VWR International sympHony User Manual

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Sampling Equipment

Decontamination

Number: SOP-E-044

Page 1 of 5

Revision: 1

Date: --/--/--

APPROVAL PAGE

SAMPLING EQUIPMENT DECONTAMINATION

APPROVALS

Environmental Coordinator:

Date:

Program Manager:

Date:

QA Manager:

Date:

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Sampling Equipment

Decontamination

Number: SOP-E-044

Page 2 of 5

Revision: 1

Date: --/--/--

SAMPLING EQUIPMENT DECONTAMINATION

1.0 PURPOSE

The purpose of this procedure is to describe the methods for decontamination of nondedicated sampling equipment used in association with water quality monitoring and soil,

sediment or vegetation sampling.

2.0 SCOPE

This procedure applies to the decontamination of all sampling equipment that is used

during water, soil, sediment or vegetation sampling associated with activities of the

Cotter Corporation (N.S.L.) (“Cotter”), Canon City Milling Facility. It applies only to

equipment that is not dedicated to an individual sampling site.

3.0 REFERENCES

3.1 Current Colorado Radioactive Materials License.

3.2 Quality Assurance Project Plan (QAPP), current version.

4.0 DEFINITIONS

4.1 Reagent Grade Water: ASTM Type 2 water prepared by distillation or other

equal process, followed by polishing with a mixed bed of ion exchange materials

and a 0.2 micron membrane filter, such that the resulting water has a maximum

electrical conductivity of 1 µS/cm at 25˚C from the lab or a minimum electrical

resistivity of 100 MΩ/cm at 25˚C.

4.2 EDTA: ethylene diamine tetra acetic acid.

4.3 Field Staff: the sampling technician or other qualified individual designated by

the Environmental Coordinator (EC).

5.0 EQUIPMENT AND MATERIALS

5.1 EQUIPMENT

5.1.1 Plastic tubs or buckets.

5.1.2 Scrub brushes, plastic or fiber bristles.

5.1.3 Wash solution bottle(s).

5.2 MATERIALS

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Sampling Equipment

Decontamination

Number: SOP-E-044

Page 3 of 5

Revision: 1

Date: --/--/--

5.2.1 Non-Phosphate, non-ionic cleaning solution containing EDTA.

5.2.2 Disposable wipes or paper towels.

5.2.3 Deionized water.

5.2.4 Tap water.

5.2.5 0.1 N HCL (hydrochloric acid solution).

5.2.6 Plastic bags.

5.2.7 Brush.

5.3 MAINTENANCE/CALIBRATION

5.3.1 None for this procedure

6.0 HEALTH AND SAFETY

6.1 Acids are potentially dangerous chemicals. Read the individual Safety Data Sheet

(SDS) for each chemical before use.

6.2 Store all acids according to manufactures recommendations.

6.3 Wear latex gloves and safety glasses when preparing and handling acids.

7.0 RESPONSIBILITY

7.1 It is the responsibility of the EC to make sure that personnel performing this task

are properly trained.

7.2 It is the responsibility of field staff personnel conducting this procedure to follow

it.

8.0 INSTRUCTIONS

8.1 This procedure should be used after sampling at each site to eliminate the

potential for cross contamination of future samples.

8.2 When choosing a site for decontamination, avoid fugitive dust, oils, gasoline, fuel

oils, organic solvents, sources of radioactive contamination, and any other

possible source of contamination, which may affect equipment or sample

integrity.

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Sampling Equipment

Decontamination

Number: SOP-E-044

Page 4 of 5

Revision: 1

Date: --/--/--

8.2.1 If decontamination is performed at a site other than the location where the

equipment was used, carefully transport equipment to the decontamination

area in a manner that minimizes the spread of contaminants.

8.3 For water quality monitoring, use the following sequence for equipment used with

organic and inorganic target analytes.

8.3.1 Remove any gross contamination such as loose soil with brush and tap

water.

a. Non-dedicated pumps will have solution pumped through it and all

associated sampling lines

b. Filtration equipment will be disassembled and washed with a

bristle brush.

c. Stainless, Teflon or other containers used for sampling will be

washed with a bristle brush.

8.3.2 Wash all sampling equipment with a non-Phosphate, non-ionic cleaning

solution containing EDTA, example, Liquinox8 in concentrations

recommended by the manufacture.

8.3.3 Rinse or pump 0.1 N HCL (hydrochloric acid solution) or 0.1 N HNO

3

(nitric acid solution) through or on equipment.

8.3.4 Rinse or pump tap water through or on equipment thoroughly.

8.3.5 Rinse or pump Type 2 reagent water on or through equipment.

8.3.6 Measure the conductivity of the Type 2 water rinse.

a. If measured conductivity is <50 uS/cm the decontamination is

deemed adequate, otherwise repeat the cleaning procedure.

8.3.7 Store equipment to prevent contaminating equipment for next use.

8.4 For vegetation, soil or sediment sampling use the following sequence for

equipment decontamination.

8.4.1 Remove any gross contamination such as loose soil, sediment or

vegetation with brush and then rinse with Type 2 reagent water.

8.4.2 Wipe dry with paper towel or let air dry before moving to next sampling

location.

8.4.3 Store equipment to prevent contaminating equipment for next use.

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Sampling Equipment

Decontamination

Number: SOP-E-044

Page 5 of 5

Revision: 1

Date: --/--/--

9.0 RECORDS

9.1 For water quality monitoring record the measured field conductivity value from

the QA rinsate in the field sampling logbook or equivalent.

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 1 of 6

Revision: 1

Date: --/--/--

APPROVAL PAGE

OXIDATION REDUCTION POTENTIAL MEASUREMENTS

APPROVALS

Environmental Coordinator:

Date:

Program Manager:

Date:

QA Manager:

Date:

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 2 of 6

Revision: 1

Date: --/--/--

1.0 PURPOSE

This procedure describes the activities necessary for measuring the Oxidation-reduction

potential (ORP) in unfiltered water samples during water quality monitoring activities at

the Cotter Corporation (N.S.L.) (“Cotter”), Canon City Milling Facility.

2.0 SCOPE

This procedure applies to oxidation-reduction potential (ORP) measurements within a

millivolt range of +/- 1999.9 mV in water samples taken for water quality measurements

by Cotter Corporation (N.S.L.), Canon City Milling Facility.

3.0 REFERENCES

3.1 Quality Assurance Project Plan, current version.

3.2 Colorado Radioactive Materials License, current version.

4.0 DEFINITIONS

4.1 Oxidation-reduction potential (ORP) measurements are used to monitor chemical

reactions, quantify ion activity or determine the oxidizing or reducing properties

of solutions. While ORP measurements are somewhat similar to those of pH, the

potential value must be carefully interpreted to achieve meaningful results. The

field measured ORP values are corrected to correlate to Standard Hydrogen

Electrode (SHE).

5.0 APPENDICES

5.1 ORP reference solution offset correction addition factors.

5.2 VWR SympHony SP80PC Meter Instruction and Operating Manual

6.0 EQUIPMENT AND MATERIALS

6.1 EQUIPMENT

6.1.1 VWR SympHony SP80PC Meter or the equivalent.

6.1.1.1 This meter measures millivolts in the range of +/- 1999.9 mV.

6.1.1.2 If the reading exceeds this range, an error message is displayed.

6.1.2 Refillable Platinum combination ORP electrode, or the equivalent

6.2 MATERIALS

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 3 of 6

Revision: 1

Date: --/--/--

6.2.1 Electrode uses a 4M KCL reference solution saturated with Ag/Ag CI.

6.2.2 Thermo Scientific ORP Standard Solution.

6.2.3 Wash bottle with ASTM Type 2 water.

7.0 HEALTH AND SAFETY

7.1 Refer to the Safety Data Sheet (SDS) for chemical reagent handling precautions.

7.2 ORP standard will stain hands and clothing. In case of contact, flush with affected

area with water.

8.0 RESPONSIBILITY

8.1 Field Sampling technicians are responsible for following this procedure when

measuring the ORP of water samples.

9.0 EQUIPMENT INSPECTION

9.1 Refer to specific pH/mV meter operating manual for troubleshooting and

maintenance.

9.2 Check the meter before taking it into the field.

9.3 Visually inspect the instrument, examining all cables and probes for damage.

9.4 Connect the electrode to the meter.

10.0 EQUIPMENT CALIBRATION AND FREQUENCY

10.1 Check the calibration of the instrument each time it is turned on or at each

sampling location. Recalibrate when needed.

10.2 Insert the electrode into the ORP reference standard solution. Make sure standard

has not expired.

10.3 Record the following information in the field sampling logbook or equivalent:

10.3.1 Ttemperature of the ORP reference solution.

10.3.2 mV reading of reference solution during calibration.

10.3.3 Date and time of calibration in the field sample logbook or equivalent.

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 4 of 6

Revision: 1

Date: --/--/--

10.4 If the mV meter will not calibrate refer to the specific meter/instrument operating

instruction manual for troubleshooting and maintenance information or replace

the meter or probe with a spare meter or mV probe.

11.0 MEASUREMENT INSTRUCTIONS

Direct measurements for ORP are made by simply taking a measurement of a sample,

correcting to units of Standard Hydrogen Electrode (SHE) and reporting a result.

11.1 Direct Measurement Of Samples.

11.1.1 Insert a proper functioning electrode into the water sample to be measured.

11.1.2 Take a reading in mV by following the directions in the pH/mV meter

operator's manual.

11.1.3 When the reading stabilizes, record the sample temperature and mV value

as displayed on the meter.

11.1.4 It is necessary to report the value relative to the results achieved by a

"normal standard hydrogen electrode" as the reference electrode. To do

this you must add the observed mV result to the potential of the reference

electrode being used - in this case a 4 M KCL with Ag/Ag CI electrode,

which has a value of 200 mV at 25o C. This is necessary since the value of

the "normal standard hydrogen electrode” is defined as having a value of

0.0 mV under the same conditions.

11.1.5 Refer to appendix 5.1 for the offset correction factor to use for

measurements at temperatures different than 25oC

Where

Eh = the value of the potential of the sample relative to the “normal

standard hydrogen electrode”

Eo = the potential observed with the ORP electrode (the result from the

meter)

11.1.6 Cf = Correction Addition Factor is the constant offset factor in potential

due to the reference electrode in use (in this example 200 mV for a

temperature of 25oC).

11.1.7 If your meter reported a value of 450 mV at a temperature of 25oC, your

reported result would be Eh = 450 + 200, or 650 mV (SHE). If the value

reported was -599 at a temperature of 25oC your reported result would be

Eh = -599 + 200, or -399 mV (SHE).

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 5 of 6

Revision: 1

Date: --/--/--

11.1.8 After the samples mV measurement has been recorded, remove the

electrode from the sample and rinse completely with de-ionized water.

11.1.9 You can proceed to the next sample or store the electrode.

12.0 RECORDS

12.1 Field sampling logbook, field data sheet, or tablet.

Cotter Corporation (N.S.L.)

Cañon City Milling Facility

Cañon City, Colorado

Procedure

Oxidation Reduction

Potential Measurements

Number: E-046

Page 6 of 6

Revision: 1

Date: --/--/--

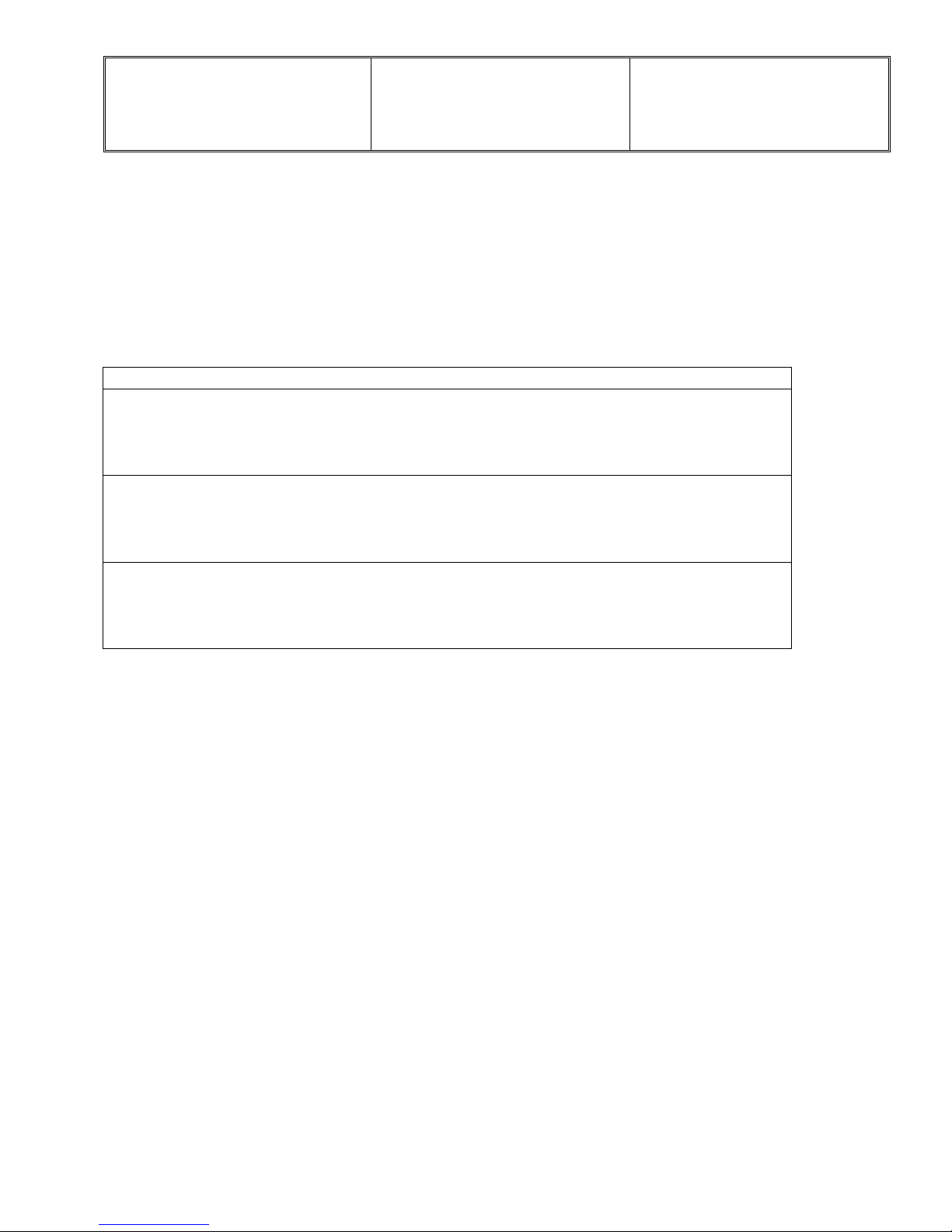

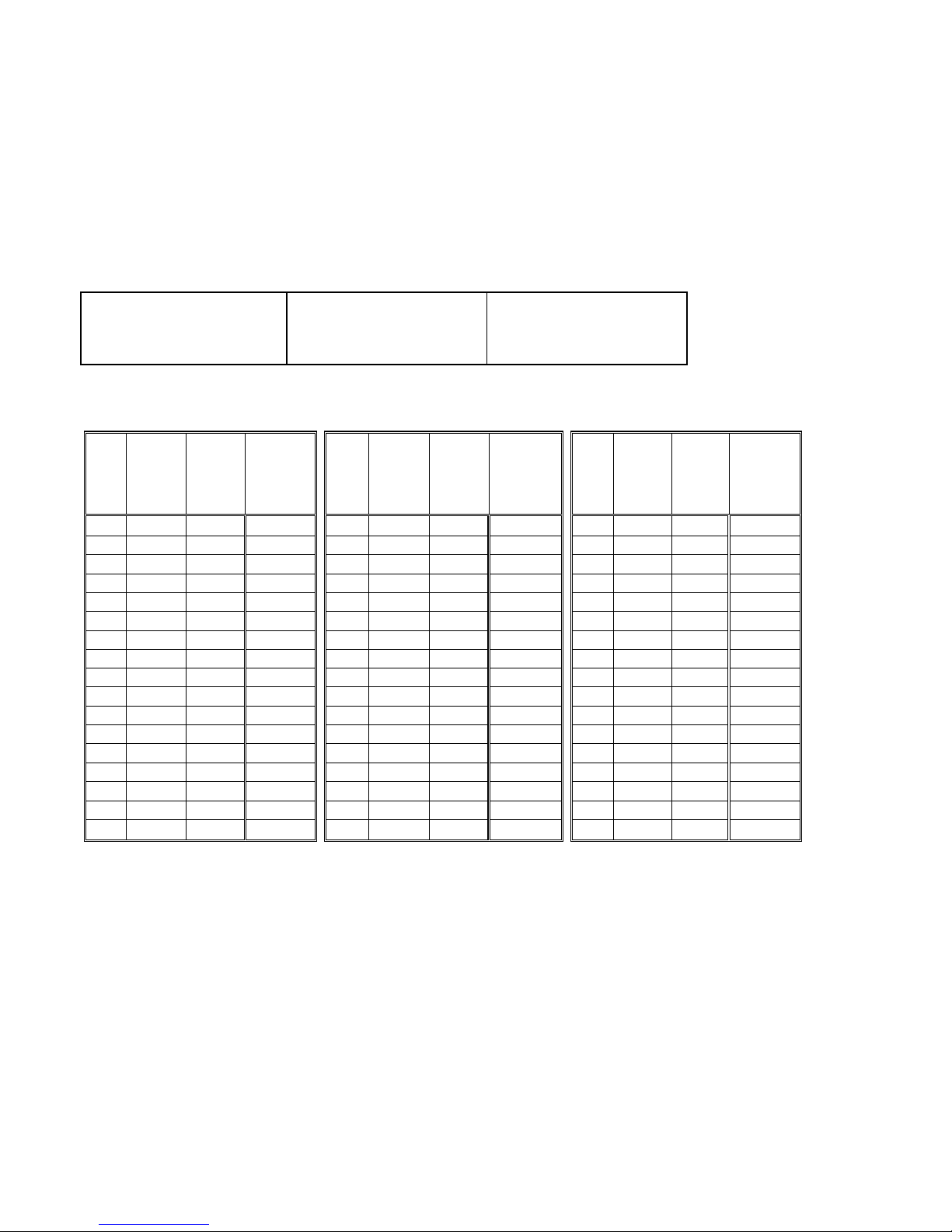

Appendix 5.1

ORP Reference Solution Offset Correction Addition Factors

Temp%

(0C)%

ORP%

Standard%

Solution%

*(mV)%

Eh%(SHE)%

(mV)%

Correction%

Addition%

Factor%

Temp%

(0C)%

ORP%

Standard%

Solution%

(mV)%

Eh%(SHE)%

(mV)%

Correction%

Addition%

Factor%

Temp%

(0C)%

ORP%

Standard%

Solution%

(mV)%

Eh%(SHE)%

(mV)%

Correction%

Addition%

Factor%

0%

218%

438%

220%

17%

219%

426%

207%

34%

220%

412%

192%1%218%

437%

219%

18%

219%

425%

206%

35%

220%

411%

191%2%218%

437%

219%

19%

219%

424%

205%

36%

220%

410%

190%3%218%

436%

218%

20%

219%

424%

205%

37%

220%

409%

189%4%218%

435%

217%

21%

219%

423%

204%

38%

220%

408%

188%5%218%

435%

217%

22%

219%

422%

203%

39%

220%

407%

187%6%218%

434%

216%

23%

219%

421%

202%

40%

220%

406%

186%7%218%

433%

215%

24%

220%

420%

200%

41%

220%

405%

185%8%218%

433%

215%

25#

220#

420#

200#

42%

220%

404%

184%9%219%

432%

213%

26%

220%

419%

199%

43%

220%

403%

183%

10%

219%

431%

212%

27%

220%

418%

198%

44%

220%

402%

182%

11%

219%

430%

211%

28%

220%

417%

197%

45%

220%

401%

181%

12%

219%

430%

211%

29%

220%

416%

196%

46%

220%

400%

180%

13%

219%

429%

210%

30%

220%

415%

195%

47%

220%

399%

179%

14%

219%

428%

209%

31%

220%

414%

194%

48%

220%

398%

178%

15%

219%

428%

209%

32%

220%

413%

193%

49%

220%

397%

177%

16%

219%

427%

208%

33%

220%

412%

192%

50%

220%

396%

176%

Note:%*%Using%pH/mV%electrode%with%4M%KCL%Ag/Ag%CL%reference%solution%

VWR sympHony

Meter User Guide

Exhibit 5.2

I

sympHony™ Meter User Guide

Table of Contents

Chapter I Introduction

Convenient Meter Features ............................................ 1

Chapter II Display

General Description .................................................. 3

Chapter III Keypad

General Description .................................................. 5

Key Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter IV Preparation

Installing the Power Adapter............................................ 7

Installing the Batteries ................................................ 8

Connecting the Electrodes ............................................. 9

Turning on the Instrument .............................................10

Meter Maintenance ..................................................10

Chapter V Meter Setup

Setup Menu ........................................................11

Setup Menu Table ..................................................12

Enabling or Disabling the Setup Menu Password..........................13

General Menu Settings................................................14

Time and Date Setup .................................................15

AUTO-READ™, Continuous or Timed Measurement Selection ..................16

Selecting the Measurement Parameter ...................................17

Method Setup...................................................... 18

Chapter VI pH Technique

pH Setup Menu .....................................................19

pH Calibration ...................................................... 20

pH Measurement ................................................... 21

mV, Relative mV and ORP Technique .................................... 22

II

sympHony™ Meter User Guide

Chapter VII Dissolved Oxygen Technique

Dissolved Oxygen Setup Menu ........................................ 23

Dissolved Oxygen Calibration.......................................... 24

Dissolved Oxygen Measurement ....................................... 26

Chapter VIII Conductivity Technique

Conductivity Setup Menu ............................................. 27

Conductivity Calibration .............................................. 28

Conductivity Measurement ........................................... 30

Chapter IX ISE Technique

ISE Setup Menu .................................................... 31

ISE Standards Preparations ........................................... 32

ISE Calibration ..................................................... 33

ISE Measurement................................................... 34

Chapter X Data Archiving and Retrieval

Datalog and Calibration Log ........................................... 35

Chapter XI Declaration of Conformity

Declaration of Conformity............................................. 37

WEEE Compliance .................................................. 38

Chapter XII Troubleshooting

Meter Self Test ..................................................... 39

Meter Error Codes .................................................. 40

General Troubleshooting .............................................. 42

Chapter XIII Meter Specifications

Meter Specifications................................................. 45

Ordering Information ................................................ 48

Appendix A Special Meter Setup Menu Features

pH Setup Menu Features ............................................. 51

Dissolved Oxygen Setup Menu Features ................................. 51

Conductivity Setup Menu Features ..................................... 52

ISE Setup Menu Features............................................. 54

Tabl e of C on te nts

1

sympHony™ Meter User Guide

Chapter I

Introduction

Congratulations! You have selected a VWR® sympHony™ meter designed for

electrochemistry measurements in the field or in the laboratory.

• Single parameter meters provide single measurement of pH, dissolved oxygen,

or conductivity.

• Dual parameter meters provide dual measurements of pH/dissolved oxygen,

pH/conductivity, or pH/ISE (ion selective electrode).

• Multiple parameter meters provide multiple measurements of pH, ISE, dissolved

oxygen, and conductivity.

All meters include a temperature measurement function. All meters with pH

measurement capability include a mV/relative mV/ORP function.

Convenient Meter Features

Built to meet the demands of busy, multiple user laboratories or plant environments,

all meters are microprocessor controlled aiding in the delivery of accurate and

precise measurements. To better meet the needs of users in environmental

protection and control, food and beverage, pharmaceutical, and consumer product

laboratories, the sympHony meters include these key features:

• Password Protected Methods – The meter will save up to ten custom

measurements and calibrations for future reference. Password protection of the

setup menu eliminates any tampering with methods as multiple users access

only the procedure most appropriate to their work.

• AUTO-READ™ – The meter will take a measurement and automatically print or

log the data when the reading becomes stable. The measurement is frozen on

the display until the user prompts the meter to take a new measurement.

2

sympHony™ Meter User Guide

• Stirrer Control – Benchtop meters have a control for the stirrer probe and the

AUTO-STIR™ BOD probe, eliminating the need for additional stir plates and bars.

• Display Backlight – When the meter is on, a quick press of will turn

the backlight on and off. When the meter is operating on battery power, the

backlight will automatically turn off after two minutes to conserve power. When

batteries are low, the backlight will no longer turn on.

• Automatic Shut-off – All sympHony meters will shut down after 20 minutes

without a keypress. This maximizes battery power on portable meters and

benchtop meters that are being run on battery power.

• Audible Signals – The meter will beep whenever a key is pressed, providing

immediate verification that the user’s input was received.

• Visual Alarm Signals – Flashing and icons indicate that calibration

settings need adjustment. For more detail, refer to subsequent sections of this

user guide that discuss specific measurement techniques.

An easy-to-use reference guide, attached to each meter, supports daily meter use.

Note: Please read this user guide thoroughly before using your benchtop or

portable meter. Any use outside of these instructions may invalidate your warranty

and cause permanent damage to the meter.

Introduction

3

sympHony™ Meter User Guide

Chapter II

Display

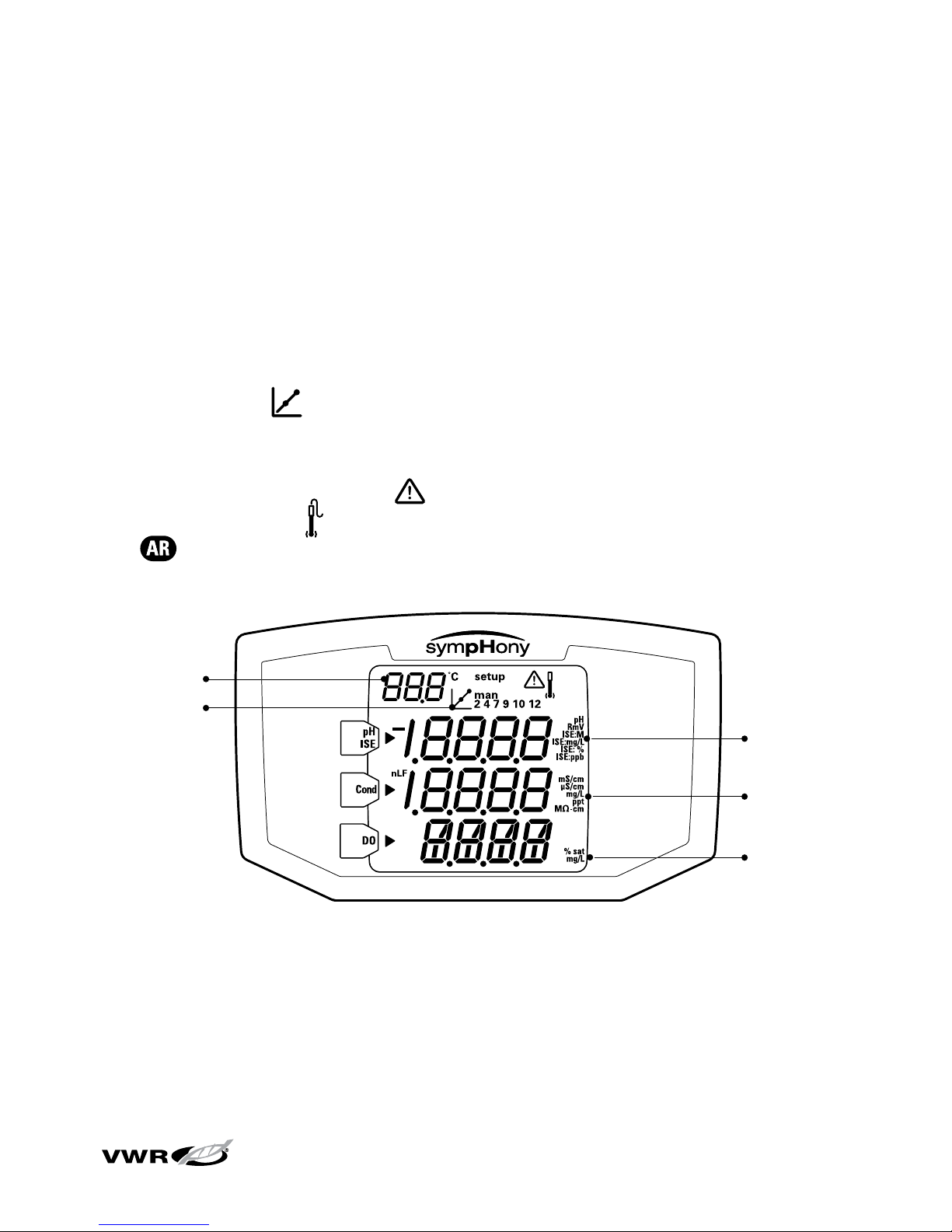

General Description

Throughout a given process, the display on a sympHony meter provides

temperature and calibration data. The temperature appears in the left, top corner

of the display. The icon indicates that a calibration mode or calibration setup

menu is active. The man, 2, 4, 7, 9, 10, and 12 icons indicate which pH buffers

were saved after a pH calibration is performed. The setup icon only appears when

the meter is in setup mode. The icon indicates an error condition and when

it is displayed with the icon, a calibration alarm or sensor quality issue exists.

The icon indicates that the AUTO-READ measurement mode is active and is

discussed in greater detail in the Meter Setup section.

Multi-Parameter Meter

This is the display of the sympHony meter capable of multi-parameter

measurements. The single and dual parameter meters will have fewer

measurement lines, depending on the meter capabilities.

Note: In the measurement mode, the three main lines of data on the meter

display correspond to what is being measured.

Temperature

Calibration

pH/ISE/ORP

Unit

Conductivity

Unit

DO Unit

4

sympHony™ Meter User Guide

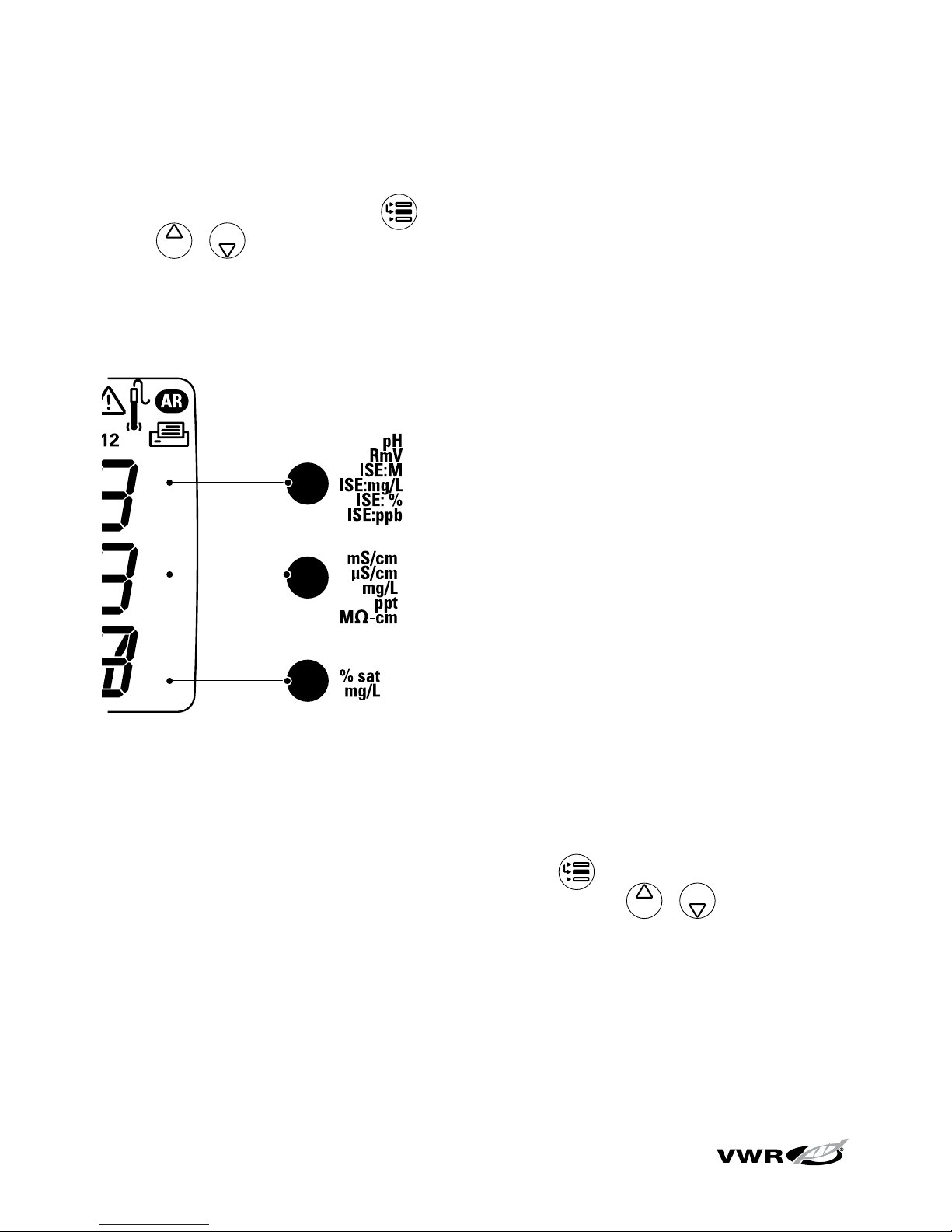

Measurement Unit Icons

In the measurement mode, the arrow icon on the left side of the display screen

indicates the active line. Press to move the arrow icon to the desired line and

press / to scroll through the measurement unit icons associated with

the selected line. The measurement unit icons for the sympHony multi-parameter

meter are shown below. The single and dual parameter meters will have fewer

measurement lines and icons, depending on the meter capabilities.

A

pH, mV, relative mV or ISE

B

Conductivity, TDS, salinity or

resistivity

C

Dissolved oxygen as % saturation,

dissolved oxygen as concentration,

or barometric pressure

The units of measurement, which are displayed on the right side of the screen, will

flash until the reading is stable.

Note: If a measurement line is not needed, press to move the arrow

icon to the measurement line that is not needed and press / until the

measurement line is completely blank.

Display

5

sympHony™ Meter User Guide

Chapter III

Keypad

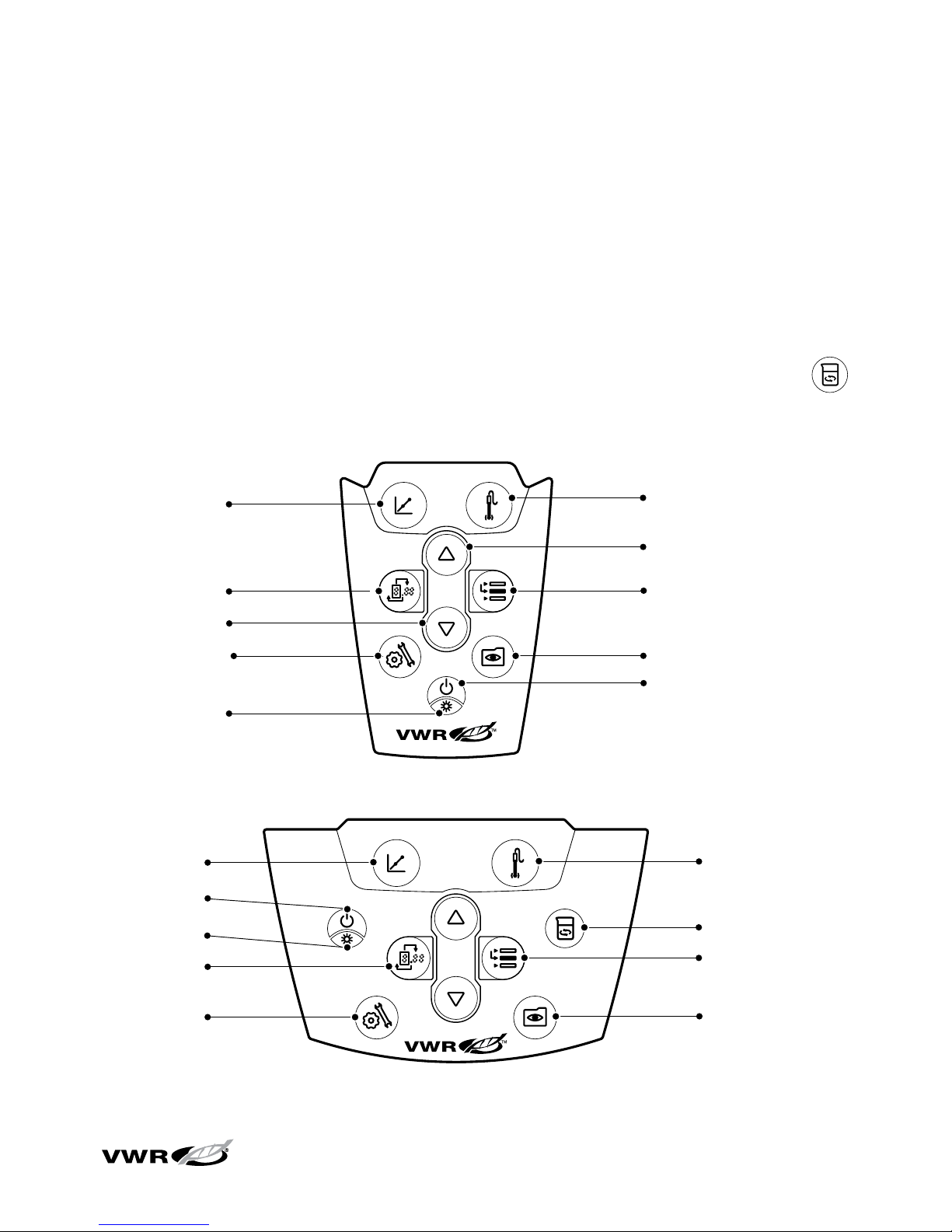

General Description

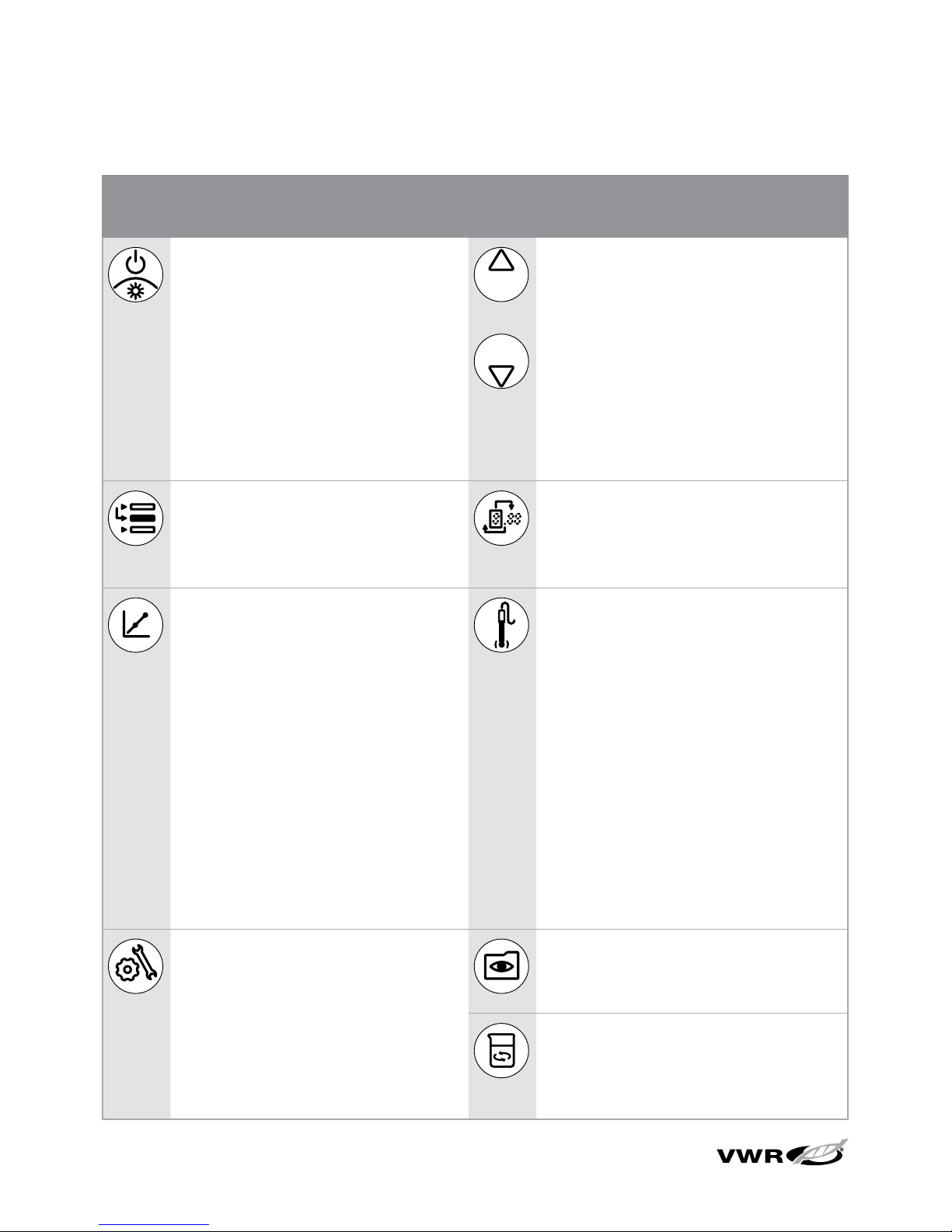

The keypad layout is the same for all sympHony meters. The portable meters have

nine keys. The benchtop meters have ten keys due to the addition of the stir key .

Portable Keypad

Benchtop Keypad

setup view log

calibrate

measure

save/print

Backlight

Power

Measure

Save/Print

View Log

Line Select

Digits

Setup

Calibrate

Scroll Up

Scroll Down

setup view log

calibrate

measure

save/print

Stirrer On/Off

Measure

Save/Print

View Log

Power

Line Select

Digits

Setup

Calibrate

Backlight

6

sympHony™ Meter User Guide

Key Definitions

Key Description Key Description

Turns the meter on, if the meter

is off.

Toggles the backlight on and off,

if the meter is on.

If the meter is on, hold down

the key for about three seconds

to turn off the meter.

Changes the measurement

units of the selected line in the

measurement mode.

Changes the value on the

selected line in the setup,

methods and log view modes.

Edits the value of the flashing

digit for setup, password entry

and calibration modes.

Scrolls the arrow icon on left of

screen among the three display

lines, so the selected line can

be edited or calibrated.

Selects the next digit to edit

and moves the decimal point

for setup, password entry and

calibration modes.

Starts the calibration for

the selected line in the

measurement mode.

If the arrow icon points to the

top line and the displayed units

are pH, pressing the key will

start a pH calibration.

Each time the key is pressed in

the calibration mode, the meter

will accept the calibration point

and move to the next point

until the maximum number of

calibration points are reached.

Prints and logs a measurement

in the continuous or timed

measurement modes.

Prints, logs and freezes the

display when the reading

becomes stable in the AUTOREAD measurement mode.

Exits the setup menu and returns

to measurement mode.

Accepts the calibration and

returns to measurement mode.

Enters the setup menu, starting

with selected line in the

measurement mode.

If the arrow icon points to the

top line and the displayed units

are ISE, pressing the key will

enter the ISE setup screen.

Enters the log view and

download menu.

Turns the stirrer on and off.

Keypad

7

sympHony™ Meter User Guide

Chapter IV

Preparation

Installing the Power Adapter

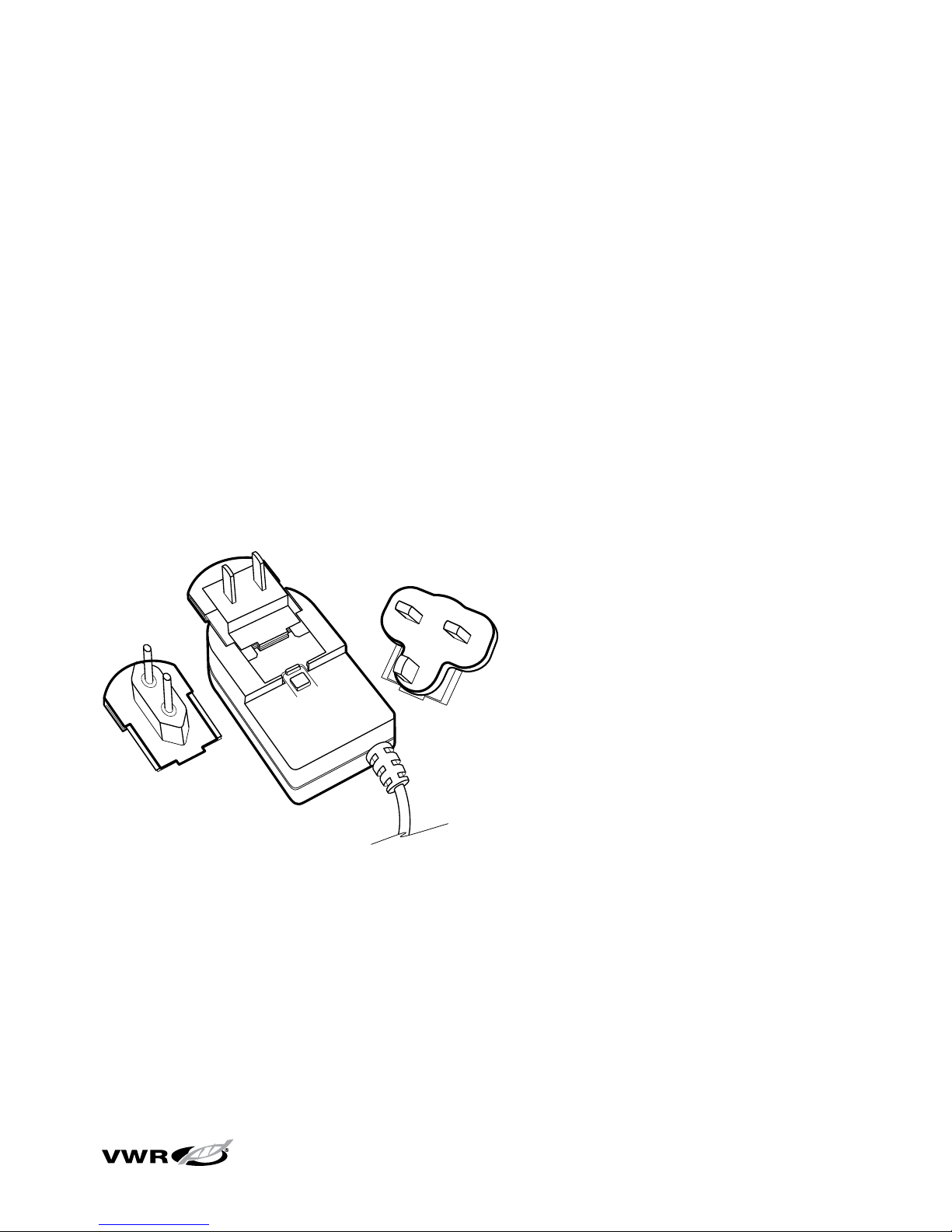

The universal power adapter that is included with your benchtop meter is the only

power adapter recommended for use with this unit. The use of any other power

adapter will void your meter warranty. The external electrical power adapter is rated

to be operated at 100 to 240 VAC, 0.5 A, 50/60 Hz.

Based on your wall outlet, select one of the four plug plates provided (110 V, 220 V,

240V) and slide it into the grooves on the adapter. A click will be heard when the

plug is properly in place.

Connect the output plug of the power adapter to the power input on the benchtop

meter. Refer to the diagram in the Connecting the Electrodes section.

Batteries can be installed in the benchtop sympHony meters, so the meter setup

settings are protected if the meter is disconnected from the wall outlet or a brief

power outage occurs.

8

sympHony™ Meter User Guide

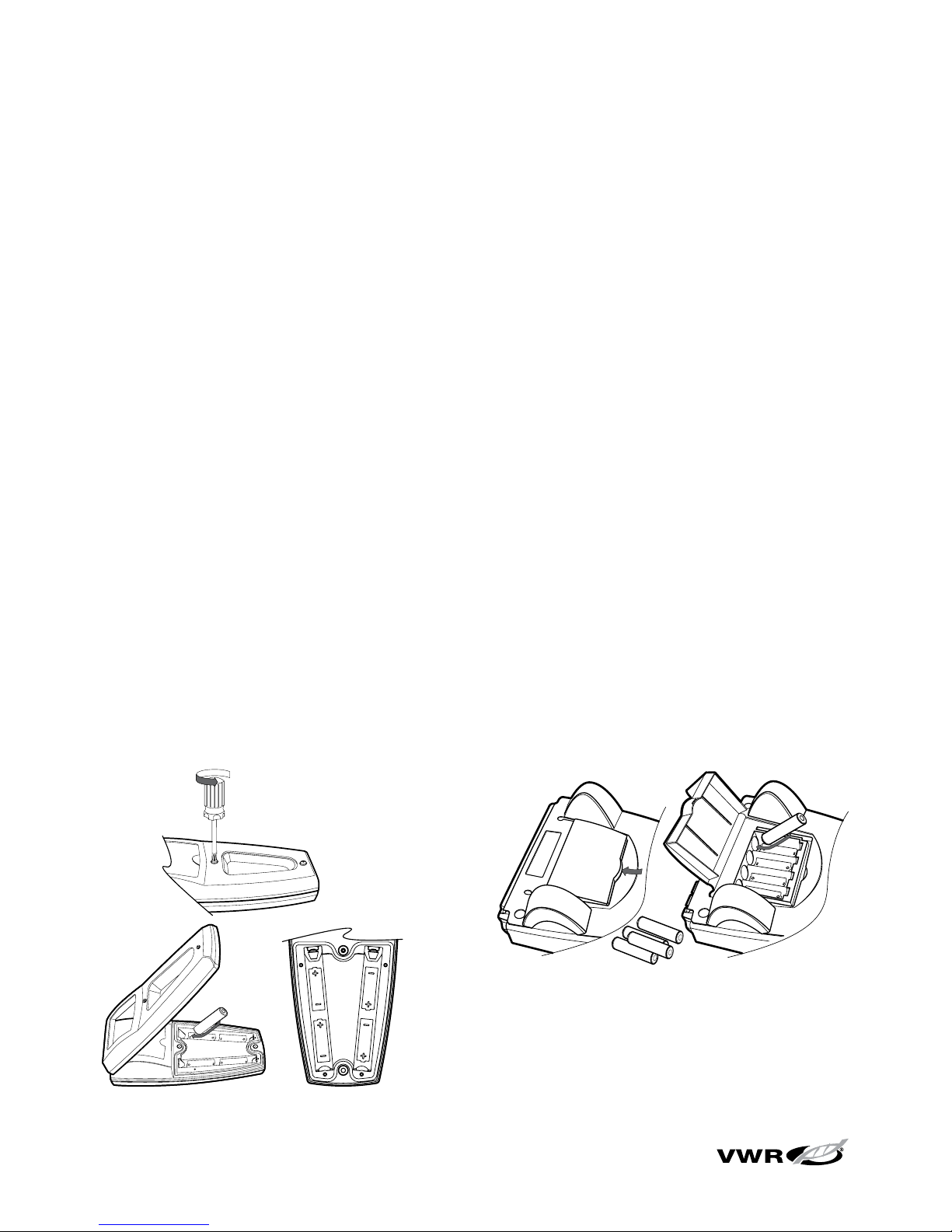

Installing the Batteries

The sympHony meters use four AA alkaline batteries. Do not use lithium or

rechargeable batteries. Improper installation of non-alkaline batteries could create

a hazard.

Note: For benchtop meters, the installation of batteries is not required if the unit

will always be connected to a power source via the universal power supply. For

portable meters, the batteries are supplied from the factory. To access the battery

compartment in portable meters, loosen the two screws in the back of the meter.

1. Confirm that the meter is off and gently place the meter upside down on a

clean, lint-free cloth to prevent scratching the display.

2. Remove the battery case cover.

3. Insert new batteries with the + side orientation as depicted in the battery

compartment housing.

4. Replace the battery case cover.

5. Stored data, calibrations and methods will remain in the meter’s nonvolatile

memory when the batteries are being replaced. However, the date and time

may need to be reset when the batteries are changed.

Preparation

9

sympHony™ Meter User Guide

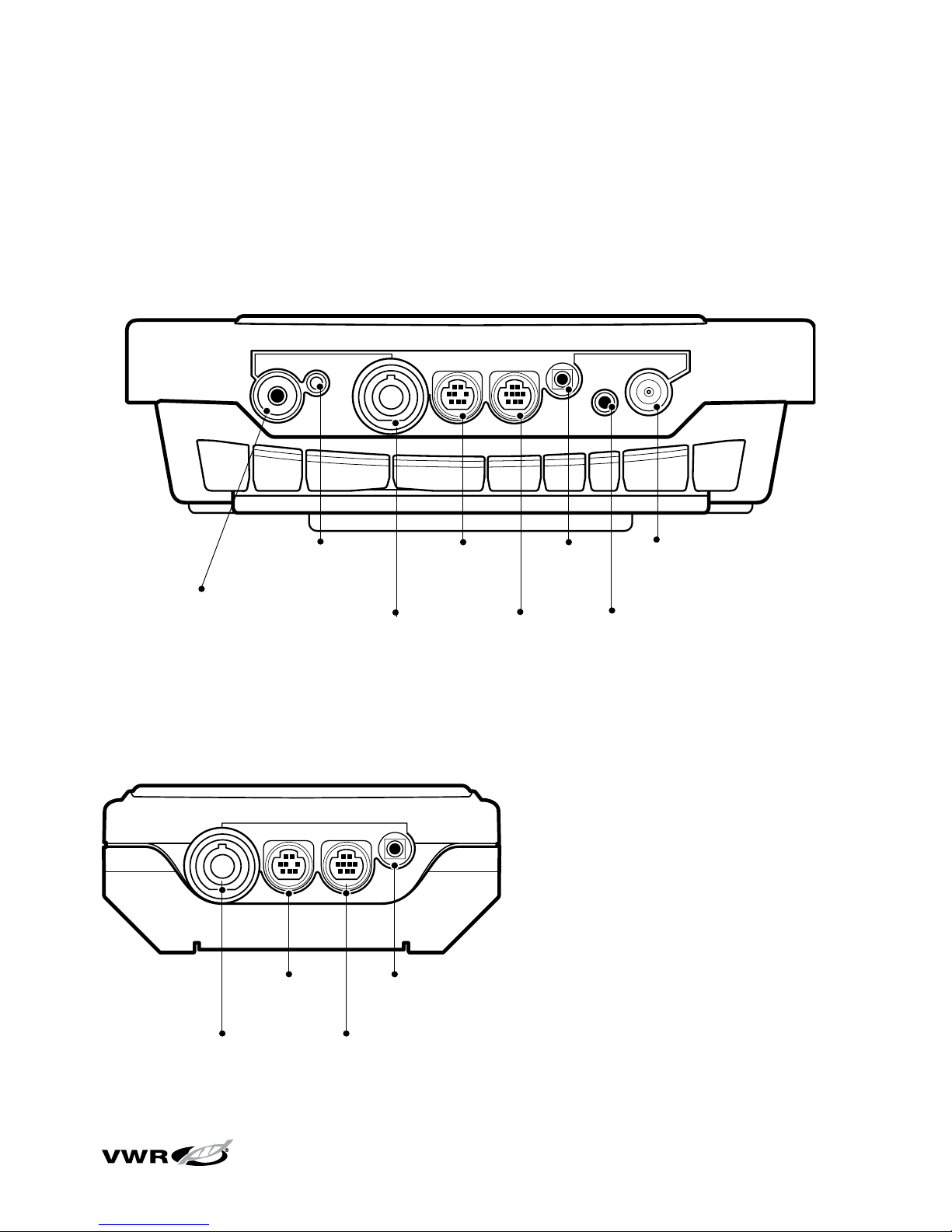

Connecting the Electrodes

Follow the diagrams below to correctly connect electrodes and probes to the meter.

The multi-parameter meter is depicted; single parameter and dual parameter meters

will have fewer connections, depending on the meter measurement capabilities.

Benchtop Meter – Electrode Connections

Stirrer jack,

stirrer or DO

AUTO-STIR probe

Reference,

pH or ISE

Cond or

ATC, 8 pin

MiniDIN

DO, 9 pin

MiniDIN

Ground

BNC,

pH or ISE

Power

RS232

Portable Meter – Electrode Connections

RS232

BNC,

pH or ISE

Cond or

ATC, 8 pin

MiniDIN

DO, 9 pin

MiniDIN

Preparation

10

sympHony™ Meter User Guide

Preparation

Meter Connections with Multiple Functions

• Use the BNC input to connect pH, ISE and ORP electrodes with a BNC or

waterproof BNC connector.

• Benchtop meters have a reference input for connecting a separate reference

electrode. Reference electrodes require an appropriate sensing electrode for

measurements.

• Use the waterproof 8 pin MiniDIN input for conductivity probes or for automatic

temperature compensation (ATC) probes.

• The DO AUTO-STIR probe uses the waterproof 9 pin MiniDIN input and the

stirrer jack.

Turning on the Instrument

With the batteries installed in the portable meters and the power adapter attached

or the batteries installed in the benchtop meter, press to turn on the meter.

Press when the meter is powered on to toggle the backlight on and off.

When the benchtop meter is drawing line power, the backlight will stay on until

is pressed.

To t ur n off t he m et er, pr es s an d ho ld for about three seconds.

Meter Maintenance

For routine meter maintenance, dust and wipe the meter with a damp cloth. If

necessary, a warm water or a mild water-based detergent can be used.

Immediately remove any spilled substance from the meter using the proper cleaning

procedure for the type of spill.

11

sympHony™ Meter User Guide

Chapter V

Meter Setup

Setup Menu

To navigate the setup menu:

1. Press to enter the setup menu.

2. Press / until the desired setup option is displayed on the top line.

3. Press to move the arrow icon to the middle line.

4. Press / until the desired setup option is displayed on the middle line.

5. Press to move the arrow icon to the bottom line.

6. To s cr ol l th ro ug h a li st o f op ti on s on t he b ott om l in e, p re ss / until the

desired option is displayed. To enter a numeric value for an option on the bottom

line, press / to adjust each digit and to move to the next digit.

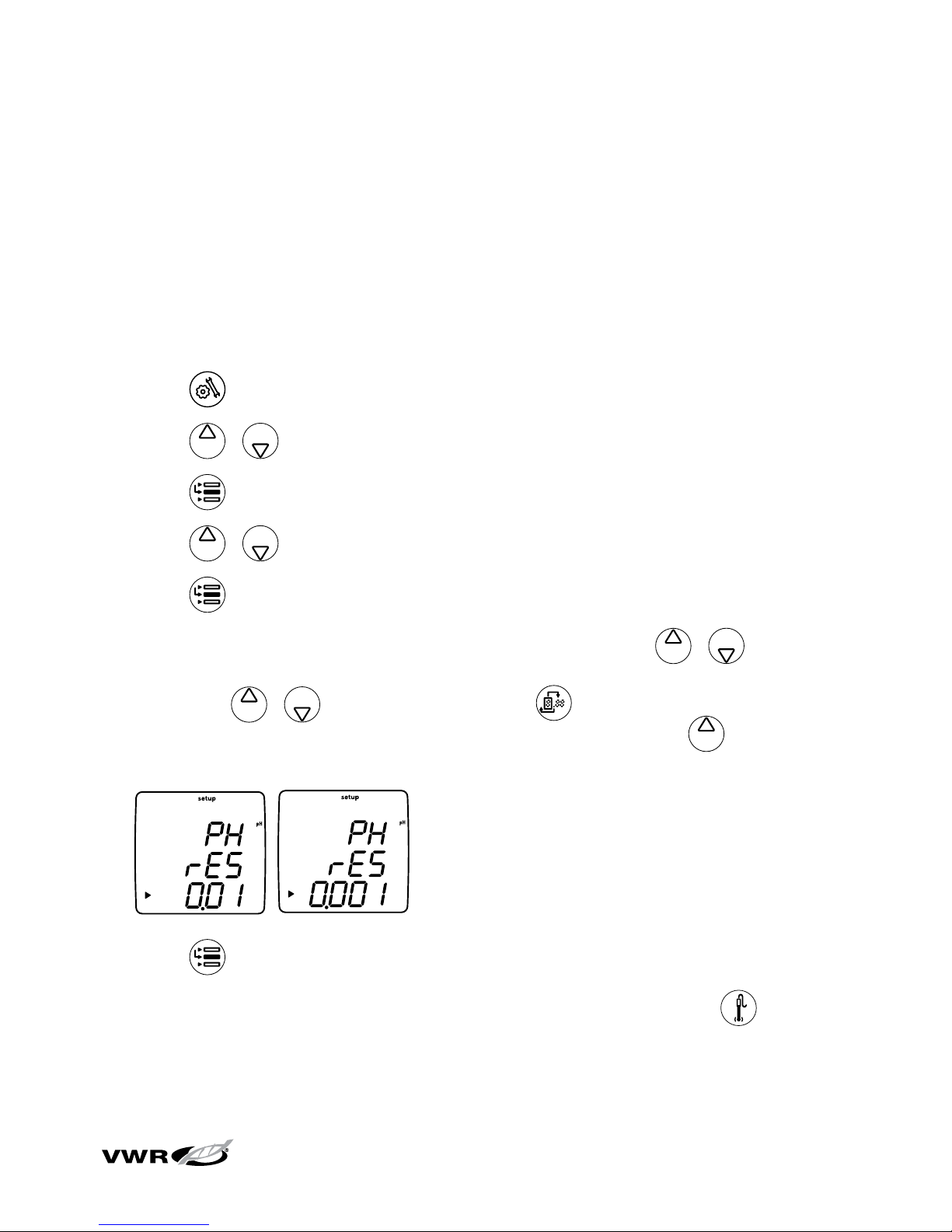

For example, to change the pH measurement resolution press to scroll from

0.01 t o 0.001 on the bottom display line.

7. Press to move the arrow icon to the top line.

8. Repeat steps 2 through 7 to program a new setup option or press to exit

the setup menu and return to the measurement mode.

12

sympHony™ Meter User Guide

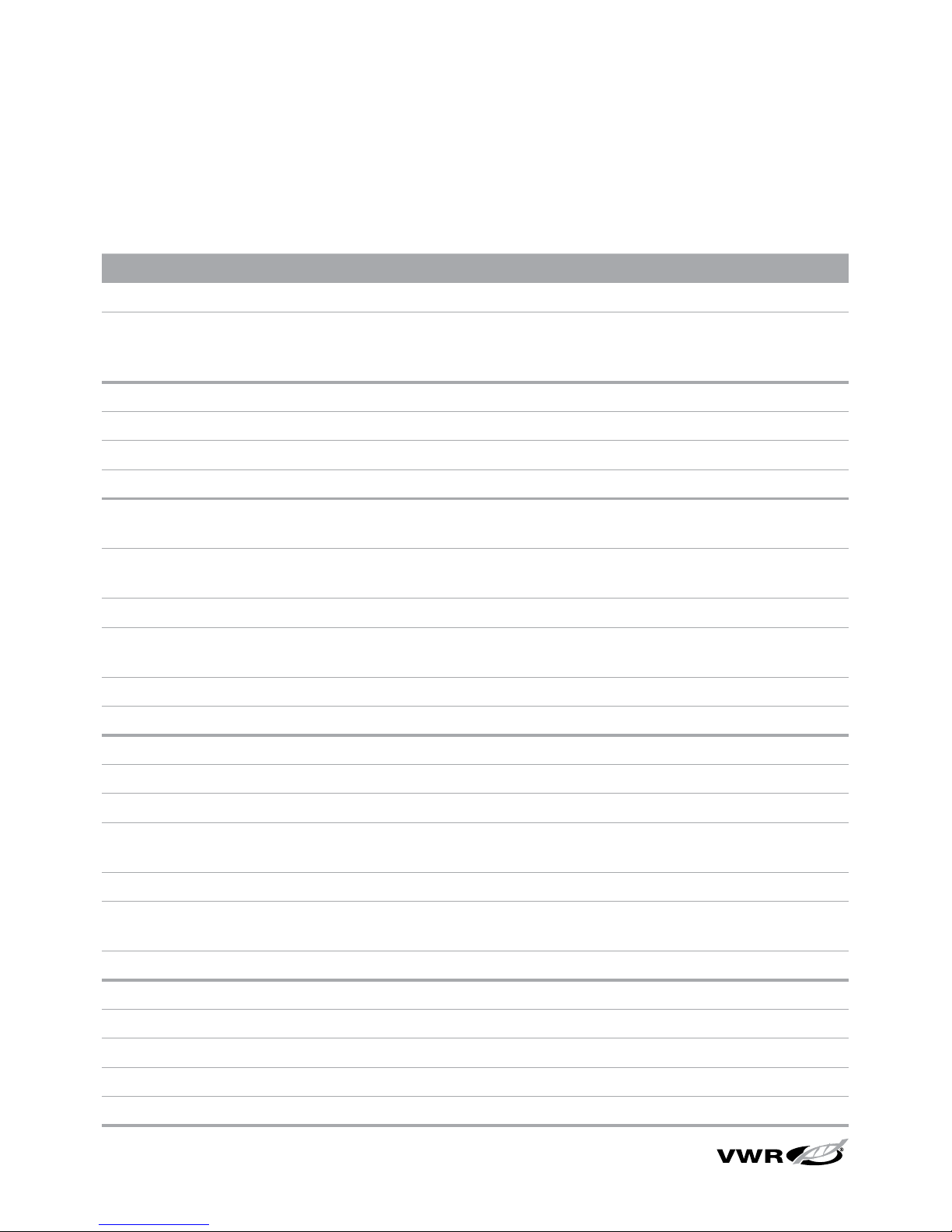

Setup Menu Table

The following table is for the complete line of sympHony meters. Some sympHony

meters may not include all of the options listed in this table. Refer to Appendix A

for additional information on the special setup menu features.

Top Line Middle Line Bottom Line Setup Menu Description (default setting, method specific)

PH rES 0.1, 0.01, 0.001 pH measurement resolution (0.01, yes)

PH bUF USA, EUr0 pH buffer set for automatic buffer recognition during calibration,

USA buffers are 1.68, 4.01, 7.00, 10.01, 12.46 and EUrO buffers are

1.68, 4.01, 6.86, 9.18 (USA, yes)

ISE rES 1, 2, 3 ISE measurement resolution in significant figures (1, yes)

ISE UnIt m, mgL, PEr, PPb, n0nE ISE measurement units (PPb, yes)

ISE rAng L0w, HIgH ISE concentration range for calibration stability criteria (HIgH, yes)

ISE nLIn AUt0, 0FF ISE automatic blank correction for low-level calibration (AUt0, yes)

C0nd tC 0FF, LIn, nLF Conductivity temperature compensation type, LIn is for linear, nLF is

for non-linear pure water samples (LIn, yes)

C0nd C0EF 0.0 to 10.0 Conductivity temperature compensation coefficient in % change in

conductivity per °C, appears if LIn was selected for tC (2.1, yes)

C0nd tdSF 0.00 to 10.0 Conductivity TDS factor value (0.49, yes)

C0nd CELL 0.001 to 199.0 Conductivity default cell constant value for automatic conductivity

calibration mode (0.475, yes)

C0nd trEF 15, 20, 25 Conductivity reference temperature (25, yes)

C0nd tyPE Std, 1, 2, 3, 4, 5, 6, 7 Conductivity cell type and selectable range (Std, yes)

d0 rES 0.1, 1 % sat DO % saturation measurement resolution (0.1, yes)

d0 rES 0.01, 0.1 mg/L DO mg/L measurement resolution (0.01, yes)

d0 bAr AUt0, mAn DO barometric pressure compensation type (AUt0, yes)

d0 PrES 450.0 to 850.0 DO manual barometric pressure compensation value, appears if

mAn was selected for bAr (760.0, yes)

d0 SAL AUt0, mAn DO salinity correction type (AUt0, yes)

d0 SALF 0 to 45 DO manual salinity correction value, appears if mAn was selected

for SAL or a DO meter without a conductivity mode is used (0, yes)

d0 CALt AIr, H20, mAn, SEt0 DO calibration type (AIr, yes)

dUE PH 0 to 9999 pH calibration alarm value in hours, 0 is off (0, yes)

dUE 0rP 0 to 9999 ORP calibration alarm value in hours, 0 is off (0, yes)

dUE ISE 0 to 9999 ISE calibration alarm value in hours, 0 is off (0, yes)

dUE C0nd 0 to 9999 Conductivity calibration alarm value in hours, 0 is off (0, yes)

dUE d0 0 to 9999 DO calibration alarm value in hours, 0 is off (0, yes)

Meter Setup

13

sympHony™ Meter User Guide

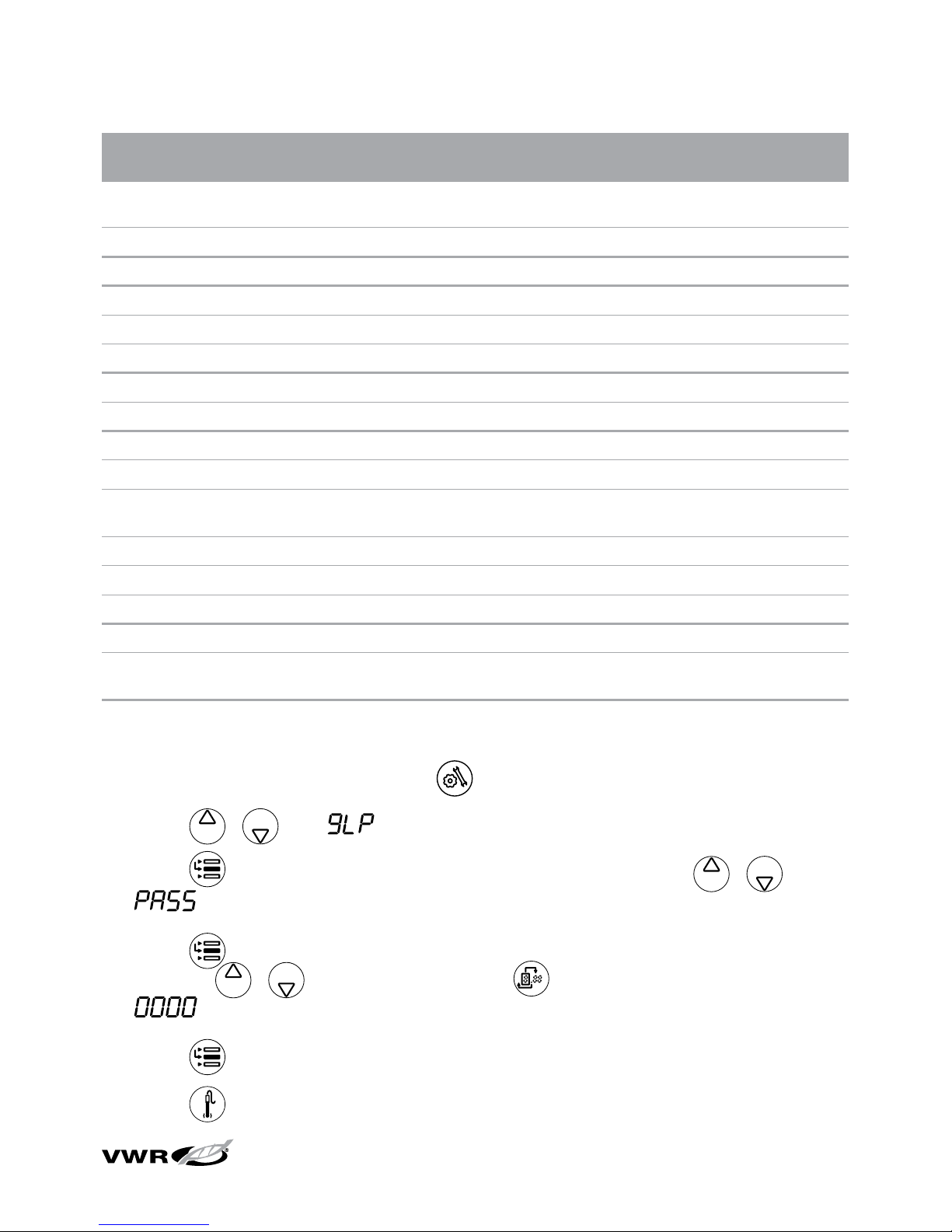

Top Line Middle Line Bottom Line Setup Menu Description

(default setting, method specific)

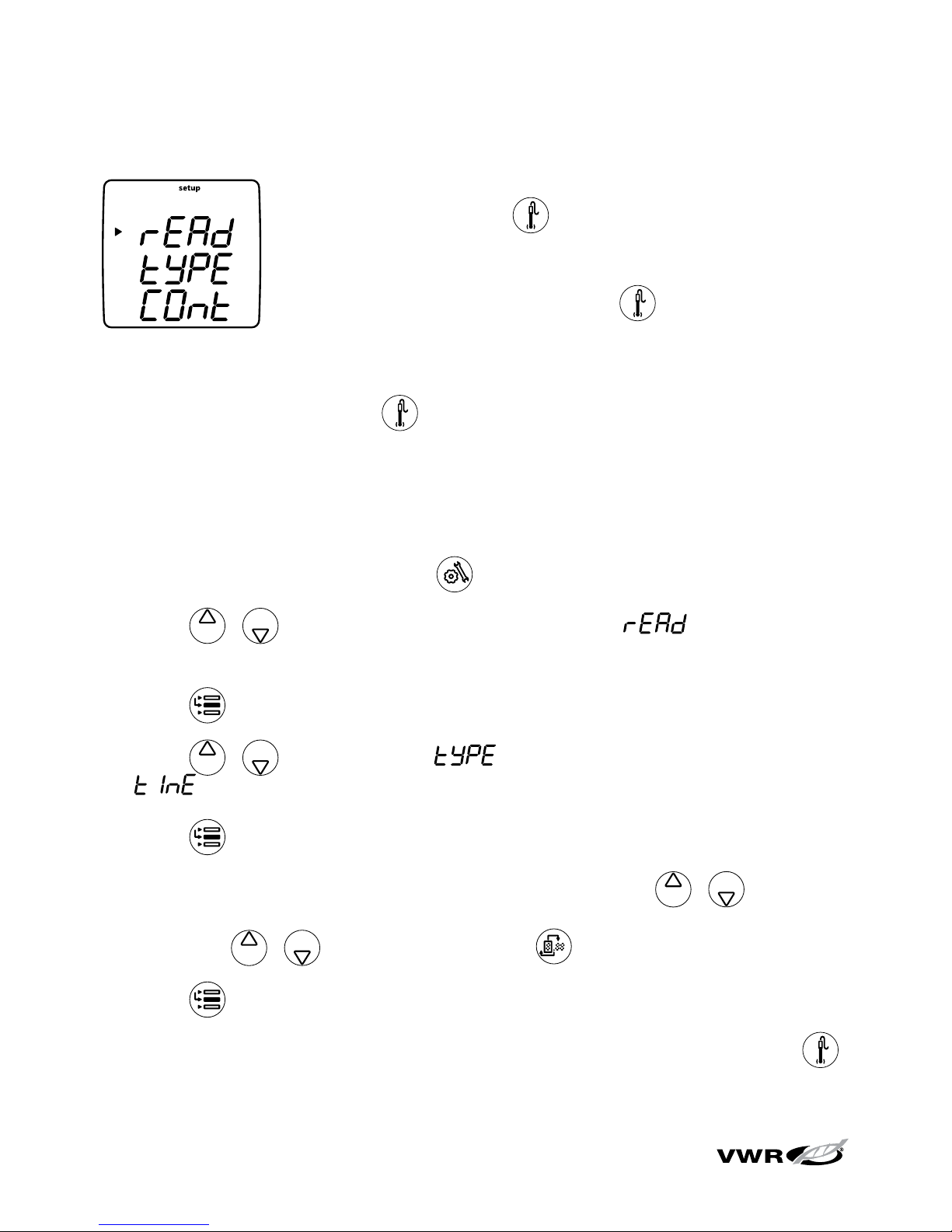

rEAd tyPE AUt0, tImE, C0nt, Measurement read type as AUTO-READ, timed or continuous

(AUt0, yes)

rEAd tInE 00:05 to 99:59 Timed measurement value in minutes and seconds (01:00, yes)

L0g dEL n0, YES Delete datalog after download option (n0, yes)

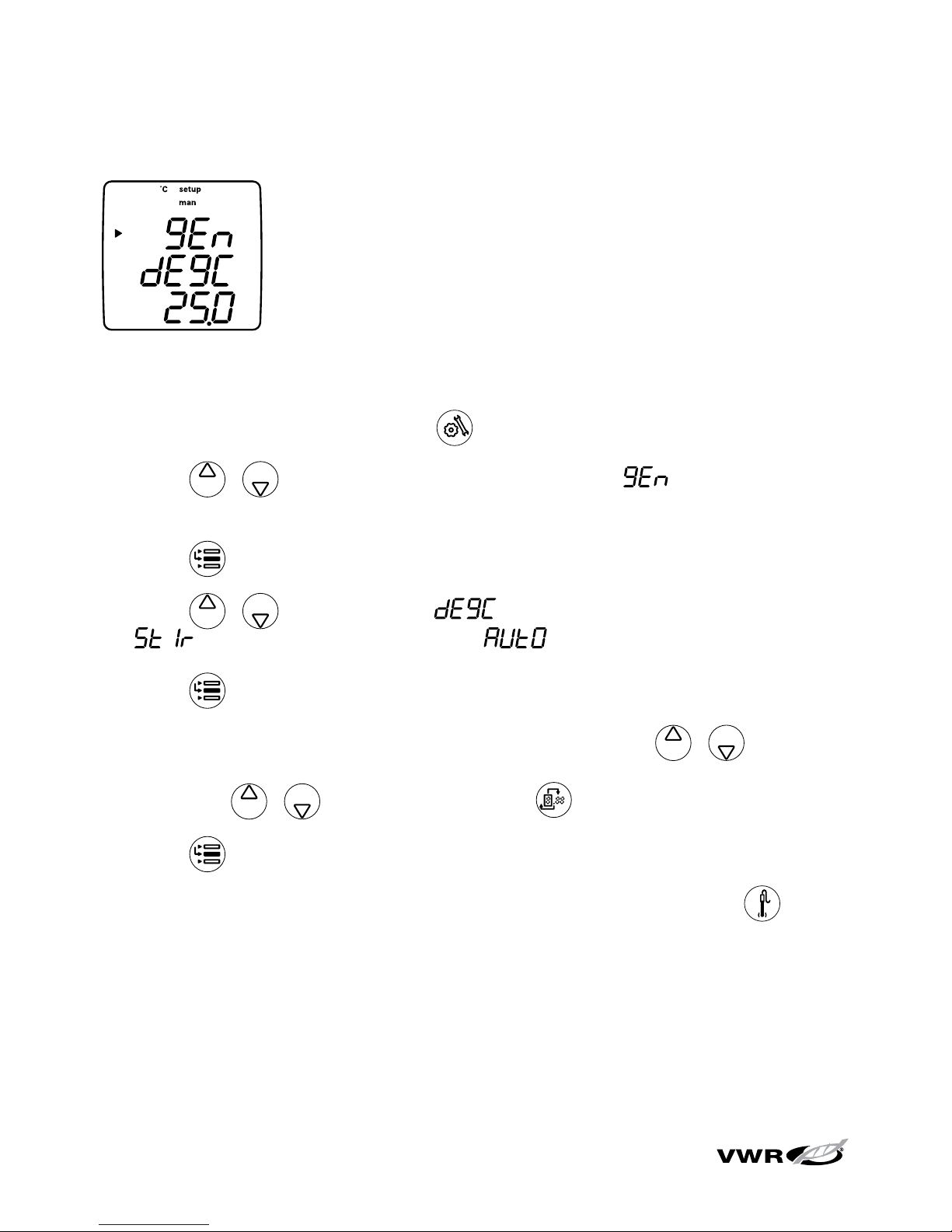

gEn dEgC -5.0 to 105 Manual temperature value (25.0, yes)

gEn StIr 0FF, 1, 2, 3, 4, 5, 6, 7 Stirrer speed – benchtop meters only (4, yes)

gEn AUt0 0n, 0FF Automatic meter shutoff option (0n, no)

gLP SEt 0FF, 0n GLP option, GLP feature enables or disables methods (0FF, no)

gLP PASS 0000 to 9999 Password entry (0000, no)

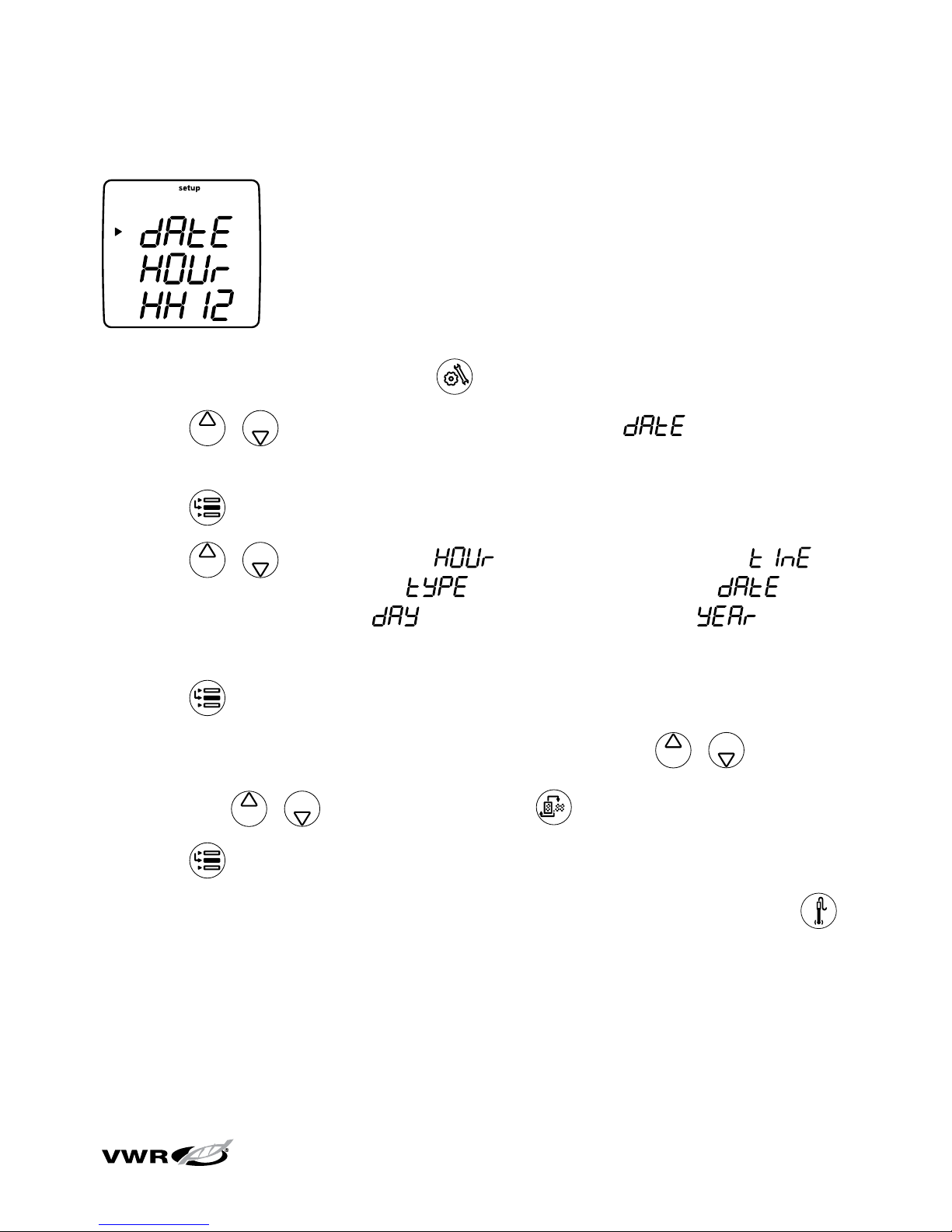

dAtE H0Ur HH00 to HH23 Hour setting (HH12, no)

dAtE tInE mm00 to mm59 Minute setting (mm00, no)

dAtE tYPE mdY, dmY Displayed date format as month, day, year or day, month, year

(mdY, no)

dAtE YEAr 2000 to 2099 Year setting (2004, no)

dAtE dAtE mm01 to mm12 Month setting (mm01, no)

dAtE dAY dd01 to dd31 Day of the month setting (dd01, no)

r232 bAUd 1200, 2400, 4800, 9600 Baud rate setting (9600, no)

r232 0UtF Prnt, C0mP Output format for printer or computer, C0mP format is comma

delimited (Prnt, no)

Enabling or Disabling the Setup Menu Password

1. In the measurement mode, press .

2. Press

/ until is displayed on top line.

3. Press

to move the arrow icon to the middle line and press / until

is displayed.

4. Press

to move the arrow icon to the bottom line and enter a password by

pressing / to enter each digit and to move to the next digit. Enter

to disable the password and allow unlimited access to the setup menu.

5. Press

to move the arrow icon to the top line.

6. Press

to exit the setup menu and return to the measurement mode.

Meter Setup

14

sympHony™ Meter User Guide

General Menu Settings

• Manual Temperature controls temperature compensation

when no temperature sensor is attached to the meter.

• Stirrer Speed sets the stirrer speed from 1 (slowest)

through 7 (fastest) and off – benchtop meters only.

• Automatic Shutoff controls whether the instrument will

automatically turn off after 20 minutes without a keypress.

1. In the measurement mode, press .

2. Press / to scroll through the setup menu until is displayed on the

top line.

3. Press to accept the selection and move the arrow icon to the middle line.

4. Press / to scroll through for the manual temperature setting,

for the stirrer speed setting and for the automatic shutoff setting.

5. Press to accept the selection and move the arrow icon to the bottom line.

6. To s cr ol l th ro ug h a li st o f op ti on s on t he b ott om l in e, p re ss / until the

desired option is displayed. To enter a numeric value for an option on the bottom

line, press / to adjust each digit and to move to the next digit.

7. Press to accept the selection and move the arrow icon to the top line.

8. Repeat steps 3 through 7 to change another general setting or press to

return to the measurement mode.

Meter Setup

15

sympHony™ Meter User Guide

Time and Date Settings

• The date and time settings are saved with the datalog

points and are included with the data that is sent to a

computer or printer.

• The date format can be set to read month, day, year or

day, month, year according to the user’s preference.

1. In the measurement mode, press .

2. Press / to scroll through the setup menu until is displayed on

the top line.

3. Press to accept the selection and move the arrow icon to the middle line.

4. Press / to scroll through for the current hour setting,

for the current minute setting, for the date format setting, for

the current month setting, for the current day setting and for the

current year setting.

5. Press to accept the selection and move the arrow icon to the bottom line.

6. To s cr ol l th ro ug h a li st o f op ti on s on t he b ott om l in e, p re ss / until the

desired option is displayed. To enter a numeric value for an option on the bottom

line, press / to adjust each digit and to move to the next digit.

7. Press to accept the selection and move the arrow icon to the top line.

8. Repeat steps 3 through 7 to change another time and date setting or press

to return to the measurement mode.

Meter Setup

16

sympHony™ Meter User Guide

AUTO-READ™, Continuous or Timed Measurement Settings

• In the AUTO-READ mode, the meter starts taking

a measurement when is pressed. Once the

measurement is stable, the display freezes and the data is

logged and printed. The AUTO-READ mode also controls

the stirrer. The stirrer starts when is pressed and stops

when the measurement becomes stable.

• In the continuous mode, the meter is constantly taking measurements and

updating the display. Press to log and print a measurement in this mode.

• In the timed mode, the meter is constantly taking measurements and updating

the display. The meter logs and prints the measurement at the selected

time interval.

1. In the measurement mode, press .

2. Press / to scroll through the setup menu until is displayed on

the top line.

3. Press to accept the selection and move the arrow icon to the middle line.

4. Press / to scroll through for the measurement read type and

for the timed reading interval.

5. Press to accept the selection and move the arrow icon to the bottom line.

6. To s cr ol l th ro ug h a li st o f op ti on s on t he b ott om l in e, p re ss / until the

desired option is displayed. To enter a numeric value for an option on the bottom

line, press / to adjust each digit and to move to the next digit.

7. Press to accept the selection and move the arrow icon to the top line.

8. Repeat steps 3 through 7 to change another measurement setting or press

to return to the measurement mode.

Meter Setup

Loading...

Loading...