Page 1

O

PERATOR’S MANUAL

G

LASSWARE

W

ASHERS

Page 2

Page 3

Copyright © 2017 VWR International. All marks herein are used under license.

All brand or product names mentioned may be trademarks or registered trademarks of their respective

companies.

Part Number 100002431

Rev 007, 06/17

Original Instructions

The U.S. English version of this document is the original instructions.

All other languages are a translation of the original instructions.

VWR International

Website

This Glassware Washer Operator’s Manual contains confidential and proprietary information of VWR

International and may be used only by a recipient designated by and for purposes specified by VWR

International.

Reproduction of, dissemination of, modifications to, or the creation of derivative works from this

Glassware Washer Operator’s Manual, by any means and in any form or manner, is expressly prohibited,

except with the prior written permission of VWR International. Permitted copies of this document must

retain all proprietary notices contained in the original.

The information in this document is subject to change without prior notice. Always confirm with VWR

International that you are using the most current version of this document. VWR International is free to

modify any of its products and services, in any manner and at any time, notwithstanding the information

contained in this document.

THE CONTENTS OF THIS DOCUMENT SHALL NOT CONSTITUTE ANY WARRANTY OF ANY KIND,

EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE OR GIVE RISE TO ANY

LIABILITY OF VWR INTERNATIONAL, ITS AFFILIATES OR ITS SUPPLIERS.

The terms and conditions governing the use of this Glassware Washer Operator’s Manual shall consist of

those set forth in written agreements with VWR International.

Radnor Corporate Center

Building One

Suite 200

PO Box 6660

100 Matsonford Road

Radnor, PA 1987-8600

http://us.vwr.com

Rev 007, 06/17 i

© VWR2017

Page 4

Important Symbols

WARNING! INJURY OR EVEN

DEATH MAY RESULT IF A

RECOMMENDATION MARKED

WITH THIS SYMBOL IS NOT

HEEDED.

CRUSH HAZARD. KEEP HANDS

CLEAR WHEN OPERATING DOOR.

Safety Warnings

Always verify that the electric service and other utilities match the unit’s requirements before

connecting to power.

Always read the instruction manual before operating the washer.

Always wear safety glasses when using glass flasks.

Always practice team lifting when moving heavy equipment.

Always ensure that only an authorized technician services the washer.

Always assume that external and internal parts may be very hot. Utilize personal protective

equipment to avoid burns.

Never clean with solvents. Use mild detergent and water only.

Never operate the unit without all covers in place.

Never use with toxic, corrosive, flammable or organic materials unless special precautions are in

place to prevent injury to personnel or damage to equipment.

ELECTRIC SHOCK DANGER!

USE APPROPRIATE CAUTION

TO AVOID INJURY OR DEATH.

BURN DANGER! POTENTIALLY

HOT SURFACE. USE

APPROPRIATE CAUTION.

DO NOT STORE FLAMMABLE

MATERIALS IN CHAMBER.

WEAR SAFETY GLASSES.

CORROSIVE CHEMICAL. WEAR

SUITABLE GLOVES, SAFETY

GLASSES, AND PROTECTIVE

CLOTHING.

PROPERTY CAUTION! TO PREVENT

DAMAGE TO CHAMBER EQUIPMENT AND/OR LOAD, ADHERE TO

PROCEDURES MARKED BY THIS

SYMBOL.

PRACTICAL OPERATING TIP.

THESE RECOMMENDATIONS

STREAMLINE UNIT OPERATION

AND PREVENT COMMON

OPERATOR ERRORS.

EXPLOSIVE MATERIALS HAZARD!

KEEP OBJECTS AWAY FROM HEAT.

ii Rev 007, 06/17

© VWR 2017

Page 5

Warranty Information

VWR washers are warranted by VWR International to be free of defects in material and workmanship when operated

under normal conditions as specified in the instructions provided in this manual. Please take this opportunity to locate

the serial tag on your new VWR and record the information below for future reference. VWR International also

recommends that you complete and return your unit’s warranty registration card.

Model Number

Serial Number

Part Number

Limited Warranty

VWR International (the “Company”) shall warrant each of its products against defects in material or workmanship for a

period of 24 months from the date of shipment provided that the product is used in a reasonable manner under

appropriate conditions and consistent with the applicable operating instructions.

The obligation of the Company shall be, at its option, to repair or replace, without charge any parts that prove to be

defective within the warranty period, if the purchaser notifies the Company promptly in writing of such defect. No

product shall be returned to the Company without prior approval of the Company.

This limited warranty shall cover the costs of parts and labor to repair or replace all defective product(s) at the Seller’s

factory. For all products installed by the Company and located within the Company service travel areas, this warranty

shall cover transportation charges to ship the product to and from the Company’s factory and/or the costs of travel,

room and board if the Company’s employees conduct repair at the Buyer’s location. In lieu of repair or replacement at

the Company’s factory, the Company may, in its discretion, authorize a third party to perform the repair or replacement

at the Buyer’s location, and at the Company’s sole expense.

The Company shall not be responsible for labor charges payable with respect to persons other than Company

employees. Replacement or repair of parts pursuant to this warranty shall not in any way extend the original warranty

period. The Company shall not be responsible for any unauthorized repairs, replacements or product modifications, nor

will it be responsible for any product failures resulting from such unauthorized repairs, replacements or product

modifications negligently or otherwise made by persons other than Company employees or authorized representatives

of the Company. The buyer shall assume transportation charges to ship the product to and from the Company’s factory

and the costs of travel, room and board if the Company’s employees conduct repair at the Buyer’s location within the

warranty period if the product was not installed by the Company’s and/or is not located within the Company’s service

travel areas.

THE COMPANY DOES NOT MAKE AND EXPRESSLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, WITH

RESPECT TO THE SALE, INSTALLATION, DESIGN OR USE OF ITS PRODUCTS. ADDITIONALLY, THE

COMPANY SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OF OR

ANY DEFECTS IN ITS PRODUCTS.

The Company’s employees are available to provide general advice to customers concerning the use of the Company’s

products; however, oral representations are not warranties with respect to particular products or their uses and may not

be relied upon if they are inconsistent with the relevant product specifications for the items set forth herein.

Notwithstanding the above, the terms and conditions set forth in the Company’s formal sales contracts shall be

controlling and supersede any inconsistent terms contained herein, and any changes to such contracts must be made

in writing and signed by an authorized executive of the Company.

WARNING! THE DISPOSAL AND/OR EMISSION OF SUBSTANCES USED IN CONNECTION WITH

THIS EQUIPMENT MAY BE GOVERNED BY VARIOUS FEDERAL, STATE OR LOCAL

REGULATIONS. ALL USERS OF THIS EQUIPMENT ARE URGED TO BECOME FAMILIAR WITH

ANY REGULATIONS THAT APPLY IN THE USERS AREA CONCERNING THE DUMPING OF

WASTE MATERIALS IN OR UPON WATER, LAND OR AIR AND TO COMPLY WITH SUCH

REGULATIONS.

Rev 007, 06/17 iii

© VWR 2017

Page 6

iv Rev 007, 06/17

© VWR 2017

Page 7

Contents

Important Symbols ............................................................................................................................................... ii

Safety Warnings ................................................................................................................................................... ii

Warranty Information .......................................................................................................................................... iii

Contents ...................................................................................................................... v

Introduction ................................................................................................................. 1

Overview .............................................................................................................................................................. 1

Key Features ................................................................................................................................................... 1

Installation and Startup ............................................................................................... 3

Initial Inspection ................................................................................................................................................... 3

Service Connections ............................................................................................................................................ 4

Required Plumbing Supplies ................................................................................................................................ 4

Dimensional Requirements .................................................................................................................................. 5

Undercounter Washer Site Preparation ............................................................................................................... 5

Water Connections .............................................................................................................................................. 5

Electrical Connection ........................................................................................................................................... 6

Freestanding Washer Site Preparation ................................................................................................................ 6

Approximate Rear Connection Locations ............................................................................................................. 7

Washer Setup ...................................................................................................................................................... 7

Washer Components ................................................................................................ 11

On / Off Power Switch ........................................................................................................................................ 11

Handle Cover ..................................................................................................................................................... 12

Ventilation Port ................................................................................................................................................... 12

Control Panel ..................................................................................................................................................... 12

Internal Components .......................................................................................................................................... 13

Detergent / Neutralizer Dispenser ................................................................................................................. 13

Spray Arms .................................................................................................................................................... 14

Filtration ......................................................................................................................................................... 14

Racks ............................................................................................................................................................ 15

Optional Spindle Racks ................................................................................................................................. 15

Operation .................................................................................................................. 17

Cycle Overview .................................................................................................................................................. 17

Pre-Washes ................................................................................................................................................... 17

Rev 007, 06/17 v

© VWR2017

Page 8

Contents

V

Main Wash .................................................................................................................................................... 17

Rinses ........................................................................................................................................................... 17

Drying ............................................................................................................................................................ 18

Detergent Recommendations ............................................................................................................................ 18

Select Dosage ............................................................................................................................................... 18

Before Starting a Cycle ...................................................................................................................................... 18

Starting a Cycle .................................................................................................................................................. 18

Control Panel ................................................................................................................................................. 19

Selecting a Program ...................................................................................................................................... 20

Heavy Wash “Time Saver” Option ................................................................................................................. 20

Stopping or Changing a Program .................................................................................................................. 20

Option/Set Navigation ........................................................................................................................................ 21

Drying Options ............................................................................................................................................... 21

Delayed Start ................................................................................................................................................. 21

Set Time ........................................................................................................................................................ 21

Start/Stop ...................................................................................................................................................... 22

Pausing a Cycle ................................................................................................................................................. 22

WR

Safety Features ......................................................................................................... 23

Overfill Protection ............................................................................................................................................... 23

Door Switch ........................................................................................................................................................ 23

Maintenance ............................................................................................................. 25

Daily Maintenance ............................................................................................................................................. 25

Coarse Filter .................................................................................................................................................. 25

Fine Filter ...................................................................................................................................................... 25

Reassembling Filters ..................................................................................................................................... 26

Weekly Maintenance .......................................................................................................................................... 26

Reassembling Racks ......................................................................................................................................... 27

Unheated Storage .............................................................................................................................................. 27

Cleaning ............................................................................................................................................................. 28

Appendix A: Troubleshooting .................................................................................... 29

Appendix B: Fault Indicators ..................................................................................... 31

vi Rev 007, 06/17

© VWR 2017

Page 9

Overview

Key Features

Chapter

1

Introduction

VWR glassware washers offer extreme durability with stainless steel chambers, easyto-use touch-based controls, six cycle program selections, selectable wash

temperature, deionized (DI) water final rinsing

saving settings.

Equipped with built-in door dispensers for detergent and liquid neutralizer, all models

are available in the undercounter configuration, as well as freestanding and mobile

configurations. A wide variety of optional specialty baskets and inserts are available to

facilitate washing test tubes, Petri dishes, small graduated cylinders, bottles and other

loads that require special consideration. Most models can also accommodate optional

spindle racks for more effective cleaning of narrow-neck glassware such as volumetric

and Erlenmeyer flasks.

1

and a variety of time- and energy-

Digital microprocessor controller with display.

Five selectable wash cycle settings.

Separate wash and drain pumps.

Optional final deionized water rinses for some cycles.

Triple filtration system to protect plumbing and pumps from broken glass and

debris.

Dual drying fans for optimal drying.

1

Deionized water rinsing is not available on some units.

Rev 007, 06/17 1

© VWR2017

Page 10

Introduction

V

WR

2 Rev 007, 06/17

© VWR 2017

Page 11

Initial Inspection

Your VWR glassware washer was carefully packed and thoroughly inspected before

leaving the factory. However, in the unlikely event that shipping damage has occurred,

retain all packing material and contact your freight carrier immediately.

DO NOT ACCEPT damaged shipments from a carrier without a signed notification of

damages.

Upon receiving your shipment, inspect all contents of your equipment for damage.

Check packing material for small accessory items. Remove all packing material

carefully and inspect for concealed shipping damage. Inspect the inside of the

machine for any visible damage. If concealed damage or loss is discovered, contact

the freight carrier immediately.

paperwork intact until a written report is obtained.

Note: VWR International will cooperate in the matter of collecting your claim, but is not

responsible for the collection or free replacement of the material. When possible, replac ement

parts will be shipped and invoiced to you, making them a part of your claim.

Installation and Startup

2

Keep all contents, packing material and related

Chapter

2

2

“Concealed damage or loss” refers to damage or loss that does not become apparent until the merchandise has been

unpacked and inspected. Should damage or loss be discovered, you may make a written request for inspection by the carrier's

agent within 15 days of the delivery date. You may then file a claim with the freight carrier or VWR International, depending on

the terms of your shipment. If your shipment was “FOB Destination” file your claim with VWR International and include the

inspection report and any other supporting documents. If your shipment was “FOB Shipping Point” file your claim with the

freight carrier and include the inspection report and any other supporting documents.

Rev 007, 06/17 3

© VWR 2017

Page 12

Installation and Startup

V

Service Connections

PROPERTY CAUTION! ONLY QUALIFIED PERSONNEL FAMILIAR WITH LOCAL PLUMBING AND

ELECTRICAL CODES AND ORDINANCES SHOULD INSTALL THE WASHER. FOR A FIRST-TIME

INSTALLATION, ALL SITE PREPARATION WORK MUST BE COMPLETED BEFORE THE

WASHER CAN BE INSTALLED WITH FINAL UTILITY CONNECTIONS. IF THE NEW WASHER

REPLACES AN EXISTING UNIT, VERIFY THAT ALL PLUMBING AND ELECTRICAL

CONNECTIONS ARE PROPERLY SIZED AND LOCATED.

The service connections that you intend to use must meet the following requirements:

Requirement Specification

Tap Water Supply

(All Models)

Deionized Water Supply

(All Models Except H-1105)

WR

Minimum Flow Requirement:

3 gpm (11 lpm) @ 18 – 60 psig (124 – 414 kPa)

Although not required, hot water speeds water heat-up and decreases

cycle time. Hot water supply must not exceed 60 °C (140 °F)

Minimum Flow Requirement:

3 gpm (11 lpm) @ 18 - 60 psig (124 - 414 kPa)

Resistivity 1 M/cm

Although not required, installing a shutoff valve (not supplied) in the

water supply line at a readily accessible location will help facilitate

service of the unit.

Electrical Requirements

(All Models)

120 VAC, 1, 60 Hz, 15 A.

Installation Overvoltage Category II.

Main supply voltage fluctuations not to exceed ±10% of normal voltage.

This product is intended for indoor use in the following

Environmental Conditions

Altitudes up to 6500 ft (2000 m)

Temperatures from 5 to 40 °C (41 to 104 °F)

Maximum relative humidity of 80% for temperatures up to 31 °C (88 °F),

Required Plumbing Supplies

Your unit is supplied with rear-mounted PEX plastic hose with 3/8-inch brass

compression fittings

applicable). Various hose and compression adaptors will be provided for additional

water and plumbing needs. It is recommended that you install a shutoff valve at the

water supply connection. An appropriate fitting for connecting the supplied drain hose

to the drain system is also required.

3

for connection to your facility’s tap and DI water supplies (if

environmental conditions:

decreasing linearly to 50% relative humidity at 40 °C (104 °F).

3

Model UCW-VA00001 uses a compression fitting.

4 Rev 007, 06/17

© VWR 2017

Page 13

V

WR Installation and Startup

Dimensional Requirements

For all units, allow at least 26.5 inches of clearance in front of the unit for door

extension and at least two (2) inches of clearance on each side of the door. Prepare

an installation space or cabinet recess consistent with these and the other dimensions

as specified for your model.

Recommended cabinet recess dimensions for undercounter washers are shown

below.

34-1/2"

(876 mm)

25"

(635 mm)

24-1/8"

(613 mm)

Undercounter Washer Site Preparation

During undercounter washer installation, ensure that the water and electrical services

enter the cabinet recess within the shaded area shown below.

2 to 3-1/2”

(50-90 mm)

7 to 9”

(180-230 mm)

Rev 007, 06/17 5

© VWR 2017

Page 14

Installation and Startup

V

Water Connections

Plan the fitting connections and the route for water supply tubing from the washer to

your water supplies. Drill appropriately sized cabinet entry holes as required, keeping

within the shaded area pictured on the previous page. With the washer outside of the

cabinet recess, feed the water supply tubing through the cabinet hole(s) toward the

water source connectors. Route the unit’s drain hose toward a connection to your

facility’s main drain, but do not make any connections at this time.

For units requiring a DI water connection, use plastic or stainless fittings. Brass fittings

may corrode from DI water and are therefore not recommended.

Electrical Connection

WARNING! THE ELECTRICAL RECEPTACLE MUST BE PROPERLY GROUNDED AND COMPLY

WITH APPLICABLE PORTIONS OF NATIONAL AND LOCAL ELECTRICAL CODES. ALL WASHER

SERVICING SHOULD OCCUR WITH THE POWER CORD DISCONNECTED FROM POWER.

For convenience, the unit is provided with a prewired electrical cable and plug. Locate

or install a code-conforming electrical receptacle within reach of the washer’s supplied

cable. The electrical supply should be a dedicated circuit that is properly grounded

and equipped with an appropriately-sized breaker.

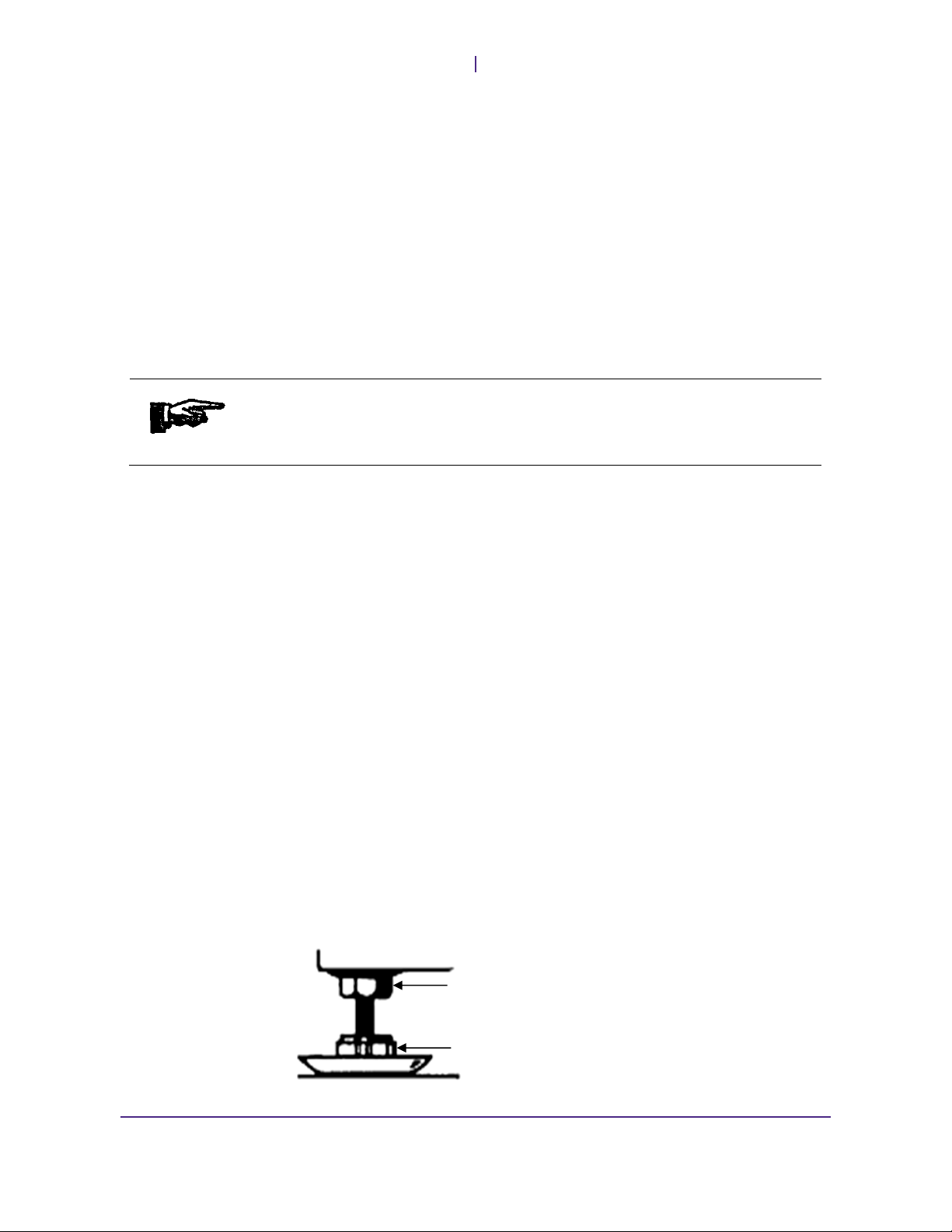

Drill a cabinet entry hole for the power cable. Refer to the image below:

WR

Shutoff

Valve

AC Receptacle

Hole for Power Cable

Your VWR glassware washer should not share a circuit with any other appliances.

Provide a local disconnect or switch to ensure safe maintenance access.

Freestanding Washer Site Preparation

For freestanding units, ensure that the water and electrical service connections have

sufficient slack. Excessive tension in water hoses strains fitting connections and can

cause host leakage and/or breakage.

Position the unit on a firm, level floor. Follow the instructions in the Washer Setup

section of this chapter to level and secure the unit.

6 Rev 007, 06/17

© VWR 2017

Page 15

V

WR Installation and Startup

Approximate Rear Connection Locations

Saddle

Drain Hose

Deionized (DI)

Water Inlet

(All models

except H-1105)

Tap Inlet

Note: Your unit may vary from the

image shown, depending on the

model.

Washer Setup

Your VWR glassware washer must be enclosed on the top and back, and on both

sides. The cabinet enclosure into which undercounter units are installed supplies this

protection. Freestanding and mobile units are wrapped with stainless steel panels.

To install your VWR glassware washer:

1. Connect the washer drain hose to your facility’s main drain, ensuring that the

“high-loop” configuration is preserved (as shown below).

The drain connection must conform to the following requirements:

No part of the drain hose should exceed 35 inches (90 cm) above

the bottom of the washer.

Rev 007, 06/17 7

© VWR 2017

Page 16

Installation and Startup

V

PRACTICAL OPERATING TIP. DRILL AN APPROPRIATELY SIZED CABINET ENTRY HOLE AS

REQUIRED TO REACH THE DRAIN CONNECTION. FEED THE SUPPLIED DRAIN HOSE

THROUGH THE CABINET HOLE TOWARD THE DRAIN CONNECTION AND CONNECT THE

DRAIN HOSE TO YOUR DRAIN.

2. Connect the washer to a tap water supply and tighten all connections

WR

The drain connection must be at least 20 inches (50 cm) above the

bottom of the washer.

The drain hose should extend no more than 10 feet (3 m).

Any joints or fittings must be 3/4-inch (18 mm) ID or larger.

Do not connect the drain hose directly to a floor well or its

equivalent as this could cause a siphoning action that could empty

the machine during cycles. Never connect the drain line to a check

valve.

Do not route the washer drain through a vent or air gap, as this may

impede flow during some drain phases. If the drain cannot be hardpiped, secure the drain hose over an open counter drain or floor

drain instead.

securely. If your unit is equipped with a DI water connection, connect the DI

water supply and tighten all connections securely.

3. Connect the unit to the appropriate electrical supply.

4. Test the unit for leaks before leveling and securing the washer in place.

To test for leaks:

Turn on the electrical power and water supplies.

Close and secure the door.

Select and operate a Daily Wash. This cycle executes both tap

water and DI water rinses (if applicable).

While the cycle is operating, carefully check all water supply and

drain connections to ensure that there are no leaks. Correct any

observed leaks before continuing.

5. Position the unit in its final location. For freestanding and mobile units, secure

the unit by depressing the caster break levers on the unit’s casters.

6. Adjust the leveling legs as required.

On undercounter units, leg height may be adjusted by using a 5/8-inch (16

mm) wrench. Any inclination must be ≤ 2 degrees. Use the locking nut to lock

your adjustments

Locking Nut

Foot / Slider

8 Rev 007, 06/17

© VWR 2017

Page 17

V

WR Installation and Startup

7. Secure the washer in its final location.

For undercounter units:

To prevent forward tilting when downward force is applied to the

open door, or when heavily loaded baskets are pulled outward, use

the supplied screws to fasten the washer to the cabinet. Secure the

washer to the cabinet using either option “A” or option “B” (one

screw on each side) as follows:

For freestanding and mobile units:

If your application creates a potential for forward tilting, use the

supplied Tip Guards or similar brackets to secure the washer’s rear

casters to the wall or floor.

Tip Guard

Position for

Casters Only

Mounting

Holes

Tip Guard Position

for Leveling Feet or

Casters

Rev 007, 06/17 9

© VWR 2017

Page 18

Installation and Startup

V

8. Install the optional Toe-Kick Plate, if desired. The Toe-Kick Plate attaches to

WR

the washer’s lower front to optimize appearance, but is not required for

operation of your unit.

To install the Toe-Kick Plate, position each of the two Plate Support Brackets

inward or outward to the desired depth (pulling its catch inward to release the

bracket). Then, simply hook the Toe-Kick Plate on to the front of the bracket.

Catch

Toe-Kick Plate

Plate Support Bracket

10 Rev 007, 06/17

© VWR 2017

Page 19

On / Off Power Switch

Ventilation Port

Note: Your unit may vary from the image shown, depending on the model.

On / Off Power Switch

Chapter

3

Washer Components

Handle Cover

Open your washer’s door to view the On/Off power switch and

control panel. Pushing down on the On/Off power switch will turn the

washer on and off. When on, the unit will energize and the control

panel indicator will illuminate.

On / Off Power Switch Control Panel

Rev 007, 06/17 11

© VWR 2017

Page 20

Washer Components

V

Handle Cover

To unlatch the door, insert your hand, palm up, into the handle cover and pull the latch

forward. When closing the door, push the door closed firmly to reactivate the latch. A

switch within the door handle detects when the door is opened.

Ventilation Port

During the drying phase, fan-circulated air exhausts from this port. Avoid obstructing

this port during washer operation.

Control Panel

VWR glassware washers are equipped with a user-friendly panel of touch-based

controls and indicator lights, located on the upper ledge of the door. Note that

operating the control panel requires a light touch of the fingertip rather than a hard

push.

WR

1. Navigation button < (left)

2. Navigation button > (right)

3. Option/Set

4. Display

5. Rinse Aid Indicator

6. Salt Indicator

4

7. Start/Stop

Note: For descriptions of available cycle programs, please see the Operation section of this

manual (i.e., Chapter 4).

4

Salt indicator functionality not available on all units.

12 Rev 007, 06/17

© VWR 2017

Page 21

V

WR Washer Components

Internal Components

Upper Spray Arm

Lower Spray Arm (All Models)

Coarse Strainer

Filter Screen

Prewash Detergent

Compartment

Detergent Door Latch

Detergent

Compartment Cover

Neutralizer / Rinse

Aid Cover

Main Wash Detergent

Compartment

Rev 007, 06/17 13

© VWR 2017

Page 22

Washer Components

V

Detergent / Neutralizer Dispenser

Spray Arms

During the Pre-Wash, Main Wash and Rinse phases of each cycle, these rotating

nozzles shower the underside of the load with circulating water.

Filtration

Coarse Strainer

This strainer removes large debris items from water circulation. Check and clean it

regularly to prevent obstructions to water flow. The strainer rests inside the Fine Filter

Basket.

Filter Screen

WR

The Detergent Door Latch opens the spring-loaded Detergent Door when

pressed. After detergent filling, snap the door closed.

The Pre-Wash and Main Wash detergent compartments can be filled with

detergent according to preference. During cycles, any detergent loaded into

the Pre-Wash compartment dissolves passively into the chamber early in the

cycle. The Detergent Door later opens automatically at the start of the Main

Wash phase, emptying the Main Wash compartment.

If neutralizer is desired, open the Neutralizer Dispenser latch and pour

neutralizer into the well to fill the dispenser. The dispenser injects a metered

dose of neutralizer into the chamber during the penultimate Rinse phase.

This filter helps remove smaller particles from the water circulation path. Check and

clean it regularly to prevent obstructions to water circulation. The filter is fastened to

the base of the washer chamber by the Fine Filter Basket, which is hand-screwed into

place.

14 Rev 007, 06/17

© VWR 2017

Page 23

V

WR Washer Components

Racks

Lower and upper spray arms dispense tap and deionized5 water upward onto

glassware loaded in standard VWR open racks.

Standard open racks provide ample loading space for glassware, specialty racks,

baskets and inserts.

Optional Spindle Racks

VWR washer models UCW-VA20001, UCW-VA20101, UCW-VA30001,

UCW-VA30101, VSW-VA21001, and VSW-VA22001 can also accept optional spindle

racks, which provide an effective means to thoroughly wash the interiors of narrowneck glassware such as volumetric and Erlenmeyer flasks. Ensure that spindles are

inserted through the deck plates in the forward position.

Use forward position

As illustrated below, optional spindle racks must provide proper “boot sealing” and

therefore cannot be intermixed with standard open racks:

Spray Tube

Flask

Support

Spring Clip

Optional Spindle Racks Optional Tall Spindle Rack

Boot

When using spindle racks, the height of each plastic flask support must be set to

ensure that the spray tube does not touch the bottom of the inverted glassware

positioned above it. Do this by squeezing and then repositioning the spring clip.

5

Deionized water is available on models UCW-VA10001, UCW-VA10101, UCW-VA20001, UCW-VA20101, UCW-VA30001,

UCW-VA30101, VSW-VA11001, VSW-VA21001, and VSW-VA22001 only.

Rev 007, 06/17 15

© VWR 2017

Page 24

Washer Components

V

If your unit is equipped with optional spindle racks, check the rack collar gap on each

rack before using it for the first time and adjust if necessary. The gap should be

approximately the thickness of a postcard.

GAP

WR

RUBBER

BOOT

SET

SCREW

COLLAR

To adjust the gap, loosen the collar’s setscrew and move the collar up or down to

achieve proper gap. Re-tighten the setscrew before using the rack.

16 Rev 007, 06/17

© VWR 2017

Page 25

Cycle Overview

Your VWR glassware washer allows you to select and customize a variety of cycle

phases to design a cycle best suited for your application. In the Main Wash and

Heated Rinse phases, an inline heating element heats water to a programmed

temperature.

PRE-

WASHES

Overall time to complete a cycle varies depending on the cycle and control panel

functions selected, and the facility’s water temperature. Although not required, hot

source water speeds water heat-up and dry time, decreasing overall cycle time.

Note: On some program cycles, not all of the phases are utilized. DI Water Rinse phases do

not apply to models UCW-VA00001 and UCW-VA00101.

Pre-Washes

Operation

6

Cycles then proceed through the following sequence of phases:

MAIN

WASH

TAP WATER

RINSE(S)

OPTIONAL DI

WATER RINSE

Chapter

4

DRYING

PHASE

In Pre-Wash phases, the chamber sump well fills with tap water and the circulation

pump activates to wet down the load from the rotating spray arms and from the

spindles, if equipped with an optional spindle rack.

Main Wash

The chamber fills with tap water, which is heated to the temperature setpoint. At the

start of the Main Wash phase, the detergent compartment cover hinges open to

introduce detergent. The load is bathed with recirculating heated water. The Main

Wash phase concludes by draining all water from the chamber.

Rinses

During each rinse phase, water fills the chamber and then circulates over the load.

The final Rinse phase is heated to the temperature called for by the selected program

and option-button settings. If neutralizer is loaded, it is delivered into the chamber

during the Rinse phase(s). Rinsing concludes by draining all water from the chamber.

6

Heated-Phase durations are determined by the cycle program selected and the required water heat-up time. Therefore, total

cycle time is influenced by the source-water temperature and operator control selections.

Rev 007, 06/17 17

© VWR 2017

Page 26

Safety Features

V

Drying

During the Drying phase, two separate fans circulate and vent chamber air to speed

drying. Although not required, hot source water speeds water heat-up and dry time,

decreasing overall cycle time.

Detergent Recommendations

Use only detergents or wetting agents intended for use in glassware washers.

Note: Do not load detergent or neutralizer into the unit for Rinse cycles.

Select Dosage

Excessive neutralizer/rinse aid can lead to foam buildup. If your water is particularly

soft, you can dilute the rinse aid (e.g., 1 part rinse aid and 1 part water). Too much

neutralizer/rinse aid can cause streaks on glassware, while too little can result in

water stains.

Before Starting a Cycle

8. Open any required tap and/or deionized water supply shut-off valves, and turn

on any switch or circuit breaker supplying AC voltage to the washer.

WR

9. If optional spindle rack use is desired, remove both standard open racks and

10. Choose the basket and insert accessories appropriate for the type load you

11. Load objects with the concave side down to prevent items from protruding into

12. Load the Neutralizer/Rinse Aid Dispenser as desired. Close and latch the

13. Firmly push the washer door closed to latch it securely. Cycles will not begin

Starting a Cycle

14. Turn the washer on by pressing the On/Off power switch. The control panel’s

15. Search for cycle options by using the left and right arrow buttons.

16. After selecting a cycle option, select the desired program type by pressing the

replace them with upper and lower spindle racks, or with one tall spindle rack.

Note: The collar gap must be adjusted before the first use of a spindle rack.

will be washing (e.g., test tube baskets for test tubes).

the path of the spray arm(s).

Detergent Door when done.

until the door is latched.

display and indicators will energize.

control panel’s Option/Set button until the desired program is displayed. To

exit the Option/Set menu, cycle through until the Exit option is displayed;

touch the Option/Set button to select Exit.

17. Depending on which cycle is selected, you will see options to delay the start

of a cycle, set long or short drying times, set a time for a program (only

available in the Time Program selection) or change the temperature to a lower

setting (only available in the Heavy Wash selection).

18 Rev 007, 06/17

© VWR 2017

Page 27

V

WR Basic Operation

18. To begin the cycle, press the Start/Stop button. The section of the control

panel that displays the selected cycle’s time will begin to flash. It will continue

flashing until the door is closed.

19. To stop or cancel an active cycle, gently touch and hold the Start/Stop button

for three seconds.

Control Panel

1. Navigation button < (left)

2. Navigation button > (right)

3. Option/Set

4. Display

5. Rinse Aid Indicator

6. Salt Indicator

7

7. Start/Stop

7

Salt indicator functionality not available on all units.

Rev 007, 06/17 19

© VWR 2017

Page 28

Safety Features

V

Selecting a Program

WR

Use the left and right arrow buttons in addition to the Option/Set button to cycle

through the available programs until the desired program is displayed.

a. Normal Wash. Select for normally soiled loads.

b. Rinse. Select to rinse loaded items that you are not yet ready to wash.

c. Time Program. For lightly to heavily soiled loads, depending on selected

time. Longer time provides for a more thorough wash.

d. Heavy Wash. Select for heavily soiled loads.

e. Daily Wash. Select for daily washing.

Heavy Wash “Time Saver” Option

Heavy Wash is the only cycle selection that allows the user to program the wash at a

different temperature. By selecting the Time Saver option through the Option/Set

menu, the temperature of the wash cycle is reduced to 55 °C (as opposed to the

default 70 °C).

Stopping or Changing a Program

If a program needs to be changed during an active cycle, open the door and press

and hold Start/Stop for three seconds. Add more detergent if the lid on the detergent

dispenser has opened. Then choose a new program, press Start/Stop and close the

door.

20 Rev 007, 06/17

© VWR 2017

Page 29

V

WR Basic Operation

Option/Set Navigation

Press Option/Set and then the left and right navigation buttons to select an option for

a wash cycle. Confirm your selection by pressing Option/Set.

Drying Options

Through the Option/Set menu on a selected cycle, a wash cycle can be programmed

to have either a long or short drying time. This selection determines how long the dual

fans will run after a wash cycle is completed.

Indicator Light

When a drying option is set as Long, the white indicator light on the Right Arrow

Button will light up and stay lit during the duration of the cycle.

Delayed Start

Through the Option/Set menu on a selected cycle, a wash cycle’s start time can be

delayed by up to 24 hours, selected in increments of one hour.

Press the left and right navigation buttons to select the desired amount of time. Press

Start/Stop after a selection has been made. The washer will count down 1 hour at a

time and starts after the selected delay.

When a delay is set, a white indicator light will illuminate on the Option/Set button.

Press and hold Start/Stop for three seconds if you want to cancel the Delayed Start

option.

Indicator Light

Set Time

Select the Time Program by cycling through the menu with the left and right arrow

buttons. Touch the Option/Set button to go into the Set Time screen. This will allow

adjustment to the duration of the cycle.

Cycle through the seven Set Time options with the left and right arrow buttons. Times

will increase in 15 minute increments for the first four selections. After one hour is

reached on the display, times will cycle through 30 minute increments, up to 2:30.

To exit Set Time setup, press the Option/Set button.

Rev 007, 06/17 21

© VWR 2017

Page 30

Safety Features

V

Start/Stop

Use this button to begin or end a cycle. If no cycle is running, pressing Start/Stop will

activate the selected program. To stop an active cycle, press and hold Start/Stop for

three seconds.

Pausing a Cycle

To pause cycle operation, insert your hand, palm up, into the door’s handle cover and

pull the latch. Wait a few moments for spray-arm movement to stop and pull the door

slightly open. To resume the cycle from the point at which it paused, close the door

and ensure that it is securely latched.

Note: If a cycle is terminated (e.g., the door is opened or a power failure occurs), the water

introduction sequence will not reset until the cycle is allowed to run through to the Drying phase

and the drying fan runs. Unless the unit enters the Drying phase, the valve sequence will

continue from where it was terminated, even if the cycle is restarted.

WR

22 Rev 007, 06/17

© VWR 2017

Page 31

Overfill Protection

In the unlikely event that an equipment malfunction causes the chamber to overfill, an

overflow float sensor device automatically activates chamber draining.

Door Switch

The unit is equipped with a door switch that will automatically suspend operation of

the washer if the door is opened during a cycle. The wash cycle will continue from the

point of interruption after the door is closed.

Note: The washer will not start until the door is properly closed.

PRACTICAL OPERATING TIP. SAFE OPERATION REQUIRES KNOWLEDGEABLE OPERATORS.

TO ENSURE SAFE OPERATION, PLEASE FOLLOW THESE RECOMMENDATIONS:

Chapter

5

Safety Features

f. Read all instructions carefully before using the washer.

g. Properly ground the glassware washer prior to operation.

h. Utilize only detergents and neutralizers recommended by

VWR International for us in glassware washers.

i. Before opening the door, always listen for signs of

washer operation and wait for the sounds of rotating

spray arms and circulating water to stop.

j. Do not wash plastic items unless they are marked

“washer safe.” Check with the item’s manufacturer if

unmarked.

k. Remove the door before discarding an old washer.

Rev 007, 06/17 23

© VWR 2017

Page 32

Safety Features

V

WR

24 Rev 007, 06/17

© VWR 2017

Page 33

ALWAYS REMOVE POWER FROM THE UNIT BEFORE PERFORMING MAINTENANCE

PROCEDURES.

ALWAYS NOTIFY VWR INTERNATIONAL SERVICE BEFORE PERFORMING REPAIRS TO A

UNIT THAT IS UNDER WARRANTY. FAILURE TO NOTIFY VWR INTERNATIONAL SERVICE

WILL VOID THE FACTORY WARRANTY.

Daily Maintenance

Inspect and clean the following chamber components daily, or at a frequency

appropriate for your facility’s washer usage and load characteristics.

Coarse Filter

Chapter

6

Maintenance

The coarse filter is a cylindrical sieve that catches larger pieces of debris. To remove

the coarse filter, turn the plastic handle counter-clockwise and lift up.

Fine Filter

The fine filter is a flat mesh sieve that catches smaller pieces of debris during

draining. Regular inspection is important to prevent the accumulation of lime sediment

or other deposits that may clog the mesh of this filter over time. To remove the fine

filter, remove the coarse filter and lift the fine filter up. Clean the filter by gently rubbing

it with a brush or similar device.

Rev 007, 06/17 25

© VWR 2017

Page 34

Maintenance

V

Reassembling Filters

To reassemble the filters, reverse the process used for removal. Replace the fine

mesh filter and insert the coarse filter into position. Turn the plastic handle clockwise

to secure the filters in place.

Weekly Maintenance

Clean exterior washer surfaces with warm soapy water if necessary. On a weekly or

monthly schedule, inspect the Outlet Pump fins and nearby piping for debris. Clean

with a 4-inch (10 cm) pipe cleaner if necessary. The Outlet Pump area is accessible

beneath a removable plug located at the 9 o’clock position in the floor beneath the

Fine Filter Basket.

WR

Examine the holes in the top surface of the Spray Arms and optional spindles, if

equipped, for mineral deposits or clogs. Remove any such blockages with a needle,

wire or other appropriate tool.

Inspect Spray Arms to verify smooth rotation.

If a spray arm is not rotating freely, look for debris or mineral deposits at the arm’s

axle joint. If you have difficulty cleaning the axle in place, remove the spray arm for

closer inspection. To remove the spray arm from its axle, apply quick upward pressure

on the arm while bracing to prevent hitting nearby parts when the arm snaps free.

Clean debris as necessary.

26 Rev 007, 06/17

© VWR 2017

Page 35

V

WR Maintenance

Reassembling Racks

Take care to reassemble racks in the correct configuration if they are disassembled

during cleaning.

The image below illustrates the correct position for reassembling the wheels of the

upper rack.

Wheels on

Upper Studs

(Upper Rack Only)

Wheels on

Upper Studs

(Upper Rack

Only)

Reassembly of Upper Rack

Unheated Storage

Always drain all water from the washer before storing it for any extended period. This

includes any water trapped in the washer’s internal pumps and inlet valves.

Malfunctions caused by component freezing are excluded from warranty coverage.

Rev 007, 06/17 27

© VWR 2017

Page 36

Maintenance

V

Cleaning

The inner chamber of your VWR glassware washer is made of stainless steel and is

typically kept clean through normal use. However, if you have calciferous (hard)

water, lime deposits can form in the washer. In this case, add two tablespoons of citric

acid to the washer detergent compartment and run a normal wash program.

The following table outlines other effective methods for cleaning stainless steel.

PROPERTY CAUTION! ALWAYS USE THE MILDEST CLEANING PROCEDURE THAT WILL DO

THE JOB EFFECTIVELY. RUB IN THE DIRECTION OF POLISHED LINES TO MAXIMIZE

EFFECTIVENESS AND AVOID MARRING THE SURFACE. RINSE THOROUGHLY WITH WATER

AFTER EVERY CLEANING AND WIPE DRY.

Cleaning Required Cleaning Agent8 Application Method9 Effect on Finish

HEAT TINT OR HEAVY

DISCOLORATION

TENACIOUS DEPOSITS,

RUSTY DISCOLORATIONS,

INDUSTRIAL

ATMOSPHERIC STAINS.

HARD WATER SPOTS AND

SCALE.

Penny-Brite or Copper-Brite

Paste Nu-Steel, DuBois

Temp, Tarnite, or Kelox

Revere Stainless Steel

Cleaner, Take-Off, or AC-60

Allen Polish, Steel Bright,

Wyandotte, Bob-O, Zud,

Dubrite, or Prepare Dex

Oakite No. 33, Dilac, Texo

12, Texo N.Y., Flash-Klenz,

Caddy Cleaner, Turco Scale

4368, or Permag 57

Vinegar

Dilac, Oakite No 33, Texo 12,

Texo N.Y.

Use in direction of polish lines

on No. 4 (polished) finish.

Wipe with dry cloth.

Rub with dry cloth or stainless

steel wool.

Apply with damp sponge or

cloth.

Rub with a damp cloth.

Swab and soak with clean

cloth. Allow to stand 15

minutes or more, per

directions on package. Then

rinse and dry.

Swab or wipe with cloth.

Rinse with water and dry.

Swab with cloth or soak. Let

stand 10-15 minutes. Always

follow with neutralizer rise

and dry.

May scratch No. 2 (mil) and

Nos. 7 and 8 (polished)

finishes.

Use in direction of polish

lines on No. 4 (polished)

finish. May scratch No. 2

(mil) and No. 7 and 8

(polished) finishes.

Use in direction of polish

lines on No. 4 (polished)

finish. May scratch No. 2

Use in direction of polish

lines on No. 4 (polished)

finish. May scratch No. 2

(mil) and Nos. 7 and 8

(polished) finishes.

Satisfactory for use on all

finishes.

Satisfactory for use on all

finishes.

Satisfactory for use on all

finishes. Effective on

tenacious deposits or where

scale has built up.

WR

8

Use of proprietary names is only intended to indicate a type of cleaner, and does not constitute any endorsement (nor does

omission of any proprietary name imply its inadequacy). All products should be used in strict accordance with instructions and

warnings on the product package.

9

In all applications, a stainless steel wool, sponge fibrous brush, or pad is recommended. Avoid use of ordinary steel wool or

steel brushes for scouring stainless steel.

28 Rev 007, 06/17

© VWR 2017

Page 37

Appendix A: Troubleshooting

Problems Possible Causes Action

Glassware hazy or not clean.

Stains or film on glassware.

Water remains in washer after

use, or excessive water in sump

area.

Too little water. Check that the water valve is fully

open. Make sure that the water

pressure meets the specification.

Check any strainers in the water

supply line for clogging; clean as

required. Check drain hose.

Incorrect dosage of detergent. Dispense according to the level of

water hardness.

Hard water. If your facility has hard water, try

adding more detergent and/or more

neutralizer.

Wrong detergent. Change detergent as required.

The spray arms rotate poorly or are

not rotating.

Holes on spray arms clogged. Clean as required.

Wrong wash program selected. Heavier programs are longer, and

Incorrect loading of the dishwasher. Try not to place too much tall

Glassware has tipped over during

the wash.

Excessive neutralizer is causing

over-foaming.

Phosphate-free detergent in

combination with hard water.

Too high a temperature and/or too

much detergent can cause etching

on glass.

Too high dosage of rinse aid. Reduce dosage. Try diluting the

Coarse filter clogged. Clean as required.

Outlet pump fins clogged. Clean as required.

Drainage hose is kinked, folded, out

of saddle or extended too long.

Drainage hose is clogged. Clean as required.

Check that spray arms rotate freely

and that load items do not obstruct

movement. Lift off the arms and

clean.

use higher temperatures for dirtier

loads. Use a heavier program better

suited for the load.

glassware in the corners of the

baskets. Make sure washer is not

overloaded and that items are not

blocked from receiving spray.

Load the glassware securely.

Decrease neutralizer metering.

Change detergent.

Wash glassware at a low

temperature and use detergent

sparingly.

rinse aid with water (e.g., 1 part

rinse aid, 1 part water).

Correct as required.

Appendix

A

Rev 007, 06/17 29

© VWR 2017

Page 38

Appendix A: Troubleshooting

V

Problems Possible Causes Action

Washer cycles take too long to

complete.

Washer will not start or cannot

select and begin a cycle.

Marks or discoloration.

Yellowish marks.

Silicon Film.

Glassware does not dry

sufficiently.

Door will not close.

Rattling sound heard during

washing.

Machine will not start.

WR

Tap water not hot enough. Check tap water temperature.

Colder temperatures prolong cycle

time.

Power problem. Check breaker.

Door not completely latched. Push the door firmly to engage the

latch.

Washer is in Delay Start mode. Ensure the Delay Start indicator is

off.

Mineral-rich water. Check water hardness.

Wrong type of detergent. Use correct amount and type of

detergent.

Iron-rich water. Temporary Solution: Pour

approximately 0.5 oz (15 ml) of

citric acid into the Pre-Wash

Detergent Compartment and run

the Heavy program.

Permanent Solution: Install an iron

removal system in the water supply.

Softened hard water. Add additional detergent to the

wash. To improve rinsing, do not

load the machine to full capacity.

Machine is not fully loaded. Load the machine fully.

Rinse aid is out or set for too small

a dosage.

High residual moisture in internal

chamber.

Items incorrectly loaded. Load items with concave side

Standing water in washer. Check drain system and outlet

The baskets are not correctly

placed.

The glassware is not properly

loaded or the spray arms are not

rotating.

You have forgotten to switch on the

main switch.

The door is not closed properly. Check.

The circuit breaker has tripped. Check.

The unit’s rear ETL circuit breaker

has tripped.

The plug is not plugged in. Check.

The water tap is off. Check.

Overfilling/leakage. Call VWR Service at

Fill or increase the amount of rinse

aid.

Open the door slightly once the

program has finished.

down.

pump.

Make sure the baskets are in a

horizontal position. Check that the

basket water connector is aligned

with the spray pipe.

Check that the glassware is loaded

securely. Spin the spray arms to

make sure they rotate.

Check.

Check.

(800) 932-5000

30 Rev 007, 06/17

© VWR 2017

Page 39

Appendix

B

Appendix B: Fault Indicators

If there is an error in the washer, it will make a ringing sound to signal that there is a

fault. The washer will present the fault description on the control panel display. To

view, open the washer door to see the panel on the upper ledge.

Display Description Action

Too much water in the machine.

Water inlet fault.

Valve leakage.

Blocked drain.

Clogged filter.

Note: To remove fault indicators from the display, push the On/Off Power Switch twice to turn it

off and back on again.

Call VWR Service at (800) 932-5000.

Check that the water is on.

Switch off the water tap and call VWR Service

at (800) 932-5000.

See possible causes in Appendix A:

Troubleshooting.

Clean the filters. See the Maintenance chapter

for more information.

Rev 007, 06/17 31

© VWR 2017

Page 40

VWR International

Radnor Corporate Center

100 Matsonford Road

Radnor, PA 19087

http://us.vwr.com

Building One

Suite 200

PO Box 6660

USA

(800) 932-5000

Loading...

Loading...