Vulcan-Hart VRH8 ML-152020, VRH88 ML-152021, VRH8, ML-152020, VRH88 Installation & Operation Manual

...

INSTALLATION &

OPERATION MANUAL

VRH SERIES

OVENS

MODELS:

VRH8 ML-152020

VRH88 ML-152021

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN 3600 NORTH POINT BLVD.

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC BALTIMORE, MD 21222

www.vulcanequipment.com Vulcan ©2012 All Rights Reserved F-41207 (11-12)

VRH SERIES OVENS F-41207 (11-12)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD ST ARTUP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITYOF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment,

alteration, service, or maintenance can

cause property damage, injury, or death.

Read the installation, operating and

maintenance instructions thoroughly

before installing or servicing equipment.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE

1

VRH SERIES OVENS F-41207 (11-12)

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRINCIPLES OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BENEFITS OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

COMPARISON OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MECHANICAL CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BEFORE FIRST USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TESTING THE OVEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATING INSTRUCTIO NS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

EXTENDED SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

STAINLESS STEEL CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DOOR GASKET CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COOKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

COOKING RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

COOKING AND HOLDING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 – 14

RETHERMALIZATION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GRAMS – LBS./OZ. CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TEMPERATURES CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LOCKOUT / TAGOUT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SERVICE & PARTS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

VRH SERIES OVENS F-41207 (11-12)

GENERAL

INTRODUCTION

Vulcan Ovens are produced with quality

workmanship and material. Proper

installation, usage, and maintenance of

your oven will result in many years of

satisfactory performance.

The Vulcan Cook & Hold Oven is more

than just an oven – it’s a “System”;

precisely controlled heat, regulated to

retain ascorbic acid and maximize the

nutritional value, taste and eye-appeal

of food. In this environment, virtually

any food product can be prepared to

delicious perfection in just ONE oven!

“System” food preparation eliminates

the need for multiple ovens with

duplicate features.

This manual is provided to assist

persons responsible for the operation

and maintenance of the oven with a

simple, but comprehensive understanding of its proper use. We

recommend that you thoroughly read

this entire manual and carefully follow all

of the instructions provided prior to

placing the oven into operation.

As with any piece of food service

equipment, this oven system requires a

minimum of care and maintenance.

Recommended procedures are

contained in this manual and should

become a regular part of the operation

of the unit.

The Vulc an Cook & Hold Oven is the

right choice for low temperature food

preparation.

PRINCIPLES OF

COOK & HOLD OVENS

Vulcan Cook & Hold Ovens are

designed and perfected for cooking at a

lower temperature. The principles of

Low Temperature Cooking and Holding

can be summarized into several

objectives: increased product yields,

increased profits from increased

yields, increased moisture retention,

increased tenderization, and

consistency of doneness.

When the Vulcan Cook & Hold Oven

finishes the cooking cycle, it

automatically switches to the hold cycle.

Throughout this manual we recommend

holding temperatures such as 140⁰F

(60⁰C). This temperature refers to the

oven’s hold temperature setting and not

to the internal temperature of the food

being roasted. The internal product

temperature will run below the hold

temperature. (For example: roast beef

held at 140⁰F will be about 130⁰F

internally or medium rare.)

All meat products contain enzymes.

These enzymes perform the

important function of tenderizing the

meat when they reach temperatures

of 100⁰F (38⁰C) to 140⁰F (60⁰C). As

these enzymes are heated, they break

down the connective tissue that is

inherent in all red meat products.

The hold cycle allows this natural

tenderization process to proceed in an

orderly manner. As long as the internal

3

VRH SERIES OVENS F-41207 (11-12)

temperature of the meat does not

exceed 140⁰F, the process will continue.

Once the temperature reaches 140⁰F

the process will stop, because the

enzymes will be deactivated.

This tenderization process makes the

meat more flavorful. It is similar to aging

meat before it is sold. The longer the

hold, the higher degree of tenderization.

Each hour of holding is equal to one

day of aging.

BENEFITS OF

COOK & HOLD OVENS

Superior Results: Low temperature

roasting has been recognized as the

best method for preparing meat and

poultry because of increased

tenderness, more even roasting, and a

juicer product.

Increased Sales: You will attract more

customers and have more repeat

business because you are now

producing a superior product in your

market area. All of your products will be

unique, from prime rib and chicken to

BBQ ribs, pork roasts, and even bakery

items!

Reduced Energy Costs: It costs

significantly less to run a Vulcan Cook &

hold Oven instead of a conventional

oven. Also, in most areas, no exhaust

hood is needed.

Reduced Shrinkage of Product: You

can cut your percent of shrinkage from

25 to 30% down to 5 to 10%. This

means more servings to sell to your

customers! The Vulcan Cook & Hold

Oven can pay for itself in just months,

depending on your volume.

Reduced Labor Cost: Your cooks do

not have to come in early to put roasts

in or stay late to take them out of the

oven. Holding banquet foods in a

Vulcan Cook & Hold Oven reduces that

last minute party prep to almost nothing.

COMPARISON OF

COOK & HOLD OVENS

“The Comparison Stops Here” –

more than a catchy slogan, it’s a fact.

Convection ovens, unlike Vulcan Cook

& Hold Ovens, blast high temperature

dry air over the product. The end result

with convection oven cooking is

excessive and unnecessary shrinkage.

Vulcan Cook & Hold Oven Systems:

1. Offer a lifetime heating element

warranty.

2. Provide a natural roasted

brown, caramelized product

without coloring agents.

“You can taste the difference.”

3. Do not require a ventilation

hood. (See pg. 5)

4. Are accurate, plus or minus

5⁰F.

5. Are easy to clean.

6. Have stainless steel construction

inside and out.

4

VRH SERIES OVENS F-41207 (11-12)

INSTALLATION

Before installing, verify that the

electrical service agrees with the

specifications on the rating plate

located on the lower back corner of

the oven. (Fig. 4) If the supply and

equipment requirements do not agree,

do not proceed with unpacking and

installation. Contact your Vulcan

Customer Service Department

immediately.

UNPACKING:

The oven was inspected before leaving

the factory. The transportation company

assumes full responsibility for safe

delivery upon acceptance of the

shipment. Immediately after unpacking,

check for possible shipping damage to

the oven.

If the oven is found to be damaged,

save the packaging material and

contact the carrier within 15 days of

delivery.

Carefully unpack and place in a work

accessible area as near the installation

position as possible.

1. Open oven door(s) and remove

packing material.

2. Check under oven or separate

package for racks, pans, etc.

3. Peel off vinyl protection film from

oven.

CLEANING:

The oven should be thoroughly cleaned

prior to putting into service. Refer to

cleaning instructions in this manual.

LOCATION:

For efficient oven operation, choose a

location that will provide easy loading

and unloading without interfering with

the final assembly of food orders. The

installation location must allow adequate

clearances for servicing and proper

operation.

VRH88

The VRH88 oven is simply two (2)

VRH8 ovens stacked on top of each

other. One (1) oven will come with a

caster kit and a stacking assembly on

top. The oven without casters is

placed inside the stacking assembly.

VENTILATION HOOD

REQUIREMENTS

Some local State Codes require the use

of a ventilation hood for equipment

operating in excess of 250⁰F. Many will

allow operation of Rethermalization

Ovens at lower temperatures. Please

contact a Service Agency to modify this

parameter, if needed to meet local State

Codes.

5

VRH SERIES OVENS F-41207 (11-12)

ELECTRICAL REQUIREMENTS

ELECTRICAL CODES & STANDARDS:

The oven must be installed in

accordance with:

In the United States of America:

1. State and Local Codes.

2. National Electrical Code, ANSI/

NFPA-70 (latest edition.) Copies

may be obtained from: The

National Fire Protection

Association, 1Batterymarch Park,

Quincy, MA 02269.

1-617-770-3000 www.nfpa.org

In Canada:

1. Local Codes.

2. Canadian Electrical Code, CSA

C22.1 (latest edition.) Copies

may be obtained from: The

Canadian Standard Association.

www.csa.ca

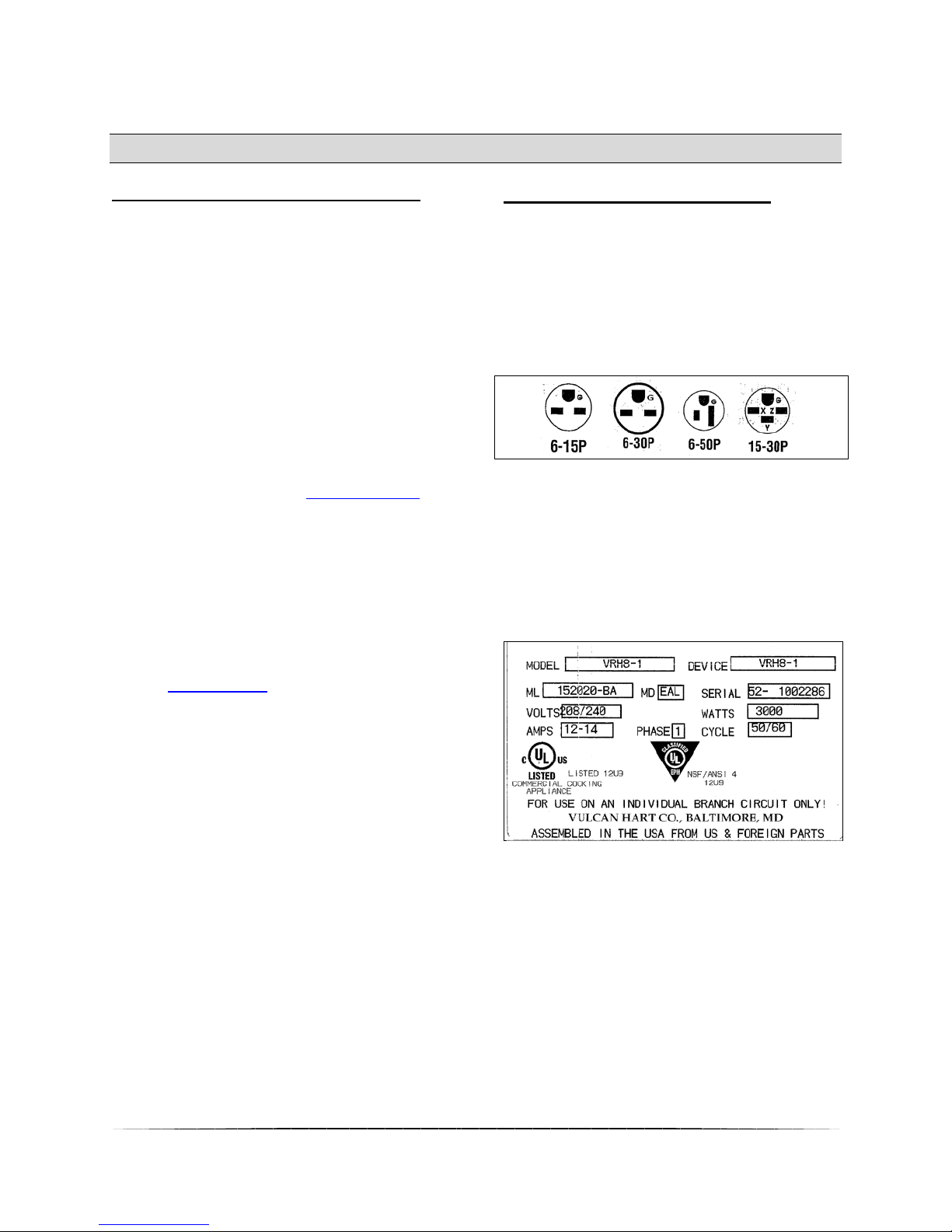

ELECTRICAL CONNECTIONS:

The oven is factory wired for single

phase 208/240 volt or three phase

operation. All ovens are equipped with

a 6 foot cord and NEMA 6-15, 6-30, 650, or a 15-30 plug as standard

equipment. (Fig. 3)

.

(Fig.3)

Refer to wiring diagrams and

Specification Chart in the back of this

manual.

The cord and plug supplied is a suitable

durable cord with a proper strain relief.

SERIAL DATA PLATE

(Fig. 4)

6

VRH SERIES OVENS F-41207 (11-12)

OPERATION

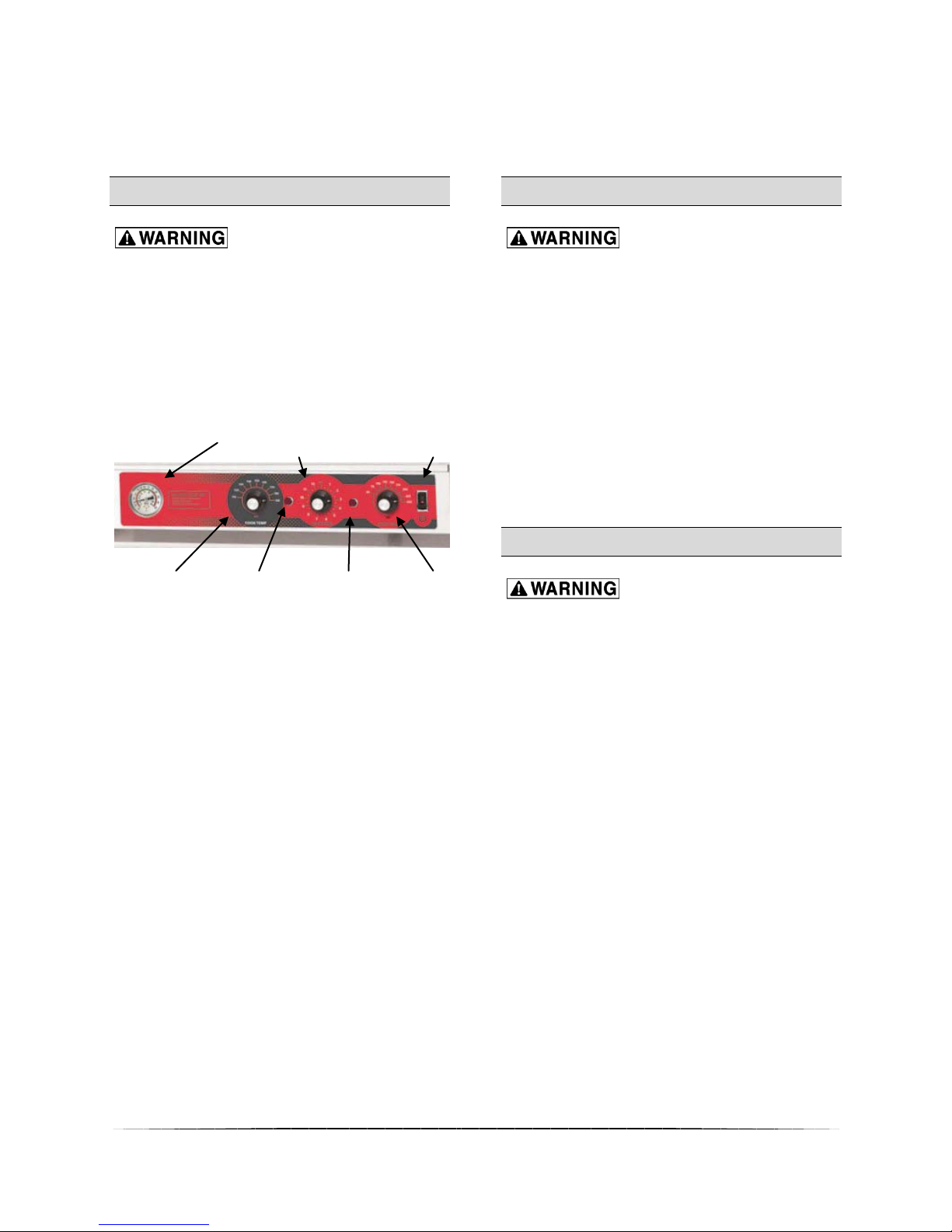

CONTROLS

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

All operating controls are located on the

front Control Panel(s). The oven is

supplied with individual operating

controls for each oven cav i ty.

POWER

THERMOMETER COOKING TIME ON / OFF

KNOB SWITCH

COOKING COOKING HOLDING HOLDING

TEMP. MODE MODE TEMP.

KNOB LIGHT LIGHT KNOB

Thermometer: Indicates the interior

temperature of the oven.

Cooking Time Knob: Sets the desired

cooking time from ½ hour to 12 hours.

Power ON/OFF Switch: Turns the

oven On or Off.

Cooking Temperature Knob: Sets the

desired cooking temperature.

Cooking Mode Light: Indicates oven is

in Cooking Mode.

Holding Mode Light: Indicates oven is

in Holding Mode.

Holding Temperature Knob: Sets t he

desired holding temperature.

BEFORE FIRST USE

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

1. Thoroughly clean the oven

before initial use. Please refer

to cleaning instructions in this

manual.

2. Test the oven to verify that the

oven operates normally. Please

refer to “Testing The Oven”

procedure in this manual.

TESTING THE OVEN

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

Before using the oven for the first time,

verify that the oven operates normally.

1. Check that the oven is connected

to the correct power source.

2. Set the COOKING TIME knob

to 0.

3. Turn the HOLDING TEMP ERATURE knob to 140⁰ F.

4. Set Power ON/OFF Switch to

ON position.

5. Check that the Oven Circulating

Fan(s) are running.

7

Loading...

Loading...