Page 1

SERVICE MANUAL

VSX BOILER BASE SERIES

CONVECTION STEAMERS

(GAS, ELECTRIC, DIRECT AND REGENERATED)

VSX24G ML-52163 VSX24D ML-52827

VSX36G ML-52360 VSX36D ML-52830

VSX42GT ML-52376 VSX42DT ML-52834

VSX24E ML-52164 VSX36R ML-52831

VSX36E ML-52829 VSX42RT ML-52835

VSX42ET ML-52833

VSX24G SHOWN

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not atte nded a Vulca n Servic e School f or this produc t, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

- NOTICE -

A product of VULCAN-HART LO UISVILLE, KY 40201-0696

Form 24627 ( 12/98)

Page 2

VSX SERIES STEAMERS

TABLE OF CONTENTS

GENERAL............................................................................. 4

Introduction ........................................................................ 4

Compartment Pan Capacity ........................................................ 4

Model Designations .............................................................. 4

Specifications ...................................................................... 5

Gas Steamers .................................................................. 5

Electric Steamers................................................................ 5

Steam Supply ................................................................... 5

Water Supply ................................................................... 6

Tools ............................................................................. 6

Water Conditi oning .................................................................. 6

STEAMER OPERATION.................................................................. 7

Cabinet Base Boilers ................................................................. 7

Gas Powered Steam Boiler ........................................................ 7

Electrically Powered Steam Boiler ................................................... 8

Direct Steam Powered Cooker ...................................................... 8

Regenerated Steam Powered Boiler .................................................. 8

Boiler Blowdown and Steamer Shut off ................................................... 8

Cooking Compartment Controls......................................................... 9

COMPONENT FUNCTION AND LO CA TION ................................................. 10

Cabinet Base Boiler Controls .......................................................... 10

Cooking Compartment Controls........................................................ 14

SERVICE PRO CE DURE S ................................................................ 15

Cabinet Bases ..................................................................... 15

Boiler ........................................................................ 15

Descaler...................................................................... 16

Water Level Controls

(Low Level Cut-Off and Different ial) ............................................. 16

Water Level Gauge Assembly ..................................................... 17

Pressure Switches (Gas and Electric Models) .......................................... 17

High Limit Thermostat ........................................................... 18

Removing The Boiler Assembly .................................................... 18

Fill and Cold W ater Solenoid Valv es ................................................ 18

Water Not Being Supplied to Boiler ................................................. 19

Blowdown Solenoid Valve Does Not Drain ............................................ 19

Steamer A chieves Pressure Slower Than Normal ...................................... 20

Inlet Water Strainer ............................................................. 21

Gas Models ................................................................... 21

Pilot , Thermoc ouple or Main Burner s ............................................ 21

Automatic Ignition Systems.................................................... 22

Gas Combination Control Valve Replacement ..................................... 23

Manifold Pressure Adjustment ................................................. 23

Electric Models ................................................................. 24

Magnetic Cont actor .......................................................... 24

Heating Element............................................................ 24

Direct Steam Models ............................................................ 26

Regenerated Steam Models (Steam Coil) ............................................. 26

COOKING COMPARTMENT.......................................................... 26

Controls ...................................................................... 26

Steam Supply Solenoid .......................................................... 26

Water Accumulating in Compartment................................................ 27

Cooking Cycl e Cannot Be Activated ................................................. 27

Intake Shut-Off Valve Adjustment (Steam Flow)........................................ 27

Door......................................................................... 27

Page 2 of 80

Page 3

VSX SERIES STEAMERS

ELECTRICAL OPERATION .............................................................. 30

Water Level Controls................................................................ 30

Solid State -

Low level Cut-Off & Differential Control .......................................... 30

Electro Mechanical - Low level Cut-Off & Differential Contr ol .............................. 32

Sequence of O per ation .............................................................. 34

Gas Models ................................................................... 34

Electric Models ................................................................. 37

Schematics, Gas Steamers, Boiler Controls

VSX24G, 36G and 42GT ......................................................... 41

Manual Igni tion, St andar d Controls .............................................. 41

Electronic Ignition, Standar d Controls ............................................ 42

Manual Igni tion, CSD-1 Code Cont r ols ........................................... 43

Electronic Ignit ion, CSD-1 Code Controls ......................................... 44

Wiring Diagrams, Gas Steamers, Boil er Controls

VSX24G, 36G AND 42GT ........................................................ 46

Manual Igni tion, St andar d Controls .............................................. 46

Electronic Ignition, Standar d Controls ............................................ 48

Manual Igni tion, CSD-1 Code Cont r ols ........................................... 50

Electronic Ignit ion, CSD-1 Code Controls ......................................... 52

Schematics, Electric Steamers, Boiler Controls

VSX24E, 36E AND 42ET ......................................................... 54

Auto Blowdown, Standard Controls .............................................. 54

Auto Blowdown, Cal-Code Controls .............................................. 55

Auto Blowdown, Standard Controls .............................................. 56

Auto Blowdown, Cal-Code Controls .............................................. 57

Wiring Diagrams, Elec tric Steamers, Boiler Controls

VSX24E, 36E AND 42ET ......................................................... 58

Auto Blowdown, Standard Controls .............................................. 58

Auto Blowdown, Cal-Code Controls .............................................. 60

Auto Blowdown, Standard Controls .............................................. 62

Auto Blowdown, Step Down Transformer, S tandard Controls .......................... 64

Auto Blowdown, Step Down Transformer, Cal-Code Controls (2 contactors) ............... 66

Auto Blowdown, Step Down Transformer, Cal-Code Controls (4 contactors) ............... 68

Wiring Diagr ams, Electric Heater Circuits

VSX24E, 36E AND 42ET ......................................................... 70

Schematic, Direct Steamers, Cabinet Base

VSX24D, 36D and 42DT .......................................................... 73

Wiring Diagram, Direct Steamers, Cabinet Base

VSX24D, 36D and 42DT .......................................................... 73

Wiring Diagrams, Regenerated Steamers, Boi ler Controls

VSX36R and 42RT (Older Models) .................................................. 74

Schematic All Models - Compart ment Controls ............................................ 76

Wiring Diagram, All Models - Compartment Controls ........................................ 77

TROUBLESHOOTING .................................................................. 78

© VULCAN 1998

Page 3 of 80

Page 4

VSX SERIES STEAMERS - GENERAL

GENERAL

INTRODUCTION

General

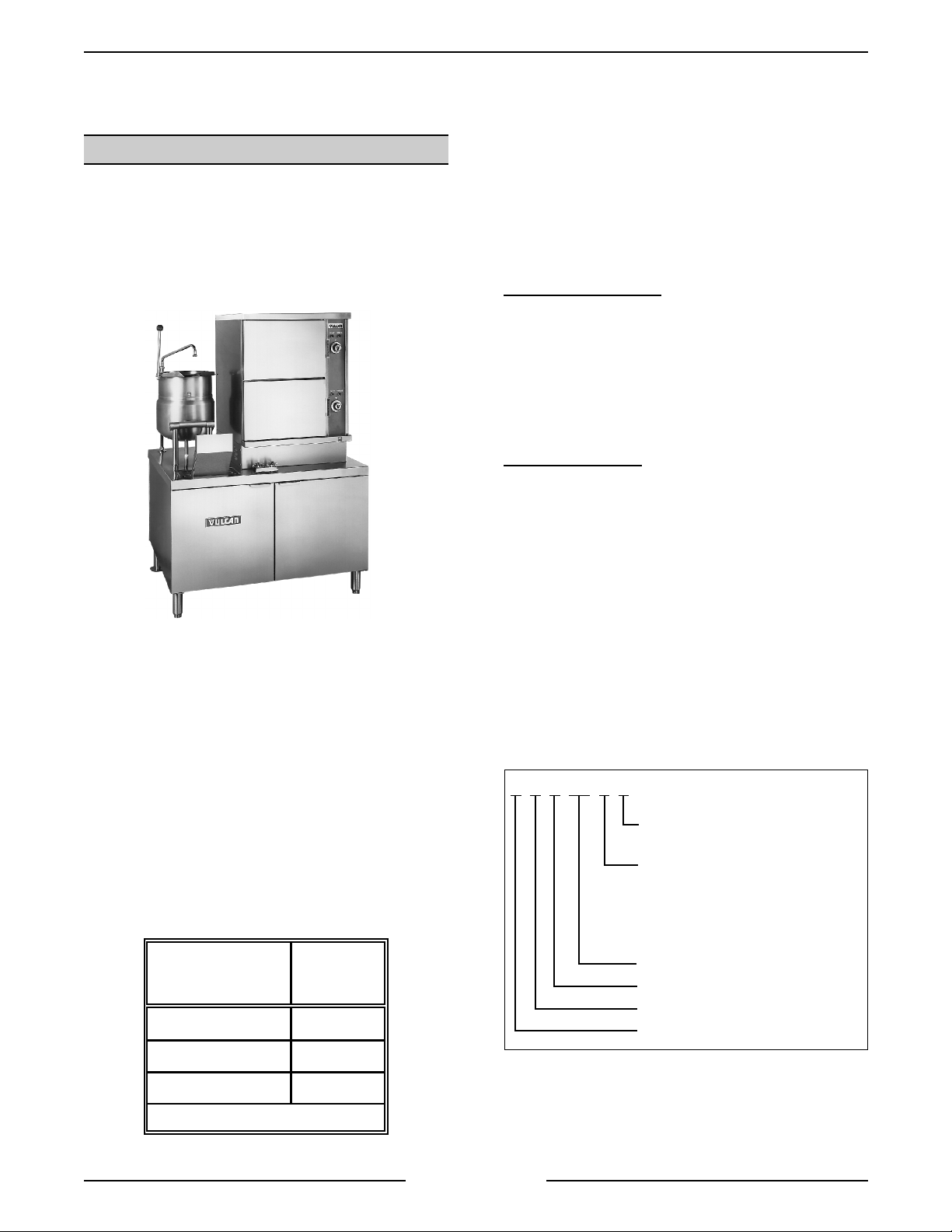

This manual is applic able for all models listed on the

cover page. A conv ection steam er on a 42 inch

base with a til ting kettle is pictur ed below for

reference.

VSX42RT SHOWN

Steam Cooking

Pressure-less steamers offer an ef ficient way to

produce many foods in smal l portions or l ar ger

batches. Pressure-less, convecti on steam cooking

will steam cook fresh foods or will steam defrost and

cook froz en foods providing the maxi mum color,

flavor and nutr itional value with the least

expendit ur e of energy and l abor . The pressure-less

steaming compartment allows the operator to open

and close the door, anyti me during a cooking cycle.

The steam supply will shut off when the door is

opened, then re-start when the door is closed.

Compartment P an Capacity

NUMBER OF

PANS PER

COMPARTMENT

24.0

DEPTH

(INCHES)

Boiler Code Descriptio ns

Vulcan-Hart incorporates redundant c ontrols in

compliance with California Code (Cal-Code) and

CSD-1 as an option on steam equipment when

required by stat e and/or local building code

requirements. Descriptions of the codes are listed

below.

Cal-Code Construct ion

electrical safety circuits that, i f tri pped, must

manually be reset after the condit ion causing the trip

subsides. These controls consist of - (1) dual

function water level cycling and low level cut off

control and ( 1) si ngle funct ion low water level cut- off

control ( A ux - LLCO) and a hi gh pr essure rel ief

switch in conj unc tion with a m ec hanical pressure

relief valve.

CSD-1 Constructi on

electrical safety circuits that, i f tri pped, must

manually be reset after the condit ion causing the trip

subsides. These controls consist of - (1) dual

function water level cycling and low level cut off

control and ( 1) si ngle funct ion low water level cut-off

control ( LLCO) and a high pressure reli ef switch in

conjunction with a mechanical pressure relief valve.

Additi onally, both circui ts have individual indicator

lights that will illum inate for a visual verification of

the shutdown mode.

Cal-Code and CSD-1 constr uc tion both requi r e

operator intervention in the event of a shutdown.

CSD-1 is mor e informative by using indicator lights

to show which safety system was shutdown.

Model Desi gnations

S X XX X X

V

- Redundant controls in the

- Redundant controls in the

T - Tilting kettle (24 qt.) found

on 42" wide cabinet base onl y .

Heating System:

G - Gas

E - Electric

D - Direct

R - Regenerated

Cabinet Base Width ( inches)

Pressure-less

Steamer

Vulcan

32.5

61.0

Pan Size 12" x 20"

Page 4 of 80

Page 5

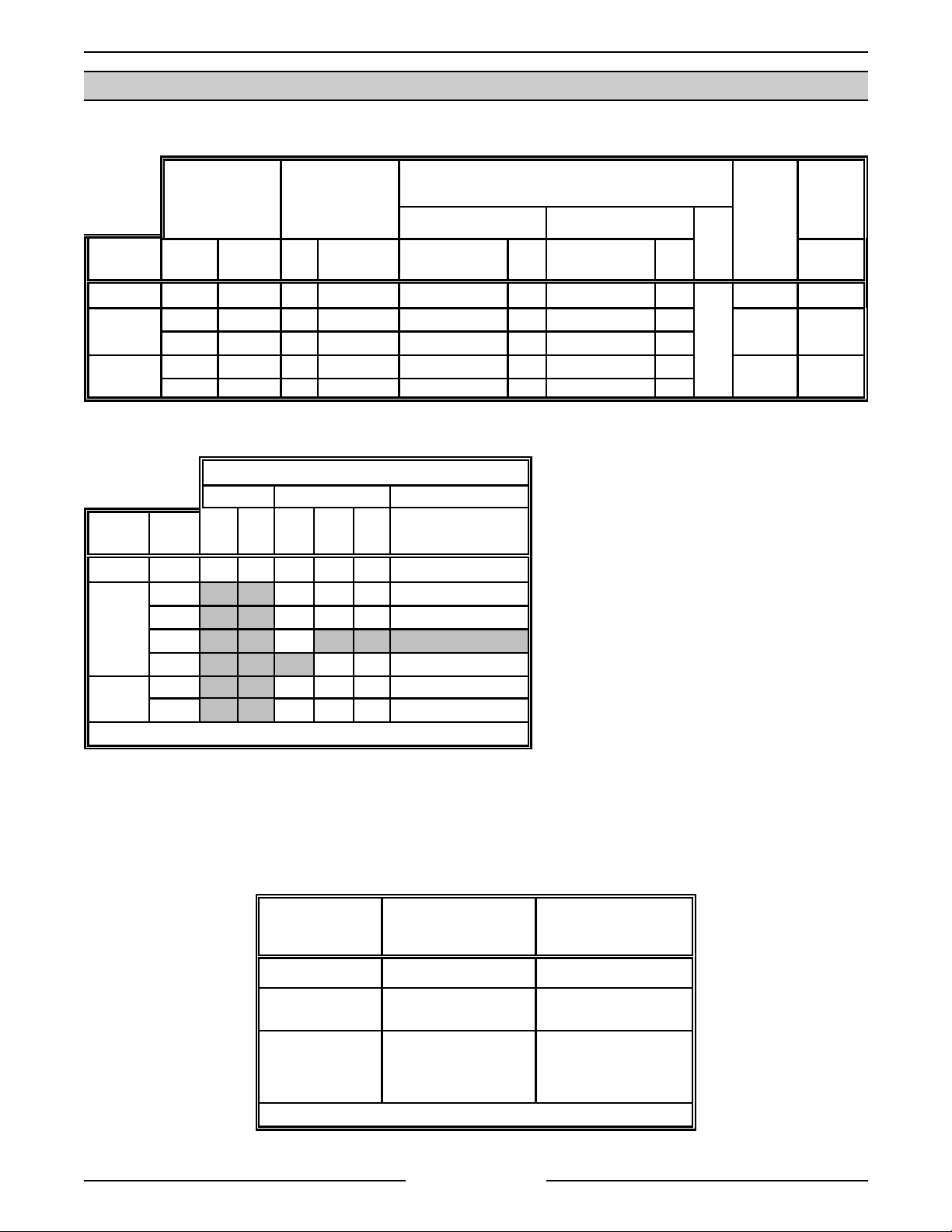

Gas Steamers

VSX SERIES STEAMERS - GENERAL

SPECIFICATIONS

INPUT

(BTU/HR)

MODEL NAT. PROP. NAT. PROP. RECOMMEND MIN RECOMMEND MIN

VSX24G 200,000 200,000 4.0 10.0 7.0 5.0 11.0 11.0

VSX36G

VSX42GT

200,000 200,000 4.0 10.0 7.0 5.0 11.0 11.0

240,000 240,000 4.0 10.0 7.0 5.0 11.0 11.0

200,000 200,000 4.0 10.0 7.0 5.0 11.0 11.0

240,000 240,000 4.0 10.0 7.0 5.0 11.0 11.0

MANIFOLD

PRESSURE

(INCHES W.C.)

NATURAL PROPANE

LINE PRESSURE

(INCHES W.C.)

Electric Steamers

AMPERAGE

1 PHASE 3 PHASE 3 PHASE - 4 WIRE

MODEL

VSX24E 24* 116 100 67 58 29 34

VSX36E

VSX42ET

*std

TOTAL

208V 240V 208V 240V 480V 220/380V & 240/415V

KW

24* 67 58 29 34

36 100 87 44 50

42 117

48 116 58 67

24* 67 58 29 34

36 100 87 44 50

MAX

14.0

LOAD

(WATTS)

360 3.0

360 3.0

360 3.0

AMPS

(MAX)

120V

60HZ

Steam Supply

Dry steam must be prov ided to the steam er . If t he steam is heavy with condensate, a Ball Fl oat Trap must be

used in the line and plumbed in before the pr essure reducing valve. To ensure rapid heat up of heavy c old loads,

the steam supply line must be si z ed to maint ain pressure as outlined bel ow.

DIRECT STEAM

STEAMERS

(POTABLE)

Supply Pressure 15 psi (max.) 15 psi (max.)

Flow Rate 100 lb. per hour total

Pre ssure Reducing

Valve Output

*Potable stea m is no t required for regenerated models but could be used.

(min.)

10 psi (furnished) set accordingly for good

REGENERA TED STEAM

STEAMERS

(*NON-POTABLE)

125 lb. per hour total

(min.)

steam gene ration but no

higher than 15 psi.

(furnished)

Page 5 of 80

Page 6

VSX SERIES STEAMERS - OPERATION

Water Supply

Supply pressure should be 20-80 psig

In line strainer f or suppl y line (Not Supplied)

Supply connection cold

Total dissolved solids (TDS)* less than 60 ppm

Total alkalinity less than 20 ppm

Silica less than 13 ppm

Chloride less than 30 ppm

PH fact or 7 to 8

(*17.1 ppm = 1 grain of har dness)

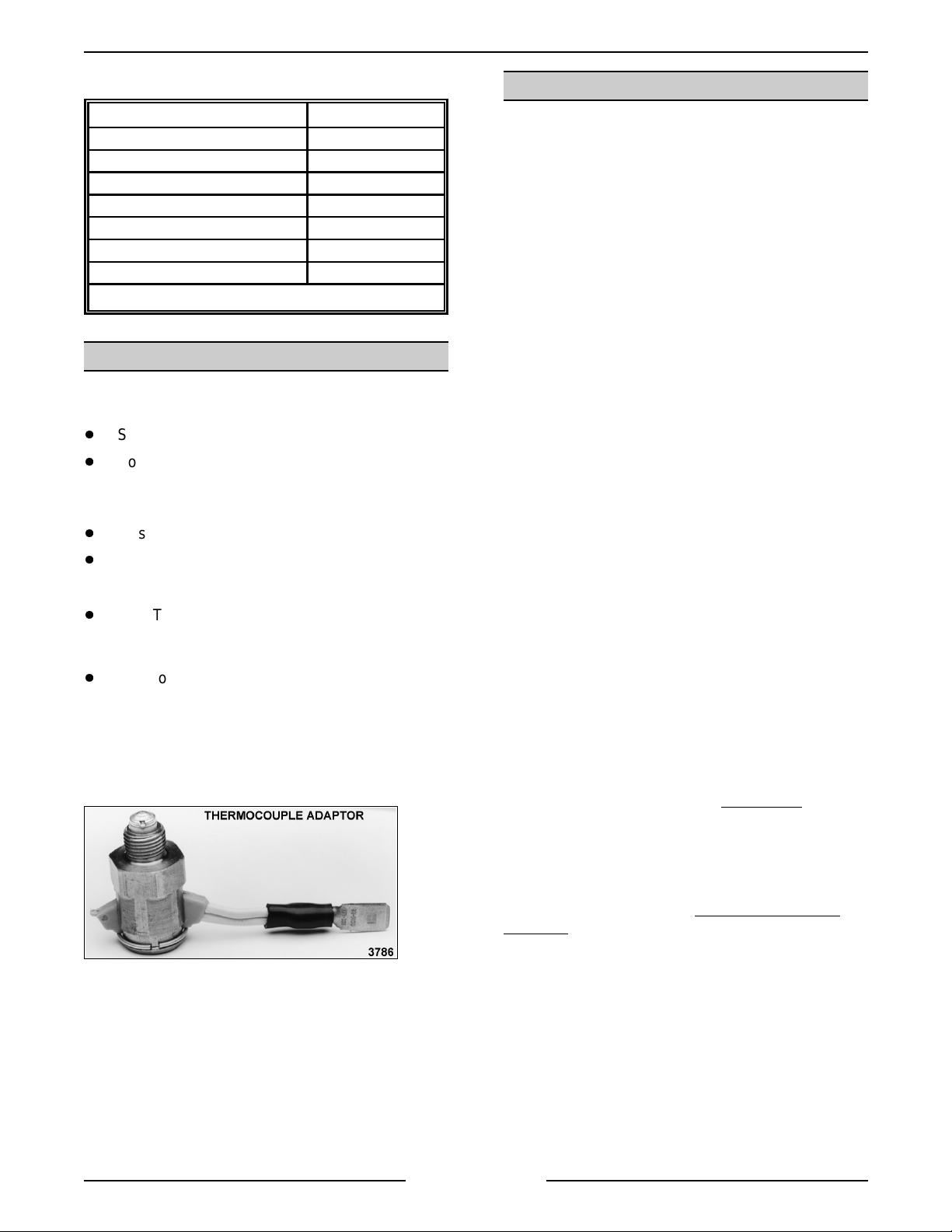

TOOLS

Standard

Standard set of hand tools.

Volt-Ohm-Meter (VOM) with AC current tester.

(Any quality VOM wit h a sensit ivity of at least

20,000 ohms per volt c an be used)

Gas leak checking equipment.

Gas Pressure Manometer

Special

CLR Treatm ent Kit - Used to remov e

Calcium/Lime/Rust fr om a boiler ( Contact

Vulcan Authorized Service Cent er s ).

Adaptor to test thermocouple closed circuit

voltages (DC) on gas models with manual

ignition (purchase locally).

NOTE:

An exam ple of one adaptor type is pict ur ed

below.

Adaptors v ary between manuf ac turers.

WATER CONDITIONING

Furnishing the boiler wit h soft water to reduce scale

formation is important. Scale formation will reduce

steam output, cause premature c omponent f ailure,

and shorten equipm ent life. Most water supplies

contain scal e pr oduc ing miner als such as Calcium

and Magnesium. A s steam is generated, the

minerals remain and dissolve into the water. As the

concentration of these minerals inc r eases past a

certain point, they pr ec ipitate from the water and

coat the inside of the boiler, heating elements,

thermostat bulbs and water level probes. Because of

the high temperature of these surfaces, the

precipitated minerals bake onto them and become

very difficult to remove.

This causes several problems:

1. Reduce the heat transfer efficiency of the

heating system .

2. Cause premature failure of E lectric heaters.

3. Water l evel pr obes will give false readings.

4. Thermostat bulbs will sense temperature

incorrectly.

These problem s are common to any manufacturer's

steamer regardless of design, but t hey c an all be

prevented by furnishing the boiler with soft water.

Vulcan recommends the water cont ain less than

60ppm of “ total dissolved soli ds” (TDS) and hav e a

PH fact or between 7 to 8. These water properties

can be achieved by using a properly maintained

water softener.

Other chemical pr oper ties in water supplies can also

affect good steam generation and vary fr om within

each state and locality.

The water level probes in the boiler use ions i n the

water to detect the water level.

demineralized or de-ionized water since it is "non

conductive" and the water level can not be detect ed.

Do not use

fully

NOTE:

remove mi nerals from the water.

Vulcan recommends that a local water treatment

specialist be consulted before t he installat ion of any

steam generating equipment.

Steamers that operate over a long peri od of time

without the benefit of a water softener, which have

developed a heavy scale build up, should be

cleaned bef or e using a water softener.

Page 6 of 80

The use of strainers, or filters will not

Page 7

VSX SERIES STEAMERS - OPERATION

STEAMER OPERATION

WARNING:

SERVICING THE STEAMER. THE COOKING COMPARTMENT CONTAINS LIVE STEAM. STAY CLEAR

WHEN OPENING EACH DOOR.

Ensure that all utility connections to the steamer

have been made and are turned on.

On model s that are Cal-Code/CS D- 1 equipped,

amber col ored lights for Hi pressure and low water

level will illuminate and stay on until the boiler is full

and the manual reset switch pressed.

Gas Powered Steam Boiler

1. Open the cabinet door and turn main power

THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING OR

On Models with Automatic Ignition

CABINET BASE BOILERS

switch ON. The red light will illuminate, water

will begin filling the boiler and the blowdown

solenoid valve will close. The boiler should fill,

in four to eleven minut es. Observe water l evel

gauge glass to verify that water is in boi ler and

that the l evel in the gauge glass is about hal f

full. Both valves on gauge glass assembly m ust

be open to fill the gauge. Older models

equipped with a manual “ball” type blowdown

valve must be closed for the boiler to fill. The

cycling pressure switch will maintain the proper

steam pressure in the boiler by cyc ling the

heating system on and off to generate steam

pressure.

On Models with Manual Ignition

A.

knob on the gas combination contr ol valve

has three positions (O n- P ilot-O ff) for

control of main burners and pilot. Turn

knob on gas combination valve to PILOT

then depress and light pilot burner with a

lit taper. Maintain knob in depressed

position for about 30 seconds and release.

Observe that pilot burner flame stays on. If

the flame should go out, wai t 5 minut es

before relighti ng.

- The

B.

The knob on the gas com bination cont r ol

valve has two positions (On-Off) for

control of main burners and pilot. For the

automatic ignition system t o work, the

knob must be set i n the ON position or gas

for the pilot and main burners will not flow.

Also, the ignition c ontrol module

ON/OFF/RESET switch must be in the ON

position to operate. Thi s switch is located

on the upper left side of the electrical

control box for the ignition control module.

A red light will illuminate when the switch

is in the ON posi tion. DO NO T ATTEMPT

TO MANUALLY LIGHT THE PILOT IN AN

AUTOMATIC TYPE IGNITION SYST EM.

After the main power switch is turned ON

and the ignition control modules RESET

switch is in the ON position, sparking will

begin three seconds lat er to light the

standing pilot. If the pilot light s, a si gnal is

sent back through the igniti on c able

indicat ing the presence of pilot flame and

sparking stops. If the water level i n the

boiler has reached the minimum level, the

burners will ignite and begin to heat t he

water in the boi ler. After approximately 15

minut es, st eam should be present f or

cooking product. Observe that the boi ler

pressure gauge indicates steam pressure

of 8-10 psi. If a pilot flame i s not

established immedi ately, sparki ng will

continue for 90 seconds. After that

duration, the ignition control module will

lock out and needs to be r eset to start the

pilot and burner lighting cycle again.

-

Turn knob on gas combination cont r ol

valv e to ON. If the water level in the boiler

has reached the minimum level, burners

will ignite and begin to heat the water in

the boiler . After approximately 15 minutes,

steam should be present for cooking

product. Observe that the boiler pressure

gauge indicat es steam pressure of 8-10

psi.

Page 7 of 80

Page 8

VSX SERIES STEAMERS - OPERATION

Electrically Powered Steam Boiler

Open the cabinet door and turn m ain power switch

ON. The red light will illuminate, water will begin

filling the boiler and the blowdown solenoid val ve

will close. The boiler should fill, in 4 to11 minutes.

Observe water level gauge glass to v er ify t hat water

is in boiler and that the level in the gauge gl ass is

about half full. Both valves on gauge glass

assembly m ust be open to fill the gauge. Older

models equipped wi th a manual “ball” type

blowdown valve must be closed for the boiler to fill.

If t he water level in the boiler has reached the

minimum level, the magnetic cont ac tors will close,

the heaters will energize and begin to heat the water

in the boiler. After approx imately 15 minutes, steam

should be present for c ook ing product. O bserve that

the boiler pressure gauge indicates steam pr essure

of 11-13 psi.

Direct Steam Powered Cooker

1. Open the cabinet door and turn main power

switch ON.

A. The red light on the switch will illuminate.

B. If steam pr essure is above the m inimum

setting on the cooking compar tment

pressure switch then the switch will close,

ready light will come ON and power to the

other controls will be supplied.

C. Observe that the steam pressure gauge in

the cabinet base, indicates 10-12 psi.

2. Steamer is ready t o c ook pr oduc t.

Regenerated Steam Powered Boiler

BOILER BLOWDOWN AND

STEAMER SHUT OF F

Turn the steamer off at least once daily and blow

down the boiler t o r emov e sedi ments, scalants and

lime build-up in the boil er . Always blowdown the

boiler when it is under maximum pressure and no

steam is bei ng used.

1.

Automatic blowdown.

A. Newer Models

and turn main power switch OFF. The

switches’ red light will go out, the

blowdown/drain solenoid valve will be deenergized and the boiler will begin to

drain. The cold water condenser solenoid

will continue to operat e, as needed, to

condense steam and to cool the water

going into the drain.

B. Older Models

and depress blowdown timer butt on.

Blowdown timer will operate for 4 minutes.

At the end of blowdown, turn fill switch to

ON and allow boi ler to f ill.

2.

Manual blowdown.

A. All Models

blowdown valve loc ated on the bottom

front of the cabi net base. After the boiler

has completely drained, c lose blowdown

valve and t ur n fill switch to ON and allow

boiler to fill.

- Open the cabi net door

- Turn power switch OFF

- Turn power switch OFF. Open

1. Open the cabinet door and turn main power

switch ON. The pilot light will illuminate, water

will begin filling the boiler and the blowdown

solenoid valve will close. Models equipped with

a manual “ball type” blowdown valve need to

be closed for the boiler to f ill. The boiler should

fill, in approximately 15 minutes. Observe

water level gauge glass to verify that water i s i n

boiler and t hat the level i n the gauge glass is

about half full.

Both valves on the gauge glass assembly must

be open to fill the gauge. When the water

reaches the minimum level, the steam solenoid

valve will open, allowing steam to enter the

steam coil in the heat exchanger tank and

begin heating the water. Af ter approxi mately 20

minut es, a sufficient amount of pressuriz ed

steam should be present for cooking pr oduc t.

Page 8 of 80

Page 9

VSX SERIES STEAMERS - OPERATION

COOKING COMPARTMENT

CONTROLS

When the steam pressure in the c ook ing

compartment manifold reaches approximately 3 psi ,

the cooking compartment pressure switch closes,

suppling power to the ot her c ontrols. The ready

lights will illuminate and after approximately one

minute, the steam pressure in the boiler will reach

the upper li mit of 10 psi. If the pressure drops below

approximately 3 psi , the pressure switch will open,

removing power f r om the cooki ng c ompartm ent

controls.

NOTE:

the ready light comes on, a loud clanki ng sound wil l

be heard (oil c anning) and the ready l ights will flash

for several seconds. This condition is caused by the

manifold pressure being on t he “fringe” of the

pressure switch set point. When a cook t imer i s set,

the compartment steam solenoid valve opens

causing the manifold steam pressure to drop,

slightly below the pressure switch set point. At the

same time, steam pressure is still increasing in the

boiler. This opposing condit ion causes a pressure

“bounce” to occur but after the steam pressure

passes approximat ely 4 psi this condition subsides.

Under normal steam cycling pressures, this

conditi on will not be seen.

If a cook ing timer is set immediat ely aft er

5. When timer knobs reach "0", buz z ers will

sound, steam generation will cease, cooking

lights will go off and ready lights will come on.

To silence buz z er s, turn timer knobs to off

position.

6. During a cooking cycle, the heat ing system will

cycle on and off as necessary to maintain

steam pressure in the boiler.

NOTE:

occur due to the r egulated constant steam supplied

from the building. Steam will come on for cooking

when a cook tim er is set and go off at the end of

that time.

7. Turn power switch off t o r emov e power from

8. Blowdown boiler. See “BOILER BLOWDOWN

On direct st eam units, no steam cycling will

the steamer and the red light will go out.

AND STEAMER SHUT-OFF” under

“STEAMER OPERATION”.

1. With both tim er knobs at the off position, open

the compartment doors and observe that no

steam has entered the c ook ing compart ments,

then close the doors.

2. Set both tim er knobs at 2 minut es. The ready

lights will go off, the cooking lights will come

on, and steam will begin to enter the

compartments.

3. After one minute, open each door and observe

that steam has ceased to enter each

compartment, cook ing light s go back to ready,

and one minut e is remaining on each cook

timer.

4. Close doors and steam generation and cook

timing will resume. Observe the floor drain to

ensure that live steam from compart ments is

being cooled by cold water fr om the cold water

condenser solenoid valve.

Page 9 of 80

Page 10

VSX SERIES ST E A M E RS - COMPONENT FUNCTION AND LOCATION

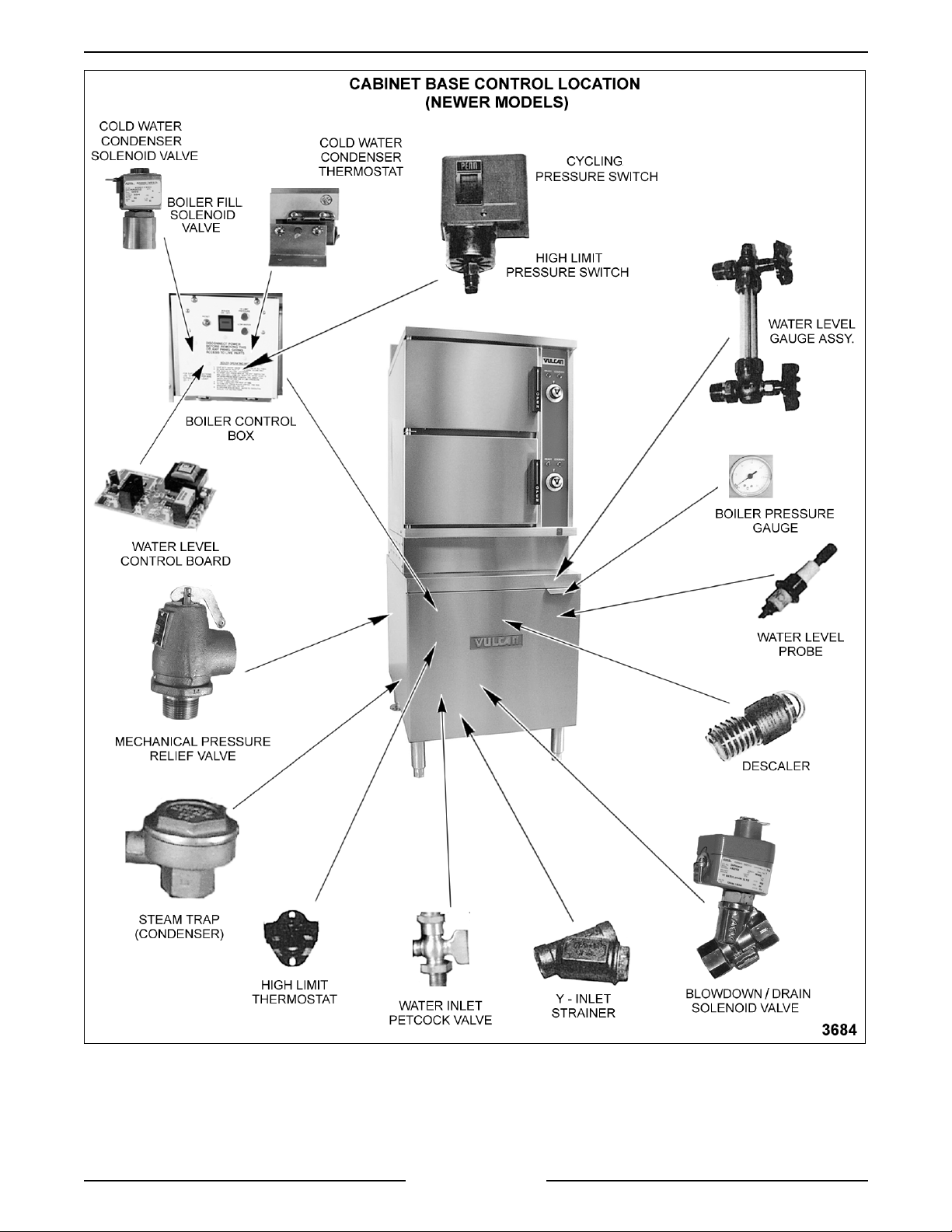

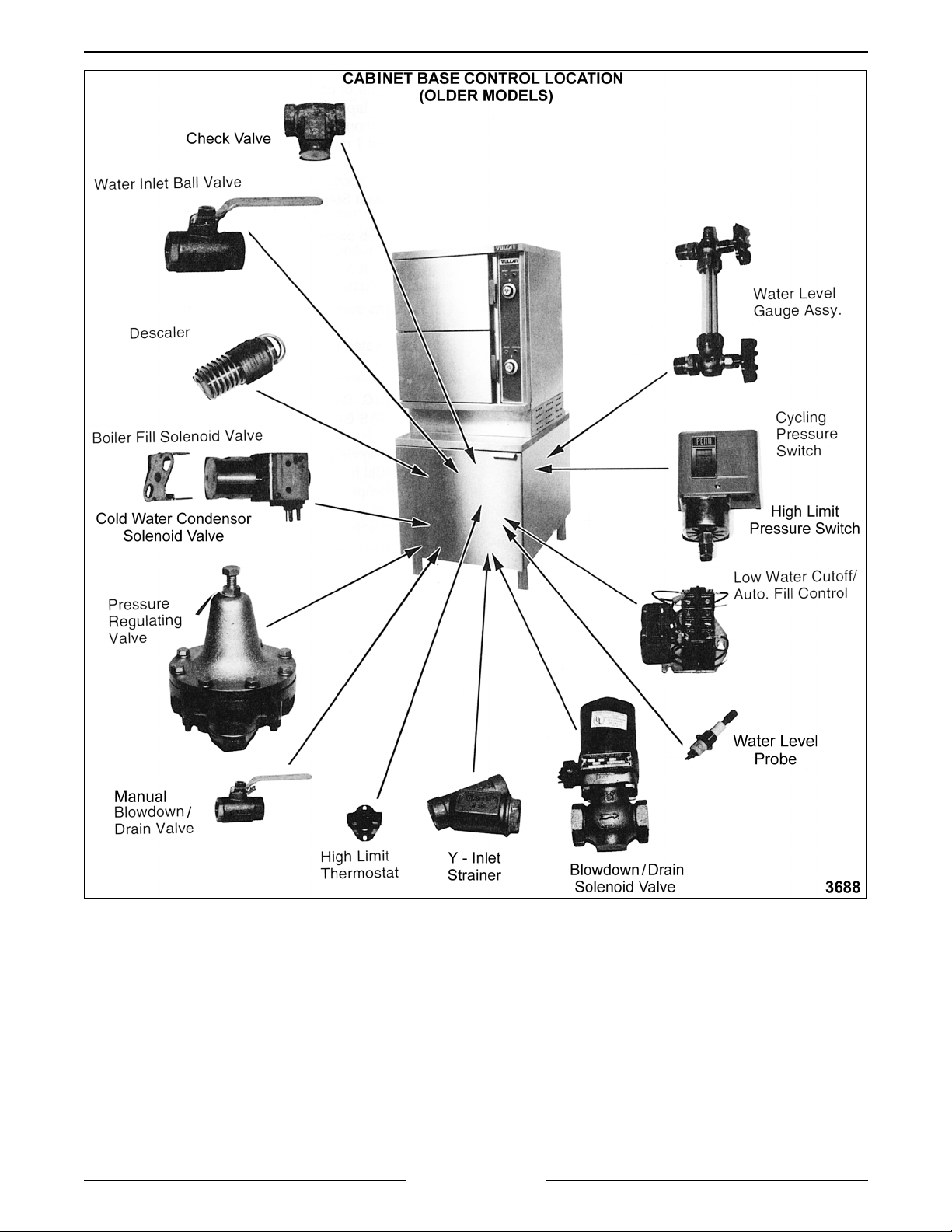

COMPONENT FUNCTION AND LOCATION

CABINET BASE BOILER

CONTROLS

WARNING

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHEN OPENING EACH DOOR.

Water Level Gauge Assembly

confi r mation that water level is bei ng maintained in

the boiler during operati on. The correct water level

is a point one-half of the height of the glass. The

manual valves at the top and bottom of this

assembly m ust be full y open and only closed if the

glass tube is damaged.

Observe that the water is clean and clear in the

glass tube. The appearance of ext r eme murkiness

in the water i ndicates inadequate water quality and

will cause failure of controls and the steamer.

War ranty does not cover mal functi on due to poor

water conditions. Blowdown and/or clean out t he

boiler as outlined in “BOILER BLOWDOWN AND

STEAMER SHUT-OFF” under “STEAMER

OPERATION” and “BOILER” under “SERVICE

PROCEDURES”.

Water Level Control and Level Sensing Probes

these controls al low water to enter the boiler to f ill

and maint ain the proper water l evel. They will also

shut off the heat source to the boiler i f the water

level drops too low.

The water level cont r ol works by using three

different probe lengths to monitor the water level.

The probes consist of a high level (HL), low level

(LL) and low water cut-off (LLCO). The level sensing

probes may easil y be r emov ed to inspect f or lime

build up. A s a rule, the condi tion of these devic es

will indicate the overall water condition of t he boiler.

Clean the probes if needed.

NOTE:

clogging will occur if a daily blowdown procedure is

not followed.

Boiler Fill Solenoid Valve

boiler when dem anded by the water level control to

maintain the correct water level in the boiler.

Cold Water Condenser Solenoid Valve

cold water flow into the boiler blowdown drain box to

condense steam and cool the hot water before its

discharge int o the drain.

: THE STEAMER AND ITS PARTS ARE

- permits visual

-

Controls m ay not function and serious

- admits water to the

- allows

Cycling P ressure Switch

between prescribed limit s by t ur ning the heat source

on and off.

High Limit Pressure Sw itch

design to the cyc ling pressure switch but used as a

high li mit. The pressure settings are at hi gher and

lower limits than the cycli ng pressure switch in order

to turn off the heat sourc e before the boi ler pressure

reaches its limit and automati c ally resets af ter the

pressure drops below the lower limit set point.

Blowdown/Drain Solenoid Valve

plumbed into the drai n pipe of the boiler. Newer

steamer models will automatically blowdown when

power is turned off by using a normally open

solenoid valve. Older models can have a solenoid

valve t hat is activated by depr essing a separate

blowdown timer button or have a manual “ball” type

valve. Daily boiler blowdown is essential to proper

operation and component life by removing sediment

and scalants that may be lodged in the chamber of

the boiler .

Strainers

to prevent foreign matt er from becoming lodged in

the fill or cold water condenser solenoid valves and

to keep unwanted parti c les out of the system. A "Y"

strainer should be inserted upstream of the fill

solenoid valve.

On model s using a direct steam suppl y , a strainer i s

used in the pressure regulating valve.

Power Switch

to the controls and the steam generat ing process is

started in the boiler. The power switch is located on

the front of the boiler contr ol box.

Water Inlet Valve

stop water fl ow to t he steamer when the steamer is

being serv iced. Newer models will have a sm all

Petcock type val ve whil e older model s will be a

“ball” type valve. This valve should remain open

during normal operati on.

High Limit Thermostat

shuts off the heat source if the boil er temperature

exceeds a specified limit . All standard models are

equipped with a surface high limit .

Descaler

boiler and is used to help control boiler surf ac e

scaling. Two descalers are used in each boiler.

Handhole Cover Assembly

removed, allows internal ex amination and cleaning

of boiler shell and its components if required.

- a strainer is used in the water inlet line

- when turned ON, power is suppli ed

- the water inlet v alve is used to

- hangs submerged in water i nsi de the

- control s boi ler pressure

- a switch of identical

- this valve is

- a protective device that

- when unbolted and

Page 10 of 80

Page 11

VSX SERIES ST E A M E RS - COMPONENT FUNCTION AND LOCATION

Pressure Gaug e

- indicates boiler steam pressure.

Normal operating pressures are listed below.

STEAMER

TYPE

Gas 8 -10

Electric 11 - 13

Direct 10 - 12

Regenerated 10 - 12

- drains steam c ondensate and water from

Drain

PSI

cooking compartments and boiler.

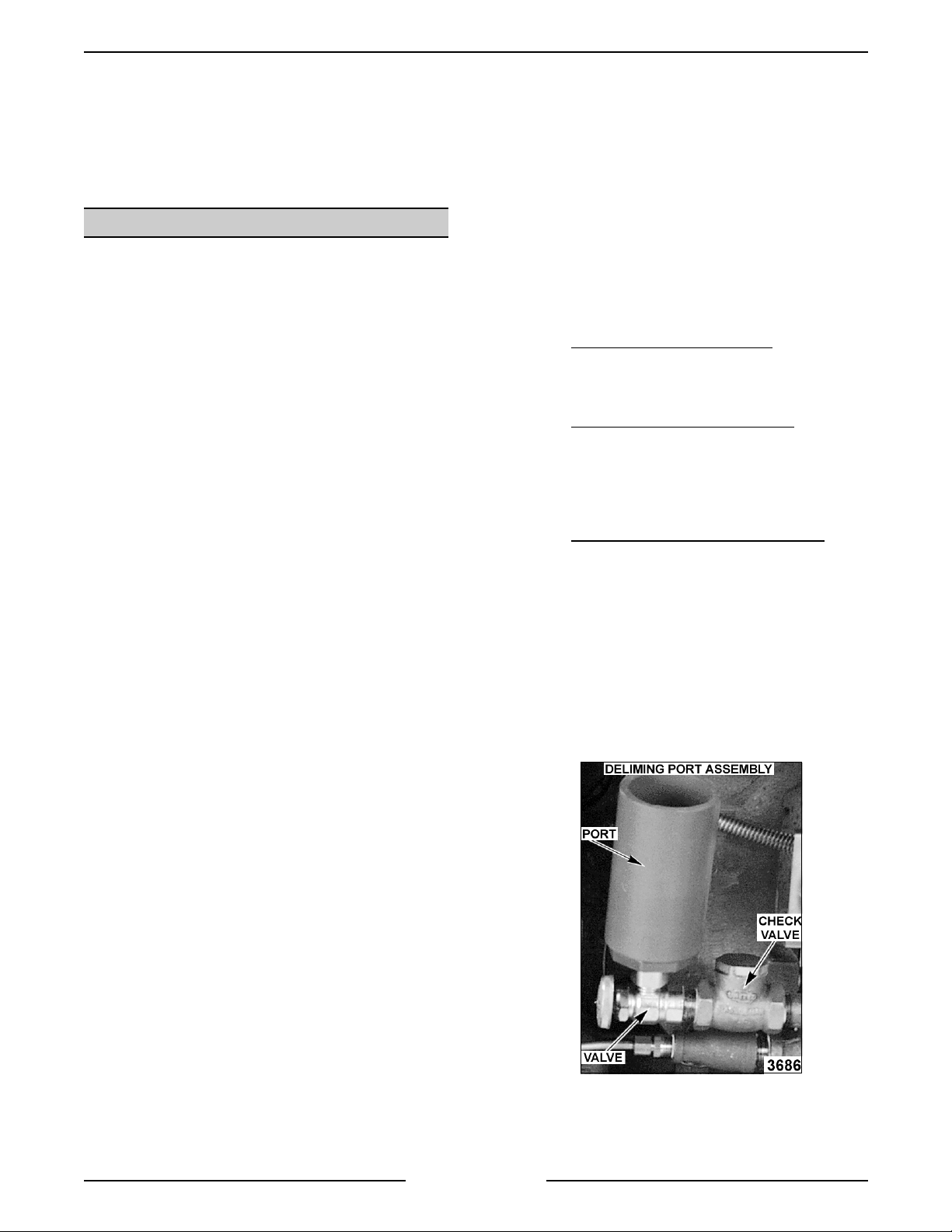

Check Valve

- On models with the deli me piping

assembly option, prevents the ejection of hot water

and steam out of the deli me funnel if the manual

delime fill valve were to be opened.

Delime Port Assembl y

- On models with the deli me

piping assembly option, allows the boiler and other

internal components to easily be delimed to remove

calcium, lime and rust bui ld up. See ”BOILER”

under “SERVICE P ROCEDURES”.

Standing Pilot (Gas Boilers)

- should always

remain lit t o light the main burners upon a cal l for

heat unless the steamer will not be in use for an

extended period. If the pilot flame goes out, wait 5

minut es before relighting.

Main Burn ers ( Gas Boilers)

- heats the water in

the boiler to generate steam.

Combination Control Valve (Gas Boilers)

- a gas

solenoid that opens t o allow gas flow when a call for

heat is made and also regulates the m anifol d gas

pressure.

Pressure Regul ating Valve (Direct &

Regenerated Steam)

- regulates the manifold

steam pressure between 10-12 psi.

Magnetic Contactor (E lectric Boil ers)

- when coil

is energized, suppl ies power to the electric heating

elements.

Heating Elements (Electric Boilers)

- heats the

water in the boi ler to generate steam.

Page 11 of 80

Page 12

VSX SERIES ST E A M E RS - COMPONENT FUNCTION AND LOCATION

Page 12 of 80

Page 13

VSX SERIES ST E A M E RS - COMPONENT FUNCTION AND LOCATION

Page 13 of 80

Page 14

VSX SERIES ST E A M E RS - COMPONENT FUNCTION AND LOCATION

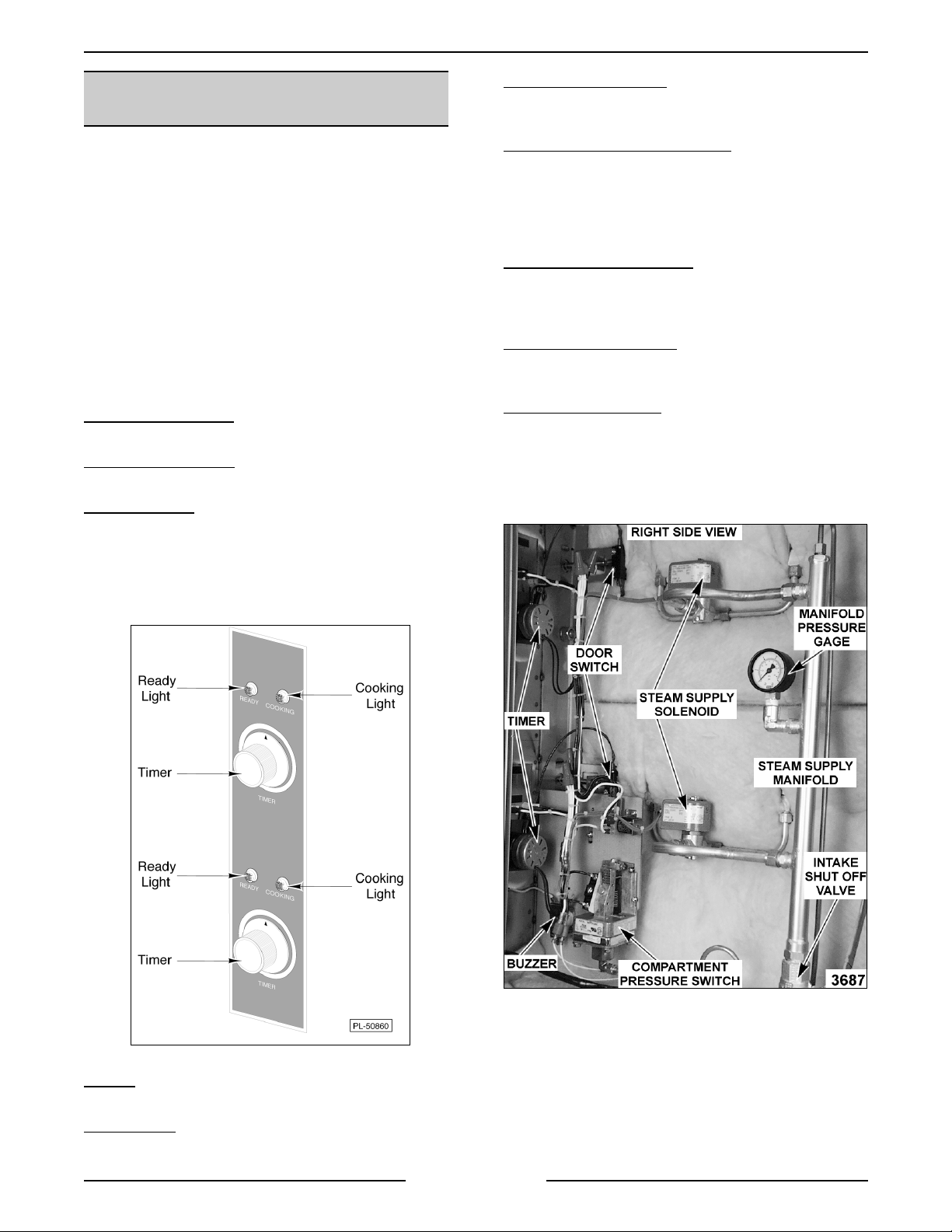

COOKING COMPARTMENT

CONTROLS

WARNING:

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENT CONTAINS LIVE STEAM. STAY

CLEAR WHEN OPENING EACH DOOR.

The upper section of the steam er c onsi sts of two

separate cooking compartm ents. Each compartment

functions independently with its own set of contr ols.

Power is supplied to t he c ontrols only after the

steam pressure rises above 3 psi to close the

compartment pressure switch. The switc h remains

closed as long as steam pressure stays above 3 psi

but will open i f the pressure drops below that setting.

Ready Light (Green)

is ready to cook.

Cooking Light (Red)

is in a cooking cycle.

Cooking Timer

tim e between 0-60 minutes. When a timer i s set, the

steam supply solenoid valve is energized to al low

steam int o the cooking compartment but only after

the boiler has reac hed its operating pressure. Also,

energizes the buzzer when time expires.

THE STEAMER AND ITS PARTS ARE

- when lit, indicates steam er

- when lit, indicates steam er

- use to set desired cooking cycle

Steam Solenoid Valve

allow steam into the cooking compartment (normally

closed v alve).

Compartment P r essure Switch

the control s only after the steam pressure rises

above 2. 3 psi to close the compartment pr essure

switch. The switch remains closed as long as steam

pressure stays above 2.3 psi but will open if the

pressure drops below that setting.

Manifold Pressure Gauge

of steam pressure in manifold. T he intake shut-off

valve should be adjusted so manifold pressure

remains at 9 psi with both compartments on.

Steam Supply Manifold

from the boiler for each cook ing compart ment.

Supplies steam up to the steam sol enoid valve.

Intake Shut-Off Valve

from the boiler to the steam suppl y manifold. This

valve should NOT be left fully OPEN to boiler steam

supply. See “INTAKE SHUT-OFF VALVE

ADJUSTMENT (STEAM FLOW) under “SERVICE

PROCEDURES”.

- when energized, opens to

- supplies power to

- indicates the amount

- main st eam supply line

- main st eam supply shut-off

Buzzer

turned off manually.

Door Switch

timer.

- signals end of a cook cycl e, must be

- removes electr ical power to the

Page 14 of 80

Page 15

VSX SERIES ST E AMER - SERVICE PROCEDURES

SERVICE PROCEDURES

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

BOILER

Inspection

It is recommended that the boiler be thoroughly

inspected f or excessive scale and li me build up on a

quarterly basi s. In hard water areas or for units

heavily used, a more frequent interval should be

used. This inspection consists of an i nternal

examination and cleaning of the boiler shel l, an

examination and possibl e r eplacement of the

descaler, a check of li me build up on the water level

sensing probes, and a check of all boiler controls,

including the pressure switches.

Periodic servi c e must be perfor med as outlined in

these procedures. See “WATER CONDITIONING”

under “GENERAL”.

WARNING

INSTRUCTI ONS ON THE CLR BO TTLE. USE

PLASTIC OR RUBBER GLOVES TO AVOID SKIN

CONTACT. IF CLR LIQUID COMES IN CONTA CT

WIT H THE SKI N, RINSE WITH CLEAN W AT ER.

Clean-Out (All Boiler Models)

1. Turn steamer OFF and drain boiler.

2. Remove hand hol e plate and gasket (top front)

3. Remove ol d descaler retaining springs if

CERTAIN PROCEDURES IN THIS SECTION REQUIRES ELECTRICAL TEST OR

CABINET BASES

: READ AND FOLLOW THE

from the boiler by removing the nut and clamp,

then tapping t he c over lightly to free i t while

holding the c over stud. This prev ents the cover

from dropping into boiler.

present.

NOTE:

to nine gallons for both gas and el ec tric m odels

depending on the boiler size and BTU/KW rating.

NOTE:

contact wit h steamer components, lightly rinse of f

with clean water.

Boiler water c apac ities vary between seven

If deliming solution acc idently comes in

A. Models with Blowdown Timer

deliming solution into boiler shell. Mix the

solution in accordance with the instructions

on its container. Proceed to step 9.

B. Models without Blowdown Timer

the incoming water supply. Turn the unit

ON to close t he dr ain valve. Pour deliming

solution into boiler shell. Mix the solution

in accordance with the instruct ions on its

container. Proceed to step 9.

C. Models with Del iming P ort Assembly

Before mixing and pouring del iming

solution into boiler , clean the seati ng

surfaces for the hand hole gasket and then

install a new gasket. Position t he hand

hole plate and tighten down. Turn off the

incoming water supply. Tur n the unit ON

to close the drain valve. Open the

deliming assembly valve and pour the

deliming solution into the port. Mix the

solution in accordance with the instructions

on its contai ner. Close the deliming

assembly valve and proceed to step 10.

- Pour

- Turn off

-

4. With a wire brush, or equivalent, dislodge and

remove all loose scale from boiler shel l. The

loose mater ial must be either scooped fr om the

boiler or flushed through t he dr ain.

5. Check probe canister and f loat valve assembly

(regenerated models) for a scale build up and

clean as necessary.

6. Check drain hole f or obstructions.

7. Install two new descalers.

8. Mix the deliming solution according to the

instructions for the chemical in use then add

solution to boiler.

Page 15 of 80

9. Clean the seating surfac es for the hand hole

gasket and then Instal l a new gasket. Position

and tighten t he hand hole plate.

Page 16

VSX SERIES ST E AMER - SERVICE PROCEDURES

10. Cooking c ompartm ent timers are to be in the

OFF position. Turn the boiler switch ON and

open water valve if necessary.

11. Boiler is to operate under pressure for 90

minut es or per the instructions for the chemical

in use.

12. Drain boiler by normal methods. Refill boiler

and allow heat until f ully pressurized.

13. Repeat step 12 thr ee times.

14. The steamer is now ready for nor mal operation.

Deliming Only

(Models with Deli ming Port Assembly)

Boiler delim ing should be perfor med on a weekly,

bi-weekly or monthly basi s, depending on the quali ty

of the local water supply.

On steamers using a water purifi c ation system,

follow the instructions for that system to deli me the

boiler. Only use the type of chemical recommended

or described in the instructions for deliming wit h this

type of system.

1. Turn steamer OFF and drain boiler.

2. Mix the deliming solution according to the

instructions for the chemical in use then add

solution to boiler.

NOTE:

Boiler water c apac ities vary between seven

to nine gallons for both gas and el ec tric m odels

depending on the boiler size and BTU/KW rating.

NOTE:

If deliming solution acc idently comes in

contact wit h steamer components, lightly rinse of f

with clean water.

A.

Models with Blowdown Timer

- Open

the deliming assembl y valve and pour the

deliming solution into the port. Mix the

solution in accordance with the instructions

on its contai ner. Close the deliming

assembly valve and proceed to step 3.

B.

Models without Blowdown Timer

- Turn

off the incoming water supply. Turn the

unit ON t o close the drain valve. Open the

deliming assembly valve and pour the

deliming solution into the port. Mix the

solution in accordance with the instructions

on its contai ner. Close the deliming

assembly valve and proceed to step 3.

3. Top compartments are to be in the OFF

position. Turn the boiler switch ON and open

water valve if necessary.

4. Boiler is to operate under pressure for 90

minut es or per the instructions for the chemical

in use.

5. Drain boiler by nor mal m ethods. Refill boiler

and allow to heat up and build steam pr essure.

6. Repeat step 5 three times.

7. Unit is now ready for normal operation.

Descaler

The descaler i s accessible through the hand hole

opening. It is a coiled wire wound around a solid

cylindrical cor e, and hangs by an open loop from the

shell's horiz ontal stay rod, about 4 inches from the

front of the shell . If t he wi r e is eaten through, or if

the core of the descaler is eaten away to half its

original size, a new descaler should be i nstalled.

To install a new descaler, stretch its wire coil so that

the descaler hangs with i ts core completely below

the mi nimum water level in the boiler, but hanging

free. The descaler must not contact the bottom of

the boiler shell, elec tric heating element s or t he

regenerating steam coil s on uni ts so equipped.

Water Level Cont rols

(Low L evel Cut-Off and Different ial)

Solid State

1. Ensure that water is filling the boiler.

2. Check for correct voltage being applied to the

board.

3. Verify the water level control boar d oper ation

as outlined in “WATER LEVEL CONTROLS”

under “ELECTRICAL OPERATION”.

A. Does the HL LED light up and the HL r elay

energize to change the contact stat e at

power on?

B. As the boiler fills, does the LLCO LED light

up and the LLCO relay energize to change

the contact state after the water level

reaches the LLCO probe?

Page 16 of 80

Page 17

VSX SERIES ST E AMER - SERVICE PROCEDURES

C. Does the HL LED go out and the HL relay

de-energize, allowing the cont ac t state to

switch back to i ts starting condition after

the water level reaches the HL pr obe?

4. If water is in t he boiler but is not being detected

by the water level probes, the probes may need

cleaned and/or boiler delimed. See “BOILER”.

5. After checking the abov e items, if the water

level control board does not appear to be

functioning as outlined, then repl ac e the board.

6. Check unit for proper operation.

Electro Mech anical

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Loose electri c al connections may prev ent the heat

from coming on or may cause the boiler to overfill.

Accumulation of boiler scale on or near the sensing

probes may cause them to retain water on the

insulator surface. This may prevent the boiler from

filling or cause dry firing. Dry firing will result in

damage to heating elements or to the boiler. Verify

the water level cont r ols operation as outlined in

“WATER LEVEL CONTROLS” under “ELECTRICAL

OPERATION”.

With the individual probe l ead wir e r emov ed, check

the probes and contactor s as outl ined below:

1. With an ohmmeter , check the probe bet ween

the wire connection and shell. An open c ircuit

should be present when the boiler is empty. If

resistance is present, r emov e and c lean the

probes. Also check for a cracked insulator, then

reinstall probes and check. When the boiler is

full of water, a resistance reading should be

measurable bet ween the probes and shell only.

NOTE:

Actual resistance reading will depend on

water qualit y and pr obe c ondition.

2. Check low level and dif ferenti al water level

controls. Wi th the power switch ON, use a

voltmeter to check the i nput voltage across

terminals 1 & 2. Meter shoul d r ead 115V . With

the boiler empty, ac r oss terminals 9 & 10, y ou

should read 300 to 350V. If you do not r ead this

voltage, then coil is bad and contac tor should

be replaced.

3. Remove sensing probe. First rem ove the

bolted cover over the sensor cluster. Then

remove the wire from the pr obe and unscrew

the probe with a wrench. Be c ar eful to note the

locati on of each probe and the number of the

wire connected to it. Incor r ec tly connected

wires will cause the controls to malfunction.

4. Clean probe thoroughly, r emov ing ALL deposits

from the insulat or . Do not use an abrasiv e on

the insulator; use a soft cl oth.

5. Inspect through the probe socket for the

presence of water. Water must drain from the

probe housing. If in doubt, pour water into the

housing and observe that it drains quickly. If

the housing fails to drai n, remove the housing

or housing cover and clean the interior

mechanically.

Water Level Gauge Assembly

Close the valve at the top and at the bottom of the

gauge assembly. Unscrew the packing nuts at the

top and bottom of the glass tube. Slide the glass

tube upwards, until the bottom of the tube is clear of

the fitting and lift it out.

When r einstalling the tube, use new sealing

washers. Do not over t ighten the packing nuts; it

could break the gauge glass. Check that both top

and bottom valves are f ully open.

Pressure Swit ches (Gas and E lectric Models)

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Remove the boil er control box cov er to access the

two controls. T he pr essure switch on the left is the

cycling or prim ar y c ontrol; the one on the right i s the

high li mit c ontrol. They ar e identical switches,

differing only in their settings.

Turn the power ON and l et the boiler c ome up to

pressure. Aft er the ready light comes ON, t ur n one

of the cook ing compartment timers on to exhaust

steam f rom the boi ler. Observe boiler pr essure

gauge readings for sev eral cycles and compare

them with the pressure settings in the chart. If the

readings differ, adjust the pressure settings as

described below.

Two slotted and square headed adjustment screws

extend thr ough the top of t he swit c h c ase with dials

and pointers to indicate the appr oxim ate setting.

The adjustment screw directl y above the dial

changes both the cut-out (off) and the cut-in (on)

points. Set it first to give the proper off setting.

Turning the scr ew cl oc k wise i ncreases the pressure.

Then set the second adjustment screw to give the

proper on setting. The pressure settings for eac h

switch are li sted below.

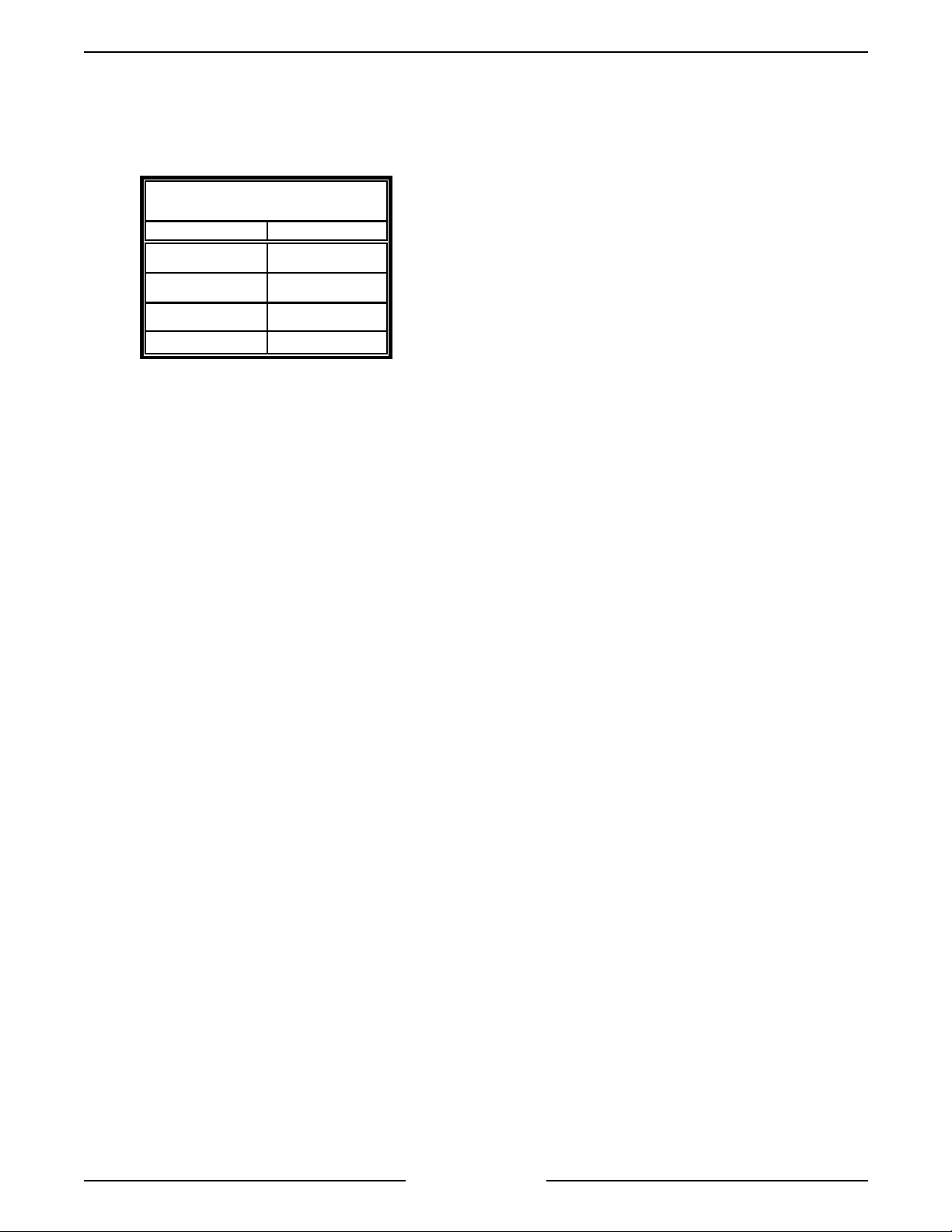

PRESSURE SETTINGS (PSI)

CYCLING HIGH LI MIT

UNIT ON OFF ON OFF

Gas 8 10 6 15

Electric 11 13 6 15

Page 17 of 80

Page 18

VSX SERIES ST E AMER - SERVICE PROCEDURES

High Limit Thermostat

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Remove thermostat (bi-metallic disk type) and

inspect f lat surfac e of thermostat for c or r osi on or

rust. Replace if rusted.

Clean thermostat mount ing and thermostat surfaces

before remounting or r eplacing. A good

metal -to-met al contact is essential for pr oper

functioning of the thermostat. This service m ust be

performed at least once a y ear .

On gas boilers, the high li mit t her mostat is loc ated

on the face of the boiler close to t he si ght glass on

the right side. For access, remove t he small metal

cover placed ov er the therm ostat.

On electr ic boil er s, the high li mit t her mostat is

located behi nd the contactor box cover. On elec tric

boilers with two heating elem ents, the therm ostat is

connected to one of the heating element lugs. On

electric boiler s with four heati ng elements, t he

thermostat is located bet ween the center pair of

element s at the top of t he elements.

Removing The Boi ler Assembly

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING:

ALL GAS JOINTS DISTURBED

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS BEYOND GAS

VALVE (SOLENOID) AFTER UNIT IS LIT.

Blow down the boiler and

Newer Steamer Mod els

-

allow to cool, if necessary. Ensure that all utilities to

the steamer are off. Drain any ex cess water from

the boiler . Disconnect the steam supply line, power

leads and drain l ines from the cooking compartment

top to the boi ler base. Remove the cooking

compartment top by unscrewing the bolts holdi ng

the cooking compartment top to the boiler base. The

bolts are loc ated behind the small louvered access

panels on the left and right side of the steamer. Lift

the top of f the boiler base and place to t he si de.

Remove the remaining plumbing and elec trical

connections from the boiler to t he c ontrols. Remove

the bolts securi ng the boiler t o the frame and lift it

out. Reverse procedure to i nstall a new boiler.

Older Steamer M odels

- Blow down the boiler and

allow to cool, if necessary. Turn off all utilities to the

steamer and di sconnect supply lines. Dr ain any

excess water from the boiler. Remove the screws

holding any control box that would obstruct removal

of the boiler through the front of the base.

Disconnect the 1/4 inch diameter water inlet tubing.

Disconnect the wir e and c onduit fr om the low water

cut-of f probes, high limit thermostat, and the

automatic blowdown valve (if so equipped).

Uncouple the uni on on the steam outlet and blow

down the lines.

Remove all t he scr ews holdi ng the flue and flue

collector to the base. Remove t he anc hor screws

holding the boiler to the frame. Sli de the boiler

forward. T he bur ner box, anchored onl y by the

boiler, must be prevented fr om slidi ng forward with

the boiler .

Fill and Cold Water Solenoid Valves

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Turn off the water supply to the steamer.

2. Open the base doors and remov e the two

screws from the top of the boiler control box.

3. Pull the quick connect power leads off the

solenoid valve being serviced.

4. Disconnect the water li nes for the valve being

servi ced and remove the valve from the unit.

5. Reverse procedure to install.

Disassembly

NOTE:

It is recommended that the v alve be

removed from the unit for cl eaning to prevent

damage to the lines and fittings when the stem is

removed from the body.

1. Remove the c oil assembly from the valve stem

by lifting up on t he retaining c ap at the top of

the solenoid valve and sliding the met al cov er

plate off.

2. Clamp the body of the v alve in a vise.

3. Mark a scribe line on the stem nut to the valve

body for proper retightening.

Page 18 of 80

Page 19

VSX SERIES ST E AMER - SERVICE PROCEDURES

4. Remove the stem locking nut to remove t he

stem f rom the valve body.

5. All parts are now accessible for inspecti on and

cleaning.

NOTE:

If internal solenoid parts appear to be

damaged or worn, then r eplace the solenoid valve.

Do not reuse damaged or worn parts. No internal

solenoid parts are available as a service

replacement. Pay careful attention to proper

orientation and placement of parts during

reassembly.

A. Check rubber seal on bottom of plunger .

B. Check plunger spring.

C. Check O-ring in valve body.

D. Check ports in valve body.

6. Reverse procedure to install.

Water Not Being Supplied to Boiler

Turn the steamer on. Check that water suppl y is

available to the steamer. A fter approximately 10

minut es, if no water is observed in t he water level

gauge sight glass, then chec k for a problem with the

water solenoid valve or water level cont r ol probe.

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Scalants may be cov er ing the water level cont r ol

probe giving a f alse indicat ion of a suf ficient water

level in the boiler. Detach, remove and thoroughly

clean the water level probe and canister assembl y

to remove scalant s and l ime build up. This condition

indicat es extremely poor water quali ty being

supplied to the boiler and/or boiler cl ean out/and

deliming has not been performed. T he water

conditi on must be cleared up imm ediately wit h a

proper water condit ioner to avoid f ur ther problem s

with the steam er . Replace the water l evel pr obes

and canister assembl y . Perform a boiler c lean-out

and deliming procedure. S ee “BOILER”.

Water may be draining through an open boiler

blowdown solenoid v alve as qui c k ly as it’s fed to the

boiler. Loose wiring, a burned out coil or particles of

scale trapped i n the valve seat may prevent the

valve from closing.

Newer steamer models use a plunger type rod that

raises and lowers to permit steam/water flow out of

boiler. If debris has accumulated around the water

orif ice, the plunger may not seat pr oper ly to close

off the opening. I f this symptom i s suspect, remov e

the solenoid as outlined in “FILL AND COLD

WATER SOLENOID VALVES”. Remove any debris

found on seali ng surfaces, reassemble and install. If

the solenoid valve still does not function properl y ,

replace it with a new valve and chec k for proper

operation.

Older steamer model s have a movable blade and

when closed, the blade reac ts as a guillotine that

should be free t o move fully down into the valve

pocket (projection at bottom of valve) so that the

pierced hole in the blade aligns perfectly with the

body opening. If debris has accumulated in the

bottom of the valve pocket, then the blade will not

move into the pocket completely. If this symptom is

suspect, remove the solenoid as outlined i n “FILL

AND COLD WATER SOLENOID VALVES”.

NOTE:

On this valve body, remove t he two

assembly bolts holding the brass body together and

remove the loose i nternal parts. Remove any debr is

found on seali ng surfaces, reassemble and install. If

the solenoid valve still does not func tion properly ,

replace it with a new valve and chec k for proper

operation.

Blowdown Solenoid Valve Does Not Drain

If your steamer has an automatic blowdown drain

valve.

Older Models

- when the blowdown timer button is

pressed, the boiler blowdown valve opens. If y our

steamer has a manual blowdown drain v alve, close

the v alve.

Newer Models

- are equipped with nor mally open

solenoid valves that close when energized by the

main power switch. When the main power switch is

turned off, the solenoid valve is de-energized and

the boiler blowdown valve re-opens.

The water contai ned in the boil er , being under

pressure, should be blown through this valve and be

noticeabl y visible exhausting out the steam er dr ain.

If t he blowdown operation appears to func tion

sluggishly or not at all, considerable scalants may

be lodged in the dr ain pipe and/or the valve.

Disconnect the valve f rom the drain line and i nspect

both the valve and the drain pipe fixed to the boi ler.

If consi derable scalants or l ime build up is apparent,

then not only the valve, but also the boiler and water

level control must be thoroughly cleaned. S ee “FILL

AND COLD WATER SOLENOID VALVES” for a

cleaning procedure of a solenoid valve and

"BOILER” for a cleaning proc edur e of the boiler.

Page 19 of 80

Page 20

VSX SERIES ST E AMER - SERVICE PROCEDURES

Steamer Achieves Pressure Sl ower Th an Normal

If t he boiler requires more than 15 minutes (20

minut es for regenerated models) to achi eve normal

operating pressure as li sted in below, then check the

following conditions.

NORMAL OPERATING

STEAM PRESSURES

UNIT RANGE (PSI)

Gas 8 - 10

Electric 11 - 13

Direct 10 - 12

Regenerated 10 - 12

1.

All Models (With Boiler)

A. A heavy bui ld-up of scal ants has possibly

coated the interior of the boil er . The

insulating eff ect of the scalants hampers

heat transfer. Unbolt and remov e the hand

hole cover plate and gasket assembly.

Exam ine interior of boiler and if scalants

and/or li me buil d up is apparent, perform a

boiler clean-out and deliming pr oc edur e.

See “BOILER”. If consi der able scalants

are evident, then bot h the boiler blowdown

solenoid valve and the water level control

must also be examined.

2.

Gas Model s

A. Low incoming gas pressure causes

reduced BTU output . Check incoming line

and manifold gas pressures as outlined i n

“MANIFOLD PRESSURE ADJUSTMENT.”

B. Gas combination control valve

malfunction. Check incoming and manifol d

gas pressures as outlined in “MANIFOLD

PRESSURE ADJUSTMENT.” If pressure

adjustment s are made and mani fold

pressure remains low, replace the

combination valve and test unit for proper

operation.

C. Gas burner ports clogged or obstruction

around air shutter . After a per iod of time,

gas burners can accumul ate carbon in

their ports or become clogged by food and

grease debris from kitc hen c leaning,

restrict ing performance. To clean burners,

remove them from burner box and boil in

water for 10 -15 minutes to dislodge clog.

Clean-out any remaining debris from the

gas ports using a wire brush, scribe or pic

type met al instrument. Remove any other

forei gn objects that appear to be

obstructing the gas ports or air shutters.

D. Gas orifice clogged or obstructed around

air shutter. It is possible for debris to

become lodged in the smal l gas orifice

opening over time. Clean-out the gas

orif ice using a round m etal instrument of

the same hole diameter or sl ightly sm aller.

Clean as needed. If clogging r eappear s,

the orifice should be remov ed, cleaned

and reinstalled. Remove any other foreign

objects that appear to be obstructi ng the

gas orifice or air shutt er s.

3.

Electric Mo dels

A. Heavy scale build up on heating element

causes reduced heating.

B. One or more elec tric heating element s

malfunctioning.

C. One or m or e magnetic c ontactors not

pulli ng in, to power heati ng elements.

D. If unit operates under three phase power,

then one of t he phases m ight be lost.

4.

Direct Steam Models

A. Building steam supply pressure low.

B. Cooking compart ment steam sol enoid

valve malf unc tion.

C. Steam pr essure regulator adjusted too

low.

D. Clogging in the steam line reduces steam

supply.

5.

Regenerated (S t eam Coil) Steamers

A. Heavy scale build up inside copper steam

coil.

B. Building steam supply pressure low

C. Cooking compartment steam solenoid

valve malf unc tion.

Page 20 of 80

Page 21

VSX SERIES ST E AMER - SERVICE PROCEDURES

Inlet Water Strainer

The in-line Y strainer shoul d be located upstream of

the fill valve solenoid. Unscrew the cap f r om the

body on the leg of the Y that shoul d be pointing

downwards toward the floor. Remove the screen

and any foreign particles trapped in the opening.

Rinse the screen thoroughly to remove accumulated

debris and replace the screen in the valve body. If

screen can not be thoroughly cleaned, replace it

with a new one. Reinstall the cap and ensure that

the Y strainer is positioned with t he c ap pointing

downward to catch debris.

The pressure regulating valve strainer will become

clogged if dirty steam lines are connected to dir ec t

steam models. Remove the hex nut on the bottom

of the pressure regulating valve to clean the strainer

and valve seat.

GAS MODELS

Pilot, Thermocouple or Main Burners

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

DISCONNECT THE ELECTRICAL

NOTE:

settings are m ade, always replace the adj ustment

cover scr ew to assure proper gas control operation.

If adjustments in gas or pilot pressure

WARNING:

SERVICING THE UNIT.

The pilot thermoc ouple supplies a millivolt signal

(DC) to an int ernal solenoid valve on the gas

combination control valve when heated. This

solenoid valve is designed to shut off the gas flow to

the pilot and main bur ner s i n c ase of a malfuncti on

in the system . When ener gized by the thermocouple

voltage, the valve is held in the open positi on to

permit gas flow. The pilot burner flame is controlled

by an adjustable needle valve located under a small

cap screw on the combi nation control valve.

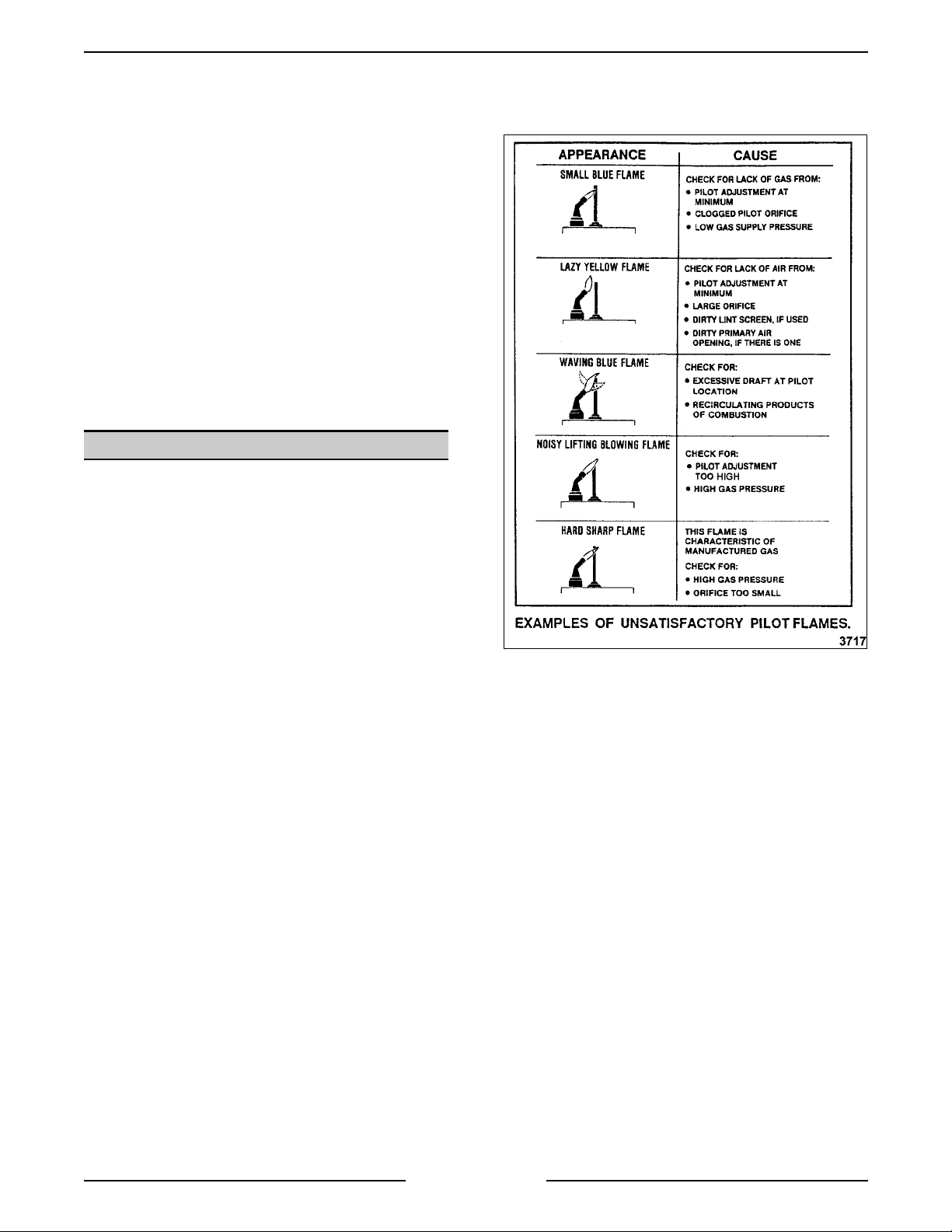

When experiencing nuisance pil ot outages, v isually

check pilot flame for the proper contact on

thermocouple and the flame color. Also, chec k to

see that unusually str ong floor drafts are not

interfering with pr oper heating of the thermocouple

by the pil ot flame.

The pilot flame should be a steady blue flame that

envelopes the thermoc ouple tip. The flame should

be about one inch l ong wi th half its length extending

beyond the outer edges of the pilot shield. If the pilot

flame does not appear to be this length and color ,

then an adjustment is necessary. See the diagram

below for an example of un satisf ac tory pilot flames.

Turn cloc k wise to dec r ease pi lot flame and

counterclockwise to increase.

SHUT OFF THE GAS BEFORE

If adjustment does not resul t in a pil ot flame of

proper size, t hen gas might not be flowing properly

to the pilot. Check for a plugged pi lot orifice, a

kinked or plugged pilot gas supply tube and for l ow

gas supply pressure. The pil ot operates unregulated

at gas supply pressures while the pressure regulat or

in the combination control valve regulat es pressure

to the main burners only. V isually check the

thermocouple tip (hot end) and tube lead for kinks or

pinches that might be causing a short between the

tube and the wire i nsi de. Also, check t he threaded

connector tip for cor r osi on, tarnish or dir t which can

cause a poor connection. If t he thermocoupl e shows

either of these signs, it shoul d be r eplaced with a

new one.

NOTE:

thermocouple tip t o the control valve is an elec trical

connection and must be clean. Do not use any

sealing compound on the threads or over tight en the

threaded connection. Finger tighten the nut plus 1/4

turn with a wrench. O ver tightening the nut could

crush the insulat or , shorting the ther mocouple.

If t he pilot flame is correct and ther e ar e no dr afts,

then the problem is in t he thermocoupl e output

voltage or the gas solenoid valve in the combination

control.

The connecti on of the tubing from the

Page 21 of 80

Page 22

VSX SERIES ST E AMER - SERVICE PROCEDURES

Check the thermocouple output voltage (DC

millivolts) with a VOM. If a meter is not available,

replace the t hermocouple with a new one and

recheck operation. Fir st, take a closed ci r c uit

reading (adaptor r equired) with the pilot on. Next,

take an open circuit readi ng by disconnecting the

thermocouple tube from the valve and connecting

meter leads to the tube and threaded end. Manually

press and hold down OFF/PI LOT/ON knob and light

the pilot. All ow the pilot to heat the therm oc ouple for

one to two minutes and compare the readings with

the chart bel ow.

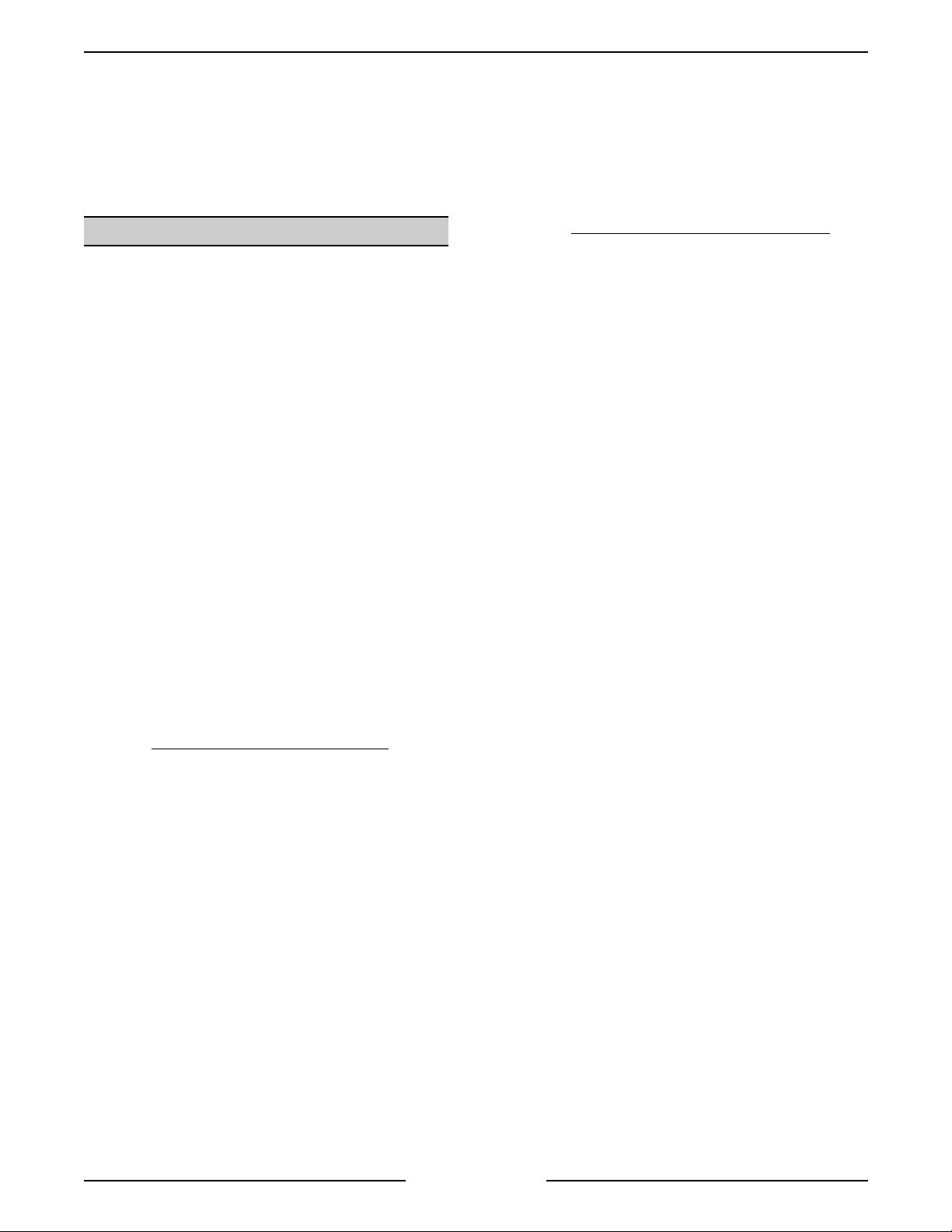

THERMOCOUPLE

MV

READINGS

CLOSED

CIRCUIT

Typical 15

Range 10 - 20 20 - 35

OPEN

CIRCUIT

If either of the readings is less than the minimum or

thermocouple is not operating as described, replac e

the therm ocouple. To replace, rem ove the pilot

assembly by di sconnecting thermocouple and pilot

gas supply tubing from the c ombination control

valve and remov e the two screws holding the pil ot

to its brack et. Replace the thermocoupl e or pilot

assembly and check for proper operat ion. If after

replacing thermocouple, the pilot or main burners

are still not functioning properly, then a problem in

the gas combination control valve exists as well.

Replace the combination control valve as outlined in

“GAS COMBINATION CONTROL VALVE

REPLACEMENT” then check for pr oper oper ation.

NOTE:

Gas combination control valves are not

servi ceable and should not be di sassembl ed. Once

you have isolated the problem to t his control,

replace it. Do not attempt to repair the assembly.

The mai n burners are lanced port steel burners (5 or

7 burners, depending on the unit) and have

adjustable air shutters. Fi xed orifice type hoods are

used to establish the gas flow to each burner. Set

each burner air shutter opening just large enough to

eliminate any yellow tip i n the burner flame.

To remove main burners, lift burner and sl ide it to

the rear just enough to clear the gas ori fice hood.

Lower the front end of burner and bri ng it for ward

under the manifold pipe. When reinstal ling burners,

ensure that locating pin i s i n the hole for pr oper

positioning and to prevent burner f r om roll ing over .

Automatic Ignitio n Systems

When the main power switch is turned ON and the

ignition control modules reset switch is i n the ON

position, the ignit ion control module is energized

with 24 v olts between terminals five and six.

High voltage is sent from t er minal nine to the spark

electrode and an out put of 24 volts i s sent from

terminals two and three to the pilot coil in the

combination valve, allowi ng gas to flow to the pilot.

The sparking will continue for 90 seconds or until

the flame sensor has confi r med that an adequate

pilot flame is present.

Once the pilot flame is confirmed, a 24 volt output

from terminal one will be sent, allowing the cycling

coil of the com bination valve to operat e at the

request of the cycl ing pressure switch.

Terminals:

1. Main Voltage

- 24V AC will be present on

terminal #1 with the pilot sensing elec trode

sensing an adequate pilot fam e. This output will

remain present as long as the pilot flame

remains adequat e.

2. Common (MV/P V ).

3. Pilot Voltage

- 24V AC will be present on

terminal #3 at the instant an input voltage is

supplied to the module. This voltage will

remain present on terminal #3 providing an

adequate pilot flame is established within 90

seconds. In the event that an adequate pilot

flame is not establ ished within 90 seconds this

output voltage will drop out.

4. Ground (burner).

5. Ground (24VAC Neutral) .

6. 24V AC Input.

7. High Voltage to spark el ectrode (The pi lot

flame current is sensed by the Ignitor Module

via the spark elect r ode high voltage wire and

terminal #9).

Page 22 of 80

Page 23

VSX SERIES ST E AMER - SERVICE PROCEDURES

Spark Ignition Control Test

1. If the ignition contr ol modul e does not appear

to be sparking to ignite gas, perform t he

following checks.

A. Check to ensure that all electrical terminal

connections on the igniti on c ontrol module

and the ignitor are clean and t ight.

B. Verify that the ignition contr ol module and

the ignitor have good ground wire

connections. The ignitor mounting brac k et

should have good metal t o metal c ontact

to its m ounting surfac e.

C. Turn the main power switch ON. Turn the

ignition control modules re-set switch OFF

then ON.

D. Check f or 24V A C output on the ignition

control module transformer.

1) If 24VAC is present then replace

ignition control module and re-t est.

2) If 24VAC is not present t hen ensure

that transformer is receiving 120VAC

input. I f igni tion control module

transformer is recei ving pr oper

voltage, then replace ignition control

module t ransformer and r e- test.

2. If the ignition contr ol modul e and transform er

are funct ioning properly, then check the

following ignitor conditions.

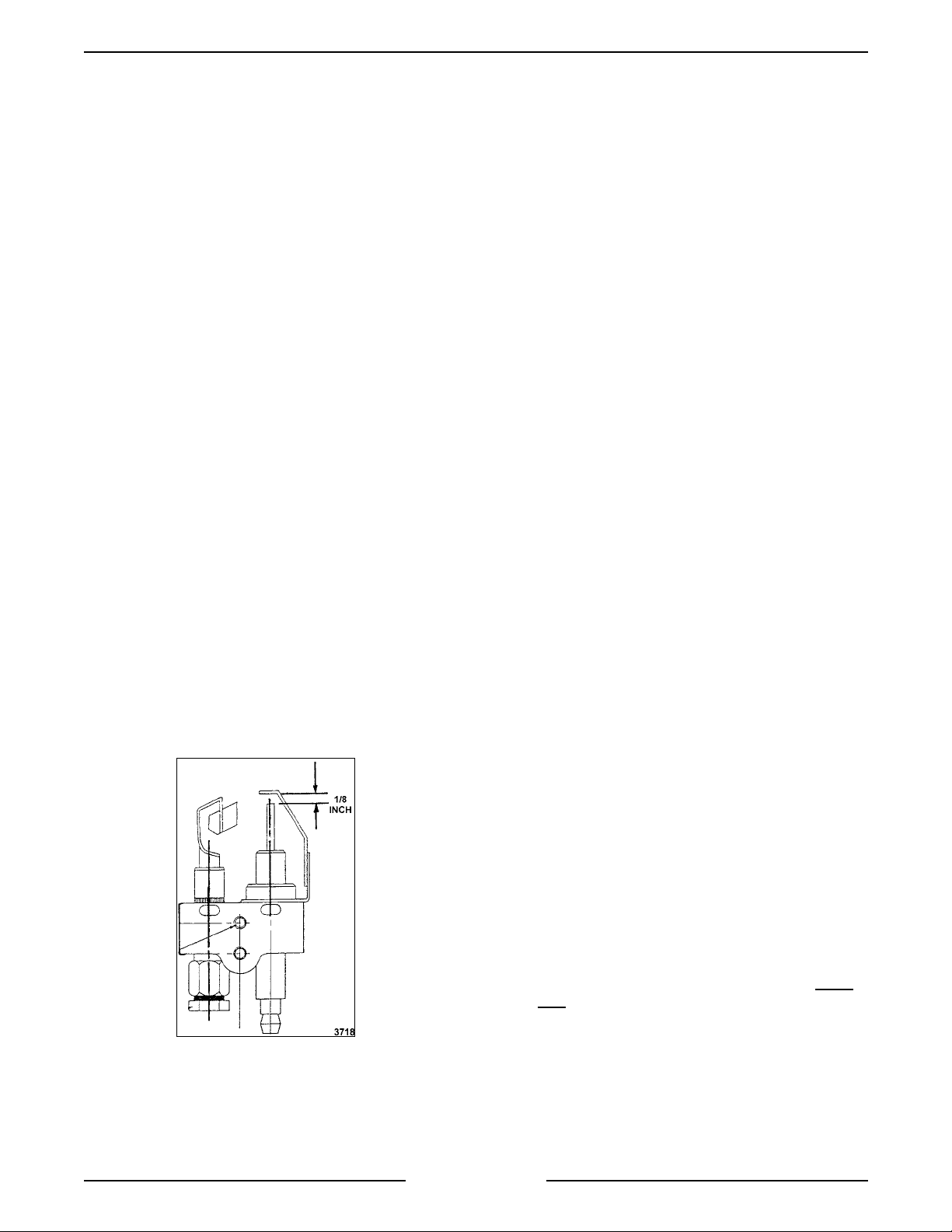

A. The gap between the spark probe and the

ground clip should be approximately 1/8

inch. If the gap appears to be excessive or

poor sparking is occur r ing, remove the

electronic ignition pil ot and adjust gap.

C. Check the i gnition cable for tightness or

damaged insulation.

3. Check unit for proper operation.

Gas Combination Co ntrol Valve Replacement

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING:

ALL GAS JOINTS DISTURBED

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS BEYOND GAS

VALVE (SOLENOID) AFTER UNIT IS LIT.

NOTE:

Gas combination control valves are not

servi ceable and should not be di sassembl ed. Once

the problem has been isolated to t his control,

replace it. Do not attempt to repair the assembly.

Remove the two screws on the control box cov er .

Disconnect electrical supply wires and conduit

running to the c ombination control valve.

Disconnect the thermocoupl e lead and pilot gas

supply tube f rom control and pipe connections on

each side of t he control. Reverse procedure t o

install and check unit for proper operat ion.

Manifold Pressure Adju st ment

B. Inspect the ceramic flame rod insul ator for

cracks or evidence of exposure to ex treme

heat, which can permit leakage to ground.

If either of these conditions exist, then

replace the pilot i gnitor assembly.

Page 23 of 80

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

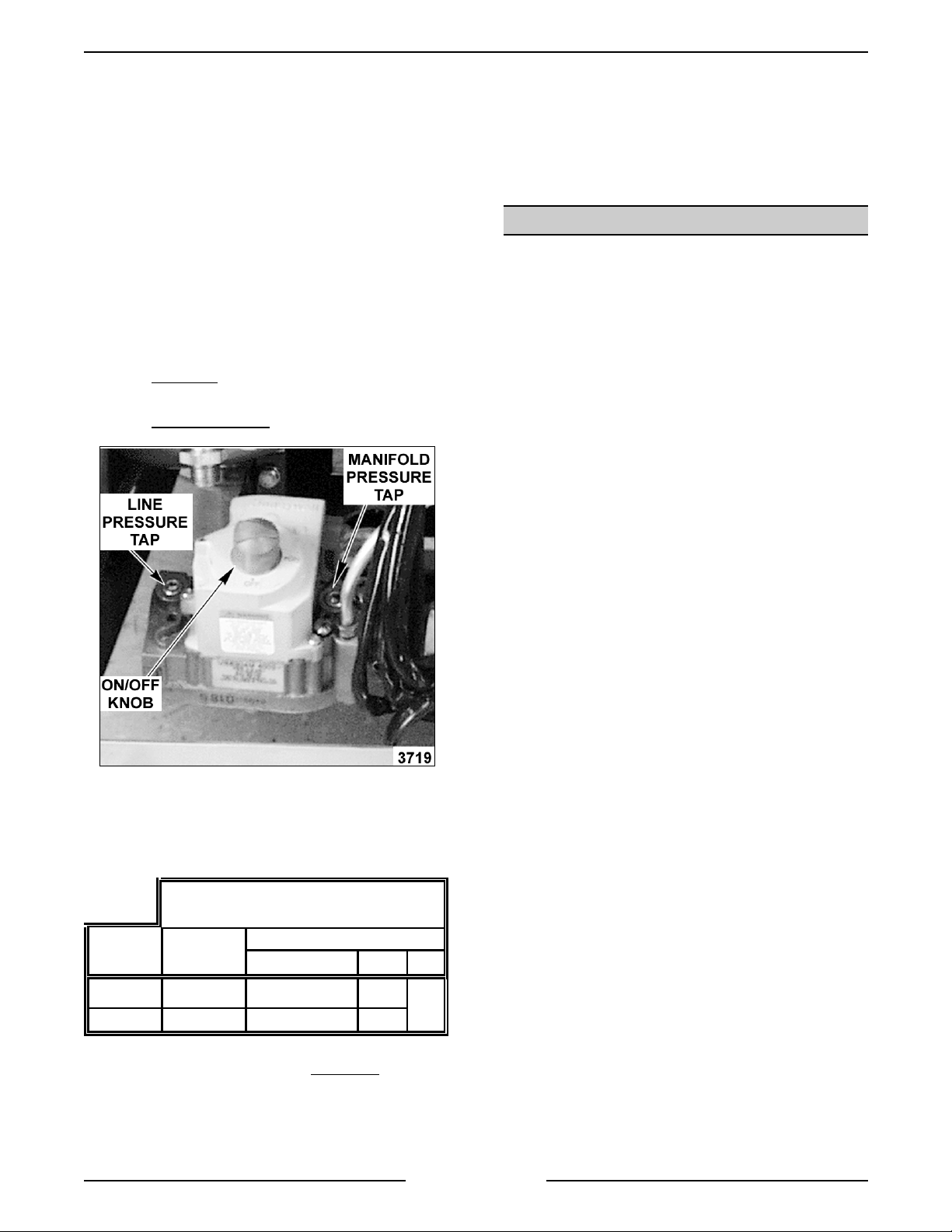

1. Open the front cabinet doors and turn the Gas

Combinat ion Control Valve OFF.

2. To measure the manifold pr essure, remov e the

1/8 inch NPT plug (pressure tap) on the outlet

side of the valve and attach a manometer .

3. Turn the gas combinat ion control valve and the

main power switch to ON.

4. Observe the m anometer pressure reading and

compare to the pressure chart near the end of

this procedure.

Page 24

VSX SERIES ST E AMER - SERVICE PROCEDURES

A. If other appliances are connected t o the