Vulcan-Hart VHL3 & VH3616, MHB24G, VH3616D ML-136002, VH3616E, VH3616G Installation & Operation Manual

...

INSTALLATION &

OPERATION MANUAL

VHX24, VHL2, VHL3 & VH3616 SERIES FOOD

STEAMERS & MHB24 SERIES STEAM

GENERATORS

MODELS

VHX24E ML-136033

VHX24E5 ML-136034

VHX24G ML-136031

VHX24G5 ML-136032

VHX24D ML-136035

VHX24D5 ML-136036

VHL2G ML-126323

VHL3G ML-126324

VHL2E ML-126855

VHL3E ML-126856

VHL2D ML-126858

VHL3D ML-126859

MHB24E ML-126857

MHB24G ML-114954

VH3616G ML-136000

VH3616E ML-136001

VH3616D ML-136002

Model VHX24E

Model MHB24G

Model VHL2G

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART P.O. BOX 696, LOUISVILLE, KY 40201-0696

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC TEL. (502) 778-2791

WWW.VULCANHART.COM FORM 35419 (Dec. 2004)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

© VULCAN-HART, 2004

– 2 –

TABLE OF CONTENTS

GENERAL 5

INSTALLATION 5

Unpacking 5

Installation Codes and Standards 5

Leveling — All Steamers & Steam Generators 6

Plumbing Connections — All Steamers & Steam Generators 6

Water Supply Connection 6

Water Requirements 6

Drain Connection 6

Location — Gas Powered Steamers & Steam Generators 7

Gas Supply Connection 7

Testing the Gas Supply System 8

Flue Gas Exhaust 8

Electrical Connection — Gas Steamers & Steam Generators 8

Location — Electric Steamers & Steam Generators 9

Electrical Connection 9

Connection of Other Steam Cooking Equipment to an Electric

or Gas Boiler 10

Sequential Startup of Other Steam Cooking Equipment

Connected to a Boiler 10

Location — Direct Connected Steamers 10

Direct Steam Connections 10

Startup Test Run — VHX24 & VH3616 Series Steamers 11

Startup Test Run — VHL2 & VHL3 Series Steamers 12

OPERATION 14

Boiler Controls — Gas or Electric 14

Gas Boiler 15

Electric Boiler 15

Compartment Controls — VHX24 & VH3616 Series Steamers 16

Preheating 16

Operating VHX24 & VH3616 Series Steamers 17

Extended Shutdown 17

– 3 –

Standard Automatic Compartment Controls — VHL2 & VHL3 Steamers 18

Preheating 18

Operating VHL2 & VHL3 Steamers with Standard Automatic

Compartment Controls

19

Pre-Vent Compartment Controls — VHL2 & VHL3 Steamers 20

Operating VHL2 & VHL3 with Pre-Vent Compartment Controls 21

Selection of Pans for Steam Cooking in VHL2 & VHL3 Steamers 22

Cooking Hints 23

Suggested Cooking Guidelines 23

Cleaning 26

Cooking Compartment Drains 26

Boiler Blowdown 26

Compartments 26

Door Gaskets 26

Leave Compartment Doors Open 26

Guidelines for Maintaining Stainless Steel Surfaces 27

MAINTENANCE 28

Water Treatment System 28

Boiler Blowdown 28

Boiler Pressure Relief Valve 28

Door Gaskets — VHX24, VHL2 & VHL3 Series Steamers 28

Water Level Gauge 28

Flue 28

Inspection of Boiler Interior 28

Scale Related Maintenance (Gas & Electric Boilers) 29

Probe Housing Blowdown Valve (Gas & Electric Boilers) 29

Lubrication — VHL Series 29

TROUBLESHOOTING 30

Service and Parts Information 30

– 4 –

Installation, Operation and Care of

VHX24, VHL2, VHL3 & VH3616 SERIES FOOD STEAMERS

& MHB24 SERIES STEAM GENERATORS

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Vulcan food steamers and steam generators are produced with quality workmanship and material.

Proper installation, usage and maintenance will result in many years of satisfactory performance. It is

suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

Models with E in the model number have electric steam generators. Models with D in the model number

must be connected to a direct steam source. Models with G in the model number are equipped with

a high-efficiency gas steam generator.

1

Models VHX24E, VHX24G and VHX24D can accommodate three 2

compartment. Models VHX24E5, VHX24G5 and VHX24D5 can accommodate five 21/2" deep (6.4 cm)

steam pans per compartment. Models VHL2G and VHL3G can accommodate a selection of pans; refer

to page 28. Model VH3616 can accommodate sixteen 1" deep pans, or eight 21/2" deep pans, or six

4" deep pans per compartment. Models MHB24G and MHB24E are steam generators used to provide

steam for other equipment and do not have steaming compartments.

/2" deep (6.4 cm) steam pans per

INSTALLATION

Before installing, verify that the type of gas (natural or propane), the electrical supply and any direct

steam supply required for the equipment covered by this manual agree with the specifications on the

rating plate located on the lower door of the boiler base. If the supply and equipment requirements do

not agree, do not proceed with the installation. Contact your dealer or Vulcan-Hart Company

immediately.

UNPACKING

This steamer was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment.

IMPORTANT: Immediately after unpacking, check for possible shipping damage. If the steamer is

found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

INSTALLATION CODES AND STANDARDS

In the United States, the Vulcan steamer must be installed in accordance with state and local codes,

with the National Fuel Gas Code, (ANSI-Z223.1, latest edition) available from the American Gas

Association, 1515 Wilson Boulevard, Arlington, VA 22209, with the National Electrical Code (ANSI/

NFPA No. 70, latest edition) available from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269 and with Vapor Removal from Cooking Equipment, (NFPA-96, latest edition)

available from NFPA.

In Canada, the steamer must be installed in accordance with local codes, with the National Fuel Gas

Code (CAN/CGA-B149.1, latest edition) available from the Canadian Gas Association, 178 Rexdale

Boulevard, Etobicoke, Ontario, Canada M9W 1R3, and with the Canadian Electrical Code (CSA C22.2

No.3, latest edition) available from the Canadian Standards Association, 178 Rexdale Boulevard,

Etobicoke, Ontario, Canada M9W 1R3.

– 5 –

LEVELING — ALL STEAMERS & STEAM GENERATORS

Position the steamer or steam generator in its final installed location. Place a level on the horizontal

area of the cabinet. Adjust the feet to level the steamer or steam generator in both the left-to-right and

front-to-rear directions.

On VHX steamers only, elevate the front

the adjusting nut on the rear legs in the proper direction 1 to 1

1

/16" to 1/8" (0.2 cm to 0.3 cm) to give proper drainage by rotating

1

/2 turns. Check drainage in the steamer

compartments by pouring a little water in the compartment. All the water should drain. On VHL

1

steamers only, elevate the right side legs

/16" to 1/8" (0.2 cm to 0.3 cm) to give proper drainage.

The rear feet have holes in the flanges for anchor bolts. Direct steam models (steamers without

generators) must be anchored to the floor.

PLUMBING CONNECTIONS — ALL STEAMERS & STEAM GENERATORS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY,

SAFETY AND PLUMBING CODES.

Water Requirements

Proper water quality can improve the taste of

the food prepared in the steamer, reduce

liming in the steam generator and extend

equipment life. Local water conditions vary

from one location to another. Ask your

municipal water supplier for details about

your local water supply prior to installation.

Supply Pressure 20 — 60 psig

Hardness* less than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

pH range 7 — 8

Undissolved Solids less than 5 microns

* 17.1 ppm = 1 grain of hardness

WATER REQUIREMENTS

Presence of sediment, silica, excess chlorides or other dissolved solids may lead to a recommendation

for alternate form(s) of water treatment. Test the water with the test strip included with the steamer.

Other factors affecting steam generation are iron content, amount of chloridation and dissolved gases.

A local water treatment specialist should be consulted before installation of steam generating

equipment.

Water Supply Connection

Connect the treated water supply line to the

the untreated water supply line to the

1

1

/2" NPT (1.3 cm) inlet at the rear of the steamer. Connect

/4" (0.6 cm) copper tube inlet, also at the rear of the steamer.

A water filter system is recommended for the water supply line going to the treated water inlet of your

steamer. Follow the recommendations for use and installation instructions shipped with the water filter.

If a water filter is not installed, the steamer or steam generator warranty may be limited.

Drain Connection

1

The 1

(

length. Provide a suitable floor sink with a minimum depth of 12" (

/4" NPT (3.175 cm) threaded fitting on the condenser box must be extended

30.5 cm

)

to an open air gap

type drain. Do not reduce the 11/4" (

3.175 cm

30.5 cm). The floor sink is NOT to

a maximum of 12"

)

drain piping throughout its

be directly under the steamer and should be at a distance so that steam vapors will not enter the

steamer from underneath. The drain pipe should be either iron or copper. DO NOT use PVC pipe; PVC

pipe may lose its rigidity or glue may fail.

CAUTION: In order to avoid any back pressure in the steamer, do not connect solidly to any

drain connection.

– 6 –

Temperatures in the boiler can briefly reach as high as 212°F (100°C). Local codes require that the

temperature of drain water be no greater than 140°F (60°C). At the end of the day, when purging the

boilers, some provision for lowering the water temperature must be provided by the user or installer

to meet this code requirement.

LOCATION — GAS POWERED STEAMERS & STEAM GENERATORS

The equipment area must be kept free and clear of combustible substances.

The recommended clearance for proper operation is 36" (

91.4 cm) at the front. The required clearance

from combustible or non-combustible construction is 0" at the sides and back. The recommended

clearance for service access is 18" (

45.7 cm) at the sides and back.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air openings into

the combustion chamber must be provided. Make sure there is an adequate supply of air in the room

to replace air taken out by the ventilating system. If you have any questions, contact the ventilation

system installer.

An exhaust system should be located directly above the steamer to exhaust steam, flue exhaust and

heat generated by the steamer.

Do not permit fans to blow directly at the steamer. Avoid wall-type fans which create air crosscurrents

within the room.

Avoid open windows next to the steamer.

IMPORTANT: Do not locate the boiler base directly over a drain.

GAS SUPPLY CONNECTION

All gas supply connections and any pipe joint compound used must be resistant to the action of propane

gases. A 1" (

2.5 cm) minimum inside diameter gas supply line is required. If quick-disconnect devices

are used, make sure they are rated to meet or exceed the required 270,000 BTU/Hr rate. Make sure

the pipes are clean and free of obstructions. Codes require that a gas shutoff valve be installed in the

gas line ahead of the steamer.

The burner is equipped with fixed gas and air orifices for use with natural or propane gas.

The gas line must be capable of delivering gas to the boiler without excessive pressure drop at the

minimum 270,000 BTU/Hr rate specified on the rating plate. Inadequate gas supply would result in

burner noise and poor burner performance. An indication of inadequate supply would be evidenced

1

/4" W.C. or greater reduction in pilot burner pressure when the main burner comes on.

by a

The boiler is equipped with a factory-preset pressure regulator. Check gas pressures with a

manometer at time of installation to verify that they agree with the pressures in the table, below.

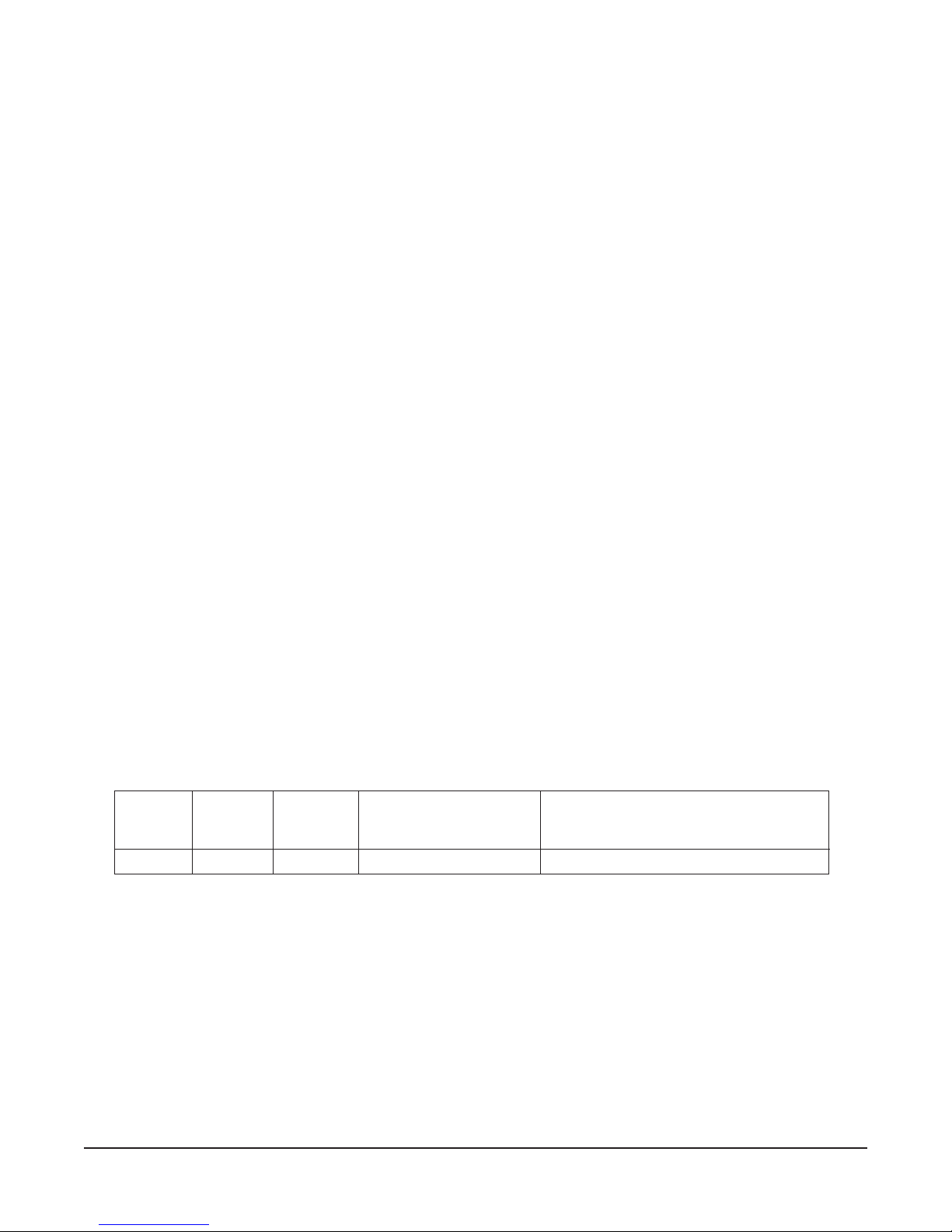

GAS SUPPLY PRESSURES

GAS TYPE

Natural

Minimum Maximum Valve Pressure Pressure

7.0" W. C. 14.0" W.C. 3.0" W.C. 3.5" W.C.

Line Pressure Main Boiler Pilot Valve

(1.75 kPa)(3.5 kPa)(0.75 kPa)(0.88 kPa)

Propane

11.0" W.C. 14.0" W.C. 3.0" W.C. 3.5" W.C.

(2.7 kPa)(3.5 kPa)(0.75 kPa)(0.88 kPa)

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR

LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

– 7 –

TESTING THE GAS SUPPLY SYSTEM

When the gas supply pressure exceeds 1/2 psig (

be disconnected from the gas supply piping system.

must

When the gas supply pressure is

1

/2 psig (3.45 kPa) or less, the steamer should be isolated from the gas

3.45 kPa

), the steamer and its individual shutoff valve

supply system by closing its individual manual shutoff valve.

FLUE GAS EXHAUST

DO NOT obstruct the flow of flue gases from the flue located on the rear of the steamer.

It is recommended that the flue gases be vented to the outside of the building through a ventilation

system installed by qualified personnel.

Information on the construction and installation of ventilating hoods may be obtained from Vapor

Removal from Cooking Equipment, NFPA-96 (latest edition) available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTION — GAS STEAMERS & STEAM GENERATORS

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG WHICH MUST BE CONNECTED INTO

A PROPERLY GROUNDED THREE PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT THE

PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THE PLUG.

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING:

LOCKOUT /

DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

TAGOUT PROCEDURES.

ELECTRICAL DATA

Minimum Circuit Ampacity

Volts Hertz Phase Machine Amps Maximum Protective Device

AMPS

120 60 1 3.0 15

Compiled in accordance with the National Electrical Code, NFPA-70 (latest edition).

The cord and plug supplied, is a suitable durable cord with molded plug and is provided with a proper

strain relief.

If a hard-wired conduit type connection is desired, remove the cord and plug and connect the electrical

7

/8" (

2.2 cm

)

supply circuit to the terminal block located in the boiler control box. A

1.27 cm) trade-size conduit is provided on the side of the control box. Use copper wire suitable for at

(

diameter hole for 1/2"

least 75°C. A grounding wire must be connected to the ground lug.

The wiring diagram is located on the door of the boiler.

Connect the steamer to the electrical supply after the gas connections have been made.

– 8 –

LOCATION — ELECTRIC STEAMERS & STEAM GENERATORS

Position the steamer or steam generator in its final location.

The recommended clearance for proper operation is 36" (

91.4 cm) at the front. The required clearance

from combustible or non-combustible construction is 0" at the sides and back. The recommended

clearance for service access is 18" (

45.7 cm) at the sides and back. Clearances less than 18" may

require removal of adjacent equipment during servicing at customer's expense.

An exhaust system should be located directly above the steamer to exhaust steam and heat generated

by the steamer.

IMPORTANT: Do not locate the boiler base directly over a drain.

ELECTRICAL CONNECTIONS — ELECTRIC STEAMERS & STEAM GENERATORS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING:

TAGOUT PROCEDURES.

/

DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW LOCKOUT

Connect the electrical supply circuit to the terminal block in the field connection box located behind the

left side panel at the rear. A 1

7

/8" (4.8 cm) diameter hole for 11/2" (3.8 cm) trade-size conduit is provided

on the side of the control box. Use copper wire suitable for at least 75°C. A grounding wire must be

connected to the ground lug.

The wiring diagram is located on the door of the boiler.

ELECTRICAL DATA

Minimum Circuit Ampacity

Volts Hertz Phase Total KW Machine Amps Maximum Protective Device

AMPS

208 60 1 24 115.4 150

24 66.6 90

208 60 3 36 99.9 125

42 116.6 150

240 60 1 24 100 125

24 57.7 90

240 60 3 36 86.6 125

48 115.5 150

24 28.9 50

480 60 3 36 43.3 70

48 57.7 90

Compiled in accordance with the National Electrical Code, ANSI-NFPA-70 (latest edition).

– 9 –

CONNECTION OF OTHER STEAM COOKING EQUIPMENT TO AN ELECTRIC OR GAS BOILER

Steam can be supplied to additional steam equipment from

the auxiliary steam port on the boiler, or Steam Line Connection

(Fig. 1). When additional equipment is added, appliance

efficiency will be affected. To be certain that you will be

operating at optimum efficiency, contact the Vulcan-Hart

STEAM LINE CONNECTION

WATER

LEVEL

PROBE

HOUSING

sales representative in your area for steam boiler horsepower

calculations.

The connection point for the steam line to other equipment is

3

a

/

4" NPT tee (female) fitting (1.9 cm) on the left side of the boiler

near the top and towards the rear. Remove the

plug (Fig. 1) (

1.9 cm) and use the piping kit available from

3

/4" NPT pipe

Fig. 1

PL-41764-1

Vulcan-Hart.

SEQUENTIAL STARTUP OF OTHER STEAM COOKING EQUIPMENT CONNECTED TO A BOILER

After the boiler is operating and producing steam, start the equipment that is farthest away until it is

preheated and up to temperature before starting the next piece of equipment. It is recommended that

all kettles be started before any compartment steamers. This will allow the larger equipment or the

equipment with greater steam requirements to be properly warmed up before smaller, nearer units

which require less steam. This will prevent the system from being overwhelmed by initial demand. For

configurations or recommendations, contact your Vulcan-Hart representative.

LOCATION — DIRECT CONNECTED STEAMERS

Position the steamer in its final location.

The recommended clearance for proper operation is 36" (

91.4 cm) at the front. The required clearance

from combustible or non-combustible construction is 0" at the sides and back. The recommended

clearance for service access is 18" (

45.7 cm) at the sides and back. Clearances less than 18" may

require removal of adjacent equipment during servicing at customer's expense.

An exhaust system should be located directly above the steamer to exhaust steam and heat generated

by the steamer.

IMPORTANT: Do not locate the steamer directly over a drain.

DIRECT STEAM CONNECTIONS

Provide dry steam to the inlets. If the steam is heavy with condensate, install a ball float trap before

the pressure regulator valve. To ensure rapid heatup of heavy, cold loads, the steam supply line must

be sized to provide the following:

1. To maintain steam at a pressure of 10 to 12 psi (

2. A minimum flow rate of 40 pounds (

3. A minimum flow rate of 67 pounds (

18.2 kg) of steam per hour per compartment for model VHX24D.

30.4 kg) of steam per hour per compartment for model

68.9 to 82.7 kPa).

VHX24D5.

4. A minimum flow rate of 34 pounds (

steamers.

A pressure-reducing valve is furnished and set at 10 psi (

modules can be interconnected to the steamer. Consult Vulcan-Hart for recommendations.

15.4 kg) of steam per hour per compartment for VHL series

68.9 kPa). Additional steam kettles and kettle

– 10 –

Loading...

Loading...