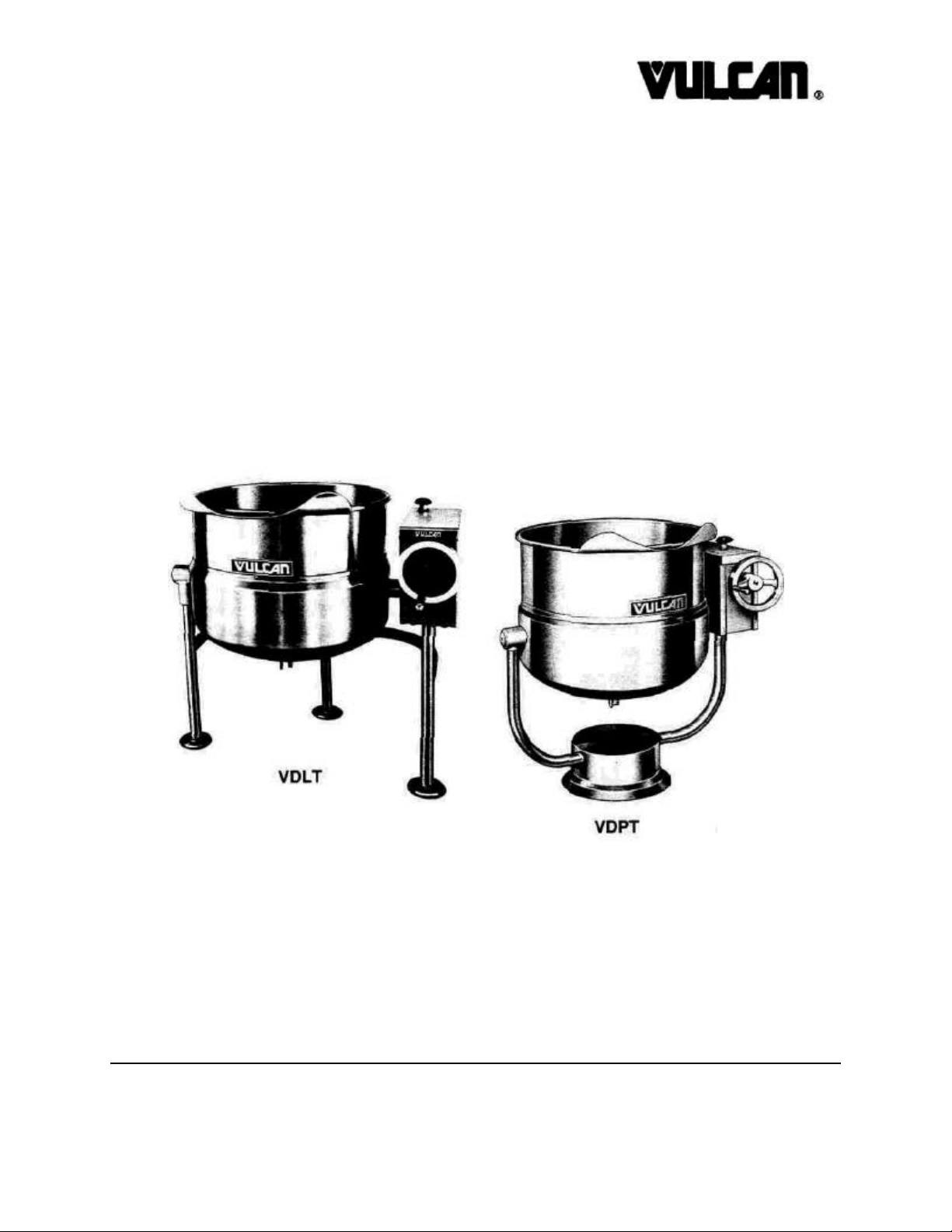

Page 1

INSTALLATION, OPERATING,

SERVICE AND PARTS MANUAL FOR

DIRECT STEAM FLOOR MOUNTED

TILTING 2/3 JACKETED KETTLES

SERIES: VDLT&VDPT

Vulcan service agencies are located throughout the

United States. For location and phone

number of one near you, call your local Vulcan

dealer.

VULCAN-HART CORPORATION, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30015(2-90)

Page 2

IMPORTANT

OPERATING, INSTALLING AND SERVICE PERSONNEL

The operating information on this equipment has been prepared for use by qualified and/or

authorized operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/

or authorized installation or service personnel, with the exception of any part marked with a D in front

of the part number.

To obtain the name and location of an authorized Vulcan service agency, contact your Food Service

Equipment dealer.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this

manual and are familiar with the equipment's functions or have had previous experience with the

operation of the equipment covered in this manual.

1. For the installation of gas piping from the outlet side of the gas meter, or the service regulator

when the meter is not provided, and the connection and installation of the gas appliance,

qualified installation personnel must be experienced in such work, be familiar with all precautions

required, and have complied with all requirements of state or local authorities having jurisdiction.

In the absence of local codes, installation must comply with National Fuel Gas Code ANSI

Z223.1 latest edition.

2. For the installation of electrical wiring from the electric meter, main control box or service outlet

to the electric appliance, qualified installation personnel must be experienced in such work, be

familiar with all precautions required, and have complied with all requirements of state or local

authorities having jurisdiction. In the absence of local codes, installation must comply with the

National Electrical Code ANSI NFPA No. 70 latest edition.

3. For the installation of steam piping from the source of supply to the service inlet of the appliance,

qualified installation personnel must be experienced in such work, be familiar with all precautions

required, and have complied with all requirements of state or local authorities having jurisdiction.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with this equipment who have been endorsed

by our company. All authorized service personnel are required to be equipped with a complete set of

service and parts manuals and stock a minimum amount of parts for this equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed

by skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE - Be certain this is noted on freight bill or express receipt and

signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY - Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE- If damage is unnoticed until merchandise is unpacked,

notify transportation company or carrier immediately, and file "concealed damage" claim with

them. This must be done within fifteen (15) days of the date the delivery is made to you. Be sure

to retain container for inspection.

We cannot assume responsibility for damage of loss incurred in transit. We will, however, be glad to

furnish you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

2

Page 3

INDEX

Your Vulcan Steam Jacketed Tilting Kettle is produced

with quality workmanship and material. Proper installation, usage and maintenance will result in many years

of satisfactory performance.

The manufacturer suggests that you thoroughly read

this entire manual and carefully follow all of the

instructions provided. Save this manual for future

reference.

A data plate with the unit model number, serial

number, and direct steam supply that the unit can use

is on the kettle

DESCRIPTION PAGE

DEFINITIONS OF PERSONNEL OPERATING, INSTALLATION and

SERVICE AND SHIPPING DAMAGE CLAIM PROCEDURES (Inside Front Cover)

INDEX 3

DESCRIPTION 4

CAPACITIES 4

INSTALLATION 5

OPERATION 6

OPERATING 6

CLEANING 7

SERVICE 8

PARTS LIST: TILTING MECHANISM 9-10

PARTS LIST: COUNTERBALANCED HINGED COVER 11

PARTS LIST: SPRING ASSISTED HINGE ASSEMBLY (OPTIONAL) 12

PARTS LIST: DRAW OFF VALVE (OPTIONAL) AND FLANGED FOOT 13

3

Page 4

DESCRIPTION

The Vulcan direct steam jacketed kettles in this manual

are pressure vessels of double-wall stainless steel construction forming a sealed jacket reservoir around the

lower two thirds of the kettle bowl surface.

The kettle bowl is the container for the food product

which ideally should be a liquid or semi-liquid for complete contact with the bowl surface and to fully absorb

the heat transmitted through the surface from the pressurized steam generated in the kettle jacket. All kettles

CAPACITIES

All models end with either 20, 30, 40, 60, 80 or 100 to

indicate the capacity of that kettle in gallons. Model

VDLT40 is a two thirds jacketed tilting direct steam kettle

mounted on legs, with a capacity of 40 gallons. A

VDPT30 is a direct steam tilting kettle mounted on a

pedestal base with a capacity of 30 gallons.

are tilting, and are to be permanently floor mounted

either on legs with adjustable flanged feet or on a

pedestal. All kettles are equipped with a drain valve, a

relief valve and a steam control valve. Options on

kettles are a lift off cover, a counterbalanced cover, or

a hinged spring assisted stainless steel lid covering the

kettle bowl opening. Also available is a stainless steel

tangent draw off valve as an alternate method for the

removal of the food product from the kettle bowl.

4

Page 5

INSTALLATION

WARNING: PLUMBING CONNECTIONS MUST

COMPLY WITH APPLICABLE

HEALTH, SAFETY AND PLUMBING

CODES.

A. Select a location to provide drainage directly below

the draw-off valve (optional). Allow sufficient rear

clearance from the wall for the kettle cover to lift

upright freely without obstructions.

B. Mark anchoring hole locations through flanged

adjustable feet (VDLT models), or holes in the

pedestal base (VDPT models).

C. With hole locations marked, drill holes and insert

expansion plugs to accommodate 5/16" size lag

bolts.

D. Reposition the kettle. On VDLT models level the

kettle by making necessary adjustments using the

flanged feet.

E. Bolt the kettle down and seal with a high grade

sealing compound. Sealant must be applied not

only to bolt heads but around the flanges or pedestal base and must be making contact with floor

surface to meet N.S.F. requirements. Wipe off

excess sealant immediately.

F. Connect steam line (3/4" pipe size) to the kettle,

making sure there is a steam control valve

strainer (not supplied) fairly convenient to the

kettle.

G. Connect the kettle condensate return line to a

drain or to a boiler return line. Each kettle return

line must have a suitable steam trap (not

supplied). Boiler return lines must have a check

valve (not supplied).

H. The relief valve on the kettle must not be adjusted

or closed off as it is set to relieve excess pressure

in the kettle.

I. If the incoming steam pressure is greater than

kettle maximum operating pressure, then a

pressure reducing valve (not supplied) must be

installed in the line.

J. If large amounts of water accumulate in the steam

line, it will be necessary to install one or more ball

float traps (not supplied) in the line to eliminate

the water.

K. A steam line pressure gauge (not supplied) is

also recommended to determine the actual

amount of steam coming to the kettle.

L. Turn unit "ON" and check for proper operation.

5

Page 6

OPERATION

The relief valve is installed towards the rear of the

kettle jacket. If the pressure in the jacket reaches the

rated pressure of the kettle, the relief valve will open

automatically and release excessive steam pressure.

The temperatures required for the cooking process to

function adequately must be greater than the boiling

point of the liquid food product, that is, water. The

greater the steam pressure used, the higher the temperature and the quicker the cooking process. For

example, steam pressurized at 30 p.s.i. reaches a temperature of 274°F (135°C). Since air is an unsuitable

media through which heat may be transferred, for effi-

ciency the air should be exhausted from the jacket by

opening the relief valve until the air has been

completely replaced by pressurized steam.

In the initial stages of the cooking process when the

steam comes in contact with the cold kettle bowl

surface it condenses and forms considerable amounts

of water. A separately purchased thermostatic steam

trap should be installed at the exit end of the kettle

jacket. This trap is a mechanical device that closes on

high temperatures and opens when the temperature

drops, allowing the water formed from condensate to

exhaust, but retaining the steam under pressure.

OPERATING

A. Check that the draw-off valve is closed.

B. Fill the kettle with product to the desired level.

NOTE: Food products with milk or egg base should be

placed into a cold kettle and then the cooking

operation begun. Avoid sudden contact of these

food products with a hot kettle surface because

the food will stick to the surface.

C. Slowly turn the steam control valve ON to the full

open position (counter-clockwise).

D. Slowly open the relief valve to allow all air to

escape. Stay clear of the valve outlet during this

operation to avoid very hot steam.

E. The water or food should boil 3 to 4 minutes per

gallon. If it does not, then incoming pressure

should be checked to determine that it is adequate

to operate the kettle efficiently.

F. Regulate the steam control valve depending on

the type of food being prepared.

G. When the food is cooked, turn off the steam,

remove the food and add water, clean the kettle

immediately to prevent residue from drying on the

kettle bowl.

WARNING: THE KETTLE IS HOT. USE CARE

WHEN OPERATING AND

SERVICING THE KETTLE.

6

Page 7

CLEANING

The kettle interior and exterior should be thoroughly

washed after each use when a different food is to be

cooked next or when cooking is completed for the day.

Before cleaning check that the kettle has cooled

enough to touch it.

A. Check that the steam supply is turned "OFF".

B. Pre-rinse the inside of the kettle thoroughly and

drain to remove any food particles.

C. Using a nylon brush, clean kettle with a mild

detergent and warm water rinse. Never use steel

wool or scouring powder as it will scratch

stainless steel. Also, plain steel wool can leave

small pieces of steel wool which can rust.

D. Tilt kettle to full tilt or open the (optional) tangent

draw off valve to allow the detergent and water

solution to drain. Rinse thoroughly with clean

water.

E. On draw off models, by hand, turn the large hex

nut on the (optional) draw off valve

counterclockwise until it is completely disengaged

from the threads. Grasp the valve knob and

slowly pull out the valve stem and disk. Do not

allow the disk to come in contact with hard

surfaces as it can be damaged and cause valve

leakage. Wash the valve stem, disk and handle.

Insert a nylon brush wet with detergent and water

into the valve body and the tanget draw-off tube.

Brush vigorously.

F. Replace the valve stem assembly and turn the

hex nut until snug. Rinse the kettle with clean

warm water.

G. Leave the draw off valve open when the kettle is

not in use.

H. Wipe the exterior of the kettle with a clean damp

cloth.

7

Page 8

SERVICE

MAINTENANCE

DRAW OFF VALVE LEAKS (DRAW OFF

VALVE IS OPTIONAL)

No general maintenance is required other than

following the cleaning procedures.

EXTREMELY SLOW COOKING TIME

If the cooking time is abnormally slow, then the

difficulty may be due to insufficient steam pressure

and/or volume. First determine that the pressure on

incoming steam line at kettle is within 5 p.s.i. of the

rated kettle pressure. Note that a pressure approaching

the rated kettle pressure is liable to set off the relief

valve. If the required pressure is available at the kettle,

then possibly the volume of steam is not sufficient.

Minimum 3/4" pipe size is required to the kettle but if

the steam generating source is at a great distance from

the kettle, larger pipe will be required. Finally, the core

of the steam supply pipe may have debris or scalants

that impede steam flow and the pipe will require

disassembly and inspection.

If a leak occurs through the valve stem, replace the "0"

ring. If the leak is due to faulty sealing between the

stem disc and valve seat, this problem can usually be

corrected by cleaning off the dried on food residue with

an extremely fine emery cloth. If the disc or valve

seats are found to be excessively damaged, either or

both must be replaced.

However, if only slight damage to either the disc or

seat has occurred, then the following lapping

procedure should correct it.

A. Follow cleaning procedures.

B. Remove the knob handle from the end of the

stem. Unscrew and remove the bonnet from the

stem. Put the knob back on the stem.

C. Apply a fine grade lapping compound around the

sealing edge of the disc and insert it into the

valve making light contact against seat.

D. By hand, rotate the stem disc against the valve

seat, allowing the stem to wobble slightly in the

space previously occupied by the bonnet.

8

E. Repeat steps C and D several times.

F. Reassemble, close the valve and test it for leaks.

G. If leakage persists, then repeat this lapping

procedure.

Page 9

PARTS LIST: GEAR BOX ASSEMBLY

9

Page 10

PARTS LIST: TILTING MECHANISM___________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 881962 Handwheel 1

2 SC-047-42 Set Screw 1

3 836936 Tilting Shaft 1

4 836952 Tension Pin 1

5 881965 Worm Gear 1

6 881963 Thrust Bearing 2

7 NS-013-50 Jam Nut 2

8 881984 Steam Control Valve 1

9 *Small Segment Gear or 1

10 836971 Spacer Collar 1

11 SC-090-12 Fastening Bolt 4

12 WL-004-06 Lock Washer 4

13 SC-047-42 Set Screw 1

14 836970 Outbore Bearing 1

881964 Targe Segment Gear 1

836949 Key (Not Visible) 1

881967 "O" Ring (Not Visible) 4

Note: Item No. 14, Outbore Bearing as shown, is standard for all kettles without Hinged Covers. If option

of Hinged Cover has been exercised, specify part number as well as Model and Capacity of Kettle

when ordering this part.

* Small Segment Gear is used on 20, 30 and 40 Gallon Kettles

* Large Segment Gear is used on 60, 80 and 100 Gallon Kettles

10

Page 11

PARTS LIST: HINGED COUNTERBALANCED COVER (OPTIONAL)

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 Bolt 1

2 Washer 1

3 836994-X Cover (Specify Model No.) 1

4 836964 Knob 1

5 836984-X Handle Assembly (Specify Model No.) 1

6 WS-007-20 Fiber Washer 4

7 SC-041-42 Bolt 2

8 NS-015-16 Nut 2

11

Page 12

PARTS LIST: SPRING ASSISTED HINGE ASSEMBLY (OPTIONAL)

ITEM NO. PART NO. DESCRIPTION (20 to 40 Gal. Kettles) QUANTITY

1 836977 Lock Pin 1

2 836978 End Lock Plate 1

3 836979 Stationary Disc 1

4 836980 Cores 2

5 836981 Spring 1

6 836982-X Handle Assembly (Specify Model No.) 1

7 836983 Rotary Disc 1

8 836932 End Stop Plate 1

9 SC-041-50 Cap Screws 4

10 2-W6S6 Washer (Also 60 to 100 Gal. Kettles) 1

11 1-65S6 Bolt (Also 60 to 100 Gal. Kettles) 1

12 836964 Knob (Also 60 to 100 Gal. Kettles) 1

ITEM NO. PART NO. DESCRIPTION (60 to 100 Gal. Kettles) QUANTITY

1 836986 Lock Pin 1

2 836987 End Lock Plate 1

3 836988 Stationary Disc 1

4 836989 Cores 2

5 836990 Spring 1

6 836991-X Handle Assembly (Specify Model No.) 1

7 836992 Rotary Disc 1

8 836993 End Stop Plate 1

9 SC-041-01 Cap Screws 4

836994 Cover (Not Shown - Specify Model No.) 1

12

Page 13

PARTS LIST: DRAW OFF VALVE (OPTIONAL) & FLANGED FOOT

ITEM NO.

1 836939 836939 836940 Nut 1

2 836967 836967 836942 Handle 1

3 836943 836944 836945 Hex. Assembly Nut 1

4 836946 836947 836948 Bonnet 1

5 836949 836950 836951 Disc & Stem Assembly 1

6 836966 836953 836954 "O" Ring 1

7 836955 836956 836957 Valve Body 1

1" Valve 2" Valve 3" Valve

PART NO. DESCRIPTION QUANTITY

PART NO. DESCRIPTION QUANTITY

836958 Flanged Adjustable Foot 3

13

Loading...

Loading...