Page 1

SERVICE MANUAL

VC4E & VC6E

SERIES

FULL SIZE

ELECTRIC CONVECTION

OVENS

MODEL ML

VC4ES 126743

VC4ED 126744

VC4EC 126745

VC6ES 126746

VC4ED SHOWN

- NOTICE -

This Manual is prepared for the use of train ed Vulcan Service

Technicians and should not be used by those not properly

qualif ied. If you have att ended a Vu lcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produc t, you sho uld

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e necessary tools, instruments and skills should be

performed b y a trained Vu lcan Service Technician .

VC6ED 126747

VC6EC 126748

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

.

F25105 (Decem ber 2001)

Page 2

FULL SIZE ELECTRIC CONVECTION OVENS

TABLE OF CONTENTS

GENERAL............................................................................. 4

Introduction ........................................................................ 4

Installation......................................................................... 4

Operation.......................................................................... 4

Cleaning .......................................................................... 4

Lubrication ......................................................................... 4

Tools ............................................................................. 4

Specifications ...................................................................... 5

REMOVAL AND REPLACEMENT OF PARTS ................................................. 6

Covers And Panels .................................................................. 6

Control Panel Components ............................................................ 7

Component Panel Components ......................................................... 8

Temperat ure Probe (Solid State Control) .................................................. 8

Heating Elements ................................................................... 9

Blower And Motor .................................................................. 10

Door Switch ....................................................................... 11

Door W indow ...................................................................... 12

Ov en Door s and Bear ings (Independent Doors) ............................................ 12

Ov en Door s (S imultaneous Doors) ...................................................... 13

Door Catch Roller Assembly (Independent Doors) .......................................... 14

Mechanical (KX) Thermostat .......................................................... 14

High Limit Thermostat ............................................................... 15

Interior Lights...................................................................... 15

Cooling Fan ....................................................................... 16

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 17

Solid State Temperature Control Calibration .............................................. 17

Mechanical (KX) Thermostat Calibration ................................................. 18

Solid State Temperature Control Test ................................................... 19

Temperat ure Probe Test (Sol id State Contr ol) ............................................. 20

Heating Element Test ............................................................... 20

Blower Adjustment.................................................................. 21

Door Adjustment ................................................................... 22

Door Catch Roller Adjustment (Independent Doors) ......................................... 22

Door Switch Adjustment.............................................................. 23

Door Chain Adjustment (Simultaneous Doors) ............................................. 23

Computer Control .................................................................. 24

Computer Control Temperature Calibration ............................................... 26

Computer Cont rol Operational Test ..................................................... 26

ELECTRICAL OPERATION .............................................................. 29

Component Func tion ................................................................ 29

Component Locat ion ................................................................ 30

Sequence of O per ation .............................................................. 34

VC4ES, VC6ES wi th Mechanical K X Ther mostat ....................................... 34

VC4ED, VC6ED with Solid State Temperature Control................................... 34

Timer Cycle, Cooking (KX Thermostat or Solid State Control) ............................. 35

Cool Down Cycle (KX Thermostat or Solid State Control)................................. 35

VC4EC, VC6EC (Computer Control) ................................................ 35

Temperat ure and Tim e Cy c le (Cooking) .......................................... 36

Cook and Hold Cycl e ........................................................ 36

Cool Down Cycle ........................................................... 36

Schematics ....................................................................... 37

VC4ES, VC6ES wi th Mechanical ( K X) Cont r ols, 208-240V ................................ 37

VC4ES, VC6ES wi th Mechanical ( K X) Cont r ols, 480V ................................... 38

VC4ED, VC6ED wit h S olid Stat e Temperature Control, 208-240V .......................... 39

VC4ED, VC6ED wit h S olid Stat e Temperature Control, 480V .............................. 40

F25105 (Decem ber 2001) Page 2 of 60

Page 3

FULL SIZE ELECTRIC CONVECTION OVENS

VC4EC, VC6EC Computer Control, 208-240V (Roast & Hol d S tandard) ...................... 41

VC4EC, VC6EC Computer Control, 480V (Roast & Hold S tandard) ......................... 42

Wiring Diagrams ................................................................... 44

VC4ES, VC6ES wi th Mechanical ( K X) Cont r ol, 208-240V ................................. 44

VC4ES, VC6ES wi th Mechanical ( K X) Cont r ol, 480V .................................... 46

VC4ED, VC6ED wit h S olid Stat e Temperature Control, 208-240V .......................... 48

VC4ED, VC6ED wit h S olid Stat e Temperature Control, 480V .............................. 50

VC4EC, VC6EC Computer Control, 208-240V (Roast & Hol d S tandard) ...................... 52

VC4EC, VC6EC Computer Control, 480V (Roast & Hold S tandard) ......................... 54

TROUBLESHOOTING .................................................................. 56

All Models ........................................................................ 56

Computer Cont rol Models Only ........................................................ 57

CONDENSED SPARE PARTS LIST ........................................................ 60

© Vulcan 2001

F25105 (Decem ber 2001)Page 3 of 60

Page 4

FULL SIZE ELECTRIC CONVECTION OVEN - GENERAL

GENERAL

INTRODUCTION

Procedures in this manual will apply to all models unless specified. Pictur es and illustrations can be of any model

unless the picture or illustration needs to be model specific.

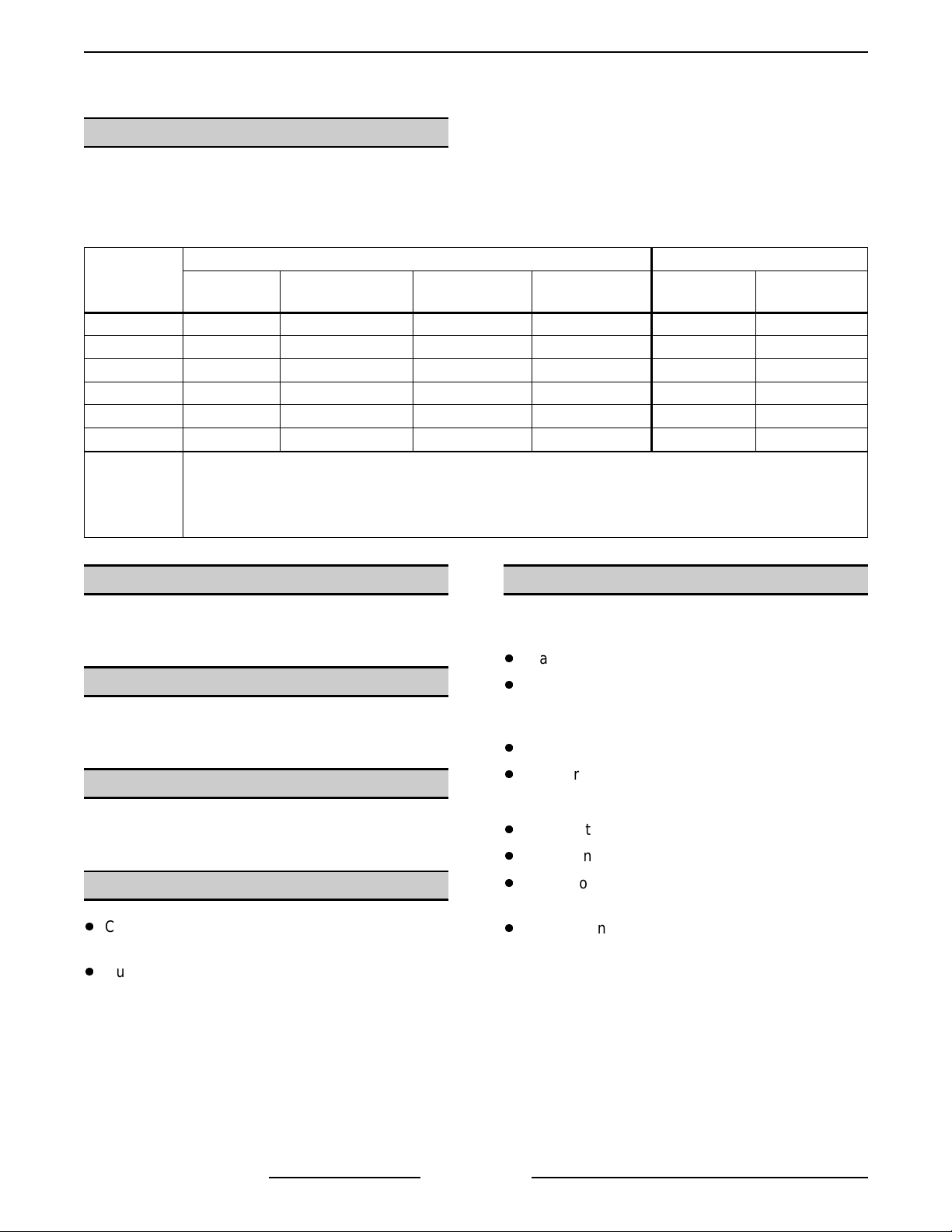

Models

FEATURES OPTIONS

MODEL

VC4ES

VC4ED

VC4EC

VC6ES

VC6ED

VC6EC

NOTES

4

4

:

CAVITY

DEPTH

26.5" Mechanical (KX) Independent

26.5" Solid State Independent

26.5" Computer Independent

30.5" Mechanical (KX) Independent

30.5" Solid State Independent

30.5" Computer Independent

1. Sim ultaneous doors are optional (with or w/o window).

2. Stainless steel doors w/o window (standard).

3. Stainless steel doors with window (standard)

4. In February 2001, this model was discontinued.

TEMPERATURE

CONTRO L

DOORS

(50/50)

TIMER

1, 2

1-Hour Dial 5-Hour Dial N/A

1, 3

1-Hour Dial 5-Hour Dial N/A

1, 3

24-Hour Digital Built in Built in

1, 2

1-Hour Dial 5-Hour Dial N/A

1, 3

1-Hour Dial 5-Hour Dial N/A

1, 3

24-Hour Digital Built in Built in

COOK

COOK

TIMER

COOK &

HOLD

INSTALLATION

Refer to the Instructions Manual for detailed

installation instr uc tions on single or stacked ovens.

OPERATION

Refer to the Instructions Manual for specific

operating i nst r uc tions.

CLEANING

Refer to the Instructions Manual for specific

cleaning instructions.

LUBRICATION

Cavity blower m otor has sealed bearings and

requires no addit ional lubrication.

Huskey’s TF1000 grease or equivalent high

temperat ure Teflon grease.

TOOLS

Standard

Standard set of hand tools

VOM with A. C. current tester ( A ny quality VOM

with a sensitivit y of at least 20,000 ohms per volt

can be used)

Gear Puller to rem ove blower

Temperat ure tester (thermocouple type)

Special

Manometer

Clamp on amp meter

Spring force gauge, pull type with a minimum 30

pound full scale range (purchase l oc ally)

RTV sealant, 736 DOW silicone high t emp

(P/N 542133) or equivalent

F25105 (Decem ber 2001) Page 4 of 60

Page 5

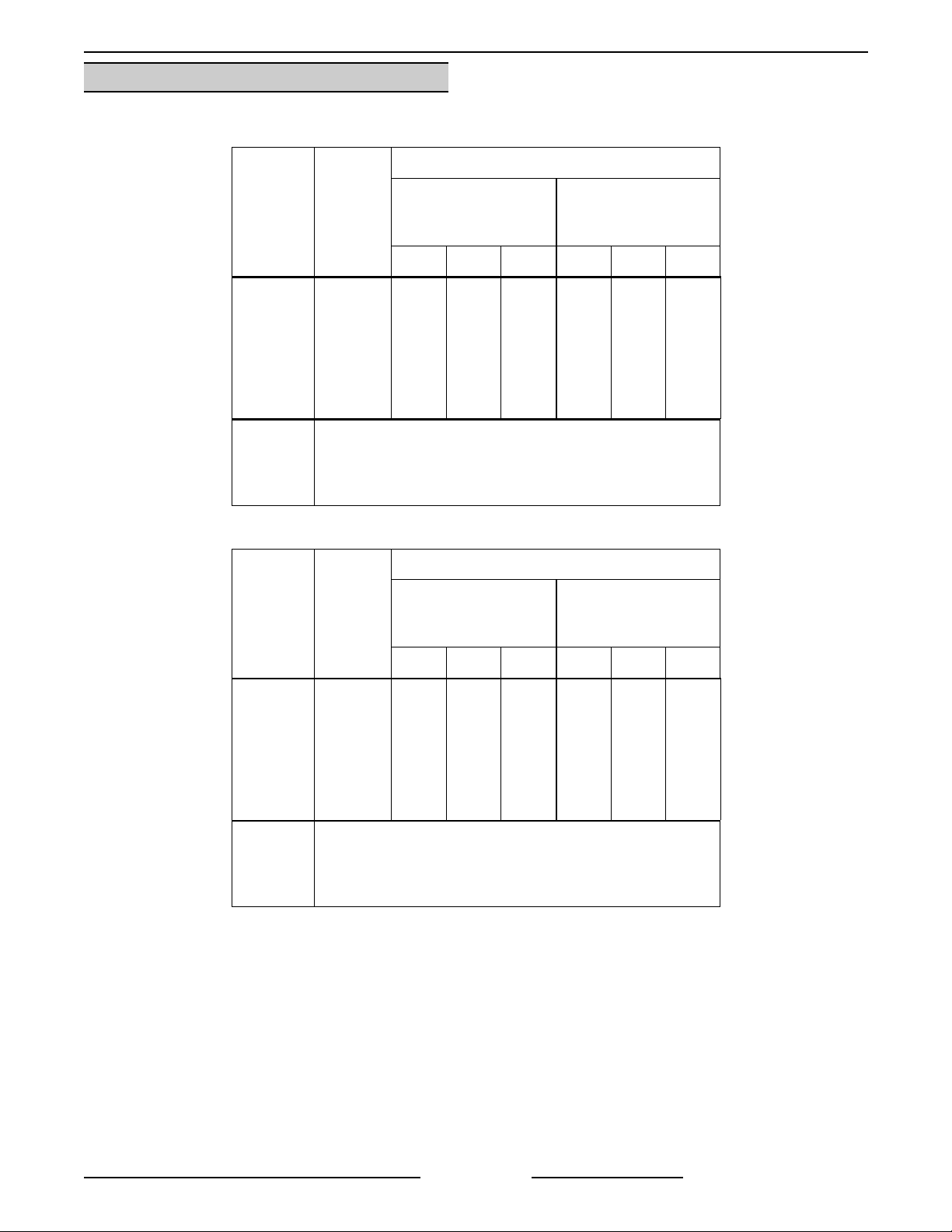

Electrical

FULL SIZE ELECTRIC CONVECTION OVEN - GENERAL

SPECIFICATIONS

AMPERAGE - 3 PHASE/ 60HZ

MODEL

VC4ES

VC4ED

VC4EC

VC6ES

VC6ED

VC6EC

NOTES:

MODEL

TOTAL

POWER

(KW)

PER LINE

1

RECOMMENDED

CIRCUIT

PROTECTION

2

208V 240V 480V 208V 240V 480V

12.5 353315454020

1. Amperage values in the table are nominal.

Tolerance is +5/-10%.

2. Complied in accordance wi th National E lectric Code,

ANSI/NFPA 70, latest edition.

AMPERAGE - 1 PHASE/ 60HZ

TOTAL

POWER

(KW)

PER LINE

1

RECOMMENDED

CIRCUIT

PROTECTION

2

VC4ES

VC4ED

VC4EC

VC6ES

VC6ED

VC6EC

NOTES:

208V 240V 480V 208V 240V 480V

12.5 605226807035

1. Amperage values in the table are nominal.

Tolerance is +5/-10%.

2. Complied in accordance wi th National E lectric Code,

ANSI/NFPA 70, latest edition.

F25105 (Decem ber 2001)Page 5 of 60

Page 6

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

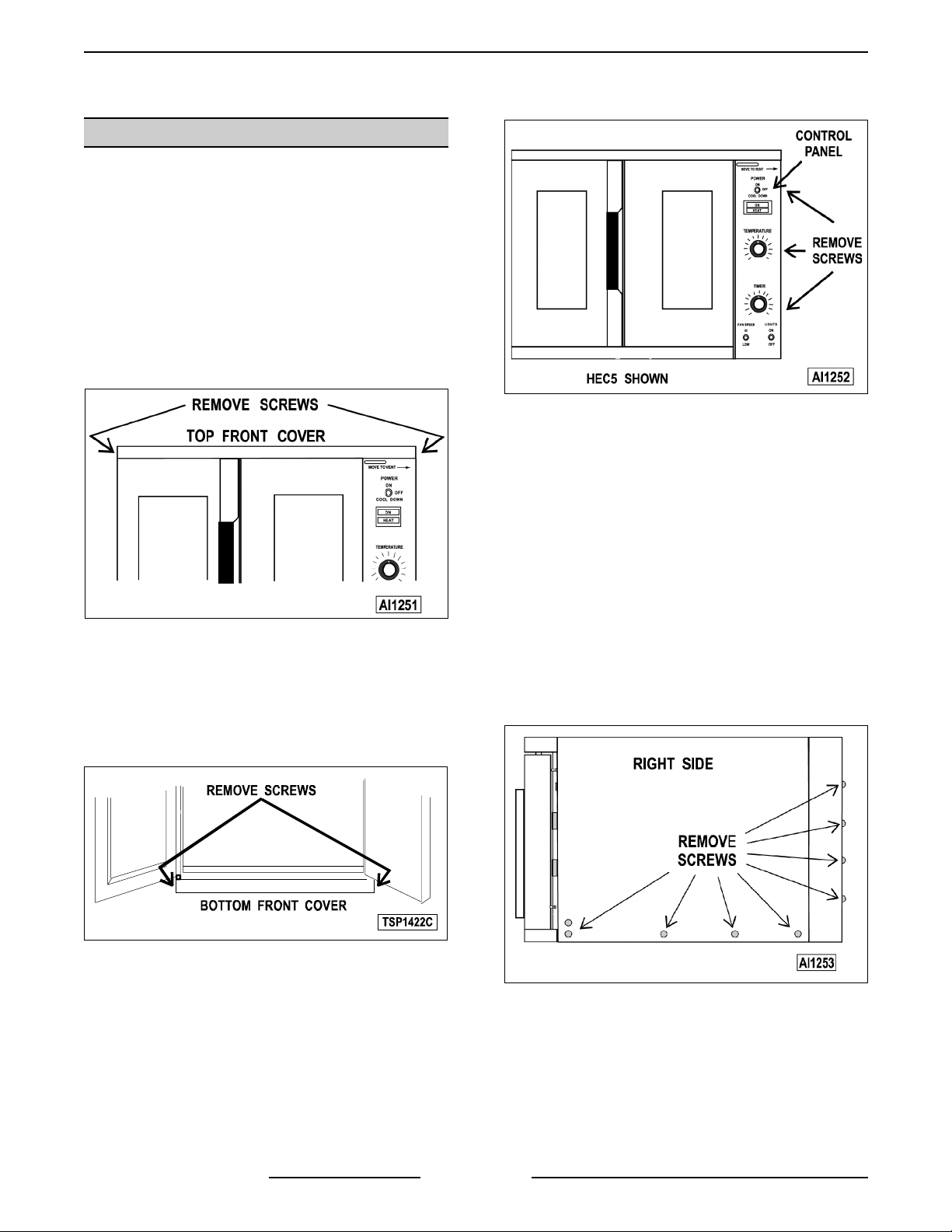

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Top Front Cover

1. The top f r ont cover is secured with four ( 4)

screws, two on each side of cover. Rem ove

these screws then remove the cover from the

oven.

2. Reverse the procedure to install.

Bottom Front Cover

1. The bottom front c over i s secured wit h four (4)

screws, two on each side of cover. Rem ove

these screws then remove the cover from the

oven.

DISCONNECT THE ELECTRICAL

NOTE:

thermostat, it must be removed fr om the control

panel first, bef ore removing the control panel.

2. Disconnect the temperature pr obe leads from

3. Unplug the wire harness connector to the

4. Reverse the procedure to install.

Right Side Panel

1. Remove the two screws near front of ov en,

2. Remove the remaining sev en scr ews securing

If t he oven has a mechanical (KX ty pe)

the solid stat e temperature c ontrol.

control panel components.

which secure the bottom front cover and c ontrol

panel.

the right side panel.

2. Reverse the procedure to install.

Control Panel

1. Remove three (3) screws on the right side

which secure the control panel then pul l the

panel away from the oven.

F25105 (Decem ber 2001) Page 6 of 60

3. Pull t he right side panel out at the bottom then

4. Reverse the procedure to install.

down to remove.

Page 7

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

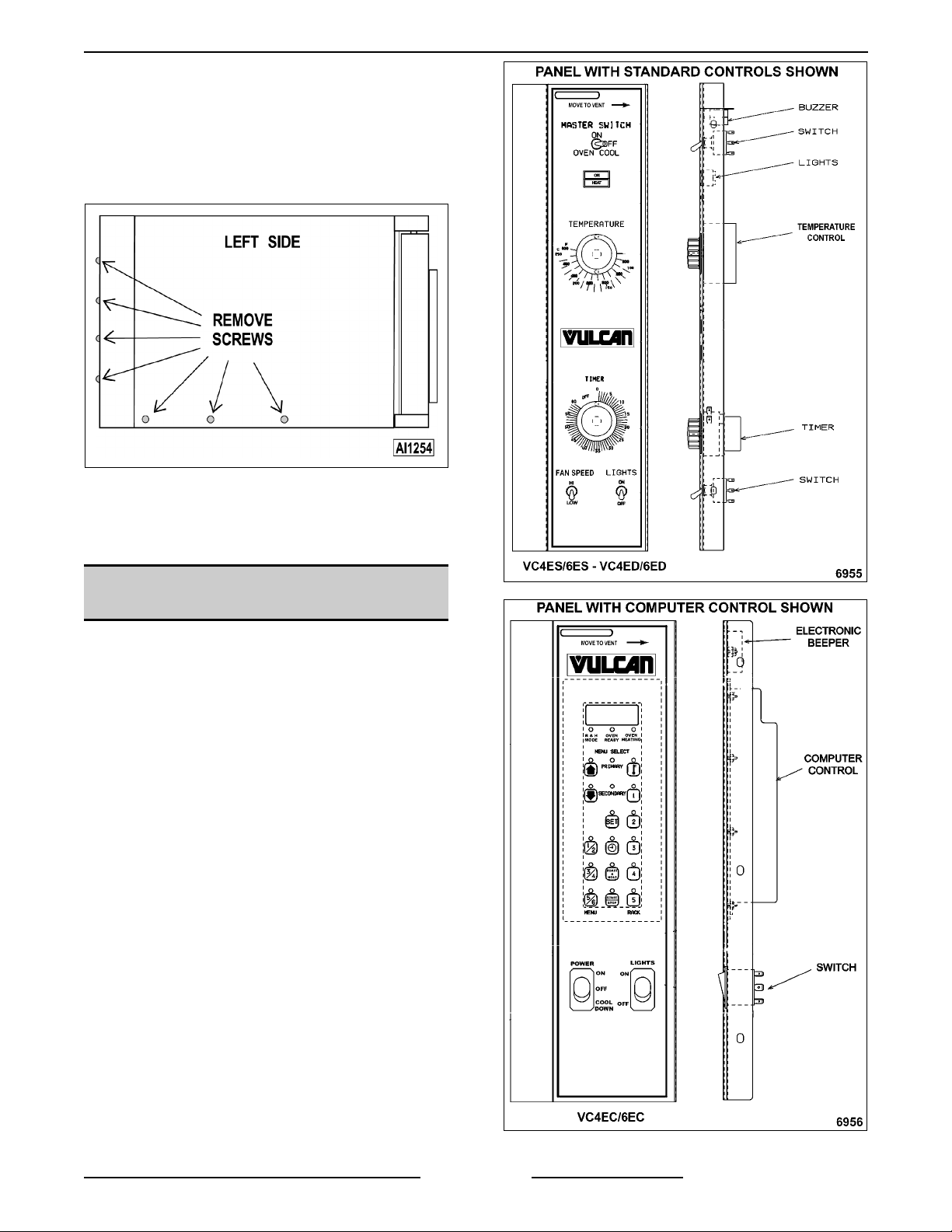

Left Side Panel

1. Remove the screws which secure the left side

of the t op front cover, bot tom f r ont cover and

control panel.

2. Remove the seven screws securing t he left

side panel.

3. Pull t he left side panel out at the bottom then

down to remove.

4. Reverse the procedure to install.

CONTROL PANEL

COMPONENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removable Components

1. Remove the control panel as outlined under

"COVERS AND PANELS".

2. Remove the component being replaced.

3. Reverse the procedure to install the

replacement component, then check oven for

proper operati on.

DISCONNECT THE ELECTRICAL

F25105 (Decem ber 2001)Page 7 of 60

Page 8

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

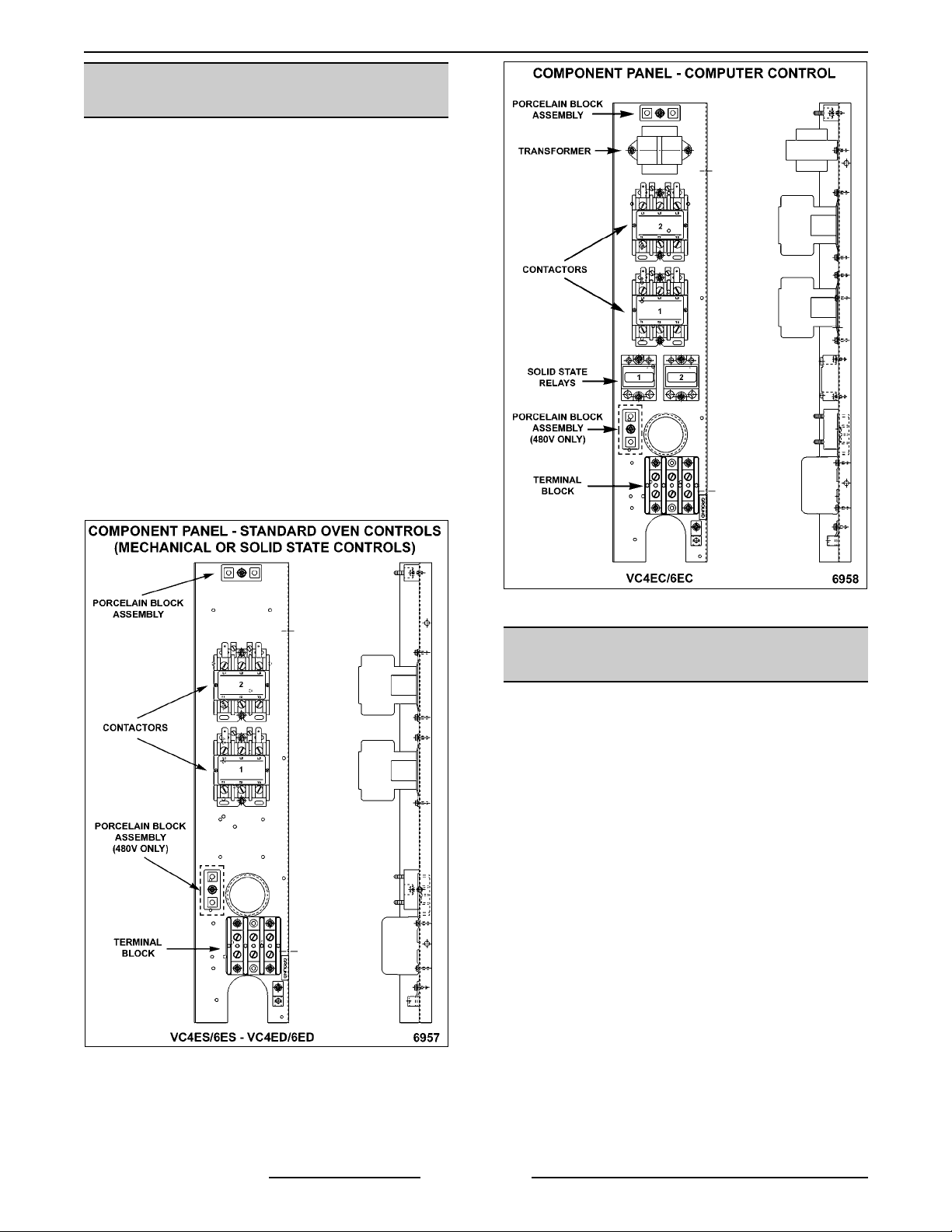

COMPONENT PANEL

COMPONENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removable Components

1. Remove the right side panel as outli ned under

"COVERS AND PANELS".

NOTE:

component can be servic ed by r emov ing the control

panel as outli ned under "COVERS AND PA NE LS " .

2. Disconnect the wir e leads to the component

being replaced.

3. Remove the component.

4. Reverse the procedure to install the

replacement component and check oven for

proper operati on.

DISCONNECT THE ELECTRICAL

If right side panel is not accessible, t his

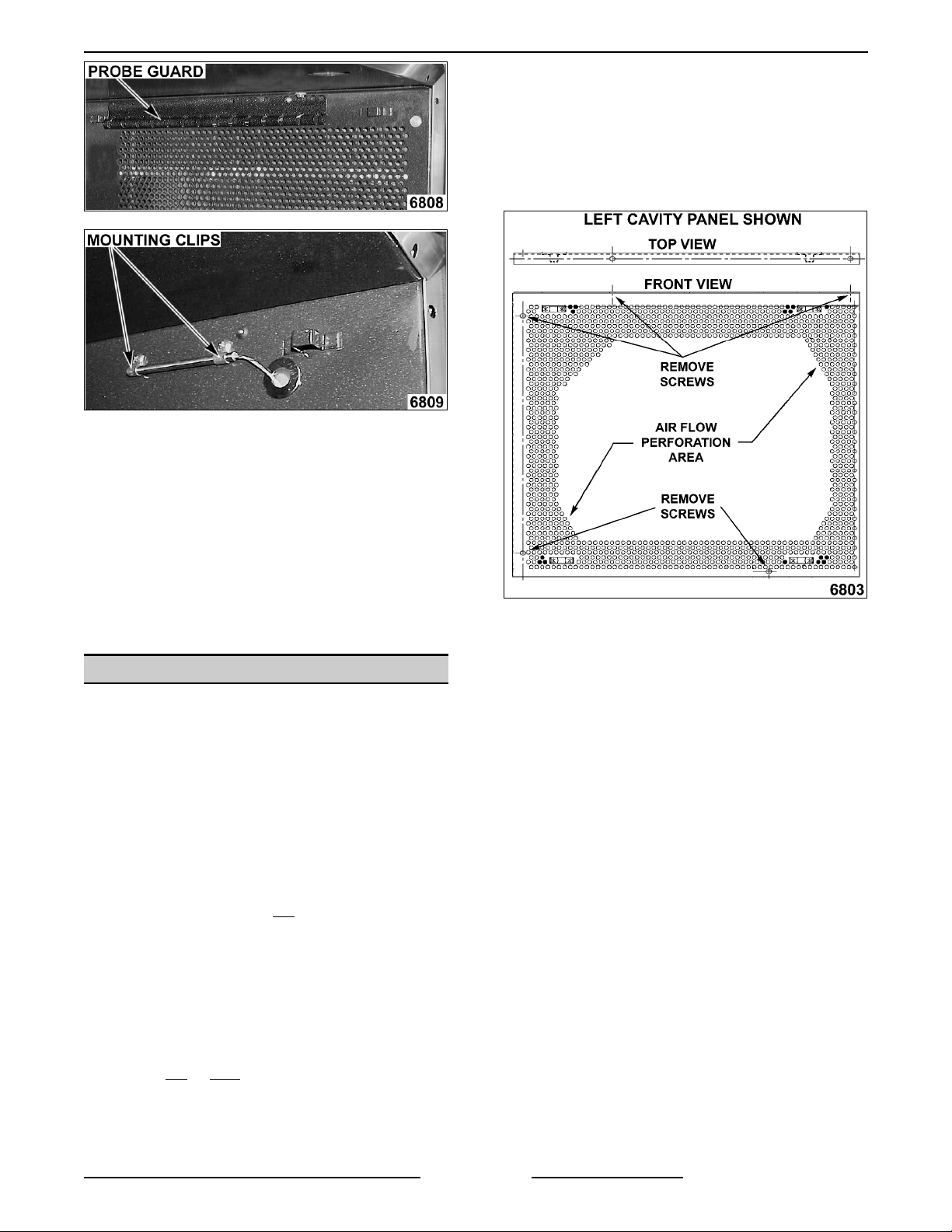

TEMPERATURE PROBE

(SOLID STATE CONTROL)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

"COVERS AND PANELS".

NOTE:

component can be servic ed by r emov ing the control

panel as outli ned under "COVERS AND PA NE LS " .

2. Disconnect the pr obe leads from the solid state

temperat ure control.

3. Remove the racks and ri ght rack support.

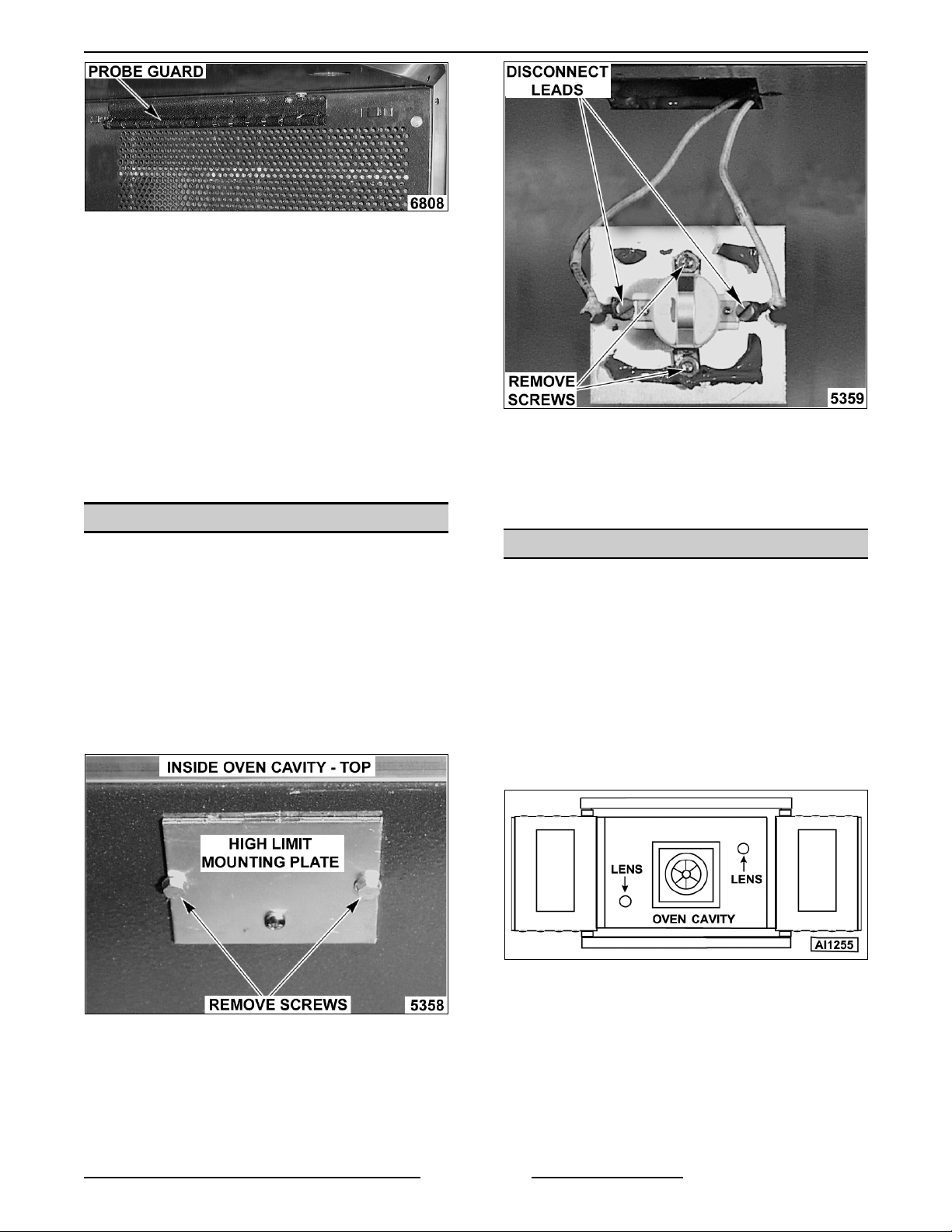

4. Remove the probe guard or mounting clips.

DISCONNECT THE ELECTRICAL

If right side panel is not accessible, t his

F25105 (Decem ber 2001) Page 8 of 60

Page 9

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

5. Remove probe by pushing it through the oven

wall and int o the control panel area.

A. Measure the current draw of the heating

element s as outlined under "HEAT ING

ELEMENT TEST" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

4. From inside the oven cavity, remove the

perforat ed panel from the same side of the

element being replaced.

NOTE:

line up straight with the oven cavity outer shell,

therefor e the probe must be removed at an angle.

6. Reverse the procedure to install the

7. Adjust the temperature control as outlined

The hole in the oven cavity wall does not

replacement probe.

under "SOLID STATE TEMP E RA TURE

CONTROL CALI B RA TION" in " S E RV ICE

PROCEDURES AND ADJUSTMENTS".

HEATING ELEMENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

NOTE:

the top cavity panel will have 3/4" square holes for

easier element removal. Ovens m anufactured prior

to this date have 1/2" r ound holes that sometimes

make it difficult to remove elements thru the cavity.

A serial number cut off will not

the procedures f or element remov al as outlined

below.

DISCONNECT THE ELECTRICAL

Starti ng wi th production in October, 2001,

be available. Follow

A. If r emov ing the right side panel, also

remove the probe guard or mounting clips.

B. Run the probe wire t hr u the panel opening

before l ifting panel out.

5. From t he element being replaced, r emov e the

hold down clam ps, the mounti ng br ac k et

screws at the top, then remove the element .

Front Access

1. Remove the oven racks and rack supports.

2. Remove the "top" door seal from the oven.

3. Determine if the heating element to replace is

on the left

element locations from front to back are: Right

side - R1, R2 & R3; Left side - R4, R5 & R6.

or right si de in the oven cavity. The

F25105 (Decem ber 2001)Page 9 of 60

Page 10

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

LEFT SIDE ELEMENTS SHOWN

NOTE:

which may still hold the element after the screws are

removed. Also, in some cases, the ri ng terminal

connected to the element may interfere with easy

removal. I f access to the l eft side panel and/or the

top panel is available, see "ALTERNATE ACCESS".

6. Disconnect the lead wires from the elem ent.

7. Clean RTV residue from the mati ng surface

The mounting bracket i s sealed with RTV

inside the oven, apply new hi gh temperature

RTV to the heat ing element mounti ng bracket

and rever se proc edur e to install .

3. If t he element is on the right

A. Remove the top panel and pull back the

insulation to expose the el ement

terminals.

B. Remove the lead wires from the element

being replaced.

4. From t he same element, remove the two

clamps holding the element vertical, the

screw’s securing mounting brac k et at the top,

and then remove the el ement.

NOTE:

which may still hold the element after the screws are

removed.

5. Clean RTV residue from the mati ng surface

6. Check for proper operation.

The mounting bracket i s sealed with RTV

inside the oven, apply new hi gh temperature

RTV to the heat ing element mounti ng bracket

and rever se proc edur e to install .

side:

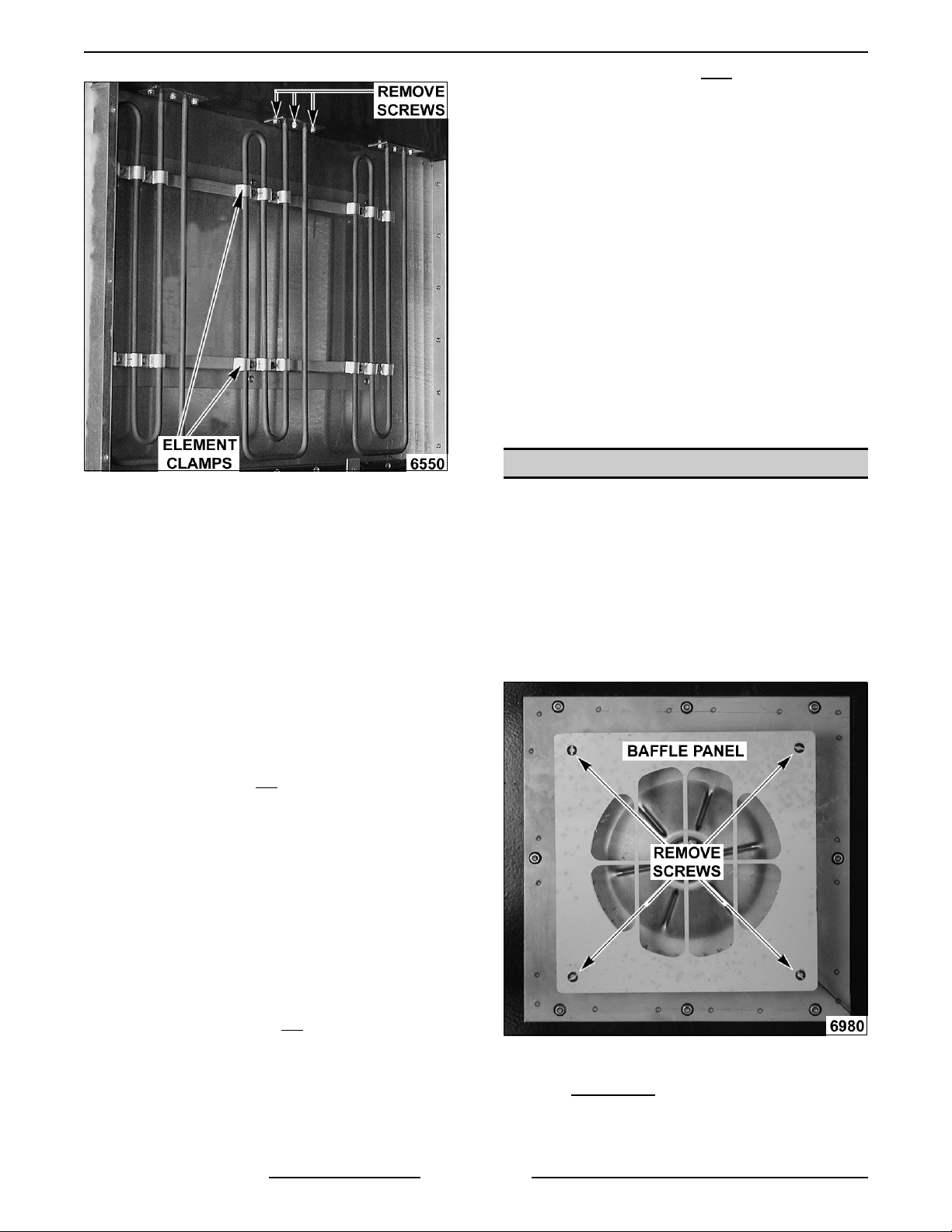

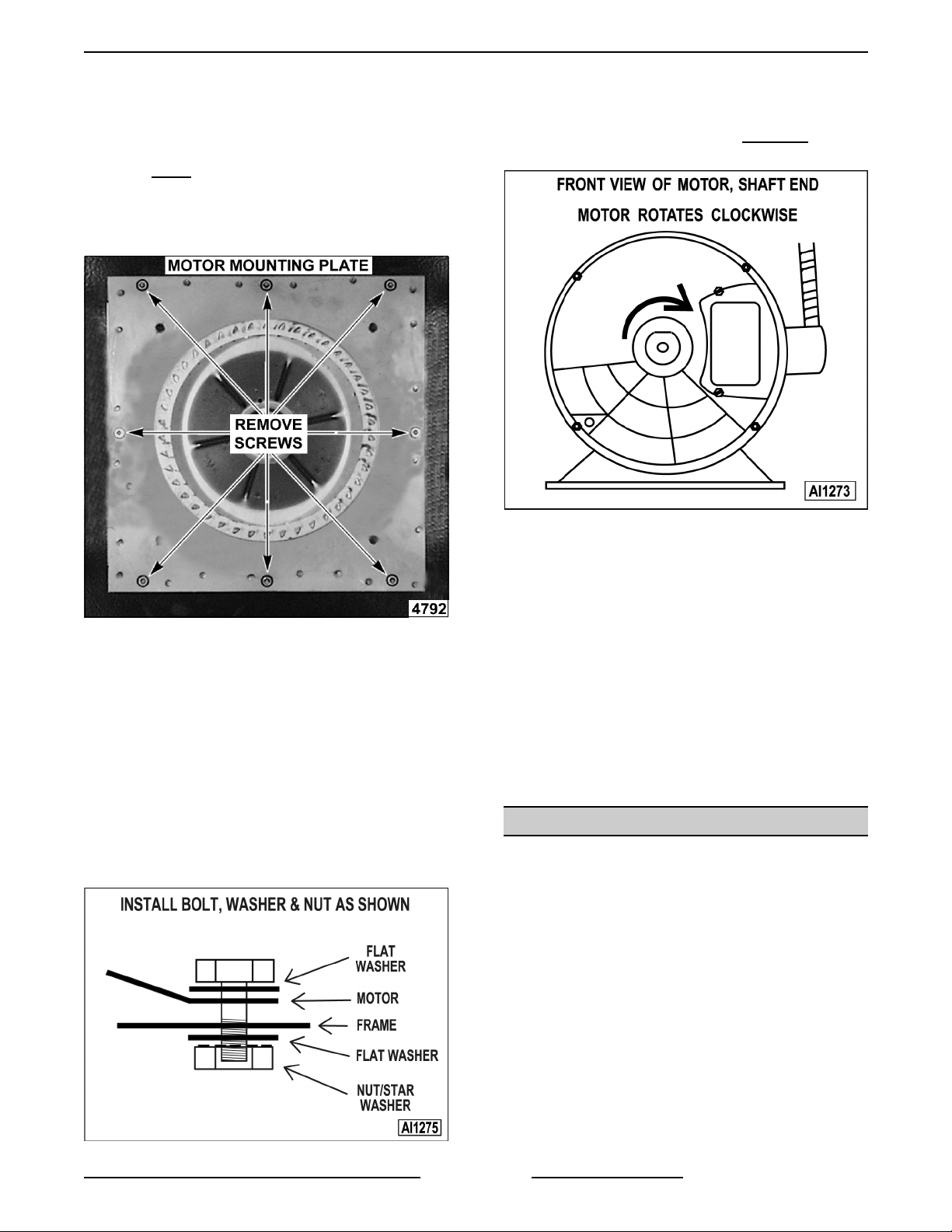

BLOWER AND MOTOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Take out the racks and rack supports.

2. Remove screws securing baffle panel and

remove the panel.

DISCONNECT THE ELECTRICAL

8. Check for proper operation.

Alternate Access

If t he heating element is not

inside the oven cavity, and ac cess to the left side

panel and/or the top panel is available, this al ternate

removal m ethod may be used.

NOTE:

being serv iced and the heating element to replace is

on the right side, the ovens must be unstacked to

access the heating el ement terminals through the

top. Once unstacked, fol low the removal procedur e

below.

1. Perform steps 1 thru 4 under "FRONT

2. If t he element is on the left

On stacked ovens, if the bottom oven is

ACCESS".

A. Remove the left side panel and pull back

the insulation at the top t o expose the

element terminals.

B. Remove the lead wires from the element

being replaced. Proceed to step 4.

removing easily from

side:

3. If replacing:

A. Blower Only

blower hub and using a bearing puller,

remove blower from motor shaft.

- Loosen set screws on

F25105 (Decem ber 2001) Page 10 of 60

Page 11

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

1) Reverse procedure to install and

adjust blower position as outlined

under "BLOWER ADJUST MENT" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

B. Motor

4. Remove the nuts that secure the motor

mounti ng plate to the rear wall.

- perform step 3A and continue

procedure.

10. Reconnect lead wires at the motor, replace

conduit and j unction box cover.

NOTE:

schematic. The motor must rotate clockwise

viewed from t he shaft end.

Check data plat e on motor for wiring

when

5. Place a piece of cardboard on the bottom of

the ov en c avity to protect its surface from any

damage during motor assembl y r emov al.

6. Pull t he motor assembl y into the oven cavity

and place it on the cardboard.

7. Remove the junct ion box cover f r om the motor,

disconnect l ead wir es and remove the conduit.

8. Remove motor mounting bolts and flat washers

then lift the motor f r om the mounting plate.

9. Position the replacem ent motor on t he motor

mounti ng plate and install mount ing bolts and

washers.

Hand tighten mounting bolts only

11. Slide blower onto motor shaft until hub is flush

with end of shaft then ti ghten set screws.

12. Adjust motor position until blower is parallel to

motor mounting pl ate as outlined under

"BLOWER ADJUSTMENT" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

13. Position motor mounting pl ate on the rear wall

and secure with nuts and washers.

14. Replace t he baffle panel.

15. Remove cardboard from t he bottom of the

oven cavity.

16. Check oven for pr oper operation then replace

rack guides and racks.

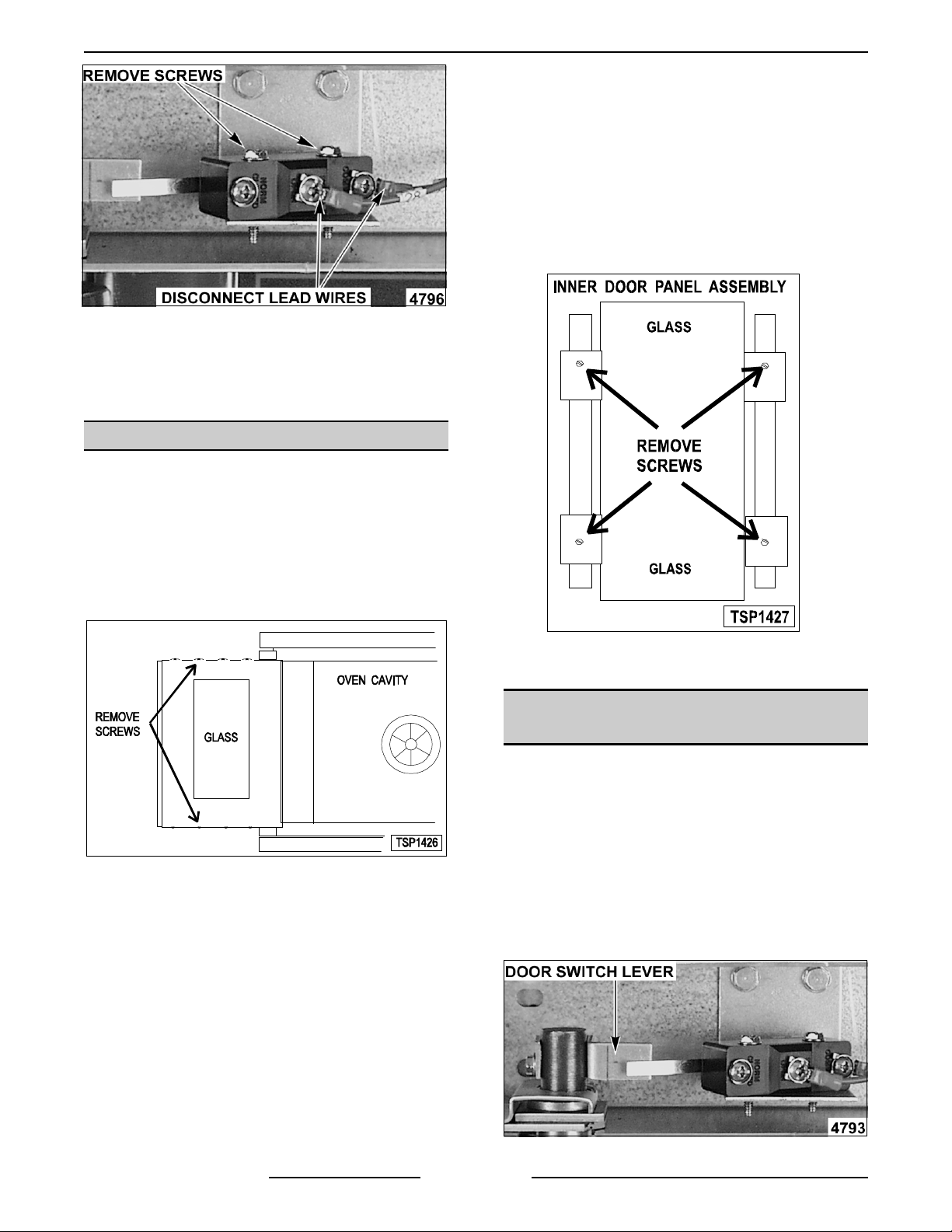

DOOR SWITCH

.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top front cover as outlined under

"COVERS AND PANELS".

DISCONNECT THE ELECTRICAL

2. Disconnect the lead wires to the door switch.

3. Remove the switch.

F25105 (Decem ber 2001)Page 11 of 60

Page 12

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

4. Reverse proc edur e to install the replacem ent

switch and check for proper adjustment as

outlined under "DOOR SWITCH

ADJUSTMENT " in "SERVICE P ROCEDURES

AND ADJUSTMENTS".

DOOR WINDOW

1) Lift out the inner door panel and

window assembly.

2) If replaci ng window on the right door,

remove the screws along the insi de

edge (if applicable) of the door then

remove the inner door panel and

window assembly.

4. Remove the screws securing the window “tabs”

to the door brack et and lift the window

assembly out from t he door frame.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the screws at the top and bott om of

door.

2. Independent doors:

A. Remove the door handl e then remove the

B. Lift out the i nner door panel and window

DISCONNECT THE ELECTRICAL

outer door panel.

assembly.

5. Reverse proc edur e to install the replacem ent

window.

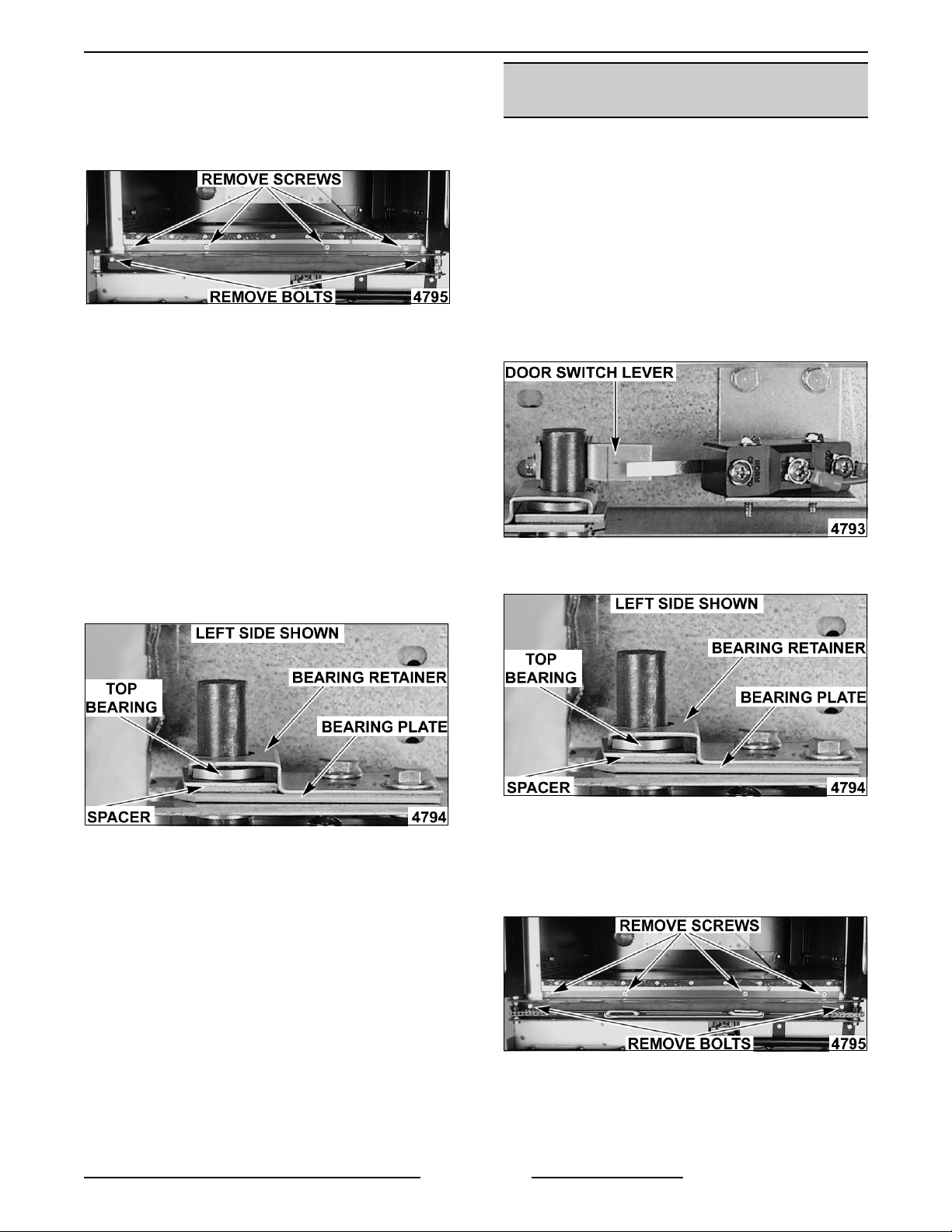

OVEN DOORS AND BEARINGS

(INDEPENDENT DOORS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top front cover and bottom front

cover as outlined under "CO V E RS A ND

PANELS".

2. Remove the door switch lever.

DISCONNECT THE ELECTRICAL

NOTE:

the inside edge of the door.

3. Simultaneous doors:

A. If r eplacing window on the left door,

F25105 (Decem ber 2001) Page 12 of 60

Left door only - rem ove door seal from

remove the handle from t he front of the

door then remove door seal from the

inside edge of the door.

Page 13

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

3. Remove the lower door seal strip to expose the

mounti ng scr ews of the door assembly.

4. Remove the two (2) lower sill bolts by the lower

door shaft and the four (4) counter-sunk screws

from the lower sill.

NOTE:

down once the last screw is removed. If removing

door assembly with- out assistance, use caution.

5. Tilt the top of the door slightly forward and l ift

6. Lay the door f lat to prevent dam age.

7. The top and bottom bearings are now

The door assembly is heavy and will drop

the door up until the bottom of the door shaft

clears the openi ng in the sill.

accessible for inspection and/or replacement if

needed.

OVEN DOORS

(SIMULTANEOUS DOORS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Assembly Removal

1. Remove the top front cover and bottom front

cover as outlined under "CO V E RS A ND

PANELS".

2. Remove the door switch lever.

DISCONNECT THE ELECTRICAL

A. If bear ings are ok, proceed to step 8.

B. If r eplacing the top bearing, remove the

top bearing retainer and top bearing.

C. If replacing the bottom bearing, remove it

from the door shaft or the lower sill

opening.

8. Reverse proc edur e to install door assembly

and check for proper adjustment as outlined

under "DOOR ADJ US TMENT" and "DO OR

SWIT CH ADJUSTMENT" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

3. Remove the top beari ng r etainers and top

bearings.

4. Remove the lower door seal strip to expose the

mounti ng scr ews of the door assembly.

A. Remove the two (2) lower sill bolts by the

lower door shaft and the four (4)

counter-sunk screws from the lower sill.

NOTE:

down once the last screw is removed. If removing

door assembly with- out assistance, use caution.

The door assembly is heavy and will drop

F25105 (Decem ber 2001)Page 13 of 60

Page 14

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

5. Lift up on the door assembly and swing the

right side out then move the assembly to the

left to clear t he slots in the upper door sill.

6. Lay the door assembly on a flat c ushi oned

surface for disassembly.

7. Reverse proc edur e to install door assembly

and check for proper adjustment as outlined

under "DOOR ADJ US TMENT", "DOOR CHAIN

ADJUSTMENT (SIMULTANEOUS DOORS)"

and "DOOR SWITCH A DJ US TMENT" i n

"SERVICE PROCEDURES AND

ADJUSTMENTS".

Disassembly

1. Remove the door assembly as outlined in

"OVEN DOO R S ( S IMULTANEOUS) " under

"ASSEMBLY REMOVAL".

2. Remove the door chain by loosening one of the

turnbuckles.

3. Loosen the set screw on the sprocket of door

being replaced.

4. Drive out the spirol pin fr om the sprocket of

door being repl ac ed.

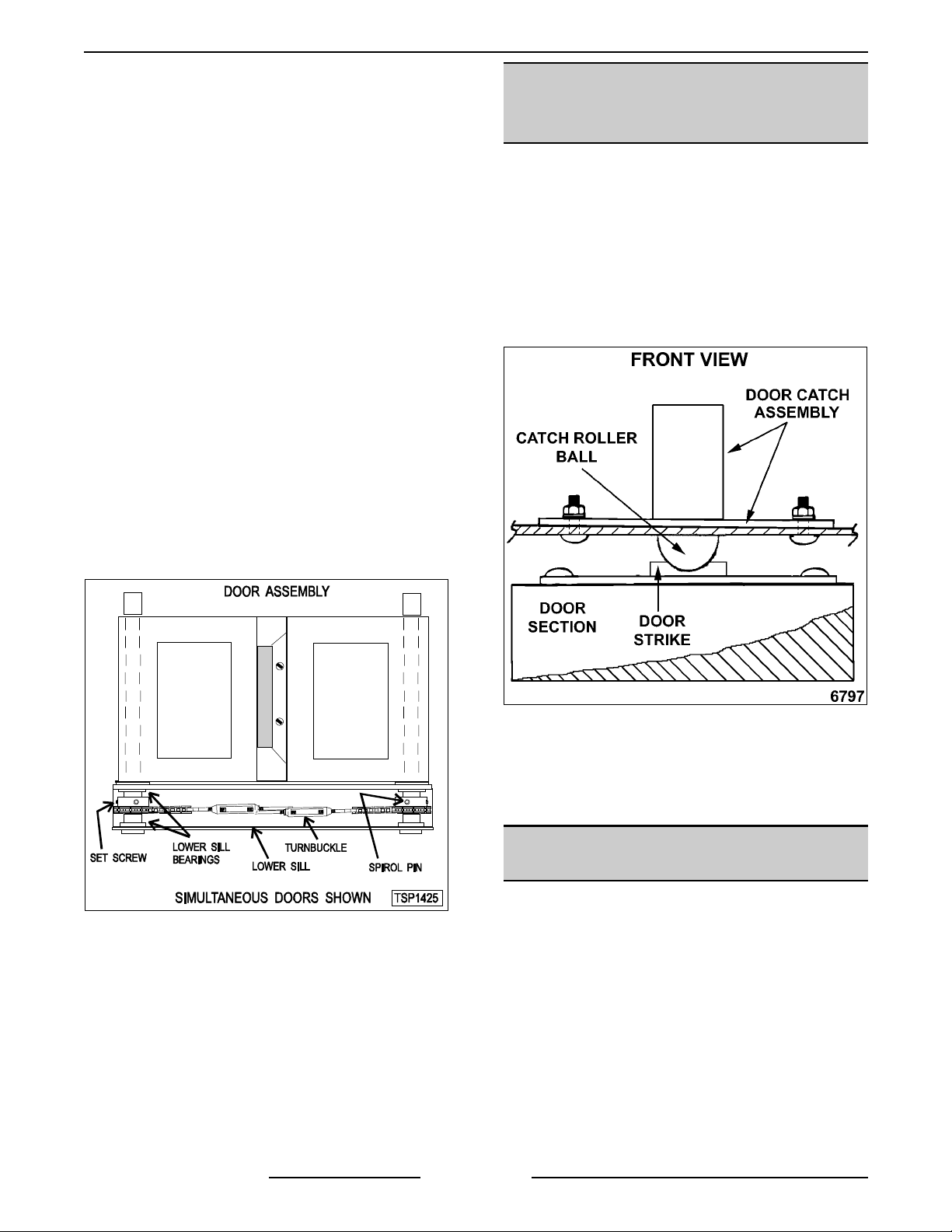

DOOR CATCH ROLLER

ASSEMBLY

(INDEPENDENT DOORS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top front cover as outlined under

“COVERS AND PANELS”.

2. Remove the catch roller assembly .

DISCONNECT THE ELECTRICAL

5. Remove the door f r om lower sill bearings and

sprocket.

A. Door assembly par ts are now accessible

for i nspection and/or replacement if

necessary.

6. Reverse proc edur e to re-assemble the door

assembly parts and check for proper

adjustment as outlined under "DO OR CHAIN

ADJUSTMENT (SIMULTANEOUS DOORS)" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

3. Reverse proc edur e to install .

4. Adjust the catch roller as outlined under

“DOOR CATCH (ROLLER) ADJUSTME NT

(INDEPENDENT DOORS)” in “SERVICE

PROCEDURES AND ADJUSTMENTS”.

MECHANICAL (KX)

THERMOSTAT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the racks and ri ght rack support.

2. Remove the thermostat knob and mount ing

screws from the c ontrol panel and t hen r emov e

the control panel.

3. Remove the probe guard from the oven cavity

wall.

DISCONNECT THE ELECTRICAL

F25105 (Decem ber 2001) Page 14 of 60

Page 15

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

NOTE:

should not ext end beyond the guard.

4. Remove the thermostat bulb from the oven

NOTE:

line up straight with the oven cavity outer shell,

therefor e the probe must be removed at an angle.

5. Reverse the procedure to install.

6. Adjust the thermostat as outl ined under

When installing probe guard, the probe

cavity by pushing it through the oven wall and

into the control panel ar ea.

The hole in the oven cavity wall does not

"MECHANICAL (K X) T HE RM OSTAT

CALIBRATI ON " in "SERVICE PROCEDURES

AND ADJUSTMENTS".

HIGH LIMIT THERMOSTAT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Take out rack s from the oven.

DISCONNECT THE ELECTRICAL

NOTE:

and mati ng surfaces inside the oven cavity and

apply new high temperature RTV seal er before

installing.

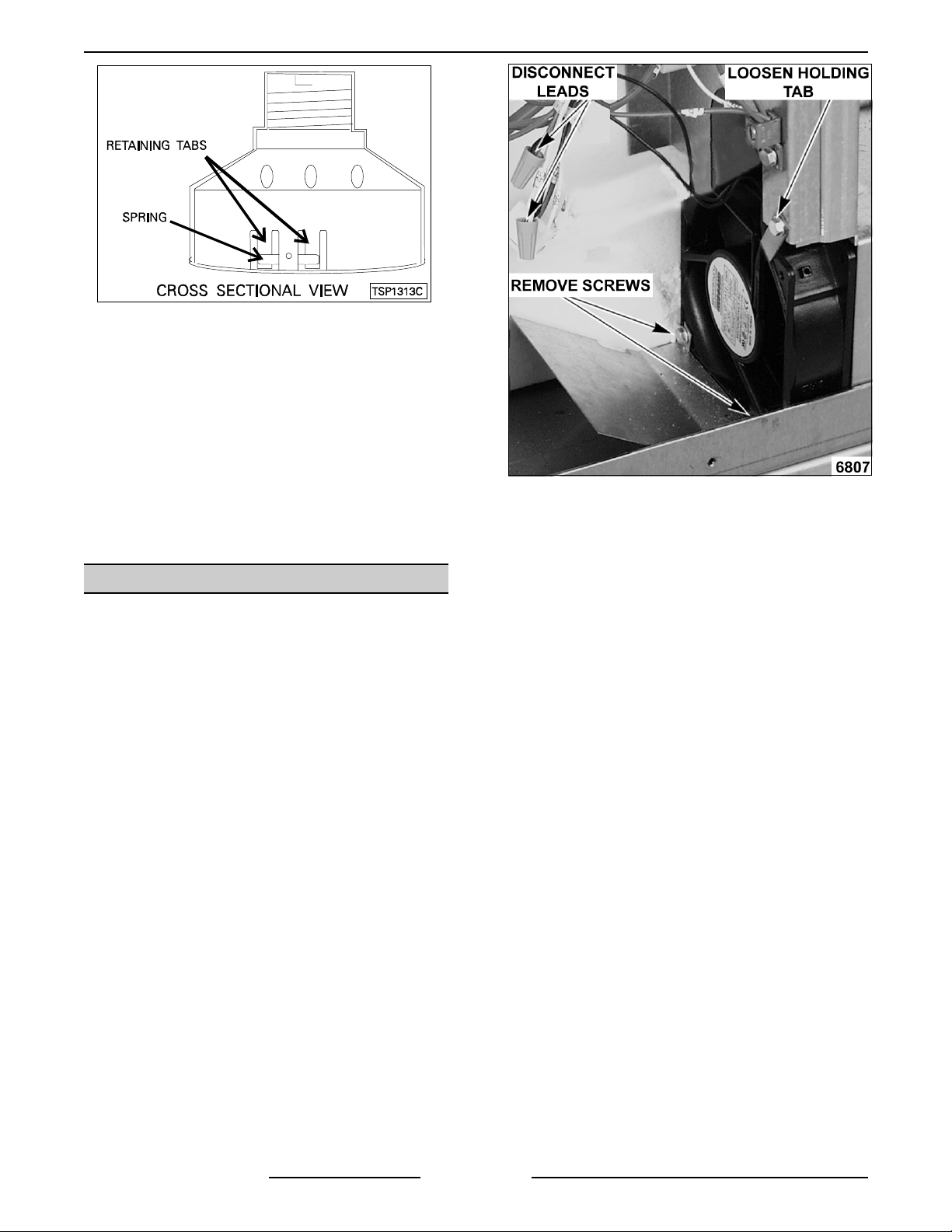

4. Reverse proc edur e to install .

Remove the old RTV seal er from the cover

INTERIOR LIGHTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

DISCONNECT THE ELECTRICAL

2. Remove the high l imit thermostat

cover /mounti ng plate fr om inside t he oven

cavity at the top.

3. Disconnect lead wi r es from hi gh limit

thermostat then remove high limit therm ostat

from cover /mounti ng plate.

Lamp

1. Remove the racks.

2. Unscrew the glass lens for the light bei ng

replaced then unscrew the bulb.

3. Replace bulb t hen reverse the pr oc edur e to

install.

Lamp Assembly

1. Remove the lens and bulb.

2. Remove the springs from the ret aining tabs (2

places) on the socket.

F25105 (Decem ber 2001)Page 15 of 60

Page 16

FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT OF PARTS

3. Depress the retaini ng tabs and pull the socket

out from the oven, far enough to disconnect the

lead wires.

4. Remove the socket from the oven.

5. Attach the lead wires to the repl ac ement

socket.

6. Insert the socket into the hole in the oven and

push until the sock et is held in place by the

retaini ng tabs.

7. Install the light bulb and lens.

8. Check for proper operation.

COOLING FAN

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

"COVERS AND PANELS".

DISCONNECT THE ELECTRICAL

4. Reverse the procedure to install the

replacement fan and check for proper

operation.

NOTE:

from outside the rear of the oven and blown into t he

control ar ea. The arrow on the fan body indicates

“air f low” directi on and shoul d be pointing toward the

controls.

NOTE:

air tube and the oven bott om.

NOTE:

at approximatel y 30 degrees to properly direct the

air f low.

The fan must be installed so air is pulled

Ensure fan is seated “squarely” against the

The air deflector should be angled upwards

NOTE:

component can be servic ed by r emov ing the control

panel as outli ned under "COVERS AND PA NE LS " .

2. Disconnect the lead wires to the f an motor by

3. Remove the screws securing the air deflect or

F25105 (Decem ber 2001) Page 16 of 60

If right side panel is not accessible, t his

removing wire nut s.

to the f an then loosen the tab screw holdi ng the

fan to t he c omponent panel. Rotate the tab so

that the fan will clear and remove the fan.

Page 17

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

SOLID STATE TEMPERATURE

CONTROL CALIBRATION

1. Place a thermocouple in the geometr ic center

of the oven cavity.

2. Set the power switch to O N.

3. Set the temperature control dial to 350 °F.

4. Allow the oven temperature to stabilize

(normally 3 cycles).

5. Record the temperature at which the Heat lamp

goes OFF and comes ON for at least two

complete heat ing cycles.

6. Calculat e the differenti al by subtracting the

temperat ure indicat ed when the lamp goes out

from the temper ature indic ated when the lamp

comes on.

A. If the average temperature is 10 °F or

, from the dial setting, t he thermostat

less

is properly c alibrated.

B. If the average temperature is more

than

10 °F from the dial setting, the therm ostat

calibration must

be adjusted.

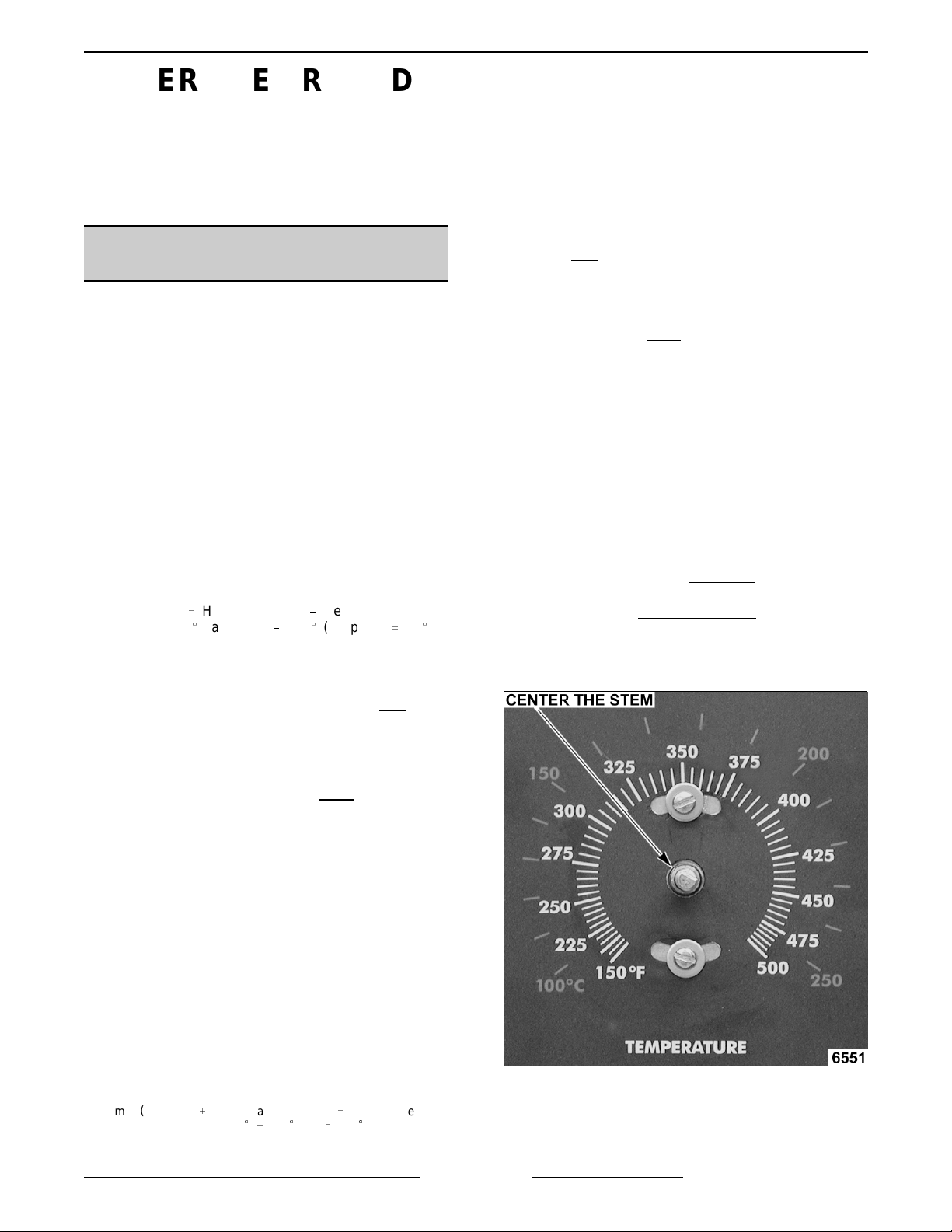

1) Loosen the tem per ature control k nob

set screw and remove the knob fr om

the stem.

2) Loosen temperature control mounting

screws only enough to rotate t he

control.

a. Place thumb and forefinger on

the head of t he mounting

screws, apply pressure and

slightly rotate the screw heads

(body of control) i n the slot.

Rotate clockwise

to increase

temperat ure and

DifferentialHeat lamp OFFHeat lamp ON

Example

: 360((

lamp off

)340((

lamp on

)20

A. The differential calculated should be less

than 20 °F.

counterclockwise

(

b. Center the stem in the opening

and re-tighten the temper ature

control mounting screws.

to decrease.

1) If the differential is 20 °F or less

, the

temperat ure control circuit is

functioning properly.

a. Proceed to step 7.

2) If the differential is more

than 20 °F:

a. Check the temperature probe as

outlined under "TEMPERAT URE

PROBE TEST (SOLID STATE

CONTROL)".

b. If t he pr obe is functioning

properly t hen temperature

control is malfunctioning.

a) Install a replacement

temperat ure control and

check calibration.

7. Calculat e the average temperatur e by adding

the temper ature indic ated when the lamp goes

out to the temperature i ndicated when the lamp

comes on and dividi ng this answer by 2.

[

Temp.(lamp off

)

Example

Temp.(lamp on

: 360

340(÷ 2350

(

)] ÷ 2

Average Temp

(

.

c. Replace knob and re-tighten set

screw .

F25105 (Decem ber 2001)Page 17 of 60

Page 18

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

d. Rotate the knob t o the lowest

temperat ure setting then back to

350°F.

e. Repeat the average temper ature

calculation in step 7.

NOTE:

Allow the oven to cycle

at least two times between

adjustment s before perf or ming

the calculation.

a) If the av erage temperat ur e

still differs more

than 10 °F

from the dial setting, adjust

the therm ost at calibration

until the average

temperat ure is within

tolerance.

C. If the above adjustment cannot be

obtained:

1) Turn the power switch O FF.

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

2) If the differential is more

than 30 (F,

the therm ost at is malfuncti oning.

a. Install a replacement thermostat

and check calibration.

7. Calculat e the average temperatur e by adding

the temper ature indic ated when the heat lamp

goes out to the temperature indicated when the

heat lam p c omes on and dividing t his answer

by 2.

[

Temp.(lamp off

)

Example

Temp.(lamp on

: 360

340(÷ 2350

(

)] ÷ 2

Average Temp

(

A. If the average temperature is 15 (F or less

from the dial setting, the t hermostat i s

properly calibrated.

B. If the average temperature is more

than

15 (F of t he dial setti ng, the thermostat

calibration must

be adjusted.

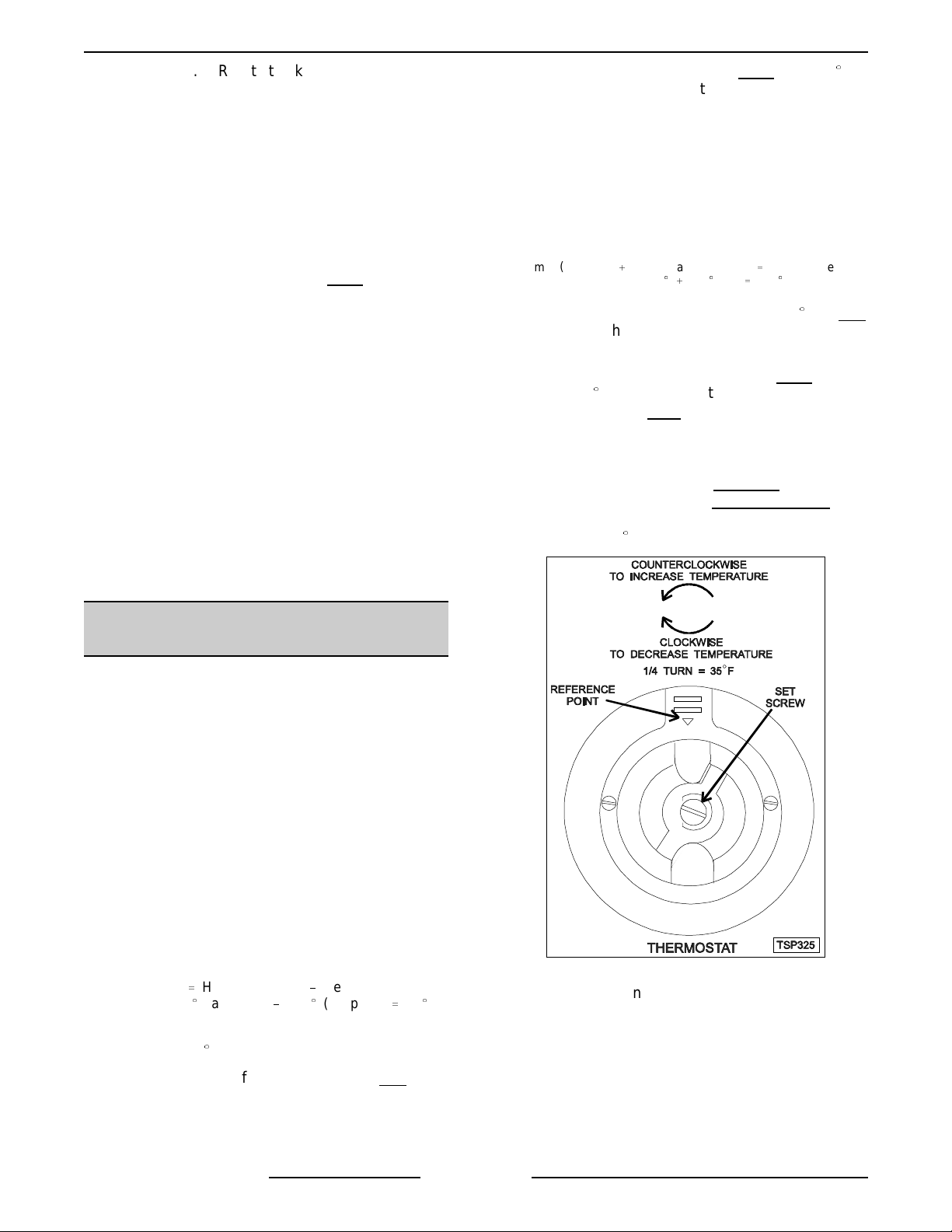

1) Remove the thermostat knob.

2) Hold the thermostat shaft and turn the

inner set screw clockwise

temperat ure or countercl oc k wise

to decrease

to

increase temperature (¼ turn =

35(F).

.

2) Replace the temperat ur e c ontrol and

check calibration.

MECHANICAL (KX)

THERMOSTAT CALIBRATION

1. Place a thermocouple in the geometr ic center

of the oven cavity.

2. Set the power switch to O N.

3. Set the thermostat dial to 350 °F.

4. Allow the oven temperature to stabilize

(normally 3 cycles).

5. Record the temperature when the thermostat

cycles OFF and ON for at least three complete

cycles.

6. Calculat e the differenti al by subtracting the

temperat ure indicat ed when heat lamp goes out

from temperat ure indicat ed when heat lamp

comes on.

DifferentialHeat lamp OFFHeat lamp ON

Example

: 360((

A. The differential calculated should be less

than 30(F.

1) If the differential is 30 °F or less

lamp off

)340((

lamp on

)20

, the

thermostat is funct ioning properl y .

a. Proceed to step 7.

(

8. Replace the knob and verify the setting is stil l

at 350°F.

9. Repeat step 7 until the av er age temperatur e is

within tolerance.

NOTE:

Allow the oven to cycle at least two times

between adjustment s before perfor ming the

calculation.

F25105 (Decem ber 2001) Page 18 of 60

Page 19

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

A. After the final adjustment is made and the

average temperature is within tolerance,

remove the knob and apply a nonpermanent t ype sealer around the head of

the set screw.

10. If the abov e adjustment cannot be obtained:

A. Turn the power switch O FF.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

B. Install a replacement therm ostat and

DISCONNECT THE ELECTRICAL

check calibration.

SOLID STATE TEMPERATURE

CONTROL TEST

1. Remove the right side panel as outli ned under

"COVERS AND PANELS" in "REMOVAL AND

REPLACEMENT OF PARTS".

NOTE:

component can be servic ed by r emov ing the control

panel as outli ned under "COVERS AND PA NE LS " .

2. Place a thermocouple in the geometr ic center

NOTE:

3. Set the temperature control to the maximum

4. Check machine data plate for correct voltage to

5. Turn the power switch to O N.

If right side panel is not accessible, t his

of the oven cavity.

Ov en temperature must

setting.

oven. Refer to di agr am below for pr oper

terminal locations and voltages before

checking the c ontrol. Use the cor r ec t terminals

for the c orresponding v oltage.

be below 450°.

A. If c orrect, proceed to step 7.

B. If incorrect, problem is not

temperat ure control. S ee

"TROUBLESHOOTING".

7. Check relay volt ages on t he boar d:

A. For 208-240VA C c ontrols - check across

terminals 7 & 10 for input to the internal

relay and 6 & 10 for output from the

internal relay.

1) If input voltage t o the internal relay is

correct, pr oc eed to step 8. If input

voltage to the i nternal relay is not

present, problem is not with the

temperat ure control. S ee

"TROUBLESHOOTING".

2) If output voltage from the internal

relay is cor r ec t proceed to step 8. If

output voltage from the internal relay

correct, c hec k temperature

is not

probe as outlined under

"TEMPERATURE PROBE TEST

(SOLID STATE CONTROL)".

8. Set the temperature control to the minimum

setting.

NOTE:

9. Check for zero (0) volts AC across terminals 6

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Ov en temperature must

& 10 (208-240VAC) for no output from t he

internal relay.

A. If c orrect, temperature cont r ol is

functioning properly.

B. If incorrect, check tem per ature probe as

outlined under "TEMPERAT URE P ROBE

TEST (SOLID STATE CONTROL)".

1) If temperature probe is ok:

a. Turn the power switch OF F.

DISCONNECT THE ELECTRICAL

with the

be above 300°F.

6. Check for proper voltage across terminals 8 &

10 (208-240VAC) for power to the control.

b. Replace the temperature control

and check calibration as outlined

under "SOLID S TATE

TEMPERAT URE CONTROL

CALIBRATION".

F25105 (Decem ber 2001)Page 19 of 60

Page 20

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

TEMPERATURE PROBE TEST

(SOLID STATE CONTROL)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

NOTE:

with the Solid State Temperature cont rol is an RTD

(resistance temperature detector) of t he Thermistor

type. As temperature inc r eases the resistanc e value

decreases.

1. Remove the right side panel as outli ned under

"COVERS AND PANELS" in "REMOVAL AND

REPLACEMENT OF PARTS".

NOTE:

component can be servic ed by r emov ing the control

panel as outli ned under "COVERS AND PA NE LS " .

2. Place a shielded thermocouple in the geometric

center of the oven cavity and determine the

temperat ure in the oven cav ity.

3. Remove the probe lead wir es from the sol id

state temperature control.

4. Test the probe with an ohmmeter .

A. If the measured resistance values are

B. If the measured resistance values are

5. Reverse proc edur e to install .

TEMP (°F) OHMS* TEMP (°F) OHMS*

(*) Resistance in ohms ± 10%

DISCONNECT THE ELECTRICAL

The temper ature probe used in conjunc tion

If right side panel is not accessible, t his

inside the given tolerance then the pr obe

is funct ioning properly.

outside the given tolerance then repl ac e

the probe and retest.

1) Check oven for pr oper oper ation.

77 90,000 360 822

240 4,077 380 656

260 3,016 400 529

280 2,266 425 424

300 1,726 450 334

320 1,332 475 266

340 1,041

HEATING ELEMENT TEST

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

1. Turn the power switch ON and set t he oven

temperat ure control t o the highest setting.

2. Measure the voltage at the heating element

terminals and verify it against t he data plate

voltage.

A. If voltage is incorrec t

B. If voltage is correct

NOTE:

resistance check when a clamp on type am p

meter is available.

C. If unable to chec k current draw, a

3. Check for proper operation.

VOLTAGE

208

240

480

NOTES:

THE FOLLOWI NG ST EPS REQUIRE

, find the source of

the problem.

, check curr ent draw

(amps) through the heating element lead

wires.

This method is preferr ed over a

1) If current draw is correc t then heating

element is functioning properl y .

table below for proper values.

2) If current draw is not

power switch OFF and

the electrical supply to the oven.

a. Replace heati ng element t hen

proceed to step 3.

resistance check may

malfunctioning element.

1) Turn the power switch O FF and

disconnect the electrical supply to

the oven.

2) Remove the l ead wi r es from the

heating element and check r esi stanc e

(ohms).

values.

KW PER

ELEMENT

1. Values in the table are nominal.

Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. Resistance values (ohms) are @

room temperature.

See table below for proper

AMPS PER

ELEMENT

1 PH 3 PH

2603521

2523328

2 15 4 111

correct, turn the

disconnect

indicate a

OHMS PER

LEAD

See

ELEMENT

F25105 (Decem ber 2001) Page 20 of 60

Page 21

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

BLOWER ADJUSTMENT

WARNING:

PLACE A TAG ON THE CIRCUIT B OX INDICATING THE CIRCUIT I S B E ING SERVICED.

1. Remove the blower motor and mounting assembly by following steps 1 through 7 as outlined under

"BLOWER AND MOTOR" in "REMOVAL AND REPLACEMENT OF PARTS".

2. Loosen the motor mounting bolts.

3. Adjust the motor position until the blower is parall el to and 1/4 inc h away from the motor m ounting plate.

Check for squareness of the blower to the m otor mounting plate at t he top, bottom, left and right of the

blower.

A. If the blower is square then ti ghten motor mounting bol ts and proceed to step 4.

B. If the blower is not square continue adjusting until proper spacing is achieved then tight en motor

NOTE:

DISCONNECT THE ELECTRICAL POWE R TO THE MACHINE A T THE MAIN CI RCUIT BOX.

mounti ng bolts.

If necessary, place shims between motor and frame.

4. Reverse the procedure to install.

F25105 (Decem ber 2001)Page 21 of 60

Page 22

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

DOOR ADJUSTMENT

1. Check the doors to make sure they have an

equal gap between them and that the vertical

edge of the door is parallel to the vertical door

seal. If the doors are not positioned in thi s

manner, adjust the doors as described.

DOOR CATCH ROLLER

ADJUSTMENT

(INDEPENDENT DOORS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top front cover as outline under

"COVERS AND PANELS" in "REMOVAL AND

REPLACEMENT OF PARTS".

2. Open the doors and inspect the door strike for

proper shape.

DISCONNECT THE ELECTRICAL

2. Remove the top front cover.

3. Loosen the screws that secure the upper door

bearings and relat ed har dware, just enough to

allow door m ovem ent.

4. Move the door until proper alignment is

achieved then tighten the screws on the upper

door bearing hardware.

5. Repeat step 3 and 4 on the opposite door , if

necessary.

A. Replace i f bent and adjust as out lined in

this procedure.

3. Open and close the doors several times while

observi ng the catch rol ler operation.

A. Replace i f malfunctioning and adjust as

outlined in this procedure.

NOTE

: Shims may be requir ed under the

door strike t o r aise it, before the proper

door tension adjustment can be set.

4. Apply lubricant around t he spring. See

“LUBRICATION” under “GENERAL”.

5. Close the doors and check them for pr oper

alignment.

A. Doors should be centered and parallel at

the top and bottom, in t he oven cavity

opening. See "DOOR ADJUSTME NT".

F25105 (Decem ber 2001) Page 22 of 60

Page 23

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

6. With the doors closed, observe the posit ion of

the catch roller "bal l" in rel ation to the door

strike.

A. Ensure the catc h r oller "bal l" is centered

(lef t to right) to the door stri k e.

1) Adjust alignment, if necessary.

B. Open the right side door and view the left

side door catch roller and stri k e. Ensure

the door catch r oller "bal l" is resting upon

the angular surface of the door strike.

Repeat on the opposite door.

1) If adjustment is necessary, loosen the

mounti ng scr ews then sli de the door

strike from "front to back " until the

roller r ests upon the angular surface

of the door strike. Tighten screws and

check operation.

2) If proper adjustment cannot be

achieved, add shims beneath the

door strike. Repeat step 6 thru this

step. DO NOT B E ND THE DOOR

STRIKE.

7. Each ov en door should open with a forc e of 8

to 25 pounds when pulled at the handle. See

"TOOLS " under " GENERAL".

DOOR SWITCH ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top front cover as outlined under

"COVERS AND PANELS" in "REMOVAL AND

REPLACEMENT OF PARTS".

2. Door operation:

A. Independent doors

B. Simultaneous doors

3. If adjustment i s necessary, bend the switch

actuator to obtain the proper setting.

DISCONNECT THE ELECTRICAL

- The switch actuator

should be operated by the switc h lever

when the right door is between 1" and 1 ½

" from being cl osed.

- The switch actuator

should be operated by the switc h lever

when the right door is ½ " from being

closed.

A. Adjust catch roller tension as follows:

1) Turn the set screw inside the catch

assembly housing clockwise

increase tension on t he c atch roller

and counterclockwise

tension on the catch roller.

: The amount of tension on the

NOTE

catch roller determines the opening force

of the door.

2) Continue adjustment until proper door

operation i s achieved.

to

to decrease

4. Install the top front cover .

5. Apply power to the oven and check for proper

operation.

DOOR CHAIN ADJUSTMENT

(SIMULTANEOUS DOORS)

Introduction

When the oven doors are in proper adjustment, as

the doors come t ogether, the ri ght door will lead the

left door in closing by about 1/4 inc h. The doors will

feel like they ar e self cl osi ng the last ½ inch of

travel.

Procedure

1. Remove the lower sill cover as outline under

"COVERS AND PANELS" in "REMOVAL AND

REPLACEMENT OF PARTS".

2. Close doors and check door chai n for f ac tory

setting.

F25105 (Decem ber 2001)Page 23 of 60

Page 24

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

A. Turnbuckles should be 5 to 5 ½ inches

apart.

B. Short eye bolt should be connected to the

end of the chain that goes to the front of

the sprocket.

C. 2 links of the c hain should not be engaged

at the rear of the sprocket.

D. Chain must be tight enough that the doors

move simul taneously when opened or

closed.

E. When the doors are opened, the

turnbuckles will move away from each

other.

F. The stop cable must be positioned where it

moves freely and does not get pinched.

3. Position door c hain assembly to factory sett ing

if the conditi ons in step 2 are not met .

B. If door s operate properly, c ontinue to step

7.

7. Install the lower front cover .

COMPUTER CONTROL

Operation

Refer to the Instructions Manual for specific

operating i nst r uc tions.

Setup mode

NOTE:

is configured to the factory settings which result in

the proper operation of the oven. If the CAL1

parameter is other than zero, determine if i t is still

needed before resetting to zero. S ee " COMPUTER

CONTROL TE M P E RA TURE CALIBRATION".

CAUTION: Ch anging t he C_F, InP 1, rL1 & rH1

parameters will default all

settings.

1. Use this key sequence to access the setup

Use the setup mode to verify

menus to the factory

mode.

that the cont r ol

4. If right door does not lead the left door in

closing:

A. Loosen locknuts on both turnbuckles.

B. Loosen left turnbuckl e.

C. Tighten right turnbuckle.

D. Tighten locknuts on both turnbuckles.

5. If t he r ight door leads the left door by more

than 3/8 inch:

A. Loosen locknuts on both turnbuckles.

B. Loosen right t ur nbuc k le.

C. Tighten left turnbuckle.

Up arrow; Rack 1; Temperature; Temperature;

Down arr ow; Rack 1

2. Once in the setup mode the displ ay will

alternate between the parameter and

programmed data.

• To change data to t he factory set ting, use

the arrow keys.

• To select the next parameter, press the

Rack 1 key.

• After the last Param eter and Data is

viewed, press the Rack 1 key a final ti me

to exi t the setup mode and return to

operations m ode. The current set point

temperature will be displayed.

• After 1 minute of no key activat ions, the

control will return to operation m ode.

3. Listed are the parameters and data you should

find.

D. Tighten locknuts on both turnbuckles.

6. Check door for proper operation.

NOTE:

the adjustment will not hold.

F25105 (Decem ber 2001) Page 24 of 60

The locknut s must be tight dur ing testing or

A. If door s do not c lose properly, repeat step

4, 5 and 6.

Page 25

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

ALTERNATI NG ON

MENU

DISPLAY

PARAMETER DATA

Celsius_Fahrenheit C_F F

Guard Band gb 4000

Temperature

Compensation

tcnP OFF

Input Type 1 InP1 J

Range Low 1 rL1 75

Range High 1 rH1 500

Hysteresis HYS1 3

Calibrat ion Offset CAL1 0

Exit Setup Mode and

return to Operation

Mode.

set point temperature i s

displayed or if cal l for

heat, dashes (----)

displayed.

Probe Test

If t he oven is not heating or displaying the proper

temperat ure, the temperature probe m ay be

malfunctioning. Determine if the probe is good or

causing the operational problem. Temporarily ,

disconnect the existing pr obe lead wires from the

computer control and connect the lead wires f r om a

known good "J" type thermocouple. S ec ure the

sensing end of the thermocouple near the probe.

Turn the power switch ON and set t he dial to 350°F.

If t he oven reaches the set tem perature and cycles

with the temporary thermocouple, t hen the existing

probe is malfunctioning. Repl ac e temperature pr obe

with the correc t part and check for proper operation.

Solid S t ate Relay Test

The solid stat e r elays "SSR1 or SSR2" suppl y power

to the blower motor "high" or "low" fan speed

terminals when the SSR is energiz ed by the output

voltage from the com puter.

To test soli d state relay "SSR1" (high fan speed),

the comput er control should be in the "Norm al

Cooking Mode". To test solid state r elay "SSR2"

(low fan speed), the computer c ontrol should be in

the "Cook & Hol d M ode" .

1. Remove the right side panel as outli ned under

"COVERS AND PANELS".

2. Turn the power switch ON.

A. If the blower motor c omes on, the SSR i s

functioning properly.

B. If the blower motor does not c ome on,

proceed to step 3.

3. Check for +5 VDC on the input si de of SSR

(terminals 3 & 4).

A. If +5 VDC is present, cont inue to step 4.

B. If no voltage is present, computer control

is not func tioning proper ly.

4. Check for proper input voltage on t he load side

of SSR t erminal 1 and the power connection on

the other side of the supply.

A. On 208 & 240 volt ovens, the supply

connection is on the terminal block ( L2 for

single phase, L3 for three phase).

The measured voltage shoul d be identical

to the supply.

B. On 480 volt ovens, the supply connec tion

is on the secondary side of the 480V

transformer, terminal X4 (wire # 79) .

The measured voltage shoul d be 240

volts.

5. If input v oltage is correc t on the load side of

SSR terminal 1, pr oc eed to step 6.

A. If input voltage is not

correct, find the

source of the pr oblem.

6. Check output voltage on the load side of S S R

terminal 2.

F25105 (Decem ber 2001)Page 25 of 60

Page 26

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

A. If voltage is correct, SSR is func tioning

properly.

B. If no voltage is present on the load si de of

SSR terminal 2, the SSR is not

properly.

7. Turn the power switch OF F.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

8. Replace the SSR and check for pr oper

operation.

DISCONNECT THE ELECTRICAL

functioning

COMPUTER CONTROL

TEMPERATURE CALIBRATION

1. Place a thermocouple in the geometr ic center

of the oven cavity.

2. Turn the power switch ON.

A. If the set point temperature is 350°F,

proceed to step 4.

B. If the set point temperature is ot her than

350°F, proceed t o step 3 to change the

temperature.

3. Press the set key then temperature key t o enter

the temper ature set mode.

A. The display will alternate between the term

"StPt" ( set point) and the curr ent oven

temperat ure setting.

B. Press the up or down arrow keys to make

the proper select ion.

C. Press the set key again to save the

change and exit the temper ature set

mode.

4. Allow the oven temperature to stabilize

(normally 3 cycles).

5. Compare the controls set point temperature to

the therm ocouple meter reading when the heat

light goes out.

A. A tem perature v ariance mor e

indicat es an adjustment i s needed.

1) To make the adjustment, proceed to

step 6.

2) If temperature var iance is less

5°F, com puter control is functioning

properly.

6. Enter the setup mode as outlined i n "SETUP

MODE" under "COMPUTER CONT ROL".

than 5°F

than

1) If the thermocouple reading is higher

than set point t emperature, pr ess the

down arrow key and enter a negative

offset value that is equal to the

number of degrees above the 5°F

tolerance.

2) If the thermocouple reading is lower

than set point t emperature, pr ess the

up arrow key and enter a positive

offset value that is equal to the

number of degrees below the 5°F

tolerance.

3) Exit the setup mode.

7. Allow the oven to cycle at least two times

between adjustment s.

A. If the temperature variance still differs

than 5°F from the set point, verify

more

the correct c alibration offset value was

entered and retained.

1) Adjust the calibration offset value as

outlined in step 6, until the cycling

temperat ure is within tolerance.

B. If the above adjustment cannot be

obtained:

C. Turn the power switch OFF.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

D. Replace the computer control and chec k

DISCONNECT THE ELECTRICAL

for proper operation.

COMPUTER CONTROL

OPERATIONAL TEST

The comput er controls "Cal ibration Mode" is used to

manually test:

• Outputs of the control

• Keypad functionali ty

• Verify display and LEDs functional ity

Additi onally, if a problem is encounter ed dur ing the

output test, a "Restore Factory S ettings" option is

available.

CAUTION: The calibration mode contains

several adjust able parameters that must not

changed. For the "CALY" (Calibration)

Parameter, the default data option selected must

be "no".

be

A. Advance through the menu until CA L1

(Calibr ation Offset) appears.

F25105 (Decem ber 2001) Page 26 of 60

Page 27

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Listed below are the parameters and data you

should fi nd in the calibration Mode.

ALTERNATI NG ON

MENU

DISPLAY

PARAMETER DATA

Calibrate

(must di spl ay no

Logic Output Test

(see step 3)

Logic Inputs "LI"

(Factory Only)

Keyboard

(see step 4)

Disp lay Test

(All segments of

display and the

LED’s are tested )

Exit Calibration

Mode and return

to Operation

Mode

NOTE:

While in t he c alibration mode, on all

)

CALY no

LgOt*

*g displays as a 9

0

LI 21

HEY 0

sequence

of

---

characters

in display

window

Set point temperature is

displayed or if cal l for heat ,

dashes (----) displayed.

parameters except the Logi c Output Test (LgO t), the

control outputs will be OFF.

• To change the programmed data, use the arrow

keys.

• To select the next parameter, press the Rack 1

key.

• At the end of the test, the c ontrol automatical ly

exit s the Calibration Mode and returns to the

Operation Mode.

• After 1 minute of no key activat ions, the control

will return to operation mode.

1. Use this key sequence to access the cal ibration

mode.

Up a rro w; Down arrow; Rac k 1; Down arr ow;

Temperat ure; Rack 1

NOTE:

If t he c ontrol was calling for heat when

the cali bration m ode was entered, heating will

resume after exiting the test mode.

3. Press the Rack 1 key to acc ept the default "no"

under the "CALY" ( c alibrate) parameter and

advance the display m enu to the "LgOt" ( logic

output) test. In this mode, the control and logic

outputs can be turned ON for testi ng only.

A. Use the arrow keys to change the display

to the appropriate number for testing.

Each test starts automatically, several

seconds after number is selected.

1) #0 - All control outputs are OFF

(fan & heat OFF).

#1 - Heat comes ON

(2CON is energized).

#5 - Convec tion fan c omes ON

(High or Low speed SSR is

energized).

#8 - Electronic beeper (external)

sounds.

B. If the output tests are completed

successfully , proceed to step 4.

C. If the output tests are not

completed

successfully , find the source of the

problem. If t he pr oblem cannot be

repaired, r eplace the com ponent and

check for proper operation.

4. Press the Rack 1 key twice to advance past the

"LI" (Logi c Inputs test) and reach the " HE Y

(keyboard) test.

A. Press the desired key t o display the

corresponding hex adec imal c ode. This

code is used internally by the control to

identify the key being pressed. See table

below.

KEY CODE KEY CODE

Up Arrow 40 Start/Stop 4

Down Arrow 80 Temp 20

1/2 menu 800 Rack 1 10*

2. Once in the c alibration mode the display will

alternate between the parameter and

programmed data. The computer contr ol

outputs are turned O FF.

A. Conv ec tion fan stops.

B. Heating stops.

3/4 menu 4000 Rack 2 400

5/6 menu 2 Rack 3 2000

Set 200 Rack 4 1

Tim e 1000 Rack 5 8

Cook & Hold 8000

*displays 10 momentarily then alt er nates

between Hey and 0. If pressed again, advanc es

to the next test.

F25105 (Decem ber 2001)Page 27 of 60

Page 28

FULL SIZE ELECTRIC CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

B. If the code displayed is not correct for the

key pressed, then the keyboar d is

malfunctioning.

1) Turn the power switch O FF.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

C. Replace the computer control and chec k

5. Press the Rack 1 key to advance the display

menu to the "dISP" (di spl ay ) test. A test

sequence automatically r uns on the display and

control LEDs for a v isual v er ifi cation that all

segments in the LED display and the i nternal

LEDs are functioning.

6. At the end of the test, the c ontrol exits the

calibration mode and r eturns to the Operation

Mode.

Restore Facto ry S et t ings

NOTE:

be functioning properly, do not

settings unti l ver ifying the control is configur ed

properly as outlined in "SE TUP MODE" under

"COMPUTE R CONTROL" and performi ng the

"COMPUTER CONTROL OPERATIONAL TEST" as

outlined in the above section.

DISCONNECT THE ELECTRICAL

for proper operation.

If t he c omputer control does not appear to

restore fac tory

9. Enter the "S E TUP MODE" as outl ined under

"COMPUTE R CONTROL" and perform the

procedure.

1. Enter the "Calibration Mode" by using the key

sequence stated in step 1 under "CO M P UTER

CONTROL OPERATIONAL TEST".

A. The com puter control outputs are turned

OFF.

B. The display will alternate between "CALY"

and "no".

2. Press the up or down arrow key until the "rESt"

parameter displays.

3. Press the Rack 1 key and "no" displays.

4. Press the up or down arrow key to change the

display to "YES".

5. Press the Rack 1 key to selec t this data option

and then adv anc e the menu to the "LgOt" (l ogic

output test).

NOTE:

6. Press the Rack 1 key twice to advance past the

7. The "dISP" ( display) test sequence

The "g" in LgOt displays as a "9".

"LI" (Logi c Inputs test) and the "HEY "

(keyboard) test.

automatically runs.

8. At the end of the test, the c ontrol exits the

calibration mode and r eturns to the Operation

Mode.

F25105 (Decem ber 2001) Page 28 of 60

Page 29

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Switch (S1)............

Oven Light Switch (S2) ........

Fan Speed Switch (S3) ........

Alarm/Buzzer ................

Cook Timer .................

Door Switch.................

Blower Motor................

Transformer (T1) .............

Transformer (T2) .............

Solid S t ate temperature

Control.....................

Determines the mode of oper ation; ON, OFF, or COOL DOWN.

Controls the oven cavity lights.

Controls blower motor speed between High and Low settings (VC4ES/ 6E S

and VC4ED/6ED only ) .

Signals the end of a "Cook" cycle when cooking ti me expires.

Counts the "Cook" time of the product and signals the buzzer at the end of

the cycle (VC4ES/6ES and VC4ED/6ED only).

Allows the oven to operate when the doors are closed but stops the oven

from operating when the doors are opened.

Operates the oven cavity bl ower (c onvection fan).

Prov ides 24VAC power to the Computer Control (V C4E C/6EC only).

Prov ides 240VAC power to the oven control c ircuit and blower motor

(480VAC models only).

Monitors temperature sensor and regulat es the oven cavity temperature by

controlling 2CON to ener gize the heati ng elements when the control calls

for heat.

High Limit Thermostat ........

Computer Control ............

SSR1 & SSR2 ...............

1CON & 2CON ...............

Power ON Light..............

Protects the oven f r om temperatures above 550°F by removing power

from the heating circuit. Auto resets at 500°F.

Monitors temperature sensor and regulat es the oven cavity temperature by

controlling 2CON to ener gize the heati ng elements when the control calls

for heat. Also, counts the " Cook " time (normal cook ing) of t he pr oduc t and

signals the electr onic alarm at the end of the cycl e. If "Cook" & " Hold"

mode is selected, when the "Cook" (then hold) time expir es, the oven

heating stops and the oven enters "Hold" mode. Once t he oven cavity

temperat ure drops to 150°F, the heat comes back on and the oven cycles

at this temperature to hold the cooked product . Cook & Hold is standard on

computer models. The sel ec ted mode also determines the fixed blower

speed of High for "Cook" and Low for " C ook & Hold".

When S S R1 is energized by computer control, connects power to blower

motor for High fan speed operation i n nor mal "Cook" mode. In "Cook &

Hold" Mode onl y , SSR1 is de-energiz ed and S S R 2 is energized by

computer control and connects power to blower motor for Low fan speed

operation (VC4EC/6EC only).

Prov ides power to heating elements when both are energized. 1CON is

energized when power switch is turned ON. 2CON is energiz ed by the

temperat ure control when a call for heat is made.

Lit whenev er the power switch (S1) is turned to ON or Cool Down mode.

Heat Light ..................

Lit whenev er temperat ur e c ontrol is cal ling f or heat.

F25105 (Decem ber 2001)Page 29 of 60

Page 30

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

Temperature Probe ...........

Mechanical Temperature Control

KX thermostat ...............

Cooling Fan .................

Fuses ......................

COMPONENT LOCATION

Senses the oven temperature for the soli d state temperat ur e c ontrol or the

computer control. On oven models using the soli d state control, c onverts

the temper ature into a resi stanc e valve which i s monitored by t he

temperat ur e control board. The probe is an RTD (resistance temperature

detector) of the Thermistor ty pe. As temperatur e increases the resistance

value decreases.

On ov en models using the computer contr ol, the probe i s a "J" type

thermocouple.

Regulates the oven cavity temperature by controlling 2CON to energi z e

the heating elements when the control calls for heat (VC4ES/6ES only).

Circulates cooler air from outside the oven to cool components in the

control ar ea.

Protect control ci r c uit.

F25105 (Decem ber 2001) Page 30 of 60

Page 31

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

VC4ES/6ES w ith Mechanical KX thermost at - Plug, S ocket and Components

F25105 (Decem ber 2001)Page 31 of 60

Page 32

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

VC4ED/6ED wi t h Solid S t at e Control - P lug, So cket and Components

F25105 (Decem ber 2001) Page 32 of 60

Page 33

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

VC4EC/6EC - Pl ug, Socket and Components (Cook & Hold Standard)

F25105 (Decem ber 2001)Page 33 of 60

Page 34

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

VC4ES, VC6ES with Mechanical KX Thermostat

Schematic diagram 6532 will be used to explain the

electrical sequence of oper ation.

Cook Cycle

1. Conditions.

A. Oven connected to cor rect v oltage and is

properly grounded.

B. Power switch (S1) OFF.

C. Temperature di al set to lowest

temperat ur e (fully CCW ) .

D. High limit thermostat CLOSED.

E. Oven doors closed (door switch cont ac ts

CLOSED).

F. Oven cavity temperature below 140°F.

2. Power switch (S1) turned O N.

A. Power ON light (Amber) comes ON.

B. 1CON coil energized.

C. Blower motor energi z ed.

NOTE:

position of fan speed switch (S3) .

D. Component cooling fan energized.

E. Power to oven cavity light switch (S3) wire

#1. Turns cavity lights ON/OFF and does

not affect "Cook" cycle.

3. Set thermostat to desired "Cook " temperatur e

and thermostat CLOSES.

A. Heating light (Cl ear) comes ON.

B. 2CON coil energized.

1) Heating elements powered and

4. Ov en r eac hes set t emperature and ther mostat

OPENS.

A. Heat light goes out.

B. 2CON coil de-energized.

1) Power removed f r om heating

5. The oven will continue to cycle on the

thermostat until the doors are opened or the

power switch (S1) is turned t o the OFF or

COOL DOWN position.

Motor speed (Hi/ Low) depends on

heating starts.

element s and heating stops.

Cook Cycle

1. Conditions.

A. Oven connected to cor rect v oltage and is

properly grounded.

B. Power switch (S1) OFF.

C. Temperature di al set to lowest

temperat ur e (fully CCW ) .

D. High limit thermostat CLOSED.

E. Oven doors closed (door switch cont ac ts

CLOSED).

F. Oven cavity temperature below 140°F.

2. Power switch (S1) turned O N.

A. Power ON light (Amber) comes ON.

B. 1CON coil energized.

C. Solid state temperature contr ol energized.

1) Heating light (Clear) comes ON.

2) 2CON coil energized.

a. Heating elements powered and

heating starts.

D. Blower motor energi z ed.

NOTE:

position of fan speed switch (S3) .

E. Component c ooling f an energized.

F. Power to oven cav ity light switch (S3) wire

#1. Turns cavity lights ON/OFF; does not

affect "Cook" cycle.

3. Set tem per ature dial to desired "Cook"

temperature.

4. Ov en r eac hes set t emperature.

A. Temper ature control de- ener gizes internal

relay and the nor mally open ( N.O.)

contacts OPEN .

1) Heat light goes out.

2) 2CON coil de-energiz ed.

5. The oven will continue to cycle on the

temperat ure control unt il the doors are opened

or power switch (S1) is turned to the OFF or

COOL DOWN position.

Motor speed (Hi/ Low) depends on

a. Power removed from heating

element s and heating stops.

VC4ED, VC6ED with Solid State Temperature

Control

Schematic diagram 6534 will be used to explain the

electrical sequence of oper ation.

F25105 (Decem ber 2001) Page 34 of 60

Page 35

FULL SIZE ELECTRIC CONVECTION OVENS - ELECTRICAL OPERATION

Timer Cycl e, Cooking

(KX Th ermostat or Solid State Control)

NOTE:

The "Cook" timer operat es i ndependently of

the heating cycle. Additi onal tim e can be set or t he

tim er can be turned OFF throughout the cook ing

cycle.

1. With the power switch turned ON, power is

supplied to "Cook " timer terminal 1.

2. Set "Cook" t imer to desi r ed time .

A. Contacts 1 & 3 close, timer motor is

energized and timing " down" begi ns.

3. Tim e expires on "Cook" timer .

A. Contacts 1 & 3 open, timer motor is de-

energized and timing stops.

B. Contacts 1 & 4 close.

1) Buzzer energized and sounds.