Page 1

SERVICE MANUAL

GRA SERIES GAS FRYERS WITH

KLEENSCREEN PLUS®

FILTRATION SYSTEMS

MODEL ML MODEL ML

1GR45A 136647 3GR85AF 136655

1GR65A 136648 4GR45AF 136656

1GR85A 136649 4GR65AF 136657

2GR45AF 136650 4GR85AF 136681

2GR65AF 136651 2XGR45AF 136658

2GR85AF 136652 2XGR65AF 136659

3GR45AF 136653 2XGR85AF 136660

2GR45AF KLEENSCREEN

FRYER BATTERY

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly qualified.

This manual is not intended to be all encompassing. If you have not

attended a Vulcan Service School for this product, you should read,

in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do not

have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual, without

the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

3GR65AF 136654

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F25377 (March 2010)

Page 2

GRA SERIES GAS FRYERS

TABLE OF CONTENTS

GENERAL ................................................................................3

Introduction ............................................................................ 3

Single Floor Model Fryers ................................................................ 3

Kleenscreen Filtration System ............................................................. 4

Specifications .......................................................................... 4

Electrical ..........................................................................4

Gas Pressures ..................................................................... 4

Tools................................................................................. 4

REMOVAL AND REPLACEMENT OF PARTS .................................................... 5

Splash Guard (Kleenscreen Fryers Only) ..................................................... 5

Cooking Controls ....................................................................... 5

Discard Valve Switch (Kleenscreen Fryers Only) ............................................... 5

Gas Burners ........................................................................... 6

Gas Orifice ............................................................................ 7

Gas Combination Valve .................................................................. 7

Gas Pilot .............................................................................. 8

Temperature Probe ..................................................................... 9

High Limit Thermostat ................................................................... 9

Power Supply Box Components ........................................................... 10

Fill Solenoid Valve (Kleenscreen Fryers Only) ................................................ 11

Pump and Motor (Kleenscreen Fryers Only) ................................................. 11

Fry Tank Assembly..................................................................... 12

SERVICE PROCEDURES AND ADJUSTMENTS................................................. 14

Temperature Probe Test ................................................................ 14

Cooking Control Calibration .............................................................. 15

Electronic Ignition System ............................................................... 15

Flame Sense Current Check ............................................................. 16

Electronic Ignition Control Test............................................................ 16

Gas Manifold Pressure Adjustment ........................................................ 18

ELECTRICAL OPERATION .................................................................. 19

Component Function ...................................................................19

Power Supply Box Components ........................................................... 21

Sequence of Operation .................................................................22

Kleenscreen Filtering System ......................................................... 23

Schematic Diagrams ................................................................... 24

Fryers Without Kleenscreen Filtration System ............................................24

Fryers with Kleenscreen Filtration System ............................................... 25

Wiring Diagrams ....................................................................... 26

Frymate (Dump Station) ............................................................. 30

TROUBLESHOOTING ...................................................................... 31

All Models ............................................................................ 31

Ignition Module ........................................................................ 32

Frymate (Dump Station) with Optional Heater ................................................ 35

Kleenscreen Filtering System ............................................................. 36

© VULCAN 2010

F25377 (March 2010)

Page 2 of 36

Page 3

GRA SERIES GAS FRYERS - GENERAL

GENERAL

INTRODUCTION

This Service Manual covers specific service

information related to the models listed on the front

cover. GRA series gas fryers come equipped with

behind-the-door solid state controls. The features

and operation of the cooking controls are the same

for both single floor model fryers and kleenscreen

battery fryers.

Model

1GR45A

1GR65A

1GR85A

2GR45AF

NO. OF HEAT TUBES

EACH FRY TANK

4 120,000 15.5 45-50

5 150,000 21.0 65-70

5 150,000 21.0 85-90

4 120,000 31.0 45-50

EACH FRY TANK

Fryers with the Filter-Ready option installed, use the

Mobile Filter. For service information related to the

Mobile filter refer to F24599 MOBILE FILTERS.

A GRO Frymate (dump station) can be configured in

a battery with fryers 15 1/2 inches or 21 inches in

width.

BTU/HOUR

SINGLE FLOOR MODEL FRYERS

FRYER WIDTH

(INCHES)

SHORTENING

CAPACITY (LBS)

EACH FRY TANK

3GR45AF

4GR45AF

2GR65AF

3GR65AF

4GR65AF

2GR85AF

3GR85AF

4GR85AF

2XGR45AF

2XGR65AF

2XGR85AF

4 120,000 46.5 45-50

4 120,000 62.0 45-50

5 150,000 42.0 65-70

5 150,000 63.0 65-70

5 150,000 84.0 65-70

5 150,000 42.0 85-90

5 150,000 63.0 85-90

5 150,000 84.0 85-90

4 120,000 31.0 45-50

5 150,000 42.0 65-70

5 150,000 42.0 85-90

Page 3 of 36

F25377 (March 2010)

Page 4

GRA SERIES GAS FRYERS - GENERAL

KLEENSCREEN FILTRATION

SYSTEM

The Kleenscreen filtration system is integrated into

the GRA Series fryer battery. The filter is housed in a

pull-out drawer assembly at the base of the fryer.

The filtering components in the drawer include a

stainless steel filter tank, crumb-catch basket and a

dual element mesh filter screen. With the filter

drawer closed, a self-seating oil return line provides

the path to return the filtered shortening to the fry

tank.

This system is designed to provide a thorough and

easy method to filter the shortening.

Some of the benefits include:

• Self-contained system eliminating the use of

external filter equipment.

• Paperless filtering system.

• Easy to clean and low maintenance.

Kleenscreen fryer batteries are available in a

minimum of two and a maximum of four fryer

sections. The fryer size of each section is identical.

TOOLS

Standard

• Standard set of hand tools.

• VOM with A/C current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per

volt can be used).

• Temperature tester (thermocouple type).

• U-Tube Manometer.

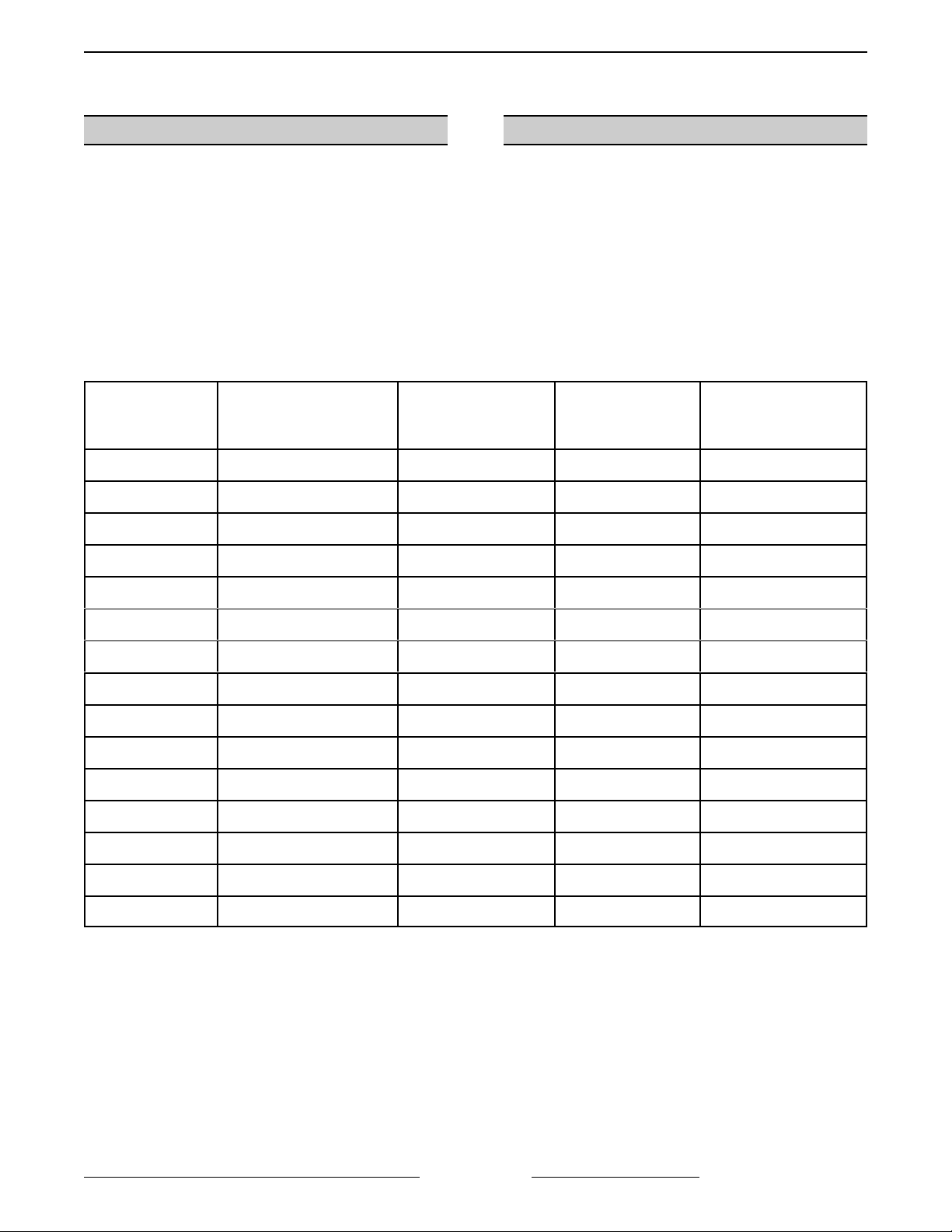

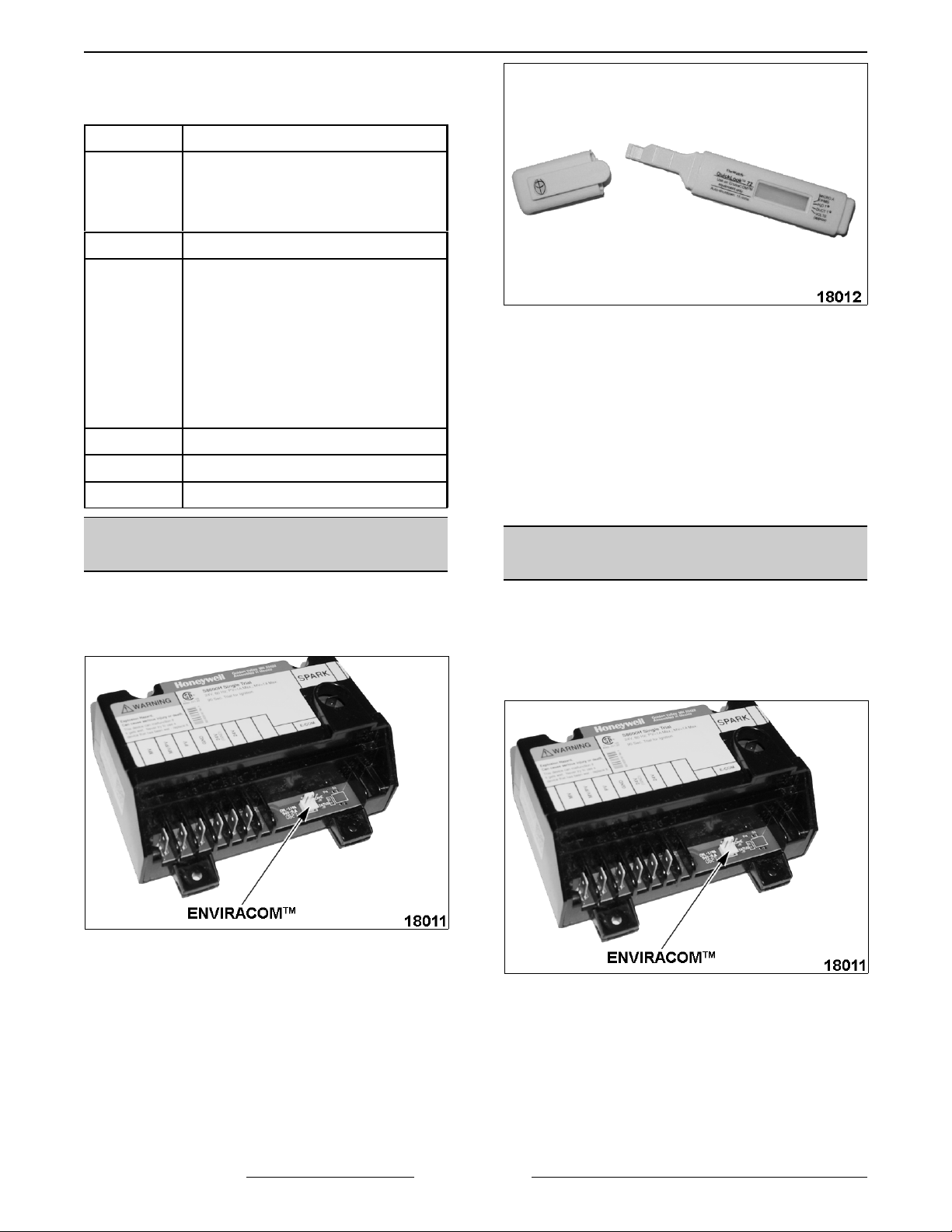

Special

• Field service grounding kit (available locally)

• OnWatch QuickLook™ 72, checks flame sense

and input voltage to the Honeywell S8600

series ignition control module with an

EnviraCOM™ port.

A GRO Frymate (dump station) can also be included

as one or more of the sections.

SPECIFICATIONS

Electrical

• 120VAC supply. A 24VAC transformer provides

power for the fryer controls and the filtering

controls on Kleenscreen battery fryers.

Gas Pressures

Manifold (per fryer section):

• Natural - 4" W.C.

• Propane - 10" W.C.

Building supply pressure (Min):

• Natural - 5" W.C. (7" W.C. battery units)

• Propane - 11" W.C. (12" W.C. battery units)

NOTE: Propane or Natural gases -14" W.C. (Max)

You can order the QuickLook™ 72 on line at

www.onwatchinc.com. The OnWatch Combo

Item #721014 includes both the QuickLook™ 72

and a 3 ft. data port extension cable.

• Burndy pin extraction tool RX2025 GE1;

Newark Electronics Catalog Number 16F6666.

Used for removing pin terminals on Burndy

connectors.

F25377 (March 2010) Page 4 of 36

Page 5

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

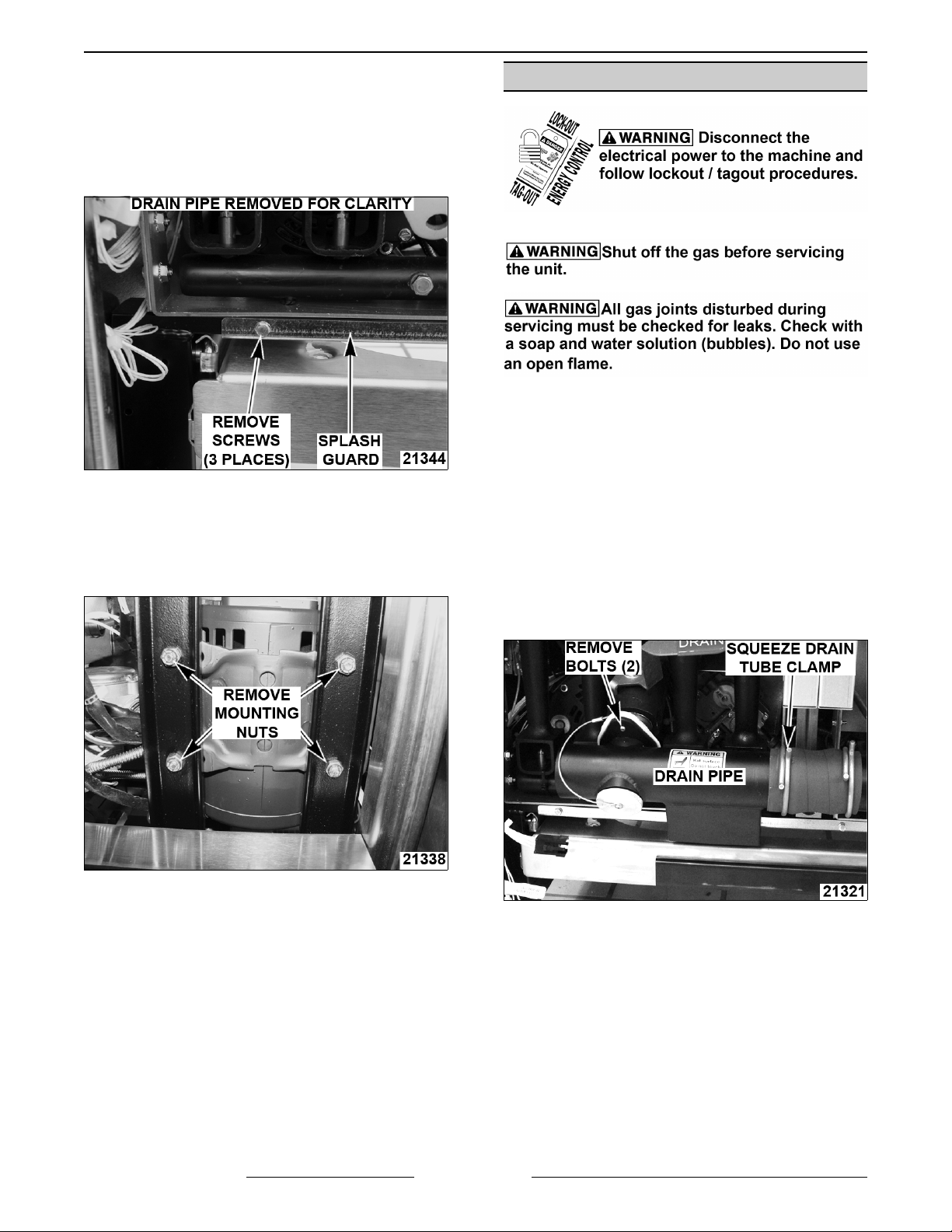

SPLASH GUARD

(KLEENSCREEN FRYERS ONLY)

1. Open fryer section doors.

2. Remove screws securing splash guard.

3. Remove screws securing controls.

4. Remove cooking controls.

5. Disconnect lead wires from the component

being replaced then remove from control box.

3. Remove splash guard.

4. Reverse procedure to install.

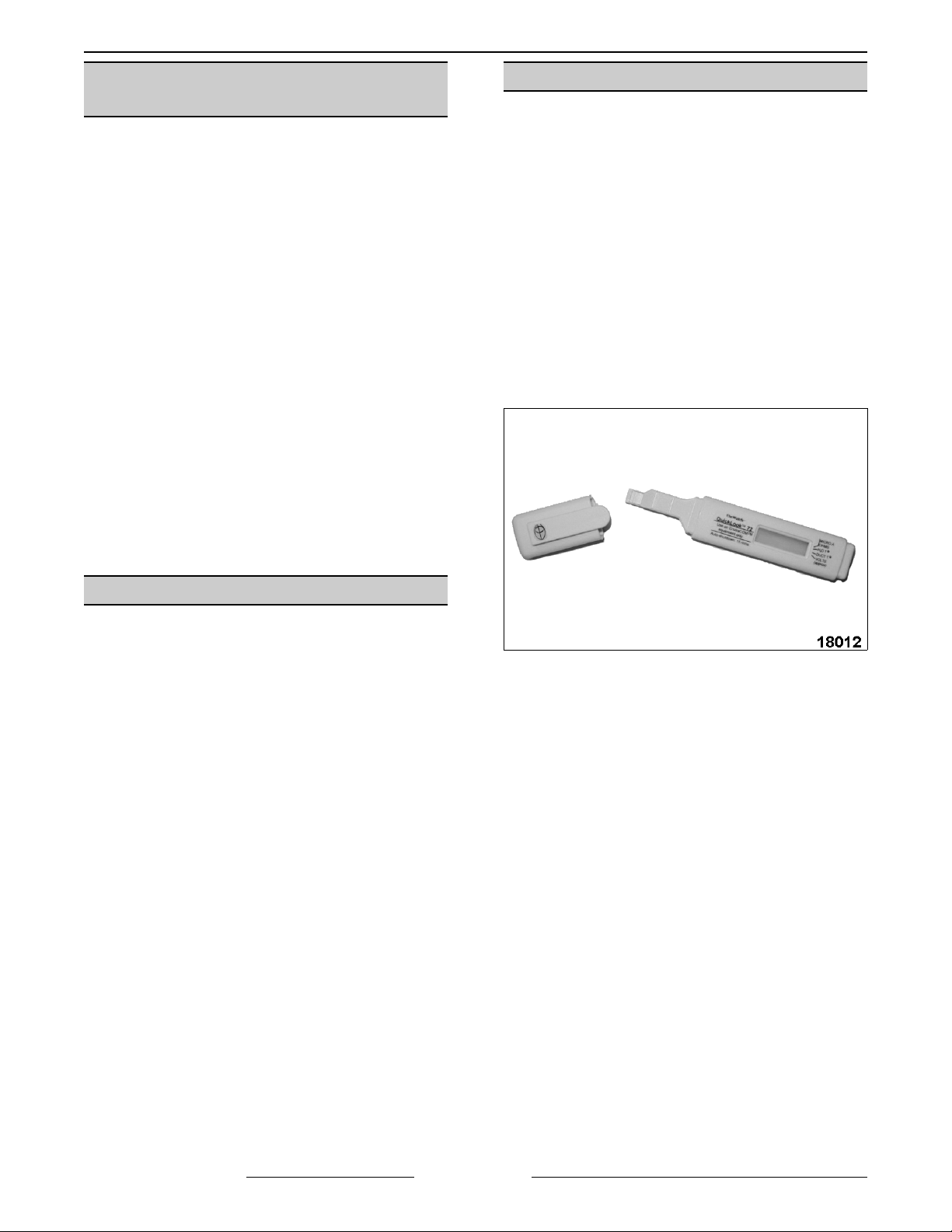

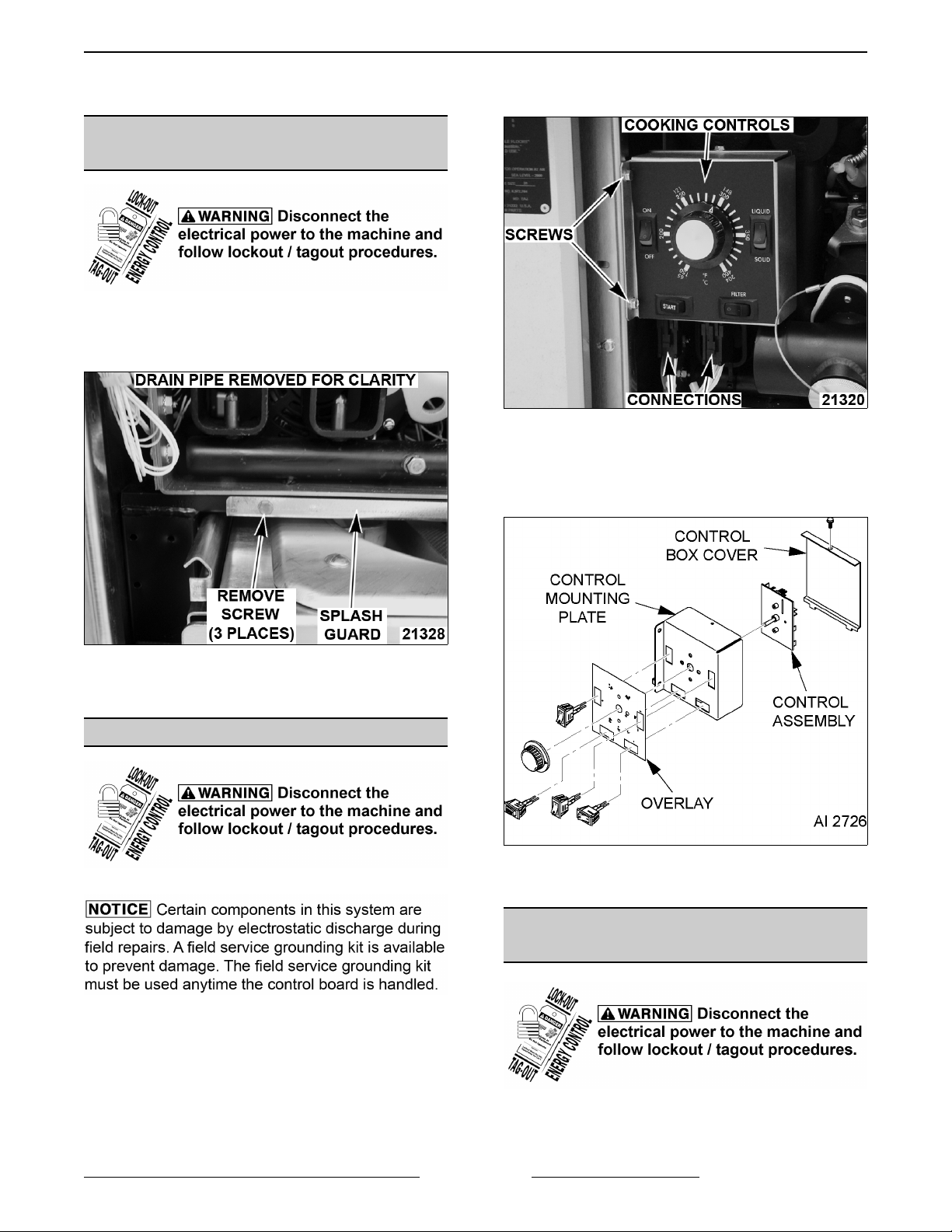

COOKING CONTROLS

1. Open fryer section door(s).

2. Remove connections to cooking controls.

6. Reverse procedure to install and check for

proper operation.

DISCARD VALVE SWITCH

(KLEENSCREEN FRYERS ONLY)

1. Open the fryer section doors above filter pan.

F25377 (March 2010)Page 5 of 36

Page 6

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

2. Pull filter drawer out, remove filter tank

assembly and push the tank support arms back

into place under the fryer.

3. Remove splash guard from base frame.

4. From underneath the fryer:

A. Disconnect the discard valve switch lead

wire connector from power supply box.

2. Remove cooking controls to access burner(s) if

necessary.

3. Remove drain pipe to access burner(s) if

necessary.

B. Remove switch mounting screws.

5. Reverse procedure to install and check for

proper operation.

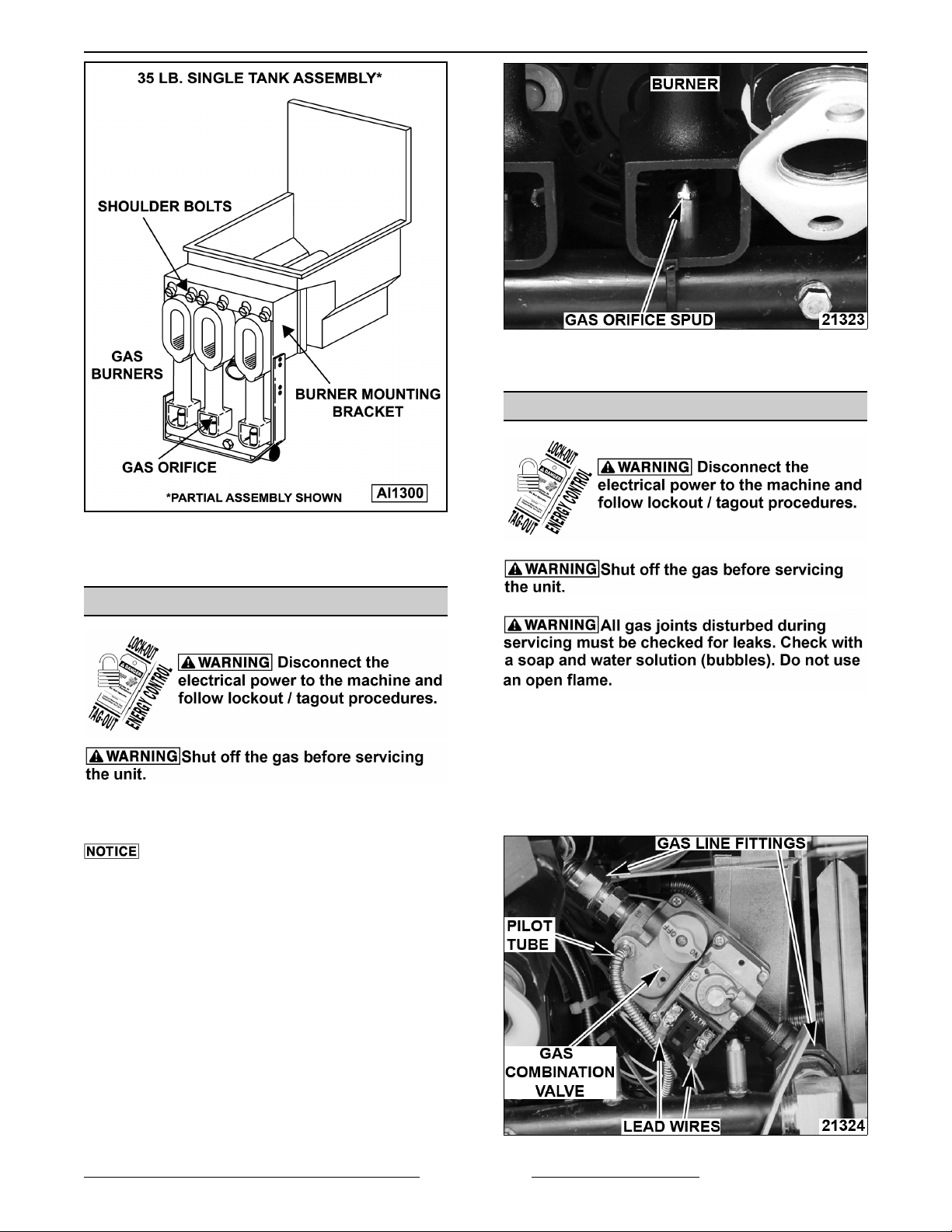

GAS BURNERS

4. Remove gas burner shipping ties (if installed).

5. Lift gas burner up and tilt the top of burner

1. Open the door to the fryer section being

serviced.

F25377 (March 2010) Page 6 of 36

NOTE: The burners mount to the burner mounting

bracket by shoulder bolts that rest in the keyway slot.

toward fryer tank until it clears the gas orifice at

the bottom.

Page 7

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

2. Reverse procedure to install and check for

proper operation.

GAS COMBINATION VALVE

6. Remove burner.

7. Reverse procedure to install and check for

proper operation.

GAS ORIFICE

1. Remove gas orifice spud from orifice extension.

The spud screws into orifice extension.

When installing, do not over tighten the spud or

damage to the threads may occur.

NOTE: If a gas combination valve is malfunctioning,

do not attempt to disassemble the valve for repair.

Install a replacement gas combination valve.

1. Remove GAS BURNERS.

2. Disconnect lead wires from gas combination

valve.

F25377 (March 2010)Page 7 of 36

Page 8

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

3. Disconnect pilot tube from gas combination

valve.

4. Disconnect gas line fittings then remove gas

combination valve.

A. Remove gas line fittings from gas

combination valve and install (in same

orientation) on the replacement valve.

5. Reverse procedure to install and check for

proper operation.

A. Clean the pipe threads and apply pipe joint

compound to threads. Any pipe joint

compound used must be resistant to the

action of propane gases.

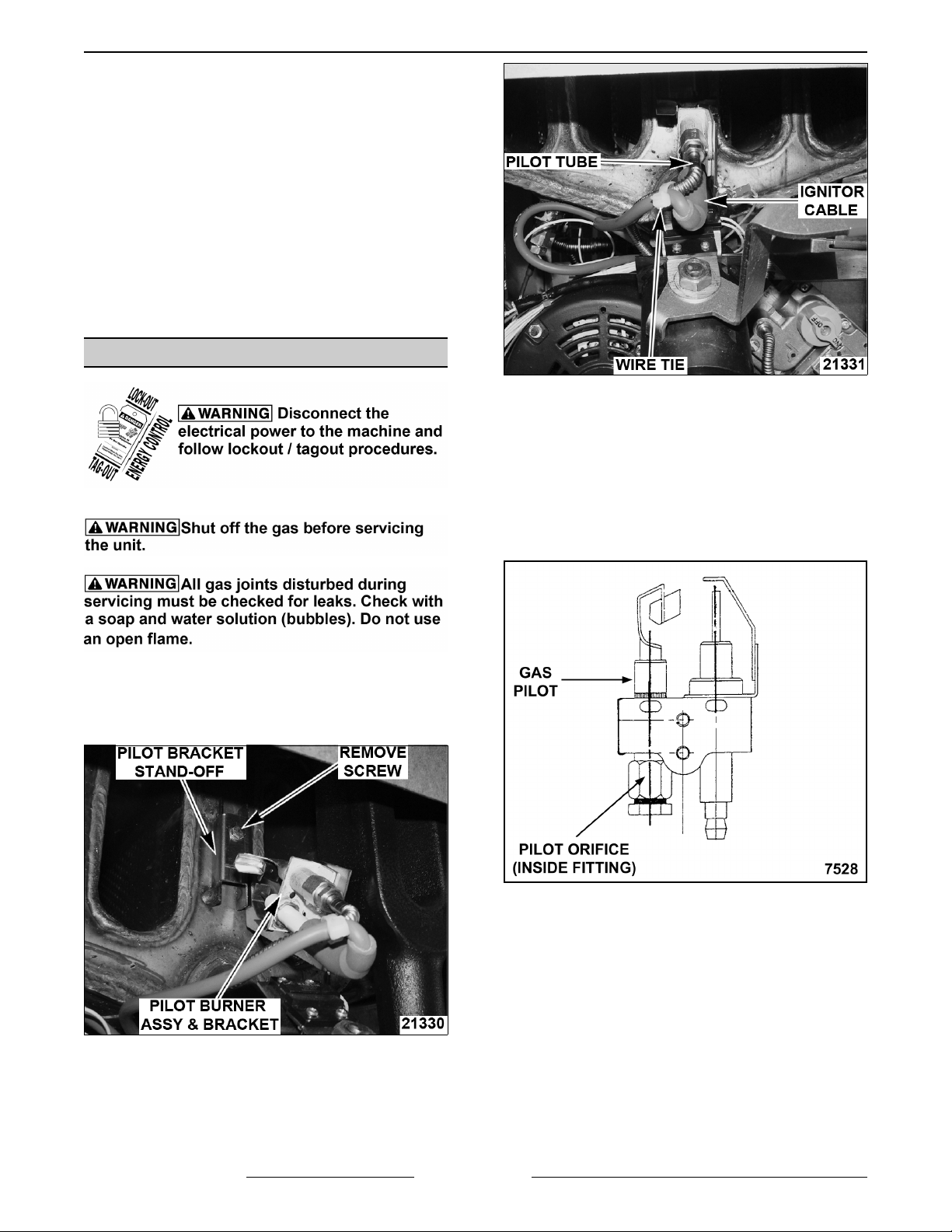

GAS PILOT

4. Disconnect pilot tube from gas pilot.

5. Remove screws (2) securing gas pilot to

mounting bracket.

A. To remove gas orifice from pilot for

inspection or cleaning, disconnect the gas

orifice fitting from pilot body.

1. Remove GAS BURNERS as necessary.

2. Remove pilot burner assembly and bracket from

pilot bracket stand-off on the fry tank.

B. If orifice is clogged with debris, clean with

air or liquid only.

GAS PILOT FOR ELECTRONIC IGNITION SHOWN

6. Reverse procedure to install and check for

proper operation.

3. Remove wire tie and disconnect ignitor cable

from ignitor/flame sense electrode on the gas

pilot.

F25377 (March 2010) Page 8 of 36

A. Secure ignitor to pilot tube with wire tie.

Page 9

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

TEMPERATURE PROBE

Do not sharply bend and kink, or clamp

down on the capillary tube or damage may occur.

1. Drain shortening from fryer tank.

2. Disconnect smaller, 6-pin male connector.

(Temperature probe and drain valve interlock

(DVI) connector)

and probe to the fryer heat tube (inside tank)

then remove probe.

7. Reverse procedure to install and check for

proper operation.

8. Check COOKING CONTROL CALIBRATION

under SERVICE PROCEDURES AND

ADJUSTMENTS.

3. Remove the temperature probe lead wires from

pins 1 and 3 of the 6-pin male connector.

4. Remove GAS BURNERS as necessary.

5. Remove the probe retaining and packing nuts.

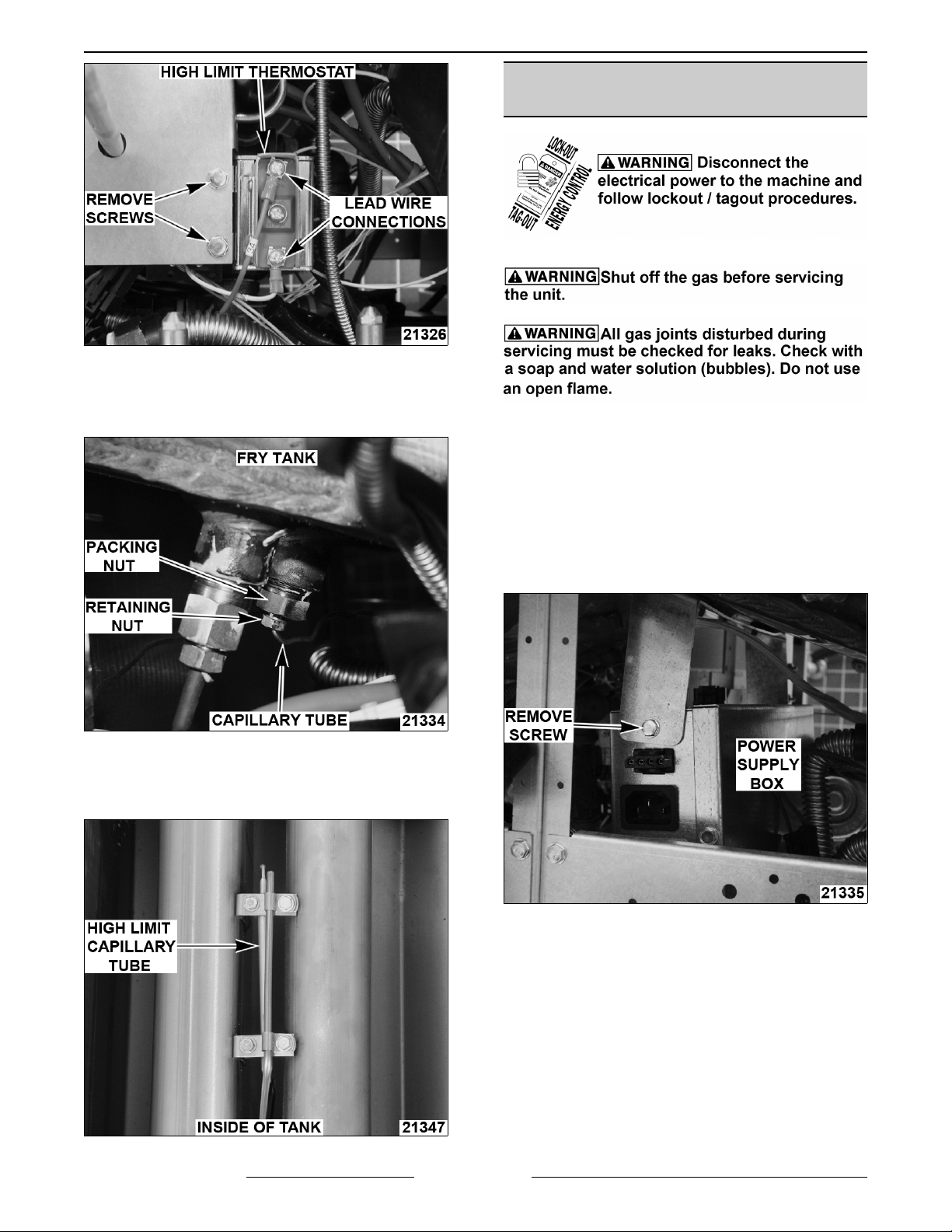

HIGH LIMIT THERMOSTAT

Do not sharply bend and kink, or clamp

down on the capillary tube or damage may occur.

1. Drain shortening from fryer tank.

2. Remove GAS BURNERS as necessary.

3. Disconnect lead wires from high limit

thermostat.

6. Remove screws securing probe mounting clips

F25377 (March 2010)Page 9 of 36

Page 10

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

4. Remove screws securing the high limit to

mounting bracket.

5. Remove the capillary tube retaining and packing

nuts.

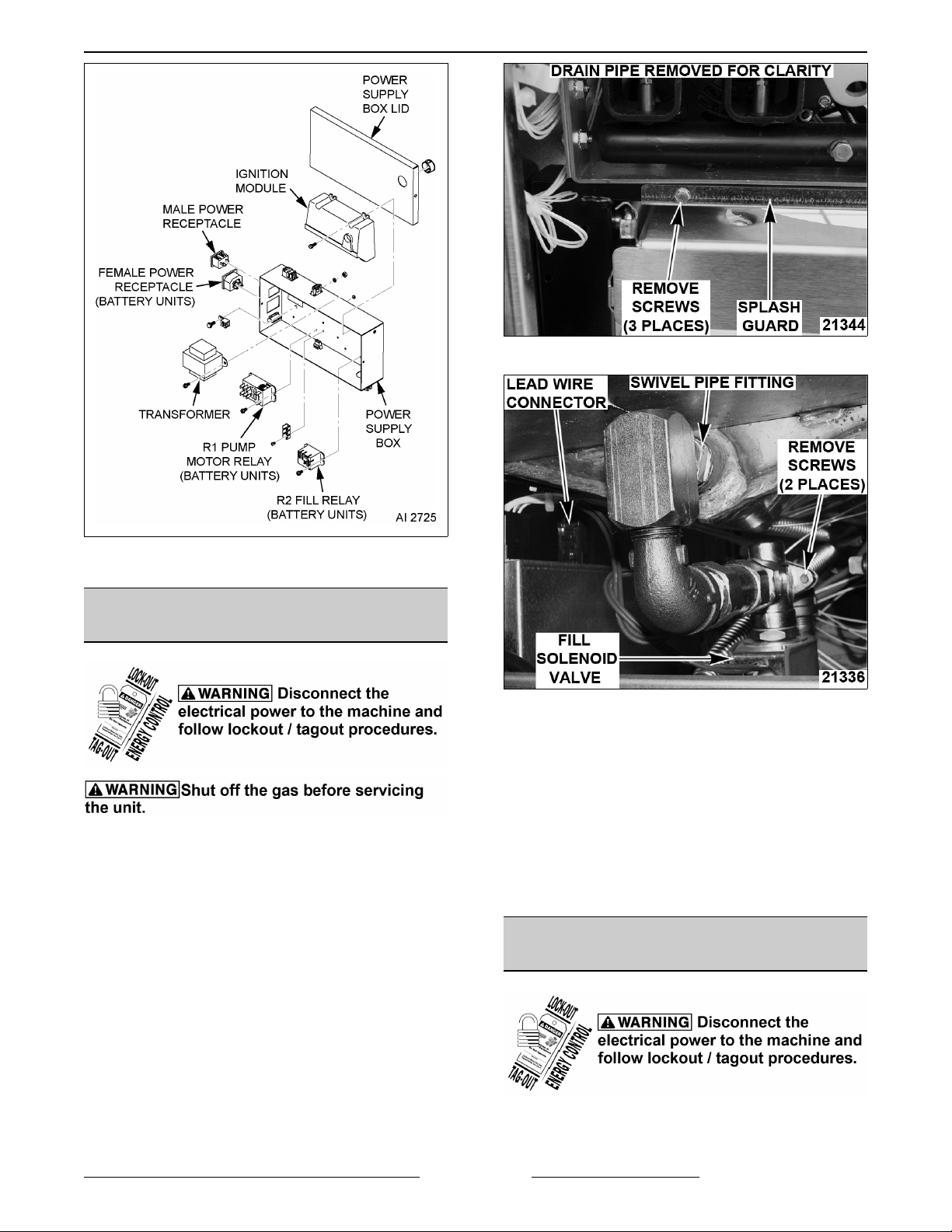

POWER SUPPLY BOX

COMPONENTS

NOTE: The power supply box must be removed to

access the following components: Ignition control

module, transformer, R1 pump motor relay, R2 fill

relay.

6. Remove screws securing mounting clips and

capillary tube to the fryer heat tube (inside tank)

then remove capillary tube.

1. Disconnect all wiring harness connectors and

power cords from power supply box.

2. From rear, remove screw securing power

supply box to mounting bracket.

NOTE: Power supply box is slotted at the front and

secured by a hanging bracket (loose fit).

3. Remove cover from power supply box.

4. Disconnect lead wires from the component

7. Reverse procedure to install.

F25377 (March 2010) Page 10 of 36

being replaced then remove from power supply

box.

Page 11

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

4. Disconnect swivel pipe fitting at rear of fry tank.

5. Reverse procedure to install and check for

proper operation.

FILL SOLENOID VALVE

(KLEENSCREEN FRYERS ONLY)

1. Open the fryer section doors above filter pan.

2. Pull filter drawer out, remove filter tank

assembly and push the tank support arms back

into place under the fryer.

3. Remove splash guard.

REAR VIEW SHOWN

5. Disconnect fill solenoid valve lead wire

connector (4 pin) from power supply box.

6. Remove screws (2) securing the solenoid valve

body flange to pipe tee then remove the

assembly from fryer.

A. Remove pipe fittings from solenoid valve

and install on replacement valve.

7. Reverse procedure to install and check for

proper operation.

PUMP AND MOTOR

(KLEENSCREEN FRYERS ONLY)

1. Drain filter tank of shortening.

F25377 (March 2010)Page 11 of 36

Page 12

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

2. Open the fryer section doors above the filter

tank drawer.

3. Pull filter drawer out, remove filter tank

assembly and push the tank support arms back

into place under the fryer.

4. Remove splash guard from base frame.

5. Disconnect pump motor lead wire connector.

6. From underneath the fryer:

A. Disconnect flexible line fittings from pump.

7. Remove pump motor assembly from fryer.

FRY TANK ASSEMBLY

1. Drain shortening from fryer tank.

2. Disconnect the gas supply line to allow access

to fryer from all sides.

3. Remove fryer baskets, crumb screen and

basket hanger.

NOTE: If the fryer is a battery section, remove

grease strip and split the silicone seal between the

fryer section tanks with a utility knife.

4. On battery fryer sections only, remove bolts

securing the drain pipe flange to the manual

drain valve.

A. Remove pipe fittings from the pump and

install on replacement pump.

8. Reverse procedure to install and check for

proper operation.

F25377 (March 2010) Page 12 of 36

5. Disconnect temperature probe and drain valve

interlock switch (DVI) connector (6 pin).

Page 13

GRA SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

6. Remove POWER SUPPLY BOX.

7. On battery fryer sections only, remove splash

guard from base frame.

8. Remove gas manifold and frame assembly from

the fryer<s base frame:

A. Remove gas burners as necessary.

B. For the fryer sections above the filter

drawer assembly on battery fryers or single

floor model fryers, remove mounting nuts

securing gas manifold and frame assembly

to the fryer’s base frame.

C. For all other fryer sections in a battery only,

remove mounting nuts securing gas

manifold and frame assembly to the V

shaped frame support bracket.

9. Disconnect swivel fitting from fry tank at the rear

(shortening line inlet to fry tank).

10. Disconnect flexible gas line fitting at manual

shutoff valve (gas supply inlet to valve).

11. Remove screws securing the top of fry tank to

the flue wrap.

NOTE: Remove wire ties securing lead wires and

wiring harnesses as necessary before removing fry

tank; and when removing components from fry tank

for reuse.

12. Grasp the fry tank at the top (by flue) and front

lip, then lift fry tank assembly from the fryer

body. Place the assembly on floor or table for

removal of components.

13. Remove GAS PILOT.

14. Remove TEMPERATURE PROBE.

15. Remove HIGH LIMIT THERMOSTAT.

16. On battery fryer sections only, when removing

fry tank from sections with the mechanical

discard valve:

A. Loosen u-bolt securing discard pipe with

male quick disconnect fitting to the

mounting bracket.

B. Remove pipe from elbow on mechanical

discard valve.

17. Remove bolts securing gas manifold and frame

assembly to the fry tank.

18. Pull the gas manifold assembly from fry tank.

19. Disconnect drain valve interlock switch (DVI)

connector (2 pin) and remove manual drain

valve.

20. Remove screws securing flue box to fry tank

then remove flue box.

21. Reverse procedure to install all the parts

removed from original fry tank onto replacement

fry tank, then install the assembly.

F25377 (March 2010)Page 13 of 36

Page 14

GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

TEMPERATURE PROBE TEST

The temperature probe is an RTD (resistance

temperature detector) of the thermistor type. As

temperature increases the resistance value

decreases.

Probe Fault

If a temperature probe fault occurs, red diagnostic

LED on back of control assembly (inside control box

cover) will flash. The heat demand outputs are

de-activated.

This will continue until the fault clears, power is

cycled or problem resolved.

A temperature probe fault can be caused by a lead

break or a lead short.

To Check:

1. Turn power switch off.

2. Disconnect the temperature probe & the drain

valve interlock (DVI) connector.

3. Test the probe using a VOM to measure

resistance.

3 on the male connector.

A. If the measured resistance values are

B. If the measured resistance values are

Temperature (ºF) Resistance (Ω)

NOTE:

Connect the meter leads to pins 1 &

within the allowable range, the probe is

functioning properly. Reverse procedure to

install.

outside the allowable range, install a

replacement probe and check for proper

operation.

32 315,915 - 386,119

77 90,000 - 110,000

212 5,016 - 6,130

275 1,804 - 2,204

300 1,254 - 1,534

350 604 - 836

1

460

1. Shorted probe equivalent temperature.

191 - 233

F25377 (March 2010) Page 14 of 36

Page 15

GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

COOKING CONTROL

CALIBRATION

NOTE: Verify condition of temperature probe as

outlined under TEMPERATURE PROBE TEST

before proceeding.

1. Check the level of shortening in fry tank. The

level must be between the MIN & MAX fill lines

before proceeding.

2. Allow shortening to cool below 300EF.

3. Place a thermocouple in the geometric center of

the fry tank one inch below the shortening

surface.

4. Set the cooking control to 350EF and turn the

fryer on.

5. Monitor the burners as they cycle on and off.

NOTE: Agitate the shortening, to eliminate any cold

zones.

A.

Allow burners to cycle three times to

stabilize shortening temperature.

B. Record meter reading from thermocouple

when the burners cycle off and on for at

least two complete heating cycles.

6. Calculate the average temperature by adding

the temperature reading when the burners go

out to the temperature reading when the

burners come on & divide this answer by 2.

[ Temp. (Burners off) + Temp. (Burners on) ] ÷ 2 = Average

Example: 360° + 340° ÷ 2 = 350°F.

The average temperature should be

350EF (± 5EF).

A. If the average temperature reading is

within tolerance, cooking control is properly

calibrated.

B. If the average temperature reading is out of

tolerance, loosen set screw to remove

temperature knob and adjust calibration

potentiometer.

Temp.

1) Adjust calibration potentiometer

clockwise to increase temperature,

and counterclockwise to decrease

temperature.

a. If over 25E of adjustment is

necessary, replace cooking

control.

7.

Repeat the average temperature calculation for

up to three attempts. Allow the cooking control

to cycle at least two times between adjustments

before performing the calculation.

8. If calibration is unsuccessful, the cooking

control may be malfunctioning and cannot be

adjusted properly. Install a replacement cooking

control

and check calibration.

ELECTRONIC IGNITION SYSTEM

Operation

When the main power switch is turned on the ignition

control module is energized with 24 volts between

terminals 5 and 6.

An output of 24 volts is sent from terminals 2 and 3

to the pilot coil on the combination valve, allowing

gas flow to the pilot; and spark voltage is sent from

SPARK terminal to begin sparking at the

ignitor/flame sense electrode. The sparking will

continue until an adequate pilot flame is sensed or

for a maximum of 90 seconds.

If pilot is not established within the 90 second ignition

trial time, the ignition module locks out power to the

gas valve. Controls will be disabled.

The system remains locked out until the power

switch is cycled to reset the system and re-start the

ignition trial cycle.

Once the pilot flame is confirmed, a 24 volt output

from terminal 1 will provide the ignition status input

signal to the cooking control. When the cooking

F25377 (March 2010)Page 15 of 36

Page 16

GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

control calls for heat, the heat output is activated and

the main valve coil on the combination valve is then

energized, allowing gas flow to the burners.

Terminal Description

MV (main voltage) - 24VAC output

1

2 MV/PV (common).

3

4 Burner ground.

5 24VAC ground.

6 24VAC hot (input).

will be present, providing the

ignitor/flame sense electrode is

sensing an adequate pilot fame.

PV (pilot voltage) - 24VAC output

will be present after the ignition

module is powered. The voltage will

remain present, providing an

adequate pilot flame is sensed. If the

pilot flame is not sensed within the

ignition trial time, the ignition module

locks out which removes the output

voltage.

4. Meter reading should be above 1.0 micro amp

(minimum) and steady.

A. If reading is greater than or equal to the

value given, then flame sense current is

within tolerance.

NOTE: Yellow Flame LED next to port should show

continuous 1/2 second on-1/2 second off heartbeat.

B. If reading is less than the value given,

perform ELECTRONIC IGNITION

CONTROL TEST.

FLAME SENSE CURRENT

CHECK

1. Turn the power switch OFF.

2. Access the ignition control module in the power

supply box and locate the EnviraCom™ port.

3. Connect the QuickLook™ 72 meter to the

EnviraCom™ port. Turn power switch ON.

ELECTRONIC IGNITION

CONTROL TEST

If the ignition control module is not generating a

spark to ignite gas pilot, perform the following

checks.

1. Access the ignition control module in the power

supply box and locate the EnviraCom™ port.

2. Connect the QuickLook™ 72 meter to the

F25377 (March 2010) Page 16 of 36

EnviraCom™ port.

Page 17

GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

3. Turn the power switch on and verify the ignition

control module is receiving power from the

transformer.

A. If 24VAC is present, then module is

receiving power. Turn the power switch off

and continue with procedure.

B. If 24VAC is not present then find the

source of the problem.

4. Disconnect power to the machine.

5. Verify all electrical connections on the ignition

control module are secure.

6. Verify the ground wire connections on the

ignition control module and the gas pilot

mounting bracket are clean and secure. The

gas pilot should have good metal to metal

contact to the pilot mounting bracket on the

fryer.

7. Remove the gas pilot and check the following:

A. Inspect the ceramic insulator on the

ignitor/flame sense electrode for cracks or

evidence of exposure to extreme heat,

which can permit leakage to ground. If

either of these conditions exist, then install

a replacement gas pilot.

B. Inspect the ignitor electrode and ground

clip for contaminates, or corrosion. Clean

those surfaces as necessary.

C. The gap between the ignitor/flame sense

electrode and the ground clip should be 1/8

inch. If the gap is outside of this dimension,

bend the ground clip as necessary, to

make the adjustment.

ELECTRONIC IGNITION GAS PILOT SHOWN

D. Check the ignitor cable connection for

tightness and damaged insulation. If the

ignitor cable appears to be damaged, then

install a replacement ignitor cable.

8. With gas pilot installed and the ignitor cable

connected, reconnect power and turn the gas

supply on.

9. Turn power switch on and observe spark from

ignitor.

A. If spark from ignitor is present and ignites

the gas for the pilot, and burners light, then

the system is working properly.

B. If gas pilot lights but does not maintain an

adequate flame during the trial for ignition

(90 sec.), check pilot orifice for clogging.

NOTE: If orifice is clogged with debris, clean with air

or water only.

C. If spark from ignitor is present but does not

ignite pilot gas before the ignition control

module locks out, there may not be enough

gas in the line for ignition.

Turn the power switch off to re-set the

module. Wait 5 minutes between ignition

tries for unburned gas to vent. Turn the

power switch on and sparking should

resume to ignite pilot. The module may

need re-set several times before ignition

takes place.

D. If ignitor is still not sparking, turn the power

switch off, disconnect power and turn the

gas supply off.

10. Install a replacement ignition control module

and check for proper operation.

F25377 (March 2010)Page 17 of 36

Page 18

GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

GAS MANIFOLD PRESSURE

ADJUSTMENT

1. Open the door(s) and remove drain pipe.

2. To measure the manifold pressure, remove plug

and attach manometer to pressure tap in

manifold.

adequate sizing.

B. If adjustment is necessary, continue with

procedure.

5. Remove burners as necessary.

6. Remove the adjustment screw cap to access

the pressure adjustment screw on gas

combination valve.

NOTE: Gas manifold pressure can also be

measured by removing the 1/8 inch NPT plug

(pressure tap) on the outlet side of the gas

combination valve and attaching a manometer.

3. Turn the gas supply, gas combination valve and

the main power switch to on.

A. Verify burners light.

4. Observe the manometer pressure reading and

compare to the pressure chart near the end of

this procedure.

A. If other appliances are connected to the

same gas line, turn them all on and check

manometer pressure reading again. If a

pressure drop of 1/2 inch water column or

more is observed, then the gas supply

needs to be checked by the gas line

installer or the local gas company for

A. To increase pressure, turn the screw

clockwise. To decrease pressure, turn the

screw counterclockwise.

NOTE: Accurate gas pressure adjustments can only

be made with the gas on and the burner lit.

7. Set the pressure as outlined below:

PRESSURE READINGS

GAS

TYPE

MANIFOLD

Natural 4 7 5

Propane 10 11 11

(INCHES W.C.)

LINE

RECOMMENDED MIN MAX

14

NOTE: If the incoming line pressure is less than the

minimum stated, then the manifold pressure can not

be set correctly.

8. Once the correct pressure has been set, turn

the power switch off, replace the adjustment

screw cap and manifold plug.

9. Install drain pipe and burners.

10. Check for proper operation.

F25377 (March 2010) Page 18 of 36

Page 19

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

FRYER CONTROLS

Cooking Control .............. Monitors and evaluates input signals to the control: Activates heat output

signal to maintain shortening temperature; and activates filter output signal

to power the fill solenoid valve.

Transformer ................. Supplies 24VAC to the cooking control ignition control module. Transformer

is energized when power switch is turned on.

Power Switch ................ Supplies power to control circuit for fryer operation and filtering.

Melt Select Switch ............ Controls burner operation based on type of shortening being used (liquid/

solid).

Gas Combination Valve ........ Allows gas flow to the pilot when pilot valve coil is energized; and gas flow to

the burners when main valve coil is energized. Also, regulates the gas

manifold pressure.

High Limit Thermostat ......... Prevents the shortening from reaching temperatures over 450EF (auto reset

@ 415°F, normal operation resumes when temperature falls below this

point).

Temperature Probe ........... Senses temperature of shortening. Converts the temperature into a

resistance which is monitored by the cooking control. The probe is an RTD

(resistance temperature detector) of the Thermistor type. As temperature

increases the resistance value decreases.

Ignition Control Module ........ Controls and monitors gas pilot ignition. Energizes pilot valve coil on the

combination control valve and generates spark for pilot ignition. Monitors the

presence of a flame and supplies an ignition status input signal to the

cooking control.

Ignitor/Flame Sense ........... Ignites the gas pilot and senses the presence of a flame. The flame

presence generates a micro-amp flame sense current that is rectified to the

ignition control module.

Drain Valve Interlock

Switch (DVI) ................. A magnetic reed switch mounted on the manual drain valve that supplies a

drain valve position signal (open/closed) to the cooking control. When drain

valve is open, the drain interlock input to the control is removed (magnetic

reed switch contacts open). This prevents gas burners from coming on with

the fry tank empty.

Page 19 of 36

F25377 (March 2010)

Page 20

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

KLEENSCREEN FILTER CONTROLS

Fill Solenoid Valve ............ When energized by filter switch, the solenoid valve opens to allow the flow of

shortening thru filtering system.

Pump Motor ................. Operates pump to circulate shortening through filtering system.

Start Switch.................. Supplies power to temperature control module.

Filter Switch ................. Supplies power to pump motor thru R1 and fill solenoid valve thru R2.

Discard Valve Switch .......... A magnetic reed switch mounted on the mechanical discard valve that

closes when discard valve handle is extended to discard the shortening.

Prevents R2 filter relay N.C. contacts from suppling power to the fill solenoid

valve when filter key is pressed.

R1 Pump Motor Relay ......... When 24VAC relay coil is energized by filter switch, supplies 120VAC to

pump motor; and fill solenoid valve thru R2 fill relay N.C. contacts.

R2 Fill Relay ................. When 24VAC relay coil is energized by filter switch, supplies 24VAC to the

fill solenoid valve to open the valve and allow shortening to flow thru filter

system.

F25377 (March 2010)

Page 20 of 36

Page 21

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

POWER SUPPLY BOX

COMPONENTS

F25377 (March 2010)Page 21 of 36

Page 22

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Refer to schematic diagram AI 2727 for Cooking Control operation.

NOTE: Make sure melt select switch reflects type of shortening being used (solid/liquid).

1. Conditions.

A. Fryer connected to correct supply voltage and properly grounded.

B. Gas supply is on and gas combination valve is open.

C. Power switch to the fryer section in the off position.

D. Shortening at proper level in fry tank and below last set point temperature used.

E. Manual drain valve closed (drain valve interlock switch N.O. is closed).

F. High limit thermostat closed.

2. Turn power switch on.

A. 24VAC transformer energized.

3. Ignition module is powered (24VAC), initializes and generates spark at ignitor.

A. Pilot voltage (PV) N.O. contacts close, pilot valve coil energized and valve opens for gas flow to pilot.

1) Pilot flame established. A micro amp flame sense current is rectified to ignition module through

ignitor cable and sparking stops.

2) Main voltage (MV) N.O. contacts close and provides ignition status input signal (24VAC) to cooking

control.

B. If pilot is not established within 90 seconds of the ignition module being energized, the ignition module

locks out power to gas valve.

1) The system remains locked out until the power switch is cycled to reset the system and re-start the

ignition trial cycle. (wait 5 minutes for gas to dissipate)

4. Cooking control evaluates input signals from: Ignition status; Drain valve interlock; and temperature probe.

A. Main valve coil energized and valve opens for gas flow to burners.

1) Burners light and heat the shortening in fry tank.

NOTE: As long as the ignition control module senses a pilot flame, the internal main voltage (MV)

contacts (N.O.) on the ignition module remain closed, and main gas valve stays on.

5. Shortening reaches set temperature.

A. Cooking control de-activates the heat output (24VAC).

1) Main valve coil de-energized and valve closes.

2) Gas flow stops and burners go out.

6. Cooking control cycles heat output on shortening temperature until: power switch is turned off; ignition input

status is removed; drain valve interlock input status is removed; temperature probe input is outside

acceptable limits or a high limit condition occurs.

7. If shortening reaches 450EF or higher: high limit thermostat opens, power is removed from the pilot valve coil

and valve closes to stop pilot gas flow.

A. Ignition trial cycle will start but pilot will be unable to light.

B. Fryer operation can resume when the temperature drops below 415°F.

F25377 (March 2010)

Page 22 of 36

Page 23

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

Kleenscreen Filtering System

Refer to schematic diagram AI 2728 for Kleenscreen Filter System operation. Refer to Installation & Operation

manual and Kleenscreen Filtration System Supplement manual for specific instructions on filtering.

NOTE: The discard valve handle is connected to a mechanical valve and magnetic reed switch assembly to route

the flow of shortening in the filtering system and supply power to the pump motor.

1. Conditions.

A. Fryer connected to correct supply voltage and is properly grounded .

B. Power switch to fryer section to filter turned on.

C. The cooking control should be setup properly and ready to use.

D. Cooking control temperature setting between 300°F (minimum) and 350°F (maximum).

NOTE: Shortening should not be filtered outside of this temperature range. At lower temperatures the

shortening is thicker which may increase filtering time and place a greater load on the pump. At higher

shortening temperatures, oil seal life is decreased.

E. Filter drawer assembly installed properly.

F. Discard valve handle (yellow) retracted.

1) Discard valve switch N.O. contacts open. Mechanical discard valve closed.

2. Allow shortening to cycle between 300°F and 350°F for approximately 10 minutes.

NOTE: If using solid shortening, once it has melted, stir the shortening to eliminate any solid shortening in cold

zone of the fry tank.

3. Open the drain valve to the fryer section in need of filtering and drain the shortening into filter tank.

A. Drain valve interlock contacts open and the position of the drain valve is indicated to the cooking control.

NOTE: If using solid shortening, allow hot shortening to stand in filter tank for approximately 6 minutes prior to

filtering.

4. Turn filter switch on cooking controls to ON.

A. R1 pump motor relay coil (24VAC) is energized and both sets of N.O. contacts close.

NOTE: Jumper wire number 24 connects one set of R1 N.O. contacts to R2 COM.

1) Fill solenoid valve is energized (120VAC) thru R2 fill relay N.C. contacts and valve opens.

2) Pump motor is energized (120VAC) and pump circulates shortening through filtering system.

5. When filtering is completed, close the drain valve and allow the fry tank to refill.

A. Drain valve interlock contacts close and the position of the drain valve is indicated to the cooking control.

6. When all filtered shortening is returned to the fry tank, turn filter switch on cooking controls to OFF.

A. Power is removed from fill solenoid valve and pump motor.

NOTE: If using solid shortening, when all filtered shortening is returned to the fry tank and pump motor is off,

open the filter drawer approximately one inch. Allow the remaining shortening in the line to drain into the filter

tank to prevent possible clogging after the shortening cools and solidifies. Close the filter drawer when

complete.

Page 23 of 36

F25377 (March 2010)

Page 24

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

SCHEMATIC DIAGRAMS

Fryers Without KleenScreen Filtration System

F25377 (March 2010) Page 24 of 36

Page 25

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

Fryers With KleenScreen Filtration System

F25377 (March 2010)Page 25 of 36

Page 26

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

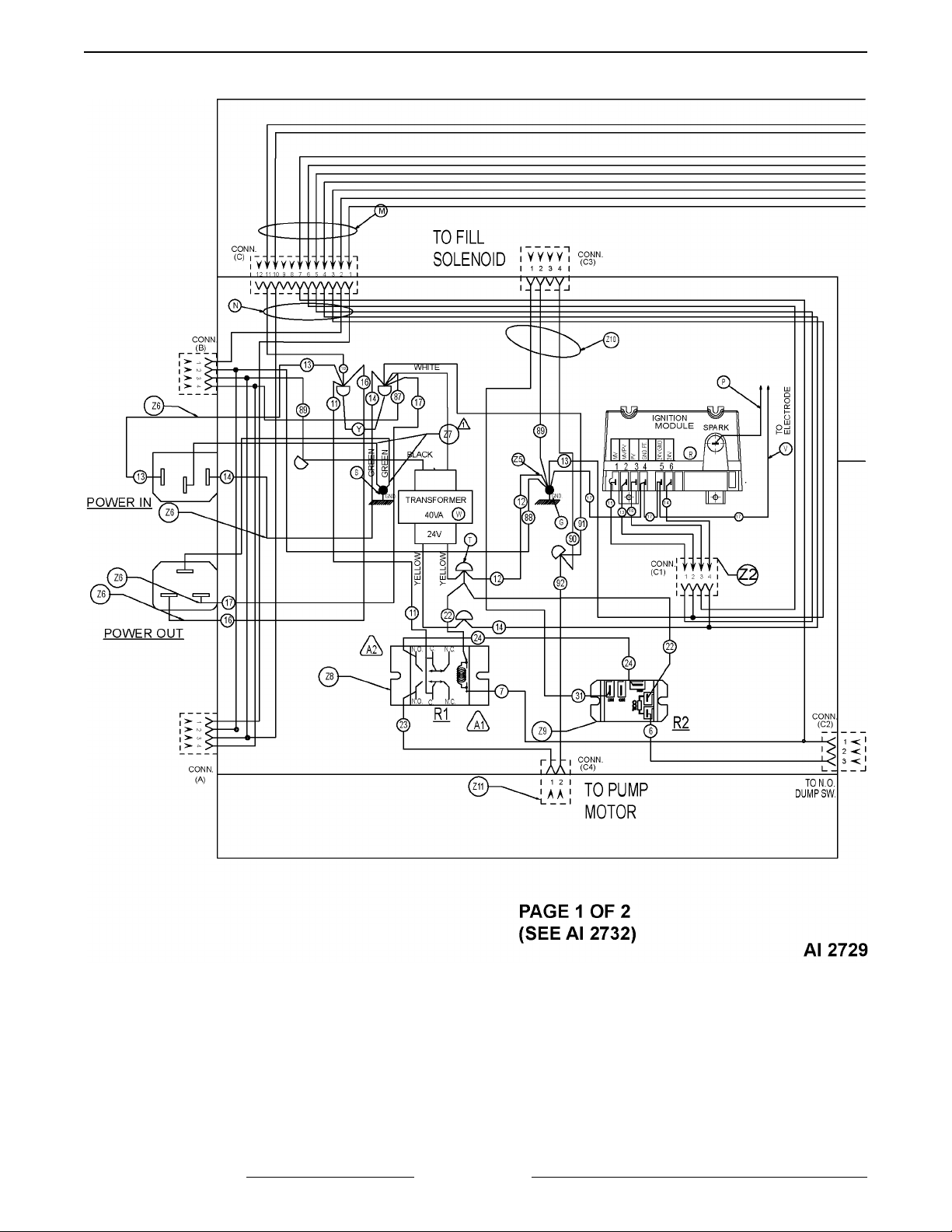

WIRING DIAGRAMS

Fryers Without KleenScreen Filtration System

F25377 (March 2010) Page 26 of 36

Page 27

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

F25377 (March 2010)Page 27 of 36

Page 28

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

Fryers With KleenScreen Filtration System

F25377 (March 2010) Page 28 of 36

Page 29

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

F25377 (March 2010)Page 29 of 36

Page 30

Frymate (Dump Station)

GRA SERIES GAS FRYERS - ELECTRICAL OPERATION

F25377 (March 2010)

Page 30 of 36

Page 31

GRA SERIES GAS FRYERS - TROUBLESHOOTING

TROUBLESHOOTING

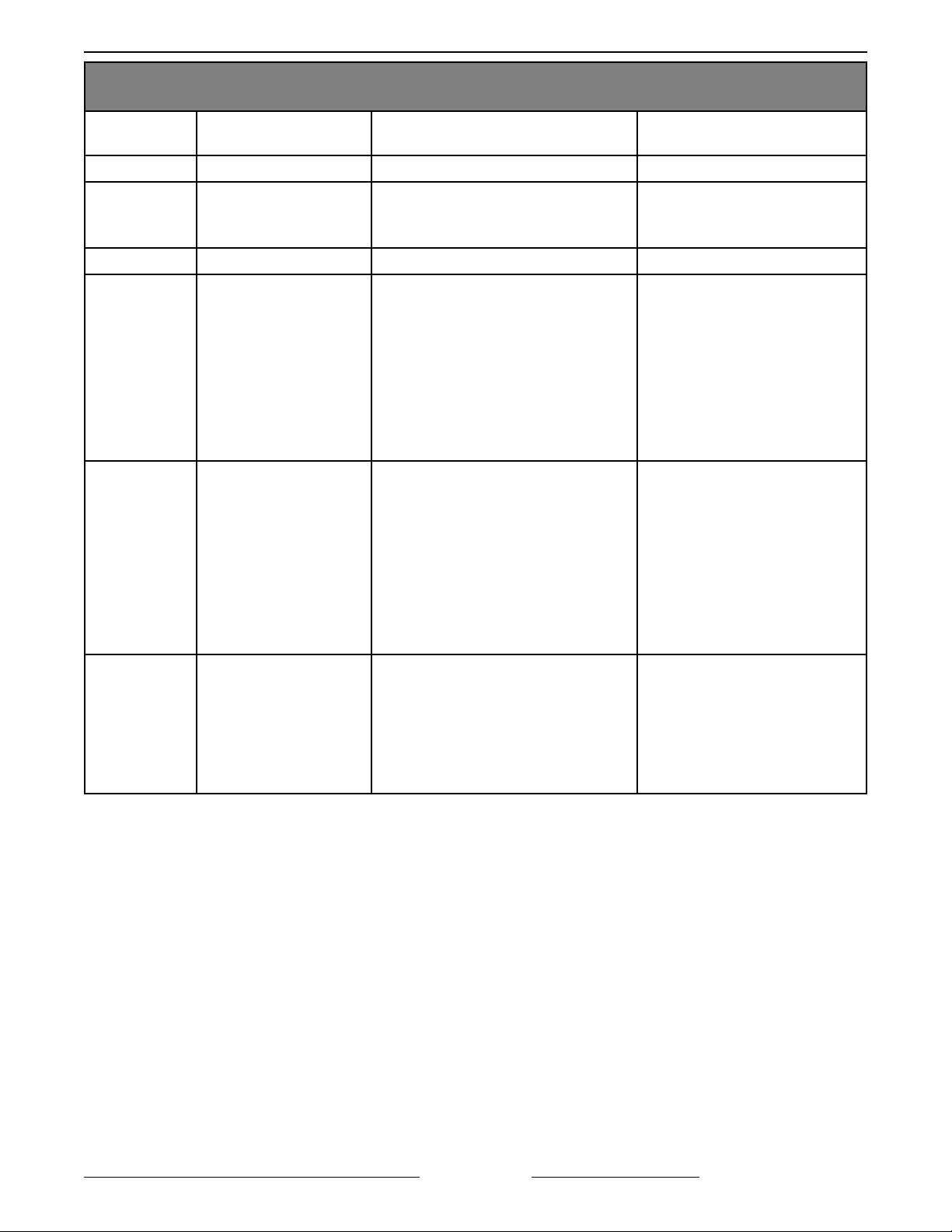

ALL MODELS

SYMPTOMS POSSIBLE CAUSES

No spark to ignite pilot gas. 1. Drain valve switch open or switch malfunction.

2. Shorted electrode or an improper ground on ignitor/flame

sense.

3. Ignitor cable open.

4. Interconnecting wiring malfunction.

5. Ignition Module malfunction.

Sparks but gas does not ignite. 1. Service gas valve closed.

2. Gas supply off or insufficient gas pressure.

3. Gas supply quick disconnect coupling not properly mated.

4. Gas combination valve off or inoperative.

5. High limit thermostat open.

6. Interconnecting wiring malfunction.

7. Ignition Module malfunction.

Gas pilot ignites but will not maintain flame. 1. Ignitor ground inoperative.

2. Ignitor/flame sense misaligned or malfunction.

3. Insufficient gas pressure.

4. Ignition module malfunction.

Gas burners ignite but will not maintain flame. 1. Gas pressure incorrect.

2. Gas orifice obstructed or incorrect.

3. Burner malfunction.

4. Gas pilot malfunction.

Excessive or low heat. 1. Cooking controls need calibrated.

2. Temperature probe malfunction.

3. Gas pressure incorrect.

4. Gas orifice obstructed or incorrect.

5. Cooking control malfunction.

6. Interface board malfunction.

Intermittent problems. 1. High ambient temperatures.

2. Wiring connections loose.

No power to cooking control, fryer does not

heat.

High limit thermostat shutting off gas burners. 1. Shortening level below minimum fill line.

Excessive time to melt shortening

(more than 45 minutes).

1. Power switch off or malfunction.

2. Transformer inoperative.

3. Interconnecting wiring malfunction.

2. Probe malfunction.

3. Cooking control malfunction.

4. High limit thermostat malfunction.

1. Insufficient gas pressure.

2. Gas orifice plugged or obstructed.

3. Probe malfunction.

4. Cooking control malfunction.

Page 31 of 36

F25377 (March 2010)

Page 32

GRA SERIES GAS FRYERS - TROUBLESHOOTING

IGNITION MODULE

The ignition module has two LED's; one for flame sensing and one for ignition system status.

• Flame LED (Yellow) - Indicates pilot burner flame presence and signal strength.

• Status LED (Green) - Indicates ignition system operation status and error conditions.

LED Flash Code Descriptions - Flame LED (yellow) or Status LED (green):

• Fast Flash - Rapid blinking during startup and self check.

• Heartbeat - Cycles bright 1/2 second; dim 1/2 second.

• Single Flash - LED flashes X times at 2Hz, remains off for two seconds then repeats flash sequence.

• Double Flash - LED flashes X times at 2Hz, remains off for two seconds, flashes Y times at 2Hz,

remains off for three seconds then repeats flash sequence (X+Y).

FLAME LED CODES (YELLOW) - PART NO. 857207-1 IGNITION MODULE

LED

Flash

Code

Indicates Possible Causes

Heartbeat

2 Weak pilot flame signal. Ignition system will operate

1 Marginal pilot flame signal (less than 2 µA). Ignition

OFF No pilot flame or flame sense signal below minimum for

Normal pilot flame signal None

reliably but flame signal is less than desired.

NOTE: Code may flash temporarily just after pilot burner

lights then operate normally after flame signal stabilizes.

system may not operate reliably over time.

NOTE: Code may flash temporarily just after pilot burner

lights then operate normally after flame signal stabilizes..

ignition system operation. Pilot burner spark is good.

Check the following:

1. Gas supply.

2. Pilot burner flame.

3. Spark/flame sense wiring.

4. Flame sense electrode

contaminated or out of position.

5. Pilot burner ground.

Check the following:

1. Gas supply.

2. Pilot burner flame.

3. Spark/flame sense wiring.

4. Flame sense electrode

contaminated or out of position.

5. Pilot burner ground.

6. Ignition module malfunction.

Check the following:

1. Gas supply.

2. Pilot burner flame.

3. Spark/flame sense wiring.

4. Flame sense electrode

contaminated or out of position.

5. Pilot burner ground.

6. Ignition module malfunction.

F25377 (March 2010)

Page 32 of 36

Page 33

GRA SERIES GAS FRYERS - TROUBLESHOOTING

IGNITION SYSTEM STATUS LED CODES (GREEN) - PART NO. 857207-1

SINGLE TRY LOCKOUT IGNITION MODULE

LED Flash

Code

OFF No Call for Heat None None

Fast Flash Startup

- Pilot flame sense

Heartbeat Normal operation None None

3 Restart ignition trial

- Pilot flame failed

4 Pilot flame sensed out

of sequence

7 Pilot flame sense

leakage to ground

Indicates System Action Possible Causes

calibration

while main burner

on

Flame sense calibration

automatically occurs immediately

after pilot lights.

Trial for ignition auto re-starts. Flash

code will remain through the ignition

trial until pilot flame is proved.

If ignition system self corrects within

10 seconds, ignition module returns

to normal operation. If flame sense

out of sequence continues, module

changes to Flash Code 6+4.

Module will not proceed to trial for

ignition. When fault is corrected,

module resumes trial for ignition,

after a one minute delay.

None

If pilot burner fails to light on

next trial for ignition - check:

1. Gas supply.

2. Pilot burner.

3. Spark/flame sense wiring.

4. Flame sense electrode

5. Pilot burner ground.

1. Check pilot burner.

1. Check spark/flame sense

2. Check flame sense

3. Check flame sense

contaminated or out of

position.

A. If pilot flame present,

replace gas valve. If

no pilot flame, cycle

Call for Heat, or

power.

B. If error repeats

(continual or

intermittent), replace

ignition module.

wiring.

electrode position.

electrode ceramic for

cracks.

Page 33 of 36

F25377 (March 2010)

Page 34

GRA SERIES GAS FRYERS - TROUBLESHOOTING

IGNITION SYSTEM STATUS LED CODES (GREEN) - PART NO. 857207-1

SINGLE TRY LOCKOUT IGNITION MODULE

LED Flash

Code

8 Low voltage to ignition

module

- Below 15.5 VAC

6+2 Lockout

- Failed 90 second

6+3 Lockout

- More than 5 pilot

Indicates System Action Possible Causes

trial for ignition

flame failures while

main burner was on

during the same

Call for Heat.

Module will not proceed to trial for

ignition. When fault is corrected,

module resumes trial for ignition,

after a one minute delay.

Remains in lockout until power is

cycled.

Remains in lockout until power is

cycled.

1. Check voltage to ignition

module during trial for

ignition.

2. Check supply voltage to

machine.

If pilot burner fails to light on

next trial for ignition - check:

1. Gas supply.

2. Pilot burner.

3. Spark/flame sense wiring.

4. Flame sense electrode

contaminated or out of

position.

5. Pilot burner ground.

If pilot burner fails to light on

next trial for ignition - check:

1. Gas supply.

2. Pilot burner.

3. Spark/flame sense wiring.

4. Flame sense electrode

contaminated or out of

position.

5. Pilot burner ground.

6+4 Flame sensed out of

sequence

- longer than 10

seconds

ON Soft lockout due to

error during self check

When pilot flame is no longer

sensed (pilot out), the ignition

module enters soft lockout. Flash

code continues. Module auto resets

from soft lockout after one hour and

restarts trail for ignition.

Ignition module auto resets from soft

lockout after one hour and restarts

trail for ignition.

1. Check pilot burner.

A. If pilot flame present,

replace gas valve. If

no pilot flame, cycle

Call for Heat, or

power.

B. If error repeats

(continual or

intermittent), replace

ignition module.

1. Cycle Call for Heat, or

power to reset. If error

repeats, replace ignition

module.

F25377 (March 2010)

Page 34 of 36

Page 35

GRA SERIES GAS FRYERS - TROUBLESHOOTING

FRYMATE (DUMP STATION)

WITH OPTIONAL HEATER

SYMPTOM POSSIBLE CAUSES

No heat. 1. Unplugged.

2. Power switch off or inoperative.

3. Main circuit breaker off or open.

4. Malfunctioning heater assembly.

Page 35 of 36

F25377 (March 2010)

Page 36

GRA SERIES GAS FRYERS - TROUBLESHOOTING

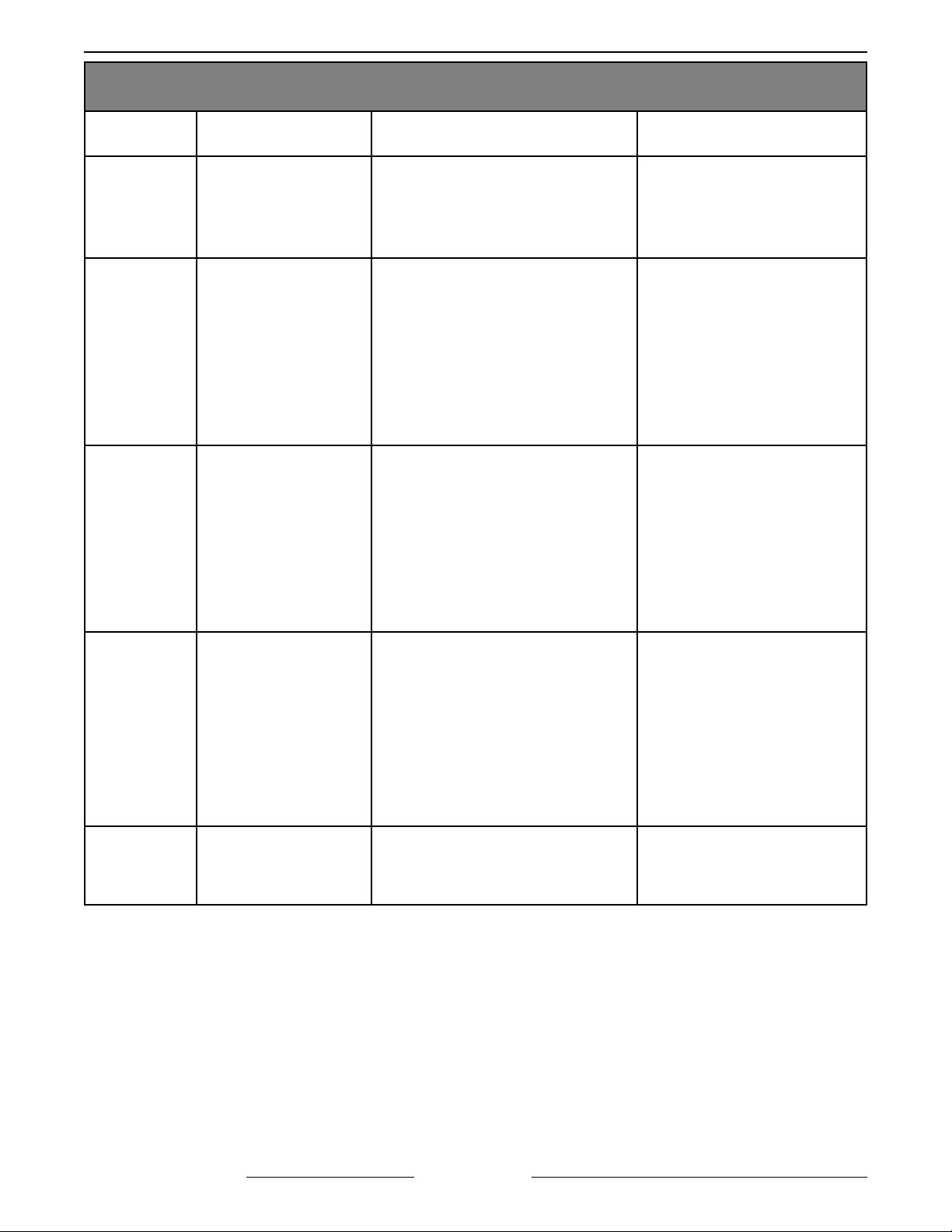

KLEENSCREEN FILTERING

SYSTEM

SYMPTOM POSSIBLE CAUSES

Shortening not filtering, pump motor is

energized.

Shortening not discarding, pump motor

energized.

1. Filter screen plugged.

2. Clog in filter system lines.

NOTE: If using solid shortening, when all filtered shortening

is returned to the fry tank and filter power switch is off, open

the filter drawer approximately one inch. Allow the remaining

shortening in the line to drain into the filter tank to prevent

possible clogging after the shortening cools and solidifies.

Close the filter drawer when complete.

3. Shortening below 300°F to thick.

4. R2 fill relay N.C. contacts are open.

5. Fill solenoid valve malfunction.

6. Interconnecting wiring malfunction.

7. Pump is inoperative.

1. Filter screen plugged.

2. Clog in filter system lines.

NOTE: If using solid shortening, when all filtered shortening

is returned to the fry tank and filter power switch is off, open

the filter drawer approximately one inch. Allow the remaining

shortening in the line to drain into the filter tank to prevent

possible clogging after the shortening cools and solidifies.

Close the filter drawer when complete.

3. Shortening below 300°F to thick.

4. Discard valve switch malfunction (N.O. contacts not

closing to energize R2 fill relay coil).

5. R2 fill relay malfunction (contacts remain closed).

NOTE: The fill solenoid valve should not be energized

during discard operation so that shortening will flow thru

manual discard valve only.

6. Discard valve mechanical malfunction.

7. Discard hose connection not fully engaged.

8. Pump is inoperative.

Pump motor is not energized to circulate

shortening thru filtering system.

Pump motor is not energized to discard

shortening.

F25377 (March 2010) Printed in U.S.A.

1. Filter switch on cooking controls not turned on.

2. Pump needs reset. (Reset button located on pump)

3. R1 pump motor relay malfunction.

4. Cooking control malfunction.

5. Interconnecting wiring malfunction.

6. Pump motor inoperative.

1. Filter switch on cooking controls not turned on.

2. Pump needs reset. (Reset button located on pump)

3. Discard handle (yellow) not extended.

4. R1 pump motor relay malfunction.

5. Cooking control malfunction.

6. Interconnecting wiring malfunction.

7. Pump motor inoperative.

Loading...

Loading...