Page 1

ONE POWERFUL PACKAGE

OPERATIONS MANUAL

V SERIES HDR

GAS RANGES

TOPS

Open Top

Hot Top

Griddle Top

Work Surface

- NOTICE -

This manual is prepared for use by trained service technicians and

should not be used by those not properly qualified. If you have

attended a service school for this product, you may still be qualified to

perform the procedures described in this manual. This manual is not

intended to be all encompassing. If you have not attended a service

school for this product, you should read, in its entirety, the repair

procedure you wish to perform to determine if you have the necessary

tools, instruments and skills required to perform the procedure.

Procedures for which you do not have the necessary tools,

instruments and skills should be performed by a trained service

technician.

BASES

Standard Oven

Convection Oven

Cabinet Base

For additional information on Vulcan- Hart or to locate an authorized parts and service

provider in your area, visit our website at www.VulcanHart.com.

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F-37403 (02-09)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

Do not store or use gasoline or other

ammable vapors or liquids in the

vacinity of this or any other appliance.

Impr oper in stal lati on, adjustment,

alteration or modication, service or

maintenance c an cau se pro per ty

dama ge, inj ury or deat h. R ead the

installation, operating and maintenance

instructions tho rou ghl y b efo re

installing or servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

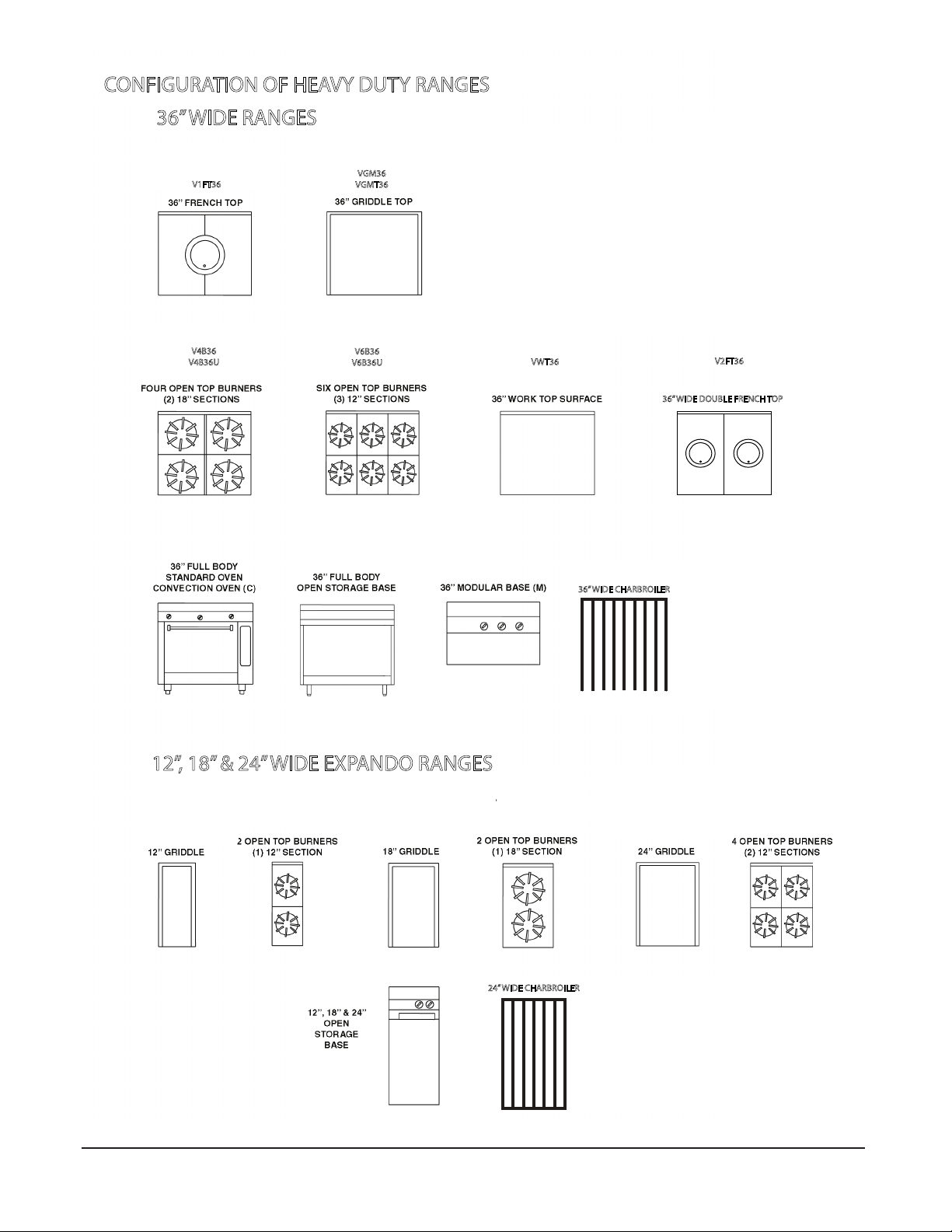

CONFIGURATION OF HEAVY DUTY RANGES

36” WIDE RANGES

V1FT36

V4B36

V4B36U

VGM36

VGMT36

V6B36

V6B36U

V236H

VWT36

36” WIDE CHARBROILER

V2BG18

V2BG8T

V2FT36

36” WIDE DOUBLE FRENCH TOP

12”, 18” & 24” WIDE EXPANDO RANGES

— 3 —

24” WIDE CHARBROILER

Page 4

Installation, Operation and Care Of

HEAVY DUTY SECTIONAL GAS RANGES

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Heavy duty sectional ranges are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNPACKING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully unpack range(s) and place in the approximate installation position, whether as a battery or

single stand-alone range.

Remove parts (packed in a cardboard box) from oven cavity, or cabinet body, or on top of modular

range(s).

Remove wire or nut from rear of each burner before installing the range.

Before installing, check the electrical service (Convection Oven Models only) and type of gas supply

(natural or propane) to make sure they agree with the specications on the rating plate located on the

inside of the burner box lower panel. The rating plate will show the voltage, phase, cycle, full load

ampere, BTU, as well as the type of gas. If the supply and equipment requirements do not agree, do

not proceed with the installation. Contact your dealer or manufacturer.

LOCATION

The equipment area must be kept free and clear of combustible substances.

The minimum installation clearances from combustible and noncombustible construction for ranges

using inputs of 30,000 BTU/Hr. per open top burner are:

Combustible Noncombustible

Sides 10” 0”

Rear 10” 0”

— 4 —

Page 5

The ranges are suitable for installation on combustible oors when 6" (152 mm) adjustable legs are

used. When legs are removed, use only on noncombustible oors, curb, or platform, with front

appliance projecting 3" (76 mm) beyond curb or platform.

Ranges with convection ovens should be installed on 6" (152 mm) legs or casters, allowing 6" (152 mm)

clearance from the rear of the range. If ranges with convection ovens are installed directly on curbs,

without legs, or in back-to-back installations, provisions must be made for adequate air circulation, and

these provisions must be approved by the manufacturer's Service Department. Contact the Service

Department at the address or phone number shown on the front cover of this manual.

All modular ranges are to be installed only on non-combustible oors.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 35" (889 mm) is required.

The range(s) must be installed so that the ow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber(s) must be provided. Make sure

there is an adequate supply of air in the room to allow for combustion of the gas at the burners.

INSTALLATION CODES AND STANDARDS

Your range(s) must be installed in accordance with:

In the United States:

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1/NFPA #54 (latest edition). Copies may be obtained

from The American Gas Association, Accredited Standards Committee Z223 @ 400 N.

Capital St. NW, Washington, DC 2001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park, Quincy, MA 02169-7471.

NOTE: In the Commonwealth of Massachusetts, All gas appliances vented through a

ventilation hood or exhaust system equipped with a damper or with a power means of

exhaust shall comply with 248 CMR.

3. Vapor Removal From Cooking Equipment, NFPA #96 (latest edition). Copies may be

obtained from The National Fire Protection Association, Batterymarch Park, Quincy MA

02169-7471.

4. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electrical Code (latest edition).

The above are available from The Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

— 5 —

Page 6

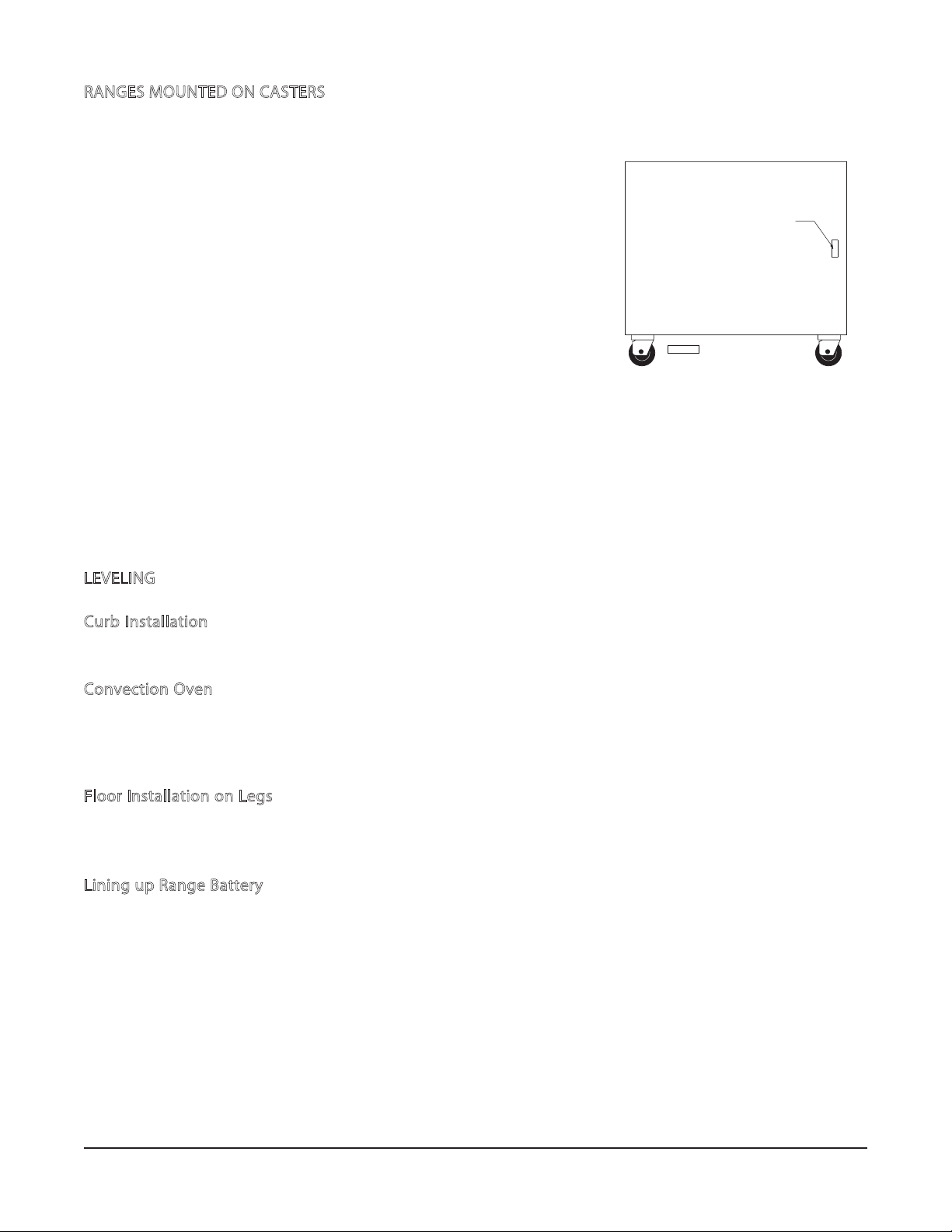

RANGES MOUNTED ON CASTERS

Ranges mounted on casters must use a exible connector

(not supplied by manufacturer) that complies with the

Standard for Connectors for Movable Gas Appliances,

ANSI Z21.69 • CSA 6.16 and a quick-disconnect device

that complies with the Standard for Quick-Disconnect

Devices for Use With Gas Fuel, ANSI-Z21.41 • CSA 6.9. In

CONNECT GAS LINE

STRAIN

RELIEF HERE

addition, ad equate means m ust be provide d to limi t

movement of the appliance without depending on the

connector and the quick-disconnect device or its associated

piping to limit appliance movement. Attach the restraining

device at the rear of the range as shown in Fig. 1.

PL-5121 9

If disconnection of the restraint is necessary, turn o the gas

supply before disconnection. Reconnect this restraint prior to

Fig. 1

turning the gas supply on and returning the range to its

installation position.

Separate instructions for installing casters to the range are included with the casters.

Note: If the range is installed on casters and is moved for any reason, it is recommended that the range

be releveled front to back and side to side.

LEVELING

Curb Installation

Ranges must overhang curb 3" (76 mm) in front.

Convection Oven

Remove lower front kick plate. Remove two screws holding electric gas valve and move valve o to

the side. Pull oven burner out of compartment through opening. Adjust four corner bolts to level range.

Replace burner valve and kick plate.

Floor Installation on Legs

The 6" (152 mm) adjustable legs must be tightened securely. Level each range by turning the foot

portion of the adjustable legs.

Lining up Range Battery

In batteries of ranges, it is recommended that the center range be installed and leveled rst. Level each

range, one at a time, to line up high shelf and roll front with adjacent range. Bolt the high shelves and

roll fronts together.

— 6 —

Page 7

CONNECTION OF MANIFOLDS IN BATTERY

Two or more ranges can be coupled together at the manifold by removing the front control panel to

make necessary connections. Be sure to cap open ends. To connect:

1. In a large battery of eight or more ranges, gas should be fed from both ends of the battery.

“T” gas connections can be installed whenever necessary for increased gas supply.

For further details, consult your gas company.

2. Align the front edge of the ranges and adjust the legs to bring the manifolds together

inline for connection. Clamps may be used to pull the ranges together.

3. Connect the unions between the gas manifolds.

4. Use the battery clip at the back of the range base to hold the units together.

5. Before replacing the manifold covers, check all gas connections for leaks. (See GAS

CONNECTIONS in this manual. )

If appliance has rear gas connection, carefully check for open gas lines.

The gas pressure regulator must have proper outlet pressure capacity for this battery application.

— 7 —

Page 8

GAS CONNECTIONS

All gas supply connections and any pipe joint compound used must be resistant

to the action of propane gases.

This appliance must be connected with a gas supply line as large or larger ID (net inside diameter) than

the gas pipe inlet provided on the rear of the appliance. Connect gas supply to the range(s). Make sure

the pipes are clean and free of obstructions, dirt, and piping compound.

Codes require that a gas shuto valve be installed in the gas line ahead of the range(s).

An external gas pressure regulator must be installed on the unit at the time of installation. The

regulator must be listed by a nationally recognized testing agency. These appliances are rated at the

following pressure: Natural Gas - 5" W.C. (Water Column) (1.25 kPa); Propane Gas - 10" W.C.

(2.49 kPa).

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open ame.

A. Check all joints prior to the gas valve (solenoid) before lighting unit.

B. Check all joints beyond gas valve (solenoid) after unit is lit.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the range and its individual shuto valve must be

disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the range must be isolated from the gas supply

system by closing its individual manual shuto valve.

FLUE CONNECTIONS

DO NOT obstruct the ow of ue gases from the ue duct located on the rear of the range. It is

recommended that the ue gases be ventilated to the outside of the building through a ventilation

system installed by qualied personnel.

A minimum of 18" (457 mm) must be maintained between the ventilation system and the cooking

surface.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "

Vapor Removal from Cooking Equipment

," NFPA No. 96 (latest edition), available from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

— 8 —

Page 9

ELECTRICAL CONNECTIONS

Electrical and grounding connections must comply with the applicable

portions of the national electrical code and/or other loc a l electrica l

codes.

Appliances equipped with a exible electric supply cord are provided with

a three-prong grounding plug. It is imperative that this plug be connected

properly into a properly grounded three-prong receptical. If the receptical is not the

proper grounding type, contact an electrician. Do not remove the grounding prong

from this plug.

Do not connect the range to electrical supply until after gas connections have been made.

— 9 —

Page 10

LIGHTING AND SHUTTING DOWN PILOTS

Open Top, Griddle Top, and Hot Top

1. Turn the main gas supply ON.

2. Turn all top burner valves to ON to purge gas line of air. (Length of time to purge air will vary.)

3. Turn top burner valve knobs to OFF.

4. Wait 30 seconds.

5. Using a taper, light the pilot(s).

6. If pilot fails to light, wait 5 minutes and repeat Steps 1 through 5.

Nightly Shutdown: Turn burner valve OFF; pilot will remain lit.

Complete Shutdown: Turn burner valve OFF; pilot will remain lit. Turn main gas valve OFF.

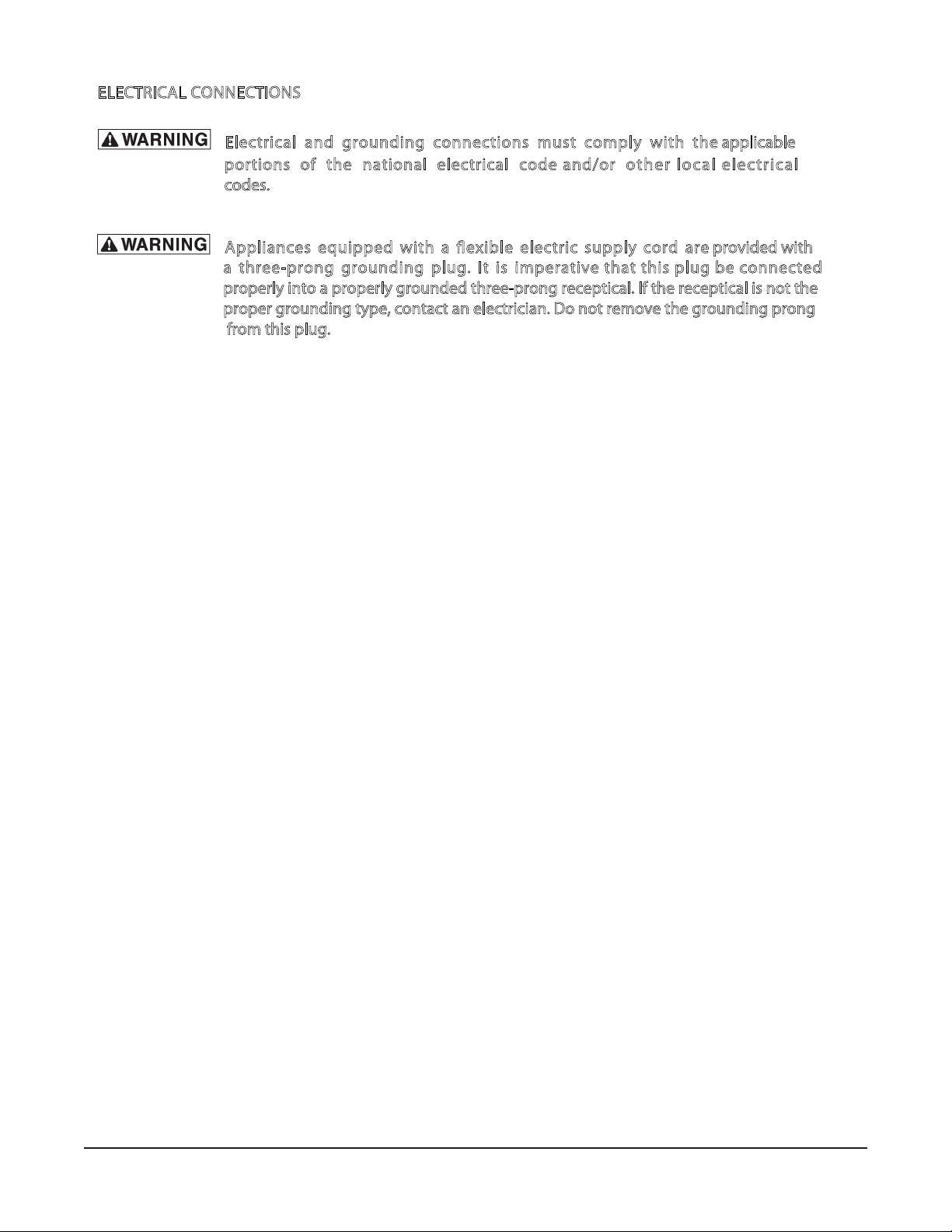

Standard Oven - “S” Model (Fig. 2)

1. Turn Thermostat and Shut-Off Valve to the OFF position.

2. Wait 5 minutes.

3. Remove lower panel to locate pilot cutout.

4. Using a taper, light oven pilot by depressing the red ignition button located

on the side control panel below the thermostat knob.

5. Continue to hold down Red Button for at least 30 seconds.

RED BUTTON

(SAFETY)

THERMOSTAT

DIAL

6. When Red Button is released, Pilot should remain lit.

7. Turn Shut-Off Valve to the ON position and turn the Thermostat to the desired

temperature.

SHUT-OFF

VALVE

8. Replace lower panel.

9. If pilot flame becomes extinguished or does not light, repeat Steps 1 through 6.

Nightly Shutdown: Turn Thermostat to OFF; pilot will remain lit.

Complete Shutdown: Turn Thermostat and Shut-Off Valve to OFF. Turn main gas valve OFF.

FIG 2

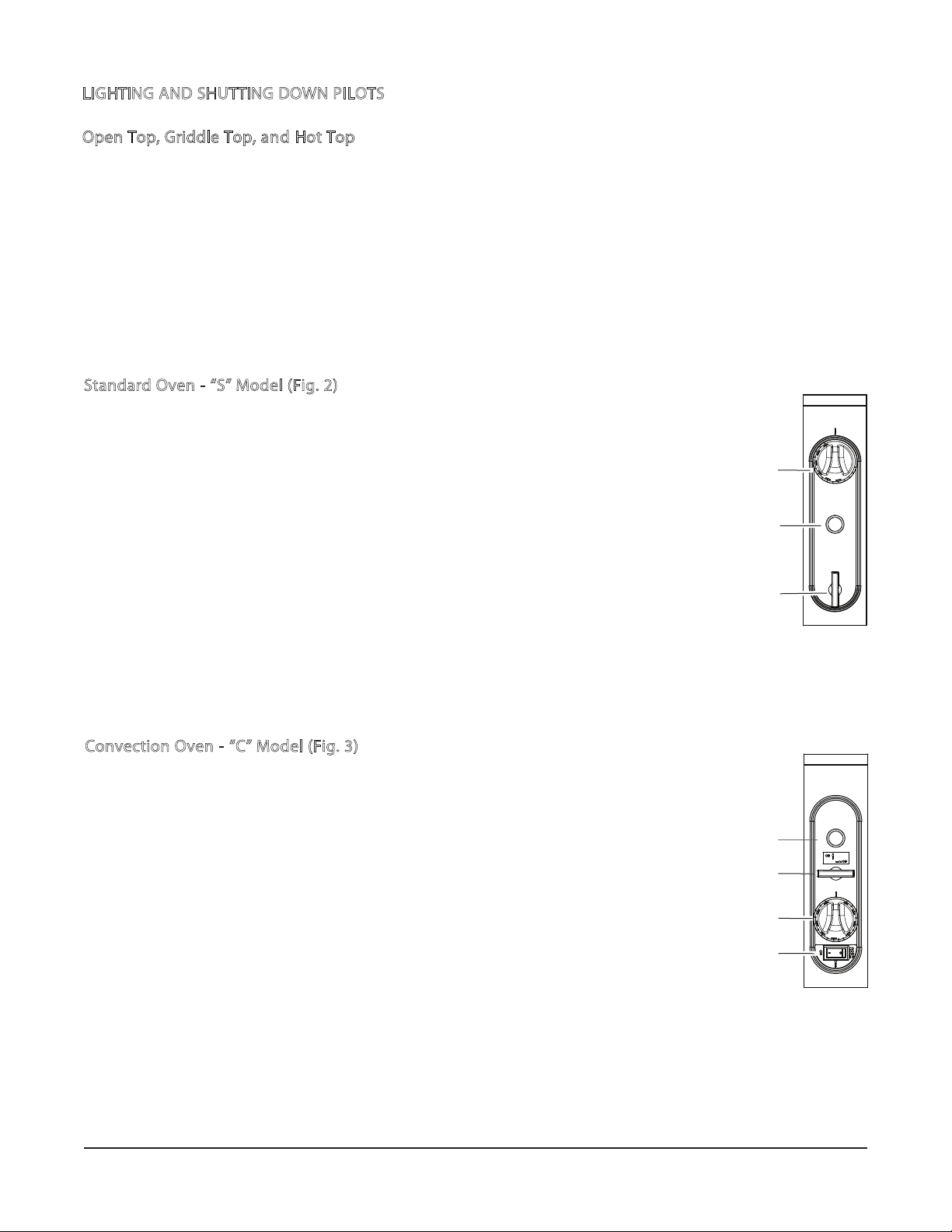

Convection Oven - “C” Model (Fig. 3)

1. Connect range to main electrical supply.

2. Turn Thermostat and Shut-Off Valve to the OFF position.

3. Turn Fan Switch to OFF position.

4. Wait 5 minutes.

5. Remove lower panel to locate pilot cut out.

6. Using a taper, light oven pilot by depressing the red ignition button located

on the side control panel above the Shut-Off Valve.

7. Continue to hold down the Red Button for at least 30 seconds.

8. When Red Button is released, Pilot should remain lit.

9. Turn Shut-Off Valve to the ON position and turn the Thermostat to the desired

setting.

10. Replace lower panel.

11. If pilot flame becomes extinguished or does not light, repeat Steps 1 through 8.

Nightly Shutdown: Turn Thermostat to OFF; pilot will remain lit.

Complete Shutdown: Turn the Thermostat, Shut-Off Valve, and Fan Switch to OFF. Turn

main gas valve OFF.

— 10 —

RED BUTTON

(SAFETY)

SHUT-OFF

VALVE

THERMOSTAT

DIAL

FAN

SWITCH

FIG 3

Page 11

OPERATION

The range and its parts are hot. Use care when operating, cleaning or

servicing the range.

BEFORE FIRST USE

Griddle Tops: Before using your griddle, the protective coating that was applied at the factory must

be completely removed with a commercial degreaser. After a thorough cleaning, apply a

high temperature, salt-free frying oil and you are ready to use the griddle.

The griddle requires no “breaking-in” or “seasoning”.

OPERATING SUGGESTIONS

Standard Oven: If you have a standard oven, use your normal recipe times and temperatures.

Convection Oven: The convection oven does everything a regular oven can do, but with less energy

consumption. The oven pre-heats faster, and baking time, temperature settings, and

shrinkage are reduced.

In general, reduce temperature 25°F (10°C) from conventional recipes.

Check product at half the time of the regular recipe.

Level pans bake more evenly; warped pans will give uneven baking results.

— 11 —

Page 12

CLEANING

Turn o gas supply to the machine.

Disconnect the electrical power and follow lockout / tagout procedures.

Open Top Burners

Daily

Remove grates and clean under and around open burners.

1. Clean bottom drip pan. To remove drip pan, reach under and lift rear of pan about 1" (25 mm),

1

slide pan to the rear about

/2" (13 mm), and drop front end of pan free. Slide pan forward

between the front legs. To replace pan, reverse this procedure.

Weekly

1. Clean each burner thoroughly. Clean stainless steel or chromed surfaces with a damp cloth and

polish with a soft dry cloth. A detergent may be used for cleaning. To remove discolorations, use

a non-abrasive cleaner, always rubbing with the grain of the metal.

2. Burner air shutter openings must be kept clean.

3. Main burner ports and throats must be thoroughly cleaned. Venturi must be free from grease

and lint. To clean burners, run through a dish washer. Stand on air shutter end to air dry.

DO NOT insert pick in burner port hole.

Griddle Top

Empty grease daily. Clean griddle top regularly.

KEEP GRIDDLE PLATE SURFACE CLEAN. To produce evenly cooked, browned products, keep

griddle free of carbonized grease. Carbonized grease on the surface hinders the transfer of heat from

the griddle surface to food. This results in spotty browning and loss of cooking eciency, and

carbonized grease tends to stick to the griddled foods, giving them a highly unsatisfactory and

unappetizing appearance.

To keep the griddle clean, follow these simple instructions:

After Each Use

Clean griddle with a wire brush or exible spatula.

Daily

1. Thoroughly clean backsplash, sides and front. Remove grease drawer, empty it and wash it out

in the same manner as any ordinary cooking utensil.

2. Clean griddle surface thoroughly. Use a griddle stone, wire brush or stainless steel wool on the

surface. Rub with the grain of the metal while the griddle is still warm. A detergent may be used

on the plate surface to help clean it, but you must ensure the detergent is thoroughly removed.

3. Clean stainless surfaces with a damp cloth and polish with a soft dry cloth. To remove

discolorations, use a non-abrasive cleaner.

— 12 —

Page 13

Exterior

Daily

Clean exterior nish with a mild solution of soap or grease-dissolving cleaner.

Range Tops

Daily

1. Wipe top while still warm with a soft cloth.

2. Clean drip pan under burners.

Weekly

Boil open top grates and burners in a solution of washing soda and water.

Range Ovens

Daily

Clean oven and door daily.

Do not use scouring powder on nishes. Scouring powder is extremely dicult to remove completely.

It can build up accumulations that will damage the oven or remove corrosion resistant nishes.

STAINLESS STEEL

Here are a few simple cleaning procedures that have been found eective for keeping stainless steel

equipment clean, sparkling and bright.

General Cleaning

Use ordinary soap or detergent and water for routine cleaning of stainless steel. To prevent water spots

and streaks, rinse thoroughly with warm water and wipe dry with a soft clean cloth. The addition of a

rinsing agent will also help prevent spotting.

Fingerprints

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They can be

minimized by applying a cleaner that will leave a thin oily or waxy lm.

To use these cleaners, simply wipe on and remove excess with a soft dry cloth. After using, subsequent

ngerprints will usually disappear when wiped lightly with a soft cloth or with a cloth containing a little

of the cleaner. If the surface is especially dirty to start, wash rst with soap or detergent and water.

Burned-On Foods and Grease

Soaking with hot soapy water will help greatly to remove burned-on foods and grease.

— 13 —

Page 14

Precautions

When scraping o heavy deposits of grease or oil from stainless steel equipment, never use ordinary

steel scrapers. Particles of ordinary steel may become embedded in, or lodge on, the surface of the

stainless steel. These will rust, causing unsightly stains and possible contamination of food. Where it

is necessary to scrape, use stainless steel, wood, plastic or rubber tools.

— 14 —

Page 15

MAINTENANCE

Turn o gas supply to the machine.

Disconnect the electrical power and follow lockout / tagout procedures.

LUBRICATION

All moving parts must be checked for wear and lubricated. Contact your local Vulcan authorized servicer.

All valves and controls should be lubricated by your local Vulcan authorized servicer, using a high-temperature

grease.

Motors in these convection ovens are permanently lubricated and require no additional maintenance.

FLUE

Annually check the ue when it is cool to be sure it is free of obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Authorized Service Agency

in your area (refer to the manufacturer's website for a complete listing of Authorized Service and Parts

depots) or contact 1-800-814-2028 for Technical service and parts assistance.

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

— 15 —

Page 16

TROUBLESHOOTING

OVEN

SESUAC ELBABORPMELBORP

Too Much Bottom Heat Insucient heat input. (Call Service)

Overactive ue. (Call Service)

.erutarepmet wol ooTekaB nevenU

Improper operation.

Fluctuating gas pressure. (Call Service)

.erutarepmet hgih ooTtaeH poT hcuM ooT

Faulty ventilation. (Call Service)

Excessive heat input. (Call Service)

Thermostat needs calibration. (Call Service)

Uneven Bake - Side to Side Range not level side to side.

Oven burner, bottom or baes improperly installed.

.snap depraWnaP fo egdE ot gnilluP

Oven not level.

)ecivreS llaC( .gnittes ssapyb reporpmIgninruB ediS

Uneven Bake - Front to Rear Overactive ue. (Call Service)

Range not level front to back.

Door not closing properly.

.erutarepmet wol ooTstcudorP tuO deirD

Too long baking time.

Thermostat calibration. (Call Service)

Pilot Outage

Pilot ame too low. (Call Service)

Restriction in pilot orice. (Call Service)

Problem with safety valve. (Call Service)

CONVECTION OVEN MODELS ONLY:

Cavity leaking. (Call Service)

Gasket problems. (Call Service)

Convection oven tube blocked.

Blower running backwards. (Call Service)

Excessive Meat Shrinkage Roasting temperature too high.

)ecivreS llaC( .tneiciffus ton ylppus saGegatuO toliP

— 16 —

Page 17

TOP BURNER OPERATION

SESUAC ELBABORPMELBORP

Improper Burner Combustion Improper ventilation. (Call Service)

Excessive Valve Handle Temperatures Poor door t. (Call Service)

Sticking Top Burner Valves Oven door left open.

Poor air-to-gas adjustment. (Call Service)

Restriction in pilot orice. (Call Service)

Restriction in main burner ignition port. (Call Service)

Restriction in control valve. (Call Service)

Restriction in gas orice. (Call Service)

)ecivreS llaC( .tupni sag tneiciffusnInoitingI rooP

— 17 —

Page 18

UNE ÉQUIPE DU TONNERRE

IOLPME'D EDOM

GRILLOIRS HDR

DE LA SÉRIE V

SURFACES BASES

Brûleur découvert Four conventionnel

Plaque à bouillir Four à air pulsé

Plaque à frire Sur meuble

Surface de travail

- AVIS -

Ce manuel a été préparé à l’intention de techniciens de l’entretien qui

ont reçu une formation et ne devrait pas être utilisé par des personnes

qui ne sont pas qualifiées. Si vous avez assisté à un atelier de

formation sur ce produit, vous pouvez aussi être qualifié pour exécuter

les procédures décrites dans ce manuel.

Ce manuel peut ne pas couvrir tous les aspects de cet appareil. Si

vous n’avez pas assisté à un atelier de formation sur cet appareil,

vous devriez lire, en entier, la procédure qui se rapporte à la

réparation que vous désirez effectuer pour déterminer si vous avez

les outils, les instruments et les compétences requises pour la faire.

Si ce n’est pas le cas, vous devrez avoir recours à un technicien

qualifié de l’entretien.

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de

pièces et de service autorisé le plus près, visiter notre site Web à : www.vulcanhart.com

VULCAN-HART 3600 NORTH POINT BLVD.

CLL ,ERIATNEMILA TNEMEPIUQÉ WTI EPUORG ED NOISIVID ENU BALTIMORE, MD 21222

WWW.VULCANHART.COM F-37403 (02-08)

Page 19

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET AUTORISÉ

À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À EFFECTUER LE

DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE DES APPAREILS

CONCERNÉS DANS CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL

PAR LE ROBINET D’ARRÊT PRINCIPAL ET

COMMUNIQUER AVEC LA COMPAGNIE DE GAZ

LA PLUS PRÈS OU AVEC LE FOURNISSEUR DE

GAZ ATTITRÉ POUR L’ENTRETIEN.

MESURE DE SÉCURITÉ

Ne pas ranger ni utiliser de l’essence ni tout

autre liquide ou vapeur inflammable à

proximité de cet appareil ou de tout autre

appareil

!

AVERTISSEMENT

L’installation, le réglage, la modification et

l’entretien incorrects de cet appareil peuvent

causer des dommages matériels, des

blessures et même la mort. Lire les

instructions d’installation, de fonctionnement

et d’entretien avant de procéder à toute

installation ou tout entretien.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

— 2 —

Page 20

CONFIGURATIONS DES CUISINIÈRES À SERVICE INTENSE

CUISINIÈRES DE 914 MM (36 PO)

V1FT36 VGMT36 V236H V2BG8T

PLAQUE CIRCULAIRE PLAQUE À FRIRE (2) PLAQUES À BOUILLIR BRÛLEUR DÉCOUVERT

DE 914 MM (36 PO) DE 914 MM (36 PO) DE 457 MM (18 PO) DE 457 MM (18 PO)

V4B36 V6B36

V4B36U V6B36U VWT36 V2FT36

4 BRÛLEURS DÉCOUVERTS 6 BRÛLEURS DÉCOUVERTS SURFACE DE TRAVAIL PLAQUE CIRCULAIRE

(2) SECTIONS DE 457 MM (18 PO) (3) SECTIONS DE 305 MM (12 PO) DE 914 MM (36 PO) DOUBLE DE 914 MM (36 PO)

VGM36 V2BG18

DE 457 MM (18 PO)

PLAQUE À FRIRE

FOUR CONVENTIONNEL

FOUR À AIR PULSÉ BASE DE RANGEMENT

914 MM (36) PO (C) OUVERTE PLEINE GRANDEUR BASE MODULAIRE

PLEINE GRANDEUR 914 MM (36 PO) DE 914 MM (36 PO) (M)

CUISINIÈRES EXPANDO DE 305, 457 ET 610 MM (12, 18 ET 24 PO) DE LARGEUR

2 BRÛLEURS 2 BRÛLEURS 4 BRÙLEURS

PLAQUE À FRIRE (1) SECTION DE FRIRE DE 457 MM (1) SECTION DE FRIRE DE (2) SECTIONS DE

DE 305 MM (12 PO) 305 MM (12 PO) (18 PO) 457 MM (18 PO) 610 MM (24 PO) 305 MM (12 PO)

DÉCOUVERTS PLAQUE À DÉCOUVERTS PLAQUE À DÉCOUVERTS

BASE DE RANGEMENT

OUVERTE DE 305, 457 ET 610 MM

(12, 18 ET 24 PO)

— 3 —

Page 21

Installation, fonctionnement et entretien

CUISINIÈRES AU GAZ À SECTIONS

À SERVICE INTENSE

DOCUMENT À CONSERVER EN CAS DE BESOIN.

GÉNÉRALITÉS

Les cuisinières au gaz à service intense à sections sont fabriquées avec le plus grand soin et à

partir des meilleurs matériaux. Leur installation, utilisation et entretien appropriés permettront d’en

obtenir un rendement optimal pendant de nombreuses années.

Il est recommandé de lire ce manuel au complet et de suivre attentivement toutes les instructions.

INSTALLATION

DÉBALLAGE

Cette cuisinière a été inspectée avant de quitter l’usine. En acceptant de livrer cette marchandise,

le transporteur en assume l’entière responsabilité jusqu’à la livraison. Immédiatement après avoir

déballé l’appareil, vérifier s’il n’a pas été endommagé lors du transport. En cas de dommages, conserver

le matériel d’emballage et aviser le transporteur dans les 15 jours suivant la date de réception.

Sortir l’appareil de sa caisse avec soin et le placer le plus près possible de l’emplacement prévu,

seul ou en série.

Enlever toutes les pièces emballées dans une boîte de carton qui se trouve dans l’enceinte de

cuisson, le meuble ou sur le dessus des cuisinières modulaires.

Enlever le câble ou écrou à l’arrière de chaque brûleur avant d’installer la cuisinière.

Avant l’installation, s’assurer que l’alimentation électrique (modèles pourvus d’un four à air pulsé

seulement) et le type de gaz (naturel ou propane) de l’immeuble correspondent aux spécifications

de la plaque signalétique se trouvant à l’intérieur de la boîte du brûleur du panneau inférieur. La

plaque signalétique indique l’alimentation, la phase, le cycle, le courant à pleine charge, le nombre

de BTU ainsi que le type de gaz. S’ils ne correspondent pas, ne pas installer l’appareil et

communiquer sans tarder avec votre détaillant.

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de cet appareil.

Lors de l’installation de cuisinières, observer les dégagements minimaux suivants de toute

construction combustible et incombustible de 30 000 BTU/h par brûleur découvert

Construction Construction

combustible incombustible

Côtés : 254 mm (10 po) Aucun

Arrière : 254 mm (10 po) Aucun

— 4 —

Page 22

L’installation des cuisinières peut se faire sur un plancher combustible lorsqu’on utilise des

pattes réglables de 152 mm (6 po). Lorsque les pattes sont enlevées, installer l’appareil

seulement sur un plancher incombustible, un muret ou une plate-forme, le devant de l’appareil

dépassant de 76 mm (3 po) le muret ou la plate-forme.

Installer les cuisinières munies de fours à air pulsé sur des pattes ou roulettes de 152 mm (6 po),

en observant un dégagement de 152 mm (6 po) à l’arrière de l’appareil. Si les cuisinières munies

de fours à air pulsé sont installées directement sur un muret, sans pattes, ou lors d’installations

dos-à-dos, prévoir un dégagement suffisant pour assurer une circulation d’air adéquate qui doit

être approuvé par le service de l’entretien de votre fabricant. L’adresse et le numéro de téléphone

sont inscrits à la page couverture de ce manuel.

Toutes les cuisinières modulaires doivent être installées sur un plancher incombustible seulement.

Les cuisinières doivent se trouver dans un endroit suffisamment espacé pour permettre leur

entretien et leur fonctionnement appropriés. Un dégagement minimal de 889 mm (35 po) est

requis devant l’appareil.

Installer les cuisinières de manière à assurer la circulation de l’air nécessaire à la combustion des

gaz et à la ventilation appropriées de l’appareil. Observer un dégagement suffisant autour des

ouvertures d’approvisionnement d’air de la chambre de combustion. S’assurer d’une bonne

ventilation dans le local pour permettre la combustion des gaz.

CODES D’INSTALLATION ET NORMES

L’installation de votre cuisinière doit se faire selon les codes suivants :

Aux États-Unis :

1. Codes locaux

2. Norme ANSI/Z223.1/NFPA No 4 (dernière édition) du National Fuel Gas Code dont on peut se

procurer un exemplaire auprès de l’American Gas Association Inc., Comité de normalisation

reconnu Z223, 400 N. Capital St. NW, Washington, DC 2001 ou le Secrétaire du Comité de

normalisation, NFPA, 1 Batterymrch Park, Quincy, MA 02169-7471.

NOTA : Dans l’État du Massachusetts, tous les appareils au gaz ventilés par une hotte de

ventilation ou un système d’évacuation muni d’un registre ou de moyens d’évacuation à

puissance doivent être conformes à la réglementation 248 CMR.

3. Évacuation de la fumée des appareils de cuisson, norme NFPA No 96 (dernière édition) dont

on peut se procurer un exemplaire auprès de la National Fire Protection Association,

Batterymarch Park, Quincy MA 02169-7471.

4. Norme ANSI/NFPA-70 (dernière édition) du National Electrical Code dont on peut se procurer un

exemplaire auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

On peut se procurer un exemplaire des normes ci-dessus auprès de l’Association canadienne de

normalisation, 5060 Spectrum Way, Bureau 100, Mississauga, Ontario, Canada L4W 5N6.

Au Canada :

1. Codes locaux.

2. Norme CSA B149.1 du Code d’installation des appareils fonctionnant au gaz naturel et propane.

3. Norme CSA C22.1 du Code canadien de l’électricité (dernière édition).

— 5 —

Page 23

CUISINIÈRES SUR ROULETTES

Si l’appareil doit être installé sur des roulettes, se munir

d’un connecteur flexible (non fourni par le fabricant)

conforme aux normes ANSI-Z21.69 • CSA 6.16 sur les

connecteurs des appareils au gaz mobile et d’un raccord à

débranchement rapide conforme aux normes ANSI-Z21.41

• CSA 6.9. En plus, prendre les moyens nécessaires pour

limiter le mouvement de l’appareil sans devoir compter sur

le connecteur ou le raccord à débranchement rapide, ni

même sur la tuyauterie pour le garder immobile. Fixer le

dispositif de retenue à l’arrière de la cuisinière (Fig. 1).

FIXER LA CHAÎNE DE RETENUE

DE LA CONDUITE

D’ALIMENTATION EN GAZ ICI

CONNECT GAS LINE

STRAIN

RELIEF HERE

S’il s’avère nécessaire de détacher le dispositif de retenue,

PL-51219

couper l’alimentation en gaz de l’appareil. Le rattacher

avant de rétablir l’alimentation en gaz et de remettre

Fig. 1

l’appareil en position d’exploitation.

Des instructions pour l’installation de roulettes sont incluses avec les roulettes séparément.

Nota : Si la cuisinière est installée sur des roulettes et doit être déplacée pour une raison ou une

autre, il est conseillé de la niveler à nouveau d’avant en arrière et d’un côté à l’autre.

NIVELAGE

Installation sur un muret

Les cuisinières doivent dépasser le devant du muret de 76 mm (3 po).

Four à air pulsé

Enlever la plaque de bas de porte. Enlever les deux vis qui retiennent la soupape à gaz électrique

et la pousser sur le côté à Off (arrêt). Retirer le brûleur du compartiment à travers l’ouverture.

Régler les boulons aux quatre coins pour niveler la cuisinière. Replacer la soupape du brûleur et

la plaque de bas de porte.

Installation des pattes sur un plancher

Attacher les pattes de 152 mm (6 po) réglables de façon sécuritaire. Niveler chaque cuisinière en

tournant la partie du pied des pattes réglables.

Alignement d’une cuisinière raccordée en batterie

Pour les cuisinières raccordées en batterie, il est conseillé d’installer et de niveler la cuisinière

centrale en premier. Niveler chaque cuisinière, une à la fois, pour aligner la tablette surélevée et la

pièce d’appui arrondie avant avec la cuisinière adjacente. Boulonner les tablettes surélevées et

les pièces arrondies avant ensemble.

— 6 —

Page 24

RACCORDEMENT DE LA TUBULURE D’ALIMENTATION EN BATTERIE

Deux cuisinières ou plus peuvent être raccordées ensemble à la tubulure d’alimentation en enlevant

le panneau de commande avant pour effectuer les raccordements nécessaires. S’assurer de

couvrir les extrémités ouvertes. Pour raccorder :

1. Dans une grande batterie de huit cuisinières ou plus, l’alimentation en gaz devrait se faire des

deux côtés de la batterie. Les raccordements de gaz en "T" peuvent être installés, si

nécessaire, pour une alimentation en gaz accrue. Pour plus de détails, communiquer avec

votre compagnie de gaz.

2. Aligner le bout avant des cuisinières et régler les pattes de façon à ce que les tubulures

d’alimentation soient en ligne pour le raccordement. Utiliser des brides pour joindre les

cuisinières ensemble.

3. Raccorder les raccords-unions entre la tubulure d’alimentation du gaz.

4. Utiliser la pince pour raccordement en batterie à l’arrière de la base de la cuisinière pour

maintenir les appareils ensemble.

5. Avant de replacer les panneaux de la tubulure d’alimentation, vérifier tous les raccordements

de gaz pour s’assurer qu’il n’y a aucune fuite. (Se reporter à la section BRANCHEMENT DU

GAZ de ce manuel.)

Si l’appareil est muni d’un raccordement de gaz arrière, bien s’assurer que la conduite de gaz est

ouverte.

Le régulateur de pression de gaz doit avoir une capacité de pression de sortie adéquate pour le

raccordement en batterie.

— 7 —

Page 25

BRANCHEMENT DU GAZ

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de

tuyaux doivent résister à l’action du gaz propane.

La conduite de gaz doit être composée d’un tuyau de la même dimension ou supérieur à celui de

l’entrée de gaz qui se trouve à l’arrière de l’appareil (diamètre net à l’intérieur). Raccorder la conduite

de gaz à la cuisinière. S’assurer que les tuyaux sont propres et qu’ils ne comportent aucun corps

étranger ni saleté ou de pâte à joints.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz, en

avant de l’appareil.

Un régulateur de pression de gaz externe doit être installé sur l’appareil. Il doit être certifié par une

agence nationale d’essais reconnue. Ils doivent être préréglés à une pression de 1,25 kPa (5 po)

de colonne d’eau pour le gaz naturel et de 2,49 kPa (10 po) de colonne d’eau pour le gaz propane.

Avant de procéder à l’allumage, faire circuler de l’eau savonneuse

!

AVERTISSEMENT :

dans tous les joints de la conduite de gaz pour s’assurer qu’ils ne présentent aucune fuite.

Ne pas se servir d’une flamme nue.

A. Vérifier tous les joints conduisant à la soupape à gaz (vanne électromagnétique)

avant de procéder à l’allumage de l’appareil.

B. Vérifier tous les joints à partir de la soupape à gaz après l’allumage.

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour évacuer tout l’air

qu’elle contient.

ESSAIS DE LA CANALISATION DE GAZ

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de

pression, débrancher la cuisinière et son robinet d’arrêt de la conduite de gaz.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

canalisation de gaz en fermant son robinet d’arrêt manuel.

CONDUIT D’ÉVACUATION

NE PAS obstruer le débit des gaz de combustion dans le conduit d’évacuation à l’arrière de

l’appareil. Il est recommandé que les gaz de combustion soient ventilés à l’extérieur de l’immeuble

par un système de ventilation installé par un personnel qualifié.

Maintenir un dégagement minimum de 457 mm (18 po) entre l’extrémité du conduit d’évacuation

de l’appareil et les filtres de la hotte de ventilation.

Les informations sur la construction et l’installation des hottes de ventilation sont comprises dans

la norme NFPA n° 96 (dernière édition) relative à l’installation de matériel pour l’évacuation de la

fumée des appareils de cuisson dont on peut se procurer un exemplaire auprès de la National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269-7471.

— 8 —

Page 26

RACCORDEMENT ÉLECTRIQUE

!

AVERTISSEMENT :

Le raccordement électrique et la mise à la terre doivent être

conformes aux normes concernées du code canadien de l’électricité ou tout autre code

d’électricité en vigueur.

!

Les appareils munis d’un cordon d’alimentation flexible sont

AVERTISSEMENT :

pourvus d’une fiche de mise à la terre à trois broches. La prise dans laquelle elle est

branchée doit être correctement mise à la terre. Si elle ne l’est pas, communiquer avec un

électricien. Ne pas enlever la broche de mise à la terre de la fiche.

Ne pas établir l’alimentation électrique tant que les raccordements de gaz ne sont pas terminés.

— 9 —

Page 27

ALLUMAGE ET ARRÊT DES VEILLEUSES

Veilleuses de brûleur découvert, plaques à frire et à bouillir

1. Mettre le robinet de gaz principal à ON (marche).

2. Mettre le robinet de tous les brûleurs découverts à ON (marche) pour évacuer

l’air de la conduite de gaz. (Le temps pour évacuer l’air peut varier.)

3. Mettre le robinet de tous les brûleurs découverts à OFF (arrêt).

4. Attendre 30 secondes.

5. Allumer la veilleuse des brûleurs à l’aide d’une bougie.

6. Si la veilleuse refuse de s’allumer, attendre 5 minutes et reprendre les étapes 1 à 5

Arrêt nocturne : Mettre le robinet du brûleur à OFF (arrêt); la veilleuse demeure allumée.

Arrêt complet : Mettre le robinet des brûleurs à OFF (arrêt); la veilleuse demeure allumée.

Mettre le robinet de gaz principal à OFF (arrêt).

Four conventionnel – « S » (Fig. 2)

1. Mettre le thermostat et le robinet d’arrêt à OFF (arrêt).

2. Attendre 5 minutes.

3. Enlever le panneau inférieur pour localiser le coupe-circuit de la veilleuse.

4. À l’aide d’une bougie, allumer la veilleuse du four en appuyant sur le bouton rouge

d’allumage sur le côté du panneau de commande sous le bouton du thermostat.

5. Maintenir le bouton rouge enfoncé pendant au moins 30 secondes.

6. Lorsqu’on relâche le bouton, la veilleuse devrait rester allumée.

7. Mettre la soupape d’arrêt à On (marche) et mettre le thermostat à la

température désirée.

8. Replacer le panneau inférieur.

9. Si la flamme s’éteint ou refuse de s’allumer, reprendre les étapes 1 à 6.

Arrêt nocturne : Mettre le thermostat à OFF (arrêt); la veilleuse demeure

allumée.

Arrêt complet : Mettre le thermostat et le robinet d’arrêt à OFF (arrêt). Mettre le

robinet de gaz principal à OFF (arrêt).

BOUTON ROUGE

(SÉCURITÉ)

THERMOSTAT

CADRAN DE

ROBINET

D’ARRÊT

Fig. 2

Four à air pulsé – Modèle « C » (Fig. 3)

1. Raccorder la cuisinière à l’alimentation électrique principale.

2. Mettre le thermostat et le robinet d’arrêt à OFF (arrêt).

3. Mettre l’interrupteur du ventilateur à OFF (arrêt).

4. Attendre 5 minutes.

5. Enlever le panneau inférieur pour localiser le coupe-circuit de la veilleuse.

6. À l’aide d’une bougie, allumer la veilleuse du four en appuyant sur le bouton rouge

BOUTON ROUGE

d’allumage sur le côté du panneau de commande au-dessus du robinet d’arrêt.

7. Maintenir le bouton rouge enfoncé pendant au moins 30 secondes.

8. Lorsqu’on relâche le bouton, la veilleuse devrait rester allumée.

9. Mettre la soupape d’arrêt à On (marche) et mettre le thermostat à la

température désirée.

10. Replacer le panneau inférieur.

11. Si la flamme s’éteint ou refuse de s’allumer, reprendre les étapes 1 à 8.

INTERRUPTEUR

DE VENTILATEUR

Arrêt nocturne : Mettre le thermostat à OFF (arrêt); la veilleuse demeure

allumée.

Arrêt complet : Mettre le thermostat, le robinet d’arrêt et l’interrupteur du

ventilateur à OFF (arrêt). Mettre le robinet de gaz principal à OFF (arrêt).

— 10 —

(SÉCURITÉ)

ROBINET

D’ARRÊT

CADRAN DE

THERMOSTAT

Fig. 3

Page 28

FONCTIONNEMENT

!

AVERTISSEMENT :

prudence lors de son utilisation, nettoyage ou entretien.

AVANT UNE PREMIÈRE UTILISATION

Plaques à frire : Avant d’utiliser votre plaque à frire, enlever complètement la couche de

La plaque à frire ne requiert aucune préparation ou apprêtage.

SUGGESTIONS D’UTILISATION

Four conventionnel : Si vous possédez un four conventionnel, vous pouvez utiliser vos recettes

Four à air pulsé : Le four à air pulsé peut faire la même chose qu’un four régulier, mais en consommant

Vérifier le produit lorsqu’il est rendu au milieu de son temps de cuisson.

Des tôles placées de niveau permettent une cuisson plus égale alors que des tôles gauchies

donnent de mauvais résultats.

La cuisinière et ses composants sont chauds. Exercer une extrême

protection appliquée à l’usine à l’aide d’un produit de dégraissage commercial.

Après un nettoyage en profondeur, appliquer une huile à frire sans sel, à

haute température, et vous êtes maintenant prêt à utiliser votre plaque à frire.

normales de cuisson et de températures.

moins d’énergie. Le four préchauffe les aliments plus rapidement et réduit le

temps de cuisson, les réglages de température et le flétrissement.

Normalement, on réduit la température de 10 °C (25 °F) comparativement aux

recettes conventionnelles.

— 11 —

Page 29

NETTOYAGE

!

Couper l’alimentation en gaz de l’appareil.

AVERTISSEMENT :

!

Débrancher l’alimentation électrique et suivre les procédures de

AVERTISSEMENT :

verrouillage et d’étiquetage.

Brûleurs découverts

Nettoyage quotidien

Enlever les grilles et nettoyer en dessous et autour des brûleurs découverts.

1. Nettoyer la lèchefrite inférieure. Pour l’enlever, passer la main en dessous et soulever l’arrière

d’environ 25 mm (1 po), la glisser ensuite d’environ 13 mm (1/2 po) vers l’arrière, et laisser tomber

l’extrémité avant. La glisser vers l’avant entre les pattes avant. Pour la remettre en place,

procéder selon l’ordre inverse.

Nettoyage hebdomadaire

1. Nettoyer chaque brûleur à fond. Nettoyer les surfaces en acier inoxydable et chromées à l’aide

d’un chiffon humide et les polir ensuite à l’aide d’un chiffon doux et sec. On peut aussi utiliser

un détergent. Pour enlever les taches de décoloration, utiliser un nettoyant non abrasif, toujours

en frottant dans le sens du grain du métal.

2.. Garder les ouvertures de l’obturateur d’air des brûleurs propres.

3. Nettoyer les orifices des brûleurs principaux à fond. Garder le venturi exempt de graisse et de

charpie. Pour nettoyer les brûleurs, les laver au lave-vaisselle. Incliner l’obturateur d’air pour

faire sécher à l’air. NE PAS insérer de cure-dents dans les orifices du brûleur.

Plaque à frire

Vider la graisse à tous les jours. Nettoyer la plaque à frire régulièrement.

MAINTENIR LA SURFACE DE LA PLAQUE À FRIRE PROPRE. Pour obtenir une cuisson uniforme

et des produits parfaitement dorés, ne jamais laisser de la graisse carbonisée sur une plaque. Elle

nuit au transfert de la chaleur de la plaque à la surface des aliments, en ne les brunissant que partiellement

et en réduisant la qualité de cuisson. Pire encore, la graisse carbonisée a tendance à adhérer aux

aliments cuits sur la plaque, leur donnant une apparence peu appétissante.

Pour garder la plaque à frire propre, suivre les directives suivantes :

Après chaque usage

Nettoyer la plaque à frire à l’aide d’une brosse métallique ou d’une spatule flexible.

Nettoyage quotidien

1. Nettoyer à fond le dosseret, les côtés et le devant de la cuisinière. Enlever et vider le tiroir de

propreté pour le laver de la même manière qu’un ustensile de cuisson ordinaire.

2. Nettoyer à fond la surface de la plaque. Au besoin, utiliser une pierre pour plaque à frire, une

brosse métallique ou une laine d’acier inoxydable. La frotter dans le sens du grain de métal pendant

qu’elle est encore chaude. Pour faciliter la tâche, utiliser du détergent. Toutefois, il est

important qu’aucune trace du détergent ne demeure sur la surface.

3. Nettoyer les surfaces en acier inoxydable à l’aide d’un chiffon humide et les polir ensuite à l’aide

d’un chiffon doux et sec. Enlever les taches de décoloration à l’aide d’un nettoyant non abrasif.

— 12 —

Page 30

Revêtement extérieur

Nettoyage quotidien

Nettoyer le revêtement extérieur avec une solution d’eau savonneuse douce ou un produit pour

dissoudre la graisse.

Surfaces de cuisson

Nettoyage quotidien

1. Essuyer la surface de cuisson pendant qu’elle est encore chaude à l’aide d’un chiffon doux.

2. Nettoyer la lèchefrite sous les brûleurs.

Nettoyage hebdomadaire

Faire bouillir les plaques à frire et les brûleurs dans une solution d’eau et de soda.

Fours de cuisinière

Nettoyage quotidien

Nettoyer le four et la porte quotidiennement.

Ne pas utiliser de la poudre à récurer sur le revêtement. Elle s’enlève très difficilement et peut

s’accumuler, ce qui risque d’endommager le four et d’enlever le revêtement anti-corrosif.

ACIER INOXYDABLE

Suivre les indications qui suivent pour le nettoyage de l’acier inoxydable pour qu’il demeure

propre, brillant et étincelant.

Nettoyage général

Utiliser du savon ordinaire ou du détergent et de l’eau pour le nettoyage quotidien de l’acier

inoxydable. Pour éviter la présence de taches d’eau et de rayures, rincer l’appareil à fond à l’eau

chaude et l’essuyer à l’aide d’un chiffon sec, doux et propre. L’ajout d’agent de rinçage peut

également s’avérer efficace.

Empreintes de doigts

Les empreintes de doigts constituent parfois un problème sur les surfaces en acier inoxydable très

polies. Il est possible de minimiser leur formation au moyen d’un nettoyant qui laissera un léger

film d’huile et de cire.

Étendre ce type de nettoyant sur la surface et enlever l’excédent d’huile à l’aide d’un chiffon doux

et sec. Par la suite, les empreintes de doigts disparaîtront en les essuyant légèrement à l’aide

d’un chiffon doux ou d’un chiffon contenant une petite quantité du nettoyant. Si la surface est

particulièrement sale au départ, la laver d’abord à l’eau savonneuse ou au détergent.

Graisse et aliments brûlés

La graisse et les aliments brûlés s’enlèvent facilement à l’eau savonneuse.

— 13 —

Page 31

Précautions

Ne jamais utiliser une racle ordinaire pour enlever les dépôts tenaces de graisse ou d’huile sur

une surface en acier inoxydable. Des particules ou de l’acier ordinaire risquent de s’incruster ou

de se loger dans la surface en acier inoxydable, provoquant une légère formation de rouille et

possiblement la contamination des aliments. S’il est absolument nécessaire de gratter, utiliser des

outils pour acier inoxydable, en bois, en plastique ou en caoutchouc.

— 14 —

Page 32

ENTRETIEN

!

AVERTISSEMENT :

Couper l’alimentation en gaz de l’appareil

!

AVERTISSEMENT :

Couper l’alimentation électrique de l’appareil et suivre les procédures de

verrouillage et d’étiquetage.

LUBRIFICATION :

Toutes les pièces mobiles doivent être vérifiées et lubrifiées. Communiquer avec le service de

l’entretien autorisé le plus près.

Toutes les soupapes et commandes doivent être lubrifiées par un technicien Vulcan autorisé en

utilisant une graisse à température élevée.

Les moteurs des fours à air pulsé sont lubrifiés en permanence et ne requièrent aucun autre

entretien.

CONDUIT D’ÉVACUATION

Une fois par année, s’assurer que le conduit d’évacuation n’est pas obstrué.

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

Pour l’entretien de l’appareil ou pour obtenir des renseignements sur des pièces de rechange,

communiquer avec le service de l’entretien autorisé le plus près. Pour une liste complète de nos

succursales de service de l’entretien et de pièces autorisées, visiter notre site Web ou téléphoner

au 1 800 814-2028.

Lors d’une demande de service, fournir les renseignements suivants : le numéro de modèle, le

numéro de série, la date de fabrication et l’alimentation électrique.

— 15 —

Page 33

FOUR

DÉPANNAGE

PROBLÈME

Fond du produit trop chauffé

Cuisson inégale

Côtés brûlés

Dessus du produit trop chauffé

Cuisson inégale d’un côté à l’autre

Le produit gravite vers un côté de la tôle

Cuisson inégale d’avant en arrière

Produits déshydratés

Extinction de la veilleuse

Flétrissement excessif de la viande

CAUSES POSSIBLES

Entrée de chaleur insuffisante (Communiquer avec le service de

l’entretien).

Conduit d’évacuation trop actif (Communiquer avec le service

de l’entretien).

Température trop basse.

Mauvais fonctionnement.

Conduit de dérivation mal réglé (Communiquer avec le service

de l’entretien).

Pression de gaz instable (Communiquer avec le service de

l’entretien.

Température trop élevée.

Ventilation défectueuse (Communiquer avec le service de

l’entretien).

Entrée de chaleur excessive (Communiquer avec le service de

l’entretien).

Thermostat mal étalonné (Communiquer avec le service de

l’entretien).

Cuisinière mal nivelée d’un côté à l’autre.

Brûleur du four, sole et déflecteurs mal installés.

Tôles gauchies.

Four mal nivelé.

Conduit d’évacuation trop actif (Communiquer avec le service

de l’entretien.

Cuisinière mal nivelée d’avant en arrière.

Porte ne fermant pas bien.

Température trop basse.

Cuisson trop longue.

Thermostat mal étalonné (Communiquer avec le service de

l’entretien).

Alimentation en gaz insuffisante (Communiquer avec le service

de l’entretien).

Flamme de la veilleuse trop faible (Communiquer avec le

service de l’entretien).

Injecteur de la veilleuse obstrué (Communiquer avec le service

de l’entretien).

Soupape de sûreté défectueuse (Communiquer avec le service

de l’entretien).

MODÈLES MUNIS D’UN FOUR À AIR PULSÉ SEULEMENT :

Fuite dans l’enceinte de cuisson. (Communiquer avec le service

de l’entretien).

Joints d’étanchéité défectueux. (Communiquer avec le service

de l’entretien).

Tube du four à air pulsé obstrué.

Ventilateur fonctionnant en sens inverse. (Communiquer avec

le service de l’entretien).

Rôtissage à une température trop élevée

— 16 —

Page 34

BRÛLEURS DE LA SURFACE DE CUISSON

PROBLÈME CAUSES POSSIBLES

Mauvaise combustion du brûleur

Poignée de robinet excessivement chaude

Robinets de la surface de cuisson figés

Mauvais allumage

Mauvaise ventilation (Communiquer avec le service de

l’entretien).

Porte mal réglée (Communiquer avec le service de

l’entretien).

Porte du four restée ouverte.

Entrée de gaz insuffisante (Communiquer avec le

service de l’entretien).

Rapport air-gaz mal réglé (Communiquer avec le

service de l’entretien).

Injecteur de la veilleuse obstrué (Communiquer avec le

service de l’entretien).

Lumière d’allumage principale du brûleur obstruée

(Communiquer avec le service de l’entretien).

Robinet de commande obstrué (Communiquer avec le

service de l’entretien).

Injecteur de gaz obstrué (Communiquer avec le service

de l’entretien.

— 17 —

Page 35

F-37403 (02-08) IMPRIMÉ AUX É.-U.

— 18 —

Loading...

Loading...