Page 1

VWR® ELECTRONIC PIPETTE

INSTRUCTION MANUAL

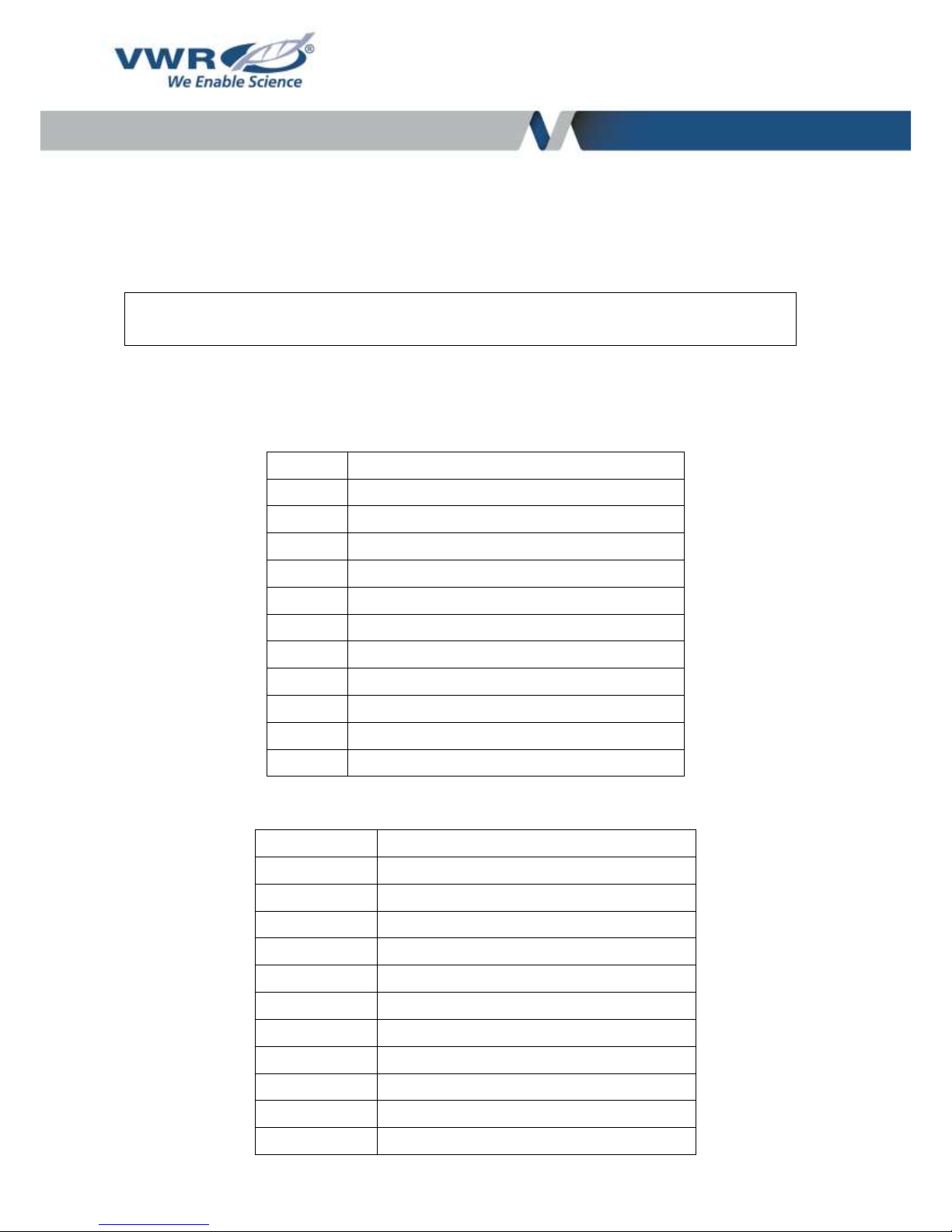

North American Catalog Numbers

10827-884

VWR ELECTRONIC PIPETTE 10µL

10827-918

VWR ELECTRONIC PIPETTE 20µL

10827-920

VWR ELECTRONIC PIPETTE 300µL

10827-922

VWR ELECTRONIC PIPETTE 1200µL

10827-924

VWR ELECTRONIC PIPETTE 8X10µL

10827-926

VWR ELECTRONIC PIPETTE 8X20µL

10827-928

VWR ELECTRONIC PIPETTE 8X300µL

10827-930

VWR ELECTRONIC PIPETTE 8X1200µL

10827-932

VWR ELECTRONIC PIPETTE 12X10µL

10827-934

VWR ELECTRONIC PIPETTE 12X20µL

10827-936

VWR ELECTRONIC PIPETTE 12X300µL

10827-938

VWR ELECTRONIC PIPETTE 12X1200µL

European Catalog Numbers:

613-5415

VWR ELECTRONIC PIPETTE 10µL

613-5416

VWR ELECTRONIC PIPETTE 20µL

613-5417

VWR ELECTRONIC PIPETTE 300µL

613-5418

VWR ELECTRONIC PIPETTE 1200µL

613-5419

VWR ELECTRONIC PIPETTE 8X10µL

613-5420

VWR ELECTRONIC PIPETTE 8X20µL

613-5421

VWR ELECTRONIC PIPETTE 8X300µL

613-5422

VWR ELECTRONIC PIPETTE 8X1200µL

613-5423

VWR ELECTRONIC PIPETTE 12X10µL

613-5424

VWR ELECTRONIC PIPETTE 12X20µL

613-5425

VWR ELECTRONIC PIPETTE 12X300µL

613-5426

VWR ELECTRONIC PIPETTE 12X1200µl

Page 2

2

Version: 1

Issued: 02/18/2016

United States

Europe

VWR International, LLC

VWR International bvba

100 Matsonford Rd

Researchpark Haasrode 2020

Radnor, PA 19087

Geldenaaksebaan 464

800-932-5000

B-3001 Leuven

http://www.vwr.com

+ 32 16 385011

http://be.vwr.com

Country of origin: FRANCE

Intended use :

VWR® ELECTRONIC PIPETTE is intended to be used in liquid handling applications for dispensing

liquids in volume range of 0.5 μl to 1200 µl.

This liquid handling device is designed and manufactured to be used as general purpose laboratory

equipment. Before operating it is recommended to read the user manual, which contains useful

information e.g. for good pipetting practice.

Page 3

3

Table of Contents

Page

1 - INTRODUCTION 4

2 - PARTS CHECK LIST AND ACCESSORIES 5

3 - GETTING STARTED 6

4 - DESCRIPTION 6

5 - PIPETTING 8

6 - PIPETTING MODES 8

7 - PIPETTING SPEED CONTROL 14

8 - GUIDELINES FOR GOOD PIPETTING 14

9 - PERSONALIZE YOUR VWR ELECTRONIC PIPETTE 16

10 - GOOD LABORATORY PRACTICE FEATURES 17

11 – VWR ELECTRONIC PIPETTE POWER MANAGEMENT 17

12 - CONFIGURATION 19

13 - MAINTENANCE OF YOUR VWR ELECTRONIC PIPETTE 20

14 - CLEANING AND DECONTAMINATION 25

15 - LEAK TEST 27

16 - TROUBLESHOOTING 28

17 - SPECIFICATIONS 28

18 - SAFETY PRECAUTIONS AND LIMITATIONS OF USE 29

19 - REPLACEMENT PARTS 31

APPENDICES 32:

Appendix 1: Example of a performance check 32

Appendix 2: Z Factor 33

Appendix 3: Evaporation Loss 34

Appendix 4: VWR Protocol Builder Software 34

WARRANTY 53

Page 4

4

1 INTRODUCTION :

Ease-of-use: Only 2 buttons and 5 pipetting modes

including the CUSTOM Mode which allows to create

pipetting protocols easily and rapidly

Advanced Ergonomics: Lightweight and Perfectly

Balanced, it requires virtually no force to

significantly reduce RSI

Fully Motorized Piston Drive: For an even and regular sample delivery across each

channel

Large Volume range: 4 single channels (from 0.5 μL to 1200 µL) and 8 multichannels

(from 0.5 μL to 1200 μL)

Use while Charging: VWR Electronic Pipette can be used while charging without

compromising performance

VWR Two-Year Warranty

Ideal Electronic pipette with outstanding performances in all pipetting modes. VWR Electronic

pipette requires virtually no force to aspirate and dispense samples and significantly reduces RSI

(Repetitive strain injury) associated with routine work. It combines superior accuracy, precision

and robustness with advanced ergonomics design: it fits comfortably in either left or right hand

and allows a 360° rotating manifold. This pipette is a unique electronic pipette as easy to use as a

mechanical one. With only two buttons to enable the pipette and reach modes/functions: The

Push-Button to set the volume by turning the button left or right and pipette with a simple push and

the Mode-Button to access the 5 essential pipetting modes and pipettes functions. The VWR

electronic pipette has an intuitive interface with 5 available modes: PIPET, REPETITIVE, MIX,

REVERSE and CUSTOM Mode into which you can create, quickly and easily, specific protocols

thanks to VWR Protocol Builder Software .

Choose from a wide range of electronic pipettes covering volumes from 0.5 µL to 1200 µL in

single channel and in multichannel versions - all engineered to optimize your pipetting tasks.

Page 5

5

2 PARTS CHECK LIST AND ACCESSORIES:

Contents:

Take a moment to verify that the following items are in the box:

• VWR Electronic Pipette

• Power Supply 5V with AC adapter and cable

• 4 Battery side tags

• Lubricant (except for 10µl and the multichannel models)

• Tip-ejector extension (10µl model only)

• Quick Start Guide

• Certificate of conformity

• 2-year warranty

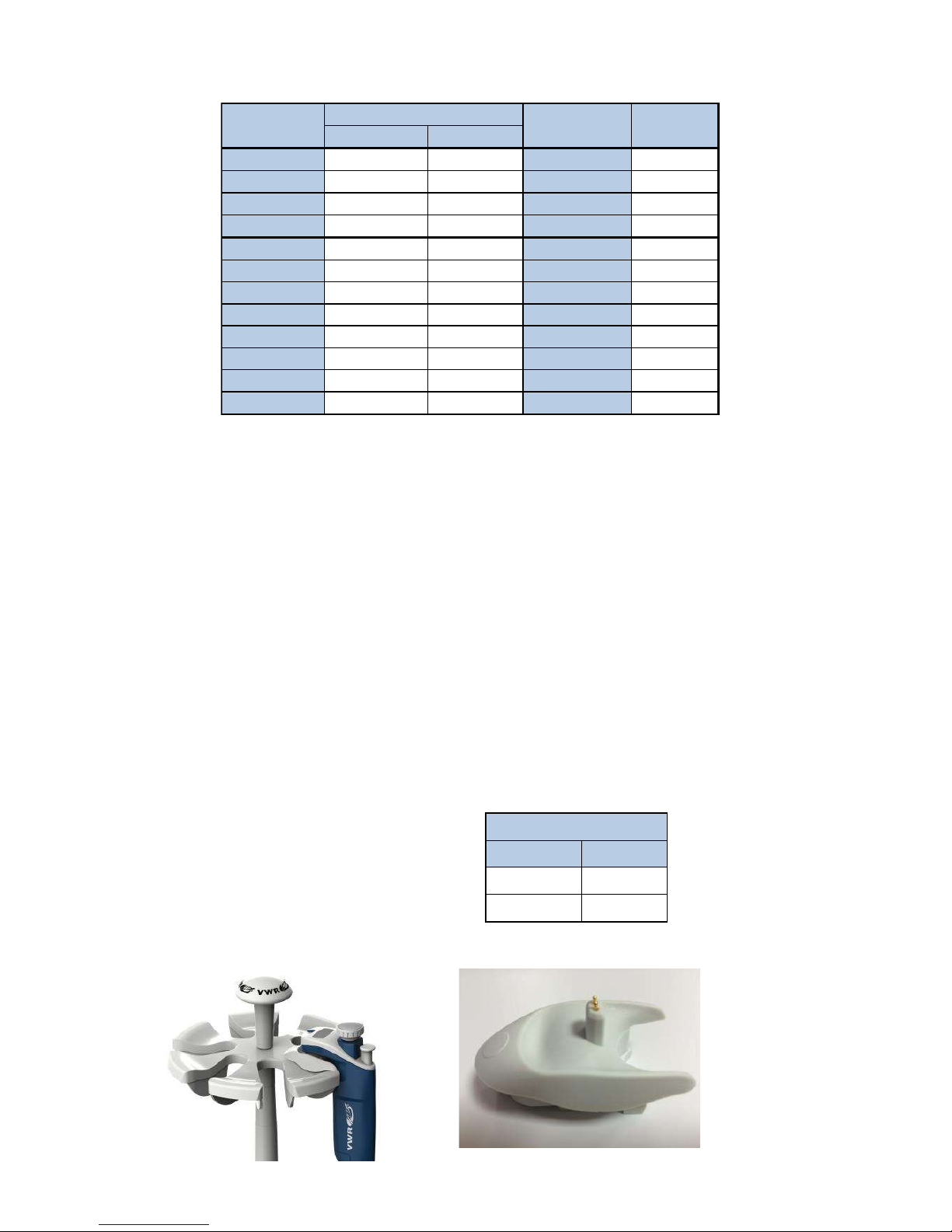

Accessories:

Catalog Number

The following items are sold separately:

US

Europe

• VWR CARROUSEL PIPETTE STAND

10827-940

613-5427

• VWR CHARGING STAND ADAPTER WHITE

10827-942

613-5428

US Europe

VWR 10 10827-884 613-5415 0,5-10µl Red

VWR 20 10827-918 613-5416 2-20µl Pale Yellow

VWR 300 10827-920 613-5417 20-300µl Green

VWR 1200 10827-922 613-5418 100-1200µl Blue

VWR 8x10 10827-924 613-5419 0,5-10µl Red

VWR 8x20 10827-926 613-5420 1-20µl Pale Yellow

VWR 8x300 10827-928 613-5421 10-300µl Green

VWR 8x1200 10827-930 613-5422 50-1200µl Blue

VWR 12x10 10827-932 613-5423 0,5-10µl Red

VWR 12x20 10827-934 613-5424 1-20µl Pale Yellow

VWR 12x300 10827-936 613-5425 10-300µl Green

VWR 12x300 10827-938 613-5426 50-1200µl Blue

Model

Catalog Number

Volume range

Color code

Page 6

6

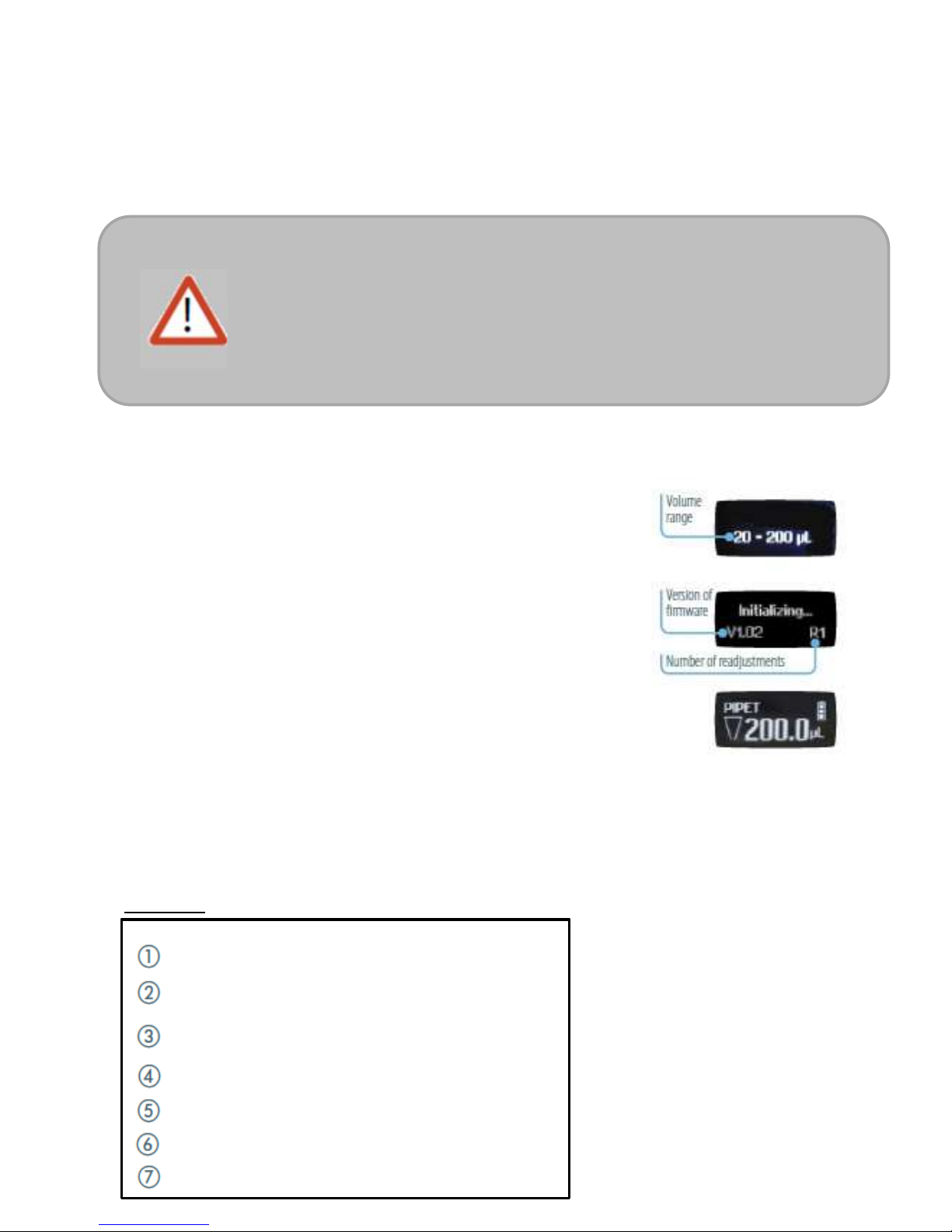

3 GETTING STARTED

Switch on your VWR Electronic Pipette:

Press the Push-button to activate the pipette. The start-up screen

appears:

The pipette will do a self-calibration test, the firmware resets

the piston.

During initialization, displayed on the screen, you will see the

volume range,version of firmware and the number of readjustments.

Your VWR Electronic Pipette is preset on PIPET mode and is now

ready to pipette (see Chapter 5).

VWR Electronic Pipette goes into sleep mode after 3 minutes

of inactivity. The display will shut off.

Just press the Push-button to reactivate the pipette, your last setting

and pipetting mode will appear on the screen.

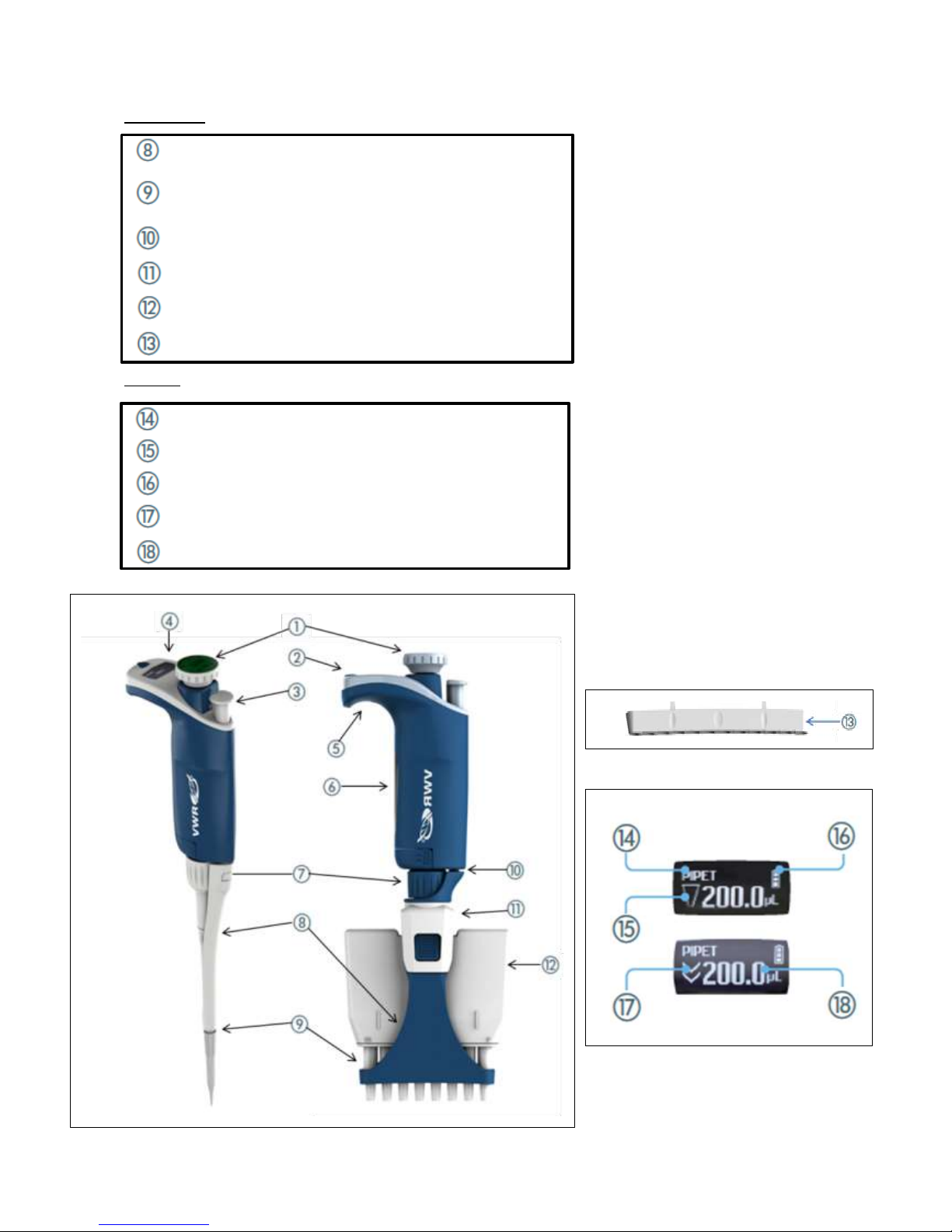

4 DESCRIPTION

VWR Electronic Pipette single and multichannel models:

Upper part:

VWR Electronic Pipette is provided with a minimal battery charge. Before

using it, we strongly recommend you to fully charge the battery. VWR

Electronic pipette charges 80 % of its full battery capacity in less than an hour;

it takes three hours to fully charge the battery.

Please refer to VWR Electronic pipette power management for charging

procedure.

Push-button and volume adjustment knob

Mode-button: direct access to all menu functions

Tip-ejector button

Display

Elastomer plug to cover the battery charging port

Identity-tag window

Connecting nut – attaches handle to lower part

Page 7

7

Lower part:

Screen:

Tip-ejector: removable access to tip-holder

Optimized tip-holder to reduce tip fitting and ejection forces,

removable for cleaning and servicing

Ejector clip

Ejector support

Cover

Ejector spacer (only for Multi 1200µl)

Pipetting Mode

Aspirate and dispense indicator

Battery status

Purge indicator

Volume

Page 8

8

Reset: To reset your pipette, simultaneously press on the Push-button and the Mode-button for at

least 5 seconds.

Switch off: To switch off your VWR Electronic Pipette, press the Push-button for at least 5 sec.

Display: The VWR Electronic Pipette display is an OLED screen. It shows the current mode and

operation step, pipetting volume, battery indicator and piston status (aspirated and dispensed

volume) in real time.

Warning messages appear in the place of volume.

5 PIPETTING

Your VWR Electronic Pipette is set by default on “PIPET Mode”, that means forward pipetting.

You can select a volume and start to pipette.

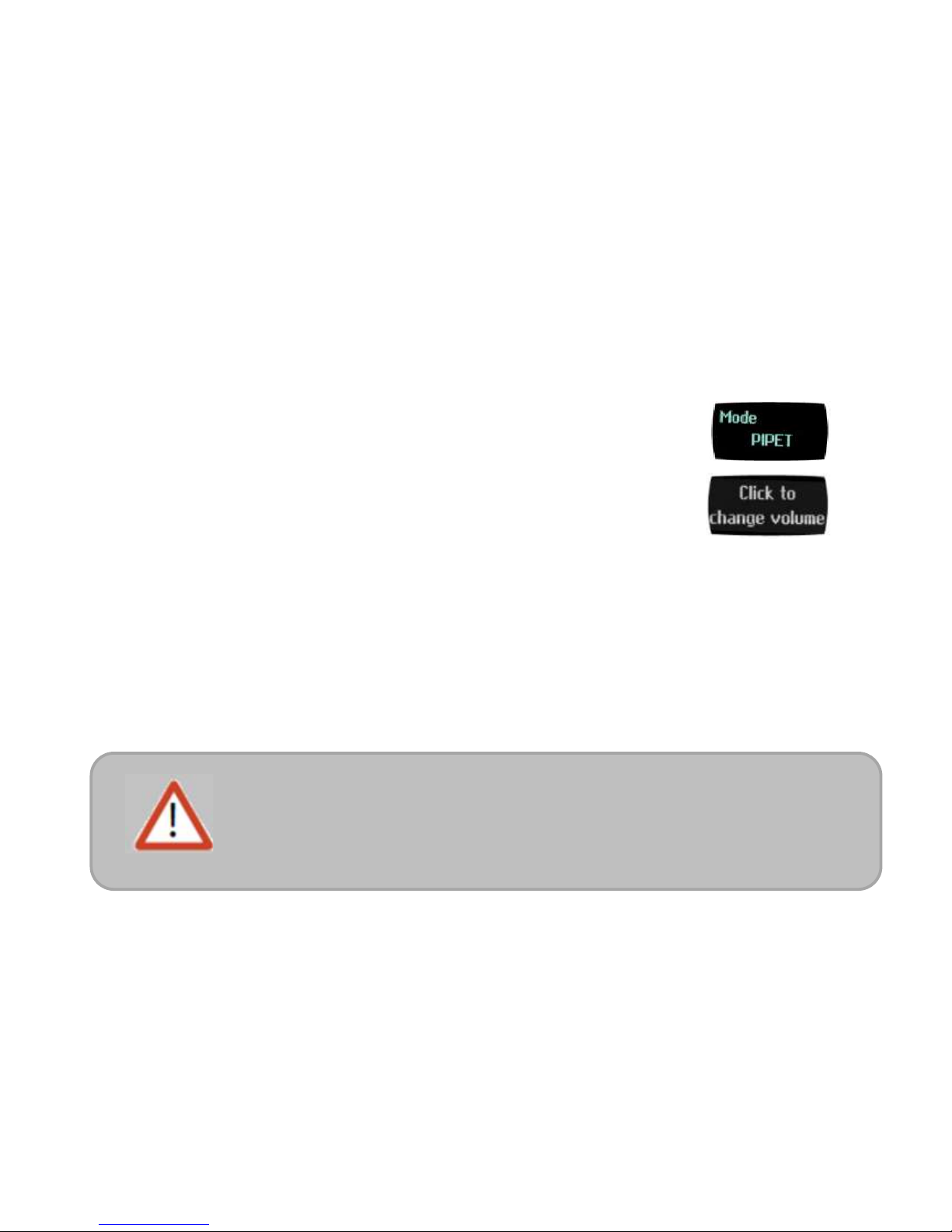

Switch on

Press Push-button.

Adjust the volume setting

• Hold your VWR electronic pipette in pipette position.

• Turn the Push-button half way (quite quickly), the screen will display:

“click to change volume”

• Now press the Push-button; the volume on the display will start blinking, you can now adjust the

volume:

• Turn the Push-button either clockwise to decrease volume or counter clockwise to increase

volume, like indicated on the button.

• Press the Push-button one time when finished. The volume is locked.

You are ready to pipette!

6 PIPETTING MODES

VWR Electronic Pipette offers essential pipette modes for a large number of applications: you will

find all pipetting modes in the menu (for system settings refer to the chapters 7 and 13). Access the

menu by pushing the Mode-button. To choose one of the pipetting modes, turn the

Push-button and confirm your selection with a simple click!

The tip can be emptied at any time during a pipetting cycle. To do so, turn

the Push-button quickly: the message “click to abort” will appear on the

screen. Click on the Push-button to validate: the liquid will be dispensed

and an automatic purge followed by piston reset to zero will occur.

Page 9

9

PIPET Mode

This is the classic pipette mode (forward pipetting), your pipette is simply aspirating and dispensing.

• Fit a suitable tip

• Press the Push-button to aspirate the selected volume.

• To dispense: Click (press and release) the Push-button. Three things happen: sample dispense,

automatic purge and piston reset to zero.

Or Keep your thumb pressing the Push-button until the end of the dispense cycle: the piston reset

takes place after releasing the Push-button again. This feature enables you to remove the tip from

the liquid, without aspirating anything.

• Eject tip by pressing the ejection button.

VWR electronic pipette is ready again for next pipetting cycle while maintaining the volume and the

last settings!

Continue pipetting as you would as if you were using a mechanical pipette.

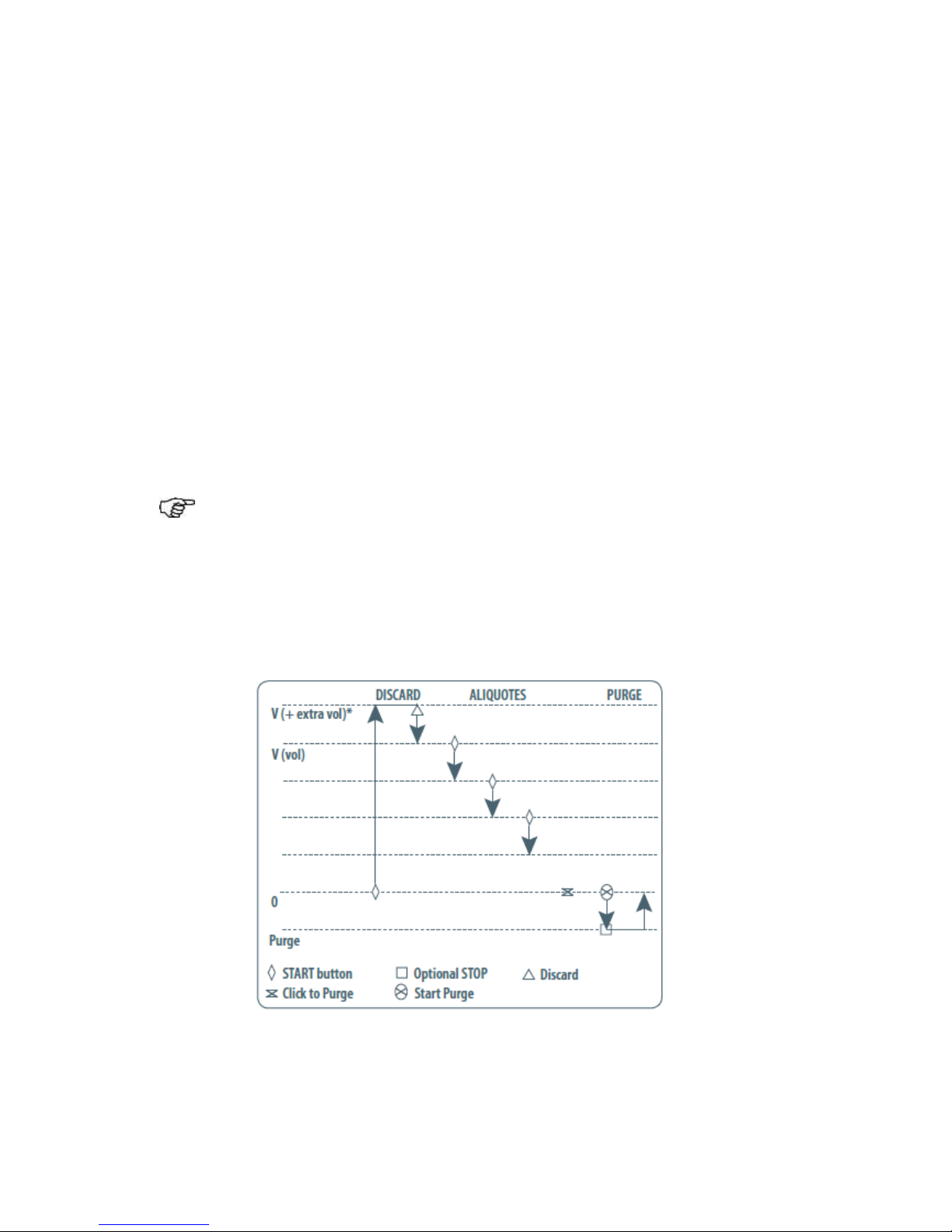

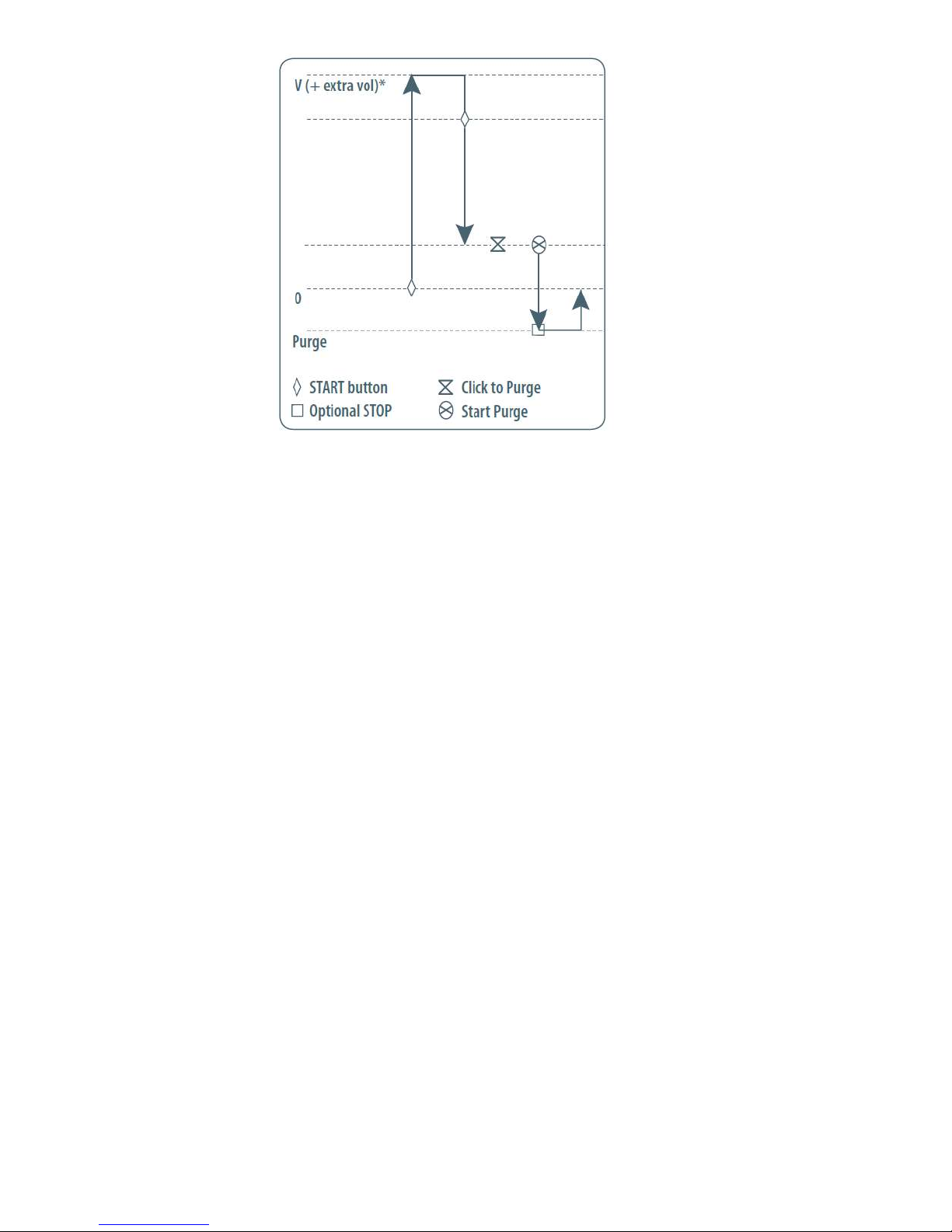

REPETITIVE Mode

The REPETITIVE Mode allows you to distribute the same volume repeatedly in predefined number

(N) of equal aliquots. You supply the aliquot volume (AV) and the pipette automatically calculates

the number of aliquots possible from the nominal (maximum) volume (NV) of the pipette as follows:

N = NV/AV (e.g. 120 μL x 10 for VWR 1200).

You also can decrease the number of repetitions (e.g. 120 μL x 10-(n ≥1) for VWR 1200).

• Press the Mode-button to access system menu, where you can choose between different pipette

modes by turning left or right the Push-button.

Select REPETITIVE Mode by turning the Push-button.To confirm your selection click on the

Push-button.

• Turn the Push-button half way, the screen will display: “click to change volume”

Page 10

10

• Set the aliquot volume : Press the Push-button; the volume on the display will start to blink, you

can now adjust the volume by turning left or right the Push-button. Then, click on the Push-button to

confirm the volume choosen. The maximum number of aliquots has been calculated by your

pipette.

• Set the aliquot number: the Aliquot numbers will start blinking: set the desired numbers of aliquots

by turning the Push-button and click again to confirm your settings.

You are ready to pipette!

1/ Fit a suitable tip

2/ Click the Push-button to aspirate total volume. The volume aspirated will be a little bit more than

required (extra volume). The extra volume is necessary to ensure equal operating conditions for

each dispensed aliquot.

3/ To dispense: click the Push-button. “DISCARD” appears on the screen. Discard the extra volume

and continue dispensing the aliquots. VWR electronic pipette distributes the aliquot volume each

time you click the push-button. The number of aliquots left to dispense is displayed on the screen.

A warning beep indicates the last aliquot!

4./ To purge: Press the Push-button, “PURGE” appears on the screen, click again to purge and

reset the piston. Keep your thumb pressing the push-button until the end of the purge: the piston

reset takes place after you release the push-button again. This feature enables you to remove the

tip from the liquid, without aspirating anything.

5/ Eject tip by pressing the ejection button.

Page 11

11

MIX Mode

This is the classic pipette mode (forward pipetting) followed by a mixing phase, composed of

repeatedly aspirating and dispensing, as well as an optional forward pipetting step.

• Press the Mode-button to access menu, where you can choose between different pipette modes.

Select “MIX Mode” by turning the Push-button, to confirm your selection click on the Push-button.

• Set the first volume, named “VOLUME 1”: click the Push-button, set the volume by turning the

Push-button and click to confirm your selection. This is the first volume you will aspirate and

dispense.

Set the second volume, named “VOLUME 2”: click the Push-button, you can now set the second

volume by turning the Push-button. Click again to confirm your settings.

If you set “VOLUME 1” or “VOLUME 2”= 0 μL, the step will not appear. If you set

“VOLUME 1” and “VOLUME 2” = 0 μL the cycle will start directly with the MIX step.

• Set the MIX volume: click the Push-button, set the volume by turning the Push-button. Confirm

your settings with a simple click. This is the volume which will be aspirated and dispensed

repeatedly. “MIX” as long as you press the push-button.

• Set the additional pipetting volume, named “VOLUME 3”: You can choose a volume to be

aspirated and dispensed after the mixing step, so you can continue routine pipetting.

Click the Push-button, set the volume by turning the Push-button. Confirm your settings by a

simple click.

If you set the “VOLUME 3 “= 0 μL the cycle will stop after the MIX step.

You are ready to mix!

1/ Fit a suitable tip

2/ To aspirate “VOLUME 1” press the Push-button

3/ To dispense: Click (press and release) the Push-button: three things happen: sample dispense,

automatic purge and piston reset to zero

or

Keep your thumb pressing the Push-button until the end of the dispense cycle: the piston reset

takes place after you release the Push-button again. This feature enables you to remove the tip

from the liquid, without aspirating anything.

4/ To aspirate and dispense the second volume “VOLUME 2”, repeat steps 2 and 3.

5/ To mix: press the Push-button; as long as you keep your thumb pressing the button, the pipette

continues mixing. Release the Push-button to complete the current mixing cycle.

6/ To purge: press push-button, “PURGE” appears on the screen, click again to purge and reset

the piston.

7/ To pipette: if you have chosen a “VOLUME 3” > 0, you can now aspirate and dispense this

volume by repeating steps 2 and 3.

Page 12

12

If you choose VOLUME1 = 0, step 2 won’t occur, if you choose VOLUME 2 = 0 μL, step 4

won’t occur, as well if you set

VOLUME 1 and 2 = 0 μL, step 1-4 will disappear. If you set VOLUME 3 = 0 μL step 7 will not

occur.

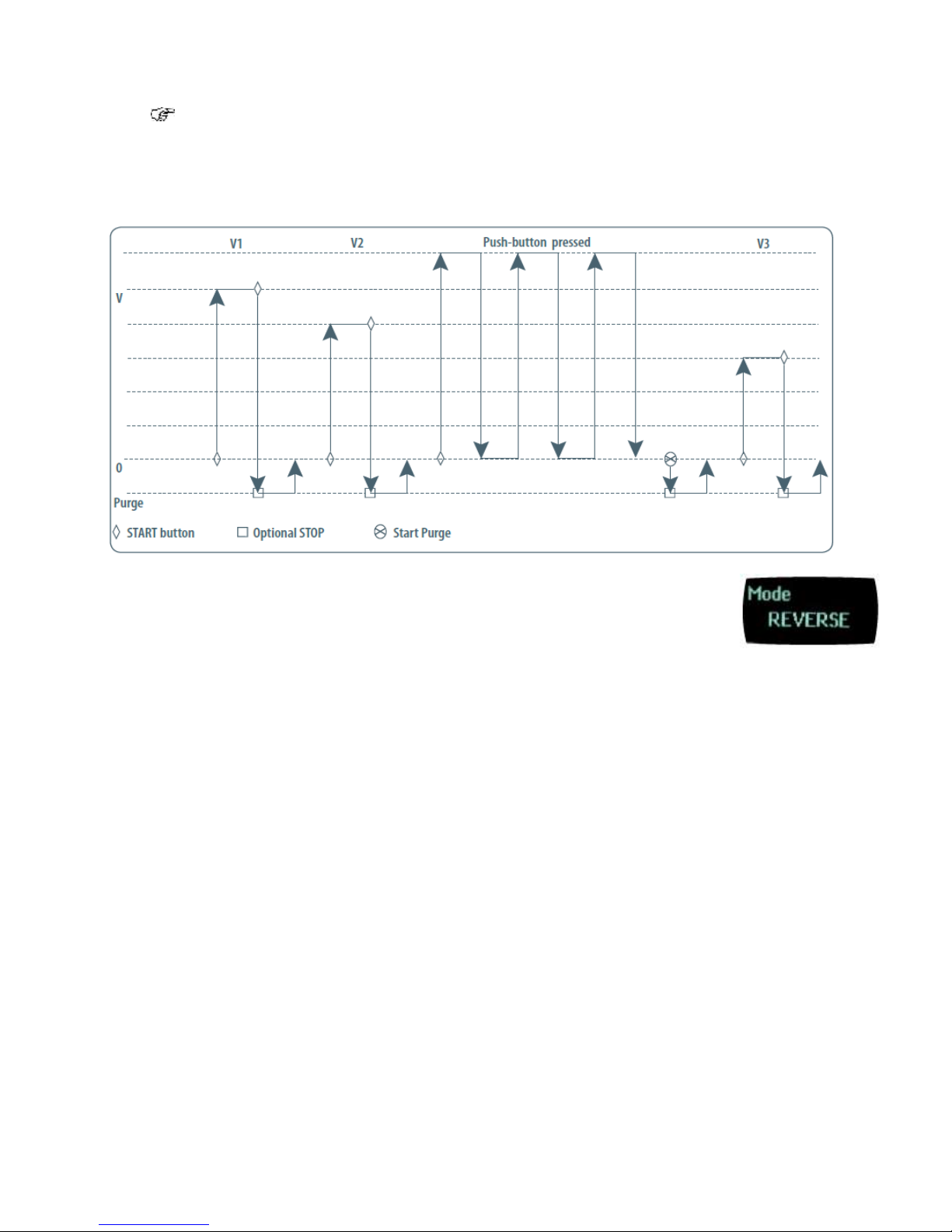

REVERSE Mode

The REVERSE Mode is reverse pipetting with a manual pipette. During aspiration,

additional liquid is added. After delivery, the excess volume remains in the tip and is discarded.

• Press the Mode-button to access system menu, where you can choose between different pipette

modes.

Select REVERSE Mode by turning the Push-button, to confirm your selection click the Push-button.

• Set the volume: click the Push-button, set the volume by turning the Push-button and click again

to confirm your settings.

You are ready to do reverse pipetting!

1/ Fit a suitable tip

2/ Click the Push-button to aspirate the selected volume. An amount of liquid equal to the amount of

purged air is added, the volume aspirated will be a little bit more than the set volume.

3/ Click the Push-button to dispense the volume, the additional amount of liquid remains in the tip.

4/ To purge: press the Push-button, “PURGE” appears on the screen, click again to purge and

reset the piston. Keep your thumb pressing the push-button until the end of the purge: the piston

reset takes place after you release the Push-button again. This feature enables you to remove the

tip from the liquid, without aspirating anything.

5/ Eject tip by pressing the ejection button.

Page 13

13

CUSTOM Mode

The CUSTOM Mode enables personalized pipetting protocol creation on a computer for transfer

to VWR Electronic Pipette through VWR Protocol Builder software, an easy-to-use software.

To use this mode, the software has to be installed on the computer (file downloadable on

www.vwr.com/e-pipette).

To install VWR Protocol builder software:

1/ Download the appropriate VWR Protocol builder software installation file for your

operating system to the computer (Windows 32bits/ Windows 64 bits)

2/ Double-click the installer and follow the instructions on the screen to complete the installation.

3/ When completed, the VWR Protocol builder software icon will appear on desktop of the computer

if “Create desktop shortcut” is checked.

4/ If VWR Protocol builder software is not launched automatically double-click the VWR Protocol

builder icon on the desktop.

5/ Once installed, the VWR Protocol builder software can be run by any user on the installed

computer.

You can then create, edit, import or export custom protocols easily and rapidly.

To create a protocol, choose among the available tasks VWR Protocol builder software:

• Aspirate: aspirates specified volume into the tip

• Dispense: dispenses specified volume from the tip

• Dispense all: dispenses all remaining volume from the tip followed by a purge action

• Repeat: enables repetition of any other tasks once or more

• Mix: mixes the specific volume in one or more cycles

• Purge: dispenses all remaining volume from the tip followed by purging extra volume

• Wait: introduces a wait for a specified number of seconds

Page 14

14

• Beep: makes pipette produce a beep sound while selected tasks are executed

To transfer a protocol to your VWR Electronic Pipette, click the “Transfer custom protocols to

pipette” button and follow the instructions on the screen.

The CUSTOM mode is available in pipettes from firmware version cf01.00.03

For more information on VWR Protocol builder software, see page 34.

7 PIPETTING SPEED CONTROL

VWR Electronic Pipette is set by default on speed 6 (maximum speed). You may need to change

the speed of aspiration or dispensing depending on your application. You can change aspiration

speed and dispensing speed independently of one other: from very slow to very fast (speed 1 –

speed 6). Your speed selection is memorized for each pipetting mode until you change it again.

• Press the Mode-button to access system menu, where you can find the different pipette modes,

the speed menu and configuration menu.

• Select SPEED by turning the Push-button, to confirm your selection click on the Push-button.

• Set ASPIRATION SPEED: aspiration speed is blinking, set the speed by turning the Push-button

and click to confirm your selection.

• Set DISPENSING SPEED: dispensing speed is blinking, set the speed by turning the Push-button

and click to confirm your selection.

• After selecting the speed you go automatically back to pipetting mode.

8 GUIDELINES FOR GOOD PIPETTING

Aspirate and dispense:

1/ Fit a suitable tip

2/ Pre-rinse the tip. Pre-rinsing consists of aspirating the first volume of liquid and then dispensing it

back into the same vessel (or to waste). Subsequent volumes that you pipette will have levels of

accuracy and precision within specifications. Some liquids (e.g. protein-containing solutions and

organic solvents) can leave a film of liquid on the inside the wall of the tip; pre-rinsing the tip

minimizes any errors that may be related to this phenomenon.

3/ Hold the pipette vertically and immerse the tip in the liquid . Press the push-button to aspirate the

set volume of liquid. Wait a few seconds then withdraw the pipette-tip from the liquid. You may wipe

any droplets away from the outside of the tip using a medical wipe, however if you do so take care

to avoid touching the tip’s orifice.

4/ Place the end of the tip against the inside wall of the recipient vessel (at an angle of 10° to 40°).

Press the Push-button.

Page 15

15

Wait for at least a few seconds before releasing the Push-button to expel any residual liquid from

the tip. While removing the pipette, draw the tip along the inside surface of the vessel.

5/ Eject the tip by pressing firmly on the tip-ejector button.

General guidelines for good pipetting:

a. Make sure that you fit new tips.

b. Each new tip should be pre-rinsed with the liquid to be pipetted.

c. When aspirating, keep the tip at a constant depth below the surface of the liquid

d. Change the tip before aspirating a different liquid, sample, or reagent.

e. Change the tip if a droplet remains at the end of the tip from the previous pipetting operation.

f. Liquid should never enter the tip holder. To prevent this:

• Never turn the pipette upside down,

• Never lay the pipette on its side when there is liquid in the tip(s),

g. The VWR charging Stand Adapter (refer to chapter 2) is recommended for use with the VWR

Carrousel Pipette Stand to store the pipette in the vertical position.

h. When pipetting liquids with temperatures different to the ambient temperature, pre-rinse the tip

several times before use in order to reach equilibrium between the temperatures of the liquid and

the pipette’s dead-volume.

i. For volatile liquids you should saturate the dead-volume by aspirating and dispensing the liquid

repeatedly before aspirating the sample.

j. After pipetting acids or other corrosive liquids that emit vapors, clean the pipette, as described in

chapter 14

k. The pipette can be used between + 4 °C and

+ 40 °C, but the specifications may vary

(refer to chapter 17).

l. Do not pipette liquids having temperatures

above 50 °C or below 4 °C.

Extreme temperature

can affect accuracy

and precision

Page 16

16

9 PERSONALIZE YOUR VWR Electronic Pipette

Tip-ejector extension for use VWR Electronic Pipette 10µl Single and Multi channels:

In order to eject 10µl tips, tip-ejector extensions are

supplied with VWR Electronic Pipette 10µl Single

and Multi channels.

The tip-ejector extension for Single channel which is made of PVDF

(polyvinylidene Fluoride),is autoclavable, as well as the one

of the Multi-channel which is in PBT.

To fit a tip-ejector extension for the Single Channel:

• Hold the pipette with the push-button upright.

• Hold the extension with the slot upright.

• Slide the extension over the tip-holder.

• Push the extension firmly onto the end of the tip-ejector until

it clicks into place (see opposite).

To remove a tip-ejector extension (see opposite):

• Hold the pipette in one hand and grip the extension with the other.

• Gently twist the extension (either direction) and pull it away from

the pipette

To fit and remove a tip-ejector extension for the Multi Channels:

• Slide the extension over the tip-holder.

• Push the extension firmly up into the slots to fit and pull it out to remove it (see below)

Page 17

17

Personal label – Name and/or application tag:

VWR Electronic Pipette offers you the possibility

to mark your pipette. You can

personalize your pipette with a name tag and/or an

application tag:

Window-tag:

• Remove the window by inserting a small screwdriver

in the access slot.

• Position the name tag on the pipette

• Clip the window back in place.

10 GOOD LABORATORY PRACTICE FEATURES

VWR Electronic Pipette is fully compliant to ISO8655 standard and is CE marked .

VWR Electronic Pipette includes the following GLP features.

General

• Lockable volume.

• Useful volume-range is printed on the push-button.

• Volume range is displayed on the screen.

• Serial number is engraved on the body (handle) of the pipette and encoded in the firmware.

• Bar code: on the box

• Personalization by nametags (for marking application and/or user name), refer to chapter 9.

Cycle counters

• From last volume setting (to count the number of cycles in the current “run”).

• From manufacture and since the last service (refer to chapter 13).

• By indicators (R1, R2, R3 … Rx) each time pipette is readjusted.

• Maintenance intervals can be specified by weeks or number of cycles elapsed.

Alarms

• Low battery warning.

• Service is overdue warning (refer to chapter 13).

• Service alert can be set “On” or “Off”.

11VWR ELECTRONIC PIPETTE POWER MANAGEMENT

The VWR Electronic Pipette battery has been designed to ensure around 900 pipetting cycles

(around 750 for Multichannel models) at maximum speed between two charge cycles (approx.

2h30 of use continuously). For service continuity when needing more

capacity, VWR Electronic Pipette can also be used while charging with the same performance as a

fully charged pipette!

Window-tag

Page 18

18

Battery charging

VWR Electronic Pipette charges 80 % of its full battery capacity in less than an hour, it takes three

hours to fully charge the battery.

1/ Charge your pipette by using the power supply:

- Connect the AC adapter to a suitable AC power supply (EU plug / UK plug….)

- Plug the adapter into the Mini USB port of the pipette.

- The pipette starts charging.

2/ Charge your pipette by using VWR Charging stand adapter:

- First place the stand adapter on your VWR Carrousel Pipette Stand

- Remove the plug. Now place your pipette on the Stand Adapter and plug the power transformer

into the stand adapter.

- The pipette starts charging.

Working with charger connected to the pipette

VWR Electronic Pipette can also be used for pipetting while charging.

- Plug the power supply into your pipette.

- Press the push-button to start your pipette.

- It’s ready to pipette.

Page 19

19

You can also recharge VWR Electronic Pipette by USB with your computer; however it will

take much longer than by power supply.

Low battery warning

VWR electronic Pipette has a low battery alert. As the battery runs down, the LOW BATTERY

message appears. The warning is replaced by a blinking symbol of an empty battery.

If it is not recharged, the pipette will switch off after a while. Settings will not be lost.

If the battery is completely discharged (= black screen, no operation) please connect the

pipette to the charger for at least five minutes, then a “batt. too low” message will appear. The

pipette will display the last settings used a few minutes later and will continue charging.

Changing the battery

If the following symptoms occur, please contact your VWR Service Center for battery change:

- VWR electronic Pipette battery won’t charge or will not operate even if connected to the charger at

least for 10 minutes.

- VWR electronic Pipette battery provides you very short cycle time or permanently needs to be

used in connected mode.

12 CONFIGURATION

Enter the menu using the mode-button. You will find not only the pipetting

programs (PIPET, REPETITIVE, MIX, REVERSE and CUSTOM) and the

speed control, but also the menu “CONFIGURATION”, including “SERVICE”

and “ADJUSTMENT” (refer to Chapter 13).

The navigation of the menus is always done in the same way: Make your

selection by rotating the Push-button, enter and confirm with a simple click!

The configuration menu allows you to set up the following items:

1. Volume limit: Here you can fix the maximal volume of the pipette (by default = nominal volume).

For example you have a VWR200 pipette, but you would like to use it with 100µl tips, you can set

the maximal volume at 100 μL and you won’t risk contamination of your pipette.

2. Beeper: You can switch the tone of your pipette on or off.

Use only the original power transformer supplied by VWR. Use of an

incompatible power supply can damage your VWR Electronic Pipette

VWR Electronic Pipette uses Lithium-Ion battery. Operation on the battery

is done at user’s risk only. Opening the pipette voids the warranty.

Page 20

20

3. Contrast: You can choose between values of 1 to 5 to set up the contrast of the screen.

4. Service: refer to chapter 13.

5. Adjustment: refer to chapter 13

6. Language: Available from the firmware version cf01.00.03. Languages available are English,

Chinese and Japanese.

To change the language, enter in the Configuration menu:

- Select your language by turning the Push-button,

- To confirm your selection, click on the Push-button,

- The language selected is blinking,

- To confirm your selection, click 2 seconds on the Mode-button.

13 MAINTENANCE OF YOUR VWR ELECTRONIC PIPETTE

VWR Electronic Pipette allows you to:

• Get service information.

• Readjust the pipette to user settings.

• Return to factory settings.

• Replace spare parts (for detailed information refer to chapters 13 and 18).

• Prepare the pipette for cleaning or autoclaving by “disassembly” of the parts specified (refer to

chapter 13).

Service information

VWR Electronic Pipette provides you with all required service information. It will help you establish

an easy diagnosis and plan any service operation with your accredited service center.

You will find in the “Service” menu following sub menus:

a. Disassembly

b. Service info

c. Service settings

d. Pipette info

The navigation of the menu is always done in the same way: Make your selection by rotating the

Push-button, enter and confirm with a simple click!

a. Disassembly:

The multichannel models should not be disassembled: only the push-button and the tip-ejector

can be replaced.

Only the lower part of the single models can be disassembled, the push-button, the connecting nut

and the tip-ejector can be replaced.

This option allows you to disassemble the lower part safely (protection of the piston and the

actuator).

If you select “DISASSEMBLY”:

You can remove the lower part of your pipette with complete security.

Page 21

21

b. Service info provides you with maintenance information; you cannot modify any of the items:

• Number of pipetting cycles since last maintenance.

• Number of weeks since last maintenance.

c. Service settings gives you the option to organize your maintenance, you can set following

service points:

• Number of cycles until next maintenance.

• Number of weeks until next service.

• Service date.

• Activate or deactivate the Service alert.

Changes of service settings will reset all the service info to zero.

d. Pipette info provides information about your pipette, you cannot modify any of the items:

• Version of firmware.

• Serial number.

• Total number of cycles (one cycle: up and down of the piston).

• Number of readjustments carried out by this pipette.

Adjustment

Press the Mode-button to enter the menu. Select “Configuration” by rotating the Push-button and

click to confirm your selection. Enter the sub-menu in the same way and select the “Adjustment”

menu. The adjustment menu allows you to access the following items:

• Standard readjustment

• Reset settings

Standard readjustment

This menu allows you to adjust the pipette using 3 calibration points: 10 %, 50 % and 100 % of

nominal volume (in according with ISO8655 recommendations).

You may want to calibrate your pipette for solutions with a density, viscosity, surface tension or

vapor pressure that are different to that of water. To return to the factory settings, choose “Reset

settings”, your VWR Electronic Pipette will be reset to the three factory calibration values which

are permanently stored in the pipette’s firmware.

In accordance with ISO 8655 VWR recommends a gravimetric procedure for pipette calibration.

This gravimetric method is used to establish the mean mass of a given volume of water (taking into

account evaporation losses, where necessary). After converting the mean mass to a volume (using

the Z factor, see appendix II), enter the measured volumes(s) into the pipette’s memory and the

software readjusts the pipette accordingly. This method requires the strict monitoring of

environmental conditions and the use of routinely controlled equipment that is adapted to the

volume being measured.

Page 22

22

Conversion to volume must take into account the density of the liquid as well as evaporation during

the cycle time. For each measurement, the corresponding volume (Vi) can be calculated as follows:

For volumes greater than 20 μL, the evaporation factor can be disregarded.

Maintenance operations

(Disassembly of VWR Electronic Pipette to change and clean parts)

It is best to inspect your pipette regularly and to routinely clean and change parts as required. To

help you to keep up a regular schedule and in the interests of GLP, you can configure your pipette

to display an alarm before servicing is due (refer to Service settings).

Maintenance warning

VWR Electronic Pipette notifies you, when maintenance is due

(Service alert is set by default to “On”). The following message (1)

will appear: after validation by a click, the following message (2)

appears: If you click to confirm within 10 sec. the pipette will

automatically switch to “disassembly” mode so you can carry

out your maintenance safely. Wait longer than 10 seconds

and the option to have a reminder in one week will appear (3).

Click to confirm. Your pipette will be operational again.

Maintenance operation for single channel models

Tip-Holder and tip-ejector

These parts must be changed if they are damaged. You may also remove these parts for cleaning

or decontamination purposes.

Changing the tip-ejector

1/ Keep the tip-ejector button depressed and grip the top of the tip-ejector

with the other hand.

2/ Gently rotate the tip-ejector counter clockwise and separate its

connector from the operating rod.

3/ Pull the tip-ejector away from the body of the pipette.

4/ Clean or autoclave the tip-ejector and refit or replace it by reversing

Wi is the weight as read on the balance

e is the mean evaporation loss during the cycle time

Z expressed inL/mg, is a conversion factor incorporating density of water buoyed in air, at test

temperature and barometric pressure (see Appendix II)

The following maintenance operations should only be done when the

pipette is in DISASSEMBLY Mode!

Page 23

23

the procedure.

Changing the tip-holder (lower part)

After removing the tip-ejector, you may remove the

lower part of the tip-holder, which is more likely to

become contaminated or damaged than the upper part.

Removal of the lower part is shown here; for the upper

part see “Removing the piston”

(special precautions are necessary).

1) Gently rotate the lower part of the tip holder

Counterclockwise to unscrew it from the upper

part.

2) Separate the parts and remove the O-ring (refer

to “Changing O-ring”)

3) Clean and if required autoclave the lower part of the tip-holder (autoclaving: 20 min. at

121°C and 0.1MPa)

4) If required, lubricate the piston (refer to “How to lubricate the piston”) and fit a new O-ring.

5) Screw the two parts together, making sure that the two parts are fully tightened, by hand.

6) Refit the tip-ejector.

After autoclaving the tip-holder and tip-ejector may change color, however this has no impact on the

performance.

Changing the seal and/or O-ring (refer to chapter 19)

The O-ring is positioned on the piston; it should not be autoclaved, if worn or damaged in any way,

it must be replaced.

To access the O-ring, remove the tip-ejector and unscrew the lower part of

the tip-holder. You should now be able to remove the O-ring from the piston.

Sometimes, the O-ring may be found in the recess at the top-end of the

lower part of the tip-holder. If required, lubricate the piston (refer to “How

to lubricate the piston”) then fit a new O-ring by sliding it onto the piston.

Reassemble the pipette. Depending on the pipette model the dimension of the O-ring will vary

(refer to chapter 19).

Servicing the piston

You may remove the piston-assembly to clean, lubricate, or change the piston.

Page 24

24

Removing the piston

1/ Remove the tip-ejector and (optionally) the lower part of the tip-holder.

If you remove the lower part, take care to remove the O-ring as described

in “Changing the O-ring”.

2) Unscrew the connecting nut (turn by hand, counterclockwise).

3) Gently remove the connecting nut and upper tip

holder.

4) Pull off the piston assembly from the body of the

pipette – separate the parts (see opposite).

5) Clean and autoclave (if required) the piston and

holder, together with any other parts that may need

to be treated in the same way.

In the case of 1200µl pipette, the piston holder,

piston and guide are a unit. Don’t try to separate them!

6) Lubricate the piston, see below.

7) Reassemble the piston and guide; then carefully insert the assembly into the body of the pipette.

The guide should hold the piston assembly inside the body of the pipette. You can hear a “click”

when the piston is back in place.

Take care not to touch the piston, and that it is dust-free. If needed, clean the assembly with a

dust-free cloth.

8) Reassemble the upper part of the tip-holder and the connecting nut, and then refit to the body of

the pipette by rotating the connecting nut clockwise until it is finger tight. Fit the O-ring (for VWR10,

the seal) and reassemble the lower part of the tip-holder. Refit the tip-ejector. The seals for VWR10

are fragile and can be used only once. So, after unscrewing the lower part of the tip-holder you

must fit a new seal.

The specification of the pipette

must be checked after changing

any part!

Don’t pull on the piston to remove

the assembly!

Page 25

25

How to lubricate the piston (except VWR10)

Use only VWR lubricant (delivered inside the pipette box).

Squeeze a small quantity from the tube onto a clean, lintless cloth. Use the cloth to transfer the

lubricant to the piston. Ensure that the piston is evenly lubricated and that you wipe away any

excess – remember only a fine film of lubricant is required (over the entire piston).

Maintenance operation for multichannel models

For multichannel models, the lower part should not be disassembled: only the Push-button, the

connecting nut and the tip-ejector can be replaced.

Changing the tip-ejector

To remove the tip-ejector, keep both ejector locks depressed. Pull the tip-ejector down.

To refit the tip-ejector, gently re-insert the tip-ejector vertically into the rails of the ejector support.

Pull lightly on the tip-ejector to check the position.

14 CLEANING AND DECONTAMINATION

VWR Electronic Pipette is designed so that the parts normally in contact with contaminants can

easily be cleaned and decontaminated.

If you use chemical solutions for decontamination or detergents for cleaning, other than those

specified below, you should check with your supplier that the solution or detergent is safe for use

with one of the following materials: PP (Polypropylene), PBT (Polybutylene Terephthalate), PC

(Polycarbonate), POM (Polyoxymethylene), PVDF (Polyvinylidene Fluoride), PEI (Polyetherimide)

and stainless steel.

Cleaning

The pipette must be cleaned, as described below, before it is decontaminated. For cleaning

VWR Electronic Pipette you may use a simple soap solution, Ethanol or Isopropanol or broad

spectrum disinfectants.

Single channel models

- External

1/ Remove the tip-ejector for cleaning (refer to chapter 13).

2/ Replace the elastomer plug to protect battery charging port.

3/ Wipe the entire pipette with a soft-cloth or lint-free tissue impregnated with soap solution, to

remove all dirty marks. If the pipette is very dirty, a brush with soft plastic bristles may be used.

Use alcohol (ethanol or isopropanol) to clean

up the dirt and dust on the tip-holder!

Liquid must not enter the handle of the

pipette!

Page 26

26

4/ To rinse, wipe the entire pipette with a soft-cloth or lint-free tissue impregnated with distilled

water.

5/ Leave to air dry.

- Internal

The following components only can be immersed in a cleaning solution: tip-ejector, tip-holder,

connecting nut and piston.

1/ Disassemble the pipette as described in chapter 13

2/ Set aside the handle in a dry and secure location.

3/ Clean the individual components using an ultrasonic bath (20 minutes at 50 °C) or with a

soft-cloth and brushes.

4/ Rinse the individual components with distilled water.

5/ Leave the parts to dry by evaporation or wipe them with a clean soft-cloth or lint-free tissue.

6/ Lubricate the piston and reassemble the pipette according to the instructions given in chapter 13.

Multichannel models

The following components only can be immersed in a cleaning solution: tip-ejector and ejector

locks.

1/ Remove the tip-ejector

2/ Immerse the tip-ejector and ejector locks in the cleaning solution or wipe them with a soft cloth or

lint-free tissue impregnated with the cleaning solution.

3/ Rinse the components with distilled water.

4/ Leave the parts to dry by evaporation or wipe them with a clean soft-cloth or lint-free tissue.

5/ Refit the tip-ejector.

Please note that although the lower part of VWR Electronic multichannel Pipette can withstand a

few number of autoclaving cycles, we do not recommend autoclaving it.

Decontamination

Autoclaving - Single channel models

However, after separation from the body, any of the following components of the volumetric module

may be autoclaved individually: tip-ejector, connecting nut, tip-holders, pistons and seals (except

O-rings).

1/ Clean the parts to be autoclaved, especially the tip-holders.

2/ Put the parts in an autoclaving bag.

3/ Autoclave for 20 minutes at 121°C and 0.1 MPa.

4/ Check that the parts are dry before reassembling the pipette.

5/ Set the pipette aside to stabilize at room temperature for at least 6 hours.

The body (handle) of the pipette is not autoclavable!

The specifications of the pipette must be checked after

autoclaving/disassembling

Page 27

27

Chemical decontamination - Single and multichannel models

You may choose to decontaminate your pipette chemically, in accordance with your own

procedures.

Whatever decontaminant you use, check that it is compatible with the plastics used in the

construction of the pipette (see Chapter 14).

- Parts that may not be immersed

1/ Wipe the handle of the pipette with a soft-cloth or lint-free tissue covered with the chosen

decontaminant.

2/ Wipe the handle of the pipette with a soft-cloth or lint-free tissue covered with distilled water.

- Parts that may be immersed

The following components only can be immersed in a decontaminant solution:

• Single channel models ->tip-ejector, tip holder (both parts), connecting nut, piston (including

holder) and guide.

• Multichannel models -> tip-ejector and ejector locks.

Please note that although the lower part of VWR Electronic multichannel Pipette can withstand a

few number of autoclaving cycles, we do not recommend autoclaving it.

1/ Disassemble the pipette as described in chapter 13.

2/ Immerse the components in the decontaminant solution or wipe them according the instructions

given by the manufacturer or supplier of the decontaminant.

3/ Rinse the individual components with distilled or sterile water.

4/ Leave the parts to dry by evaporation or wipe them with a clean, lint-free tissue or soft-cloth.

5/ Lubricate the piston and reassemble the pipette according to the instructions given in this

chapter.

15 LEAK TEST

This test may be performed at any time to check that the pipette does not leak, especially after

performing a maintenance or decontamination procedure. If a pipette fails this test, you should

replace the faulty part (e.g. O-ring, tip-holder...) and repeat this test, after making sure that the

pipette is correctly reassembled.

• Fit a suitable Tip

• Set the pipette to the nominal volume

• Aspirate the nominal volume from a beaker of distilled water

• Hold the pipette in the vertical position and wait for 20 seconds

• If a water droplet appears at the end of the tip there is a leak (refer to chapter 16)

• If you see no droplet, re-immerse the tip below the surface of water

• The water level inside the tip should remain constant; if the level goes down there is a leak (refer

to chapter 16)

Page 28

28

• For multichannel models, check if the water level between each tip is the same

16 TROUBLESHOOTING

In case of malfunction, first reset the pipette by pressing on the Push-button and the Mode-button

simultaneously at least for 8 seconds. If the problem persists, you may consult the following table

which identifies potential problems and their solutions.

17 SPECIFICATIONS

VWR Electronic Pipette is a high quality pipette that offers excellent accuracy and precision; it is

fully compliant with ISO 8655 and is CE marked. The adjustment is carried out under strictly defined

and monitored conditions:

• Basis of adjustment, Ex.

• Reference temperature, 20 °C

• Relative humidity, 50 %

• Barometric pressure, 101 kPa

• Use of distilled water grade 3 (ISO 3696)

Page 29

29

• Ten measurements for each test volume, which are nominal volume, 50 % of nominal volume and

10 % of nominal volume.

18 SAFETY PRECAUTIONS AND LIMITATIONS OF USE

For safety reasons, it is important to observe the following instructions:

1. Battery and electrical specifications:

Use AC-adaptor and stand adapter indoors.

VWR electronic Pipette uses Lithium-Ion battery. Operation on the battery is done at user’s risk

only. Opening the pipette voids the warranty.

Page 30

30

Dispose of used batteries in accordance with legal regulations. Batteries may not be disposed of

with household waste and may explode if disposed in fire!

• Li-ion battery pack; 1 Ah / 3.6 V

Charging time: approx. 3 hours for a fully discharged battery (80% in one hour).

• AC adaptor

Input voltage, country-specific: 100-240 V, 50/60 Hz (0.5A max.)

Output voltage: +5 V DC, 3.5A (17.5W max.)

• Class II this device is double insulated.

2. Do not use VWR Electronic Pipette in a potentially explosive environment

or with potentially explosive chemicals.

3. When pipetting infectious, radioactive, toxic and other hazardous solutions,

please observe all the safety precautions (e.g. wear protective clothing, goggles and gloves) and

regulations appropriate for your country.

4. Do not allow the liquid to enter the body of the pipette.

5. Storage conditions

Temperature: -20°C to 50°C - Humidity max: 80%

6. Temperature of use

Between 4°C and 40°C (specifications may vary).

7. Use only genuine VWR accessories and spare parts.

If the equipment is used in a manner not specified in this user’s guide, the protection provided in the

equipment may be impaired.

8. VWR Electronic Pipette can be used indoor and outdoor, if precautions are respected as

described above in this handbook and in the GLP.

We strongly recommend you fully charge the battery before using the pipette.

VWR Electronic Pipette is supplied with an AC adapter that is suitable for your

country. You must only use an original VWR AC adapter specific for this product.

Charge the battery in the pipette, using the AC-adapter or the stand adapter.

Page 31

31

19 REPLACEMENT PARTS

COMING SOON

Page 32

32

APPENDIX 1 - EXAMPLE OF A PERFORMANCE CHECK

(example with VWR10 at 1µl)

Page 33

33

APPENDIX 2 - Z FACTOR

Page 34

34

APPENDIX 3 - EVAPORATION LOSS

Procedure for the determination of evaporation loss

Use the same distilled water, weighing vessel and balance as you will be using for the gravimetric

check.

1. Half fill the weighing vessel with distilled water.

2. Cover the weighing vessel with its lid and place it on the balance using a pair of tweezers.

3. Aspirate a sample.

4. Tare the balance and take the weighing vessel out of the balance.

5. Take off the lid with tweezers.

6. Dispense the sample into a dummy vessel.

7. Replace the lid on the weighing vessel and, using tweezers, replace the vessel on the balance.

8. Read the negative result e1 (record the absolute value).

9. Repeat steps 3 to 8, three times to obtain e2, e3, and e4.

10. Calculate the evaporation loss e using the formula:

In normal conditions, this value is usually between 0.01 mg and 0.03 mg.

APPENDIX 4 – VWR PROTOCOL BUILDER SOFTWARE

Using the Custom Mode

Page 35

35

VWR PROTOCOL BUILDER SOFTWARE Contents:

1. Introduction

1.1 What is VWR Protocol Builder Software

1.2 Passwords and user information

1.3 Forgotten password

2. Home screen

3. Installing VWR Protocol Builder Software

3.1 Computer requirements for VWR Protocol Builder Software

3.2 Installing VWR Protocol Builder Software

3.3 Installing the drivers

3.4 Software files

4. Uninstalling VWR Protocol Builder Software

5. Creating and managing custom protocols

5.1 Creating a custom protocol

5.1.1 Default task parameters

5.1.2 Editing, cloning and deleting tasks

5.1.3 Pipette volume indicator

5.1.4 Warning and error messages

5.2 Managing existing protocols in Manage custom protocols

5.3 Importing a protocol

5.4 Practical tips for creating custom protocols

6. Transferring custom protocols to the pipette

7. Updating pipette settings

8. Other administration

8.1 Pipette management

8.2 View history

8.3 Change password

8.4 Institution/Company profile

Page 36

36

1 INTRODUCTION

1.1 What is VWR Protocol Builder Software?

VWR Protocol Builder Software is an easy-to-use software for creating custom pipetting protocols

for VWR Electronic Pipettes. Use it to create personalized pipetting protocols on your computer,

and to transfer these protocols to VWR Electronic Pipettes in the Custom Mode, where you can

execute them.

VWR Protocol Builder Software runs on Windows 7, Windows 8 and Windows 8.1.

The software file is downloadable on www.vwr.com/e-pipette.

1.2 Passwords and User information

When running the VWR Protocol Builder Software for the first time (e.g. after installation), you are

prompted to enter some information regarding your password and your institution.

- User password:

Enter user password and select a Hidden question / Hidden answer (used to recover forgotten

passwords). You can also select I don’t want to use passwords.

You can still switch to start using passwords later (in main menu select Other administration ►

Change password).

- User profile:

Provide Institution/Company details. Providing this information is optional and can also be done

later (in main menu select Other administration ►Institution/Company profile).

During the installation you are prompted to enter a Recovery password that will be used to retrieve

forgotten passwords.

Password must contain 8-30 characters, start with a letter, contain at least one numerical

digit and one uppercase letter (no special symbols allowed).

Note: When using a password, please make sure you remember or save your Recovery password

and/or the answer to the Hidden question – those are the only two means of retrieving your login

information in the event of forgetting the password (see following section).

1.3 Forgotten password

Users who use password protection have to provide the password to run VWR Protocol Builder

Software and to modify custom protocols in VWR Electronic Pipette.

In the case of a forgotten password, click the Forgotten Password button on the VWR Electronic

Pipette login window. Select one of the following options to recover the forgotten password:

• I know the answer to the hidden question

• I have the recovery password

Page 37

37

And click Next. Provide the answer to the Hidden question or the Recovery password on the

next screen and click Next. On the following window, provide a new password and click Finish.

2 HOME SCREEN

After launching VWR Protocol Builder Software you are directed to the home screen.

The Home screen offers the following options:

Manage custom protocols - Create, edit, import or export custom protocols.

Transfer custom protocols to pipette – Connect a VWR Electronic pipette via USB cable and

transfer a selected custom protocol to the VWR Electronic pipette.

Update pipette settings - Access additional pipette settings such as locking functionality, sound

alerts, maximum volume limit, or pipette firmware updates.

Other administration – Manage the inventory of your VWR Electronic pipettes, view history

of custom protocol uploads to specific VWR Electronic pipettes, manage passwords and the

Company/Institution profile.

By clicking the home icon you return to the home screen.

Menu bar offers the following options:

• File ► Exit; exit the VWR Protocol Builder Software

• Help ► Help; access the user’s guide

• Help ► About; access basic information on the VWR Protocol Builder Software

Page 38

38

3 Installing VWR Protocol Builder Software

3.1 Computer requirements for VWR Protocol Builder Software

VWR Protocol Builder Software is supported on PCs with Windows 7, Windows 8 and Windows

8.1. Table below lists the computer system requirements for the software.

3.2 Installing VWR Protocol Builder Software

i. Download the appropriate VWR Protocol Builder Software installation file for your operating

system to the computer.

ii. Double-click the installer and follow the instructions on the screen to complete the installation.

iii. When completed, the VWR Protocol Builder Software icon will appear on desktop of the

computer if Create Desktop Shortcut is checked.

iv. If VWR Protocol Builder Software is not launched automatically, double-click the VWR Protocol

Builder Software icon on the desktop.

v. Once installed, the VWR Protocol Builder Software can be run by any user on the installed

computer.

3.3 Installing the drivers

On Windows 7 systems, drivers are installed along with the installer. On some Windows 8 and

Windows 8.1 systems, drivers might need to be installed manually.

3.4 Software files

VWR Protocol Builder Software stores information about custom pipetting protocols in specific

files with the extension .pmp.

4 Uninstalling VWR Protocol Builder Software

When uninstalling VWR Protocol Builder Software, you can select to remove the user data (select

checkbox Remove user data during uninstall process). This will remove all user data, custom

protocols, pipette data and history related to pipettes and protocols.

Page 39

39

5 Creating and managing custom protocols

In Manage custom protocols you can create, edit, import or export custom protocols.

5.1 Creating a custom protocol

Start creating a new custom protocol from scratch by clicking the Create a new protocol button.

Specify the Protocol name (e.g. DNA-isolation) and click Create. The edit custom protocol screen

appears with the Protocol info and Protocol setup tabs.

In the Protocol info tab, select a pipette from a list of VWR Electronic Pipette models. Enter the

name of the user who created the protocol (protocol created by: field) and enter any comments into

the Comments box, if required.

In the Protocol setup tab, build a pipetting protocol by adding tasks from the Available

tasks list (on the left of the screen) to the Protocol panel (on the right of the screen) and modifying

the task’s default parameters:

1. Select a task in the Available task list.

2. Drag-and-drop it to the Protocol panel, use the arrow button or simply

double-click on the task).

3. Modify the task’s parameters in the Edit task window that opens automatically after you add

the task to protocol, and click Create to add the task.

4. Add further tasks to the protocol if desired.

5. When the protocol contains all desired tasks, click the Save button to store the protocol. If

you are using password protection, you will be asked to confirm this action by entering your

password.

The protocol is now listed in Manage custom protocols.

Protocols can contain up to 20 tasks.

Tasks listed in the protocol panel will be executed on the VWR Electronic Pipette from top to

bottom. You can move the task’s position in the protocol by drag-and-drop movement or by using

up/down arrows next to the task .

Page 40

40

Default tasks available:

• Aspirate: aspirates specified volume into the tip.

• Dispense: dispenses specified volume from the tip.

• Dispense all: dispenses all remaining volume from the tip followed by a purge action.

• Repeat(1): enables repetition of any task once or more.

• Mix: mixes the specific volume in one or more cycles.

• Purge: dispenses all remaining volume from the tip followed by purging extra volume.

• Wait: introduces a wait for a specified number of seconds.

• Beep: makes pipette produce a beeping sound while selected tasks are executed.

Add tasks to the protocol through drag-and-drop actions, by selecting a task and clicking the arrow

button or by double-clicking the task. Drag-and-drop actions position the tasks in the

following way: the selected task will be placed directly above the task highlighted in the protocol

section. If you are moving a task upwards or creating a new task, the task will be positioned above

the highlighted task. If you are moving the task downwards, the task will be dropped after the

highlighted task.

After you add a task to the protocol, you can modify task parameters.

Page 41

41

(1)Tasks within Repeat will be executed in a sequence for the specified number of iterations.

Example:

If Repeat contains two tasks: Aspirate 20 μL followed by Dispense 20 μL and the number of

iterations is set to 3, the tasks will be executed on VWR Electronic Pipette in the following order:

1. Aspirate 20 μL, 2. Dispense 20 μL, 3. Aspirate 20 μL, 4. Dispense 20 μL, 5. Aspirate 20 μL,

6. Aspirate 20 µl.

5.1.1. Default task parameters:

Each task has modifiable parameters, defined as follows:

Aspirate and Dispense tasks have the following parameters:

• Task name(2): specify the name of the task.

• Volume (μL)(2): specify the volume for the task in μL.

• Speed(2): specifiy the speed for aspirating and dispensing.

• Comments: enter any comments related to the task.

• Display text(2): enter text that is displayed on the pipette’s LCD screen when the task I

activated (note that the number of characters for display text is limited(3)).

Dispense all task has the following parameters:

• Task name(2): specify the name of the task.

• Speed(2): specify the speed for the dispense.

• Comments: enter any comments related to the task.

• Display text(2): enter text that is displayed on the pipette’s LCD screen when the task is

activated (note that the number of characters for display text is limited(3)).

Repeat task has the following parameters:

• Task name(2): specify the name of the task.

• Number of iterations(2): specify how many times the pipette should repeat the tasks that are

placed inside the repeat task.

• Comments: enter any comments related to the task.

Note: for certain VWR Electronic Pipette models the minimal volumes in Aspirate and

Dispense tasks might be different if these tasks are located inside Repeat loop.

Mix task has the following parameters:

• Task name(2): specify the name of the task.

• Volume (μL) (2): specify the volume for the task in μL.

• Aspiration speed(2): specify the speed for the aspiration.

• Dispense speed(2): specify the speed for the dispense.

Page 42

42

• Use Push-button mixing (checkbox): when checked, mixing will be performed continuously

for as long as the user holds the Push-button on the pipette; once the Push-button is released,

mixing stops and the next task in the protocol is executed.

• Number of cycles(2): specify how many times the volume should be mixed.

• Comments: enter any comments related to the task.

• Display text(2): enter text that is displayed on the pipette’s LCD screen when the task is

activated (note that the number of characters for display text is limited(3)).

Purge task has the following parameters:

• Task name(2): specify the name of the task.

• Comments: enter any comments related to the task.

• Display text(2): enter text that is displayed on the pipette’s LCD screen when the task is

activated (note that the number of characters for Display text is limited(3)).

Wait task has the following parameters:

• Task name(2): specify the name of the task.

• Duration(s)(2): specify the duration of the pause in seconds.

• Comments: enter any comments related to the task.

• Display text(2): enter text that is displayed on the pipette’s LCD screen when the task is

activated (note that the number of characters for Display text is limited(3)).

Beep task has the following parameters:

• Task name(2): specify the name of the task.

• Comments: enter any comments related to the task.

Example of use: in order to produce a beep sound with duration of 1 second on the

pipette before the Aspirate task, position the following set of tasks before the Aspirate

task:

- Beep task (creates the beep start and end tasks).

- Wait task (with duration 1 s), which should replace the beep placeholder task between

the two beep tasks.

(2)Parameters marked with an asterisk are mandatory.

(3)Pipettes are able to display a limited number of characters on their LCD screen. If you use

longer strings of characters in Display text not all may be displayed.

Page 43

43

5.1.2. Editing, cloning and deleting tasks:

Once the task is listed in the protocol, you can edit its parameters by selecting the task,

right-clicking on it and selecting Edit task, or by double-clicking the task. The Edit task window

opens, where you can modify the task’s parameters and store them.

You can clone a task by right-clicking on the desired task and selecting Clone task. Add task

window opens, where you can rename the task and change the parameters if desired. When done,

add the task to the protocol by clicking Create button. The task is added immediately after the

original task.

You can delete tasks from the protocol by right-clicking on the desired task and selecting

Delete task. Alternatively, you can select a task in the protocol and click the left-arrow. When

deleting a task, a pop-up window appears, where you can confirm task deletion.

5.1.3. Pipette volume indicator:

As you build a protocol, the pipette volume indicator will display how much of the pipette’s

maximum volume is used at the end of the protocol with indicator bars (green to red color). The

exact volume is also displayed next to the color bars (displayed in microliters). If you click on a

particular task, a rectangle will mark the volume of the current task (blue rectangle indicates

aspirating, and red rectangle indicates dispensing of volume).

If the volume in pipette exceeds the maximal volume, or is below the minimal volume of

the pipette, the pipette volume indicator will be surrounded with a red rectangle.

Numbers displayed next to colored bars

represents volume remaining in the pipette at

the end of protocol (displayed in microliters)

Page 44

44

5.1.4. Warning and error messages:

VWR Protocol Builder Software verifies the protocol after the addition of each task, or after

modification of a task, to determine whether the volume of the pipette is still within the volume

specifications for that particular VWR Electronic pipette model. Should the volume in pipette model

fall outside specifications, an error sign will appear next to the task that caused this. More

details about error are available if you position the mouse over the error sign. Protocols that contain

one or more error signs may be saved, however they cannot be transferred to a pipette and

cannot be exported.

In certain cases a yellow warning sign will appear next to a protocol in Manage custom

protocols and Transfer custom protocols to pipette. More details about the warning are available if

you position the mouse over the warning sign. Such protocols may be transferred to a pipette and

can be exported. However, executing these protocols on the pipette repeatedly may cause the

pipette to have an error.

5.2 Managing existing protocols in Manage custom protocols:

All protocols that have been created are listed in the Manage custom protocols window with

information on pipette model, date of creation, date of last modification, person that created the

protocol, and person that last modified the protocol. If a protocol contains a warning or an error, the

warning or error icon is displayed.

Page 45

45

For each of the protocols listed you can perform the following actions. Simply select the protocol

and click on one of the buttons:

• View: view a protocol. No parameters can be changed in the “View mode”.

• Edit: edit a protocol (change the VWR Electronic Pipette model, rename protocol, add/edit/

remove tasks).

• Clone: clone a protocol (if you are creating a similar protocol, cloning will save time).

• Export: export a protocol to a .pmp file and store it on the computer.

• Export to pdf: create a summary of the protocol in the form of a print-ready pdf document.

• Delete: delete a protocol.

Alternatively, you can perform these actions by right-clicking on a desired protocol.

Editing protocol is also available by double-clicking the selected protocol.

5.3 Importing a protocol:

You can add protocols to the Manage custom protocols by importing a previously created

protocol (.pmp files).

Click on Import a protocol from file button, navigate to the .pmp file and click Open.

The protocol is then available in Manage custom protocols.

5.4 Practical tips for creating custom protocols:

If you have existing protocols, cloning and modifying them will save you time.

VWR Protocol Builder Software enables you to easily create a similar protocol on a different

VWR Electronic Pipette model. Simply clone the protocol and change the VWR Electronic Pipette

model. If necessary, modify the volume of transfers to fit volume specifications of the new VWR

Electronic Pipette model.

6 Transferring custom protocols to the pipette

To transfer a protocol to a VWR Electronic pipette, click the Transfer custom protocols to pipette

button and follow the instructions on the screen:

1/ Connect pipette to the PC via USB cable and click Next. Note: should the pipette not be

recognized immediately, disconnect the USB cable, reconnect it and click Try again button. If a

pipette is already correctly connected when Transfer custom protocols to pipette button is clicked,

this step is skipped.

2/ By default, the protocols for the connected VWR Electronic Pipette model are listed. You can

access the protocols created for other VWR Electronic Pipette models by selecting the model from

the Show protocols for pipette model(2): drop-down list.

3/ Select a protocol in the list and click Finish.

4/ If a pipette is locked, transferring protocols will unlock it. For that purpose, a pop-up window

appears, where you can confirm that you would like to transfer the selected protocol, unlocking the

pipette in the process.

Page 46

46

5/ You can also check “Mute beeps” if you want to disable any pipette sounds during beep tasks.

6/ Disconnect the pipette. The Custom protocol is now available on the pipette.

Note: Protocols that have a red error sign cannot be transferred to pipettes.

• You can transfer a protocol created for a different VWR Electronic Pipette model to the connected

pipette, providing the protocol is using volumes within the connected pipette’s volume

specifications. Protocols that contain volumes outside connected pipette’s volume will have a red

error sign .

• The pipette must be registered in the software prior to transferring custom protocols. If the

connected pipette is not yet registered, a pop-up appears which informs you that the pipette is not

yet registered. Here, you can click on Add pipette now, which takes you to the pipette management

screen, or you can proceed to/stay at step 1 by clicking Connect different pipette.

• On the bottom left of Transfer custom protocols to pipette wizard, you can find the Pipette

connection information - An icon accompanied with text which reports the current connectivity

status.

The icon is green if there is a pipette connected to the computer if there is a pipette

connected to the computer or gray when there are no pipettes connected. The connectivity status is

refreshed when any of the buttons is clicked.

Page 47

47

7 Updating pipette settings

Here you can set the following configurations on the connected VWR Electronic pipette:

• Set the Beep to On or Off (switches the tone of the pipette to On or Off). Beep On and Off only

affects the built-in pipette protocols, as well as Aspirate, Dispense, Mix, Purge tasks (but NOT beep

task!).

• Set the Lock pipette On or Off (Lock pipette On disables access to Configuration, Speed and

Mode on VWR Electronic pipette)

• Set Maximal volume limit: this sets the maximal allowed volume on the particular pipette; it cannot

be higher than pipette’s specified maximal volume. Simply enter the volume (in μL) in the field.

• Update Firmware.

To modify these configurations, follow these steps:

1. Click Update pipette settings in the main menu.

2. If a pipette is already correctly connected, proceed to step 4.

3. Connect pipette to the PC via USB cable and click Next. Should the pipette not be recognized

immediately, disconnect the USB cable, reconnect it and click Try again button.

4. Check the checkbox for the configuration that you would like to change and then modify it (e.g.

change Beep from On to Off; or modify the Maximal volume limit);

Unchecked configurations will not be updated.

Page 48

48

5. Click Finish.

6. Disconnect pipette.

You can refresh the pipette’s Maximal volume limit to pipette’s specified maximal volume by clicking

the Reset to pipette max.

Note: the pipette must be registered in the software prior to transferring custom protocols. If the

connected pipette is not yet registered, a pop-up appears which informs you that the pipette is not

yet registered. Here, you can click on Add pipette now, which takes you to the pipette management

screen, or you can proceed to/stay at step 1 by clicking Connect different pipette.

• On the bottom left of Update pipette settings wizard, you can find the Pipette connection

information – An icon accompanied with text which reports the current connectivity

status.

The icon is green if there is a pipette connected to the computer if there is a pipette

connected to the computer or gray when there are no pipettes connected. The connectivity status is

refreshed when any of the buttons is clicked.

Updating pipette firmware

To update firmware VWR Electronic pipette follow these steps:

1. Click Update pipette settings in the main menu.

2. If a pipette is already correctly connected, proceed to step 4.

3. Connect pipette to the PC via USB cable and click Next. Should the pipette not be recognized

immediately, disconnect the USB cable, reconnect it and click Try again button.

4. Click the Update firmware button.

5. Navigate to the firmware file and click Open.

6. On the next dialog, click OK to confirm the firmware update. IMPORTANT: the pipette must not

be disconnected during firmware update. Disconnecting pipette could result in pipette

malfunction.

7. Wait for the firmware update, click OK and disconnect pipette.

8 Other administration

Here you can perform the following administrative tasks:

• Pipette management - Manage the inventory of your VWR Electronic pipettes.

• View history - View the history of protocol uploads to VWR Electronic pipettes and the

history of protocol modifications by user.

• Change password - Change the password to access VWR Protocol Builder Software.

• Institution/Company profile - Manage the information related to your Institution/Company.

Page 49

49

8.1 Pipette management:

Here you can register your individual VWR Electronic pipettes. Registering a pipette is required to

allow for transfer of your personalized protocols onto the pipette, as well as updating the pipette

settings.

Register a new pipette by clicking Register new pipette button and follow the instructions on the

screen:

1. Connect a pipette to the PC via USB cable and click Next. Should the pipette not be recognized

immediately, disconnect the USB cable, reconnect it and click Try again button. If a pipette is

already correctly connected when Register new pipette button is clicked, this step is skipped.

2. Type in the name of the pipette and click Finish.

3. Pipette is now listed in the Registered pipettes list along with the basic information (Model,

Firmware version, Serial number, Minimal volume (μL), Maximal volume (μL), Last maintenance

date, Next maintenance date).

You can rename a pipette in the Registered pipettes list by selecting the pipette, clicking the

Rename button, entering a new name and clicking Rename.