Page 1

VT1422A Remote Channel

Multi-Function DAC Module

with VT1529A/B 32 Ch Remote Strain Conditioning Unit

and VT1539A Remote Channel Signal Conditioning Plug-On

User’s and SCPI Programming Manual

Where to Find it - Online and Printed Information

Module configuration and wiring....................... This Manual

SCPI programming.............................................This Manual

SCPI example programs.....................................This Manual, Driver Disc

SCPI command reference ..................................This Manual

VXIplug&play programming ............................VXIplug&play Online Help

VXIplug&play example programs........... ..........VXIplug&play Online Help

VXIplug&play function reference ........... ... .......VXIplug&play Online Help

Soft Front Panel information..............................VXIplug&play Online Help

VISA language information...............................VISA User's Guide

VEE programming information ......................... VEE User's Manual

Manual Part Number: 82-0076-000

Printed in U.S.A. August 15, 2005

Page 2

This page is blank.

Page 3

VXI TECHNOLOGY WARRANTY STATEMENT

PRODUCT: VT1422A Remote Channel Multi-function DAC Module, DURATION OF WARRANTY: 3 years

1. VXI Technology warrants VXI Technology hardware, accessories, and supplies against defects in materials and workmanship for the

period specified above. If VXI Technology receives notice of such defects during the warranty period, VXI Technology will, at its option,

either repair or replace products which prove to be defective. Replacement products may be either new or like-new.

2. VXI Technology warrants that VXI Technology software will not fail to execute its programming instructions, for the period specified

above, due to defects in material and workmanship when properly installed and used. If VXI Technology receives notice of such defects

during the warranty period, VXI Technology will replace software media which does not execute its programming instructions due to

such defects.

3. VXI Technology does not warrant that the operation of VXI Technology products will be interrupted or error free. If VXI Technology

is unable, within a reasonable time, to repair or replace any product to a condition as warranted, customer will be entitled to a refund of

the purchase price upon prompt return of the product.

4. VXI Technology products may contain remanufactured parts equivalent to new in performance or may have been subject to incidental

use.

5. The warranty period begins on the date of delivery or on the date of installation if installed by VXI Technology. If customer schedules

or delays VXI Technology installation more than 30 days after delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) sof tware, interfacing, parts

or supplies not supplied by VXI Technology, (c) unauthorized modification or misuse, (d) operation outside of the published

environmental specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER WARRANTY

OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED AND VXI TECHNOLOGY SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTY OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY, AND

FITNESS FOR A PARTICULAR PURPOSE.

8. VXI Technology will be liable for damage to tangible property per incident up to the greater of $300,000 or the actual amount paid for

the product that is the subject of the claim and for damages for bodily injury or death, to the extent that all such damages are determined

by a court of competent jurisdiction to have been directly caused by a defective VXI Technology product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S

SOLE AND EXLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL VXI TECHNOLOGY OR ITS

SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING

LOST PROFIT OR DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR MODIFY AND ARE

IN ADDITION TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

VT1529A/B Remote Strain Conditioning Module,

VT1539A Remote Channel Signal Conditioning Plug-on,

and all other applicable Signal Conditioning Plug-ons

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991), or DFARS 252.227-7014 (Jun 1995),

as a "commercial item" as defined in FAR 2.101(a) or as "Restricted computer software" as defined in FAR 52.227-19 (Jun 1987) (or any

equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such Software and

Documentation by the applicable FAR or DFARS clause or th e

VT1422A Remote Channel Multi-Function DAC Module User's and SCPI Programming Manual

Copyright © 2005 VXI Technology, Inc. All Rights Reserved.

VXI Technology standard software agreement for the product involved.

3

Page 4

Safety Symbols

product. Indicates that the user must refer to

Alternating current (ac)Instruction manual symbol affixed to

the manual for specific WARNING or

CAUTION information to avoid personal

Direct current (dc).

injury or damage to the product.

Indicates hazardous voltages.

Indicates the field wiring terminal that must

be connected to earth ground before

operating the equipment—protects against

electrical shock in case of fault.

WARNING

Calls attention to a procedure, practice,

or condition that could cause bodily injury

or death.

Calls attention to a procedure, practice or

or

Frame or chassis ground terminal—

typically connects to the equipment's metal

CAUTION

condition that could possibly cause damage

to equipment or permanent loss of data.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. VXI Technology assumes no liability for the customer's failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type. DO NOT

use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment switched off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal unless you

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to

to ensure that safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts

or perform any unauthorized modification to the product. Return the product to VXI Technology for service and repair to ensure that

safety features are maintained.

Operating Location: Sheltered location where air temperature and humidity are controlled within th is product’s specifications and the

product is protected against direct exposure to climatic conditions such as direct sunlight, wind, rain, snow, sleet and icing, water spray

or splash, hoarfrost or dew (typically, indoor). Pollution environment for which this product may be operated is IEC 664 Pollution degree 2.

VXI Technology for service and repair

Cleaning the front panel and top/bottom Shields: Clean the outside surfaces of this module with a cloth slightly dampened with water .

Do not attempt to clean the interior of this module.

Note for European Customers

If this symbol appears on your product, it indicates that it was manufactured after August 13, 2005. This mark is placed in accordance with

EN 50419, Marking of electrical and electronic equipment in accordance with Article 11(2) of directive 2002/96/EC (WEEE). End-of-life

product can be returned to VTI by obtaining an RMA number. Fees for recycling will apply if not prohibited by national law. SCP cards for

use with the VT1422A have this mark placed on their packaging due to the densely populated nature of these cards.

4

Page 5

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: VXI Technology, Inc.

Manufacturer’s Address: 2031 Main Street

Irvine, California 92614

USA

Declares, that the product

Product Name: Remote Channel Multi-function DAC Module

Model Number: VT1422A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive

89/336/EEC (including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard Limit

Safety

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

The product was tested in a typical configuration with VXI Technology test systems.

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz

Dips: 30% 10ms; 60% 100 ms

Interrupt > 95%@5000 ms

15 March 2002

Date

Steve Mauga

Quality Assurance Manager

5

Page 6

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: VXI Technology, Inc.

Manufacturer’s Address: 2031 Main Street

Irvine, California 92614

USA

Declares, that the product

Product Name: Remote Strain Conditioning Unit

Model Number: VT1529A, VT1529B

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive

89/336/EEC (including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard Limit

Safety

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada ICES-001

Australia AS/NZS/2064

Russia GOST 23450-79

Czech Republic CSN EN55011

Hungary MSZ EN55011

The product was tested in a typical configuration with VXI Technology test systems.

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz I cycle, 100%

Dips: 30% 10 ms; 60% 100 ms

Interrupt > 95%@5000 ms

15 March 2002

Date

6

Steve Mauga

Quality Assurance Manager

Page 7

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: VXI Technology, Inc.

Manufacturer’s Address: 2031 Main Street

Irvine, California 92614

USA

Declares, that the product

Product Name: Remote Channel Signal Conditioning Plug-on

Model Number: VT1539A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive

89/336/EEC (including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard Limit

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

Canada ICES-001:1998

Australia/New Zealand AS/NZS/2064.1

Russia GOST 23450-79

Czech Republic CSN EN 55011

Hungary MSZ EN 55011

The product was tested in a typical configuration with VXI Technology test systems.

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

30 July 2001

Date

Steve Mauga

Quality Assurance Manager

7

Page 8

Notes:

8

Page 9

Contents

VT1422A Remote Channel Multi-function DAC Module

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

U.S. Government Restricted Rights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Support Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

About this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuring the VT1422A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing Signal Conditioning Plug-Ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Disabling the Input Protect Feature (Optional) . . . . . . . . . . . . . . . . . . . . . . 29

Disabling Flash Memory Access (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Instrument Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

About Example Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Verifying a Successful Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 2

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Planning the Wiring Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCP Positions and Channel Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Sense SCPs and Output SCPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Planning for Thermocouple Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 38

Faceplate Connector Pin-Signal Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Optional Terminal and Connector Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

The SCPs and Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

The RJ-45 Connector Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Spring Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Screw Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Reference Temperature Sensing with the VT1422A . . . . . . . . . . . . . . . . . . . . . . 44

Preferred Measurement Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connecting the On-Board Thermistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wiring and Attaching the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing the VT1422A Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Contents 9

Page 10

Attaching and Removing the VT1422A RJ-45 Module . . . . . . . . . . . . . . . . . . . . 53

Adding Components to the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Spring and Screw Terminal Module Wiring Maps . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 3

Programming the VT1422A & VT1529A/B for Remote Strain Measurement . . . 57

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Instrument Setup for Remote Strain Measurements . . . . . . . . . . . . . . . . . . . . . . 58

Preparing the VT1422A for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Preparing the VT1529A/B for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installing User Selected 1/4 Bridge Resistors (Optional) . . . . . . . . . . . . . . . 59

Connecting VT1529A/Bs to the VT1422A . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Two Interconnect Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting Excitation Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting the VT1529A/B to Strain Gages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Channel Connector Pin-to-Signal Relationship . . . . . . . . . . . . . . . . . . . . . . 69

VT1529A/B Bridge Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Connecting to the VT1529A/Bs Dynamic Strain Ports . . . . . . . . . . . . . . . . . . . . 73

Extending the Dynamic Strain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Dynamic Strain Port Offset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Remote Strain Channel Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Runtime Remote Scan Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Programming for Remote Strain Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . 78

Description of Strain Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Verifying Correct Bridge Completion (Shunt Cal) . . . . . . . . . . . . . . . . . . . . . . . 90

Built-in Strain Conversion Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 4

Programming the VT1422A for

Data Acquisition and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Overview of the VT1422A Multifunction DAC Module . . . . . . . . . . . . . . . . . . . 96

Multifunction DAC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Detailed Instrument Operation Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Programming Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Executing the Programming Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Power-on and *RST Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Setting up Analog Input and Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring Programmable Analog SCP Parameters . . . . . . . . . . . . . . . . 107

Linking Input Channels to EU Conversion . . . . . . . . . . . . . . . . . . . . . . . . . 109

Linking Output Channels to Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Setting Up Digital Input and Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting Up Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting Up Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10 Contents

Page 11

Performing Channel Calibration (Important!). . . . . . . . . . . . . . . . . . . . . . . . . . 122

Calibrating the VT1422A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Calibrating Remote Signal Conditioning Units . . . . . . . . . . . . . . . . . . . . . . 123

Defining an Analog Input Scan List (ROUT:SEQ:DEF). . . . . . . . . . . . . . . . . . 123

Defining C Language Algorithms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Global Variable Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Algorithm Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Pre-setting Algorithm Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Defining Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Specifying the Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Selecting the FIFO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Setting up the Trigger System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Arm and Trigger Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Programming the Trigger Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Setting the Trigger Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Sending Trigger Signals to Other Instruments . . . . . . . . . . . . . . . . . . . . . . 131

INITiating the Module/Starting Scanning and Algorithms. . . . . . . . . . . . . . . . 132

Starting Scanning and/or Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

The Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Reading Running Algorithm Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Modifying Running Algorithm Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Updating Algorithm Variables and Coefficients . . . . . . . . . . . . . . . . . . . . . 138

Enabling and Disabling Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Setting Algorithm Execution Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Example SCPI Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Example VXIplug&play Driver Function Sequence . . . . . . . . . . . . . . . . . . . . . 140

Using the Status System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Enabling Events to be Reported in the Status Byte . . . . . . . . . . . . . . . . . . 145

Reading the Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Clearing the Enable Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

The Status Byte Group’s Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Reading Status Groups Directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

VT1422A Background Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Updating the Status System and VXIbus Interrupts . . . . . . . . . . . . . . . . . . . . . 149

Creating and Loading Custom EU Conversion Tables . . . . . . . . . . . . . . . . . . . 150

Compensating for System Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Detecting Open Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

More On Auto Ranging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Settling Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Checking for Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Fixing the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Contents 11

Page 12

Chapter 5

Advanced Programming with the VT1529B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Additional Capabilities of the VT1529B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Changes to the Use Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Engineering Units Conversion Done in VXIplug&play Driver . . . . . . . . . 162

Must Count writefifo Calls in Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . 163

New SCPI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Strain Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Field Wiring for Excitation Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 165

Strain Measurement Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Strain Conversion Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Alternate Method of Computing Strain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Temperature Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Connecting the VT1586A to the VT1529B . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Field Wiring of the VT1586A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Temperature Measurement Command Sequence . . . . . . . . . . . . . . . . . . . . 174

Temperature Conversion Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Field Wiring for dc Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 176

DCV Measurement Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

DCV Measurement Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Settling Time Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Chapter 6

Creating and Running Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Overview of the Algorithm Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Example Language Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

The Algorithm Execution Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

The Main Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

How User Algorithms Fit In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Accessing the VT1422A's Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Accessing I/O Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Accessing Remote Scan Status Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Runtime Remote Scan Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Defining and Accessing Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Determining First Execution (First_loop) . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Initializing Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Sending Data to the CVT and FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Setting a VXIbus Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Determining An Algorithm's Identity (ALG_NUM) . . . . . . . . . . . . . . . . . 193

Calling User Defined Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Operating Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Overall Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Algorithm Execution Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

12 Contents

Page 13

Defining Algorithms (ALG:DEF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

ALG:DEFINE in the Programming Sequence . . . . . . . . . . . . . . . . . . . . . . 196

ALG:DEFINE's Three Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Changing a Running Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

A Very Simple First Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Writing the Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Running the Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Modifying an Example PID Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

PIDA with Digital On-Off Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Algorithm to Algorithm Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Communication Using Channel Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . 201

Communication Using Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Non-Control Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Process Monitoring Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Implementing Setpoint Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Algorithm Language Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Standard Reserved Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Special VT1422A Reserved Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Special Identifiers for Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Special Identifiers for Remote Scan Status . . . . . . . . . . . . . . . . . . . . . . . . . 208

Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Intrinsic Functions and Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Program Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Bitfield Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Language Syntax Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Program Structure and Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Declaring Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Assigning Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

The Operations Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Conditional Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Comment Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Overall Program Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Chapter 7

VT1422A Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Overall Command Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Command Fundamentals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

SCPI Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Linking Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

SCPI Command Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Contents 13

Page 14

ALGorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

ALGorithm[:EXPLicit]:ARRay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

ALGorithm[:EXPLicit]:ARRay? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

ALGorithm[:EXPLicit]:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

ALGorithm[:EXPLicit]:SCALar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

ALGorithm[:EXPLicit]:SCALar? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

ALGorithm[:EXPLicit]:SCAN:RATio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

ALGorithm[:EXPLicit]:SCAN:RATio? . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

ALGorithm[:EXPLicit]:SIZE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

ALGorithm[:EXPLicit][:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

ALGorithm[:EXPLicit][:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

ALGorithm[:EXPLicit]:TIME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

ALGorithm:FUNCtion:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

ALGorithm:OUTPut:DELay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

ALGorithm:OUTPut:DELay? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

ALGorithm:UPDate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

ALGorithm:UPDate:CHANnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

ALGorithm:UPDate:WINDow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

ALGOrithm:UPDate:WINDow? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

ARM[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

ARM:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

ARM:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

CALCulate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

CALCulate:TEMPerature:THERmistor? . . . . . . . . . . . . . . . . . . . . . . . . . . 259

CALCulate:TEMPerature:TCouple? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

CALibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

CALibration:CONFigure:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

CALibration:CONFigure:VOLTage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

CALibration:REMote? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

CALibration:REMote:DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

CALibration:REMote:DATA? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

CALibration:REMote:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

CALibration:SETup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

CALibration:SETup? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

CALibration:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

CALibration:TARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

CALibration:TARE:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

CALibration:TARE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

CALibration:VALue:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

CALibration:VALue:VOLTage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

CALibration:ZERO? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

DIAGnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

DIAGnostic:CALibration:SETup[:MODE] . . . . . . . . . . . . . . . . . . . . . . . . 277

DIAGnostic:CALibration:SETup[:MODE]? . . . . . . . . . . . . . . . . . . . . . . . 277

DIAGnostic:CALibration:TARE[:OTDetect]:MODE . . . . . . . . . . . . . . . . 278

DIAGnostic:CALibration:TARE[:OTDetect]:MODE? . . . . . . . . . . . . . . . 278

DIAGnostic:CHECksum? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

DIAGnostic:CONNect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

DIAGnostic:CUSTom:MXB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

DIAGnostic:CUSTom:MXB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

14 Contents

Page 15

DIAGnostic:CUSTom:PIECewise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

DIAGnostic:CUSTom:REFerence:TEMPerature . . . . . . . . . . . . . . . . . . . 282

DIAGnostic:IEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

DIAGnostic:IEEE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

DIAGnostic:INTerrupt[:LINe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

DIAGnostic:INTerrupt[:LINe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

DIAGnostic:OTDetect[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

DIAGnostic:OTDetect[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

DIAGnostic:QUERy:SCPREAD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

DIAGnostic:REMote:USER:DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

DIAGnostic:REMote:USER:DATA? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

DIAGnostic:TEST:REMote:NUMber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

DIAGnostic:TEST:REMote:SELFtest? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

DIAGnostic:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

FETCh?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

FORMat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

FORMat[:DATA] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

FORMat[:DATA]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

INITiate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

INITiate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

INPut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

INPut:FILTer[:LPASs]:FREQuency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

INPut:FILTer[:LPASs]:FREQuency? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

INPut:FILTer[:LPASs][:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

INPut:FILTer[:LPASs][:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

INPut:GAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

INPut:GAIN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

INPut:LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

INPut:LOW? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

INPut:POLarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

INPut:POLarity? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

MEASure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

MEASure:VOLTage:EXCitation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

MEASure:VOLTage:UNSTrained? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

MEMory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

MEMory:VME:ADDRess . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

MEMory:VME:ADDRess? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

MEMory:VME:SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

MEMory:VME:SIZE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

MEMory:VME:STATe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

MEMory:VME:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

OUTPut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

OUTPut:CURRent:AMPLitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

OUTPut:CURRent:AMPLitude? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

OUTPut:CURRent[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

OUTPut:CURRent[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

OUTPut:POLarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

OUTPut:POLarity? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

OUTPut:SHUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

OUTPut:SHUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Contents 15

Page 16

OUTPut:SHUNt:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

OUTPut:SHUNt:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

OUTPut:TTLTrg:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

OUTPut:TTLTrg:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

OUTPut:TTLTrg<n>[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

OUTPut:TTLTrg<n>[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

OUTPut:TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

OUTPut:TYPE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

OUTPut:VOLTage:AMPLitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

OUTPut:VOLTage:AMPLitude? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

ROUTe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

ROUTe:SEQuence:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

ROUTe:SEQuence:DEFine? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

ROUTe:SEQuence:POINts? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

SAMPle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

SAMPle:TIMer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

SAMPle:TIMer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

[SENSe]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

[SENSe:]DATA:CVTable? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

[SENSe:]DATA:CVTable:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

[SENSe:]DATA:FIFO[:ALL]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

[SENSe:]DATA:FIFO:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

[SENSe:]DATA:FIFO:COUNt:HALF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

[SENSe:]DATA:FIFO:HALF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

[SENSe:]DATA:FIFO:MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

[SENSe:]DATA:FIFO:MODE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

[SENSe:]DATA:FIFO:PART? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

[SENSe:]DATA:FIFO:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

[SENSe:]FREQuency:APERture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

[SENSe:]FREQuency:APERture? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

[SENSe:]FUNCtion:CONDition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

[SENSe:]FUNCtion:CUSTom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

[SENSe:]FUNCtion:CUSTom:HVOLtage . . . . . . . . . . . . . . . . . . . . . . . . . . 341

[SENSe:]FUNCtion:CUSTom:REFerence . . . . . . . . . . . . . . . . . . . . . . . . . . 342

[SENSe:]FUNCtion:CUSTom:TCouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

[SENSe:]FUNCtion:FREQuency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

[SENSe:]FUNCtion:HVOLtage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

[SENSe:]FUNCtion:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

[SENSe:]FUNCtion:STRain:FBENding . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:FBPoisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:FPOisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:HBENding . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:HPOisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain[:QUARter] . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:Q120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:Q350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

[SENSe:]FUNCtion:STRain:FBENding:POST . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:FBPoisson:POST . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:FPOisson:POST . . . . . . . . . . . . . . . . . . . . . . 349

16 Contents

Page 17

[SENSe:]FUNCtion:STRain:HBENding:POST . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:HPOisson:POST . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain[:QUARter]:POST . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:Q120:POST . . . . . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:Q350:POST . . . . . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:STRain:USER:POST . . . . . . . . . . . . . . . . . . . . . . . . . 349

[SENSe:]FUNCtion:TEMPerature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

[SENSe:]FUNCtion:TEMPerature:POST . . . . . . . . . . . . . . . . . . . . . . . . . . 353

[SENSe:]FUNCtion:TOTalize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

[SENSe:]FUNCtion:VOLTage[:DC] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

[SENSe:]REFerence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

[SENSe:]REFerence:POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

[SENSe:]REFerence:CHANnels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

[SENSe:]REFerence:CHANnels:POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

[SENSe:]REFerence:TEMPerature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

[SENSe:]REFerence:TEMPerature:POST . . . . . . . . . . . . . . . . . . . . . . . . . 360

[SENSe:]REFerence:THERmistor:RESistance:POST . . . . . . . . . . . . . . . . 361

[SENSe:]REFerence:THERmistor:RESistance:POST? . . . . . . . . . . . . . . . 362

[SENSe:]STRain:BRIDge[:TYPE] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

[SENSe:]STRain:BRIDge:[TYPE]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

[SENSe:]STRain:CONNect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

[SENSe:]STRain:CONNect? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

[SENSe:]STRain:EXCitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

[SENSe:]STRain:EXCitation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

[SENSe:]STRain:EXCitation:STATe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

[SENSe:]STRain:EXCitation:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

[SENSe:]STRain:GFACtor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

[SENSe:]STRain:GFACtor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

[SENSe:]STRain:POISson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

[SENSe:]STRain:POISson? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

[SENSe:]STRain:UNSTrained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

[SENSe:]STRain:UNSTrained? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

[SENSe:]TOTalize:RESet:MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

[SENSe:]TOTalize:RESet:MODE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

SOURce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

SOURce:FM[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

SOURce:FM:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

SOURce:FUNCtion[:SHAPe]:CONDition . . . . . . . . . . . . . . . . . . . . . . . . . . 373

SOURce:FUNCtion[:SHAPe]:PULSe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

SOURce:FUNCtion[:SHAPe]:SQUare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

SOURce:PULM[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

SOURce:PULM:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

SOURce:PULSe:PERiod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

SOURce:PULSe:PERiod? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

SOURce:PULSe:WIDTh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

SOURce:PULSe:WIDTh? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

SOURce:VOLTage[:AMPLitude] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

STATus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

The Operation Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

STATus:OPERation:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

STATus:OPERation:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Contents 17

Page 18

STATus:OPERation:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

STATus:OPERation[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

STATus:OPERation:NTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

STATus:OPERation:NTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

STATus:OPERation:PTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

STATus:OPERation:PTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

STATus:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

The Questionable Data Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

STATus:QUEStionable:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

STATus:QUEStionable:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

STATus:QUEStionable:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

STATus:QUEStionable[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

STATus:QUEStionable:NTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

STATus:QUEStionable:NTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

STATus:QUEStionable:PTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

STATus:QUEStionable:PTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

SYSTem:CTYPe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

SYSTem:CTYPe:REMote? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

TRIGger:COUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

TRIGger:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

TRIGger[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

TRIGger:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

TRIGger:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

TRIGger:TIMer[:PERiod] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

TRIGger:TIMer[:PERiod]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

IEEE-488.2 Common Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

*CAL? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

*DMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

*EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

*EMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

*ESE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

*GMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

*LMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

*PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

*RMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

*SRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

*TRG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

*WAI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

18 Contents

Page 19

Command Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

VT1422A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

VT1529A/B Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Appendix B

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Appendix C

VT1529A/B Verification & Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Dummy Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Test V-1: Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Test V-2: Cal Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Test V-3: Sense Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Test V-4: Bridge Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

Test V-5: Dynamic Strain Output Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Test V-6: Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Test V-7: Shunt Cal Resistor Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

Test V-8: Internal Shunt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Appendix D

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Appendix E

Wiring and Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Separating Digital and Analog SCP Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Recommended Wiring and Noise Reduction Techniques . . . . . . . . . . . . . . . . . 484

Wiring Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

VT1422A Guard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Common Mode Voltage Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

When to Make Shield Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Noise Due to Inadequate Card Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

VT1422A Noise Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Normal Mode Noise (Enm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Common Mode Noise (Ecm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Keeping Common Mode Noise out of the Amplifier . . . . . . . . . . . . . . . . . . 486

Contents 19

Page 20

Appendix F

Generating User Defined Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

Haversine Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

Appendix G

Example PID Algorithm Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

PIDA Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

PIDB Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 493

PIDC Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

20 Contents

Page 21

Support Resources

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Instrument Division

VXI Technology, Inc.

7525 Granger Road, Unit 7

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail: support@vxitech.com

Visit http://vxitech.com for worldwide support sites and service plan information.

Support 21

Page 22

22 Support

Page 23

About this Chapter

This chapter will explain hardware configuration before installation in a

VXIbus mainframe. By attending to each of these configuration items, the

VT1422A won't have to be removed from its mainframe later. Chapter

contents include:

• Configuring the VT1422A . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

• Installing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

• Instrument Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

• About Example Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

• Verifying a Successful Configuration. . . . . . . . . . . . . . . . . . . page 32

Configuring the VT1422A

There are several aspects to configuring the module before installing it in a

VXIbus mainframe. They are:

Chapter 1

Getting Started

• Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . page 24

• Installing Signal Conditioning Plug-Ons . . . . . . . . . . . . . . . . page 25

• Disabling the Input Protect Feature (Optional). . . . . . . . . . . . page 29

• Disabling Flash Memory Access (Optional). . . . . . . . . . . . . . page 29

For most applications, only the Logical Address switch needs to be

changed prior to installation. The other settings can be used as delivered.

Switch/Jumper Setting

Logical Address Switch 208

Input Protect Jumper Protected

Flash Memory Protect Jumper PROG

Note Setting the VXIbus Interrupt Level: The VT1422A uses a default VXIbus

interrupt level of 1. The default setting is made at power-on and after an

*RST command. The interrupt level can be changed by executing the

DIAGnostic:INTerrupt[:LINe] command in the application program.

Getting Started 23Chapter 1

Page 24

Setting the Logical

Address Switch

Follow the next figure and ignore any switch numbering printed on the

Logical Address switch. When installing more than one VT1422A in a

single VXIbus Mainframe, set each instrument to a different Logical

Address.

Setting the Logical Address Switch

Default Switch Setting

Logical Address = 208

1

24 Getting Started Chapter 1

Page 25

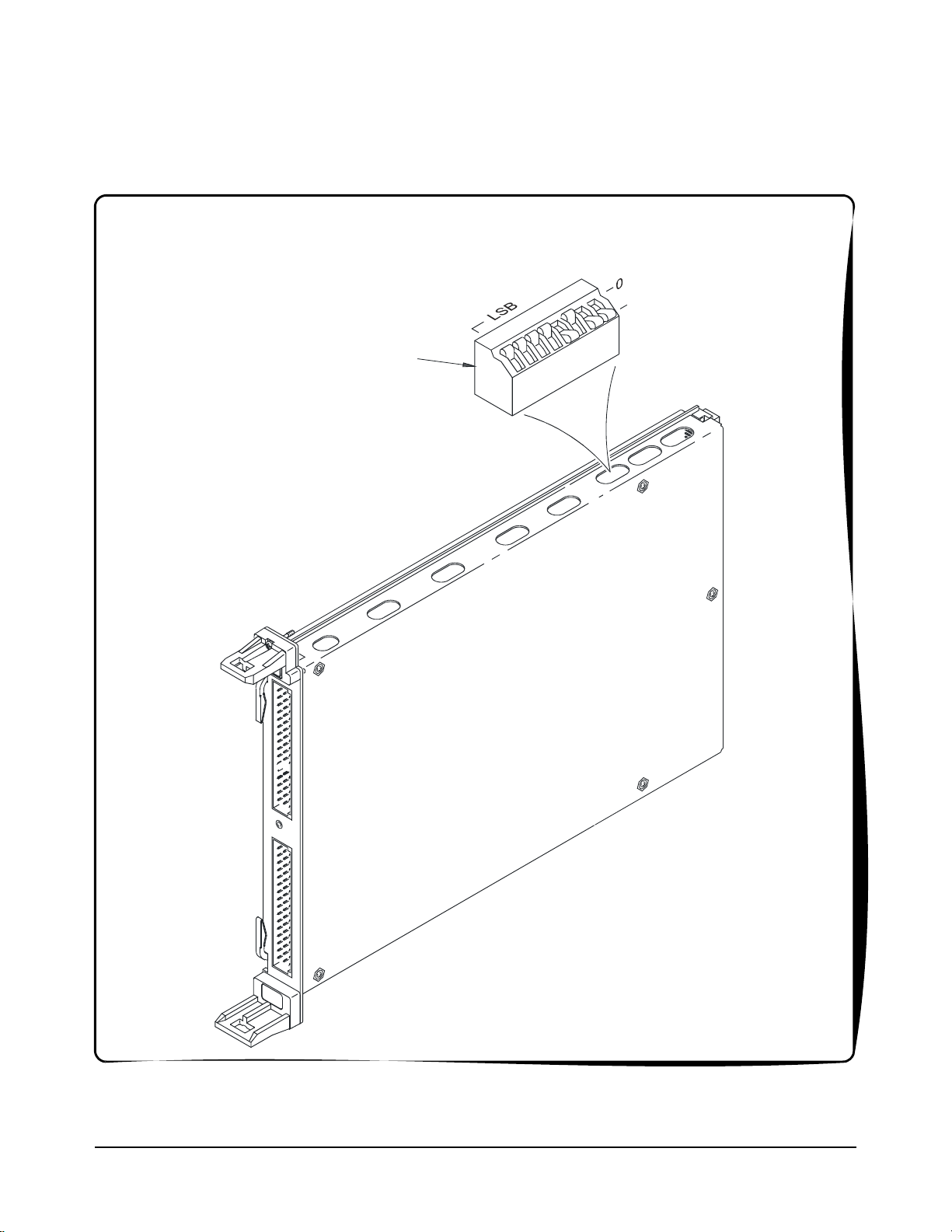

Installing Signal

Conditioning

Plug-Ons

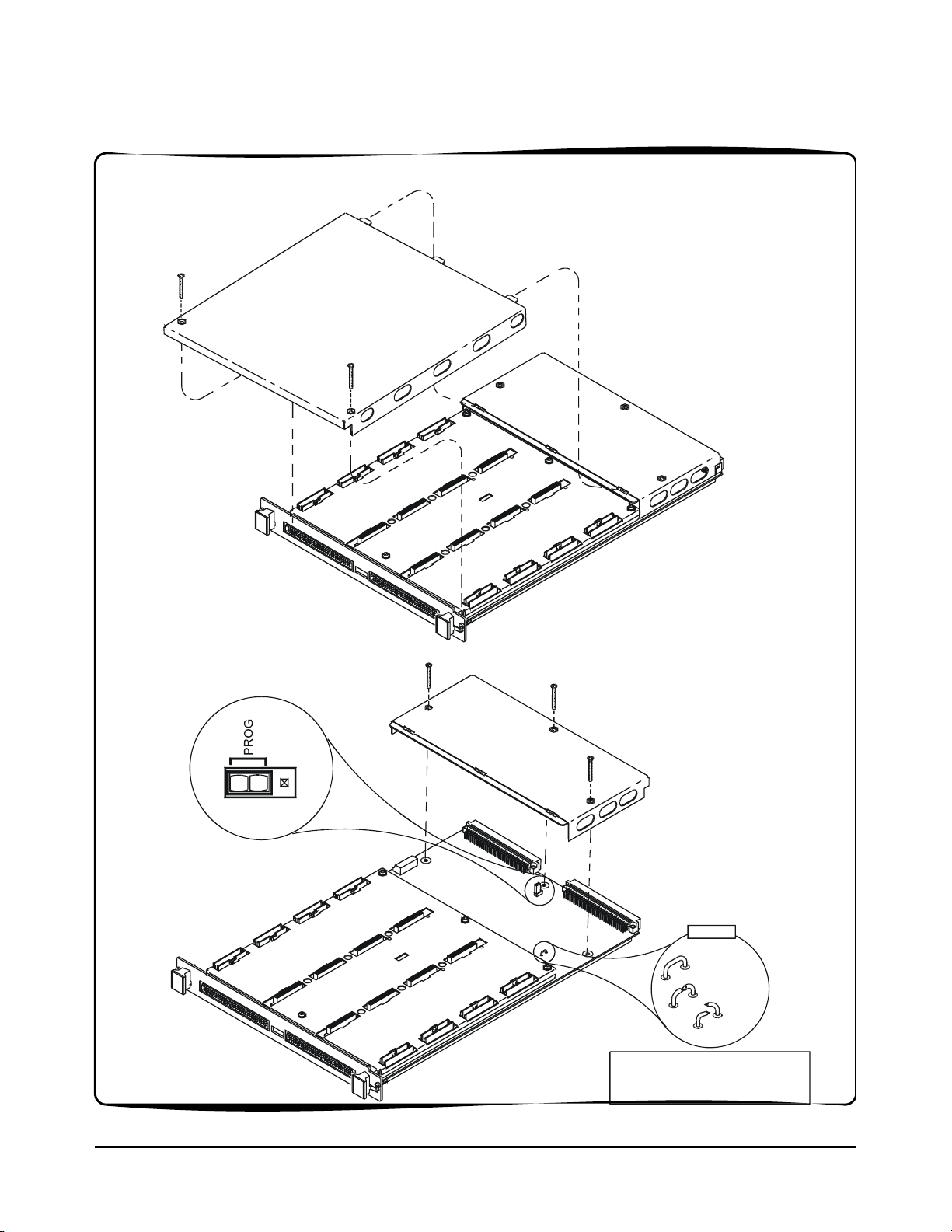

The following illustrations show the steps used to install Signal

Conditioning Plug-ons (SCPs). Before installing an SCPs, reading the

"Separating Digital and Analog SCP Signals" in Appendix E page 483 is

recommended.

Caution Use approved Static Discharge Safe handling procedures

anytime the covers are removed from the VT1422A or when

handling the SCPs.

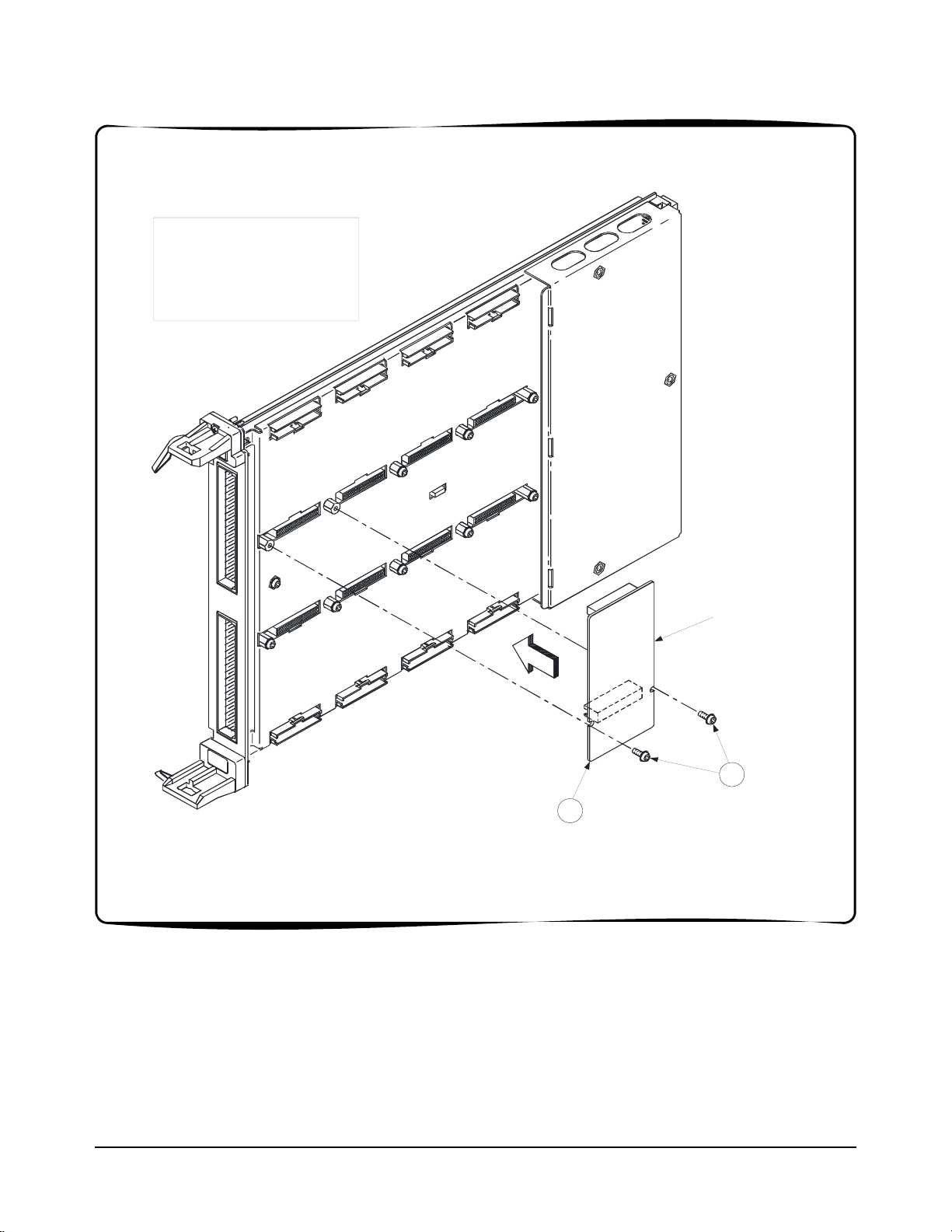

Installing SCPs: Step 1, Removing the Cover VT1422A

2

Remove the SCP

Retaining Screws

1

Remove2screws(#10Torx);

lift front and slide out tabs

Getting Started 25Chapter 1

Page 26

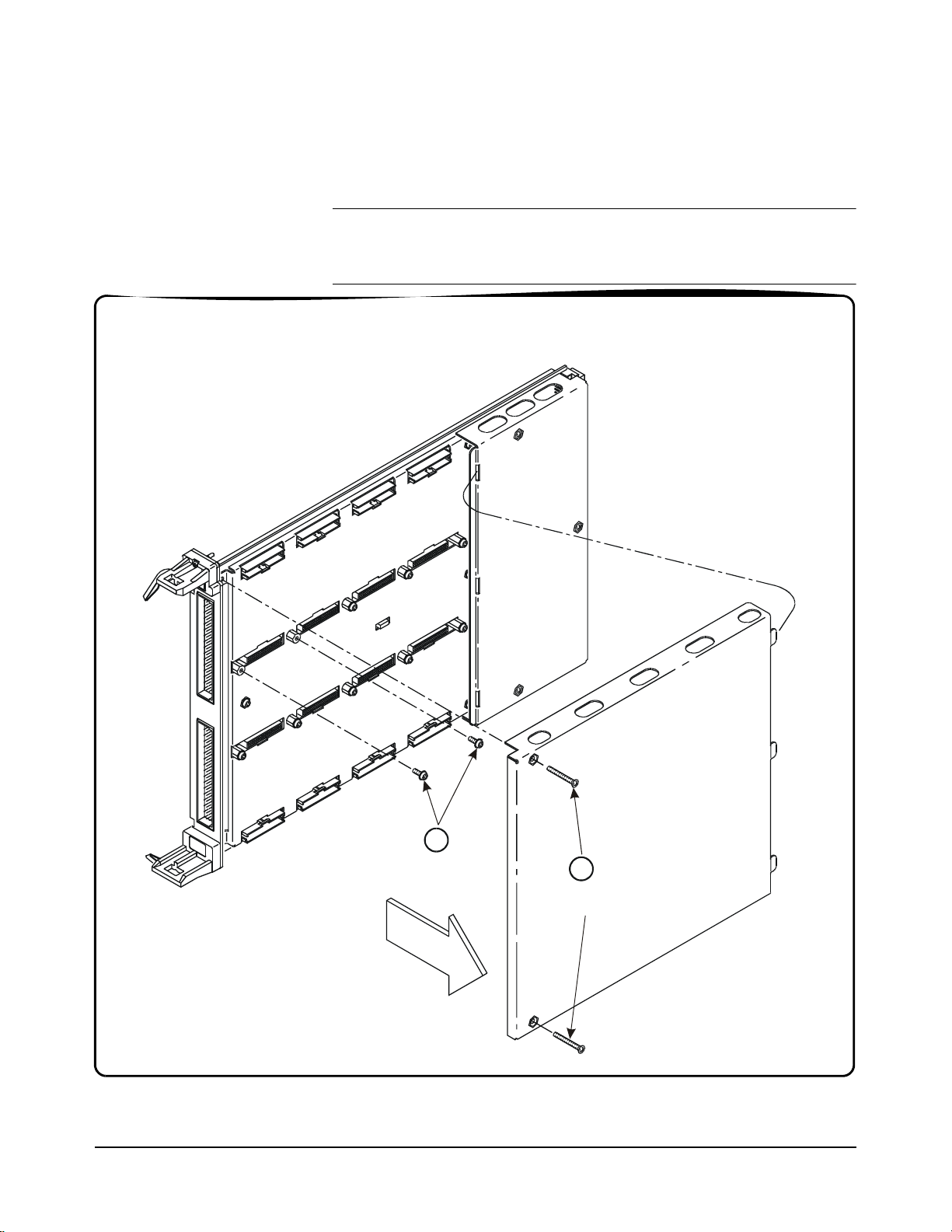

p

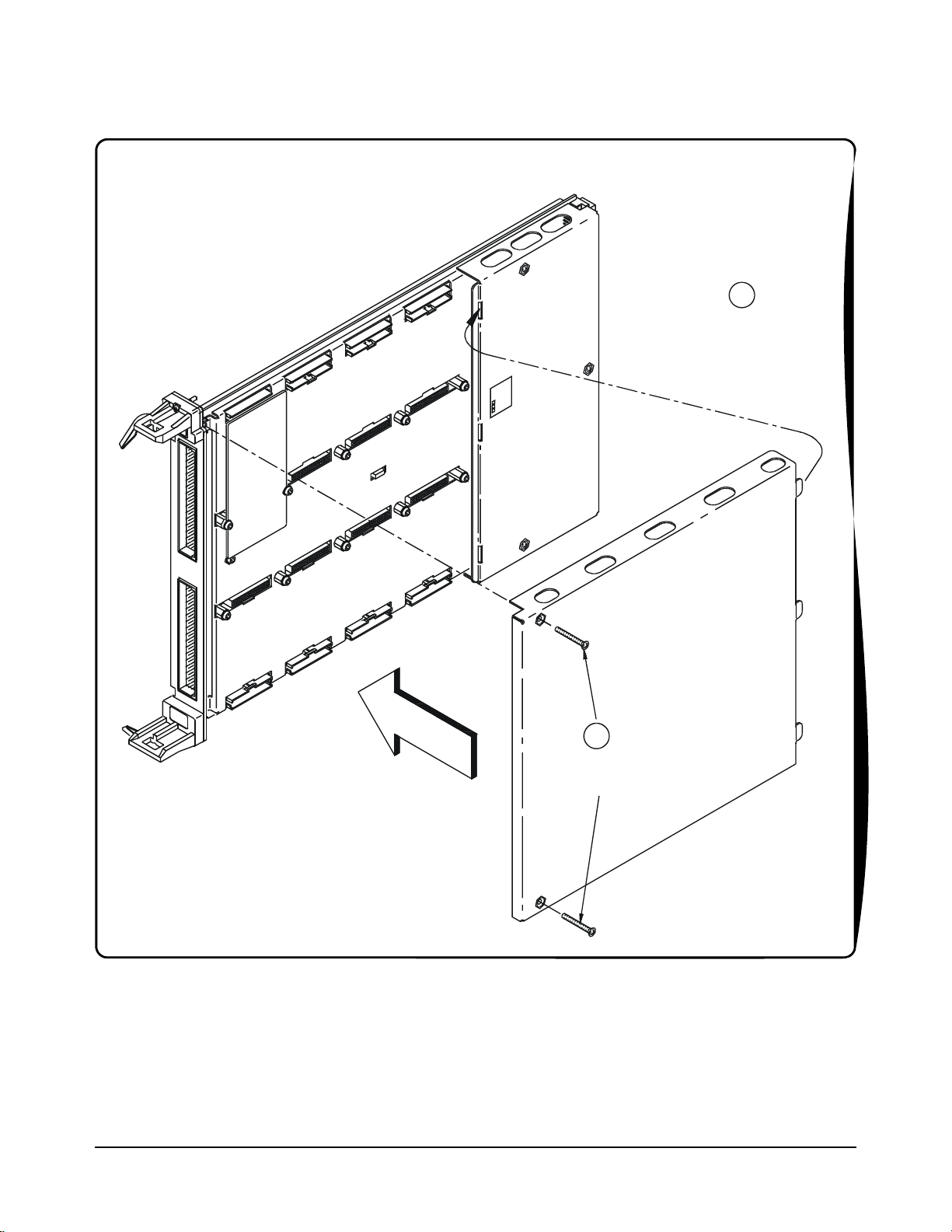

Installing SCPs: Step 2, Mounting an SCP

CAUTION

Use approved Static

Discharge handling

procedures when handling the

VT1422A Multifunction DAC

Modules and the SCPs

1

Align the SCP

connectors with the

Module connectors

and then

ush in

SCP

2

Tighten the SCP

Retaining Screws

26 Getting Started Chapter 1

Page 27

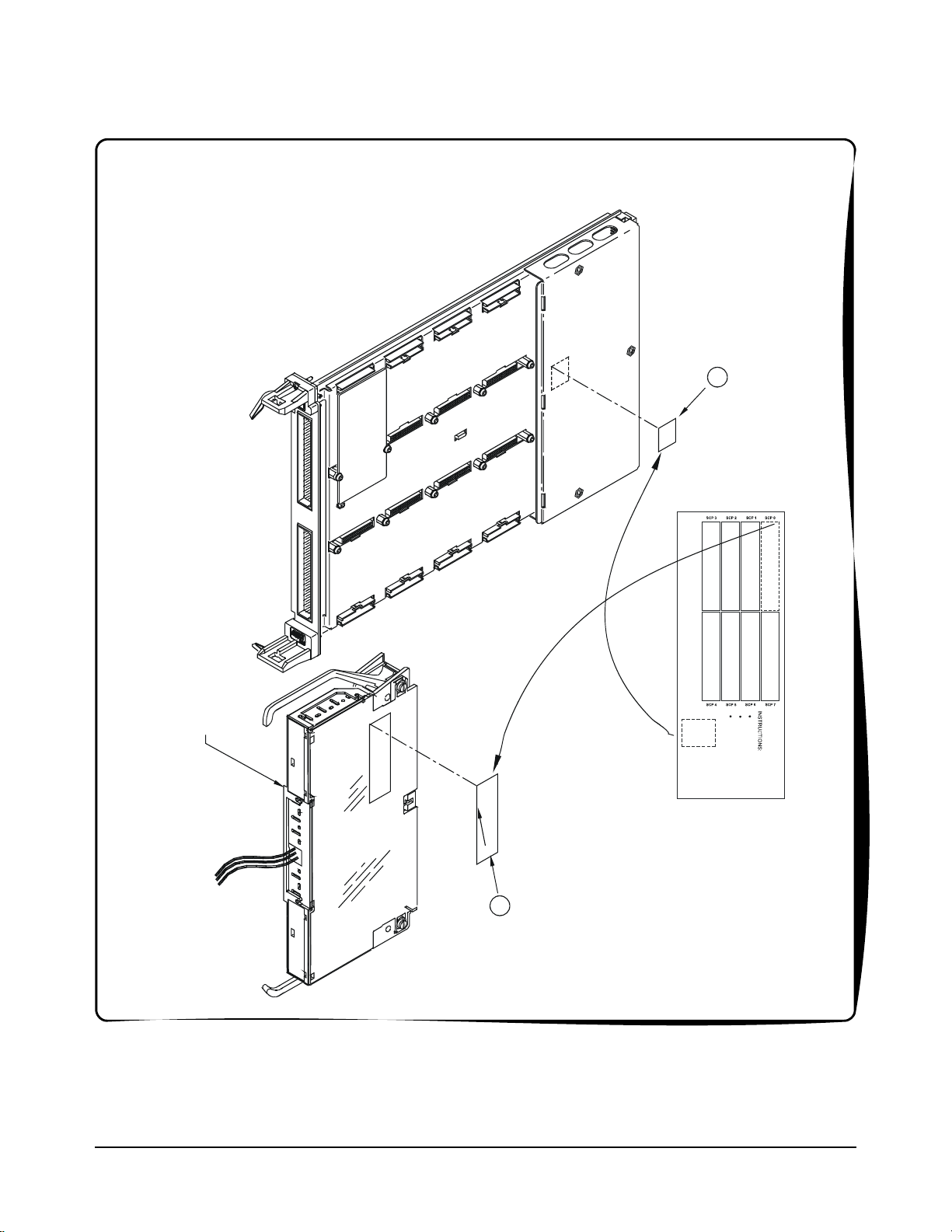

Installing SCPs: Step 3, Reinstalling the Cover VT1422A

1

Line up the 3 Tabs

with the 3 Slots;

then lower cover

onto the Module

2

Tighten

2Screws

Getting Started 27Chapter 1

Page 28

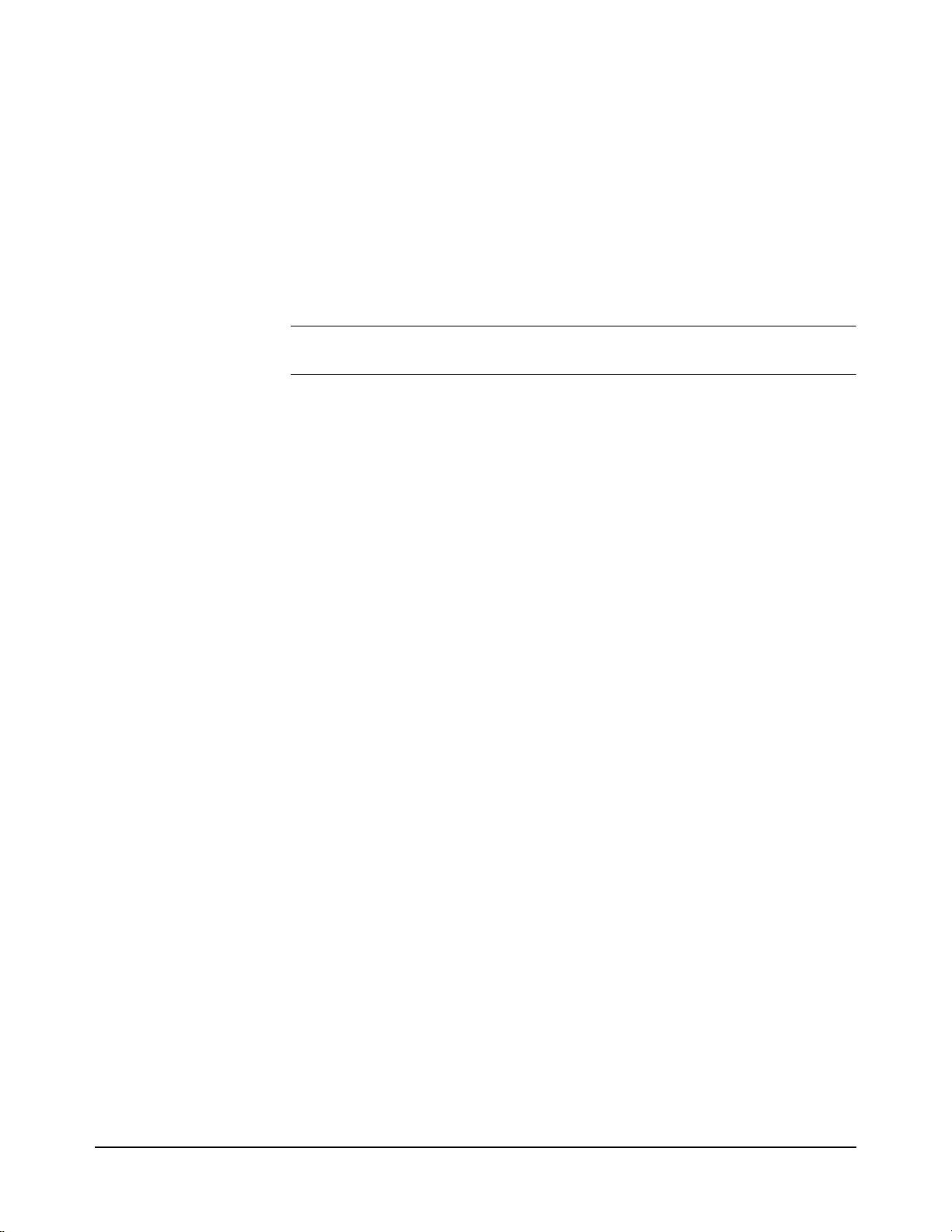

Installing SCPs: Step 4, Labeling

Peel off correct

Label from Card and

Stick on the

appropriate place on

the Cover

1

Terminal Module

(Connect t o A/D

Module Later)

S1

Stick-on Label furnished with the SCP

(Part Number: 43-0133-xxx)

2

Peel off Label from

Card and Stick on

the Terminal

Moduletobe

Connected to the

A/D Mo dule

28 Getting Started Chapter 1

Page 29

Disabling the

Input Protect

Feature

(Optional)

Voids Warranty! Disabling the Input Protection Feature voids the VT1422A's warranty.

Disabling the Input Protect feature voids the VT1422A's warranty. The Input

Protect feature allows the VT1422A to open all channel input relays if any input's

voltage exceeds ±19 volts (±6 volts for digital I/O SCPs). This feature will help to

protect the card's Signal Conditioning Plug-ons, input multiplexer, ranging

amplifier and A/D from destructive voltage levels. The level that trips the protection

function has been set to provide a high probability of protection. The voltage level

that is certain to cause damage is somewhat higher. If, in an application, the

importance of completing a measurement run outweighs the added risk of

damage to the VT1422A, the input protect feature may be disabled.

To disable the Input Protection feature, locate and cut JM2202. Make a single cut in

the jumper and bend the adjacent ends apart. See following illustration for location

of JM2202.

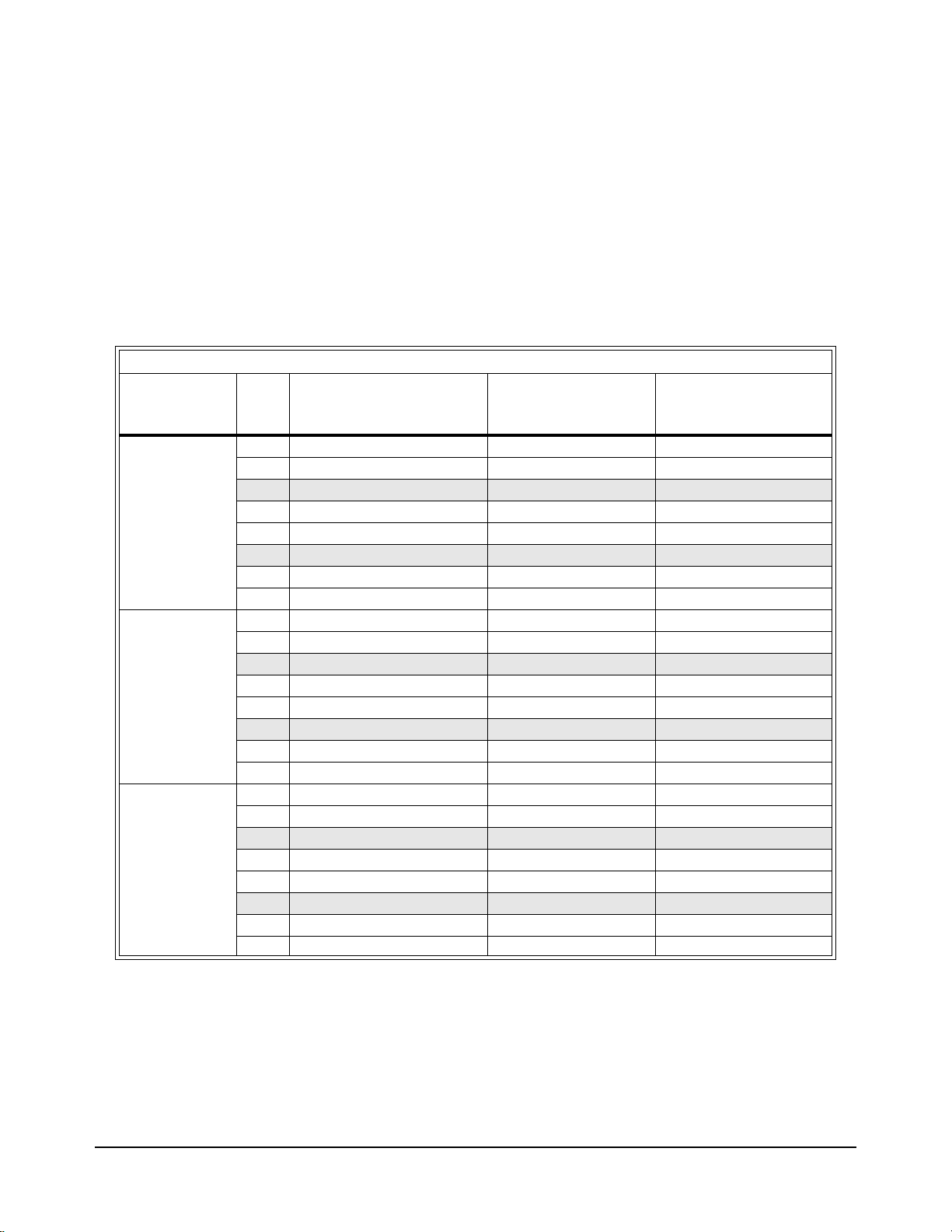

Disabling

Flash Memory

Access

(Optional)

The Flash Memory Protect Jumper (JM2201) is shipped in the “PROG” position. It

is recommended that the jumper be left in this position so that all of the calibration

commands can function. Changing the jumper to the protect position prevents the

following from being executed:

•The SCPI calibration command CAL:STORE ADC | TARE

•The register-based calibration commands STORECAL and STORETAR

•Any application that installs firmware-updates or makes any other

modification to Flash Memory through the A24 window.

With the jumper in the “PROG” position, one or more VT1422As can be completely

calibrated without removing them from the application system. A VT1422A

calibrated in its working environment will, in general, be better calibrated than if it

were calibrated separate from its application system.

The multimeter used during the periodic calibration cycle should be considered the

calibration transfer standard. Allow Calibration Organization control unauthorized

access to the calibration constants.

If access must be limited to the VT1422A's calibration constants, place JM2201 in

the protected position and cover the shield retaining screws with calibration

stickers. See the following illustration for location of JM2201.

Getting Started 29Chapter 1

Page 30

Accessing and Locating JM2201 and JM2202 VT1422A

Flash Memory Protect Jumper

Default = PROG

(recommended)

JM2201

JM2202

1 Locate

2Cut

3 Bend

Input Protect Jumper

Warning: Cutting this Jumper

VoidsYour Warranty!

30 Getting Started Chapter 1

Page 31

Installing the Module

Installation of the VT1422A VXI module is covered in the mainframe manual.

WARNING All instruments within the VXI mainframe are grounded through

the mainframe chassis. During installation, tighten the