Page 1

CT-100B SERIES

SIX-SLOT VXIBUS CHASSIS

USER’S MANUAL

82-0042-000

Rev. April 7, 2003

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

(949) 955-1894

bus

Page 2

VXI Technology, Inc.

2

Page 3

www.vxitech.com

TABLE OF CONTENTS

I

NTRODUCTION

Certification .......................................................................................................................................................4

Warranty ............................................................................................................................................................4

Limitation of Warranty ...................................................................................................................................... 4

Restricted Rights Legend ................................................................................................................................... 4

ECLARATION OF CONFORMITY .............................................................................................................................. 5

D

ENERAL SAFETY INSTRUCTIONS............................................................................................................................ 7

G

Terms and Symbols............................................................................................................................................ 7

Warnings............................................................................................................................................................ 7

UPPORT RESOURCES ..............................................................................................................................................9

S

S

ECTION 1 .................................................................................................................................................................11

NTRODUCTION ...................................................................................................................................................... 11

I

Introduction...................................................................................................................................................... 11

General Description .........................................................................................................................................12

Backplane......................................................................................................................................................... 12

Performance ..................................................................................................................................................... 12

Flexibility......................................................................................................................................................... 13

CT-100B Series Specifications ........................................................................................................................ 14

Cooling Capacity for CT-100B (Typical)........................................................................................................ 16

ECTION 2 .................................................................................................................................................................19

S

NSTALLATION ....................................................................................................................................................... 19

I

Introduction...................................................................................................................................................... 19

Line Voltage Selection..................................................................................................................................... 19

Backplane......................................................................................................................................................... 19

ACK MOUNT OPTION INSTALLATION................................................................................................................... 21

R

Overview.......................................................................................................................................................... 21

ACK MOUNT KIT INSTALLATION .........................................................................................................................22

R

Required Tools................................................................................................................................................. 22

Parts List ..........................................................................................................................................................22

Assembly Procedure ........................................................................................................................................22

ACK SLIDE INSTALLATION (20” AND 24”) ........................................................................................................... 24

R

Required Tools................................................................................................................................................. 24

Parts List ..........................................................................................................................................................24

Assembly Instructions...................................................................................................................................... 24

ACK MOUNT DOOR KIT INSTALLATION............................................................................................................... 26

R

Required Tools................................................................................................................................................. 26

Parts List ..........................................................................................................................................................26

Assembly Procedure ........................................................................................................................................26

CRYLIC RACK MOUNT DOOR KIT INSTALLATION ............................................................................................... 28

A

Required Tools................................................................................................................................................. 28

Parts List ..........................................................................................................................................................28

Assembly Procedure ........................................................................................................................................28

ECTION 3 .................................................................................................................................................................31

S

PERATION............................................................................................................................................................ 31

O

Introduction...................................................................................................................................................... 31

I

NDEX ........................................................................................................................................................................33

CT-100B Preface 3

Page 4

VXI Technology, Inc.

CERTIFICATION

VXI Technology, Inc. (VTI) certifies that this product met its published specifications at the time of shipment from

the factory. VTI further certifies that its calibration measurements are traceable to the United States National

Institute of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that

organization’s calibration facility, and to the calibration facilities of other International Standards Organization

members.

WARRANTY

The product referred to herein is warranted against defects in material and workmanship for a period of three years

from the receipt date of the product at customer’s facility. The sole and exclusive remedy for breach of any

warranty concerning these goods shall be repair or replacement of defective parts, or a refund of the purchase price,

to be determined at the option of VTI.

For warranty service or repair, this product must be returned to a VXI Technology authorized service center. The

product shall be shipped prepaid to VTI and VTI shall prepay all returns of the product to the buyer. However, the

buyer shall pay all shipping charges, duties, and taxes for products returned to VTI from another country.

VTI warrants that its software and firmware designated by VTI for use with a product will execute its programming

when properly installed on that product. VTI does not however warrant that the operation of the product, or

software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate maintenance by the buyer, buyersupplied products or interfacing, unauthorized modification or misuse, operation outside the environmental

specifications for the product, or improper site preparation or maintenance.

VXI Technology, Inc. shall not be liable for injury to property other than the goods themselves. Other than the

limited warranty stated above, VXI Technology, Inc. makes no other warranties, express or implied, with respect to

the quality of product beyond the description of the goods on the face of the contract. VTI specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

RESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of

the Rights in Technical Data and Computer Software clause in DFARS 252.227-7013.

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509 U.S.A.

4 CT-100B Preface

Page 5

www.vxitech.com

D ECLARATION OF C ONFORMITY

Declaration of Conformity According to ISO/IEC Guide 22 and EN 45014

M

ANUFACTURER’S NAME VXI Technology, Inc.

ANUFACTURER’S ADDRESS 2031 Main Street

M

Irvine, California 92614-6509

RODUCT NAME Six-Slot VXIbus Chassis

P

ODEL NUMBER(S) CT-100B

M

P

RODUCT OPTIONS All

RODUCT CONFIGURATIONS All

P

VXI Technology, Inc. declares that the aforementioned product conforms to the requirements of

the Low Voltage Directive 73/23/EEC and the EMC Directive 89/366/EEC (inclusive 93/68/EEC)

and carries the “CE” mark accordingly. The product has been designed and manufactured

according to the following specifications:

AFETY EN61010 (2001)

S

EMC EN61326 (1997 w/A1:98) Class A

CISPR 22 (1997) Class A

VCCI (April 2000) Class A

ICES-003 Class A (ANSI C63.4 1992)

AS/NZS 3548 (w/A1 & A2:97) Class A

FCC Part 15 Subpart B Class A

EN 61010-1:2001

I hereby declare that the aforementioned product has been designed to be in compliance with the relevant sections

of the specifications listed above as well as complying with all essential requirements of the Low Voltage Directive.

April 2003

_________________________

Jerry Patton, QA Manager

CT-100B Preface 5

Page 6

VXI Technology, Inc.

6 CT-100B Preface

Page 7

www.vxitech.com

GENERAL SAFETY INSTRUCTIONS

Review the following safety precautions to avoid bodily injury and/or damage to the product.

These precautions must be observed during all phases of operation or service of this product.

Failure to comply with these precautions, or with specific warnings elsewhere in this manual,

violates safety standards of design, manufacture, and intended use of the product.

Service should only be performed by qualified personnel.

TERMS AND SYMBOLS

These terms may appear in this manual:

WARNING

CAUTION

These symbols may appear on the product:

Indicates that a procedure or condition may cause bodily injury or death.

Indicates that a procedure or condition could possibly cause damage to

equipment or loss of data.

WARNINGS

ATTENTION - Important safety instructions

Follow these precautions to avoid injury or damage to the product:

Use Proper Power Cord

Use Proper Power Source

Use Proper Fuse

Frame or chassis ground

To avoid hazard, only use the power cord specified for this

product.

To avoid electrical overload, electric shock, or fire hazard,

do not use a power source that applies other than the

specified voltage.

To avoid fire hazard, only use the type and rating fuse

specified for this product.

CT-100B Preface 7

Page 8

WARNINGS (CONT.)

Avoid Electric Shock

Ground the Product

Operating Conditions

Improper Use

VXI Technology, Inc.

To avoid electric shock or fire hazard, do not operate this

product with the covers removed. Do not connect or

disconnect any cable, probes, test leads, etc. while they are

connected to a voltage source. Remove all power and

unplug unit before performing any service. Service should

only be performed by qualified personnel.

This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground.

To avoid injury, electric shock or fire hazard:

- Do not operate in wet or damp conditions.

- Do not operate in an explosive atmosphere.

- Operate or store only in specified temperature range.

- Provide proper clearance for product ventilation to

prevent overheating.

- DO NOT operate if any damage to this product is

suspected. Product should be inspected or serviced

only by qualified personnel.

The operator of this instrument is advised that if

equipment is used in a manner not specified in this

manual, the protection provided by this equipment be

may be impaired.

8 CT-100B Preface

Page 9

www.vxitech.com

SUPPORT RESOURCES

Support resources for this product are available on the Internet and at VXI Technology customer

support centers.

Internet Support

E-mail: support@vxitech.com

Web Address: http://www.vxitech.com

Telephone Support (U.S.)

Tel: (949) 955-1894 West Coast

(216) 447-8950 East Coast

Fax: (949) 955-3041 West Coast

(216) 447-8951 East Coast

VXI Technology Headquarters

Technical Support

VXI Technology, Inc.

2031 Main Street

Irvine, CA 92614-6509

Tel: (949) 955-1894

Fax: (949) 955-3041

CT-100B Preface 9

Page 10

VXI Technology, Inc.

10 CT-100B Preface

Page 11

www.vxitech.com

INTRODUCTION

INTRODUCTION

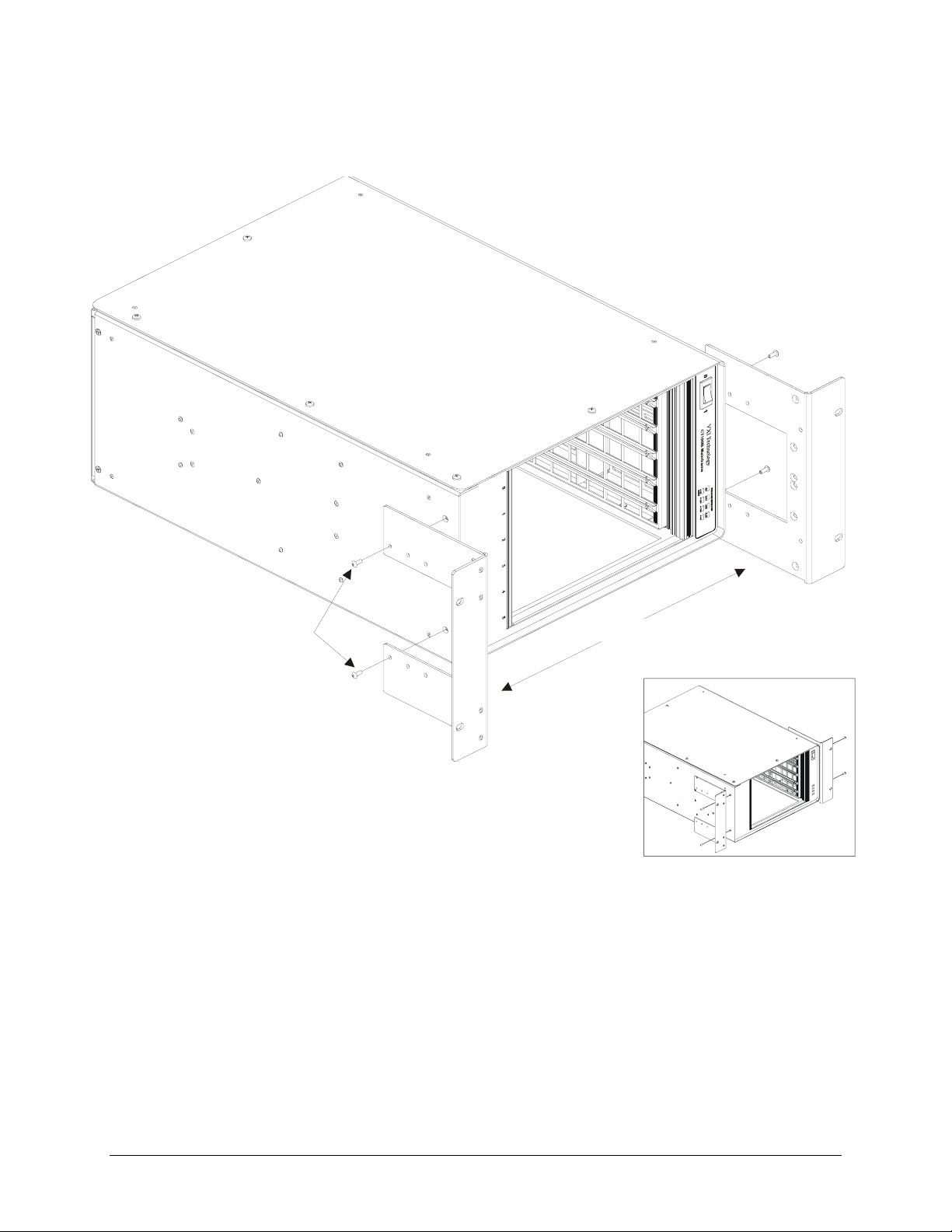

The CT-100B portable C-size VXIbus mainframe provides cost-effective test situations in a small

footprint. When using VMIP instruments such as DMMs, waveform generators, digitizers, etc.,

complete test scenarios can easily be configured.

SECTION 1

FIGURE 1-1 CT-100B SIX-SLOT CHASSIS

CT-100B Introduction 11

Page 12

GENERAL DESCRIPTION

The CT-100B chassis is a portable, C-size, six-slot, VXIbus compatible chassis that conforms

fully to VXIbus Specification Revision 1.4. The chassis employs a multi-layer backplane to

ensure premium VXIbus and VMEbus performance and provides all power supplies required by

the VXIbus specification.

The CT-100B supports conventional existing rack designs through an optional rack mounting kit

(see Section 2). The six-slot design minimizes the use of precious rack space and is an

economical alternative to a larger chassis when fewer slots are required.

The CT-100B chassis contains six slots in the card cage, five of which are available for use by

VXIbus compatible instruments. The sixth slot in the card cage (slot 0) is typically dedicated to

the VXIbus Resource Manager.

The CT-100B is designed to operate at line frequencies between 47 Hz and 63 Hz and is factory

preset to operate at a nominal line voltage of 115 VAC. The chassis auto selects between a

nominal 115 VAC or 220 VAC line, requiring only the fuse be changed to operate at a nominal

220 VAC.

The rear panel provides a connector for 5 V STANDBY. Power supplied to this connector is

passed directly to the backplane line +5VSTDBY. This allows properly configured systems to

take advantage of an alternate power supply source, i.e., battery backup of memory or energizing

high stability reference oscillators.

VXI Technology, Inc.

BACKPLANE

PERFORMANCE

The backplane is a monolithic, multi-layer design, with automatic, solid state daisy-chain

jumpering for the interrupt acknowledge and VMEbus grant lines. This eliminates the need for

manual jumpering and provides improved reliability over mechanical jumper-less backplane

designs. Instrument modules can now be added or removed without concern for the backplane

configuration.

The CT-100B uses a pressurized airflow system. As air enters the mainframe from the rear, it is

pressurized below the cards and is then evenly distributed across all slots and along the total

length of each card slot, avoiding hot spots common in other designs. The air exhausts through

the top and away from the user. This cooling approach helps increase MTBF (Mean Time Before

Failure) figures and module performance.

High-quality power supplies are used in the CT-100B that are UL, CSA and TUV approved. The

power supplies are short-circuit, over-voltage, reverse-voltage and thermal-shutdown protected.

Auto-ranging power supplies are used to avoid any concern about the voltage source used. In

addition, all supply lines are monitored and displayed on the front panel to provide user feedback

of correct operation (see Figure 3-2).

12 CT-100B Introduction

Page 13

www.vxitech.com

FLEXIBILITY

The CT-100B is designed to provide flexibility of use in bench-top and rack-mount applications,

as well as in portable environments. The outside cover is removable for easy access to the

VXIbus modules during bench-top development, troubleshooting or calibration. For rack-mount

applications, a rack-mount kit allows the CT-100B to mount flush or be recessed four inches. A

latched door is provided with the rack-mount kit, which can be user-modified to accept

connectors, switches or indicators. See Section 2 for rack-mount installation.

FIGURE 1-2 CT-100B SIX-SLOT CHASSIS - COVERS OFF

CT-100B Installation 13

Page 14

CT-100B SERIES SPECIFICATIONS

VXI Technology, Inc.

GENERAL SPECIFICATIONS

SIZE

WEIGHT

VXIbus Version

MTTR

8.2” W x 15” H x 21” D without feet and handle

8.5” W x 17” H x 21” D with feet and handle

Six C-Size VXIbus card slots

28 lbs (12.7 kg)

1.4

30 min

ENVIRONMENTAL SPECIFICATIONS

OPERATING LOCATION

TEMPERATURE

Operating

Storage

HUMIDITY

ALTITUDE

This chassis should be operated indoors in a controlled environment, protected

from exposure to the elements (i.e. direct sunlight, precipitation, wind, etc.).

0°C to +50°C

-40°C to +70°C

5 – 95% (non-condensing)

Up to 3000 m

14 CT-100B Introduction

Page 15

www.vxitech.com

}

POWER SPECIFICATIONS

USEABLE POWER

DC Supply Voltage

Output Voltage

POWER INPUT

Input Voltage

AC

Frequency

Fuse

115 V Operation

220 V Operation

+5VSTBY

POWER SUPPLIES (TBD)

450 W at 40°C

Voltage Peak Current (IMP) Dynamic Current (IMD)

+5 V 35 A 5 A

-5.2 V 25 A 4 A

-2 V 7 A 2 A

+12 V 4 A 2 A

-12 V 4 A 1.5 A

+24 V 4 A 3 A

-24 V 4 A 3 A

115 VAC, nominal 90 – 132 VAC

230 VAC, Nominal 180 – 264 VAC

47 Hz – 63 Hz

10 A slow blow

5 A slow blow

6 A max, user supplied

Standard banana jack on rear panel, voltage and ground

UL, CSA, TUV approved

Shout circuit, over-voltage, reverse voltage and thermal shutdown protection

Voltage Allowed Variation

+5 V +0.25 V / -0.125 V 50 mV 50 mV

-5.2 V -0.26 V / +0.125 V 50 mV 50 mV

-2 V -0.10 V / +0.72 V 50 mV 50 mV

+12 V +0.60 V / +0.36 V 50 mV 50 mV

-12 V -0.60 V / +0.36 V 50 mV 50 mV

+24 V +1.20 V / -0.72 V 150 mV 150 mV

-24 V -1.20 V / +0.74 V 150 mV 150 mV

Ripple/Noise

DC Load

Auto Selected

Induced Ripple

Noise

CT-100B Installation 15

Page 16

COOLING SPECIFICATIONS

COOLING REQUIREMENTS (TBD)

AIR FLOW PATH

2.5

O

2

2.0

1.5

1.0

VXI Technology, Inc.

60 W/slot for a 10°C Rise

80 W/slot for a 15°C Rise

Air is drawn into the chassis from the rear and is pressurized below the cards.

The air is then distributed across all slots along the total length of each slot and

is exhausted through the top of the mainframe. When the mainframe is rack

mounted, allow approximately 2 inches (50 mm) of clearance at the top and rear

for proper airflow.

0.5

Pressure Drop - mm H

0.0

0 2.0 4.0 6.0 8.0

Airflow - Liters/Sec

* Covers all slots, unrestricted

FIGURE 1.3 COOLING CAPACITY FOR CT-100B (TYPICAL)

16 CT-100B Introduction

Page 17

www.vxitech.com

V

21.000 (533.40)

8.100 (205.74)

14.979 (380.47)

16.404 (416.66)

VXI Techno logy

0 1

0 1

CT100B Mainframe

OLTAGE MONITOR

VOLTAGE MONITOR

-2V -24V -12V -5.2V

-2V -24V -12V -5.2V

+ 5V

+ 24V + 12V + 5V

+ 5V

+ 24V + 12V + 5V

STBY

STBY

Note: Measurements in parenthesis are in millimeter.

0.343 (8.71)

0 1 2 3 4 5

bus

+5 STANDBY

+5 STANDBY RETURN

FUSE

10A 115VAC

5A 230VAC

F

IGURE 1.2 CT-100B DIMENSIONAL DIAGRAM

CT-100B Installation 17

Page 18

VXI Technology, Inc.

18 CT-100B Introduction

Page 19

www.vxitech.com

INSTALLATION

INTRODUCTION

When the CT-100B is unpacked from its shipping carton, the contents should include the

following items:

(1) CT-100B Six-Slot Chassis

(1) CT-100B Module User’s Manual (this manual)

(2) Replacement fuses, one 10 A slow blow, one 5 A slow blow

(1) Power cord

All components should be immediately inspected for damage upon receipt of the unit.

SECTION 2

LINE VOLTAGE SELECTION

The CT-100B provides auto-ranging power supplies, which automatically sense the line power

value and set themselves accordingly. Ensure that the fuse is correctly rated for the selected line

voltage (the CT-100B is factory configured with a 10 A/115 V fuse). The fuse is located in fuseholder F1 on the rear panel of the chassis. The correct fuse ratings are:

See Figure 2-1 for the location of the line fuse.

CAUTION

Do not attempt to change the fuse with the line cord connected. Ensure that power is off

and that the unit is unplugged before changing the fuse.

BACKPLANE

The CT-100B has a jumper-less auto-configurable backplane using active-automatic daisy

chaining for the VME Interrupt acknowledge and bus grant daisy chain signal lines. This

eliminates the need to manually configure the backplane.

115 V operation 10 A slow blow

220 V operation 5 A slow blow

CT-100B Installation 19

Page 20

VXI Technology, Inc.

+5 STANDBY

+5 STANDBY RETURN

FUSE

10A 115VAC

5A 230VAC

FIGURE 2-1 CT-100B BACK PANEL

20 CT-100B Installation

Page 21

www.vxitech.com

RACK MOUNT OPTION INSTALLATION

OVERVIEW

This section contains the procedures for installing a CT-100B chassis in a standard 19” relay rack.

The available rack mounting options are:

Option 52 – Rack Mount Ear Kit

Option 53 – Rack Mount Door Kit

Option 57 – 20” Slide Kit

Option 58 – 24” Slide Kit

The rack mount ear kit provides the basic hardware necessary to rack mount the CT-100B chassis.

Because the chassis is only 15” wide, standard rack support rails cannot provide mechanical

support to the chassis. If the equipment mounted below the CT-100B cannot provide mechanical

support to the chassis, either 20” or 24” slides will be required to support the chassis in the rack.

The rack mounting ears are designed to allow the chassis to be flush mounted in the rack or

recessed 4”.

The rack mount door kit provides the necessary hardware to install either a 1/8” thick aluminum

door or a 1/8” thick acrylic door in front of the rack mounted chassis. These options require that

the rack mount ear kit also be installed and configured for recessed mounting. The door may be

customer modified to hold connectors, controls, indicators and similar components.

The 20” and 24” slide kits provide the ability to easily remove the chassis from the rack for

servicing and provides mechanical support for the chassis when installed in the rack. The 20”

slide kit is used when the chassis is flush mounted in the rack. If the chassis is to be recess

mounted, then the 24” slides are required.

CT-100B Installation 21

Page 22

RACK MOUNT KIT INSTALLATION

The rack mount kit (Option 59) provides the basic hardware necessary to rack mount the

CT-100B chassis. With the chassis being only 15” wide, standard rack support rails cannot

provide mechanical support to the chassis. If the equipment mounted below the CT-100B cannot

provide mechanical support to the chassis, either 20” or 24” rack slides will be required to support

the chassis when installed into the rack. The rack mounting ears are designed to allow the chassis

to be flush mounted in the rack or recessed 4”.

REQUIRED TOOLS

1. #2 Phillips Screwdriver

PARTS LIST

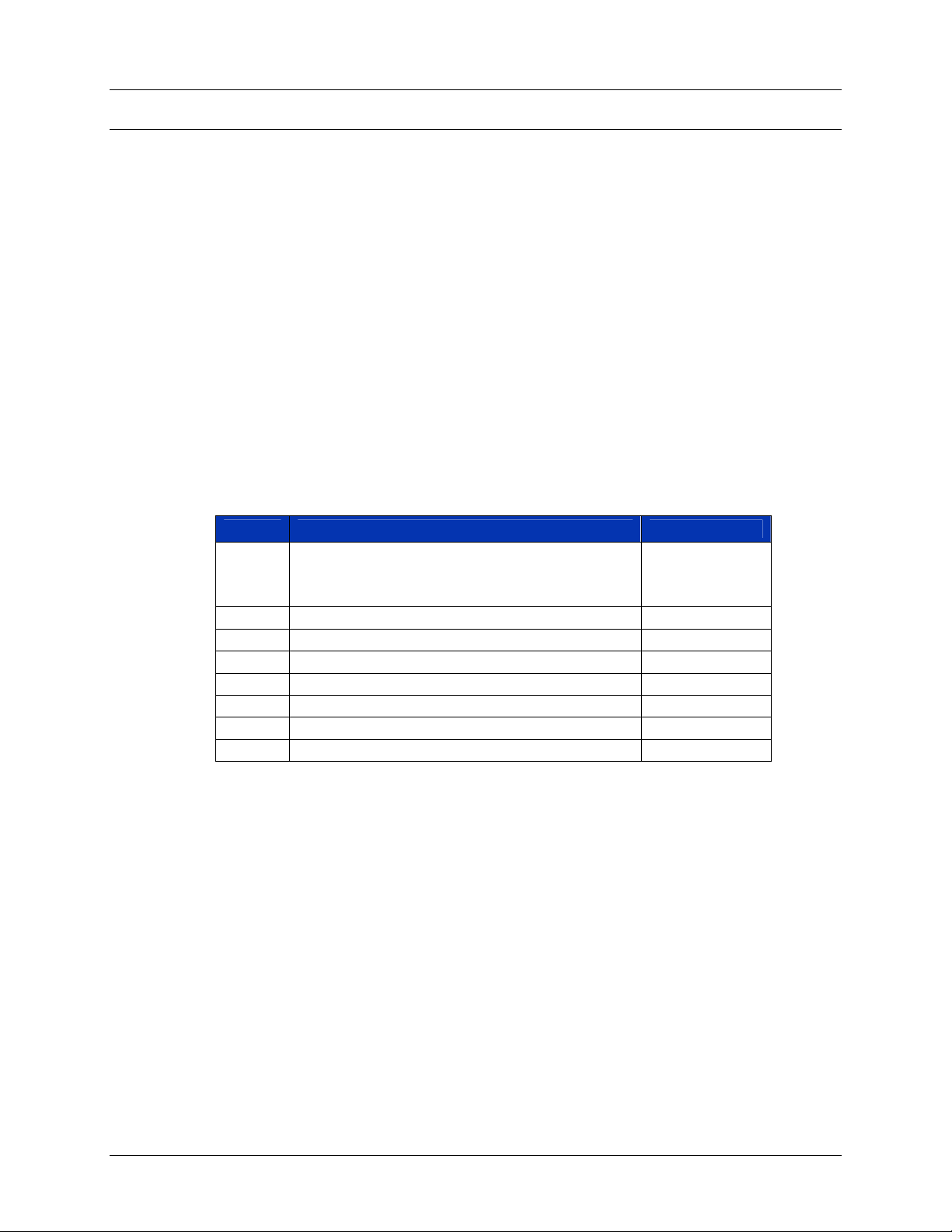

QTY ITEM VTI P/N

4 Screw, 6-32 x 1/2", Phillips/Sems 37-0028-050

1 Bracket, Rack Flange w/ hinge mounting holes 41-0135-000

1 Bracket, Rack Flange 41-0135-001

VXI Technology, Inc.

ASSEMBLY PROCEDURE

1. Remove the four (4) black plastic feet from the bottom of the chassis.

2. Lay the chassis on a protected work surface on its long side with the voltage monitor LEDs of

the chassis facing front with the power switch toward the top.

3. Locate and remove four black plastic feet on the side of the chassis and four black plastic feet

on the bottom of the chassis. Retain the feet if restoring the chassis to its original portable use

is anticipated.

4. Find two threaded holes on each side of the chassis (the plastic feet were attached to two of

these holes) towards the front of the unit.

5. Line up the rack mount ears with the threaded holes selecting the flush or recessed position as

desired. Refer to the rack mount ear installation diagram for visual assistance.

6. Secure the rack ears using the supplied #8-32 hardware.

Before installing the chassis into an EIA switch rack, the chassis handle should be removed. This

can be done by doing the following:

1. Remove the four screws located near the handle.

2. Remove the two black decorative covers at each end of the carrying handle using the flat

blade screwdriver. Place a piece of paper under the screwdriver blade to prevent scratching

the chassis cover.

3. Remove the four Phillips screws holding the handle in place and then remove the handle

itself. Retain the carrying handle components if there may be some need to restore the

chassis to its original portable use in the future.

22 CT-100B Installation

Page 23

www.vxitech.com

Black Oxide

Pan Head

Phillips Scre ws (x4 )

* Recessed Rack Mount Installation Shown

F

IGURE 2.2: RACK MOUNT EAR INSTALLATION DIAGRAM

Rack Mount Ears (x2)

Flush Rackmount Configu ration

CT-100B Installation 23

Page 24

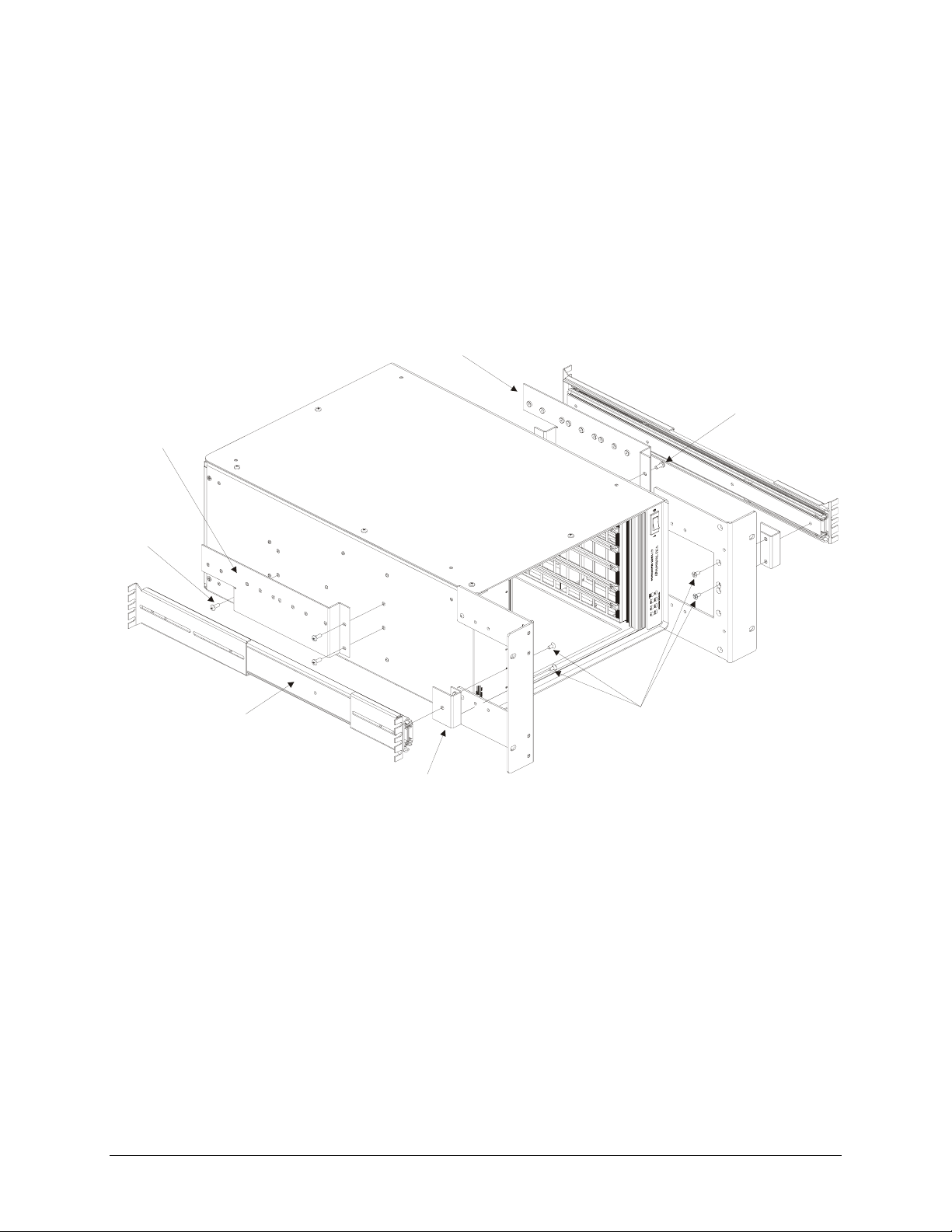

RACK SLIDE INSTALLATION (20” AND 24”)

The 20” and 24” slide hardware kits (Options 63 and 64, respectively) provide standard flanges to

mount the slides into standard EIA relay racks. It should be noted that the slide flanges in the

front should be installed behind the rack’s front panel mounting rails. This will allow the rack

mounting ears to sit flush with the front of the rack. It should also be noted that although the

hardware provided in this kit will provide all the necessary components to successfully install the

CT-100B into a rack, there are many variations in how EIA relay racks are designed and

additional adapter hardware may be required to install the chassis. Please refer to the relay rack

manufacture’s catalog for additional options.

This procedure provides instructions for installing the 20” or 24” slide kits. Note that the 20” and

24” slide kits are identical except for the length of the slide units. A 20” slide kit is used when the

chassis is flush mounted and a 24” slide kit is used when the chassis is recess mounted.

REQUIRED TOOLS

1. #2 Phillips Screwdriver

2. 1/8" Flat Blade Screwdriver

PARTS LIST

VXI Technology, Inc.

QTY ITEM VTI P/N

2 Slide, Rack Mount, Steel, 20” 37-0054-020

- or -

2 Slide, Rack Mount, Steel, 24” 37-0054-024

1 Hardware Kit, Rack Mount Slide, Steel 37-0055-000

6 Screw, 8-32 x 3/8” Pan Head Phillips, Sems Zinc 37-0073-037

6 Screw, 8-32 x 1/4” Pan Head Phillips, Steel/Zinc 37-0074-025

4 Screw, 8-32 x 3/8”, F/H Undercut Phillips, Zinc 37-0115-037

2 Bracket, Slide, Front 41-0108-000

1 Bracket, Slide, Top Side 41-0131-000

1 Bracket, Slide, Bottom 41-0132-000

ASSEMBLY INSTRUCTIONS

1. Lay the chassis on a protected work surface on its long side with the voltage monitor LEDs of

the chassis facing front with the power switch toward the top.

2. If the rack mount ears were installed flush, remove the rack mount ears and install the front

slide bracket to them as shown in the assembly drawing using a flat head screw driver. If the

rack mount ears were installed recessed, simply install the slide brackets onto the ears as

shown on the following page.

3. Reinstall the rack mount ears (if necessary).

4. Install the top and bottom slide brackets using 1/4” Phillips pan head screws. Note that the

slide mounting holes should be oriented below the centerline of the chassis.

24 CT-100B Installation

Page 25

www.vxitech.com

Slide Bracket, Bottom

5. Locate the slide hardware kit provided. Install the rack flanges to the slides as required by the

application using the hardware in the kit. Note that the screws are inserted from the inside of

the slides and the nuts would show on the outside.

6. Install the slides to the mounting brackets already installed on the chassis using the provided

hardware.

Slide Bracket, Top

1/4” Pan Head

Phillips Screw (x3)

1/4” Pan Head

Phillips Screw (x3)

Rack Mount Slide (20” or 24”)

Hardware Kit

3/8” Pan Head Phillips Screws (x6)

* Recessed rack slide configuration shown

3/8” Undercut Flathead

Phillips Screws (x4)

Slide Bracket, (x2) Front

FIGURE 2.3: RACK SLIDE INSTALLATION DIAGRAM

CT-100B Installation 25

Page 26

RACK MOUNT DOOR KIT INSTALLATION

The rack mount door kit (Option 60) provides the necessary hardware to install a 1/8” thick

aluminum door in front of the rack mounted chassis. This option requires that the rack mount ear

kit also be installed and configured for recessed mounting. The door may be customer modified

to hold connectors, controls, indicators and similar components.

REQUIRED TOOLS

1. #2 Phillips Screwdriver

2. 1/8" Flat Blade Screwdriver

3. 11/32" Open Ended Wrench

PARTS LIST

QTY ITEM VTI P/N

2 Slide, Rack Mount, Steel, 20" 37-0054-020

1 Hardware Kit, Rack Mount Slide, Steel 37-0055-000

6 Screw, 8-32 x 3/8" Pan Head Phillips, Sems Zinc 37-0073-037

6 Screw, 8-32 x 1/4" Pan Head Phillips, Steel/Zinc 37-0074-025

4 Screw, 8-32 x 3/8", F/H Undercut Phillips, Zinc 37-0115-037

2 Bracket, Slide, Front, 5 Slot Chassis, CT-100B 41-0108-000

1 Bracket, Slide, Top Side, CT-100B 41-0131-000

1 Bracket, Slide, Bottom, CT-100B 41-0132-000

VXI Technology, Inc.

ASSEMBLY PROCEDURE

1. Lay the chassis on a protected work surface on its long side with the voltage monitor LEDs of

the chassis facing front with the power switch toward the top.

2. Locate two rackmount (cross) braces. Install one each along the front of the flanges (one on

top and one on the bottom) using four (two ea.) #8 flathead screws. The lip along the long

edge of each brace goes toward the front and pointing inside. The braces fit over the flanges

and the screws are placed from the inside going through the flange and then into the brace.

3. Locate the front door and two hinges. Install the two hinges to the front door using four

black screws provided.

4. Locate the latch kit and install it into the door from the side where the hinges are mounted.

5. Locate the door latch bracket and install it on the rack mount ear opposite the end where the

hinges will be installed. Use the rack mount door installation diagram below as a reference.

6. Locate the four tapped holes on the front surface of the rack mount ear to which the door is to

be attached.

7. Install the door by its hinges to the rack mount ear using four black screws provided with the

option kit.

8. Test that the door opens and closes smoothly and adjust the latch as necessary to secure the

door when latched close.

26 CT-100B Installation

Page 27

www.vxitech.com

1/2” Pan Head

Phillips Screws (x2)

Front Door Stop

6-32 Hex Nuts (x2)

Rackmount Braces (x2)

3/8” Flat Head

Phillips Screws (x4)

Hinges (x2)

Front Door, Aluminum

3/8” Pan Head Black Oxide

Phillips Screws (x8)

Door Latch Kit

FIGURE 2.4: RACK DOOR INSTALLATION DIAGRAM

CT-100B Installation 27

Page 28

VXI Technology, Inc.

ACRYLIC RACK MOUNT DOOR KIT INSTALLATION

An acrylic rack mount door is offered as an alternative to the aluminum rack mount door. The kit

(Option 65) provides the necessary hardware to install a 1/8” thick acrylic door in front of the rack

mounted chassis. An installation diagram is provided on the following page for ease of assembly.

This option requires that the rack mount ear kit also be installed and configured for recessed

mounting.

REQUIRED TOOLS

1. #2 Phillips Screwdriver

2. 1/8" Flat Blade Screwdriver

3. 11/32" Open Ended Wrench

PARTS LIST

QTY ITEM VTI P/N

2 Screw, 6-32 x 1/2" Pan Head Phillips, Sems Zinc 37-0028-050

2 Nut, Hex, 6-32, Zinc/Steel 37-0030-632

1 Latch, Vise Action, Knob Style, Black 37-0065-000

2 Hinge, Adjustable Damping, Black 37-0066-000

4 Screw, 8-32 x 3/8" Pan Head Phillips, Black Oxide 37-0079-037

1 Stop, Front Door, CT-100B 41-0133-000

1 Door, Front, CT-100, Acrylic 41-0303-000

2 Brace, Rackmount, CT-100B 41-0136-000

4 Nut, Hex, 8-32, Zinc/Steel 37-0030-832

4 Washer, Split Lock, 8-32 Zinc 37-0013-008

4 Washer, Flat 8-32, Zinc 37-0012-008

4 Screw, 8-32 x 1/2" Pan Head Phillips, Black Oxide 37-0079-050

4 Screw, 8-32 x 3/8" Flat Head Phillips, Zinc 37-0080-037

ASSEMBLY PROCEDURE

1. Lay the chassis on a protected work surface on its long side with the voltage monitor LEDs of

the chassis facing front with the power switch toward the top.

2. Locate two rack mount (cross) braces. Install one each along the front of the flanges (one on

top and one on the bottom) using four (two ea.) #8 flathead screws. The lip along the long

edge of each brace goes toward the front and pointing inside. The braces fit over the flanges

and the screws are placed from the inside going through the flange and then into the brace.

3. Locate the front door and two hinges. Install the two hinges to the front door using four 1/2”

black oxide pan head screws through the holes of the hinge with the flat washer in contact

with the door and with the split lock washer between the hex nut and the flat washer.

4. Locate the latch kit and install it into the door from the side where the hinges are mounted.

5. Locate the door latch bracket and install it on the rack mount ear opposite the end where the

hinges will be installed. Use the rack mount door installation diagram below as a reference.

28 CT-100B Installation

Page 29

www.vxitech.com

6. Locate the four tapped holes on the front surface of the rack mount ear to which the door is to

be attached.

7. Install the door by its hinges to the rack mount ear using four 3/8” black pan head screws

provided with the option kit.

8. Test that the door opens and closes smoothly and adjust the latch as necessary to secure the

door when latched close.

Rack Mount Braces (x2)

3/8” Flat Head

Phillips Screws (x4)

8-32 Hex Nuts (x4)

8-32 Split Lock Washer

8-32 Flat Washer

Front Door, Acryli c

Hinges (x2)

3/8” Pan Head Black Oxide

Phillips Screws (x4)

1/2” Pan Head Black Oxide

Phillips Screws (x4)

Door Latch Kit

F

IGURE 2.5: ACRYLIC RACK DOOR INSTALLATION DIAGRAM

CT-100B Installation 29

Page 30

VXI Technology, Inc.

30 CT-100B Installation

Page 31

www.vxitech.com

OPERATION

INTRODUCTION

There are no operating instructions required for the CT-100B VXIbus chassis. After the chassis is

installed, operation is completely transparent to the operator. Just plug in the instruments then

power up the chassis. The power supply lines are monitored and displayed on the front panel to

provide user feedback of correct operation (see Figure 3-2).

SECTION 3

F

IGURE 3-1 CT-100B SIX-SLOT CHASSIS W/ INSTALLED INSTRUMENTS

CT-100B Operation 31

Page 32

VXI Technology, Inc.

VOLTAGE MONITOR

0 1

0 1

VXI Technology

CT100B Mainframe

VOLTAGE MONITOR

-2V -24V -12V -5.2V

-2V -24V -12V -5.2V

+ 5V

+ 24V + 12V + 5V

+ 5V

+ 24V + 12V + 5V

STBY

STBY

Green

Not Lit

Red

Voltage Monitor LEDs

: Within Voltage Specifications

: Under Voltage

: Over Voltage

0 1 2 3 4 5

bus

IGURE 3-2 FRONT PANEL VOLTAGE INDICATORS

F

32 CT-100B Operation

Page 33

www.vxitech.com

INDEX

#

5V STANDBY................................................................ 12

A

airflow....................................................................... 12, 15

B

backplane........................................................................ 12

backplane configuration.................................................. 12

D

DC supply voltage ..........................................................16

dimentions ......................................................................17

dynamic current .............................................................. 16

dynamic current (I

F

fuse ....................................................................... 7, 12, 19

J

jumpering........................................................................ 12

L

line frequencies............................................................... 12

M

MTTR............................................................................. 15

O

output voltage ................................................................. 16

P

peak current ....................................................................16

peak current (I

power supplies ................................................................ 12

R

rack mount ...................................................................... 21

rack mounting................................................................. 12

rack slide......................................................................... 21

rack-mount...................................................................... 13

S

specifications ...................................................... 14, 15, 16

cooling....................................................................... 15

environmental............................................................ 15

general ....................................................................... 15

power......................................................................... 16

survival ........................................................................... 15

V

voltage ............................................................................16

VXIbus ........................................................................... 12

VXIbus Version........................................................ 14, 15

)..................................................... 14

MD

) ........................................................... 14

MP

CT-100B Index 33

Loading...

Loading...