Page 1

OPERATOR`S MANUAL

ELECTRIC WINCH

WARNING

DO NOT INSTALL, USE OR REPAIR THIS EQUIPMENT BEFORE READING THIS

MANUAL IN ITS ENTIERETY. FAILURE TO READ AND FOLLOW THE INSTRUCTIONS

DESCRIBED IN THIS MANUAL COULD RESULT IN SERIOUS INJURY, DEATH AND/OR

MATERIAL DAMAGES.

Page 2

WARNING

The equipment described in this manual is not designed to lift or move

people nor to lift or move loads over people and must therefore not be used for

such means.

WARNING

Before putting the equipment described in this manual into service, it is

strongly recommended to familiarize oneself with the sections on using,

inspecting and maintaining lifting equipment in the standards CSA B167

Overhead cranes, gantry cranes, monorails, hoists and jib cranes and ASME B30.7

Winches. To ensure a safe work environment, each worker must be trained in

the equipment`s basic principles of operation and proper operating procedures.

DANGER

High voltages are used and present inside the enclosure and across the

conductors of this equipment. Before performing any kind of mechanical or

electrical maintenance, the machine must be disconnected from the power

source and locked out/tagged out according to applicable standards. Refer to

ANSI Z244.1 Personal Protection – Lockout/Tag out of Energy Sources for

additional details.

Page 3

Contents

Technical Specifications ............................................................................ 4

General Dimensions .............................................................................. 4

Working Loads....................................................................................... 5

Unpacking ................................................................................................. 6

Installation ................................................................................................ 7

Footprint ............................................................................................... 7

Gear Reducer Orientation and Lubrication ........................................... 8

Winding of the Wire Rope .................................................................... 9

Electrical Connections ............................................................................. 10

Using the Equipment............................................................................... 13

Inspection ................................................................................................ 16

Daily Inspection ................................................................................... 16

Periodic Inspection .............................................................................. 17

Inspection Log Book ............................................................................ 18

Hook Measuring and Discard Criteria ................................................. 18

Wire Rope Discard Criteria .................................................................. 19

Maintenance ........................................................................................... 20

Gear Reducer Lubrication ................................................................... 20

Vent Plug and Level Plug ................................................................. 20

Recommended Oil Types ................................................................ 21

External Use ........................................................................................ 21

Operating Environment ...................................................................... 21

Part List ................................................................................................... 22

Page 4

Operator`s Manual – Electric Winch 4 2018-08-03, rev 1

Technical Specifications

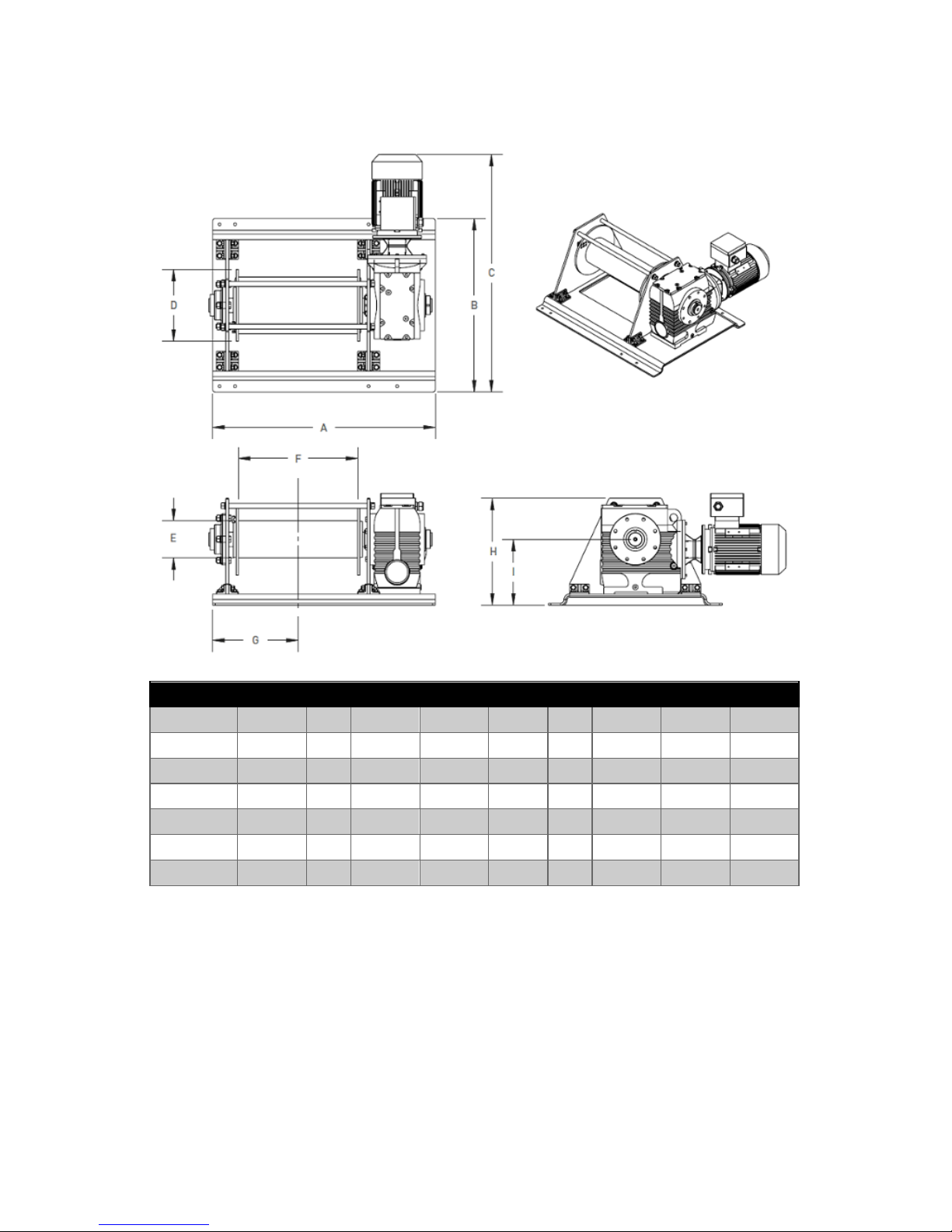

General Dimensions

General Dimensions

Model

A B C D E F G H I

W047

29.88

21

27.00

5.75

3.38

16

13.18

9.69

6.18

W057

38.38

22

28.50

6.63

3.75

24

17.18

10.63

5.63

W067

39.38

23

29.88

7.38

3.75

24

17.18

12.25

7.75

W077

41.38

28

35.50

9.38

4.75

24

17.18

14.88

9.38

W087

42.88

30

39.63

11.25

5.75

24

17.18

17.50

11.13

W097

44.88

35

48.00

14.50

7.50

24

17.18

21.50

13.25

For non-standard and custom models, consult the drawings supplied with the

equipment.

Page 5

Operator`s Manual – Electric Winch 5 2018-08-03, rev 1

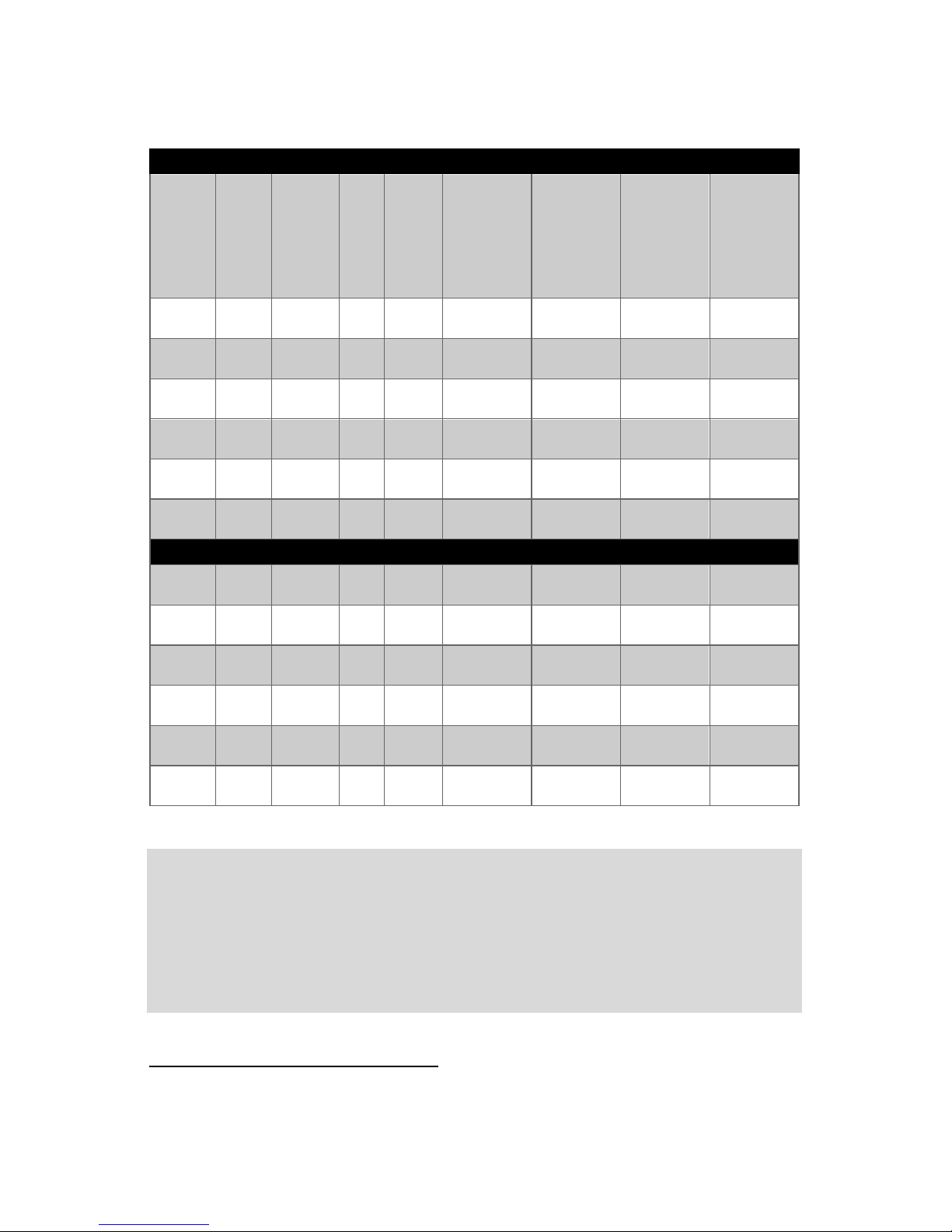

Working Loads

Limits for Hauling/Pulling

Model

Wire Rope (in)

Wire Rope (ft)

/ Layer

HP

1

Weight

(lb)

2

1

st

Layer

2

nd

Layer

3

rd

Layer

4

th

Layer

W047

1/8

115

.75

195

550 lb

22 fpm

500 lb

23.5 fpm

475 lb

25.5 fpm

450 lb

27 fpm

W057

3/16

130

1.5

290

900 lb

25 fpm

850 lb

27.5 fpm

750 lb

29.5 fpm

700 lb

32 fpm

W067

1/4

100

2

330

1650 lb

18.5 fpm

1450 lb

20.5 fpm

1300 lb

23 fpm

1200 lb

25.5 fpm

W077

5/16

100

3

510

2800 lb

13.5 fpm

2700 lb

15.5 fpm

2400 lb

17 fpm

2200 lb

18.5 fpm

W087

3/8

100

5

710

4100 lb

16 fpm

4100 lb

18 fpm

3800 lb

20 fpm

3400 lb

21.5 fpm

W097

1/2

100

7.5

1250

7000 lb

15.5 fpm

6200 lb

17.5 fpm

5600 lb

19.5 fpm

5100 lb

21.5 fpm

Limits for Lifting

W047

1/8

115

.75

195

400 lb

22 fpm

400 lb

23.5 fpm

400 lb

25.5 fpm

400 lb

27 fpm

W057

3/16

130

1.5

290

800 lb

25 fpm

800 lb

27.5 fpm

750 lb

29.5 fpm

700 lb

32 fpm

W067

1/4

100

2

330

1400 lb

18.5 fpm

1200 lb

20.5 fpm

1050 lb

23 fpm

950 lb

25.5 fpm

W077

5/16

100

3

510

1900 lb

13.5 fpm

1900 lb

15.5 fpm

1900 lb

17 fpm

1850 lb

18.5 fpm

W087

3/8

100

5

710

2800 lb

16 fpm

2800 lb

18 fpm

2800 lb

20 fpm

2600 lb

21.5 fpm

W097

1/2

100

7.5

1250

5400 lb

15.5 fpm

4800 lb

17.5 fpm

4350 lb

19.5 fpm

3950 lb

21.5 fpm

ATTENTION

The specifications above are based on the recommended wire rope

cable. Changing the size or the construction of the wire rope will affect the

performance of the machine and the working loads would have to be

recalculated.

1

Motor HP may vary with the application and certain options

2

Excluding control enclosure and cable weights; may vary for certain options

Page 6

Operator`s Manual – Electric Winch 6 2018-08-03, rev 1

ATTENTION

The wire rope capacity depends on the rolling tension and the

distribution of the wire rope over the drum. The actual capacity may be 25-30%

below the specified length due to uneven winding of the wire rope or

crisscrossing of the wire rope

Unpacking

Some models are equipped with lifting lugs to facilitate manipulation of the

equipment during the installation. Never load the lugs sideways.

ATTENTION

Any lugs and additional bolt holes serve to help maneuver the

equipment during installation. Never use these holes or lugs to support a part or

the entirety of the load.

Page 7

Operator`s Manual – Electric Winch 7 2018-08-03, rev 1

Installation

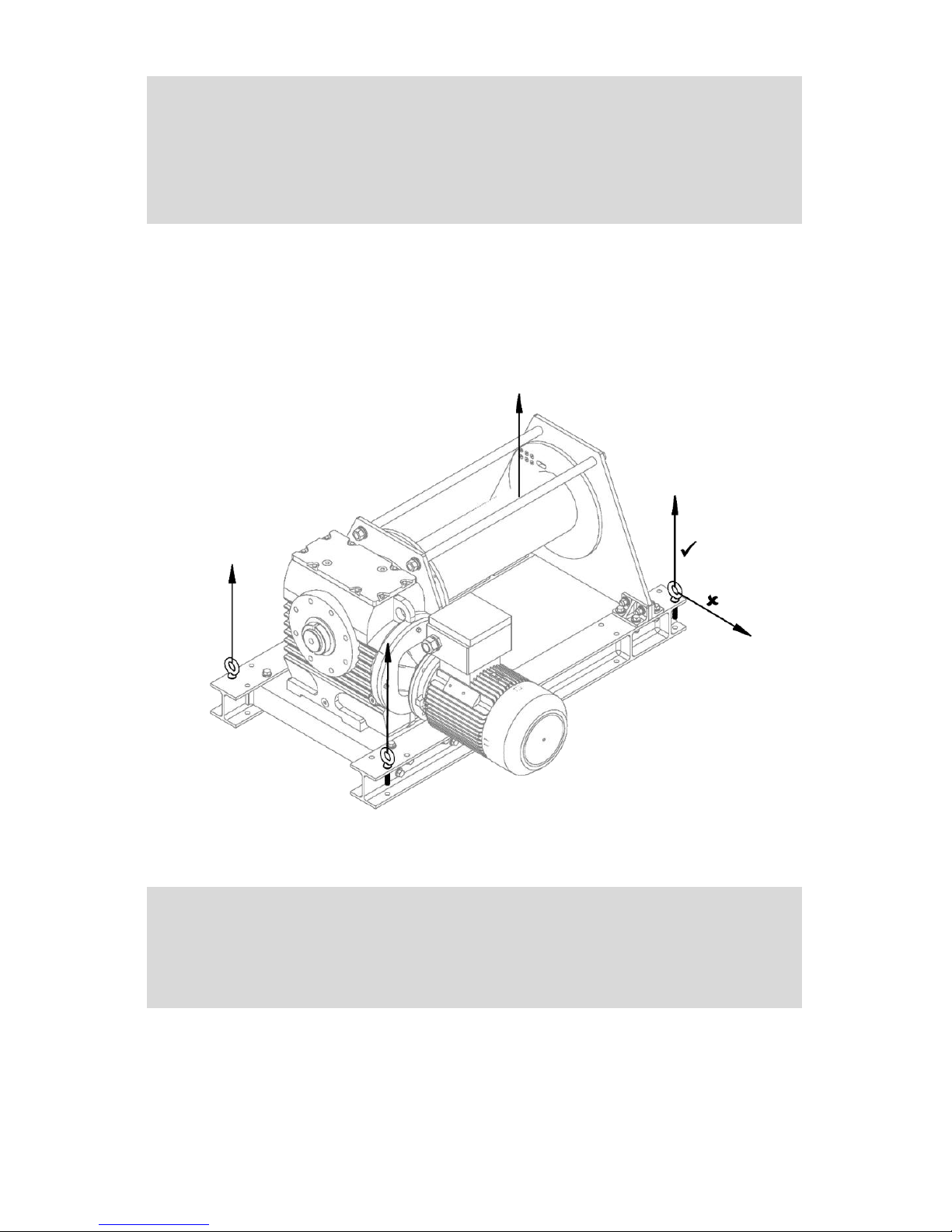

Footprint

Winch Footprint

Model

Anchor Bolts

A B J K W047

4

29.88

21

19.13

21.83

W057

4

38.38

22

20.13

30.40

W067

4

39.38

23

21.38

30.73

W077

8

41.38

28

26.13

4.23

W087

8

42.88

30

28.13

4.97

W097

8

44.88

35

32.63

5.76

WARNING

Always use the recommended number of anchor bolts (dia. ½, grade 5

or higher) to fix the winch to the floor or the supporting structure. Failure to do

so may damage the equipment and/or the supporting structure.

DANGER

It is the user`s responsibility to ensure the floor and/or the supporting

structure can safely carry the working loads with an appropriate factor of safety.

The deflection of the structure must be negligible under the working load. Failure

to respect these recommendations may damage the equipment and/or the

supporting structure.

Page 8

Operator`s Manual – Electric Winch 8 2018-08-03, rev 1

Gear Reducer Orientation and Lubrication

It is important to always maintain an adequate level of gear oil for the size and

orientation of the reducer. Unless otherwise specified, the reducer is filled for

horizontal use. Consult the maintenance section for recommended gear oil types

and amounts.

WARNING

Low oil level may result in premature wear of the gears. Consult the

maintenance section for the recommended oil types and amounts.

The reducer is always shipped with standard plugs to prevent oil from leaking

during transportation. The client must install the vent plug according to the

reducer orientation before putting the winch into service. The vent plug is

supplied in a plastic bag taped to the reducer.

Symbol

Definition

Vent plug

Level plug

Drain plug

*make sure the vent plug is

always on the top side to

ensure no leakage during the

use or the transportation of

the equipment

WARNING

Failure to install the vent plug may result in pressure built-up as the

reducer heats up causing the seals the blow out and spill the oil.

Page 9

Operator`s Manual – Electric Winch 9 2018-08-03, rev 1

Winding of the Wire Rope

WARNING

The wire rope must always be installed on the drum in a way that allows

it to come out from underneath the drum as indicated on the diagram below:

Page 10

Operator`s Manual – Electric Winch 10 2018-08-03, rev 1

Electrical Connections

WARNING

If the motor rotation is reversed some options (like the limit switches)

will not function properly which may lead to injury or equipment damage.

All electric connections must be performed by a qualified electrician. Do

not neglect to verify the current draw and the length of the power cable.

Improper connections or conductor sizing may cause the winch to overheat even

with no load.

The winch must be connected to the power source such that the motions

correspond to the indications on the control pendant, in other words the IN

button makes the wire rope wind on the drum where as the OUT button unwinds

the wire rope. The connection procedure steps are illustrated on the next page.

Page 11

Operator`s Manual – Electric Winch 11 2018-08-03, rev 1

WARNING

Never change the wiring in the control pendant to reverse the motions,

options like limit switches will not function properly.

Page 12

Operator`s Manual – Electric Winch 12 2018-08-03, rev 1

ATTENTION

Never connect 115V single phase motors in a standard household

socket. Even tough some models may work; household circuits are not sized for

such applications and the winch may interfere with other devices on the circuit.

Always consult a qualified electrician when connecting industrial equipment to

the electrical grid.

Check the voltage at the machine. The voltage should remain within ±5% of the

motor`s nominal voltage when the winch runs at full load.

Signs of Inadequate Wiring or Power Source

Rumbling or buzzing coming from the brake, motor or contactors

Flickering of lights wired to the same circuit as the winch

Excessive heating of the motor, internal components, electric conductors or

connectors

Motor stalls easily and cannot lift/pull the working load

Fuses burn often, or breakers trigger frequently

WARNING

Even though some models are equipped with thermal relays to protect

motors from overheating or from phase loss, it is the responsibility of the client

to ensure the equipment is wired to the electric grid in accordance with

applicable laws and electric standards and the means of disconnecting and

protecting the equipment from overcurrent are adequately sized.

Page 13

Operator`s Manual – Electric Winch 13 2018-08-03, rev 1

Using the Equipment

Before using any industrial equipment, the operator must be instructed on how

to use the equipment, how to stop the equipment in the event of an emergency

and how to identify, avoid and prevent risk situations. Before starting the

machine, the operator must ensure the maneuver can be performed safely (ex.:

the equipment is in order, the lift path is clear, the load will not go over other

workers, etc.). When using the machine, the operator must remain alert and

monitor the surrounding environment for arising dangers and, if a danger arises,

stop the equipment in a safe manner.

WARNING

The misuse of the winch can be very dangerous and could lead to

serious injury, death and/or property damage. To avoid risk situations, the

operator must know and follow the proper procedures described in this section.

DANGER

The winches can develop forces larger than the working load limits. It is

the operator`s responsibility to ensure the load never exceeds the working load

limit for the corresponding wire rope layer.

DANGER

All winches for lifting applications are always equipped with a brake

motor. Never use a winch without a brake motor to lift loads or pull them over a

steep slope where the load would be in danger of sliding or rolling down.

Page 14

Operator`s Manual – Electric Winch 14 2018-08-03, rev 1

ATTENTION

Never exceed a fleet angle of ±2° as indicated in the image below:

Dangerous Practices to be Avoided

DO NOT use a damaged, broken or otherwise malfunctioning winch

DO NOT use a winch before having read and understood the operator`s

manual

DO NOT use a winch that has been modified without the written approval

of the manufacture or a qualified engineer

DO NOT lift or pull more than the working load limit

DO NOT use the winch if the wire rope is twisted, pinched, damaged or

shows signs of excessive wear

DO NOT use a winch to lift, support or otherwise move people

DO NOT lift loads over people

DO NOT use a winch if people are not at a safe distance from the load or the

machine and remain at a safe distance throughout the whole maneuver

DO NOT attempt to lengthen or repair a damaged or broken wire rope

DO NOT use the wire rope as a sling or wrap it around the load in a choke

DO NOT lift with the tip of the hook or over the safety latch

DO NOT lift the load if with the weight is not evenly distributed across all

wire rope lines that pass through the pulley

DO NOT use the wire rope as an electric ground

DO NOT allow a welding electrode to touch the wire rope or the hook

DO NOT remove or modify the cautionary labels on the winch

DO NOT use a winch whose nameplate or safety and warning labels are

missing or illegible

DO NOT shock load the winch

DO NOT let an unqualified person to adjust or repair the equipment

DO NOT jog the load with the winch

Page 15

Operator`s Manual – Electric Winch 15 2018-08-03, rev 1

Recommended Practices

Inspect the winch at the beginning of each work shift. See Daily Inspection

for details

Protect the wire rope from weldment splashes and other contaminants

Be familiar with all the equipment`s functions and safety procedures

Turn off/lock out/tag out any malfunctioning equipment and inform the

person in charge as soon as possible

Make sure the limit switches (if applicable) function properly

Signal your intent to move a load to people around you

Signal the approach of a load to people around you

Keep both feet firmly on the floor while using the equipment

Use the safety latches on the hooks to prevent any below the hook

accessories from accidentally falling off

Ensure the entire path of the load is clear before moving the load

Make sure the hook moves in the same direction as indicated on the control

pendant

Inspect the hook regularly, replace damaged or worn parts and keep a

detailed register of all repairs made

Replace damaged or worn parts only with components from the original

manufacturer

Make sure the safety latches are closed before lifting a load and they do not

carry any part of the load

Do not shake the load when suspended on the hook

WARNING

The wire rope clamps on the drum are not designed to carry the full

load of the winch. You must always keep a minimum of 5 well tensioned wire

rope turns on the drum before moving a load.

Page 16

Operator`s Manual – Electric Winch 16 2018-08-03, rev 1

Inspection

Daily Inspection

The operator must conduct a daily inspection on the equipment at the beginning

of each shift or when the winch is used for the first time during the shift. The

daily inspection is a visual and auditory examination of the machine. The

following procedures should be carried out with no load:

Daily Inspection

1

Make sure the equipment is not tagged out of service

2

Make sure all functions work properly (up/down, emergency stop, horn,

etc.) and they agree with the indications on the control pendant

3

Check if the braking distance is normal

4

Check the hook for damage like cracks, grooves, excessive opening,

wear, torsion or other

5

Make sure the safety latch is present and closes/opens properly

6

Check the wire rope for signs of excessive wear like distortion, bird cages,

crushed sections, pinched sections, displaced or exposed core cable or

other

7

Check the wire rope for rust

8

Check the wire rope cable for broken wires; note the number and

distribution of the broken wires

9

Test the operation of all travel limiting devices

10

Check for oil leaks around and underneath the winch

11

Check if the winch makes any irregular or unusual noises during

operation

12

Make sure all nameplates and safety labels are present and legible

13

Check for broken, loose or missing structural components like fasteners,

brackets, link, anchors and others

Page 17

Operator`s Manual – Electric Winch 17 2018-08-03, rev 1

Periodic Inspection

An in-depth inspection of the equipment must be carried out on a regular basis

by a qualified person. The winch and its components are examined to ensure the

equipment is safe for use. The periodic inspections vary in frequency and details

according to the intensity of the equipment use but must include at least the

daily inspection procedure and a verification of the items listed below:

Periodic Inspection

1

Low oil level

2

Loose or missing bolts, nuts or rivets

3

Excessive gear backlash (should not be perceptible by the naked eye)

4

Signs of wear, corrosion, cracks or distortion on the winch components

such as, but not limited to: pulleys, bearings, chassis, drum, drum

flanges, anchor bolts, wire rope clips, shackles, bolts, shafts, gears, etc.

5

Wear or damage to the hook, see Hook Measuring and Discard Criteria

for details

6

Excessive wear of the wire rope drum

7

Cracked welds

8

Signs of heat damage, distortion, contamination or wear on the electric

and mechanical components of the brake

9

Excessive brake opening – readjust or replace brake disc according to

wear. Consult the brake manufacturer or Vulcan Hoist for details

10

Signs of pitting or other deterioration of the contact points on the

electric contactors

11

Problems with the normal use of the control buttons

12

Damaged electric wire insulation

13

Malfunction of heating elements (if applicable) on the reducer, motor,

brake, etc.

14

Inconsistent operation or poor reliability of the travel limiting devices (if

applicable)

15

Damage to the supporting structure or cracks in the concrete below the

winch

16

Damaged or missing nameplate

17

Missing or illegible safety labels

18

Wire rope cable showing signs of excessive wear such as, but not limited

to: wear, distortion, bird cages, crushed sections, pinched sections,

displaced or exposed wire rope core, corrosion. For more details, consult

Wire Rope Discard Criteria

Page 18

Operator`s Manual – Electric Winch 18 2018-08-03, rev 1

As a rule of thumb (unless indicated otherwise), replace any component whose

wear on any one dimension exceed 2.5% of the original nominal value.

Inspection Log Book

A detailed log book must be kept of all inspections, repairs and modifications

carried out on the equipment as well as a follow up on the wear of major

components like the wire rope cable, the hook, the gear reducer, the drum, etc.

These reports must be conserved for future reference and easily accessible to

members of the inspection, maintenance and repair crews.

Hook Measuring and Discard Criteria

It is recommended to replace any hook showing one or more of the following

signs of wear:

Hook Discard Criteria

1

Missing or illegible working load limit identification

2

Pitting, corrosion, cracks, grooves or deep lines on the hook body

3

Signs of weld or heat damage on the hook body, shank or swivel block

4

Wear on any dimension of the hook body exceeding 10% of the original

value

5

Permanent deformation of the hook opening exceeding 5% of the original

value

ATTENTION

It is the user`s responsibility to measure and record the initial hook

dimensions for future reference, since the shape and exact dimensions of the

hooks vary slightly from one hook to the other.

WARNING

If the hook opening exceeds the acceptable limits replace the hook. DO

NOT attempt to close the hook. The hook strength will be lowered.

Page 19

Operator`s Manual – Electric Winch 19 2018-08-03, rev 1

Wire Rope Discard Criteria

The precise discard criteria for the wire rope must be determined by a qualified

person while keeping in mind the characteristics of the application. As a rule of

thumb, any cable that shows one or more of the signs below should be replaced:

Wire Rope Discard Criteria

1

Six random broken wires over one cable lay or three broken wires in the

same strand over one cable lay

2

One broken wire close to an end fitting or a connector (bell fitting, spelter,

etc.)

3

One broken wire from the wire rope core which protrudes or loops out

from the wire rope structure

4

Sharp bends, crushed sections, bird cages or any other sign of damage

that results in severe distortion of the wire rope structure

5

Signs of heat damage (characteristic color change for example)

6

Reduction of the nominal diameter of 5% or more

Page 20

Operator`s Manual – Electric Winch 20 2018-08-03, rev 1

Maintenance

A log book of maintenance procedures, inspections findings and all repairs

carried out on the equipment must be kept for future reference.

Gear Reducer Lubrication

Vent Plug and Level Plug

Install the bent plug according to the reducer orientation before putting the

machine into service:

Symbol

Definition

Vent Plug

Level Plug

Drain Plug

*make sure the vent plug is

always on the top side to

ensure no leakage during the

use or the transportation of

the equipment

A minimum level of oil must be maintained to ensure proper gear lubrication:

Reducer Orientation and Oil Amounts

Reducer

M1 (L)

M2 (L2)

M3 (L)

M4 (L)

47

0.4

0.8

0.9

1.0

57

0.5

1.1

1.5

1.5

67

1.0

2.0

2.6

2.9

77

1.8

3.9

5.0

5.8

87

3.8

7.4

8.7

10.8

97

7.0

14.0

16.0

20.5

Page 21

Operator`s Manual – Electric Winch 21 2018-08-03, rev 1

Change the oil after the first 6 months then once every two years or more

frequently based on the use intensity

• Discard the old oil in accordance with local laws and regulations

• Do not mix different oil types inside the reducer. Certain oils may react

and affect the functionality of the reducer or damage the gears

Recommended Oil Types

Temperature

Grade

-30 à 15°C

ISO VG 150 or equivalent

-15 à 3°C

ISO VG 220 or equivalent

-3 à 23°C

ISO VG 320 or equivalent

23 à 40°C

ISO VG 460 or equivalent

40 à 80°C

ISO VG 680 or equivalent

Unless indicated otherwise, reducers are filled with Meropa 320 gear lubricant

External Use

In the case of external use, the winch must be covered and protected from rain

at all time. The risk of corrosion is increased further if high concentrations of salt

and/or humidity are present in the air. For such applications it may be necessary

to perform additional inspections and lubricate components more frequently.

Operating Environment

Unless indicated otherwise, the winch does not meet the requirements for the

following operating environments and must not be used in those environments:

• Prolonged exposure to temperatures below -20°C

• Presence of explosive gasses or vapours

• Presence of volatile solvents

• High concentration of dust or particulate matter

• Acidic or otherwise highly corrosive environment

Page 22

Operator`s Manual – Electric Winch 22 2018-08-03, rev 1

Part List

Page 23

Operator`s Manual – Electric Winch 23 2018-08-03, rev 1

Part List

Ref

Description

Part No.

W047

Qty

Part No.

W057

Qty

Part No.

W067

Qty

Part No.

W077

Qty

Part No.

W87

Qty

Part No.

W097

Qty

1

Reducer

WCH-100-4

1

WCH-100-57

1

WCH-100-67

1

WCH-100-77

1

WCH-100-87

1

WCH-100-97

1

2

Motor

1 1 1 1 1

1 3 Drum

WCH-A002-47

1

WCH-A002-57

1

WCH-A002-67

1

WCH-A002-77

1

WCH-A002-87

1

WCH-A002-97

1

4

Winch Base

WCH-004-47

1

WCH-004-57

1

WCH-004-67

1

WCH-004-77

1

WCH-004-87

1

WCH-004-97

1

5

Side Plate

WCH-007-47M

1

WCH-007-57M

1

WCH-007-67M

1

WCH-007-77M

1

WCH-007-87M

1

WCH-007-97M

1 6 Side Plate

WCH-007-47B

1

WCH-007-57B

1

WCH-007-67B

1

WCH-007-77B

1

WCH-007-87B

1

WCH-007-97B

1 7 Support Shaft

WCH-008-47

2

WCH-008-57

2

WCH-008-67

2

WCH-008-77

2

WCH-008-87

2

WCH-008-97

2 8 Support

WCH-006A

8

WCH-006A

8

WCH-006A

8

WCH-006BR

8

WCH-006BR

8

WCH-006BR

8 9 Flange Bearing

HAR173

1

HAR174

1

HAR175

1

HAR176

1

HAR177

1

HAR178

1

10

Hex Bolt

HAR139

16

HAR139

16

HAR139

16

HAR139

16

HAR139

16

HAR139

16

11

Flat Washer

HAR157

48

HAR157

48

HAR157

48

HAR157

48

HAR157

48

HAR157

48

12

Split Washer

HAR140

24

HAR140

24

HAR140

24

HAR140

24

HAR140

24

HAR140

24

13

Hex Nut

HAR141

24

HAR141

24

HAR141

24

HAR141

24

HAR141

24

HAR141

24

14

Hex Bolt

HAR142

8

HAR142

8

HAR142

8

HAR142

8

HAR142

8

HAR142

8

15

Hex Nut

HAR144

4

HAR144

4

HAR144

4

HAR141

4

HAR145

4

HAR143

4

16

Split Washer

HAR054

4

HAR054

4

HAR054

4

HAR140

4

HAR146

4

HAR059

4

17

Flat Washer

HAR147

4

HAR147

4

HAR147

4

HAR157

4

HAR158

4

HAR006

4

18

Hex Bolt

HAR159

4

HAR159

4

HAR148

4

HAR148

4

HAR148

4

HAR149

4

19

Hex Nut

HAR150

4

HAR150

4

HAR151

4

HAR151

4

HAR151

4

HAR152

4

20

Split Washer

HAR153

4

HAR153

4

HAR154

4

HAR154

4

HAR154

4

HAR155

4

21

Flat Washer

HAR156

4

HAR156

4

HAR160

4

HAR160

4

HAR160

4

HAR161

4

22

Hex Bolt

HAR164

4

HAR164

8

HAR162

4

HAR162

8

HAR163

8

HAR163

8

23

Hex Bolt

HAR169

4

HAR169

4

HAR170

4

HAR171

4

HAR171

4

HAR172

4

24

Split Washer

HAR165

4

HAR165

4

HAR166

4

HAR154

4

HAR154

4

HAR155

4

25

Flat Washer

HAR167

4

HAR167

4

HAR168

4

HAR160

4

HAR160

4

HAR161

4

26

Shaft Collar

HAR179

2

HAR180

2

HAR181

2

HAR182

2

HAR183

2

HAR184

2

27

Shim Washer

HAR185

2

HAR186

2

HAR187

2

HAR188

2

HAR189

2

HAR184

2

28

Shaft Key

HAR191

1

HAR192

1

HAR193

1

HAR194

1

HAR195

1

HAR196

1

Page 24

Vulcan Hoist Ltd

3435, Cremazie East, Montreal (Quebec) H1Z 2J2

514 728-4527

vulcanhoist.com

Loading...

Loading...