Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Page 2

bus

VT1419A

Plus

Multifunction

Measurement and Control Module

User’s Manual

APPLICABILITY

This manual edition is intended for use with the following instrument drivers:

·

Downloaded driver revision A.01.02 or later for Command Modules

·

C-SCPI driver revision D.01.02 or later

Call your local VXI Technology Sales Office for information on other drivers.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Copyright © VXI Technology, Inc., 2005

P/N: 82-0075-000

Printed: August 15, 2005

Printed in U.S.A.

Page 3

Certification

VXI Technology,Inc., certifies that this product metits published specifications at the timeof shipment fromthe factory. VXI Technology

further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology

(formerly National Bureau of Standards), to the extent allowed by that organization’s calibration facility and to the calibration facilities

of other International Standards Organization members.

Warranty

This VXI Technology product is warranted against defects in materials and workmanship for a period of three years from date of

shipment. Duration and conditions of warranty for this product may be superseded whenthe product is integratedinto (becomes a partof)

other VXITechnology products. During thewarranty period, VXI Technology, will,at its option,either repair orreplace products which

prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by VXI Technology. Buyer shall prepay

shipping charges to VXI Technology and VXI Technology shall pay shipping charges to return the product to Buyer. However, Buyer

shall pay all shipping charges, duties, and taxes for products returned to VXI Technology from another country.

VXI Technology warrants that its software and firmware designated by VXI Technology for use with a product will execute its

programming instructions whenproperly installed onthat product. VXI Technology does not warrant that the operation of theproduct or

software or firmware will be uninterrupted or error free.

Limitation Of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by Buyer, Buyer-supplied products

or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product or improper

site preparation or maintenance.

The design andimplementation of any circuit onthis product is the soleresponsibility of the Buyer. VXI Technology doesnot warrant the

Buyer’s circuitry or malfunctions of VXI Technology products that result from the Buyer’s circuitry. In addition, VXI Technology does

not warrant any damage that occurs as a result of the Buyer’s circuit or any defects that result from Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. VXI TECHNOLOGY SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREINAREBUYER’SSOLE AND EXCLUSIVE REMEDIES. VXI TECHNOLOGY SHALL NOT

BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER BASED

ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The information contained in this document is subject to change without notice. VXI TECHNOLOGY MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. VXI Technology shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material. This document

contains proprietary information which is protected by copyright. All rights are reserved. No part ofthis document may be photocopied,

reproduced, or translated to another language without the prior written consent of VXI Technology. VXI Technology assumes no

responsibility for the use or reliability of its software on equipment that is not furnished by VXI Technology.

Restricted Rights Legend

U.S. Government Restricted Rights. The Software and Documentation have been developed entirely at private expense. They are

delivered and licensedas “commercial computer software” asdefined in DFARS 252.227- 7013(Oct1988), DFARS 252.211-7015 (May

1991) or DFARS 252.227-7014 (Jun 1995), as a “commercial item” as defined in FAR 2.101(a) or as “Restricted computer software” as

defined in FAR 52.227-19 (Jun 1987)(or any equivalent agency regulation or contract clause), whichever is applicable. You have only

those rights provided for such Software and Documentation by the applicable FAR or DFARS clause or the VXI Technology standard

software agreement for the product involved.

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

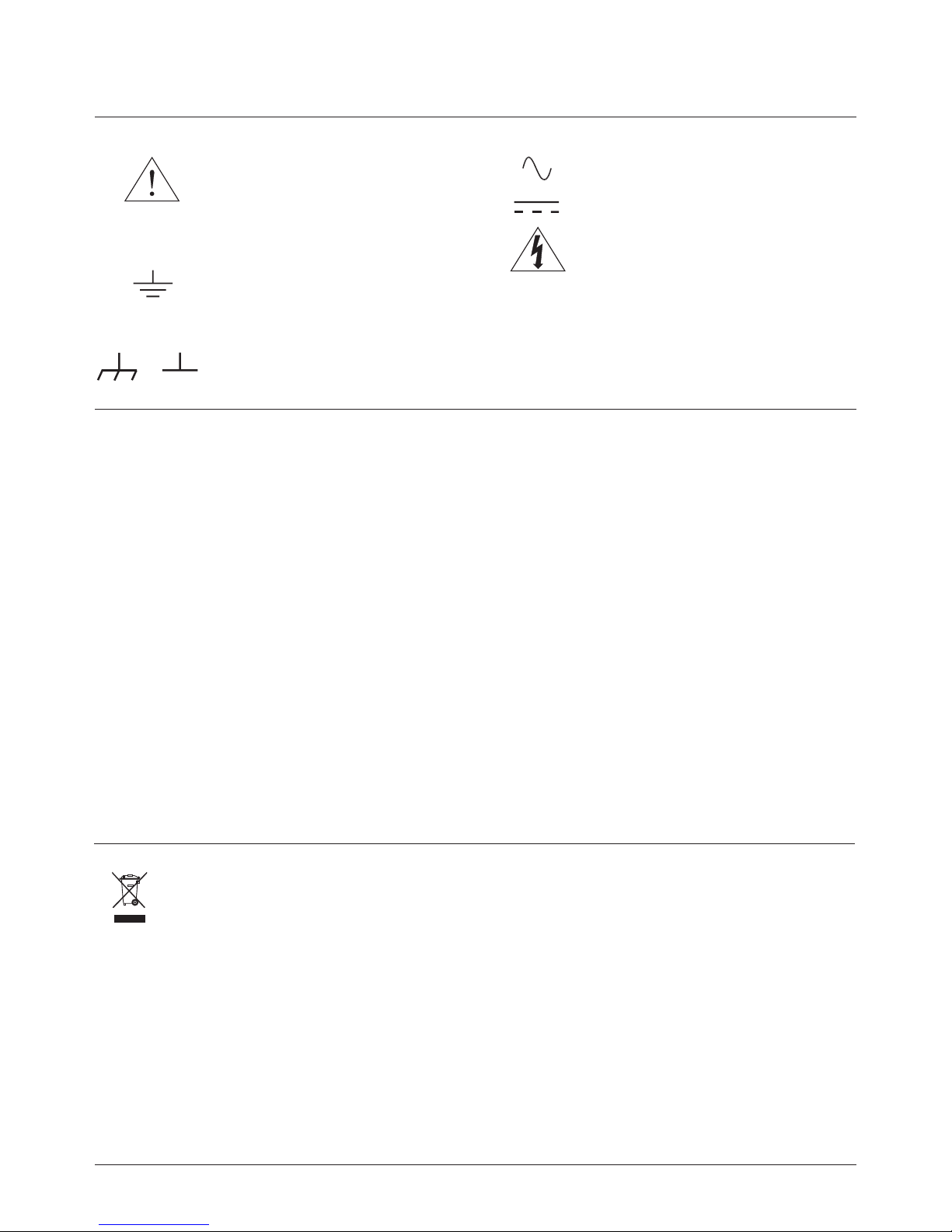

Safety Symbols

Instruction manual symbol affixed to

product. Indicates that the user must refer

Alternating current (ac).

to the manual for specific WARNING or

CAUTION information to avoid personal

injury or damage to the product.

Direct current (dc).

Indicates hazardous voltages.

Indicates the field wiring terminal that must

be connected to earth ground before

operating the equipment—protects against

electrical shock in case of fault.

or

Frame or chassis ground

terminal—typically connects to the

WARNING

CAUTION

equipment’s metal frame.

Calls attention to a procedure, practice or

condition that could cause bodily injury or

death.

Calls attention to a procedure, practice, or

condition that couldpossibly cause damage to

equipment or permanent loss of data.

Warnings

The following general safety precautions must be observed during all phases of operation, service, and repair of this product.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture and intended use of the product. VXI Technology assumes no liability for the customer’s failure to comply with

these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment switched off. To avoid dangerouselectrical shock, DO NOTperform procedures involving cover or shield removal unlessyou

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to a VXI Technology Sales and Service

Office for service and repair to ensure that safety features are maintained.

Note for European Customers

If this symbolappears on your product,itindicates that it was manufactured after August 13,2005.This markisplaced in accordance with EN

50419, Marking of electrical and electronic equipment in accordance with Article 11(2) of directive 2002/96/EC (WEEE). End-of-life

product can be returned to VTI by obtaining an RMA number.Feesforrecyclingwillapplyif not prohibited by national law. SCP cards for use

with the VT1415A have this mark placed on their packaging due to the densely populated nature of these cards.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 5

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Table of Contents

Warranty ................................................................. 2

Warnings ................................................................. 3

Safety Symbols ............................................................ 3

Note for European Customers .................................................3

Support Resources......................................................... 13

Chapter 1. Getting Started ....................................................... 15

About This Chapter ........................................................15

Configuring the VT1419A .................................................. 15

Setting the Logical Address Switch.......................................... 15

Installing SCPs ......................................................... 16

Disabling the Input Protect Feature (Optional) ................................. 21

Disabling Flash Memory Access (Optional) ...................................21

Instrument Drivers......................................................... 23

About Example Programs ................................................... 23

Verifying a Successful Configuration ..........................................23

Chapter 2. Field Wiring.......................................................... 25

About This Chapter ........................................................25

Planning the Wiring Layout ................................................. 25

SCP Positions and Channel Numbers ........................................ 25

SCP Types and Signal Paths ............................................... 25

Pairing Sense and Source SCPs for Resistance Measurements .....................27

Planning for Thermocouple Measurements....................................28

Faceplate Connector Pin-Signal Lists .......................................... 29

Optional Terminal Modules ................................................. 30

The SCPs and Terminal Module Connections.................................. 30

Option 11 Terminal Module Layout ......................................... 31

Option 12 Terminal Module Layout ......................................... 32

Reference Temperature Sensing with the VT1419A...............................33

Configuring the On-Board/Remote Reference Jumpers ............................34

Preferred Measurement Connections .......................................... 36

Wiring and Attaching the Terminal Module .....................................39

Attaching/Removing the VT1419A Terminal Module .............................41

Adding Components to the Option 12 Terminal Module ........................... 43

Option 11 Terminal Module Wiring Map .......................................44

Option 12 Terminal Module Wiring Map .......................................45

The Option A3F .......................................................... 46

Chapter 3. Programming the VT1419A Multifunction

About This Chapter ........................................................47

Overview of the VT1419A Multifunction

Multifunction

Operating Model .......................................................... 52

Executing The Programming Model ...........................................53

Power-On and *RST Default Settings ........................................ 53

Setting Up Analog Input and Output Channels ................................... 56

Configuring Programmable Analog SCP Parameters ............................56

Contents 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Plus

.................................47

Plus

Plus

?........................................................ 48

....................................48

Page 7

Setting Filter Cutoff Frequency ............................................. 57

Linking Channels to EU Conversion ......................................... 58

Linking Output Channels to Functions ....................................... 66

Setting Up Digital Input and Output Channels ................................... 66

Setting Up Digital Inputs .................................................. 66

Setting Up Digital Outputs ................................................ 67

Performing Channel Calibration (Important!)....................................71

Defining C Language Algorithms ............................................ 73

Global Variable Definition ................................................ 73

Algorithm Definition ..................................................... 74

Pre-Setting Algorithm Variables ............................................74

Defining Data Storage ...................................................... 75

Specifying the Data Format ................................................ 75

Selecting the FIFO Mode.................................................. 76

Setting up the Trigger System ................................................ 77

Arm and Trigger Sources ................................................. 77

Programming the Trigger Timer ............................................ 79

Setting the Trigger Counter ................................................79

Outputting Trigger Signals ................................................ 79

Initiating/Running Algorithms ............................................... 80

Starting Algorithms ...................................................... 80

The Operating Sequence .................................................. 81

Retrieving Algorithm Data .................................................. 81

Modifying Running Algorithm Variables .......................................85

Updating the Algorithm Variables and Coefficients .............................85

Enabling and Disabling Algorithms ......................................... 85

Setting Algorithm Execution Frequency ......................................86

Example Command Sequence................................................ 86

Using the Status System .................................................... 88

Enabling Events to be Reported in the Status Byte ..............................91

Reading the Status Byte................................................... 92

Clearing the Enable Registers .............................................. 93

The Status Byte Group’s Enable Register .....................................93

Reading Status Groups Directly ............................................ 93

VT1419A Background Operation .............................................94

Updating the Status System and VXIbus Interrupts ............................... 95

Creating and Loading Custom EU Conversion Tables .............................96

Compensating for System Offsets ............................................. 97

Special Considerations.................................................... 99

Detecting Open Transducers ................................................100

More On Auto Ranging.................................................... 101

Settling Characteristics .................................................... 101

Background ........................................................... 101

Checking for Problems .................................................. 102

Fixing the Problem ..................................................... 102

Chapter 4. The Algorithm Language and Environment ..............................105

About This Chapter .......................................................105

Overview of the Algorithm Language......................................... 106

Example Language Usage ................................................107

The Algorithm Execution Environment ....................................... 108

The Main Function

6 Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

..................................................... 108

Page 8

How User Algorithms Fit In .............................................. 108

Accessing the VT1419A’s Resources .........................................109

Accessing I/O Channels.................................................. 110

Defining and Accessing Global Variables....................................111

Determining First Execution (First_loop) .................................... 111

Initializing Variables .................................................... 112

Sending Data to the CVT and FIFO ........................................ 112

Setting a VXIbus Interrupt ............................................... 113

Calling User Defined Functions ........................................... 114

Operating Sequence....................................................... 114

Overall Sequence....................................................... 114

Algorithm Execution Order ............................................... 116

Defining Algorithms (ALG:DEF) ............................................ 116

ALG:DEFINE in the Programming Sequence................................. 116

ALG:DEFINE’s Two Data Formats ........................................ 117

Changing an Algorithm While It Is Running ................................. 118

A Very Simple First Algorithm..............................................120

Writing the Algorithm ...................................................120

Running the Algorithm .................................................. 120

Non-Control Algorithms ................................................... 121

Data Acquisition Algorithm .............................................. 121

Process Monitoring Algorithm ............................................ 121

Algorithm Language Reference ............................................. 122

Standard Reserved Keywords ............................................. 122

Special VT1419A Reserved Keywords ...................................... 122

Identifiers............................................................. 122

Special Identifiers for Channels............................................ 123

Operators ............................................................. 123

Intrinsic Functions and Statements ......................................... 124

Program Flow Control ................................................... 124

Data Types............................................................ 125

Data Structures ........................................................ 126

Using Type Float in Integer Situations ...................................... 127

Language Syntax Summary................................................. 129

Program Structure and Syntax...............................................133

Declaring Variables ..................................................... 133

Assigning Values....................................................... 133

The Operations Symbols ................................................. 134

Conditional Execution ................................................... 134

Comment Lines ........................................................ 136

Overall Program Structure................................................ 137

About This Chapter .......................................................139

Wiring Connections and File Locations for the Examples ......................... 143

Example File Location................................................... 143

Installing Example Files ................................................. 143

Virtual Front Panel Program ................................................ 144

Calibration.............................................................. 147

Function Test............................................................ 148

Programming Model Example............................................... 149

Error Checking .......................................................... 152

Configuration Display

..................................................... 153

Engineering Unit Conversion ............................................... 154

Contents 7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Custom Function Generation................................................ 156

Custom EU/Function Example .............................................. 158

Curve Fitting and EU Generation ............................................ 160

Interrupt Handling ........................................................ 161

Simple Data Logger Example ............................................... 163

Modification of Variables and Arrays ......................................... 166

Algorithm Modification.................................................... 168

Driver Download......................................................... 170

Firmware-Update Download ................................................ 171

Chapter 6. VT1419A Command Reference ......................................... 173

ABORt ................................................................ 185

ALGorithm ............................................................. 186

ALGorithm[:EXPLicit]:ARRay ........................................... 187

ALGorithm[:EXPLicit]:ARRay? .......................................... 188

ALGorithm[:EXPLicit]:DEFine ........................................... 188

ALGorithm[:EXPLicit]:SCALar ..........................................192

ALGorithm[:EXPLicit]:SCALar? ......................................... 193

ALGorithm[:EXPLicit]:SCAN:RATio ...................................... 193

ALGorithm[:EXPLicit]:SCAN:RATio? ..................................... 194

ALGorithm[:EXPLicit]:SIZe? ............................................ 194

ALGorithm[:EXPLicit][:STATe] .......................................... 195

ALGorithm[:EXPLicit][:STATe]? ......................................... 196

ALGorithm[:EXPLicit]:TIME? ........................................... 196

ALGorithm:FUNCtion:DEFine ........................................... 197

ALGorithm:OUTPut:DELay .............................................198

ALGorithm:OUTPut:DELay? ............................................ 199

ALGorithm:UPDate[:IMMediate] ......................................... 199

ALGorithm:UPDate:CHANnel ............................................200

ALGorithm:UPDate:WINDow ............................................ 202

ALGOrithm:UPDate:WINDow? .......................................... 203

ARM.................................................................. 204

ARM[:IMMediate] ..................................................... 205

ARM:SOURce ........................................................ 205

ARM:SOURce? ........................................................ 206

CALibration ............................................................ 207

CALibration:CONFigure:RESistance ...................................... 208

CALibration:CONFigure:VOLTage ........................................ 209

CALibration:SETup..................................................... 210

CALibration:SETup?....................................................210

CALibration:STORe .................................................... 211

CALibration:TARE .................................................... 212

CALibration:TARE:RESet ............................................... 214

CALibration:TARE? .................................................... 214

CALibration:VALue:RESistance ......................................... 214

CALibration:VALue:VOLTage ........................................... 215

CALibration:ZERO? .................................................... 216

DIAGnostic ............................................................. 218

DIAGnostic:CALibration:SETup[:MODE]................................... 219

DIAGnostic:CALibration:SETup[:MODE]?..................................219

DIAGnostic:CALibration:TARE[:OTDetect]:MODE ..........................220

DIAGnostic:CALibration:TARE[:OTDetect]:MODE?.......................... 220

8 Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

DIAGnostic:CHECksum? ................................................ 221

DIAGnostic:CUSTom:LINear............................................. 221

DIAGnostic:CUSTom:PIECewise.......................................... 222

DIAGnostic:CUSTom:REFerence:TEMPerature ..............................222

DIAGnostic:IEEE ...................................................... 223

DIAGnostic:IEEE? ..................................................... 223

DIAGnostic:INTerrupt[:LINe] ............................................ 223

DIAGnostic:INTerrupt[:LINe]? ........................................... 224

DIAGnostic:OTDetect[:STATe] ...........................................224

DIAGnostic:OTDetect[:STATe]? .......................................... 225

DIAGnostic:QUERy:SCPREAD? ..........................................225

DIAGnostic:VERSion? .................................................. 226

FETCh? ................................................................ 227

FORMat................................................................ 229

FORMat[:DATA] ...................................................... 229

FORMat[:DATA]? ..................................................... 230

INITiate ................................................................ 232

INITiate[:IMMediate] ................................................... 232

INPut ................................................................. 233

INPut:DEBounce:TIME ................................................. 233

INPut:FILTer[:LPASs]:FREQuency ........................................ 234

INPut:FILTer[:LPASs]:FREQuency? .......................................235

INPut:FILTer[:LPASs][:STATe] .......................................... 236

INPut:FILTer[:LPASs][:STATe]?.......................................... 236

INPut:GAIN .......................................................... 237

INPut:GAIN? ......................................................... 237

INPut:LOW ........................................................... 238

INPut:LOW? .......................................................... 238

INPut:POLarity ........................................................ 239

INPut:POLarity? ....................................................... 239

INPut:THReshold:LEVel?................................................ 239

MEMory ............................................................... 241

MEMory:VME:ADDRess ................................................ 242

MEMory:VME:ADDRess? ...............................................242

MEMory:VME:SIZE....................................................242

MEMory:VME:SIZE? ................................................... 243

MEMory:VME:STATe .................................................. 243

MEMory:VME:STATe? ................................................. 244

OUTPut ................................................................ 245

OUTPut:CURRent:AMPLitude............................................ 245

OUTPut:CURRent:AMPLitude? ........................................... 246

OUTPut:CURRent[:STATe] ..............................................247

OUTPut:CURRent[:STATe]? ............................................. 247

OUTPut:POLarity ...................................................... 248

OUTPut:POLarity? ..................................................... 248

OUTPut:SHUNt ....................................................... 248

OUTPut:SHUNt? ...................................................... 249

OUTPut:TTLTrg:SOURce ............................................... 249

OUTPut:TTLTrg:SOURce? .............................................. 250

OUTPut:TTLTrg<n>[:STATe] ............................................ 250

OUTPut:TTLTrg<n>[:STATe]?

........................................... 251

OUTPut:TYPE......................................................... 251

Contents 9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

OUTPut:TYPE?........................................................252

OUTPut:VOLTage:AMPLitude ........................................... 252

OUTPut:VOLTage:AMPLitude? .......................................... 252

ROUTe ................................................................ 254

ROUTe:SEQuence:DEFine? ............................................. 254

ROUTe:SEQuence:POINts? .............................................. 255

SAMPle ................................................................ 256

SAMPle:TIMer ........................................................ 256

SAMPle:TIMer? ....................................................... 256

[SENSe]................................................................ 258

[SENSe:]CHANnel:SETTling.............................................259

[SENSe:]CHANnel:SETTling? ............................................ 260

[SENSe:]DATA:CVTable? .............................................. 260

[SENSe:]DATA:CVTable:RESet .......................................... 261

[SENSe:]DATA:FIFO[:ALL]? ............................................ 261

[SENSe:]DATA:FIFO:COUNt? ........................................... 262

[SENSe:]DATA:FIFO:COUNt:HALF? .....................................263

[SENSe:]DATA:FIFO:HALF? ............................................ 263

[SENSe:]DATA:FIFO:MODE ............................................ 264

[SENSe:]DATA:FIFO:MODE? ........................................... 264

[SENSe:]DATA:FIFO:PART? ............................................ 265

[SENSe:]DATA:FIFO:RESet ............................................. 265

[SENSe:]FREQuency:APERture........................................... 266

[SENSe:]FREQuency:APERture? .......................................... 267

[SENSe:]FUNCtion:CONDition ...........................................267

[SENSe:]FUNCtion:CUSTom............................................. 268

[SENSe:]FUNCtion:CUSTom:REFerence ................................... 269

[SENSe:]FUNCtion:CUSTom:TCouple ..................................... 270

[SENSe:]FUNCtion:FREQuency .......................................... 271

[SENSe:]FUNCtion:RESistance ........................................... 271

[SENSe:]FUNCtion:STRain:FBENding .....................................272

[SENSe:]FUNCtion:TEMPerature ......................................... 274

[SENSe:]FUNCtion:TOTalize............................................. 275

[SENSe:]FUNCtion:VOLTage[:DC] ....................................... 276

[SENSe:]REFerence .................................................... 277

[SENSe:]REFerence:CHANnels .......................................... 278

[SENSe:]REFerence:TEMPerature ........................................ 279

[SENSe:]STRain:EXCitation.............................................. 279

[SENSe:]STRain:EXCitation?............................................. 280

[SENSe:]STRain:GFACtor ............................................... 280

[SENSe:]STRain:GFACtor? .............................................. 280

[SENSe:]STRain:POISson ............................................... 281

[SENSe:]STRain:POISson?............................................... 281

[SENSe:]STRain:UNSTrained ............................................ 282

[SENSe:]STRain:UNSTrained? ........................................... 282

[SENSe:]TOTalize:RESet:MODE.......................................... 283

[SENSe:]TOTalize:RESet:MODE?......................................... 284

SOURce................................................................ 285

SOURce:FM[:STATe]................................................... 285

SOURce:FM:STATe? ................................................... 286

SOURce:FUNCtion[:SHAPe]:CONDition

...................................286

SOURce:FUNCtion[:SHAPe]:PULSe....................................... 287

10 Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

SOURce:FUNCtion[:SHAPe]:SQUare ......................................287

SOURce:PULM[:STATe] ................................................287

SOURce:PULM:STATe? ................................................ 288

SOURce:PULSe:PERiod.................................................288

SOURce:PULSe:PERiod? ................................................ 289

SOURce:PULSe:WIDTh................................................. 289

SOURce:PULSe:WIDTh? ................................................ 289

STATus ................................................................ 291

STATus:OPERation:CONDition?..........................................293

STATus:OPERation:ENABle ............................................. 294

STATus:OPERation:ENABle? ............................................ 294

STATus:OPERation[:EVENt]? ............................................ 295

STATus:OPERation:NTRansition.......................................... 295

STATus:OPERation:NTRansition? .........................................296

STATus:OPERation:PTRansition ..........................................296

STATus:OPERation:PTRansition? ......................................... 297

STATus:PRESet ....................................................... 297

STATus:QUEStionable:CONDition? ....................................... 298

STATus:QUEStionable:ENABle .......................................... 299

STATus:QUEStionable:ENABle?.......................................... 299

STATus:QUEStionable[:EVENt]? ......................................... 299

STATus:QUEStionable:NTRansition ....................................... 300

STATus:QUEStionable:NTRansition? ...................................... 301

STATus:QUEStionable:PTRansition ....................................... 301

STATus:QUEStionable:PTRansition? ...................................... 302

SYSTem ............................................................... 303

SYSTem:CTYPe? ...................................................... 303

SYSTem:ERRor? ...................................................... 304

SYSTem:VERSion? .................................................... 304

TRIGger ............................................................... 305

TRIGger:COUNt ...................................................... 307

TRIGger:COUNt? ..................................................... 307

TRIGger[:IMMediate] .................................................. 308

TRIGger:SOURce ...................................................... 308

TRIGger:SOURce? .................................................... 309

TRIGger:TIMer[:PERiod] ............................................... 309

TRIGger:TIMer[:PERiod]? .............................................. 310

Common Command Reference ............................................. 311

*CAL? .............................................................. 311

*CLS ................................................................ 312

*DMC <name>,<cmd_data>.............................................312

*EMC ............................................................... 312

*EMC?............................................................... 312

*ESE <mask>......................................................... 312

*ESE? ............................................................... 313

*ESR? ............................................................... 313

*GMC? <name> ....................................................... 313

*IDN? ............................................................... 313

*LMC?............................................................... 313

*OPC ................................................................ 314

*OPC? ............................................................... 314

*PMC................................................................ 315

Contents 11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

*RMC <name> ........................................................ 315

*RST ................................................................ 315

*SRE <mask>.........................................................316

*SRE? ............................................................... 316

*STB? ............................................................... 316

*TRG ................................................................ 316

*TST? ............................................................... 317

*WAI ................................................................ 320

Command Quick Reference ................................................ 321

Appendix A. Specifications ...................................................... 329

Appendix B. Error Messages .................................................... 359

Appendix C. Glossary .......................................................... 367

Appendix D. Wiring and Noise Reduction Methods .................................. 371

Separating Digital and Analog SCP Signals .................................... 371

Recommended Wiring and Noise Reduction Techniques ..........................372

Wiring Checklist ....................................................... 372

VT1419A Guard Connections ............................................. 373

Common Mode Voltage Limits ............................................ 373

When to Make Shield Connections .........................................373

Noise Due to Inadequate Card Grounding ..................................... 373

VT1419A Noise Rejection ................................................. 374

Normal Mode Noise (Enm) ...............................................374

Common Mode Noise (Ecm)..............................................374

Keeping Common Mode Noise out of the Amplifier ...........................374

Reducing Common Mode Rejection Using Tri-Filar Transformers ................375

Appendix E. Generating User Defined Functions .................................... 377

Introduction ............................................................. 377

Haversine Example ....................................................... 378

Limitations.............................................................. 380

Index ........................................................................ 381

12 Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Support Resources

Support resources for this product are available on the Internet and at VXI Technology

customer support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Instrument Division

VXI Technology, Inc.

7525 Granger Road, Unit 7

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail: support@vxitech.com

Visit http://www.vxitech.com for worldwide support sites and service plan information.

Support 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

14 Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

About This Chapter

This chapter will explain hardware configuration before installation in a VXIbus

mainframe. By attending to each of these configuration items, the VT1419A won’t

have to be removed from its mainframe later. Chapter contents include:

Configuring the VT1419A ............................page 15

·

Instrument Drivers .................................. page 23

·

About Example Programs .............................page 23

·

Verifying a Successful Configuration ....................page 23

·

Configuring the VT1419A

There are several aspects to configuring the module before installing it in a VXIbus

mainframe. They are:

Setting the Logical Address Switch .....................page 15

·

Installing Signal Conditioning Plug-ons ..................page 16

·

Disabling the Input Protect Feature ..................... page 21

·

Disabling Flash Memory Access .......................page 21

·

Chapter 1

Getting Started

NOTE Setting the VXIbus Interrupt Level: the VT1419A uses a default VXIbus interrupt

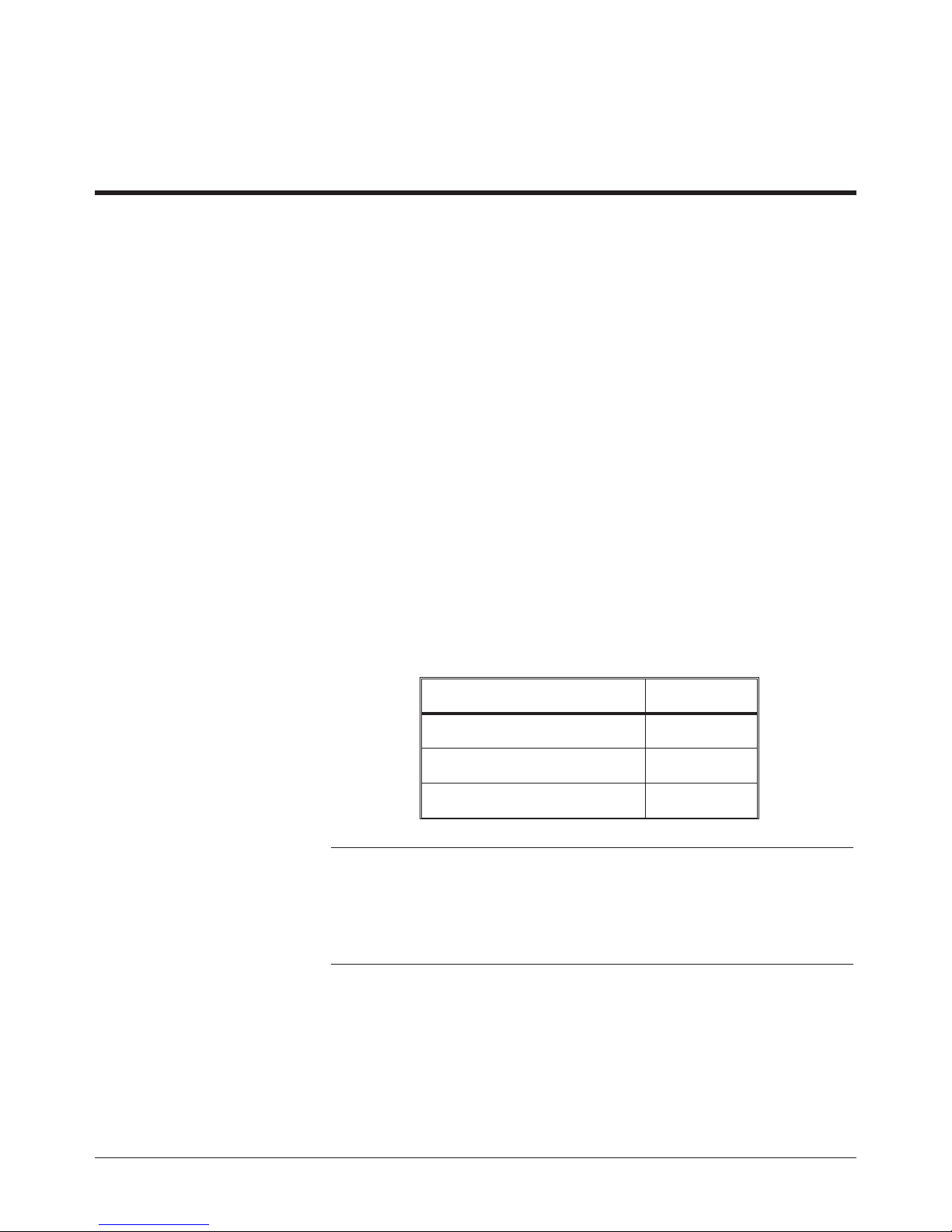

Setting the Logical

Address Switch

For most applications, only the Logical Address switch need be changed and the

SCPs installed in the mainframe prior to installation. The other settings can be

used as delivered.

Switch/Jumper Setting

Logical Address Switch

Input Protect Jumper

Flash Memory Protect Jumper

level of 1. The default setting is in effect at power-on and after a *RST command.

The interrupt level can be changed by executing the DIAGnostic:INTerrupt[:LINe]

command in the application program.

Follow the next figure and ignore any switch numbering printed on the Logical

Address switch. When installing more than one VT1419A in a single VXIbus

Mainframe, set each instrument to a different Logical Address.

208

Protected

PROG

Chapter 1 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

Getting Started

Configuring the VT1419A

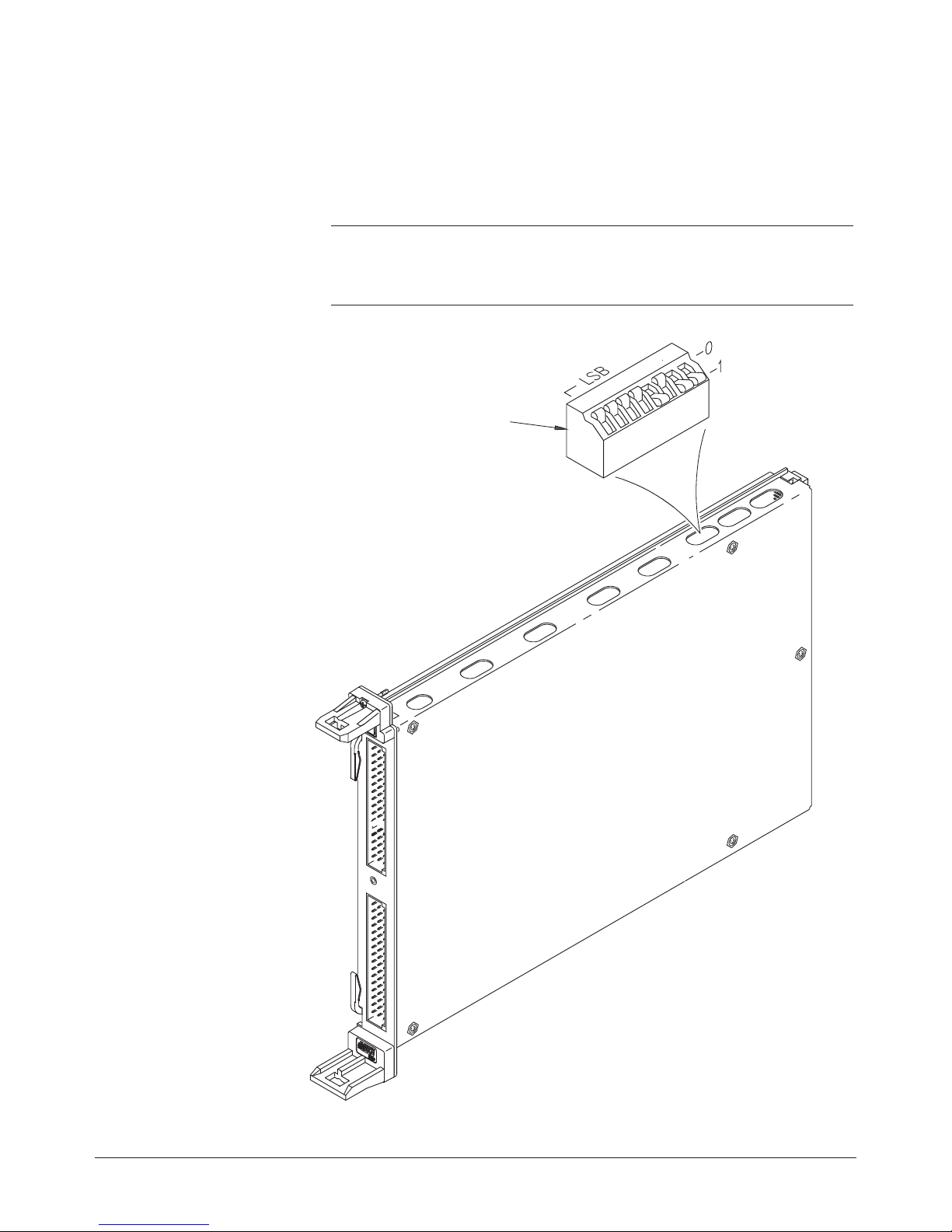

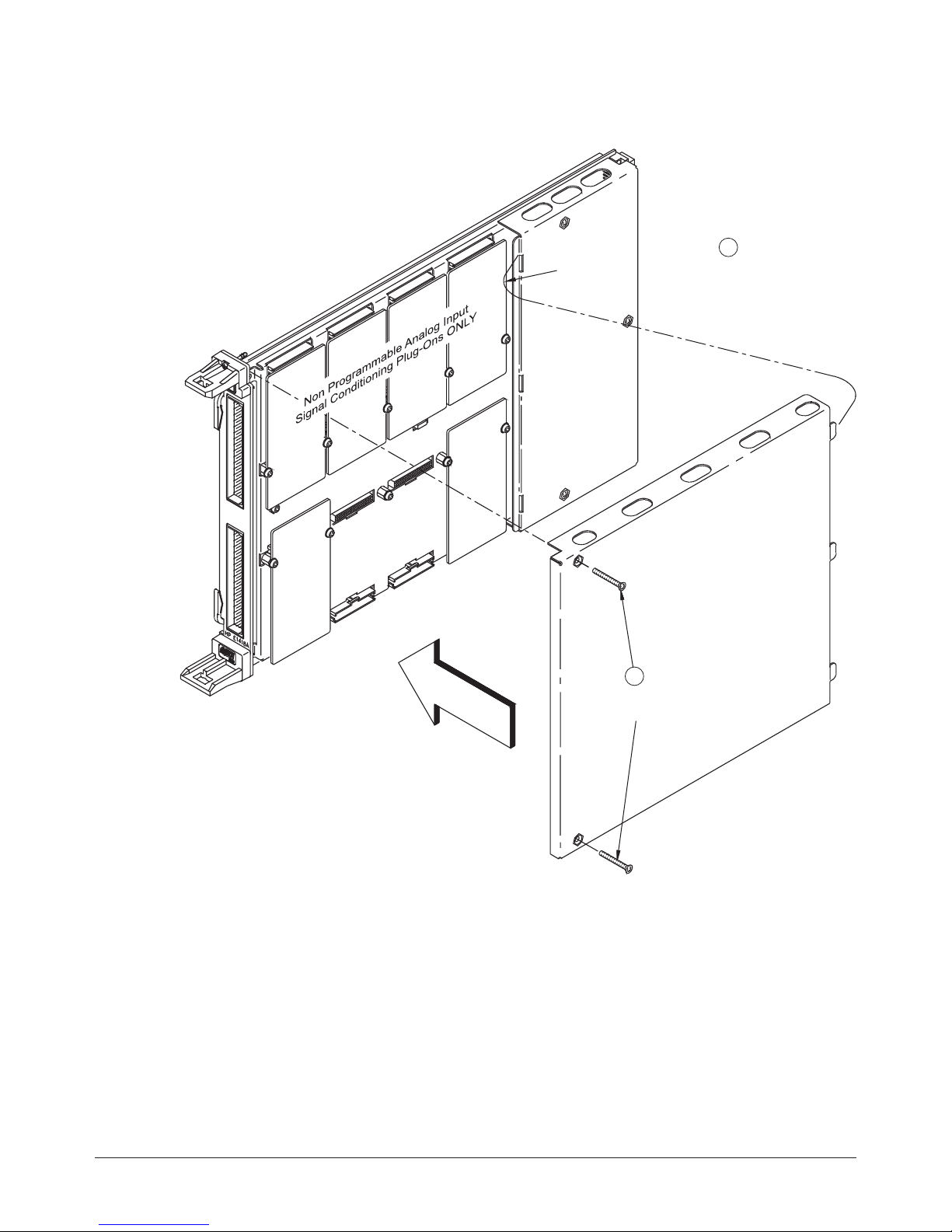

Installing SCPs The following illustrations show the steps used to install Signal Conditioning

Plug-Ons (SCPs). The VT1419A supports only non-programmable analog input

SCPs in positions 0 through 3. Any mix of SCP types can be installed in SCP

positions 4 through 7.

CAUTION Use approved Static Discharge Safe handling procedures anytime the covers are

removed from the VT1419A or are handling SCPs.

Setting Logical Address Switch – VT1419A

Default Switch Setting

LOGICAL ADDRESS = 208

16 Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Note The only SCPs supported in SCP positions 0 through 3 are:

VT1501A VT1513A

VT1502A VT1514A

VT1508A VT1515A

VT1509A VT1516A

VT1512A VT1517A

1 InstallingSCPs: Removing theCover – VT1419A

Getting Started

Configuring the VT1419A

SCP

Remove the SCP

Retainer Screws

Chapter 1 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

2

Remove 2 Screws;

Pull Cover Out

of the 3 slots

Page 19

Getting Started

Configuring the VT1419A

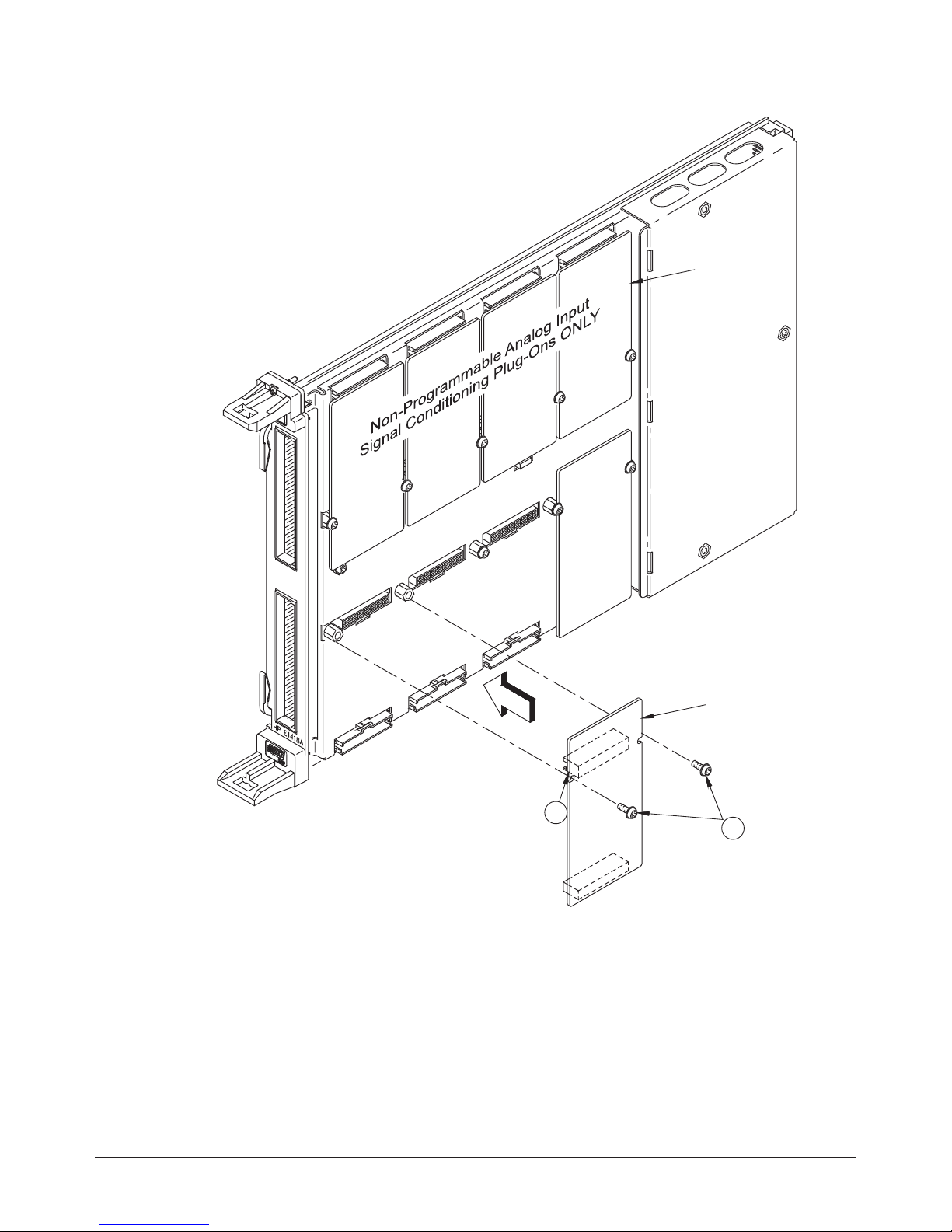

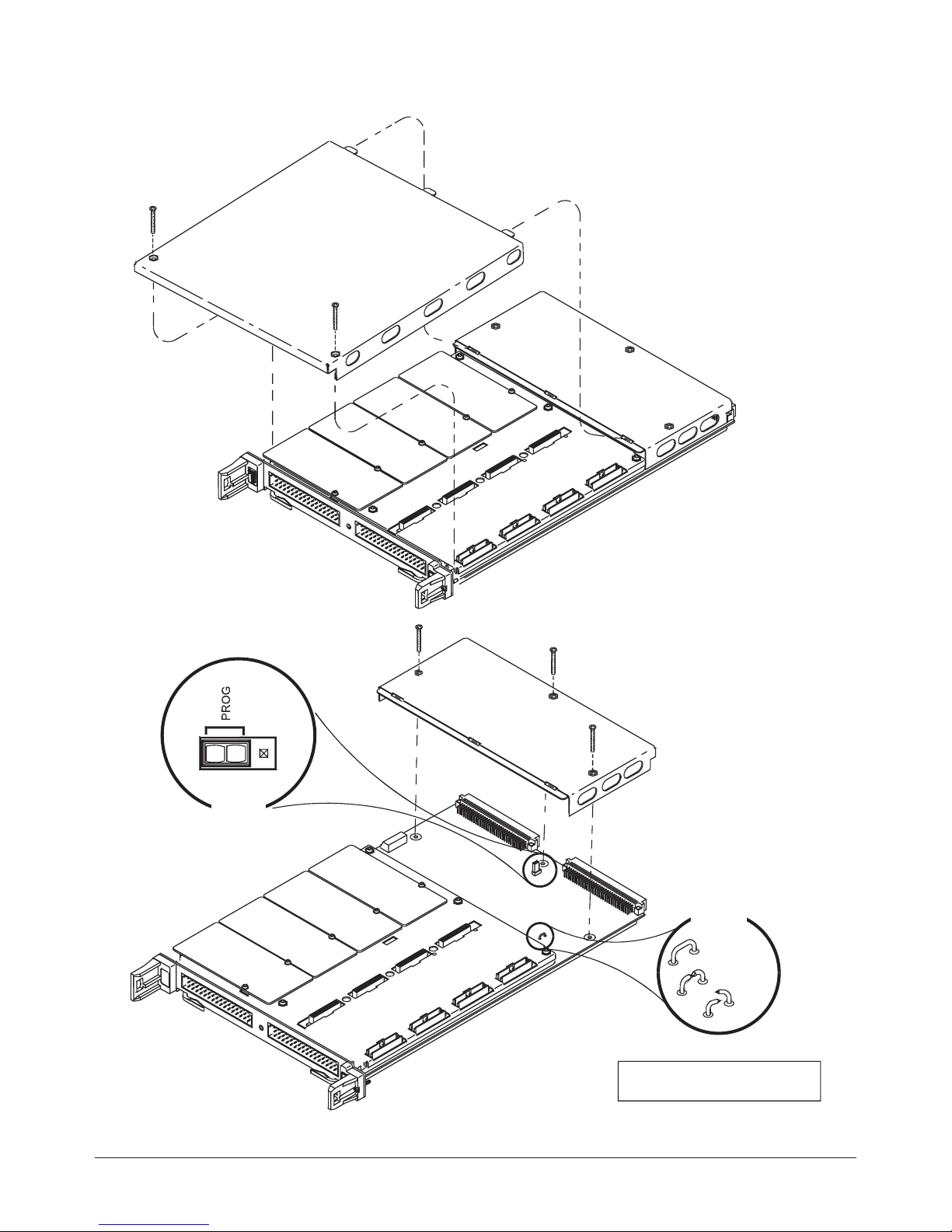

2 Installing SCPs – VT1419A

SCP

Align the SCP

Connectors with the

Module Connectors

and then Push In

SCP

1

2

Tighten the

SCP Retainer

Screws

18 Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

3 Installing SCPs: Reinstalling the Cover – VT1419A

SCP

Getting Started

Configuring the VT1419A

1

Line up the three tabs

with the three slots;

then push the cover

onto the module

2

Tighten two

screws

Chapter 1 19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Getting Started

Configuring the VT1419A

4 Installing SCPs: Labeling – VT1419A

1

Peel off label from

card and stick on

the appropriate

place on the cover

Terminal Module

(Connect to A/D

Module Later)

Terminal

Module

2

Peel off label from

card and stick on

the terminal module

to be connected

to the A/D Module

SCP

SCP

SCP

SCP

SCP

SCP

Stick-on labels

furnished with the SCP

(P/N: 43-0133-xxx)

SCP

SCP

20 Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Getting Started

Configuring the VT1419A

Disabling the Input

Protect Feature

(Optional)

Disabling the Input Protect feature voids the VT1419A’s warranty. The Input

Protect feature allows the VT1419A to open all channel input relays if any input’s

voltage exceeds ±19 volts (±6 volts for non-isolated digital I/O SCPs). This feature

helps to protect the card’s Signal Conditioning Plug-Ons, input multiplexer, ranging

amplifier and A/D from destructive voltage levels. The level that trips the protection

function has been set to provide a high probability of protection. The voltage level

that is certain to cause damage is somewhat higher. If, in an application, the

importance of completing a measurement run outweighs the added risk of

damage to the VT1419A, the input protect feature may be disabled.

VOIDS WARRANTY Disabling the Input Protection Feature voids the VT1419A’s warranty.

To disable the Input Protection feature, locate and cut JM2202. Make a single cut in

the jumper and bend the adjacent ends apart. See following illustration for location

of JM2202.

Disabling Flash

Memory Access

(Optional)

The Flash Memory Protect Jumper (JM2201) is shipped in the “PROG” position. It

is recommended that the jumper be left in this position so that all of the calibration

commands can function. Changing the jumper to the protect position prevents the

following from being executed:

The SCPI calibration command CAL:STORE ADC | TARE

·

·

The register-based calibration commands STORECAL and STORETAR

·

Any application that installs firmware-updates or makes any other

modification to flash memory through the A24 window.

With the jumper in the “PROG” position, one or more VT1419As can be

completely calibrated without being removed from the application system. A

VT1419A calibrated in its working environment will, in general, be better

calibrated than if it were calibrated separate from its application system.

The multimeter used during the periodic calibration cycle should be considered the

calibration transfer standard. Provide the Calibration Organization control

unauthorized access to its calibration constants. See the VT1415A/VT1419A Service

Manual for complete information on VT1419A periodic calibration.

If access to the VT1419A’s calibration constants must be limited, place JM2201 in

the protected position and cover the shield retaining screws with calibration

stickers. See following illustration for location of JM2201.

Chapter 1 21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

Getting Started

Configuring the VT1419A

Flash Memory Protect Jumper

Default = PROG

(recommended)

JM2201

JM2202

1 Locate

2 Cut

3 Bend

Input Protect Jumper

Warning: Cutting This Jumper

Will Void Your Warranty

22 Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Instrument Drivers

The Agilent/HP E1405B/E1406A downloadable driver is supplied with the

VT1419A on the “VXIplug&play Drivers & Product Manuals” CD-ROM and is

also available through a VXI Customer and Sales Representative.

About Example Programs

Examples on CD All example programs mentioned by file name in this manual are available on the

“VXIplug&play Drivers & Product Manuals” CD supplied with the VT1419A. See the

VEE program examples chapter, page 143 for specific location of files on the CD.

Getting Started

Instrument Drivers

Example Command

Sequences

Where programming concepts are discussed in this manual, the commands to send

to the VT1419A are shown in the form of command sequences. These are not

example programs because they are not written in any computer language. They are

meant to show the VT1419A SCPI commands in the sequence they should be sent.

Where necessary, these sequences include comments to describe program flow and

control such as loop - end loop and if - end if. See the code sequence on page 84 for

an example.

Verifying a Successful Configuration

Among the VEE example programs supplied with the VT1419A is a program (file

name “panl1419.vee”) that can be used to verify the VT1419A configuration and

installation. When the “Front Panel” program starts, it communicates with the

VT1419A and executes instructions to determine and display the installed SCP

types. It also simulates a strip chart recorder so that input channels can be selected

to monitor and display. “Buttons” are included that will run the VT1419A’s

self-test as well as well as perform an “auto-calibration.” Self-test and Cal can take

3 to 15 minutes to complete depending upon the number and type of SCPs installed

in the VT1419A.

Note When the Agilent VEE program that communicates with the VT1419A is first

loaded, it will display a dialog box asking for the GPIB address string to use.

Chapter 1 23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

24 Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

About This Chapter

This chapter shows how to plan and connect field wiring to the VT1419A’s

Terminal Module. The chapter explains proper connection of analog signals to the

VT1419A, both two-wire voltage type and four-wire resistance type measurements.

Connections for other measurement types (e.g., strain using the Bridge Completion

SCPs) refer to specific SCP manual in the “SCP Manuals” section. Chapter contents

include:

Chapter 2

Field Wiring

Planning Wiring Layout for the VT1419A ................page 25

·

Faceplate Connector Pin-Signal List .....................page 29

·

Optional Terminal Modules ............................page 30

·

Reference Temperature Sensing with the VT1419A .........page 33

·

Configuring the On-Board/Remote Reference Jumpers ......page 34

·

Preferred Measurement Connections .....................page 37

·

Wiring and Attaching the Terminal Modules ..............page 39

·

Attaching/Removing the Terminal Modules ...............page 41

·

Adding Components to the Option 12 Terminal Module .....page 43

·

Option 11 Terminal Module Wiring Map .................page 44

·

Option 12 Terminal Module Wiring Map .................page 45

·

The Option A3F .................................... page 46

·

Planning the Wiring Layout

To help plan the field wiring connections to the VT1419A, this section provides a

high-level overview of the VT1419A’s signal paths between the face plate

connectors and the Control Processor (DSP). To eliminate any surprises after the

system is wired, it also cover any configuration interdependencies or other limiting

situations (there are very few with the VT1419A).

SCP Positions and

Channel Numbers

SCP Types and

Signal Paths

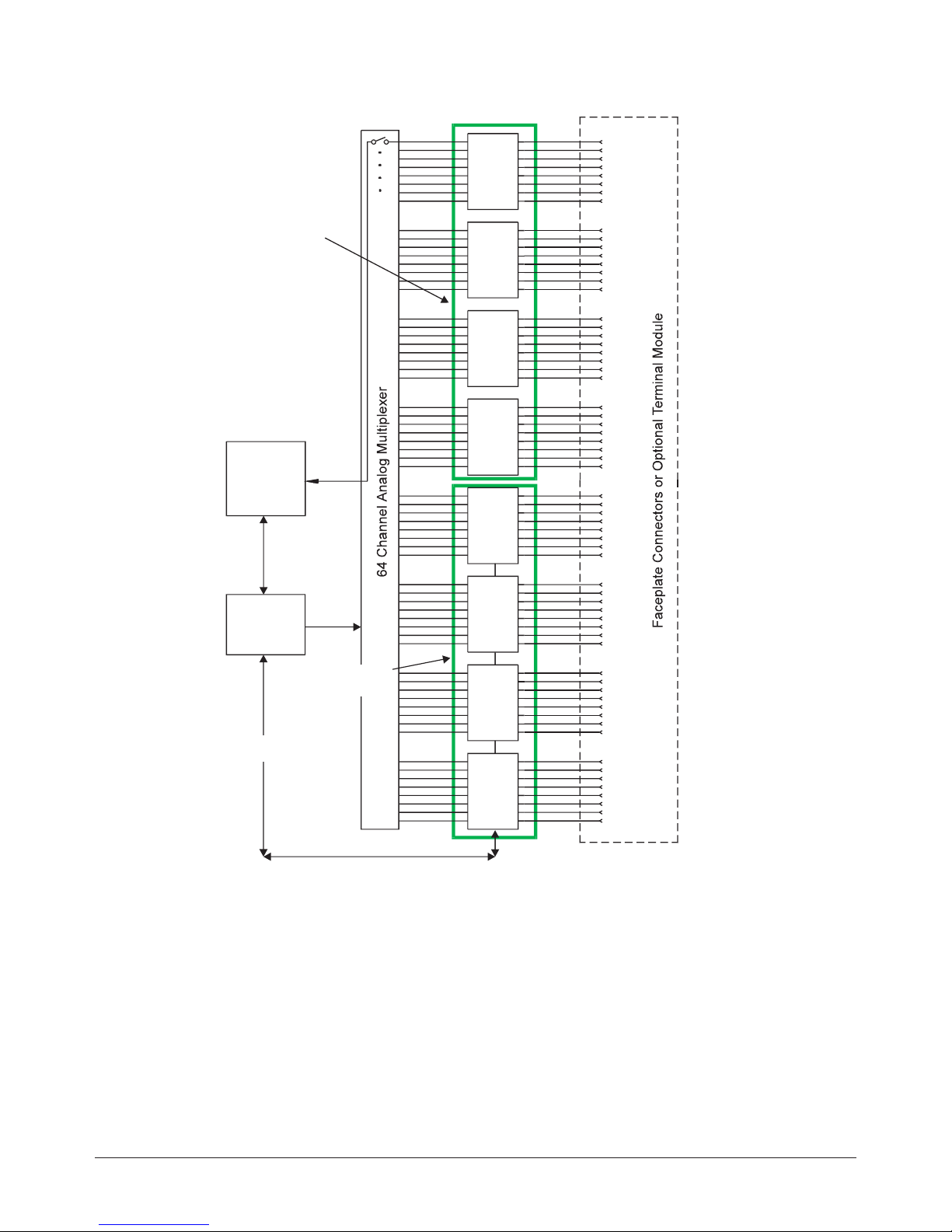

The VT1419A has a fixed relationship between Signal Conditioning Plug-On

positions and their channel assignments. See Figure 2-1 for this discussion. Each of

the eight SCP positions can connect to eight channels. Each channel signal path

consists of both a High and Low signal path (for differential analog signals). Some

SCP models will connect to fewer of these eight channels and those left

unconnected cannot be used for other purposes. The VT1533A Digital I/O SCP on

the other hand will use each High and Low channel to provide 16 digital bits from a

single SCP position.

Different SCP types (analog sense, analog source, digital I/O) use different signal

paths in the VT1419A. Each of these basic types will be discussed.

Chapter 2 25

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

Field Wiring

g

Planning the Wiring Layout

Ch 00

SCP

0

Ch 07

Non-Programmable

Sense SCPs Only

Note

Each channel line

represents both a

Hi and Lo Signal

A/D System

Control

Processor

(DSP)

Any Sense or

Source SCP

SCP

Bus

Ch 08

SCP

1

Ch 15

Ch 16

SCP

2

Ch 23

Ch 24

SCP

3

Ch 31

Ch 32

SCP

4

Ch 39

Ch 40

SCP

5

Ch 47

Ch 48

SCP

6

Ch 55

Ch 56

SCP

6

Ch 63

SCP control and di

Analog Sense SCPs Analog sense SCPs connect signals at the faceplate connector and pass these signals

26 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ital data

Figure 2-1: Channel Numbers at SCP Positions

(most with signal amplification and/or filtering) to the analog multiplexer and thus

to the A/D for measurement. Here the primary signal path is along the analog Hi

and Lo lines. The SCP Bus carries digital signals to control the programmable

parameters on the VT1503A and VT1510A.

Page 28

Field Wiring

Planning the Wiring Layout

Analog Source SCPs The primary signal path for analog source SCPs like the VT1505A Resistance

Current Source, the VT1531A Voltage DAC and the VT1532A Current DAC is

along the Hi and Lo lines from the SCP to the face plate connectors. The path from

the SCP to the analog multiplexer can be used to read and verify the approximate

output (although this path is not calibrated). The SCP Bus carries digital signals to

these SCPs to control their output levels.

Combined Analog

Source and

Sense SCPs

Digital SCPs With digital SCPs, the signal path to and from the face plate connectors and the

Pairing Sense and

Source SCPs for

Resistance

Measurements

The VT1506A, VT1507A, and VT1511A Strain Completion SCPs as well as the

VT1518A Resistance Measurement SCP combine analog sense and analog sources

in a single SCP. With these SCPs, some channels will be used to sense

measurement values while others will be used to carry analog excitation voltage or

current. Again the SCP Bus carries digital signals to control SCP source level

and/or measurement configuration.

SCP is as always, the Hi and Lo signal paths. The VT1534A, VT1536A, and

VT1538A digital SCPs provide one digital bit per Hi and Lo pair while the

VT1533A provides 16 digital bits from a single SCP position by connecting 8 bits

to the channel Hi lines and another 8 bits to the channel Lo lines. With digital

SCPs, the SCP Bus is the only data path between the Control Processor and the

SCP for both data and configuration control.

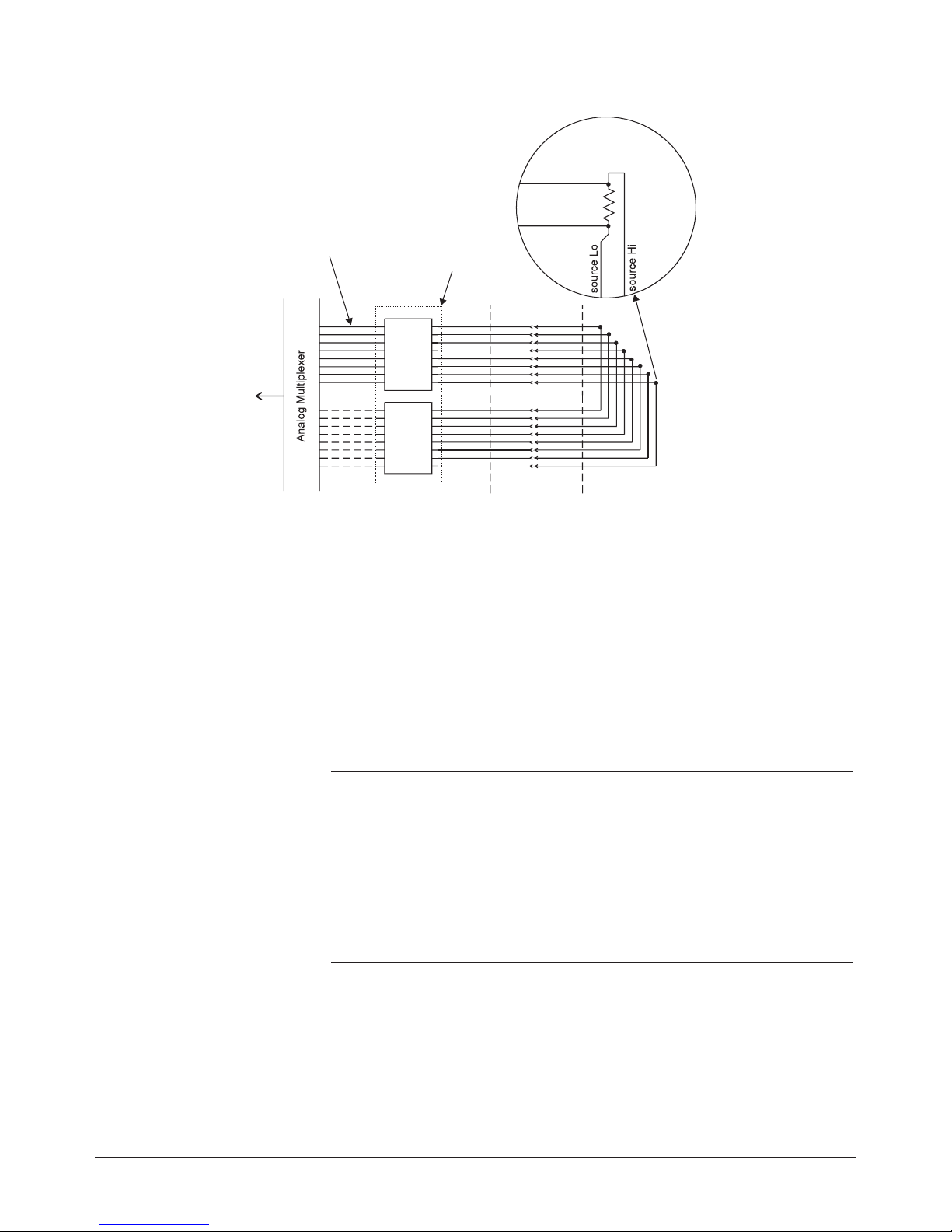

Resistance measurements and resistance-temperature measurements require

supplying an excitation current to the resistive element to be measured. With the

VT1419A, two channels are required for each resistance to be measured. Resistance

is always measured in a Four-Wire configuration. The VT1505A Current Source

SCP provides eight excitation supplies that can be paired with any available analog

sense channels to complete the measurement circuit. The VT1518A Resistance

Measurement SCP provides four excitation supplies and four amplified sense

channels on a single SCP. In either case, the source and sense channels must be

paired together to make the resistance measurement. Figure 2-2 illustrates an

example of “pairing” source SCP channels with sense SCP channels.

Chapter 2 27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Field Wiring

e

odule

Planning the Wiring Layout

sense Hi

Note

Each channel line

represents both a

Hi and Lo signal

Planning for

Thermocouple

Measurements

sense Lo

Or a Single

VT1518A

For 4 Channels

Ch 24

Sense

SCP

Ch 31

Ch 32

VT1505A

SCP

(source)

Ch 39

Faceplate Conns

or

rminalM

T

Figure 2-2: Pairing Source and Sense SCP Channels

Thermocouples and the thermocouple reference temperature sensor can be wired to

any of the VT1419A’s channels. When the scan list is executed, make sure that the

reference temperature sensor is specified in the channel sequence before any of the

associated thermocouple channels (see the [SENSe:]REF:CHAN command).

External wiring and connections to the VT1419A are made using the Terminal

Module (see page 39).

NOTE The isothermal reference temperature measurement made by a VT1419A applies

only to thermocouple measurements made by that instrument and through the

terminal blocks associated with the reference temperature sensor (for increased

isothermal reference accuracy the VT1586A Rack Mount Terminal Panel has three

reference temperature thermistors). In systems with multiple VT1419As, each

instrument must make its own reference measurements. The reference measurement

made by one VT1419A can not be used to compensate thermocouple measurements

made by another VT1419A.

28 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

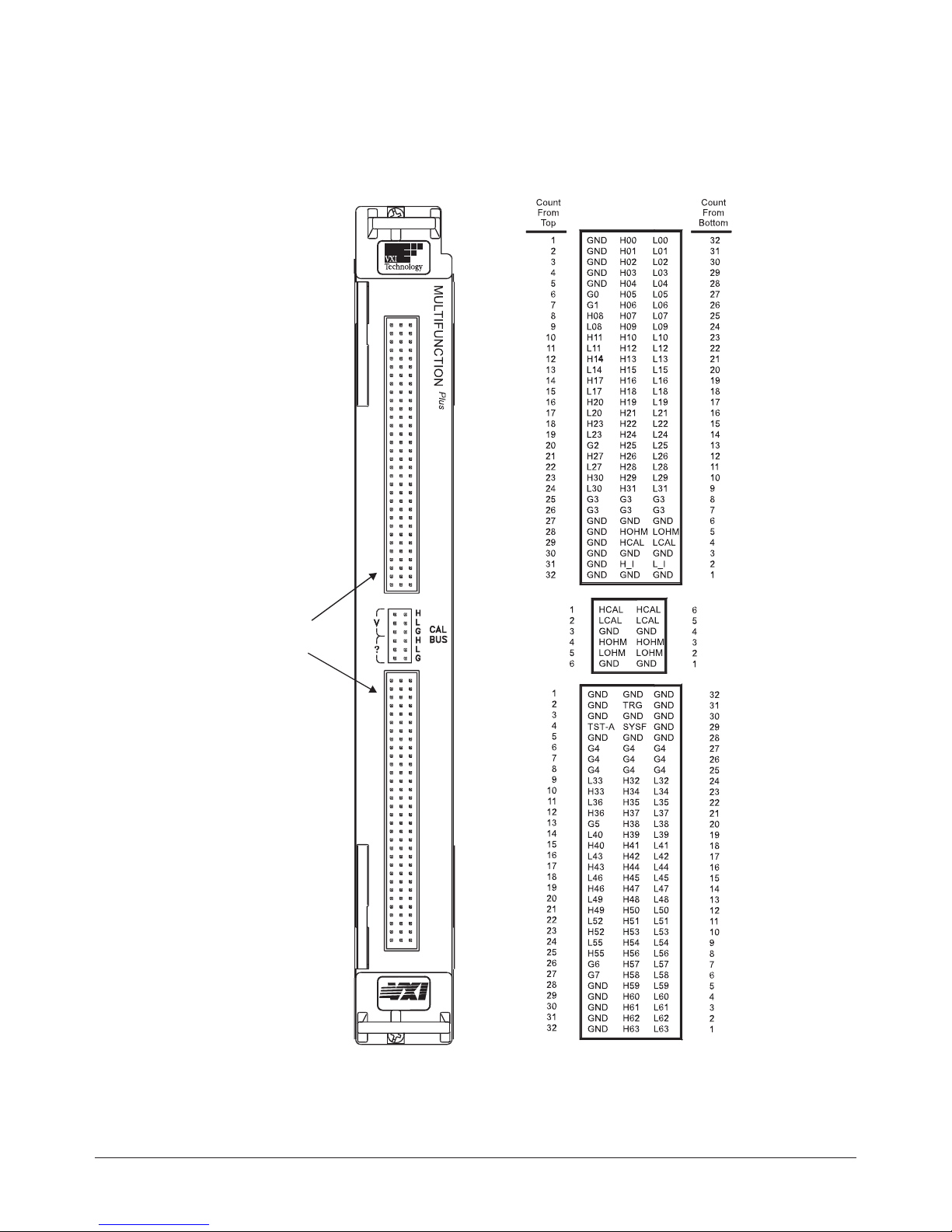

Faceplate Connector Pin-Signal Lists

Figure 2-3 shows the Faceplate Connector Pin Signal List for the VT1419A.

Field Wiring

Faceplate Connector Pin-Signal Lists

faceplate connectors

are male 96 pin DIN

Figure 2-3: VT1419A Faceplate Connector Pin Signals

VT1419A

bus

Chapter 2 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

Field Wiring

Optional Terminal Modules

Optional Terminal Modules

The VT1419A Option 11 Terminal Module has screw type terminal blocks. The

VT1419A Option 12 Terminal Module has spring clamp type terminal blocks. Both

of these Terminal Modules provide:

Terminal block connections to field wiring.

·

Strain relief for the wiring bundle.

·

Reference junction temperature sensing for thermocouple measurements.

·

The VT1419A Option A3F Terminal Module is available to interface the VT1419A

to a VT1586A rack mount terminal panel (see page 46).

The SCPs and

Terminal Module

Connections

Note The SCPs VT1531A through VT1537A do not include wiring labels for the

The same Terminal is used for all field wiring regardless of which Signal

Conditioning Plug-On (SCP) is used. Each SCP includes a set of labels to map that

SCP’s channels to the Terminal Module’s terminal blocks. See step 4 in “Installing

Signal Conditioning Plug-Ons” in Chapter 1 page 20 for VT1419A Terminal

Modules.

Option 11 terminal module. For these SCPs use the connection tables in the SCP’s

manual along with the Option 11 wiring map on page 44.

30 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Field Wiring

O

g

Optional Terminal Modules

Option 11 Terminal

Module Layout

n-Board Reference

Temperature Sensing

Figure 2-4 shows the VT1419A-011 Screw Terminal Module feature and

connector locations.

Jumper Detail

Remote Reference

Temperature Sensin

Figure 2-4: The Option 11 Screw Terminal Module

Chapter 2 31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

Field Wiring

p

Optional Terminal Modules

Option 12 Terminal

Module Layout

Jumper for Guard to

Ground Connections

Figure 2-5 shows the VT1419A-012 Spring Terminal Module features and

connector locations.

Terminal Blocks for

Signal Connections

Jumper to select

On-board or Remote

Temperature Sensing

Thermistor for On-board

Reference Tem

erature

Terminal block with Remote Reference

Temperature Sensing, Trigger and

A/D Calibration Bus Connections

Figure 2-5: The Option 12 Spring Terminal Module

32 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

Reference Temperature Sensing with the VT1419A

Reference Temperature Sensing with the VT1419A

The Terminal Modules provide an on-board thermistor for sensing isothermal

reference temperature of the terminal blocks. Also provided is a jumper set (JM1 in

Figures 2-5 and 2-4) to route the VT1419A’s on-board current source to a

thermistor or RTD on a remote isothermal reference block. Figures 2-6 and 2-7

show connections for both local and remote sensing.

Field Wiring

HI

On-Board

Current Source

LI

Terminal Module

ON

REM

BOARD

J1

Any Sense

Channel

Figure 2-6: Remote Thermistor or RTD Connections

Terminal Module

Field Wiring

HTI

LTI

HTS

LTS

Hnn

Lnn

Field Wiring

HI

On-Board

Current Source

LI

Chapter 2 33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ON

REM

Any Sense

BOARD

J1

Channel

Figure 2-7: On-Board Thermistor Connections

HTI

LTI

HTS

LTS

Hnn

Lnn

Page 35

Field Wiring

r

Configuring the On-Board/Remote Reference Jumpers

Configuring the On-Board/Remote Reference Jumpers

Figure 2-8 shows how to set the Option 12’s jumpers for on-board and remote

thermocouple reference temperature measurement. Figure 2-2 shows the jumpers on

the Option 11 Terminal Module. The Thermistor is used for reference junction

temperature sensing for thermocouple measurements.

Under Cover

ON

BOARD

J1

REM

ON

BOARD

J1

Place both J1 jumpers here to

ON BOARD

connect current source to

on-board thermistor RT1. Sense

RT1 by connecting any sense

channels to terminals HTS and

LTS .

REM

REMote

Place both J1 jumpers here to

route current source to terminals

HTI and LTI. Connect these

terminals to remote thermistor o

RTD. Sense with any sense

channel.

See figure on page 39 to remove the cover

Figure 2-8: Temperature Sensing for VT1419A Terminal Module

34 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Field Wiring

Configuring the On-Board/Remote Reference Jumpers

Terminal Module

Considerations for

Thermocouple

Measurements

The isothermal characteristics of the Terminal Modules are crucial for good TC

readings and can be affected by any of the following factors:

1. The clear plastic cover must be on the Terminal Module.

2. The thin white Mylar thermal barrier must be inserted over the Terminal

Module connector (Option 12 only). This prevents airflow from the

VT1419A into the Terminal Module.

3. The Terminal Module must also be in a fairly stable temperature

environment and it is best to minimize the temperature gradient between the

VT1419A and the Terminal Module.

4. The VXI mainframe cooling fan filters must be clean and there should be as

much clear space in front of the fan intakes as possible.

5. Recirculating warm air inside a closed rack cabinet can cause a problem if

the Terminal Module is suspended into ambient air that is significantly

warmer or cooler. If the mainframe recess is mounted in a rack with both

front and rear doors, closing both doors helps keep the entire VT1419A at a

uniform temperature. If there is no front door, try opening the back door to

allow the mainframe to cool to the temperature of the Terminal Module.

6. VXI Technology recommends that the cooling fan switch on the back of the

of an Agilent/HP E1401 Mainframe is in the “High” position. The normal

variable speed cooling fan control can make the internal VT1419A module

temperature cycle up and down, which affects the amplifiers with these

microvolt-level signals.

Chapter 2 35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

Field Wiring

Preferred Measurement Connections

Preferred Measurement Connections

For any A/D Module to scan channels at high speeds, it must use a very short

IMPORTANT!

HINTS 1. Try to install Analog SCPs relative to Digital I/O as shown in “Separating

sample period (< 10 µs for the VT1419A). If significant normal mode noise is

presented to its inputs, that noise will be part of the measurement. To make quiet,

accurate measurements in electrically noisy environments, use properly connected

shielded wiring between the A/D and the device under test. Figure 2-9 shows

recommended connections for powered transducers, thermocouples, and resistance

transducers. (See Appendix D for more information on Wiring Techniques).

Digital and Analog Signals” in Appendix D.

2. Use individually shielded, twisted-pair wiring for each channel.

3. Connect the shield of each wiring pair to the corresponding Guard (G)

terminal on the Terminal Module (see Figure 2-10 for schematic of Guard to

Ground circuitry on the Terminal Module).

4. The Terminal Module is shipped with the Ground-to-Guard (GND-GRD)

shorting jumper installed for each channel. These may be left installed or

removed (see Figure 2-10 to remove the jumper), dependent on the

following conditions:

a.

Grounded Transducer with shield connected to ground at the

transducer: Low frequency ground loops (dc and/or 50/60 Hz) can

result if the shield is also grounded at the Terminal Module end. To

prevent this, remove the GND-GRD jumper for that channel (Figure

2-9 A/C).

b.

Floating Transducer with shield connected to the transducer at the

source: In this case, the best performance will most likely be achieved

by leaving the GND-GRD jumper in place (Figure 2-9 B/D).

5. In general, the GND-GRD jumper can be left in place unless it is necessary

to remove to break low frequency (below 1 kHz) ground loops.

6. Use good quality foil or braided shield signal cable.

7. Route signal leads as far as possible from the sources of greatest noise.

8. In general, don’t connect Hi or Lo to Guard or Ground at the VT1419A.

9. It is best if there is a dc path somewhere in the system from Hi or Lo to

Guard/Ground.

10. The impedance from Hi to Guard/Ground should be the same as from Lo to

Guard/Ground (balanced).

11. Since each system is different, don’t be afraid to experiment using the

suggestions presented here until an acceptable noise level is found.

36 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Device

+

Under Test

Device

Under Test

Device

Under Test

pressure

pressure

P

to

V

– power

+ power

P

to

V

– power

power

Shield

Shield

A

Example for

Powered

Transducers

Shield

B

try either

Hnn

Lnn

Field Wiring

Preferred Measurement Connections

Hnn

Lnn

G (guard)

GND

Hnn

Lnn

G (guard)

GND

10 kOhm

(part of Term. Mod.)

Device

Under Test

Example for

Thermocouples

Shield

Shield

Example for

Resistive

Transducers

C

D

try either

E

G (guard)

GND

Hnn

Lnn

G (guard)

GND

Hnn

Lnn

G (guard)

GND

10 kOhm

(part of Term. Mod.)

10 kOhm

(part of Term. Mod.)

Chapter 2 37

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Current Hi (–)

Current Lo (+)

Figure 2-9: Preferred Signal Connections

Stimulus Current

from VT1505A

Page 39

Field Wiring

Preferred Measurement Connections

External Connections

For each

SCP Position

G0

G7

Figure 2-10: GRD/GND Circuitry Opt. 12 Terminal Module

Removing Guard to

Ground on Channel 00

Terminal Module

0.1 Fµ

0.1 Fµ

1kW

GND to GRD Jumper

(removable)

1kW

GND to GRD Jumper

(removable)

SCP

10 kW

10 kW

38 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Figure 2-11: Grounding Option 12 Guard Terminals

Page 40

Wiring and Attaching the Terminal Module

Wiring and Attaching the Terminal Module

Figures 2-12 and 2-13 show how to open, wire and attach the terminal module to a

VT1419A.

Field Wiring

Remove Clear Cover

1

Make Connections

3

Special tool P/N 8710-2127

(shipped with Terminal

Module)

A. Release Screws

B. Press Tab Forward

and Release

Ta b

Use wire

Size 20-26

AEG

5mm

0.2"

Remove and Retain Wiring Exit Penal

2

Remove 1 of the 3

wire exit panels

Route Wiring

4

Tighten wraps to

secure wires

VW1 Flammability

Rating

Push down on lever,

insert wire into terminal

and release.

Figure 2-12: Wiring and Connecting the VT1419A Terminal Module

Chapter 2 39

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Field Wiring

Wiring and Attaching the Terminal Module

Replace Wiring Exit Panel

Cut required

holes in panels

for wire exit

Keep wiring exit panel

hole as small as

possible

Install the Terminal

Module

Replace Clear Cover

A. Hook in the top cover tabs

onto the fixture

B. Press down and

tighten screws

Push in the Extraction Levers to Lock the

Terminal Module onto the VT1419A

Install Mylar Thermal Barrier

on Terminal Module

connectors

Figure 2-13: Wiring and Connecting the VT1419A Terminal Module (Cont.)

Extraction

Levers

VT1419A

Module

40 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

Attaching/Removing the VT1419A Terminal Module

Attaching/Removing the VT1419A Terminal Module

Figure 2-14 shows how to attach the terminal module to the VT1419A and

Figure 2-15 shows how to remove it.

Extend the extraction levers on the

1

Terminal Module

Field Wiring

Install Mylar Thermal Barrier

Extraction Lever

Use a small screwdriver

to pry and release the

two extraction levers

Extraction Lever

Apply gentle pressure to attach

3

on Terminal Module

the Terminal Module to the

VT1419A Module

connectors

2

VT1419A

Align the Terminal Module

connectors to the VT1419A

module connectors

Push in the extraction levers

4

to lock the Terminal Module

onto the VT1419A Module

Figure 2-14: Attaching the VT1419A Terminal Module

Chapter 2 41

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Extraction

Levers

Page 43

Field Wiring

Attaching/Removing the VT1419A Terminal Module

Release the two extraction

1

levers and push both levers

out simultaneously

Use a small screwdriver

to pry and release the

two extraction levers

Extraction Lever

Free and remove the Terminal

2

Module from the A/D Module

Extraction Lever

Figure 2-15: Removing the VT1419A Terminal Module

VT1419A

Extraction Lever

42 Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

Field Wiring

A

Adding Components to the Option 12 Terminal Module

Adding Components to the Option 12 Terminal Module

The back of the terminal module PCB (printed circuit board) provides surface

mount pads which can be used to add serial and parallel components to any