Page 1

SERVICE MANUAL

VL BOILER BASE SERIES

CONVECTION STEAMERS

(GAS, ELECTRIC, DIRE CT AND REGENERATED)

VL2GPS ML-52391 VL2DPS ML-52749

VL2GMS ML-52388 VL2DMS ML-52750

VL2GAS ML-52390 VL2DAS ML-52751

VL2GSS ML-52389 VL2DSS ML-52752

VL3GPS ML-52395 VL3DPS ML-52753

VL3GMS ML-52392 VL3DMS ML-52754

VL3GAS ML-52394 VL3DAS ML-52755

VL3GSS ML-52393 VL3DSS ML-52756

VL2EPS ML-52741 VL2RPS ML-52757

VL2GPS SHOWN

This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alifi ed. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this produc t, y ou should

read, in its entirety, th e repair procedure you wish to perform to

determine if you have the necessary tools, instruments a nd s k ills

required to perfo rm t he procedure. Procedures for which you do

not have th e n ecessary tools, instruments and skills should be

performed b y a t rained Vul can Service Technician.

VL2EMS ML-52742 VL2RMS ML-52758

VL2EAS ML-52743 VL2RAS ML-52759

VL2ESS ML-52744 VL2RSS ML-52760

VL3EPS ML-52745 VL3RPS ML-52761

VL3EMS ML-52746 VL3RMS ML-52762

VL3EAS ML-52747 VL3RAS ML-52763

VL3ESS ML-52748 VL3RSS ML-52764

- NOTICE -

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

Form 24650 (M ay 1999)

Page 2

VL SERIES STEAMERS

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

TABLE OF CONTENTS

GENERAL............................................................................. 4

Introduction ........................................................................ 4

Compartment Pan Capacity ........................................................ 4

Model Desi

Water Conditi onin

Tools ............................................................................. 5

Specifications ...................................................................... 5

Water Supply ................................................................... 5

Steam Supply ................................................................... 5

Gas Steamers .................................................................. 6

Electric Steamers................................................................ 6

Steamer Operation .................................................................. 7

Gas Powered Steam Boiler ........................................................ 7

Electrically Powered Steam Boiler ................................................... 7

Re

enerated Steam Powered Boiler .................................................. 7

Direct Steam Powered Cooker ...................................................... 8

Boiler B lowdown and Steamer Shut off ................................................ 8

Cookin

Component Func tion ................................................................ 11

Cabinet Base Boiler Controls ...................................................... 11

Cookin

nations .............................................................. 4

.................................................................. 4

Compartment Control s ..................................................... 8

Compartment Control s .................................................... 13

REMOVAL AND REPLACEMENT OF PARTS ................................................ 14

Component Locat ions ............................................................... 14

Water Level Controls - Low Level Cut off and Differ ential .................................... 17

Water Level Gau

Cyclin

Boiler Assembly.................................................................... 18

Hi

Boiler Fill and Cold W ater Condenser Solenoid Valves ...................................... 19

Pilot and Thermocoupl e A ssembly (Gas Models) ........................................... 19

Gas Combinat ion Control Valve ........................................................ 19

Compartm ent Gasket and Door Screw Nut, Door and Bushin

Heater Contactor s .................................................................. 21

Heatin

Re

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 22

Boiler............................................................................ 22

Water Level Control(s) T est ........................................................... 24

Cyclin

Fill and Cold Wat er S olenoid Valves .................................................... 26

Compartment Pressure Adjustment ..................................................... 26

Hi

Boiler Not Fillin

Boiler B lowdown Drain Solenoid Valve .................................................. 27

Boiler Slow to Pressurize............................................................. 28

Inlet Water Strainer ................................................................. 29

Pilot and Thermocoupl e A ssembly (Gas Models) ........................................... 29

Gas Burners....................................................................... 31

Automatic I

Gas Manifold Pressure Adjustment ..................................................... 33

and High Limit Pressure Switches

(Gas and Electr ic Models) ........................................................ 17

h Limit Thermostat ............................................................... 18

Elements .................................................................. 21

enerated Steam Models (Steam Coil) ................................................ 21

Inspection..................................................................... 22

Clean-out (All Boiler Models) ...................................................... 22

Delimin

Descaler...................................................................... 23

and High Limit Pressure Switches

(Gas and Electr ic Models) ........................................................ 25

h Limit Thermostat ............................................................... 27

Air Shutter Adjustment ........................................................... 31

Inspection..................................................................... 31

e Assembly ......................................................... 17

s ............................... 20

Only (Models with Deliming Port Assembly).................................... 23

with Water ........................................................... 27

nition S y stems (Gas Models) ................................................ 31

Page 2 of 88

Page 3

VL SERIES STEAMERS

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

Direct Steam Models ................................................................ 34

enerated Steam (Older Models) ..................................................... 34

Re

Heater Contactor s .................................................................. 34

Heatin

Elements .................................................................. 34

Thermal Switch - Prevent and Aut omatic M odels ........................................... 36

Water Level Gau

e Assembly ......................................................... 36

Steam Gate Valve(s) ................................................................ 37

ELECTRICAL OPERATION .............................................................. 38

Water Level Controls ................................................................ 38

Solid State - Low Level Cut-off & Differential Contr ol .................................... 38

Electro M ec hanical - Low Level Cut-off & Differential Control .............................. 40

Sequence of O per ation .............................................................. 42

Gas Models ................................................................... 42

Electric Models ................................................................. 45

Schematics, Gas Steam er s, B oiler Controls

VL2G AND VL3G - P r event, A utomati c , Standard and Manual ............................. 49

Manual I

Electronic I

Manual I

Electronic I

Wi ri n

Diagrams, Gas Steamers, Boiler Controls

nition, Standard Controls .............................................. 49

nition, Standard Controls ............................................ 50

nition, Csd-1 Code Controls ............................................ 51

nition, Csd-1 Code Controls .......................................... 52

VL2G AND VL3G - P r event, A utomati c , Standard and Manual ............................. 54

Manual I

Electronic I

Manual I

Electronic I

nition, Standard Controls .............................................. 54

nition, Standard Controls ............................................ 56

nition, Csd-1 Code Controls ............................................ 58

nition, Csd-1 Code Controls .......................................... 60

Schematics, Elect r ic Steam er s, B oiler Controls

VL2E AND VL3E - Prevent, A utomati c , Standard and Manual ............................. 62

Auto Blowdown, Standard Cont r ols .............................................. 62

Auto Blowdown, Cal-code Controls .............................................. 63

Wi ri n

Diagrams, El ec tric Steamers, Boiler Controls

VL2E AND VL3E - Prevent, A utomati c , Standard and Manual ............................. 64

Auto Blowdown, Standard Cont r ols (Contactor - 1 Std.) .............................. 64

Auto Blowdown, Standard Cont r ols (Contactors - 2 Std.) .............................. 66

Manual Blowdown, Cal-c ode Controls (Contactor s - 1 Std. 1 Aux. ) ...................... 68

Auto Blowdown, Cal-code Controls ( Contactor s - 1 Std. 1 Aux. ) ........................ 70

Auto Blowdown, Cal-code Controls (Contactor s - 2 Std. 2 Aux. ) ........................ 72

Manual Blowdown, Cal-c ode Controls (Contactor s - 2 Std. 2 Aux. ) ...................... 74

Wi ri n

Diagrams, El ec tric Heater Circuits

VL2E AND VL3E - Prevent, A utomati c , Standard and Manual ............................. 76

Schematic and Wirin

Diagrams, Dir ec t Steamers, Cabinet Base

VL2D AND VL3D - Prevent, Automati c , Standard and Manual ............................. 77

Wi ri n

Diagrams, Regenerated Steamers, Boiler Controls

VL2R AND VL3R - Prevent, Automati c , Standard and Manual ............................. 78

Schematic and Wirin

Diagrams - Compar tment Contr ols .................................... 80

Prevent ...................................................................... 80

Automatic..................................................................... 81

Standard ..................................................................... 82

Manual ....................................................................... 83

TROUBLESHOOTING .................................................................. 84

© VULCAN 1999

Page 3 of 88

Page 4

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

GENERAL

INTRODUCTION

Steam Cooking

e capacity pr essure steam er s offer an efficient

Lar

way to produce a wide v ar iety of foods in smal l

portions or lar

cook fresh foods, blanch foods for com plete cookin

later or will steam defrost and cook froz en foods.

Cookin

maximum c olor, f lavor and nutriti onal value with the

least expenditure of ener

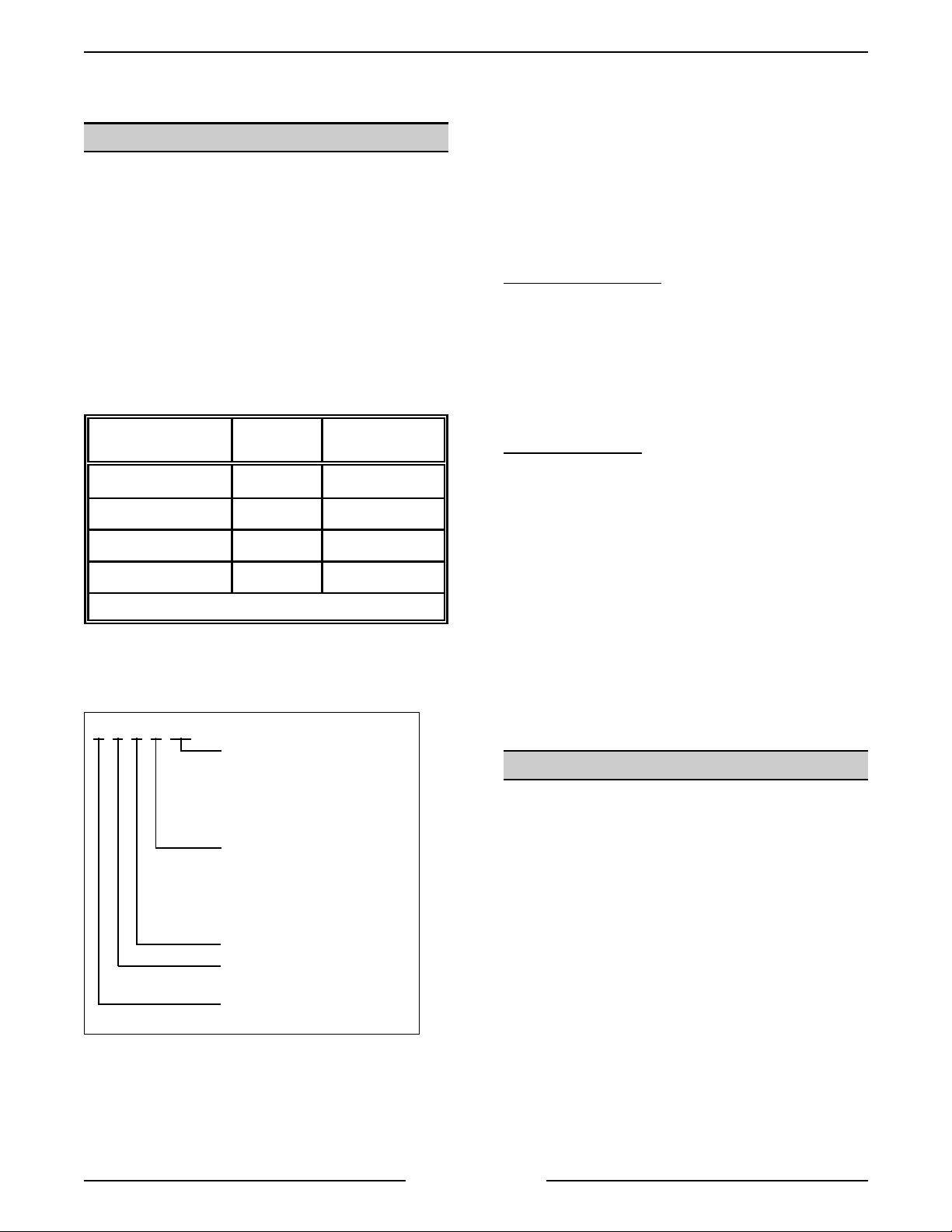

Compartment P an Capacity

PANS PER

COMPARTMENT

* Remove center support for 18x20 i nc h pans

er batches. Steamers can be used to

with steam assures the food will retain its

y and labor.

SIZE

4 12" x 20" 6.0

6 12" x 20" 4.0

8 12" x 20" 2.5

6 *18" x 20" 1.0

DEPTH

(INCHES)

Boiler Code Descriptions

Vulcan-Hart incorporates redundant controls in

compliance with Californi a Code ( Cal-Code) and

CSD-1 as an option on steam equipment when

required by state and/or local buildin

requirem ents. Descriptions of the codes are li sted

below.

Cal-Code Construction

electrical safet y c ircuits that, if tripped, must

manually be reset aft er the conditi on c ausi n

subsides. These controls consist of one dual

function water level cyclin

control and one sin

off control (A ux - LLCO) and a hi

switch in conjunc tion with a m ec hanical pressure

relief valve.

CSD-1 Constructi on

electrical safet y c ircuits that, if tripped, must

manually be reset aft er the conditi on c ausi n

subsides. These controls consist of one dual

function water level cyclin

control and one sin

off control (LLCO) and a hi

in conjunction with a m ec hanical pressure relief

valve. A dditional ly, both circuits have individual

indicator li

verifi c ation of the shutdown mode.

hts that will illuminate for a visual

- Redundant controls in the

and low level cut off

le function low water level cut-

- Redundant controls in the

and low level cut off

le function low water level cut-

h pressure relief switch

code

the trip

h pressure relief

the trip

Model Designations

L X X XX

V

Cooking Control Ty pes:

PS - Prevent Steam

AS - Automatic Steam

SS - Standard Steam

MS - Manual Steam

Heatin

G - Gas

E - Electric

D - Direct

R - Re

Number of Compartments

Lar

Steamer

Vulcan

System:

enerated

e Capacity Pr essure

Cal-Code and CSD-1 construc tion both requi r e

operator int er vention in the event of a shutdown.

CSD-1 is more informative by usin

to show which safety system was shutdown.

indicator lights

WATER CONDITIONING

Furnishing the boiler with soft water to reduc e scale

formation is important. Scale formation will reduce

steam output, cause premature component f ailure,

and shorten equipment life. Most water supplies

contain scale pr oduc in

and Ma

minerals remain and dissolve i nto the water. As the

concentration of these m inerals increases past a

certain point, they prec ipitate from the water and

coat the insi de of the boiler, heati n

thermostat bulbs and water lev el probes. Because of

the hi

precipitated mi ner als bake onto them and bec ome

very difficult t o rem ove.

nesium. As steam is generated, the

h temperat ur e of these surfaces, the

minerals such as Calcium

element s,

Page 4 of 88

Page 5

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

This causes several pr oblems:

1. Reduce the heat transfer effici enc y of the

heatin

syste m.

2. Cause premature failure of Electric heaters.

3. Water level probes will

ive false readings.

4. Thermostat bulbs will sense temperature

incorrectly.

These problems are common to any manufacturer's

steamer re

prevented by furnishin

ardless of design, but they can all be

the boiler with soft water.

Vulcan recommends the water contain less than

60ppm of “ total dissolved solids” (TDS) and hav e a

PH fact or between 7 to 8. These water properties

can be achieved by usin

a properly maintained

water softener.

Other chemical proper ties in water supplies can also

affect

ood steam generation and vary from within

each state and locality.

The water level probes in t he boiler use ions in t he

water to detect the water level. Do not use

fully

demineralized or de-ionized water since i t is "non

conductive" and the water level can not be detected.

NOTE: The use of strainers, or filters will not

remove mi ner als from the water.

Vulcan recommends that a local water treat ment

specialist be consulted before t he installat ion of any

steam

Steamers that operate over a lon

enerating equipment .

period of time

without the benefit of a water softener, whic h have

developed a heavy scale build up, shoul d be

cleaned bef or e usi n

a water softener.

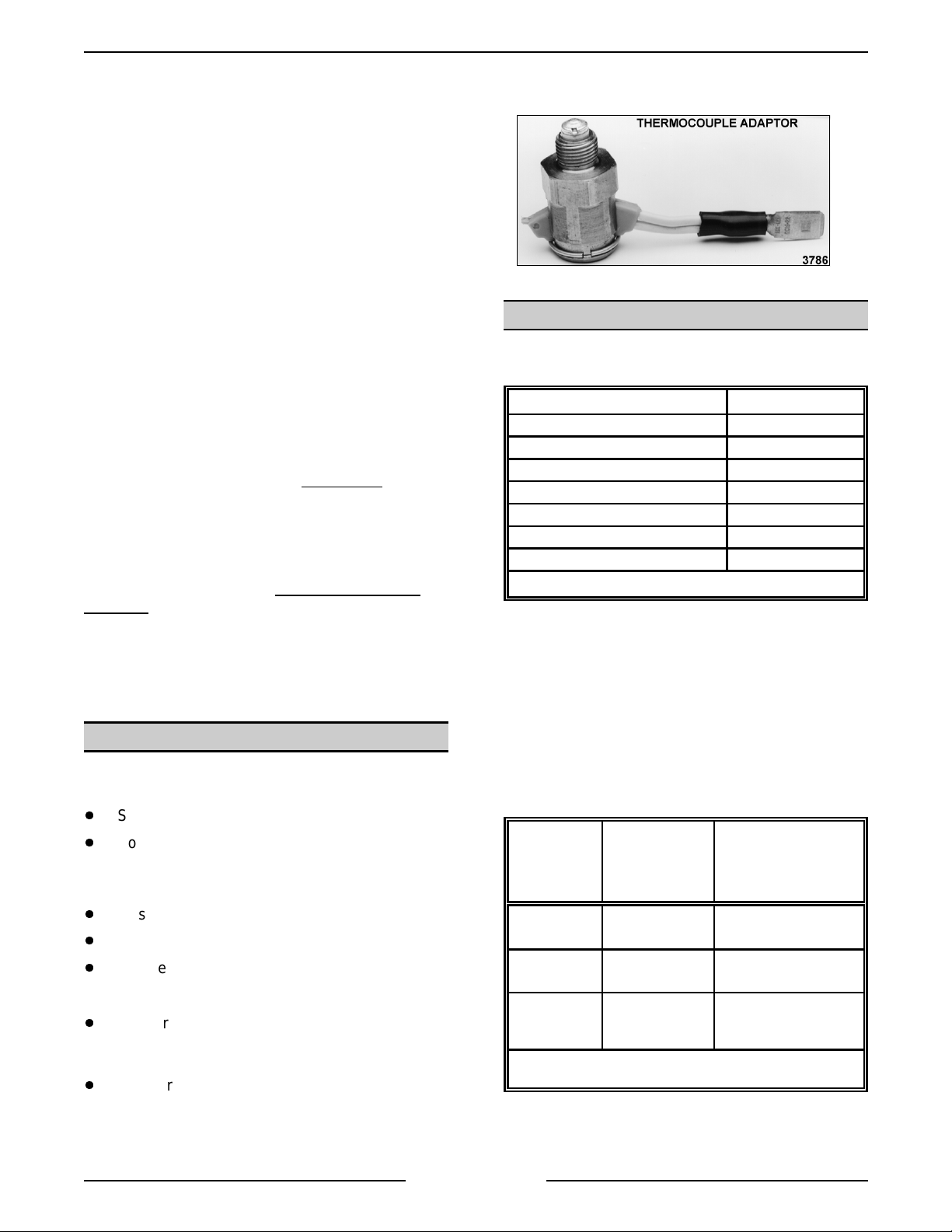

TOOLS

Standard

NOTE: A daptors vary between manufact ur er s. A n

example of one adaptor type is pictur ed below.

SPECIFICATIONS

Water Supply

Supply pressure should be 20-80 psi

In line str ainer for suppl y line (Not Supplied)

Supply connect ion cold

Total dissolved solids (TDS)* less than 60 ppm

Total alkalinity less than 20 ppm

Silica less than 13 ppm

Chloride less than 30 ppm

PH factor 7 to 8

(*17.1 ppm = 1

Steam Supply

Dry steam must be provided to the steam er for

suitable use. If the steam is heavy wit h c ondensate,

a Ball F loat Trap must be used in the li ne and

plumbed in before the pr essure reducin

ensure rapid heat up of heavy c old loads, the steam

supply line must be sized to maintain pr essure as

outlined below.

rain of har dness)

valv e. To

Standard set of hand tools.

Volt-Ohm-Meter (VOM) with AC current tester.

(Any quali ty VOM with a sensitivity of at least

20,000 ohms per volt can be used)

Gas leak checkin

Gas pressure manometer

Temperat ur e meter and thermocouple.

equipment .

Special

CLR Treatm ent Kit - Used to remov e

Calcium/Lime/Rust from a boiler ( Contact

Vulcan Author ized Service Centers ).

Adaptor to test thermocoupl e c losed circuit

es (DC) on gas models with m anual

volta

nition ( pur c hase l oc ally).

i

DIRECT STEAM

STEAMERS

(POTABLE)

Supply

Pressure Input

Flow Rate 50 lb. per hour per

Pressure

Reducing Valve

Output

*Potable stea m is no t required for regene rated models but could

be used.

15 psi (min.) 15 psi (min.)

compartment

10 psi (furnished) set accordingly for good

REGENERATED

STEAMERS OLDER MODELS

(*NON-POTABLE)

125 lb. per hour

steam generation (1012psi)

Page 5 of 88

Page 6

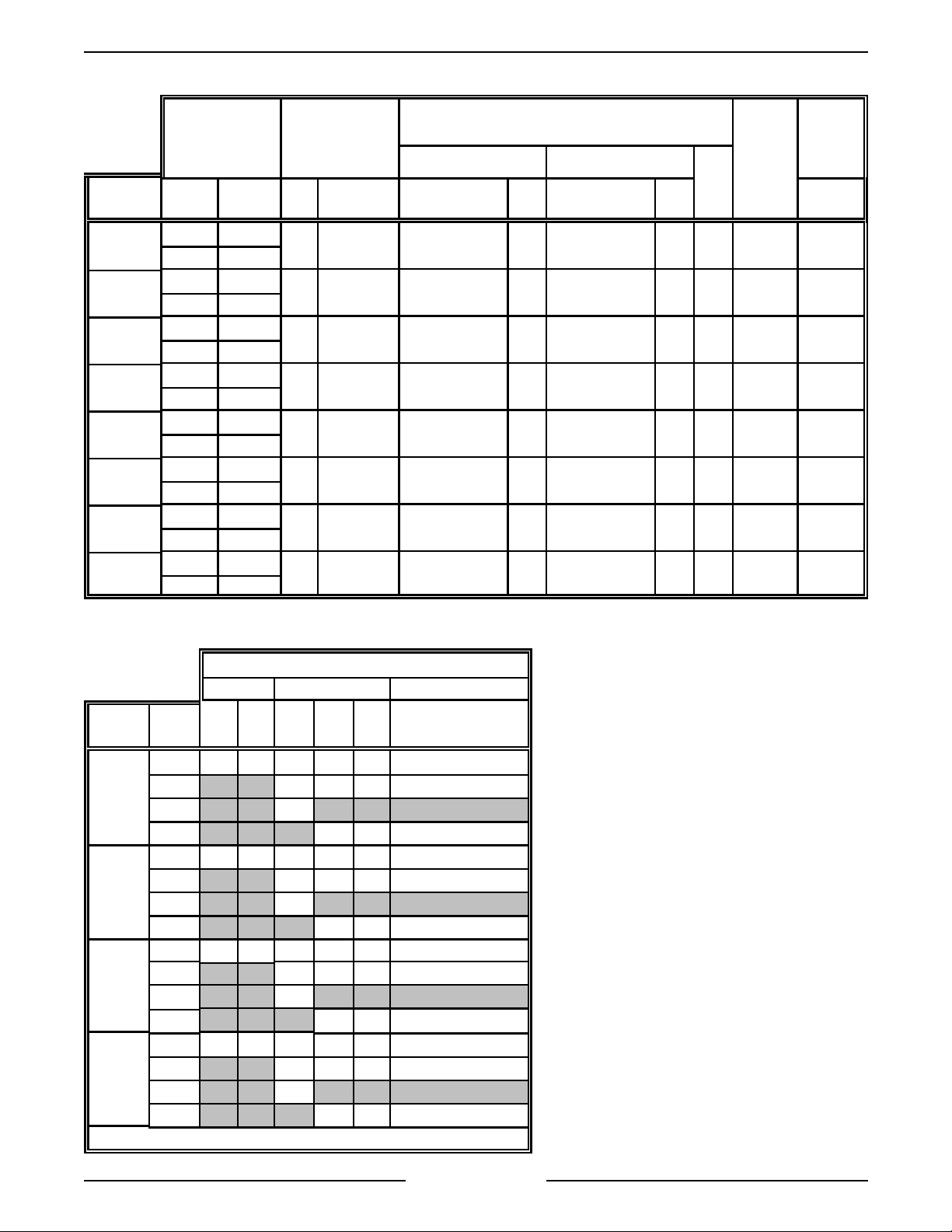

Gas Steamers

VL SERIES STEAMERS - GENERAL

INPUT

(BTU/HR)

MODEL NAT. PROP. NAT. PROP. RECOMMEND MIN RECOMMEND MIN

VL2GPS

VL2GMS

VL2GAS

VL2GSS

VL3GPS

VL3GMS

VL3GAS

VL3GSS

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

200,000 200,000

240,000 240,000

MANIFOLD

PRESSURE

(INCHES W.C.)

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

4.0 10.0 7.0 5.0 11.0 11.0 14.0 360 3.0

NATURAL PROPANE

LINE PRESSURE

(INCHES W.C.)

MAX

LOAD

(WATTS)

AMPS

(MAX)

120V

60HZ

Electric Steamers

MODEL

VL2EPS

VL2EMS

VL2ESS

VL2EAS

*std

TOTAL

KW

24* 116 100 67 58 29 34

36 100 87 44 50

42 117

48 116 58 67

24* 116 100 67 58 29 34

36 100 87 44 50

42 117

48 116 58 67

24* 116 100 67 58 29 34

36 100 87 44 50

42 117

48 116 58 67

24* 116 100 67 58 29 34

36 100 87 44 50

42 117

48 116 58 67

AMPERAGE

1 PHASE 3 PHASE 3 PHASE - 4 WIRE

208V 240V 208V 240V 480V 220/380V & 240/415V

Page 6 of 88

Page 7

VL SERIES STEAMERS - GENERAL

g

g

g

gauge g

gauge g

gauge g

gaug

g

g

g

g

g

g

g

g

g

g

g

gaug

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

gaug

g

g

g

g

g

g

gauge g

gaug

g

gaug

g

g

gaug

g

g

g

g

STEAMER OPERATION

Ensure that all utility connections to the steamer

have been made and are turned on.

On model s that are CSD-1 equipped, amber colored

hts for hi pr essure and low water level will

li

illuminate and stay on until the boiler is full and the

manual reset switc h pr essed.

Gas Powered S t eam Boiler

5. Open the cabinet door and turn main power

switch ON. The red li

will be

solenoid valve will close. The boiler should fill,

in four to eleven minut es. Observe water l evel

that the l evel in the

full. Both valves on

be open to fill the

equipped with a m anual “ball” type blowdown

valve must be closed for the boiler to fill. The

cyclin

steam pressure in the boiler by cyclin

heatin

pressure.

A.

B.

in filling the boiler and the blowdown

lass to verify that water is in boiler and

pressure switch will m aintain the proper

system on and off to generate steam

On Models with Manual Ignition

knob on the

has three positions (On- P ilot-O ff) for

control of mai n bur ner s and pi lot. Turn

knob on

then depress and li

lit taper. Maint ain knob in depressed

position for about 30 seconds and release.

Observe that pilot burner flame stays on. If

the flame should

before reli

Turn knob on

valv e to ON. If the water level in the boiler

has reached the mi nimum level, burners

will i

the boiler . After appr oxim ately 15 minutes,

steam should be present for cookin

product. Observe that the boiler pressure

psi for models with a pressure re

valve or 4- 6 psi for models without the

valve.

On Models with Automatic Ignition

The knob on the

valve has two positions (On-Of f) f or

control of mai n bur ner s and pi lot. For the

automatic i

knob must be set in the ON position or

for the pilot and main burners will not flow.

as combination valve to PILOT

nite and begin to heat t he water in

e indicat es steam pressure of 9-11

ht will illuminate, water

lass is about half

lass a ssembly must

e. Older models

the

- The

as combination control valve

ht pilot burner with a

o out, wait 5 minutes

hting.

as combination control

ulatin

-

as combination control

nition system to work, the

as

Also, the i

ON/OFF/RESET swit ch must be in the ON

position to oper ate. This switch i s l oc ated

on the upper left side of the electrical

control box for t he i

A red li

is in the ON position. DO NOT ATTEMPT

TO MANUALLY LIGHT THE PILOT IN AN

AUTOMATIC TYPE IGNITION SYSTEM.

After the main power switch i s tur ned ON

and the i

switch is in the O N posi tion, sparkin

in three seconds later to light the

be

standin

sent back throu

indicat in

sparkin

boiler has reached t he minimum l evel, the

burners will i

water in the boiler. After approximately 15

minut es, steam should be present f or

cookin

pressure

pressure of 9-11 psi for models with a

pressure re

models without the valve. If a pilot flame

is not establi shed i mmedi ately, sparki n

will continue f or 90 seconds. After that

duration, the i

lock out and needs to be reset to start the

pilot and bur ner li

Electrically Powered St eam Boiler

Open the cabinet door and turn main power switch

ON. The red li

the boiler and the blowdown solenoid valve

fillin

will close. The boiler should fill, in approximately 11

minut es. Observe water l evel

that water is in boiler and that the level in the

lass is about half full. Both valves on gauge glass

assembly must be open to fill the

models equipped with a manual “ball” type

blowdown valve must be closed for the boiler to fill.

If t he water level in the boi ler has reached the

minimum level, the heater c ontactors will close, the

heaters will ener

the boiler . After appr oxim ately 15 minutes, steam

should be present for c ook in

the boiler pr essure

of 9-11 psi for models with a pressure re

valve or 4- 6 psi for models without the valve.

Regenerated St eam P owered Boiler

Open the cabinet door and turn main power switch

ON. The pilot li

the boiler and the blowdown solenoid valve

fillin

will close. Models equipped with a manual “ball

type” blowdown valve need to be closed for the

boiler to fill. The boiler should fill, in approximately

15 minut es.

nition c ontrol module

nition c ontrol module.

ht will illuminate when the switch

nition cont rol modules RESET

will

pilot. If the pilot lights, a signal is

h the ignition c able

the presence of pilot flame and

stops. If the water level in the

nite and begin to heat t he

product. Observe that the boiler

e indicat es a steam

ulating valve or 4- 6 psi for

nition c ontrol module will

hting cycle again.

ht will illuminate, water will begin

lass to verif y

e. Older

ize and begin to heat t he water in

product. Observe that

e indicat es steam pressure

ulatin

ht will illuminate, water will begin

e

Page 7 of 88

Page 8

VL SERIES STEAMERS - GENERAL

gauge g

gauge g

gauge g

gaug

g

g

g

g

g

g

gaug

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

Observe water level

is in boiler and that the level in the

lass to verify that water

lass is

about half full.

Both valves on the

open to fill the

e. When the water reaches the

lass a ssembly must be

minimum level, the steam sol enoid valve will open,

allowin

exchan

steam to enter the steam coil in the heat

er tank and begin heating the water. After

approximately 20 minutes, a suffic ient amount of

pressurized steam should be present for cooki n

product.

Direct Steam Powered Cooker

1. Open the cabinet door and turn main power

switch ON.

A. The red li

ht on the switch will illuminate.

B. If steam pr essure is above the m inimum

settin

on the cooking compartment

pressure switch then the switch will close,

ready li

ht will come ON and power to the

other controls will be supplied.

C. Observ e that the steam pr essure

e in

the cabinet base, indicates 10-12 psi.

2. Steamer is ready to cook product .

Boiler Blowdown and Steamer Shut off

Turn the steam er off at least once daily and blow

down the boiler to r emov e sedi ments, scalants and

lime build-up in the boiler . Always blowdown the

boiler when it is under maximum pr essure and no

steam is bein

used.

3. Automatic blowdown.

A. Newer Models

- Open the cabi net door

and turn main power switch OFF. The

switches’ red li

ht will go out, the

blowdown/drain solenoid valve will be de-

ized and the boi ler will begin to

ener

drain. The c old water condenser solenoid

will continue to operat e, as needed, to

condense steam and to cool the water

oing into the drain.

B. Older Models

- Turn power switch OFF

and depress blowdown timer button.

Blowdown timer will operate for 4 minutes.

At the end of blowdown, turn fill switch ON

and allow boil er to fill.

4. Manual blowdown.

A. A ll Models

- Turn power switch OFF. Open

blowdown valve located on the bottom

front of the cabi net base. After the boiler

has completely drained, c lose blowdown

valve and t ur n fill switch to ON and allow

boiler to fill.

Cooking Compartment Controls

Close the compar tment door and t ur n the screw

handle clock wise

until the gasket touches the

compartment surfac e then ½ turn f ur ther to

adequately seal t he c ompartm ent. If steam leaks

occur after compart ment heat up and pressurization,

turn handle clockwise

again to inc r ease the seal in

force unt il the l eak stops.

Proceed to the cook in

compartment control

instructions that apply to the steamer in use.

1. Manual

A. S et the manual timer to the desired

cookin

tim e. If preheating is desired,

allow five to ten mi nutes (recomm ended)

of additional time at t he be

cook cycle. The len

th of time will v ary

inning of the

with the type, si z e, temperat ur e and

conditi on ( frozen or thawed) of the product

and must be determined f r om experience.

Pull t he steam control ar m handle forward

and lock it by pullin

This closes the steam exhaust

and opens the steam inlet

allowin

Durin

steam to enter the compartment.

preheat, cool er air and condensate

the handle down.

ate v alve

ate v alve,

are exhausted from the compartm ent

h the steam tr ap ( c ondenser) until

throu

the temper ature reaches 180°F, closin

the internal bellows. Throughout the

cookin

cycle, the compartment pressure

should be 6 psi if equipped with a

compartment pressure re

ulating valve.

On model s without the compartment

pressure re

ulating valv e, the

compartment pressure cycles with the

boiler pressure between 4 and 6 psi.

B. When the timer bell rin

s to signal the end

of a cook cycle, turn it OFF. Lift the steam

control arm handle to unlatch team c ontrol

arm. An internal sprin

will automatically

pull the ar m to the rear. This closes the

steam inlet

steam exhaust

ate v alve and opens the

ate v alve, allowing steam

and pressure to exit the compartment.

C. W ait approximately 30 seconds for the

steam to exhaust from the compartment

and to depressurize. Tur n the screw

handle on the compartment door

countercloc k wise

er seals against the compartment

lon

surface. After the remainin

until the gasket no

steam

escapes, move the latch paddle to the left

and open the door.

Page 8 of 88

Page 9

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

2. Standard

A. S et the timer to the desired c ook in

The timer must be set past five minutes to

e the state of the tim er c ontrol micro

chan

switch contacts. I f preheati n

is desired,

allow five to ten mi nutes (recomm ended)

of additional time at t he be

cook cycle. The len

th of time will v ary

inning of the

with the type, si z e, temperat ur e and

conditi on ( frozen or thawed) of the product

and must be determined f r om experience.

B. P ull the steam control arm handle forward

and lock it by pullin

the handle down.

This closes the steam exhaust

and opens the steam inlet

allowin

steam to enter the compartment.

ate v alve,

C. Press the compart ment power switch to

ize the timer and red light. The

ener

balance of the cookin

automatic. Durin

sequence is

preheat, cool er air and

condensate are exhausted from the

compartment throu

h the steam tr ap

(condenser) until the temper ature reaches

180°F, closin

Throu

hout the cooki ng cycle, the

the internal bellows.

compartment pressure should be 6 psi if

equipped with a compartment pr essure

ulating valve. On models without the

re

compartment pressure re

ulating valve,

the compartment pressure cycles with the

boiler pressure between 4 and 6 psi.

D. Approximatel y one minute before timer

reaches zero the steam c ontrol solenoid is

ized to unl atch the steam control

ener

arm. An internal sprin

will automatically

pull the ar m to the rear. This closes the

steam inlet

steam exhaust

ate v alve and opens the

ate v alve, allowing steam

and pressure to exit the compartment.

When the tim er r eac hes "0" the red li

shuts off and a buz z er sounds indicatin

the end of the cook cycle. Turn the

compartment power swi tch OFF to silence

the buzzer and remove power from the

compartment controls.

E. Turn the screw handle on the

compartment door counter c lockwise

asket no longer seals against the

the

compartment surfac e. After the remainin

steam escapes, move the l atch paddle to

the left and open the door.

time.

ate v alve

ht

until

3. Automatic

A. S et the timer to the desired c ook in

The timer must be set past five minutes to

e the state of the tim er c ontrol

chan

micro switch contacts.

B. P ull the steam control arm handle forward

and lock it by pullin

the handle down.

This closes the steam exhaust

and opens the steam inlet

allowin

steam to enter the compartment.

ate v alve,

C. Press the compart ment power switch to

supply power to the com par tment cont r ols.

The automatic com par tment cont r ols,

feature load compensated cookin

utilizin

a thermal switch. With this

feature, when the compartment

temperat ur e r eac hes 180°F (the

temperat ur e at which preheatin

defrosti n

is compl ete) the red light will

then come on and t he timer will start. For

a small food load, the delay ti me before

the timer starts mi

For a lar

e food load, the delay time coul d

ht be a mi nute or less.

be four to five minutes. Durin

cooler air and c ondensate ar e exhausted

from the compartment thr ou

h the steam

trap (condenser) until the temperature

reaches 180°F, closin

bellows. Throu

hout the cooki ng cycle, the

the internal

compartment pressure should be 6 psi if

equipped with a compartment pr essure

ulating valve. On models without the

re

compartment pressure re

ulating valve,

the compartment pressure cycles with the

boiler pressure between 4 to 6 psi.

D. Approximatel y one minute before timer

reaches zero the steam c ontrol solenoid is

ized to unl atch the steam control

ener

arm. An internal sprin

will automatically

pull the ar m to the rear. This closes the

steam inlet

steam exhaust

ate v alve and opens the

ate v alve, allowing steam

and pressure to exit the compartment.

When the tim er r eac hes "0" the red li

shuts off and a buz z er sounds indicatin

the end of the cook cycle. Turn the

compartment power swi tch OFF to silence

the buzzer and remove power from the

compartment controls.

E. Turn the screw handle on the

compartment door counter c lockwise

asket no longer seals against the

the

compartment surfac e. After the remainin

steam escapes, move the l atch paddle to

the left and open the door.

time.

ate v alve

time by

or

preheat,

ht

until

Page 9 of 88

Page 10

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

4. Prevent

A. S et the timer to the desired c ook in

The timer must be set past five minutes to

e the state of the tim er c ontrol

chan

micro switch contacts.

B. P ull the steam control arm handle forward

and lock it by pullin

This opens the steam inlet

allowin

steam to enter the compartment.

the handle down.

ate v alve,

C. Press the compart ment power switch to

supply power to the com par tment cont r ols.

The prevent compartment cont r ols feature

load compensated c ook times by utilizin

a thermal switch. With this feature, when

the compartment temperature reaches

180°F (the t emperature at whic h

preheatin

red li

or defrosting is complete) the

ht will come on and the t imer wil l

start. For a small food load, the delay time

before the timer star ts mi

or less. For a lar

e food load, the delay

ht be a mi nute

tim e c ould be four and five mi nutes.

Durin

preheat, the steam exhaust

solenoid valve (N.O.) is open to allow the

full free venti n

of cool er air and

condensate from the compar tment. When

the temper ature reaches 180°F, t he

exhaust solenoid valve is ener

closes. The com par tment should t hen

pressurize to 6 psi.

time.

ized and

D. Approximatel y one minute before timer

reaches zero the steam c ontrol solenoid is

ized to unl atch the steam control

ener

arm. An internal sprin

will automatically

pull the ar m to the rear. This closes the

steam inlet

steam exhaust

ate v alve and opens the

ate v alve, allowing steam

and pressure to exit the compartment.

When the tim er r eac hes "0" the red li

shuts off and a buz z er sounds indicatin

the end of the cook cycle. Turn the

compartment power swi tch OFF to silence

the buzzer and remove power from the

compartment controls.

E. Turn the screw handle on the

compartment door counter c lockwise

asket no longer seals against the

the

until

compartment surfac e. After the remainin

steam escapes, move the l atch paddle to

the left and open the door.

ht

Page 10 of 88

Page 11

COMPONE NT FUNCTION

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

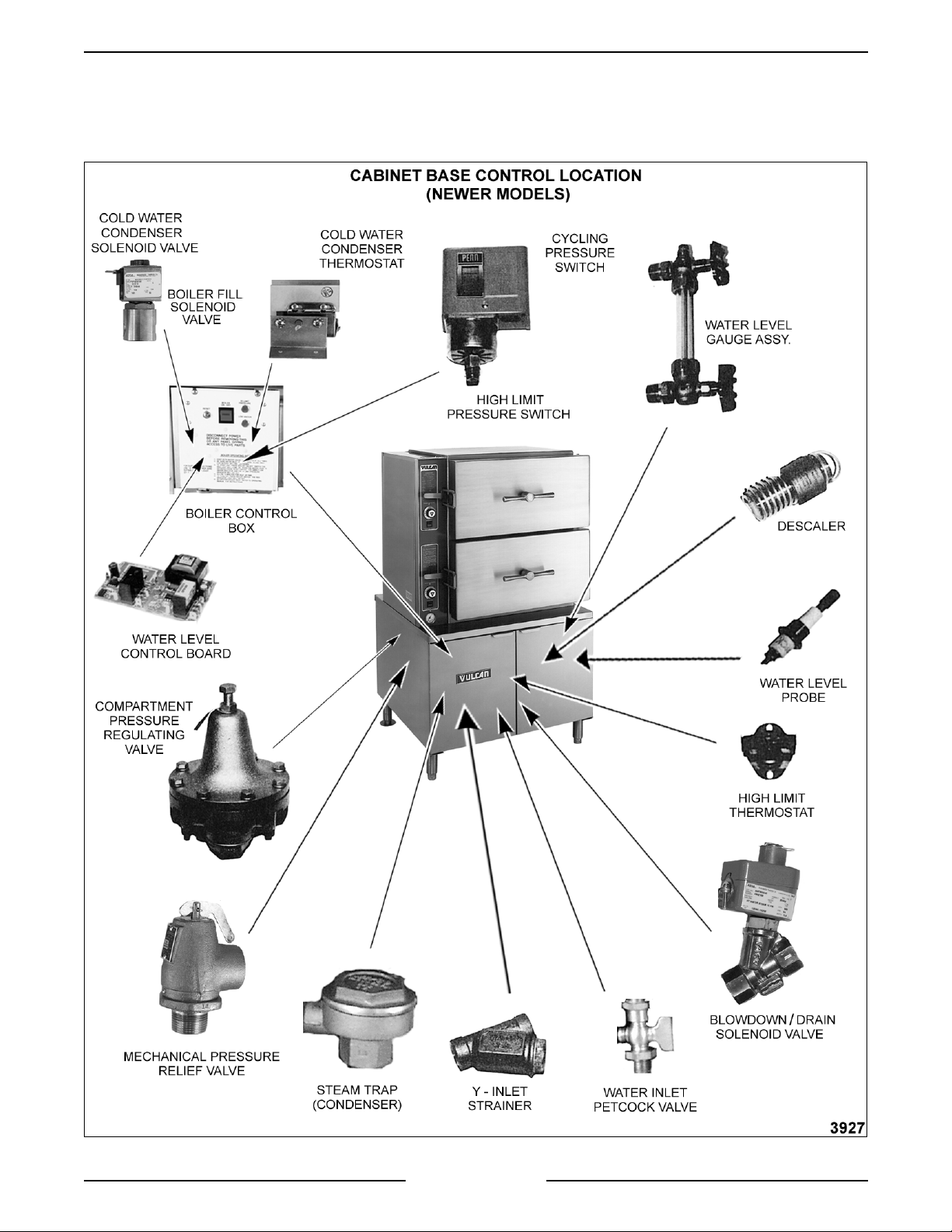

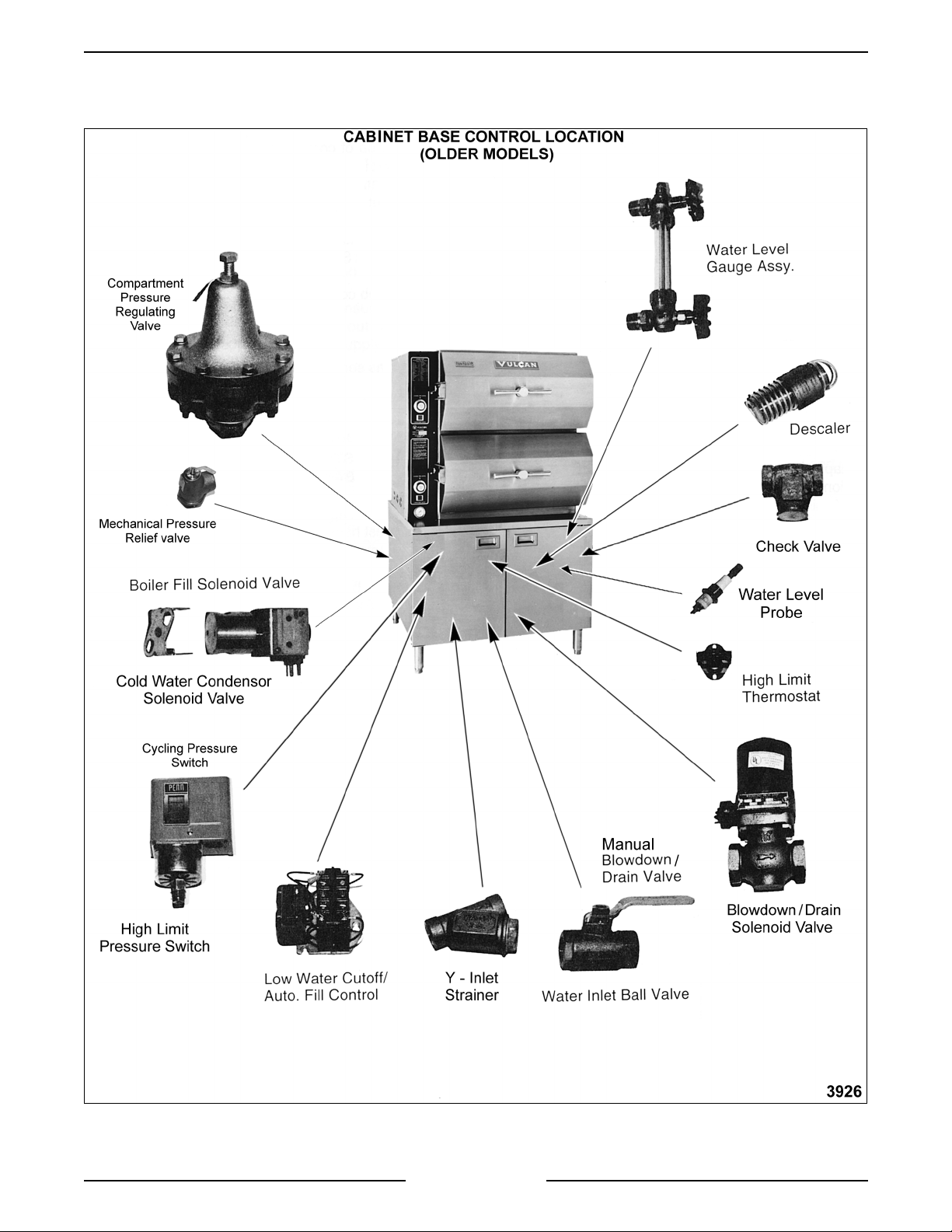

CABINET BASE BOILER CONTROLS

Water Level

Gauge Assembly ...............

Water Level Cont rol and

Level Sensing Probes ...........

VL SERIES STEAMERS - GENERAL

Permi ts a visual c onfirmation the water level is bein

boiler durin

ht of t he glass. The manual valves at t he top and bottom of this

hei

assembly must be full y open and only closed if the

dama

These controls allow water to enter the boiler to fill and maintain the

proper water level. T hey will also shut off the heat source to the boiler if

the water level drops too l ow. T he water level control works by usin

three different pr obe lengths to moni tor the water level. The probes

consist of a hi

operation. The correct water l evel is a point one-half of the

ed.

h level (HL), low level (LL) and low water cut-off (LLCO ) .

maint ained in

lass tube is

Boiler Fill Solenoid Valve ........

Cold Water Condenser

Solenoid Valve .................

Cycling Pressure Switch .........

High Limit Pressure Switch ......

Blowdown/Drain

Solenoid Valve .................

Inlet Water Strainer .............

Admits water to the boiler when dem anded by the water level control to

maintain the correct water level in the boiler.

Allows cold water flow into the boiler blowdown drain box to condense

steam and cool the hot water before its dischar

Controls boiler pressure between prescribed limits by tur nin

source on and off.

A switch of identical desi

h limit. T he pr essure settings are at higher and lower limits than t he

hi

cyclin

boiler pressure reaches its limit and autom atically resets after the

pressure drops below the lower limit set point.

This valve is plumbed into the drai n line of the boiler. Newer steamer

models will automatically blowdown when power is turned off by usi n

normally open solenoid valve. Older models can have a solenoid valve

that is activated by depressin

have a manual “ball” type valve.

A strainer i s used in t he water inlet l ine to prevent for ei

becomin

to keep unwanted partic les out of the system. A "Y" str ainer should be

inserted upstream of the fill solenoid valve. On models usin

steam supply, a str ainer is also used in the pressure re

pressure switch in order to tur n off the heat source before the

lodged in the fill or cold water condenser solenoid valves and

n to the cycling pressure switch but used as a

a separate blowdown timer button or

e into the drain.

the heat

n matter from

a direct

ulating valve.

a

Power Switch..................

Water Inlet Valve ...............

High Limit Thermostat ..........

Descaler ......................

When turned ON, power is supplied to the control s and the steam

enerating process is started in the boiler. The power switch is located

on the front of the boiler control box.

The water inlet valve is used to stop water flow to the steamer when the

steamer is bei n

valve while older models will be a “ball” type valve. This valve should

remain open dur in

A protective device that shuts off the heat source if the boiler

temperat ur e exceeds a specified limit. A ll standard m odels are equipped

with a surface hi

s submerged in water inside t he boiler and is used to hel p c ontrol

Han

boiler surface scalin

Page 11 of 88

servi c ed. Newer models will have a small Petcock type

normal oper ation.

h limit.

. Two descalers are used in each boiler.

Page 12

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

Handhole Cover Assembly ....... When unbolted and removed, allows internal examination and cleanin

of boiler shell and i ts components if required.

Boiler Pressu re Gauge .......... Indicates the amount of steam pressure in the boiler.

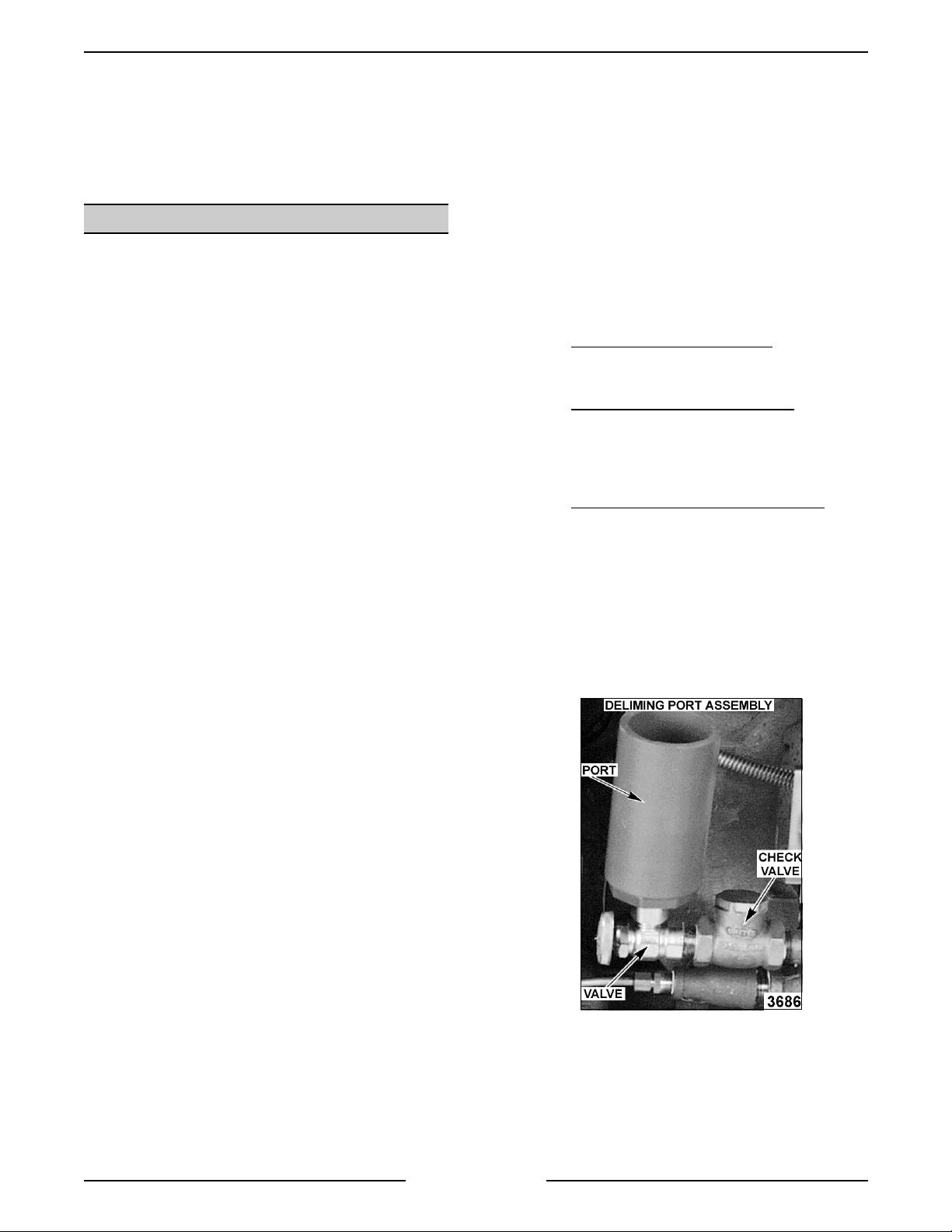

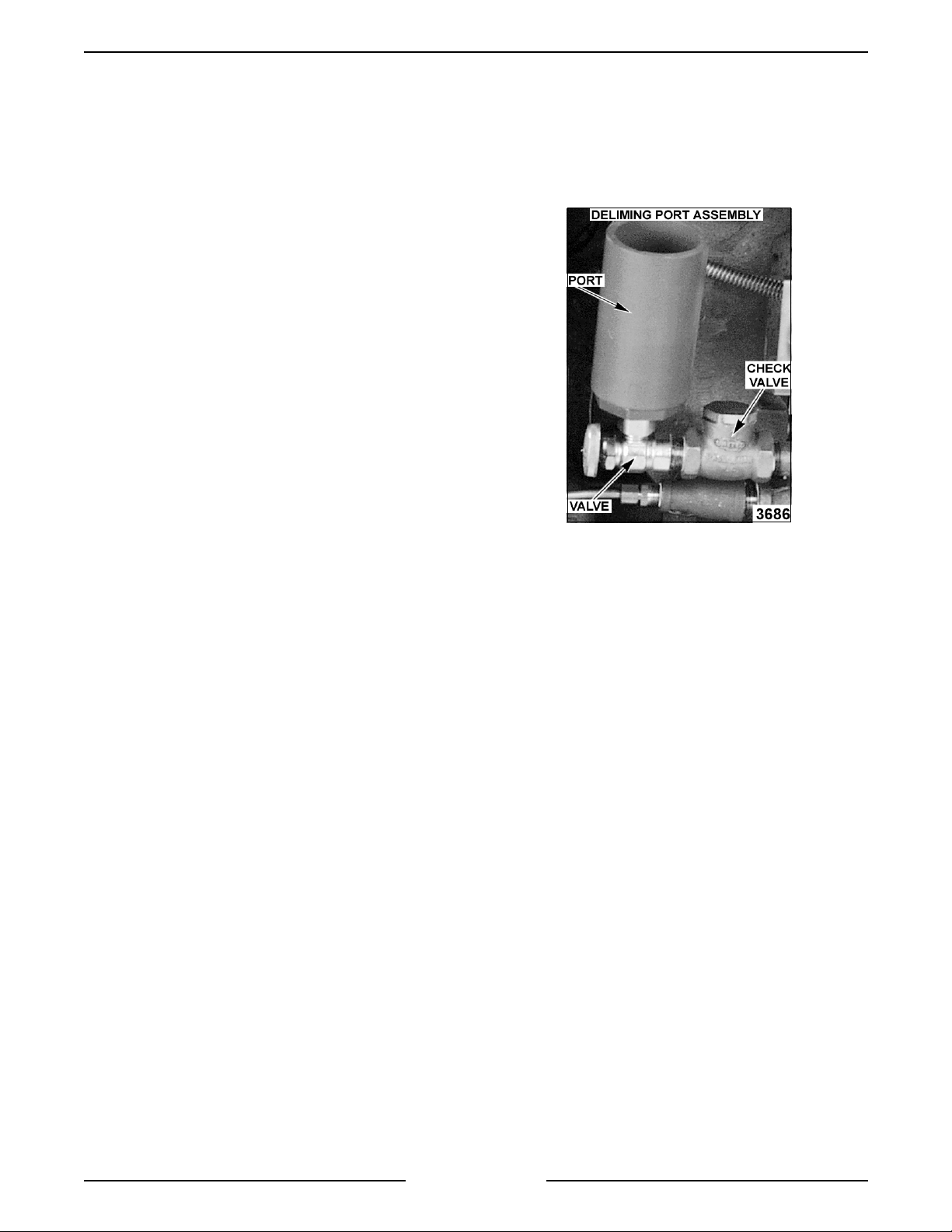

Check Valve ................... On models with the delime pipin

of hot water and steam out of the delime funnel if the manual delime fill

valve were to be opened.

Delime Port Assembl y ........... O n models with the delime pipin

other inter nal components to be delimed, easily removin

and rust build up.

Gas Pilot ..................... Shoul d always remain lit to li

ht the main burners upon a call for heat

unless the steamer will not be in use for an extended period. If the pilot

flame

oes out, wait 5 minutes before relighting.

Gas Burners................... Heats the water in the boiler to

Gas Combination Control Valve . . . A

as solenoid v alve that opens to allow gas flow when a call for heat is

made. Also re

ulates the m anifol d gas pressure and supplies the gas

pilot.

Transformer ................... Provides 24VAC power to i

electronic i

nition)

Ignition Control Module ......... Controls and monit or s

nition c ontrol module. (gas models with

as heating. Energizes pilot valve coil to supply

as to pilot, generates spark to ignite gas at the pilot, moni tors the

presence of flame and ener

supply

the

as to the mai n bur ner s. The pilot and main solenoi ds are part of

as combination control valve. (gas models with elec tronic ignition)

izes mai n valve coi l upon a call for heat to

Ignition Control Module

Reset (ON/OFF) Switch .......... Controls power to the i

module if the

nition)

i

as ignition exceeds trial tim e. (gas models with elec tronic

nition c ontrol module and allows a reset of the

assembly opti on, prevents the ejecti on

assembly opti on, allows the boil er and

calcium, lime

enerate steam.

Heater Contacto r

(Electric Bo ilers) ............... When coil is ener

ized, supplies power to the electric heating element s.

Heating Elements

(Electric Bo ilers) ............... Heats the water in the boil er to

enerate steam.

Steam Header Assembly ......... Main steam supply line fr om the boiler to the steam header inlet i n the

cookin

control compartm ent.

Pressure Relief V alve ........... A m ec hanical device that opens to relieve steam pr essure in the boiler if

the pressure exceeds 15 psi.

Compartment P ressure

Regulating Valve ............... Reduces steam pressure form t he boiler or bui ldin

enerated models) to supply the compartment s a steam pressure of 6

re

steam (dir ec t and

psi. Standard on PS , option on MS, S S and A S c ompartm ent controls.

Page 12 of 88

Page 13

VL SERIES STEAMERS - GENERAL

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

COOKING COMPARTMENT CONTROLS

The top half of t he steamer consists of two to three separate cooking compartments depending on the model .

Each compartment functions independently with i ts own set of controls. Power i s supplied to the controls throu

the compartment power switch and the cook in

models have a load compensatin

compartment reaches 180°F to close the switch.

thermal switch that prevents the contr ols from r ec eiving power until the

tim er c ontrol micro switch contacts. Prev ent and Automat ic

h

Compartment Power Switch......

Cooking Light (Red) ............

Cooking Timer .................

Buzzer .......................

Steam Exhaust S olenoid Valve . . .

Steam Header Inlet (manifold) ....

Compartment P ressure Gauge ....

Steam Contro l Arm Solenoid .....

Supplies power to the cook in

When lit, indicates steam er is in a cookin

manual)

Use to set desired cookin

the buzzer when time expir es (All models except manual). On P r event

models, also de-ener

before the end of a cook cycle to allow compartment venti n

nals end of a cook cycle, must be turned of f manual ly. (All models

Si

except manual)

A normal ly open v alve that allows full com par tment ventin

condensate up to 180°F durin

vent in

remains closed to allow compar tment pressurization to 6 psi until one

minute before the end of a cook cycle at which point t he timer control

micro switch contacts (SW2) chan

vent the compartment of pr essure and steam . (prev ent models)

Main steam suppl y line f r om the boiler for each c ook in

Supplies steam to the manual steam

Indicates the amount of steam pressure in cookin

When ener

control arm off of t he c atch, all owin

closes the steam i nlet

valve. ( pr event, automati c and standar d models)

” after energized by the closing of the t her mal switch. The valve

ized, engages the lift arm ( plunger) to raise the steam

izes the steam exhaust solenoid valve one minute

compartment controls.

cycle. (All models except

cycle time between 0-60 minutes. Energizes

.

of air and

compartment heat up and “limited free

e state and de-energize the valve to

compartment.

ate v alves.

compartments.

it to return to its rear position. This

ate v alve and opens the steam exhaust gate

Thermal S witch

(Load Compensator) ............

Steam Gate Valves .............

Steam Trap ( Condenser) .........

Controls power to the preheat cycle components. Turns the cookin

on, ener

cookin

180(F. (prevent and automatic models)

Manual valves actuated by the steam control ar m. Allows steam to flow

into the cook in

the arm is in a forward position and exhaust the steam throu

exhaust steam

use a steam exhaust solenoid valve t o exhaust the steam and a si n

steam

manual models use one steam

one additional steam

Exhausts air and condensate from c ompartm ent durin

compartment temperature reaches approx imately 180(F. The bel lows

then close, stoppi n

izes the steam exhaust solenoid valve and energizes the

timer motor to start timing, aft er the compartment reaches

compartment through the inlet steam gate v alve when

ate v alve when the arm is at the rear . Prev ent models

ate v alve as the steam inlet. The automatic, standar d and

ate v alve to exhaust the steam and

ate v alve as the steam inlet.

preheat until the

the exhaust. ( all models except prevent)

light

h the

le

Page 13 of 88

Page 14

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COMPONENT LOCATIONS

Page 14 of 88

Page 15

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Page 15 of 88

Page 16

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

COOKING COMPARTMENT CONTROLS - COMPONENT CONFIGURATIONS

1. Prevent

(shown above)

2. Autom atic same as prevent except does not

3. Standard same as automatic except does not include thermal switch.

4. Manual manual and exhaust steam

thermal switch, inlet steam

valve, steam control ar m solenoid, timer, buzzer and power switch

with li

valve but does

traps.

Includes two steam t r aps.

ht. Does not use a steam tr ap.

include an exhaust steam gate v alve and two steam

Page 16 of 88

ate v alve, steam exhaust sol enoid

include steam exhaust solenoi d

ate v alves and a manual timer.

Page 17

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

gaug

g

g

g

g

g

g

gauge g

g

g

g

g

g

g

g

g

WATER LEVEL CONTROLS -

LOW LEVEL CUT OFF AND

DIFFERENTIAL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Solid State

1. Open the cabinet base doors.

2. Remove the two screws at the top of the boiler

3. Water level control is mounted on the back

4. Disconnect lead wir es from the boar d and

5. Reverse procedur e to install and c hec k for

Electro Mech anical

DISCONNECT THE ELECTRICAL

control box and allow cover to drop down.

side of cover.

remove the water level control.

proper operation.

4. Slide t he

the tube is cl ear of the fittin

5. When r einstallin

washers. Do not over tighten the packi ng nuts;

it coul d br eak the

6. Open the top and bottom valves and check for

proper operation.

lass tube upwards until the bot tom of

and lift it out.

the tube use new sealin

lass.

CYCLING AND HIGH LIMIT

PRESSURE SWITCHES

(GAS AND ELECTRIC MODELS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base doors and remov e the

left side panel.

2. Remove the two screws at the top of the boiler

control box and allow cover to drop down.

DISCONNECT THE ELECTRICAL

1. Open the cabinet base doors.

2. Remove the two screws from t he left and r i

side of the water level control box and lift cover

off.

3. Disconnect lead wir es from the c ontrol bein

replaced and remove.

4. Reverse procedur e to install and c hec k for

proper operation.

ht

WATER LEVEL GAUGE

ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base doors and remov e the

2. Close the valve at the top and at the bottom of

3. Unscrew the packin

DISCONNECT THE ELECTRICAL

ht side panel.

ri

the

of the

e assembly.

nuts at the top and bottom

lass tube.

3. The pressure switches are located at the rear of

the box. The pressure switch on the ri

cyclin

the hi

switches, dif ferin

4. Remove the cover from the pressure switch

bein

5. Disconnect the pressure fittin

of the switch.

6. Remove the mount in

of the control box and lif t out the pressure

switch.

7. Preset the new pressure switch to the

approximate cut-out (off) and cut-i n ( on) set

points before installin

chart under “CYCLI NG AND HIGH LIMIT

PRESSURE SWITCHES (GAS AND

ELECTRIC MODELS)” in “SERVICE

PROCEDURES AND ADJUSTMENTS”.

8. Reverse procedur e to install .

9. Adjust the pressure switch(s) final set poi nts as

outlined under “ CY CLING AND HIGH LI M IT

PRESSURE SWITCHES (GAS AND

ELECTRIC MODELS)” in “SERVICE

PROCEDURES AND ADJUSTMENTS” and

check for pr oper oper ation.

or prim ar y c ontrol; the one on the left is

h limit contr ol. They are identical

only in t heir settings.

replaced and disconnect the lead wires.

s at the bottom

screws on the back side

. See the boiler pressure

ht is the

Page 17 of 88

Page 18

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

g

g

g

g

g

g

g

g

g

g

BOILER ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHE CK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Blow down the boiler and allow to cool, if

2. Ensure that all utilities to the steamer are off

3. Disconnect the steam supply li ne, power leads

4. Disconnect all plumbin

5. Disconnect the remainin

6. Remove the screws holdin

7. Remove the anchor screws holdin

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

necessary.

and disconnected. Drain any excess water fr om

the boiler .

and drain lines from the cookin

top to the boi ler base.

connections and power

leads from the components inside the control

boxes that would obstruct the removal of the

boiler throu

remove those control boxes.

electrical connections from the boiler t o the

controls.

collector to the base.

the frame. Slide the boil er forward. The burner

box, anchored only by the boiler, must be

prevented from slidin

h the front of the base, t hen

forward with the boiler.

compartment

plumbing and

the flue and flue

the boiler to

HIGH LIMIT THERMOSTAT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base doors.

2. Electric model s onl y - for

to step 3.

A. Newer Models

B. Older Models

3. Gas Models only.

A. Remov e the thermostat c over which is

4. Reverse procedur e to install and c hec k for

proper operation.

DISCONNECT THE ELECTRICAL

as models proceed

- are not equipped wit h a hi

limit thermostat but rely on the Hi l imit

pressure switch instead.

- the high limit thermostat is

located behi nd the contactor box cov er .

On electr ic boiler s with two heatin

element s, the thermostat is connected to

one of the heat in

electric boilers with four heati n

the therm ostat is located on an aluminum

plate between the cent er pair of elements

at the top of the elements. Remove the

thermostat lead wires and mounti n

replace thermostat and check for proper

operation.

located on the front of the boil er .

Disconnect the t her mostat lead wires and

remove the nuts securin

thermostat to the boiler surface.

element lugs. On

element s,

nuts,

the high limit

8. Reverse procedur e to install a new boiler and

check for leaks and proper operation.

Page 18 of 88

Page 19

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

g

g

g

g

g

g

BOILER FILL AND COLD WATER

CONDENSER SOLENOID VALVES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn off the water supply t o the steamer.

2. Open the cabinet base doors and remov e the

3. Disconnect the power lead wir es from the

4. Disconnect the water lines for t he valve bein

5. Reverse procedur e to install .

DISCONNECT THE ELECTRICAL

two screws at the top of the boiler control box

and allow cover to drop down. Both solenoid

valves are l oc ated side by side near the front of

the boiler control box with the boiler fill on the

ht and the cold water c ondenser t o the left.

ri

solenoid valve bein

servi c ed and r emov e the valve.

servi c ed.

PILOT AND THERMOCOUPLE

ASSEMBLY ( GAS MODELS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHE CK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

GAS COMBINATION CONTROL

VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHE CK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE:

servi c eable and should not be disassembled. Once

the problem has been isolated to this control,

replace it. Do not attempt to repair the assembly.

1. Open the cabinet base doors and remov e the

two screws at the top of the boiler control box

and allow cover to drop down.

2. Disconnect elec trical suppl y wir es and conduit

runnin

3. Disconnect the t her mocouple l ead ( if

applicable), pil ot

and pipe connections on each side of the

control.

4. Reverse procedur e to install .

5. Set manifold pr essure as outlined under “GAS

MANIFOLD PRESSURE ADJUSTMENT” in

“SERVICE PROCEDURES AND

ADJUSTMENTS”.

6. Check for pr oper oper ation.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

ALL GAS JOINTS DISTURBED

Gas combination control valves are not

to the com bination cont r ol valve.

as supply tube from control

1. Open the cabinet doors to access the pilot and

thermocouple assembly. T he assembly is

located to the ri

half way back from the front.

2. Disconnect thermocouple and pi lot

from the combination contr ol valve.

tubin

3. Remove the two screws holdin

bracket.

4. Replace the ther mocouple or pilot assembly

and check for pr oper oper ation.

ht of t he c enter burner and

as supply

the pilot to its

Page 19 of 88

Page 20

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

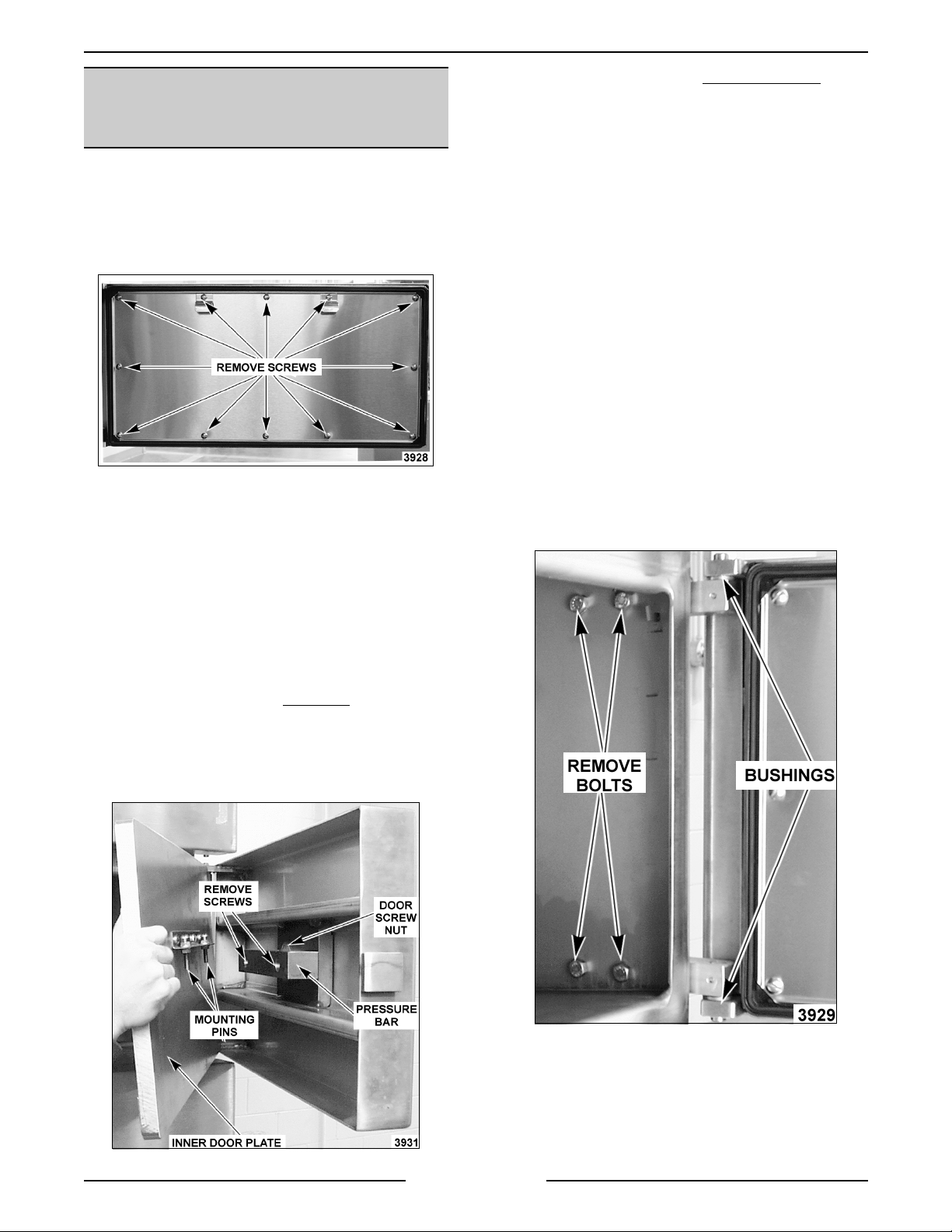

COMPARTMENT GASKET AND

DOOR SCREW NUT, DOOR AND

BUSHINGS

Gasket

1. Open the com par tment door t o be r eplaced.

2. Remove screws securin

plate to t he gasket.

3. Lift the

4. Position t he new

and rever se procedur e to install .

asket off the inner door plate.

the gasket retainin

asket on the inner door plate

4. Turn screw handle fully counter c lockwise

remove from door.

5. Remove screws mountin

the backside of the compartment door.

NOTE:

each screw. Set aside f or r euse.

6. Remove screws mountin

7. Reverse procedur e to install and c hec k for

Door and Bushing

1. Open the com par tment door t o be r eplaced.

2. Remove the ri

3. Remove the four bolts inside the compartm ent

CAUTION: Door is extremel y heavy and will drop

when bolts are removed.

A compression sprin

(bronze) to the bac k si de of the compartment

door.

proper operation.

ht side pan support inside the

compartment.

that secure the bl oc k hin

of the compartm ent.

the pressure bar to

is mounted behind

the door screw nut

es to the exter ior side

and

NOTE:

as nicks or cuts, will cause steam leaka

Door Screw Nu t

1. Open compartment door t o be serviced.

2. Turn screw handle fully cl oc k wise

3. Lift the inner door plate assembly up, until the

Dama

inner door plate assembly.

mounti n

pressure bar and set the assembly aside.

e to the gasket sealing surface, such

e.

to extend

pins are out of the holes in the

4. At this time, t he bushi n

necessary, by removin

pin on each block hin

5. Reverse procedur e to install and c hec k for

proper operation.

Page 20 of 88

s can be replaced if

the bushings from the

e.

Page 21

VL SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

g

g

g

g

g

ge g

g

g

g

g

g

g

g

HEATER CONTACTORS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base doors, remove the two

2. Disconnect the electrical lead wires to the coil

3. Remove the screws form the base of the

4. Reverse procedur e to install and c hec k for

DISCONNECT THE ELECTRICAL

screws from the contactor box c over and l ift

cover off.

and the power supply wires from the contact or

bein

replaced.

contactor and lift out.

proper operation.

HEATING ELEMENTS

REGENERATED STEAM MODELS

(STEAM COIL)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Disconnect pipe unions in the steam suppl y line

to the coils and in the condensate dischar

line from the c oils.

2. Remove header that supplies steam to the coils

by disconnecti n

3. Remove coil c ondensate c ollection header.

4. Remove bolts securin

and pull coil for ward.

5. Clean the m atin

flan

DISCONNECT THE ELECTRICAL

SHUT OFF THE STEAM SUPPLY

e

union at each coil.

the coil being replaced

surfaces of the steam coil

e and the boiler .

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CIRCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base doors, remove the two

2. Disconnect the electrical lead wires to the

3. Remove the bolts securi n

4. Clean the m atin

5. Check for leaks and proper operation.

DISCONNECT THE ELECTRICAL

screws from the contactor box c over and l ift

cover off.

element bein

e to the boiler and lift the el ement out.

flan

install a new flan

element .

replaced.

the heating element

surface of the boiler and

asket and heatin

6. Reverse procedur e to install a new steam c oil

asket.

and

7. Check steamer for proper operation.

Page 21 of 88

Page 22

VL SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

g

ging

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRES ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NTS ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST.

BOILER

Inspection

It is recommended the boiler be inspected for

excessive scale and li me build up on a quar terly

basis. In hard water areas or f or steamers heavily

used, a more frequent inter val shoul d be used. This

inspection consi sts of an internal examination and

cleanin

han

water level probes. Also, a c hec k of all boiler

controls, includin

Periodic service must be perfor med as outlined in

these procedures. See “WATER CO NDITIONING”

under “GENERAL”.

WARNING: READ AND FO LLOW THE

INSTRUCTIONS ON THE CLR BOTTLE. USE

PLASTIC OR RUBBER GLOVES TO AVOID SKIN

CONTACT. I F CLR LIQUID COMES IN CO NTACT

WITH THE SKIN, RINSE WITH CLEAN WATER.

Clean-Out (All Boiler Models)

1. Turn steamer OFF and drain boiler.

2. Remove hand hole plat e and

of the boiler, an examinat ion of the two

descalers, and for lime build up on the

the pressure switches.

asket (top f r ont)

from the boiler by r emov in

then tappin

holdin

from droppin

the cover lightly to free it while

the cover stud. This prevents the cover

into boiler.

the nut and clamp,

NOTE: B oiler water capacities vary between seven

to nine

dependin

NOTE: If delimin

contact with steamer components, li

with clean water.

allons f or both gas and electric models

on the boiler si z e and B TU/KW rating.

solution accidently comes in

htly rinse off

A. M odels with Blowdown Timer

delimin

to step 9.

B. M odels without Blowdown Timer

the incomin

switch ON to cl ose the dr ain valve. Pour

delimin

to step 9.

C. Models with Delimin

Before pourin

boiler, c lean the seatin

hand hole

asket. Position the hand hole plate and

ti

supply. Turn t he power switch O N to close

the drain valve. Open t he delimin

assembly valve and pour the delimin

solution i nto the port. Close the delimin

assembly valve and proceed to step 10.

solution into boiler shell. Proceed

water supply. Turn t he power

solution into boiler shell. Proceed

Port Assembly -

deliming solution into

asket and then instal l a new

hten down. Turn of f the inc oming water

- Pour

surfaces for the

- Turn off

springs if

used.

e and

Page 22 of 88

9. Clean the seatin

asket and then Install a new gasket. Position

hten the hand hole plate.

and ti

surfaces for the hand hole

3. Remove old descaler retainin

present.

4. With a wire brush, or equi valent, dislod

remove all loose scale from boiler shel l. The

loose material must be either scooped fr om the

h the drain.

boiler or flushed throu

5. Check probe canister and float valve assembly

enerated models) for a scale build up and

(re

clean as necessary.

6. Check drain hol e for obstructions.

7. Inspect the condi tion of the descalers as

outlined in this section and r eplace if

necessary.

8. Mix the delimin

instructions for the chemical bein

solution according to the

Page 23

VL SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

ging

g

g

10. Cooking compartment ti mers are to be in t he

OFF position. Turn the boiler switch ON and

open water valve if necessary.

11. Boiler is to operate under pressure for 90

minut es or per the instructions for the chemical

in use.

12. Drain boiler by normal methods.

13. Refill boiler and allow to heat until fully

pressurized.

14. Repeat step 13 three times.

15. The steamer is now ready for norm al operation.

Deliming Only (Models with Deliming Port

Assembly)

Boiler delimin

bi-weekly or monthly basis, dependin

should be performed on a weekly,

on the quality

of the local water supply. S ee “ WAT E R

CONDITIONING” under “GENERAL”.

On steamers usin

a water purif ication system,

follow the instructions for that system to deli me the

boiler. Only use the type of chemical recommended

or described in t he instructions for delimin

with this

type of system.

1. Turn steamer OFF and drain boiler.

2. Mix the delimin

instructions for the chemical bein

solution according to the

used.

NOTE: B oiler water capacities vary between seven

to nine

dependin

NOTE: If delimin

contact with steamer components, li

allons f or both gas and electric models

on the boiler si z e and B TU/KW rating.

solution accidently comes in

htly rinse off

with clean water.

A. Models with Blowdown Timer - Open

the delimin

delimin

delimin

assembly valve and pour the

solution i nto the port. Close the

assembly valve and proceed to

step 3.

B. Models without Blowdown Timer - Turn

off the incomin

water supply. Turn t he

power switch ON to close the drain valve.

Open the delimin

pour the deli min

Close the deli min

assembly valve and

solution i nto the port.

assembly valve and

proceed to step 3.

3. Top compartments are to be in the OFF

position. Turn the boil er switc h ON and open

water valve if necessary.

4. Boiler is to operate under pressure for 90

minut es or per the instructions for the chemical

in use.

5. Drain boiler by normal methods.

6. Refill boiler and allow to heat unti l ful ly

pressurized.

7. Repeat step 6 three times.

8. Steamer is now ready for norm al operation.

Descaler

The descaler is accessible throu

openin

cylindr ical core, and han

. It i s a coiled wire wound around a solid

s by an open loop from the

h the hand hole

shell's horizontal stay rod, about 4 inches from the

front of the shell . If t he wir e is eaten throu

h, or if

the core of the descaler is eaten away to hal f its

inal size, a new descaler should be installed.

ori

To install a new descaler, stretch its wire coil so the

descaler han

minimum water level in the boi ler, but han

s with its core completely below the

free.

The descaler m ust not contact the bottom of the

boiler shell, elect r ic heatin

enerating steam coils.

re

element s or

Page 23 of 88

Page 24

VL SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

g

g

g

g

g

g

g

g

g

gaug

g

g

g

g

g

g

g

g

gg

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

gaug

g

g

g

g

g

WATER LEVEL CONTROL(S)

TEST

Loose electric al connections may prev ent the heat

from comin

An accumulation of lime scale on or near the water

level sensin

water (moist) on the probe surface and

readin

ive a false reading. These conditions may prevent

the boiler from fillin

will result in damage to the heati ng element s on

electric models or t o the boiler on

models.

WARNING:

POW E R TO BE APPLIED TO THE UNIT DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

Solid State - Low level Cut-Of f & Differential

Control

1. Turn the power switch ON.

2. Ensure that water is fillin

A. Confirm that water supply valve(s) are

B. Observe boiler water level in the water

3. Check the volta

the board. Meter shoul d r ead 120V A C.

A. If volta

B. If boiler fill solenoid is receivin

C. If boiler fill solenoid is not

4. If boiler is fillin

reaches the low level cut- off ( LLCO) probe,

LLCO relay should ener

contacts, heat source shoul d c ome on

(standard model s onl y ) and LLCO LED will

li

on or may cause the boiler to overfill.

probes may cause them to retain

ive a false

. Also, a crac k ed or damaged insulator may

or cause dry firing. Dry firin

as or electri c

THE FOLLOWI NG ST EPS REQUIRE

the boiler .

turned on.

level

approximately 11 minutes.

(HL) relay should ener

contacts and the HL LED should li

The boiler fill solenoid should then

ener

boiler fill solenoid valve is receivin

120VAC and water is flowing through it.

no water is fl owin