Vulcan-Hart MHB24G, VHX24G5, VHX24G User Manual

SERVICE MANUAL

VHX BOILER BASE SERIES

HIGH EFFI CIENCY GAS

STEAMERS

VHX24G ML-114795

VHX24G5 ML-126590

MHB24G ML-114954 (BASE ONLY)

VHX24G SHOWN

This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician .

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

- NOTICE -

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

F24700 (October 2001)

VHX SERIES STEAMERS

TABLE OF CONTENTS

GENERAL............................................................................. 4

Installation......................................................................... 4

Maintenance ....................................................................... 4

Cleaning .......................................................................... 4

Introduction ........................................................................ 4

Steam Cooking.................................................................. 4

Compartment Pan Capacity ........................................................ 4

Model Designations .............................................................. 4

Boiler Code Descr iptions .......................................................... 4

Boiler Control Styles.............................................................. 5

Water Conditi oning .................................................................. 6

Specifications ...................................................................... 6

Water Supply ................................................................... 6

Electrical ...................................................................... 6

Boiler Pressure.................................................................. 6

Gas Supply ..................................................................... 7

Tools ............................................................................. 7

STEAMER OPERATION.................................................................. 8

Cabinet Base Boiler .................................................................. 8

Cooking Compartment Controls......................................................... 8

Boiler Blowdown and Steamer Shut off ................................................... 9

Component Func tion ................................................................ 10

Cabinet Base Boiler Controls ...................................................... 10

Cooking Compartment Controls .................................................... 12

REMOVAL AND REPLACEMENT OF PARTS ................................................ 13

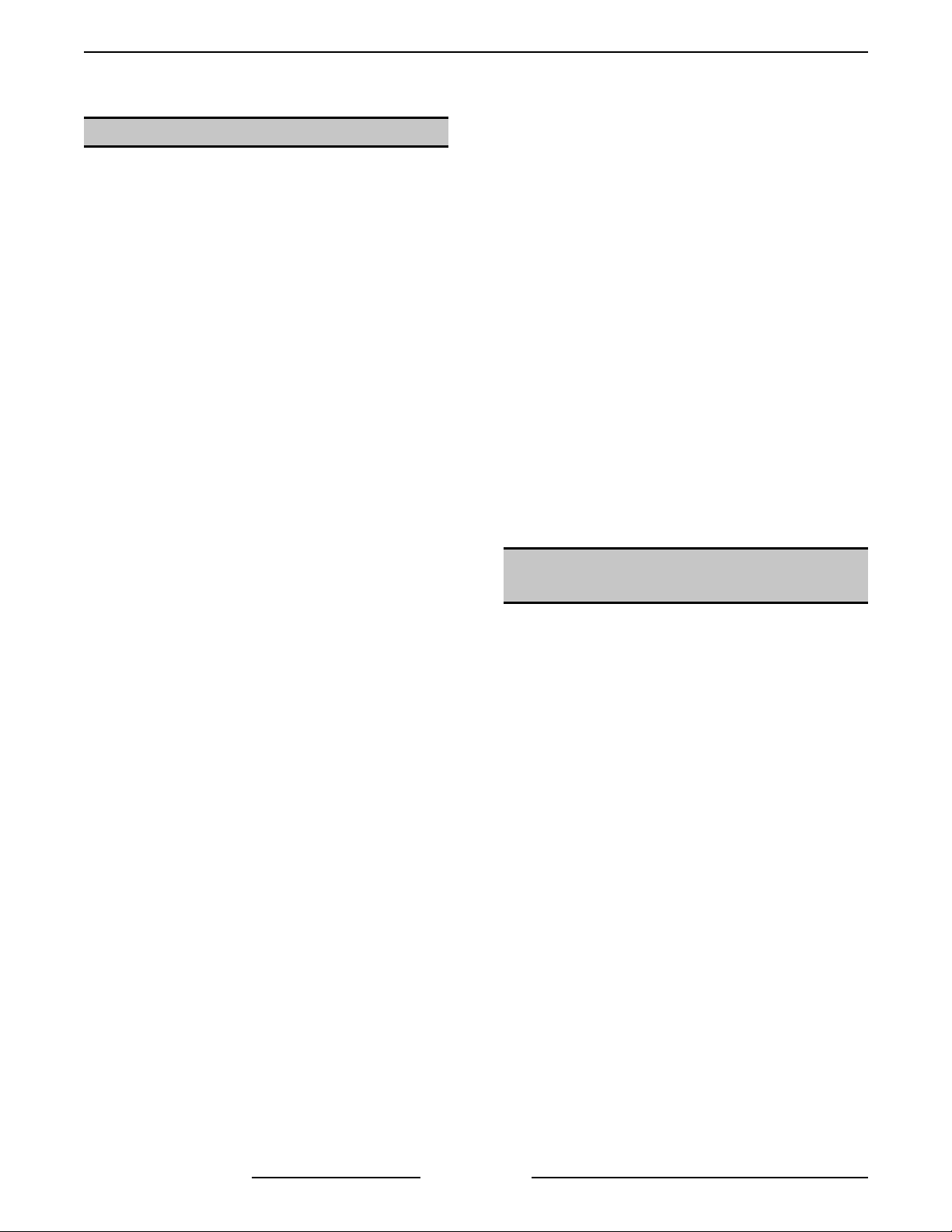

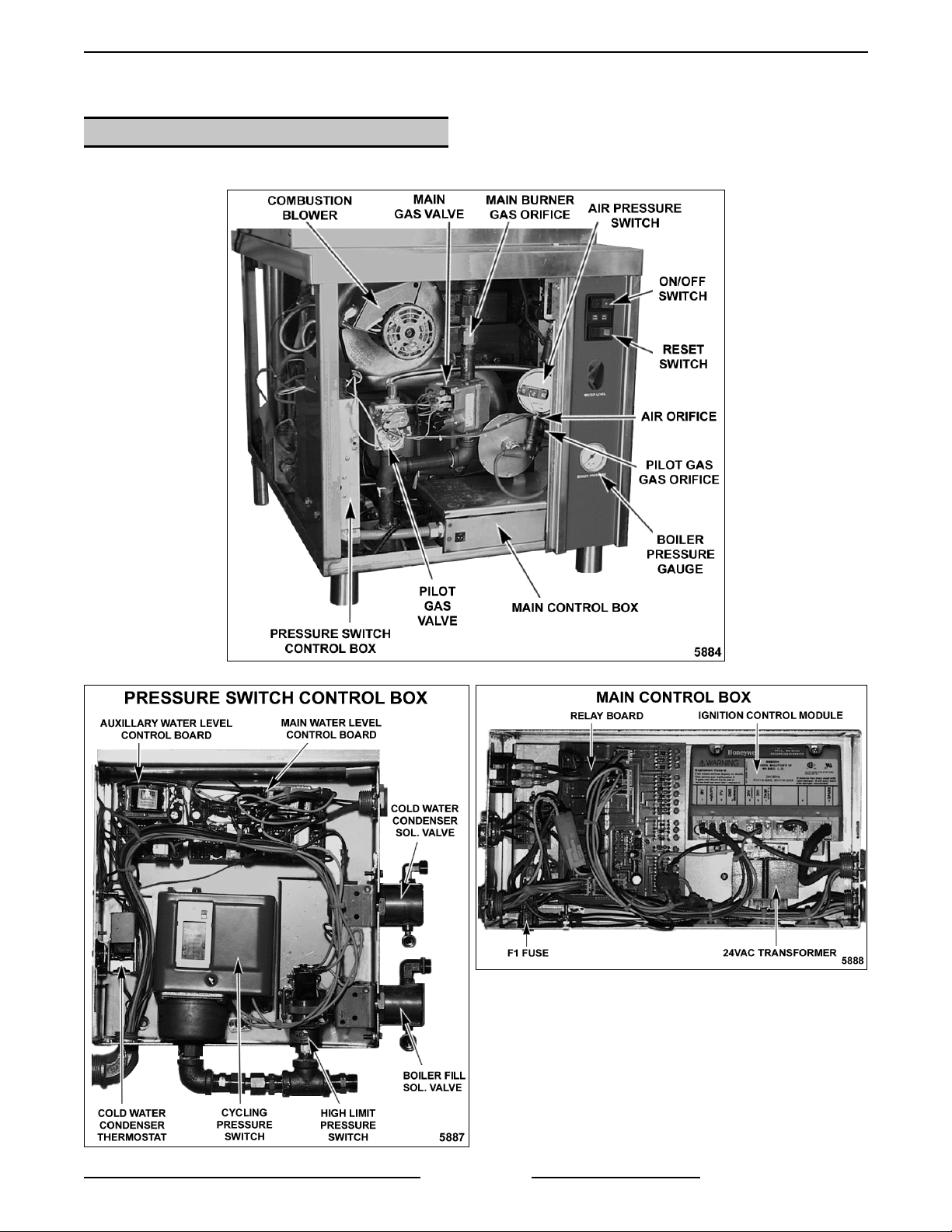

Component Locat ions ............................................................... 13

Cabinet Base Boiler Controls ...................................................... 13

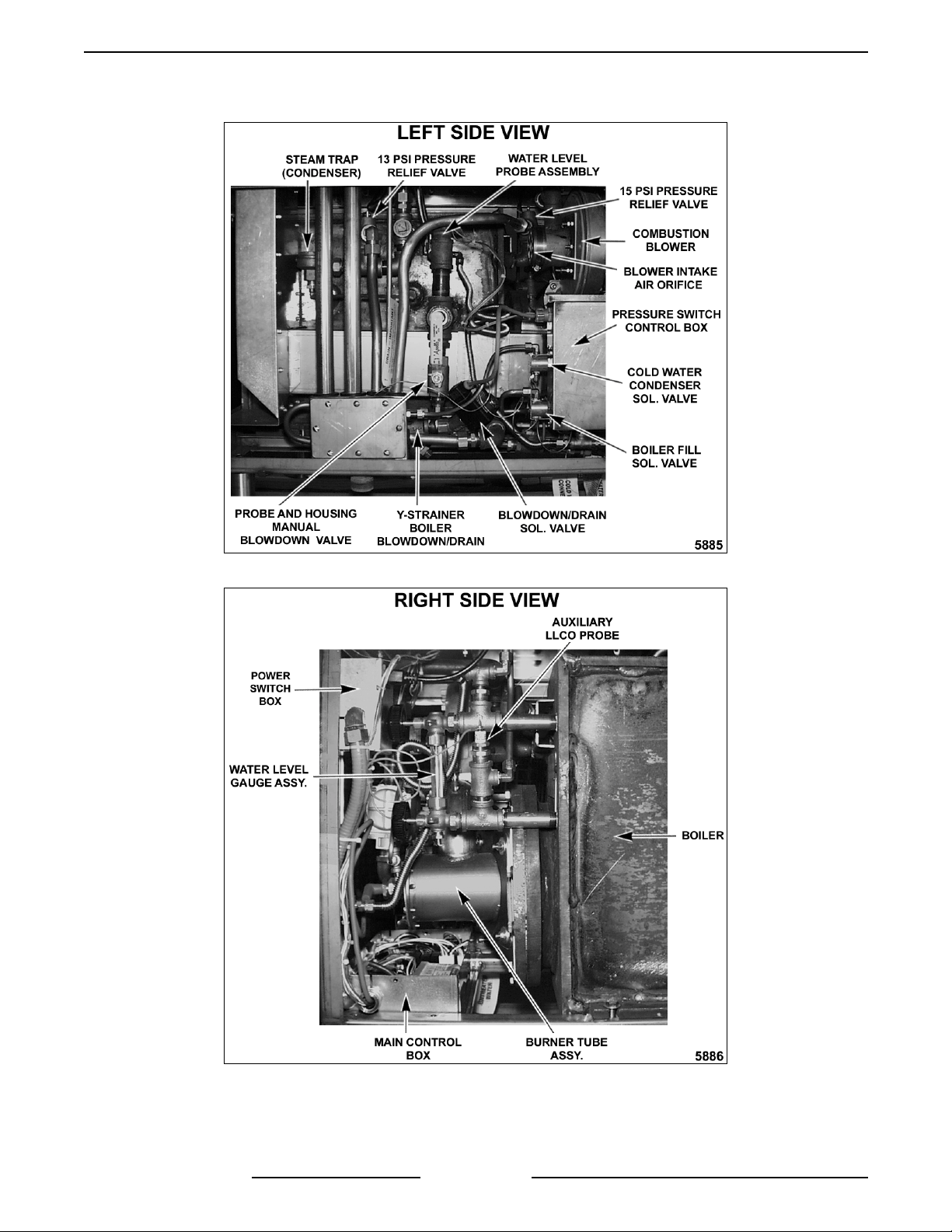

Cooking Compartment Controls .................................................... 15

Water Level Controls

(Main or Auxiliary LLCO) ......................................................... 15

Relay Board....................................................................... 15

Water Level Gauge Assembly ......................................................... 16

Pressure Switches .................................................................. 16

Boiler Assembly.................................................................... 16

Boiler Fill and Cold Water Condenser Solenoi d V alves ...................................... 17

Pilot Gas Valve .................................................................... 17

Main Gas Valve.................................................................... 17

Burner Head Assembly .............................................................. 18

Complete Burner Assembly ........................................................... 18

Heat Exchanger .................................................................... 19

Cooking Compartment Door(s)......................................................... 21

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 23

Boiler............................................................................ 23

Inspection..................................................................... 23

Clean-Out ..................................................................... 23

Deliming...................................................................... 23

Descaler (Cathodic Protector ) ...................................................... 24

Water Level Probe Housing Blowdown .................................................. 24

Water Level Controls Test ............................................................ 25

Pressure Switches .................................................................. 27

Fill and Cold W ater Solenoid V alves .................................................... 28

Boiler Blowdown/drain Solenoid Valve .................................................. 29

Inline Water S trainer Cleaning ......................................................... 29

Main Burner Ignition Checks .......................................................... 30

F24700 (October 2001) Page 2 of 68

VHX SERIES STEAMERS

Air Pressure Switch Adjustment........................................................ 33

Gas Pilot Pressure Adjustment......................................................... 34

Gas Manifold Pressure Adjustment ..................................................... 36

Ignition Control Module Checks ........................................................ 37

Cooking Compartment............................................................... 39

Intake Shut-Off Valve Adjustment (Steam Flow)........................................ 39

Door Sealing Adjustment ......................................................... 39

Door Latch Adjustment........................................................... 40

ELECTRICAL OPERATION .............................................................. 41

Water Level Controls................................................................ 41

Low Level Cut-Off & Differential Control.............................................. 41

Auxiliary Low Level Cut-Off ....................................................... 42

Relay Board....................................................................... 43

Board Layout and LED Legend ..................................................... 43

Boiler Operational Status (LED Indicator) ............................................. 44

Sequence of O per ation .............................................................. 46

New Style Controls - Boiler........................................................ 46

Old Style Controls - Boiler ........................................................ 48

Cooking Compartment Controls .................................................... 50

Schematics ....................................................................... 52

Models Built After 5/25/00 (New Style Boiler Controls) ................................... 52

Models Built Befor e 5/25/00 (Old S tyle Boiler Controls) .................................. 54

Cooking Compartment Controls .................................................... 55

Wiring Diagrams ................................................................... 56

Models Built After 5/25/00 (New Style Boiler Controls) ................................... 56

Models Built Befor e 5/25/00 (Old S tyle Boiler Controls) .................................. 58

Cooking Compartment Controls .................................................... 60

TROUBLESHOOTING .................................................................. 61

CONDENSED SPARE PARTS LIST ........................................................ 68

© VULCAN 2001

F24700 (October 2001)Page 3 of 68

VHX SERIES STEAMERS - GENERAL

GENERAL

INSTALLATION

Refer to the Installation and Operation Manual for

detailed installation instructions.

MAINTENANCE

Refer to the Installation and Operation Manual for

specific maintenance instruct ions.

CLEANING

Refer to the Installation and Operation Manual for

specific cleani ng instructions.

INTRODUCTION

Steam Cooking

Convection cooking in pressure-less steaming

compartments will steam cook fresh foods or will

steam def rost and cook froz en foods prov iding the

maximum c olor, flav or and nutritional value with the

least expenditure of energy and labor. T he pr essureless steaming compartm ents on the VHX series

allows the operator to open and close the door,

anytim e during a cooking cycle. T he steam supply

will shut off when the door is opened, then re-start

when the door is closed.

Compartment P an Capacity

PAN

DEPTH

(INCHES)

MODEL

VHX24G

NUMBER OF PANS

PER COMPARTMENT

24.0

32.5

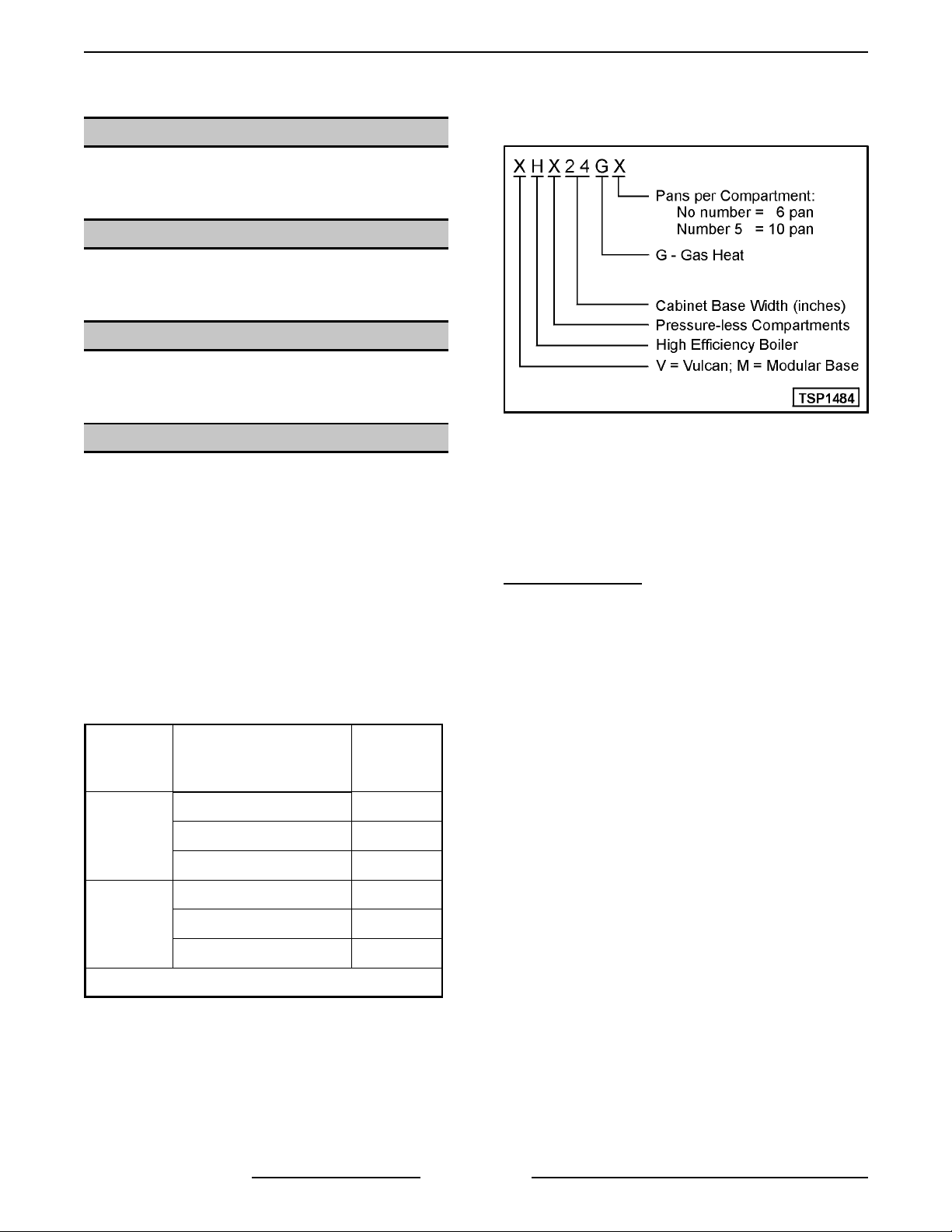

Model Desi gnations

Boiler Code Descriptio ns

Vulcan-Hart incorporates redundant c ontrols in

compliance with the CSD-1 controls and safet y

devices for boiler construction on these High

Efficienc y S team models. A Description of the c ode

is listed below.

CSD-1 Constructi on

electrical safety circuits that, i f tri pped, must

manually be reset after the condit ion causing the trip

subsides. These controls consist of - (1) dual

function water level cycling and low level cut off

control and ( 1) si ngle funct ion low water level cut-off

control ( A ux LLCO) and a high pr essure rel ief switch

in conjunction with a mechanical pr essure rel ief

valve. A dditional ly, both circuits have indi vidual

indicat or lights for low water and high pressure that

will illuminate for a visual verification of the

shutdown mode.

CSD-1 construction requires operator intervention i n

the ev ent of a shutdown. The i ndicator l ights show

the operator which safety system was shutdown.

- Redundant controls in the

61.0

34.0

VHX24G5

Pan Size 12" x 20"

F24700 (October 2001) Page 4 of 68

52.5

10 1.0

VHX SERIES STEAMERS - GENERAL

Boiler Control Styles

VHX Steamers manufactur ed usi ng the old style boiler controls ended on 5/19/00. Steamers that were in stock at

the time of the boiler contr ol changeov er were removed and equipped with the new style c ontrols without

recording t he serial number for track ing.

Refer to the pictures bel ow to differentiate between the old style and new style boiler controls.

F24700 (October 2001)Page 5 of 68

VHX SERIES STEAMERS - GENERAL

WATER CONDITIONING

Furnishing the boiler wit h treated water to reduce

scale formation is import ant. Scale format ion will

reduce steam out put, cause prematur e c omponent

failure, and shorten equi pment life. Most water

supplies contai n scale producing m inerals such as

Calcium and Magnesium. As steam is generated,

the mi nerals remai n and dissolve into the water. As

the concentrat ion of these minerals i nc r eases past a

certain point, they pr ec ipitate from the water and

coat the inside of the boi ler, heating element s, and

water level sensors. Because of the high

temperat ure of these surf ac es, the precipitated

minerals bake onto them and bec ome v er y difficult

to remove.

This may c ause several probl ems:

1. Reduced heat transf er eff iciency.

2. Premature heating element failures.

3. False readings from water l evel sensors.

These problem s are common to any manufacturer's

steamer regardless of design, but t hey c an all be

minimized by furnishing the boiler with treated

water.

Other factors affecting steam generati on ar e iron

content, amount of c hlorination and dissolved

gases.

SPECIFICATIONS

Water Supply

The fact that a water supply is potable is no

guarantee that it is suitable for steam generation.

The supply connect ion to the steam gener ator

should be “treated” water and must be within t he

guideli nes listed below. For dr ain water cooling only,

an “untreated“ water suppl y c onnec tion should be

used.

Supply pressure should be 20-60 psig

In line strainer f or suppl y line (Not Supplied)

Supply connection cold

Total dissolved solids (TDS)* less than 60 ppm

Total alkalinity less than 20 ppm

Silica less than 13 ppm

Chloride less than 30 ppm

PH fact or 7 to 8

(*17.1 ppm = 1 grain of har dness)

Electrical

Voltage - 120/ 60/1

Amps - 3.0 (max)

The desired water propert ies can best be achieved

by using a

system.

The water level probes in the boiler use ions i n the

water to detect the water level.

demineralized or de-ionized water since it is

"non conductive" and the water level can not be

detected.

The use of strainers or

remove mi nerals from the water.

Water supplies vary fr om state to state and from

locati ons wit hin a state. Therefore, a

treatment specialist should be consulted

the installation of any steam generating equipment.

Steamers that operate over a long peri od of time

without the benefit of a water treatment system,

which have developed a heavy scale build up,

should be cleaned before using the system.

properly maintained water treatment

Do not use fully

non approved

filters will not

water

before

Boiler Pressu re

Operating - 8 to 10 psi

Maximum - 15 psi

F24700 (October 2001) Page 6 of 68

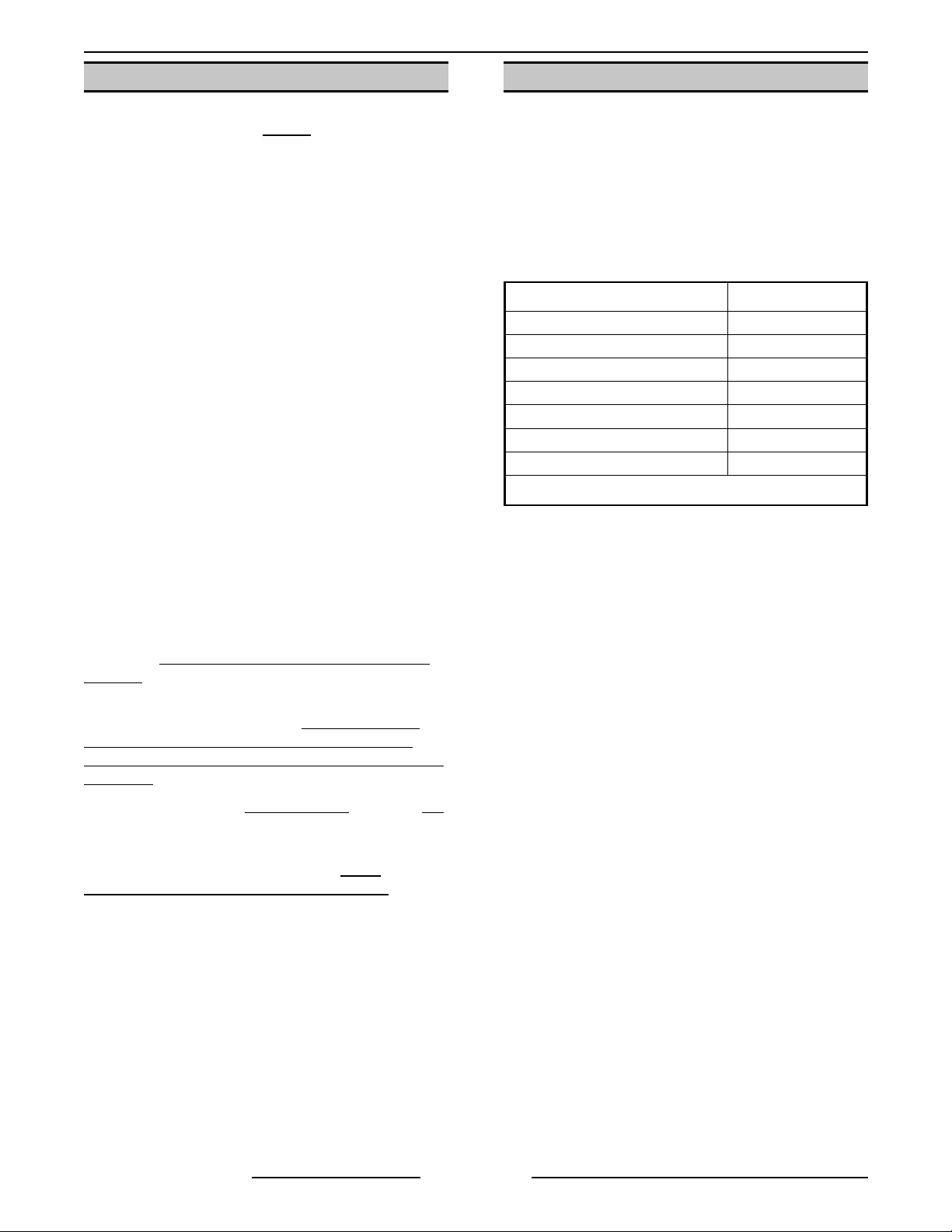

Gas Supply

VHX SERIES STEAMERS - GENERAL

MODEL

VHX24G

VHX24G5

MHB24G

NOTE

Standard

INPUT

(BTU/HR)

NAT. PROP. NAT. PROP. NAT. PROP.

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

1. Output Boiler Horsepower (BHP): 4.3 BHP for 200,000 BTU; 5.5 BHP for 270,000 BTU.

:

2. Input BTU/HR difference is based on gas orifice size and air orifi c e size.

MANIFOLD

PRESSURE

(INCHES W.C. )

PILOT

PRESSURE

(INCHES W.C. )

NATURAL PROPANE

MINIMUM

RECOMMENDED

LINE PRESSURE

(INCHES W.C. )

RECOMMENDED

TOOLS

MINIMUM

MAXIMUM

ALLOWED

14.0

Standard set of hand tools.

Volt-Ohm-Meter (VOM) with AC current tester.

(Any quality VOM wit h a sensit ivity of at least 20,000 ohm s per volt c an be used)

Gas leak checking equipment.

Gas pressure manomet er

Temperat ure meter and t her mocouple.

Special

The recommended deli ming chemical for the water treatment system in use, for deliming of the boiler.

Contact Vul c an A uthorized Service Centers.

Heat Exchanger Gasket (joi nt sealant strip, Teflon) P /N 854058-1.

F24700 (October 2001)Page 7 of 68

VHX SERIES STEAMERS - OPERATION

STEAMER OPERATION

CABINET BASE BOILER

Ensure that all utility connections to the steamer

have been made and are turned ON and t hat the

knob on the main gas valve is i n the ON positi on.

The VHX Series steam er s are CSD- 1 c ompliant and

are equipped with amber colored lights on the boiler

control panel for Hi gh P ressure and Low Water level

that illuminate and stay on until the boiler is full and

the manual reset switch pressed.

1. Turn power switch ON.

A. Amber colored lights on the boiler control

panel for High Pressure and Low Water

level will illuminate. and stay on until t he

boiler is full and the reset switch is

pressed.

B. Water will begin filling the boiler and the

blowdown solenoid v alve will close. The

boiler shoul d fill, in four to eleven minutes.

C. As water fills the boiler, observe water

level gauge glass to verify that water i s i n

boiler. See "WATER LEVEL GAUGE

ASSEMBLY" in "COMPONENT

FUNCTION” and COMPONENT

LOCATION “ under "REMOVAL AND

REPLACEMENT OF PARTS".

D. Onc e the water in the boiler reaches the

minimum level, the green ready light on

the boiler control panel will illuminate.

NOTE: If the fill has stopped, one visible inc h

of water should be in the gauge glass.

2. Press the reset switch on the boiler control

panel.

A. Low water level safety circuit will be reset

and the Low Wat er lev el light (amber) will

turn off.

B. High pressure safety circuit will be reset

and the High Pressure light (amber ) will

turn off.

C. Sparking will begin three seconds later to

light the pilot bur ner.

1) I f the pilot burner lights, a signal is

sent back through the igniti on c able

indicat ing the presence of pilot burner

flame and sparking stops.

2) I f pil ot burner flame is not

established immedi ately, sparki ng will

continue for 90 seconds. After that

duration, the ignition control module

will lock out and needs to be reset to

start the pilot and main burner li ghting

cycle again.

New Style Controls

Pilot gas valve operates on a "timer"

circuit allowing gas flow to the pilot

for approximately 15 seconds, during

ignition trial, then turns off.

D. Main gas valve opens, burner ignites and

begins to heat the water in the boil er . After

approximately 15 minutes, steam should

be present for c ook ing product. O bserve

that the boi ler pressure gauge indicates a

steam pressure of 8- 10 psi before the

burner shuts OFF.

3. The cycling pressure switch will maintain steam

pressure in the boiler by cycling the main

burner ON and OF F.

- Power to the

COOKING COMPARTMENT

CONTROLS

When the steam pressure in the c ook ing

compartment manifol d reaches approximately 3 psi,

the cooking compartment pressure switch closes,

suppling power to the ot her c ook ing compart ment

controls. The ready lights will illuminate and after

approximately one minute, the steam pressure in

the boiler will reach the upper limit of 10 psi. If the

pressure drops below approximately 3 psi, the

pressure switch will open, removing power fr om the

controls.

NOTE:

immediatel y after t he ready light c omes on, steam

solenoid chattering will be heard (oil canning) and

the ready lights will flash for several seconds. This

conditi on is caused by the mani fold steam pressure

being on the “fringe” of the pressure switch set point.

When a c ook timer is set, the compar tment steam

solenoid valve opens causing the manifold st eam

pressure to drop, slightly below the pressure switch

set point. At the same time, steam pressure is still

increasing in the boiler . This opposing condition

causes a pressure “bounce” to occur. After the

steam pressure passes approxim ately 4 psi this

conditi on subsides. Dur ing normal oper ation, this

conditi on will not be seen.

On initial startup, if a cooking ti mer is set

F24700 (October 2001) Page 8 of 68

VHX SERIES STEAMERS - OPERATION

1. With both timer knobs at the off posi tion, open

the compartment doors and observe that no

steam has entered the c ook ing compart ments,

then close the doors.

2. Set both timer knobs at 2 minutes. The r eady

lights will go off, the cooking lights will come

on, and steam will begin to enter the

compartments.

3. After one minute, open eac h door and observe

that steam has ceased to enter each

compartment, cooking lights go back to ready,

and one minut e is remaining on each cook

timer.

4. Close doors and steam generation and cook

timing will resume. Observe the floor drain to

ensure that live steam from compart ments is

being cooled by cold water fr om the cold water

condenser solenoid valve.

5. When timer k nobs reac h " 0" , buzzers will

sound, steam generation will cease, cooking

lights will go off and ready lights will come on.

To silence buz z er s, turn timer knobs to off

position.

BOILER BLOWDOWN AND

STEAMER SHUT OF F

Turn the steamer off at least once daily to bl owdown

the boiler. This will aid in the removal of sediment

and scale buil d- up in the boil er .

NOTE

: Boil er should be with-in normal operating

pressures.

1. Turn power switch OFF .

2. Boiler blowdown sequence starts.

A. The blowdown/drain solenoid valve will be

de-energized and t he boiler will begin to

drain.

B. The cold water condenser solenoid will

operate, as needed, to condense steam

and to cool the water going into the dr ain.

6. During idle t ime or a cooking cycle, the heating

system will cycle on and off as necessary to

maint ain steam pressure in t he boiler.

7. Turn power switch off to remove power from

the steamer.

A. Boiler blowdown starts.

F24700 (October 2001)Page 9 of 68

VHX SERIES STE A M E RS - COMPONENT FUNCTION

COMPONENT FUNCTION

CABINET BASE BOILER CONTROLS

Power Switch (ON/OFF)

Reset Switch (Manual)

Boiler Fill Solenoid Valve

Cold Water Condenser

Solenoid Valve

Blowdown/Drain

Solenoid Valve

Cycling P ressure Switch

High Limit Pressure Sw itch

................. Allows cold water flow into the boiler blowdown drain box to condense

................. A normally open valve (N.O.) that closes to allow boiler to fill and

......... When turned ON, supplies power to the control cir c uit.

.......... Resets the low water level safety circuit on initial startup or the

......... Controls boiler pressure between prescribed limits by turning the heat

occurrence of a low water condition and allows the boil er to fill with

water. Also, resets the high pressure lev el safety circuit on initial startup

or the occurrenc e of a high pressure condition and all ows the gas

ignition cycle to start.

........ Admits water to the boiler when dem anded by the water level control to

maintain the correct water level in the boiler.

steam and cool the hot water befor e its discharge int o the drain.

pressurize when power switch is turned ON and opens when power

switch is turned off to blowdown and drain the boiler. This valve is

plumbed into the drain line of the boiler.

source on and off.

...... Protects the boiler from pressures above 15 psi by removing power from

the heating ci rcuit. Thi s pressure setting is higher than the cycling

pressure switch in order to t ur n off the heat source before the boiler

pressure reaches its limit. A fter the pr essure drops below approximat ely

12psi, press the rest switch of the front control panel to rest the safety

circuit.

Main Water Level Control

Auxiliary Water Level Control

Transformer

Ignition Control Module

Main Gas Valve

Pilot Gas Valve

................... Provides 24VAC power to ignition control modul e and heating circ uit.

................ A gas solenoid valve that opens to allow gas flow to the main burner

................ A gas solenoid valve that opens to allow gas flow to the pilot to ignite the

........ A dual functioning control that allows water to fill and maintain the

......... Controls and m onitors gas heating. E ner gizes pilot valve coi l to supply

proper level in the boiler pr oviding dif ferenti al water level control; and

shuts off the main gas valve if the water level drops too low providing

low level cut-off protection. The water level control works by using three

different probe lengths to moni tor the water level. The probes consist of

a high level (HL) , low level (LL) and low water cut- off ( LLCO).

..... A back up to the low level cut-off on the main control. Protects the boiler

and heating system c omponents from a low water cut-off condition by

opening the 24VAC volt age path to the heati ng system circuit. Al so,

energizes the l ow water "l ight" on the front contr ol panel.

gas to pilot, generates spark to ignite gas at the pilot, monitors the

presence of flame and energizes the main and pilot valve coi ls on the

main gas valve upon a call for heat.

after the successful ignition of the pil ot burner when a call for heat is

made.

main burner when a call f or heat is made. T he valve is energized by a

tim e delay circ uit on the rel ay boar d dur ing ignit ion trial for

approximately 15 seconds. New styl e c ontrols only.

Combustion Blower

F24700 (October 2001) Page 10 of 68

............ Provides forced air to the gas/air mixture for gas pilot and m ain burner

combustion.

VHX SERIES STE A M E RS - COMPONENT FUNCTION

Relay Board

................... Provides a centralized location for wire harness connections and power

transfer through board relays (K1-K 7) to the steamer controls. Also,

provides a condition or component t r oubleshooting indicator by utilizing

seventeen LED’S on the board to represent the status of the condi tion or

component in the operation sequence. For an LED legend, see "RELA Y

BOARD" under "E LE CTRICAL OPERATION". New style c ontrols only.

: The relay’s below are mounted on the relay board and are not

NOTE

K1 Relay

...................... Energized when Aux LLCO is satisfied and turns ready light ( gr een) ON

if high limit pressure switch i s closed. Also, K1 allows K3 to be energized

when the reset switch is pressed.

K2 Relay

...................... Energized when high li mit pressure switch is closed (high limit pressure

conditi on sat isfied). When K 1 & K 2 ar e ener gized, the ready light (green)

will be ON.

K3 Relay

...................... When Aux LLCO is satisfied and the m anual reset switch is activat ed,

K3 is energized. When K 3 is energized, tur ns water error light OFF and

allows the ignition sequence to begi n. K3 must be energi z ed for ignition

sequence to begin.

K4 Relay

...................... Energized when K2 contacts are closed and manual reset switch is

activated. When K4 i s energized, the high pressure light is OFF. When

K3 and K4 are both energized, power to the ignition system is supplied.

K5 Relay

...................... Energized when operating conditions are m et and reset switch is

activated. Pr ovides power to start combustion blower.

individual ly replaceable.

K6 Relay

...................... Energized by time delay circuit for approx imately 15 seconds. When K 6

and K7 are energized, power is supplied to the pilot gas valve.

K7 Relay

...................... Energized when pilot voltage (PV) f r om the ignition module is present.

Also used in the time delay c ircuit.

......................... Ignites to light the main burner upon a call f or heat.

Pilot

Main Burner

................... Heats the water in the boiler to gener ate steam.

Water Level

Gauge Assembly

............... Permits a visual confirmation the water level is being maintained in

boiler dur ing operation. The correct water l evel is approximately one

visible inch in the glass. The manual valves at the top and bott om of this

assembly m ust be full y open and only closed if the glass tube is

damaged.

Water Inlet Valve (manual)

....... The water inlet valve is used to stop water flow to the steamer when the

steamer i s bei ng serviced. This valve should remai n open dur ing normal

operation.

Inline Water Strainer

............ A "Y" strainer is installed upstream of the blowdown solenoid valve to

prevent forei gn matter from becoming lodged in the valve. A strainer

(not supplied) shoul d also be installed in the water supply line to prevent

forei gn matter from becoming l odged in the fill or cold water condenser

solenoid valves and to keep unwanted partic les out of the system.

Pressure Relief V alve

........... A mechani c al device that opens to relieve steam pressure in the boiler if

the pressure exceeds 13 psi.

High Pressu re Relief Valve

Descaler

Boiler Pressu re Gauge

...................... Hangs below the water level inside the boi ler and is used to help cont r ol

.......... Indicates the amount of steam pressure in the boi ler.

Steam Header Assembly

....... A back-up mechanical device that opens to relieve steam pressure in

the boiler if the pressure exceeds 15 psi.

boiler surface scaling. Two descalers are used in each boiler.

......... Main steam supply line fr om the boiler to the steam header inlet in the

cooking control compar tment.

F24700 (October 2001)Page 11 of 68

VHX SERIES STE A M E RS - COMPONENT FUNCTION

COOKING COMPARTMENT CONTROLS

The upper section of the steam er c onsi sts of two separate cooking compartm ents. Each compartment functions

independently wi th its own set of contr ols. Power is supplied to the controls only after the steam pressure rises

above t he c ompartm ent pressure switch setting to close the N.O. contacts.

Ready Light (Green)

Cooking Light (Red)

Cooking Timer

Buzzer

Door Switch

Steam Solenoid Valve

Compartment P r essure Switch

Manifold Pressure Gau ge

Steam Supply Manifold

....................... Signals end of a cook cycle, must be turned off manual ly.

................... Removes electrical power to the timer. If time is dialed on the cooking

............ When lit, indicates steamer is ready to cook.

............ When lit, indicates steamer is in a cooking cycle.

................. Use to set desired cooking cycle time between 0-60 minutes. When a

........... When energi zed, opens to allow steam into the cooking compartment

........ Indicates the amount of steam pressure in manifold. The intak e shut- off

.......... Main steam supply line fr om the boiler for eac h c ook ing compart ment.

tim er is set, the steam suppl y sol enoid valve is energized to al low steam

into the cook ing compartment but only after the boiler has reached its

operating pressure. Also, energizes the buzzer when time expires.

tim er and compartments are steaming, removes power to the steam

solenoid valve when the compart ment door is opened.

(normally closed valve).

.... Supplies power to the controls only after the steam pressure ri ses above

approximately 3 psi to close the compartment pressure switch. The

switch remains closed as long as steam pressure stays above this

pressure.

valve should be adjusted so manifold pressure remains at 9 psi with both

compartments on.

Supplies steam up to the steam sol enoid valve.

Intake Shut-Off Valve

........... Main steam supply shut-off from the boiler t o the steam supply manif old.

This valve should NOT be left fully O P E N to boiler steam supply. See

“INTAKE SHUT-OFF VALVE ADJUSTMENT (STEAM FLOW)" in

“SERVICE PROCEDURES AND ADJUSTMENTS".

F24700 (October 2001) Page 12 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COMPONENT LOCATIONS

Cabinet Base Bo iler Contro ls

F24700 (October 2001)Page 13 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Cabinet Base Bo iler Contro ls Contin ued

F24700 (October 2001) Page 14 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Cooking Compartment Controls

WATER LEVEL CONTROLS

(MAIN OR AUXILIARY LLCO)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door.

2. Remove the cover from the pressure switch

control box to access the water level controls.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in "REMOVAL AND

REPLACEMENT OF PARTS".

3. Disconnect l ead wir es from the boar d being

replaced.

4. Compress the lock ing tab on the board

mounti ng "standoffs" and remove the water

level control.

5. Reverse proc edur e to install and c hec k for

proper operati on.

DISCONNECT THE ELECTRICAL

RELAY BOARD

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door.

2. Remove the cover from the main control box to

access the relay board. Refer to "CAB INET

BASE BOILER CONTROLS" under

"COMPONENT LOCATIONS" in "REMOVAL

AND REPLACEMENT OF PARTS".

3. Disconnect all lead wires f r om the board.

4. Compress the lock ing tab on the board

mounti ng "standoffs" and remove the relay

board.

5. Reverse proc edur e to install and c hec k for

proper operati on.

DISCONNECT THE ELECTRICAL

F24700 (October 2001)Page 15 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

WATER LEVEL GAUGE

ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door and remove the

right side panel.

2. Close the valve at the top and at the bottom of

the gauge assembly.

3. Unscrew the packing nuts at t he top and bottom

of the glass tube.

4. Slide t he glass tube upwards until the bottom of

the tube is clear of the fitt ing and lift it out.

NOTE

damaged or broken.

NOTE:

gauge glass may break.

5. Install the tube using new sealing washers.

6. Open the top and bottom valves.

7. Turn the power switch ON and allow boiler t o

come up to pressure.

8. Check gauge glass for water/steam leaks and i f

necessary, graduall y tighten packing nuts until

leak stops.

DISCONNECT THE ELECTRICAL

: Clean tube if dir ty or clogged and replace if

Do not ov er tighten the pack ing nuts or

PRESSURE SWITCHES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door and remove the

left side panel.

2. Remove the cover from the pressure switch

control box to access the pressure switches.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in "REMOVAL AND

REPLACEMENT OF PARTS".

3. The pressure switches are located at the

bottom of the box . The pressure switch on the

left is the cycling

the right is the high limit

4. If replacing:

A. Cycling control - remove cov er from

DISCONNECT THE ELECTRICAL

or primary control ; the one on

control.

pressure switch and disconnect the lead

wires.

1) Remove the mounti ng screws on the

back side of the control box and lift

out the pressure switch. Proc eed to

step 5.

B. High li mit control - disconnec t the lead

wires.

5. Disconnect the pressure fittings at the bottom

of the switc h.

6. Preset the new pressure switch to the

approximate cut-out (OFF) and cut-in (O N) set

points befor e installing. Refer to "PRESSURE

SW ITCHES" in " S E RV ICE PROCEDURES

AND ADJUSTMENTS".

7. Reverse proc edur e to install .

8. Adjust the pressure switch(s) final set points as

outlined under "P RESSURE SWITCHES" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

BOILER ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Blowdown the boiler and, if nec essary, allow to

cool.

2. Disconnect the steam supply line, power leads

and drain lines from the cooking compartment

top to the boi ler base.

3. Refer to " HE A T EXCHANGER" and perform

steps 3 through 12A.

4. Remove bolts securing the boiler t o frame.

5. Drain any remaining water from t he boiler.

A. The suggested methods are:

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

1) Where the dr ain line exits the boiler

on the lower left side, separate the

drain line union.

2) Remove the access panel between

the boiler and the cooking

compartment on the right side.

3) Disconnect the steam supply hose

from the cooking compartment steam

manifold.

F24700 (October 2001) Page 16 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

a. From t he bottom right side, raise

the boiler two to three inches so

it tilts to the left. When the

remaining water has drained out,

lower the boiler before.

proceeding.

B. Remove the drain/ scale clean-out plug

from the bottom of the boiler.

6. Slide t he boiler forward and remove it from

base frame.

7. Install a new boi ler and secure it t o frame.

8. Refer to " HE A T EXCHANGER" and perform

steps 13 through 15.

9. Reconnect all steam, water, dr ain and power

connections and check for proper operat ion.

BOILER FILL AND COLD WATER

CONDENSER SOLENOID VALVES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn off the water supply to the steamer.

2. Open the cabinet base door and remove the

cover from the pressure switch control box to

access the solenoid valves. Both solenoi d

valves are l oc ated side by side at the r ear of

the box with the boiler fill near the bottom and

the cold water condenser near the middle.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in “REMOVAL AND

REPLACEMENT OF PARTS”.

3. Disconnect the power l ead wir es from the

solenoid valve being serviced.

4. Disconnect the water lines for the valve bei ng

servi ced and remove the valve.

5. Reverse proc edur e to install .

DISCONNECT THE ELECTRICAL

PILOT G AS VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE:

servi ceable and should not be di sassembl ed. Once

the problem has been isolated to t his component,

replace it. Do not attempt to repair the assembly.

1. Open the cabinet door to access the Pilot gas

valve.

2. Disconnect the lead wires.

3. Remove pilot gas tubing from the top of the

valve (outlet side).

4. Remove the valve from the gas supply piping.

5. Reverse proc edur e to install and adjust pilot

pressure as outlined under "G A S P ILOT

PRESSURE ADJUSTMENT" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

ALL GAS JOINTS DISTURBED

Gas combination control valves are not

MAIN GAS VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE:

servi ceable and should not be di sassembl ed. Once

the problem has been isolated to t his component,

replace it. Do not attempt to repair the assembly.

1. Open the cabinet base door to access the mai n

gas valve.

2. Disconnect the lead wires.

3. Separate the uni on above the gas valve (outlet

side).

4. Remove the valve from the gas supply piping.

5. Reverse proc edur e to install and adjust

manifold pressure as outlined under "GAS

MANIFOLD PRESSURE ADJUSTMENT" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

ALL GAS JOINTS DISTURBED

Gas combination control valves are not

F24700 (October 2001)Page 17 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

BURNER HEAD ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Remove the pressure gauge tubing and power

cable f r om the rear of the control panel then

remove the panel.

2. Disconnect the spark igniti on c able from the

ignitor termi nal.

3. Disconnect pilot gas tubing from the air

pressure switch tee.

4. Separate the uni on above the main gas v alve

and remove the gas v alve piping assembly .

NOTE

assumes the use of a gas line quick connect or

union at the gas supply inlet to the steamer.

5. Remove the screws from the burner head

assembly end plate and pull the assembly out

from the complete burner assembly .

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

: Removal of the gas valve piping assembly

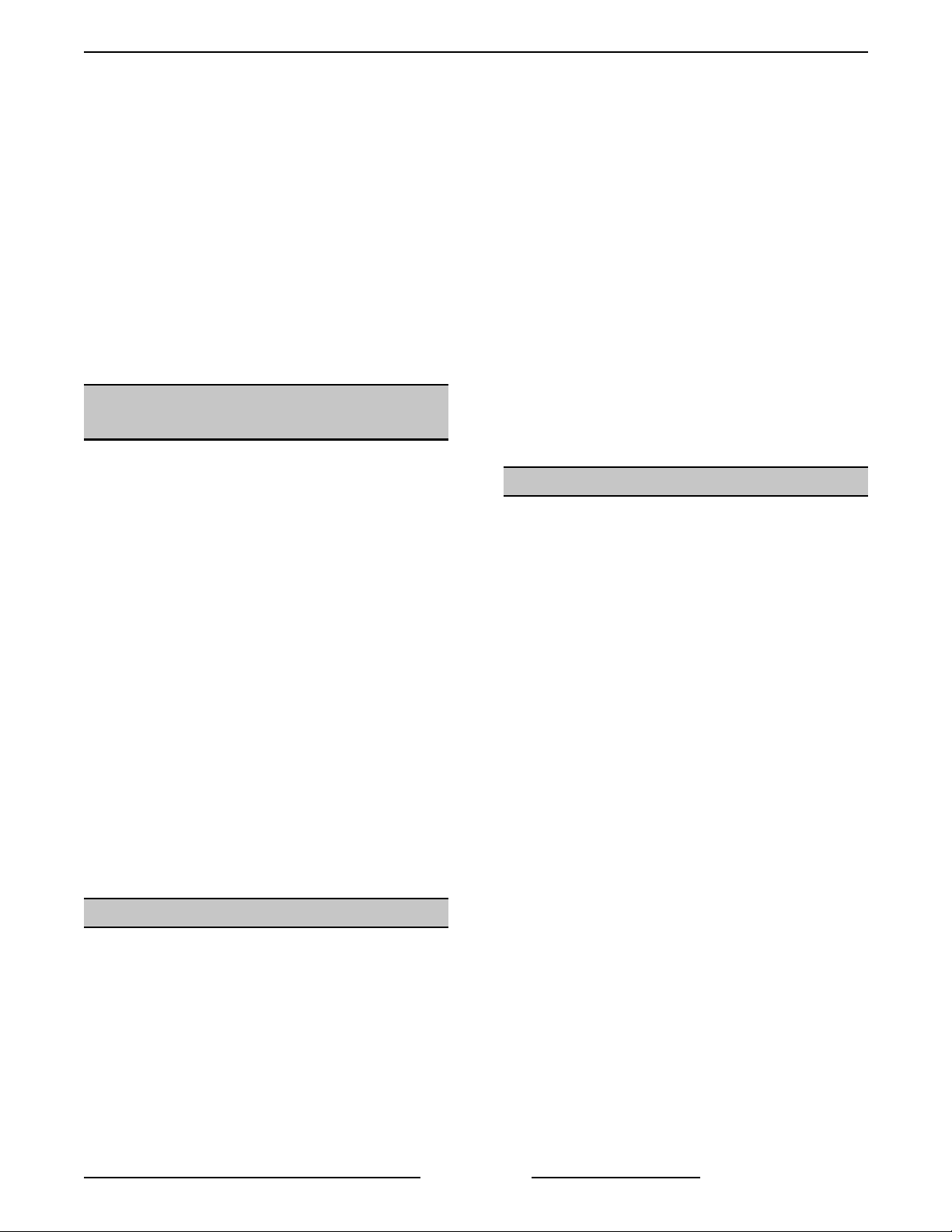

3. Remove the four nuts from the burner tube

assembly then slowly

out from the heat exchanger.

pull the assem bly straight

6. Reverse proc edur e to install and c hec k for

proper operati on.

COMPLETE BURNER

ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Refer to steps 1 thr ough 4 under "BURNER

HEAD ASSEMBLY".

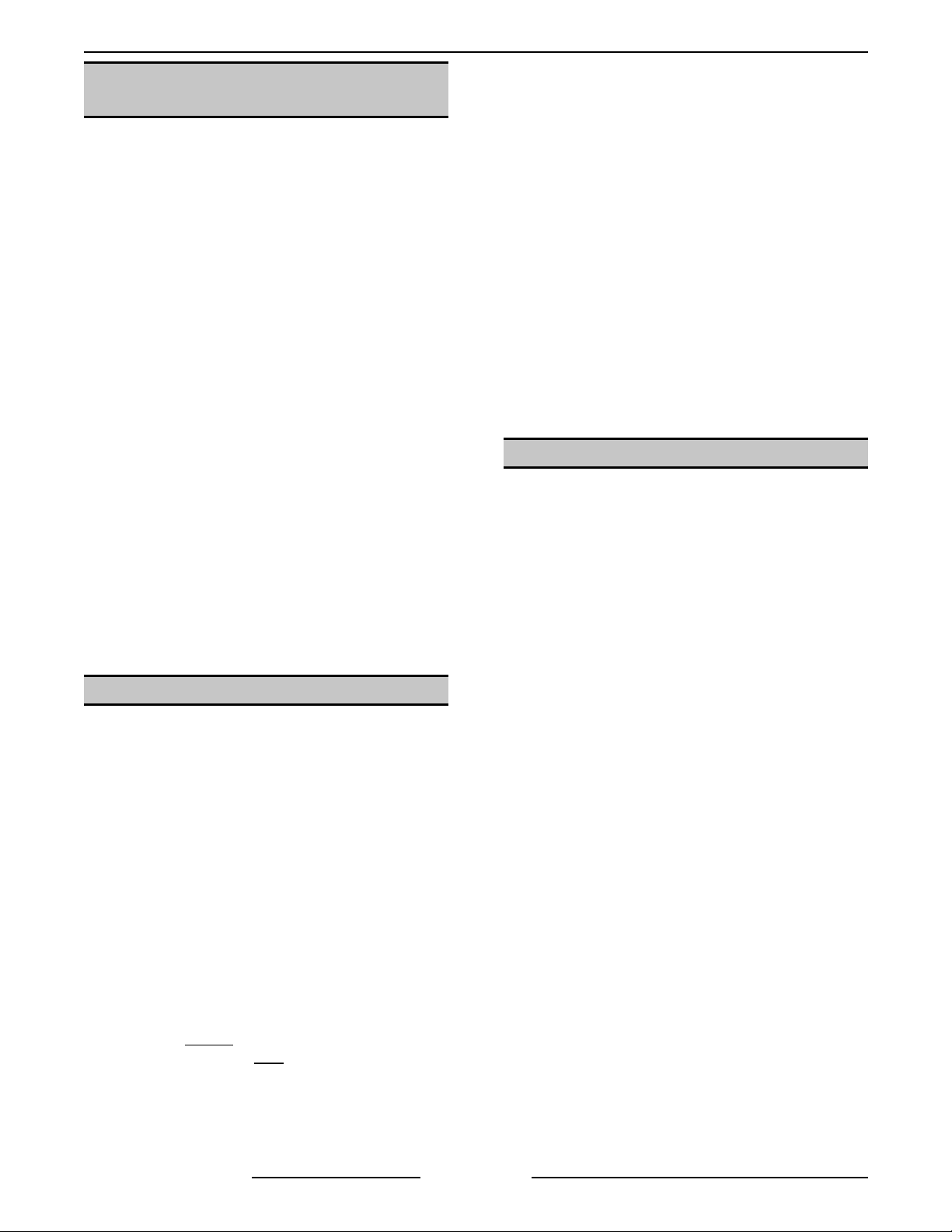

2. Remove the four nuts from c ombustion bl ower

mounti ng flange and remove blower from

burner tube assembly .

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

CAUTION: Use care w hile removing as to no t

damage the ceramic insulation surrounding the

burner.

4. Reverse proc edur e to install and c hec k for

proper operati on.

F24700 (October 2001) Page 18 of 68

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

HEAT EXCHANGER

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Blowdown the boiler and, if nec essary, allow to

cool.

2. Disconnect the electric al power to the machine

at the main circuit box. Place a tag on the

circuit box indicating the circui t is being

serviced.

3. Remove the pressure gauge tubing and power

cable f r om the rear of the control panel then

remove the panel.

4. Disconnect the electric al lead wires exiting the

boiler control box from:

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

NOTE

: Removal of the gas valve piping assembly

assumes the use of a gas line quick connect or

union at the gas supply inlet to the steamer.

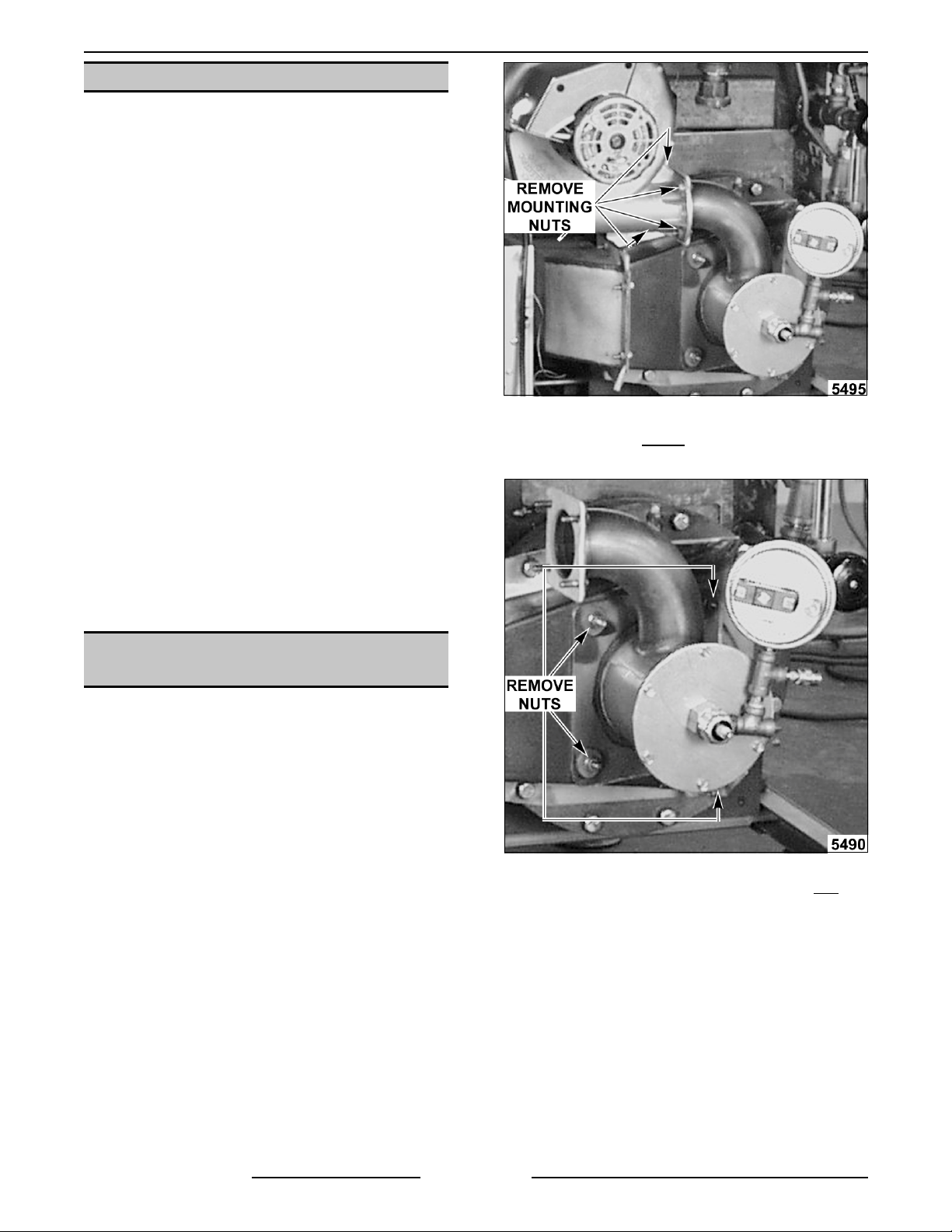

8. Remove the four nuts from c ombustion bl ower

mounti ng flange and remove blower from

burner tube assembly .

A. Auxiliary LLCO probe (Orange).

B. Burner ground (green).

C. Air pressure switch (yellow & yellow/white

stripe).

D. Main gas valve (purple & grey).

E. Pilot burner valve (red & grey).

F. Spar k ignition cable.

5. Remove bolts securing the boiler control box

(front ) to the base frame.

A. Lift up on left side of box and slide out.

6. Disconnect pilot gas tubing from the air

pressure switch tee.

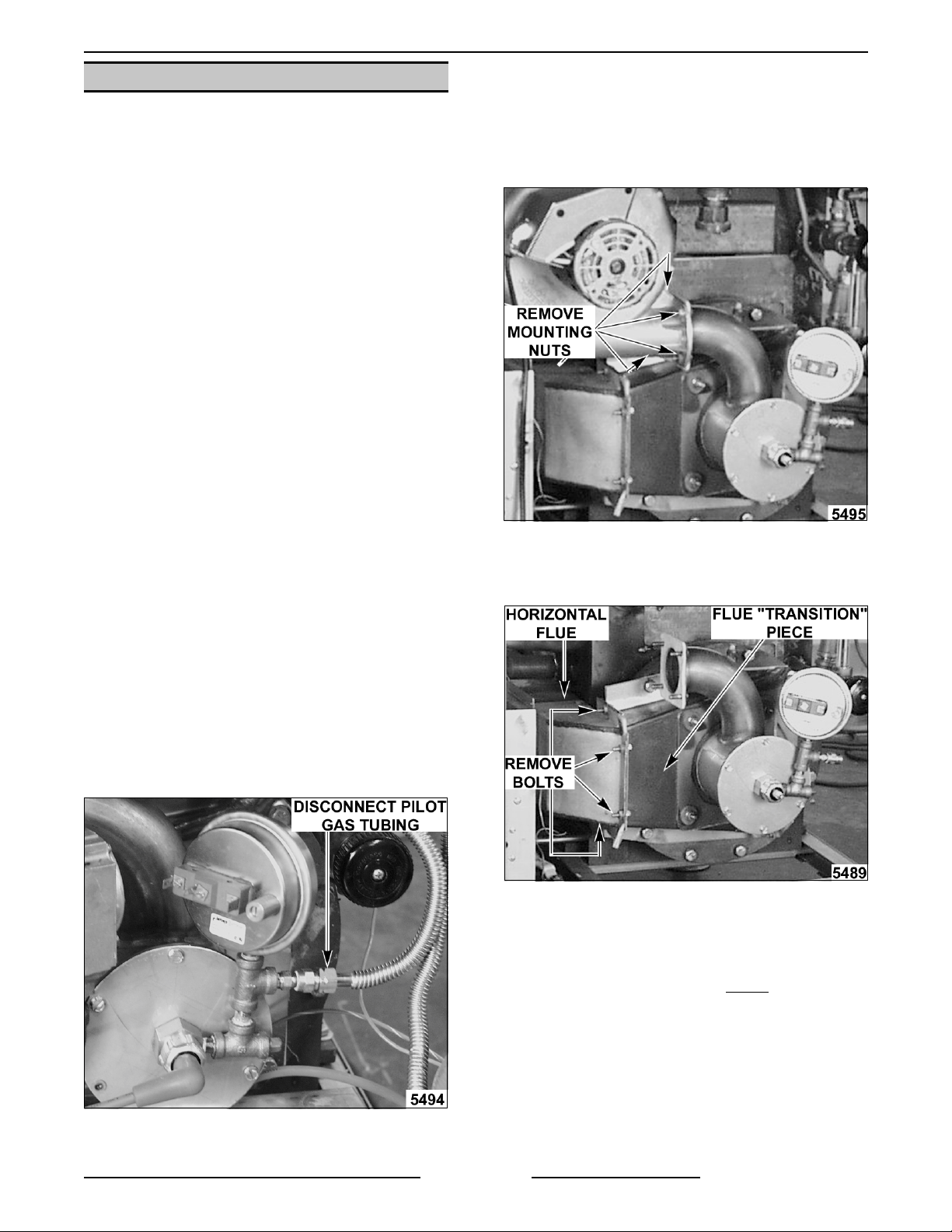

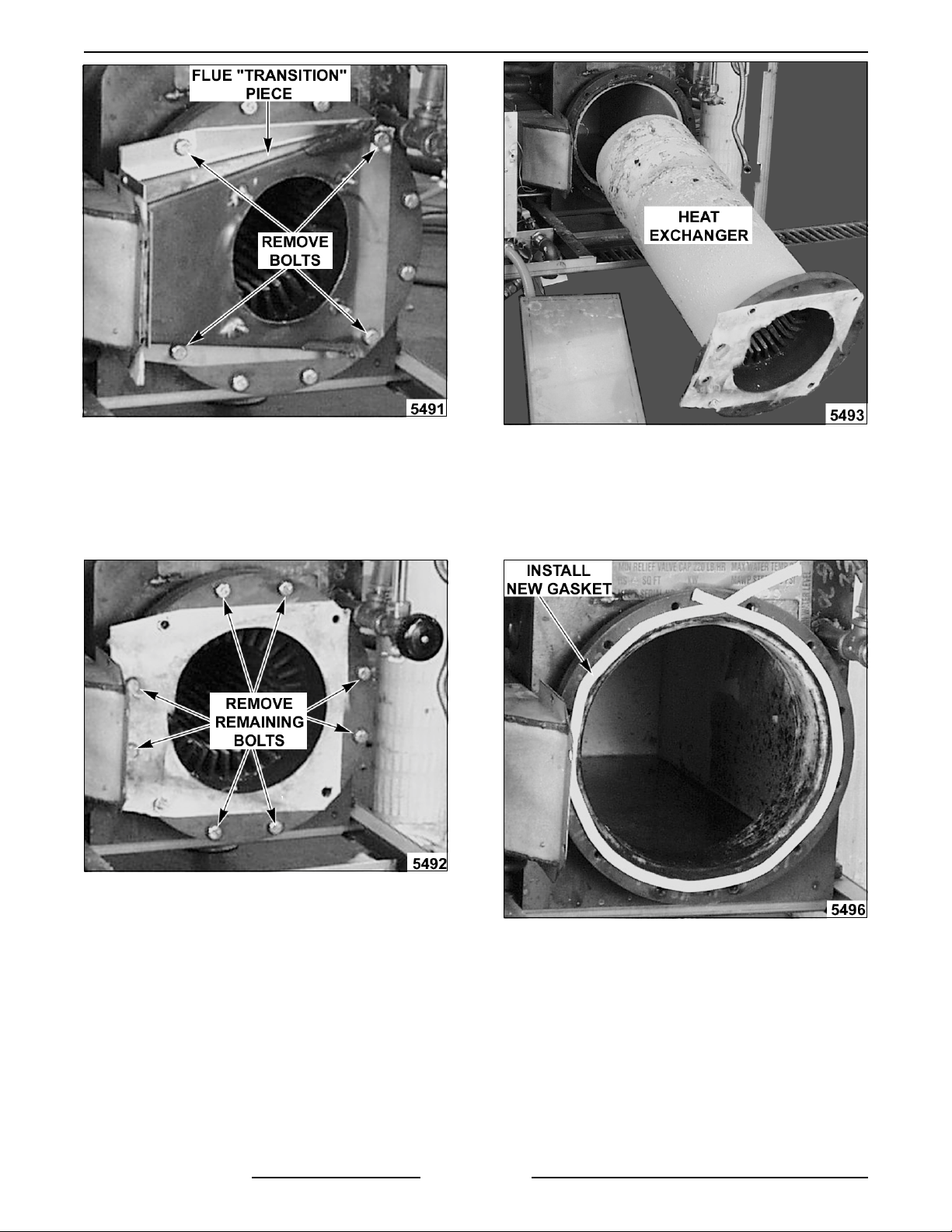

9. Remove the four bolts connecting the

horizontal flue (left of boil er) to the flue

"transition" piece.

A. Separate the horizontal flue f rom flue

"transition" piece, leaving the horizontal

flue in place.

7. Separate the uni on above the main gas v alve

and remove the gas v alve piping assembly .

10. Rem ove the four nuts fr om the com plete

burner tube assembly then slowly

assembly strai ght out from the heat exchanger.

CAUTION: Use care w hile removing as to no t

damage the ceramic insulation surrounding the

burner.

11. Rem ove the flue "tr ansi tion" piec e from the

heat exchanger.

F24700 (October 2001)Page 19 of 68

pull the

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

12. For c learance of the heat exchanger only,

remove the drain nut (petcock) and the lower

adjustment knob from the water level gauge.

A. Remove the remaining bolt s on the heat

exchanger then pull heat exchanger

straight out from the boiler.

13. To install heat exchanger:

A. Clean the m ating surfaces on the heat

exchanger and boi ler.

B. Install a new gasket on t he boiler side of

the mounting fl ange.

F24700 (October 2001) Page 20 of 68

C. Insert the heat exchanger bac k into the

boiler and line up the mounting holes

being careful not to disturb gasket.

D. At tach a 2" C-Clamp between the heat

exchanger mounting flange and the boiler

side mounting flange. Tighten clamp only

enough to allow start ing of bottom bolt into

mounti ng hole.

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

: It may be necessary to use two clamps

NOTE

to draw the bottom of the heat exchanger cl ose

enough to be clamped. Start one c lamp at a 3

o’clock position then instal l other clamp near

the bottom. Once the bolts are tight enough, CClamp will fall away.

E. Install two bolts at the bott om and two

bolts at the t op on the heat exchanger

flange and tighten the bolts a few turns at

a tim e. Starti ng wi th the bottom bolts,

tighten t he bolts in an alternating pattern

between the bottom and top for a flush

mounti ng of the heat exchanger flange

and an even compression of the gasket.

NOTE:

hand, clean out the threads with the proper si z e

tap.

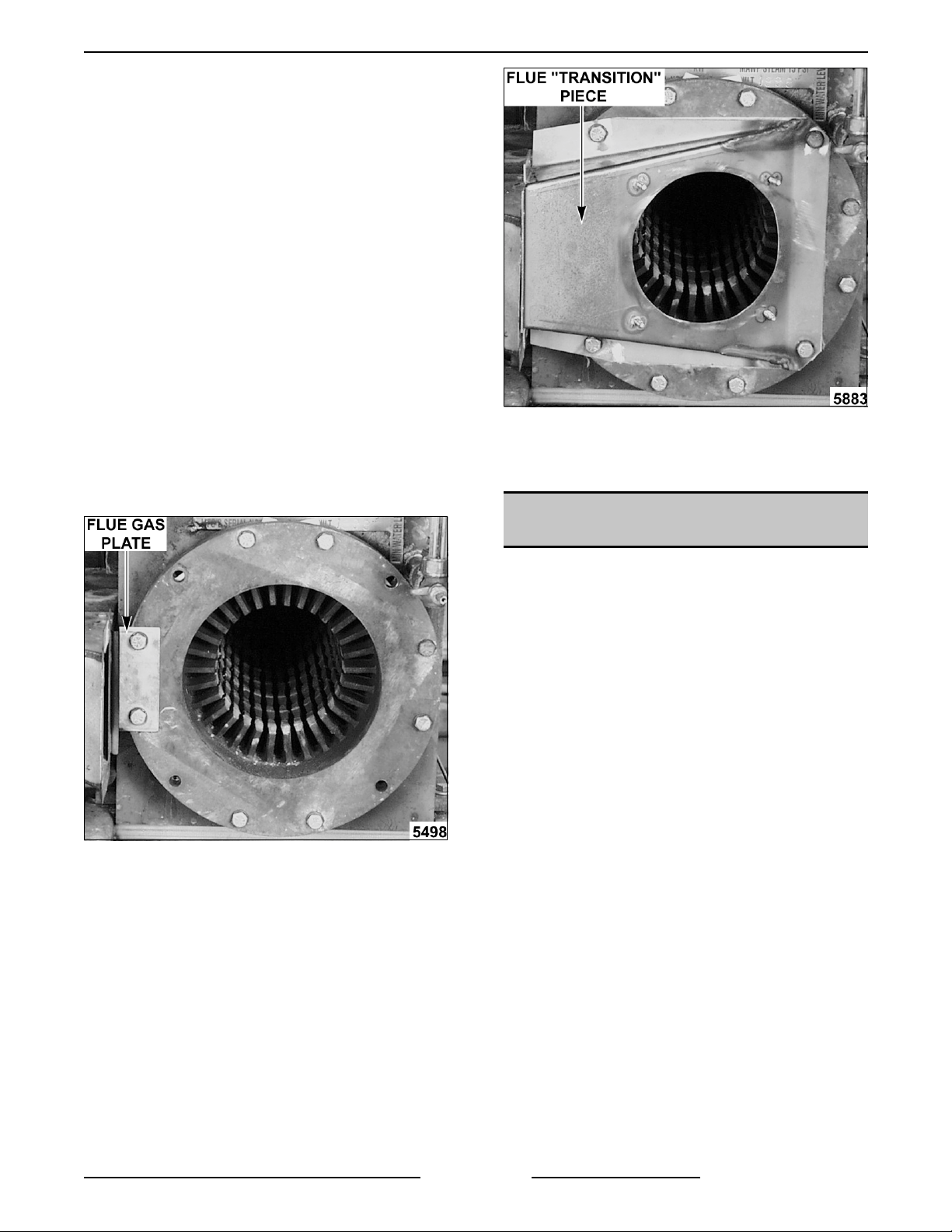

F. O nc e those bolts are tight, install the two

If a bolt is not threading in properly by

bolts to the left and t he two bolts to the

right on the heat exchanger flange. On the

left side, be sure to install the rectangular

flue gas pl ate then tight en the bolts in an

alternating pattern.

15. Star ting at step 12, reverse procedure t o install

the remaining components.

16. Check for water leaks and proper oper ation.

COOKING COMPARTMENT

DOOR(S)

Removal

1. Remove top cover.

2. Open the door.

3. Pull hinge rod up.

4. Reverse the procedure to install, m ak ing sure

the door bushings are in place.

Gasket

1. Open the door.

14. To install flue "transition" pi ec e:

A. Clean the m ating surfaces on the

"transition" piece and the heat exchanger

face.

B. Install new gasket on t he " transition" piece

then secure to the heat exchanger using

the remaining bolts.

2. Remove screws from t he gasket plate.

3. Pull t he gasket plate out from the door housing

and remove the gasket.

4. Position the new gasket on the gasket plate

and rever se t he pr oc edur e to install . Adjust the

door as outlined in " DOOR SEALING

ADJUSTMENT" under "COOKING

COMPARTMENT".

NOTE:

this will compress the gasket excessively and

interfere with proper door seal ing.

NOTE:

as nicks or cuts, will cause steam leakage.

Do not ov er tighten gasket plate screws as

Damage to the gasket sealing surface, such

F24700 (October 2001)Page 21 of 68

Loading...

Loading...