (0 - 7)

word serial command

TTL TRIGGER OUTPUT SOURCES

CLOCKED INPUT DATA SETUP

Front Panel Clock inputs (0 - 5)

≥ 2 µs

CLOCKED INPUT DATA HOLD

≥ 0

CLOCKED DATA OUTPUT SKEW

POWER REQUIREMENTS

≤ 2 µs

+5 V @ 864 mA, +12 V @ 60 mA

COOLING REQUIREMENTS

VM1548C-1

VM1548C-2

VM1548C-3

0.4 L/s

0.8 L/s

1.2 L/s

VM1548C Introduction

15

VXI Technology, Inc.

16 VM1548C Introduction

www.vxitech.com

SECTION 2

PREPARATION FOR USE

INSTALLATION

When the VM1548C is unpacked from its shipping carton, the contents should include the

following items:

(1) VM1548C VXIbus module

(1) VM1548C Open Collector Digital I/O Module User’s Manual (this manual)

All components should be immediately inspected for damage upon receipt of the unit.

Once the VM1548C is assessed to be in good condition, it may be installed into an appropriate

C-size or D-size VXIbus chassis in any slot other than slot 0. The chassis should be checked to

ensure that it is capable of providing adequate power and cooling for the VM1548C. Once the

chassis is found to be adequate, the VM1548C’s logical address and the chassis’ backplane

jumpers should be configured prior to the VM1548C’s installation.

CALCULATING SYSTEM POWER AND COOLING REQUIREMENTS

The power and cooling requirements of the VM4018 are given in the Specifications section of

Section 1 in this manual. It is imperative that the chassis provide adequate power and cooling for

this module. Referring to the chassis User’s Manual, confirm that the power budget for the system

(the chassis and all modules installed therein) is not exceeded and that the cooling system can

provide adequate airflow at the specified backpressure.

It should be noted that if the chassis cannot provide adequate power to the module, the instrument

might not perform to specification or possibly not operate at all. In addition, if adequate cooling is

not provided, the reliability of the instrument will be jeopardized and permanent damage may

occur. Damage found to have occurred due to inadequate cooling will void the warranty on the

instrument in question.

SETTING THE CHASSIS BACKPLANE JUMPERS

Please refer to the chassis User’s Manual for further details on setting the backplane jumpers.

VM1548C Preparation for Use 17

SETTING THE LOGICAL ADDRESS

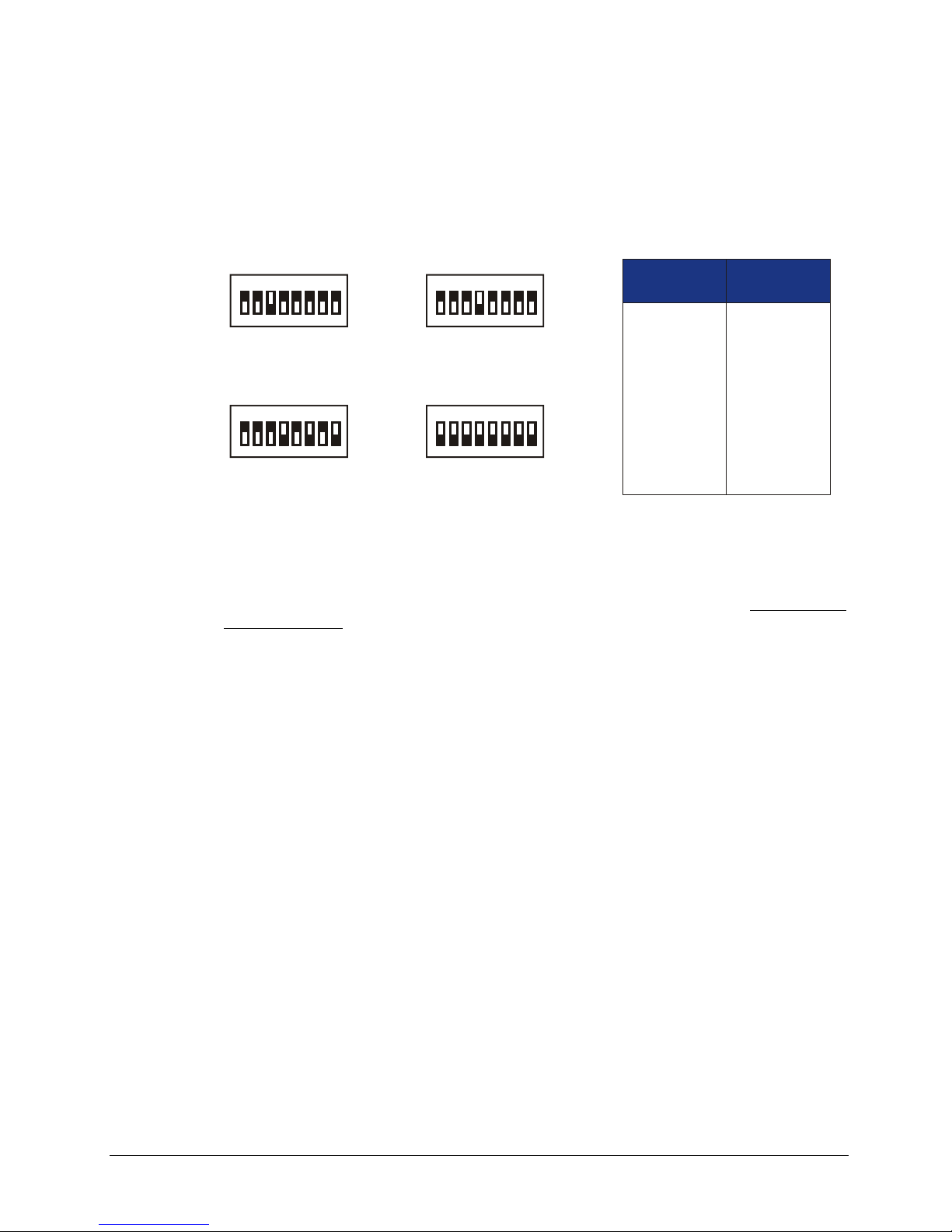

The logical address of the VM1548C is set by a single 8-position DIP switch located near the

module’s backplane connectors (this is the only switch on the module). The switch is labeled with

positions 1 through 8 and with an ON position. A switch pushed toward the ON legend will signify

a logic 1; switches pushed away from the ON legend will signify a logic 0. The switch located at

position 1 is the least significant bit while the switch located at position 8 is the most significant

bit. See

Figure 2-1 for examples of setting the logical address switch.

VXI Technology, Inc.

ON ON

1ON2345678

SET TO 4

ON ON

12345678

SET TO 168

F

IGURE 2-1: LOGICAL ADDRESS SWITCH SETTING EXAMPLES

1ON2345678

SET TO 8

1

2345678

SET TO 255

(Dynamic)

Switch

Position

1

2

3

4

5

6

7

8

Switch

Value

1

2

4

8

16

32

64

128

The VMIP may contain three separate instruments and will allocate logical addresses as required

by the VXIbus specification (revisions 1.3 and 1.4). The logical address of the instrument is set on

the VMIP carrier. The VMIP logical addresses must be set to an even multiple of 4 unless dynamic

addressing is used. Switch positions 1 and 2 must always be set to the OFF position. Therefore,

only addresses of 4, 8, 12, 16, ...252 are allowed. The address switch should be set for one of these

legal addresses and the address for the second instrument (the instrument in the center position)

will automatically be set to the switch set address plus one; while the third instrument (the

instrument in the lowest position) will automatically be set to the switch set address plus two. If

dynamic address configuration is desired, the address switch should be set for a value of 255 (All

switches set to ON). Upon power-up, the slot 0 resource manager will assign the first available

logical addresses to each instrument in the VMIP module.

If dynamic address configuration is desired, the address switch should be set for a value of 255.

Upon power-up, the slot 0 resource manager will assign logical addresses to each instrument in the

VMIP module.

18 VM1548C Preparation for Use

www.vxitech.com

FRONT PANEL INTERFACE WIRING

The VM1548C’s module interface is made available on the front panel of the instrument. The

48-channel version (VM1548C-1) will have J201, which contains all signals for this instrument.

The 96-channel version (VM1548C-2) will have J201 and J202 provided, while the 144-channel

version (VM1548C-3) will have J200, J201 and J202. The wiring for each of these connectors is

identical and since each group of 48 channels is treated as a separate instrument, the module will

have three Channel 1s, three Channel 2s, three Channel 3s, etc.

The connector used in the VM1548C is a readily available 68-pin high-density type commonly

known as a 68-pin version of the SCSI 2 connector. The mating connector is an IDC (Insulation

Displacement Connector) component and is available from a variety of sources. The connector

attaches to two 34-conductor 0.050 centers ribbon cable, and the pin out has been selected to allow

for using the twisted pair type of ribbon cable. Some manufacturers also allow the use of discrete

30 gauge stranded wires.

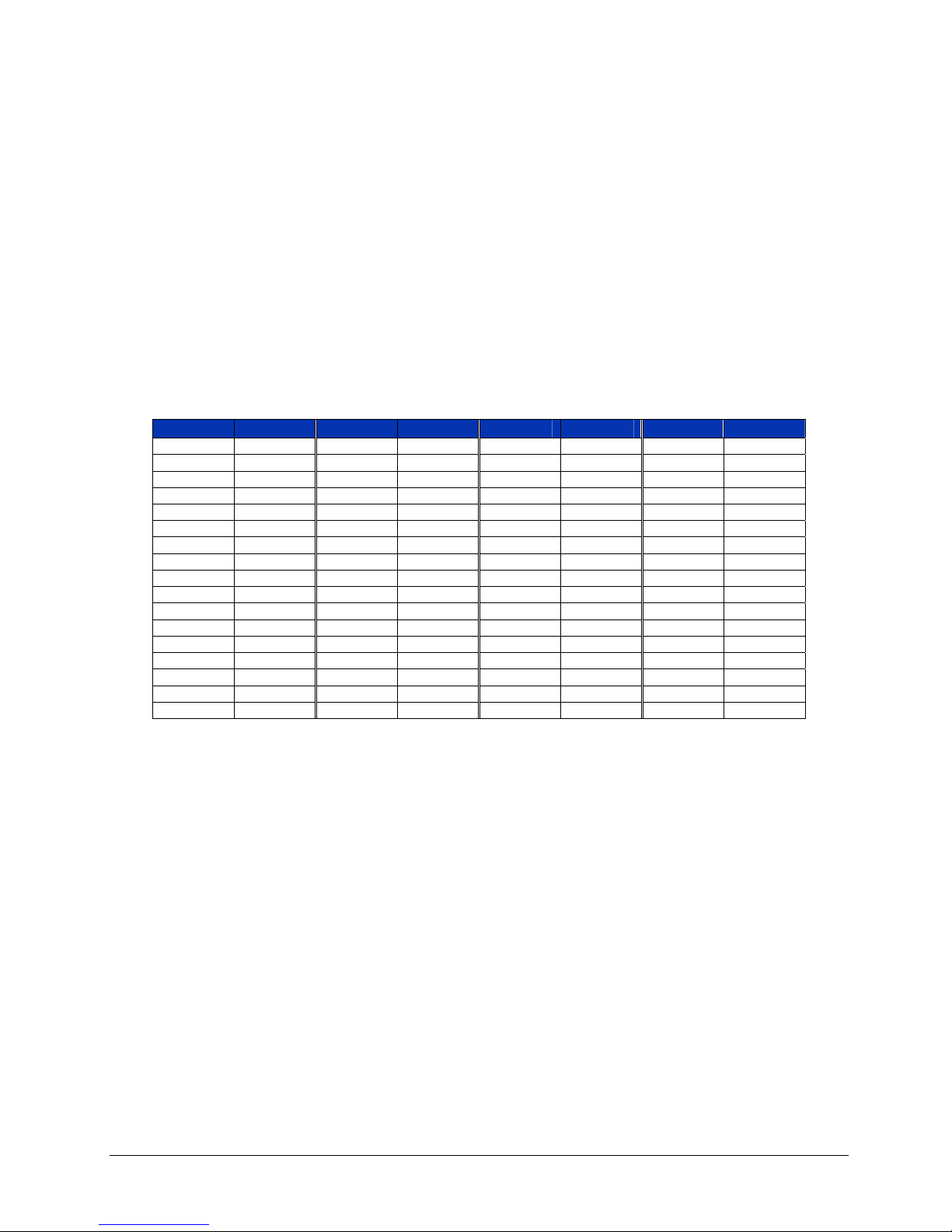

ABLE 2-1: J200, J201 AND J202 PIN OUTS

T

PIN SIGNAL PIN SIGNAL PIN SIGNAL PIN SIGNAL

1 GND 18 DATA1.5 35 GND 52 DATA4.5

2 DATA0.0 19 DATA1.6 36 DATA3.0 53 DATA4.6

3 DATA0.1 20 DATA1.7 37 DATA3.1 54 DATA4.7

4 DATA0.2 21 I/O*1 38 DATA3.2 55 I/O*4

5 DATA0.3 22 CLK1 39 DATA3.3 56 CLK4

6 DATA0.4 23 GND 40 DATA3.4 57 GND

7 DATA0.5 24 DATA2.0 41 DATA3.5 58 DATA5.0

8 DATA0.6 25 DATA2.1 42 DATA3.6 59 DATA5.1

9 DATA0.7 26 DATA2.2 43 DATA3.7 60 DATA5.2

10 I/O*0 27 DATA2.3 44 I/O*3 61 DATA5.3

11 CLK0 28 DATA2.4 45 CLK3 62 DATA5.4

12 GND 29 DATA2.5 46 GND 63 DATA5.5

13 DATA1.0 30 DATA2.6 47 DATA4.0 64 DATA5.6

14 DATA1.1 31 DATA2.7 48 DATA4.1 65 DATA5.7

15 DATA1.2 32 I/O*2 49 DATA4.2 66 I/O*5

16 DATA1.3 33 CLK2 50 DATA4.3 67 CLK5

17 DATA1.4 34 GND 51 DATA4.4 68 GND

VM1548C Preparation for Use 19

VXI Technology, Inc.

The mating connector to J200, J201 or J202 is available from the following companies:

AMP Inc.

P/N 749111-6 Connector

P/N 749204-2 Back Shell

P/N 82208 Catalog covering this series of connectors

Circuit Assembly

P/N CA-68NDP-12GT Connector

P/N CA-68NDBS-1M Back Shell

P/N DG01 Catalog covering this series of connectors

The pin locations for J200, J201, and J202 are shown in

PIN 1 PIN 35

Figure 2-2.

PIN 34

F

IGURE 2-2: J200, J201, AND J202 PIN LOCATIONS

PIN 68

SECTION 3

PROGRAMMING

INTRODUCTION

The VM1548C is a VXIbus message-based device whose command set is compliant with the

Standard Command for Programmable Instruments (SCPI) programming language.

20 VM1548C Preparation for Use

www.vxitech.com

All module commands are sent over the VXIbus backplane to the module. Commands may be in

upper, lower, or mixed case. All numbers are sent in ASCII decimal unless otherwise noted.

The module recognizes SCPI commands. SCPI is a tree-structured language based on IEEE-STD-

488.2 Specifications. It utilizes the IEEE-STD-488.2 Standard command, and the device

dependent commands are structured to allow multiple branches off the same trunk to be used

without repeating the trunk. To use this facility, terminate each branch with a semicolon.

See the Standard Command for Programmable Instruments (SCPI) Manual, Volume 1: Syntax &

Style, Section 6, for more information.

The SCPI commands are listed in upper and lower case. Character case is used to indicate

different forms of the same command. Keywords can have both a short form and a long form

(some commands only have one form). The short form uses just the keyword characters in

uppercase. The long form uses the keyword characters in uppercase plus the keyword characters

in lowercase. Either form is acceptable. Note that there are no intermediate forms. All characters

of the short form or all characters of the long form must be used. Short forms and long forms may

be freely intermixed. The actual commands sent can be in upper case, lower case, or mixed case

(case is only used to distinguish short and long form for the user). As an example, these

commands are all correct and all have the same effect:

TRIGger:SEQuence:IMMediate

trigger:sequence:immediate

TRIGGER:SEQUENCE:IMMEDIATE

TRIG:SEQuence:IMMediate

TRIG:SEQ:IMMediate

TRIG:SEQ:IMM

trig:seq:IMM

trig:seq:imm

VM1548C Programming 21

NOTATION

VXI Technology, Inc.

The following command is not correct because it uses part of the long form of TRIGger, but not

all the characters of the long form:

trigg:seq:imm (incorrect syntax - extra "g"- only trig or trigger is correct)

All of the SCPI commands also have a query form unless otherwise noted. Query forms contain a

question mark (?). The query form allows the system to ask what the current setting of a

parameter is. The query form of the command generally replaces the parameter with a question

mark (?). Query responses do not include the command header. This means only the parameter is

returned: no part of the command or "question" is returned.

Keywords or parameters enclosed in square brackets ([ ]) are optional. If the optional part is a

keyword, the keyword can be included or left out. Omitting an optional parameter will cause its

default to be used.

Parameters are enclosed by angle brackets (< >). Braces ({ }), or curly brackets, are used to

enclose one or more parameters that may be included zero or more times. A vertical bar (|), read

as "or", is used to separate parameter alternatives.

22 VM1548C Programming

www.vxitech.com

EXAMPLES OF SCPI COMMANDS

TTLTRIG CIRCUIT

A multiplexer is used to select 1 of 8 different sources as TTLTRIG. The signal is selected using

the following SCPI command:

OUTPut:TTLTrig:SOURce <source> Where <source> refers to one of

The selected signal is called GLOBAL (TRIGOUT) and after a polarity control, it is called

TTLTRIGGER, which is presented on the VXIbus as the selected TTLTRIG0-7. The specific

TTLTRIG line is selected using the following SCPI command:

OUTPut:TTLTrig <n> Where <n> refers to one of the 8

The TTLTRIGGER is enabled or disabled using the following SCPI command:

OUTPut:TTLTrig:STATe ON Enables the Trigger

OUTPut:TTLTrig:STATe OFF Disables the Trigger

The following is an example of how to produce CLK2 as TTLTRIG4 to the backplane:

OUTPut:TTLTrig:STATe ON

OUTPut:TTLTrig:POLarity NORMal

OUTPut:TTLTrig 4

OUTPut:TTLTrig:SOURce EXTERNAL2

If CLK2 is a logic low level, then the following SCPI command would allow a logic high level on

the backplane.

OUTPut:TTLTrig:POLarity INVERT TTLTRIG 4 will not pull the line

Likewise, continuing with this example, the following command would produce a logic low level

on the backplane.

OUTPut:TTLTrig:POLarity NORMal TTLTRIG 4 will pull the line low

the EXTERNAL CLK lines (CLK0-

5), IMMEDIATE or NONE.

TTLTRIG lines.

low

VM1548C Programming 23

INTERRUPT CIRCUIT

This section deals with the interrupt circuit. The VM1548C has the capability to interrupt the slot

0 controller via the VMIP with either a high going edge or with a low going edge of the IRQ*

signal. The timing and control circuitry can select one of the six EXTERNAL clocks, GLOBAL

(TRIGOUT) or NONE as the interrupt trigger. The interrupt is selected and enabled using the

following SCPI command:

STATus:INTerrupt:ENABle <source> Where <source> is EXTERNAL0-

The following SCPI command will trigger the status interrupt on a positive edge:

STATus:INTerrupt:PTRansition ON

The following SCPI command will trigger the status interrupt on a negative edge:

STATus:INTerrupt:NTRansition ON

EXAMPLES

To use GLOBAL (TRIGOUT) out as the status interrupt trigger, the following SCPI command

would be issued:

STATus:INTerrupt:ENABle GLOBAL

To trigger the status interrupt from a negative going edge external clock source from port 3, the

following SCPI commands would be issued:

STATus:INTerrupt:ENABle EXTERNAL3

STATus:INTerrupt:NTRansition ON

To trigger the status interrupt from a negative edge going external clock source from port 1, the

following SCPI commands would be issued:

STATus:INTerrupt:ENABle EXTERNAL1

STATus:INTerrupt:NTRansition ON

VXI Technology, Inc.

5, GLOBAL or NONE

24 VM1548C Programming

www.vxitech.com

OUTPUT REGISTER CIRCUIT

This section refers to the bi-directional port when configured as an output. The SCPI command

used to configure a port as an output is:

SOURce:DATA:ENABle <port #> ON

The port is programmable to allow the data to be transparent or clocked. If the port is clocked,

there are several choices for the clock source. The method for selecting clocked mode and the

source of the clock is done with one SCPI command.

OUTPut:REGister:SOURce <port #> <source> Where <port> is 1 of 6 data

The method for selecting transparent mode is:

OUTPut:REGister:SOURce <port #> NONE Where <port> is 1 of 6 data

EXAMPLES

The following SCPI commands will clock the number 205 out of port #5 using the IMMEDIATE

pulse.

SOURce:DATA:ENABle 5 ON

OUTPut:REGister:SOURce 5 IMMEDIATE

SOURce:DATA 5 205

TRIGger:SEQuence:IMMediate This provides a rising edge clock

The following is an example of writing to a port operating in transparent mode. This method

requires no clock edge for the data to be presented on the external connector.

SOURce:DATA:ENABle 5 ON

OUTPut:REGister:SOURce 5 NONE

SOURce:DATA 5 205 205 Immediately appears on the

The following example selects the external CLK5 line to clock the data port. In this example, it is

assumed the external CLK5 signal is a steady logic low and the clock edge is produced by

toggling the clock polarity.

SOURce:DATA:ENABle 5 ON

OUTPut:REGister:SOURce 5 EXTERNAL

OUTPut:REGister:POLarity 5 NORMAL

SOURce:DATA 5 205

OUTPut:REGister:POLarity 5 INVERT This provides a rising edge clock

registers and <source> is

EXTERNAL, TTLTRIG, GLOBAL

(TRIGOUT) or IMMEDIATE

registers and NONE means this

data register is transparent

External Connector

VM1548C Programming 25

INPUT REGISTER CIRCUIT

This section refers to the bi-directional port when configured as an input. The SCPI command

used to configure a port as an input is:

SOURce:DATA:ENABle <port #> OFF

The port is programmable to allow the data to be transparent or clocked. If the port is clocked,

there are several choices for the clock source. The method for selecting clocked mode and the

source of the clock is done with one SCPI command.

INPut:REGister:SOURce <port #> <source> Where <port> is 1 of 6 data

Regardless of the port’s input mode, note that data inputs to the module do not contain pull-up or

down-biasing resistors. As such, if the user does not provide either active or passive biasing of the

data inputs, a read of the port may result in either a “1” or a “0” being read from the data inputs.

The method for selecting transparent mode is:

INPut:REGister:SOURce <port #> NONE Where <port> is 1 of 6 data

EXAMPLES

The following SCPI commands will clock the data in on port #3 using the IMMEDIATE pulse.

SOURce:DATA:ENABle 3 OFF

INPut:REGister:SOURce 3 IMMEDIATE

TRIGger:SEQuence:IMMediate This provides a rising edge clock

FORMat ASCII

READ? 3 Example of read value is 255

The following is an example of reading from a port operating in transparent mode. This method

requires no clock edge for the data to be available.

SOURce:DATA:ENABle 5 OFF

INPut:REGister:SOURce 5 NONE

FORMat BINARY

READ? 5 The data presented on the external

The following example selects the external CLK3 line to clock the data port. In this example, it is

assumed the external CLK3 signal is a steady logic low and the clock edge is produced by

toggling the clock polarity.

SOURce:DATA:ENABle 3 OFF

INPut:REGister:SOURce 3 EXTERNAL

INPut:REGister:POLarity 3 NORMAL

INPut:REGister:POLarity 3 INVERT This provides a rising edge clock

FORMat HEX

READ? 3

Example of read value is #HFF

VXI Technology, Inc.

registers and <source> is

EXTERNAL, TTLTRIG, GLOBAL

(TRIGOUT) or IMMEDIATE

registers and NONE means this

data register is transparent

Example of read value is

#B11111111

connector is what will be read

26 VM1548C Programming

www.vxitech.com

BI-DIRECTIONAL CLOCK CIRCUIT

There are six independent bi-directional clock circuits connected to the 68-pin external connector.

Each clock is associated with one of the 6 ports previously described. Therefore, <port #>

terminology is used to refer to a specific clock. When the circuit is configured as an output, the

clock signal will be sourced by the module. When the circuit is configured as an input, the clock

signal is sourced by the UUT. This clock (CLK0-5) may be used for many different purposes: a

trigger source; selections for the interrupt trigger; a port’s input clock; a port’s output clock.

The following SCPI command configures the clock line as an output:

OUTPut:CLOCk:ENABle ON

The following SCPI command configures the clock line as an input:

OUTPut:CLOCk:ENABle OFF

When the circuit is operating as an output, the clock source is selectable using the following SCPI

command.

OUTPut:CLOCk:SOURce <port #> <source> Where <source> is TTLTRIG,

The polarity of the output clock signal is controlled with the following SCPI command.

OUTPut:CLOCk:POLarity <edge> Where <edge> is NORMAL or

EXAMPLES

To drive TRIGIN out as CLK1 on the external connector, the following SCPI commands would

be issued.

OUTPut:CLOCk:ENABle 1 ON

OUTPut:CLOCk:SOURce TTLTRIG

To drive TRIGOUT out as CLK3 on the external connector, the following SCPI commands would

be issued:

OUTPut:CLOCk:ENABle 3 ON

OUTPut:CLOCk:SOURce GLOBAL

To drive IMMEDIATE out as CLK5 on the external connector, the following SCPI commands

would be issued:

OUTPut:CLOCk:ENABle 5 ON

OUTPut:CLOCk:SOURce IMMEDIATE

To select no clock, the NONE parameter is used. This will always be a logic level low.

OUTPut:CLOCk:ENABle 5 ON

OUTPut:CLOCk:SOURce NONE

IMMEDIATE, GLOBAL

(TRIGOUT) or NONE

INVERT

VM1548C Programming 27

APPLICATION EXAMPLES

This section contains examples of using SCPI command strings for programming the VM1548C

module. The code is functional and will contain a brief description and block diagram of the

operation.

WRITE MODE

In this example the VM1548C will be set up prior to receiving the UUT generated clock edge.

The VM1548C will output one (1) 16-bit binary word to the UUT from ports 0 and 1.

COMMANDS

OUTP:CLOC:ENAB 0 0 Disables port 0 clock from driving front panel

OUTP:CLOC:ENAB 1 0 Same as previous command except for port 1.

OUTP:REG:SOUR 0 EXT Selects port 0 input clock (CLK0) as method of

OUTP:REG:SOUR 1 EXT Same as previous command except for port 1.

SOUR:DATA:ENAB 0 1 Selects and enables port 0 to write data to the UUT.

STAT:INT:ENAB EXT0 Set the interrupt trigger source as the port 0 clock.

STAT:INT:PTR ON Set the interrupt trigger source to the positive edge.

SOUR:DATA 0 48 Writes “48” data to port 0 for subsequent transfer to

SOUR:DATA:ENAB 1 1 Selects and enables port 1 to write data to the UUT.

SOUR:DATA 1 15 Writes “15” data to port 1 for subsequent transfer to

Figure 3-1 and the description that follows illustrates the function of each of the commands above.

DESCRIPTION

VXI Technology, Inc.

connector and enables this line as the clock input to

port 0.

triggering.

the UUT.

the UUT.

28 VM1548C Programming

www.vxitech.com

VCC

47K

120

22

100pF

CLK from

front panel

VMIP

Bus

Control Lines

Address 0,1,2

Data Bus

Read /

Write

Data

Buffer

WRITE*

DOE*

D8-D15

Timing

and

Control

Port

Decoder

F

WRITE

CLKOUT <port>

PORTENA*

Write

Clock

Data Bus

OUTENA

PORT2*

D8-D15

PORT1*

Direction

Control

Enable

IGURE 3-1: OUTPUT BLOCK DIAGRAM

OR

WRITE

CLKOUT <port>

IN*/OUT <port>

CLKOUTENA

I/O

Word

Buffer

200K

33K

Data Bus

I/O from

front panel

Output

Data

Buffer

22

ISENSE

OUTP:CLOC:ENAB 0 0 and OUTP:CLOC:ENAB 1 0 commands inform the timing and

control circuitry that the front panel clock lines are used as inputs. This allows the UUT to furnish

the clock source when ready to receive data.

The OUTP:REG:SOUR 0 EXT and the OUTP:REG:SOUR 1 EXT commands select the

external clock input as the trigger method to output data to the UUT. When these commands are

received the VM1548C timing and control circuitry will generate the PORTENA* signal to the

port decoder. The port decoder then clocks the write clock enable latch selecting the

CLKOUTENA. The CLKOUTENA signals are applied to the I/O data and word buffers enabling

the output clock line. The SOUR:DATA:ENAB 0 1 and SOUR:DATA 0 48 command enables

port 0 for a write and latches the data into the I/O word buffer respectively.

VM1548C Programming 29

READ MODE

VXI Technology, Inc.

The VM1548C timing and control circuitry generates the PORTENA* signal to the port decoder.

This decoder in turn clocks the direction latch selecting the OUTENA. This signal is OR’ed with

the external I/O direction signal from the UUT. The result is referred to as IN*/OUT and is

applied to the I/O data and word buffers configuring them as outputs. The timing and control

circuitry will generate a write pulse latching the data from the read/write data buffer into the I/O

word buffer. Port 0 is now ready to transmit the data byte “48” to the UUT. The steps are repeated

for the SOUR:DATA:ENAB 1 1 and SOUR:DATA 1 15 commands with port 1 being enabled

and loaded with the data byte “15”.

The VM1548C is now ready to transmit the data word “1548C” to the UUT. When the CLK

signals are received from the UUT, the I/O data buffers latch the data word from the I/O word

buffer. The data on the I/O data buffer’s outputs are now available to the UUT. The

STAT:INT:ENAB EXT 0 and STAT:INT:PTR ON commands enable the interrupt to occur

when the CLK 0 signal is received and sets the polarity of this interrupt to the positive edge. The

VM1548C module sends an Interrupt Request (IRQ*) informing the slot 0 controller that the

transfer has occurred.

In this example the VM1548C will be configured to clock the UUT and read 24 bits of data, when

the TTL Trigger line 1 is activated. The TTL Trigger is assumed to be pulled by another

instrument used during this test. The UUT will output data on the rising edge of the received clock

that is generated from the VM1548C. The VM1548C will capture or read data on the falling edge

of this same clock. When the VM1548C detects a TTL Trigger 1, the front panel clock lines to the

UUT are activated. The clock is sent, the UUT transmits data on the rising edge, and the data will

be latched into the VM1548C on the falling edge. An Interrupt Request is generated informing the

slot 0 controller via the VMIP that data is ready to be read.

COMMANDS

OUTP:CLOC:ENAB 3 ON Enables port 3 clock to drive the front panel

DESCRIPTION

connector

OUTP:CLOC:ENAB 4 ON Same as previous command except for port 4

OUTP:CLOC:ENAB 5 ON Same as previous command except for port 5

SOUR:DATA:ENAB 3 OFF Selects and enables port 3 to read data from the UUT

SOUR:DATA:ENAB 4 OFF Selects and enables port 4 to read data from the UUT

SOUR:DATA:ENAB 5 OFF Selects and enables port 5 to read data from the UUT

INP:REG:POL 3 INV Selects the falling edge for clocking port 3

INP:REG:POL 4 INV Selects the falling edge for clocking port 4

INP:REG:POL 4 INV Selects the falling edge for clocking port 5

INP:REG:SOUR 3 TTLT Selects VXI bus TRIGIN as the clock source for

port 3

INP:REG:SOUR 4 TTLT Same as previous command except for port 4

INP:REG:SOUR 5 TTLT Same as previous command except for port 5

INP:TTLT:STATE ON Enables the TTL trigger selection mux

INP:TTLT 1 Selects VXI bus TTL trigger line 1 to be used as

TRIGIN

STAT:INT:ENAB Set the interrupt trigger source as the default value

STAT:INT:NTR ON Set the interrupt trigger source to the negative edge

The controller waits for the interrupt and then

proceeds

READ? 3 Data is transferred from port 3 to the VMIP bus

READ? 4 Data is transferred from port 4 to the VMIP bus

READ? 5 Data is transferred from port 5 to the VMIP bus

30 VM1548C Programming

www.vxitech.com

Below, Figure 3-2 illustrates what occurs when these commands are executed. The description

that follows illustrates the role of each command.

TRIGIN0-7

Trigger

In Mux

TRIGIN*

VCC

VMIP

Bus

Control Lines

Address 0,1,2

Data Bus

Read /

Write

Data

Buffer

WRITE*

DOE*

D8-D15

Timing

and

Control

Port

Decoder

F

IGURE 3-2: READ MODE USING TTL TRIGGER IN

IN*/OUT <port>

READ

READ <port>

CLKIN <port>

PORTENA*

PORT3*

D8-D15

Trigger

Select

TINENA*

TINSEL0,1,2

Read <port>

Read

I/O

Word

Buffer

47K

120

100pF

CLKIN <port>

IN*/OUT <port>

Data Bus

22

CLKIO <port>

to front panel

Input

Data

Buffers

(ports 3,4,5)

22

VM1548C Programming 31

VXI Technology, Inc.

The OUTP:CLOC:ENAB <port> ON command configures the front panel clock connection to

the output mode. This allows the VM1548C to drive these lines clocking the UUT. The timing

and control circuitry generates the IN*/OUT <port> signal to the I/O data and word buffers

configuring them as inputs when the SOUR:DATA:ENAB <port> 1 commands are received.

The INP:REG:SOUR <port> TTLT commands select the VXI TTL trigger in as the clock input

for the trigger method to input data from the UUT. This clock is transmitted from the front panel

connectors, clocking the data out of the UUT. When the commands are received the VM1548C

timing and control circuitry will generate the PORTENA* signal to the port decoder. The port

decoder then clocks the write clock enable latch selecting the CLKINENA. The CLKINENA

signals are applied to the I/O data and word buffers enabling the input clock line.

The INP:REG:POL <port> INV command causes the timing and control circuitry to select the

falling edge of the TTL trigger in as the CLKIN <port> for the I/O data buffers.

When INP:TTLT:STATE ON command is received, the VM1548C timing and control circuitry

generates the PORTENA* signal to the port decoder. This clocks the trigger select latch selecting

the TINENA line. The TINENA signal enables the trigger in mux. INP:TTLT 1 notifies the

timing and control circuitry to select TTL trigger 1 for the clock source. The port decoder is again

enabled to clock the trigger select latch selecting the TINSEL signals. These signals are routed to

the trigger in mux that enables TTL trigger 1 to be routed to the timing and control circuitry for

clocking the UUT and the I/O data buffers. The normal polarity of the trigger is sent to the UUT

and the inverted version is used for the I/O data buffers.

The STAT:INT:ENAB command uses the default value of NONE (ground) to generate the status

interrupt onto the VXI backplane and the STAT:INT:PTR ON command set the polarity of the

interrupt. When the TTL trigger 1 occurs, the VM1548C will send a high going pulse to clock

data out of the UUT. The falling edge of this pulse is used to latch the data into the VM1548C’s

I/O data buffers. The VM1548C sends an Interrupt Request (IRQ*) informing the slot 0 controller

via the VMIP that the transfer has occurred and that the data in the I/O data buffers is now

available. The READ? <port> command causes the timing and control circuitry to generate two

READ signals. The first READ signal is routed to the I/O word buffers thereby enabling them to

output data to the read/write data buffer and onto the VMIP bus. The second signal READ (0,2,4)

then clocks the I/O word buffer. The I/O word buffer will output one 16-bit word at a time.

Note that data inputs to the module do not contain pull-up or down-biasing resistors. If the user

does not provide active or passive biasing of the data inputs, a read of the port may result in either

a “1” or “0” being read from the data inputs.

32 VM1548C Programming

www.vxitech.com

WRITE/READ MODE

In this example, a wrap-around cable will be used to configure and transfer data from port 0,

port 1, and port 2 to port 3, port 4, and port 5. The wrap-around cable pin outs used are as defined

Table 3-1. The data to be sent is port 0 = 01, port 1 = 23, and port 2 = 45. The IRQ* signal will

in

be generated from the external clock received from port 5.

COMMANDS

INP:REG:SOUR 3 EXT Selects External clock line as the clock source for

INP:REG:POL 3 INV Selects the inverted (falling) clock edge for port 3

INP:REG:SOUR 4 EXT Selects External clock line as the clock source for

INP:REG:POL 4 INV Selects the inverted (falling) clock edge for port 4

INP:REG:SOUR 5 EXT Selects External clock line as the clock source for

INP:REG:POL 5 INV Selects the inverted (falling) clock edge for port 5

OUTP:CLOC:ENAB 0 ON Enables the output clock for port 0

OUTP:CLOC:SOUR 0 IMM Selects the IMM (word serial event) to drive the

OUTP:REG:SOUR 0 IMM Selects the IMM (word serial event) as the clock

OUTP:CLOC:ENAB 1 ON Enables the output clock for port 1

OUTP:CLOC:SOUR 1 IMM Selects the IMM (word serial event) to drive the

OUTP:REG:SOUR 1 IMM Selects the IMM (word serial event) as the clock

OUTP:CLOC:ENAB 2 ON Enables the output clock for port 1

OUTP:CLOC:SOUR 2 IMM Selects the IMM (word serial event) to drive the

OUTP:REG:SOUR 2 IMM Selects the IMM (word serial event) as the clock

SOUR:DATA:ENAB 0 ON Configures port 0 I/O data buffers for write mode

SOUR:DATA:ENAB 1 ON Configures port 1 I/O data buffers for write mode

SOUR:DATA:ENAB 2 ON Configures port 2 I/O data buffers for write mode

SOUR:DATA:ENAB 3 OFF Configures port 3 I/O data buffers for read mode

SOUR:DATA:ENAB 4 OFF Configures port 4 I/O data buffers for read mode

SOUR:DATA:ENAB 5 OFF Configures port 5 I/O data buffers for read mode

SOUR:DATA 0 01 Writes data “01” to port 0’s I/O data buffer

SOUR:DATA 1 23 Writes data “23” to port 1’s I/O data buffer

SOUR:DATA 2 45 Writes data “45” to port 2’s I/O data buffer

STAT:INT:ENAB EXT 5 Set the interrupt trigger source as the port 5 clock

STAT:INT:PTR ON Set the interrupt trigger source to the positive edge

TRIG:SEQ:IMM Generates a word serial event to transfer data and

READ? 3 Read data from port 3

READ? 4 Read data from port 4

READ? 5 Read data from port 5

Figure 3-3 for the Write/read block diagram.

See

DESCRIPTION

port 3

port 4

port 5

external clock for port 0

source for port 0 I/O data buffers

external clock for port 1

source for port 1 I/O data buffers

external clock for port 1

source for port 1 I/O data buffers

clocks from ports 0, 1, and 2

VM1548C Programming 33

TRIGIN0-7

Control Lines

WRITE*

DOE*

Timing

and

Control

D8-D15

CLOCK0

WRITE0

CLKOUT <port>

IN*/OUT <port>

READ

READ <port>

CLKIN <port>

Trigger

In Mux

TRIGIN*

VCC

47K

120

22

100pF

VXI Technology, Inc.

CLK from

front panel

I/O from

front panel

200K

VMIP

Bus

Address 0,1,2

Data Bus

Read /

Write

Data

Buffer

PORTENA*

Port

Decoder

PORT3*

Data Bus

PORT2*

D8-D15

PORT1*

Data Bus

READ <port>

READ

Trigger

Select

Direction

Control

Write

Clock

Enable

TINENA*

TINSEL0,1,2

OUTENA0

WRITE0 Data Bus

I/O

Word

Buffer

OR

CLKOUT <port>

IN*/OUT <port>

CLKOUTENA0

I/O

Word

Buffer

CLKIN <port>

IN*/OUT <port>

Data Bus

I/O

Data

Buffer

(ports

0,1,2)

I/O

Data

Buffers

(ports

3,4,5)

33K

22

22

The INP:REG:SOUR <port> EXT commands select the external clock for <port> as the clock

input for the trigger method to input data from the UUT. When the commands are received, the

VM1548C timing and control circuitry will generate the PORTENA* signal to the port decoder.

The port decoder then clocks the write clock enable latch selecting the CLKINENA. The

CLKINENA signals are applied to the I/O data and word buffers enabling the input clock line.

The INP:REG:POL <port> INV command causes the timing and control circuitry to select the

falling edge of the external clock as the CLKIN <port> for the I/O data buffers.

34 VM1548C Programming

F

IGURE 3-3: WRITE/READ

www.vxitech.com

OUTP:CLOC:ENAB <port> ON commands inform the timing and control circuitry that the

front panel clock lines are used as outputs. This allows the VM1548C to furnish the clock source.

OUTP:CLOC:SOUR <port> IMM commands inform the timing and control circuitry to drive

the front panel clock lines using the immediate (word serial event) trigger.

The OUTP:REG:SOUR <port> IMM commands select the immediate (word serial event) clock

as the trigger method for the selected ports to output data to the UUT (VM1548C through wraparound cable). When these commands are received, the VM1548C timing and control circuitry

will generate the PORTENA* signal to the port decoder. The port decoder then clocks the write

clock enable latch selecting the CLKOUTENA. The CLKOUTENA signals are applied to the I/O

data and word buffers enabling the output clock line.

The SOUR:DATA:ENAB <port> ON enables the selected ports for a write, in this case ports 0,

1, and 2. The SOUR:DATA:ENAB <port> OFF enables the selected ports to read, in this case

ports 3, 4, and 5. The SOUR:DATA <port> <data> commands writes the data into the specified

ports as previously described.

The STAT:INT:ENAB EXT 5 and STAT:INT:PTR ON commands enable the interrupt to

occur when the CLK 5 signal is received and sets the polarity of this interrupt to the positive edge.

TRIG:SEQ:IMM command will generate a short pulse that will initiate the transfer of data from

ports 0, 1, and 2 to ports 3, 4, and 5. When CLK 5 has been received, the VM1548C module sends

an Interrupt Request (IRQ*) informing the slot 0 controller via the VMIP that the transfer has

occurred. The READ? <port> will then fetch the data from the specified ports.

VM1548C Programming 35

VXI Technology, Inc.

TABLE 3-1: WRAP-AROUND TEST CABLE

FROM TO

Signal Pin Signal Pin

DATA0.0 2 DATA3.0 36

DATA0.1 3 DATA3.1 37

DATA0.2 4 DATA3.2 38

DATA0.3 5 DATA3.3 39

DATA0.4 6 DATA3.4 40

DATA0.5 7 DATA3.5 41

DATA0.6 8 DATA3.6 42

DATA0.7 9 DATA3.7 43

I/O*0 10 I/O*3 44

CLK0 11 CLK3 45

DATA1.0 13 DATA4.0 47

DATA1.1 14 DATA4.1 48

DATA1.2 15 DATA4.2 49

DATA1.3 16 DATA4.3 50

DATA1.4 17 DATA4.4 51

DATA1.5 18 DATA4.5 52

DATA1.6 19 DATA4.6 53

DATA1.7 20 DATA4.7 54

I/O*1 21 I/O*4 55

CLK1 22 CLK4 56

DATA2.0 24 DATA5.0 58

DATA2.1 25 DATA5.1 59

DATA2.2 26 DATA5.2 60

DATA2.3 27 DATA5.3 61

DATA2.4 28 DATA5.4 62

DATA2.5 29 DATA5.5 63

DATA2.6 30 DATA5.6 64

DATA2.7 31 DATA5.7 65

I/O*2 32 I/O*5 66

CLK2 33 CLK5 67

36 VM1548C Programming

www.vxitech.com

REGISTER ACCESS EXAMPLES

The VM1548C module supports direct register access for very high-speed data retrieval. The

register map is as specified in

As can be seen from the register map in

ports. Therefore, in order to program a particular port, it must be ensured that the value of the

other port is untouched. This can be ensured by reading the value of the register and OR’ing the

obtained value with the value to be programmed. This final value can then be written at the

correct offset. This is true assuming that the function used to write to the register performs 16-bit

writes.

Similarly, when a register is read, it provides the data values of two ports. Therefore, the

unwanted value must be OR’ed with a proper mask. This is again assuming that the function used

to read the register performs 16-bit reads.

Example 1: For example in order program Port 1:

a) First the register value at offset 0x20 is read. Assume that the value read is as given below:

1111000010101010 (in binary format)

The lower 8 bits are the current value for Port 0. In order to maintain its value, an appropriate OR

operation is required. A bit-shift operation may also be required depending on the port to be

written to.

For example, if the new value to be written to Port 1 is 00001111, then the final value to be

written to the register is

(1111000010101010 | (00001111 << 8))

Example 2: For example in order read Port 1:

Read the register at offset 0x20. This presents the values of Ports 0 and 1. However, since the

value Port 1 is of interest, the following steps must be followed:

a) Read the register at offset 0x20. Assume that the value read is as shown below:

1010000011110000 (in binary format)

b) Since the upper 8 bits are of interest, an appropriate mask has to be applied and the value

right shifted.

The data value of port 1 is

((1010000011110000 | 0xFF00) >> 8)

Table 3-2.

Table 3-2, each 16-bit wide register is shared by two

VM1548C Programming 37

VXI Technology, Inc.

The Model VM1548C Digital I/O Module supports direct access to the six 8-bit data ports via the

Device Dependent Registers of VXIbus interface. The specific registers are located in A16

Memory at offsets 0x20 = Port1, 0x21 = Port0, 0x22 = Port3, 0x23 = Port2, 0x24 = Port5 and

0x25 = Port4. The following diagram shows A16 Memory and the Model VM1548C Data Port

Map.

ABLE 3-2: A16 MEMORY MAP

T

Offset Register

3E

3C

3A

38

36

34

32

30

2E

2C

2A

28

26

24

22

20

1E

1C

1A

18

16

14

12

10

E

C

A

8

6

4

2

Event (R/W)

Source Data Polarity (R/W)

Clear ISENSE (R/W)

IPINS (R) ISENSE (R)

Read Clocks (R) Read I/O Control (R)

Port 5 Port 4

Port 3 Port 2

Port 1 Port 0

[ A32 Pointer Low ]

[ A32 Pointer High ]

[ A24 Pointer Low ]

[ A24 Pointer High ]

Response [/Data Extended]

Protocol [/Signal] Register

[Offset Register]

Status / Control Register

Data Low

Data High

Device Type

38 VM1548C Programming

www.vxitech.com

VXIPLUG&PLAY EXAMPLES

/********************************************************************/

/*

* APPLICATION FUNCTION

* ------------------- */

/********************************************************************/

Function: vtvm1548_setupAndWriteData

Formal Parameters ViSession instrHndl

- A valid session handle to the instrument.

ViInt16 portNumber

- This parameter is used to set the port and the clock

associated with the specified port to which the 8 bit data

value is to be written.

Valid Values: Interpretation:

------------ -------------- vtvm1548_PORT_ZERO Port Zero

vtvm1548_PORT_ONE Port One

vtvm1548_PORT_TWO Port Two

vtvm1548_PORT_THREE Port Three

vtvm1548_PORT_FOUR Port Four

vtvm1548_PORT_FIVE Port Five

ViInt16 clkSource

- This parameter is used to set the source of the clock

circuit associated with the specified port.

Valid Values: Interpretation:

------------ ------------- vtvm1548_CLK_SOURCE_IMM Word Serial Event

vtvm1548_CLK_SOURCE_TTLT VXIbus TRIGIN

vtvm1548_CLK_SOURCE_GLOB TRIGOUT

vtvm1548_CLK_SOURCE_NONE Ground

ViBoolean polarity

- This parameter is used to set the polarity of the clock

circuit associated with the specified port. This parameter

is considered only if the specified clock source is either

vtvm1548_CLK_SOURCE_TTLT or tvm1548_CLK_SOURCE_GLOB.

VM1548C Programming 39

VXI Technology, Inc.

Valid Values: Interpretation:

------------ ------------- vtvm1548_POL_NORM Normal Polarity (0)

vtvm1548_POL_INVERT Inverted Polarity (1)

ViInt16 data

- This parameter is used to specify the 8 bit data value

that is to be written to the output port.

Valid Range:

---------- vtvm1548_DATA_MIN (0) to

vtvm1548_DATA_MAX (255).

Return Values: Returns VI_SUCCESS if successful.

Else returns error value.

Description This function is an application function that shows

how the user can use core functions to set up the

specified port as output and write the specified data

value to it. It then triggers the port to output its

data.

/********************************************************************/

ViStatus _VI_FUNC vtvm1548_setupAndWriteData (ViSession instrHndl,

ViInt16 portNumber, ViInt16 clkSource,

ViBoolean polarity, ViInt16 data)

{

/*

* Variable used to store return status of the function.

*/

ViStatus status = VI_NULL;

/*

* Setup the specified port as output and configure the clock