Page 1

ELECTRIC COUNTER

CONVECTION

STEAMERS

MODELS

C24EA3

ML – 136037 208/240V 8.5KW PRO

ML – 136043 208/240V 8.5KW BASIC

ML – 136044 480V 9.25KW PRO

ML – 136045 480V 9.25KW BASIC

INSTALLATION &

OPERA TION MANUAL

C24EA5

ML – 136038 208/240V 15.75KW PRO

ML – 136046 208/240V 15KW BASIC

ML – 136047 480V 15.75KW PRO

ML – 136048 480V 15KW BASIC

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www .vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F-35428 (2-06)

Page 2

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL THIS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLA TION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHL Y BEFORE INST ALLING OR SERVICING

THIS EQUIPMENT .

© VULCAN-HART, 2006

IN THE EVENT OF A POWER FAILURE, DO NOT

A TTEMPT TO OPERA TE THIS DEVICE.

— 2 —

Page 3

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY....................................................................................................... 2

INTRODUCTION.................................................................................................................................... 5

GENERAL......................................................................................................................................... 5

INSTALLATION................................................................................................................................. 5

UNPACKING..................................................................................................................................... 5

INSTALLATION CODES AND STANDARDS ................................................................................. 5

LOCATION........................................................................................................................................ 6

LEVELING FEET .............................................................................................................................. 6

LEVELING......................................................................................................................................... 6

ANCHORING STEAMER ................................................................................................................. 6

STACKING STAND .......................................................................................................................... 6

ELECTRICAL CONNECTION ......................................................................................................... 7

PLUMBING CONNECTIONS ........................................................................................................... 8

Water Requirements ................................................................................................................. 8

Water Treatment ........................................................................................................................ 8

Water Supply Connection .......................................................................................................... 8

DRAIN CONNECTIONS .................................................................................................................. 8

VENT HOOD .................................................................................................................................... 9

OPERATION .........................................................................................................................................10

CONTROLS ....................................................................................................................................10

Drain Handle (Basic model) .....................................................................................................10

Main Power Switch Light (Professional model) ......................................................................10

Ready Light (Professional model)............................................................................................10

Cooking Light (Professional model).........................................................................................10

Timer..........................................................................................................................................10

START UP (BASIC MODEL) ..........................................................................................................10

OPERATION .............................................................................................................................11

Drain Handle ........................................................................................................................11

Timer ....................................................................................................................................11

PREHEATING............................................................................................................................11

STEAMING .................................................................................................................................11

SHUTDOWN .............................................................................................................................11

EXTENDED SHUTDOWN ........................................................................................................11

— 3 —

Page 4

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

TABLE OF CONTENTS (CONTINUED)

START UP (PROFESSIONAL MODEL)........................................................................................11

OPERATION .............................................................................................................................12

Main Power Switch Light (Professional model).................................................................12

Timer ....................................................................................................................................12

Ready Light ..........................................................................................................................12

Cooking Light .......................................................................................................................12

PREHEATING............................................................................................................................12

STEAMING .................................................................................................................................12

SHUTDOWN .............................................................................................................................12

EXTENDED SHUTDOWN ........................................................................................................12

CLEANING .............................................................................................................................................13

COOKING COMPARTMENT DRAIN..............................................................................................13

DRAINING GENERATOR ...............................................................................................................13

COMPARTMENT.............................................................................................................................13

DOOR GASKET ..............................................................................................................................13

LEAVE COMPARTMENT DOOR OPEN .......................................................................................13

GUIDELINES FOR MAINTAINING STAINLESS STEEL SURFACES...........................................13

MAINTENANCE .....................................................................................................................................15

WATER TREATMENT SYSTEM ....................................................................................................15

REMOVAL OF LIME SCALE DEPOSITS ......................................................................................15

Professional model ...................................................................................................................15

Basic model ...............................................................................................................................16

DOOR GASKET ..............................................................................................................................17

DRAINING THE BOILER.................................................................................................................17

COOKING HINTS..................................................................................................................................18

PREPARATION...............................................................................................................................18

Frozen Food Items....................................................................................................................18

Acceptable Pan Sizes ..............................................................................................................18

COOKING GUIDELINES.................................................................................................................18

PRODUCTS TO BE COOKED IN SOLID PANS..........................................................................19

PRODUCTS TO BE COOKED IN PERFORATED PANS ...........................................................20

TROUBLESHOOTING..........................................................................................................................22

SERVICE AND PARTS INFORMATION ..............................................................................................23

— 4 —

Page 5

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

INTRODUCTION

GENERAL

Vulcan convection steamers are produced with

quality workmanship and material. Proper

installation, usage and maintenance will result

in many years of satisfactory performance. It is

suggested that you thoroughly read this entire

manual and carefully follow all of the instructions

provided.

The C24EA3 and C24EA5 convection steamers

are single compartment, electric, pressureless

steam cookers with an internal electric steam

generator that maintains water temperature at

approximately 195°F. The C24EA3 is rated 8.5

KW (Basic model), and 9.25 KW (Professional

model). The C24EA5 is rated 15 KW (Basic)

and 15.75 KW (Professional).

Model C24EA3 can accommodate three 2 1/2"

deep (6.4 cm) steam pans. Model C24EA5 can

accommodate five 2 1/2"deep (6.4 cm) steam

pans. The C24EA3 and C24EA5 electric

convection steamers are designed for cooking

vegetables, eggs, and other foods, in commercial

kitchens. The steamer has a 0 to 60 minute timer.

The steamers are designed for countertop

installation.

UNPACKING

This steamer was inspected before leaving the

factory. The transportation company assumes

full responsibility for safe delivery upon

acceptance of the shipment. Immediately after

unpacking, check for possible shipping damage.

If steamer damage is found, save the packaging

material and contact the carrier within 15 days

of delivery.

INSTALLATION CODES AND

STANDARDS

In the United States, the Vulcan steamer must

be installed in accordance with:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No.70,

latest edition) available from the National

Fire Protection Association, Batterymarch

Park, Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition) available from

NFPA.

In Canada, the Vulcan steamer must be installed

in accordance with:

INSTALLATION

Before installing, verify that the electrical supply

agrees with the specifications on the data plate

located on the back panel. If the supply and

equipment requirements do not agree, do not

proceed with the installation. Contact your dealer

or Vulcan-Hart immediately

This unit is shipped pre wired for 208/60/3.

240v & single phase operation require changes

to the heater connection 240/60/3, 240/60/1

and 208/60/1. This unit will operate at 60Hz or

50Hz.

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No.3,

latest edition) available from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.

— 5 —

Page 6

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

LOCATION

Allow space for plumbing and electrical

connections. Minimum clearance is 6" (15.2

cm) on the back for proper air circulation. Allow

adequate access for operating and servicing

the steamer (36" at the front of the steamer, 15"

(38 cm) above the steamer and 18" (45.7 cm)

on right side of steamer).

LEVELING FEET

This steamer is shipped with four 2" leveling

feet. Optional 4" leveling feet are available. The

2" feet can be removed and the optional 4" feet

can be threaded into holes on the bottom of the

unit.

LEVELING

Using a spirit level or pan of water in the bottom

of the steamer, adjust the leveling feet or the

feet on the adjustable legs to level the steamer

side to side with a slight tilt front to back to allow

for proper cavity draining. After the drain is

connected, check for level by pouring water

onto the floor of the compartment. All water

should drain through the opening at the back of

the compartment cavity.

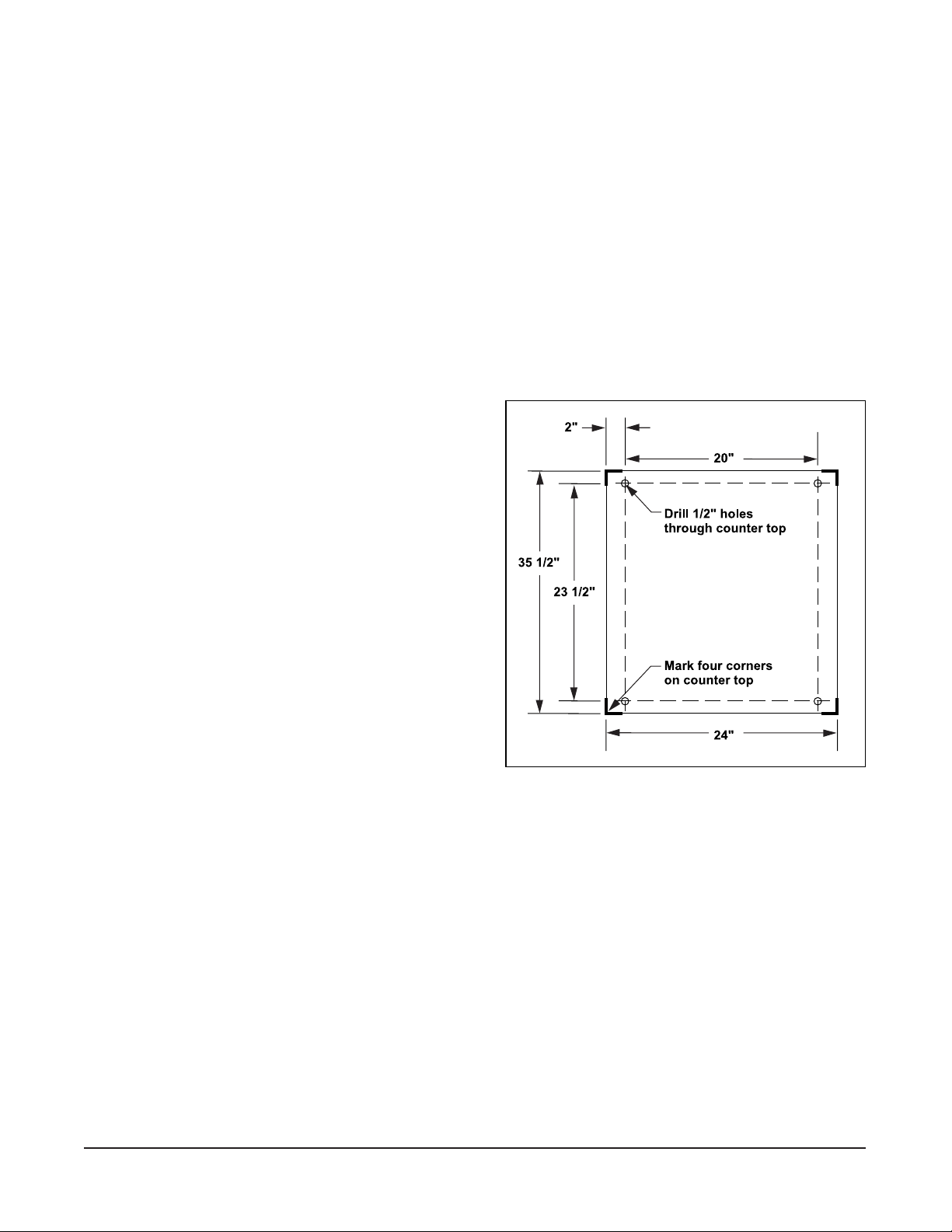

ANCHORING STEAMER

1. Place steamer in the desired location on the

countertop and mark four corners. Remove

the steamer and drill 1/2" holes as indicated in

Figure 1.

2. Apply a bead of RTV or other NSF approved

sealant around the bottom edge of the

steamer. If anchoring the steamer, this

bottom seal is necessary to meet NSF

requirements.

3. Set steamer on countertop and bolt down

securely with 3/8 -16 bolts (not supplied).

Note: Steamer must be installed level side to

side with a slight tilt front to back to allow

for proper draining.

Figure 1.

STACKING STAND

Instruction to install convection steamers on

stacking stand are included with the stacking

stand.

— 6 —

Page 7

ELECTRICAL CONNECTION

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

WARNING: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY

WITH APPLICABLE PORTIONS

The wiring diagram is located on the right side

panel as you face the steamer. This steamer is

hard wired.

OF THE NATIONAL ELECTRICAL

CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

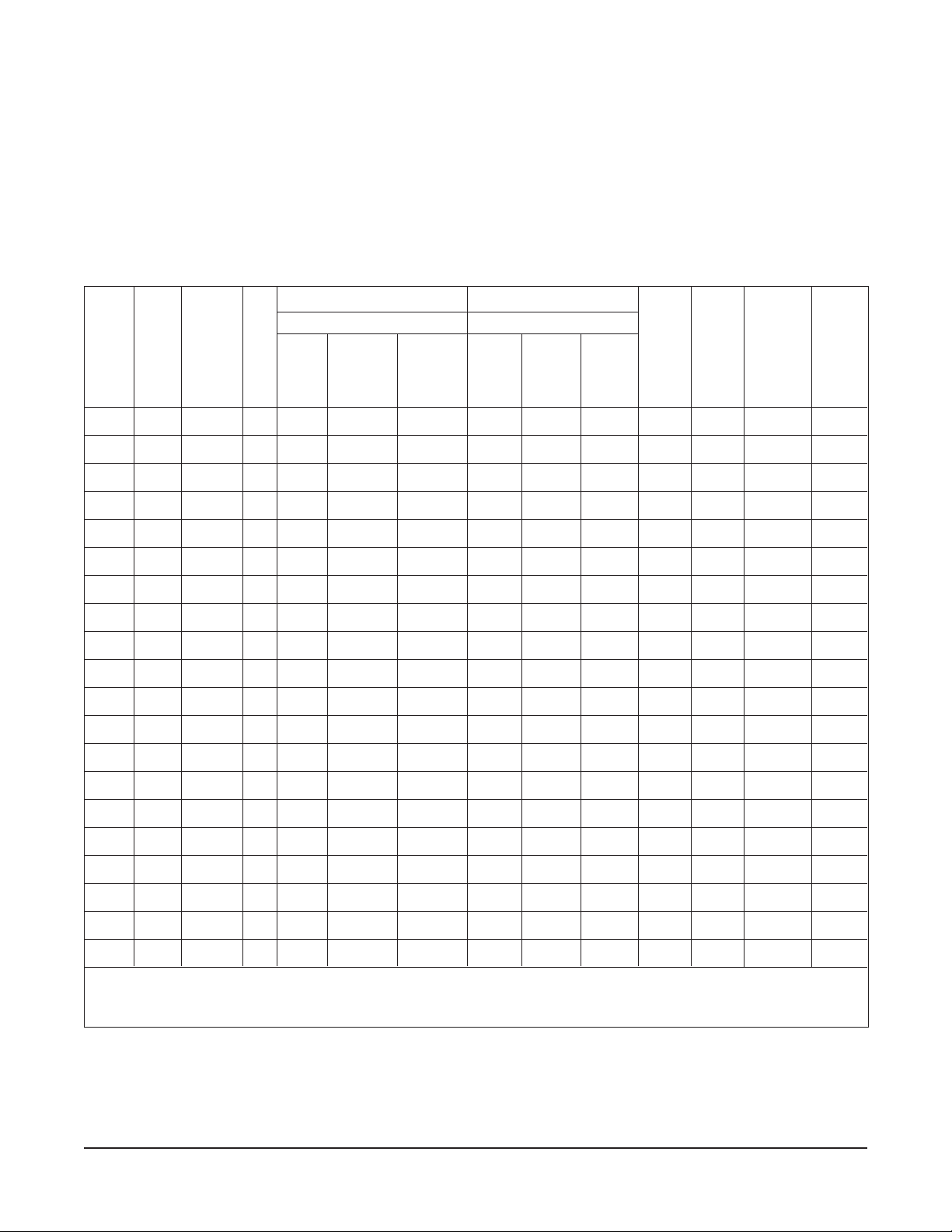

Total Volts Hz Ph KW Per Phase Rated Amps Circuit Fuse 90°C

KW

L1-L2 L2-L3 L3-L1 L1 L2 L3

8.5 208 50/60 1 40.87 60 60 8

8.5 240 50/60 1 35.42 50 50 8

8.5 208 50/60 3 4.25 2.12 2.12 26.54 26.54 17.70 35 35 10

8.5 240 50/60 3 2.83 2.83 2.83 20.50 20.50 20.50 30 25 10

8.5 480 50/60 3 2.83 2.83 2.83 10.30 10.30 10.30 15 15 16

9.25 208 50/60 1 43.57 60 60 6

3-Phase Amps Per Line

Single Size Size Copper

Phase Amps or Min.

Circuit Wire

Breaker Size

Size*

(Amps)

9.25 240 50/60 1 38.54 50 50 8

9.25 208 50/60 3 4.25 2.69 2.12 26.54 28.88 20.04 35 35 10

9.25 240 50/60 3 2.83 3.58 2.83 20.45 23.15 23.15 30 30 10

9.25 480 50/60 3 2.83 3.58 2.83 10.21 11.57 11.57 15 15 16

15 208 50/60 1 72.12 90 9 0 4

15 240 50/60 1 62.50 75 7 5 6

15 208 50/60 3 7.50 3.75 3.75 46.84 46.84 31.23 60 60 6

15 240 50/60 3 5.00 5.00 5.00 36.08 36.08 36.08 50 50 8

15 480 50/60 3 5.00 5.00 5.00 18.04 18.04 18.04 25 25 14

15.75 208 50/60 1 74.82 90 90 4

15.75 240 50/60 1 65.63 80 80 4

15.75 208 50/60 3 7.50 4.31 3.75 46.84 49.18 33.57 60 60 6

15.75 240 50/60 3 5.00 5.75 5.00 36.08 38.79 38.79 50 50 8

15.75 480 50/60 3 5.00 5.75 5.00 18.04 19.40 19.40 25 25 14

2002 National Electric Code

*Dual Element Time-Delay Fuse or Inverse Time Circuit Breaker

Circuit Size (minimum) & Fuse/Circuit Breaker Size (maximum) compiled in accordance with the

National Electrical Code (ANSI/NFPA 70), 2002 Edition.

— 7 —

Page 8

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST

COMPLY WITH APPLICABLE

SANITARY, SAFETY AND

PLUMBING CODES.

Water Requirements

Proper water quality can improve the taste of

the food prepared in the steamer, reduce liming

in the steam generator and extend equipment

life. Water conditions vary from one location to

another. Ask your municipal water supplier for

details about your local water supply prior to

installation. Presence of sediment, silica, excess

chlorides or other dissolved solids may lead to

a recommendation for alternate form(s) of water

treatment. Test the water with the test strip

included with the steamer. Other factors

affecting steam generation are iron content,

amount of chloridation and dissolved gases.

If the water supply fails to meet these standards,

it will be necessary to install a water conditioner

on the generator water feed. The use of strainers

or filters will not remove minerals from the

water.

Water Supply Connection

Connect the treated cold water supply line to the

3/4" (19 mm) (male hose thread) inlet. Connect

the untreated cold water supply line to the 3/4"

(19 mm) (male hose thread) inlet marked

UNTREATED WATER.

A water filter system is recommended for the

water supply line going to the treated water inlet.

Follow the recommendations for use and

installation instructions shipped with the water

filter. If a water filter is not installed, the steam

generator warranty may be limited.

A manual shutoff valve must be provided in a

convenient location near the steamer.

Water Treatment

A local water treatment specialist should be

consulted before installation of steam generating

equipment.

Supply Pressure 20 - 60 psig

Hardness* No more than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

PH range 6.5 - 8

Undissolved Solids less than 5 microns

*17.1 ppm = 1 grain of hardness

DRAIN CONNECTIONS

The drain connection (Figure 2) must be 1 1/2"

(38 mm) down, preferably with one elbow only,

maximum length of 6' and piped to an open gap

type drain.

CAUTION: In order to avoid any back

pressure in the steamer, do

not make a solid connection to

any drain. FAILURE TO DO SO

CAN DAMAGE THE STEAMER

AND VOIDS THE WARRANTY.

A vent must be installed to avoid creating a

vacuum or pressure in the cooking chamber.

— 8 —

Page 9

Figure 2

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

VENT HOOD

Local codes may require the steamer to be

located under an exhaust hood. Information on

the construction and installation of ventilating

hoods may be obtained from Vapor Removal

from Cooking Equipment, NFPA standard No.

96 (latest edition).

— 9 —

Page 10

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

OPERATION

CONTROLS

Drain Handle (Basic model only)

Push the handle in to turn on the steamer. Pull

the handle out to turn off and drain the steamer.

Note: Controls for the Basic and Professional

models are shown in Figure 3.

Cooking Light (Professional model only)

The cooking light indicates that the steamer is in

the cooking cycle.

Timer

Set the cooking time (0 to 60 minutes). Steam

cooking will begin when the door is closed. The

cooking cycle will be interrupted if the door is

open during the cooking cycle; resume cooking

by closing the door.

When done, a buzzer sounds and steam stops

being supplied to the cooking chamber. Turn

the timer OFF to stop the buzzer.

START UP (BASIC MODEL)

WARNING:

THE STEAMER AND ITS PARTS

ARE HOT. USE CARE WHEN

OPERATING, CLEANING OR

SERVICING THE STEAMER. THE

COOKING COMPARTMENT CONTAINS LIVE STEAM. STAY CLEAR

WHILE OPENING THE DOOR.

Figure 3

Main Power Switch Light (Professional

model only)

ON The boiler will automatically fill and begin

heating to the preset temperature.

OFF The boiler will drain, switch power light

will turn off.

Ready Light (Professional model only)

The ready light indicates that the steamer is

ready for the cooking cycle.

Once the steamer is installed and all mechanical

connections have been made, thoroughly test

the steamer before operation.

1. Check that proper water, drain, and electrical

connections have been made.

2. Open water valve.

3. Push handle in to turn the steamer on. Wait

approximately 15-20 minutes.

4. Open the door and observe that no steam is

entering the compartment.

5. Set the timer to the 5 minute position. Close

the compartment door. Steam should be

heard entering the compartment. Wait

approximately 2-3 minutes.

6. Check drain line to ensure that water from

the cold-water condensate valve is flowing

through the drain line.

7. Open the compartment door and observe

that steam supply to the compartment stops.

— 10 —

Page 11

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

8. Close compartment door and let cooking

cycle finish. When timer returns to 0, the

buzzer will sound, signaling the end of the

cooking cycle. To silence the buzzer, turn

the timer dial to OFF.

To shut down the steamer, pull the handle to turn

9.

off and drain. Leave the compartment doors

slightly open to allow the inside to dry out.

OPERATION

Drain Handle

Push the handle in to turn the steamer on. Pull

the handle out to turn off and drain the steamer.

Timer

Set to the desired cooking time. Timer range is

0-60 minutes.

When the timer reaches 0, the buzzer sounds

and steam stops entering the cooking

compartment. Turn the timer to the off position

to stop the buzzer.

PREHEATING

SHUTDOWN

Pull drain handle until it stops. The power light

will turn off before the handle stops. Leave the

compartment door open to allow the inside to

dry out.

EXTENDED SHUTDOWN

To shut down for an extended period:

1. Pull drain handle to the OFF/DRAIN position.

2. Turn off the water and the main power supply.

3. Clean the compartment.

4. Disconnect power.

START UP

(PROFESSIONAL MODEL)

WARNING: THE STEAMER AND ITS PARTS

ARE HOT. USE CARE WHEN

OPERATING, CLEANING OR

SERVICING THE STEAMER.

THE COOKING COMPARTMENT

CONTAINS LIVE STEAM. STAY

CLEAR WHILE OPENING THE

DOOR.

Preheat the cooking compartment when the

steamer is first used for the day, or whenever

the compartment is cold.

Set the timer to 5 minutes. When the buzzer

sounds, turn the timer to the OFF position. The

steamer is ready to cook.

STEAMING

When the compartment is preheated, place

pans of food into the cooking compartment and

close the door.

Set the timer to the desired cooking time. At this

point, the cooking cycle begins. Opening the

door interrupts the cooking cycle. Close the

door to resume cooking.

The buzzer will sound when the cooking cycle ends.

Turn the timer to the OFF position to silence the

buzzer. Open the door and remove the cooked food.

Once the steamer is installed and all mechanical

connections have been made, thoroughly test

the steamer before operation.

1. Check that proper water, drain, and electrical

connections have been made.

2. Open water valve.

3. Press the power switch to the ON position.

Wait approximately 8-10 minutes.

4. Open the door and observe that no steam is

entering the compartment, and that the ready

light is ON and the cooking light is OFF.

5. Set the timer to the 5 minute position. Close

the compartment door. The cooking light should

now be lit and steam should be heard entering

the compartment. Wait approximately 2-3

minutes.

6. Check drain line to ensure that water from

the cold-water condensate valve is flowing

through the drain line.

— 11 —

Page 12

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

7. Open the compartment door and observe

that steam supply to the compartment stops

and that the cooking light is OFF.

8. Close compartment door and let cooking

cycle finish. When timer returns to 0, the

buzzer will sound, signaling the end of the

cooking cycle. To silence the buzzer, turn

the timer dial to OFF.

9. To shut down the steamer, turn off the power

switch. Leave the compartment doors slightly

open to allow the inside to dry out.

OPERATION

Main Power Switch

ON The power light will illuminate, and the

generator will automatically fill and begin

heating to the preset temperature.

OFF The power light will turn off, and the

generator will drain.

Timer

When the ready light is on, set the timer to 5

minutes. The cooking light will illuminate. When

the buzzer sounds, turn the timer to the OFF

position. The steamer is ready to cook.

STEAMING

When the compartment is preheated, place

pans of food into the cooking compartment and

close the door.

Set the timer to the desired cooking time. At this

point, the cooking cycle begins. Opening the

door interrupts the cooking cycle. Close the

door to resume cooking.

The buzzer will sound when the cooking cycle

ends.

Turn the timer to the OFF position to silence the

buzzer. Open the door and remove the cooked

food.

If the timer is set to constant steam, the steamer

will steam continuously and the buzzer will not

sound.

Set to the desired cooking time, or set to the

constant position. Timer range is 0-60 minutes.

When the timer reaches 0, the buzzer sounds

and steam stops entering the cooking

compartment. Turn the timer to the off position

to stop the buzzer. If constant steam is selected,

the steamer will steam continuously, and the

timer will not time out.

Ready Light

The ready light indicates that the steamer is

ready to cook.

Cooking Light

The cooking light indicates that the steamer is

cooking.

PREHEATING

Preheat the cooking compartment when the

steamer is first used for the day, or whenever

the compartment is cold.

SHUTDOWN

Set the main power switch to the OFF position.

The boiler will automatically blow down. Leave

the compartment door open to allow the inside

to dry out.

Note: Power supplied to the steamer must

remain on for 15 minutes after the main

power switch is set to the OFF position.

This will allow the blowdown cycle to

complete.

EXTENDED SHUTDOWN

To shut down for an extended period:

1. Press the power switch to the OFF position.

2. Turn off the water and the main power supply.

3. Clean the compartment.

4. Disconnect power.

— 12 —

Page 13

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

CLEANING

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES BEFORE

CLEANING.

COOKING COMPARTMENT DRAIN

Keep compartment drain running freely. Inspect

compartment drains daily for blockage. Remove

any particles or debris from the perforated

strainer daily (or more often if needed).

After cooking greasy foods or seafood, close

the doors and operate each compartment for 25

to 30 minutes to flush any residual grease and

oils down the compartment drain. Make a

solution of warm water and non-chloride

detergent and pour 1/2 gallon (1.9 liters) of it

down the compartment drain. Rinse by pouring

1/2 gallon (1.9 liters) of hot water down the

compartment drain.

COMPARTMENT

Wash the inside of the compartment with a

solution of warm water and non-chloride

detergent. Rinse with warm water.

Once a week, thoroughly clean the exposed

surfaces (sides, front, door and top) with a

damp cloth and polish with a clean cloth. To

remove discolorations, use a nonabrasive

cleaner.

DOOR GASKET

Clean the gasket sealing surface of the

compartment door to remove food acids for

maximum gasket life. Do not use any solvents

or sharp instruments. Wash with a cloth

moistened in a solution of mild detergent and

warm water. Rinse with a fresh cloth moistened

with warm water to remove all traces of

detergent.

DRAINING GENERATOR

To prevent malfunction of controls and clogging,

it is essential to drain the generator every day.

This will flush out any accumulated minerals

from the feed water. It will also aid in preventing

internal scale buildup which would interfere with

proper generator operation. Failure to drain the

generator every day will void the steamer

warranty. The presence of minerals in

suspension is indicated by a murky or milky

condition in the first portion of the water drained.

WARNING:

After the generator has been in operation, turn

the unit off with the power switch located on

cooking compartment to drain the generator.

The generator will drain for approximately 15

minutes, removing sediment, scale and lime

buildup in the generator.

THE WATER BEING DRAINED IS

HOT AND UNDER PRESSURE.

USE CARE WHEN CLEANING OR

SERVICING THE GENERATOR.

Wipe dry with a clean cloth. Never apply food

oils or petroleum lubricants directly to the door

gasket. Petroleum-based solvents and

lubricants will reduce gasket life.

LEAVE COMPARTMENT DOOR OPEN

Leave the compartment door slightly open when

the steamer is not in use. When the compartment

is idle, never latch the door and apply pressure

to the door gasket. Leaving the gasket under

pressure can cause permanent deformation

and reduce gasket life.

GUIDELINES FOR MAINTAINING

STAINLESS STEEL SURFACES

There are four things that will break down

stainless steel and allow corrosion to develop:

1) Abrasion

2) Deposits

3) Water

— 13 —

4) Chlorides

Page 14

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

Avoid rubbing with steel pads, wire brushes or

scrapers that can leave iron deposits on stainless

steel. Instead, use plastic scouring pads or soft

cloths. For stubborn stains, use products such

as Cameo, Talc or Zud First Impression. Always

rub parallel to the polish lines or with the grain.

Hard water will leave deposits that promote rust

on stainless steel. Treated water from softeners

or certain filters can eliminate these mineral

deposits. Other deposits from food or lubrication

must be properly removed by cleaning. Use

mild detergent and non-chloride cleaners. Rinse

thoroughly. Wipe dry. Where appropriate, apply

a polish recommended for stainless steel (such

as Benefit or Super Sheen) for extra protection

and luster.

— 14 —

Page 15

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

MAINTENANCE

WARNING: THE STEAMER AND ITS PARTS

ARE HOT. USE CARE WHEN

OPERATING, CLEANING OR

SERVICING THE STEAMER. THE

COOKING COMPARTMENT

CONTAINS LIVE STEAM. STAY

CLEAR WHEN OPENING DOOR.

WATER TREATMENT SYSTEM

A water treatment system is recommended for

the steamer. Refer to your supplier's manual for

normal maintenance procedures for proper

scale-free operation.

REMOVAL OF LIME SCALE DEPOSITS

The steamer should be delimed when symptoms

occur (see Troubleshooting Chart). This is in

accordance with the minimum preventive

maintenance schedule required by the

Warranty.

Items Required (not provided)

• Deliming material

• Funnel

• Plastic or rubber gloves

• Safety goggles or face shield

• Measuring cup

• 1-gallon container for mixing deliming

solution

• Petrol-Gel Lubricant or equivalent foodgrade grease for coating deliming port

threads

Note: Deliming solution may cause the surface

of aluminum measuring tools to tarnish or

etch.

Professional Unit (Automatic Drain)

Note: This procedure is not intended to take

the place of a water treatment program.

WARNING: READ AND FOLLOW THE IN-

STRUCTIONS ON THE DELIMING

MATERIAL PACKAGE. AVOID

CONTACT WITH SKIN AND

EYES. WEAR PLASTIC OR

RUBBER GLOVES AND SAFETY

GOGGLES WHEN HANDLING.

WASH THOROUGHLY AFTER

HANDLING. IF DELIMING

SOLUTION COMES IN CONTACT

WITH THE SKIN OR EYES,

RINSE THOROUGHLY WITH

CLEAN WATER.

WARNING: THE STEAMER AND ITS PARTS

ARE HOT. USE CARE WHEN

OPERATING, CLEANING OR

SERVICING THE STEAMER.

THE COOKING COMPARTMENT

CONTAINS LIVE STEAM. STAY

CLEAR WHEN OPENING DOOR.

1. Turn power switch OFF. Wait 5 minutes for

steam generator to completely drain and the

drain valve to close.

2. Turn cooking timers to OFF.

3. Prepare deliming solution according to the

instructions on the deliming material

package. Follow all manufacturer's

instructions.

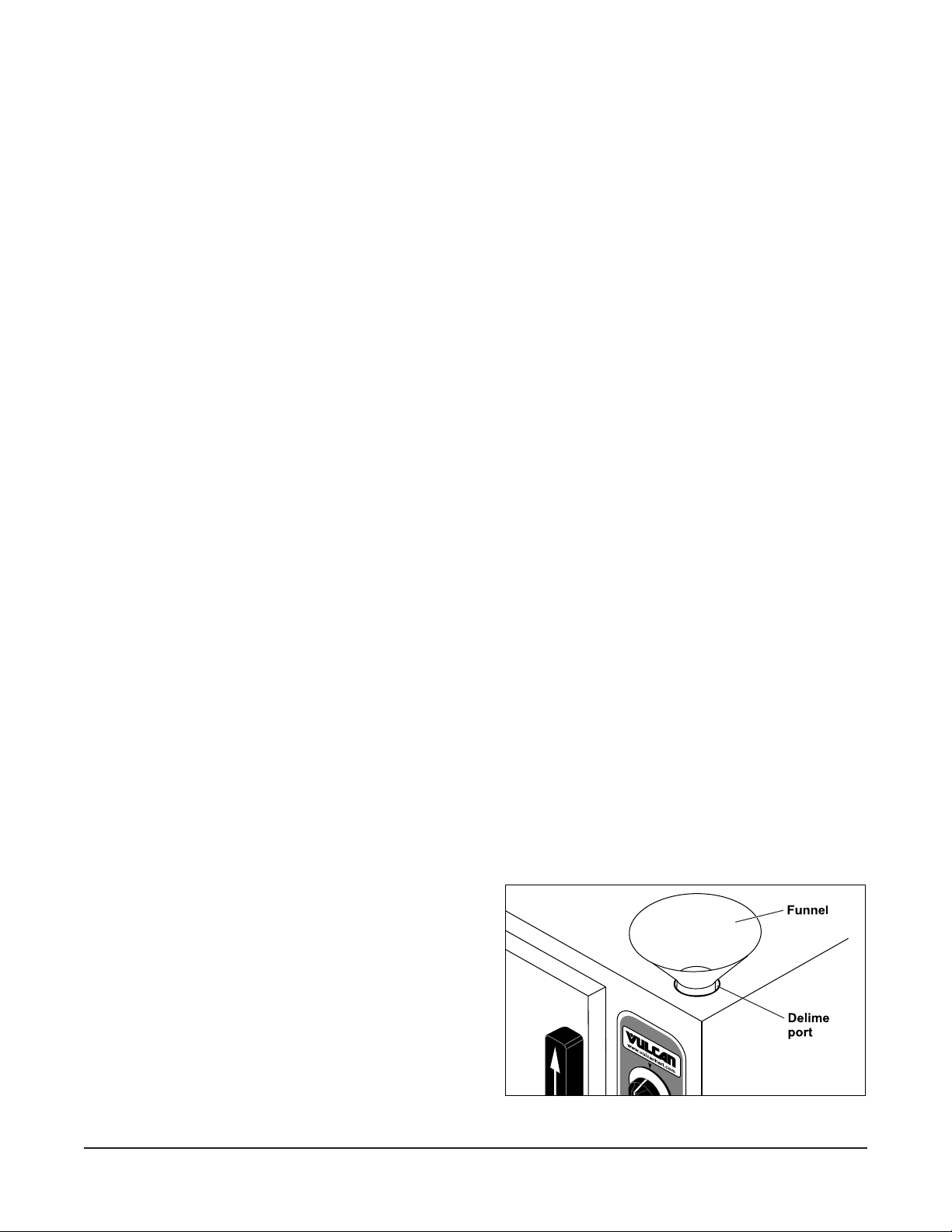

4. Remove delime port cap on top of unit and

insert funnel into delime port (Figure 4).

— 15 —

Figure 4

Page 16

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

5. Pour deliming solution into the steam

generator slowly to avoid spillage.

6. Remove funnel from delime port then rinse

port with clean water.

7. Lightly coat delime port threads with PetrolGel then install delime port cap. Cap must

be installed and tightened securely at all

times.

8. Turn power switch ON.

9. When ready light comes on, turn cooking

timer on for 3 minutes to delime the steam

tubes and nozzles.

10. After 40 minutes, turn power switch OFF

and allow steam generator to completely

drain, 5 minutes.

11.Rinse steam generator with clean water:

A . Turn power switch ON. When ready light

comes on, turn cooking timer on for 3

minutes to rinse the steam tubes and

nozzles.

3. Prepare deliming solution according to the

instructions on the deliming material

package. Follow all manufacturer's

instructions.

4. Remove delime port cap on top of unit and

insert funnel into delime port.

5. Lightly coat delime port threads with PetrolGel.

6. Push drain lever in to close the drain valve

and turn the unit on.

7. Pour deliming solution into the steam

generator slowly to avoid spillage.

8. Immediately remove funnel from delime port

then rinse port with clean water.

9. Immediately install delime port cap. Cap

must be installed and tightened securely at

all times.

Note: Steps 6, 7, 8 and 9 must be completed

within a 5-minute time period.

B. Turn power switch OFF and allow steam

generator to completely drain.

C. Turn cooking timer to OFF.

D. Repeat steam generator rinse one time.

12.Clean exterior and interior using a mild

solution of soap and water. Rinse with clean

water then dry with a soft cloth.

13.Leave compartment door open when not in

use.

14.The steamer is ready for operation or

shutdown.

Basic Unit (Manual Drain Lever)

Note: This procedure is not intended to take

the place of a water treatment program.

1. Pull drain lever out to open generator drain

and turn unit off. Wait 5 minutes for steam

generator to completely drain.

2. Turn cooking timer to OFF.

10.After 30 minutes, turn cooking timer on for

3 minutes to delime the steam tubes and

nozzles.

11.After 50 minutes, pull drain lever out to turn

the unit off and allow steam generator to

completely drain, 5 minutes.

12.Rinse steam generator with clean water:

A. Push drain lever in to close drain and

turn power on. Wait 20 minutes then turn

cooking timer on for 30 seconds to rinse

the steam tubes and nozzles.

B. Pull drain lever in and allow steam

generator to completely drain.

C. Turn cooking timer to OFF.

D. Repeat steam generator rinse one time.

13.Clean exterior and interior using a mild

solution of soap and water. Rinse with clean

water then dry with a soft cloth.

14.Leave compartment door open when not in

use.

15.The steamer is ready for operation or

shutdown.

— 16 —

Page 17

DOOR GASKET

If the door gasket is leaking due to a nick or cut,

it must be replaced. Damage to the gasket

sealing surface will cause steam leakage.

DRAINING THE BOILER

Drain the boiler at the end of each day to flush

out minerals and minimize scale build-up. The

generator drains automatically for approximately

15 minutes after the power switch is turned

OFF on the Professional model, or the drain

handle is pulled on the Basic model.

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

— 17 —

Page 18

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

COOKING HINTS

The steamer efficiently cooks vegetables and

other foods for immediate serving. Steam cooking

should be carefully time controlled. Keep hot food

holding-time to a minimum to produce the most

appetizing results. Prepare small batches. Cook

only enough to start serving, then cook additional

amounts to meet demand.

PREPARATION

Prepare vegetables, fruits, meats, seafood and

poultry normally by cleaning, separating, cutting,

removing stems, etc. Cook root vegetables in a

perforated pan. Other vegetables may be cooked

in a perforated pan unless juices are being saved.

Liquids can be collected in a solid 12" x 20" pan

placed under a perforated pan.

Perforated pans are used for frankfurters, wieners

and similar items when juices do not need to be

preserved. Solid pans are good for cooking

puddings, rice, and hot breakfast cereals.

Vegetables and fruits are cooked in solid pans in

their own juice. Meats and poultry are cooked in

solid pans to preserve their juice or retain broth.

Canned foods can be heated in their opened

cans (cans placed in 12" x 20" solid pans) or the

contents may be poured into solid pans. DO

NOT place unopened cans in the steamer.

than 15 minutes of cooking time. When a cover

is used, approximately one-third additional

cooking time is necessary.

Cooking time for frozen foods depends on the

amount of defrosting required. If time permits,

allow frozen foods to partially thaw overnight in a

refrigerator. This will reduce their cooking time.

Acceptable Pan Sizes

The steamer accommodates combinations of

full, half and one-third size pans, solid or

perforated.

Model Number of Pans Accommodated

Depth of Pan

1" 2 1/2" 4" 6"

C24EA3 6321

C24EA5 10 5 3 2

COOKING GUIDELINES

The steamer cooks vegetables, frankfurters,

eggs in their shells, and certain other meats or

food items at atmospheric pressure.

Frozen Food Items

Separate frozen foods into smaller pieces to

allow more efficient cooking.

Use a pan cover for precooked frozen dishes

that cannot be cooked in the covered containers

in which they are packed if they require more

These cooking guidelines are suggestions only.

You should experiment with your food products

to determine the cooking times that will give you

the best results. Variables which affect cooking

time include size, weight, thickness of foods,

temperature, density, previous condition of the

foods (fresh, pre-blanched or frozen) and degree

of doneness desired.

— 18 —

Page 19

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

PRODUCTS TO BE COOKED IN SOLID PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

Eggs, Scrambled 9 - 12 8 Doz.

Rice, Long Grain (Cover with 4 cups water/lb.) 23 - 25 2 Lb.

Pasta (Place perforated pan inside solid pan,

cover with cold water)

Sp aghetti – Regular/Vermicelli 10 - 15

Macaroni - Shells/Elbows 13 - 18

Noodles - 1/2" Wide 10 - 15

Lasagna Noodles 13 - 18

Frozen Casseroles, Lasagna 33 - 35 Full Pan

Meat Loaf, 3-5 Lb. Each 38 - 40 15 Lb.

Beef

Ground Chuck 19 - 25 10 Lb

Sliced as Purchased 33 - 40 10 Lb.

Shrimp, Frozen, 10 Shrimp per Lb. 4 - 5 4 Lb.

Beans

Baked 8 - 9 10 Lb. Can

Refried 8 - 9 10 Lb. Can

Canned Vegetables 5 - 6 10 Lb. Can

Prunes, Dried 11 - 15

— 19 —

Page 20

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

PRODUCTS TO BE COOKED IN PERFORATED PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

SEAFOOD

Clams

Frozen 9 - 12 3 Doz.

Fresh, Cherrystone 4 - 6 3 Doz.

King Crab, Frozen

Claws 3 - 4 2 1/2 Lb.

Legs 3 - 6 4 1/2 Lb.

Lobster Tail, Frozen 5 - 6 10 Lb.

Lobster, Live, 10" - 12" 4 - 5 4 Per Pan

Salmon Fillets, Frozen, 8 ounce each 4 - 5 7 1/2 Lb.

Scallops, Fresh 3 - 4 3 Lb.

Scrod Fillets, Fresh 3 - 5 4 Lb.

EGGS

Hard Cooked 14 - 15 4 Doz.

Soft Cooked 8 - 10 4 Doz.

Soft Yoke for Caesar Salad 5 - 8 4 Doz.

MEATS

Chicken — Breasts, Legs, Thighs 19 - 20 15 Lb.

Turkey, Frozen

Breasts (2) 86 - 90 6 to 7 Lb. Each

Cut Lengthwise 53 - 55 20 to 25 Lb.

Corned Beef 40 - 75 6 to 8 Lb.

Hot Dogs and Wieners 2 - 3 80 to 100 Count

VEGETABLES

Asparagus Spears

Frozen 10 - 12 3 Lb.

Fresh 4 - 5 5 Lb.

Beans

Green 2" Cut, Frozen/Fresh 5 - 6 5 Lb.

Lima, Frozen 7 - 8 5 Lb.

Baby Lima, Frozen 4 - 5 5 Lb.

Brussel Sprouts, Frozen 5 - 6 5 Lb.

— 20 —

Page 21

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

VEGETABLES (Cont’d.)

Broccoli

Spears, Frozen 6 - 8 4 Lb.

Spears, Fresh 4 - 6 5 Lb.

Flowerettes, Frozen 4 - 6 5 Lb.

Cabbage, Fresh, 1/6 Cut 6 - 8 5 Lb.

Carrots

Baby Whole, Frozen 6 - 8 7 Lb.

Crinkle Cut, Frozen 7 - 8 4 Lb.

Sliced, Fresh 9 - 11 9 Lb.

Cauliflower , Flowerettes

Frozen 4 - 6 4 Lb.

Fresh 7 - 8 5 Lb.

Celery , 1" Diagonal Cut 5 - 7 5 Lb.

Corn

Yellow Whole Kernel, Frozen 3 - 5 5 Lb.

Cobbettes, Frozen 6 - 8 27 Ears

Corn-On-Cob, Fresh 16 - 18 80 Ears

16 - 18 54 Ears

10 - 12 18 Ears

Peas, Green 4 - 6 5 Lb.

Potatoes, Whole Russet 50 - 55 40 Lb.

Spinach

Chopped, Frozen 15 - 17 6 Lb.

Defrosted 4 - 5 6 Lb.

Fresh Cut 2 - 3 2 Lb.

Squash, Acorn Halves 22 - 25 10 Halves

Zucchini, Slices 6 - 8 10 Lb.

Frozen Mixed V egetables 6 - 7 5 Lb.

FRUIT

Fruit, Blanch for Peeling

Grapefruit, Oranges 2 - 3

Pineapple, Whole for Cutting 2 - 4

— 21 —

Page 22

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

TROUBLESHOOTING

SYMPTOMS

Steamer not steaming

Steamer not heating/

steaming properly

Door leaks

POSSIBLE CAUSES

No main power source

Power switch in OFF position

(Professional)

Handle out (OFF) position (Basic)

Water not being supplied to

steamer

Excessive lime build up in the

steamer

Damaged door gasket

Improper drain

Plugged drain

REMEDY

Check the power source.

Set power switch to the ON

position.

Push handle in.

Refer to symptom WATER NOT

BEING SUPPLIED TO STEAMER.

Descale the steamer (see

REMOV AL OF LIME SCALE

DEPOSITS).

Check door gasket for damage.

If adjustment is needed, contact

your Authorized Vulcan-Hart

Servicer.

Water accumulates in

compartment

Water not being supplied

to steamer

Damage to gasket sealing surface

Plugged drain or screen

Unit not leveled properly

Drain clogged

Water supply valve is off

Water pressure low

Water filter is plugged

Valve inlet screen clogged

Clear compartment cavity

screen. If symptom persists,

contact your Authorized V ulcanHart Servicer .

See leveling instructions in the

installation section of this

manual.

Unclog drain.

Turn valve on.

Check water supply pressure.

Refer to water filter manual. If

symptom persists, contact your

Authorized Vulcan-Hart Servicer .

Contact your Authorized VulcanHart Servicer .

— 22 —

Page 23

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

SERVICE AND P ARTS INFORMATION

To obtain service and parts information concerning this steamer, contact the Vulcan-Hart Service

Agency in your area (refer to listing supplied with the steamer), or contact the Vulcan-Hart Service

Department at the address or phone number shown on the front cover of this manual. Parts and service

are also available at www.vulcanhart.com.

— 23 —

Page 24

C24EA SERIES ELECTRIC COUNTER CONVECTION STEAMERS

F-35428 (2-06)

— 24 —

PRINTED IN U.S.A.

Loading...

Loading...