Page 1

INSTALLATION &

OPERATION MANUAL

SG SERIES

GAS CONVECTION OVENS

MODEL

SG4D ML-114875

SG4C ML-114876

SG6D ML-114877

SG6C ML-114878

MODEL SG4D

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 31024 Rev. B (Aug. 2000) www.vulcanhart.com

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT

TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY, 1997

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing Basic Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ovens Mounted on Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling the Legs to the Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling the Stand to the Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling Stacked Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vent System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controls — Models SG4D and SG6D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lighting the SG4D and SG6D Ovens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using the SG4D and SG6D Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls — Models SG4C and SG6C Built before October 1999 . . . . . . . . 11

Thermostat Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Time / Power Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Two-Speed Fan Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Master Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lighting the SG4C and SG6C Ovens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the SG4C and SG6C Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Error Messages — SG4C and SG6C Ovens. . . . . . . . . . . . . . . . . . . . . . . . . 14

Controls — Models SG4C and SG6C Built after October 1999 . . . . . . . . . . 15

Manually Setting the Cook Time, Temperature, and Power Level . . . . . . . 16

To Program Menu Item and Rack # Cook Times . . . . . . . . . . . . . . . . . . . . . 16

Setting the Oven For Roast and Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Roast and Hold Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Conserving Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cooking Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rack Arrangements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Recommended Temperature, Time and PowerLevel Settings for Roasting. 19

Special Procedures for Baking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cooking Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

High Limit Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing Lamps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

– 3 –

Page 4

Installation, Operation and Care of

SG4D, SG4C, SG6D & SG6C

GAS CONVECTION OVENS

KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Model SG4D, SG4C, SG6D and SG6C are equipped with a two-speed 1/2 HP (0.37 kw) electric motor,

porcelain interior, and two 30,000 BTU/hr burners as standard equipment. A power level control

permits variable burner input from 15,000 BTU/hr to 60,000 BTU/hr. Ovens are furnished with five

nickel plated oven racks and have eleven rack positions. Oven cool switch allows rapid cool down.

Oven interior is porcelain enamel on steel.

Models SG4D and SG6D are equipped with solid state temperature control and 60 minute timer (5 hour

timer is optional).

Models SG4C / SG6C have different controls than SG4D / SG6D. Models SG4C and SG6C built before

October 1999 had electronic Roast and Hold controls and a Gentle Bake feature. Models SG4C and

SG6C built after October 1999 have a programmable control with individual programmable rack times.

Models SG6D and SG6C have a 4"

Two single ovens can be ordered with a stacking kit for mounting one oven on top of the other.

Independently opening doors with window are standard; independently opening doors without window

or simultaneously opening doors with / without window are optional.

Standard ovens are equipped for 120 volt / 60 hertz / 1 phase electrical service. Available options for

models SG4D / SG4C or SG6D / SG6C include: 208 volt / 60 hertz / 1 phase; 240 volt / 60 hertz /

1 phase electrical service; additional oven racks; stainless steel drip pan; casters; and an open stand

with lower storage rack and legs or casters.

3

A set of four legs 25

stacking kit are 8"

Vulcan Gas Convection Ovens are produced with quality workmanship and material. Proper

installation, usage and maintenance will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

⁄4" (82.5 cm) are available with feet or with casters. Legs or casters included with

(20.3 cm) high.

(10 cm) deeper oven cavity than models SG4D and SG4C.

INSTALLATION

Before installing, verify that the electrical service and type of gas supply (natural or propane) agree with

the specifications on the rating plate located behind the top trim panel on the front of the oven. If the

supply and equipment requirements do not agree, do not proceed with the installation. Contact your

dealer or Vulcan Company immediately.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the oven is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

– 4 –

Page 5

Carefully unpack oven and place in a work-accessible area as near to its final installed position as

possible.

Do not use the doors or their handles to lift the oven.

LOCATION

The equipment area must be kept free and clear of combustible substances.

When installed, minimum clearance from combustible construction must be 1"

(10 cm) at the right side, and 6" (15 cm) at the rear. Minimum clearance from non-combustible

4"

construction must be 0"

(0 cm) at the left side, 4" (10 cm) at the right side, and 6" (15 cm) at the rear. The

(2.5 cm) at the left side,

oven may be stored on combustible floors.

The installation location must allow adequate clearances for servicing and proper operation.

The oven must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for that required for combustion of gas at the oven

burners.

Do not permit fans to blow directly at the oven. Wherever possible, avoid open windows next to the

oven. Avoid wall-type fans which create air cross currents within the room.

INSTALLATION CODES AND STANDARDS

In the United States, Vulcan gas ovens must be installed in accordance with: 1) State and local codes;

2) National Fuel Gas Code, ANSI-Z223.1 (latest edition), available from American Gas Association,

1515 Wilson Boulevard, Arlington, VA 22209; 3) NFPA-96,

Vapor Removal from Cooking Equipment

(latest edition); and 4) National Electrical Code, NFPA-70 (latest edition) available from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada, Vulcan gas ovens must be installed in accordance with: 1) Local codes; 2) CAN/CGAB149.1

Natural Gas Installation Code

(latest edition) or CAN/CGA-B149.2

Propane Installation Code

(latest edition), available from Canadian Standards Association, 178 Rexdale Boulevard, Etobicoke,

Ontario, Canada M9W 1R3; and 3)

Canadian Electrical Code,

Features of Fuel Burning Equipment

(latest edition).

CSA Standard C22.2 No. 3,

Electrical

INSTALLING BASIC OVEN

The basic oven must be installed on legs or be mounted on a modular stand. Installations on concrete

bases or other supports restricting air circulation underneath the oven is not advisable and may void

the warranty.

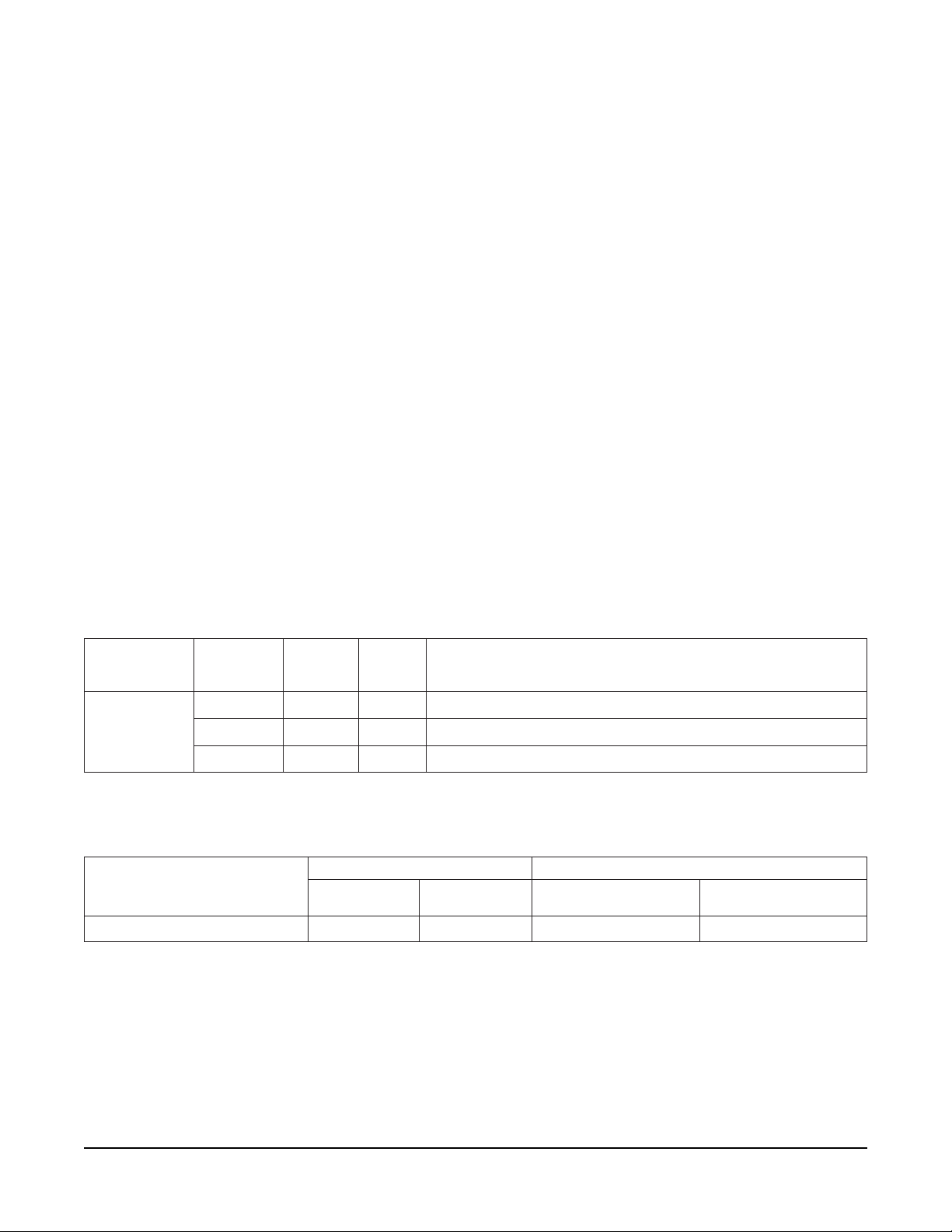

Ovens Mounted on Casters

When the oven is mounted on casters, it must be installed with the

casters supplied, a connector complying with either ANSI-Z21.69

(latest edition) or CAN/CGA 6.16 (latest edition), and a quickdisconnect device complying with either ANSI-Z21.41 (latest edition)

or CAN1-6.9 (latest edition). Provide a restraining device for the gas

line to limit movement of the oven without depending on the connector

and/or any quick-disconnect device or its associated piping to limit

oven movement. Remove two screws from the rear of the oven and

install the tie down strap shipped with the casters using these screws

(Fig. 1). Attach the gas line strain relief to the tie down strap at the

CONNECT

GAS LINE

STRAIN RELIEF

HERE

PL-53563

Fig. 1

rear of the oven (Fig. 1).

– 5 –

Page 6

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

the restraint prior to turning the gas supply back on.

Separate instructions for installing casters to the oven are included with the casters.

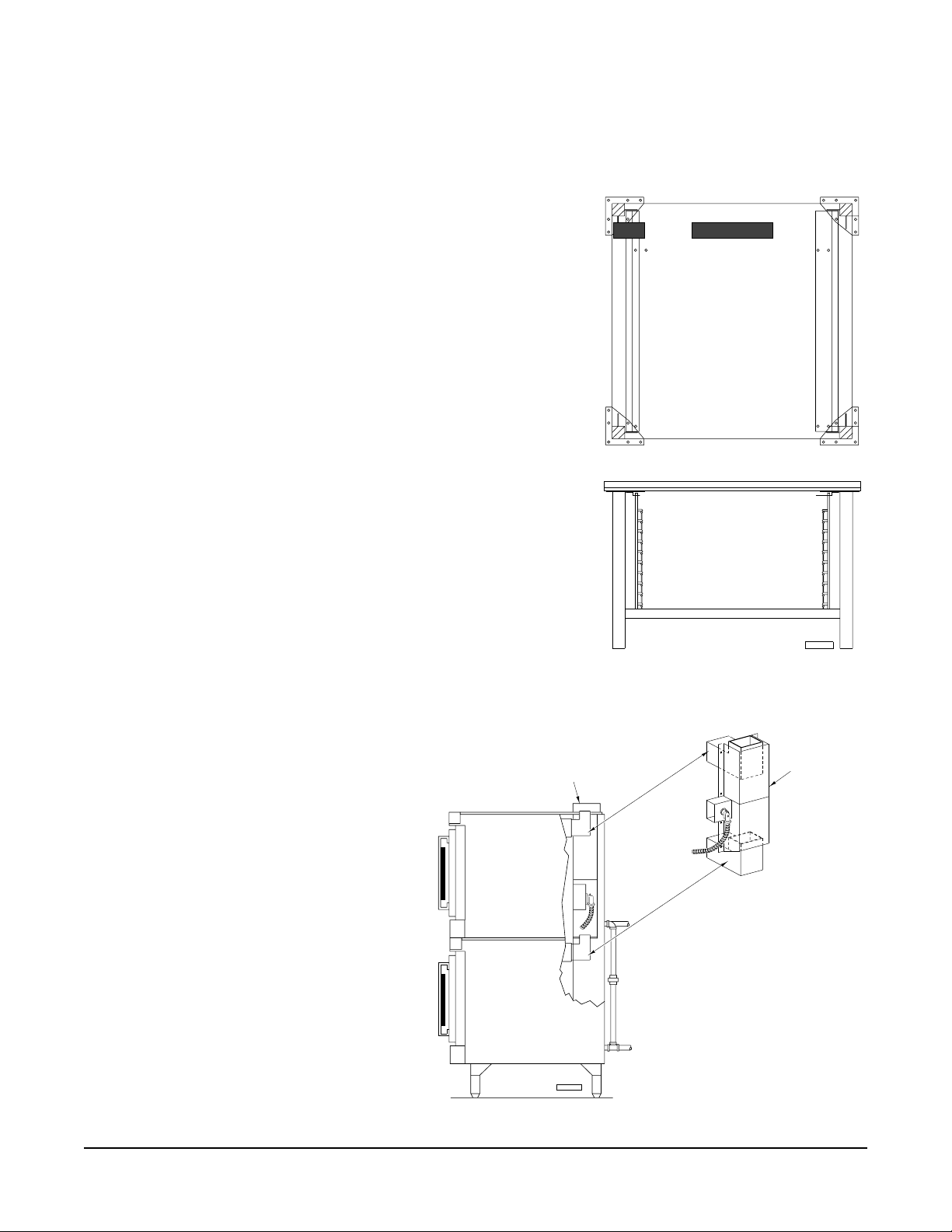

Assembling the Legs to the Oven

BACK

The legs must be installed on the bottom of the oven. Position

oven on its back, taking care not to scratch or damage it. The gas

pipe connection protrudes beyond the back; provide for this when

the oven is tipped back by resting it on suitable spacers (2 x 4's

etc.).

Attach each of the four leg assemblies to the bottom of the oven

with the 24 bolts and lockwashers (6 per leg). Carefully raise the

oven to its normal position.

FRONT

Assembling the Stand to the Oven

Attach each of the four leg assemblies to the bottom of the oven

with the 24 bolts and lockwashers (6 per leg). Carefully raise the

oven to its normal position.

Attach the undershelf to the legs with 8 bolts and lockwashers (2

per leg).

Install the rack guides into the shelf at desired locations (for pan

or flat rack), then attach the rack supports to the top end of the rack

guides. Attach rack supports to the leg assembly by removing one

middle bolt and reattaching back through the end holes in the rack

support (Fig. 2).

ASSEMBLING STACKED OVENS

Unpack the ovens and stack kit. Position

VENT GUARD

the lower oven on its back for access to the

oven bottom, taking care not to scratch or

damage it. The gas pipe protrudes beyond

the back; provide for this when the oven is

tipped back by resting it on suitable

spacers, 2 x 4's, etc. Attach the four leg

assemblies with 24 bolts and lockwashers

(6 per leg).

Place the lower oven (with legs or casters)

7

on the floor and remove two

⁄16" (1.1 cm)

diameter knockouts on each side of the top

cover. Remove vent guard and discard it.

Fig. 2

PL-52821

TWO PIECE

STACKING

COMMON FLUE

Move the oven to the installed position and

place upper oven on top of lower oven

using the locating studs.

PL-52884

Fig. 3

– 6 –

Page 7

Remove the rear panel from the upper oven. Install the two-piece stacking common flue (Fig. 3) with

the four screws provided. Replace the upper oven's rear panel.

Connect the piping between the upper and lower oven. Pipe compound must be resistant to the action

of propane gases. The manual gas valve, located behind the small door in the lower front panel, should

remain off until all electrical and gas connections are made and the ovens are ready to be used.

LEVELING

Make sure that the oven racks are level in the final installed position. If the oven is installed on legs,

turn the adjustable feet in or out to level the oven front-to-back and side-to-side. If the oven is installed

on casters, loosen set screws and turn casters in or out to level the oven front-to-back and side-to-side.

Retighten set screws after leveling.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

WARNING: APPLIANCES EQUIPPED WITH FLEXIBLE ELECTRICAL POWER SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THIS PLUG MUST BE CONNECTED TO

A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT THE

PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE GROUNDING

PRONG FROM THE PLUG.

A wiring diagram is located on the inside of the right side panel.

ATADLACIRTCELE

ledoMstloVztreHesahPeciveDevitcetorPmumixaM

SPMA

D4GS

C4GS

D6GS

C6GS

021061 51

802061 51

042061 51

.)noitidetsetal(07-APFN,edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

GAS CONNECTION

ATADSAG

rH/UTBtupnIerusserPdlofinaM

ledoM

C6GS,D6GS,C4GS,D4GS000,06000,06)aPk9.0(.C.W"5.3)aPk5.2(.C.W"01

larutaN

sesaGPL

)enaporP(

larutaN

sesaGPL

)enaporP(

Gas supply connections and any pipe joint compound must be resistant to the action of propane gases.

The oven is provided with a regulator integral to the gas solenoid valve and requires no external

regulator. Location of the gas inlet is at the rear of the oven. Codes require that a gas shutoff valve

must be installed in the gas line ahead of the oven.

Connect the oven(s) to the gas supply after leveling. The gas supply line must be at least the equivalent

3

⁄4"

(1.9 cm) iron pipe. Make sure the pipes are clean and free of obstructions, dirt, or pipe joint

of

compound. The ovens are equipped with fixed burner orifices which match the installation elevation.

– 7 –

Page 8

Natural gas pressure regulators are preset for 3.5" W.C. (Water Column) (0.9 kPa); propane gas

pressure regulators are preset for 10" W.C.

(2.5 kPa).

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

1

When gas supply pressure exceeds

⁄2 psig (3.45 kPa), the oven and its individual shutoff valve must be

disconnected from the gas supply piping system during any pressure testing of the system.

1

When gas supply pressure is

⁄2 psig (3.45 kPa) or less, the oven should be isolated from the gas supply

system by closing its individual manual shutoff valve during any pressure testing of the system.

ADJUSTMENTS

Air Adjustment

Although main burner air is adjusted before shipment, it should be checked at the time of installation.

Excessive air will cause flames to lift off a burner when cold or may cause flash-back during normal

cycling of the oven, particularly when propane gas is used.

Insufficient air will cause flames to burn with a yellow tip and result in carbon accumulation in the flame

chamber and heat exchanger tubes.

Contact your local Vulcan-Hart authorized servicer if required.

VENT SYSTEM

DO NOT obstruct the flow of flue gases from the flue located on the rear of the oven. It is recommended

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

Ovens may use an optional down draft diverter flue method. This optional down draft diverter must be

purchased from the oven manufacturer and vented to the outside; otherwise, the installation of any

such device will void all oven certifications and warranties. When the diverter is supplied, it may be

connected to a Type “B” vent.

From the termination of the flue to the filters of the hood venting system, a minimum clearance of

(45.7 cm) must be maintained.

18"

Information on the construction and installation of ventilating hoods may be obtained from

Removal from Cooking Equipment

, NFPA Standard No. 96 (latest edition), available from National Fire

Vapor

Protection Association, Batterymarch Park, Quincy, MA 02269.

– 8 –

Page 9

OPERATION

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

CONTROLS — Models SG4D and SG6D (Fig. 4)

Master Switch • Turns oven control circuits ON or

OFF. • OVEN COOL allows the fan motor to run with the

doors ajar to speed oven cooling.

MASTER SWITCH

OVEN

COOL

OFF

ON

HEAT

IGNITION

THERMOSTAT

350

375

325

300

275

250

225

2

3

60

55

50

FAN SPEED

LIGHTING INSTRUCTIONS

TURN GAS "ON", PUSH MASTER SWITCH "ON"

IF BURNER FAILS TO LIGHT TURN GAS "OFF"

WAIT 5 MINUTES FOR RETRIAL

SHUTDOWN INSTRUCTIONS

TURN MASTER SWITCH OFF

150

POWER LEVEL

OFF

1

4

5

TIMER

0

OFF

45

40

35

HI ON

LOW

400

475

500

10

9

8

7

6

5

10

15

20

25

30

LIGHTS

OFF

MASTER SWITCH

On Light (Amber) • Lit when Master Switch is ON.

Heat Light (White) • Comes on and goes off when the burner

ON LIGHT

ON

HEAT LIGHT

NO IGNITION LIGHT

cycles on and off.

No Ignition Light (Red) • Comes on if burner fails to ignite.

When lighting the oven, the No Ignition Light flashes.

THERMOSTAT

Thermostat • Controls oven temperature during cooking

operation.

425

450

POWER LEVEL LIGHT

POWER LEVEL

CONTROL

Power Level Light • When ON, indicates the power level

control is operating in the range between the high and low

settings.

Power Level Control • Selects the % heat input between OFF

and 100%. Power Level Control must be on for oven to work.

TIMER

TWO SPEED

FAN SWITCH

LIGHT SWITCH

PL-52683

Dial Setting Percent of Full Input

10 100%

9 77%

8 73%

7 68%

6 60%

5 53%

4 45%

3 37%

2 28%

1 22%

OFF 0%

Fig. 4

Timer (1 Hr. or 5 Hr.) • Selects the cooking cycle time. Buzzer

sounds continuously when elapsed time counts down to 0;

oven does not turn off. Turn timer dial OFF to silence buzzer.

When oven is not in use, keep timer at OFF position.

Two-Speed Fan Switch • Adjusts air velocity in the oven.

Light Switch • Turns lights in the oven on or off.

BEFORE FIRST USE

Before using the oven for the first time, it must be "burned in" to release any odors that might result from

heating the new surfaces in the chamber.

1. Using a clean damp cloth, wipe the inside of the oven, including the racks.

2. Close the oven doors, push the Master Switch ON, turn the Thermostat to 300°F

(149°C), and allow

the oven to cycle for 6 to 8 hours before pushing the Master Switch OFF.

– 9 –

Page 10

LIGHTING THE SG4D AND SG6D OVENS

1. Turn the main gas supply ON.

2. Turn the gas control valve (located behind the small door on the lower front panel) ON.

3. Push the Master Switch ON and turn Thermostat to its maximum setting. Both the ON and HEAT

lights should come on. If HEAT light is not on, make sure the oven door(s) are closed.

4. If the oven fails to light, the red No Ignition light will be lit and remain on. Push the Master Switch

OFF. Turn gas off.

5. Wait 5 minutes before repeating Steps 1 through 4.

If the oven does not light after three trials, turn off the main gas valve and call a qualified servicer.

USING THE SG4D AND SG6D OVENS

Preheating

1. Select the proper rack arrangement for the product to be cooked. Refer to RACK ARRANGEMENTS,

page 19.

2. Make sure the doors are closed.

3. Push the Master Switch ON. The amber ON light will come on, indicating that power to the oven

is on.

4. Set the Power Level Control as desired. A power level control setting of 10 is recommended for

preheating.

5. Set the two-speed Fan Switch to the desired setting.

6. Set the Thermostat as desired. The Heat light will come on and remain on until the oven reaches

the set temperature (approximately 10 to 15 minutes for settings from 300°F

(149°C) to 400°F (204°C).

Refer to SUGGESTED COOKING GUIDELINES for temperatures and times for various products.

7. Prepare product and place in suitable pans. When the white Heat light goes off, the oven has

reached the desired preheat temperature.

Cooking

1. Open doors and load the product into the oven. Place pans in the center of the racks. Close the

doors.

2. Set the Timer. After the preset time lapses, turn timer OFF to stop buzzer.

3. When product is done, open doors and carefully remove cooked product from the oven. Wipe up

any spills.

End of Day

1. Turn the Thermostat and Power Level Controls OFF.

2. Push Master Switch to OVEN COOL. Leave door ajar while the fan is on to cool the oven.

3. When oven has cooled sufficiently, push Master Switch OFF.

4. Turn gas valve (located behind panel) OFF and clean oven.

Extended Shutdown

Repeat Steps 1 through 4 above. Unplug oven and shut off manual gas valve.

– 10 –

Page 11

CONTROLS — Models SG4C and SG6C Built before October 1999 (Fig. 5)

THERMOSTAT CONTROL

Temperature Display (When not timing product, displays set

cook temperature while roast temperature LED is lit and

TEMPERATURE

HEAT

ROAST

TIMETIMETIME

TIME

TIME

/POWER

COOK

TIME

POWER

LEVEL

FANSPEED

HI

LOW

POWER

LIGHTING INSTRUCTIONS

TURN GAS VALVE "ON"

PUSH MASTER SWITCH TO

"ON" POSTION. IF OVEN

FAILS TO LIGHT. PUSH

MASTER SWITCH TO "OFF"

TURN GAS VALVE OFF WAIT

5 MINUTES FOR RETRIAL.

TO SHUT-OVEN OFF

PLACE POWER SWITCH IN

"OFF" POSTION TURN GAS

VALVE OFF

READY

HOLD

LEVEL

START

STOP

GENTLE

BAKE

LIGHTS

ON

OFF

ON

OFF

OVEN

COOL

THERMOSTAT CONTROL

TIME / POWER LEVEL

CONTROL

2 SPEED FAN - HI / LO

LIGHT SWITCH

MASTER SWITCH

actual oven temperature for 10 seconds after

Button is pushed).

1. The Time / Power Level Display will be lit while the actual

temperature is being displayed.

2.

The Time / Power Level Display indicator goes off when the

display returns t

o the set temperature.

Temperature Display (When product is being timed, displays

set hold temperature while Hold button LED is lit and the

actual oven temperature for 10 seconds after the Thermometer

Button is pushed).

1.

The Time / Power Level Display indicator will be lit while the

actual temperature

is being displayed.

2. The Time / Power Level Display indicator goes off when the

display returns to the set temperature.

PL-52885

Temperature Knob (When not timing product).

the

the Thermometer

1. Sets the roast temperature when the roast indicator is lit. The

Fig. 5

roast indicator can be turned on by pressing the Roast Button.

2. Sets the hold temperature when the Hold indicator is lit. The

hold indicator can be turned on by pressing the Hold Button.

Temperature Knob (When product is being timed).

1. Sets the roast temperature when the roast indicator light is lit. The roast indicator cannot be

changed by pressing the Roast Button.

2. Sets the hold temperature when the hold indicator light is lit. The roast indicator cannot be changed

by pressing the Roast Button.

Roast Mode Indicator (If On and not timing product, indicates the roast mode is selected).

1. The displayed temperature settings will be for the roast temperature except for time that the actual

temperature indicator is lit.

2. Rotating the Thermostat Knob will change the roast set temperature.

3. When the power level indicator is lit, the roast power setting will be displayed

and can be adjusted.

Power level settings are changed using the Time / Power Level Knob.

4. Cook time can be adjusted using the Time/Power Level Knob, provided the power level indicator is

not lit.

5. The time displayed is the initial set cook time.

6. It is possible to select the Hold mode using the Hold Button.

Roast Mode Indicator (If On and product is being timed, indicates the roast mode is selected).

1. The displayed temperature settings will be for the roast temperature except for the time that the

actual temperature indicator is lit.

2. Rotating the Temperature Knob will change the roast set temperature.

– 11 –

Page 12

3. When the power level indicator is lit, the roast power setting will be displayed

and can be adjusted.

Power level settings are changed using the Time / Power Level Knob.

4. Cook time cannot be adjusted using the Time / Power Level Knob, if the power level indicator is not

lit.

5. It is not possible to select the Hold mode using the Hold Button.

6. The time displayed is the time counted down from the initial cook time set.

Roast Button

1. Lights the roast mode indicator. Refer to Roast Mode Indicator, page 11.

2. Selects the Roast mode.

3. Has no effect if timing in the Hold mode.

Temperature Button and Indicator Light • Displays the actual oven temperature for about eight

seconds, then returns temperature display to the set temperature.

Heat Light • When lit, indicates that power is being supplied to the burners.

Ready Light • Will be lit any time the actual temperature is within plus or minus 5 F°

(3 C°) of the set

temperature for the current mode.

TIME / POWER LEVEL CONTROL

Time / Power Level Display (While not timing product).

1. Displays the set cook time if Cook Button indicator is lit.

2. Displays cook power level setting if the Power Level indicator is lit and in the roast mode (Roast

Button indicator is lit).

3. Displays hold power level setting if the Power Level indicator is lit and in the hold mode (Hold

button

indicator is lit).

Time / Power Level Display (While product is being timed).

1. Displays the counted down cook time if the Cook Time indicator is lit and in the Roast mode.

2. Displays the counted up hold time if the Hold Button indicator is lit and in the

up of hold time does not begin until cavity temperature

reaches the hold temperature.

Hold mode. Count-

3. Pressing the Power Level Button will cause the power level to be displayed and / or adjusted. If in

the Roast mode, the roast power level is displayed and can be adjusted. If in the Hold mode, the

hold power level is displayed and can be adjusted.

Time / Power Level Display Colon • Flashes if product is timing; does not flash if not timing product.

Cook Time Button • Switches the Time / Power Level display to display time.

Cook Time Indicator • Indicates that the Time / Power Level Display is displaying time.

Time / Power Level Knob

1. Sets the cook time when not already timing and the Cook Time indicator is lit.

2. Sets the power level if the Power Level indicator is lit.

a. Sets the roast power level if the Roast Button indicator is lit.

b. Sets the hold power level if the Hold Button indicator is lit.

Power Level Button • Causes the Power Level indicator to turn on for about eight seconds, after

which it will return to indicate the time display mode.

1. Roast power level can be changed if the Roast Button indicator is lit.

2. Hold power level can be changed if the Hold Button indicator is lit.

3. Press the Cook Time Button to return to time display.

– 12 –

Page 13

Power Level Indicator •

When lit, indicates the power level

can be changed.

1. Displays roast power level when in the Roast mode (Roast Button indicator is lit).

2. Displays hold mode power level when in the hold mode (Hold Button indicator is lit).

Gentle Bake Button • Use when cooking delicate product, such as strudel, muffins, cupcakes,

meringue pies, etc., to keep product from forming waves on the top. Toggles between the selection

of gentle bake mode and no gentle bake mode.

Gentle Bake Mode • The Gentle Bake button is lit to indicate you are in Gentle Bake mode.

1. The fan cycles with the heat while in the roast mode and timing product at the power level selected

for the roast mode. For instance, ON 15 seconds, OFF 15 seconds at 50% power; On 6 seconds,

OFF 14 seconds at 20% power.

2. The fan stays on while the heat cycles in hold at the power setting selected for the hold mode.

3. The fan stays on while heat cycles at 100% power when not timing.

4. Can be switched at any time.

Not in Gentle Bake Mode • The Gentle Bake button is not lit.

1. Fan stays on while the heat cycles while in the Roast mode and timing product at the power level

selected for roast mode.

2. Fan stays on while heat cycles in Hold at the power setting selected for the hold mode.

3. Fan stays on while heat cycles at 100% power when not timing.

4. Can be switched at any time.

Stop / Start Button • Press once to start the timer when cooking a product if a cook time has been

set. Press a second time to stop the timer after it has been started.

Hold Button • Press to select Hold mode and to specify a hold temperature. The Hold button is lit

to indicate you are in Hold mode. Blank temperature ---°F

When not timing, allows setting / enabling a hold mode setting of ---°F

1.

(---°C) indicates there is no hold mode.

(---°C), meaning no hold

will take effect.

2. Any other temperature means that when the actual cook time has ended, the oven will enter the Hold

mode and use the hold temperature.

Two-Speed Fan Switch • Adjusts air velocity in the oven.

Light Switch • Turns lights in the oven on or off.

Master Switch • Turns oven control circuits ON or OFF; OVEN COOL allows the fan motor to run with

the doors ajar to speed oven cooling.

BEFORE FIRST USE

Before using the oven for the first time, it must be "burned in" to release any odors that might result from

heating the new surfaces in the chamber.

1. Using a clean damp cloth, wipe the inside of the oven, including the racks.

2. Close the oven doors, push the Master Switch to the ON position, turn the Thermostat to 300°F

(149°C) and allow the oven to cycle for 6 to 8 hours before pushing the Master Switch to OFF.

– 13 –

Page 14

LIGHTING THE SG4C AND SG6C OVENS

1. Turn gas supply ON (if required).

2. Turn the gas control valve (located behind the small door on the lower front panel) ON.

3. Push Master Switch to the ON position and set Thermostat to its maximum setting. The Heat light

should come on. If Heat light is not on, make sure door is closed.

4. If the oven fails to light, push Master Switch to the OFF position. Wait 5 minutes before retrial.

USING THE SG4C AND SG6C OVENS

✫ Refer to SUGGESTED COOKING GUIDELINES for Time, Temperature and Power Level settings.

Preheating

1. Push Master Switch ON. The Heat light will come on, indicating that power is on.

2. Set Thermostat as desired.

3. Set Power Level as desired.

4. Prepare product and place in suitable pans. When Ready light comes on, oven has reached

desired preheat temperature.

Cooking

1. Open doors and load the product into the oven. Place pans in the center of the racks. Close doors.

2. Set Roast temperature and time. Set Hold temperature and Gentle Bake time, if desired. Gentle

Bake time may not be more than Roast time. Gentle Bake will cycle the fan during the set time at

the beginning of the cooking cycle.

3. Set Power Level Control as desired.

4. Press the Start/Stop button to start the cooking cycle.

5. At the end of the cooking cycle, the buzzer will sound continuously if the Hold mode is OFF. If the

Hold mode is ON, there will be a short beep at the beginning of Second Stage Cooking (oven

temperature will begin to decline to the Hold temperature), and a long beep (20 seconds) at the end

of the cooking cycle. Refer to ROAST AND HOLD OPERATION.

6. When the product is done, open the doors and carefully remove the cooked product from the oven.

Wipe up any spills.

End of Day

1. Push Master Switch to OVEN COOL. Leave door ajar while the fan is on to cool the oven.

2. When oven has cooled sufficiently, push Master Switch OFF and clean the oven.

Extended Shutdown

Push Master Switch OFF. Turn the gas valve OFF.

ERROR MESSAGES — SG4C AND SG6C OVENS

E-01 High limit error. Contact Vulcan authorized service.

E-02 Low limit error. Contact Vulcan authorized service.

E-03 High ambient temperature, 215°F

E-04 Low ambient temperature, 32°F

(102°C). Contact Vulcan authorized service.

(0°C). Let control warm up after cold storage.

E-05 Ignition failure. After trying ignition 3 times, contact Vulcan authorized service.

E-06 Thermocouple probe open. Contact Vulcan authorized service.

– 14 –

Page 15

CONTROLS — Models SG4C and SG6C Built after October 1999

Always displays [HR:Min] when setting the Time.

Displays [HR:Min] if the countdown time is more than 1 Hour.

Displays [Min:Sec] if the countdown time is less than 1 Hour.

Displays Temperature in °F.

R & H

MODE

OVEN

READY

OVEN

HEATING

MENU SELECT

PRIMARY

SECONDARY

1

%

1/2

3/4

5/6

MENU RACK

SET

ROAST

&

HOLD

START

STOP

2

3

4

5

R & H

MODE

OVEN

READY

OVEN

HEATING

PRIMARY

SECONDARY

%

SET

Indicates the oven is in the Roast and Hold Mode.

Indicates the oven is preheated and ready for cooking.

Indicates the oven is preheating.

Primary indicates Menu Items 1, 3, or 5.

Secondary indicates Menu Items 2, 4, or 6.

Up arrow increases; Down arrow decreases — a displayed

Time or Temperature value if arrow keys are lit.

Adjusts the oven heating rate or Power Level from 20 to 100 %.

TEMPERATURE: Use with SET to set the oven Temperature.

SET: Use with Time or Temperature.

POWER LIGHTS

ON

ON

OFF

OVEN

COOL

OFF

PL-53504

1/2

2 3 4

1

ROAST

HOLD

START

STOP

&

3/4

TIME: Use with SET to manually set the cooking Time.

Selects Roast and Hold mode; also selects Low Fan Speed.

Press once to start; press a second time to stop.

Select Menu Cook Times. Press once for Primary (1, 3, or 5).

5/6

Press a second time for Secondary (2, 4, or 6). See next page.

Rack Buttons select individual Menu / Rack # Cook Times —

5

once programmed.

– 15 –

Page 16

MANUALLY SETTING THE COOK TIME, TEMPERATURE, AND POWER LEVEL

To Set the Cook Time

Tine

• Press the SET button. Press the TIME button.

displays to indicate TIME.

• Use the Up and Down Arrow keys to increase or decrease the displayed Cook Time (HR:min).

• Press the SET button again to save the Time setting in the computer.

To Set the Temperature

StPt

• Press the SET button. Press the TEMPERATURE button;

displays to indicate Setpoint.

• Use the Up and Down Arrow keys to increase or decrease the displayed Temperature value.

• Press the SET button again to save the Temperature setpoint in the computer.

To Set the Power Level

• Press the SET button. Press the % button.

• Use the Up and Down Arrow keys to increase or decrease the displayed Power Level value.

• Press the SET button again to save the desired Power Level value in the computer.

To Start Cooking

• Press the START / STOP button.

• The manual Cook Time counts down to 00:00. Displays [HR:Min] above 1 hour; [min: sec] below.

• The buzzer will sound. To silence the buzzer, press the START / STOP button again.

* The control retains the manual settings for Cook Time, Temperature, and Power Level.

TO PROGRAM MENU ITEM and RACK # Cook Times

Factory Preset and Programmable Cook Times are shown in the table, below:

NOITCELESUNEM

yramirP2/11.nim01

yradnoceS2/12.nim51

yramirP4/33.nim02

yradnoceS4/34.nim52

yramirP6/55.nim03

yradnoceS6/56.nim53

UNEM

METIMETI

METIMETI

METI

TESERPYROTCAF

METIUNEMMETIUNEM

METIUNEMMETIUNEM

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

1KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

2KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

SEULAVELBAMMARGORP

3KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

4KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

5KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

The Primary indicator light with Menu 1 / 2 selects Menu Item 1 (Factory Preset Cook Time = 10

minutes). The Secondary indicator light with Menu 1 / 2 selects Menu Item 2 (Factory Preset Cook Time

= 15 minutes). Similarly, for Menu Buttons 3 / 4 or 5 / 6. Any Menu Item Cook Time can be changed

using the procedure below. Rack # Cook Times may be programmed if desired but are not required.

To Change the Time Setting for any Menu Item (1 – 6)

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

✤ Select the Menu Item to be programmed (1 – 6).

Tine

displays to indicate TIME. Use the Up and

Down arrow buttons to increase or decrease the Menu Item's COOK TIME. Repeat this step for

any other Menu Items.

• Press the START / STOP button; LOC displays. Press the START / STOP button a second time

to save the Menu Item(s)' COOK TIME(s).

• Press the START / STOP button once to begin cooking (with the Menu Item's Cook Time). To

exit, press the START / STOP button a second time.

To Program Individual Rack # Cook Times for a Menu Item

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

Tine

• Select the Menu Item to be programmed (1 – 6);

✤ Then select the Rack # (1 – 5). [

t 1

] indicates Rack #1; [

displays to indicate TIME.

t 2

] indicates Rack #2; ... [

t 5

] indicates

Rack #5. Use the Up and Down arrows to increase or decrease the COOK TIME for any Rack #.

LOC

• Press the START / STOP button;

displays. Press the START / STOP button a second time

to save the Menu / Rack #'s COOK TIME(s).

• To exit program mode, press START / STOP twice.

– 16 –

Page 17

Always Set the Temperature Before Setting the Time

StPt

• Press the SET button. Press the TEMPERATURE button;

displays. Use the Up and Down

Arrow keys to increase or decrease the Temperature. To save, press the SET button again.

At startup, the display will initially show a

GROWING BAR

. When the oven temperature reaches the Set

Point, the set temperature displays. The READY light is lit, the HEAT light goes out, and the oven is

ready for you to select the Cook Time, Menu Item Cook Time, or Menu / Rack # Cook Time.

Starting a Timed Cycle On All Racks

door

• Open the door,

will display.

• Place the desired product on any of the five racks.

• Close the door. The display should return to the set temperature or the

GROWING BAR

.

• Press the Menu Key once for Primary or twice for Secondary to select a Menu Item Cook Time.

• Press the START / STOP button *.

• The timer will count down the time remaining for the Menu Item Cook Time.

• When the time has counted down to 00:00, the buzzer will sound and all Rack Buttons will flash.

• To silence the buzzer, press the START / STOP button.

Pressing the START / STOP button after making a menu selection will time all racks for the

*

selected menu time.

Starting a Timed Cycle Using Programmed Individual Menu / Rack # Cook Time(s)

door

• After the set Temperature is reached, open the door;

• Close the door. The display returns to the set Temperature or the

displays. Place product(s) in oven.

GROWING BAR

.

• Select the Menu Item (once for Primary or twice for Secondary) and the Rack # to select the

Menu / Rack # Cook Time. If using simultaneous cook times, select the other Menu / Rack #'s.

• The timer selects the Rack # with the shortest Cook Time and counts down to 00:00.

• The buzzer sounds and the Rack # flashes. To silence the buzzer, press the flashing Rack #.

door

• Open the door;

displays; remove the finished product; close the door.

✣ The next shortest Cook Time displays, its Rack # flashes and the time counts down to 00:00.

• The buzzer sounds. Press the flashing Rack #. Open the door,

door

displays. Remove the

product, close the door. Repeat from ✣ until all Rack #'s are done.

To Display the Actual Oven Temperature

• Press and hold the Temperature button for 3 seconds to display Actual Oven Temp until released.

To End a Cooking Cycle

At the end of a cooking cycle, the alarm will sound. To silence the alarm and end a Menu Item cooking

cycle, press START / STOP. To silence the alarm and end a Rack # cooking cycle, press the Rack #.

To cancel a cooking cycle which might have been started in error, press and hold the Rack button to

be terminated and press START / STOP at the same time.

Door and Timing

Opening the door while loading additional product will interrupt all timing functions until the door is

closed and the timer resumes. For example, if a product time had diminished to 1 minute and the door

was opened for 30 seconds and then closed, the timer would still show 1 minute.

SETTING THE OVEN FOR ROAST & HOLD

• Press the Roast & Hold button to select Roast & Hold.

• Set the first stage Temperature and the Cook Time as described in: M

ANUALLY SETTING THE

TEMPERATURE AND COOK TIME. Press START / STOP to begin cooking.

The HOLD Temperature is preset by the computer control at 150°F

*

*

The LOW FAN SPEED is present during Roast & Hold. Use R&H to select LOW FAN SPEED.

– 17 –

(66°C)

.

Page 18

ROAST AND HOLD OPERATION

Roast and Hold cooks the product in two stages. During First Stage Cooking, the oven temperature

is regulated by the Roast thermostat for the amount of time set on the Timer. After the lapsed time

counts down to 00:00, Second Stage Cooking begins. During Second Stage Cooking, the burners are

off as the temperature in the oven declines to the Hold Temperature. The doors should remain closed

during Second Stage Cooking.

When the Hold Temperature is reached, cooking is done. The Time Display counts up the Hold time

and flashes "Hold." Temperature in the oven will be maintained at the Hold temperature until the oven

is turned off.

ROAST AND HOLD DIAGRAM - Time vs. Temperature

400ºF

300ºF

200ºF

100ºF

TEMP.

TIME

PL-51607

PREHEAT FIRST STAGE COOKING SECOND STAGE

CONSERVING ENERGY

OVEN TEMPERATURE

TIMER DISPLAY COUNTS DOWN,

COLON FLASHES.

COOKING FROM

STORED HEAT

LOAD PRODUCT

INTO OVEN

PRODUCT TEMPERATURE

SHORT BEEP.

TIMER DISPLAY FLASHES 00:00.

ROAST THERMOSTAT OFF.

BURNERS OFF UNTIL HOLD

TEMPERATURE IS REACHED.

LONG BEEP (20 SEC.)

BURNERS MAINTAIN

HOLD TEMPERATURE.

TIMER DISPLAY COUNTS UP

HOLD TIME AND FLASHES

"HOLD."

HOLDING

COOKING

(DO NOT OPEN

DOORS)

• Turn off unused equipment.

• Adjust menu patterns and cooking/baking schedules for optimum equipment use.

• Reduce thermostat settings in slack periods since gas equipment heats up and recovers quickly.

• Preheat only to required cooking temperature for specific food — not higher.

• Do not open the oven door unless absolutely necessary.

• Keep area around the oven door clean and free of food particles.

• Any obstruction that prevents the door from closing completely will adversely affect oven efficiency.

COOKING GUIDELINES

Recommended temperatures, times, number of racks, and power level control settings are intended

as a guide only. Adjustments must be made to compensate for variations in recipes, ingredients,

preparation, and personal preference in product appearance.

The oven does not require special recipes. Excellent results can be obtained from any good

commercial recipe with reduced cooking times.

– 18 –

Page 19

RACK ARRANGEMENTS

All models are supplied with five racks and have a maximum operating capacity of six racks per oven.

The eleven-position rack supports provide for flexibility and proper rack spacing.

The following arrangements are recommended. The position numbers are in numerical sequence

starting at the bottom (Fig. 6).

Arrangement #1 — Five racks in Positions #2, #4, #6, #8,

and #10 are for oven broiling, cookies or reconstitution of

frozen lunches at maximum capacity. These are also the

recommended positions for general baking in sheet pans

1

with products not over 2

⁄2" (6.4 cm) high.

Arrangement #2 — Four racks in Positions #1, #4, #7, and

#10 are for general baking in sheet pans, muffin pans, pie

1

or cake tins, and pudding pans 3

products not over 4"

(10.2 cm) high. This arrangement can

⁄2" (8.9 cm) high with

also be used for casseroles or meat dishes in #200 series

1

food service pans 12" x 20" x 2

⁄2" (30.4 x 50.8 x 6.4 cm).

Arrangement #3 — Three racks in Positions #1, #5, and #9

are for baking breads or cakes in loaf or tube pans and high

meringue pies. This arrangement can also be used for

1

casseroles, meat dishes or roasting in pans up to 5

(14 cm) deep with products up to 6" (15.2 cm) high.

⁄2"

RACK POSITION

Fig. 6

#11

#10

#9

#8

#7

#6

#5

#4

#3

#2

#1

PL-52806

Arrangement #4 — Two racks in Positions #1 and #6 are for roasting turkeys and other roasts up to

7"

(17.8 cm) high. With the rack in Position #1, there is a limited amount of space for a water pan.

When mixed loads or partial loading is regular practice, some users have developed other rack

arrangements to suit their particular needs.

RECOMMENDED TEMPERATURE, TIME, AND POWER LEVEL SETTINGS FOR ROASTING

Meat roasting is most satisfactory at temperatures of 225°F to 325°F

poultry, and ham; 325°F

A 12" x 20" x 1"

(30.4 x 50.8 x 2.5 cm) pan with water may be placed in the oven bottom to supply humidity

(162°C) for fresh pork as recommended by USDA and American Meat Institute.

(107°C to 162°C) for beef, lamb,

to reduce shrinkage. Add water during roasting as needed.

1

Roasting pans should be no deeper than necessary to hold drippings, usually 2" to 2

⁄2" (5.1 to 6.4 cm).

Cooking time and shrinkage may vary with roasting temperature, cut, grade of meat, and degree of

doneness. Smaller cuts will generally show greater time savings than larger cuts at a given temperature.

ROASTING TEMPERATURE CHART

TEMP POWER LEVEL

PRODUCT

Standing Rib Roast — Oven Ready 250 (121) 10 100% 3 to 4 Hrs. — Rare

Rolled Rib Roasts — 20 to 22 lb. (9.1 to 10 kg) 275 (135) 10 100% 4 Hrs. — Med.

Veal Roast — 15 lb. (6.8 kg) 300 (148) 10 100% 3 Hrs. — Med. Well

Turkeys — 15 to 20 lb.

Meat Loaf — 8 to 10 lb. (3.6 to 4.5 kg) 350 (176) 10 100% 45 to 60 Minutes

(6.8 to 9.1 kg) 300 (148) 10 100% 3 Hrs.

°F (°C)

SG4D,SG6D SG4C, SG6C

APPROXIMATE TIMES

1

4 to 4

⁄2 Hrs. — Med.

– 19 –

Page 20

RECOMMENDED TEMPERATURE, TIME, AND POWER LEVEL SETTINGS FOR BAKING

POWER LEVEL

TEMP. TIME IN NO. OF SETTINGS

PRODUCT

Cakes

Sheet Cake 18x26x1" (45.7x66x2.5 cm)

Scaled 4

1

⁄2 to 6 lb. (2-2.7 kg) / pan 325-360 (162-182) 20 to 23 5 7 to 4 68 to 45%

Scaled 6 to 71⁄2 lb. (2.7-3.4 kg) / pan

Sheet Cake 18x26x2" (45.7x66x5 cm)

Scaled 10 to 12 lb. (4.5-5.4 kg) / pan 300-325 (149-162) 25 to 35 4 6 to 4 60 to 45%

Or, two 12x18x2" (30.5x45.7x5 cm)

Scaled 5 to 6 lb. (2.3-2.7 kg) / pan 300-325 (149-162) 25 to 35 3 6 to 4 60 to 45%

Angel Food or Sponge Cakes

Sheet Pans 18x26x1" (45.7x66x 2.5 cm)

Scaled 5 to 6 lb. (2.3 to 2.7 kg) / pan

Loaf or Tube Pans 315-340 (157-171) 20 to 30 3-4 4 to 1 45 to 22%

Cupcakes 350-400 (177-204) 6 to 12 4 6 to 4 60 to 45%

Frozen Fruit Pies 350-375 (177-190) 30 to 45 4 6 to 4 60 to 45%

Pumpkin or Custard Pies 300-350 (149-177) 30 to 45 4 6 to 4 60 to 45%

Cobblers

12x18x2" (30.5x45.7 x 5 cm) or

12x20x21⁄2" (30.5x50x6.3 cm)

°

F(

°

C) MINUTES RACKS

SG4D, SG6D SG4C, SG6C

335-350 (168-177) 22 to 25 4 6 to 4 60 to 45%

300-325 (149-162) 15 to 20 4 3 37%

3 4 45%

3 4 to 3 45 to 37%

350-400 (177-204) 30 to 45 4 6 60%

3 4 45%

Meringue Pies 350-425 (177-218) 6 to 10 4 6 to 4 60 to 45%

3 6 to 4 60 to 45%

2 6 to 4 60 to 45%

Fruit Turnovers

18x26x1" (45.7x66x2.5 cm) Pans 350-375 (177-190) 15 to 25 5 6 to 4 60 to 45%

NOTE: Pies and cobblers; fruit, custard, and 4 6 to 4 60 to 45%

pumpkin pies in pie pans should be placed on 3 4 to 3 45 to 37%

18x26x1" (46x66x2.5 cm) pans.

Cookies

Rolled or Pressed 350-400 (177-204) 6 to 12 5 6 to 3 60 to 37%

4 4 to 3 45 to 37%

3 3 37%

Drop 350-400 (177-204) 6 to 15 5 6 to 4 60 to 45%

4 4 to 3 45 to 37%

3 3 37%

Brownies 350 (177) 12 to 20 5 6 to 4 60 to 45%

4 4 to 3 45 to 37%

Yeast Breads (after proofing)

Rolls — 1 oz. 350-400 (177-204) 5 to 10 4 6 to 4 60 to 45%

3 4 45%

1

1

⁄2 to 21⁄2 oz. 350-400 (177-204) 8 to 15 4 6 to 4 60 to 45%

3 4 to 3 45 to 37%

Loaf Bread — 1 lb. (453.4 g) 325-375 (162-190) 20 to 40 3(30) Pans 4 45%

2(20) Pans 3 37%

– 20 –

Page 21

RECOMMENDED TEMPERATURE, TIME, AND POWER LEVEL SETTINGS FOR BAKING

POWER LEVEL

TEMP. TIME IN NO. OF SETTINGS

PRODUCT

°F(°C) MINUTES RACKS

SG4D, SG6D SG4C, SG6C

Sweet Rolls & Danish Pastry 325-375 (162-190) 5 to 15 4 6 to 4 60 to 45%

3 4 to 3 45 to 37%

1

Biscuits — Rolled

⁄2" (1.3 cm) Thick 350-400 (177-204) 5 to 15 4 6 to 4 60 to 45%

3 4 to 3 45 to 37%

Muffins 325-375 (162-190) 6 to 18 4 4 45%

3 4 to 3 45 to 37%

Corn Bread

18x26x1" (46 x 66 x 2.5 cm) 335-400 (168-204) 10 to 20 4 6 to 4 60 to 45%

Pan, 5-7 lb. (2.3-3.2 kg) per pan

18x26x2" (46 x 66 x 5 cm) 335-400 (168-204) 15 to 25 4 6 to 4 60 to 45%

Pan, 8-20 lb. (3.6-9 kg) per pan

Corn Muffins 335-385 (168-196) 10 to 20 4 6 to 4 60 to 45%

3 4 to 3 45 to 37%

REHEATING PREPARED FOODS

Frozen French Fries 400-450 (204-232) 6 to 8 4 8 to 6 73 to 60%

2 to 3 7 to 4 68 to 45%

Frozen TV Dinners 350-400 (177-204) 10 to 12 4 to 5 10 to 6 100 to 60%

2 to 3 7 to 4 68 to 45%

Frozen Entrees

3

⁄4" - 1" (1.9 – 2.5 cm) Thick 300-350 (149-177) 10 to 20 2 to 5 10 to 6 100 to 60%

Frozen Meals — 8 oz. Foil Pkg. 350-400 (177-204) 20 to 30 2 to 5 10 100%

OVEN BROILING OR FRYING

Fish Sticks & Portions

Frozen Breaded — 1 oz. 350-400 (177-204) 6 to 10 4 8 to 6 73 to 60%

1

2

⁄2 to 3 oz. 350-375 (177-190) 8 to 15 4 7 to 6 68 to 60%

Chicken Pieces

Broiled or Oven Fried

1

2 to 2

⁄2 lb. (.9 to 1.1 kg) bird 375-425 (190-218) 8 to 15 4 to 5 8 to 6 73 to 60%

1

2

⁄2 to 3 lb. (1.1 to 1.4 kg) bird 350-400 (177-204) 15 to 25 4 7 to 6 68 to 60%

Lobsters — 1 to 1

1

⁄2 lb. (.45 to .7 kg) 400-450 (204-232) 8 to 14 2 to 4 10 to 6 100 to 60%

Lobster Tails — Frozen

1

⁄2 to 3⁄4 lb. (.2 to .3 kg) 350-400 (177-204) 10 to 15 2 to 4 8 to 6 73 to 60%

Hamburger Patties

8 per lb., Med. to Well Done 400-450 (204-232) 5 to 6 4 to 6 8 to 7 73 to 68%

6 per lb. 400-450 (204-232) 7 to 10 4 to 6 10 to 8 100 to 73%

4 per lb. 375-450 (190-232) 8 to 12 4 to 6 10 100%

2 to 3 7 to 4 68 to 45%

2 to 3 6 to 4 60 to 45%

2 to 3 7 to 4 68 to 45%

2 to 3 6 to 4 60 to 45%

2 to 3 7 to 6 68 to 60%

2 to 3 8 to 7 73 to 68%

2 to 3 8 to 7 73 to 68%

– 21 –

Page 22

CASSEROLES & MISCELLANEOUS PRODUCTS

POWER LEVEL

TEMP. TIME IN NO. OF SETTINGS

PRODUCT

Food Service Pans

2" to 3" (5.1 to 7.6 cm) deep 325-375 (162-190) 15 to 25

3" to 4" (7.6 to 10.1 cm) deep 325-375 (162-190) 20 to 35 2 to 4 7 to 4 68 to 45%

°F(°C) MINUTES RACKS

SG4D, SG6D SG4C, SG6C

Ramekins or Foil Pans 350-400 (177-204) 5 to 6 4 to 5 10 to 7 100 to 68%

Up to 1

Frozen 10 to 15

Baked Potatoes

120 count per 50 lb. (22.7 kg) 400-450 (204-232) 20 to 25 2 to 5 8 to 6 73 to 60%

100 count per 50 lb. (22.7 kg) 400-450 (204-232) 25 to 40 2 to 5 7 to 6 68 to 60%

80 count per 50 lb. (22.7 kg) 400-425 (204-218) 30 to 45 2 to 5 7 to 4 68 to 45%

Pizzas — Frozen or With

Prebaked Crust 425-475 (218-232) 5 to 10 4 8 to 6 73 to 60%

"Grilled" Cheese Sandwiches 400-425 (204-218) 8 to 10 4 8 to 6 73 to 60%

1

⁄2" (3.8 cm) deep 2 to 4 7 to 6 68 to 60%

2 to 3 6 to 4 60 to 45%

2 to 3 7 to 4 68 to 45%

SPECIAL PROCEDURES FOR BAKING

When baking yeast breads, cooking starts immediately in the convection oven. Yeast breads do not

usually rise as much in a convection oven as in a conventional oven. Therefore, it is usually necessary

1

to allow fuller proof, 2

⁄2 to 3 times increase in volume for best results.

When baking pies in your convection oven, 3 or 4 pies should be put on an 18x26" sheet or bun pan.

This procedure helps the bottom crust to bake, makes handling easier, and reduces the possibility of

boilover spoiling the appearance of the pies on the lower racks.

COOKING HINTS

Forced air convection cooking is faster than conventional oven cooking, and therefore, overcooking

is more common. Do not cook products faster than is practical for the best results. Since forced

convection supplies heat to the surface of the product, the thicker or more massive a product is for its

type, the longer it will take to absorb enough heat to cook.

If four racks of a product cook properly at 350°F (177°C) with a power level control setting of 6 in 15

minutes, one rack should also cook properly at 350°F

1

rack you have only a

⁄4 load, not as much heat is needed. By changing the power level control to 1,

(177°C) in 15 minutes. However, since with one

the single rack load will receive a proportionally smaller amount of heat. It will take the same time at

the same temperature as the four-rack load and be cooked to the same browned and finished

consistency.

The oven will cook or bake full or partial loads at standard recipe temperatures when the power level

control is properly set. As with any oven, you may wish to use a temperature of up to 25 F°

(14 C°) higher

or lower than the recipe, for the particular product result that you prefer.

When established, note convection oven times and power level control settings on your recipe.

HIGH LIMIT SWITCH

All ovens are equipped with a high limit switch which senses the temperature of the oven to prevent

overheating. The high limit switch operates independently and will automatically shut the oven down

should the primary control fail. If this situation occurs, DO NOT attempt to bypass the high limit. Shut

the oven down and contact your local Vulcan authorized service agency.

– 22 –

Page 23

CLEANING

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE

CLEANING.

Allow the oven to cool before cleaning.

Snorkel Tube

The Snorkel tube opening should never be blocked. If usage of aluminum foil is a common practice

during the operation of this oven, be sure to periodically check the Snorkel tube for foil particles. The

Snorkel tube should be kept clean at all times for proper operation of the oven. Clean this tube with

standard oven cleaner at least once a week. Be sure to thoroughly clean all cleansing solution off the

tube before using the oven again. It is also recommended that the oven be run at 400°F

minutes before using to burn off any cleaning solution that was not thoroughly rinsed from the tube.

Daily

Exterior stainless steel oven panels should be cleaned with a damp cloth. Stubborn soil may be

removed with detergent. (DO NOT USE "DAWN".) Rinse thoroughly and wipe dry with a soft clean

cloth. Clean porcelain oven interior daily with soap or detergent and water. Rinse thoroughly and wipe

dry with a soft clean cloth. Nickel plated racks and rack supports may be removed for cleaning.

For burned-on foods and grease which resist simple soap and water cleaning, an abrasive cleanser

(scouring powder) mixed into a paste may be used. Apply with stainless steel wool or sponge, always

rubbing with the "grain." This treatment is equally effective for "heat tint" (slightly darkened areas

caused by oxidation). Again, remember to rub in the direction of the polish lines. Rinse with clear water

and dry with a soft cloth.

(204°C) for 20

Do not use scouring powder on the glass window; it will scratch and fog the glass.

After processing some foods at low temperatures, odors may linger in the oven. These odors may be

cleared by setting the thermostat at 500°F

oven to run unloaded for 30 to 45 minutes.

(260°C) and the power level control at 10 and allowing the

MAINTENANCE

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE

PERFORMING ANY MAINTENANCE.

LUBRICATION

The fan motor comes with sealed bearings and requires no lubrication.

VENT

Periodically check the flue, when the oven is cool, to be sure it is free of obstructions.

REPLACING LAMPS

• Allow oven to cool.

• Remove all racks by pulling forward, lifting up and out.

• Unscrew glass dome from light body.

• Replace the bulb.

• Reassemble glass dome and racks.

– 23 –

Page 24

TROUBLESHOOTING

PROBLEM

Uneven browning or overcooking

at edges of pans.

Product pulling to edge of pan or

spilling.

Product overbrowning before

done or shrinking and overbrowning at edges.

POSSIBLE CAUSE

1. Power level control setting too

high.

2. Too many racks used.

1. Oven out of level.

2. Sheet pans warped.

Power level control setting too high.

SUGGESTED CORRECTIVE

1. Reduce power level control

setting. (Refer to Cooking

Guidelines.)

2. Reduce number of racks used.

1. Level oven, on the racks, from

side to side and front to back.

The rack should check dead

level side to side and from level

to 1⁄8" low at the front from front

to back.

2. Keep pans used for baking

batter separate from general

purpose pans. If any pan

shows a tendency to warp,

remove it from the baking

group.

Reduce power level control

setting. (Refer to Cooking

Guidelines.)

Excessive shrinkage.

No Ignition Light remains lit for

more than 20 seconds after 3

trials (Models SG4D and SG6D),

or "E-05" appears in the display

after 3 trials (Models SG4C and

SG6C).

1. Failure to maintain water in

oven.

2. Roasting temperature too high.

1. Place pan of water (approx.

12"x20"x1" (30.5x51x2.5 cm)

in bottom of oven.

2. Reduce temperature.

1. Turn oven off for 5 minutes

before attempting to re-light.

2. Check gas supply valves to be

sure they are open.

3. Check electrical power source

and connections.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this oven, contact the Vulcan Service Agency in

your area (refer to listing supplied with the oven), or Vulcan-Hart Company Service Department at the

address or phone number shown on the front cover of this manual.

FORM 31024 Rev. B (Aug. 2000) PRINTED IN U.S.A.

– 24 –

Loading...

Loading...