Vulcan-Hart VI2, VI3, VI33, VI22, VI23 Service Manual

SERVICE MA NUAL

INDUCTION

COOKERS

MODEL ML

VI2 114713

VI3 114714

VI22 114715

VI33 114716

Model VI22 shown

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

VI23 114717

- NOTICE -

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

Form 24591 ( Rev. A, 12-98) Supercedes (5-97)

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ........................................................................ 3

How to Distinguish a Usable P an .................................................... 3

Usable Pans Which Have Slower Rates of Heat Transfer.................................. 3

Recomm ended P ans ............................................................. 4

Unusable Pans.................................................................. 5

Tools ............................................................................. 5

Location........................................................................... 5

Controls........................................................................... 5

Specifications ...................................................................... 6

Cleaning .......................................................................... 6

REMOVAL AND REPLACEMENT OF PARTS ................................................. 7

Top Cover ......................................................................... 7

Inverter Assembly ................................................................... 7

Fan Motors ........................................................................ 8

Controll er Board, Led and Potent iometer .................................................. 9

Knob Gasket ....................................................................... 9

Inverter Coil........................................................................ 9

High Volt age B oard ................................................................. 10

Low Voltage Board .................................................................. 10

EMI Board ........................................................................ 11

Fuse on EMI Board ................................................................. 11

Thermistor, Tension Spr ing and Support ................................................. 11

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 12

Thermistor Test .................................................................... 12

Controller Board Potentiometer Test .................................................... 12

High Volt age B oard Test ............................................................. 12

Inverter Coil Test ................................................................... 13

Power Output Adjustment ............................................................ 13

Access Hole Modification............................................................. 16

Transformer Test ................................................................... 18

ELECTRICAL OPERATION .............................................................. 18

Component Func tion ................................................................ 18

Component Locat ion ................................................................ 19

Sequence of O per ation .............................................................. 20

Plug Layout ....................................................................... 21

Wiring Diagram .................................................................... 22

TROUBLESHOOTING .................................................................. 24

© VULCAN 1997, 1998

2

INDUCTION COOKERS - GE NE RA L

GENERAL

INTRODUCTION

Model VI2 is a single 2.2KW cooker.

Model VI3 is a single 3KW cooker.

Model VI22 is a double 2.2KW cooker.

Model VI33 is a double 3KW cooker.

Model VI23 is a double cooker with one 2. 2K W cook er and one 3K W cooker .

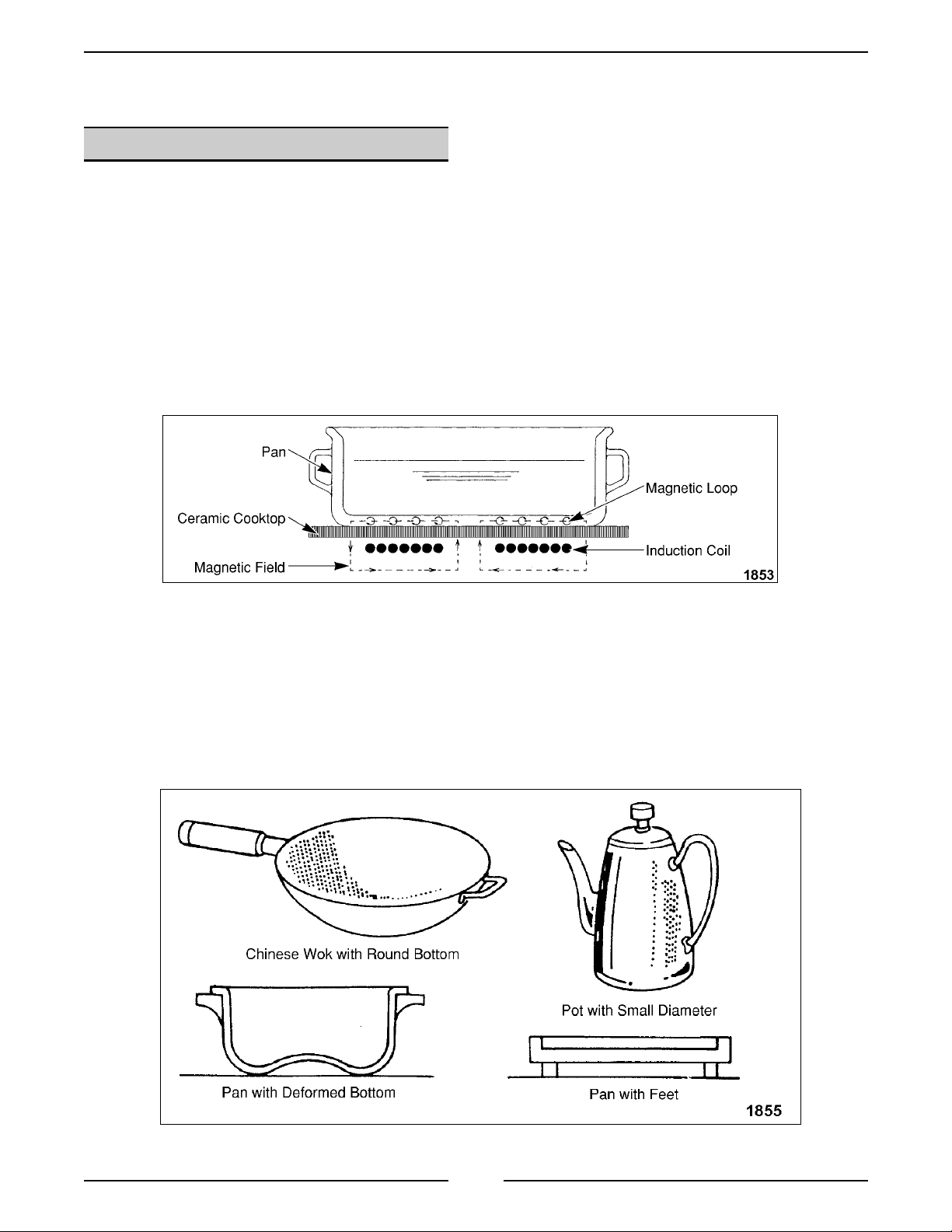

The induction cooktop will not heat the way a resistance heater conduct s to the pan. A magnet ic induction coil is

beneath the ceramic top. This coil c reates a magneti c fiel d that requires a steel or iron pan to complete the

magneti c loop. If the pan is not present, the cooktop stays in a “c ool” ready state wit hout using much cur r ent. It i s

necessary to use iron or steel pans, or special pans designed for induction use. Cer amic, glass, pottery and some

special stai nless steel pans will not complete the magnetic loop and, t her efore, will not heat properly, and should

not be used.

How to Distinguish a Usable Pan

Put the pan filled with water on the center of the cooktop and turn the contr ol knob to the desir ed c ook ing level.

The indicator light will light continuously for a usable pan and will blink for an unusable pan.

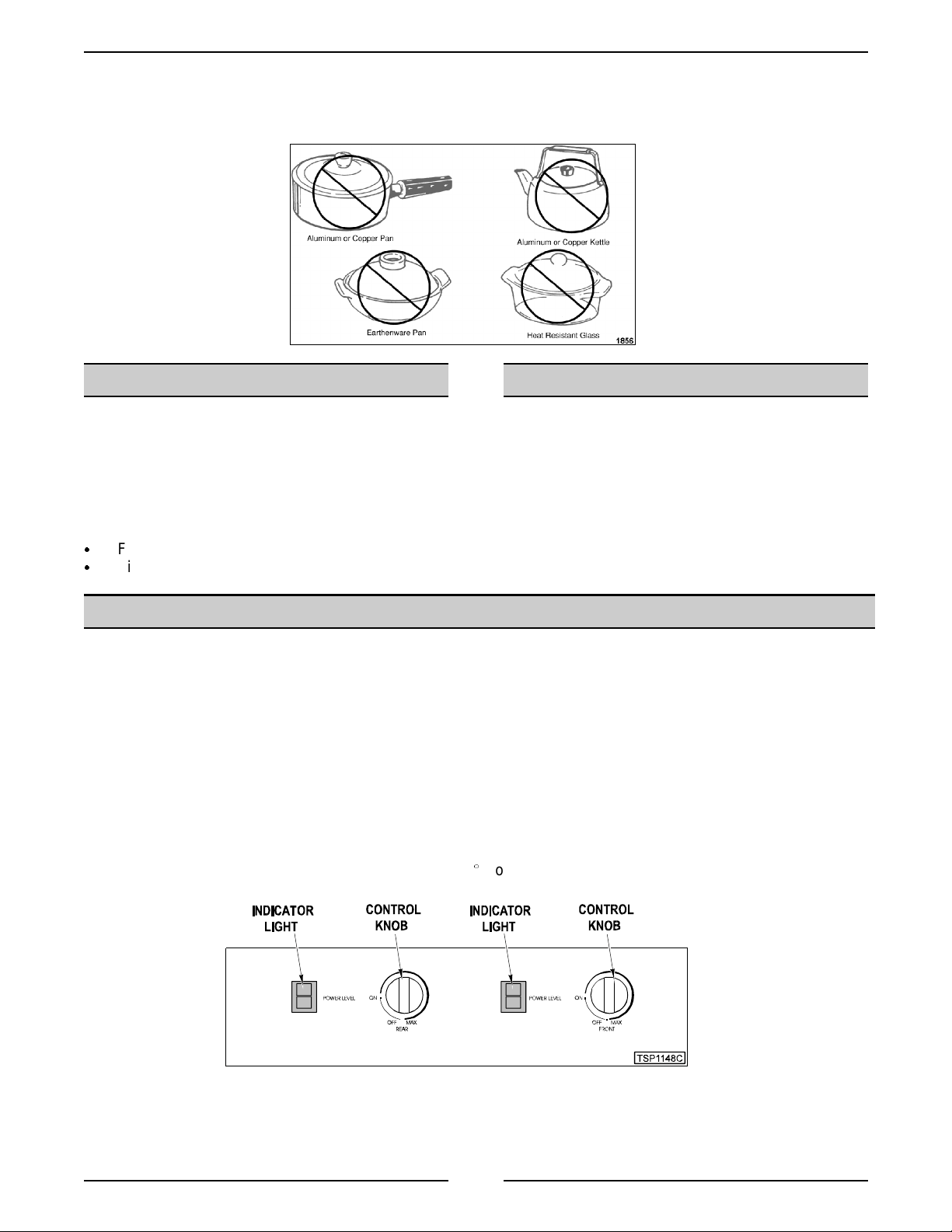

Usable Pans Which Have Slower Rates of Heat Transfer

Pans with smaller bottom diameter or partially contacting bottom may be usable but will have reduced heat

transfer r ates. These may be accept able for warming but not for frying.

3

INDUCTION COOKERS - GE NE RA L

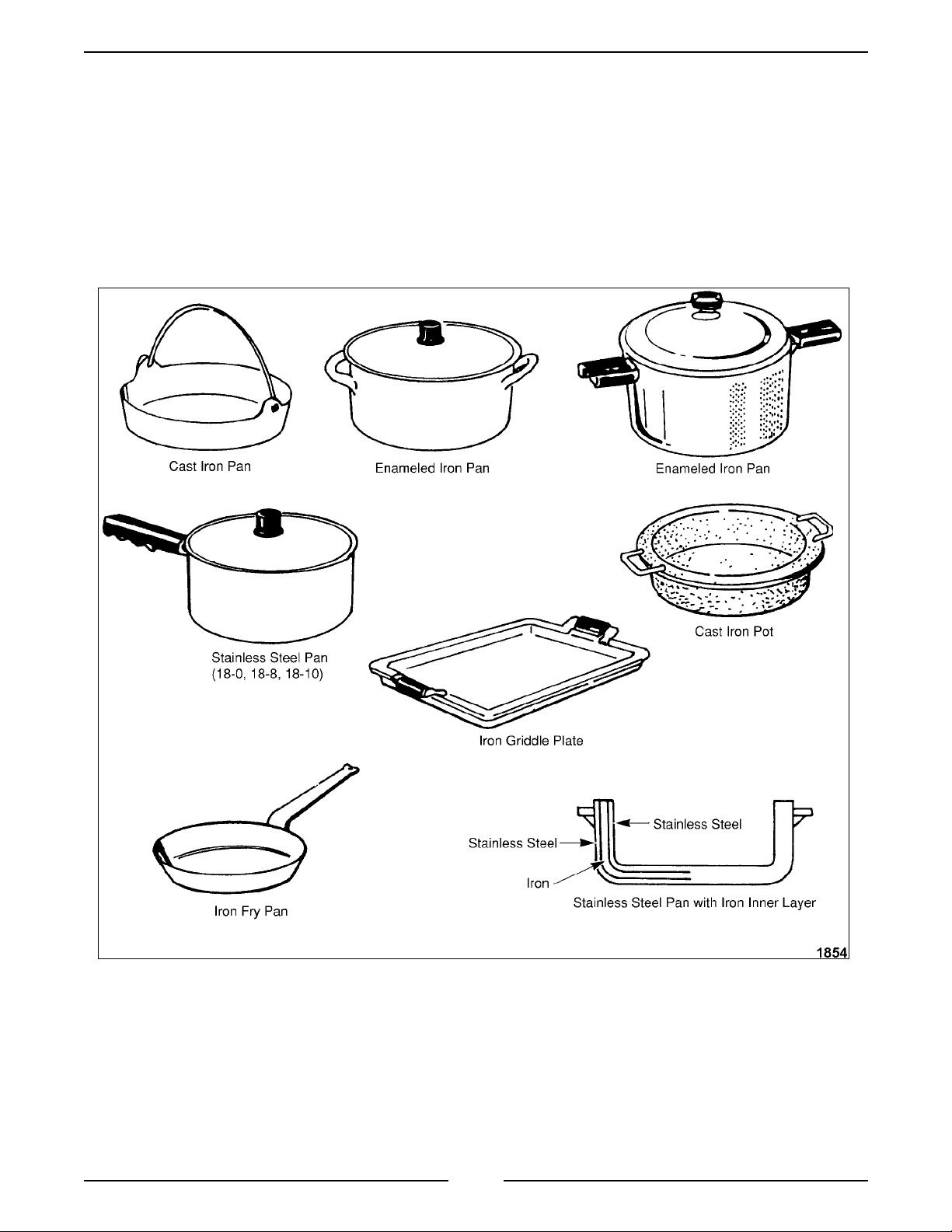

Recommended Pans

Pans made of c ast iron, enameled iron, or stainless steel with an i r on inner layer are r ecommended. Stainl ess

steel pans with 18-0, 18-8, 18-10, and 18-Cr m aterial ar e ac c eptable if a magnet will attach itself to the pan and if

the shape of the pan is acceptable. P ans with a flat bottom 5" to 10½" in diameter are recommended. Thin pans

may deform during heating; a t hicker wall and bottom are rec ommended. P ans made of 18-8 stai nless steel and

pans with a small er diameter bottom may hav e sl ower rat es of heat transfer.

4

INDUCTION COOKERS - GE NE RA L

Unusable Pans

Pans made of por celain, ear thenware, heat-resistant glass, copper, or aluminum ar e not recommended because

they do not transfer heat from the magnetic induction field.

TOOLS

• Standard set of hand tools

• VOM with AC current tester (Any VOM with a

sensitivity of at least 20,000 ohms per volt can

be used.)

• Thermal compound Part # 819643

• Demeyere sauce pan with 26c m top opening

and 24cm bott om PMI Par t # 424971-1

Fiberglass screwdriver Part # 424998-1

&

Field S ervice Grounding Kit Part #TL-84919

&

Position the cooktop on a suitable level countertop

surface. Do not locate the cook top near fryers, a hot

stove, or over an oven. The electri c al controls i nsi de

the cooktop will shut down if they overheat (above

110°F). Refer to the Installation and Operation

Manual f or complete install ation instruc tions.

LOCATION

CONTROLS

Control Knob Turn counterc lockwise to OFF ; clockwise to desir ed c ooking level.

Indicator Light:

On Indicates that power is ON and at what cooking lev el.

Blinking If t he indicator light bl inks continuously , it indicates the cookt op is in stand-by m ode. This

means no pan is detect ed and heat is OFF. Cook top will shut off in 3 minutes.

If cook top is in stand-by and has shut off after 3 minutes, it must be reset. Reset cooktop by

turning cont rol knob to OFF, then ON to desired cooking level.

If t he indicator light bl inks intermittently f or 2 or 3 seconds and then stops, it indicates an

elevated cooking temperature of 380(F or higher. This is norm al. The cooktop is ensuring

that maximum int er nal temper atures are not exceeded.

DOUBLE COOK E R CONTROLS SHOWN

5

INDUCTION COOKERS - GE NE RA L

SPECIFICATIONS

MODEL VOLTAGE PLUG

TYPE

VI2 208/60/1

220/240/60/1

VI3 208/60/1

220/240/60/1

VI22 208/60/1

220/240/60/1

VI23 208/60/1

220/240/60/1

VI33 208/60/1

220/240/60/1

6-20P 10.6

6-20P 14.6

6-30P 21.2

6-30P 25.2

6-30P 29.2

MAX.

AMPS

9.1/9.1

12.3/12.5

18.2/18.2

21.4/21.6

24.6/25.0

BREAKER

CLEANING

WARNING:

BEFORE CLEANING.

Clean the ceramic cooktop surface by using a c loth

moistened in warm water, or a solut ion of det er gent

and warm water. For stubbor n stains, ScotchBr ite or

a soft paste of cleanser may be used; do not use

abrasiv e materi als or harsh scouring acti on bec ause

this could damage the surfac e.

DISCONNECT ELECTRICAL POWER

SIZE

15

15

15

15

30

30

30

30

30

30

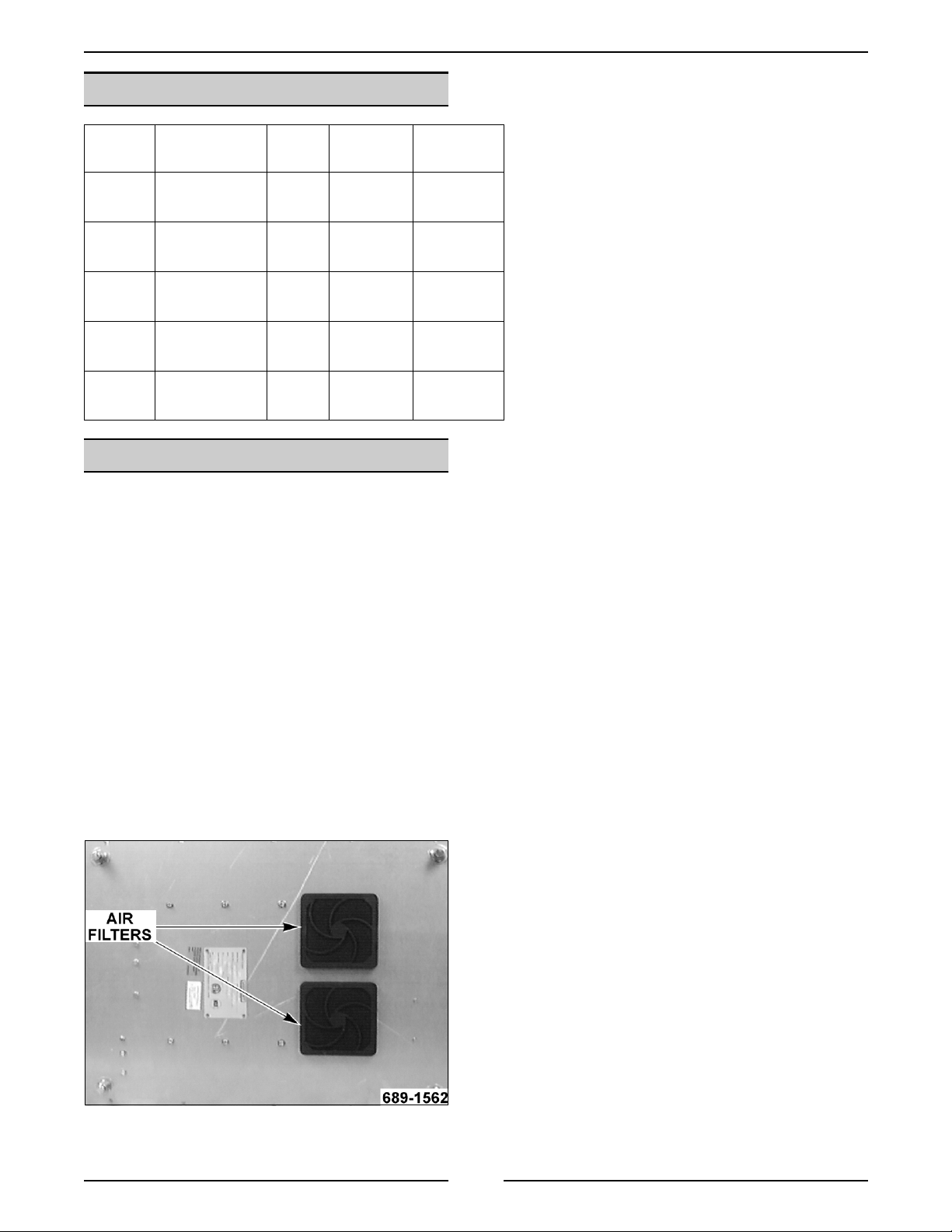

Snap out air fil ters located on the bot tom of the

cooktop and wash them i n a si nk . Dry filters before

reinstalling.

NOTE:

must be kept clean to prevent unit from overheating.

Keep area around unit clear to i nsure proper air

circulation.

Do not operate without filters in plac e. Fil ters

6

INDUCTION COOKERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

TOP COVER

WARNING:

1. Remove the screws securing the top cover to

the back of the unit.

2. Turn the unit on its side to acc ess and rem ove

the screws securing the cover to the bottom.

3. Put the unit upright and pull the top cover

straight off so not t o smear the thermal

compound.

4. Disconnect the lead wires at the controller

board if necessary.

5. Reverse proc edur e to install .

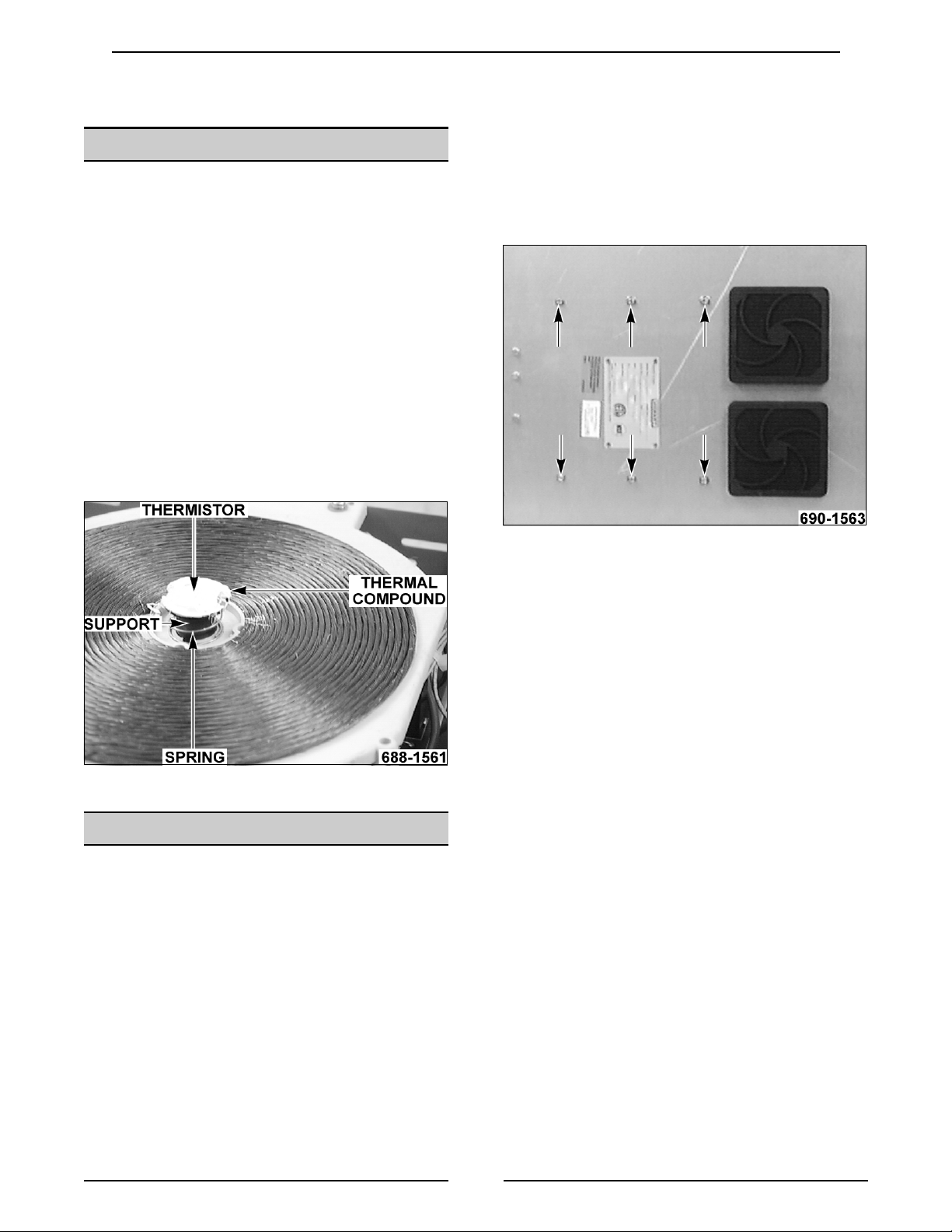

NOTE:

applied to c enter of inverter coil to contact top c over

when it is installed.

UNPLUG UNIT BEFORE SERVICING.

There must be suffi c ient thermal com pound

6. Remove control ler board and potentiometer as

outlined in “CONTROLLE R B OARD, LED AND

POTENTIOMETER”.

7. Remove six screws securing inverter asse mbly

to the base.

8. Reverse proc edur e to install .

INVERTER ASSEMBLY

WARNING:

1. Remove the top cover as outlined under “TOP

COVER”.

2. Identify and disconnect the fan plugs.

3. Remove any cable t ies securing fan wir es to

inverter frame.

4. Disconnect power leads from terminal block

and remove screws securing terminal bloc k to

base.

UNPLUG UNIT BEFORE SERVICING.

9. Apply a liberal amount of t her mal compound to

thermistor in center of inverter c oil to cont ac t

top cover as noted in “TOP COVER”.

10. Adjust power output as outlined under

“POWER OUTPUT ADJUSTMENT”.

5. Remove cable clamp securing ferrite filter on

ground wire.

7

INDUCTION COOKERS - REMOVAL AND REPLACEMENT OF PARTS

FAN MOTORS

WARNING:

1. Remove the top cover as outlined under “TOP

COVER”.

2. Disconnect the lead wire plug for the fan motor

being removed.

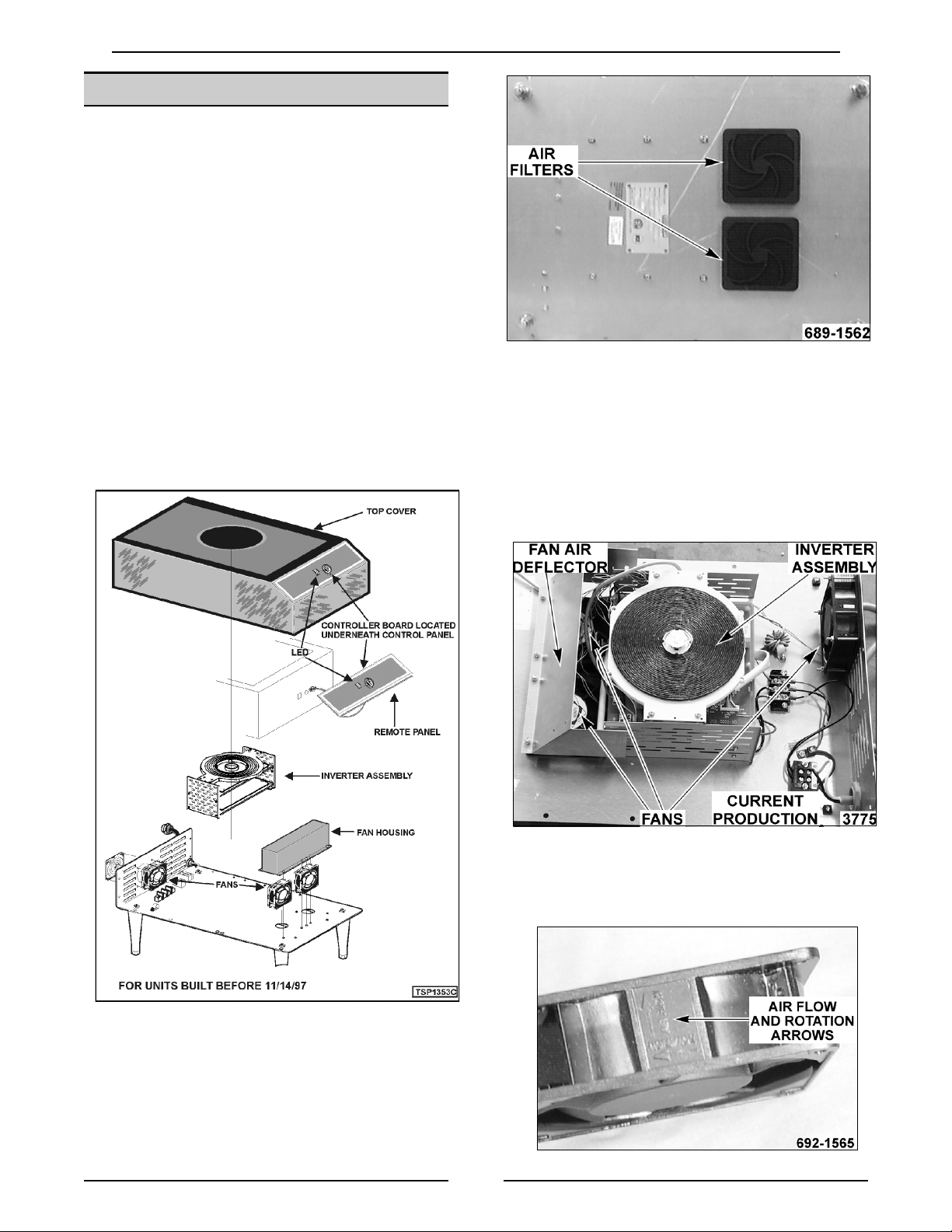

Units Bui lt Before 11/14/ 97

1. Intake fan only:

A. Snap off filters located underneath unit.

B. Remove screws securing fan housing to

C. Remove f an housi ng.

D. Remove f an from fan housing.

2. Discharge fan:

A. Remove fan.

UNPLUG UNIT BEFORE SERVICING.

base.

Current Production Units

1. Intake fan only:

A. Snap off filters located underneath unit.

B. Remove screws securing fan air deflector

to base.

C. Remove f an air deflector.

D. Remove rem aining screws securing fan to

be removed.

2. Reverse proc edur e to install .

NOTE:

flow and rotation. Air fl ow is entering unit through

base and exiting out rear of unit.

8

Fans have arrows indicating direction of air

Loading...

Loading...