Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

SMP7500

OPEN COLLECTOR

IGITAL I/O MODULE

D

USER’S

ANUAL

M

P/N: 82-0058-000

Released July 31, 2009

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949) 955-1894

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

bus

VXI Technology, Inc.

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

TABLE OF CONTENTS

INTRODUCTION

T

ABLE OF CONTENTS................................................................................................................................................3

Certification..........................................................................................................................................................5

Warranty...............................................................................................................................................................5

Limitation of Warranty.........................................................................................................................................5

Restricted Rights Legend......................................................................................................................................5

DECLARATION OF CONFORMITY...............................................................................................................................6

GENERAL SAFETY INSTRUCTIONS.............................................................................................................................7

Terms and Symbols..............................................................................................................................................7

Warnings ..............................................................................................................................................................7

SUPPORT RESOURCES ...............................................................................................................................................9

SECTION 1..................................................................................................................................................................11

INTRODUCTION.......................................................................................................................................................11

Introduction ........................................................................................................................................................11

Features............................................................................................................................................................... 12

Description .........................................................................................................................................................12

Programming and Data Access...........................................................................................................................14

SECTION 2..................................................................................................................................................................17

PREPARATION FOR USE...........................................................................................................................................17

Introduction ........................................................................................................................................................17

Calculating System Power and Cooling Requirements......................................................................................17

Setting the Chassis Backplane Jumpers..............................................................................................................17

Setting the Logical Address................................................................................................................................18

Example 1......................................................................................................................................................18

Example 2......................................................................................................................................................19

Selecting the Extended Memory Space..............................................................................................................19

Front Panel Interface Wiring..............................................................................................................................20

Hardware Jumper Selection................................................................................................................................21

Hardware Resistor Network Pull-Up Selection..................................................................................................22

SECTION 3..................................................................................................................................................................25

PROGRAMMING.......................................................................................................................................................25

Introduction ........................................................................................................................................................25

Register Access...................................................................................................................................................25

Addressing..........................................................................................................................................................25

Description of Registers - A16...........................................................................................................................27

Description of SMIP II Module Registers - A24 / A32 - Extended Memory.....................................................35

Description of Registers – A24/A32 ..................................................................................................................36

Control Register BUSYN Select ........................................................................................................................41

Example of a Port Set as an Output....................................................................................................................44

Example of a Port Set as an Input.......................................................................................................................46

Example Of A Port Output Write To A Port Input Read ...................................................................................48

REGISTER ACCESS EXAMPLES ................................................................................................................................51

SECTION 4..................................................................................................................................................................53

COMMAND DICTIONARY.........................................................................................................................................53

Terminology.......................................................................................................................................................53

SECTION 5..................................................................................................................................................................55

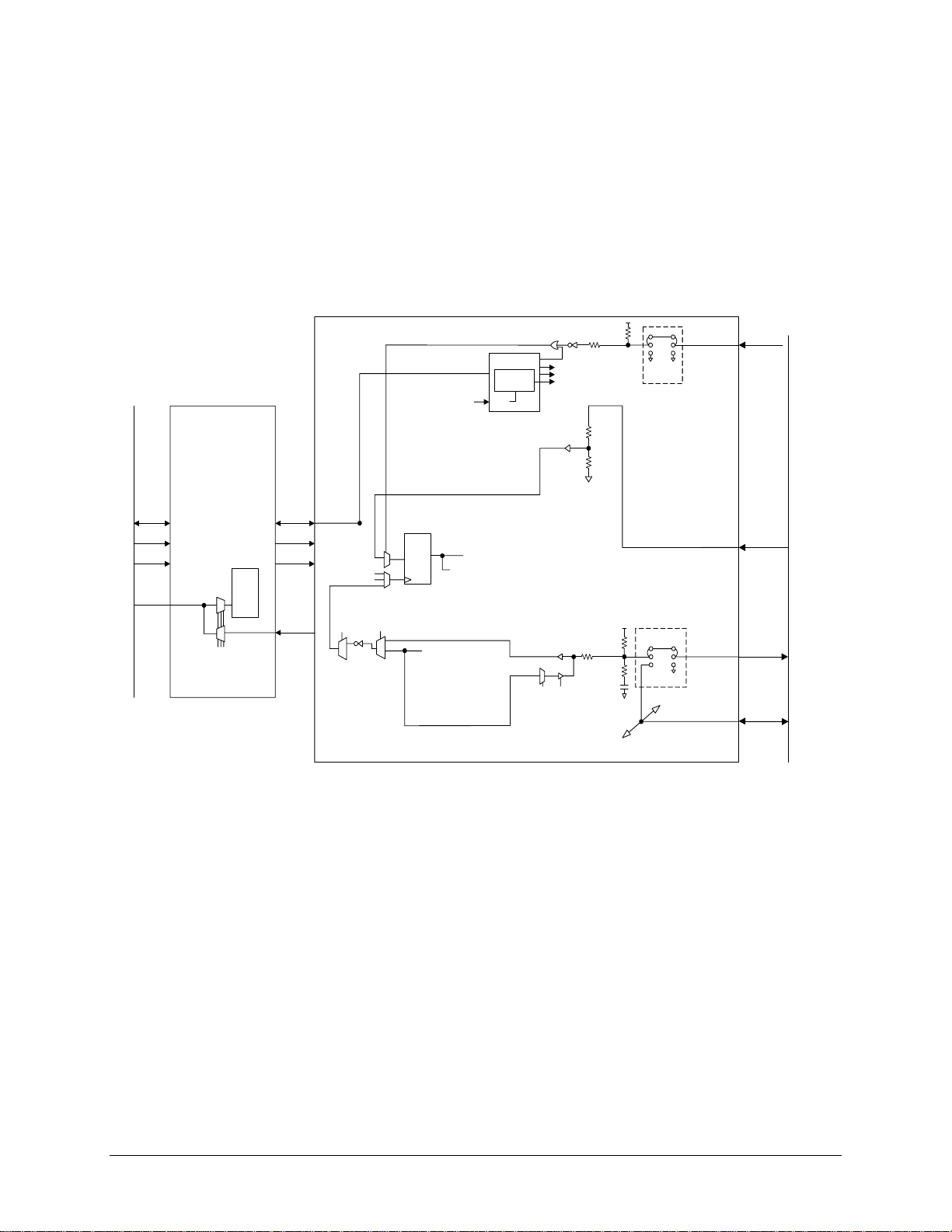

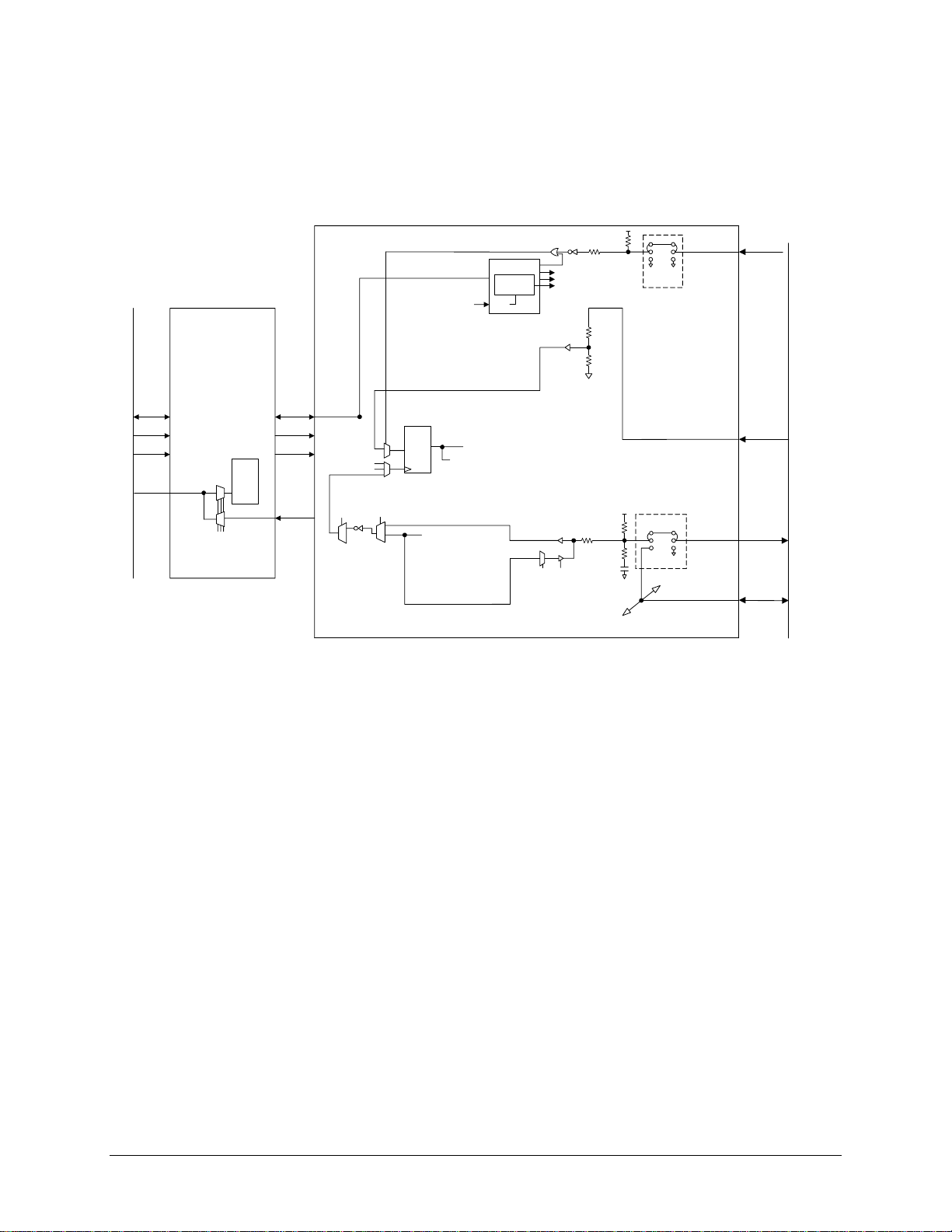

THEORY OF OPERATION..........................................................................................................................................55

Introduction ........................................................................................................................................................55

VXI INTERFACE......................................................................................................................................................56

Device Transfers (Output Mode)........................................................................................................................56

SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

VXI Technology, Inc.

Direction.............................................................................................................................................................56

Clock Enable ......................................................................................................................................................56

Data Load ...........................................................................................................................................................56

Device Triggering (TTL Trigger).......................................................................................................................58

Device Transfers (Read Mode)...........................................................................................................................59

Direction.............................................................................................................................................................59

Clock Enable ......................................................................................................................................................59

Latch Data ..........................................................................................................................................................61

Read Data ...........................................................................................................................................................61

INDEX.........................................................................................................................................................................62

4 SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

CERTIFICATION

VXI Technology, Inc. (VTI) certifies that this product met its published specifications at the time of shipment from

the factory. VTI further certifies that its calibration measurements are traceable to the United States National

Institute of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that

organization’s calibration facility, and to the calibration facilities of other International Standards Organization

members.

WARRANTY

The product referred to herein is warranted against defects in material and workmanship for a period of three years

from the receipt date of the product at customer’s facility. The sole and exclusive remedy for breach of any warranty

concerning these goods shall be repair or replacement of defective parts, or a refund of the purchase price, to be

determined at the option of VTI.

For warranty service or repair, this product must be returned to a VXI Technology authorized service center. The

product shall be shipped prepaid to VTI and VTI shall prepay all returns of the product to the buyer. However, the

buyer shall pay all shipping charges, duties, and taxes for products returned to VTI from another country.

VTI warrants that its software and firmware designated by VTI for use with a product will execute its programming

when properly installed on that product. VTI does not however warrant that the operation of the product, or

software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate maintenance by the buyer, buyersupplied products or interfacing, unauthorized modification or misuse, operation outside the environmental

specifications for the product, or improper site preparation or maintenance.

VXI Technology, Inc. shall not be liable for injury to property other than the goods themselves. Other than the

limited warranty stated above, VXI Technology, Inc. makes no other warranties, express or implied, with respect to

the quality of product beyond the description of the goods on the face of the contract. VTI specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

RESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of

the Rights in Technical Data and Computer Software clause in DFARS 252.227-7013.

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509 U.S.A.

SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

VXI Technology, Inc.

D ECLARATION OF C ONFORMITY

Declaration of Conformity According to ISO/IEC Guide 22 and EN 45014

ANUFACTURER’S NAME VXI Technology, Inc.

M

ANUFACTURER’S ADDRESS 2031 Main Street

M

Irvine, California 92614-6509

RODUCT NAME Open Collector Digital I/O Module

P

ODEL NUMBER(S) SMP7500

M

RODUCT OPTIONS All

P

RODUCT CONFIGURATIONS All

P

VXI Technology, Inc. declares that the aforementioned product conforms to the requirements of

the Low Voltage Directive 73/23/EEC and the EMC Directive 89/366/EEC (inclusive 93/68/EEC)

and carries the “CE” mark accordingly. The product has been designed and manufactured

according to the following specifications:

AFETY EN61010 (2001)

S

EMC EN61326 (1997 w/A1:98) Class A

CISPR 22 (1997) Class A

VCCI (April 2000) Class A

ICES-003 Class A (ANSI C63.4 1992)

AS/NZS 3548 (w/A1 & A2:97) Class A

FCC Part 15 Subpart B Class A

EN 61010-1:2001

The product was installed into a C-size VXI mainframe chassis and tested in a typical configuration.

I hereby declare that the aforementioned product has been designed to be in compliance with the relevant sections

of the specifications listed above as well as complying with all essential requirements of the Low Voltage Directive.

June 2006

Steve Mauga, QA Manager

6 SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

Review the following safety precautions to avoid bodily injury and/or damage to the product.

These precautions must be observed during all phases of operation or service of this product.

Failure to comply with these precautions, or with specific warnings elsewhere in this manual,

violates safety standards of design, manufacture, and intended use of the product.

Service should only be performed by qualified personnel.

TERMS AND SYMBOLS

These terms may appear in this manual:

WARNING

CAUTION

These symbols may appear on the product:

GENERAL SAFETY INSTRUCTIONS

Indicates that a procedure or condition may cause bodily injury or death.

Indicates that a procedure or condition could possibly cause damage to

equipment or loss of data.

ATTENTION - Important safety instructions

WARNINGS

Frame or chassis ground

Indicates that the product was manufactured after August 13, 2005. This mark is

placed in accordance with EN 50419, Marking of electrical and electronic

equipment in accordance with Article 11(2) of Directive 2002/96/EC (WEEE).

End-of-life product can be returned to VTI by obtaining an RMA number. Fees

for take-back and recycling will apply if not prohibited by national law.

Follow these precautions to avoid injury or damage to the product:

Use Proper Power Cord

Use Proper Power Source

Use Proper Fuse

To avoid hazard, only use the power cord specified for this product.

To avoid electrical overload, electric shock, or fire hazard, do not

use a power source that applies other than the specified voltage.

To avoid fire hazard, only use the type and rating fuse specified for

this product.

SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

WARNINGS (CONT.)

Avoid Electric Shock

Ground the Product

Operating Conditions

Improper Use

VXI Technology, Inc.

To avoid electric shock or fire hazard, do not operate this product

with the covers removed. Do not connect or disconnect any cable,

probes, test leads, etc. while they are connected to a voltage source.

Remove all power and unplug unit before performing any service.

Service should only be performed by qualified personnel.

This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground.

To avoid injury, electric shock or fire hazard:

- Do not operate in wet or damp conditions.

- Do not operate in an explosive atmosphere.

- Operate or store only in specified temperature range.

- Provide proper clearance for product ventilation to prevent

overheating.

- DO NOT operate if any damage to this product is suspected.

Product should be inspected or serviced only by qualified

personnel.

The operator of this instrument is advised that if the equipment is

used in a manner not specified in this manual, the protection

provided by the equipment may be impaired.

Conformity is checked by inspection.

8 SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

Support resources for this product are available on the Internet and at VTI Instruments customer

support centers.

VTI Instruments Corp.

World Headquarters

VTI Instruments Corp.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VTI Instruments

Cleveland Instrument Division

5425 Warner Road

Suite 13

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VTI Instruments

Lake Stevens Instrument Division

3216 Wetmore Avenue, Suite 1

Everett, WA 98201

Phone: (949) 955-1894

Fax: (949) 955-3041

VTI Instruments, Pvt. Ltd.

Bangalore Instrument Division

642, 80 Feet Road

Koramangala IV Block

Bangalore – 560 034

India

Phone: +91 80 4040 7900

Phone: +91 80 4162 0200

Fax: +91 80 4170 0200

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail:

Visit

http://www.vtiinstruments.com for worldwide support sites and service plan information.

SUPPORT RESOURCES

support@vtiinstruments.com

SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

VXI Technology, Inc.

10 SMP7500 Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

A

SECTION 1

INTRODUCTION

INTRODUCTION

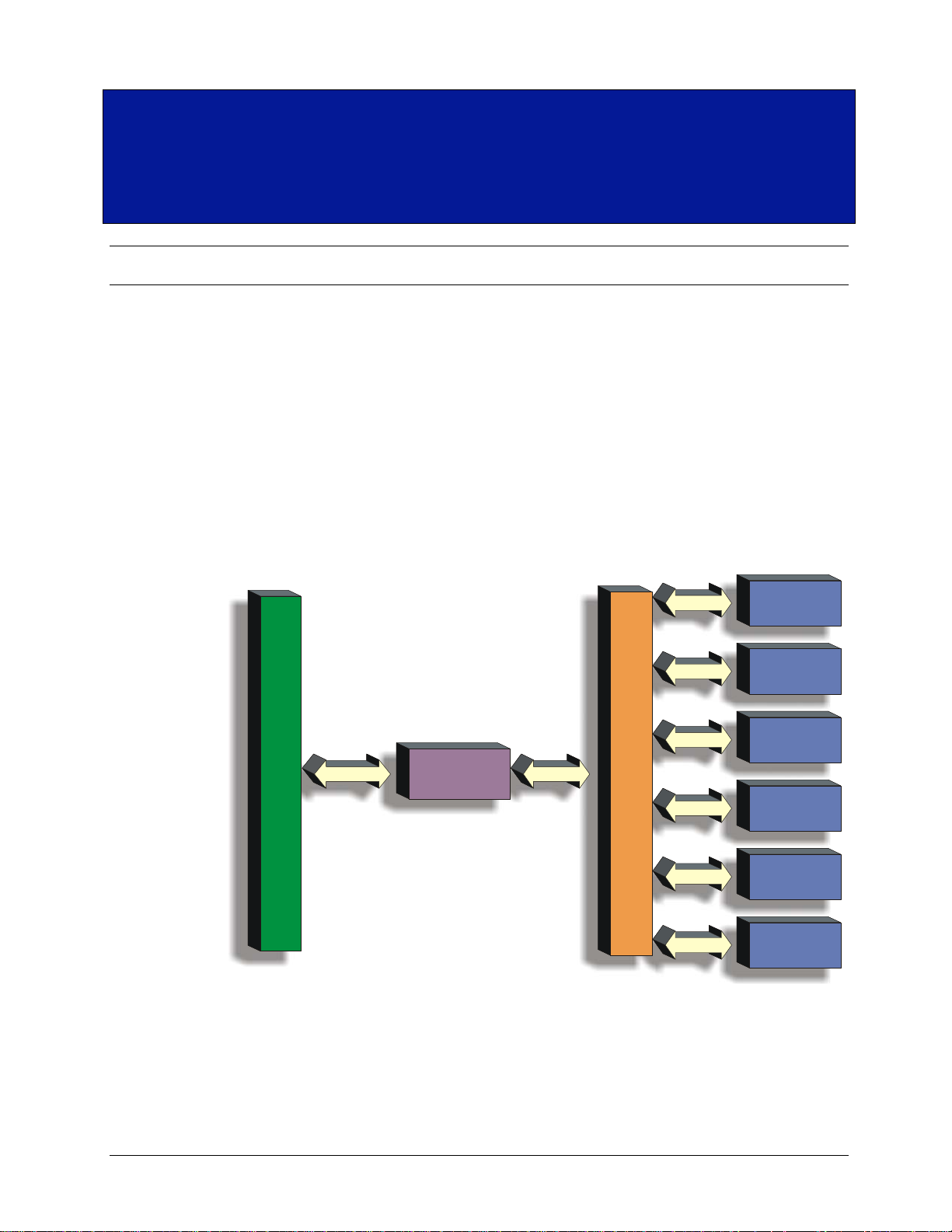

The SMP7500 is a high-performance I/O module that has been designed for high data throughput

and flexibility of configuration. The instrument uses direct register access for very high-speed data

input and retrieval.

The SMP7500 is a member of the VXI Technology SMIP II™ (Switch Modularity Instrumentation

Platform) family and is available as a 96-channel, single SMIP Plug-In Module. As many as six

SMP7500s may be configured in a single double-slot VXI module, and 2 in a single-wide VXI

module. This would allow as many as 576 for a double-wide or 192 digital I/O for a single-wide

VXI Module. In addition, the SMP7500 may be combined with any of the other members of the

SMIP family to form a customized and highly integrated instrument/switch test solution. This

allows the user to reduce system size and cost by combining the SMP7500 with another

instrument/switch function in a single wide, C-size VXIbus module.

I

N

T

V

X

I

B

SMIP

INTERFACE

U

S

IGURE 1-1: SMIP™ SWITCH MODULARITY INSTRUMENTATION PLATFORM

F

E

R

N

L

S

M

I

P

B

U

S

SMIP SWITCH

MODULE #1

SMIP SWITCH

MODULE #2

SMIP SWITCH

MODULE #3

SMIP SWITCH

MODULE #4

SMIP SWITCH

MODULE #5

SMIP SWITCH

MODULE #6

SMP7500 Introduction 11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

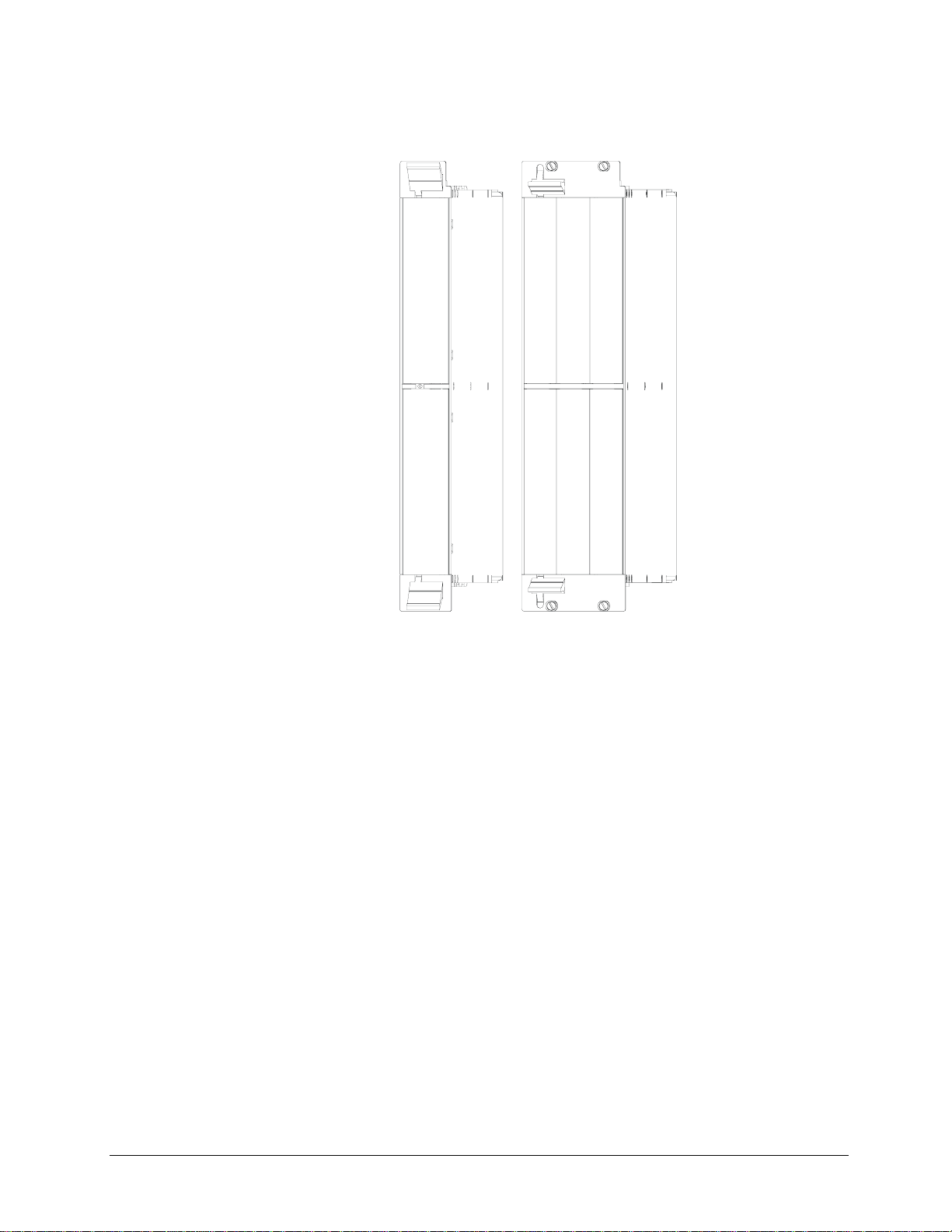

Regardless of whether the SMP7500 is configured with other SMP7500 modules or with other

SMIP II modules, each group of 96 channels is treated as an independent plug-in in the SMIP II

module and as such, each group has its own FAIL/POWER and ACCESS/ERROR indicators.

M

M

M

O

D

U

L

E

#0

M

O

D

U

L

E

#1

M

O

D

U

L

E

#2

M

O

D

U

L

E

#5

O

O

D

D

U

U

L

L

E

E

#0

#1

M

M

O

O

D

D

U

U

L

L

E

E

#3

#4

FEATURES

DESCRIPTION

SMP1100 SMP1200

F

IGURE 1-2: FRONT PANEL LAYOUT

• 96 Channels, 12 groups of 8 bits. Up to 576 channels in a double-slot C-size card, up to

192 channels in a single C-size card.

• Group-wise programmable, as an input or an output, through user TTL input or VXI A24/32

registers.

• Group-wise programmable polarity through VXI A24/32 registers as an active high or low.

• Input: 0 V to 60 V, V

• Output: Open collector (N-DMOS), 0 V to 60 V, up to 300 mA continuous with over-voltage

and over-current protection.

• Data throughput: 5 µs typical system speeds, 200 kilobytes per second (kb/s) using D8 access,

400 kb/s using D16 access.

• Data Input/Output Clock Sources: For each group, from Front Panel (F/P) clock input, or VXI

Register Writes.

• Capture clock edge programmable as rising edge or falling edge.

• Register based data access for fast throughput.

The SMP7500 Open Collector Digital I/O module is a high performance I/O module that has been

designed for high voltage, current and data throughput. The instrument uses direct register access

for very high-speed data through-put.

IN (high)

≥ 2.0 V, V

≤ 1.5 V, input impedance ≥ 65 kΩ.

IN(low)

12 SMP7500 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

A single SMP7500 provides 96 open collector digital I/O line that are configurable as inputs or

outputs in twelve groups of 8 channels each. The module can drive up to 60 V with sink current of

up to 300 mA per channel. Each group of 8 bits is referred as a PORT. Each PORT can be

configured as an input port or an output port under program control. The SMP7500 has the

flexibility to configure the sourcing of the input and output clocks from either the front panel (F/P

GND_I/O) (one input per PORT), or via a VXI A24/A32 control register. There is also a Global

Clock Line from the front panel that may be user selected via hardware jumpers to drive selected

PORT clocks. By using the appropriate clocking configuration, very large numbers of channels

may by synchronized to collect or present data to a UUT (unit under test).

Each clock input is internally pulled to a logic high level and has an RC termination network to

reduce multiple clocking edges due to line ringing. The RC network consists of a 120 Ω resistor in

series with a 100 pF capacitor, giving a time constant of 12 ns.

The SMP7500 can be combined with any member of the SMIP II family to form a customized and

highly integrated instrument/switch.

SMP7500 Introduction 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

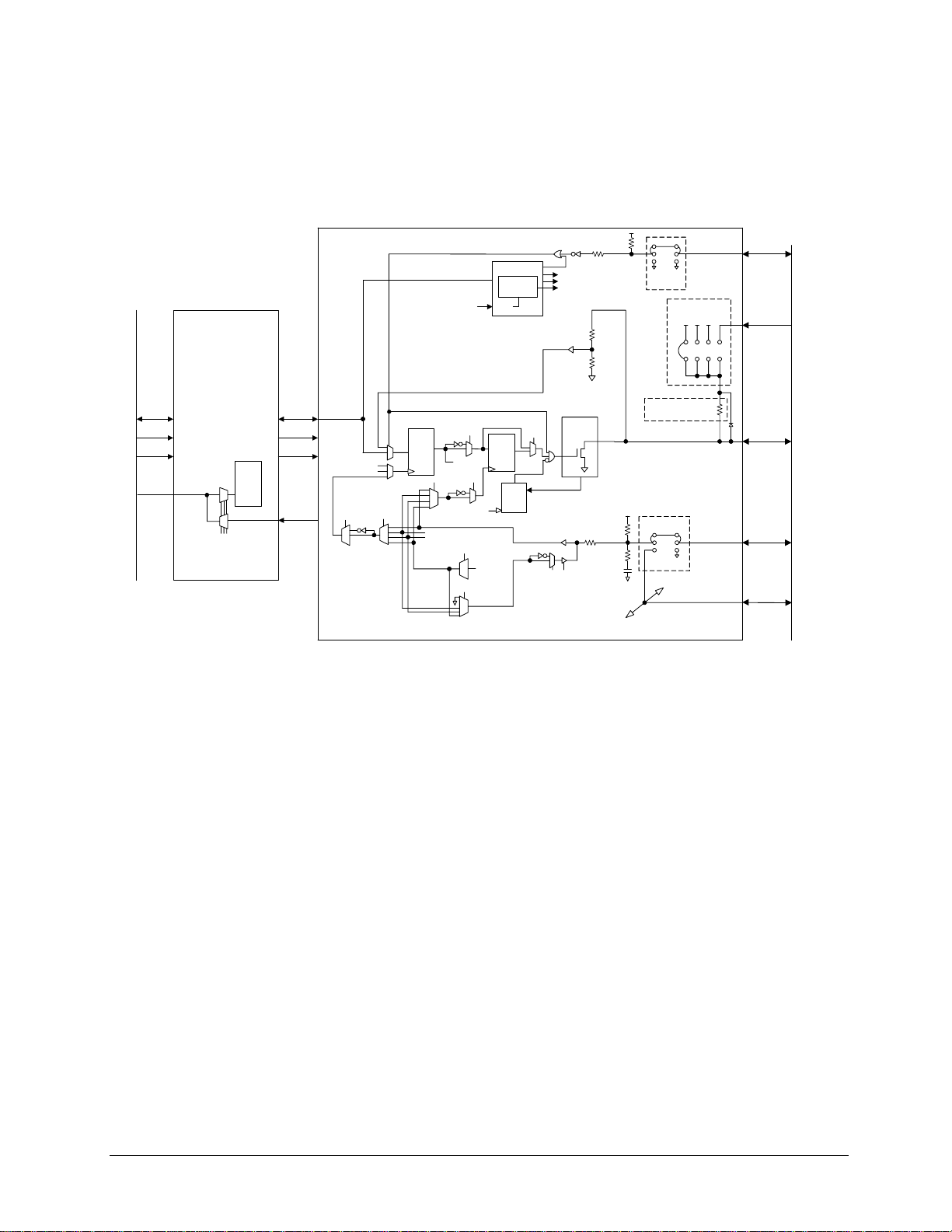

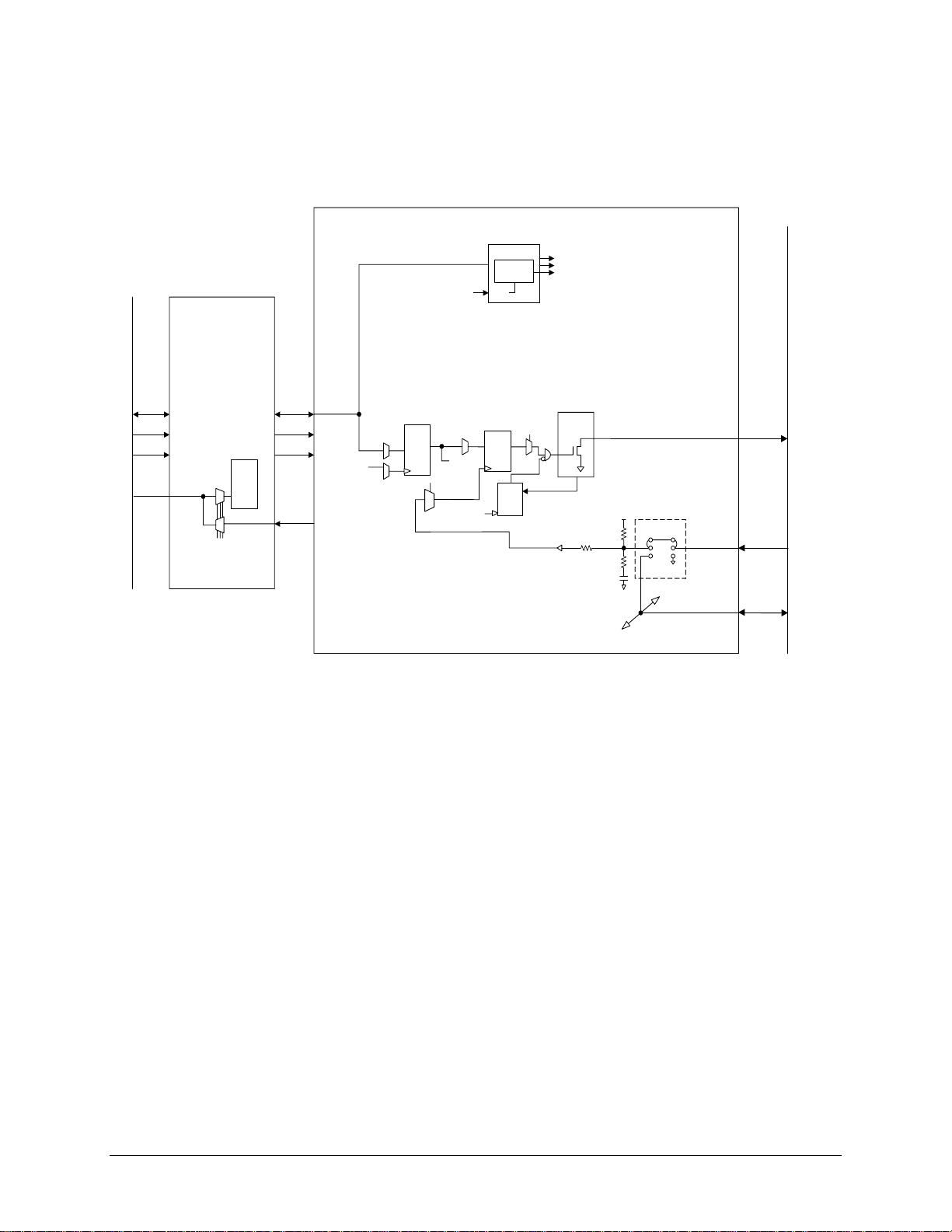

PROGRAMMING AND DATA ACCESS

Register-based Data Access: The I/O ports are directly mapped into the VXI user

SMIP INTERFACE

MODULE

DATA

ADDRESS

CONTROL

BUSYN

Backplane Load

Transparent

Polarity

ADDRESS

CONTROL

VXI BACKPLANE

DATA

TTL

TRIGGER

BUS

0-7

Control

Trace

Memory

Control

I/O Data

Buffer

Data

WR Event

Relay Req. 000Ch Write Event

SMP7500 MODULE

Control

R/B

Polarity

Latched

Output

Data

Buffer

R/B

PolarityControl

Over Current

Reset

Control

All Other

Available F/P

CLK Lines

Control

VXI Technology, Inc.

definable registers in the A24 or A32 address space.

Data access occurs in approximately 500 ns,

depending on the controller and software used.

USER CONNECTOR

GND_I/O

CLAMP

Fly Back Protection Diode

DATA

GND_CLK

GLOBAL

CLK

Control

Writes to

Specific Port

Addresses

Over

Current

Sense /

Control

Immediate

Double

Buffered

Over Current Sense

Shut Down

Control

Relay Req. 000Ch Write Event

WR EVENT

Output

Drivers

ISENSE

2

2

Polarity Enable

47k

22

200K

33K

47K

120

100pf

User Selectable

HW Jumpers

User Selectable

HW Jumpers

+5V +12V +24V

User Configurable 100K

Pull-Up Resistor Network (SIP)

User Selectable

HW Jumpers

Off To All Other Ports

F

IGURE 1-3: SMP7500 MODULE BLOCK DIAGRAM

14 SMP7500 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

SMP7500 SPECIFICATIONS

GENERAL SPECIFICATIONS

NUMBER OF CHANNELS

DIRECTION

DATA ACCESS TYPES

DATA THROUGHPUT

PHYSICAL INTERFACE

CHANNEL INPUT CHARACTERISTICS

V

V

V

IN(high)

IN(low)

IN(max)

Input Impedance

CHANNEL OUTPUT CHARACTERISTICS

V

OUT(max)

Current Sink (Maximum)

Switch On Time

CLOCK AND CONTROL INPUT CHARACTERISTICS

V

V

IN(high)

IN(low)

Current In (VIN = 5.0 V)

DATA INPUT CLOCK SOURCES

DATA OUTPUT CLOCK SOURCES

TTL TRIGGER OUTPUT SOURCES

CLOCKED INPUT DATA HOLD

POWER REQUIREMENTS

COOLING REQUIREMENTS

96 (12 groups of 8 bits)

Selectable as input or output

Direct register access

5 µs typical system (500 µs register cycle time)

200 kb/s using D8 access

400 kb/ using D16 access

N channel DMOS transistor (TPIC2601KTC for rev. A PCBs, STS4DNF60L

for Rev. B or higher) with a current protection circuit on the output side, and a

voltage divider and voltage comparator on the input side

≥ 2.0 V

≤ 1.5 V

≤ 60 V

≥ 65 kΩ

≤ 60 V

≤ 300 mA

≤ 1 µs

> 2.0 V

< 0.8 V

< 10 µA

12 Front Panel, plus 1 Global Clock, A24/A32 Register Write

12 Front Panel, A24/A32 Register Write

Board Busyn controlled

≥ 2 µs

+5 V @ 864 mA, +12 V @ 60 mA

0.4 L/s

SMP7500 Introduction 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

16 SMP7500 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

SECTION 2

PREPARATION FOR USE

INTRODUCTION

When the SMP7500 is unpacked from its shipping carton, the contents should include the

following items:

(1) SMP7500 VXIbus module

(1) SMP7500 Open Collector Digital I/O Module User’s Manual (this manual)

All components should be immediately inspected for damage upon receipt of the unit.

Once the SMIP II is assessed to be in good condition, it may be installed into an appropriate C-

size or D-size VXIbus chassis in any slot other than slot zero. The chassis should be checked to

ensure that it is capable of providing adequate power and cooling for the SMIP II. Once the

chassis is found adequate, the SMIP II’s logical address and the chassis’ backplane jumpers

should be configured prior to the SMIP II’s installation.

CALCULATING SYSTEM POWER AND COOLING REQUIREMENTS

It is imperative that the chassis provide adequate power and cooling for this module. Referring to

the chassis operation manual, confirm that the power budget for the system (the chassis and all

modules installed therein) is not exceeded and that the cooling system can provide adequate

airflow at the specified backpressure.

It should be noted that if the chassis cannot provide adequate power to the module, the instrument

might not perform to specification or possibly not operate at all. In addition, if adequate cooling is

not provided, the reliability of the instrument will be jeopardized and permanent damage may

occur. Damage found to have occurred due to inadequate cooling could also void the warranty of

the module.

SETTING THE CHASSIS BACKPLANE JUMPERS

Please refer to the chassis operation manual for further details on setting the backplane jumpers.

SMP7500 Introduction 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

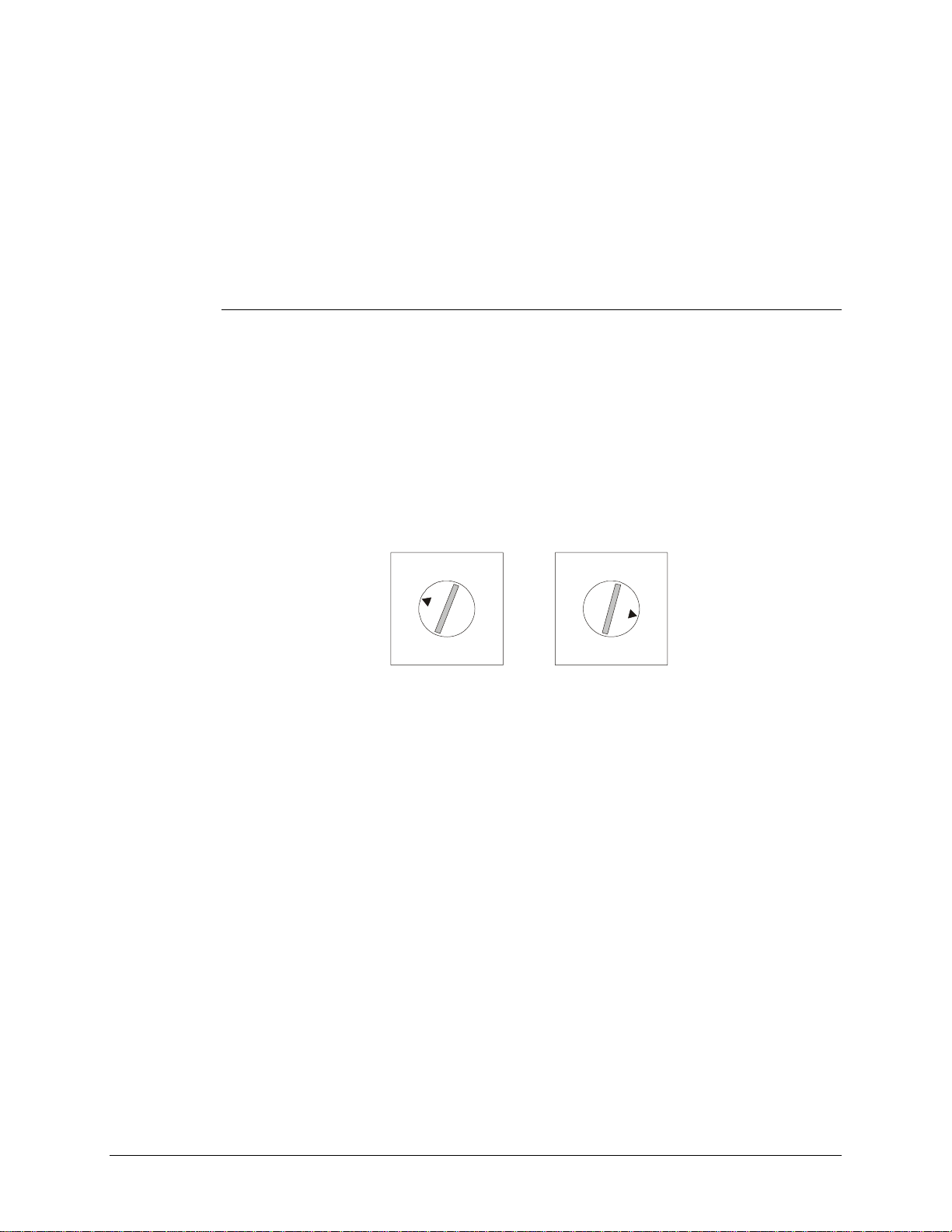

SETTING THE LOGICAL ADDRESS

The logical address of the SMIP II is set by two rotary switches located on the top edge of the

interface card, near the backplane connectors. Each switch is labeled with positions 0 through F.

The switch closer to the front panel of the module is the least significant bit (LSB or “Front”),

and the switch located towards the back of the module is the most significant bit (MSB or

“Back”). To set the Logical Address (LA), simply rotate the pointer to the desired value. For

example, to set the LA to 25, first convert the decimal number to the hexadecimal value of 19.

Next, set the back switch to 1, and the front switch to 9. See

conversion examples:

Example 1

VXI Technology, Inc.

Figure 2-1. Here are a couple of

LA

(decimal)

Divide

by 16

MSB LSB

25 25 / 16 = 1 w/ 9 remaining Divide the decimal value by 16 to get

the MSB and the LSB.

= 0001 1001 The 1 is the MSB, and the remainder of

9 is the LSB.

= 1 9 Convert to hexadecimal. Set the back

switch to 1 and the front switch to 9.

BACK FRONT

5

4

6

3

2

1

0

F

F

IGURE 2-1: LOGICAL ADDRESS EXAMPLE 1

7

8

9

A

B

E

C

D

Here is another way of looking at the conversion: LA = (back switch x 16) + front switch

LA = (1 x 16) + 9

LA = 16 + 9

LA = 25

4

5

6

3

2

1

0

F

7

8

9

A

B

E

C

D

18 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

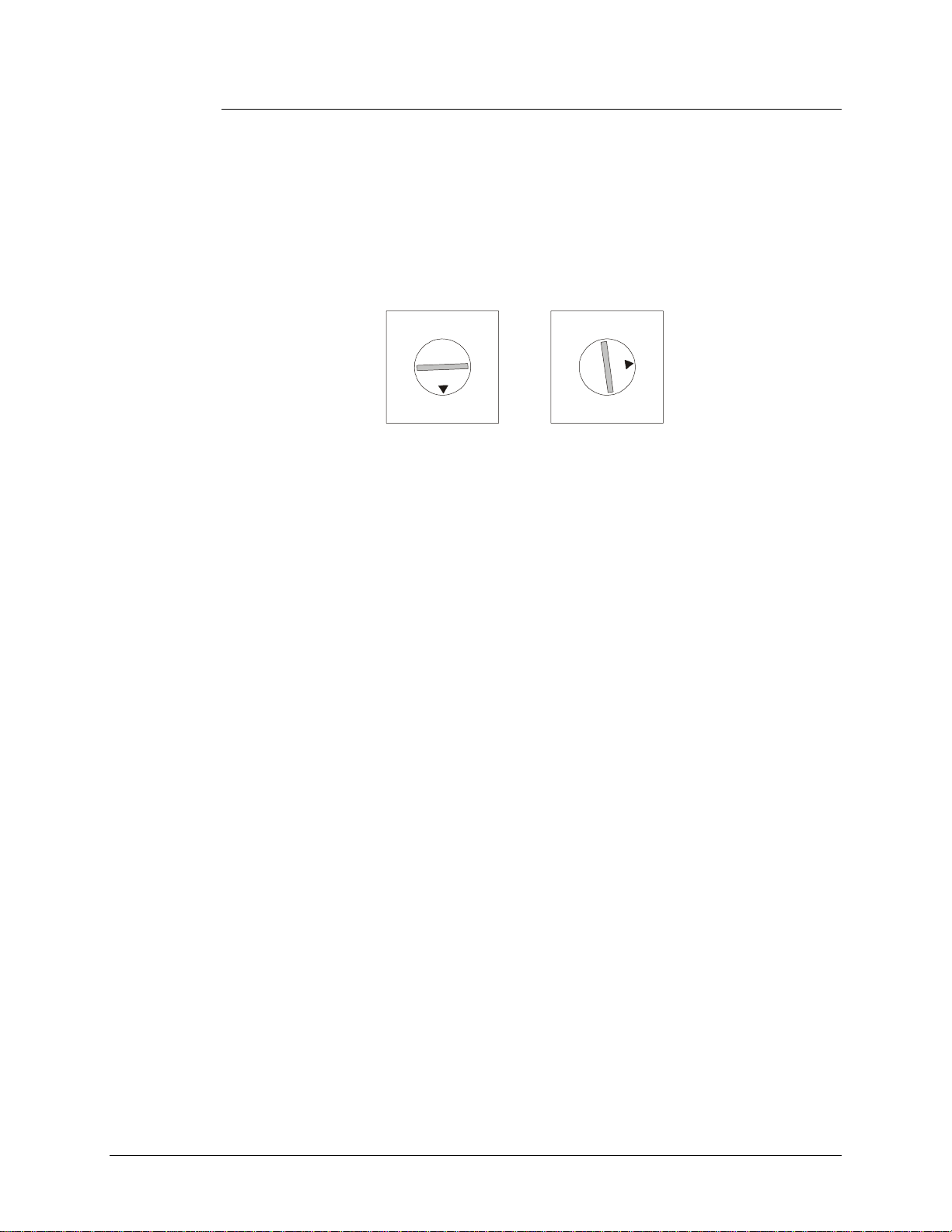

Example 2

LA

(decimal)

Divide

by 16

MSB LSB

200 200 / 16 = 12 w/ 8 remaining Divide by 16.

= 1100 1000 Convert to MSB and LSB.

= C 8 Convert to hexadecimal. Set the back

switch to C and the front switch to 8.

BACK FRONT

5

4

6

3

2

1

0

F

F

IGURE 2-2: LOGICAL ADDRESS EXAMPLE 2

7

8

9

A

B

E

C

D

Set the address switches to FF (factory default) for dynamic configuration. Upon power-up, the

resource manager will assign a logical address. See Section F - Dynamic Configuration in the

VXIbus Specification for further information.

There is only one logical address per SMIP II base unit. Address assignments for individual

modules are handled through the A24/A32 address space allocation.

4

5

6

3

2

1

0

F

7

8

9

A

B

E

C

D

SELECTING THE EXTENDED MEMORY SPACE

The Extended Memory Space of the SMIP II is set by a dip-switch that is located on the bottom

edge of the interface card. Position 1, located to the left on the dip-switch, selects between A24

and A32 memory address space. In the UP position, the SMIP II will request A24 space. In the

DOWN position, the SMIP II will request A32 space. (Position 2 is not currently used.) The

selection of the address space should be based upon the memory allocation requirements of the

system that the SMIP II module will be installed. The amount of memory allocated to the SMIP II

module is independent of the address space selected.

SMP7500 Programming 19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FRONT PANEL INTERFACE WIRING

The SMP7500’s module interface is made available on the front panel of the instrument. The

160-pin connector contains all of the signals available for this instrument. The connector used on

the SMP7500 is a readily available 160-pin 5 row DIN type connector. Many mating options are

available for this connector style, anything from crimp-and-poke to screw terminal connections.

Several cable shroud options are also available.

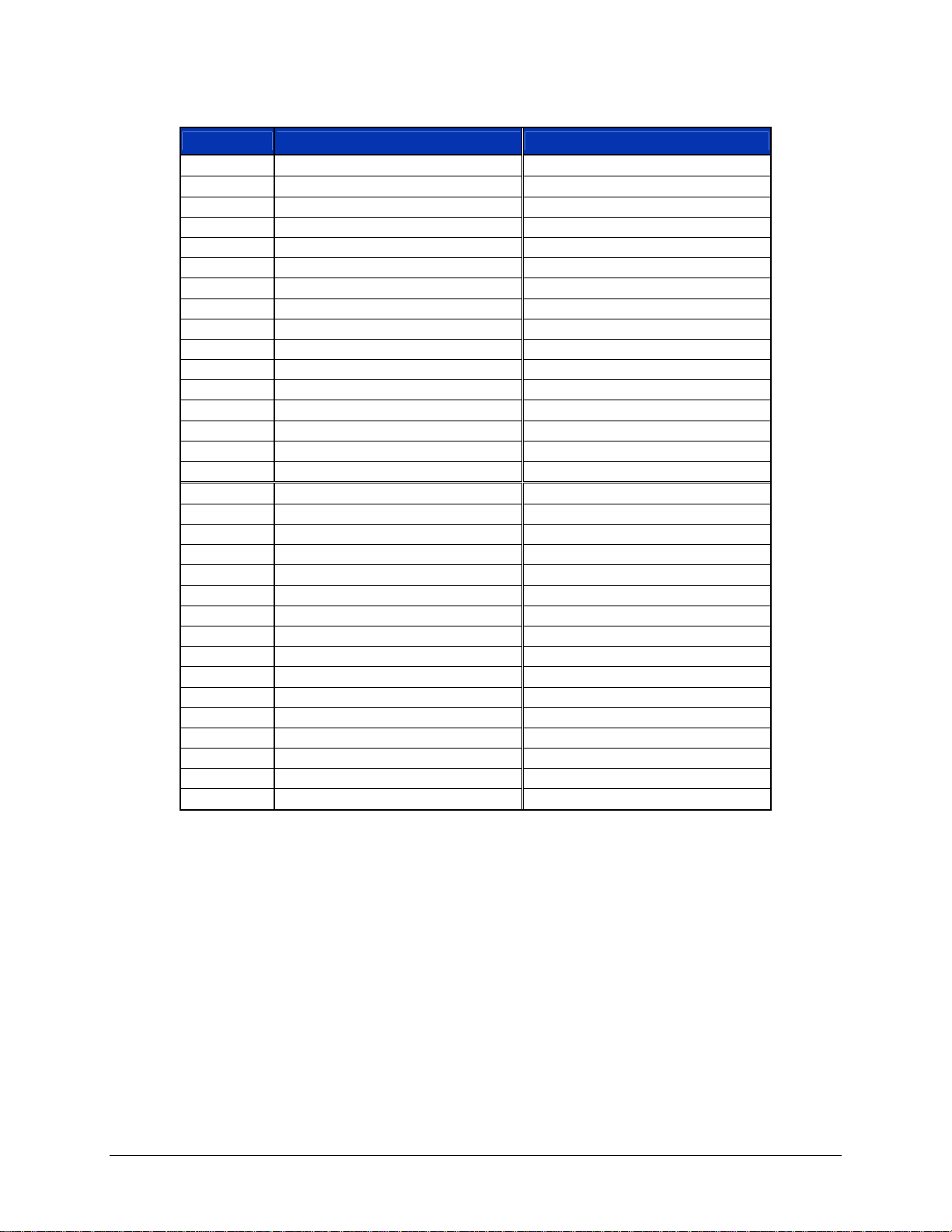

ABLE 2-1: J100 PIN OUTS

T

VXI Technology, Inc.

ROW

A

1 DATA0.0 1 DATA2.0 1 DATA4.0 1 CLAMP0 1 CLAMP1

2 DATA0.1 2 DATA2.1 2 DATA4.1 2 GND/CLK0 2 GND/CLK1

3 DATA0.2 3 DATA2.2 3 DATA4.2 3 GND/IO0 3 GND/IO1

4 DATA0.3 4 DATA2.3 4 DATA4.3 4 GND 4 GND

5 DATA0.4 5 DATA2.4 5 DATA4.4 5 CLAMP2 5 CLAMP3

6 DATA0.5 6 DATA2.5 6 DATA4.5 6 GND/CLK2 6 GND/CLK3

7 DATA0.6 7 DATA2.6 7 DATA4.6 7 GND/IO2 7 GND/IO3

8 DATA0.7 8 DATA2.7 8 DATA4.7 8 GND 8 GND

9 DATA1.0 9 DATA3.0 9 DATA5.0 9 CLAMP4 9 CLAMP5

10 DATA1.1 10 DATA3.1 10 DATA5.1 10 GND/CLK4 10 GND/CLK5

11 DATA1.2 11 DATA3.2 11 DATA5.2 11 GND/IO4 11 GND/IO5

12 DATA1.3 12 DATA3.3 12 DATA5.3 12 GND 12 GND

13 DATA1.4 13 DATA3.4 13 DATA5.4 13 CLAMP6 13 CLAMP7

14 DATA1.5 14 DATA3.5 14 DATA5.5 14 GND/CLK6 14 GND/CLK7

15 DATA1.6 15 DATA3.6 15 DATA5.6 15 GND/IO6 15 GND/IO7

16 DATA1.7 16 DATA3.7 16 DATA5.7 16 GND 16 GND

17 DATA6.0 17 DATA8.0 17 DATA10.0 17 CLAMP8 17 CLAMP9

18 DATA6.1 18 DATA8.1 18 DATA10.1 18 GND/CLK8 18 GND/CLK9

19 DATA6.2 19 DATA8.2 19 DATA10.2 19 GND/IO8 19 GND/IO9

20 DATA6.3 20 DATA8.3 20 DATA10.3 20 GND 20 GND

21 DATA6.4 21 DATA8.4 21 DATA10.4 21 CLAMP10 21 CLAMP11

22 DATA6.5 22 DATA8.5 22 DATA10.5 22 GND/CLK 10 22 GND/CLK 11

23 DATA6.6 23 DATA8.6 23 DATA10.6 23 GND/IO10 23 GND/IO11

24 DATA6.7 24 DATA8.7 24 DATA10.7 24 GND 24 GND

25 DATA7.0 25 DATA9.0 25 DATA11.0 25 GND 25 GND/GCLK

26 DATA7.1 26 DATA9.1 26 DATA11.1 26 GND 26 GND

27 DATA7.2 27 DATA9.2 27 DATA11.2 27 GND 27 GND

28 DATA7.3 28 DATA9.3 28 DATA11.3 28 GND 28 GND

29 DATA7.4 29 DATA9.4 29 DATA11.4 29 GND 29 GND

30 DATA7.5 30 DATA9.5 30 DATA11.5 30 GND 30 GND

31 DATA7.6 31 DATA9.6 31 DATA11.6 31 GND 31 GND

32 DATA7.7 32 DATA9.7 32 DATA11.7 32 GND 32 GND

SIGNAL

ROW

B

SIGNAL

ROW

C

SIGNAL

ROW

D

SIGNAL

ROW

E

SIGNAL

20 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

HARDWARE JUMPER SELECTION

The SMP7500 module contains many user selectable hardware jumpers. The jumpers are of the

2-pin finger removable type found on most personal computers and hard disk drives. These

jumpers set the fly-back protection voltage, the functionality of the front panel (F/P) GND_I/O,

GND_CLK and Global CLK lines, as well as the direction of the PORTs. The

shows the appropriate jumper settings for the module setup desired.

Front Panel CLAMP Lines

The F/P CLAMP lines are available for user defined voltages that are to be used to suppress

inductive fly-back transients on the PORT lines. This helps protect other circuitry on the PORT’s

data lines from an over-voltage condition. The F/P CLAMP line is only one of several sources that

may be selected to drive the fly-back protection diodes that are installed on the module. Hardware

selectable jumpers on the module can also be used to select either +24 V dc, +12 V dc, or

+5 V dc. The voltage selected is routed to the cathode of a fly-back protection diode, whose anode

is then connected to the associated PORT’s data line. Every PORT data line has a fly-back

protection diode installed. If no protection voltage is desired, simply hardware jumper the clamp

voltage to the F/P CLAMP line and do not connect that lin e to any voltage.

Front Panel GND_I/O Lines

The F/P GND_I/O lines may be configured as either GrouND, or an input line that controls the

direction of the associated PORT. If used as inputs the F/P GND_I/O lines are pulled-up to +5 V

via a 47 kΩ resistor. If these lines are configured as input control lines and are not driven low,

they will pull-up setting the associated port as an input. If pulled low, they will set the port to an

output. All F/P GND_I/O lines may be overridden either by a hardware jumper setting or

programmatically to set the port direction to output.

Table 2-2 below

If set to GrouND, these lines can be used as additional user employable Ground pins to the

module. This increases the user attachments to the system’s ground. For high speed switching of

many simultaneous channels it may be necessary to use these pins as ground in order to reduce

signal bounce caused by switching transients. If these lines are used as GND, and they are not

overridden, then they are internally pulled-up and set the PORT’s direction as input.

There are two ways to override the F/P GND_I/O lines. A hardware jumper may be used to select

the PORT as an output, or the PORT may be programmatically set to an output. If these lines are

overridden, then they have no effect on the module.

Front Panel GND_CLK Lines

The F/P GND_CLK lines may be configured as either GrouND, an input line, or an output line

that controls data capture of the associated PORT. If used as inputs the F/P GND_CLK lines are

pulled-up to +5 V via a 47 kΩ resistor. There is as well a network of a 120 Ω resistor in series

with a 100 pF capacitor for termination of the F/P_CLK lines. The polarity of the clock lines are

programmable as well.

If set to GrouND, they can be used as additional user employable Ground pins to the module. This

increases the user attachments to the system’s ground. For high speed switching of many

simultaneous channels it may be necessary to use these pins as ground in order to reduce signal

bounce caused by switching transients.

A Global CLK Line is available on the front panel. This line is to be used to gang several, or all,

PORT clock lines into a single source/destination. The Global CLK line is routed to the required

PORTs via hardware jumpers. If a PORT is configured to use the Global CLK line, then its

associated F/P GND_CLK line has no effect on the module.

SMP7500 Programming 21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HARDWARE RESISTOR NETWORK PULL-UP SELECTION

The SMP7500 module contains user selectable hardware resistor networks that are used to pull-up

the F/P data lines to the selected CLAMP voltage. The networks are of the 9-pin 8-resistor singlein-line (SIP) type. Examples of this type of resistor network are:

Dale Electronics, Inc CSC09A01104G (100 kΩ)

BI Technologies BH9-1104 (100 kΩ)

VXI Technology, Inc.

RR R R R R R R

Pin 1

Pin 2Pin 3Pin 4Pin 5Pin 6Pin 7Pin 8Pin 9

F

IGURE 2-3: RESISTOR NETWORK 9P8R SIP

The values of these resistor networks may be selected and the networks replaced per customer

requirements. Care should be taken to follow the power rating of the networks selected and the

application voltage used so as not to create a potenially dangerous situation. VXI Technology,

Inc. does not carry other values of these resistor networks.

Front Panel CLAMP Lines

The F/P CLAMP lines are available for user defined voltages that are to be used to suppress

inductive fly-back transients on the PORT lines. This helps protect other circuitry on the PORT’s

data lines from an over-voltage condition. The F/P CLAMP line is only one of several sources that

may be selected to drive the fly-back protection diodes that are installed on the module. Hardware

selectable jumpers on the module can also be used to select either +24 VDC, +12 VDC, or

+5 VDC. The voltage selected is routed to the cathode of a fly-back protection diode, whose

anode is then connected to the associated PORT’s data line. Every PORT data line has a fly-back

protection diode installed. If no protection voltage is desired, simply hardware jumper the clamp

voltage to the F/P CLAMP line and do not connect that lin e to any voltage.

22 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

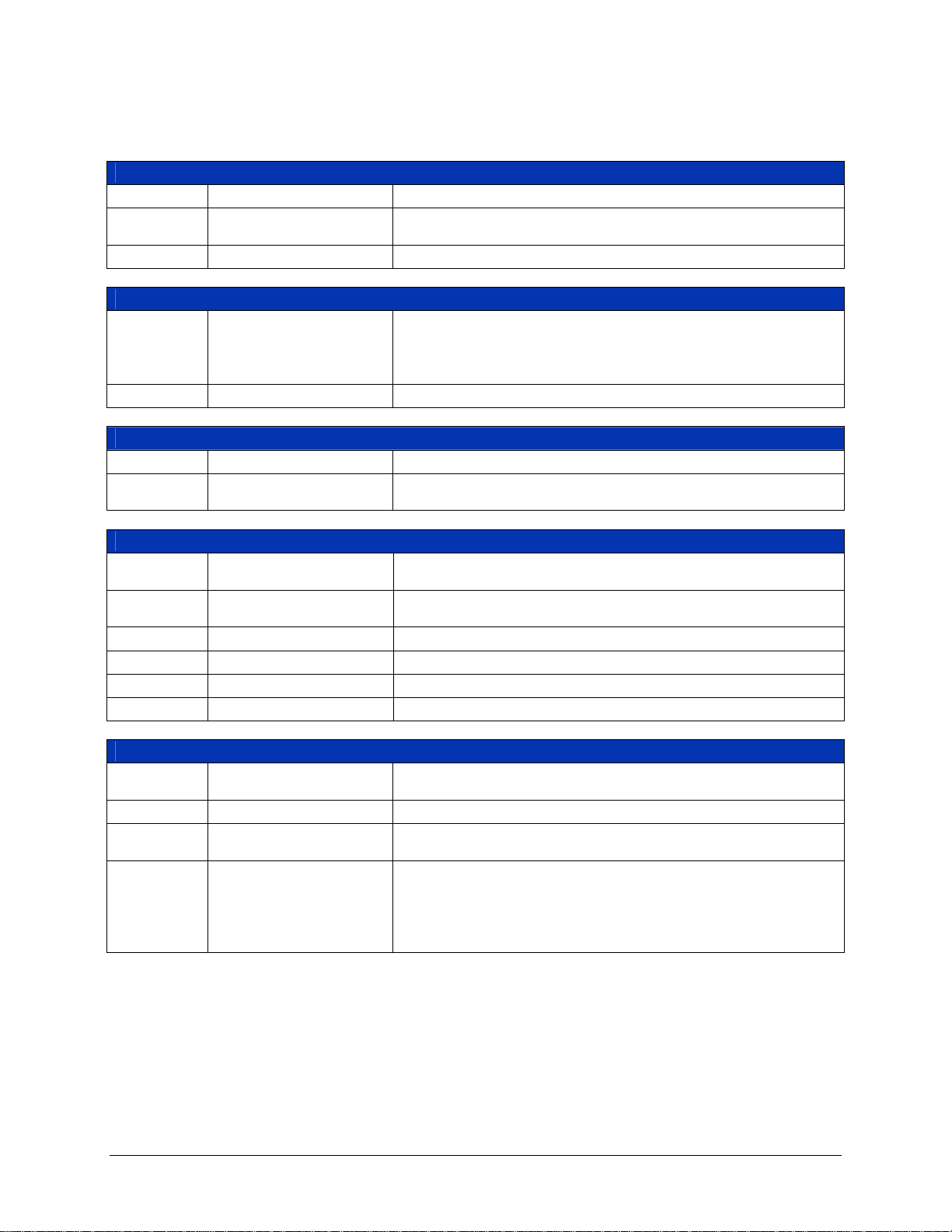

TABLE 2-2: HARDWARE JUMPER CONFIGURATION

HARDWARE JUMPERS INSTALLED (HW = HARD WIRED via JUMPER)

FUNCTION PORT 0 PORT 1 PORT 2 PORT 3 PORT 4 PORT 5

GND_I/O = GND J1 – 1 to 2 J7 – 1 to 2 J14 – 1 to 2 J11 – 1 to 2 J22 – 1 to 2 J19 – 1 to 2

GND_I/O = I/0 * J1 – 2 to 3

J2 – 2 to 3

J7 – 2 to 3

J6 – 2 to 3

J14 – 2 to 3

J13 – 2 to 3

J11 – 2 to 3

J10 – 2 to 3

J22 – 2 to 3

J21 – 2 to 3

J19 – 2 to 3

J18 – 2 to 3

PORT HW AS OUTPUT * J2 – 1 to 2 J6 – 1 to 2 J13 – 1 to 2 J10 – 1 to 2 J21– 1 to 2 J18– 1 to 2

GND_CLK = GND J3 – 1 to 2 J5 – 1 to 2 J12 – 1 to 2 J9 – 1 to 2 J20 – 1 to 2 J17 – 1 to 2

GND_CLK = INPUT OR

OUTPUT *

J3 – 2 to 3

J4 – 1 to 2

J5 – 2 to 3

J8 – 1 to 2

J12 – 2 to 3

J15 – 1 to 2

J9 – 2 to 3

J16 – 1 to 2

J20 – 2 to 3

J23 – 1 to 2

J17 – 2 to 3

J24 – 1 to 2

GLOBAL CLK = INPUT * J4 – 2 to3 J8 – 2 to3 J15 – 2 to3 J16 – 2 to3 J23 – 2 to3 J24 – 2 to3

CLAMP = EXT * J49 – 1 to 2 J52 – 1 to 2 J55 – 1 to 2 J58 – 1 to 2 J61 – 1 to 2 J64 – 1 to 2

CLAMP = +24V * J49 – 2 to 3

J50 – 1 to 2

CLAMP = +12V * J49 – 2 to 3

J50 – 2 to 3

J51 – 1 to 2

CLAMP = +5V * J49 – 2 to 3

J50 – 2 to 3

J51 – 2 to 3

J52 – 2 to 3

J53 – 1 to 2

J52 – 2 to 3

J53 – 2 to 3

J54 – 1 to 2

J52 – 2 to 3

J53 – 2 to 3

J54 – 2 to 3

J55 – 2 to 3

J56 – 1 to 2

J55 – 2 to 3

J56 – 2 to 3

J57 – 1 to 2

J55 – 2 to 3

J56 – 2 to 3

J57 – 2 to 3

J58 – 2 to 3

J59 – 1 to 2

J58 – 2 to 3

J59 – 2 to 3

J60 – 1 to 2

J58 – 2 to 3

J59 – 2 to 3

J60 – 2 to 3

J61 – 2 to 3

J62 – 1 to 2

J61 – 2 to 3

J62 – 2 to 3

J63 – 1 to 2

J61 – 2 to 3

J62 – 2 to 3

J63 – 2 to 3

J64 – 2 to 3

J65 – 1 to 2

J64 – 2 to 3

J65 – 2 to 3

J66 – 1 to 2

J64 – 2 to 3

J65 – 2 to 3

J66 – 2 to 3

HARDWARE JUMPERS INSTALLED (HW = HARD WIRED via JUMPER)

FUNCTION PORT 6 PORT 7 PORT 8 PORT 9 PORT 10 PORT 11

GND_I/O = GND J33 – 1 to 2 J31 – 1 to 2 J29 – 1 to 2 J45 – 1 to 2 J39 – 1 to 2 J37 – 1 to 2

GND_I/O = I/0 * J33 – 2 to 3

J32 – 2 to 3

J31 – 2 to 3

J30 – 2 to 3

J29 – 2 to 3

J28 – 2 to 3

J45 – 2 to 3

J44 – 2 to 3

J39 – 2 to 3

J38 – 2 to 3

J37 – 2 to 3

J36 – 2 to 3

PORT HW AS OUTPUT * J32 – 1 to 2 J30 – 1 to 2 J28 – 1 to 2 J44 – 1 to 2 J38– 1 to 2 J36– 1 to 2

GND_CLK = GND J35 – 1 to 2 J26 – 1 to 2 J47 – 1 to 2 J46 – 1 to 2 J41 – 1 to 2 J40 – 1 to 2

GND_CLK = INPUT OR

OUTPUT *

J35 – 2 to 3

J34 – 1 to 2

J26 – 2 to 3

J27 – 1 to 2

J47 – 2 to 3

J25 – 1 to 2

J46 – 2 to 3

J48 – 1 to 2

J41 – 2 to 3

J42 – 1 to 2

J40 – 2 to 3

J43 – 1 to 2

GLOBAL CLK = INPUT * J34 – 2 to3 J27 – 2 to3 J25 – 2 to3 J48 – 2 to3 J42 – 2 to3 J43 – 2 to3

CLAMP = EXT * J73 – 1 to 2 J67 – 1 to 2 J70 – 1 to 2 J76 – 1 to 2 J79 – 1 to 2 J82 – 1 to 2

CLAMP = +24V * J73 – 2 to 3

J74 – 1 to 2

CLAMP = +12V * J73 – 2 to 3

J74 – 2 to 3

J75 – 1 to 2

CLAMP = +5V * J73 – 2 to 3

J74 – 2 to 3

J75 – 2 to 3

J67 – 2 to 3

J68 – 1 to 2

J67 – 2 to 3

J68 – 2 to 3

J69 – 1 to 2

J67 – 2 to 3

J68 – 2 to 3

J69 – 2 to 3

J70 – 2 to 3

J71 – 1 to 2

J70 – 2 to 3

J71 – 2 to 3

J72 – 1 to 2

J70 – 2 to 3

J71 – 2 to 3

J72 – 2 to 3

J76 – 2 to 3

J77 – 1 to 2

J76 – 2 to 3

J77 – 2 to 3

J78 – 1 to 2

J76 – 2 to 3

J77 – 2 to 3

J78 – 2 to 3

J79 – 2 to 3

J80 – 1 to 2

J79 – 2 to 3

J80 – 2 to 3

J81 – 1 to 2

J79 – 2 to 3

J80 – 2 to 3

J81 – 2 to 3

J82 – 2 to 3

J83 – 1 to 2

J82 – 2 to 3

J83 – 2 to 3

J84– 1 to 2

J82 – 2 to 3

J83 – 2 to 3

J84 – 2 to 3

SMP7500 Programming 23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

24 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

SECTION 3

PROGRAMMING

INTRODUCTION

The SMP7500 is accessed like any other SMIP II plug-in module. Although its register map is

slightly different than that of the switch control maps of the other SMIP plug-in modules.

References to switch, relay, or port registers are all terms used to describe the same hardware

registers contained on this module. The standard SMIP II Switch modules use the PORT registers

on this module as relay/switch registers.

REGISTER ACCESS

ADDRESSING

The SMIP II modules are VXIbus register-based devices for high-speed data retrieval. Registerbased programming is a series of reads and writes directly to the switch module registers. This

eliminates the time for command parsing thus increasing speed.

The VTI switching modules utilize either the A24 or A32 space of the shared-memory

architecture. To read or write to a module register, a register address needs to be specified. This is

done by using the offset value (assigned by the resource manager) and multiplying it by 256 or

64 k to get the base address in A24 or A32 address space, respectively

A24 Base Address = Offset value * 0x00FF (or 256)

A32 Base Address = Offset value * 0xFFFF (or 65,535)

The A24 or A32 offset value, assigned by the resource manager, can also be accessed by reading

the A16 Offset Register. To address the A16 Offset Register use the following formula:

A16 Base Address = (Logical Address * 64) + 0xC000 (or 49,152)

then

A16 Offset Register Address = A16 Base Address + 6

See following for the A16 Memory Map and the A24/A32 address space allocation.

SMP7500 Programming 25

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

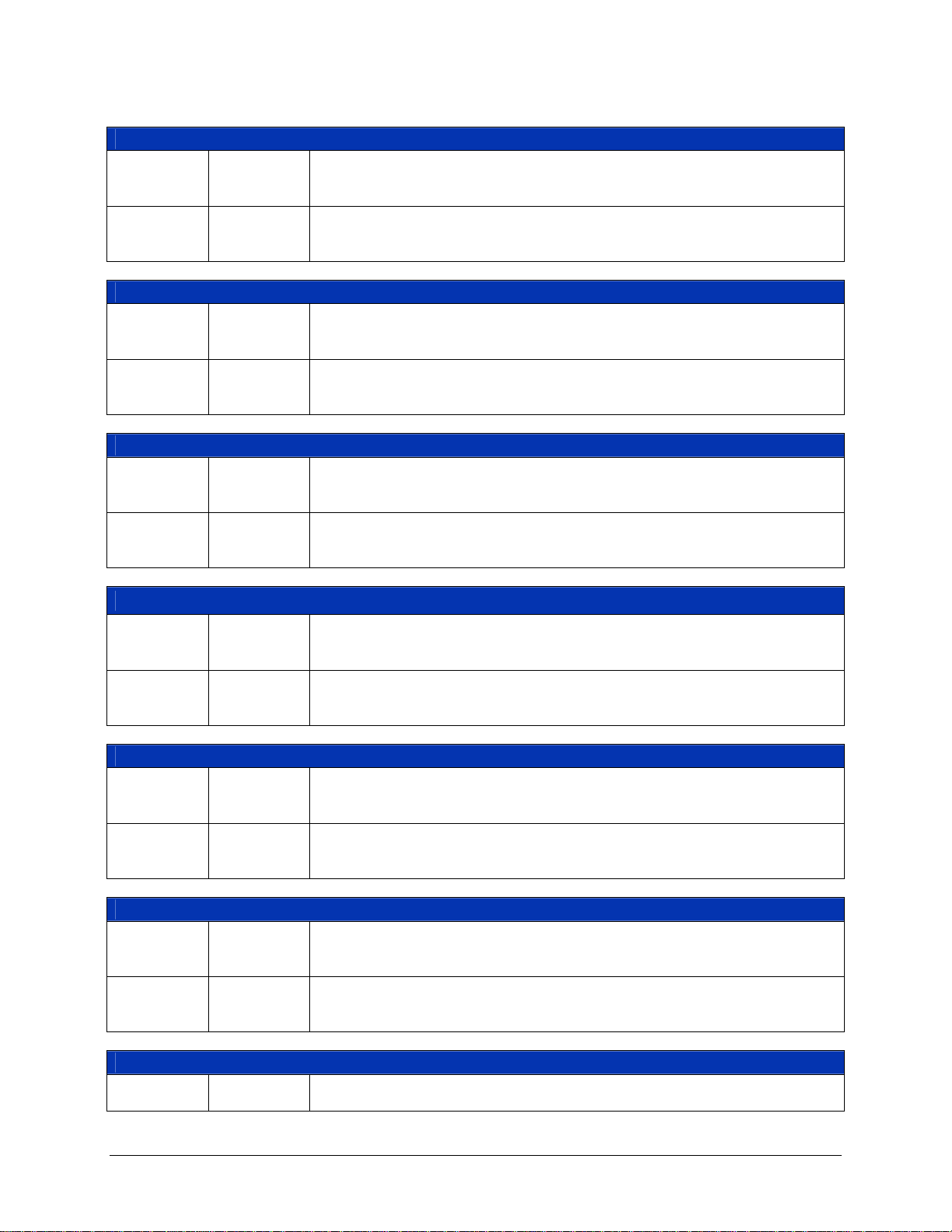

TABLE 3-1: SMIP II REGISTER MAP - A16

OFFSET WRITE FUNCTION READ FUNCTION

3E Trace Advance Board Busy

3C Busy Trigger Control Busy Trigger Control

3A Trace RAM Control Trace RAM Control

38 TTL Trigger Polarity Reserved

36 Open Trigger Select Reserved

34 Trace ADV Trigger Select Reserved

32 Trace RAM Address LOW Trace RAM Address LOW

30 Trace RAM Address HIGH Trace RAM Address HIGH

2E Trace RAM End LOW Trace RAM End LOW

2C Trace RAM End HIGH Trace RAM End HIGH

2A Trace RAM Start LOW Trace RAM Start LOW

28 Trace RAM Start HIGH Trace RAM Start HIGH

26 Module 5, 4 Used Address Reserved

24 Module 3, 2 Used Address Reserved

22 Module 1, 0 Used Address Reserved

20 NVM Access Register NVM Access Register

1E Reserved Subclass Register

1C Interrupt Control Interrupt Control

1A Reserved Interrupt Status

18 Reserved Reserved

16 Reserved Reserved

14 Reserved Reserved

12 Reserved Reserved

10 Reserved Reserved

E Reserved Version Number

C Reserved Serial Number LOW

A Reserved Serial Number HIGH

8 Reserved Reserved

6 Offset Register Offset Register

4 Control Register Status Register

2 Reserved Device Type Register

0 LA Register ID Register

26 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

DESCRIPTION OF REGISTERS - A16

The following describes the registers shown in the SMIP II Register Map for A16 address space.

ID Register- Read Only

D11-D0 Manufacturer's ID VXI Technology, Inc., set to F4B

D13-D12 Address Space

A16/A24

A16/A32 = 012

D15-D14 Device Class Extended register based device, set to 01

Logical Address Register - Write Only

Sets the new logical address in a dynamically configured module.

D7-D0 Logical Address

When set for dynamic configuration (set to FF

alter the configured logical address, while a hard reset will set the

register back to FF

D15-D8 Reserved Writing to this range has no effect.

Device Type Register - Read Only

D11-D0 Model Code Model 277, set to 115

D15-D12 Required Memory

2 Mbytes, set to 2

2 Mbytes, set to A

Status Register - Read Only

D15 A24/A32 Active

D14 MODID*

D13-D4 Reserved These bits always read as 11,1111,11112

D3 Ready This bit always reads as 12

D2 Passed This bit always reads as 12

D1-D0 Reserved These bits always read as 112

1 = indicates that A24/A32 memory space access is enabled

0 = indicates that A24/A32 memory space access is locked out

1 = indicates that the module is not selected by the MODID line

0 = indicates that the module is selected by the MODID line.

Control Register - Write Only

D15 A24/A32 Enable

D14-D2 Reserved Writes to these bits have no effect.

D1 Sysfail Inhibit

D0 Reset

1 = write a 1 to this bit to enable A24/A32 memory access

0 = to disable access

Write a 1 to this bit to prevent the module from asserting the

SYSFAIL* line.

1 = write a 1 to this bit to force the registers on the SMIP II interface

board into a reset state

0 = write a 0 to release this soft reset state

Note: This does not reset relays on the SMIP II plug-in modules.

= 00

2

.

16

16

, for A24

16

, for A32

16

16

2

) a soft reset will not

16

SMP7500 Programming 27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

Offset Register - Read and Write

The value written to this 16-bit register, times 256, sets the base

address of the A24 memory space used by the module. The value

written to this 16-bit register, times 65,536, sets the base address of

D15-D0 A24/A32 Memory Offset

the A32 memory space used by the module. A read from this register

reflects the previously written value. Because of the required

memory size, bits D4-D0 are disregarded on writes and always read

back as 0s. Upon receiving a hard reset, all bits in this register are set

to 0s. A soft reset does not effect the value in this register.

Serial Number High Register- Read Only

D15-D0 Not Implemented Always read back as FFFF

16

Serial Number Low Register - Read Only

D15-D0 Not Implemented Always read back as FFFF

16

Version Number Register - Read Only

D15-D8

D7-D4

D3-D0

Firmware Version

Number

Major Hardware Version

Number

Minor Hardware Version

Number

Not applicable, reads back as FF

16

Depends on the specific hardware revision of the SMIP II interface

board.

Depends on the specific hardware revision of the SMIP II interface

board.

Interrupt Status Register - Read Only

D15 Scan Function done The latest scan list update is complete.

D14

Openbus Active Event

true

The Openbus was activated by one or more programmed inputs. See

description of the Openbus in the module register section.

D13 = Module 5 …, and D8 = Module 0.

The programmed Busy signal from one of the modules has timed

out. This indicates that the relays actuated for that Busy cycle have

D13-D8

Modules 0-5 Busy

complete

settled and a measurement may take place.

D7-D0 Reserved Always reads back as FF

16

Note: This status register may be used in a polled fashion rather than allowing the events above to generate an

Interrupt. A read of this register will clear any active bits. Bits that are not set, or are about to be set, are

not effected by a read of this register.

28 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

Interrupt Control Register - Read and Write

D15

D14

D13-D8

Scan Function done mask

bit

Openbus Active Event

true mask bit

Module 0-5 Busy

complete

D7 IR ENA*

D6 IH ENA*

D5-D3 Interrupter IRQ Line

D2-D0 Handler IRQ Line

Note that all bits in this register are set to 1s upon receipt of a hard or soft reset.

0 = enabled

1 = disabled

0 = enabled

1 = disabled

0 = enabled

1 = disabled

D13 = Module 5,… and D8 = Module 0.

0 = writing a 0 to this bit enables interrupter capabilities

1 = writing a 1 to this bit disables interrupter capabilities

The module has no interrupt handler capability, therefore writing a 1

or 0 has no effect. A 1 is always read back for this bit.

The complement of the value programmed into these three bits

reflects the selected IRQ line used by the module. A value of 011

would select IRQ4, a value of 000

would disconnect the IRQ lines.

of 111

2

would select IRQ7, and a value

2

The module has no interrupt handler capability; therefore writing to

these bits has no effect. A 111

is always read back for these bits.

2

Subclass Register - Read Only

D15 VXIbus Extended Device Always reads as 1.

D14-D0 Extended Memory Device Always reads as 7FFD

16

NVM Access Register - Read

D15-D1 Unused All Bits are always 1.

D0

Reads back the serial data stream from the selected SMIP II board.

Note that only one SMIP II board may be read back at a time.

NVM Access Register - Write

D15-D7 Unused Data written to these bits have no effect.

D6 Serial clock for module 5; should be a logic 1 when not used.

D5 Serial clock for module 4; should be a logic 1 when not used.

D4 Serial clock for module 3; should be a logic 1 when not used.

D3 Serial clock for module 2; should be a logic 1 when not used.

D2 Serial clock for module 1; should be a logic 1 when not used.

D1 Serial clock for module 0; should be a logic 1 when not used.

D0 Serial data input for all modules; must be a logic 1 when not used.

Board X, Y Used Address Register - Read and Write

D15-D8

D7-D0

Sets the actual number of words of address space used by the relays

on board's X.

Sets the actual number of words of address space used by the relays

on board's Y.

Trace RAM Start High Register - Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1s.

D3-D0

Sets the four most significant bits of the starting address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

2

SMP7500 Programming 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Technology, Inc.

Trace RAM Start Low Register - Read and Write

D15-D0

Sets the 16 least significant bits of the starting address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Trace RAM End High Register - Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1s.

D3-D0

Sets the four most significant bits of the ending address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Trace RAM End Low Register - Read and Write

D15-D0

Sets the 16 least significant bits of the ending address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Trace RAM Address HIGH Register - Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1s.

Sets and reads back the four most significant bits of the current

D3-D0

address of the Trace RAM, allowing the current trace RAM address

to be queried and changed.

Trace RAM Address LOW Register - Read and Write

Sets and reads back the sixteen least significant bits of the current

D15-D0

address of the Trace RAM, allowing the current trace RAM address

to be queried and changed.

30 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

Trace Advance Trigger Select Register - Write Only

Sets the TTLTRIG line or lines, which are configured as outputs, and

will toggle when Trace Advance condition occurs in the module.

D15-D8

D7-D0

D15 corresponds to TTLTRIG7, D14 to TTLTRIG6, … and D8 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit

to 0 disables the corresponding line. All bits are set to 0s when either

a soft or a hard reset is received by the module.

Sets the TTLTRIG line or lines, which are configured as inputs, and

will cause a Trace Advance event to occur in the module. D7

corresponds to TTLTRIG7, D6 to TTLTRIG6, … and D0 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit

to 0 disables the corresponding line. All enabled TTLTRIG lines are

or'd together to allow more than one TTLTRIG line to cause a Trace

Advance event to occur. All bits are set to 0s when the module

receives either a soft or a hard reset.

Open Trigger Select Register - Write Only

Sets the TTLTRIG line or lines, which are configures as outputs, and

will toggle when Relay Open condition occurs in the module. D15

D15-D8

D7-D0

corresponds to TTLTRIG7, D14 to TTLTRIG6, … and D8 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit

to 0 disables the corresponding line. All bits are set to 0s when either

a soft or a hard reset is received by the module.

Sets the TTLTRIG line or lines, which are configured as inputs, and

will cause a Relay Open event to occur in the module. D7

corresponds to TTLTRIG7, D6 to TTLTRIG6, … and D0 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit

to 0 disables the corresponding line. All enabled TTLTRIG lines are

or'd together to allow more than one TTLTRIG line to cause a Relay

Open event to occur. All bits are set to 0s when the module receives

either a soft or a hard reset.

TTL Trigger Polarity Register - Write Only

D15-D14 Unused Data written to these bits have no effect.

D13-D8 FAIL LED Control D13 is for module 5, … D8 is for module 0. 0 = off, 1 = on.

D4 Board Busy Trigger Slope 0 acts on the falling edge, 1 acts on the rising edge.

D3 Relay Open Input Slope 0 acts on the falling edge, 1 acts on the rising edge.

D2 Relay Open Output Slope 0 sets the falling edge active, 1 sets the rising edge active.

D1

D0

Note: A hard or a soft reset sets D3-D0 to 0s.

Trace Advance Input

Slope

Trace Advance Output

Slope

0 advances on the falling edge, 1 advances on the rising edge.

0 sets the falling edge active, 1 sets the rising edge active.

SMP7500 Programming 31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Trace RAM Control Register - Read and Write

D15-D10 Modules Installed

D9-D4

D3-D2 Unused

D1 LOOP ENABLE

D0 TRACE ENABLE

Modules used in trace

mode

Busy Trigger Control Register - Read and Write

D15-D8 TTLTRIG Select

D7-D6 Unused

D5-D0 Busy Trigger Enable

Trigger Advance Register - Write Only

D15-D0 Unused

VXI Technology, Inc.

D15 is for module 5, D10 is for module 0. Set to 0 if the module is

installed or set to a 1 if not installed. These bits are set to 0 at power

on. By setting a 1, the SMIP II Interface PCB will generate DTACK

for any read or write cycles to the memory space of the uninstalled

plug-in modules.

D9 is for module 5, D4 is for module 0. Set to 1 if the module is used

in trace mode, set to 0 if not in trace mode.

Data written to these bits have no effect. The value written is read

back.

1 = enabled, 0 = disabled. If enabled, the trace resumes at the start of

active RAM and continues from there. If disabled, the trace stops at

the end of active RAM and clears the TRACE ENABLE bit.

1 = enabled, 0 = disabled. If the LOOP ENABLE bit is set and the

end of active trace RAM is reached, this bit will not be reset.

Sets the TTLTRIG Line or Lines, which are configured as outputs,

and will toggle at the de-assertion of a Board Busy condition sent by

the plug-in modules. D15 corresponds to TTLTRIG7, D14 to

TTLTRIG6, … and D8 to TTLTRIG0. Setting a bit to a 1 enables the

trigger line, setting a bit to a 0 disables the corresponding line. All

bits are set to 0's when either a soft or a hard reset is received by the

module.

Data written to these bits have no effect. The value written is read

back.

Enables the Board Busy signals received from the plug-in modules to

generate a trigger condition on the TTL Trigger Bus. D5 corresponds

to Board Busy Module 5, D4 to Board Busy Module 4, … and D0 to

Board Busy Module 0. Setting a bit to a 1 enables the generation of a

Trigger condition, setting a bit to a 0 disables the corresponding line.

All bits are set to 0's when either a soft or a hard reset is received by

the module.

Software can be written to enable the last board updated to generate

the TTLTrigger condition, alerting any other instruments that the

plug-in modules' relays have settled. Alternatively, all of the plug-in

modules may be enabled to generate the TTLTrigger condition.

The act of writing to this location causes a Trace Advance event to

occur in the module. The specific data written to these bits has no

effect.

32 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

Board Busy Register - Read Only

D15-D7 Unused These bits always read back as 1s.

Indicates whether the SMIP II platform is a single or double wide.

D6

0 = single wide

1 = double wide

D5

D4

D3

D2

D1

D0

A 0 read from this bit indicates the relays on module 5 have settled, a

1 indicates that the relays on module 5 are still changing state.

A 0 read from this bit indicates the relays on module 4 have settled, a

1 indicates that the relays on module 4 are still changing state.

A 0 read from this bit indicates the relays on module 3 have settled, a

1 indicates that the relays on module 3 are still changing state.

A 0 read from this bit indicates the relays on module 2 have settled, a

1 indicates that the relays on module 2 are still changing state.

A 0 read from this bit indicates the relays on module 1 have settled, a

1 indicates that the relays on module 1 are still changing state.

A 0 read from this bit indicates the relays on module 0 have settled, a

1 indicates that the relays on module 0 are still changing state.

Reserved Registers - Read and Write

D15-D0 Unused

Writing to these registers has no effect and will always read back as

.

FFFF

16

SMP7500 Programming 33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VXI Configuration Space

2MB of A24 or A32

Address Space Reserved

for VTI SMIP Module

(Assigned by the Controller)

1MB RAM

1KB Each Module

1M Memory

Allocated to Store

Module Settings

1M Memory

Allocated for

Configuration/

Relay Registers

1K Each Module

1MB RAM

Unused

Module 5 Configuration - 512 bytes

Module 5 Relays - 512 bytes

Module 4 Configuration - 512 bytes

Module 4 Relays - 512 bytes

Module 3 Configuration - 512 bytes

Module 3 Relays - 512 bytes

Module 2 Configuration - 512 bytes

Module 2 Relays - 512 bytes

Module 1 Configuration - 512 bytes

Module 1 Relays - 512 bytes

Module 0 Configuration - 512 bytes

Module 0 Relays - 512 bytes

VXI Technology, Inc.

Configurat ion Space

Switch Module Sp ecific

Configuration Registers

Relay Space

Utilized as sh o w n

in the Relay Register Map

(See Module Appendices)

F

IGURE 3-1: A24/A32 ADDRESS SPACE

34 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

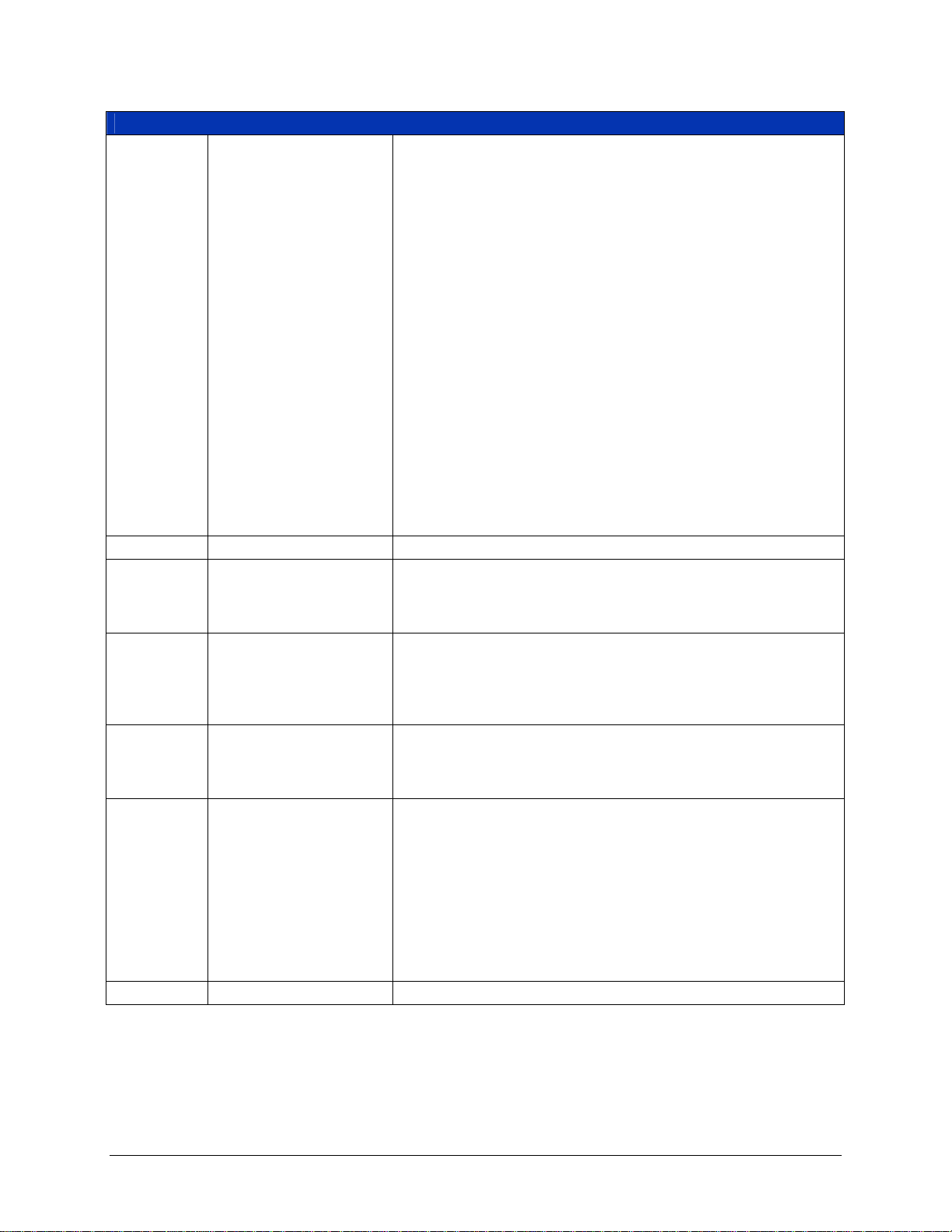

DESCRIPTION OF SMIP II MODULE REGISTERS - A24 / A32 - EXTENDED MEMORY

The SMP7500 Digital I/O Module supports direct access to the twelve 8-bit data ports via

Register Based Access of the VXIbus interface. The specific registers are located in A24 or A32

Memory Space at the offsets shown below. The data ports and control registers have been

separated to help identify their intended use. The following diagram shows A24 or A32 Memory

and the SMP7500 Data Port and Control Register Map. Note that all addresses are referenced

from the VXI module’s base address.

ABLE 3-2: A24/A32 MEMORY MAP

T

Offset Register

228 Control Reg Relay Register Write Event Select

226 Control Reg BUSYN Delay Timer

224 Control Reg BUSYN Select

222 Control Reg F/P CLK Select

220 Control Reg F/P CLK Lines R/B

21E Control Reg F/P In/Outn Lines R/B

21C Control Reg Over Current Reset

21A Control Reg Latched Over Current Sense R/B

218 Control Reg F/P Over Current Sense R/B

216 Control Reg Port 11

214 Control Reg Port 10

212 Control Reg Port 9

210 Control Reg Port 8

20E Control Reg Port 7

20C Control Reg Port 6

20A Control Reg Port 5

208 Control Reg Port 4

206 Control Reg Port 3

204 Control Reg Port 2

202 Control Reg Port 1

200 Control Reg Port 0

C Relay Register Write Event Register

A Port 11 Port 10

8 Port 9 Port 8

6 Port 7 Port 6

4 Port 5 Port 4

2 Port 3 Port 2

SMP7500 Programming 35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

DESCRIPTION OF REGISTERS – A24/A32

PORT 1/0 – Read and Write

Digital I/O PORT 0.

D7-D0 PORT 0

D15-D8 PORT 1

D7-D0 PORT 2

D15-D8 PORT 3

D7-D0 PORT 4

D15-D8 PORT 5

D7-D0 PORT 6

D15-D8 PORT 7

D7-D0 PORT 8

D15-D8 PORT 9

D7-D0 PORT 10

D15-D8 PORT 11

D15-D0 Unused

Pon state = hFF

Digital I/O PORT 1.

Pon state = hFF

PORT 3/2 – Read and Write

Digital I/O PORT 2.

Pon state = hFF

Digital I/O PORT 3.

Pon state = hFF

PORT 5/4 – Read and Write

Digital I/O PORT 4.

Pon state = hFF

Digital I/O PORT 5.

Pon state = hFF

PORT 7/6 – Read and Write

Digital I/O PORT 6

Pon state = hFF

Digital I/O PORT 7

Pon state = hFF

PORT 9/8 – Read and Write

Digital I/O PORT 8.

Pon state = hFF

Digital I/O PORT 9.

Pon state = hFF

PORT 11/10 - Read and Write

Digital I/O PORT 10.

Pon state = hFF

Digital I/O PORT 11.

Pon state = hFF

PORT WRITE EVENT- Write

A write to this register location causes an event that can be used to clock selected

PORTs on the module. Data is a don’t care.

VXI Technology, Inc.

36 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

CONTROL REGISTER PORT 11 thru 0 – Read and Write

D0 PORT Inn/Out Select

D1 PORT Register Out Select

D2 PORT Polarity Select

D4-D3

D5

D7-D6

PORT Clock to PORT

Output Select

PORT Clock to PORT

Output Polarity Select

PORT Output Clock

Select

Set to 0 to allow F/P control line to determine Port direction. Set to 1

to set Port to Output.

Note: This bit overrides the F/P In/Outn line.

Pon state = 0

Set to 0 for immediate Port operation.

Set to 1 for double buffered Port operation.

Pon state = 0

Set to 0 for non-inverted Port operation.

Set to 1 for inverted Port operation.

Pon state = 0

Value Clock selected

0 F/P CLK 11/0 respectively

1 Relay Register Write Event MUX

2 Relay Register 000Ch Write Event

3 F/P CLK Select MUX

Pon state = 0

Set to 0 for non-inverted Port Clock operation.

Set to 1 for inverted Port Clock operation.

Pon state = 0

Value Clock selected

0 GND

1 Relay Register Write Event MUX

2 Relay Register 000Ch Write Event

3 F/P CLK Select MUX

When the F/P CLK Select MUX is selected, the Port Output Clock

follows directly the F/P CLK selected. When the Relay Register

Write Event MUX or Relay Register 000Ch Write Event are

selected, the Port Output Clock will produce a 250 ns pulse at the

event selected.

Pon state = 0

SMP7500 Programming 37

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTROL REGISTER PORT 11 thru 0 (Continued) – Read and Write

Set to 0 for non-inverted Output Clock operation.

D8

D9

D11-D10

D12

D13 PORT Input Clock Select

D15-D14 Unused A write to these bits has no effect.

PORT Output Clock

Polarity Select

PORT Output Clock

Enable

PORT Clock to Input Port

Select

PORT Clock to Input

PORT Polarity Select

Set to 1 for inverted Output Clock operation.

Pon state = 0

Set to 0 to disable Output Clock generation.

Set to 1 to enable Output Clock generation.

Pon state = 0

Value: Clock selected:

0 F/P CLK 11/0 respectively

1 Relay Register Write Event MUX

2 Relay Register 000Ch Write Event

3 F/P CLK Select MUX

Pon state = 0

Set to 0 for non-inverted Clock to Input Port operation.

Set to 1 for inverted Clock to Input Port operation.

Pon state = 0

Set to 0 to select asynchronous input Port operation

Set to 1 to select synchronous input Port operation.

Pon state = 0

CONTROL REGISTER F/P OVER CURRENT SENSE - Read

The SMP7500 has 16 separate over current sense circuits. This is due

to the nature of the output drivers that are used on the module. They

are portioned by 6, and not by 8 like the PORTs themselves. A read

back of this register is a direct read back of the hardware over

current sense circuits. The non-Over Current state of these bits is 0.

Pon state = Dependent

D15-D0

Over Current Sense Lines

[15:0] Read Back

CONTROL REGISTER LATCHED OVER CURRENT SENSE - Read

The SMP7500 has 16 separate over current sense circuits. This is due

to the nature of the output drivers that are used on the module. They

are portioned by 6, and not by 8 like the PORTs themselves. A read

back of this register is a read back of a latched version of the over

D15-D0

Latched Over Current

Sense Lines [15:0] Read

Back

current sense circuits.

These bits are set to 1 by an over current occurrence. They will

remain set until reset by the corresponding Over Current Reset bit.

The non-Over Current state of these bits is 0.

Pon state = Dependent

VXI Technology, Inc.

38 SMP7500 Programming

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.vtiinstruments.com

CONTROL REGISTER OVER CURRENT RESET – Read and Write

Set to 0 for normal Over Current Sense Line operation. Set to 1 to

reset the corresponding Over Current Sense Line.

Note that the operation of the Over Current Reset Bits is edge

sensitive. The reset of an Over Current Line is initiated on the rising

D15-D0

Over Current Reset Bits

[15:0]

CONTROL REGISTER F/P IN/OUTN LINES – Read

D5-D0

D7-D6 Unused These bits are unused.

D13-D8

D15-D14 Unused These bits are unused.

F/P In/Outn Lines [5:0]

Read Back

F/P In/Outn Lines [11:6]

Read Back

CONTROL REGISTER F/P CLK LINES – Read

D5-D0

D7-D6 Unused These bits are unused.

D13-D8

D15-D14 Unused These bits are unused.

F/P CLK Lines [5:0] Read

Back

F/P CLK Lines [11:6]

Read Back

edge of the corresponding Over Current Reset Bit. If an over current

situation still exists after the reset has been initiated, the PORT/s will

remain off until the over current cause is removed, and another reset

edge is generated. This register’s read back will indicate the last

value written to the reset register.

Pon state = 0

The state of these lines is dependent on the setup of the F/P In/Outn

lines 5 thru 0. If the F/P lines are used as GND, then the read back