VE40 SHOWN

SERVICE MANUAL

ELECTRIC BRAISING PANS

(30 & 40 GALLON)

VE30 ML-126849

VE40 ML-126850

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F35410 (May 2003)

ELECTRIC BRAISING PAN

TABLE OF CONTENTS

GENERAL ................................................................................ 3

Installation, Operation and Cleaning ......................................................... 3

Introduction ............................................................................ 3

Control Panel ...................................................................... 3

Model Designations ................................................................. 3

Tools................................................................................. 3

Specifications ..........................................................................4

REMOVAL AND REPLACEMENT OF PARTS .................................................... 4

Covers and Panels ...................................................................... 4

Power Supply Box Components ............................................................ 5

Temperature Controller .................................................................. 6

Pan Position/Down Limit Switch ............................................................ 7

Up Limit Switch ......................................................................... 9

Lid Switch ............................................................................. 9

Thermocouple Probe .................................................................... 9

DC Lift Motor ......................................................................... 10

Gear Reducer ......................................................................... 11

Heating Elements ...................................................................... 12

High Limit Thermostat .................................................................. 13

Lid Springs ........................................................................... 13

SERVICE PROCEDURES AND ADJUSTMENTS ................................................. 15

Temperature Controller Calibration ........................................................ 15

Temperature Controller Test ............................................................. 16

Thermocouple Test .................................................................... 16

Heating Element Test ................................................................... 17

DC Motor Controller Test ................................................................ 17

Pan Position/Down Limit Switch Adjustment ................................................. 18

Lid Switch Adjustment .................................................................. 19

Lid Spring Tension Adjustment............................................................ 20

ELECTRICAL OPERATION .................................................................. 21

Component Function ................................................................... 21

Component Location ................................................................... 22

Sequence of Operation .................................................................. 23

Schematic Diagram .................................................................... 25

Wiring Diagrams ....................................................................... 26

Heating Element Circuits ............................................................ 26

Terminal Block Wiring .............................................................. 27

TROUBLESHOOTING ...................................................................... 28

Electric Heating (Manual Lift or Motorized Lift Option) .......................................... 28

Motorized Lift Option Only ............................................................... 29

CONDENSED SPARE PARTS LIST ........................................................... 32

© VULCAN 2003

F35410 (May 2003) Page 2 of 32

ELECTRIC BRAISING PAN

GENERAL

INSTALLATION, OPERATION

AND CLEANING

Refer to the Installation & Operation Manual for

specific instructions.

INTRODUCTION

The tilting braising pan (skillet) is a versatile piece

of cooking equipment. It can be used to stew,

simmer, steam, sear, pan fry, grill or saute food

products over an evenly distributed heating surface.

Once the product is fully cooked, the pan can be

tilted for ease of product removal.

Control Panel

Model Designations

! VE30 - 30 gallon capacity

! VE40 - 40 gallons capacity

TOOLS

Standard

! Standard set of hand tools.

! VOM with an AC current tester.

NOTE: Any quality VOM with a sensitivity of

20,000 ohms per volt can be used.

! Temperature tester (thermocouple type) with

surface probe.

Special

! 1 5/8" open end wrench. Used for removing lid

springs and adjusting lid spring tension.

! Field service grounding kit P/N TL- 84919.

Page 3 of 32

F35410 (May 2003)

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

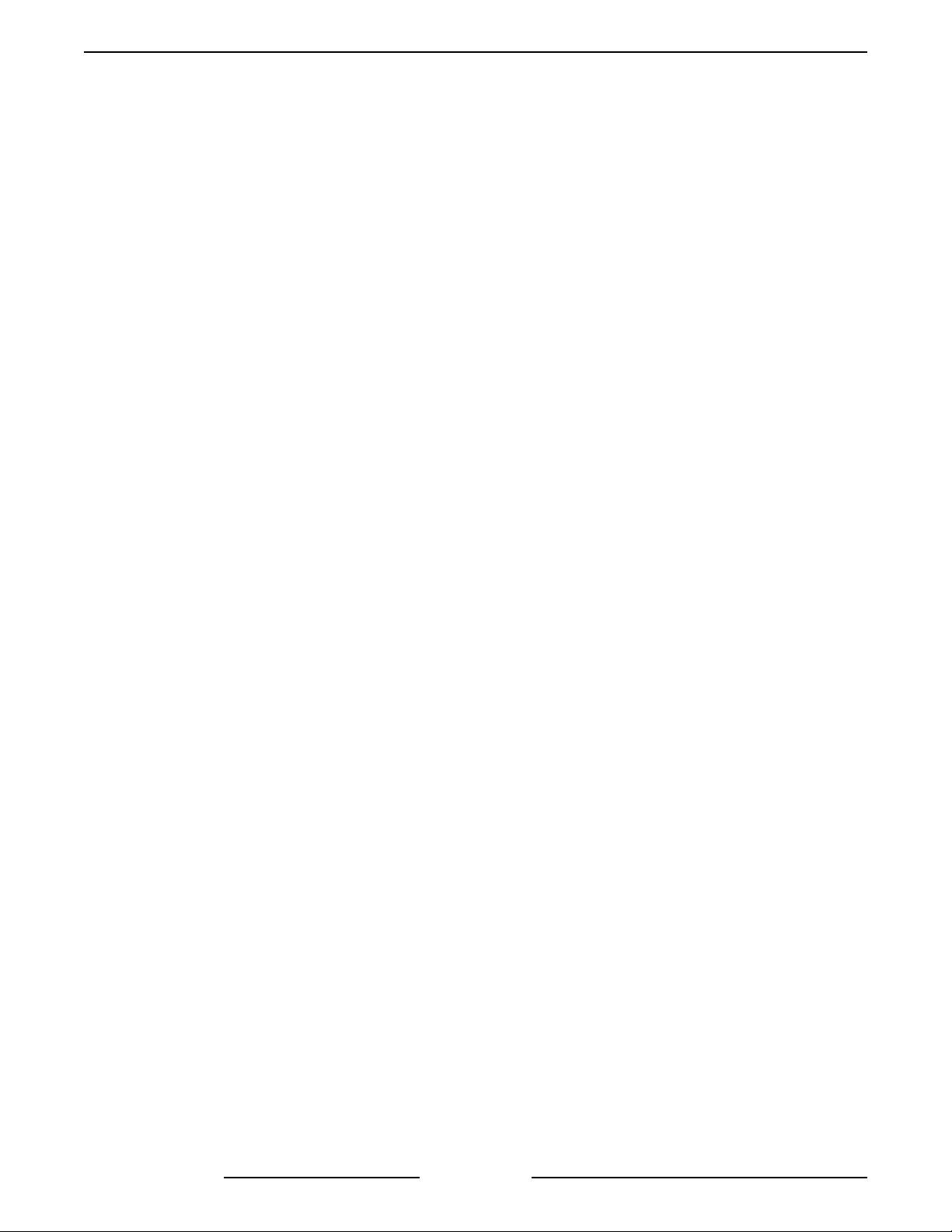

SPECIFICATIONS

AMPERAGE PER LINE

VOLTS PHASE

TOTAL

208 1 9 43 12 58 58 ---

2401 1250166767---

208 3 9 25 12 39 39 25

2403 122916464629

4803 121516232315

NOTES:

1. Amperage values in the table are nominal. Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. All models are shipped for 208/240V three phase connections. If a 208/240V single phase connection is

needed, the machine is field convertible at the terminal block. See wiring diagram AI1378.

4. On all 208V machines, the 240V heating element is being used (total KW output is reduced).

5. On VE40 three phase machines only, the heating elements are wired to be an unbalanced load.

VE30 VE40

TOTAL

KW

KW

L1-L3

L1 L2 L3

REMOVAL AND REPLACEMENT OF PARTS

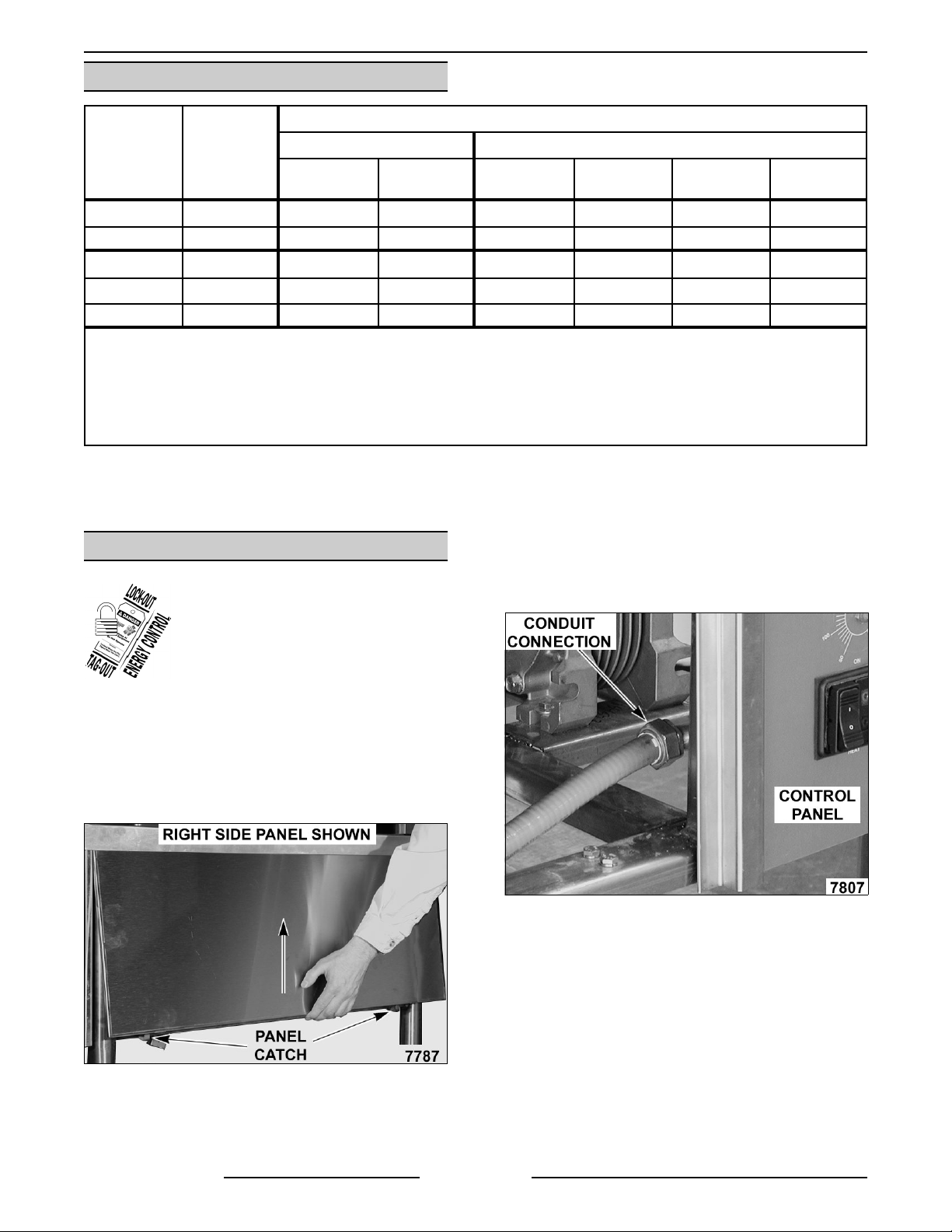

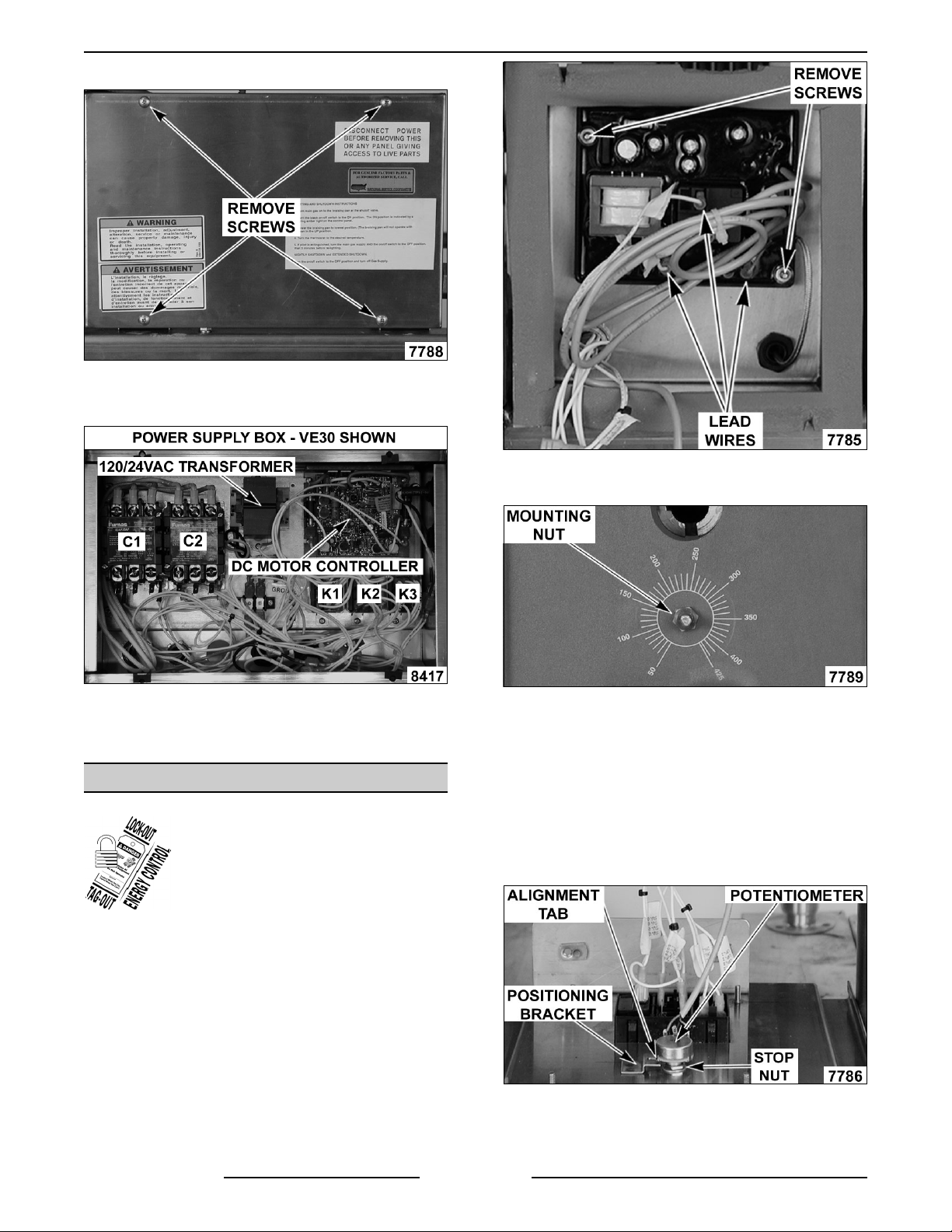

COVERS AND PANELS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

Control Panel

1. Remove front panel.

2. Disconnect conduit from control box.

Front, Rear & Side Panels

1. Lift up on the bottom edge of panel until it clears

the catch.

2. Tilt outwards and allow the panel to drop down.

3. Reverse procedure to install.

3. Remove manual lift crank handle (if installed).

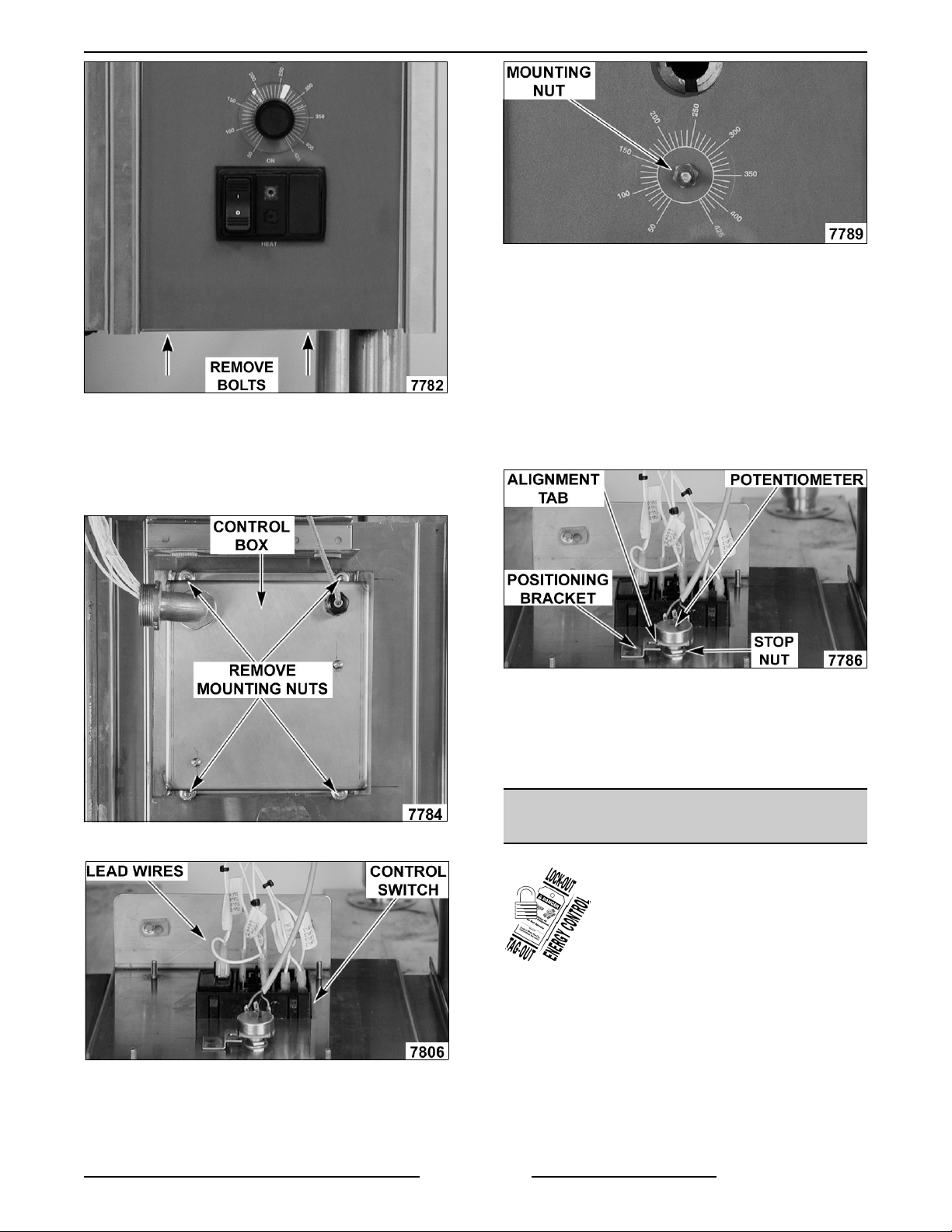

4. Remove bolts securing control panel to braising

pan frame. Bolts are recessed in the frame

channel.

F35410 (May 2003) Page 4 of 32

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

5. Tilt bottom of control panel outwards and pull

down.

9. Control panel is removed.

10. To install.

A. Align tab on potentiometer with positioning

bracket on panel.

B. Install mounting nut and tighten.

C. Adjust stop nut on potentiometer body (as

necessary) to ensure a water tight seal on

mounting nut.

NOTE: The control panel should be supported to

remove lead wire strain.

6. Remove control box from control panel.

7. Disconnect lead wires from control switch.

D. Attach temperature dial.

11. Reverse procedure from step 6 to complete the

installation.

12. Check calibration as outlined under

TEMPERATURE CONTROLLER

CALIBRATION.

POWER SUPPLY BOX

COMPONENTS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

8. Pull temperature dial from potentiometer shaft

and remove mounting nut.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service grounding kit

is available to prevent damage. The field service

grounding kit must be used anytime a control

board is handled.

1. Remove front panel as outlined under

Page 5 of 32

COVERS AND PANELS.

F35410 (May 2003)

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

2. Remove power supply box cover.

Disconnect lead wires then remove the

3.

component being replaced

.

4. Pull temperature dial from potentiometer shaft

and remove mounting nut.

4. Reverse procedure to install the replacement

component.

5. Check braising pan for proper operation.

TEMPERATURE CONTROLLER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove control box from the control panel as

outlined under COVERS AND PANELS.

2. Disconnect lead wires from temperature

controller.

3. Remove temperature controller from control

box.

5. To install:

A. Align tab on potentiometer with positioning

bracket on panel.

B. Install mounting nut and tighten.

C. Adjust stop nut on potentiometer body (as

necessary) to ensure a water tight seal on

mounting nut.

D. Attach temperature dial.

6. Reverse procedure from step 3 to complete the

installation.

F35410 (May 2003) Page 6 of 32

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

7. Check calibration as outlined under

TEMPERATURE CONTROLLER

CALIBRATION.

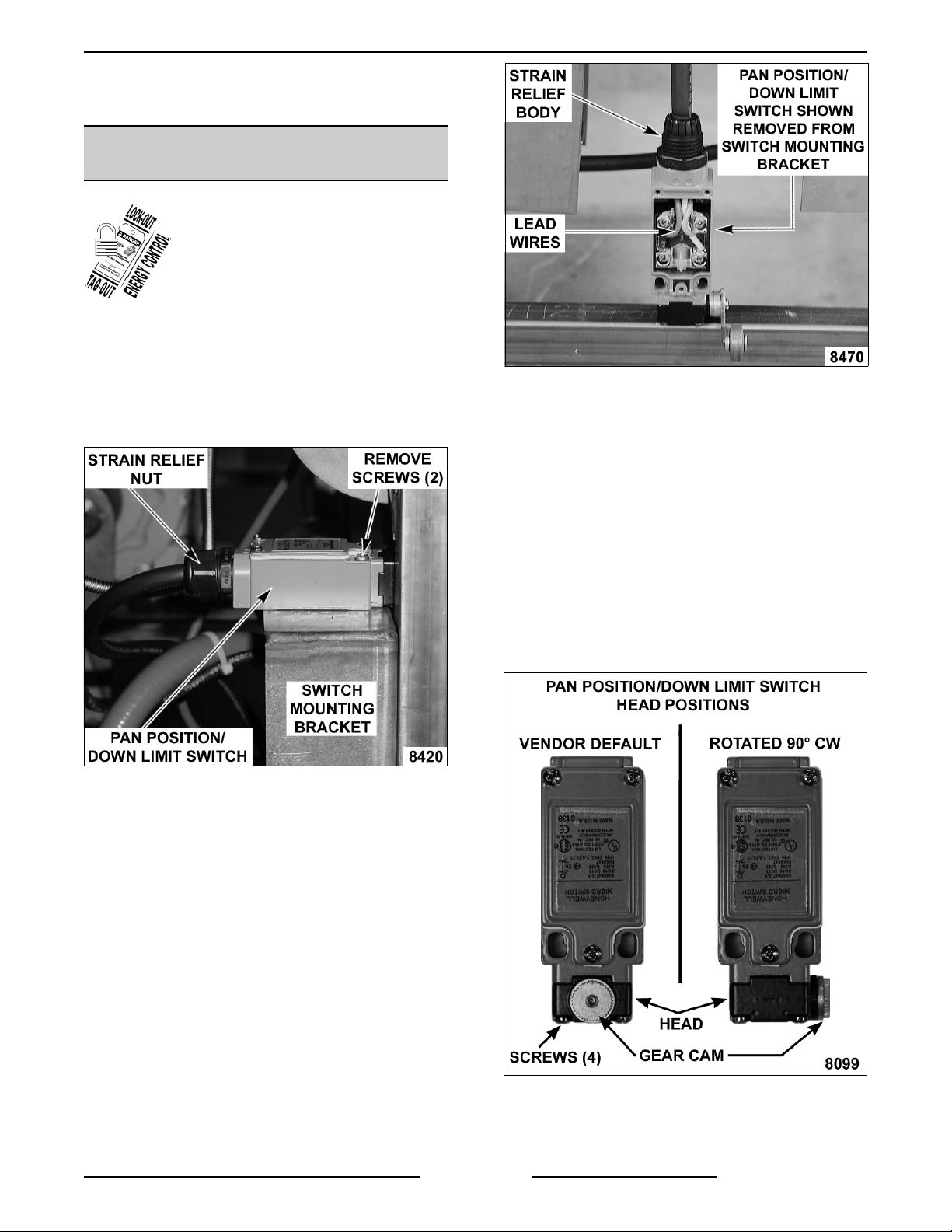

PAN POSITION/DOWN LIMIT

SWITCH

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove front and left side panels as outlined

under COVERS AND PANELS.

2. Remove strain relief nut from end of strain

relief body and remove pan position/down limit

switch from switch mounting bracket.

LEFT SIDE VIEW SHOWN

NOTE: When installing, ensure the o-ring seal is

inserted into the strain relief body (around power

cable) before tightening strain relief nut.

6. To install:

A. Position the switch with the head pointing

toward installer and gear cam pointing up.

3. Remove cover from switch.

4. Disconnect lead wires and pull wires thru strain

relief body.

5. Remove strain relief body from switch.

NOTE: The plunger on the head is spring loaded

and will push the head away from switch body when

the last screw is removed.

B. Remove screws securing the head to

switch body, rotate 90° clockwise and

tighten screws to secure.

TOP VIEW SHOWN

Page 7 of 32

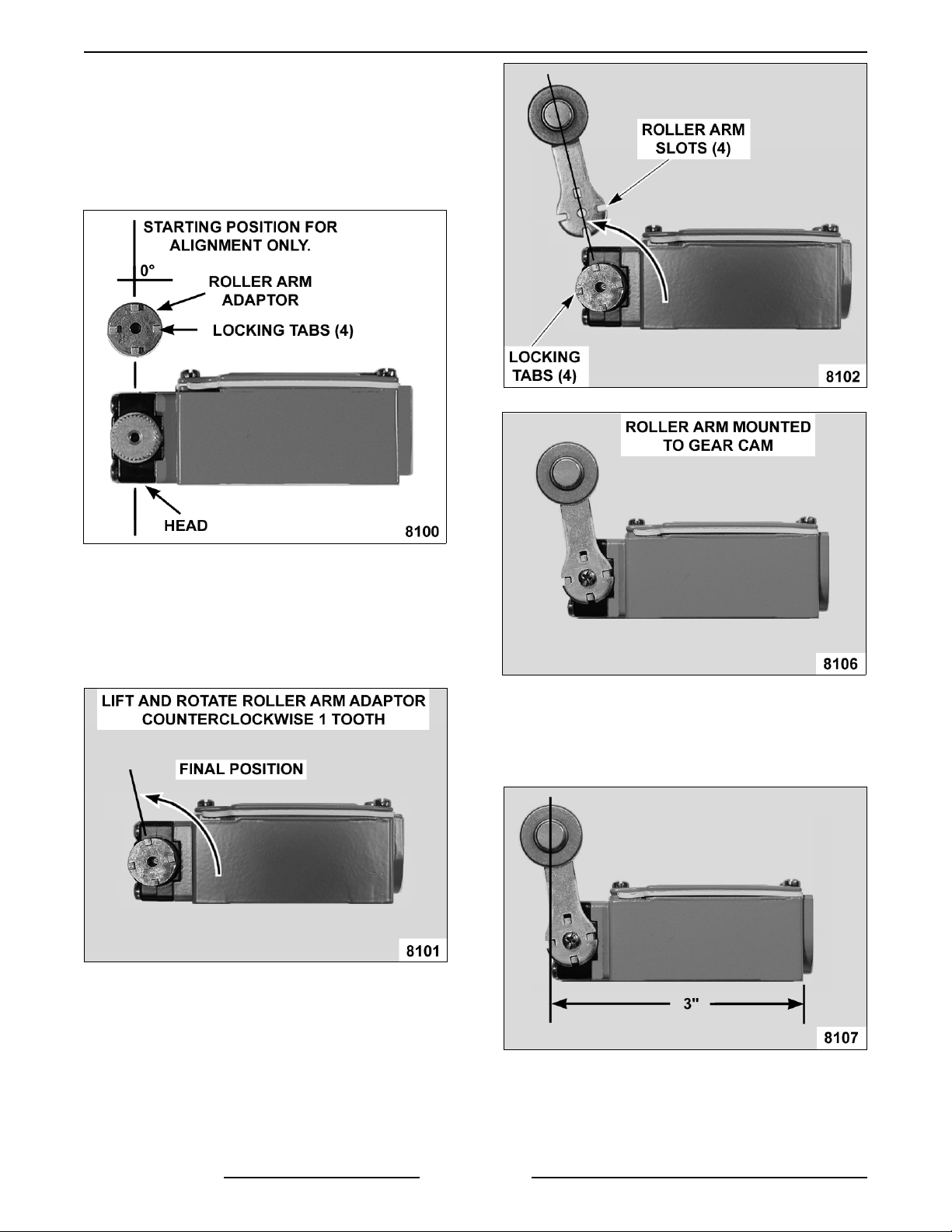

C. Place switch on its side with the head to

the left and gear cam pointing up.

F35410 (May 2003)

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

D. Align roller arm adaptor with the four

locking tabs pointing up and position one

of the tabs at 0°.

NOTE: The 0° position of the roller arm locking tab

is the starting point for alignment only. The locking

tab cannot remain at the 0° position.

SIDE VIEW SHOWN

E. Place roller arm adaptor on the gear cam

to engage the teeth. Lift the adaptor until

the teeth just slightly disengage from the

gear cam. Rotate the roller arm adaptor

counterclockwise 1 tooth, re-engage teeth

and release the adaptor.

F. Align the roller arm slots with the four

locking tabs on the roller arm adaptor and

tighten mounting screw to secure.

G. Verify roller arm position on switch.

1) Measure the distance from the rear of

the switch body to the center of the

roller. The distance should be 3".

F35410 (May 2003) Page 8 of 32

H. If distance is ok, proceed to step 7.

I. If distance is not ok, adjust the roller arm

position (as necessary) to obtain the 3"

roller arm dimension.

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

7. Reverse procedure from step 5 to complete the

installation.

8. Adjust pan position/down limit switch on switch

mounting bracket as outlined under PAN

POSITION/DOWN LIMIT SWITCH

ADJUSTMENT in SERVICE PROCEDURES

AND ADJUSTMENTS.

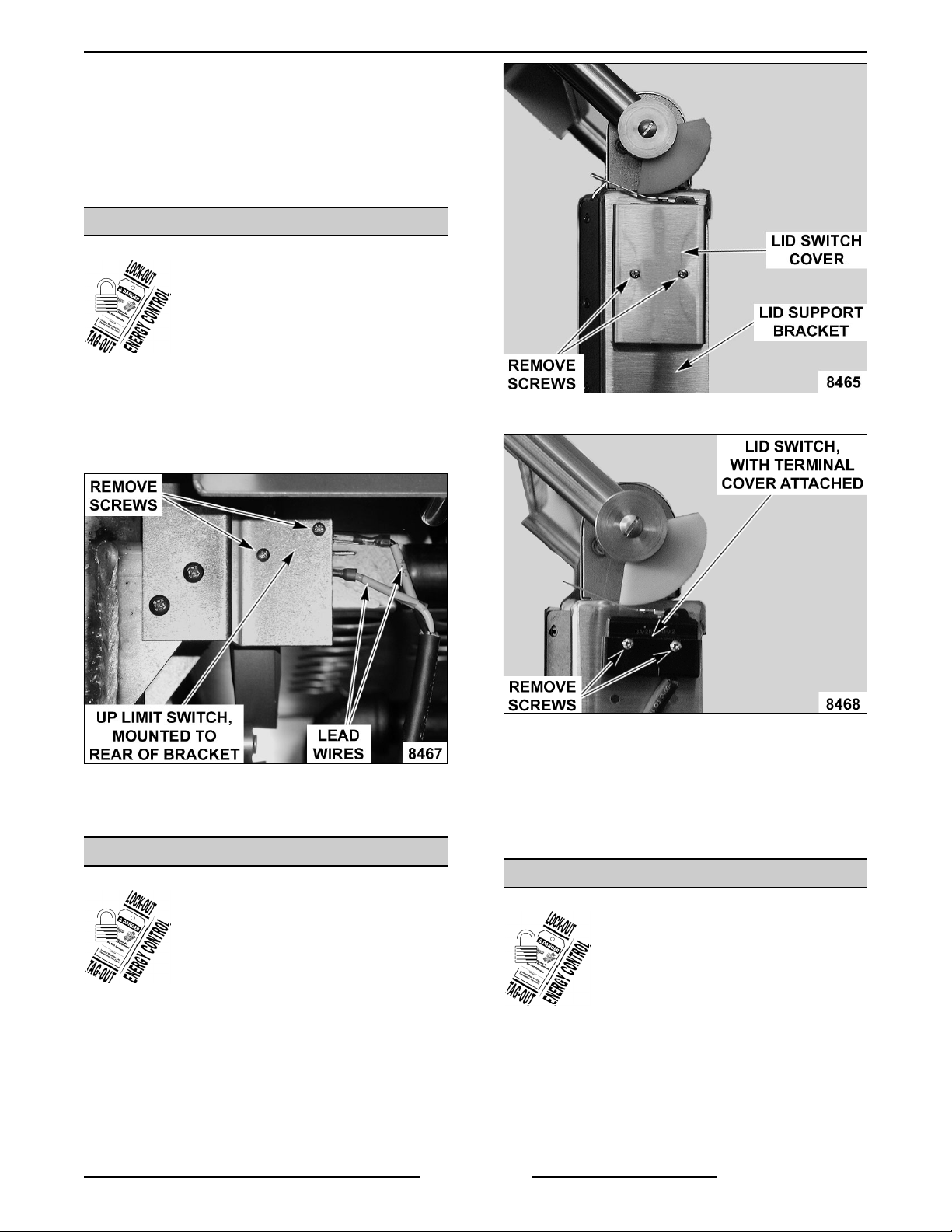

UP LIMIT SWITCH

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove front panel as outlined under

COVERS AND PANELS.

2. Disconnect lead wires

Remove switch from mounting bracket.

3.

from switch.

2. Remove switch from lid support bracket.

4. Reverse procedure to install and check for

proper operation.

LID SWITCH

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove lid switch cover from lid switch

support bracket.

3. Lift terminal cover off switch body and

4. Reverse procedure to install and adjust switch

1. Access temperature controller as outlined under

2. Disconnect thermocouple lead wires.

3. Raise the pan to the full tilt position.

4.

Page 9 of 32

disconnect lead wires.

as outlined under LID SWITCH ADJUSTMENT

in SERVICE PROCEDURES AND

ADJUSTMENTS.

THERMOCOUPLE PROBE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

TEMPERATURE CONTROLLER .

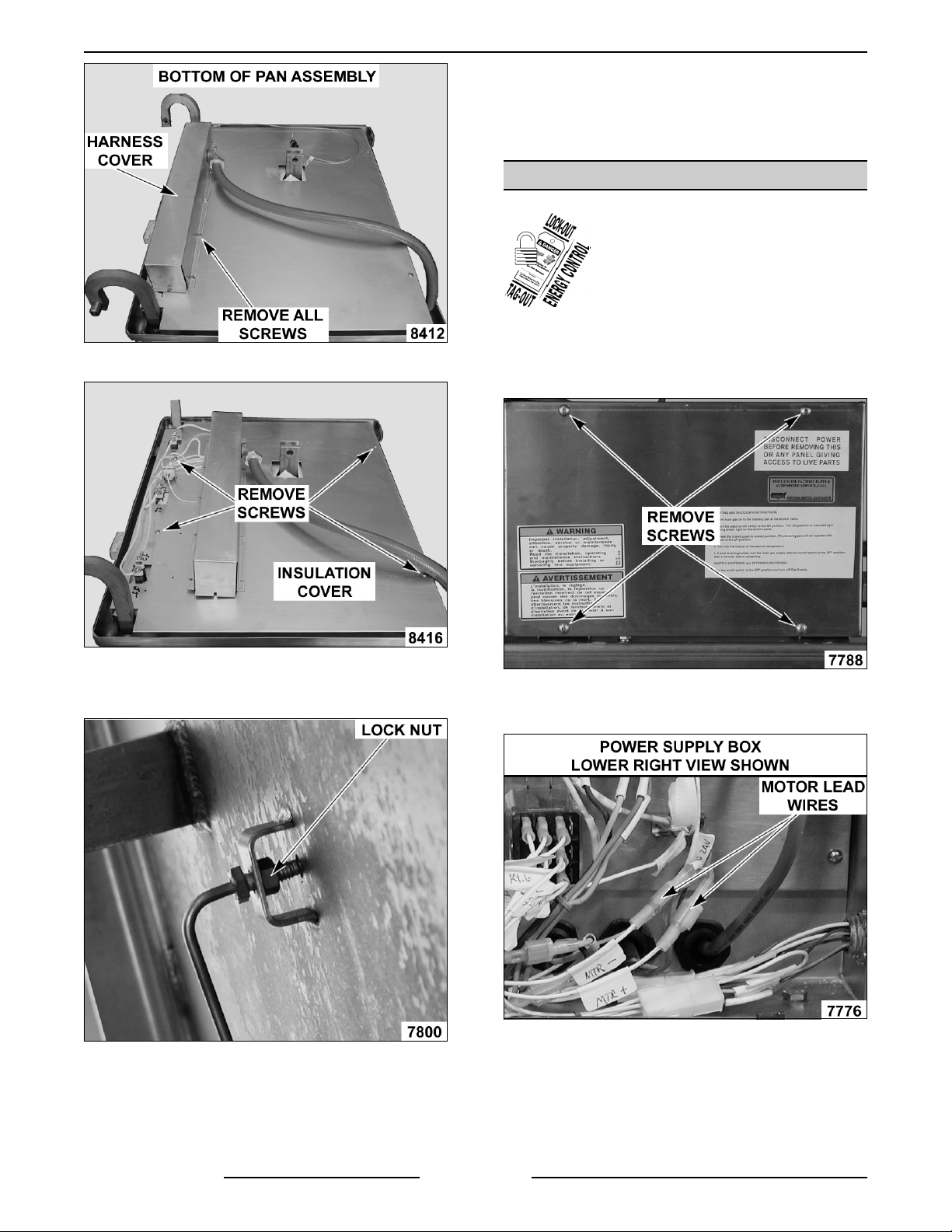

Remove harness cover.

F35410 (May 2003)

ELECTRIC BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

5. Remove the insulation cover.

NOTE: When installing: Route thermocouple wire in

the same manner thru the metal clamps on the hinge

& frame. Tighten thermocouple just until it touches

the pan; do not over tighten or damage to the

thermocouple may occur.

DC LIFT MOTOR

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove front, rear and right side panels as

outlined under COVERS AND PANELS.

2. Remove power supply box cover.

6. Loosen lock nut and remove threaded probe

from pan.

7. Reverse procedure to install and check braising

pan for proper operation.

3. Disconnect DC lift motor lead wires labeled

MTR+ (positive) & MTR - (negative).

NOTE: Lead wires can be identified by label or

marking on the wire.

F35410 (May 2003) Page 10 of 32

Loading...

Loading...