Page 1

INSTALLATION &

OPERATION MANUAL

GAS CONVECTION STEAMERS

MODELS VHX7G & VHX10G

MODELS

VHX7G ML-126835

VHX10G ML-126834

Model VHX10G

For additional information on Vulcan-Hart Company or to locate an authorized

parts and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 31212 (June 2002)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY, 2002

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vent Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Drain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Testing the Gas Supply Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operational Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stand By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Steaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daily Shutdown Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Procedure for Complete or Prolonged Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . 11

Steam Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compartment Accommodation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Deliming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Steam Unloader Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

– 3 –

Page 4

Installation, Operation and Care of

MODELS VHX7G & VHX10G

GAS CONVECTION STEAMERS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

The VHX7G and VHX10G gas-fired convection steamers are designed for cooking vegetables, eggs

and other foods — in commercial kitchens. It is not intended for household use. Each compartment

has a 0- to 60a cabinet base for floor installation.

minute timer. (The buzzer requires manual shutoff.) The steamers are equipped with

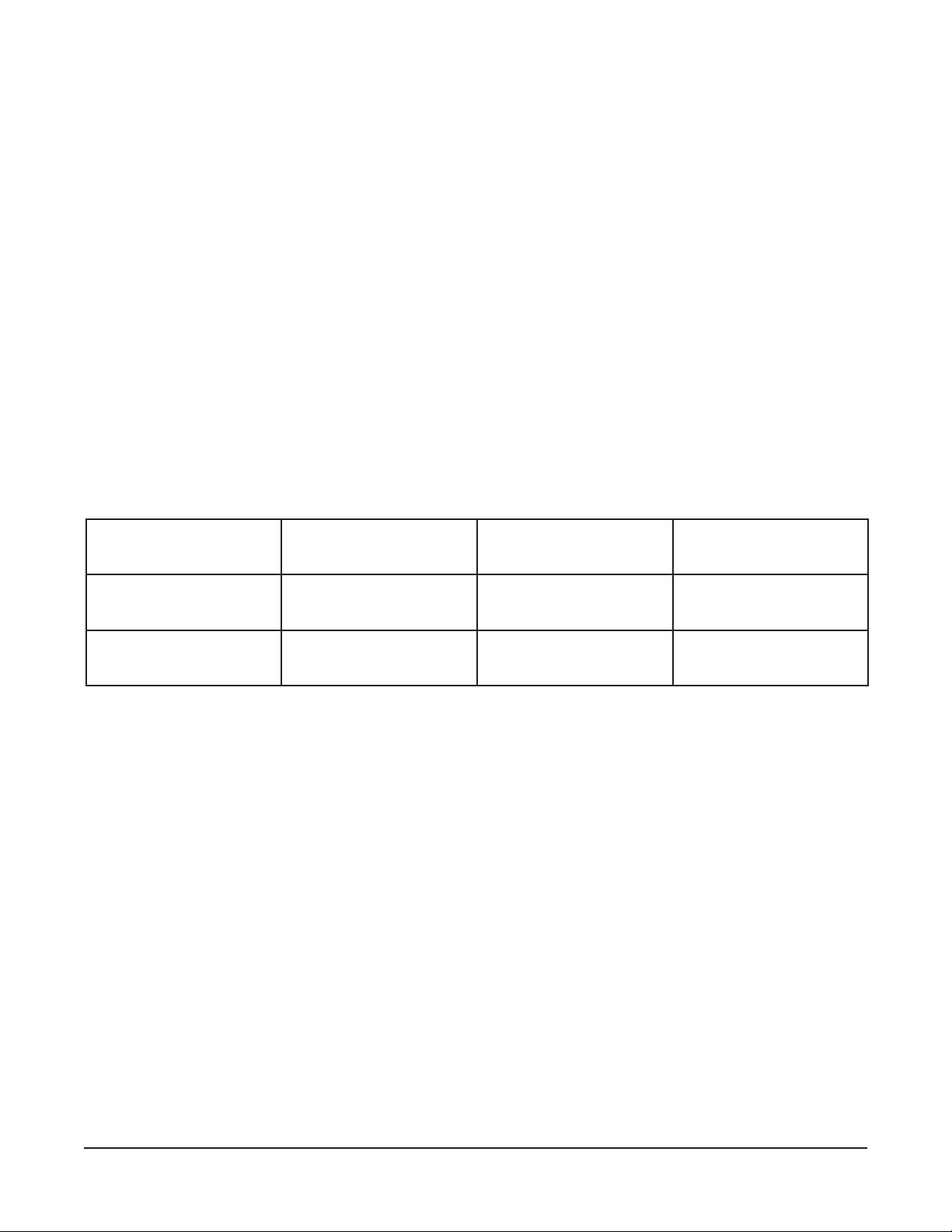

ACCOMMODATION AND GAS RATING

LEDOMSTNEMTRAPMOC

G7XHV27 rh/UTB000,541

G01XHV201rh/UTB000,091

FOREBMUNLATOT

SNAPPEED)MC6("5.2

GNITARSAG

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the steamer is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Before installing, verify that the gas (natural or propane) and the electrical supply agree with the

specifications on the data plate, which is located on the inside of the door panel.

– 4 –

Page 5

INSTALLATION CODES AND STANDARDS

In the United States, the steamer must be installed in accordance with:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition), available from the American Gas

Association, 1515 Wilson Boulevard, Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA No. 70 (latest edition), available from the National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

4. NFPA Standard #96, Vapor Removal from Cooking Equipment (latest edition), available from

the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada, the steamer must be installed in accordance with:

1. Local codes.

2. Canadian Gas Code CAN/CGA B149.1 (Natural Gas Installation Code) or B149.2 (Propane

Installation Code) (latest edition), available from The Canadian Gas Association, 178 Rexdale

Boulevard, Etobicoke, Ontario, Canada M9W1R3.

3. Canadian Electrical Code, Part 2, CSA Standard C22.2 (latest edition), available from The

Canadian Standard Association, 178 Rexdale Boulevard, Etobicoke, Ontario, Canada M9W1R3.

LOCATION

CAUTION: Do not locate the steamer over an open drain. Steam and moisture vapors could

damage the steamer and may not be covered under warranty.

The installation location must be kept free and clear of combustibles. Do not obstruct the flow of

combustion and ventilation air. Minimum clearances from noncumbustible and combustible construction

are 0" on the right side, 0" on the left side and 6" (15 cm) at the rear for proper air circulation. Install

the steamer on a noncumbustible floor. Provide adequate clearances for cleaning, maintenance,

service and proper operation.

Allow 18" (45.7 cm) between any other piece of equipment or a wall for service access. Service for the

controls for the steamer compartments requires access to the upper right side panel.

Allow sufficient air to enter the room to compensate for the amount of air removed by any ventilating

system and for combustion of the gas burners. Do not obstruct the air flow into and around the

appliance. Do not obstruct the flow of flue gases from the flue duct(s) located at the rear and above

the steamer. Position the steamer in its final location. Check that there are sufficient clearances to

service the controls, for doors to swing and to allow the required supply and drain connections.

VENT HOOD

Install an exhaust system directly above the steamer to vent steam and combustion gases generated

by the steamer and gas boilers. Refer to NFPA Standard #96,

Equipment

.

– 5 –

Vapor Removal from Cooking

Page 6

LEVELING

Using a spirit level, adjust the leveling feet to level the steamer front-to-back and side-to-side.

Mark hole locations on the floor through the anchoring holes provided in the rear flanged adjustable

feet. Move the steamer and drill holes in the floor at the marked locations. Insert proper anchoring

devices. Set the steamer back in the proper position. Bolt and anchor the leveled steamer securely

to the floor. Seal bolts and flanged feet with Silastic or equivalent compound.

After the drain is connected, check for level by pouring water onto the floor of the compartment.

All water should drain through the opening at the back of the compartment.

SERVICE CONNECTIONS (Fig. 1)

SERVICE CONNECTIONS

UNLESS OTHERWISE SPECIFIED, ELECTRICAL CONNECTION TO BE 120 VOLTS, 60 HERTZ SINGLE PHASE WITH

GROUND. FURNISHED WITH 4 1/2 FOOT CORD WITH 3 PRONG PLUG. MAXIMUM 4.0 AMPS.

DRAIN: 2" IPS PIPED TO OPEN FLOOR DRAIN. NO SOLID CONNECTION. MAXIMUM 24" LENGTH BEFORE

OPEN AIR GAP OPENING. (NO BENDS OR ELBOWS).

GAS CONNECTION: 3/4" IPS SUPPLY LINE REQUIRED.

CONDENSING COLD WATER: 3/8" O.D. TUBING AT 25-50 PSI (170 TO 345 kPa).

GENERATOR WATER: 3/8" O.D. TUBING AT 20 TO 60 PSI (138 TO 413.7 kPa).

ELECTRICAL CONNECTION

CONDENSING COLD

WATER CONNECTION

GENERATOR WATER

CONNECTION

GAS CONNECTION

STEAM UNLOADER PORTS

DRAIN

Fig. 1

– 6 –

PL-56413

Page 7

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

Water Supply Connections

The water filter system, provided, must be installed in the water supply line going to the treated water

inlet of your steamer or the warranty may be voided. For incoming water supply line pressures, refer

to the water filter manual shipped with the water filter. Follow the recommendations contained in it.

Water pressure to the steamer should be 20 to 60 psig.

The two incoming cold water supply connections at the rear of the steamer cabinet (Fig. 1) require 3/8"

tubing (10 mm). Water supply to the boiler must be provided with a backflow preventer device to comply

with the Basic Plumbing Code of the Building Officials and Code Administrators International, Inc.

(BOCA) and the Food Service Sanitation Manual of the Food and Drug Administration (FDA). Supply

normal tap water to the condensing cold water connection at the rear of the steamer. This water supply

condenses steam prior to discharge into the open drain.

Water Requirements

Proper water quality to the boiler can improve the taste of the food prepared in the steamer, reduce

liming in the steam generator and extend equipment life. Local water conditions vary from one location

to another. Ask your municipal water supplier for details about your local water supply prior to

installation.

Recommended water parameters are included in the water filter manual shipped with the steamer;

follow the recommendations contained in it.

Presence of sediment, silica, excess chlorides or other dissolved solids may lead to a recommendation

for alternate form(s) of water treatment. Be sure to test the water with the test strip included with the

water filter.

DRAIN CONNECTION

Temperatures in the boiler can briefly reach as high as 212°F (100°C). Local codes will require that

the temperature of the drain water be 140°F (60°C) or lower. At the end of the day when purging the

boilers, some provision for lowering the water temperature must be provided by the user or installer to

meet this code requirement.

1

The steamer drain requires 2" IPS (51 mm) {1

/4" NPS} (Fig. 1), and should be piped to an open floor

drain near the steamer. To avoid back pressure in the drain, there should not be a solid drain

connection.

is 6' (183 cm),

An open gap between the steamer and the floor drain is required. Maximum length of drain

minimum length is 24" (610 mm). There should be no bends or elbows in the drain line.

– 7 –

Page 8

GAS CONNECTION

The data plate on

the inside of the door panel indicates the type of gas your steamer is equipped to burn.

DO NOT connect to any other gas type.

Keep the appliance area free and clear from combustible substances. Do not obstruct the flow of

combustion and ventilation air.

3

/4" NPT threaded fitting is provided at the rear of the steamer for the gas supply connection (Fig. 1).

A

Each steamer is equipped with an internal pressure regulator which is set at 3.5" W.C. (0.87 kPa)

1

manifold pressure for natural gas or 10" W. C. (2.5 kPa) for propane gas. Use the

/8" pipe tap on the

burner manifold for checking pressure.

An adequate gas supply is necessary. Undersized or low-pressure lines will restrict the volume of gas

required for satisfactory performance. A steady supply pressure from 7" W.C. (1.75 kPa) for natural

gas and from 11" W.C. (2.75 kPa) for propane gas is recommended. With all steamers operating

simultaneously, the manifold pressure on all steamers should not show any appreciable drop.

Fluctuations of more than 25% on natural gas and 10% on propane gas will create problems and affect

burner operation. Contact your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt or foreign matter before connecting the line to the

steamer.

Use pipe joint compound that is resistant to the action of liquified petroleum or propane gases on all

threaded connections.

Codes require that a gas shutoff valve be installed in the gas line prior to the steamer. Make sure the

pipes are clean and free of obstructions, dirt and piping compound. A manual gas shutoff valve is

supplied for each gas burner unit.

WARNING: PRIOR TO STARTUP, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

Do not connect the steamer to the electrical supply until after the gas connection has been made.

TESTING THE GAS SUPPLY PIPING

1

When test pressures exceed

/2 psig (3.45 kPa), the steamer and its individual shutoff valve must be

disconnected from the gas supply piping system during any pressure testing of the system. When test

1

pressures are

/2 psig (3.45 kPa) or less, the steamer must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure testing of the system.

ELECTRICAL CONNECTION (Fig. 1)

WARNING: THE STEAMER IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THE

OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT

REMOVE THE GROUNDING PRONG FROM THE PLUG.

Refer to the data plate and the electrical diagram located on the inside surface of the right side panel.

– 8 –

Page 9

ELECTRICAL DATA

SLEDOMESAHP/ZTREH/STLOVSPMAENIHCAM

YTICAPMATIUCRICMUMINIM

ECIVEDEVITCETORPMUMIXAM

SPMA

G7XHV

G01XHV

1/06/0215.151

OPERATIONAL TEST PROCEDURE

WARNING: THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE STEAMER. THE COOKING COMPARTMENT CONTAINS LIVE

STEAM. STAY CLEAR WHILE OPENING THE DOOR.

Once the steamer is installed and all mechanical connections have been made, thoroughly test the

steamer before operation.

1. Check that proper water, drain, electrical and gas connections have been made.

2. Turn main power switch to the ON position. After approximately 19 minutes, the ready light should

come on, indicating that the water temperature has reached 205°F (96°C).

3. Check that the ignition light comes on and cycles on and off.

4. When the ready light comes on, set the timer to the 5-minute position. With the door open, observe

that no steam is entering the compartment and the cooking light is off.

5. Close the compartment door. The cooking light should now be lit and steam should be heard

entering the compartment after about 45 seconds.

6. Check the drain line to be sure that water from the cold water condenser is flowing through the

drain line.

7. Open the compartment door and observe that steam supply to the chamber stops, the ready light

comes on and the cooking light goes off.

Close the compartment door and let the cooking cycle finish. When the timer returns to the

8.

position, a buzzer will sound, signaling the end of the cooking cycle. To silence the buzzer, turn

0

the dial timer to the OFF position.

9. Complete the above steps for each cooking compartment.

10. To shut the cooker down, turn the main power switch to the OFF position and close the manual

gas shutoff valves. Leave the compartment doors slightly open to allow the inside to dry out.

– 9 –

Page 10

OPERATION

WARNING: THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE STEAMER. COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHEN OPENING DOORS.

CONTROLS (Fig. 2)

DOOR LATCH

READY LIGHT

COOKING LIGHT

TIMER

MAIN POWER SWITCH

IGNITION LIGHTS

PL-56397

Fig. 2

Main Power Switch

ON Boiler tank fills [requires 12 minutes], heats water in the boiler tank to

205°F (96°C) [requires 7 minutes more] and maintains this temperature.

OFF Boiler tank drains.

Ready Light Boiler temperature has reached 205°F (96°C) — steamer is ready to start

a cooking cycle.

Cooking Light A cooking cycle is in progress.

Timer Allows you to set the cooking time (0 to 60 minutes) — steam cooking

begins when the door is closed. Steaming stops if the door is opened

during the cooking cycle; resume cooking by closing the door.

When the timed cycle is finished, a buzzer sounds and steam stops flowing

into the compartment. Turn timer to the OFF position to stop the buzzer.

Ignition Lights

Boiler tank has filled, burner has ignited and tank water is heating.

NOTE: If the ignition light fails to remain on until the ready light comes on or the gas supply is

interrupted, a 5-minute period of complete shutoff is required before restarting.

– 10 –

Page 11

STARTUP PROCEDURE

Open gas supply and ensure the steamer doors are closed.

Turn main power switch to the ON position. After the boiler fills with water, the ignition light will come

on. If the ignition light fails to remain on until the ready light comes on or the gas supply is interrupted,

a 5-minute period of complete shutoff is required before restarting.

Ignition must be complete in 8.5 seconds or the boiler control goes into lockout. Shut off the power, wait

5 minutes, then turn power back on to restart ignition.

STAND BY

Set the timer to the OFF position and leave the door slightly open.

STEAMING

Each steaming compartment has its own controls.

With the ready light lit, the steamer is ready for use.

• Place pans of food to be cooked into the compartment and shut the door.

• Set the timer to the desired cooking time. Steaming begins.

• The cooking cycle may be interrupted at any time by opening the compartment door — resume

cooking by closing the door.

• When the buzzer sounds, the timed steaming cycle has finished. Steaming stops, the cooking

light goes off and the ready light comes on. To silence the buzzer, turn the timer OFF.

DAILY SHUTDOWN PROCEDURE

Each compartment has its own boiler. Each compartment must be shut down.

Turn the main power switch to the OFF position; close the manual gas shutoff valve.

PROCEDURE FOR COMPLETE OR PROLONGED SHUTDOWN

Each compartment has its own boiler. Each compartment must be shut down.

Turn the timer and the main power switch to the OFF position — the boiler will drain.

Close the manual water valves and the manual gas shutoff valves.

Disconnect the power cord.

– 11 –

Page 12

STEAM COOKING

The steamer efficiently cooks vegetables or other foods for immediate serving. Steam cooking should

be carefully time-controlled. Keep hot food holding time to a minimum to produce the most appetizing

results. Prepare small batches. Cook only enough to start serving, then cook additional amounts to

meet demand. Separate frozen foods into smaller pieces to allow more efficient cooking.

Cooking time for frozen foods depends on amount of defrosting required. If time permits, allow frozen

foods to partially thaw overnight in a refrigerator. This will reduce their cooking time.

Precooked Frozen Products

If the product cannot be cooked in its covered container and requires more than 15 minutes of cooking

time, use a pan cover. When a cover is used, approximately one-third additional time is necessary.

PREPARATION

Prepare vegetables, fruits, meats, seafood and poultry normally by cleaning, separating, cutting,

removing stems, peeling, etc. Cook root vegetables in a perforated pan unless juices are being saved.

Liquids can be collected in a solid 12" x 20" (30 cm x 51 cm) pan placed under a perforated pan.

Perforated pans are used for frankfurters, wieners and similar items when juices do not need to be

preserved. Solid pans are good for cooking puddings, rice and hot breakfast cereals. Vegetables and

fruits are cooked in solid pans in their own juices. Meats and poultry are cooked in solid pans to preserve

their own juices or to retain broth. Canned foods can be heated in their opened cans (cans placed in

12" x 20" solid pans) or the contents may be poured into solid pans. DO NOT place unopened cans

in the steamer.

COMPARTMENT ACCOMMODATION

Steamers are designed to accept combinations of 12" x 20" (30 cm x 51 cm) pans (solid or perforated),

up to the following limitations:

LEDOMTNEMTRAPMOC

G7XHV

G01XHV

HTPEDNAP

)MC5.2("1

tnemtrapmoCpoTsnaP6snaP3snaP2naP1

tnemtrapmoCmottoBsnaP8snaP4snaP2snaP2

tnemtrapmoCpoTsnaP01snaP5snaP3snaP2

tnemtrapmoCmottoBsnaP01snaP5snaP3snaP2

HTPEDNAP

)MC6("5.2

HTPEDNAP

)MC01("4

HTPEDNAP

)MC51("6

– 12 –

Page 13

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

CAUTION: Do not spray with hose or steam cleaner. Doing so will cause extensive damage (not

covered under warranty).

At the end of each day, or between cooking cycles if necessary . . .

Turn the main power switch to the OFF position. Remove pans and racks from the compartment(s) and

wash in a sink. Wash the compartment interior with clean water. Never use steel wool or abrasive

scouring pads, as they will scratch and ruin the general surface appearance of the steamer.

Use warm, soapy water with a cloth or sponge to clean the exposed bead of the door gasket. Rinse

with warm, clear water and wipe dry with a dry cloth.

Wipe surfaces that touch the door gasket with a cloth or sponge and warm, soapy water. Rinse with

warm, clear water and wipe with a dry cloth. CAUTION: Do not allow the door gasket to come in

contact with food oils, petroleum solvents or lubricants.

Wipe all solids away from the drain openings in the compartments to prevent clogging. Keep the

cooking compartment drains working freely. After cooking grease-producing foods or seafood, operate

1

the steamer with compartments empty for 30 minutes at the end of the day, or pour

1

of warm, soapy water down the drain, followed by

/2 gallon (2 liters) of warm, clear water. After cooking

/2 gallon (2 liters)

seafood, run the compartment empy for 5 to 10 minutes at least once a day to keep the drain clear.

Leave the door slightly open when the steamer is not in use to allow the inside to dry out.

Weekly, or more often if necessary . . .

Clean the exterior with a damp cloth and polish with a soft, dry cloth. Use a nonabrasive cleaner to

remove discolorations.

Corrosive cleaning agents such as chlorides, acids, salts or vinegar may cause pitting and corrosion

which will reduce the life of the appliance. Never spray water into electric controls. Climatic conditions

(salt air) may require more thorough and frequent cleaning, or the life of the appliance may be adversely

affected.

For hard-to-remove stains: Apply cleanser on a damp cloth or sponge and gently rub metal in the

direction of the polish lines. Avoid marring the stainless steel. Do not rub in a circular motion.

If the previous procedure fails, ScotchBrite or stainless steel wool pads may be used. Do not use

ordinary steel wool, as particles left on the surface will rust and spoil the finish. Never use a wire brush,

steel scraper, putty knife, file, steel wool pads (except stainless steel) or other steel tools. Marring the

surface will make it more difficult to clean and will increase the possibility of corrosive attack.

Heat tint is a darkened area on stainless steel which was subjected to excessive heat. It is not harmful,

but can usually be removed by vigorous scouring in the direction of the polish lines. Use ScotchBrite

scouring pads or a stainless steel wool, combined with a moist paste of powdered cleanser.

– 13 –

Page 14

MAINTENANCE

WARNING: THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR SERVICING THE STEAMER. COMPARTMENTS CONTAIN LIVE STEAM. STAY CLEAR WHEN

OPENING DOORS.

DELIMING

Refer to the water filter manual shipped in the box with your steamer.

STEAM UNLOADER PORTS

Your steamer is equipped with two 5 psi steam unloader ports at the rear of the steamer (see Fig. 1).

If steam pressure reaches 5 psi or more, steam will be exhausted through these ports .

may be caused by clogged cooking cavity steam ports, clogged steam tubing from the generator to the

cooking cavity, clogged drain plumbing or a blocked cooking cavity drain. Check and clear the cooking

cavity drain. If steam is still exiting the steam unloader ports, contact your local Vulcan-authorized

servicer.

This pressure

– 14 –

Page 15

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Burner does not come on. Gas supply is off; power cord is unplugged; or switch is off.

Burner control goes into 100% lockout — see page 11. If

symptom persists, contact Service.

Boiler dirty (carbon black). Contact Service.

Water flows into compartment. Contact Service.

Door leaks. 1. Check door gasket for damage. If adjustment is needed,

contact Service.

2. Plugged drain or screen. Clear compartment cavity

screen. If symptom persists, contact Service.

Water accumulates in compartment. Drain clogged.

Water not being supplied to boiler. 1. Water supply valve is off. Check water supply pressure.

2. Water filter is plugged. Refer to water filter manual.

If symptom persists, contact Service.

Water flows into drain when unit is off. Contact Service.

Steam is exiting from steam unloader 1. Cooking cavity drain is clogged. Clean cooking cavity

ports.

SERVICE AND PARTS INFORMATION

For any repairs or adjustments needed on this equipment, contact the Vulcan-Hart authorized service

agency in your area or Vulcan-Hart Service Department at the address or phone number on the front

cover of this manual.

drain. If steam is still exiting steam unloader ports,

contact Service.

2. Internal blockage problem. Contact Service.

– 15 –

Page 16

— NOTES —

FORM 31212 (June 2002) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...