Page 1

INSTALLATION INSTRUCTIONS

Surface Mount Plasma

Installation

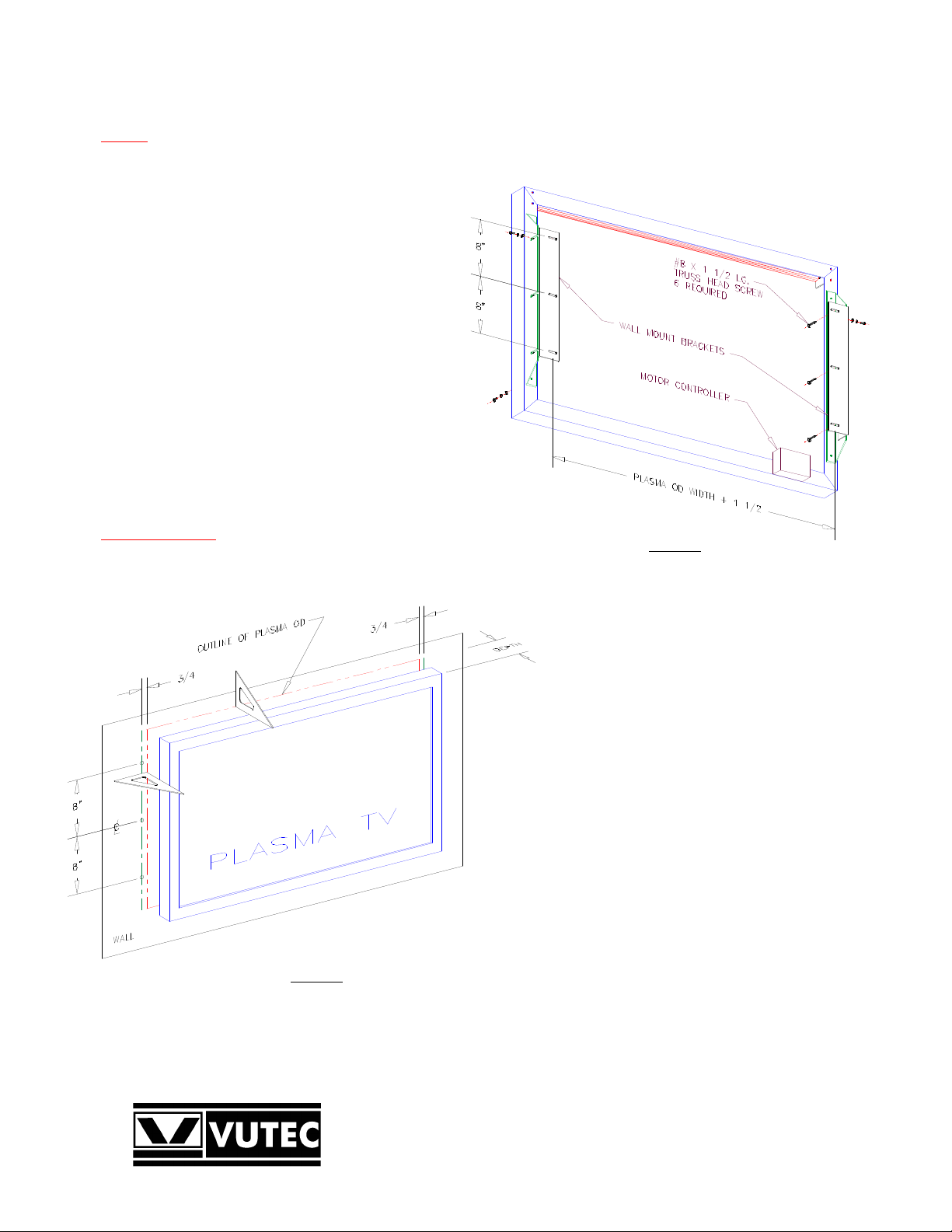

The Plasma must be straight and not tilted for the Art Screen to work properly. Tilting of the Plasma is not recommended.

Referring to Figure 2, use a triangle to determine the Plasma

OD onto the wall. Verify the outline accuracy for a problem

free installation.

Determine the depth of the Plasma – from the wall to the

front bezel surface.

Determine the mounting locations for the wall mount

brackets (Figures 1 & 2). Use proper wall anchors (not

supplied) for drywall installation.

Drill pilot holes for #8 screws or install wall anchors as

required.

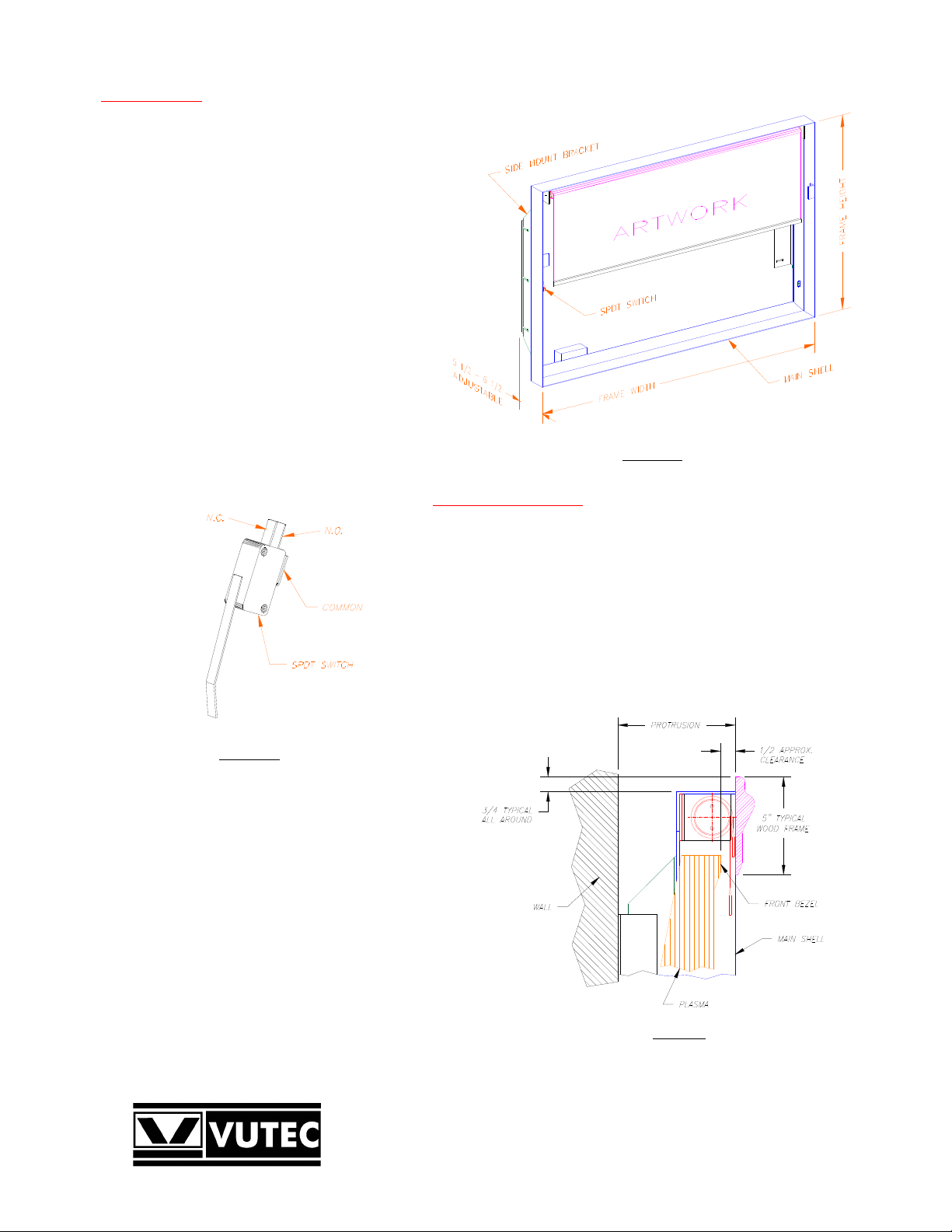

Install the Art Screen frame (Figure 3) around the Plasma.

Adjust the Art Screen frame so that it is center around the

Plasma. Tighten the screws.

Adjust the depth of the Art Screen frame so that it is 1/2 to

5/8 (Figure 4) inch more than the depth of the Plasma. This

clearance is required for the Art Screen to travel.

Route the motor wires to the backside for connection later.

Wood Frame Installation

A typical wood frame including the liner is approximately 5

Figure 2

Outlining the Plasma OD onto Wall

Figure 1

Rear View of Frame

inches wide to properly cover the assembly. The wood

overhangs the main shell approximately 3/4 inch when

attached.

Two corner woods are attached to the backside of the

wood frame to take-up the weight.

The wood frame attaches to the main shell by two

clips on the backside (see Picture Frame Installation

and Removal Section) and hold in place by the ears of

the main shell.

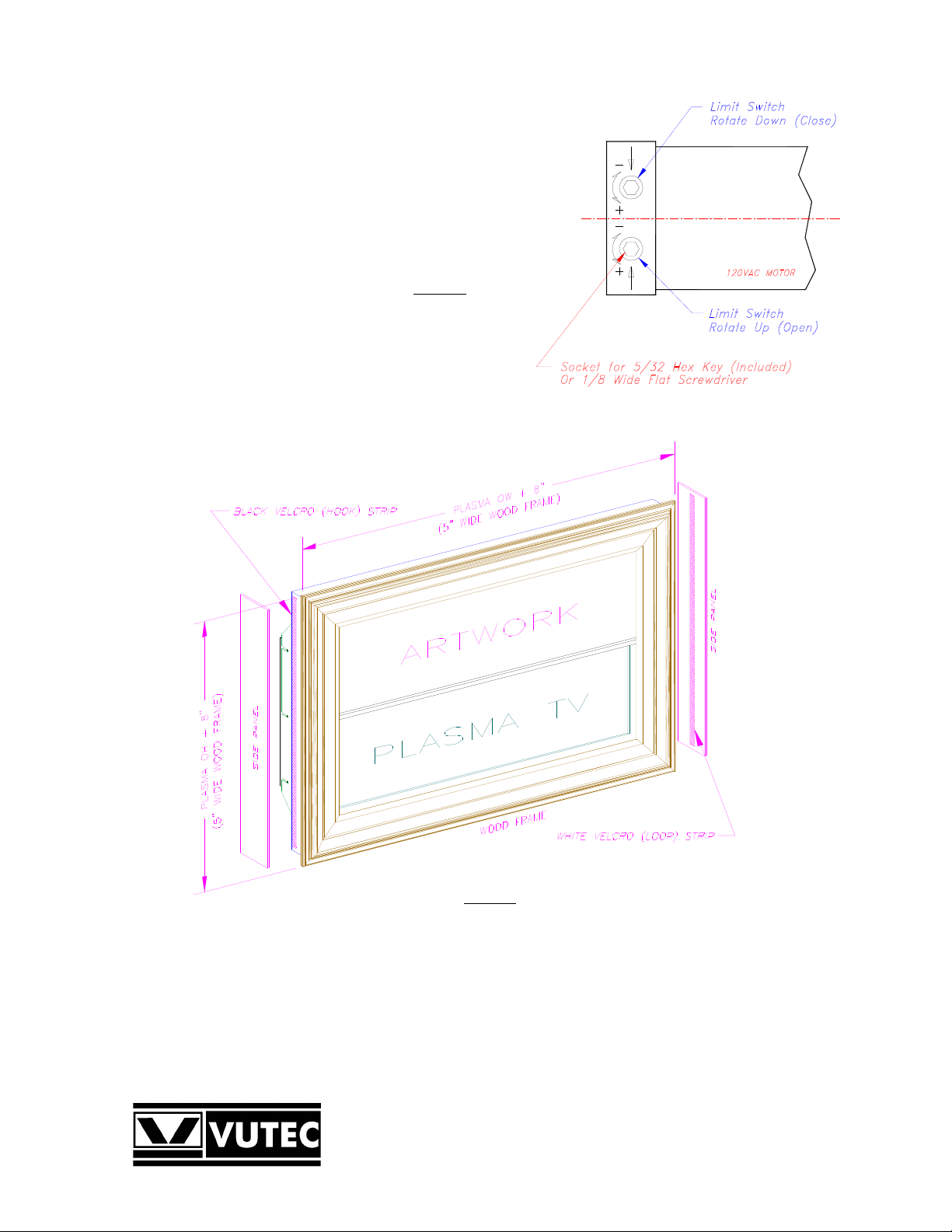

Referring to Figure 6, two side panels are provided for

covering the sides of the Art Screen frame. The panels

apply to the frame by Velcro strips supplied.

The Velcro strips are cut to length. Apply the black

part (Hook) of the Velcro to the sides of the frame.

Apply the white part (Loop) of the Velcro to each of

the panels (Figure 6).

Apply the side panels to the Art Screen frame for a

complete installation. The top and bottom of the Art

Screen frame are left open for proper ventilation for

the plasma.

Optionally, custom-made side panels may be installed

as desired.

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 2

Electrical Connections

The Art Screen comes with IR remote control for

operations. It is ready for use; no wiring connections are

required.

Place the IR sensor so that it can be seen by the

transmitter.

Plug the power cord to a 120VAC outlet.

The IR remote control has manual inputs for Home

Automation systems, i.e. AMX, Crestron, etc. See IR

remote control manual (included) for detail information.

The SPDT switch (Figure 3b) may be used for security

purpose; its contacts may be connected to an audible

alarm system or monitoring system. The breach of

security will be activated when the wood frame is

removed.

The normal states of the contacts are shown when the

wood frame is not presented.

Contact Rating: 10Amp, 1/2HP, 125/250VAC

or 6Amp, 30VDC.

Figure 3a

Art Screen Frame

Open and Close Limits Setting

The Open limit switch has been properly set for correct stop position. It

should not be adjusted unless a change in the motor or the motor had been

removed for service.

Note each full turn of the limit switch (360 degrees) causes the screen to

travel approximately 1/2 inch.

1. To lower the closed limit of the Art Screen. Send the Art Screen

down to it closed position. Turn the Close limit socket

counter-clockwise (Figure 5); the Art Screen will advance downward

as each full turn is made. Stop at the desired position.

2. To raise the closed limit of the Art Screen. Send the Art Screen

Figure 3b

SPDT switch

down to it closed position. Determine the number of turns

to stop the screen above the desired close limit. Turn the

Close limit socket clockwise to raise the limit. The motor

will not move for this direction.

Figure 4

Side View

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 3

3. Send the screen up halfway then stop. Send the screen down to its

closed limit. The screen must stop above the desired position. If it

is not, repeat step 2

4. When the Art Screen stopped above the desired closed limit; do

Step 1 to set the desired closed limit.

5. Check and adjust the closed and open limits as necessary.

Figure 5

Motor Limit Switches

Figure 6

Complete Art Screen

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 4

Accessories Included

Description QTY.

Main Shell including Artwork and Motor 1

Side Mount Bracket 2

Wall Mount Bracket 2

Wood Frame (Complete) 1

Side Panel 2

Velcro Strips 2

IR Receiver in Box 1

IR Sensor (6 Feet Long) 1

IR Transmitter 1

#8 x 1 1/2 Long, Truss Head Phillip Screw 6

#10-32 x 1/2 Long, Pan Head Phillip Screw 12

#10 Flat Washer 12

#10 Helical Washer 12

Limit Switch Setting Tool 1

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 5

PICTURE FRAME INSTALLATION & REMOVAL

SPILC GNIDILS HTIW

Figure 1

Metal frame without picture frame

The backside of the picture frame is in full contact with the front edges of the metal frame. Position the two corner woods and clips to

be guided by the vertical edges of the metal frame. Carefully pushes down (Figure 3b) on the picture frame to set it in place. Corner

woods will make slight noise when they are bottom out to the metal frame. Push up picture frame (2 inches approx.) to remove.

A SPDT switch is provided for security connection (optional). Contact rating: 10A, 1/2HP, 125/250VAC or 6A, 30VDC

Backside of picture frame

Figure 2

Figure 3a

Frame clip and ear prior to engagement Pi degagne ylluf pilC nwod sehsup emarf erutc

Figure 3b Figure 3c

noitallatsni tnuoM ecafruS fo mottob troppuS

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 6

VUTEC CORPORATION

www.vutec.com

TEL: (954) 545 9000 - FAX: (954) 545 9011

E-MAIL: info@vutec.com

Page 7

DISPLAY PANEL REAR VIEW

DISPLAY PANEL WALL INSTALLATION

CAUTION: A LOW PROFILE WALL MOUNT BRACKET MUST BE USED FOR THIS APPLICATION INSTALLATION.

ASSEMBLY INSTRUCTION (LCD SLIM LINE 1 1/2" PANEL DEPT H )

1. A LOW PROFILE WALL MOUNT BRACKET MUST BE USED FOR THIS INSTALLATION

APPLICATION

2. REPLACE EXISTING IEC POWER CORD WITH THE (VUTEC SUPPLIED) NEMA 5-15

ROTATING UNIVERSAL IEC POWER CORD PRIOR TO PROCEEDING WITH

THE LCD DISPLAY INSTALLATION

3. THE LCD DISPLAY SHOULD BE EQUALLY SPACED WITHIN THE INTERNAL FRAME SPACE

4. PROPER WALL ANCHORS (NOT SUPPLIED) MUST BE USED TO FASTEN THE ARTSCREEN

FRAME THE WALL AND INSURE PROPER ALIGHN AS ILLUSTRATED BELOW.

Loading...

Loading...