Page 1

VT1538A

ENHANCED FREQUENCY/TOTALIZE/ PWM

SIGNAL CONDITIONING PLUG-ON

USER’S MANUAL

82-0093-000

Release April 28, 2003

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949) 955-1894

bus

Page 2

VXI Technology, Inc.

2

Page 3

www.vxitech.com

INTRODUCTION

On May 1, 2003, VXI Technology, Inc. acquired Agilent Technology’s mechanical data acquisition product

segment. During the transition period, Agilent branded manuals will be provided with the dynamic and static data

acquisition products until the manuals have been rebranded. The following products are provided for in this manner.

Dynamic DAC Products

VTI Part Number Agilent Part Number Description

VT1432A E1432A 16-Channel 51.2 kSamples/s Digitizer Plus DPS

VT1433B E1433B 8-Channel 196 kSamples/s Digitizer Plus DPS

VT1434A E1434A 4-Channel 65 kSamples/s Arbitrary Source

VT3240A E3240A Voltage Input Breakout Box

VT3241A E3241A ICP/Voltage Input Breakout Box

VT3242A E3242A 4-Channel Charge/Voltage ICP Breakout Box

VT3243A E3243A 4-Channel Microphone/Voltage ICP Breakout Box

VT2216A N2216A VXI/SCSI Interface Module

Static DAC Products

VTI Part Number Agilent Part Number Description

VT1413C E1413C 64-Channels Muxed to 16 Bit, 100 kSamples/s A/D

VT1415A E1415A Algorithmic Closed Loop Controller

VT1419A E1419A Multi-Function Measurement and Control

VT1422A E1422A Remote Channel Multi-Function DAC Module

VT1501A E1501A Direct Input 8-Channel SCP

VT1502A E1502A Low Pass Filter Signal Conditioning Plug-On

VT1503A E1503A Gain/Filter SCP

VT1505A E1505A Current Source SCP

VT1506A E1506A 120 Ω Strain Gauge SCP

VT1507A E1507A 350 Ω Strain Gauge SCP

VT1508A E1508A 8-Channel Fixed x 16 Gain/Filer SCP

VT1509A E1509A 8-Channel Fixed x 64 Gain/Filter SCP

VT1510A E1510A 4-Channel Sample and Hold SCP

VT1511A E1511A 4-Channel Transient Strain SCP

VT1512A E1512A Low Pass Filter Signal Conditioning Plug-On

VT1513A E1513A Attenuator Input SCP

VT1518A E1518A Resistance Measurement SCP

VT1529B E1529B 32 Ch. Remote Strain Conditioning and Voltage

Unit

VT1531A E1531A 8-Channel Voltage Output Signal Conditioning

Plug

VT1532A E1532A 8-Channel Current Output Signal Conditioning

Plug-On

VT1533A E1533A 16-Bit Digital Input/Output Signal Conditioning

VT1536A E1536A Isolated 8-Bit Digital I/O Signal Conditioning

VT1538A E1538A Enhanced Frequency/Totalize/PWM Signal

Conditioning

VT1539A E1539A Remote Channel Signal Conditioning Plug-On

VT1563A E1563A 800 kSamples/s, 2-Channel Digitizer 14 Bits

VT1564A E1564A 800 kSamples/s, 4-Channel Digitizer 14 Bits

VT1586A E1586A Rack Mount Terminal Panel for 32 Channels

When rebranded manuals become available, they can be downloaded at: http://www.vxitech.com/download.asp.

3

Page 4

VXI Technology, Inc.

SUPPORT RESOURCES

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Division

VXI Technology, Inc.

7525 Granger Road, Unit 7

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail: support@vxitech.com

See http://www.vxitech.com for worldwide support sites.

4

Page 5

Agilent 75000 Series C

Agilent Technologies E1538A

Enhanced Frequency/Totalize/PWM

Signal Conditioning Plug-on

User’s and SCPI Programming Manual

Where to Find it - Online and Printed Information:

System installation (hardware/software)............VXIbus Configuration Guide*

Agilent VIC (VXI installation software)*

Module configuration and wiring.......................This Manual

SCPI programming.............................................This Manual

VXIplug&play programming ............................VXIplug&play Online Help

VXIplug&play example programs .....................VXIplug&play Online Help

VXIplug&play function reference......................VXIplug&play Online Help

Soft Front Panel information..............................VXIplug&play Online Help

VISA language information........ ........................Agilent VISA User’s Guide

Agilent VEE programming information.............Agilent VEE User’s Manual

*Supplied with Agilent Command Modules , Embedded Controllers, and VXLink.

Manual Part Number: E1538-90004

Printed in U.S . A . E0600

Page 6

Page 7

Enhanced Frequency/Totalize/PWM SCP

About this Manual

Agilent E1538A

This manual describes how to configure the Signal Conditioning Plug-on

(SCP) using SCPI commands and explains the cap abilities of thi s SCP. The

contents of this manual are:

• Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

• Identifying the Plug-on (IMPORTANT). . . . . . . . . . . . . . . page 5

• Setting Configuration Switches . . . . . . . . . . . . . . . . . . . . . page 6

• Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

• Connecting To The Terminal Module. . . . . . . . . . . . . . . . . page 7

• Recommended Signal Connections . . . . . . . . . . . . . . . . . . page 8

• Input and Output Characteristics. . . . . . . . . . . . . . . . . . . . . page 9

• Programming With SCPI Commands. . . . . . . . . . . . . . . . page 11

--Configuring I/O Direction . . . . . . . . . . . . . . . . . . . . . . page 12

• Programming Input Channels . . . . . . . . . . . . . . . . . . . . . . page 12

--Setting the Input Threshold Level . . . . . . . . . . . . . . . . page 12

--Set Input Logic Sense. . . . . . . . . . . . . . . . . . . . . . . . . . page 13

--Reading Static Digital State . . . . . . . . . . . . . . . . . . . . . page 14

--Totalize Positive or Negative Edge State Changes. . . . page 15

--About Period and Frequency Measurements . . . . . . . . page 16

--Measure Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

--Measure Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

--Measure Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

--Sense Quadrature Position . . . . . . . . . . . . . . . . . . . . . . page 21

--Sense Rotational Velocity. . . . . . . . . . . . . . . . . . . . . . . page 22

• Programming Output Channels. . . . . . . . . . . . . . . . . . . . . page 24

--Controlling Output Polarity . . . . . . . . . . . . . . . . . . . . . page 24

--Output Static Digital State . . . . . . . . . . . . . . . . . . . . . . page 24

--Variable Width Pulse Per Trigger. . . . . . . . . . . . . . . . . page 25

--Variable Width Pulse Train (PWM) . . . . . . . . . . . . . . . page 26

--Variable Frequency Fixed Width Pulse Train (FM) . . . page 27

--Variable Frequency Square-Wave Pulse Train (FM) . . page 28

--Rotationally Positioned Pulse Output. . . . . . . . . . . . . . page 29

--Rotational Pulse Command Usage. . . . . . . . . . . . . . . . page 30

--Stepper Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . page 37

• *RST and *TST (important!) . . . . . . . . . . . . . . . . . . . . . . page 41

• SCPI Command Reference . . . . . . . . . . . . . . . . . . . . . . . . page 42

• Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 77

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 3

Page 8

Introduction

The Agilent E1538A provides eight TTL compatible channels of digital I /O.

Channels can be individu ally configured to perfor m any one of the following

functions:

•Input:

-- Static digital state

-- Frequency measurement

-- Period meaurement

-- Totalize positive or negative signal transitions

-- Pulse width measurement

-- Rotational velocity (senses added or missing cogwheel teeth)

-- Quadrature position. (requires 2 channels)

•Output (configurable as Open Drain or passive pull-up):

-- Static digital state

-- Single pulse-per-trigger: Generates a pulse at each algorithm

execution. The pulse width is controlled by the algorithm.

-- Pulse Width Modulation: A free-running pulse train where a SCPI

command pre-configures the frequency and the algorithm controls

the pulse width.

-- Frequency Modulation: A free-running pulse train where a SCPI

command pre-configures th e puls e width and t he alg ori thm con trols

the frequency. In this FM mode the duty cycle varies with

frequency.

-- Frequency Modulation: A free-running pulse train where the duty

cycle remains constant at 50% while the algorithm controls the

frequency.

-- Rotationally positioned pulse: The algorithm controls the angular

pulse position (relative to an input sensing rotational velocity). The

pulse width is fixed by a SCPI command. (requires a reference

channel in addition to any rotational pulse output channels)

-- Rotationally positioned pulse: The algorithm controls the width of

the pulse. The angular pulse position (relative to an input sensing

rotational velocity) is fixed by a SCPI command.(requires a

reference channel)

-- Stepper Motor Control: Controls 2-phase and 4-phase motors in

4 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 9

both full and half step modes.(requires 2 or 4 channels)

The logical sense of i nput and output c hannels can be conf igured as inverte d

or normal.

Input-configured c hannels have individ ually programmable t hreshold levels

that can range from -46V to +46V.

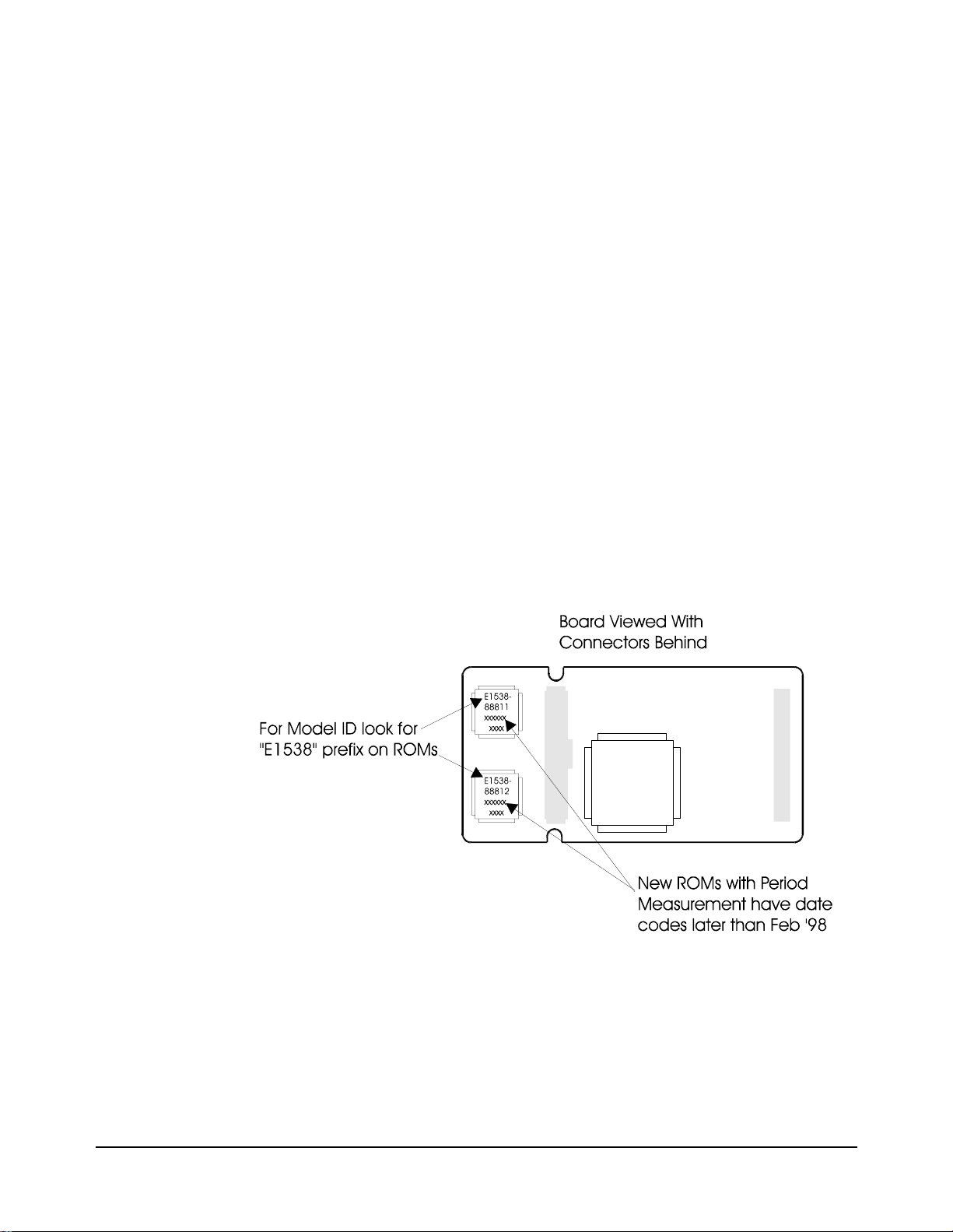

Identifying the Plug-on (IMPORTANT)

There are two versions of the E1538A. The e arly vers ion does not support a

PERiod measurement command set. Early versions have ROM revision

February 1998 and e ar lier . The l at er version adds period me asu re me nt, and

an improved frequency mea surement function. The later v ersions have ROM

revision after February 1998.

In order to access t he additional f unctions of the la ter E1538A, you must us e

one of the following drivers:

•The Plug & Play driver with revision A.02.07 or later

•The Command Module driver with revision A.05.11 or later

To determine the driver revision, execute the *IDN? command.

Figure 1. Identifying the SCP and its ROM Revision

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 5

Page 10

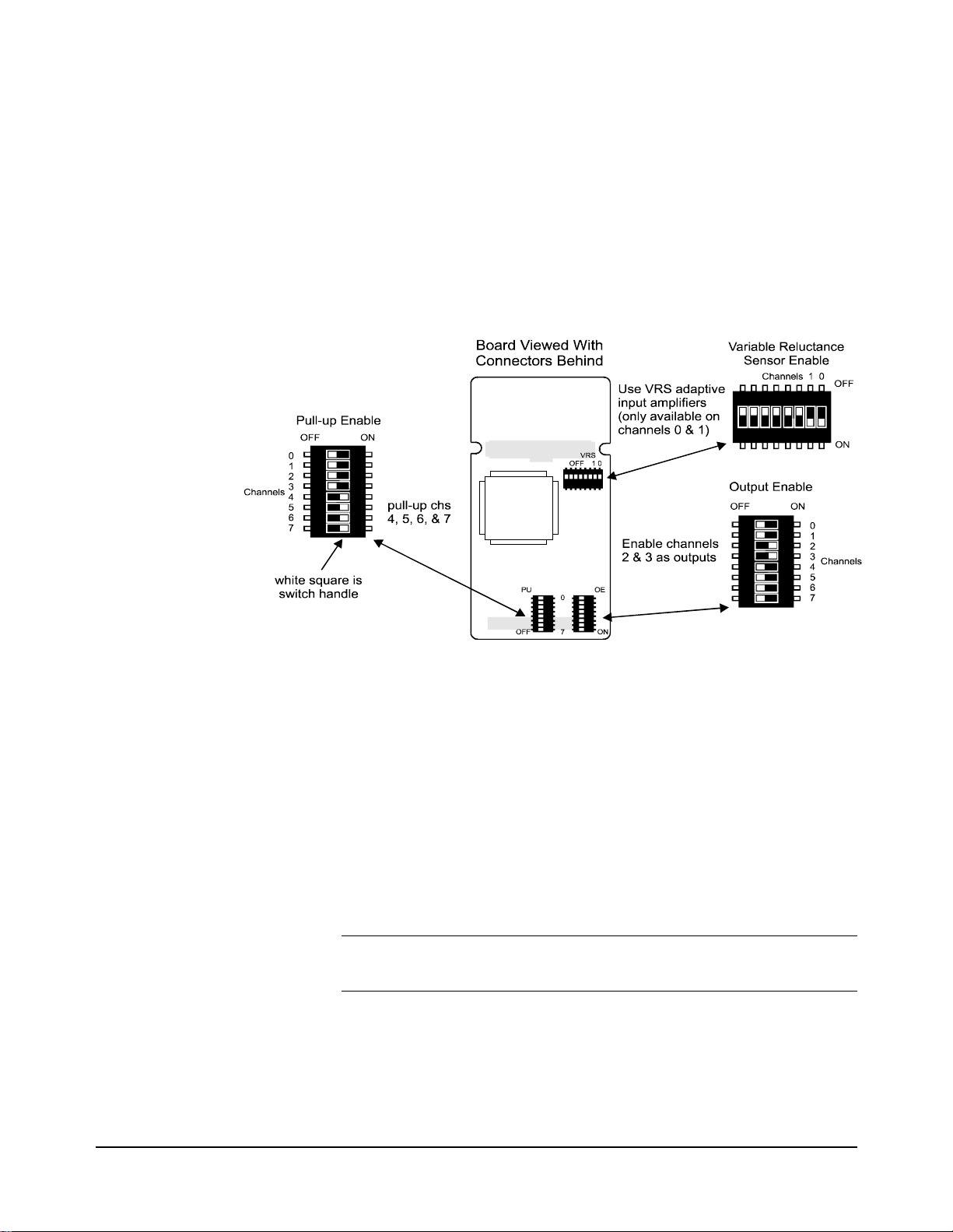

Setting Configuration Switches

The SCP has three packages of eight switches ea ch. The package labele d OE

(Output Enable) determines a channel’s I/O direction. The package labeled

PU (pull-up) controls whethe r or not a channel is float ing or pulled up to an

internal 5V supply. The package labeled VRS (for channels 0 and 1 only)

can enable special input signal conditioning compatible with variable

reluctance sensors. Fo r a discussion on using t he VRS mode, see "VRS Mode

Input Operation" on page 10.

Locating switches Figure 2 shows the location of each channel’s configuration switches.

Configuring Input-

Output direction

Configuring Channel

Pull-up Resistor

Note Pull-Up enable ON is not allowed for channels that have their VRS enable

Figure 2. Switch Location and Example Settings

Refer to Figure 2 for the location of t he eight Output Enable (OE) swit ches.

Move the channel’s switch handle to the ON pos it io n for output, and to t he

OFF position for input.

Refer to Figure 2 for the location of the eight Pull-up Enable (PU) switches.

Move the switch handle to the ON position to connect the pull-up resistor

(connected f rom channel terminal to an internal +5V), and to the OFF

position to disconn ect the pul l-up resis tor (high im pedance input/ open drain

output).

ON (VRS is only available on channels 0 and 1).

6 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 11

Installation

Installation for this Plug-on is identical to other SCPs and is covered in

Chapter 1 of your Agilent E1415 or E1419 User’s Manual.

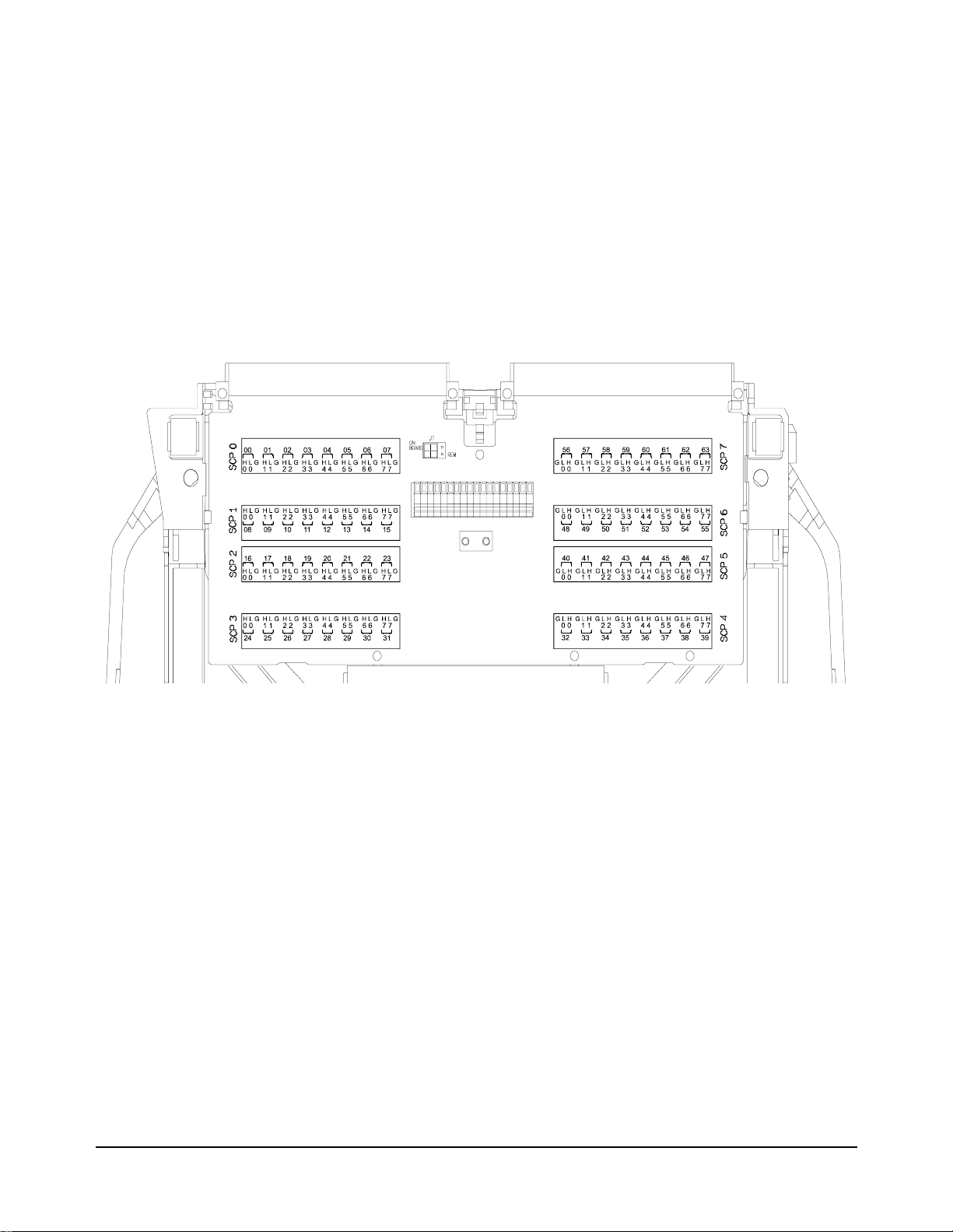

Connecting To The Terminal Module

The SCP connections for the Terminal Modules are shown on the

self-adhesive labels that come with the SCP. Use these to label terminal

definitions on your t erminal module. The connections are shown in Figure 3.

Figure 3. E1538A Terminal Module Connections

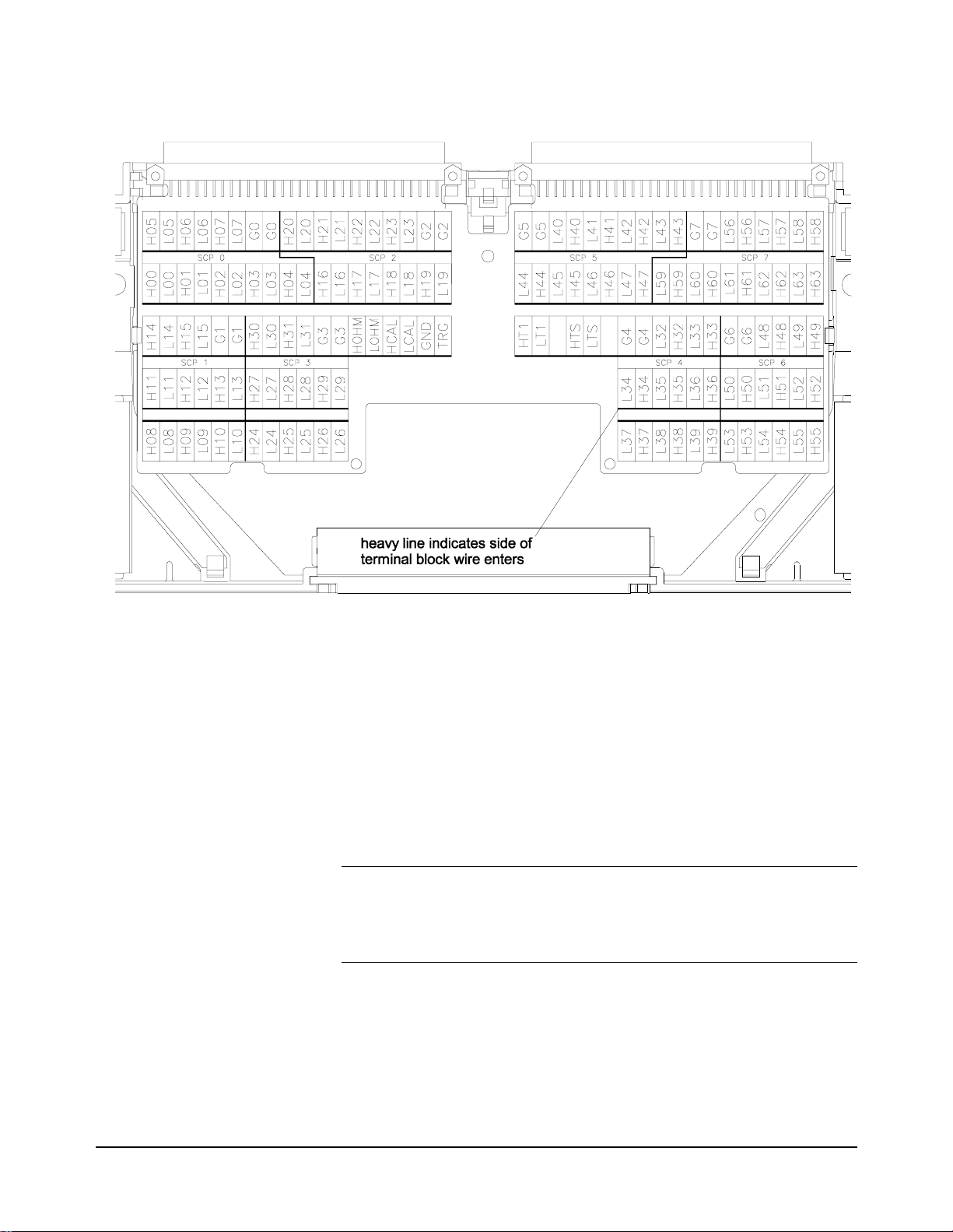

Figure 4 shows the screw terminal Option 11 for the E1419A.

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 7

Page 12

Figure 4. E1419A Option 11 Terminal Module Connections

Recommended Signal Connections

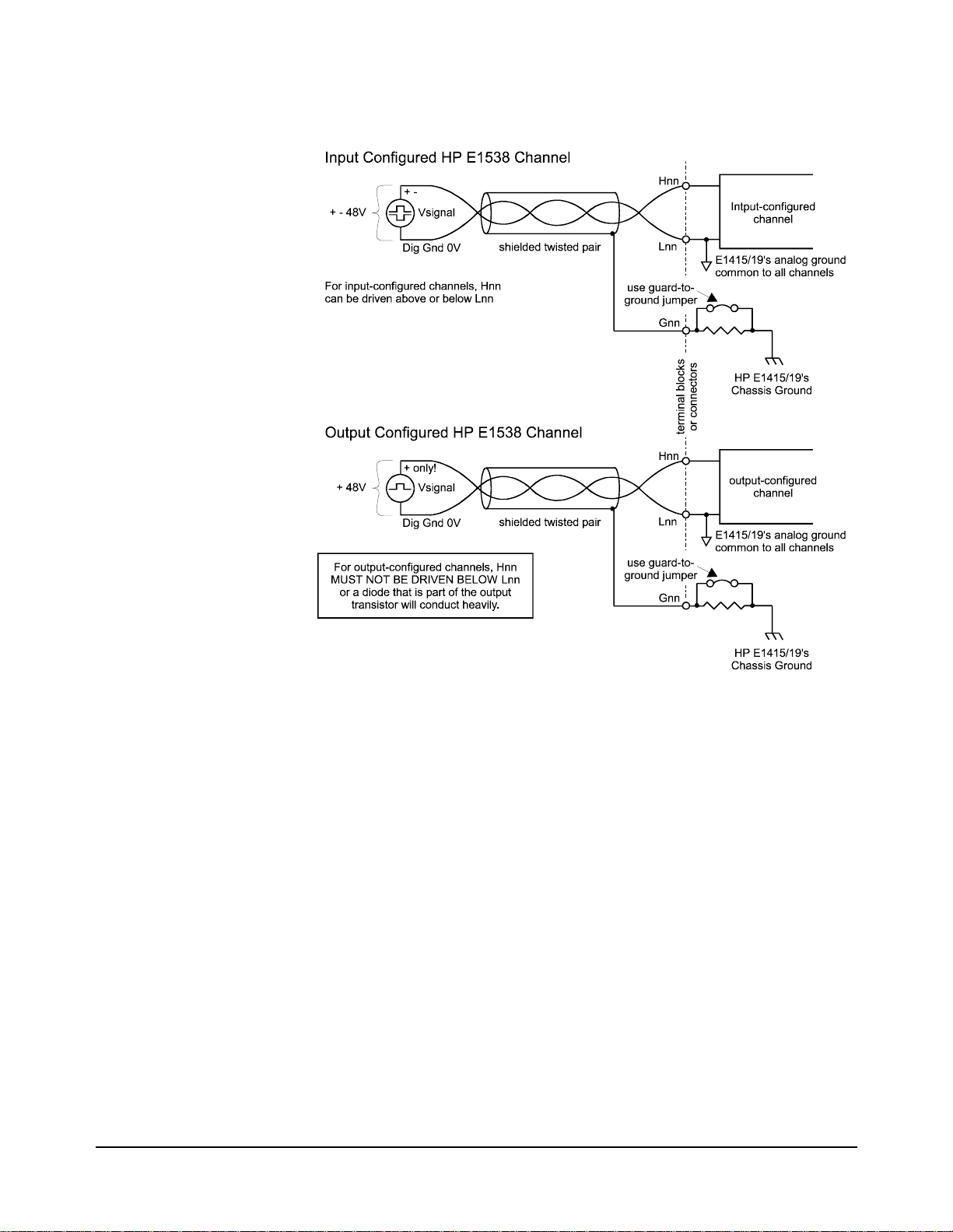

Figure 5 shows the reco mmended meth od of wir ing di gital I/O ch annel s, as

well as the maximum voltage limitation s for the E1538 A.

Figure 5 shows the shields connected directly to the E1415 ground. This is

to limit potential nois e on the digital wiring from affecting low- level analog

channel wiring within the Terminal Module.

Note The G (analog guard) terminals are connected through 10K Ohm resistors

to chassis ground. To connect the shields directly to chassis ground on the

E1415 and the E1419 Option 12 Terminal Module, install the

guard-to-ground jumpers for the E1538 channels

8 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 13

Figure 5. Recommended Connections and Voltage Limits

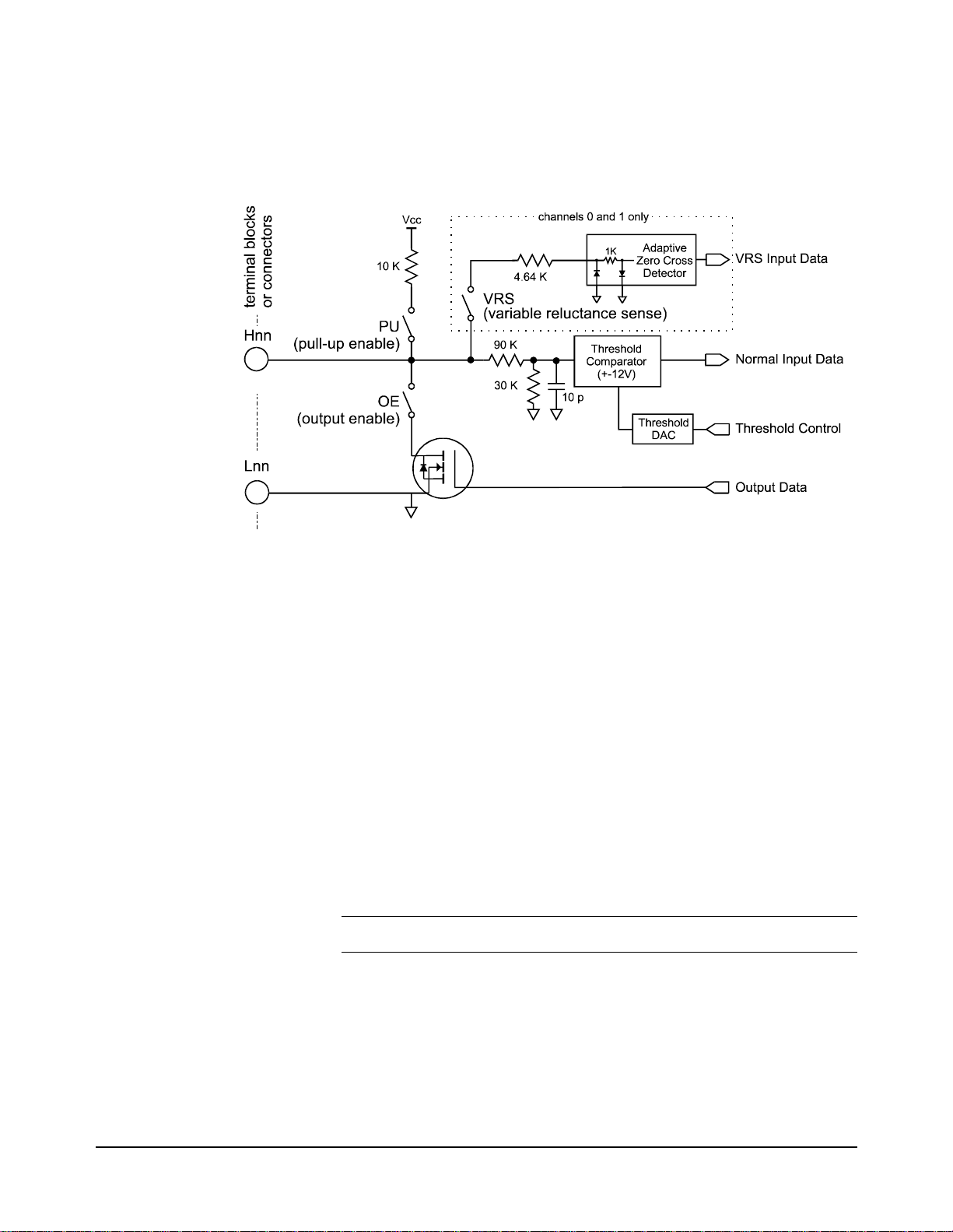

Input and Output Characteristics

This section describes the E1538’s channel input and output electrical

characteristics. Refer to Figure 6 for the following discussions.

Input Characteris tics When configured for input, E1538 channels provide digital i nput through the

threshold comparator . The digital input threshold l evel is programmable with

a SCPI command from -48 to +47.625 VDC in .375V steps (relative to the

Lnn terminal). The threshold amplifier also provides typically 0.5 volts of

hysteresis regardless of the threshold level setting. The input impedance in

this configuration is greater than 100KΩ (as long as the 10KΩ pull-up resistor

is OFF).

Channels 0 and 1 also provide the cap abi li ty (when the VRS switch is ON)

to read the output of vari able reluctance sensors. Because the ou tput of a VRS

varies in rela tion to the velocity of the toothed wheel it is r eading, the E1538A

provides adaptive ampl ifiers for these channels. The fu nction of the amplifier

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 9

Page 14

is to maintain a constant-l evel digital o utput while the input varies from

millivolts to several tens of volts.

For simple sensing of switches and open collector logic devices, a channel ’s

pull-up resistor can be connected by closing its PU switch.

Figure 6. The E1538A Input/Output Characteristics

VRS Mode

Input Operation (SCP

channels 0 & 1 only)

Note VRS enable ON is not allowed if PU enable is ON.

When the VRS configuration swit ch is set to on, the input signal conditioning

for that channel is changed to make it compatible with a typical variable

reluctance sensor. The var iable reluctance sensor is common ly used to detect

rotational shaft po sition and/or velocity. Because th e voltage output of a VRS

is proportional t o t he rate of change of a magnetic field, d if fe ren t rotational

velocities genera te different signal ampli tudes. The VRS-configured chann el

detects the negative going zero-crossin g point of the signal. To mini mize the

effects of input nois e, the zer o-crossi ng detecto r can only be tr iggered i f the

positive-going portion of the signal exceeded an "arming" threshold. The

arming circuit is reset whe n zero-cross ing detector is triggered s o it can’t

re-trigger until after the signal exceeds the arming threshold again. The

arming threshold t racks the positive p eak input level and i s 80% of t his peak

value. By sensing th e "zero-crossing" point of t he input signal, the VRS mode

isolates signal amplitude changes from affecting signal timing.

At high rotational speeds, variable reluctance sensors can generate voltage

levels over 100VAC. The VRS i nputs must be protecte d against signal levels

over 17.5 Volts. If your VRS will generate voltages over 17.5, you must

provide a resistor in series with the VRS input. The user-supplied resistor,

together with the VRS input’s 5.38K input impedance form a voltage di vider

that attenuates the input signal at the channel’s Hi input terminal. Use the

10 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 15

V

formula to calculate the p rotection resis tor’s value.

R

external

---------------------------------------

=

sensor

0.0032

17.5–()

Figure 7 shows the VRS mode input characteristics.

Figure 7. VRS Mode Input Characteristics

Output Characteristics The output stage of the E1538A is simply a MOS FET transistor that is

configured as "open-drain" when the pull-up resistor is not connected (PU

switch is OFF). For simple interfacing to logic devices, the pull-up resistor

can be connected by t urning the PU switch ON. Oper at in g vo lt age s ( out put

transistor off) at an out put-c onfigu red c hannel can range from 0 to 4 8 volt s.

The output can sink up to 100mA of current (output transistor on).

Caution If the Hnn terminal is driven below the Lnn terminal while a

channel is output-configured, an "inherent diode" in the output

transistor will conduct heavily. This reverse current must be

limited to 100mA, or damage to the SCP could result.

Note The *RST and power-on condition (true also after *TST) for output-

configured channels will output a logical one (open-drain output off). You

should keep this behavior in mind when applying the E1415 to your

system. It is best to have your system’s digital inputs use a high (one) as

their safe state.

Programming With SCPI Commands

The SCPI commands shown here conf igure E1538 functions. The E1415 and

E1419 don’t provide SCPI commands to read an input channel or control an

output channel. This communication with the SCP is provided by the

Algorithm Language. Examples will show communicat ion wit h al gori t hms.

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 11

Page 16

Checking the ID

of the SCP

To verify the SCP type(s) installed on your VXI module, use the

SYSTem:CTYPe? (@<channel>) command.

•The channel parameter specifies a single channel in the channel range

covered by the SCP of inter est. The first chann el number for each of the

eight SCP positions are; 0,8,16,24,32,40,48, and 56.

The value returned for the E1538A SCP is:

HEWLETT-PACKARD,E1538A Enhanced Frequency/Totalize/PWM SCP,0,0

To determine the type of SCP installed on channels 0 through 7 send

Configuring the

Channels

SYST:CTYPE? (@100)

enter statement here

The E1538A has eight digit al channels. The Power -on and *RST state is that

all input-configured channels sense static digital state

(SENS:FUNC:COND), and all output-configured channels output static

digital state (SOUR:FUNC:COND). Logical sense is normal

(INP:POL NORM and OUTP:POL NORM).

query SCP type @ ch 0

enter response string

Configuring I/O Direction Channels are configured for input or output with the I/O direction switches

(see "Setting Configuration Switches" on page 6).

Programming Input

Channels

Setting the Input

Threshold Level

This section deals wit h all asp ects of progr amming inpu t channel functions.

Channels are configured for input with the I/O direction switches (see

"Configuring Input-Output direction" on page 6). A related error message:

3123,"E1538 OE switch ON conflicts with this command."

The E1538 allows progra mmatically setting the input threshold level for each

input configured channel. The input threshold can be set from -46VDC to

+46VDC with .375V resolution. While input polarity is set to NORMAL, an

input level higher than the threshold level is considered a logic one, and an

input level lower than the threshol d level is considere d a logic zero. If input

polarity is set to INVerted, an input level higher than the threshold level is

considered a logic zero and an input level lower than the threshold level is

considered a logic one. To set input threshold level use the command

INPut:THReshold:LEVel <level>,(@<ch_list>)

•<level> is a value between -46 and +46 inclusive. The resolution for

<level> is 0.375 Volts. The *RST and power-on default for <level> is

1.78 volts.

Note The value se nt for <level> will be rounded to the nearest multiple of 0.375

Volts. For instance, 5 would be 4.875, 10 would be 10.125, 9.5 would be

9.375, and 15 would be 15. The INP:THR:LEV? query will return the

actual setting.

12 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 17

•Channels in <ch_list> must be input configured channels

Determining the Input

Threshold Level

To determine a channel’s input threshold level, use the command:

INPut:THReshold:LEVel? (@<channel>)

Note Because the E1538 rounds <level> to the nearest multiple of 0.375, the

returned value can be different from the value sent.

•<channel> must specify a single input-configured channel.

•INP:THR:LEV? returns a numeric value between -46 and +46. The

C-SCPI type is int32.

To query the threshold level on the second channel at SCP position 4 send:

INP:THR:LEV? (@133)

enter statement here

Set Input Logic Sense Use INPut:POLarity NORMal | INVerted,(@<ch_list>) to configure inp ut

channel logic sense. The operation is as follows:

INP:POL NORM input voltage greater than the threshold level sends a

value of 1 (one) to the algorithm channel specifier.

query 2nd chan on SCP pos. 4

returns threshold value

INP:POL INV input voltage greater than the threshold level sends a

value of 0 (zero) to the algorithm channel specifier.

To configure channels 40 to 43 to sense low input as logic 1

INP:POL INV,(@140:143)

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 13

Page 18

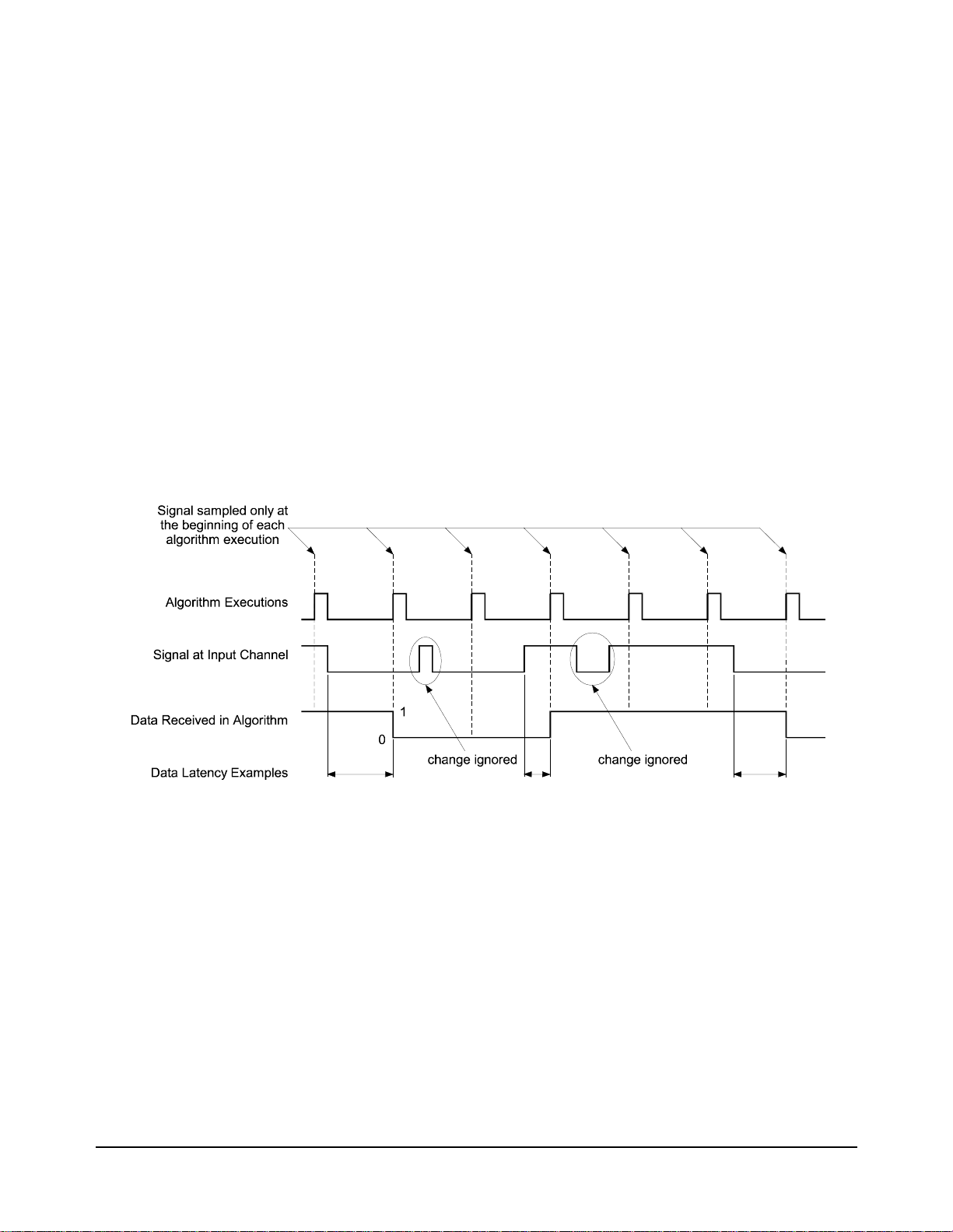

Reading Static

Digital State

This means reading a channel’s current digital state when an algorithm

executes. This is the default function assigned to all digital input channels

after *RST and at power-up. To set individual channels to this function use

the SCPI command [SENSe:]FUNCtion:CONDition (@<ch_list>). The

value returned to an algorithm is a floating point representation of 0 or 1,

depending on the stat e of the input signal and the channel’s INP:POL setting.

To set channels 40 through 43 to input digital states

*RST

SENS:FUNC:COND (@140:143)

ALG:DEF ’ALG1’,’ writecvt(I140,40); writecvt(I141,41); writecvt(142,42);

writecvt(143,43);’

INIT

do loop

SENSE:DATA:CVT? (@40:43)

read 4 CVT values

end loop

default for all dig inputs

Figure 8. Input Static Digital States

14 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 19

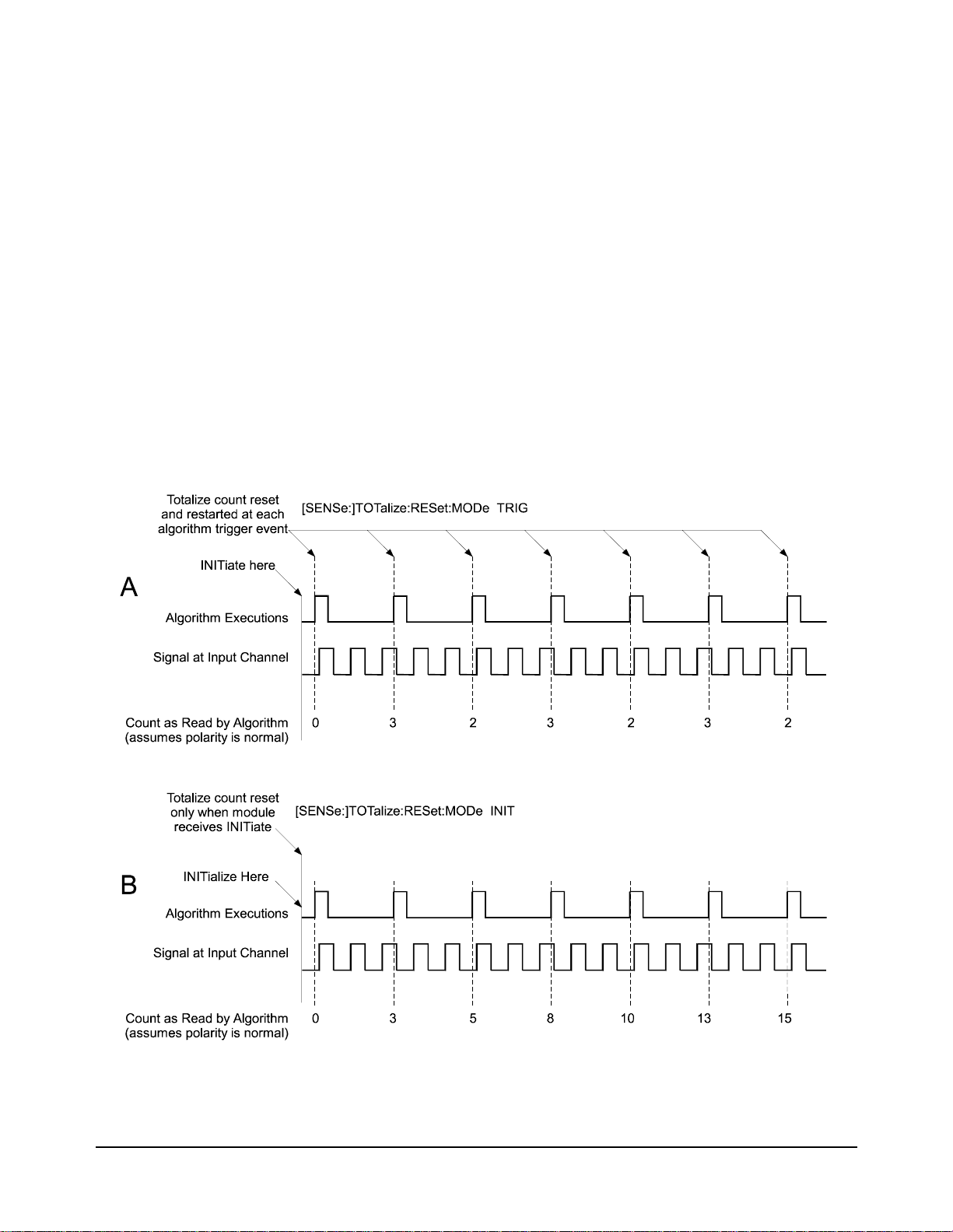

Totalize Positive or

Negative Edge State

Changes

Use [SENSe:]FUNCtion:TOTalize (@<ch_list>) to configure channels to

totalize. Totalize means to simply count state transitions (either positive

going, or negative going). Figure 9 A shows totalizing transitions between

each algorithm executi on. Figure 9 B shows totalizing all transitions starti ng

from the time the module last received an INITiate command.

Use [SENSe:]TOTalize:RESet:MODe INIT | TRIG,(@<ch_list>) to

configure the total ize channel to either reset its count once each trigger e vent,

or only when the module is INI Tiated. Use INP:POL INV to sen se negati ve

edges. The count capacity is 16,777,215 (24-bits, unsigned)

To totalize state changes at channel 44 starting fro m INITiate time

*RST

SENS:TOT:RES:MOD INIT,(@144)

SENS:FUNC:TOT (@144)

ALG:DEF ’ALG1’,’writecvt(I144,44);’

INIT

. . .

SENS:DATA:CVT? (@44)

ch 44 totalize reset at INIT

ch 44 is totalize input

alg sends coun t to CVT

get totalize count from cvt

Figure 9. Input Totalize Count

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 15

Page 20

About Period and

I

Frequency

Measurements

The E1538A actually measures signal period for both the period and

frequency functions. If the measurement function is set to frequency rather

than period, the SCP returns the recipro cal of the measured period. The

resolution of each per iod measurement is ba sed on the time proce ssor chip’s

timer period (238.4nS). To improve resolution on faster input signals,

multiple signal periods can be measured and averaged. For period

measurements there are two dif fe ren t mode s tha t ca n be used to control the

number of periods to average. For frequency measurements only the

APERture mode is available.

1. The [SENSe:]PERiod:NPERiod mode explicitly sets the number of

signal periods to measure and average. The time it takes the SCP to

return a reading is dependent on the input signal period (for a given

NPERiod setting), longer signal periods take longer to return a

reading.

In NPERiod mode the actual measurement resolution (in seconds) is

fixed while the relati ve r eso lut i on (as a percentage of the inpu t si gna l

period) is variable. That is, when NPERiods is set to provide an

adequate resolution for short period signals, long period signals will

have increased resolution.

2. The APERture mode sets a fixed duration that the SCP will use to

measure multiple signal periods. The actual effective APERture

<time> will be:

<time>

.

--------------------------------

NT

signal_period

signal_period×

The minimum aperture will be 1 signal peri od, and the maximum wil l

be 255 signal periods.

In APERture mode, the effective resolution (in seconds) varies with

the period of the input signal. That is, as the signal period is reduced,

the number of measurements averaged increases, thereby improving

the effective resolution. However, the relative resolution (as a

percentage of the input signal period) is fairly constant with changes

in signal period.

Generally, more measurements (greater NPERiod count or longer APERture

time) means a more accura te frequency value. Of course more measurements

means that the read ing retur ned contains mor e latency (i s “older” in relati on

to the signal's c urrent frequency). To trac k fast changing frequen cy, you have

to trade-off some accuracy with a shorter aperture time.

16 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 21

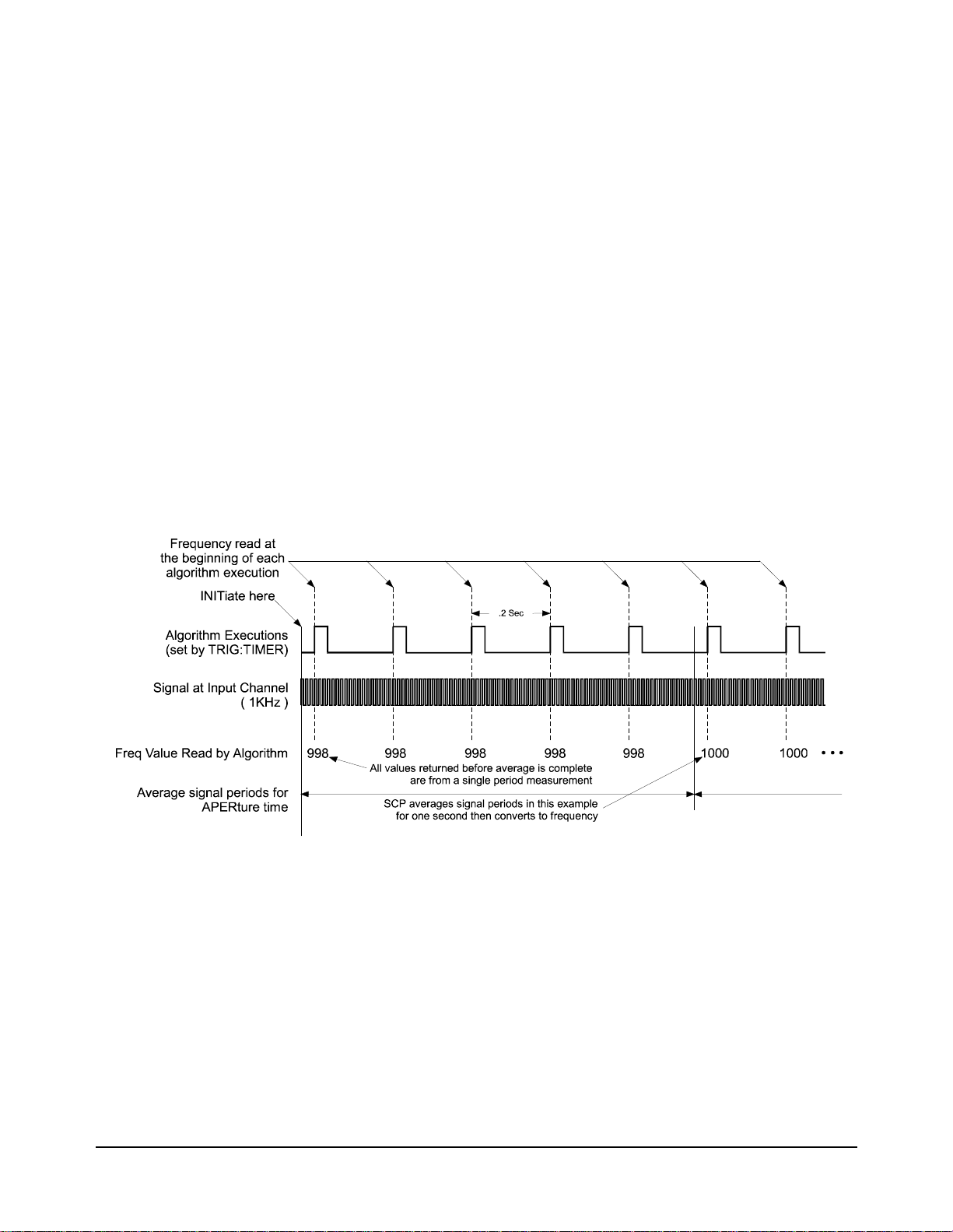

Measure Frequency Use [SENSe:]FREQuency:APERture <time>,(@<ch_list>) to configure

the frequency counter channels’ measurement interval.

Use [SENSe:]FUNCtion:FREQuency (@<ch_list>) to configure channels

to measure signal frequency.

To measure frequency at channel 45 with aperture of 1 second

*RST

TRIGGER:TIMER .2

SENS:FUNC:FREQ (@145)

SENS:FREQ:APER 1,(@145)

ALG:DEF ’ALG1’,’writecvt(I145,45);’

INIT

do loop

SENS:DATA:CVT? (@45)

read value from CVT query above

end loop

Alg executes at .2 sec intervals

ch 45 is frequency counter

meas and avg sig periods for 1S

alg puts frequency in CVT

start algorithm execution

get frequency from CVT

Figure 10. Input Frequency

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 17

Page 22

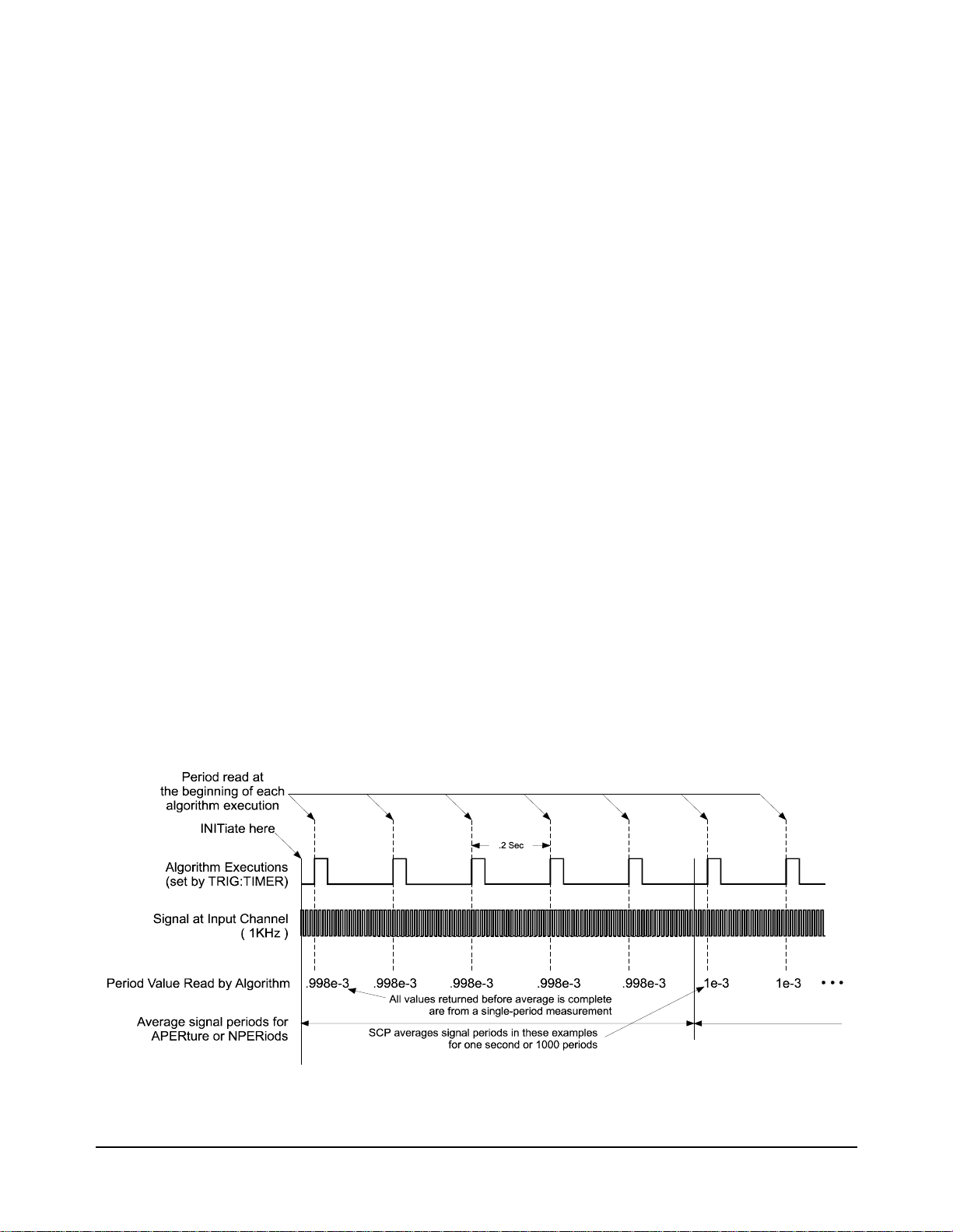

Measure Period Use [SENSe:]PERiod:MODe APERture | NPERiods,(@<ch_list>) to select

the measurement interval setting mode.

Depending on the mode selected above use

[SENSe:]PERiod:APERture <time>,(@<ch_list>) or

use [SENSe:]PERiod:NPERiods <n_periods>,(@<ch_list>) to set the

interval for measuring and averaging signal periods.

For PERiod function, the E1538 spports two distinct measurement ranges:

1. When SENS:PER:RANGE is set to 1sec, the E1538 can measure

periods from 10usec - 1sec . The value of SENS: PER:APER can range

from 10usec - 1sec.

2. When SENS:PER:RANGE is set to 4sec, the E1538 can measure

periods from 40usec - 4sec . The value of SENS: PER:APER can range

from 40usec - 4sec. See SENS:PER:RANGE command on page 61

Use [SENSe:]FUNCtion:PERiod (@<ch_list>) to configure channels to

measure signal period.

To measure the signal period at channel 45 with aperture of 01 second

*RST

TRIGGER:TIMER .2

SENS:FUNC:PER (@145)

SENS:PER:RANGE 1,(@1 45)

SENS:PER:MODE APER(@145)

SENS:PER:APER 1,(@145)

ALG:DEF ’ALG1’,’writecvt(I145,45);’

INIT

do loop

SENS:DATA:CVT? (@45)

read value from CVT query above

end loop

Alg executes at .2 sec intervals

ch 45 to measure signal period

set period range 10µsec - 1sec

set meas and avg interval mode

meas and avg sig periods for 1S

alg puts period in CVT

start algorithm execution

get period from CVT

Figure 11. Input Period

18 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 23

To measure period at channel 45 as the average of 1000 signal periods:

*RST

TRIGGER:TIMER .2

SENS:FUNC:PER (@145)

SENS:PER:RANGE 1,(@1 45)

SENS:PER:MODE NPER(@145)

SENS:PER:NPER 1000,(@145)

ALG:DEF ’ALG1’,’writecvt(I145,45);’

INIT

do loop

SENS:DATA:CVT? (@45)

read value from CVT query above

end loop

Alg executes at .2 sec intervals

ch 45 to measure signal period

set period range 10µsec - 1sec

set meas interval by n periods

meas and avg 1000 sig periods

alg puts period in CVT

start algorithm execution

get period from CVT

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 19

Page 24

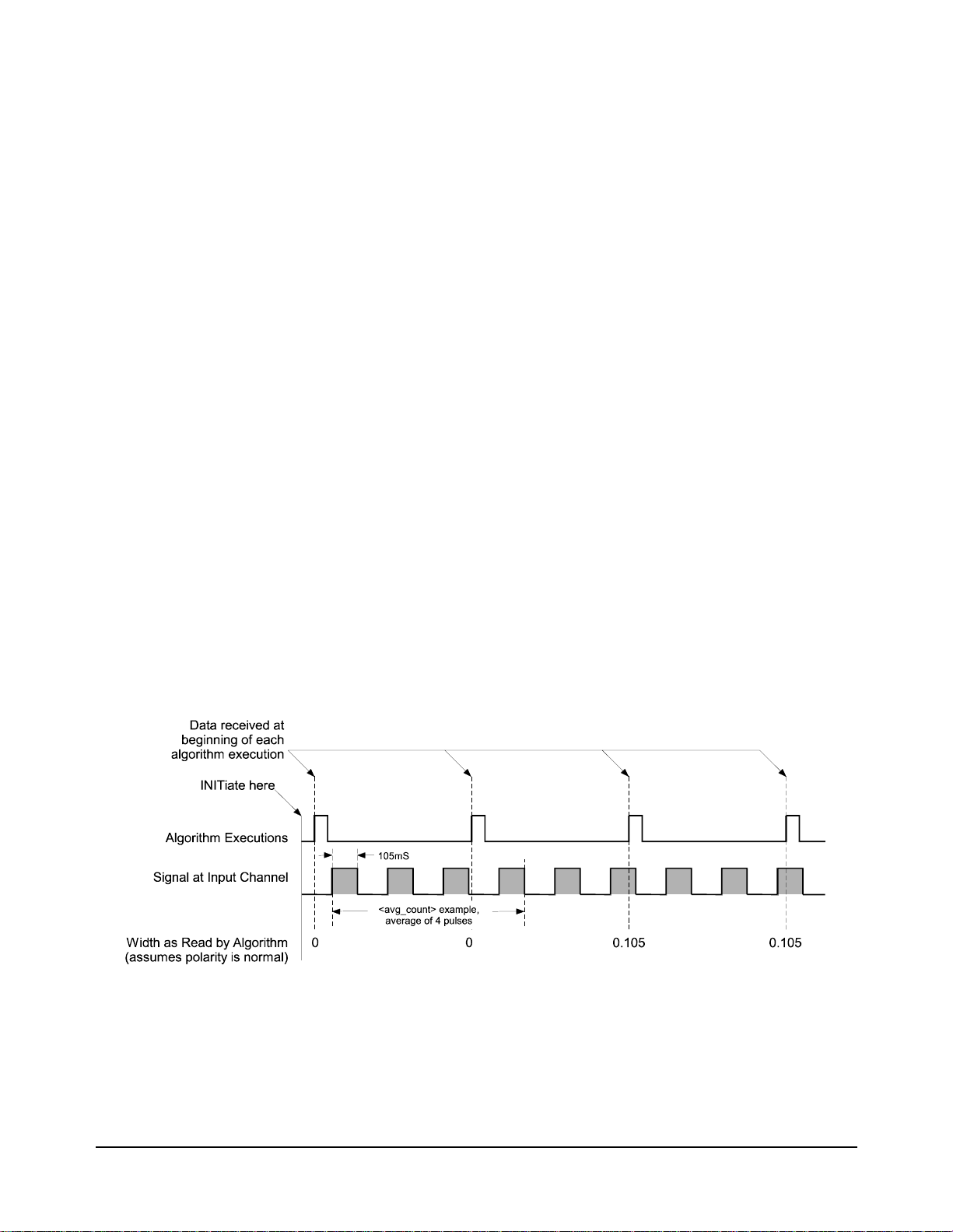

Measure Pulse Width This means that the E1538 will measure the width of the logic 1 portion of

a pulse. The pulse width is sent to the algorithm in units of seconds. To

measure the high portion of a pulse (positive going edge to negative going

edge) set the channel input polarity to INP:POL NORM,(@<ch_list>). To

measure the low port ion of the pulse (negat ive g oing e dge to posit ive go ing

edge) set the channel input polarity to INP:POL INV,(@<ch_list>).

The value returned to an algorithm can be from 5µSec to 1 Second with

59.6nSec resolution.

To configure channels to measure pulse width use the command

[SENSe:]:FUNCtion:PWIDth <avg_count>,(@<ch_list>)

•<avg_count> sets the number of pulses to average when forming the

pulse duration value. More counts give more accurate readings, but

slower response to changing pulse widths.

•<ch_list> specifies the channels that will read pulse widths

To measure pulse width on channels 46&47

*RST

SENS:FUNC:PWID 4,(@146,147)

Algorithm reads the pulse widths on channels 146 and 147 and returns these

values in CVT elements 46 and 47

ALG:DEF ’ALG1’,’writecvt( I146, 46 ); writecvt( I147, 47 );’

INIT

. . .

SENS:DATA:CVT? (@46,47)

read puls width on chs 46&47

start algorithm

read pulse widths from CVT

Figure 12. Measure Pulse Width

20 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 25

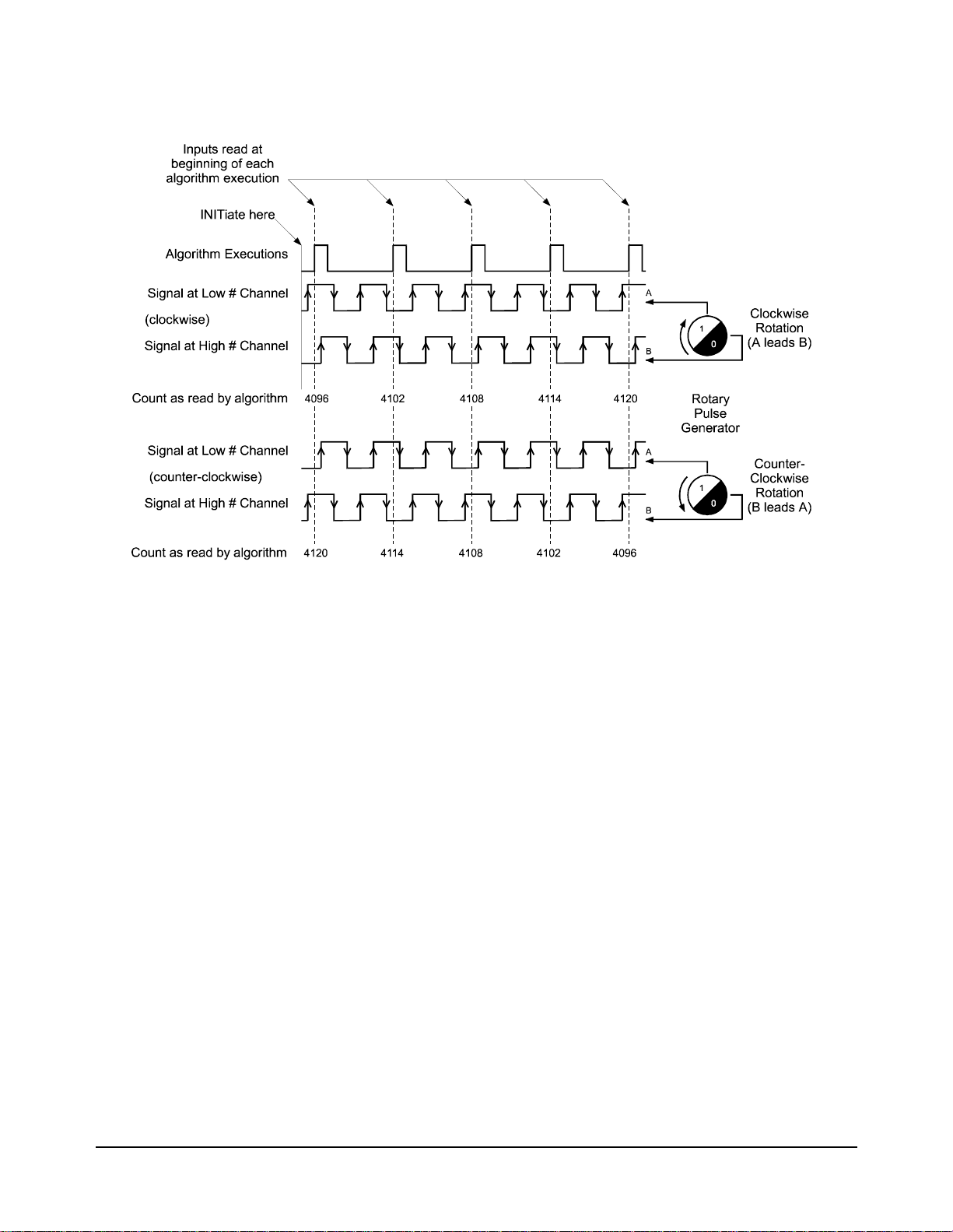

Sense Quadratur e

Position

This means that the E1538 will conv ert a digital quadratur e s ign al pa ir int o

an absolute 24-bit count. The count value can be read by the algorithm.

The E1538’s quadrature position function increments a counter value each

time there is a t ran si tion on either of t he quadrature chann el pai r. W hen the

lower numbered channel’s signal LEADS the higher numbered channel, the

function counts up. When the lower numbered channel LAGS the higher

numbered channel, the function counts down.

To configure a pair of channels to sense quadrature count use

[SENSe:]FUNCtion:QUADrature [<count_preset>,](@<ch_list>)

•<count_preset> if included, allows presetting the absolute counter

associated with the ch anne l pair . All qua dratu re pairs i n <c h_lis t> will

be preset to the same value. If not included, the default count at

algorithm start will be zero. <count_preset> can range from 0 to

16,777,215. The variable type is int32

•<ch_list> must always specify both channels of a pair. More than one

pair can be specified. Both channels of any pair must be adjacent.

<ch_list> can specify channels on more than one E1538. The channel

numbers in <ch_list> must be in ascending order. The related error

messages are:

3115, "Channels specified are not in ascending order."

3116, "Multiple channels specified are not grouped correctly."

3117, "Grouped channels are not adjacent."

3122, "This multiple channel function must not span multiple SCPs."

The algorithm reads the current count through the low numbered

channel. The count is an unsigned 24-bit value ranging from 0 to

16,777,215. The counter can roll over from 16,777,2215 to 0, and roll

under from 0 to 16,777,215 is 16,777,215.

To configure channels 42 and 43 as one qua drature pair, and channels 48 and

49 as another pair

*RST

SENS:FUNC:QUAD 8192,(@142,143)

SENS:FUNC:QUAD 0,(@148,149)

algorithm will retrieve values from input channels and place in CVT elements

ALG:DEF ’ALG1’,’writecvt(I142,42); writecvt(I148,48);’

INIT

begin loop

SENS:DATA:CVT? (@42,48)

display or otherwise use count info

end loop

pair 42&43 preset to count of

8192

pair 48&49 preset to 0

start algorithm execution

loops between here and end loop

get quadrature position coun t

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 21

Page 26

Figure 13. Sense Quadrature Position

Sense Rotational Velocity This means that th e E1538 will read the rota tional velocity of a toothed wheel

sensor. The E1538 measures too th-to-toot h period and conve rts it int o units

of revolutions per second (RPS). This function can only be linked to the

E1538’s first channel. The function works for wheels that h ave either a

missing, or an extra tooth to mark their index position. Figure 14 shows a

wheel sensed with a variabl e reluctance sensor (using the VRS input option),

but any wheel sensing method is applicable as long as it provides a digital

output to the RVEL channel.

The value read by the algorithm can range from RPS to RPS.

As well as sensing rotational velocity, SENS:FUNC:RVEL provides the

reference position to the SOUR:FUNC:RPULse function that generates

angular positioned pulses. See page 30 for more informat ion on RPULse.

To assign a channel to sense rotational velocity, use the command:

[SENSe:]FUNCtion:RVELocity <n_teeth>,<index_type>,(@<ch_list>)

•<n_teeth> is the number of teeth that the wheel would have if it didn’t

have missing or e xtra teeth. For example, we would set <n_tee th> to 12

for the wheel shown in Figure 14, eve n t houg h wi th the missing tooth,

there are only 11. <n_teeth> can range from 3 to 255.

22 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

1

-------------nteeth

100 000,

-------------------- nteeth

Page 27

•<index_type> can be either of the strings "MISSing", or "EXTRa"

•<ch_list> must be the first channel on the SCP, but can contain more

than one channel provided that each c hannel is on a separat e

following note. The related Error Messages are:

3110, "Channel specified is invalid for RVELocity function.

Note Only one channel on any E1538 SCP can be assigned to the

SENS:FUNC:RVEL function, and it must be the first channel on the SCP."

E1538. See

Figure 14. Sense Rotational Velocity

Example of Rotational Velocity Sense

Channel 40 senses RVEL and the algorithm reads and returns the velocity

value in CVT element 40

*RST

SENSE:FUNC:RVEL 12,MISSING,(@140)

ALG:DEF ’ALG1’,’writecvt(I140,40);’

INIT

loop always

SENS:DATA:CVT? (@40)

display the RVEL value

end loop

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 23

12 toothed wheel with one

missing, from channel 40

simply puts value from ch 40 into

CVT element 40

start the algorith m

will loop from "end loop" to here

query the value from CVT 40

Page 28

Programming Output

Channels

This section deals wi th all aspects of progr amming output channel func tions.

Channels are configured for output with the I/O direction switches (see

"Configuring Input-Output direction" on page 6). A related error message:

3124, "E1538 OE switch OFF conflicts with this command."

Controlling Output

Polarity

Output Static

Digital State

Use OUTPut:POLarity NORMal | INVerted,(@<ch_list>) to configure

output channel logic sense. The operations is as follows:

OUTP:POL NORM a logical 1 output from the algorithm, or generated

within the E1538 (single or repetitive pulses) will

turn off the output transistor (can be pulled up).

OUT:POL INV a logical 1 output from the algorithm, or generated

within the E1538 (single or repetitive pu lses) will turn

off the output transistor (pulls low).

To configure channels 40 to 43 to drive their outputs low for a logic 1

OUTP:POL INV,(@140:143)

This means setting a channel’s digital state when an algorithm executes. To

set individual channels to this function use the SCPI command

SOURce:FUNCtion[:SHAPe]:CONDition (@<ch_list>)

To configure channels 40 through 43 as static digital outputs, send

*RST

SOUR:FUNC:COND (@140:143)

ALG:DEF ’ALG1’,’static float ch0=0, ch1=1, ch2=0, ch3=1; O140=ch0;

O141=ch1; O142=ch2; O143=ch3;’

INIT

default for all digital outputs

Figure 15. Output Static Levels

24 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 29

Variable Width Pulse Per

Trigger

This means that the channel generates a pulse whose width is specified by

the algorithm each time the algorithm executes. The value sent by the

algorithm can range from 7.87µSec to 7.812mSec.

The command sequence to se t-up this mode is:

SOURce:FUNCtion:PULSe (@<ch_list>) to ena ble pulse generation.

the following two commands return the E1538 to the Single pulse-per-trigger

mode from either the FM or Pulse Width Modulation modes. Since Single

pulse-per-trigger is the default pulse mode at power-up or after *RST, only *RST

then SOUR:FUNC:PULS (@<ch_list>) are actually need ed.

SOURce:FM[:STATe] OFF,(@<ch_list>) to disable FM mode.

SOURce:PULM[:STATe] OFF,(@<ch_list>) to disable PWM mode.

To configure channel 44 to outpu t a single contr olled width pulse per trigger

*RST

after *RST, sour:func:puls is all that is required to enable the default single

pulse-per-trigger mode.

SOUR:FUNC:PULS (@144)

ALG:DEF ’ALG1’,’static float outpulse=0.001; O144=outpulse;’

INIT

. . .

ALG:SCAL ’ALG1’,’outpulse’,5E-4

ALG:UPDATE

channel sources puls es...

start alg execution

.5ms pulse

Figure 16. Output Variable Width Pulse per Trigger

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 25

Page 30

Variable Width Pulse

Train (PWM)

This means that the E1538 ou tputs a conti nuous t rain of pulse s whose l ogic

1 pulse width is control led by the a lgorithm. Th e frequenc y is set by a SCPI

command before INIT. Use the fol lowing command sequen ce to set up this

mode:

SOURce:FUNCtion:PULSe (@<ch_list>) to ena ble pulse generation.

SOURce:PULM[:STATe] ON,(@<ch_list>) to select the PWM mode

SOURce:PULSe:PERiod <period>,(@<ch_list>) to set the pu lse repetition

period (frequency = 1/<period>). <period> can range from 25µSec to

7.812mSec.

The pulse width value sent by the algorithm can range from 7.87µSec to

<period>-7.87µSec. Resolution within this range is 238.4nSec.100%

duty-cycle is output whe n t he algorithm sends a val ue gre at er tha n or e qual

to <period>. 0% duty-cycle is out put when t he algo rithm s ends a val ue les s

than or equal to 0.

To configure channel 45 to output a variable pulse width continuous train

SOUR:FUNC:PULS (@145)

SOUR:PULM ON,(@145)

SOUR:PULS:PER .0005,(@145)

channel sources puls es...

and continuous PWM train

.5 msec period (2KHz freq)

The algorithm can now output a value to channel 45 to control pulse width

of the logic 1 portion of the waveform:

O145 = 333E-6 /* channel 45 pulse width will be 333 µsec */

Figure 17. Output Pulse-Width-Modulated Signal

26 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 31

Variable Frequency Fixed

Width Pulse Train (FM)

This means that the E1538 outputs a continuous train of pulses whose

frequency is control led by the alg orithm. The logi c 1 level pulse wi dth is set

by a SCPI command before INIT. Use the following command sequence:

SOURce:FUNCtion:PULSe (@<ch_list>) to ena ble pulse generation.

SOURce:FM[:STATe] ON,(@<ch_list>) to select the FM mode.

SOURce:PULSe:WIDTh <width>,(@<ch_list>) to pre-set the pulse widt h

of the logic 1 porti on of the wavefo rm. <widt h > can range f rom 7.87µSec t o

7.812mSec.

The frequency value sent by the algorithm can range from 128Hz to 40KHz.

2

f

out

The frequency resolution is

---------------------------

4.194 MHz

To configure channel 45 to outp ut vari able fre quency co ntinuo us t rain with

fixed pulse width

SOUR:FUNC:PULS (@145)

SOUR:FM ON,(@145)

SOUR:PULS:WIDT .001,(@145)

channel sources puls es...

and continuous pulse train

1 msec fixed pulse width

The algorithm can now output a frequency value to channel 45:

O145 = 250 /* channel 45 will source 250 Hz pulse train */

Figure 18. Output Fixed Pulse Width Variable Frequency (FM)

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 27

Page 32

Variable Frequency

Square-Wave Pulse Train

(FM)

This means that the E1538 outputs a continuous train of pulses whose

frequency is control led by the algorithm. The the dut y-cycle of the waveform

is always 50%. Use the following command sequence:

SOURce:FUNCtion:SQUare (@<ch_list>) to enable square-wave

generation.

SOURce:FM[:STATe] ON,(@<ch_list>) to se lect the FM mod e.

The frequency value sent by the algorithm can range from 64Hz to 40KHz.

2

f

out

The frequency resolution is

---------------------------

4.194 MHz

To configure channel 45 to outpu t variable freque ncy continuous tr ain with

50% duty cycle (square wave)

SOUR:FUNC:SQUARE (@145)

SOUR:FM ON,(@145)

channel sources square wave...

and continuous PWM train

The algorithm can now output a frequency value to channel 45:

O145 = 2000 /* channel 45 will source 2 KHz square wave */

Figure 19. Output Square Wave Variable Frequency (FM)

28 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 33

Rotationally Positioned

Pulse Output

This means that the E1538 will gene rate pulses which are positioned by angle

(usually shaft angle). The rotational pulse function requires a rotational

reference, and this is provided by the SENS:RVEL function fr om the SCP’s

first channel. Ther e are four rela ted co mmands that set u p rota tiona l pulses .

Combinations of these commands can set up four different rotational pulse

modes. Figure 20 shows these modes and the command sequence for each.

Following Figu re 20 is the command reference fo r all four comman ds.

Following that are examples of each of the four modes.

Figure 20. Four Modes of Rotationally Positioned Pulses

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 29

Page 34

Rotational Pulse

Command Usage

Use SOURce:FUNCtion:RPULse (@<ref_channel>),(@<ch_list>) to

link channels in <ch_list> to the rotational pulse function. The channel in

<ref_channel> will be linked to the SENS:FUNC:RVEL function to provide

the rotational reference information to SOUR:FUNC:RPUL.

The commands:

SOURce:RPULse:POSition[:ANGLe] <degrees>,(@<ch_list>),

SOURce:RPULse:WIDTh[:ANGLe] <degrees>,(@<ch_list>), and

SOURce:RPULse:WIDTh:TIME <seconds>,(@<ch_list>) fix the

channels’ rotational pulse position (SOUR:RPUL:POS:ANGL), or the

rotational pulse wi dth (SOUR:RPUL:WIDT:ANGL and :TI ME) bef ore the

INITiate command. The remaining pulse property - the property NOT

specified in one of these commands - will be controlled withi n the algorit hm.

•<ch_list> specif ies the SOUR:FUNC:RPUL chan nel(s) tha t will be set

to the property specified by the command syntax.

•For pulse position, <degrees> can range from -33, 554,430 to 33,554,430

degrees, with a resolution of 1 degree. The pulse is positioned at

<degrees> modulo 360.

For pulse width, <degrees> can range from 0 to 360 degrees, with a

resolution of 1 degree.

•<time> specifi es pulse width in se conds, ranging from .0 0000787 (7.87

µS) to .015624 (15.624mS), with a resolution of 238.4nS

The command:

SOUR:RPULse:VARType ANG Le | TIME,(@<ch_list>) specifies the

type of value that will be controlled (varied) by the algorithm.

•ANGLe specifies that the algorithm will send values of angle (in

degrees) to the channel(s).

TIME specifies tha t the algor ithm will send va lues of time (in seconds)

to the channel(s).

•<ch_list> specifies the SOUR:FUNC:RPUL channel(s) that will be

controlled (varied) by the algorithm.

30 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 35

Rotational Pulse Mode:

Variable Angular Position, Preset Pulse Width (by angle)

In this mode, the angula r position of the pulses is cont rolled by the algorithm,

and the width (durat ion in degr ees) is pre set before INI T. See Figure 21.Use

the following command sequence:

SOURce:FUNCtion:RPULse (@<ref_channel>),(@<ch_list>) to select the

channels that will output angular positioned pulses, and to specify the

reference channel.

SOURCe:RPULse:WIDTh[:ANGLe] <degrees>,(@<ch_list>) to preset

the pulse width in degrees. The algorithm will control the angular pulse

position.

Example of variable position, preset width (by angle):

Set up channel 40 as the reference channel, and channels 45 through 47 to

output variable position pulses:

*RST

SENS:FUNC:RVEL 12,MISS,(@140)

SOUR:FUNC:RPULSE (@140),(@145:147)

SOUR:RPULSE:WIDT:ANGL 15,(@145:147)

Algorithm outputs pulses on al l three channels with variable position.

ALG:DEF ’ALG1’,’static float Pos1, Pos2, Pos3;O145 = Pos1; O146 =

Pos2;O147 = Pos3;’

ALG:SCALAR’ALG1’,’Pos1’,60

ALG:SCALAR’ALG1’,’Pos2’,180

ALG:SCALAR’ALG1’,’Pos3’,300

ALG:UPDATE

INIT

•

•

•

ALG:SCALAR 'ALG1','Pos1',NewPos1

ALG:SCALAR 'ALG1','Pos2',NewP os2

ALG:SCALAR 'ALG1','Pos3',NewP os3

ALG:UPDATE

sense rvel for reference channel

3 rotational pulse output chans

preset pulse width to 15 degrees

preset ch 45’s pulse pos to 60°

preset ch 46’s pulse pos to 180°

preset ch 47’s pulse pos to 300°

.

start algorithm execution

calculate values for NewPos(n)

later, adjust channel 45’s

position while algorithm running

later, adjust channel 46’s

position while algorithm running

later, adjust channel 47’s

position while algorithm running

values in update queue sent to

variables

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 31

Page 36

Figure 21. Variable Position, Width Preset by Angle

Rotational Pulse Mode:

Variable Angular Position, Preset Pulse Width (by time)

In this mode, the angula r position of the pulses is cont rolled by the algorithm,

and the width (duration in seconds ) is preset before INIT. See Figure 22. Use

the following command sequence:

SOURce:FUNCtion:RPULse (@<ref_channel>),(@<ch_list>) to select the

channels that will output angular positioned pulses, and to specify the

reference channel.

SOURCe:RPULse:WIDTh:TIME <seconds>,(@<ch_list>) to preset the

pulse width in second s. The algorithm will control th e angular pulse positi on.

Example of variable position, preset width:

Set up channel 40 as the reference channel, and channels 45 through 47 to

output variable position pulses:

*RST

SENS:FUNC:RVEL 12,MISS,(@140)

SOUR:FUNC:RPULSE (@140),(@145:147)

SOUR:RPULSE:WIDT:TIME .001,(@145:147)

Algorithm outputs pulses on al l three channels with variable position.

ALG:DEF ’ALG1’,’static float Pos1, Pos2, Pos3;O145 = Pos1; O146 = Pos2;

O147 = Pos3;’

ALG:SCALAR’ALG1’,’Pos1’,60

ALG:SCALAR’ALG1’,’Pos2’,180

sense rvel for reference channel

3 rotational pulse output chans

preset pulse width to 1 millisec.

preset ch 45’s pulse pos to 60°

preset ch 46’s pulse pos to 180°

32 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 37

ALG:SCALAR’ALG1’,’Pos3’,300

ALG:UPDATE

INIT

•

•

•

ALG:SCALAR 'ALG1','Pos1',NewPos1

ALG:SCALAR 'ALG1','Pos2',NewP os2

ALG:SCALAR 'ALG1','Pos3',NewP os3

ALG:UPDATE

preset ch 47’s pulse pos to 300°

.

start algorithm execution

calculate values for NewPos(n)

later, adjust channel 45’s

position while algorithm running

later, adjust channel 46’s

position while algorithm running

later, adjust channel 47’s

position while algorithm running

values in update queue sent to

variables

Figure 22. Variable Position, Width Preset by Time

Rotational Pulse Mode:

Var iabl e Pu lse Width (by angle), Preset Angular Position

In this mode, the an gular puls e width is control led by the algorithm, and the

angular position is preset before INIT. See Figure 23. Use the following

command sequence:

SOURce:FUNCtion:RPULse (@<ref_channel>),(@<ch_list>) to select the

channels that will output angular positioned pulses, and to specify the

reference channel.

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 33

Page 38

SOURce:RPULse:POSition[:ANGLe] <degrees>,(@<ch_list>), to preset

the angular pulse position in degrees. The algorithm will control the pulse

duration.

SOUR:RPULse:VARType ANGLe,(@<ch_list>) to set the type of value

that will vary with algorithm control (in this case pulse width ANGLe).

Example of variable width (by angle), preset position:

Set up channel 40 as the reference channel, and channels 45 through 47 to

output variable width pulses:

*RST

SENS:FUNC:RVEL 12,MISS,(@140)

SOUR:FUNC:RPULSE (@140),(@145:147)

SOUR:RPULSE:POS:ANGL 20,(@145)

SOUR:RPULSE:POS:ANGL 140,(@14 6)

SOUR:RPULSE:POS:ANGL 260,(@14 7)

SOUR:RPULSE:VART ANGL,(@145:147)

Algorithm outputs pulses on al l three channels with variable width.

ALG:DEF ’ALG1’,’static float Width1, Width2, Width3;O145 = Width1; O146

= Width2; O147 = Width3;’

ALG:SCALAR’ALG1’,’Width1’,5

ALG:SCALAR’ALG1’,’Width2’,10

ALG:SCALAR’ALG1’,’Width3’,15

ALG:UPDATE

INIT

•

•

•

ALG:SCALAR 'ALG1','Width1',NewWidth1

ALG:SCALAR 'ALG1','Width2',NewWidth2

ALG:SCALAR 'ALG1','Width3',NewWidth3

sense rvel for reference channel

3 rotational pulse output chans

preset channel 45 pulse posit ion

to 20 degrees

preset channel 46 pulse posit ion

to 140 degrees

preset channel 47 pulse posit ion

to 260 degrees

algorithm will contro l pulse

width by ANGLE

preset ch 45’s pulse width to 5°

preset ch 46’s pulse width to 10°

preset ch 47’s pulse width to 15°

.

start algorithm execution

calculate NewWidth(n)

later, adjust channel 45’s width

while algorithm is running

later, adjust channel 46’s width

while algorithm is running

later, adjust channel 47’s width

while algorithm is running

ALG:UPDATE

34 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 39

Figure 23. Fixed Position, Variable Width by Angle

Rotational Pulse Mode:

Variable Pulse Width (by time), Preset Angular Position

In this mode, the pulse durati on (in sec onds) is controlle d by the alg orith m,

and the angular position is preset before INIT. See Figure 24. Use the

following command sequence:

SOURce:FUNCtion:RPULse (@<ref_channel>),(@<ch_list>) to select the

channels that will output angular positioned pulses, and to specify the

reference channel.

SOURce:RPULse:POSition[:ANGLe] <degrees>,(@<ch_list>) to preset

the angular pulse position in degrees. The algorithm will control the pulse

duration.

SOUR:RPULse:VARType TIME,(@<ch_list>) to set the type of value that

will vary with algorithm control (in this case pulse duration in seconds).

Example of variable width (by time), preset position:

Set up channel 40 as the reference channel, and channels 45 through 47 to

output variable width pulses:

*RST

SENS:FUNC:RVEL 12,MISS,(@140)

SOUR:FUNC:RPULSE (@140),(@145:147)

SOUR:RPULSE:POS:ANGL 20,(@145)

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 35

sense rvel for reference channel

3 rotational pulse output chans

preset channel 45 pulse posit ion

to 20 degrees

Page 40

SOUR:RPULSE:POS:ANGL 140,(@146)

SOUR:RPULSE:POS:ANGL 260,(@14 7)

SOUR:RPULSE:VART TIME,(@145:147)

Algorithm outputs pulses on al l three channels with preset duration.

ALG:DEF ’ALG1’,’static float Width1, Width2, Width3;O145 = Width1; O146

= Width2; O147 = Width3;’

ALG:SCALAR’ALG1’,’Width1’,.005

ALG:SCALAR’ALG1’,’Width2’,.010

ALG:SCALAR’ALG1’,’W id t h3 ’,.015

ALG:UPDATE

INIT

•

•

•

ALG:SCALAR 'ALG1','Width1',NewWidth1

ALG:SCALAR 'ALG1','Width2',NewWidth2

ALG:SCALAR 'ALG1','Width3',NewWidth3

ALG:UPDATE

preset channel 46 pulse posit ion

to 140 degrees

preset channel 47 pulse posit ion

to 260 degrees

algorithm will contro l pulse

duration by TIME

preset ch 45 pulse width to 5ms

preset ch 46 pulse width to 10ms

preset ch 47 pulse width to 15ms

start algorithm execution

calculate NewWidth(n)

later, adjust channel 45’s width

while algorithm is running

later, adjust channel 46’s width

while algorithm is running

later, adjust channel 47’s width

while algorithm is running

values in update queue sent to

variables

Figure 24. Fixed Position, Variable Widt h by Time

36 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 41

Stepper Motor Control Use the command

SOURce:FUNCtion:STEPper <preset_pos>,<mode>,<max_vel>,<min_vel

>,(@<ch_list>)

to control stepper motor s. The E1538 can operate 2 or 4 pha se motors in full,

and half step mode. Position values are sent from the algorithm to the first

channel of a 2 or 4 channel "motor gr oup" . The al gor it hm rea d s t he cur re nt

position from the second channel of the group.

Four-phase stepper motors that require less than 100mA phase current can

be directly driven by the SCP. See Figure 29 for a connection diagram that

also shows the required user-supplied output protection components.

•<preset_pos> defines the position count at algorithm start-up.

•<mode> is used to select the stepping mode. the allowable values are:

<mode> string Stepping Mode Speed Channel

MFSFC2 Full Full 2

FSFC4 Full Full 4

M

FSHC2 Full Half 2

M

MFSHC4 Full Half 4

Table 1. Stepping <mode> values

HSFC2 Half Full 4

M

•<min_vel> is s pecified in steps per second and is the beg inning step rate

at the start of the 14 or 38 s tep ramp-up to <max_vel>.

<max_vel> is specified in steps per second and is the maximum step

rate that will be sent to the motor after ramp-up is complete.

Figure 25 show s the relationship betwe en these parameters. A rela ted

error message: 3120, "Minimum velocity parameter must not exceed

maximum velocity parameter."

Figure 25. Relationship of

min_vel

, and

max_vel

•<ch_list> specifies the channels that will control stepper motors. A

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 37

Page 42

motor phase channel group can not be split across SCPs.

The algorithm sends new position values to the first channel in a

motor-group. The algorithm reads the current position value from the

second channel in the motor-group.

Example of full step, full speed, 4 phase stepper motor operation:

*RST

preset count to 0, full step, half s peed, 4 channe l, min speed 64s/s,

max speed 256s/s (in half speed mode, actual speed=half specified speed)

SOUR:FUNC:STEP 0,MFSFC4,128,512,(@144:147)

SENS:FUNC:VOLT (@100 )

Algorithm reads voltage a t channel 00, multiplies it by 100 t o derive the value

to send to the motor. Only when the expected motor position (previously sent to

ch44) and the actual motor posit i on (read from ch 45) agree, is a new motor

position is sent to ch44.

ALG:DEF ’ALG1’,’static float MotorDrive;MotorDrive = ( I100 * 100 ) - 512;

/*5.12V =0 MtrDrv */

If ( !(O144 - I145) ) O144 = MotorDrive;’

INIT

channel 0 rea ds voltage

start algorithm

The following figures show the step waveforms for the five built-in step

modes.

Figure 26. Full Step Mode, Full and Half Speed, 2-Channel

38 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 43

Figure 27. Full Step Mode, Full and Half Speed, 4-Channel

Figure 28. Half Step Mode, Full Speed, 4-Channel

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 39

Page 44

Figure 29. Directly Driving 4-Phase Stepper Motors

40 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 45

*RST and *TST (important!)

The *RST and power-on condition (true also after *TST) for outputconfigured channels will output a logical one (open-drain output off). You

should keep this behavior in mind when applyi ng the E1415 to your system.

It is best to have your system’s digital inputs use a high (one) as their safe

state.

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 41

Page 46

SCPI Command Reference

Most of the E1538’s co mmands were available since its introduction. A small

number of commands are only available with E1538’s built after February

1998. The following table indicates these new commands with an X in the

"for newer units only" column. See "Identifying the Plug-on" on page 5

Table 2.

Command Syntax For newer

units only

INPut:POLarity NORM | INV,(@<

INPut:POLarity? (@<ch_list>) 44

INPut:THReshold[:LEVel] <level>,(@<ch_list>) 45

INPut:THReshold[:LEVel]? (@<channel>) 45

[SENSe:]FUNCtion:CONDition (@<ch_list>) 50

[SENSe:]FUNCtion:FREQuency (@<ch_list>) 51

SENSe:FREQuency:APERture <time>,(@<ch_list>) 47

SENSe:FREQuency:APERture? (@<channel>) 48

SENSe:FREQuency:LIMit:LOWer <freq_limit>,(@<ch_list>) X 48

SENSe:FREQuency:LIMit:LOWer? (@<channel>) X 50

[SENSe:]FUNCtion:PERiod (@<ch_list>) X 51

SENSe:PERiod:APERture <time>,(@<ch_list>) X 56

SENSe:PERiod:APERture? (@<channel>) X 57

SENSe:PERiod:LIMit:UPPer <per_limit>,(@<ch_list>) X 57

SENSe:PERiod:LIMit:UPPer? (@<channel>) X 59

SENSe:PERiod:MODE APERture | NPERiods,(@<ch_list>) X 59

SENSe:PERiod:MODE? (@<channel>) X 60

SENSe:PERiod:NPERiods <count>,(@<ch_list>) X 60

SENSe:PERiod:NPERiods? (@<channel>) X 61

SENSe:PERiod:RANGe[:UPPer] <count>,(@<ch_list>) X 61

SENSe:PERiod:RANGe[:UPPer]? (@<channel>) X 62

ch_list

>)

Page

Discussed

44

[SENSe:]FUNCtion:PWIDth <avg_count>,(@<ch_list>) 52

[SENSe:]FUNCtion:QUADrature [<preset_count>,](@<ch_list>) 52

[SENSe:]FUNCtion:RVELocity <n_teeth>,<index_type>,(@<ch_list>) 53

[SENSe:]FUNCtion:TOTalize (@<ch_list>) 55

[SENSe:]TOTalize:RESet:MODE INIT | TRIG,(@<ch_list>) 62

42 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 47

Table 2.

Command Syntax For newer

units only

[SENSe:]TOTalize:RESet:MODE? (@<channel>) 63

OUTPut:POLarity NORM | INV,(@<ch_list>) 46

OUTPut:POLarity? (@<channel>) 46

SOURce:FUNCtion:RPULse (@<ref_chan),(@<ch_list>) 65

SOURce:RPULse:POSition[:ANGLe] <degrees>,(@<ch_list>) 72

SOURce:RPULse:POSition[:ANGLe]? (@<channel>) 73

SOURce:RPULse:WIDTh[:ANGLe] <degrees>,(@<ch_list>) 74

SOURce:RPULse:WIDTh[:ANGLe]? (@<channel>) 75

SOURce:RPULse:WIDTh:TIME <seconds>,(@<ch_list>) 75

SOURce:RPULse:WIDTh:TIME? (@<channel>) 76

SOURce:RPULse:VARType ANGLe | TIME,(@<ch_list>) 73

SOURce:RPULse:VARType? (@<channel>) 74

SOURce:FUNCtion[:SHAPe]:CONDition (@<ch_list>) 66

SOURce:FUNCtion[:SHAPe]:PULSe (@<ch_list>) 66

SOURce:FM[:STATe] ON | OFF,(@<ch_list>) 63

SOURce:FM[:STATe]? (@<channel>) 64

SOURce:PULSe:WIDTh <width>,(@<ch_list>) 71

SOURce:PULSe:WIDTh? (@<channel>) 72

SOURce:PULM[:STATe] ON | OFF,(@<ch_list>) 69

SOURce:PULM[:STATe]? (@<channel>) 70

SOURce:PULSe:PERiod <period>,(@<ch_list>) 70

SOURce:PULSe:PERiod? (@<channel>) 71

Page

Discussed

SOURce:FUNCtion[:SHAPe]:SQUare (@<ch_ list >) 67

SOURce:FM[:STATe] ON | OFF,(@<ch_list>) 63

SOURce:FM[:STATe]? (@<channel>) 64

SOURce:FUNCtion:STEPper <preset_pos>,<mode>,<min_vel>,<max_vel>,(@<ch_list>) 67

SYSTem:CTYPe? (@<channel>) 12

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 43

Page 48

INPut:POLarity

INPut:POLarity <

SCP channel.

mode

>,<

ch_list

> sets logical input pola rity on a digital

Parameters

Parameter

Name

mode discrete (string) NORMal | INVerted none

ch_list string 100 - 163 none

Parameter

Type

Range of

Values

Default

Units

Comments •If the channels sp ecified are on an SCP that doesn’t support this function,

an error will be gener ated. See your SCP’s User’s Manual to determin e

its capabilities.

•Related Commands: for output sense; SOURce:PULSe:POLarity

•*RST Condition: INP:POL NORM for all digital SCP channels.

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Usage INP:POL INV,(@140:14 3)

invert first 4 channels on SCP at

SCP position 5. Channels 40

through 43

INPut:POLarity?

Parameters

Comments •<channel> must specify a single channel.

INPut:POLarity? <

SCP channel.

Parameter

Name

channel string 100 - 163 none

Parameter

Type

channel

> returns the logical input polarity on a digital

Range of

Values

Default

•If the channel speci fied is on an SCP that doesn’t support this function,

an error will be gener ated. See your SCP’s User’s Manual to determin e

its capabilities.

•Returned Value: returns "NORM" or "INV". The type is string.

•Send with VXIplug&play Function: hpe14XX_cmdString_Q(...)

Units

44 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 49

INPut:THReshold[:LEVel]

INPut:THReshold[:LEVel] <

programmatically setting the input threshold level for each input

configured channel.

level

>,(@<

ch_list

Parameters

Parameter

Name

level numeric (float32) -46 VDC to +46 VDC none

ch_list string 100 - 163 none

Parameter

Type

Range of

Values

Comments •<level> can be set to a resolution of .375V

•. While input polari ty is set to NORMAL, an input level higher than the

threshold level is c onsider ed a lo gic one, a nd an inp ut l evel lo wer th an

the threshold level is considered a logic zero. If input polarity is set to

INVerted, an inpu t level h igher tha n the t hreshold level i s consi dered a

logic zero and an input level lower than the threshold level is consi dered

a logic one .

Note The value se nt for <level> will be rounded to the nearest multiple of 0.375

Volts. For instance, 5 would be 4.875, 10 would be 10.125, 9.5 would be

9.375, and 15 would be 15. The INP:THR:LEV? query will return the

actual setting.

>) •allows

Default

Units

INPut:THReshold[:LEVel]?

INPut:THReshold[:LEVel]? (@<

for <channel>.

Parameters

Parameter

Name

channel string 100 - 163 none

Comments •<channel> must specify a single channel.

•Related Commands: INPut:POLarity, INP:THR:LEV?

•*RST Condition: INP:THR:LEV = 1.875

•Send with VXIplug&play Function: hpe14XX_cmd(...)

channel

Parameter

Type

>) returns the threshold level set

Range of

Values

Default

Units

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 45

Page 50

Note Because the E1538 rounds <level> to the nearest multip le of 0.375, the

returned value can be different from the value sent.

•INP:THR:LEV? returns a numeric value between -46 and +46. The

C-SCPI type is float32.

•Related Commands: INPut:POLarity, INP:THR:LEVel

•*RST Condition: INP:THR:LEV = 1.875

•Send with VXIplug&play Function: hpe14XX_cmdReal64_Q(...)

Usage To query the threshold level on the second channel at SCP position 4 send:

OUTPut:POLarity

Parameters

Comments •If the channels specified do not support this function, an error will be

INP:THR:LEV? (@133)

enter statement here

OUTPut:POLarity <

output channels in <ch_list>.

Parameter

Name

select discrete (string) NORMal | INVerted none

ch_list string 100 - 163 none

Parameter

Type

generated.

select

>,(@<ch_list>) sets the polarity on digital

query 2nd chan on SCP pos. 4

Range of

Values

•Related Commands: INPut:POLarity, OUTPut:POLarity?

•*RST Condition: OUTP:POL NORM for all digital channels

Default

Units

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Usage OUTP:POL INV,(@144)

OUTPut:POLarity?

OUTPut:POLarity? (@<

channel in <channel>.

46 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

channel

invert output logic sense on

channel 44

>) returns the polar ity on the digital output

Page 51

Parameters

Parameter

Name

channel string 100 - 163 none

Comments •Channel must specify a single channel

•Returned Value: returns one of NORM or INV. The type is string.

•Send with VXIplug&play Function: hpe14XX_cmdString_Q(...)

[SENSe:]FREQuency:APERture

[SENSe:]FREQuency:APERture <

allowed to determine s ignal frequency and r eturn a reading to the algorithm.

When APERture is large enou gh to contain more than one si gnal period , the

SCP measures and averages the number of signal periods t hat will fit within

this APERture time. If the specified APERture is less than the input signal

period, the SCP stretches th e aperture in or der to measure at least one signal

period. This is known a Adaptive Aperture.

Parameters

Parameter

Type

Range of

Values

aperture

>,<

ch_list

Default

Units

> sets the time

Parameter

Name

aperture numeric (float32) .001 to 1 (.001 resolution) seconds

ch_list string 100 - 163 none

Parameter

Type

Range of

Values

Default

Units

Comments •For APERture to effect the meas urement, SENS:FREQ:MODE must be

set to APERture.

•If the channel s specified are on an SCP that doesn’t support this function,

an error will be generated. See your SCP’s User’s Manual for its

capabilities.

•Related Commands: SENS:FREQ:MODE, SENS:FREQ:NPERiods,

SENS:FREQ:LIM:LOWer, SENS:FUNC:FREQ

•*RST Condition: .001 sec

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Usage SENS:FREQ:APER .01,(@144)

set channel 44 aperture to

10msec

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 47

Page 52

[SENSe:]FREQuency:APERture?

[SENSe:]FREQuency:APERture? <

APERture time.

Parameters

Parameter

Name

channel string 100 - 163 none

Parameter

Comments •If the channel specifi ed is on an SCP that doesn’t support this function,

an error will be generated. See your SCP’s User’s Manual for its

capabilities.

•Related Commands: SENS:FREQ:APER

•Returned Value: returns numeric aperture in seconds, The type is

float32.

•Send with VXIplug&play Function: hpe14XX_cmdReal64_Q(...)

SENSe:FREQuency:LIMit:LOWer

Type

channel

Range of

Values

> returns the currently set

Default

Units

[SENSe:]FREQuency:LIMit:LOWer <

specify a frequency lower limit beyond which the E1538A will stop waiting

for a signal transi tion and will return a frequency va lue of zero. Conceptually,

this is an input signal period time-out.

freq_limit

Parameters

Parameter

Name

freq_limit numeric (float32) .01667 to 250 Hz

ch_list string 100 - 163 none

Parameter

Type

Range of

Values

Comments •<ch_list> must be channels on an E1538A SCP.

Note Although SENS:FREQ:LIM:LOW can set a "timeout perio d" as long as 60

seconds (.01667Hz), the lowest frequency measurement supported by the

E1538A is 1 Hertz.

•The period associated with the FREQ :LIMit:LOWer frequency is the

time the SCP will allow for any single cycle period.

>,<

ch_list

> allows you to

Default

Units

At any time during the frequency measurement, if the signal’s period

48 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 53

exceeds the time-ou t period (i .e. frequenc y below LIMit: LOWer), then

a frequency of 0 Hz will be returned to the E1415/19/22 algorithm.

•Typical use for this command is to allow the user to bound the period

of time that is allowed for making a frequency measurement, thus,

preventing the SCP from “hanging” during measurement.

In this case, typical ly, th e LIMi t:LOWe r fre quency wou ld be t he same

as, or slower than the frequency associated w/the APERture time.

•An unusual (but valid) use is to set the LIMit:LOWer frequency to be

greater than the frequ ency associated wit h the APERture period, whi ch

can provide a means to abort a frequency measurement if at any point

during the measure ment, the input wavefo rm f req uenc y i s s lo we r tha n

the configured LIMit:LOWer frequency.

Note The lower limit set by SENS:FREQ: LIM:LOW is for a si ngle signal peri od,

not the sum of NPERiods. Unless at least one period of the input signal

exceeds the limit value set, then NPERiods will be measured and averaged

to return a reading. For instance if;

SENS:FREQ:MODE NPERiods,<ch_list>

SENS:FREQ:NPERiods 255

SENS:FREQ:LIMit:LOWer 0.01667 ! 60 second period

...

INIT

As long as the input signal frequency is slightly greater than the

LIMit:LOWer frequency , then the SCP will n ot time-out and will take 255 *

(~60sec) = ~255 minutes to take a single frequency measurement.

Alternativ ely, if even one of the input waveforms has a freq uency that is

lower than the LIMit:LOWer frequency, then 0 Hz would be immediately

returned to the E1415/19/22 algorithm.

•Related Commands: SENS:FREQ:APER, SENS:FREQ:LOW?

•*RST Condition: is “MINimum” frequency (i.e. 0.01667 Hz [period

= 60sec]).

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 49

Page 54

SENSe:FREQuency:LIMit:LOWer?

[SENSe:]FREQuency:LIMit:LOWer? <channel> returns the lower

frequency limit currently set for <channel>

Parameters

Parameter

Name

channel string 100 - 163 none

Comments •<channel> must be a single channel on an E1538A SCP.

•Returned Value: .01667 to 250, The type is float32.

•Send with VXIplug&play Function: hpe14XX_cmdReal64_Q(...)

[SENSe:]FUNCtion:CONDition

[SENSe:]FUNCtion:CONDition <

the digital state for cha nnels in <ch_list>. See “Rea ding Static Digital State”

on page 14.

Parameters

Parameter

Name

Parameter

Type

Parameter

Type

ch_list

Range of

Values

> sets the SENSe function to inp ut

Range of

Values

Default

Units

Default

Units

ch_list string 100 - 163 none

Comments •The E1538 SCP senses the single bit digital state on each channel

specified by this command .

•If the channels specified are not on a digital SCP, an error will be

generated.

•Use the INPut:POLarity command to set input logical sense.

•Related Commands: INPut:POLarity

•*RST Condition: SENS:FUNC:COND and INP:POL NORM for all

digital SCP channels.

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Usage See “Reading Static Digital State” on page 14.

To set upper 4-bits of E1538 at SCP position 5 to digital inputs send:

50 Agilent E1538A Enhanced Frequency/Totalize/PWM SCP

Page 55

SENS:FUNC:COND (@144:147)

[SENSe:]FUNCtion:FREQuency

[SENSe:]FUNCtion:FREQuency <

ch_list

> sets the SENSe function to

frequency for channels i n <ch_list >. Also config ures the cha nnels speci fied

as digital inputs.

page 16.

See “About Period and Frequency Measurements” on

Parameters

Parameter

Name

ch_list string 100 - 163 none

Parameter

Type

Range of

Values

Default

Units

Comments •If the channels sp ecified are on an SCP that doesn’t support this function,

an error will be generated. See your SCP’s User’s Manual for its

capabilities.

•Related commands: SENS:FREQ:APER, SENS:FREQ:MODE

•*RST Condition: SENS:FUNC:COND and INP:POL NORM for all

digital SCP channels

•Send with VXIplug&play Function: hpe14XX_cmd(...)

Usage See “About Period and Frequency Measurements” on page 16.

SENS:FUNC:FREQ (@144)

[SENSe:]FUNCtion:PERiod

[SENSe:]FUNCtion:PERiod (@<

period for channels in <ch_list>. Also configures the channels specified as

digital inputs.

page 16.

Parameters

Parameter

Name

ch_list string 100 - 163 none

Comments •If the channels sp ecified are on an SCP that doesn’t support this function,

ch_list

See “About Period and Frequency Measurements” on

Parameter

Type

>) sets the SENSe function to

Range of

Values

an error will be generated. See your SCP’s User’s Manual for its

capabilities.

•Related commands: SENS:PER:APER, SENS:PER:NPER,

Agilent E1538A Enhanced Frequency/Totalize/PWM SCP 51

Default

Units

Page 56

Usage See “About Period and Frequency Measurements” on page 16.

SENS:FUNC:PER (@144)

[SENSe:]FUNCtion:PWIDth

SENS:PER:MODE