Page 1

SERVICE MANUAL

Heavy Duty Gas Griddles

MODEL

24RRG ML-135339-00024

36RRG ML-135340-00036

48RRG ML-135341-00048

60RRG ML-135342-00060

www.vulcanhart.com

MLS

48RRG

ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

FORM F-36986 (Rev. 11-08)

Page 2

TABLE OF CONTENTS

INSTALLATION…………………………………………………………..

OPERATION……………………………………………………………...

CLEANING………………………………………………………………..

LUBRICATION……………………………………………………………

SPECIFICATIONS……………………………………………………….

COMPONENT LOCATION……………………………………………...

CONTROL PANEL……………………………………………………….

BULLNOSE……………………………………………………………….

BACK PANEL…………………………………………………………….

IDENTIFICATION PLATE……………………………………………….

FLUE……………………………………………………………………….

THERMOSTAT…………………………………………………………...

THERMOSTAT TROUBLESHOOTING.............................................

SYMPTON-BURNER WILL NOT COME ON………………………….

SYMPTON-GRIDDLE SURFACE TEMPERATURE IS MORE

THAN 5° F OFF THERMOSTAT SETPOINT………………………….

THERMOSTAT REMOVAL……………………………………………...

TEMPERATURE PROBE……………………………………………….

TEMPERATURE PROBE REMOVAL………………………………….

TEMPERATURE PROBE INSTALLATION……………………………

ADJUSTMENTS………………………………………………………….

CALIBRATION……………………………………………………………

POWER ON/OFF SWITCH……………………………………………...

POWER SWITCH TROUBLESHOOTING……………………………..

SYMPTON-NO POWER SUPPLIED TO UNIT………………………..

POWER SWITCH REMOVAL AND INSTALLATION………………...

INDICATOR LIGHT………………………………………………………

INDICATOR LIGHT TROUBLESHOOTING…...................................

SYMPTON-LIGHT DOES NOT COME ON WHEN THERMOSTAT

AND BURNER ARE ON…………………………………………………

INDICATOR LIGHT REMOVAL…………………………………………

SAFETY IGNITION MODULE…………………………………………..

SAFETY IGNITION MODULE TROUBLESHOOTING……………….

SYMPTON-NO SPARK BETWEEN PILOT HEAD AND

ELECTRODE……………………………………………………………..

SYMPTON-ELECTRODE CONTINUALLY SPARKS AFTER PILOT

IS LIT………………………………………………………………………

SYMPTON-BURNER SOLENOID VALVE OPENS WITHOUT

ESTABLISHED PILOT FLAME…………………………………………

SAFETY IGNITION MODULE REMOVAL…………………………….

SOLENOID VALVES…………………………………………………….

SOLENOID VALVE TROUBLESHOOTING…………………………...

SYMPTON-NO GAS FLOW TO BURNER…………………………….

SOLENOID VALVE REMOVAL…………………………………………

PILOT……………………………………………………………………...

PILOT TROUBLESHOOTING…………………………………………..

SYMPTON-PILOT WILL NOT LIGHT………………………………….

PILOT ASSEMBLY REMOVAL…………………………………………

4

4

4

4

4

5

6

6

6

6

6

7

7

7

7

8

8

8

8

9

9

10

10

10

10

11

11

11

11

11

12

12

12

12

12

12

13

13

13

14

14

14

14

-

2 -

Page 3

BURNER…………………………………………………………………..

BURNER TROUBLESHOOTING……………………………………….

BURNER REMOVAL…………………………………………………….

BURNER ADJUSTMENT………………………………………………..

GAS REGULATOR………………………………………………………

REGULATOR TROUBLESHOOTING………………………………….

SYMPTOM-UNIT WILL NOT MAINTAIN CONSISTENT GAS

PRESSURE……………………………………………………………….

GAS PRESSURE MEASUREMENT…………………………………...

PRESSURE TAP LOCATION…………………………………………..

SEQUENCE OF OPERATION………………………………………….

WIRING DIAGRAMS…………………………………………………….

24-INCH GRIDDLE……………………………………………………….

36-INCH GRIDDLE……………………………………………………….

48-INCH GRIDDLE……………………………………………………….

60-INCH GRIDDLE……………………………………………………….

15

15

15

16

17

17

17

17

18

18

19

19

20

21

22

-

3 -

Page 4

GENERAL

INTRODUCTION

This manual is prepared for the use of trained service technicians and should only be used by those

who are properly qualified. This manual is not intended to be all encompassing. You should read, in

it's entirety, the repair procedure you wish to perform to determine if you have the necessary tools,

instruments and skills required to perform the procedure. Procedures for which you do not have the

necessary tools, instruments and skills should not be attempted.

Disconnect the electrical power and follow lockout / tagout procedures

Certain procedures in this manual require electrical test or

measurements while power is applied to the machine. Exercise extreme caution at all

times when attempting these procedures. Before testing, disconnect electrical power

and follow lock/out tagout procedures, then attach test equipment and reapply power to

test.

Procedures in this manual will apply to all RRG models unless specified. No procedure in this

manual will require the removal or raising of the griddle plate. Pictures and illustrations can be of any

model unless the picture or illustration needs to be model specific.

INSTALLATION

Generally, installations are made by the dealer or contracted by the dealer or owner. Detailed

installation instructions are included in the Installation and Operation Manual that is sent with each unit.

However, it should be noted that an improperly installed unit, especially an unlevel unit can lead to

premature electrical component failures. A unit that is higher in the front will cause the flue gases to

vent improperly and gather in the front near the electrical components. All RRG models must be

installed with an externally mounted regulator.

OPERATION

Detailed operation instructions are included in the Installation & Operation Manual sent with each

unit and are also available at WWW.VULCANHART.COM

CLEANING

Detailed cleaning procedures are included in the Installation & Operation manual sent with each

unit.

LUBRICATION

No lubrication is required on this equipment.

SPECIFICATIONS

All RRG models operate on 120 volt, 60 hertz, single phase at 1.0 amps. All models are equipped

with electric solid state thermostats, automatic spark igniters and pilot safety circuit. All models are

equipped with 27,500 BTU/HR burners as standard equipment. One burner is used for every 12 inches

of griddle surface. Natural gas models are to operate at 5.0" W.C. manifold pressure and LP models at

10.0" W.C. manifold pressure with all burners on.

.

-

4 -

Page 5

919

PRESSURE CHECK PLUG

TEMPERATURE

CONTROLLER

498438

SAFETY IGNITION MODULE

498443

DUAL SOLENOID VALVE

713656

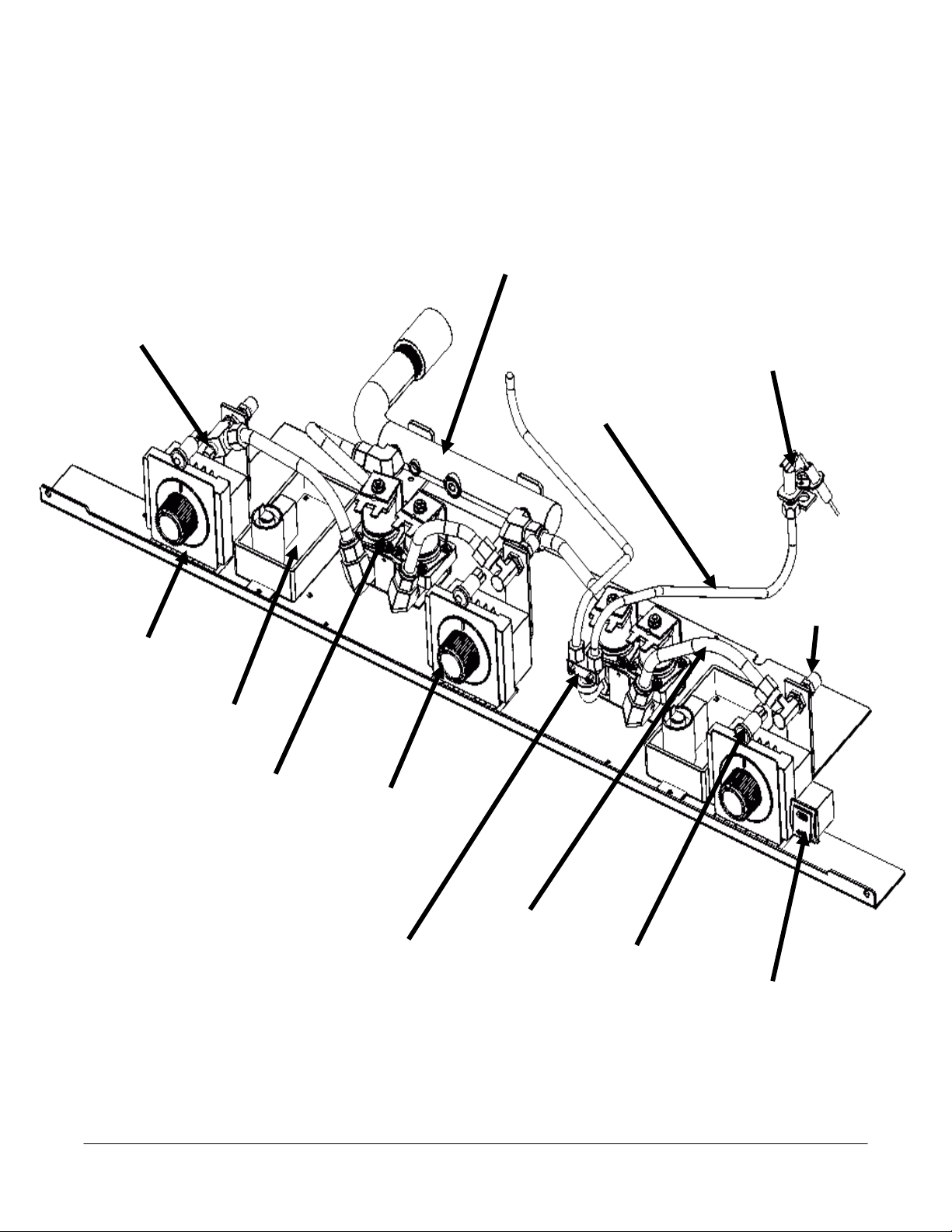

COMPONENT LOCATION

GAS MANIFOLD

720122

¼” FLEX TUBE

KNOB

498438-1

3/8” FLEX TUBE

PILOT ADJUSTMENT VALVE

71

4

INDICATOR LIGHT

720017

36RRG CONFIGURATION SHOWN

PILOT SPARK ASSEMBLY

713930

BURNER ORIFICE

POWER SWITCH

810280-1

-

5 -

Page 6

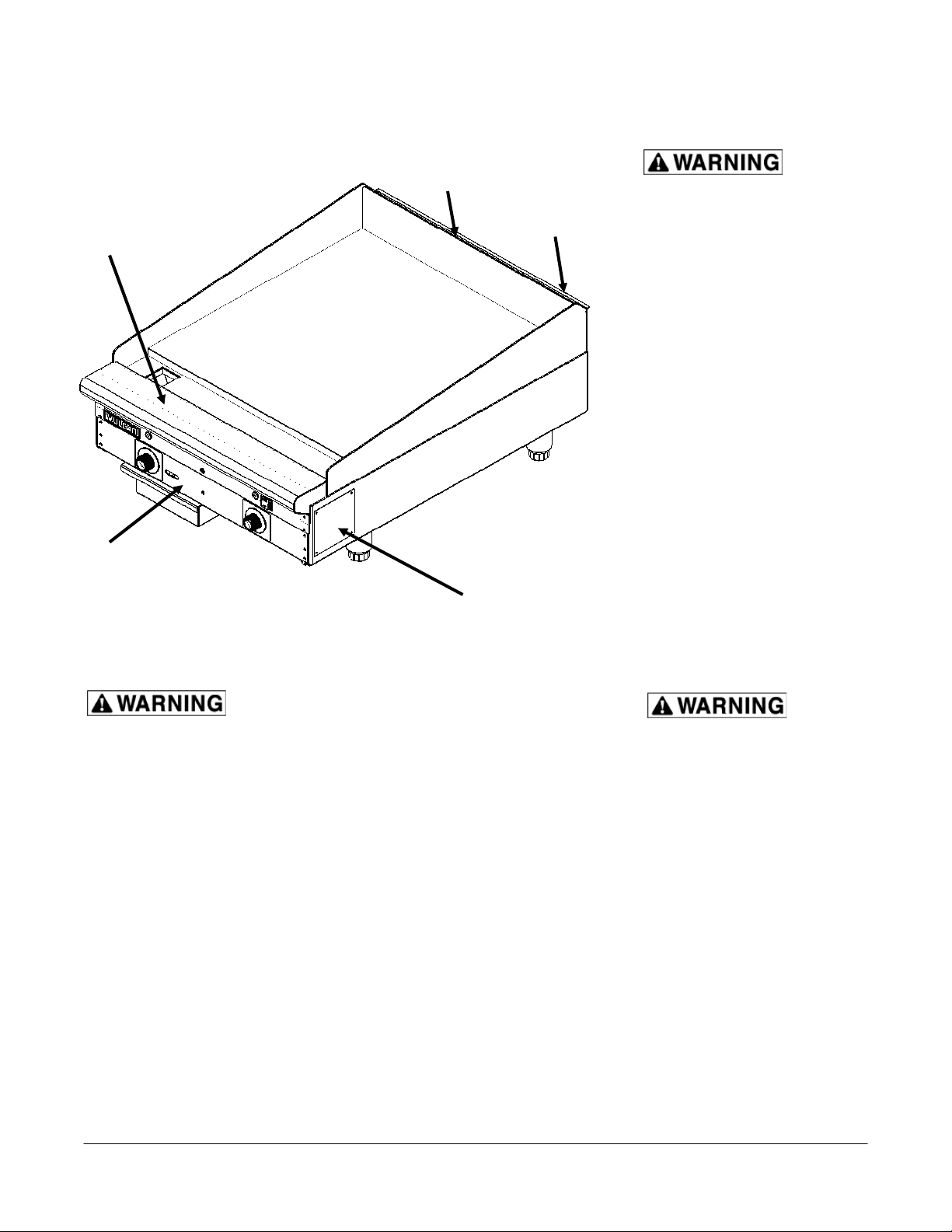

EXTERIOR PANELS

CONTROL PANEL

BULLNOSE

CONTROL PANEL

BACK PANEL

FLUE

BACK PANEL

IDENTIFICATION PLATE

Disconnect the electrical

power and follow lockout

/ tagout procedures

The Control Panel holds the

thermostats, indicator lights

and power switch.

REMOVAL

1. Remove the four screws

securing the front of the

control panel. There are

two screws at each end

of the panel.

2. Remove the screws that

secure the bottom of the

control panel to the

underside of the chassis.

3. Pull the control panel

forward and lay face

down directly in front of

the unit while servicing.

4. Reverse the procedure to

install.

BULLNOSE

Disconnect the electrical power and

follow lockout / tagout procedures

It will be necessary to remove the back panel when changing a

burner, temperature probe or to remove excessive grease build up

from the flue area.

REMOVAL

1. Disconnect gas supply at griddle.

2. Remove all screws from rear of griddle securing the back panel.

3. Reverse the procedure to install.

IDENTIFICATION PLATE

The identification plate contains the unit’s full model and serial

number along with BTU rating and clearance information. The

identification plate is located on the right side panel towards the

front of the unit.

FLUE

The flue is the outlet for gases left over from combustion and

excess heat. The flue should never be blocked or covered.

-

6 -

Disconnect the electrical

power and follow

lockout / tagout

procedures

The Bullnose acts as a front

rail or shelf during griddle

operation.

1. Remove the Control

Panel.

2. The bullnose assembly is

secured with several

screws, one at each end

of the bottom of the

assembly and several

more (depending on

size) facing the griddle

plate.

3. Reverse the procedure

to install.

REMOVAL

Page 7

THERMOSTAT

WIRING CONFIGURATION FRONT VIEW

The thermostat is a solid state control. The thermostat supplies power to the burner solenoid valves

and indicator lights when turned on or until the temperature setpoint is reached.

THERMOSTAT TROUBLESHOOTING

SYMPTOM – BURNER WILL NOT COME ON

1. Check for loose or excessively greasy/dirty connections at thermostat terminals

2. Check that thermostat is set higher than griddle plate surface temperature.

A. Check for 120 voltage going to L1 terminal on thermostat

B. If no voltage, check wiring and power switch.

3. Check safety ignition module.

4. Check for resistance (approx. 50 Ω) from L2 wire to ground when safety circuit should be made.

A. If no resistance, check that pilot is lit and check safety ignition module.

SYMPTOM – GRIDDLE SURFACE TEMPERATURE IS MORE THAN ±5°F OF THERMOSTAT SET

POINT

1. Ensure that you are using a high quality, calibrated surface temperature measuring device.

A. Do not use an infrared thermometer – these are highly inaccurate on a griddle plate.

B. Refer to instructions on page 8 for proper placement of probe and method.

2. Check that burners are properly adjusted.

3. Check that burner valves are operating correctly.

4. Check that there are no burner orifice obstructions

5. Check that the high temp. thermostat probe wire insulation is completely covering the wire. If

you have found no problems in steps 1 – 5, proceed page 9 for calibration instructions.

6. If thermostat will not calibrate after all previous steps – replace thermostat.

Disconnect the electrical power and follow lockout / tagout procedures

-

7 -

Page 8

Disconnect the electrical power and follow lockout/tagout procedures

THERMOSTAT REMOVAL

1. Remove the control panel

2. Remove the knob

3. Label and disconnect the wires

4. Remove the thermostat retaining nut on the knob shaft.

5. Reverse procedure to install while being careful to install the thermostat in the same orientation.

TEMPERATURE PROBE

498432-A

The temperature probe is an embedded K

type thermocouple assembly.

Disconnect the

electrical power and follow

lockout/tagout procedures

TEMPERATURE PROBE REMOVAL

1. Remove the control panel

2. Remove the back panel

3. Label and disconnect the lead wires at

the temperature controller

4. Unthread the probe retaining nut and

remove the probe from the back of the

unit.

TEMPERATURE PROBE INSTALLATION

1. Insert lead wires from back of heatshield

through to temperature controller.

2. Apply a thin coating of high temp(500°

F min. rated),copper based heat transfer

and anti-seize compound to the probe tip

and retaining nut.

3. Insert probe end into plate socket and

hand tighten probe retaining nut.

4. Tighten the probe an additional ½ turn

only with a wrench. Over tightening can

strip threads and damage probe tip.

-

8 -

Page 9

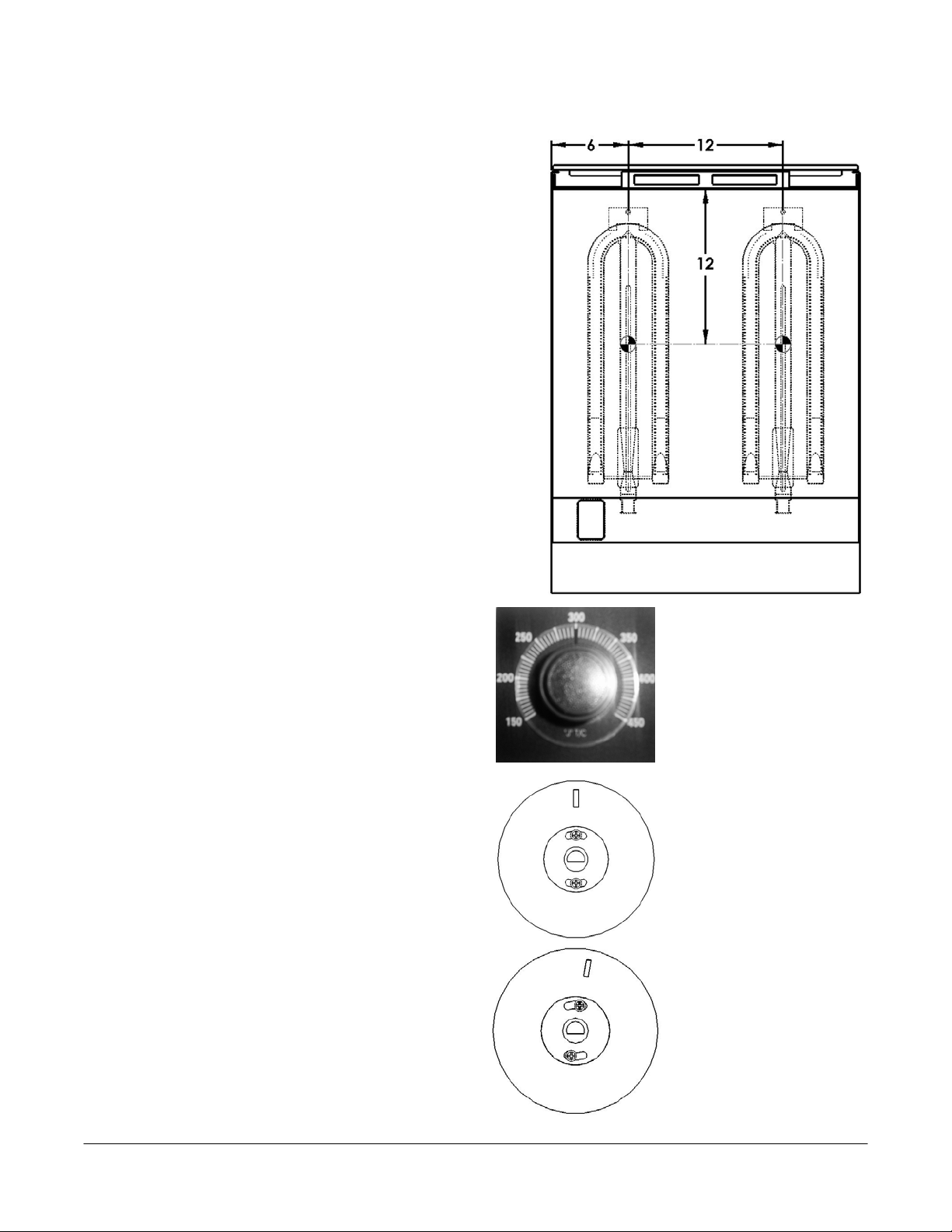

ADJUSTMENTS

CALIBRATION

1. Each temperature controller controls a 12” zone

of the griddle. Using a Surface Probe

temperature measurement device, observe the

temperatures at the center points of the

cooking zones. These points are located by

starting 6” from the side splash (left or right)

and every 12” across the width of the griddle,

with all points located 12” back from the front

edge of the griddle plate.

NOTE: Use of infrared thermometers is not

recommended. These devices are highly

sensitive to surface color (clean or dirty), angle

of reading and distance from the unit.

2. Set thermostats to 350°F and allow to stabilize,

allowing the indicator light to cycle ON and

OFF at least two times.

3. Watch for indicator light to cycle OFF, then

measure the temperature for that zone. The

temperature should be 350°F ±5°F. If not,

continue to Step 4.

4.

a. Set the temperature controller to

350° F. DO NOT allow the knob to

turn. Carefully remove the knob

from the temperature control

shaft.

b. Loosen screws on the back of

knob and turn the transparent ring

around the black knob to the

desired position. Knob will have to

be placed back on the shaft to

verify adjustment.

IMPORTANT: NEVER ADJUST THE

SCREW ON THE BACK SIDE OF THE

TEMPERATURE CONTROLLER. This

will ruin the factory calibration; the

temperature controller will no longer

operate properly and will need to be

replaced.

5. Once calibration is achieved, tighten the

knob screws.

Step 4a. Set knob &

check temperature.

Remove knob

Step 4b. – Adjust

the position of outer

knob ring relative to

black knob body &

verify temperature

setting

Step 4c. –Replace

knob and verify the

reading. Carefully

remove the knob &

tighten screws

-

9 -

Page 10

TEMPERATURE

CONTROLLER

# 1 TERMINAL

# 3 TERMINAL

# 2 TERMINAL

POWER

SWITCH

INDICATOR

LIGHT

POWER ON/OFF SWITCH

The Power Switch controls the power supply to all other electronic components.

Disconnect the electrical power and follow lockout / tagout procedures

POWER SWITCH TROUBLESHOOTING

SYMPTOM – NO POWER BEING SUPPLIED TO THE UNIT

1. Check for loose or excessively greasy/dirty connections at terminals.

2 With power wires disconnected check for continuity/resistance between the 1 and 2 terminals

A. If continuity/resistance with switch in OFF position – replace switch

B. If no continuity/no resistance with switch in ON position – replace switch

3. Check for 120 voltage from #2 terminal to ground

A. If no voltage – check main wiring from j box and power cord/plug

B. If getting voltage to #2 terminal – check voltage to #1 terminal to ground with switch in

“on” position.

1. If no voltage – replace switch

POWER SWITCH REMOVAL

1. Remove the control panel.

2. Label and disconnect the wires to the power switch.

3. Squeeze the switch retainers and slide the switch out through the front of the

control panel.

4. Reverse the procedure to install and check for operation.

-

10 -

Page 11

INDICATOR LIGHT

The indicator light illuminates fully to indicate that the corresponding thermostat and burner have turned

on and gas is flowing through the corresponding solenoid valve. The indicator light will illuminate at a

lower intensity when the pilot safety circuit is being made (pilot lit) but the corresponding burner

solenoid valve and thermostat are not on. The indicator light will exhibit no illumination if the pilot safety

circuit is not made (pilot not lit).

INDICATOR LIGHT TROUBLESHOOTING

SYMPTOM – LIGHT DOES NOT COME ON WHEN THERMOSTAT AND BURNER ARE ON.

1. Check for loose or excessively greasy/dirty terminal connections

2. Check for approx. ½ line voltage between the two indicator light terminals with the

corresponding burner and thermostat off.

A. If no voltage – check wires coming in from the corresponding safety ignition module to the

solenoid to the light for shorts or breaks.

3. With thermostat on and corresponding burner lit – check for 120 voltage between both wires

at the light.

A. If no voltage – check wires coming from the corresponding thermostat to the solenoid to the

light for shorts or breaks. Check thermostat and safety ignition module

B. If you have 120V – replace indicator light.

Disconnect the electrical power and follow lockout / tagout procedures

INDICATOR LIGHT REMOVAL

1. Remove the control panel

2. Label and disconnect wires to the light

3. Squeeze the light retainers and slide the light out through the front of the control panel

4. Reverse the procedures to install and check for proper operation

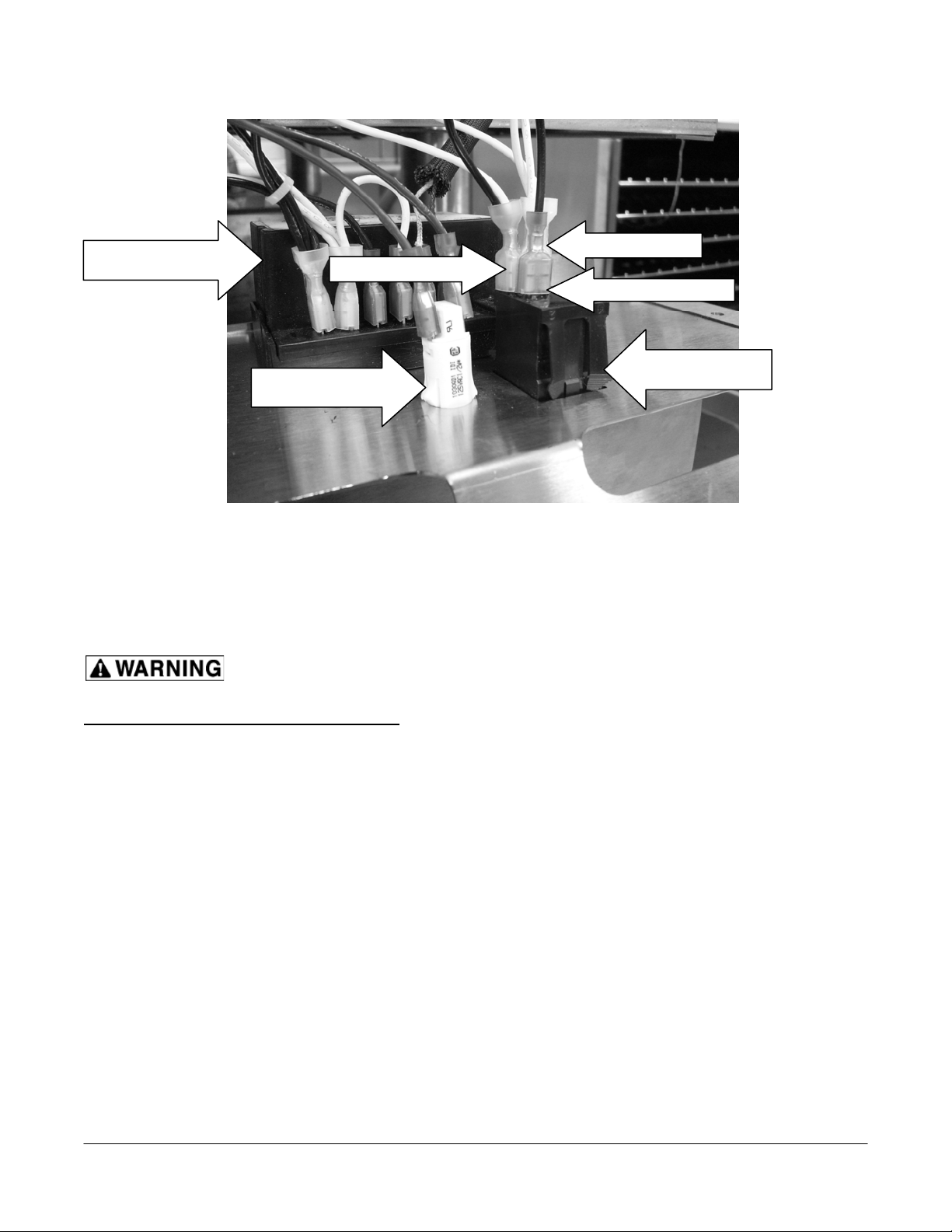

SAFETY IGNITION MODULE

The safety ignition module is a direct

spark ignition control that utilizes a

microprocessor circuit for ignition and

flame sensing. The flame sensing is

achieved via flame rectification. The unit

will continue to spark and keep the

corresponding solenoid valves locked out

until a minimum flame current of 1.0 μA is

achieved.

Pin 1

Pin 2

Pin 3

Pin 4

-

11 -

Page 12

Disconnect the electrical power and follow lockout / tagout procedures

SAFETY IGNITION MODULE TROUBLESHOOTING

SYMPTOM – NO SPARK BETWEEN PILOT HEAD AND ELECTRODE

1. Check for loose or greasy/dirty connections at all terminals (including electrode wire)

2. Check for 120 voltage from pin 4 wire to ground.

a. If no voltage check on/off switch and wiring for shorts or breaks

3. Check electrode wire for damage and continuity – if damaged or no continuity change

spark/pilot assembly

a. Check spark gap between electrode and pilot head. The spark gap should be between

.094” to 0.156” – or approx. 1/8”.

4. If component has passed above checks and is not sparking – then replace ignition module.

SYMPTOM – ELECTRODE CONTINUALLY SPARKS AFTER PILOT IS LIT

1. Check that electrode is engulfed by pilot flame

2. Increase pilot flame height

3. Check electrode and electrode wire for damage

4. Check that power cord grounding wire is securely attached to J box.

5. Check that ground wire from pin 1 is securely grounded to chassis.

SYMPTON – BURNER SOLENOID VALVE OPENS WITHOUT ESTABLISHED PILOT FLAME

1. Check burner solenoid valve.

2. Check for voltage from pin 2 wire of safety ignition module

a. Replace safety ignition module if voltage

IGNITION MODULE REMOVAL

1. Remove the control panel.

2. Label and disconnect the wires from the igniter module.

3. Disconnect the electrode wire and control wire harness.

4. Remove the two mounting bolts.

5. Remove the safety ignition module.

6. Reverse the procedure to install and check for proper operation.

SOLENOID VALVES

The RRG series griddles use both single and dual solenoid valves in differing applications. A single

or dual valve can be either a pilot valve or main burner valve. Pilot valves can be identified by the fact

that they will have adjustment screws for the pilot flame at the output of the valve body. Pilot solenoid

valves will receive power and remain on as long as the power switch is in the ON position. Main burner

solenoid valves will remain on until the thermostat set point has been satisfied.

-

12 -

Page 13

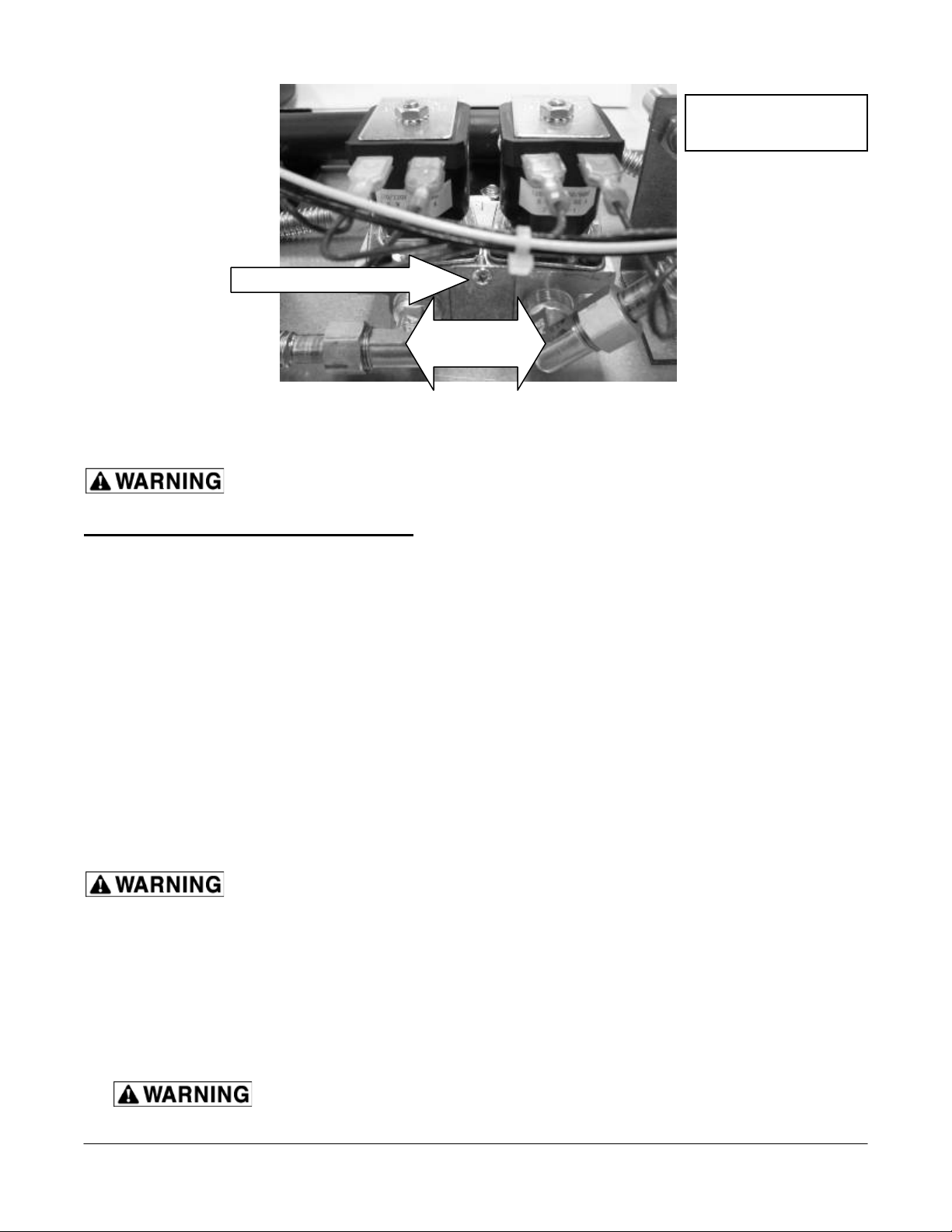

INPUT GAS LINE

IN BACK CENTER

RETAINING SCREW

Retaining screw

OUTPUT

GAS LINES

DOUBLE SOLENOID VALVE

Disconnect the electrical power and follow lockout / tagout procedures

SOLENOID VALVE TROUBLESHOOTING

SYMPTOM – NO GAS FLOW TO BURNER

1. Check terminals for loose or greasy/dirty connections

2. Check gas pressure – check for orifice obstructions.

3. With thermostat, indicator light and power switch on – check for 120 voltage between the two

terminals on the solenoid.

A. On pilot solenoid if no voltage – check wiring and on/off power switch

B. On main burner solenoid if no voltage – check wiring, safety ignition module and

thermostat

4. If you have 120 voltage between the two terminals after performing steps 1- 3, replace the

solenoid valve.

5. Check for a shorted coil by checking resistance between the two terminals with the wires

disconnected. Readings of 100 ohms or less would indicate a shorted coil, replace the

solenoid.

SOLENOID VALVE REMOVAL

Shut off gas supply

1. Remove the control panel.

2. Label and disconnect the wires to the solenoid terminals.

3. Remove the two retaining screws that are holding the valve body in the bracket.

4. Disconnect the input compression fitting and the output compression fitting(s).

5. Remove the solenoid valve

6. Reverse the procedure to install. Be careful to attach the input lines to the ports on the valve

body that are stamped IN

7. Verify gas

pressure and check for proper operation.

All gas joints disturbed during servicing must be checked for leaks.

Check with a soap and water solution. Do not use an open flame.

-

13 -

Page 14

PILOT

The RRG Series Griddles utilize a solenoid valve with

a brass pilot valve to control gas flow to pilot burners.

BRASS PILOT

PILOT TROUBLESHOOTING

SYMPTOM – PILOT WILL NOT LIGHT

1. Check pilot adjustment at solenoid valve

2. Check that power switch is on

3. Check that pilot solenoid valve is working

4. Check that safety ignition module and power switch are working

5. Check gas pressure

6. Check for air in the line

PILOT ASSEMBLY REMOVAL

One to three pilot flames can be fed by one valve –

one leg of which may be branched.

Disconnect the electrical power and follow lockout / tagout procedures

Shut off gas supply

1. Remove control panel. Reaching

underneath the front of the unit,

remove the pilot tube fitting and

disengage the pilot tube from the pilot.

2. Reaching underneath the front of the

BRACKET RETAINING SCREW

unit, remove the pilot bracket retaining

screw(#2 Phillips) and remove the

entire assembly out through the pilot

ELECTRODE

access cutout and out from under the

unit.

3. Disconnect the electrode wire from the

from the safety ignition module.

4. Remove the pilot from the bracket.

5. Reverse procedure to install

6. Verify gas pressure and check for

proper operation

All gas joints disturbed during servicing must be checked for leaks.

Check with a soap and water solution. Do not use an open flame.

PILOT ASSEMBLY

PILOT

ACCESS

-

14 -

Page 15

HELPFUL HINT – If the unit is attached to a flexible gas line, you can extend the bullet feet out to their

fullest extension to raise the griddle and allow yourself more clearance while reaching under the unit.

Remember to relevel the unit if you chose to do this.

BURNER

The RRG Series Griddle utilizes U-shaped burners with a single center inlet for every 12 inches of

griddle width. Each burner is rated for 27,500 BTU/hr.

Disconnect the electrical power and follow lockout / tagout procedures

BURNER TROUBLESHOOTING

SYMPTOM – ALL BURNERS HAVE A LOWER OR HIGHER FLAME THAN NORMAL.

1. Check gas pressure

SYMPTOM – ONE OR MORE BURNERS HAVE LOWER FLAME LEVEL THAN THE OTHERS.

1. Check gas pressure

2. Check burner orifice for obstructions

3. Adjust burner air shutter

4. Check solenoid valve

SYMPTOM – ONE BURNER HAS A DELAYED IGNITION; A SEVERAL SECOND LAPSE BETWEEN

THE INDICATOR LIGHT TURING ON AND WHEN THE BURNER ACTUALLY LIGHTS.

1. Check gas pressure

2. Check that burner locater pin is properly seated with retaining clip attached

3. Check that burner ignition ports, pilot flash tube and pilot burner are all aligned.

4. Check burner shutter adjustment

5. Check pilot flame adjustment

6. Check thermostat, safety ignition module and solenoid valve operation.

BURNER REMOVAL

Shut off gas supply

1. Remove the back panel

-

15 -

Page 16

2. Reach through the back of the unit. Squeeze the burner retaining clip and slide off burner

(U

retaining pin.

3. Lift the burner up so the retaining pin clears the corresponding hole in the chassis, then pull

the burner out through the back of the unit.

4. Replace by inserting the burner through the rear of the unit and engaging the burner venturi

onto the burner orifice at the front of the unit.

5. Seat the retaining pin in the hole in the chassis and attach the retaining clip.

6. Remove the control panel to check that the venturi is properly fitted over the orifice.

7. Reassemble the control and back panels, then check for proper operation.

BURNER ADJUSTMENT

For efficient burner operation, it is important that a proper balance of gas volume and primary air

supply is maintained to give complete combustion. Insufficient air supply results in a yellow streaming

flame. Primary air supply is controlled by the air shutter on the front of the burner venturi. Loosen the

screw on the venturi and adjust the air shutter to just eliminate yellow tips on the burner flames. Lock

the air shutter in place in place by tightening the screw. Repeat this procedure as necessary with all

burners.

BURNER CLIP

NDERNEATH)

FLASH TUBE

PILOT ASSY

IGNITION PORTS

AIR SHUTTER

ORIFICE

MAIN BURNERS

These photos are for reference – it should not be necessary to remove the griddle top to perform the

procedures listed in this manual.

-

16 -

Page 17

GAS REGULATOR

The RRG series units must have an

exterior machine gas regulator installed. The

units are shipped with a regulator that has a

vent limiter. These regulators must be

VENT LIMITER

ADJUSTMENT

COVER

installed as close as possible to the unit in a

horizontal, upright position for optimal

performance. They are adjusted by

removing the adjustment cover – then by

turning the adjustment screw clockwise to

increase and counter clockwise to decrease.

The regulator and griddle can be damaged

by gas pressures that exceed 14” W.C. or ½

psig.

Natural Gas Regulator 408279-25

LP Gas Regulator 408279-21

REGULATOR INSTALLED IN A HORIZONTAL,

UPRIGHT POSITION

REGULATOR TROUBLESHOOTING

SYMPTOM – UNIT WILL NOT MAINTAIN CONSISTENT PRESSURE

1. Check that vent limiter is not clogged by grease and debris

2. Check store gas pressure before regulator with all equipment on that line turned on and

consuming gas

A. For natural gas should be between 7” and 14” W.C.

B. For propane gas should be between 12” and 14” W.C.

3. Check that regulator is installed in a horizontal, upright position

4. If no problems found in steps 1 – 3, replace the regulator

GAS PRESSURE MEASURMENT

1. Set the power on/off switch to the OFF position.

2. Turn the gas supply off at a manual shutoff valve.

3. Remove the control panel.

4. Remove the pressure tap plug from the far left/#1 burner port and attach manometer

5. Turn gas back on and turn power switch to the ON position

6. Turn all thermostats on to the maximum setting so that all burners are on.

7. Turn all the equipment on the same supply line on.

8. Check gas pressure

9. Gas pressure should read 5” W.C. for natural and 10” W.C. for propane gas.

10. Turn off the power switch.

11. Turn gas supply off, disconnect manometer and reinstall pressure tap plug.

-

17 -

Page 18

12. Turn power switch and gas supply back on.

All gas joints disturbed during servicing must be checked for leaks.

Check with a soap and water solution. Do not use an open flame.

PRESSURE TAP AT #1 BURNER

SEQUENCE OF OPERATION

Operation is the same for all size griddles. The neutral wire from the power source is directly

connected to each thermostat and each safety ignition module.

1. The power on/off switch is set to the ON position.

2. Voltage is applied to the following terminals

A. Terminal L1 on each thermostat.

B. Pin 4 terminal of each safety ignition module.

C. Both terminals of the pilot solenoid – energizing the solenoid.

3. The igniter electrode sparks against the pilot head and lights the pilot burner

4. When the pilot flame is sensed – the igniter stops sparking and the igniter safety module allows

voltage to pass to one terminal of each of the corresponding burner solenoid valves and one

terminal of each indicator light – the indicator light illuminates at dim.

5. If the griddle plate temperature is lower than the thermostat set points - the thermostat(s) will

send voltage to the remaining burner solenoid terminal and remaining indicator light terminal.

A. The solenoid will then energize - gas flows to the corresponding burner and is ignited

by the pilot flame.

B. The corresponding indicator light will go from dim to full illumination.

-

18 -

Page 19

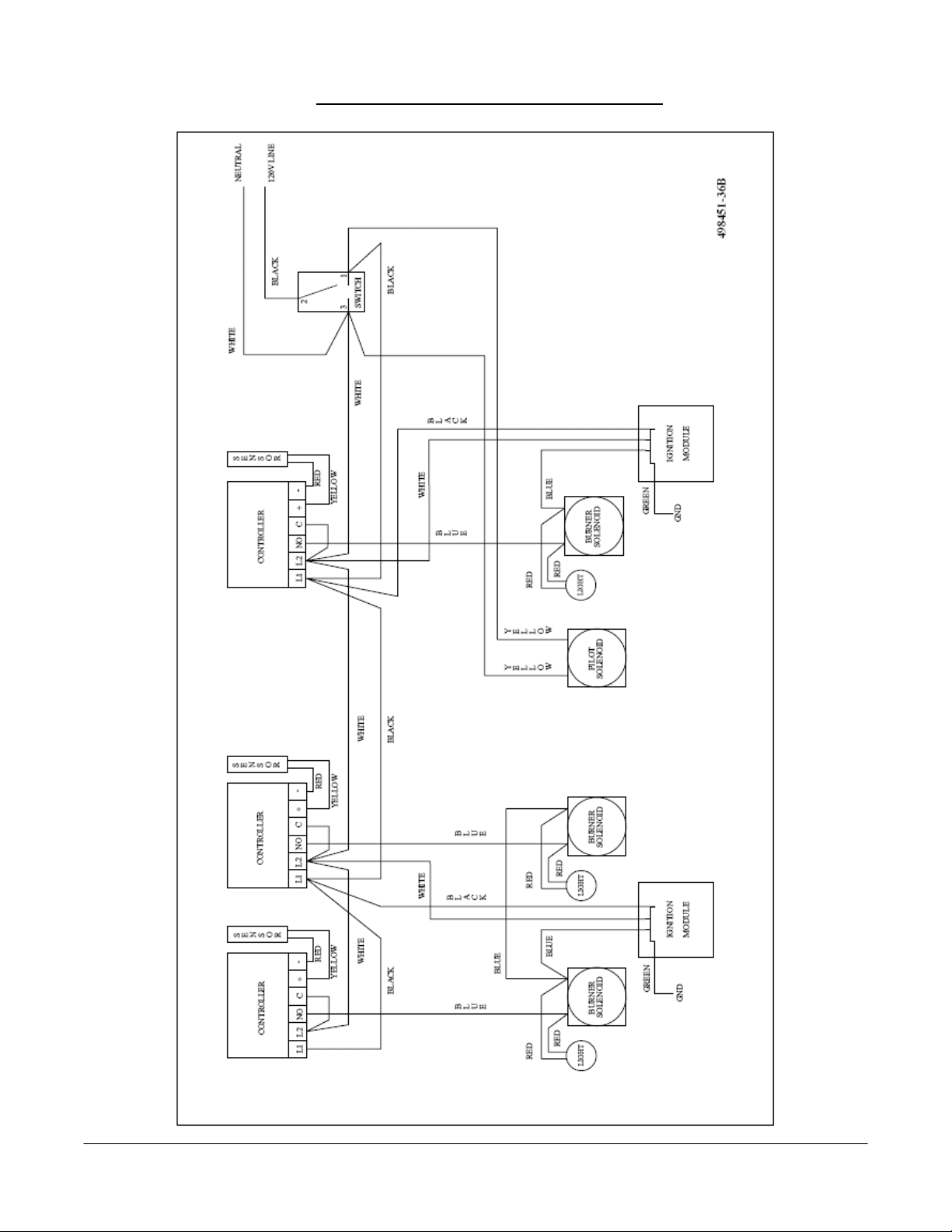

WIRING DIAGRAMS

WIRING DIAGRAM – 24-INCH GRIDDLE

-

19 -

Page 20

WIRING DIAGRAM – 36-INCH GRIDDLE

-

20 -

Page 21

WIRING DIAGRAM – 48-INCH GRIDDLE

-

21 -

Page 22

WIRING DIAGRAM – 60-INCH GRIDDLE

-

22 -

Loading...

Loading...