Page 1

SM7100

MICROWAVE MATRIX

SER’S MANUAL

U

P/N: 82-0055-000

Released February 13, 2006

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949)

955-1894

bus

Page 2

VXI Technology, Inc.

2

Page 3

www.vxitech.com

TABLE OF CONTENTS

INDTRODUCTION

T

ABLE OF CONTENTS................................................................................................................................................3

Certification..........................................................................................................................................................4

Warranty...............................................................................................................................................................4

Limitation of Warranty.........................................................................................................................................4

Restricted Rights Legend......................................................................................................................................4

DECLARATION OF CONFORMITY...............................................................................................................................5

GENERAL SAFETY INSTRUCTIONS.............................................................................................................................6

Terms and Symbols..............................................................................................................................................6

Warnings ..............................................................................................................................................................6

SUPPORT RESOURCES ...............................................................................................................................................8

SECTION 1....................................................................................................................................................................9

INTRODUCTION.........................................................................................................................................................9

Overview ..............................................................................................................................................................9

Programming........................................................................................................................................................9

Automatic Scanning........................................................................................................................................9

Programmable Timing Delays.......................................................................................................................10

Safety Interrupt..............................................................................................................................................10

SM7100 Specifications.......................................................................................................................................10

SECTION 2..................................................................................................................................................................11

PREPARATION FOR USE...........................................................................................................................................11

Introduction ........................................................................................................................................................11

Calculating System Power and Cooling Requirements......................................................................................11

Setting the Chassis Backplane Jumpers..............................................................................................................11

Setting the Logical Address................................................................................................................................12

Example 1......................................................................................................................................................12

Example 2......................................................................................................................................................13

Selecting the Extended Memory Space..............................................................................................................13

SECTION 3..................................................................................................................................................................15

SWITCH CONFIGURATION .......................................................................................................................................15

Front Panel Connection - SM7000.....................................................................................................................15

SECTION 4..................................................................................................................................................................21

PROGRAMMING.......................................................................................................................................................21

Register Access...................................................................................................................................................21

Addressing..........................................................................................................................................................21

Description of Registers - A16...........................................................................................................................23

Description of SMIP II Module Registers - A24 / A32 - Extended Memory.....................................................29

DEVICE MEMORY MAP...........................................................................................................................................33

Relay Register Offset..........................................................................................................................................33

Writing to the Relays..........................................................................................................................................33

Programming......................................................................................................................................................34

INDEX.........................................................................................................................................................................35

SM7100 Preface 3

Page 4

VXI Technology, Inc.

CERTIFICATION

VXI Technology, Inc. (VTI) certifies that this product met its published specifications at the time of shipment from

the factory. VTI further certifies that its calibration measurements are traceable to the United States National

Institute of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that

organization’s calibration facility, and to the calibration facilities o f other International Standards Organization

members.

WARRANTY

The product referred to herein is warranted against defects in material and workmanship for a period of one year

from the receipt date of the product at customer’s facility. The sole and exclusive remedy for breach of any warranty

concerning these goods shall be repair or replacement of defective parts, or a refund of the purchase price, to be

determined at the option of VTI.

For warranty service or repair, this product must be returned to a VXI Technology authorized service center. The

product shall be shipped prepaid to VTI and VTI shall prepay all returns of the product to the buyer. However, the

buyer shall pay all shipping charges, duties, and taxes for products returned to VTI from another country.

VTI warrants that its software and firmware designated by VTI for use with a product will execute its programming

when properly installed on that product. VTI does not however warrant that the operation of the product, or

software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate maintenance by the buyer, buyersupplied products or interfacing, unauthorized modification or misuse, operation outside the environmental

specifications for the product, or improper site preparation or maintenance.

VXI Technology, Inc. shall not be liable for injury to property other than the goods themselves. Other than the

limited warranty stated above, VXI Technology, Inc. makes no other warranties, express or implied, with respect to

the quality of product beyond the description of the goods on the face of the contract. VTI specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

RESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of

the Rights in Technical Data and Computer Software clause in DFARS 252.227-7013.

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509 U.S.A.

4 SM7100 Preface

Page 5

www.vxitech.com

D ECLARATION OF C ONFORMITY

Declaration of Conformity According to ISO/IEC Guide 22 and EN 45014

ANUFACTURER’S NAME VXI Technology, Inc.

M

ANUFACTURER’S ADDRESS 2031 Main Street

M

Irvine, California 92614-6509

RODUCT NAME Microwave Matrix

P

ODEL NUMBER(S) SM7100

M

RODUCT OPTIONS All

P

RODUCT CONFIGURATIONS All

P

VXI Technology, Inc. declares that the aforementioned product conforms to the requirements of

the Low Voltage Directive 73/23/EEC and the EMC Directive 89/366/EEC (inclusive 93/68/EEC)

and carries the “CE” mark accordingly. The product has been designed and manufactured

according to the following specifications:

AFETY EN61010 (2001)

S

EMC EN61326 (1997 w/A1:98) Class A

CISPR 22 (1997) Class A

VCCI (April 2000) Class A

ICES-003 Class A (ANSI C63.4 1992)

AS/NZS 3548 (w/A1 & A2:97) Class A

FCC Part 15 Subpart B Class A

EN 61010-1:2001

The product was installed into a C-size VXI mainframe chassis and tested in a typical configuration.

I hereby declare that the aforementioned product has been designed to be in compliance with the relevant sections

of the specifications listed above as well as complying with all essential requirements of the Low Voltage Directive.

February 2006

Steve Mauga, QA Manager

SM7100 Preface 5

Page 6

Review the following safety precautions to avoid bodily injury and/or damage to the product.

These precautions must be observed during all phases of operation or service of this product.

Failure to comply with these precautions, or with specific warnings elsewhere in this manual,

violates safety standards of design, manufacture, and intended use of the product.

Service should only be performed by qualified personnel.

TERMS AND SYMBOLS

These terms may appear in this manual:

WARNING

CAUTION

These symbols may appear on the product:

VXI Technology, Inc.

GENERAL SAFETY INSTRUCTIONS

Indicates that a procedure or condition may cause bodily injury or death.

Indicates that a procedure or condition could possibly cause damage to

equipment or loss of data.

ATTENTION - Important safety instructions

WARNINGS

Frame or chassis ground

Indicates that the product was manufactured after August 13, 2005. This mark is

placed in accordance with EN 50419, Marking of electrical and electronic

equipment in accordance with Article 11(2) of Directive 2002/96/EC (WEEE).

End-of-life product can be returned to VTI by obtaining an RMA number. Fees

for take-back and recycling will apply if not prohibited by national law.

Follow these precautions to avoid injury or damage to the product:

Use Proper Power Cord

Use Proper Power Source

Use Proper Fuse

To avoid hazard, only use the power cord specified for this product.

To avoid electrical overload, electric shock, or fire hazard, do not

use a power source that applies other than the specified voltage.

To avoid fire hazard, only use the type and rating fuse specified for

this product.

6 SM7100 Preface

Page 7

www.vxitech.com

WARNINGS (CONT.)

Avoid Electric Shock

Ground the Product

Operating Conditions

Improper Use

To avoid electric shock or fire hazard, do not operate this product

with the covers removed. Do not connect or disconnect any cable,

probes, test leads, etc. while they are connected to a voltage source.

Remove all power and unplug unit before performing any service.

Service should only be performed by qualified personnel.

This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground.

To avoid injury, electric shock or fire hazard:

- Do not operate in wet or damp conditions.

- Do not operate in an explosive atmosphere.

- Operate or store only in specified temperature range.

- Provide proper clearance for product ventilation to prevent

overheating.

- DO NOT operate if you suspect there is any damage to this

product. Product should be inspected or serviced only by

qualified personnel.

The operator of this instrument is advised that if the equipment is

used in a manner not specified in this manual, the protection

provided by the equipment may be impaired.

Conformity is checked by inspection.

SM7100 Preface 7

Page 8

VXI Technology, Inc.

SUPPORT RESOURCES

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

VXI Technology

World Headquarters

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Phone: (949) 955-1894

Fax: (949) 955-3041

VXI Technology

Cleveland Instrument Division

5425 Warner Road

Suite 13

Valley View, OH 44125

Phone: (216) 447-8950

Fax: (216) 447-8951

VXI Technology

Lake Stevens Instrument Division

VXI Technology, Inc.

1924 - 203 Bickford

Snohomish, WA 98290

Phone: (425) 212-2285

Fax: (425) 212-2289

Technical Support

Phone: (949) 955-1894

Fax: (949) 955-3041

E-mail:

Visit

support@vxitech.com

http://www.vxitech.com for worldwide support sites and service plan information.

8 SM7100 Preface

Page 9

www.vxitech.com

SECTION 1

INTRODUCTION

OVERVIEW

The SM7100 Microwave Matrix is a member of the VXI Technology SMIP II™ (Switch

Modularity Interface Platform) family. It offers a modular design allowing custom switching

configurations in a single chassis.

The SM7100 is a double-wide, C-size VXI module, which can support customized microwave

switch configurations for many applications.

Using the SMIP II family for microwave switching, the user obtains the following benefits over

other VXI microwave switch solutions:

Density: Up to eight (1x6) microwave relays can be housed in a double-wide VXIbus

slot, saving a complete C-Size slot.

Weight: The miniature relay technology reduces the overall weight considerably. Where

possible, ultralight cabling is used maintaining the total weight under five

pounds.

PROGRAMMING

The SMIP II family of switch modules is programmed using direct register access for fast data

throughput.

Automatic Scanning

A predefined sequence of channels can be programmed into an extensive scan list that can be

incremented by a trigger. This approach relieves the host controller from having to tie up the

VXIbus backplane when scanning.

SM7100 Introduction 9

Page 10

Programmable Timing Delays

A delay can be programmed between relay closures to allow for settling times of other system

resources. When used with triggers, a controlled synchronous switching system can easily be

configured.

Safety Interrupt

This is a programmable fail-safe feature that allows all relays to open based upon the occurrence

of a selected TTL backplane trigger. This allows signals to be removed from the unit under test if

a system fail-safe occurs, such as inadvertent removal of a test adapter.

SM7100 SPECIFICATIONS

SM7000 SPECIFICATIONS

MAXIMUM POWER HANDLING (CW)

At 18 GHz

SWITCHING TIME

RF IMPEDANCE

FREQUENCY (GHz) dc – 3 3 – 18 18 – 20

Isolation (dB min)

Insertion Loss (dB max)

VSWR

SWITCH LIFE

CONNECTORS

POWER REQUIREMENTS

COOLING REQUIREMENTS

20 W, 100 W peak pulse

< 15 ms

50 Ω

90 80 60

1.0 2.8 3.0

1.2:1 1.6:1 2.0:1

1,000,000 cycles per switch

SMA

+5 V @ 0.30 A

-5.2 V @ 0.10 A

-2 V @ 0.10 A

160 mA current draw per relay closure at +24 V

2.22 L/s

VXI Technology, Inc.

10 SM7100 Introduction

Page 11

www.vxitech.com

SECTION 2

PREPARATION FOR USE

INTRODUCTION

When the SMIP is unpacked from its shipping carton, the contents should include the following

items:

(1) SMIP VXIbus module

(1) SM7100 Microwave Matrix User’s Manual (this manual)

All components should be immediately inspected for damage upon receipt of the unit.

Once the SMIP II is assessed to be in good condition, it may be installed into an appropriate Csize or D-size VXIbus chassis in any slot other than slot zero. The chassis should be checked to

ensure that it is capable of providing adequate power and cooling for the SMIP II. Once the

chassis is found adequate, the SMIP’s logical address and the chassis’ backplane jumpers should

be configured prior to the SMIP’s installation.

CALCULATING SYSTEM POWER AND COOLING REQUIREMENTS

It is imperative that the chassis provide adequate power and cooling for this module. Referring to

the chassis operation manual, confirm that the power budget for the system (the chassis and all

modules installed therein) is not exceeded and that the cooling system can provide adequate

airflow at the specified backpressure.

It should be noted that if the chassis cannot provide adequate power to the module, the instrument

may not perform to specification or possibly not operate at all. In addition, if adequate cooling is

not provided, the reliability of the instrument will be jeopardized and permanent damage may

occur. Damage found to have occurred due to inadequate cooling would also void the warranty of

the module.

SETTING THE CHASSIS BACKPLANE JUMPERS

Please refer to the chassis operation manual for further details on setting the backplane jumpers.

SM7100 Preparation for Use 11

Page 12

SETTING THE LOGICAL ADDRESS

The logical address of the SMIP II is set by two rotary switches located on the top edge of th e

interface card, near the backplane connectors. Each switch is labeled with positions 0 through F.

The switch closer to the front panel of the module is the least significant bit (LSB or “Front”),

and the switch located towards the back of the module is the most significant bit (MSB or

“Back”). To set the Logical Address (LA), simply rotate the pointer to the desired value. For

example, to set the LA to 25, first convert the decimal number to the hexadecimal value of 19.

Next, set the back switch to 1, and the front switch to 9. See

provided below:

Example 1

VXI Technology, Inc.

Figure 2-1. Two examples are

LA

(decimal)

Divide

by 16

MSB LSB

25 25 / 16 = 1 w/ 9 remaining Divide the decimal value by 16 to get

the MSB and the LSB.

= 0001 1001 The 1 is the MSB, and the remainder of

9 is the LSB.

= 1 9 Convert to hexadecimal. Set the back

switch to 1 and the front switch to 9.

BACK FRONT

5

4

6

3

2

1

0

F

F

IGURE 2-1: LOGICAL ADDRESS EXAMPLE 1

7

8

9

A

B

E

C

D

4

5

6

3

2

1

0

F

7

8

9

A

B

E

C

D

12 SM7100 Preparation for Use

Page 13

www.vxitech.com

Example 2

LA

(decimal)

Divide

by 16

MSB LSB

200 200 / 16 = 12 w/ 8 remaining Divide by 16.

= 1100 1000 Convert to MSB and LSB.

= C 8 Convert to hexadecimal. Set the back

BACK FRONT

4

3

2

1

0

F

E

D

F

IGURE 2-2: LOGICAL ADDRESS EXAMPLE 2

Here is another way of looking at the conversion: LA = (back switch x 16) + front switch

LA = (1 x 16) + 9

LA = 16 + 9

LA = 25

Set the address switches to FF for dynamic configuration. Upon power-up, the resource manager

will assign a logical address. See Section F - Dynamic Configuration in the VXIbus Sp ecification

for further information.

There is only one logical address per SMIP II base unit. Address assignments for individual

modules are handled through the A24/A32 address space allocation.

SELECTING THE EXTENDED MEMORY SPACE

switch to C and the front switch to 8.

5

6

7

8

9

A

B

C

4

5

6

3

2

1

0

F

7

8

9

A

B

E

C

D

The Extended Memory Space of the SMIP II is set by a dip switch that is located on the bottom

edge of the interface card. Position 1, located to the left on the dip switch, selects between A24

and A32 memory address space. In the UP position, the SMIP II will request A24 space. In the

DOWN position, the SMIP II will request A32 space. (Position 2 is not currently used.) The

selection of the address space should be based upon the memory allocation requirements of the

system that the SMIP II module will be installed. The amount of memory allocated to the SMIP II

module is independent of the address space selected.

SM7100 Preparation for Use 13

Page 14

VXI Technology, Inc.

14 SM7100 Preparation for Use

Page 15

www.vxitech.com

SECTION 3

SWITCH CONFIGURATION

FRONT PANEL CONNECTION - SM7000

SM7100 EXPANDABLE

MICROWAVE SWITCH MATRIX

INPUTS

2

1

EXP INPUTS

1

2

3

4

EXPANSION OUTPUTS

2

1

EXTERNAL DRIVE

3

3

PWR/

FAIL

ACC/

ERR

4

OUTPUTS

1

2

3

4

4

This section details the SM7100 schematics, relays, and pinouts. See Section 4,

Programming, for information on relay addressing.

NOTE Although pin numbers between the SM7000 and the HP equivalent

differ, the signals remain in the same location. This makes it possible to

use the same mating connector and cabling for either system. See Table

3-1 and Figure 3-3 for more information on connector J17.

IGURE 3-1FIGURE 3-1 SM7100 FRONT PANEL

F

SM7100 Module Configuration 15

Page 16

VXI Technology, Inc.

TABLE 3-1: SM7100 FRONT-PANEL EXTERNAL DRIVE CONNECTOR PIN ASSIGNMENTS – J17

SIGNAL RELAY NUMBER PIN NUMBER HP EQUIVALENT

EXT 1 K49 J17-1 1

EXT 2 K51 J17-2 3

EXT 3 K53 J17-3 5

EXT 4 K55 J17-4 7

EXT 5 K57 J17-5 9

EXT 6 K59 J17-6 11

EXT 7 K61 J17-7 13

EXT 8 K63 J17-8 15

EXT 9 K65 J17-9 17

EXT 10 K67 J17-10 19

N/C N/C J17-11 21

+24V +24V J17-12 23

GND GND J17-13 25

EXT 14 K50 J17-14 2

EXT 15 K52 J17-15 4

EXT 16 K54 J17-16 6

EXT 17 K56 J17-17 8

EXT 18 K58 J17-18 10

EXT 19 K60 J17-19 12

EXT 20 K62 J17-20 14

EXT 21 K64 J17-21 16

EXT 22 K66 J17-22 18

EXT 23 K68 J17-23 20

+24V +24V J17-24 22

RETURN GND J17-25 24

FIGURE 3-2: TYPICAL DRIVER OUTPUT

1213

910

11

SM7100 PIN LOCATION

8

22232425 1415161718192021

67

34

5

12

2325

1719

21

18202224 246810121416

HP PIN LOCATION

1113

15

57

9

13

FIGURE 3-3: SM7100/HP EXTERNAL DRIVE PIN CROSS-REFERENCE

16 SM7100 Module Configuration

Page 17

www.vxitech.com

SM7100 Module Configuration 17

Page 18

INPUTS

1 2 3 4

K1 - K6 K7 - K12 K13 - K18 K19 - K24

VXI Technology, Inc.

COAX

1

2

3

EXPANSION INPUTS

4

50

Ω

K25 - K30

1

K31 - K36

2

OUTPUTS

K37 - K42

3

K43 - K48

4

1 2 3 4

EXPANSION OUTPUTS

FIGURE 3-4: SM7100 MATRIX SCHEMATIC

18 SM7100 Module Configuration

Page 19

www.vxitech.com

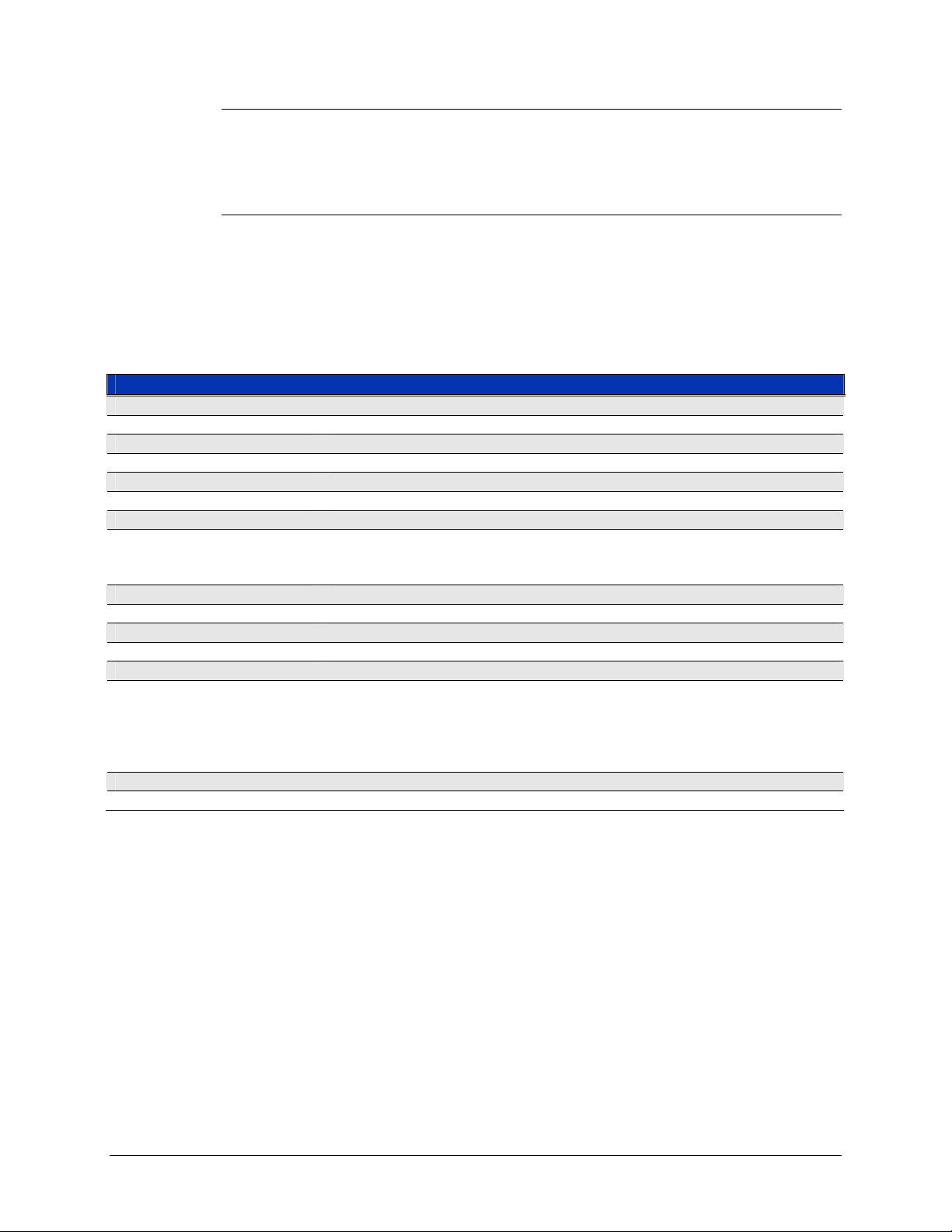

TABLE 3-2: SM7100 RELAY REGISTER MAP

Offset

(Hex)

12

10

E

C

A

8

6

4

2

0

K68 K67 K66 K65

K64 K63 K62 K61 K60 K59 K58 K57 K56 K55 K54 K53 K52 K51 K50 K49

K48 K47 K46 K45 K44 K43 K42 K41 K40 K39 K38 K37 K36 K35 K34 K33

K32 K31 K30 K29 K28 K27 K26 K25 K24 K23 K22 K21 K20 K19 K18 K17

K16 K15 K14 K13 K12 K11 K10 K9 K8 K7 K6 K5 K4 K3 K2 K1

SM7100 Module Configuration 19

Page 20

VXI Technology, Inc.

20 SM7100 Module Configuration

Page 21

www.vxitech.com

SECTION 4

PROGRAMMING

REGISTER ACCESS

The SMIP II modules are VXIbus register-based devices for high-speed data transfers. Register-

based programming is a series of reads and writes directly to the switch module registers. This

eliminates the time for command parsing thus increasing speed.

ADDRESSING

The VTI switching modules utilize either the A24 or A32 space of the shared-memory

architecture. To read or write to a module register, a register address needs to be specified. This is

done by using the offset value (assigned by the resource manager) and multiplying it by 256 or 64

k to get the base address in A24 or A32 address space, respectively

A24 Base Address = Offset value * 0x0100 (or 256)

A32 Base Address = Offset value * 0x10000 (or 65,536)

The A24 or A32 offset value, assigned by the resource manager, can also be accessed by reading

the A16 Offset Register. To address the A16 Offset Register use the following formula:

A16 Base Address = (Logical Address * 64) + 0xC000 (or 49,152)

then

A16 Offset Register Address = A16 Base Address + 6

Table 4-1 for A16 Memory Map and A24/A32 address space allocation.

See

SM7100 Programming 21

Page 22

VXI Technology, Inc.

TABLE 4-1: SMIP II REGISTER MAP - A16

OFFSET WRITE FUNCTION READ FUNCTION

3E

3C

3A

38

36

34

32

30

2E

2C

2A

28

26

24

22

20

1E

1C

1A

18

16

14

12

10

E

C

A

8

6

4

2

0

Trace Advance Board Busy

Busy Trigger Control Busy Trigger Control

Trace RAM Control Trace RAM Control

TTL Trigger Polarity Reserved

Open Trigger Select Reserved

Trace ADV Trigger Select Reserved

Trace RAM Address LOW Trace RAM Address LOW

Trace RAM Address HIGH Trace RAM Address HIGH

Trace RAM End LOW Trace RAM End LOW

Trace RAM End HIGH Trace RAM End HIGH

Trace RAM Start LOW Trace RAM Start LOW

Trace RAM Start HIGH Trace RAM Start HIGH

Module 5, 4 Used Address Reserved

Module 3, 2 Used Address Reserved

Module 1, 0 Used Address Reserved

NVM Access Register NVM Access Register

Reserved Subclass Register

Interrupt Control Interrupt Control

Reserved Interrupt Status

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Version Number

Reserved Serial Number LOW

Reserved Serial Number HIGH

Reserved Reserved

Offset Register Offset Register

Control Register Status Register

Reserved Device Type Register

LA Register ID Register

22 SM7100 Programming

Page 23

www.vxitech.com

DESCRIPTION OF REGISTERS - A16

The following describes the registers shown in the SMIP II Register Map for A16 address space.

ID Register (0x00) — Read Only

D11-D0 Manufacturer's ID VXI Technology, Inc., set to F4B

D13-D12 Address Space

A16/A24

A16/A32 = 012

= 00

2

D15-D14 Device Class Extended register based device, set to 01

16

Logical Address Register (0x00) — Write Only

Sets the new logical address in a dynamically configured module.

D7-D0 Logical Address

When set for dynamic configuration (set to FF

alter the configured logical address, while a hard reset will set the

register back to FF

.

16

D15-D8 Reserved Writing to this range has no effect.

Device Type Register (0x02) — Read Only

D11-D0 Model Code Model 277, set to 115

D15-D12 Required Memory

2 Mbytes, set to 2

2 Mbytes, set to A

16

, for A24

16

, for A32

16

Status Register (0x04) — Read Only

D15 A24/A32 Active

D14 MODID*

D13-D4 Reserved These bits always read as 11,1111,11112

D3 Ready This bit always reads as 12

D2 Passed This bit always reads as 12

D1-D0 Reserved These bits always read as 112

1 = indicates that A24/A32 memory space access is enabled

0 = indicates that A24/A32 memory space access is locked out

1 = indicates that the module is not selected by the MODID line

0 = indicates that the module is selected by the MODID line.

Control Register (0x04) — Write Only

D15 A24/A32 Enable

D14-D2 Reserved Writes to these bits have no effect.

D1 Sysfail Inhibit

D0 Reset

1 = write a 1 to this bit to enable A24/A32 memory access

0 = to disable access

Write a 1 to this bit to prevent the module from asserting the

SYSFAIL* line.

1 = write a 1 to this bit to force the module into a reset state

0 = write a 0 to release the reset state

2

) a soft reset will not

16

SM7100 Programming 23

Page 24

VXI Technology, Inc.

Offset Register (0x06) — Read and Write

The value written to this 16-bit register, times 256, sets the base

address of the A24 memory space used by the module. The value

written to this 16-bit register, times 65,536, sets the base address of

D15-D0

A24/A32 Memory

Offset

the A32 memory space used by the module. A read from this register

reflects the previously written value. Because of the required memory

size, bits D4 - D0 are disregarded on writes and always read back as 0.

Upon receiving a hard reset, all bits in this register are set to 0. A soft

reset does not affect the value in this register.

Reserved Register (0x0A) — Read Only

D15-D0 Not Implemented Always read back as FFFF

16

Reserved Register (0x0C) — Read Only

D15-D0 Not Implemented Always read back as FFFF

16

Version Number Register (0x0E) — Read Only

D15-D8

D7-D4

D3-D0

Firmware Version

Number

Major Hardware

Version Number

Minor Hardware

Version Number

Not applicable, reads back as 00

16

Depends on the specific hardware revision of the SMIP II interface board.

Depends on the specific hardware revision of the SMIP II interface board.

Interrupt Status Register (0x1A) — Read Only

D15 Scan Function done The latest scan list update is complete.

D14

Openbus Active Event

true

D13-D9 Unused Data written to these bits have no effect.

D8 Module Busy Complete

D7-D0 Reserved Always reads back as FFFF

Note: This status register may be used in a polled fashion rather than allowing the events above to generate an

Interrupt. A read of this register will clear any active bits. Bits that are not set, or are about to be set are not

affected by a read of this register.

The Openbus was activated by one or more programmed inputs. See

description of the Openbus in the module register section.

The programmed Busy signal from the module has timed out. This

indicates that the relays actuated for that Busy cycle have settled and a

measurement may take place.

16

24 SM7100 Programming

Page 25

www.vxitech.com

Interrupt Control Register (0x1C) — Read and Write

D15

D14

Scan Function done

mask bit

Openbus Active Event

true mask bit

D13-D9 Unused Data written to these bits has no effect

D8 Module Busy Complete

D7 IR ENA*

D6 IH ENA*

D5-D3 Interrupter IRQ Line

D2-D0 Handler IRQ Line

Note that all bits in this register are set to 1 upon receipt of a hard or soft reset.

Subclass Register (0x1E) — Read Only

D15

D14-D0

VXIbus Extended

Device

Extended Memory

Device

NVM Access Resister (0x20) — Read Only

D15-D1 Unused All Bits are always 1.

D0

NVM Access Resister (0x20) — Write Only

D15-D2 Unused Data written to these bits have no effect.

D1 Serial clock for the switch module; should be a logic 1 when not used.

D0

Board X, Y Used Address Register (0x22, 0x24, 0x26) — Read and Write

D15-D8

D7-D0

0 = enabled

1 = disabled

0 = enabled

1 = disabled

0 = enabled

1 = disabled

0 = writing a 0 to this bit enables interrupter capabilities

1 = writing a 1 to this bit disables interrupter capabilities

The module has no interrupt handler capability; therefore writing a 1 or

0 has no effect. A 1 is always read back for this bit.

The complement of the value programmed into these three bits reflects

the selected IRQ line used by the module. A value of 011

IRQ4, a value of 000

would select IRQ7, and a value of 1112 would

2

would select

2

disconnect the IRQ lines.

The module has no interrupt handler capability; therefore writing to

these bits has no effect. A 111

is always read back for these bits.

2

Always reads as 1.

Always reads as 7FFD

16

Reads back the serial data stream from the selected SMIP II board.

Note that only one SMIP II board may be read back at a time.

Serial data input for the switch module; must be a logic 1 when not

used.

Sets the actual number of words of address space used by the relays on

board's X.

Sets the actual number of words of address space used by the relays on

board's Y.

SM7100 Programming 25

Page 26

VXI Technology, Inc.

Trace RAM Start High Register (0x28) — Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1.

D3-D0

Trace RAM Start Low Register (0x2A) — Read and Write

D15-D0

Trace RAM End High Register (0x2C) — Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1.

D3-D0

Trace RAM End Low Register (0x2E) — Read and Write

D15-D0

Trace RAM Address HIGH Register (0x30) — Read and Write

D15-D4 Unused Data written to these bits have no effect and always read back as 1.

D3-D0

Trace RAM Address LOW Register (0x32) — Read and Write

D15-D0

Trace Advance Trigger Select Register (0x34) —Write Only

D15-D8

D7-D0

Sets the four most significant bits of the starting address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Sets the 16 least significant bits of the starting address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Sets the four most significant bits of the ending address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Sets the 16 least significant bits of the ending address of the Trace

RAM, allowing the available RAM to be divided into multiple traces.

Sets and reads back the four most significant bits of the current

address of the Trace RAM, allowing the current trace RAM address to

be queried and changed.

Sets and reads back the sixteen least significant bits of the current

address of the Trace RAM, allowing the current trace RAM address to

be queried and changed.

Sets the TTLTRIG line or lines, which are configured as outputs, and

will toggle when Trace Advance condition occurs in the module. D15

corresponds to TTLTRIG7, D14 to TTLTRIG6, … and D8 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit to

0 disables the corresponding line. All bits are set to 0 when either a

soft or a hard reset is received by the module.

Sets the TTLTRIG line or lines, which are configured as inputs, and

will cause a Trace Advance event to occur in the module. D7

corresponds to TTLTRIG7, D6 to TTLTRIG6, … and D0 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit to

0 disables the corresponding line. All enabled TTLTRIG lines are

OR'd together to allow more than one TTLTRIG line to cause a Trace

Advance event to occur. All bits are set to 0 when the module receives

either a soft or a hard reset.

26 SM7100 Programming

Page 27

www.vxitech.com

Open Trigger Select Register (0x36) —Write Only

Sets the TTLTRIG line or lines, which are configures as outputs, and

will toggle when Relay Open condition occurs in the module. D15

D15-D8

D7-D0

corresponds to TTLTRIG7, D14 to TTLTRIG6, … and D8 to

TTLTRIG0. Setting a bit to a 1 enables the trigger line, setting a bit to

0 disables the corresponding line. All bits are set to 0 when either a

soft or a hard reset is received by the module.

Sets the TTLTRIG line or lines, which are configured as inputs, and

will cause a Relay Open event to occur in the module. D7 corresponds

to TTLTRIG7, D6 to TTLTRIG6, … and D0 to TTLTRIG0. Setting a

bit to a 1 enables the trigger line, setting a bit to 0 disables the

corresponding line. All enabled TTLTRIG lines are OR'd together to

allow more than one TTLTRIG line to cause a Relay Open event to

occur. All bits are set to 0 when the module receives either a soft or a

hard reset.

TTL Trigger Polarity Register (0x38) —Write Only

D15-D9 Unused Data written to these bits have no effect.

D8 FAIL LED Control

D4

D3 Relay Open Input Slope 0 acts on the falling edge, 1 acts on the rising edge.

D2

D1

D0

Note: A hard or a soft reset sets D3 - D0 to 0.

Board Busy Trigger

Slope

Relay Open Output

Slope

Trace Advance Input

Slope

Trace Advance Output

Slope

0 = off

1 = on

0 acts on the falling edge, 1 acts on the rising edge.

0 sets the falling edge active, 1 sets the rising edge active.

0 advances on the falling edge, 1 advances on the rising edge.

0 sets the falling edge active, 1 sets the rising edge active.

Trace RAM Control Register (0x3A) — Read and Write

D15-D11 Unused Data written to these bits have no effect.

Set to 0 if the module is installed or set to a 1 if not installed. These

D15-D10 Modules Installed

D9-D5 Unused Data written to these bits have no effect.

D4

D3-D2 Unused

D1 LOOP ENABLE

D0 TRACE ENABLE

Modules used in trace

mode

bits are set to 0 at power on. By setting a 1, the SMIP II Interface PCB

will generate DTACK for any read or write cycles to the memory

space of the uninstalled plug-in module.

D9 is for module 5, D4 is for module 0. Set to 1 if the module is used

in trace mode, set to 0 if not in trace mode.

Data written to these bits have no effect. The value written is read

back.

1 = Enabled, 0 = Disabled. If enabled, the trace resumes at the start of

active RAM and continues from there. If disabled, the trace stops at

the end of active RAM and clears the TRACE ENABLE bit.

1 = enabled, 0 = disabled. If the LOOP ENABLE bit is set and the end

of active trace RAM is reached, this bit will not be reset.

SM7100 Programming 27

Page 28

Busy Trigger Control Register (0x3C) — Read and Write

Sets the TTLTRIG Line or Lines, which are configured as outputs, and

will toggle at the de-assertion of a Board Busy condition sent by the

D15-D8 TTLTRIG Select

D7-D1 Unused

D0 Busy Trigger Enable

plug-in modules. D15 corresponds to TTLTRIG7, D14 to TTLTRIG6,

… and D8 to TTLTRIG0. Setting a bit to a 1 enables the trigger line,

setting a bit to a 0 disables the corresponding line. All bits are set to 0

when either a soft or a hard reset is received by the module.

Data written to these bits have no effect. The value written is read

back.

Enables the Board Busy signal received from the switch module to

generate a trigger condition on the TTL Trigger Bus. Setting a bit to 1

enables the generation of a Trigger condition, setting a bit to a 0

disables the corresponding line. This bit is set to 0 when either a soft

or a hard reset is received by the module.

Trigger Advance Register (0x3E) — Write Only

The act of writing to this location causes a Trace Advance event to

D15-D0 Unused

occur in the module. The specific data written to these bits has no

effect.

Board Busy Register (0x3E) — Read Only

D15-D7 Unused These bits always read back as 1.

Indicates whether the SMIP II platform is a single or double wide.

D6

D5-D1 Unused Data written to these bits have no effect.

D0

0 = single wide

1 = double wide

A 0 read from this bit indicates the relays on the switch module have

settled, a 1 indicates that the relays on the switch module are still

changing state.

Reserved Registers — Read and Write

D15-D0 Unused

Writing to these registers has no effect and will always read back as

.

FFFF

16

VXI Technology, Inc.

28 SM7100 Programming

Page 29

www.vxitech.com

DESCRIPTION OF SMIP II MODULE REGISTERS - A24 / A32 - EXTENDED MEMORY

Each module is assigned 1 k (1024) bytes of memory as shown in the SMIP II

Configuration/Relay Register Map for A24/A32 address space. The upper 512 bytes of memory

space is used for module configuration registers. The following describes these registers.

Control Register - Read and Write

ADDR

D15-D10 Unused

Plug-In LA+0x200

0 = Normal polarity relay data is read back from this module

1 = Inverted polarity relay data is read back from this module

Pon state = 0

D9

D8

Relay Data

Read Back

Polarity Bit

ACFAILN

Enable Bit

VXI

Backplane

Write a "1" to

close relay

w/ bit set to 0:

write a "1" =

"0" returned

w/ bit set to 1:

write a "1" =

"1" returned

SMIP

Interface

Board

Relay Data

Read Back

Polarity Bit

0=non-inverted

1=inverted

10

"1" to close

relay

"0" returned

from module

SMIP

Relay

Module

Relay:

"1"

1 = Closed

0 = Open

This bit may be used to invert the relay data read back from the plug-in module.

Control, Delay, and Status Register read backs are not effected by this bit.

0 = ACFAILN is enabled to reset this module's relays

1 = ACFAILN is disabled from resetting this module's relays

Pon state = 0

SM7100 Programming 29

Page 30

VXI Technology, Inc.

Control Register - Read and Write (continued)

0 = BBM (Break-Before-Make) / MBB (Make-Before-Break) is disabled

1 = BBM/MBB operation is enabled

Pon state = 0

NOTE: This bit should remain a 0 (disabled) for the SM7100.

If this bit is set, the relays will be sequenced to effect proper BBM or MBB

operation. If this bit is not set, the module will process the newly written relay data

as immediate data, writing it directly to the relay driver ports. No BBM or MBB

sequencing will take place.

While this feature is enabled, the initial write to the module will start the delay

timer running and begin the BBM or MBB operation. Since the relays are

controlled by the 16-bit registers, only the effected 16 relays will perform the

BBM/MBB operation. To overcome this fact, any subsequent writes to the module,

during the initial delay timer time-out period, will be accepted and processed. In

addition, the delay time will be reset and begin counting down again. Once the

delay timer has timed-out (this indicates that the relays have settled into their

BBM/MBB state), writes to the module will not be accepted and may result in a

Bus Error depending on the value programmed into the delay timer. This is because

the delay timer is reset at the end of the initial time-out and is used to time the final

relay closure into their post BBM/MBB state. The module Busy signal will only

complete once the final relay closure state is reached.

If this bit is set and no value has been loaded into the Delay Register, the module

will act as if this enable bit is not set and load all of the relay drivers with

immediate data.

0 = BBM operation is selected

1 = MBB operation is selected

Pon state = 0

NOTE: This bit should remain a 0 (BBM) for the SM7100.

0 = non-active

1 = active

Pon state = 0

Lights the Access LED red when activated.

0 = The Openbus and Front Panel Open signals are not enabled to reset the relays

1 = The Openbus or Front Panel Open signal may be selected to reset the relays

Pon state = 0

0 = Front Panel Open signal is selected to reset the relays

1 = The Openbus signal is selected to reset the relays

Pon state = 0

Many plug-in modules may be programmed to be listeners on the Openbus.

0 = Disables the Front Panel Open signal from driving the Openbus signal

1 = Enables the Front Panel Open signal to drive the Openbus

Pon state = 0.

D7

D6

D5

D4

D3

D2

BBM/MBB

Enable Bit

BBM/MBB

Select Bit

Access

LED Fail

Bit

Relay

Reset

Enable Bit

Relay

Reset

Select Bit

Openbus

Out Enable

Bit

30 SM7100 Programming

Page 31

www.vxitech.com

Front Panel

D1

Polarity Bit

Front Panel

D0

Operation

Select Bit

Open

Signal

Open

Signal

Control Register - Read and Write (continued)

0 = Non-inverted Front Panel Open signal polarity

1 = Inverted Front Panel Open signal polarity

Pon state = 0

Non-inverted: If set in pulse mode, the Front Panel Open signal will generate a

reset pulse on a falling edge. If set in level mode, the Front Panel Open signal will

generate a reset signal on a low input signal.

Inverted: If set in pulse mode, the Front Panel Open signal will generate a reset

pulse on a rising edge. If set in level mode, the Front Panel Open signal will

generate a reset signal on a high input signal.

0 = Pulse mode

1 = Level mode

Pon state = 0

Pulse mode: An edge seen at the Front Panel Open signal pin will generate a reset

pulse that may be used to reset system relays. The pulse is of approximately 300 ns

duration.

Level mode: A level present on the Front Pan el Open signal pin will generate a

reset signal that may be used to reset system relays. This signal will remain active

as long as the input is active.

On the front panel of most SMIP II plug-in modules, there are two pins for access

to the Front Panel Open signal of the module. These are the Front Panel Open

signal pin and a ground reference pin. The purpose of the Front Panel Open signal

is to allow user access to a configurable interlock feature that will reset all of the

SMIP II system relays. The Front Panel Open signal may be used to reset the relays

only on the module, which initiated the Front Panel Open signal fault condition. It

also may be used to broadcast to all the other SMIP II plug-in modules installed in

a SMIP II Interface Module via what is called the Openbus. Any plug-in module

may be programmed to drive and/or listen to the Openbus. The Openbus signal

may also be used to generate a wider chassis level fault signal via the TTL Trigger

Bus (see the register definitions for A16 address space). The Front Panel Open

signal is meant to be driven by either a switch closure or TTL/CMOS logic gate. It

is pulled high on the module.

SM7100 Programming 31

Page 32

ADDR

D15-D0

Plug-In LA+0x202

Data Bus

16 Bit

ADDR

D15-D13

D12-D1 Unused

D0

Plug-In LA+0x204

Hardware

Revision

Code

Front Panel

Open

signal set

by this

module

VXI Technology, Inc.

Delay Register - Read and Write

This register is used to set the time that the plug-in module will hold the Board

Busy signal active. The Board Busy signal is set every time the plug-in receives a

Write to a relevant Relay Register memory space. The Board Busy signal will be

removed at the end of the time out that is set by the value contained in this register.

For each count loaded into this register, the Board Busy signal will be held active

for 1 µs. The delay may be set from 0 to approximately 65 ms, thus accommodating

a wide variation in test station requirements.

The Board Busy signal may be monitored by the user, in either a polled or an

interrupt fashion, and is to be used as an indication that the relays in the newly

actuated path have settled. Alternatively, the Board Busy sign al may also be used to

drive the TTL Trigger Bus. See the Board Busy, Interrupt Control and Busy

Trigger Control Register descriptions in the A16 address space.

Status Register - Read Only

0 = Indicates that the module's Front Panel Open signal was not activated by the

user

1 = An indication that the module's Front Panel Open signal was activated as

programmed by the user

Pon state = 0

A read of this bit location will indicate whether the Front Panel Open signal was

triggered from the front panel of the module. A read of this register clears this bit to

0.

32 SM7100 Programming

Page 33

www.vxitech.com

DEVICE MEMORY MAP

RELAY REGISTER OFFSET

The Relay Register Offset is located within the A24/32 address space of the module. When you

send data to the register, the relay register offset is added to the A24/A32 base address and

module base address:

Relay Register Address = A24/A32 Base Address + Module Base Address + Register Offset

or

Relay Register Address = Module Relay Address + Register Offset

WRITING TO THE RELAYS

Each bit of a 16-bit register represents the state of the relay (1 = closed, 0 = open). To change the

state of any relay, it is only necessary to write a 16-bit integer to the specified register with the

new configuration:

Relay Register Address, data

For example:

• writing a data value of "0" to the register at offset "0" would open the first sixteen relays

• writing a data value of 65535 to the same register would close the first 16 relays

• writing a data value of 65534 to the same register would close all relays except K1, which

would be open

NOTE Energize only one coil in a group of six at one time.

SM7100 Programming 33

Page 34

PROGRAMMING

With the introduction of VISA, sending a command to a register-based device is as simple as

sending a command to a message-based device. Whether the application is graphical or standard,

sending commands to the register-based device is just as intuitive. The VISA template for

transferring data to a register-based device, utilizing A32 extended memory space, is as follows:

The following example is for a SM5001, 80 channel SPST relay card utilizing A32 extended

memory space. To close relays K1, K33 and K48 while leaving the other relays open, the

following commands would be sent:

VISA is the software architecture standard instituted by the VXIplug&play Alliance and is at a

very high level of communication to a VXIbus device. The same philosophy and simplicity

applies if the instrument is being programmed via lower level commands of an API (Application

Programmer's Interface).

The device Relay Register Map is shown in the following table.

VXI Technology, Inc.

viOut16 (Handle, VI_A32_SPACE, Offset, Data)

Handle is passed by reference whenever a VISA session to a particular device is opened.

VI_A32_SPACE is defined in the VISA header file. (VI_A16_SPACE and

VI_A24_SPACE are also valid.)

Offset is determined from the memory map and is in decimal format.

Data is a 16-bit signed integer value representing the state of the relays.

viOut16 (Handle, VI_A32_SPACE, 0, 1) 'closes relay 1

viOut16 (Handle, VI_A32_SPACE, 4, 32769) 'closes relay 33 and 48

34 SM7100 Programming

Page 35

www.vxitech.com

INDEX

A

A16 address space.............................................................23

A16 Base Address.............................................................21

A16 Offset Register..........................................................21

A16 Offset Register Address............................................ 21

A24 address space.............................................................21

A24 Base Address.............................................................21

A24/A32 Active................................................................23

A24/A32 Enable...............................................................23

A24/A32 Memory Offset..................................................24

A32 address space.............................................................21

A32 Base Address.............................................................21

Access LED Fail Bit.........................................................30

ACFAILN Enable Bit.......................................................29

address space ....................................................................13

Address Space...................................................................23

B

backplane jumpers............................................................11

BBM/MBB Bit .................................................................30

BBM/MBB Enable Bit .....................................................30

C

Cause/Status......................................................................24

command parsing..............................................................21

configuration registers......................................................29

cooling..............................................................................11

D

Data Bus ...........................................................................32

delay ................................................................................. 10

delay timer........................................................................30

Device Class.....................................................................23

direct register access...........................................................9

dynamic configuration......................................................23

E

Extended Memory Device................................................25

Extended Memory Space..................................................13

F

Firmware Version Number...............................................24

Front Panel Open Signal Operation Select Bit..................31

Front Panel Open Signal Polarity Bit................................31

Front Panel Open signal set by this module......................32

H

Handler IRQ Line.............................................................25

Hardware Revision Code..................................................32

I

IH ENA*.......................................................................... 25

Interrupt Mask.................................................................. 25

Interrupter IRQ Line ........................................................ 25

IR ENA* .......................................................................... 25

IRQ line............................................................................ 25

L

logical address................................................ 11, 12, 13, 23

LSB (least significant bit) .......................................... 12, 13

M

Major Hardware Version Number.................................... 24

Manufacturer's ID ............................................................ 23

memory space .................................................................. 29

message-based.................................................................. 21

Minor Hardware Version Number....................................24

Model Code...................................................................... 23

MODID*.......................................................................... 23

Module Relay Address.....................................................33

MSB (most significant bit).........................................12, 13

O

Offset Register ................................................................. 21

offset value.......................................................................21

Openbus Out Enable Bit................................................... 30

P

polled fashion...................................................................24

power................................................................................11

R

register address................................................................. 21

register-based device........................................................34

registers...................................................................... 21, 23

Relay Data Read Back Polarity Bit.................................. 29

Relay Register Address.................................................... 33

Relay Register Offset....................................................... 33

Relay Reset Enable Bit ....................................................30

Relay Reset Select Bit ...................................................... 30

Required Memory ............................................................ 23

Reset................................................................................. 23

S

scan list...............................................................................9

Sysfail Inhibit...................................................................23

T

triggers ............................................................................. 10

SM7100 Index 35

Page 36

VXI Technology, Inc.

U

utilizing A32 extended memory space..............................34

V

VISA.................................................................................34

VXIbus .......................................................................11, 21

VXIbus Extended Device .................................................25

W

WEEE.................................................................................6

36 SM7100

Loading...

Loading...