Page 1

SVM2608

4-Channel, 100 kSamples/s

Analog-to-Digital Converter

SER’S MANUAL

U

P/N: 82-0066-000

Released February 23, 2007

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949) 955-1894

Page 2

VXI Technology, Inc.

2

Page 3

www.vxitech.com

TABLE OF CONTENTS

INTRODUCTION

TABLE OF CONTENTS................................................................................................................................................3

Certification..........................................................................................................................................................5

Warranty ...............................................................................................................................................................5

Limitation of Warranty.........................................................................................................................................5

Restricted Rights Legend......................................................................................................................................5

DECLARATION OF CONFORMITY ...............................................................................................................................6

GENERAL SAFETY INSTRUCTIONS............................................................................................................................. 7

Terms and Symbols ..............................................................................................................................................7

Warnings...............................................................................................................................................................7

SUPPORT RESOURCES ...............................................................................................................................................9

SECTION 1.................................................................................................................................................................. 11

INTRODUCTION ....................................................................................................................................................... 11

Introduction ........................................................................................................................................................11

Overview ............................................................................................................................................................11

Acquiring Data ..............................................................................................................................................13

Triggering......................................................................................................................................................13

Linear Mode ..................................................................................................................................................14

Pre-Trigger .................................................................................................................................................... 14

Delayed Trigger.............................................................................................................................................14

FIFO Mode.................................................................................................................................................... 15

Calibrations ...................................................................................................................................................15

Test Bus.........................................................................................................................................................15

Commands.....................................................................................................................................................15

Option -01 .....................................................................................................................................................16

Physical Description...........................................................................................................................................18

Front Panel Interface Wiring ..............................................................................................................................19

SVM2608 Specifications ....................................................................................................................................20

SECTION 2.................................................................................................................................................................. 23

PREPARATION FOR USE...........................................................................................................................................23

Introduction ........................................................................................................................................................23

Calculating System Power and Cooling Requirements ......................................................................................23

Setting the Chassis Backplane Jumpers.............................................................................................................. 23

Setting the Base Address ....................................................................................................................................24

Example 1......................................................................................................................................................25

Example 2......................................................................................................................................................26

Module Installation/Removal .............................................................................................................................26

SECTION 3.................................................................................................................................................................. 27

PROGRAMMING....................................................................................................................................................... 27

Introduction ........................................................................................................................................................27

Device Memory Maps ........................................................................................................................................27

Function Offset..............................................................................................................................................27

Register Offset...............................................................................................................................................27

Data(Byte) Ordering ...........................................................................................................................................30

Determining the Register Address......................................................................................................................31

Accessing the Registers ...................................................................................................................................... 32

Description of Registers .....................................................................................................................................32

Microprocessor Commands................................................................................................................................41

SVM2608 Preface 3

Page 4

VXI Technology, Inc.

Measurement Commands..............................................................................................................................41

Captured Data Calculations........................................................................................................................... 42

Resistance Measurement – Offset Method.................................................................................................... 43

Resistance Measurement – Dynamic Method ...............................................................................................43

Self Test Command.......................................................................................................................................43

Preset Setting Measurement Commands .......................................................................................................44

Calibration Commands..................................................................................................................................45

Error Processing ............................................................................................................................................47

Diagnostic Commands ..................................................................................................................................49

Examples ............................................................................................................................................................51

Example 1: Setting the Channel 2 and 4 Sample Rate to 123 ms (8.13 kHz)................................................51

Example 2: Setting Channel 2 to Acquire 200,000 Samples.........................................................................51

Example 3: Setting Channel 2 to Pre-acquire 100,000 Samples ...................................................................52

Example 4: Setting Channel 2 to Delay Acquisition by 1,500,000 Samples.................................................52

Example 5: Setting Channel 2 and 4 Timeout Register to Timeout after 2.5 s .............................................53

APPENDIX A...............................................................................................................................................................55

APPENDIX A ...........................................................................................................................................................55

Data Swapping Example.....................................................................................................................................55

INDEX......................................................................................................................................................................... 57

4 SVM2608 Preface

Page 5

www.vxitech.com

CERTIFICATION

VXI Technology, Inc. (VTI) certifies that this product met its published specifications at the time of shipment from

the factory. VTI further certifies that its calibration measurements are traceable to the United States National

Institute of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that

organization’s calibration facility, and to the calibration facilities of other International Standards Organization

members.

WARRANTY

The product referred to herein is warranted against defects in material and workmanship for a period of one year

from the receipt date of the product at customer’s facility. The sole and exclusive remedy for breach of any warranty

concerning these goods shall be repair or replacement of defective parts, or a refund of the purchase price, to be

determined at the option of VTI.

For warranty service or repair, this product must be returned to a VXI Technology authorized service center. The

product shall be shipped prepaid to VTI and VTI shall prepay all returns of the product to the buyer. However, the

buyer shall pay all shipping charges, duties, and taxes for products returned to VTI from another country.

VTI warrants that its software and firmware designated by VTI for use with a product will execute its programming

when properly installed on that product. VTI does not however warrant that the operation of the product, or

software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate maintenance by the buyer, buyersupplied products or interfacing, unauthorized modification or misuse, operation outside the environmental

specifications for the product, or improper site preparation or maintenance.

VXI Technology, Inc. shall not be liable for injury to property other than the goods themselves. Other than the

limited warranty stated above, VXI Technology, Inc. makes no other warranties, express or implied, with respect to

the quality of product beyond the description of the goods on the face of the contract. VTI specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

RESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of the

Rights in Technical Data and Computer Software clause in DFARS 252.227-7013.

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509 U.S.A.

SVM2608 Preface 5

Page 6

VXI Technology, Inc.

D ECLARATION OF C ONFORMITY

Declaration of Conformity According to ISO/IEC Guide 22 and EN 45014

ANUFACTURER’S NAME VXI Technology, Inc.

M

ANUFACTURER’S ADDRESS 2031 Main Street

M

Irvine, California 92614-6509-6509

RODUCT NAME 4-Channel, 100 kSamples/s Analog-to-Digital Converter

P

ODEL NUMBER(S) SVM2608

M

RODUCT OPTIONS All

P

RODUCT CONFIGURATIONS All

P

VXI Technology, Inc. declares that the aforementioned product conforms to the requirements of

the Low Voltage Directive 73/23/EEC and the EMC Directive 89/366/EEC (inclusive 93/68/EEC)

and carries the “CE” mark accordingly. The product has been designed and manufactured

according to the following specifications:

AFETY EN61010 (2001)

S

EMC EN61326 (1997 w/A1:98) Class A

CISPR 22 (1997) Class A

VCCI (April 2000) Class A

ICES-003 Class A (ANSI C63.4 1992)

AS/NZS 3548 (w/A1 & A2:97) Class A

FCC Part 15 Subpart B Class A

EN 61010-1:2001

The product was installed into a C-size VXI mainframe chassis and tested in a typical configuration.

I hereby declare that the aforementioned product has been designed to be in compliance with the relevant sections

of the specifications listed above as well as complying with all essential requirements of the Low Voltage Directive.

February 2007

Steve Mauga, QA Manager

6 SVM2608 Preface

Page 7

www.vxitech.com

Review the following safety precautions to avoid bodily injury and/or damage to the product.

These precautions must be observed during all phases of operation or service of this product.

Failure to comply with these precautions or with specific warnings elsewhere in this manual,

violates safety standards of design, manufacture and intended use of the product.

Service should only be performed by qualified personnel.

TERMS AND SYMBOLS

These terms may appear in this manual:

WARNING

CAUTION

These symbols may appear on the product:

GENERAL SAFETY INSTRUCTIONS

Indicates that a procedure or condition may cause bodily injury or death.

Indicates that a procedure or condition could possibly cause damage to

equipment or loss of data.

WARNINGS

ATTENTION - Important safety instructions

Frame or chassis ground

Indicates that the product was manufactured after August 13, 2005. This mark is

placed in accordance with EN 50419, Marking of electrical and electronic

equipment in accordance with Article 11(2) of Directive 2002/96/EC (WEEE).

End-of-life product can be returned to VTI by obtaining an RMA number. Fees

for take-back and recycling will apply if not prohibited by national law.

Follow these precautions to avoid injury or damage to the product:

Use Proper Power Cord

To avoid hazard, only use the power cord specified for this

product.

Use Proper Power Source

To avoid electrical overload, electric shock or fire hazard, do

not use a power source that applies other than the specified

voltage.

Use Proper Fuse

To avoid fire hazard, only use the type and rating fuse

specified for this product.

SVM2608 Preface 7

Page 8

WARNINGS (CONT.)

Avoid Electric Shock

Ground the Product

Operating Conditions

Improper Use

VXI Technology, Inc.

To avoid electric shock or fire hazard, do not operate this product

with the covers removed. Do not connect or disconnect any cable,

probes, test leads, etc. while they are connected to a voltage source.

Remove all power and unplug unit before performing any service.

Service should only be performed by qualified personnel.

This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground.

To avoid injury, electric shock or fire hazard:

- Do not operate in wet or damp conditions.

- Do not operate in an explosive atmosphere.

- Operate or store only in specified temperature range.

- Provide proper clearance for product ventilation to prevent

overheating.

- DO NOT operate if any damage to this product is suspected.

Product should be inspected or serviced only by qualified

personnel.

The operator of this instrument is advised that if the equipment is

used in a manner not specified in this manual, the protection

provided by the equipment may be impaired. Conformity is checked

by inspection.

8 SVM2608 Table of Contents

Page 9

www.vxitech.com

Visit

SUPPORT RESOURCES

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Instrument Division

5425 Warner Road

Suite 13

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail:

support@vxitech.com

http://www.vxitech.com for worldwide support sites and service plan information.

SVM2608 Preface 9

Page 10

VXI Technology, Inc.

10 SVM2608 Preface

Page 11

www.vxitech.com

SECTION 1

INTRODUCTION

INTRODUCTION

The SVM Series leverages off VXI Technology’s line of high-density modular VXIbus

instruments, but are optimized for the VMEbus. All SVM instruments are designed to provide all

the features of test instrumentation in other platforms such as GPIB or VXI. These features are

achieved in hardware rather than in a driver. This approach to the interface design guarantees the

user that all communications to the module occur in microseconds, as opposed to several

milliseconds, considerably improving system throughput. The board is equipped with a

microprocessor which significantly increases the module’s functionality and task performing

capabilities.

The SVM2608 is a ruggedized circuit card designed for insertion into a convection-cooled VME

chassis. It is a double height VME size module (6U) of single slot width and conforms to all

physical requirements as specified by VME specifications. The VME interface is compatible with

the VME32/64x configuration with two 160-pin (32 x 5) backplane connectors (P0 – P1). The

SVM2608 consists of four low-speed (100 kSamples/s) channels and, with the addition of the -01

Option, can include two, high-speed (20 MHz) channels.

OVERVIEW

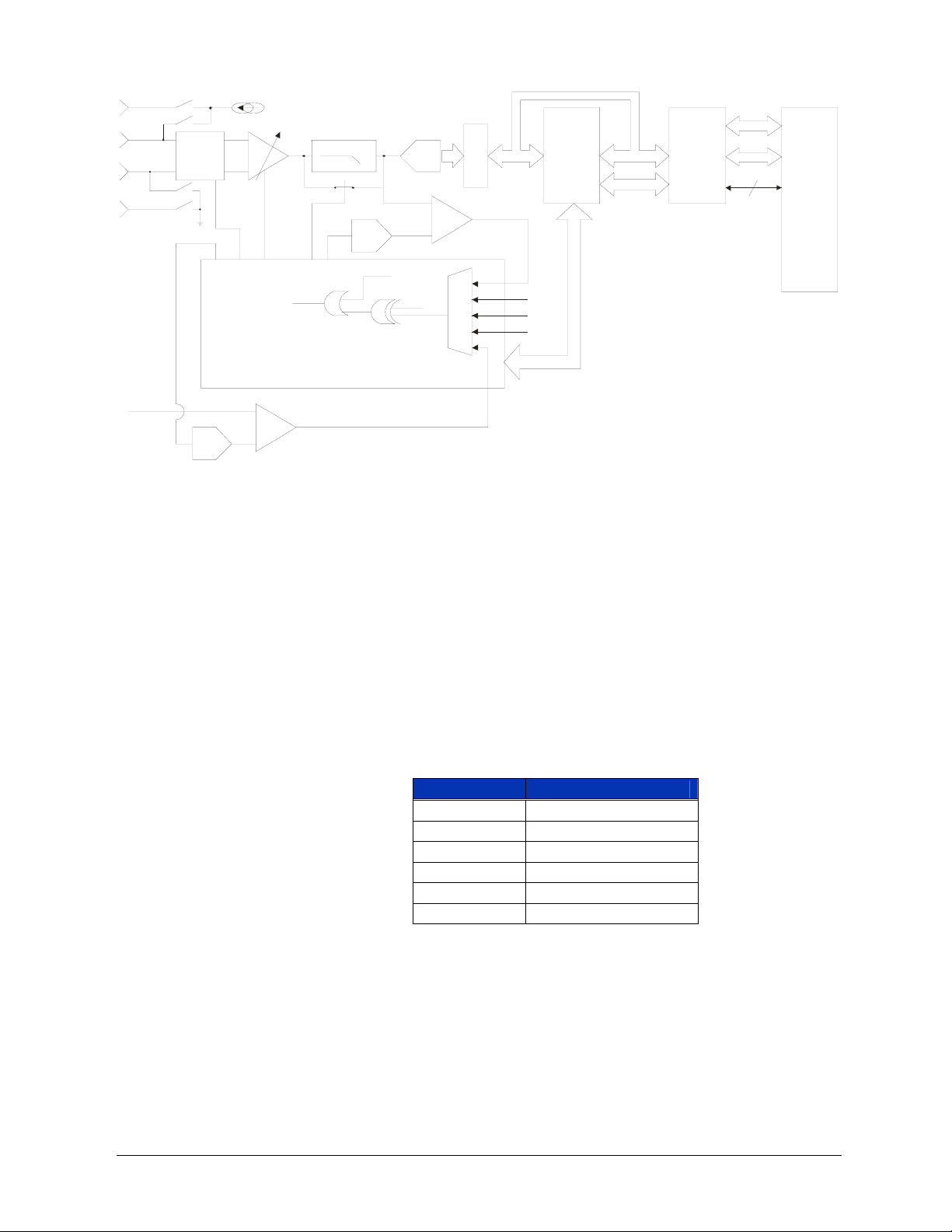

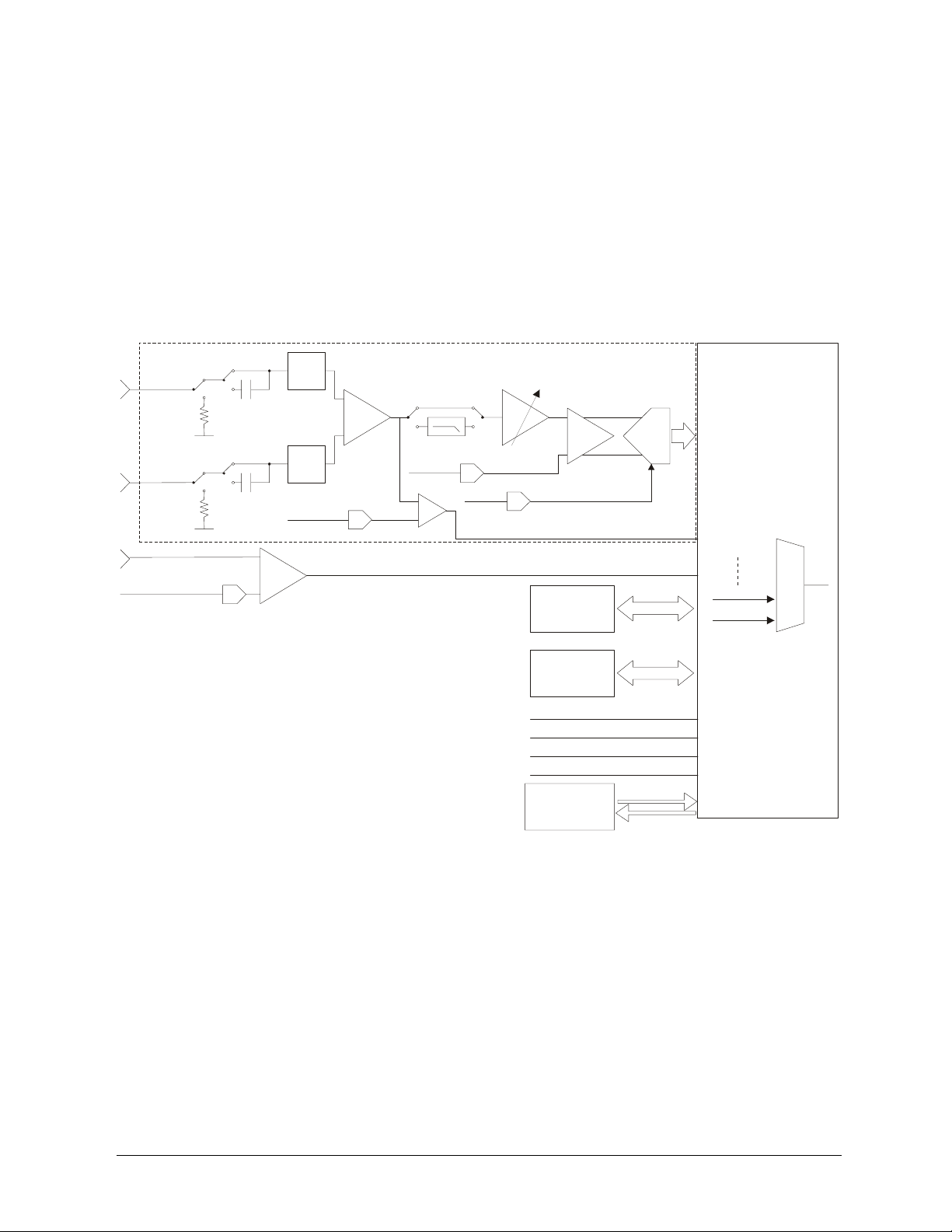

The SVM2608 is a precision, four channel digitizer capable of capturing data on all four channels

simultaneously either in FIFO (or “real-time”) mode or Linear (or “burst”) mode. A processor

enables the user to perform a variety of calculations with the data acquired. Each channel is also

capable of measuring voltage and resistance. All four channels can measure voltage at the same

time, but resistance can only be measured one channel at a time. Resistance can be measured in

two different modes: 2-wire or 4-wire. Both modes use a local current source to inject a current

into the resistor under test and then measure voltage across the resistor.

All four channels are independent of one another. The front end of each channel has both a

variable gain amplifier and an attenuator, thus allowing for full ADC scale measurements of

signals from 1 V to 100 V. Before being digitized, the signal can be passed through a Low Pass

Filter (LFP) with a cut-off frequency of 20 kHz. The ADC is a 16-bit converter capable of taking

as many as 100 kSamples/s on a scale of -10 V to +10 V. To compensate for offset and gain

variation in the ADCs, each channel has two 12-bit DACs that are used to calibrate the offset and

the gain on each channel ADC. These calibrations are performed at the factory using precision

voltage reference sources.

SVM2608 Introduction 11

Page 12

CHn +I

CHn+

CHn–

CHnI–

EXT TRIG

VXI Technology, Inc.

DATA

ADDRESS

VME INT ERFACE

CON TROL S

÷ 1

÷ 10

DAC

1x, 2x, 5x, 10x

attn

GLUE LO GIC

+

–

gain1

gain0

+

–

TRIG

LPF

FILTER

DAC

EXT TRIG

FORC E

POL

ADC

16

+

–

MEMORY

CHANNEL 0

TRIG

CHANNEL 1 TRIG

CHANNEL 2 TRIG

CHANNEL 3 TRIG

μP

DATA &

CONTROLS

DATA & CONTROL

FIGURE 1-1: SVM2608 BLOCK DIAGRAM

The acquisition process is controlled by two FPGAs that allow for greater flexibility along with

higher speed and precision during the digitizing process. As the data is digitized, it is placed in

memory. It is then available to the user through the VME interface. Each channel has its own

channel memory that can store up to one million samples of data. This data is also made available

to the microprocessor for data processing. The samples are stored as words (16 bits). The first

sample of a channel is located at the channel’s base address at Offset 0 (0x000000 for Channel 0,

0x200000 for Channel 1, 0x400000 for Channel 2 and 0x600000 for Channel 3). The next sample

is located at Offset 2 (0x000002 for Channel 0, etc.) and the third sample is located at Offset 4,

etc.

In order to provide better resolution for the measurement, the input signal is amplified

accordingly to generate a ±10 V

weight of a bit of digitized data will be different:

The following equation is used to determine the bit weight at a specified scale:

Bit Weight = Full Scale / 32,768

For example, the Bit Weight of the 10 V range is:

10.0 volts / 32768 = 0.0003051757813 V/count

≈ 305.176 µV/count

signal at the input of the ADC. Thus, on different scales, the

P-P

SCALE (V) Bit Weight (μV/count)

1 30.518

2 61.035

5 152.588

10 305.176

20 610.352

50 1525.879

VME BAC KPLANE

12 SVM2608 Introduction

Page 13

www.vxitech.com

The counts stored in memory are 16 bits SIGNED integers. The most significant bit represents

the SIGN. Thus, the hex number 0x4000 and the hex number of 0xC000 represent the same

signal amplitude but in opposite directions, where 0x4000 represents a positive signal while

0xC000 is a negative signal with the same amplitude.

To translate a raw count value into a voltage, multiply the raw count value by the bit weight. The

following example shows this conversion for a SVM2608 using the 10.0 V range:

A reading of 0x4000 = 16,384 counts

Voltage = Counts * Bit Weight

Voltage = 16384 counts* 305.176 µV/count

≈ 5.0 volts.

A reading of 0xC000 = -16,384 counts

Voltage = -16384 counts * 305.176 µV/count

≈ -5.0 volts.

Similarly, for the 5 volt range:

A reading of 0x4000 = 16,384 counts

Voltage = 16,384 counts * 152.588 µV/count

≈ 2.5 volts.

Data acquisition can be made in two modes: Linear or FIFO. In FIFO mode, data can only be

read from a fixed address (FIFO register), while in Linear mode, data can be read from any

address in the memory space of a channel. Linear mode also offers a two more options for

acquisition: Pre-Trigger and Delayed Trigger.

In FIFO mode, data can be retrieved while the acquisition is still in progress. However, if the

memory is not read and the acquisition continues running, new incoming data will overwrite

older data and the older data will be lost. It is also NOT possible to run a measurement command

in FIFO mode.

Acquiring Data

To acquire data, a channel must first be Armed. When a channel is armed, it starts its local

Sample Clock and waits for a Trigger Event to begin sampling. The channel must remain Armed

for the entire duration of the acquisition process. Clearing the ARM bit will reset the internal

state-machines and stop acquisition. Data capturing starts when a Trigger Event occurs. A trigger

event can be caused by an external trigger source, the signal under test or forced by setting a bit

in a register.

Triggering

An external signal, other than one of the sampled signals, can be used to trigger any or all of the

channels. This external signal is compared to a threshold level set by a local DAC and a highspeed comparator is used to generate an External Trigger signal.

The signal under test can also be used to trigger an acquisition. The signal is compared to a

threshold level set by a local DAC and a high-speed comparator is used to generate a Channel

Trigger signal. Each channel has its own DAC and its own comparator, thus, each channel can

generate a Trigger signal independent of the other channels. Acquisition on any channel can be

triggered by any other Channel Trigger signal (Channel 0 can be triggered by Channel 0 Trigger,

Channel 1 Trigger, Channel 2 Trigger, or Channel 3 Trigger) even if the other channels are not

armed and are not acquiring any data. Only one channel can be the trigger source at any time and

the trigger sources cannot be AND’ed or OR’ed together.

SVM2608 Introduction 13

Page 14

VXI Technology, Inc.

In absence of a Trigger signal, the acquisition can be forced by setting a control bit, the FORCE

bit. Forcing an acquisition on a channel only starts acquisition on that channel. Each channel has

its own corresponding FORCE bit.

Linear Mode

In Linear mode, the total number of samples collected (also referred to as Sample Points) is

determined by the value programmed into the Sample Points register. The first sample (also

referred to as Sample Zero) is stored in memory when a Trigger Event occurs. Sample Zero is

from the value read from the channel’s base address at offset zero (0x000000 for Channel 0,

0x200000 for Channel 1, 0x400000 for Channel 2 and 0x600000 for Channel 3).

Pre-Trigger

In Linear mode, it is also possible to store samples that occur before a Trigger Event. When a

channel is armed and the Pre-Trigger register is programmed with a value other than zero, that

channel will begin sampling immediately, without waiting for an External Trigger. After it stores

the number of samples specified in the Pre-Trigger register (also referred to as Pre-Trigger

Points), it begins monitoring the Trigger Event. Until the Trigger Event occurs, the channel

continues sampling and storing. When the Trigger Event occurs, Sample Zero is stored. After the

Trigger Event, the number of data points collected is determined by the following equation:

AFTER TRIGGER POINTS = SAMPLE POINTS – PRETRIGGER POINTS

When the user reads from offset zero of a channel, the data returned is Sample Zero followed by

Sample Zero + 1, etc. The Pre-Trigger Points can be read from the top of that channel’s memory.

For example, if 0x100 Pre-Trigger Points were sampled on Channel 0 after the acquisition is

completed, the samples can be retrieved from locations 0x1FFE00, 0x1FFE02 …0x1FFFFE with

the data at 0x1FFFFE being the last Pre-Trigger Sample before the trigger event.

Delayed Trigger

In Linear mode, it is also possible to delay storing Sample Zero by a number of sample clocks,

where a sample clock is defined by the Sample Clock Rate register. The number of sample clocks

an acquisition is delayed (also referred to as Delayed Points) is programmed in the Delayed

Trigger register. Samples are taken and stored immediately when the Trigger Event occurs, but

Sample Zero will be stored only after the specified number of Delayed Points passes. Data stored

during the Delayed period can be viewed by the user at the top of the memory space of the

respective channel (same as in Pre-Trigger mode as above), assuming that the following

condition is observed:

SAMPLE POINTS < 1 MSamples

As opposed to the Pre-Trigger acquisition, the number of samples taken after the Trigger Event is

not affected by the number of samples taken before it:

AFTER TRIGGER POINTS = SAMPLE POINTS

If the following condition is met:

DELAYED POINTS < 1 M – SAMPLE POINTS

Then all the samples collected before the Trigger Event are available to the user.

14 SVM2608 Introduction

Page 15

www.vxitech.com

FIFO Mode

In FIFO mode, the user can retrieve data from the board as acquisition progresses. The memory

behaves as a FIFO: data is written into a circular buffer with new data overwriting older data

when the buffer is full. A Threshold Flag is available to monitor the status of the buffer and

prevent overwriting the data or under-reading it.

The Sample Points register that is used in Linear mode to determine the amount of data to be

captured is used in FIFO mode to determine the size associated with the FIFO Threshold Flag.

When the number of samples stored in memory equals the number of points set in the Sample

Points register, the FIFO Threshold flag is asserted. In this manner, the user can wait until a

certain number of samples are captured before they download data from the board. If the user

fails to retrieve the data from the card in time and new data overwrites older data, then the FIFO

Overrun flag is asserted. Conversely, if the user attempts to read more data than has been stored,

the FIFO Underrun flag is asserted. The FIFO Threshold flag is cleared when data is read from

the board and the total amount of “new (unread)” data in the buffer is less than the THRESHOLD

value. The FIFO Overrun and Underrun flags are cleared only when a new acquisition is

initiated.

Calibrations

Due to the nature of the semiconductors and passive components, not all parts have exactly the

same characteristics. Slight differences exist from component to component. While these

inconsistencies are unavoidable, they do not affect the basic functionality of the electronic

instrumentation. The precision of the instrument, however, can be altered by these variances.

One way to eliminate these slight variations is to use expensive, precision parts or to perform a

rigorous parts selection procedure to ensure consistency. These measures, however, would

dramatically increase the cost of the board. Another way to compensate for offset and gain

variations is to take a number of measurements using precision calibrated instruments of known

voltage and resistance. Their known values are then compared against the values attained for

each channel and the difference is used to adjust future measurements. These adjustments are

called calibrations. They are performed at the factory using approved calibration sources.

Test Bus

The SVM2608 is capable of performing a self-test to check for functionality and accuracy. Using

a local voltage reference source and local resistance references, basic function tests can be

performed. Four different voltage reference sources are available on the board: ±9.45 V and

±0.945 V. Two Resistance References are available: 128 Ω and 81.92 kΩ. Two different signal

generators can also be used for different tests: a RAMP generator and a PULSE generator. Any

of these locally generated test sources can be placed on the internal Test Bus (TB). The Test Bus

can then be connected to the input of any or all of the channels. Only one of the test signals can

be connected to the Test Bus at one time. The test sources can be connected to the Test Bus using

microprocessor commands. The Test Bus is also available to the user for monitoring on pins 24

and 13 of the Front Panel Connector. (See

Front Panel Interface Wiring for more detail.)

The self-test is performed by sending a command to the microprocessor, instructing it to run the

self-test (see

3Microprocessor Commands). When the microprocessor runs the self-test, a Test

Result is returned (see the description of the Self Test Command for a more detailed description).

Commands

The SVM2608 is equipped with a processor. While the processor is not directly involved in the

acquisition process, its presence on the board significantly enhances the capabilities of the

SVM2608 digitizer.

The user can choose to download the data on to a CPU and perform custom data processing, or

they can instruct the on-board microprocessor to perform one or several predefined calculations

SVM2608 Introduction 15

Page 16

VXI Technology, Inc.

sets. (See 3Microprocessor Commands for more details on available commands.) The command is

sent to the microprocessor via the Command register. Since there are four independent channels

on the board, each of them can take a different command and each of them has its own command

register. The result of the microprocessor calculation is returned in the Result register for the

corresponding channel.

The data stored in the channel memory is raw data. When the microprocessor performs a

resistance calculation, it uses calibrated data, meaning that the microprocessor takes the

calibrations for the Local Current Sources (see above) values into consideration. The raw data the

user downloads from the board represents calibrated voltage measurements. The result calculated

by the microprocessor and placed in the Result register when a Resistance Measurement

command is issued is based on calibrated Current measurements. While the user can perform

calibrated voltage measurements by simply reading the raw data, the calculations for resistance

cannot be accurately performed by the user as they do not have the calibrated current values (the

exact values injected in the resistance under test by the board’s current source). Although it is

possible for the user to read the calibration values (see the

Calibration Commands section) and

use the raw data to perform all the calibrated measurements on their own, the manufacturer

encourages the use of the microprocessor’s capabilities to perform all calibrated resistance

calculations.

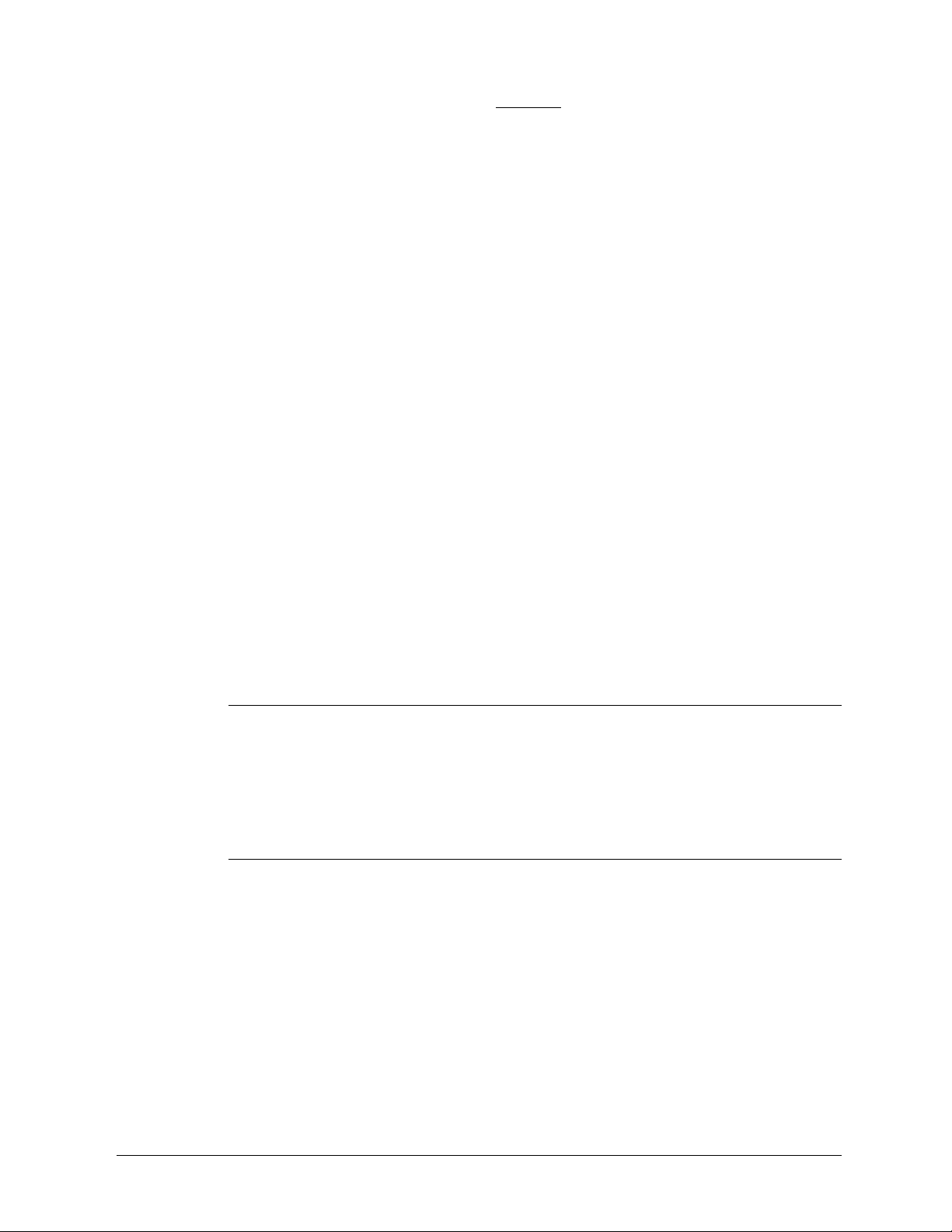

Option -01

With the addition of the SVM2608-01 option, two additional channels are available with a

sample rate of 20 MHz and 12-bits of resolution. This option may be purchased at the same time

as the SVM2608 or is factory upgradeable.

The high-speed channels available on Option -01 function independently. The front end of each

channel has both a variable gain amplifier and an attenuator, similar to the low-speed channels. A

5 MHz low-pass filter (LPF) is available on these channels, as opposed to the 20 kHz LPF found

on the low-speed channels. The ADC converter is a 12 bits converter capable of taking as many

as 20 MSamples/s on a scale of -2 V to +2 V. To compensate for offset and gain variation in the

ADCs, each channel has two 12 bits DACs that are used to calibrate the offset and the gain on

each ADC channel. These calibrations are performed at the factory using precision voltage

reference sources. A block diagram for Option -01 is provided on the following page.

16 SVM2608 Introduction

Page 17

www.vxitech.com

HS_CHnI+

50 Ohm

HS_CHn–

50 Ohm

HS_EXT_TRIG

EXT_TRIG_LVL

GLUE LOGIC

12 BITS

CHANNEL_1 TRIG

TRIG

CHANNEL_5 TRIG

EXT_TRG

TO

SINGLE

HIGH SPEED

CHANNEL

ADC

16 BITS, 120 MHz

÷ 1

÷ 10

+

DIFF TO

SINGLE

÷ 1

÷ 10

TRIG_LVL

–

DAC

LPF

OFFSET_LVL

+

–

+

–

DAC

DAC

REF_LVL

CHNL TRIG

1x, 2x, 4x

+

–

OFFSET

ADJ

DAC

+

SINGLE

DIFF

–

REFERENCE

CHNL TRIG

SDRAM

2 MB

ADJ

VM2608

MAIN BOA RD

LOW_SPEED_CHNLS

16 BITS, 10 MHz

REF_LVL

TRIG_LVL

OFFSET_LVL

HS_TRIG_LVL

DATA &

CONTROLS

LS_TRIG

HS_TRIG

FIGURE 1-2: SVM2608 BLOCK DIAGRAM

SVM2608 Introduction 17

Page 18

CH 4 +

VXI Technology, Inc.

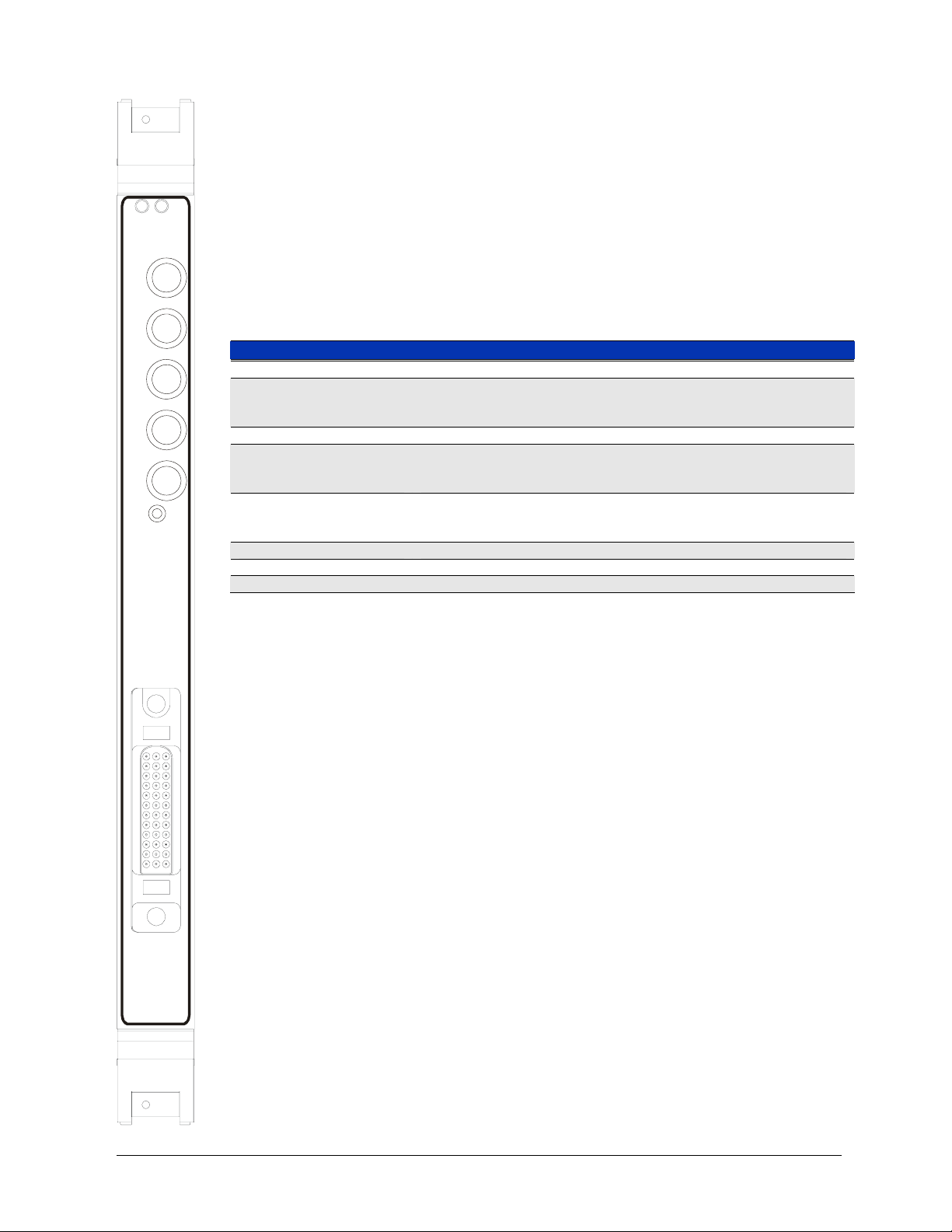

PHYSICAL DESCRIPTION

The SVM2608 has a protective coating applied to it to ensure that the effects of environmental

hazards are minimized. This coating endows the modules with resistance to salt sprays, moisture,

dust, sand, and explosive environments, as the polymer coating provides a hermetic seal. The

module is designed to withstand the stress and rigors of shock and vibration, allowing the module

P/FA/E

to be deployed in a variety of applications without concern for damage due to the surrounding

physical environment. The following table details the environmental specifications of this

module.

CH 4 -

HS TRIG

CH 5 +

CH 5 -

J100

TABLE 1-1: SVM2608 ENVIRONMENTAL SPECIFICATIONS

SVM ENVIRONMENTAL SPECIFICATIONS

CLASSIFICATION

TEMPERATURE

OPERATIONAL

NON-OPERATIONAL

HUMIDITY

ALTITUDE

OPERATIONAL

SUSTAINED STORAGE

RANDOM VIBRATION

O

PERATIONAL

ON-OPERATIONAL

N

FUNCTIONAL SHOCK

SALT ATMOSPHERE

SAND AND DUST

The SVM2608 has two indicator LEDs located on its front panel. The A/E (Access/Error) LED

flashes green when read/write commands are being sent to the module. Should the SVM2608

receive an error, the LED glows red. This LED can be overridden by the user by setting the Sysfail

bit in the

Reset, Sys Fail Control, Interrupt Levels Register. The P/F (Power/Fail) LED glows

green indicates the status of a processor driven self-test. If the self-test is successful, the P/F LED

glows green, if the test fails, however, the LED will glow red. Both the A/E and P/F LEDs can be

programmed to glow red when a fail condition occurs.

MIL-T-28800E Type III, Class 5, Style E or F

Meets functional shock requirements of MIL-T-28800E, Type III, Class 5

-20°C to 65°C

-40°C to 71°C

5% to 95% (non-condensing)

Sea level to 15,000 ft (4,570 m)

Sea level to 40,000 ft (12,190 m)

Three axis, 30 minutes total, 10 minutes per axis

0.27 g

2.28 g

total from 5.0 Hz to 55.0 Hz

rms

total from 5.0 Hz to 55.0 Hz

rms

Half sine, 30 g, 11 ms duration

> 48 hrs operation

> 6 hrs operation in a dust environment of 0.3 g/ft3 blowing at 1750 ft/min

FIGURE 1-3: SVM2608 FRONT PANEL

18 SVM2608 Introduction

Page 19

www.vxitech.com

3

FRONT PANEL INTERFACE WIRING

Front-panel connector, J101, contains all the instrument signals for the Channels 0 through 3.

PIN NUMBER SIGNAL PIN NUMBER SIGNAL PIN NUMBER SIGNAL

1 GND 13 TB- 25 GND

2 CH1I- 14 GND 26 CH3I3 CH1- 15 GND 27 CH34 CH1+ 16 GND 28 CH3+

5 CH1I+ 17 GND 29 CH3I+

6 GND 18 GND 30 GND

7 GND 19 EXTTRIGIN 31 GND

8 CH0I- 20 GND 32 CH2I-

9 CH0- 21 GND 33 CH210 CH0+ 22 GND 34 CH2+

11 CH0I+ 23 GND 35 CH2I+

12 GND 24 TB+ 36 GND

Pin 1

Pin 1

Pin 12

Pin 24

Pin 25

Pin 36

FIGURE 1-4: SVM2608 PIN LOCATIONS

Note The SMA connectors associated with the high-speed channels are labeled on the front panel and

are capable of being triggered by a different external trigger source than the low-speed channels.

SVM2608 Introduction 19

Page 20

SVM2608 SPECIFICATIONS

GENERAL SPECIFICATIONS

NUMBER OF CHANNELS

SAMPLING RATE

Range

Resolution

Accuracy

INPUT POWER

+5 V dc

+12 V dc

-12 V dc

VMEBUS INTERFACE

Address mode

Data transfer mode

MEMORY

VOLTAGE MEASUREMENT

Range

Resolution

Accuracy

INPUT IMPEDANCE

20 & 50 V Range

1, 2, 5 & 10 V Range

RESISTANCE MEASUREMENT*

Range

Resolution

Accuracy

*Note: Resistance measurements can only be made one channel at a time.

All resistance measurements can be made accurately up to +199% of the set range.

INPUT FILTER

TRIGGER LEVELS

Internal

Range

Trigger level resolution

Level accuracy

External

Range

Trigger level resolution

Level accuracy

DELAYED TRIGGER

Range

Resolution

TIMEOUT

Range

Resolution

WARM-UP TIME

MTBF

4

0.59 Samples/s to 100.0 kSamples/s

100 ns

1%

500 mA

300 mA

300 mA

A32

D16 or D32

1 MSamples per channel

±1.0 V, ±2.0 V, ±5.0 V, ±10.0 V, ±20.0 V, ±50.0 V

15

of full scale

1/2

1%

200 kΩ

> 10 MΩ

100 Ω, 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 100% over range*

1/6,553.6 of scale

1%

20 kHz (-3 dB)

trigger level determined by selected voltage range (see Voltage Measurement above)

Range/2

1%

-10 V to +10 V

4.88 mV

1%

0 samples to (2

1 sample

10 µs to 227 hrs

10 µs to 100 s

10 min

80,000 hrs (based on 20% Ground Mobile, 80% Ground Fixed environment, T ≥ 52°C)

11

32

-1) samples

VXI Technology, Inc.

20 SVM2608 Introduction

Page 21

www.vxitech.com

OPTION 1 - SVM2608-01

NUMBER OF CHANNELS

VMEBUS INTERFACE

Address Mode

Data Transfer Mode

SAMPLING RATE

Range

Resolution

Accuracy

MEMORY

VOLTAGE MEASUREMENTS

Range

Resolution

Accuracy

INPUT IMPEDANCE

INPUT MODE

INPUT FILTER

TRIGGER LEVELS

Internal

Range

Trigger level resolution

Level accuracy

External

Range

Trigger level resolution

Level accuracy

DELAYED TRIGGER

Range

Resolution

TRIGGER ACCURACY

EXTERNAL TRIGGER ACCURACY

TIMEOUT

Range

Resolution

WARM-UP TIME

MTBF

2

A32

D16 or D32

7.15 Samples/s to 20.0 MSamples/s

8.333 ns

1%

1 MSamples per channel

±0.5 V, ±1.0 V, ±2.0 V, ±5.0 V, ±10.0 V, ±20.0 V

Range/2

1%

1 MΩ or 50 Ω (software selectable)

ac or dc (software selectable)

5 MHz (-3 dB)

trigger level determined by selected voltage range (see Voltage Measurement above)

Full scale/2

1%

-10 V to +10 V

4.88 mV

1%

0 samples to (2

1 sample

1%

1%

10 µs to 227 hrs

10 µs to 100 s

10 min

80,000 hrs (based on 20% Ground Mobile, 80% Ground Fixed environment, T ≥ 52°C)

11

11

24

-1) samples

SVM2608 Introduction 21

Page 22

VXI Technology, Inc.

22 SVM2608 Introduction

Page 23

www.vxitech.com

SECTION 2

PREPARATION FOR USE

INTRODUCTION

When the SVM2608 is unpacked from its shipping carton, the contents should include the

following items:

(1) SVM2608 4 Channel 100 kSamples/s Analog-to-Digital Converter Module

(1) SVM2608 User’s Manual (this manual)

All components should be immediately inspected for damage upon receipt of the unit. Installation

instructions for the module are discussed in the following pages of this section.

The chassis the SVM2608 is installed in should be checked to ensure that it is capable of

providing adequate power and cooling. Once it is found that the chassis meets these specifications,

the SVM2608 should be examined. If the module is found to be in good condition, the base

address of the SVM2608 and the backplane jumpers of the chassis may be configured. After

setting the base address and chassis jumpers, the SVM2608 may be installed into an appropriate

6U VMEbus mainframe in any slot other than slot zero.

CALCULATING SYSTEM POWER AND COOLING REQUIREMENTS

It is imperative that the chassis provide adequate power and cooling for this module. Referring to

the chassis operation manual, confirm that the power budget for the system (the chassis and all

modules installed therein) is not exceeded and that the cooling system can provide adequate

cooling.

It should be noted that if the chassis cannot provide adequate power to the module, the instrument

might not perform to specification or possibly not operate at all. In addition, if adequate cooling is

not provided, the reliability of the instrument will be jeopardized and permanent damage may

occur. Damage found to have occurred due to inadequate cooling could also void the warranty of

the module.

SETTING THE CHASSIS BACKPLANE JUMPERS

Please refer to the chassis operation manual for further details on setting the backplane jumpers.

SVM2608 Preparation for Use 23

Page 24

SETTING THE BASE ADDRESS

The base address of the SVM2608 is determined by using the offset value (OV), set by two rotary

switches located on the top edge of the interface card (

16,777,216) to get the base address in A32 address space. The switches are labeled with positions

0 through F. The switch located at S3 corresponds to the Most Significant Bit (MSB) and S2

corresponds to the Least Significant Bit (LSB). (Note, S1 is not used in the determination of the

base address.) To set the OV to 25, first convert the decimal number to the hexadecimal value of

0x19. Next, set switch S3 to 1, and then set switch S2 to 9. See

examples are provided on the following pages.

VXI Technology, Inc.

Figure 2-1), and multiplying it by 224 (or

Figure 2-2. Two conversion

S1 S2 S3

FIGURE 2-1: ROTARY SWITCH LOCATIONS

24 SVM2608 Preparation for Use

Page 25

www.vxitech.com

2

3

Example 1

OV

(decimal)

Divide

by 16

MSB LSB

25 25 / 16 = 1 w/ 9 remaining Divide the decimal value by 16 to get

the MSB and the LSB.

= 0001 1001 The 1 is the MSB, and the remainder of

9 is the LSB.

= 1 9 Convert to hexadecimal. Set the back

switch to 1 and the front switch to 9.

S

S

4

5

3

6

2

7

1

0

F

8

9

A

B

E

C

D

4

5

3

6

2

7

1

0

F

8

9

A

B

E

C

D

FIGURE 2-2: OFFSET VALUE EXAMPLE 1

Here is another way of looking at the conversion: OV = (S3 x 16) + S2

OV = (1 x 16) + 9

OV = 16 + 9

OV = 25

The base address is then determined by using the following formula:

A32 Base Address = Offset Value * 0x1000000 (or 16,777,216)

In this case:

A32 Base Address = 0x19 * 0x1000000 (or 16,777,216)

A32 Base Address = 0x19000000

SVM2608 Preparation for Use 25

Page 26

VXI Technology, Inc.

2S3

Example 2

OV

(decimal)

Divide

by 16

MSB LSB

200 200 / 16 = 12 w/ 8 remaining Divide by 16.

= 1100 1000 Convert to MSB and LSB.

= C 8 Convert to hexadecimal. Set the back

switch to C and the front switch to 8.

S

FIGURE 2-3: OFFSET VALUE EXAMPLE 2

Therefore, the base address in this example is:

A32 Base Address = 0xC8 * 0x1000000 (or 16,777,216)

A32 Base Address = 0xC8000000

This information is used to write to the registers of the SVM2608. (See

on SVM2608 registers.)

MODULE INSTALLATION/REMOVAL

Before installing an SVM2608 module into a 6U VME mainframe, make sure that the mainframe

is powered down. Insert the module into the base unit by orienting the module so that the flanges

at the edge of the module can be inserted into the slot of the base unit. Position the flanges so that

they fit into the module slot groove. Once the module is properly aligned, push the module back

and firmly insert it into the backplane connector. The retaining screws can then be used to secure

the module in the chassis.

To remove the module, power down the mainframe and remove all cabling from the module. The

retaining screws can then be loosened. The ejector handles can then be used as to assist in the

removal of the module.

4

5

3

6

2

7

1

0

F

8

9

A

B

E

C

D

4

5

3

6

7

2

1

0

F

8

9

A

B

E

C

D

Section 3 for more details

26 SVM2608 Preparation for Use

Page 27

www.vxitech.com

SECTION 3

PROGRAMMING

INTRODUCTION

The SVM2608 modules are VMEbus register-based devices for high-speed D16 or D32 data

retrieval. Register-based programming is a series of reads and writes directly to the module

registers. This eliminates the time for command parsing thus increasing speed.

DEVICE MEMORY MAPS

Function Offset

The function offset helps define where in A32 space a WRITE or READ operation is performed.

The offsets are defined as follows:

Function Decimal Value Hexadecimal Value

CH0 Data 0 0x000000

CH1 Data 2097152 0x200000

CH2 Data 4194304 0x400000

CH3 Data 6291456 0x600000

CH4 (Option -01) 8388608 0x800000

CH5 (Option -01) 10485760 0xA00000

Registers 12582912 0xC00000

Reserved 14680064 0xE00000

CH0 – 5 Data These addresses are used to store data.

Registers These addresses are the A32 memory registers. They are used to program the

settings for each channel, collect FIFO data, collect results or sent commands

to the microprocessor.

Reserved These addresses are reserved for future use.

Register Offset

The register offset is located within the module's A32 address space. When data is sent to a

register address, the address that is written to is the sum of the module base address, the function

offset and the register offset:

Register Address = Module Base Address + Function Offset + Register Offset

Table 3-1 shows the A32 map of the SVM2608 registers.

SVM2608 Preparation for Use 27

Page 28

VXI Technology, Inc.

TABLE 3-1: SVM2608 A32 REGISTER MAP

Note MS = Most Significant LS = Least Significant

OFFSET WRITE FUNCTION READ FUNCTION

0x00

0x02

0x04

0x06

0x08

0x0A

0x0C

0x0E

0x10

0x12

0x14

0x16

0x18

0x1A

0x1C

0x1E

0x20

0x22

0x24

0x26

0x28

0x2A

0x2C

0x2E

0x30

0x32

0x34

0x36

0x38

0x3A

0x3C

0x3E

0x40

0x42

0x44

0x46

0x48

0x4A

0x4C

0x4E

0x50

0x52

0x54

Sysfail Control, Interrupt Levels Sysfail Control, Interrupt Levels

Force Trigger/Start Force Trigger/Start

Reserved Reserved

External Trigger Level External Trigger Level

Control (Channel 0) Control (Channel 0)

Trigger Level (Channel 0) Trigger Level (Channel 0)

Sample Rate (Channel 0) – (MS) Sample Rate (Channel 0) – (MS)

Sample Rate (Channel 0) – (LS) Sample Rate (Channel 0) – (LS)

Sample Points (Channel 0) – (MS) Sample Points (Channel 0) – (MS)

Sample Points (Channel 0) – (LS) Sample Points (Channel 0) – (LS)

Pre-Trigger Points (Channel 0) – (MS) Pre-Trigger Points (Channel 0) – (MS)

Pre-Trigger Points (Channel 0) – (LS) Pre-Trigger Points (Channel 0) – (LS)

Trigger Delay (Channel 0) – (MS) Trigger Delay (Channel 0) – (MS)

Trigger Delay (Channel 0) – (LS) Trigger Delay (Channel 0) – (LS)

Timeout (Channel 0) Timeout (Channel 0)

Interrupt Enable (Channel 0) Interrupt Enable (Channel 0)

Reserved

Command Register (Channel 0) Command Register (Channel 0)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Control (Channel 1) Control (Channel 1)

Trigger Level (Channel 1) Trigger Level (Channel 1)

Sample Rate (Channel 1) – (MS) Sample Rate (Channel 1) – (MS)

Sample Rate (Channel 1) – (LS) Sample Rate (Channel 1) – (LS)

Sample Points (Channel 1) – (MS) Sample Points (Channel 1) – (MS)

Sample Points (Channel 1) – (LS) Sample Points (Channel 1) – (LS)

Pre-Trigger Points (Channel 1) – (MS) Pre-Trigger Points (Channel 1) – (MS)

Pre-Trigger Points (Channel 1) – (LS) Pre-Trigger Points (Channel 1) – (LS)

Trigger Delay (Channel 1) – (MS) Trigger Delay (Channel 1) – (MS)

Trigger Delay (Channel 1) – (LS) Trigger Delay (Channel 1) – (LS)

Timeout (Channel 1) Timeout (Channel 1)

Interrupt Enable (Channel 1) Interrupt Enable (Channel 1)

Reserved

Command Register (Channel 1) Command Register (Channel 1)

Reserved

Reserved

Reserved

Reserved

Reserved

Interrupt Status (Channel 0)

FIFO Data (Channel 0) – (MS)

FIFO Data (Channel 0) – (LS)

Result Register (Channel 0) – (MS)

Result Register (Channel 0) – (LS)

Result Register (Channel 0) – (MS)

Result Register (Channel 0) – (LS)

Interrupt Status (Channel 1)

FIFO Data (Channel 1) – (MS)

FIFO Data (Channel 1) – (LS)

Result Register (Channel 1) – (MS)

Result Register (Channel 1) – (LS)

Result Register (Channel 1) – (MS)

28 SVM2608 Programming

Page 29

www.vxitech.com

OFFSET WRITE FUNCTION READ FUNCTION

0x56

0x58

0x5A

0x5C

0x5E

0x60

0x62

0x64

0x66

0x68

0x6A

0x6C

0x6E

0x70

0x72

0x74

0x76

0x78

0x7A

0x7C

0x7E

0x80

0x82

0x84

0x86

0x88

0x8A

0x8C

0x8E

0x90

0x92

0x94

0x96

0x98

0x9A

0x9C

0x9E

0xA0

0xA2

0xA4

0xA6

0xA8

0xAA

0xAC

0xAE

0xB0

0xB2

0xB4

Reserved

Control (Channel 2) Control (Channel 2)

Trigger Level (Channel 2) Trigger Level (Channel 2)

Sample Rate (Channel 2) – (MS) Sample Rate (Channel 2) – (MS)

Sample Rate (Channel 2) – (LS) Sample Rate (Channel 2) – (LS)

Sample Points (Channel 2) – (MS) Sample Points (Channel 2) – (MS)

Sample Points (Channel 2) – (LS) Sample Points (Channel 2) – (LS)

Pre-Trigger Points (Channel 2) – (MS) Pre-Trigger Points (Channel 2) – (MS)

Pre-Trigger Points (Channel 2) – (LS) Pre-Trigger Points (Channel 2) – (LS)

Trigger Delay (Channel 2) – (MS) Trigger Delay (Channel 2) – (MS)

Trigger Delay (Channel 2) – (LS) Trigger Delay (Channel 2) – (LS)

Timeout (Channel 2) Timeout (Channel 2)

Interrupt Enable (Channel 2) Interrupt Enable (Channel 2)

Reserved

Command Register (Channel 2) Command Register (Channel 2)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Control (Channel 3) Control (Channel 3)

Trigger Level (Channel 3) Trigger Level (Channel 3)

Sample Rate (Channel 3) – (MS) Sample Rate (Channel 3) – (MS)

Sample Rate (Channel 3) – (LS) Sample Rate (Channel 3) – (LS)

Sample Points (Channel 3) – (MS) Sample Points (Channel 3) – (MS)

Sample Points (Channel 3) – (LS) Sample Points (Channel 3) – (LS)

Pre-Trigger Points (Channel 3) – (MS) Pre-Trigger Points (Channel 3) – (MS)

Pre-Trigger Points (Channel 3) – (LS) Pre-Trigger Points (Channel 3) – (LS)

Trigger Delay (Channel 3) – (MS) Trigger Delay (Channel 3) – (MS)

Trigger Delay (Channel 3) – (LS) Trigger Delay (Channel 3) – (LS)

Timeout (Channel 3) Timeout (Channel 3)

Interrupt Enable (Channel 3) Interrupt Enable (Channel 3)

Reserved

Command Register (Channel 3) Command Register (Channel 3)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Control (Channel 4) Control (Channel 4)

Trigger Level (Channel 4) Trigger Level (Channel 4)

Sample Rate (Channel 4) – (MS) Sample Rate (Channel 4) – (MS)

Sample Rate (Channel 4) – (LS) Sample Rate (Channel 4) – (LS)

Sample Points (Channel 4) – (MS) Sample Points (Channel 4) – (MS)

Sample Points (Channel 4) – (LS) Sample Points (Channel 4) – (LS)

Pre-Trigger Points (Channel 4) – (MS) Pre-Trigger Points (Channel 4) – (MS)

Result Register (Channel 1) – (LS)

Interrupt Status (Channel 2)

FIFO Data (Channel 2) – (MS)

FIFO Data (Channel 2) – (LS)

Result Register (Channel 2) – (MS)

Result Register (Channel 2) – (LS)

Result Register (Channel 2) – (MS)

Result Register (Channel 2) – (LS)

Interrupt Status (Channel 3)

FIFO Data (Channel 3) – (MS)

FIFO Data (Channel 3) – (LS)

Result Register (Channel 3) – (MS)

Result Register (Channel 3) – (LS)

Result Register (Channel 3) – (MS)

Result Register (Channel 3) – (LS)

SVM2608 Programming 29

Page 30

VXI Technology, Inc.

OFFSET WRITE FUNCTION READ FUNCTION

0xB6

0xB8

0xBA

0xBC

0xBE

0xC0

0xC2

0xC4

0xC6

0xC8

0xCA

0xCC

0xCE

0xD0

0xD2

0xD4

0xD6

0xD8

0xDA

0xDC

0xDE

0xE0

0xE2

0xE4

0xE6

0xE8

0xEA

0xEC

0xEE

0xF0

0xF2

0xF4

0xF6

0xF8 Reserved Reserved

0xFA Reserved Reserved

0xFC Reserved Reserved

0xFE

Pre-Trigger Points (Channel 4) – (LS) Pre-Trigger Points (Channel 4) – (LS)

Trigger Delay (Channel 4) – (MS) Trigger Delay (Channel 4) – (MS)

Trigger Delay (Channel 4) – (LS) Trigger Delay (Channel 4) – (LS)

Timeout (Channel 4) Timeout (Channel 4)

Interrupt Enable (Channel 4) Interrupt Enable (Channel 4)

Reserved

Command Register (Channel 4) Command Register (Channel 4)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Control (Channel 5) Control (Channel 5)

Trigger Level (Channel 5) Trigger Level (Channel 5)

Sample Rate (Channel 5) – (MS) Sample Rate (Channel 5) – (MS)

Sample Rate (Channel 5) – (LS) Sample Rate (Channel 5) – (LS)

Sample Points (Channel 5) – (MS) Sample Points (Channel 5) – (MS)

Sample Points (Channel 5) – (LS) Sample Points (Channel 5) – (LS)

Pre-Trigger Points (Channel 5) – (MS) Pre-Trigger Points (Channel 5) – (MS)

Pre-Trigger Points (Channel 5) – (LS) Pre-Trigger Points (Channel 5) – (LS)

Trigger Delay (Channel 5) – (MS) Trigger Delay (Channel 5) – (MS)

Trigger Delay (Channel 5) – (LS) Trigger Delay (Channel 5) – (LS)

Timeout (Channel 5) Timeout (Channel 5)

Interrupt Enable (Channel 5) Interrupt Enable (Channel 5)

Reserved

Command Register (Channel 5) Command Register (Channel 5)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

External Trigger Level for High-Speed Channel External Trigger Level for High-Speed Channel

Interrupt Status (Channel 4)

FIFO Data (Channel 4) – (MS)

FIFO Data (Channel 4) – (LS)

Result Register (Channel 4) – (MS)

Result Register (Channel 4) – (LS)

Result Register (Channel 4) – (MS)

Result Register (Channel 4) – (LS)

Interrupt Status (Channel 5)

FIFO Data (Channel 5) – (MS)

FIFO Data (Channel 5) – (LS)

Result Register (Channel 5) – (MS)

Result Register (Channel 5) – (LS)

Result Register (Channel 5) – (MS)

Result Register (Channel 5) – (LS)

DATA(BYTE) ORDERING

When a pair of 16-bit registers is read as a 32-bit register, the content of the register marked MS is

placed on the VME Bus on D31 - D16 and the content of the register marked LS is placed on

D15 - D0. Similarly, when a pair of 16-bit registers is written as a 32-bit register, the register

marked MS is loaded with the data present on the VME Bus on D31 - D16 and the register marked

LS is loaded with the data present on D15 - D0. All other registers should be addressed as 16-bit

registers to prevent any malfunctioning.

30 SVM2608 Programming

Page 31

www.vxitech.com

With a variety of systems and bridges that move the data between different bus types (i.e. VME to

PCI, VXI to PCI, etc.), in order to assist the user in determining how data is ordered, a known

floating point value of 0.12345678901234 is loaded at Power-Up in the Result Register for all

channels. Channel 0 values are listed as an illustration:

0x3FBF is written at address 0xC00028

0x9ADD is written at address 0xC0002A

0x3746 is written at address 0xC0002C

0xF4C6 is written at address 0xC0002E

By reading the value from these addresses, the user can identify the type of DATA(BYTE)

swapping that takes place in the system and modify their code accordingly. An example of how to

do the swapping is presented in

DETERMINING THE REGISTER ADDRESS

A user wishes to set Channel 2 to the 1.0 V range. Data is to be captured linearly without the use

of the low pass filter or timeout control and will trigger from the positive edge of data sent to

Channel 2. To accomplish this, the user will access the Control Register for Channel 2 at register

offset 0x0058. To determine the register address, this value must be added to the base address and

A32 address of the module. In this example, it is assumed that the base address switches are set to

0x19, yielding a base address of 0x19000000. Since the user must write to a register, the function

offset is 0x00C00000.

Register Address = Module Base Address + Function Offset + Register Offset

= 0x19000000 + 0x00C00000 + 0x00000058

= 0x19C00058

By observing the bits in the Control Register, it can be determined what data value should be sent:

D15

Appendix A.

Write Reason

0

D14

D13

D12

D11

D10

D9

D8

0x58

(Channel 2 Offset)

D7

D6

D5

D4

D3

D2

D1

D0

0

0

0

0

0

0

0

0

1

1

0

0

0

1

0

It is recommended that unused register bits

have 0 written to them

Disables Timeout Control

Sets the Channel for Linear Acquisition

Sets the Channel for Voltage Mo de

Sets the Channel for acquisition in the 1.0 V range

Disables the 20 kHz Filter on Channel 2

Sets the channel to trigger on a Positive Slope

Selects Channel 2 as the Trigger Source

SVM2608 Programming 31

Page 32

The binary values are then converted into a hexadecimal format:

Binary

0000 0000 0110 0010 0x0062

This determines the data value required for the aforementioned settings.

ACCESSING THE REGISTERS

With both D16 and D32 data transfer available, the user can write either 16 or 32 bits of data to

the registers. To change the settings of the module, it is only necessary to write a 16- or 32-bit

integer to the specified register with the new configuration.

All registers, as defined in the following section, are 16-bit registers. A 32-bit write can be made

to registers that are located in consecutive addresses. The consecutive 16-bit registers that can be

accessed as 32-bit registers are:

Sample Rate Register (0x0C, 0x34, 0x5C, 0x84, 0xAC, 0xD4)

Sample Points Register (0x10, 0x38, 0x60, 0x88, 0xB0, 0xD8)

Pre-Trigger Points Register (0x14, 0x3C, 0x64, 0x8C, 0xB4, 0xDC)

Trigger Delay Register (0x18, 0x40, 0x68, 0x90, 0xB8, 0xE0)

VXI Technology, Inc.

Hexadecimal

FIFO data (0x24, 0x4C, 0x74, 0x9C, 0xC4, 0xEC)

Result Register (0x28 & 0x2C, 0x50 & 0x54, 0x78 & 0x7C, 0xA0 & 0xA4, 0xC8 &

0xCB, 0xF0 & 0xF4)

NOTE Reading 32 bits from a 16-bit register may generate a BERR on the VME bus.

Writing 32 bits to a 16-bit register may generate a BERR on the VME bus or may corrupt data in

another register.

DESCRIPTION OF REGISTERS

The following pages describe the registers found in the SVM2608 Register Map for A32 address

space that starts at 0x00C0000. When multiple channels registers have the same functions, the

offsets appear in parenthesis separated by commas with Channel 0 being listed first, followed by

Channel 1, etc. For example, the description used by the Control Register Bit is applicable to all

six channels at offsets 0x08 for Channel 0, 0x30 for Channel 1, 0x58 for Channel 2 and 0x80 for

Channel 3, 0xA8 for Channel 4 and 0xD0 for Channel 5. This is indicated in the register

description by using the following notation: (0x08, 0x30, 0x58, 0x80, 0xA8, 0xD0). Unless

otherwise noted, register descriptions apply to all channels (Channels 0 – 5).

Reset, Sys Fail Control, Interrupt Levels Register (0x00) — Read & Write

D15 Unused This bit is reserved for future use.

System Fail Control - This bit controls whether or not the sysfail line

will be masked.

D14 SYSFAILCTL

D13 – D3 Unused These bits are reserved for future use.

0 = Card can assert sysfail line.

1 = Sysfail line is masked and card cannot assert sysfail line.

state = 0

P

on

32 SVM2608 Programming

Page 33

www.vxitech.com

Reset, Sys Fail Control, Interrupt Levels Register (0x00) — Read & Write

D2 – D0 INTLVL2 - 0

Force Trigger, Start Register (0x02) — Read & Write

D15 – D13 HS_TRIGSRC2 - 0

D12 EXT TRIG SLOPE

D11 – D6 FTRIG5 - 0

Interrupt Level - These bits determine the interrupt service level.

111 = Interrupt level 7

110 = Interrupt level 6

101 = Interrupt level 5

100 = Interrupt level 4

011 = Interrupt level 3

010 = Interrupt level 2

001 = Interrupt level 1

000 = No interrupt

High-Speed Trigger Source – These bits select a trigger source for the

high-speed channels.

000 = Channel 0

001 = Channel 1

010 = Channel 2

011 = Channel 3

100 = Invalid state

101 = Invalid state

110 = External

111 = Invalid state

Note: These bits are only utilized by high-speed Channels 4 and 5. These

bits are unused for Channels 0 – 3.

External Trigger Slope – This bit sets the slope of the external trigger

for low-speed Channels 0 - 3.

0 = Positive

1 = Negative

Note: This bit is only utilized by high-speed Channels 4 and 5. This bit is

unused for Channels 0 – 3.

Force Trigger - All of the channels have the ability to be triggered via

software when in the arm mode. Acquisition begins when trigger is

forced. These bits need to be reset to ‘0’ in order to allow subsequent

triggers (it is the transition of a bit from 0 to 1 that forces a trigger). One

bit is assigned to each channel as follows:

D6 for Channel 0

D7 for Channel 1

D11 for Channel 5

Having one bit per channel allows multiple channels to be triggered

simultaneously.

0 = Do not force trigger

1 = Force software trigger

P

on

state =0

SVM2608 Programming 33

Page 34

VXI Technology, Inc.

Force Trigger, Start Register (0x02) — Read & Write

Acquisition Armed - These bits control whether or not the specified

channel is to be armed for an acquisition. A channel must remain

ARMED for the entire duration of the acquisition process. Clearing an

ARM bit will reset the internal state-machines and stop the acquisition.

One bit is assigned to each channel as follows:

D0 for Channel 0

D1 for Channel 1

D5 – D0 START5 – 0

D5 for Channel 5

Having one bit per channel allows multiple channels to be triggered

simultaneously.

0 = Channel not armed for acquisition

1 = Channel armed and ready for acquisition

state = 0

P

on

Reserved (0x04)

D15 – D0 Reserved These bits are reserved for future use.

External Trigger Level (0x06) — Read & Write

D15 – D12 Unused These bits are reserved for future use.

D11 – D0 External Trigger Level Sets the level at which the module triggers from an external source.

Control Register (0x08, 0x30, 0x58, 0x80, 0xA8, 0xD0) — Read & Write

D15 – D14 Unused These bits are reserved for future use.

AC/DC Select - This bit selects between ac and dc coupling for highspeed Channels 4 – 5.

0 = AC

D13 AC/DC Coupling

D12 1 MΩ/50 Ω

D11 TIMEOUTCTL

1 = dc

Pon state= 0

Note: This bit is only utilized by high-speed Channels 4 and 5. This bit is

unused for Channels 0 – 3.

1 MΩ /50 Ohms - Selects between the 1 MΩ and 50 Ω

0 = 1 MΩ

1 = 50 Ω

Pon state= 0

Note: This bit is only utilized by High-Speed Channels 4 and 5. This bit

is unused for Channels 0 – 3.

Timeout Control - This bit controls whether or not a timeout condition

will cause the timeout bit to be set in the interrupt status register.

0 = Disable timeout status bit

1 = Enable timeout status bit

state = 0

P

on

34 SVM2608 Programming

Page 35

www.vxitech.com

Control Register (0x08, 0x30, 0x58, 0x80, 0xA8, 0xD0) — Read & Write

D10 LINEAR/FIFO

D9 - D8

D7 – D5 ATTN-GAIN1-GAIN0

2WIREOHMS/

4WIREOHMS

Linear or FIFO Memory Mode - Determines whether the data is

captured in Linear (burst) or FIFO (real time) acquisition mode.

0 = Linear mode

1 = FIFO mode

state = 0

P

on

Function Setting - The digitizer is capable of measuring voltages,

resistances in 2-wire mode or resistances in 4-wire mode. Before taking a

measurement, allow for at least 5 ms for internal circuits to settle after

making changes.

00 = Voltage mode

01 = 4-wire resistance mode

10 = 2-wire resistance mode

11 = Invalid state

Note: These bits are only utilized by Channels 0 – 3. These bits are

unused by Channels 4 and 5.

Attenuation and Gain Setting - Valid attenuation settings are x1 and

x10. Valid gain settings are 1, 2, 5, and 10. Note that there is only one

current source shared among all four channels, therefore, only one

resistance measurement can be made at any one time. Before taking a

measurement, allow for at least 5 ms for internal circuits to settle after

making changes.

VOLTAGE MODE (for channels 0-3)

011 = 1.0 V

010 = 2.0 V

001 = 5.0 V

000 = 10.0 V

110 = 20.0 V

101 = 50.0 V

100 = Invalid state

111 = Invalid state

VOLTAGE MODE (for channels 4-5)

011 = 0.5 V

001 = 1.0 V

000 = 2.0 V

111 = 5.0 V

101 = 10.0 V

100 = 20.0 V

010 = Invalid state

110 = Invalid state

RESISTANCE MODE (Valid for channels 0-3)

011 = 100 Ω; 2 mA current source setting

000 = 1 kΩ; 2 mA current source setting

000 = 10 kΩ; 200 μA current source setting

000 = 100 kΩ; 20 μA current source setting

000 = 1 MΩ; 2 μA current source setting

SVM2608 Programming 35

Page 36

Control Register (0x08, 0x30, 0x58, 0x80, 0xA8, 0xD0) — Read & Write

20 kHz (Channels 0-3)/5 MHz (Channels 4-5) LPF Control – This bit

enables/disables the low pass frequency filter for the low-speed channels

and high-speed channels, respectively. . Before taking a measurement,

D4 FILTER

allow for at least 5 ms for internal circuits to settle after making changes.

0 = Filter off

1 = Filter on

state = 0

P

on

Input Trigger Source Slope – This bit sets the slope of the input trigger

for low-speed Channels 0 - 3.

D3 TRGSLOPE

0 = Positive

1 = Negative

state = 0

P

on

Trigger Source Control - Once the trigger is armed, the acquisition can

be triggered via software (FTRIG), any of the six channels or an external

trigger.

000 = Channel 0

D2 – D0 TRIGSRC2 - 0

001 = Channel 1

010 = Channel 2

011 = Channel 3

100 = Channel 4

101 = Channel 5

110 = External

111 = External High-Speed

Trigger Level (0x0A, 0x32, 0x5A, 0x82, 0xAA, 0xD2) — Read & Write

D15 – D12 Unused This is reserved for future use.

Trigger Level Threshold Setting – These bits set the trigger threshold

(12-bit value).

D11 – D0 TRGLVL

0x800 = 0 V

0x000 = -ve full scale

0xFFF = +ve full scale

Sample Rate (0x0C, 0x34, 0x5C, 0x84) — Read & Write

D15 – D9 Unused These bits are reserved for future use.

Sample Interval – These bits set the sample rate.

D8 – D0 SAMPRAT24 – 16

Bit Weight = 100 ns/bit

Minimum Value = 100

Maximum Value = 2

24

– 1

Sample Rate (0x0E, 0x36, 0x5E, 0x86) — Read & Write

Sample Interval – These bits set the sample rate.

D15 – D0 SAMPRAT15 – 0

Bit Weight = 100 ns/bit

Minimum Value = 100

Maximum Value = 2

24

– 1

VXI Technology, Inc.

36 SVM2608 Programming

Page 37

www.vxitech.com

Sample Rate, High-Speed (0xAC, 0xD4) — Read & Write

D15 – D9 Unused These bits are reserved for future use.

Sample Interval – These bits set the high speed sample rate.

D8 – D0 SAMPRAT24 – 16

Bit Weight = 8.333 ns/bit

Minimum Value = 6

Maximum Value = 2

24

– 1

Sample Rate, High-Speed (0xAE, 0xD6) — Read & Write

Sample Interval – These bits set the high speed sample rate.

D15 – D0 SAMPRAT15 – 0

Bit Weight = 8.333 ns/bit

Minimum Value = 6

Maximum Value = 2

24

– 1

Sample Points (0x10, 0x38, 0x60, 0x88, 0xB0, 0xD8) — Read & Write

D15 – D4 Unused These bits are reserved for future use.

Waveform Capture Size - In Linear mode, this sets the number of data

D3 – D0 SIZE19 – 16

points to be captured in a single sweep. In FIFO mode, this sets the

threshold for generating a service request interrupt or status bit. The

maximum size is 1 MSamples (2 Mbytes of data).

Sample Points (0x12, 0x3A, 0x62, 0x8A, 0xB2, 0xDA) — Read & Write

Waveform Capture Size - In Linear mode, this sets the number of data

D15 – D0 SIZE15 – 0

points to be captured in a single sweep. In FIFO mode, this sets the

threshold for generating a service request interrupt or status bit. The

maximum size is 1 MSamples (2 Mbytes of data).

Pre-Trigger Points (0x14, 0x3C, 0x64, 0x8C, 0xB4, 0xDC) — Read & Write

D15 – D4 Unused These bits are reserved for future use.

Size of Pre-Trigger Data – In Linear mode, this sets the number of data

points to be stored before the trigger occurs. In FIFO mode, this register

D3 – D0 PRE19 – 16

is not used.

Minimum Value = 0

Maximum Value = (Capture Size) – 1

Pre-Trigger Points (0x16, 0x3E, 0x66, 0x8E, 0xB6, 0xDE) — Read & Write

Size of Pre-Trigger Data – In Linear mode, this sets the number of data