Vulcan-Hart VCE6H 126177, VCE10F 126179, VCE20F 126173, VCE10H 126178, VCE20H 126172 User Manual

Page 1

SERVICE MANUAL

ELECTRIC

COMBI

OVENS

MODEL ML

VCE6H 126177

VCE10H 126178

VCE10F 126179

VCE10F SHOWN ON STAND

This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not atte nded a Vulca n Servic e School f or this produc t, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e necessary tools, instruments and skills should be

performed b y a trained Vu lcan Service Technician .

VCE20H 126172

VCE20F 126173

- NOTICE -

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart, is prohibited

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

Form 24659 ( S eptember 1999)

.

Page 2

ELECTRIC COMBI OVENS

TABLE OF CONTENTS

GENERAL............................................................................. 4

Introduction ........................................................................ 4

Operation.......................................................................... 4

Cleaning .......................................................................... 4

Stacking Kit Instructions............................................................... 4

Specifications ...................................................................... 4

Water Supply ................................................................... 4

Electrical ...................................................................... 5

Oven Controls ...................................................................... 6

Water Conditi oning .................................................................. 7

Lubrication ......................................................................... 7

Tools ............................................................................. 7

REMOVAL AND REPLACEMENT OF PARTS ................................................. 8

Rack Guide/ Filter /Exhaust Assembly ..................................................... 8

Covers and Panels ................................................................... 8

Oven Temperature Probe ............................................................. 9

Programable Oven Control ........................................................... 10

Manual Oven Control s ............................................................... 11

Relay Board....................................................................... 11

Blower and Motor ................................................................... 12

Blower Motor Shaft Seal ............................................................. 13

Heating Elements .................................................................. 13

Thermal Fuse(s) ................................................................... 14

Steam G ener ator Drain Pump ......................................................... 15

Vent Damper Assembly .............................................................. 15

Water Level Sensors and Wat er Equalization Tube ......................................... 16

Steam G ener ator Tank .............................................................. 17

Oven Door........................................................................ 18

Door Lamp........................................................................ 19

Ov en Door Hinges .................................................................. 19

Door Magnetic Reed Switch ........................................................... 20

Door Seal......................................................................... 20

Door Locking Mec hanism ............................................................. 20

Oven Cavity Seal................................................................... 21

Power Supply Board and T r ansformer ................................................... 22

Contactors ........................................................................ 22

Oven Cavity Drain .................................................................. 23

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 24

Configur ation Mode - Progr amable Control ............................................... 24

Diagnostic Test Mode - Program able Control .............................................. 25

Configur ation Mode - Manual Controls ................................................... 26

Diagnostic Test Mode - Manual Contr ols ................................................. 28

Service Error Lights................................................................. 29

Heating Elements .................................................................. 30

Oven Door Adjustment............................................................... 30

Buzzer Adjustment - Programable Control ................................................ 32

Buzzer Adjustment - Manual Controls ................................................... 32

Clean Cycle Mode - Steam G enerator Deli ming ............................................ 33

Battery Backup - Programable Control................................................... 35

Page 2 of 68

Page 3

ELECTRIC COMBI OVENS

ELECTRICAL OPERATION .............................................................. 37

Component Func tion ................................................................ 37

Component Locat ion ................................................................ 40

Sequence of O per ation .............................................................. 42

Heating Mode and Cavity Fan Speeds ............................................... 42

Heating Regulation .............................................................. 42

Steam Pre-Heat ................................................................ 43

Steam Regulation ............................................................... 43

Water Injection (Humidifier) ....................................................... 44

Cool Down Mode (Manual Cont r ols) ................................................. 44

Programable Oven Control........................................................ 45

Manual Oven Control s ........................................................... 49

Wiring Diagrams ................................................................... 54

6 Level ....................................................................... 54

10 Level ...................................................................... 56

20 Level ...................................................................... 58

Electric Heater Circuits .............................................................. 60

TROUBLESHOOTING .................................................................. 63

© VULCAN 1999

Page 3 of 68

Page 4

ELECTRIC COMBI OVENS - GENERAL

GENERAL

INTRODUCTION

General

The procedures in t his manual appl y to all models

unless otherwise specified. All of the information,

illustrations and specifications contained in thi s

manual are based on t he latest product information

available at the tim e of print ing.

Combi Ovens

The Elect ric Combi ovens provide convection heat,

steam heat or a c ombination of both in a single

compartment cooking chamber. Humidificat ion is

provided from the inter nal steam generat or or by

water injection into the oven cavit y. W hen the water

is injec ted by means of an internal spray nozz le, it

vaporizes on contact wit h the hot interior surfaces.

H

The ov ens are available in two depths,

(half on 6

and 20H/F).

level only) and in three sizes (6H, 10H/F

alf and Full

OPERATION

Refer to the Installation & Operat ion Manual for

specific operating instructions.

STACKING KIT INSTRUCTIONS

When servicing stacked ovens and disassembly is

required, r efer to the S tacking Ki t Instructi ons for

specific assembly procedur es.

SPECIFICATIONS

Water Supply

The fact that a water supply is potable is no

guarantee that it is suitable for steam generation.

The supply connect ion to the steam gener ator

should be “treated” water and must be within t he

guideli nes listed below. For dr ain water cooling only,

an “untreated“ water suppl y c onnec tion should be

used.

Supply Pressure

(treated and untreated water)

Supply Connections

(treated and untreated water)

Water Hardness *

Chloride less than 30 ppm

PH fact or (range) 7 to 8

(*17.1 ppm = 1 grain of har dness)

20-80 psig

cold

2-4 grains per

gallon (gpg)

CLEANING

Refer to the Installation & Operat ion Manual for

specific cleani ng instructions.

Page 4 of 68

Page 5

Electrical

ELECTRIC COMBI OVENS - GENERAL

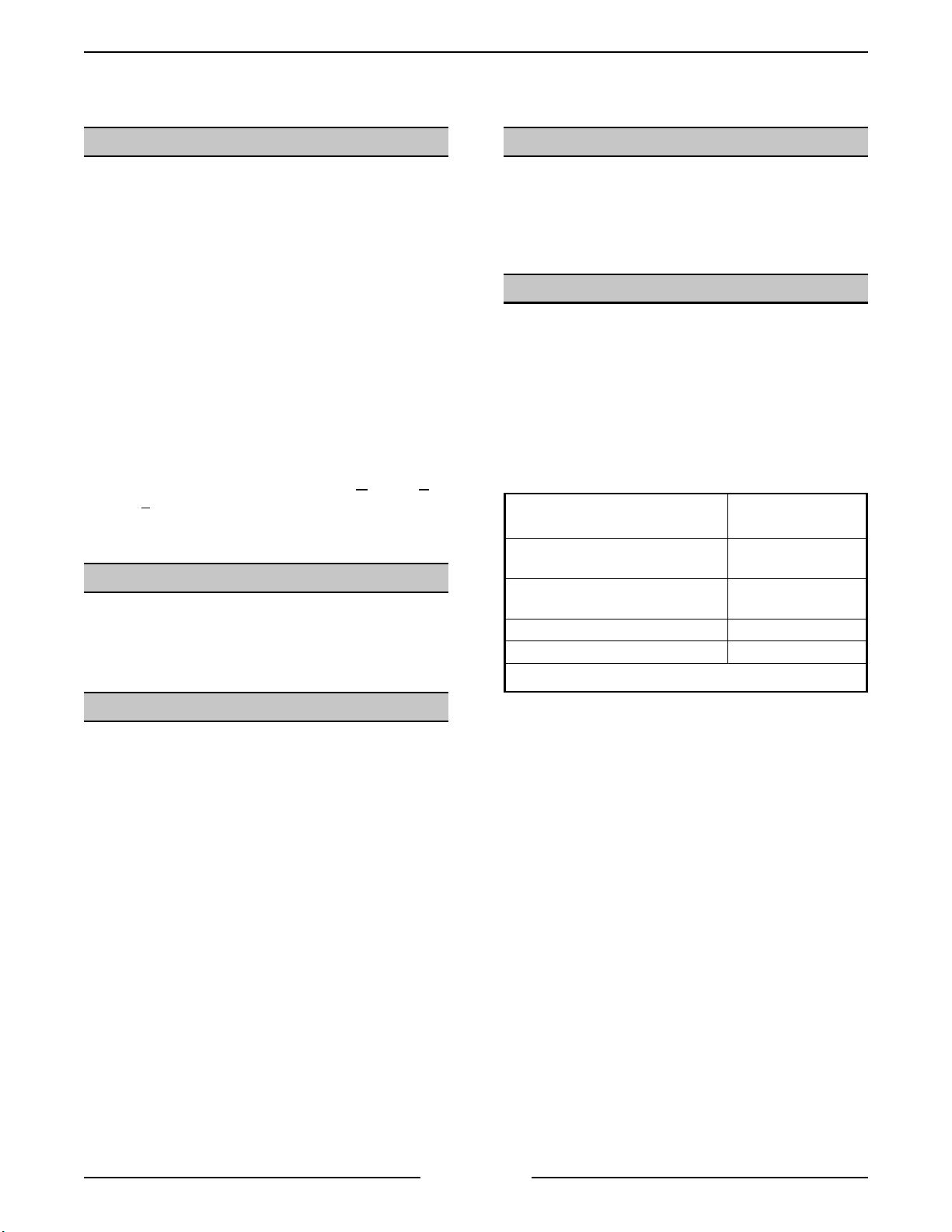

MACHINE AMPERAGE (3 PHASE/ 60HZ)

1

MODEL

VCE6H

VCE10H

VCE10F

VCE20H

VCE20F

NOTES:

POWER

(KW)

PER LINE

2

RECOMMENDED

CIRCUIT

PROTECTION

3

208V 240V 480V 208V 240V 480V

9 252211353015

18 50 43 22 70 60 30

18 50 43 22 70 60 30

24 67 58 29 90 80 40

36 100 87 43 125 110 60

1. Amperage values in t he table are nominal. T olerance

is +5/-10%.

2. Line currents must

be measured in full power

convec tion heat m ode.

3. Complied in accordance with National Electric Code,

ANSI/NFPA 70, latest edition.

MODEL

VCE6H

VCE10H

VCE10F

VCE20H

VCE20F

NOTES:

1

INDIVIDUAL AMPERAGE (3 PHASE/ 60HZ)

CONVECT ION HEAT

ELEMENTS

2

208V 240V 480V

STEAM GENE RATOR HEAT

ELEMENTS

208V 240V 480V

KW NO. KW NO.

9 1 25 22 11 8 1 22 19 10

9 2 50 43 22 8 2 45 39 19

9 2 50 43 22 8 2 45 39 19

6 4 67 58 29 8 3 67 58 29

9 4 100 87 43 8 4 89 77 39

1. Amperage values in the table are nomi nal. Tolerance is +5/-10%.

2. Convection heater currents must

be measured in full power convection

heat mode.

3. Steam generator heater currents m ust

be measured in full power steam

mode.

3

Page 5 of 68

Page 6

ELECTRIC COMBI OVENS - GENERAL

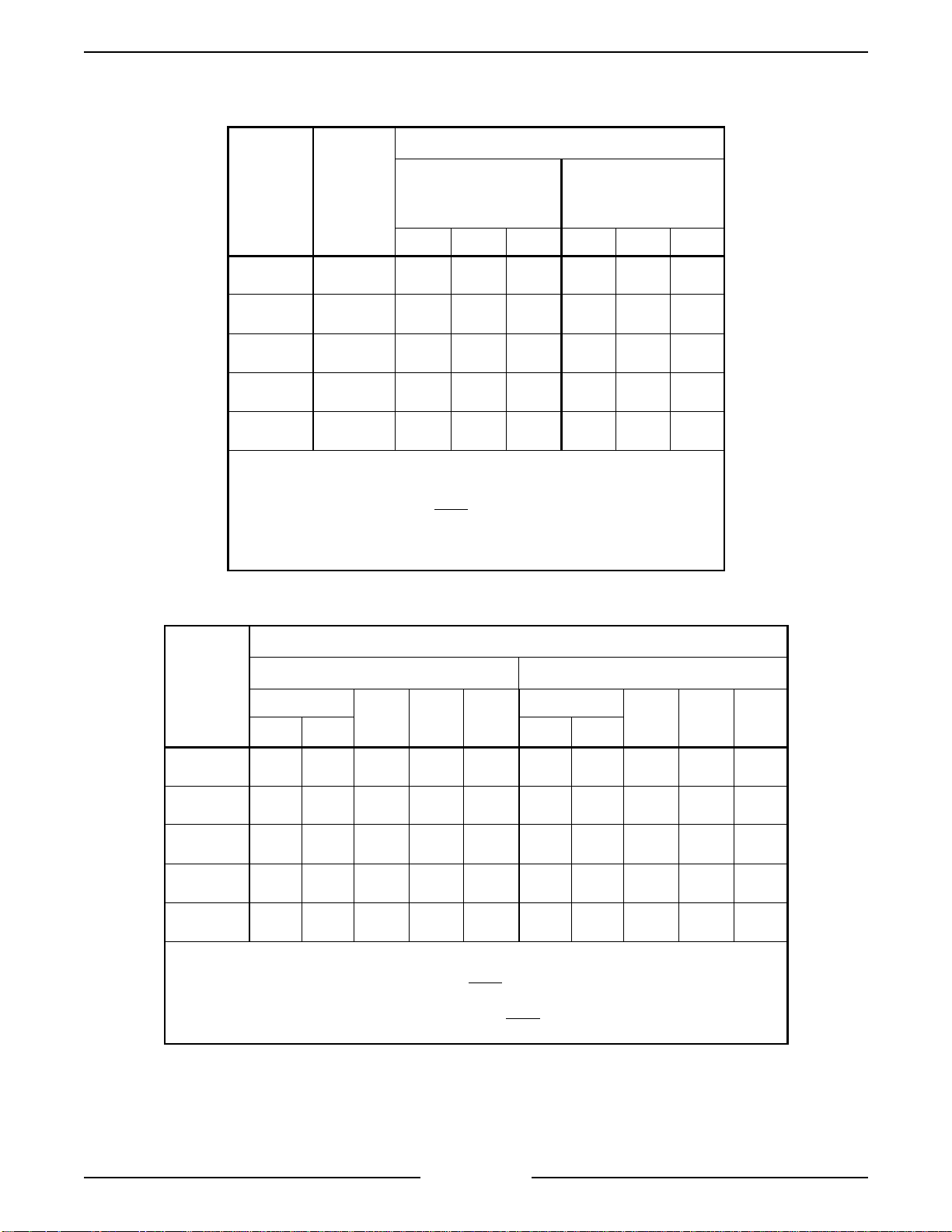

OVEN CONTROLS

PROGRAMMABLE STANDARD MANUALDELUXE MANUAL

Page 6 of 68

Page 7

ELECTRIC COMBI OVENS - GENERAL

WATER CONDITIONING

Furnishing the steam generator with treated water to

reduce scale formation is impor tant. Scal e formation

will reduce steam out put, cause prematur e

component failur e, and shorten equipm ent life. Most

water supplies contai n scale producing m inerals

such as Calcium and M agnesi um. As steam is

generated, the minerals remain and dissolve int o

the water. As the concentration of these miner als

increases past a certai n point, they pr ec ipitate from

the water and coat the inside of t he steam

generator, heating elements, and water level

sensors. Because of the high temperature of these

surfaces, the pr ec ipitated mineral s bake ont o them

and become very difficult to r emov e.

This may c ause several probl ems:

1. Reduced heat transf er eff iciency.

2. Premature heating element failures.

3. False readings from water l evel sensors.

These problem s are common to any manufacturer's

steamer regardless of design, but t hey c an all be

minimized by furnishing the steam generat or with

treated water.

Other factors affecting steam generati on ar e iron

content, amount of c hloridation and dissolved

gases.

The desired water propert ies can best be achieved

by using a

system.

The water level probes in the steam generator use

ions in the water t o detect the water level.

use fully demineralized or de-ionized water

since it is "non conductive" and the water level

can not be detected.

properly maintained water treatment

Do not

LUBRICATION

Cavity fan motor has sealed beari ngs and

requires no addit ional lubrication.

Cavity fan motor shaft seal requires lubr ication

at replacement (White silicone grease 544268).

TOOLS

Standard

Standard set of hand tools.

Metric set of hand tools.

VOM with AC c ur r ent tester (any quality VOM

with a sensitivit y of at least 20,000 ohms can

be used).

Gear puller to remove cavity fan.

Temperat ure meter wit h thermocoupl e.

Special

Red High Tem perature RTV for door seal and

probes (P/N 544313 or 542949).

Grounding kit to protec t control board( s) if

handled (P/N TL-84919).

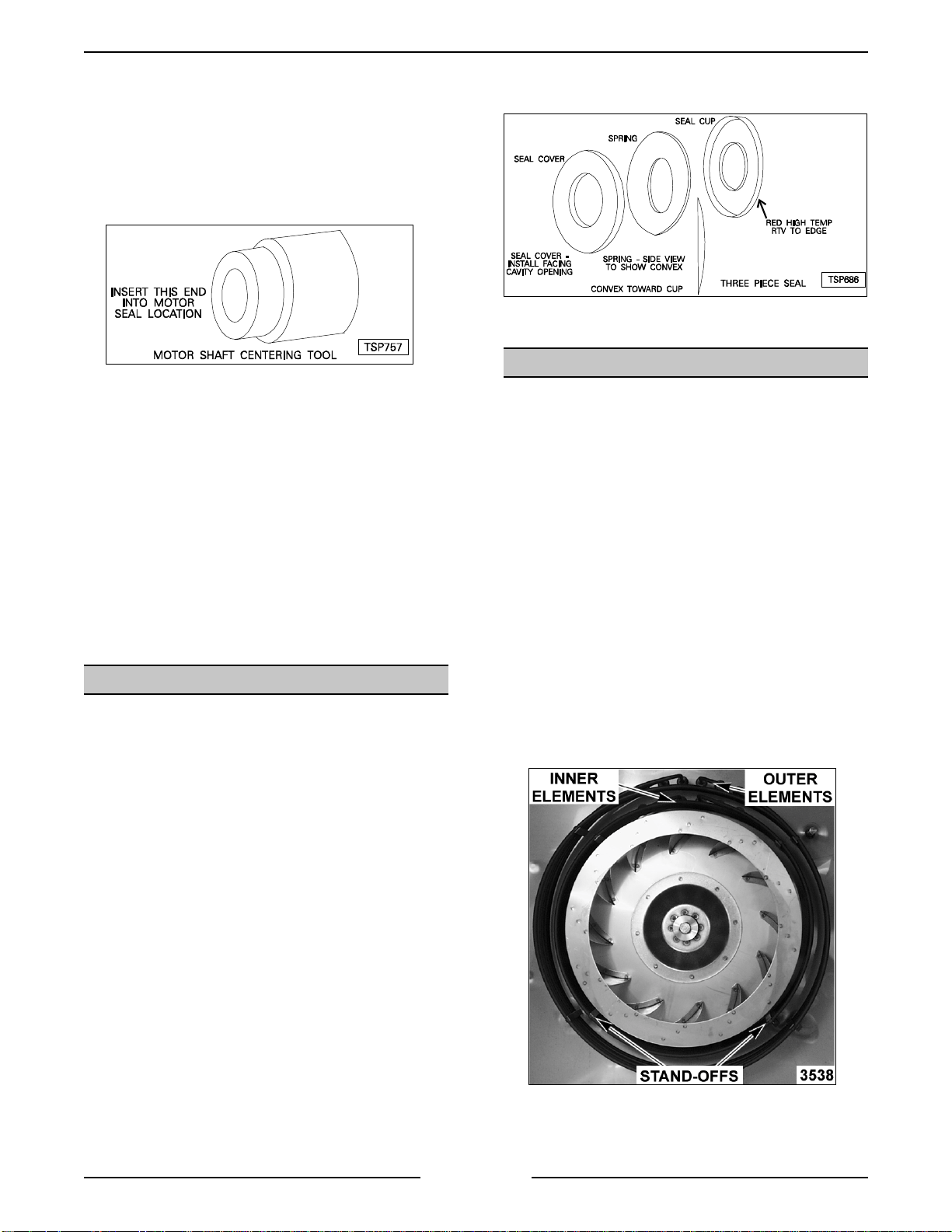

Motor Shaft Centering Tool (P/N 359450) .

28 pin EPROM extraction tool and 28 pi n

EPROM i nsert ion tool (purc hase l oc ally).

Scalekleen deliming chemical or the

recommended chemi c al for t he water treatment

system in use for deliming of the steam

generator. (S c alekleen is avail able through the

Serv ice Parts Distr ibution Center or locally

through an Everpure dealer)

The use of strainers, or filters will not remove

minerals from the water.

Water supplies vary fr om state to state and from

locati ons wit hin a state. Therefore, Vulcan

recommends that a local water treatm ent specialist

be consulted bef ore the installation of any steam

generating equi pment.

Steamers that operate over a long peri od of time

without the benefit of a water treatment system,

which have developed a heavy scale build up,

should be cleaned before using the system.

Page 7 of 68

Page 8

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

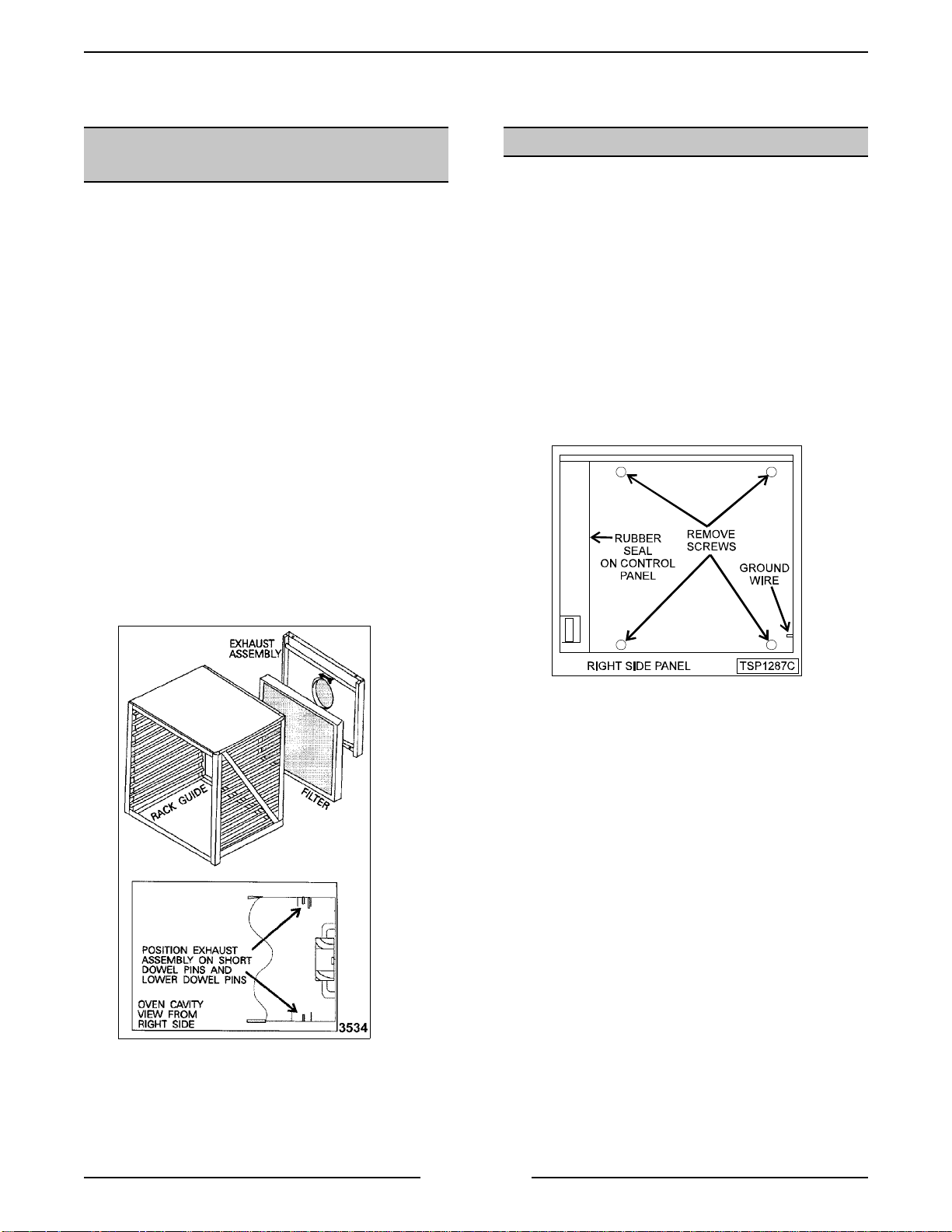

RACK GUIDE/FILTER/EXHAUST

ASSEMBLY

1. Turn the oven off.

2. Remove the racks (i f equipped).

3. Push the rack guide to rear of oven to remove

the rack guide tabs from sl ots in the exhaust

assembly (10 level).

4. Lift the rear of the rack guide up and pull the

guide out of the ov en c avity.

5. Lift the filter up, then pull forward to remove the

filter (2 filter s on 20 level).

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

6. Lift up on exhaust assembly then pull forward

at bottom to clear t he dowel pins.

7. After lower dowel pins have been c leared,

remove assembly from t op pins and remove

from oven.

DISCONNECT THE ELECTRICAL

COVERS AND PANELS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Side Panels

1. Remove the screws from the side panel f or the

side in need of access. Hold the panel in place

before removing the last screw.

2. Access the inside edge of the panel at the

bottom r ear corner and disconnect the ground

wire (if present).

DISCONNECT THE ELECTRICAL

8. Reverse proc edur e to install .

NOTE:

is seated on the dowel pins and fan direction arrow

is pointing to lef t (facing oven).

Be sure the bottom of the exhaust assembly

3. Remove the panel.

NOTE:

ensure the gasket at the rear of the contr ol panel

seals properly agai nst the front edge of the ri ght

side panel.

4. Reverse proc edur e to install .

When r e-install ing the right si de panel,

Page 8 of 68

Page 9

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

Rear Panel

1. Remove the screws from the rear ov en panel.

Hold the panel in place before removing the

last panel screw.

2. Access the inside edge of the panel at the

bottom left and disconnect the ground wire ( if

present).

3. Lower the panel to remove from oven.

4. Reverse proc edur e to install .

OVEN TEMPERATURE PROBE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the rack gui de, filter and exhaust

assembly as outlined under “RACK GUIDE/

FILTER/EXHAUST ASSEMBLY”.

2. Remove both side panels as outl ined under

“COVERS AND PANELS”.

3. Remove the retai ning nut fr om the probe inside

the ov en ( 2 probes on 20 level) and lift bracket

off.

DISCONNECT THE ELECTRICAL

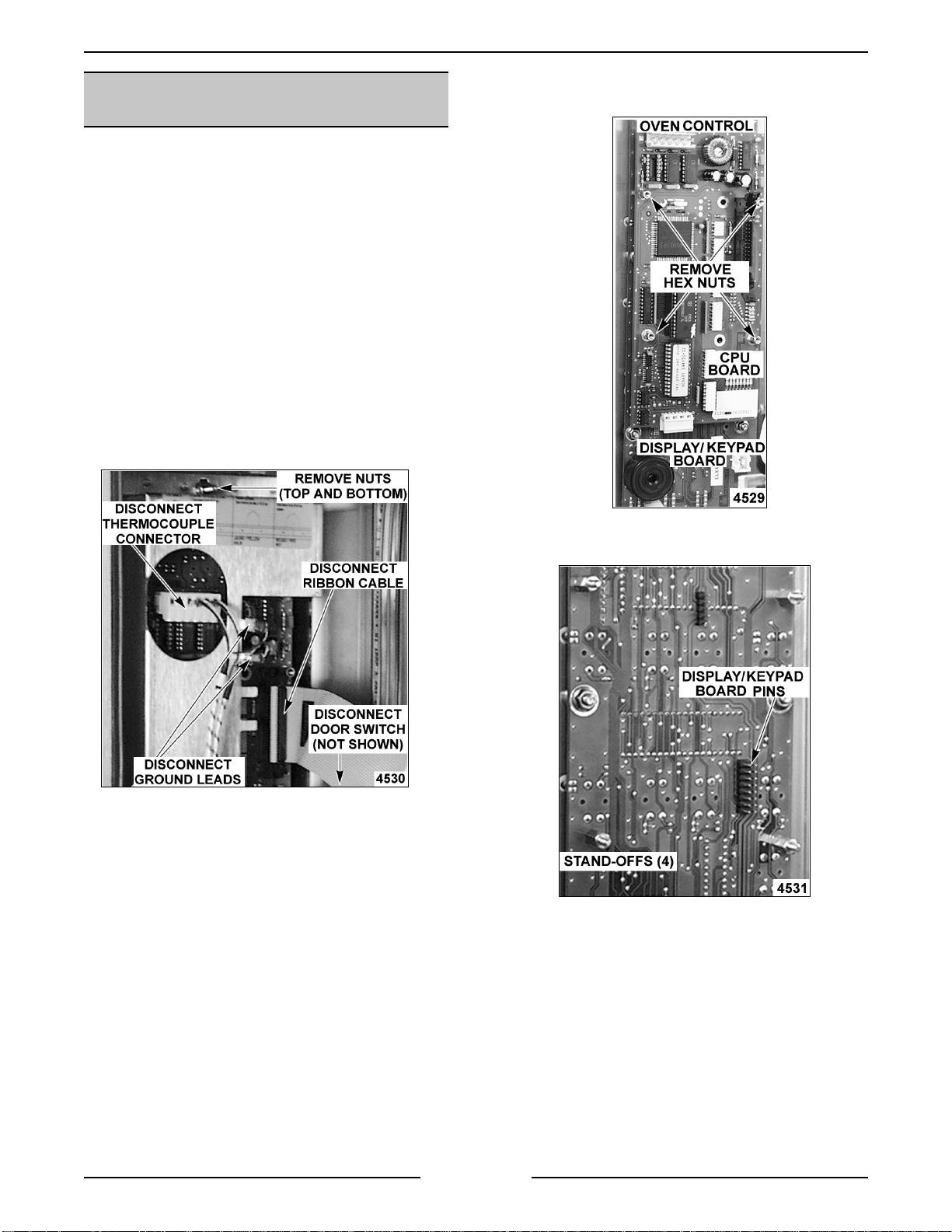

Control Panel

1. Remove the right side panel as outli ned.

2. Disconnect the r ibbon cable, t her mocouple

connector, gr ound leads and door switch

connector from the oven control board.

3. Remove the nuts at the t op and bottom of

control panel that secure it to the f r ame.

CAUTION

damage may result to the oven control if dr opped.

4. Reverse proc edur e to install .

: Hold contr ol panel duri ng r emov al or

4. Remove probe(s) through the left si de of the

oven cavity.

NOTE:

silicone between the probe and the hole in the oven

cavity wall.

NOTE:

position as shown.

5. Disconnect the pr obe leads from the control

6. Reverse proc edur e to install .

NOTE

rotate unless secured. Do not

or damage m ay result.

When r eplacing, use hi gh temperature

Be sure to replace br ac k et around probe and

board connector.

: When tightening retaini ng nut, probe will

clamp down on probe

Page 9 of 68

Page 10

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

PROGRAMABLE OVEN

CONTROL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service ground kit is

available t o prevent damage. Th e f ield service

grounding kit must be used anytime the control

board is handled.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect the r ibbon cable, connec tors and

ground leads fr om the oven control boar d.

DISCONNECT THE ELECTRICAL

4. Remove the hex nut s securi ng the CPU board

to the display/keypad board.

5. Pull out wards on the CPU boar d and lif t it off

from the display/keypad board pin connections.

3. Remove the cover from the oven control by

removing the mounting nuts at the top and

bottom.

NOTE:

keypad board, make sure that the pi ns on the

keypad board are aligned with the plug on the

control boar d.

Page 10 of 68

When installing the control board onto the

Page 11

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

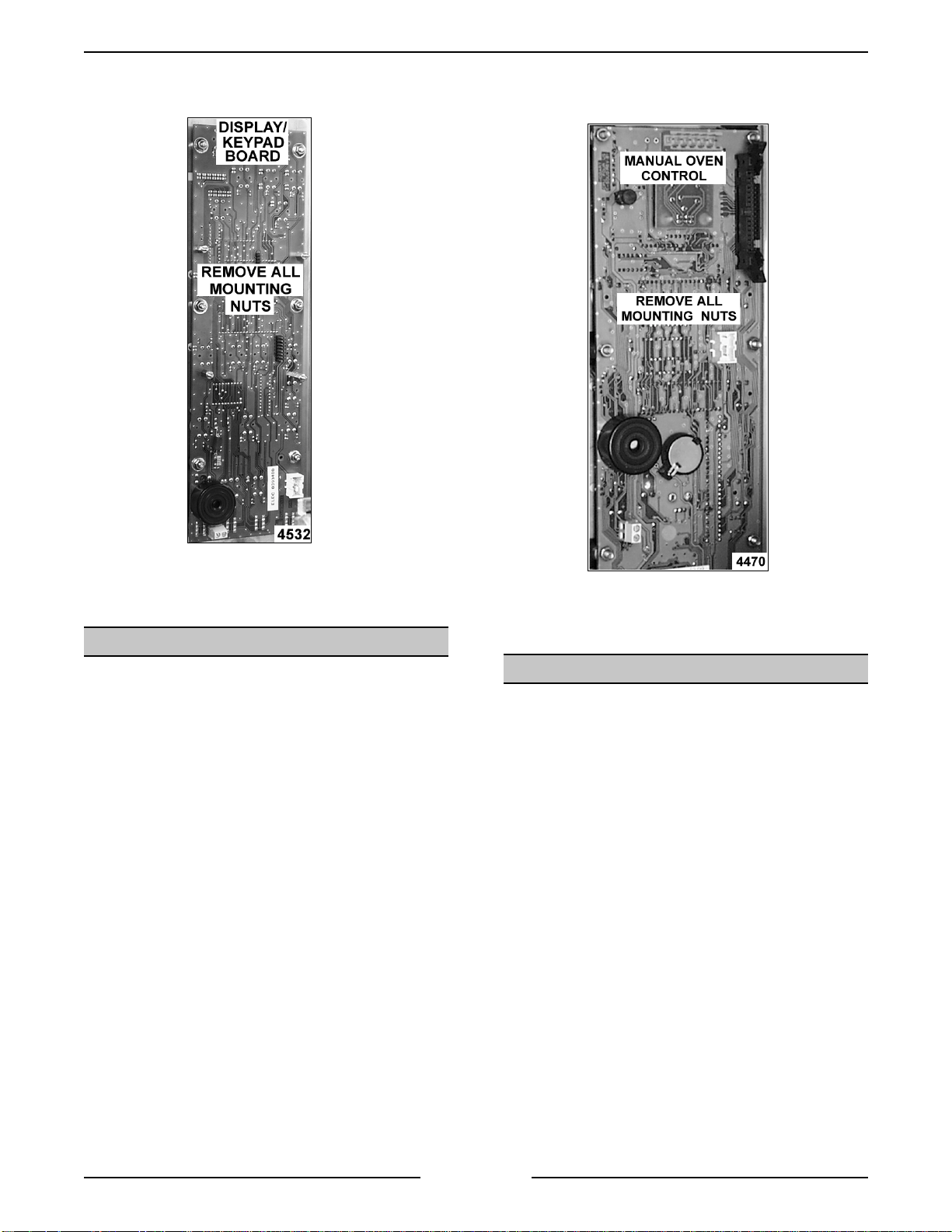

6. Remove the display/keypad board from the

control panel by removing the mounting nuts.

4. Remove the oven control board from the

control panel by removing the mounting nuts.

7. Reverse proc edur e to install .

MANUAL OVEN CONTROL S

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service ground kit is

available t o prevent damage. Th e f ield service

grounding kit must be used anytime the control

board is handled.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect the r ibbon cable, t her mocouple

connector, gr ound leads and door switch

connector from the oven control board.

3. Remove the cover from the oven control boar d

by removing the mounting nut s at the top and

bottom.

DISCONNECT THE ELECTRICAL

5. Reverse proc edur e to install .

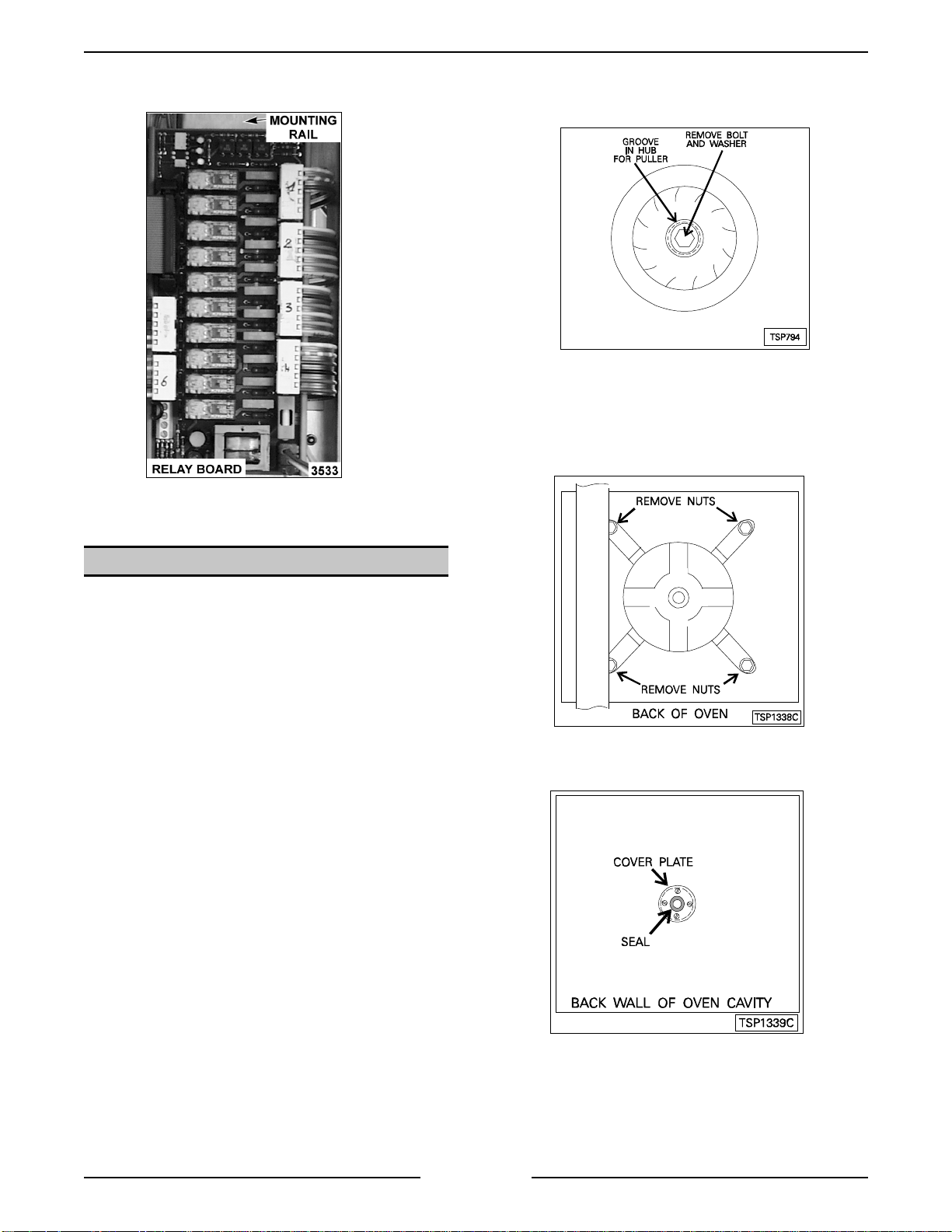

RELAY BOARD

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service ground kit is

available t o prevent damage. Th e f ield service

grounding kit must be used anytime the control

board is handled.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect lead wi r es from the r elay board.

DISCONNECT THE ELECTRICAL

Page 11 of 68

Page 12

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

3. Release the clips on the back of the mounti ng

rail.

4. Reverse proc edur e to install .

NOTE:

the procedure at this point to install.

5. Remove the rear panel as outlined under

6. Disconnect the lead wires from the motor .

7. Remove the mot or from the back of t he oven

If only the blower is bei ng r emov ed, rever se

“COVERS AND PANELS”.

by removing the mounting nut s.

BLOWER AND MOTOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Remove the rack gui de, filter and exhaust

assembly as outlined under “RACK GUIDE/

FILTER/EXHAUST ASSEMBLY”.

2. Loosen bolt (one turn) that secures the blower

and install puller.

3. Tighten t he puller, then tap the puller with a

hammer to loosen the blower from the motor

shaft.

4. Remove the pull er , bolt, washer and blower

from the motor shaft.

DISCONNECT THE ELECTRICAL

8. Remove the cover plate and seal from inside

the ov en c avity.

NOTE:

back of t he oven.

Page 12 of 68

You may have to dri ve the seal out from the

Page 13

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

Installation

1. Mount the m otor to the back of the oven.

Tighten t he bolts enough to hold the motor i n

place, but allow some movem ent.

2. Ensure that the motor shaft is centered (use

shaft center ing tool) in the mot or shaft hole and

tighten mounting bol ts.

3. Remove the shaft c entering tool .

4. Connect the lead wi r es to the motor.

5. Install seal and cover as outlined under

“BLOWER MOTO R SHAFT SEAL”.

: Remove all traces of m otor seal grease from

NOTE

the motor shaft.

6. Install the blower wheel.

7. Install exhaust assembly, fil ter, and rack gui de

as outlined under “RACK

GUIDE/FILTER/EXHAUST ASSEMBLY”.

8. Install rear panel as outlined under “COVERS

AND PANELS”.

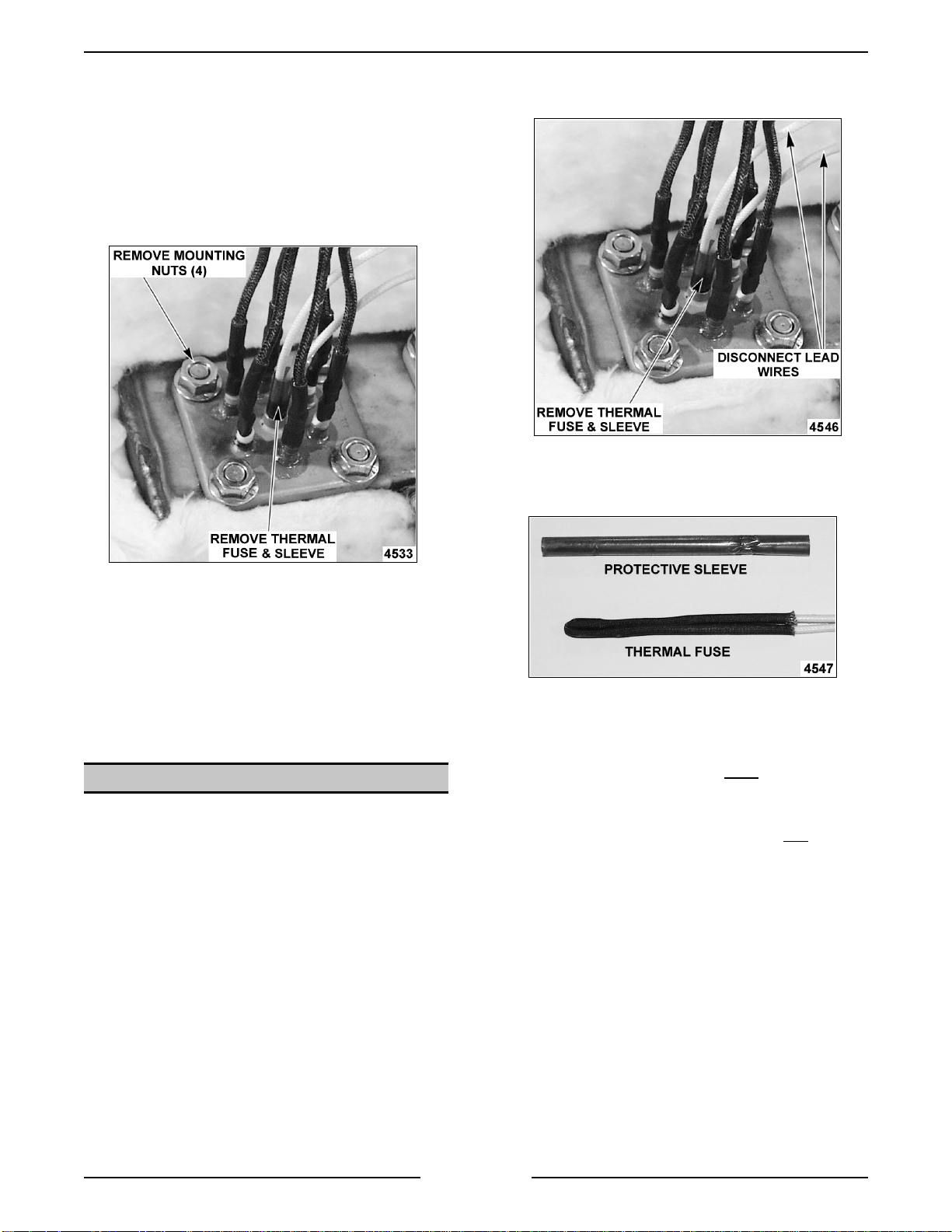

BLOWER MOTOR SHA FT SEAL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

DISCONNECT THE ELECTRICAL

: Remove all traces of m otor seal grease from

NOTE

the motor shaft.

7. Install the seal cover plate and then the blower.

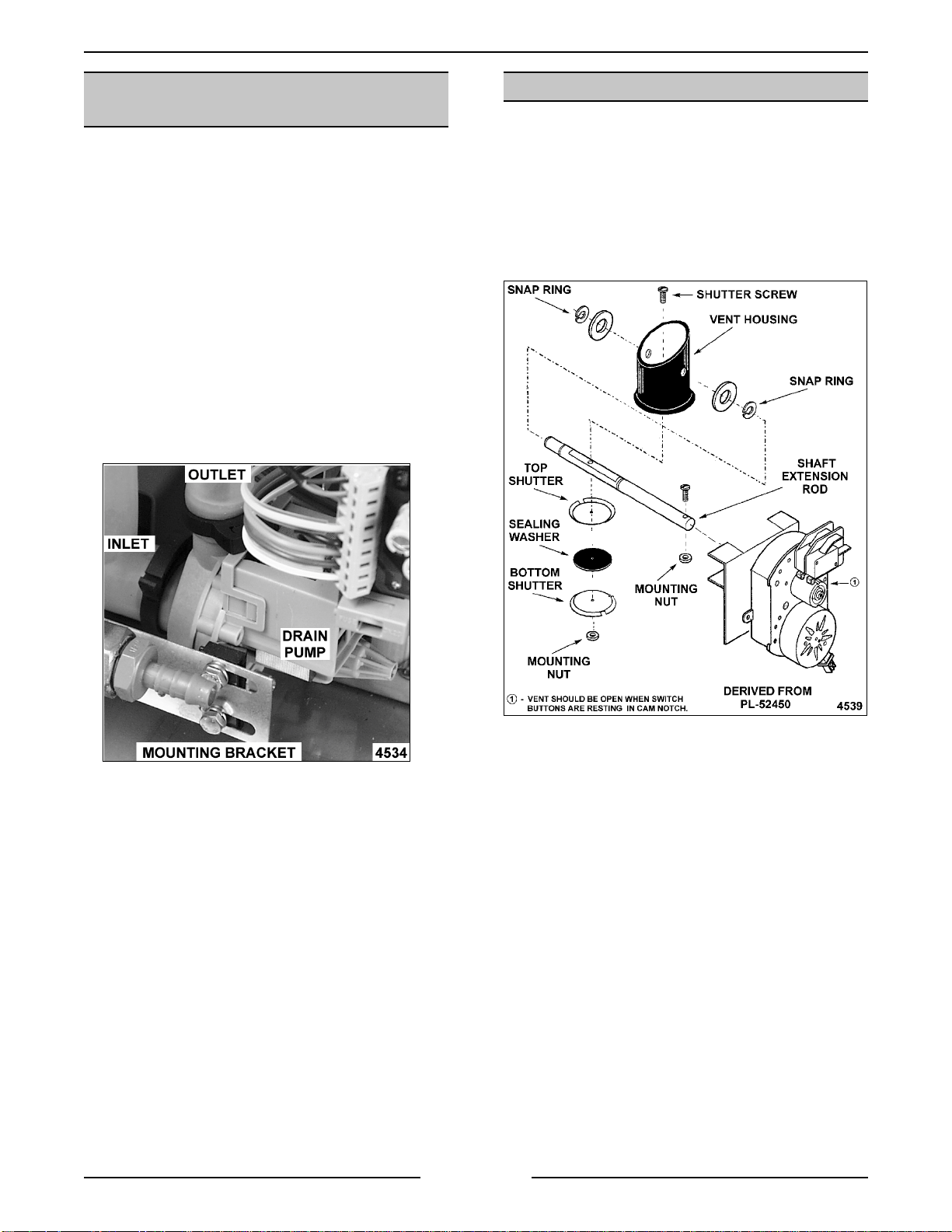

HEATING ELEMENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Oven Cavity

1. Remove the rack gui de, filter and exhaust

assembly as outlined under “RACK GUIDE/

FILTER/EXHAUST ASSEMBLY”.

2. From inside the oven cavity, remove the nuts

from the heating element stand-offs for the

element being replaced.

3. Remove the rear panel as outlined under

“COVERS AND PANELS”.

4. Disconnect the lead wires from the elem ents at

the rear of the oven.

5. Remove the nuts and washers from the

element being replaced t hen r emov e the

element.

DISCONNECT THE ELECTRICAL

1. Remove blower as outli ned under “BLOWER

AND MOTOR”.

2. Remove motor seal c over pl ate.

3. Remove the seal f r om the recess in the r ear

oven wall.

NOTE:

back of t he oven.

4. Fill replacement seal cover with white silicone

5. Assemble the motor seal with t he c onvex par t

6. Apply red high temperat ur e RTV to the outer

You may have to dri ve the seal out from the

grease.

of the spri ng toward the motor.

edge of the seal to help hold i t in the recess

and install the seal with the seal c over toward

the front of the oven cavity.

6. Reverse proc edur e to install .

Page 13 of 68

Page 14

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

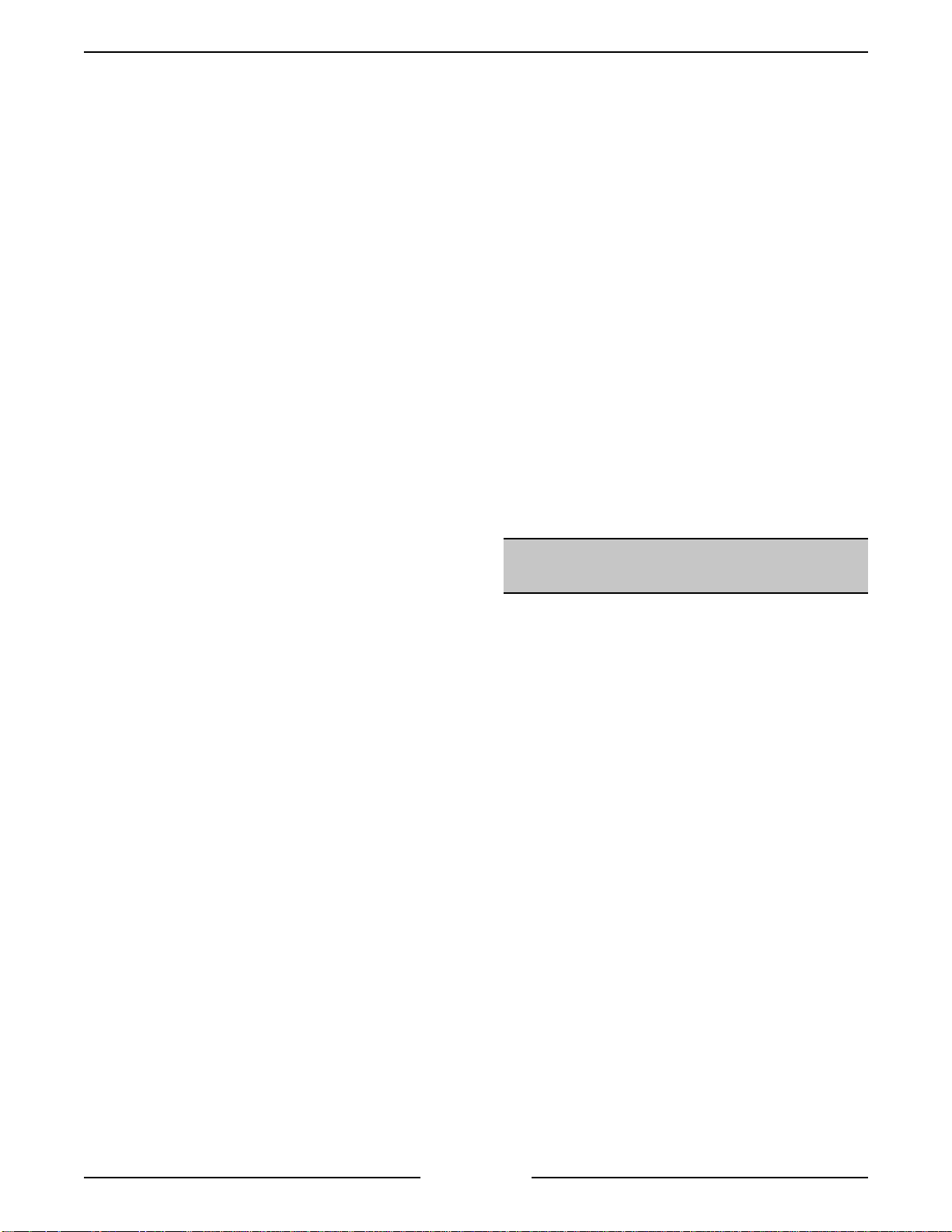

Steam Generato r

1. Turn off the water supply to the steam

generator.

2. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

3. Remove the thermal fuse and prot ective sleev e

from the heater thermowell.

2. Disconnect the t hermal fuse(s) lead wire

connections.

3. Remove the thermal fuse and prot ec tive sleeve

from the heater thermowell.

4. Disconnect the heating element lead wire

connections.

5. Remove the heating element from t he steam

generator by removing the mounting nuts.

NOTE:

supplied gasket and ensure the mating surfaces are

clean.

6. Reverse proc edur e to install .

When installing a new heater, use the

THERMAL FUSE(S)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

DISCONNECT THE ELECTRICAL

4. Reverse proc edur e to install .

: When replacing thermal fuse, be sure to

NOTE

insert the protective sleeve and thermal fuse

together. T he protective sleeve must

into the heat er thermowell with the fuse to avoid

chafi ng of the fuse leads.

: When replacing thermal fuse do

NOTE

lead wires apart. This may break the contact

juncti on or damage the connections.

be inserted

pull the

not

Page 14 of 68

Page 15

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

STEAM GENERATOR DRAIN

PUMP

1. Turn off the oven and allow the steam

generator to drain.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

2. Turn off the water supply.

3. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

4. Disconnect l ead wir es and hoses connected to

the drain pump.

5. Remove the bolts from the mounting brac ket

that secure the pump.

DISCONNECT THE ELECTRICAL

VENT DAMPER ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

DISCONNECT THE ELECTRICAL

VENT DAMPER ASSEMBLY DIAGRAM

6. Reverse proc edur e to install .

Vent Motor

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect the lead wires from the switch and

motor.

3. Remove the screw and nut behind the motor

assembly that c onnec ts motor to shaft

extension rod.

4. Remove the mot or and swit c h assembly from

the ov en by sliding the mounting brac k et out

from the ov en frame.

5. Reverse proc edur e to install .

Page 15 of 68

Page 16

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

Sealing Washer

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Open the oven door and remove the rack

guide, filter and exhaust assembly as outlined

under “RACK GUIDE/FILTER/EXHAUST

ASSEMBLY”.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE ADJUSTMENT. USE EXTREME CAUTION AT

ALL TIMES.

3. Reconnect the el ectrical power to the machine

at the main circuit box.

4. Close the door, turn the oven ON and press the

Start/S top button.

5. Observe the rotation of the vent motor cam.

When the cam stops turning then the vent

should be closed.

NOTE

opened, the vent should open automatical ly.

6. Disconnect the electric al power to the machine

at the main circuit box. P lace a tag on the

circuit box indicating the circui t is being

serviced.

NOTE

manner. I f the oven is turned OFF or the door is

opened, the vent will re-open automatical ly.

7. Open the oven door and examine the vent f r om

inside the cavit y.

A. If the mounting nut is vi si ble, proceed to

B. If the mounting nut is not visible, t hen the

8. Remove the nut securing both shutters and the

sealing washer to the shaft extension rod then

remove the shutters and sealing washer.

THE FOLLOWI NG ST EPS REQUIRE

: When the ov en is turned OFF or the door is

: Power to the oven must be removed in this

step 8.

vent needs to r otate 180 degrees.

Reconnect power to the machine and

repeat steps 3 through 7A.

4. Rotate the extension rod approximately 90

degrees by hand.

5. Exam ine the vent from inside the c avity.

A. If the mounting nut is vi si ble, proceed to

step 6.

B. If the mounting nut is not visible, t hen the

extension rod needs t o r otate

approximately 90 degrees more.

6. Remove the nut securing both shutters and the

sealing washer to the ex tension rod then

remove the shutters and sealing washer.

7. Remove the shutter screw f r om the extension

rod.

8. Release the snap ring on the left end of the

shaft (i f fac ing oven) and pull shaft extension

out.

: If the washers on the exterior of the vent

NOTE

housing come loose, red silicone must be re-appli ed

to prevent steam l eakage above the oven cavity .

9. Reverse proc edur e to install .

WATER LEVEL SENSORS AND

WATER EQUALIZATION TUBE

1. Turn the oven off and allow steam generator

tank to drai n.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

2. Turn off the water supply.

3. Remove the right side panel as outli ned under

”COVERS AND PANELS”.

4. Disconnect l ead wir es and hose clamps from

the water equali z ation tube.

DISCONNECT THE ELECTRICAL

9. Install new sealing washer and re-assemble.

Shaft Extension

1. Remove the left, ri ght and rear panels as

outlined under “COVERS AND PANELS”.

2. Open the oven door and remove the rack

guide, filter and exhaust assembly as outlined

under “RACK GUIDE/FILTER/EXHAUST

ASSEMBLY”.

3. Remove the screw and nut behind the motor

assembly that c onnec ts motor to shaft

extension rod.

NOTE

Page 16 of 68

: Some water will continue to drain out.

Page 17

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

5. Remove the water equalization tube.

4. Disconnect water and steam equalizat ion tube

from the steam generator. If necessary, loosen

or remove drain pump mounting nuts to

remove tube.

6. Reverse proc edur e to install .

STEAM GENERAT OR TANK

1. Turn the oven off and allow the steam

generator tank to drain.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

2. Turn off the water supply to the steam

generator

3. Remove the right side and rear panels as

outlined under “COVERS AND PANELS”.

DISCONNECT THE ELECTRICAL

10 LEVEL SHOWN

A. Remov e heating elements from steam

generator tank and place to the side.

NOTE

: Unless replacing the heating

element (s), it not nec essary to r emov e the

heating element lead wir es.

B. On 6 and 10 levels, remove cl amp from

the steam exhaust hose at the top of

steam generator and disconnect hose. On

20 levels, remove the nut s securing the

steam exhaust pipe to the outsi de of the

cavity.

NOTE

: When replacing tank on 20 levels, be

sure to seal the m ating surface between the

exhaust pipe and cavity wall with RT V .

5. Remove the nuts fr om the tank mounting studs

and bracket (at bottom) t hen r emov e the steam

generator f rom the oven.

6. Remove insulation from the old steam

generator and use on the repl ac ement steam

generator.

7. Reverse proc edur e to install .

Page 17 of 68

Page 18

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

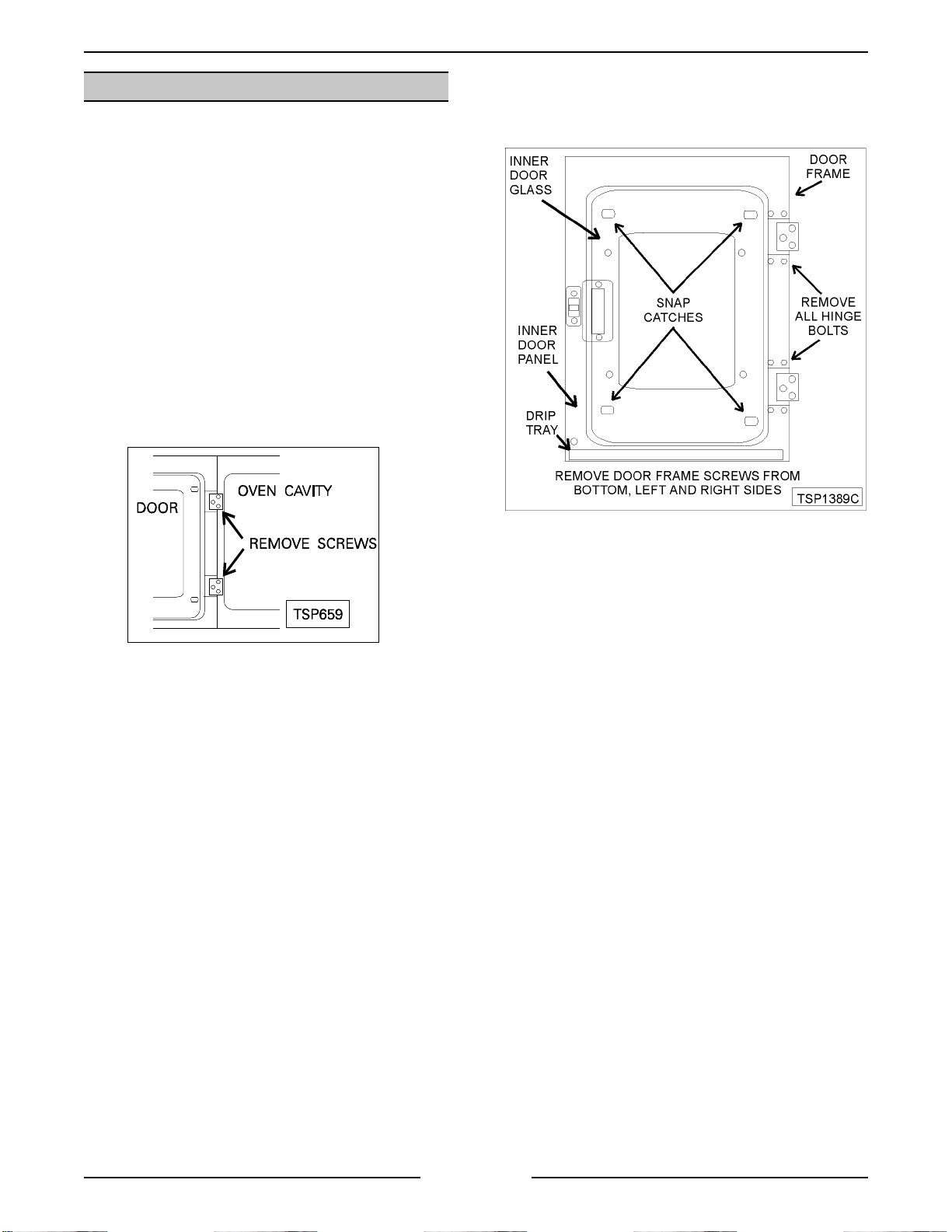

OVEN DOOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Remove the left and right si de panels as

outlined under “COVERS AND PANELS”.

2. Disconnect the lead wires to the lamp on the

power supply board term inal block and r oute

them so they can be pulled through the hole in

the frame when the door is rem oved.

3. Support the door, remove the screws from

each hinge block on the oven and r emov e

door.

DISCONNECT THE ELECTRICAL

4. Open the inner door glass and remove the cring clamps from the rear snap catches, unsnap

at the rear then lif t off.

4. Reverse proc edur e to install .

Disassembly

1. Remove the door f r om the oven as outlined

above in “REMOVAL”.

2. Lay the door on a f lat surfac e with the inside of

the door fac ing up.

3. Lift up along the inner door glass edge near the

door latch and unsnap the glass from t he “snap

catches” in the oven door.

CAUTION: When replacing the inner door glass,

it must be installed with the conductive side

toward the front o f t he oven. Use an ohmmeter

to verify the conductive side. Set the meter to

read ohms and touch glass with the meter leads.

A resistance will be measured but will vary

depending on the distance between the meter

leads, grease and/or o t her substances o n the

glass.

5. Remove the bolts securing the top and bottom

hinges to the door.

6. Remove the drip t r ay, remaining screws from

the inner door panel, the screws at the left,

right and bottom of the door and remove the

door handle.

7. Lift the inner door panel from the outer door

frame.

8. Remove the outer door glass.

9. Reverse proc edur e to install .

10. Adjust the door as outlined under “OVEN

DOOR ADJUSTMENT” in “SERVICE

PROCEDURES AND ADJUSTMENTS”.

Page 18 of 68

Page 19

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

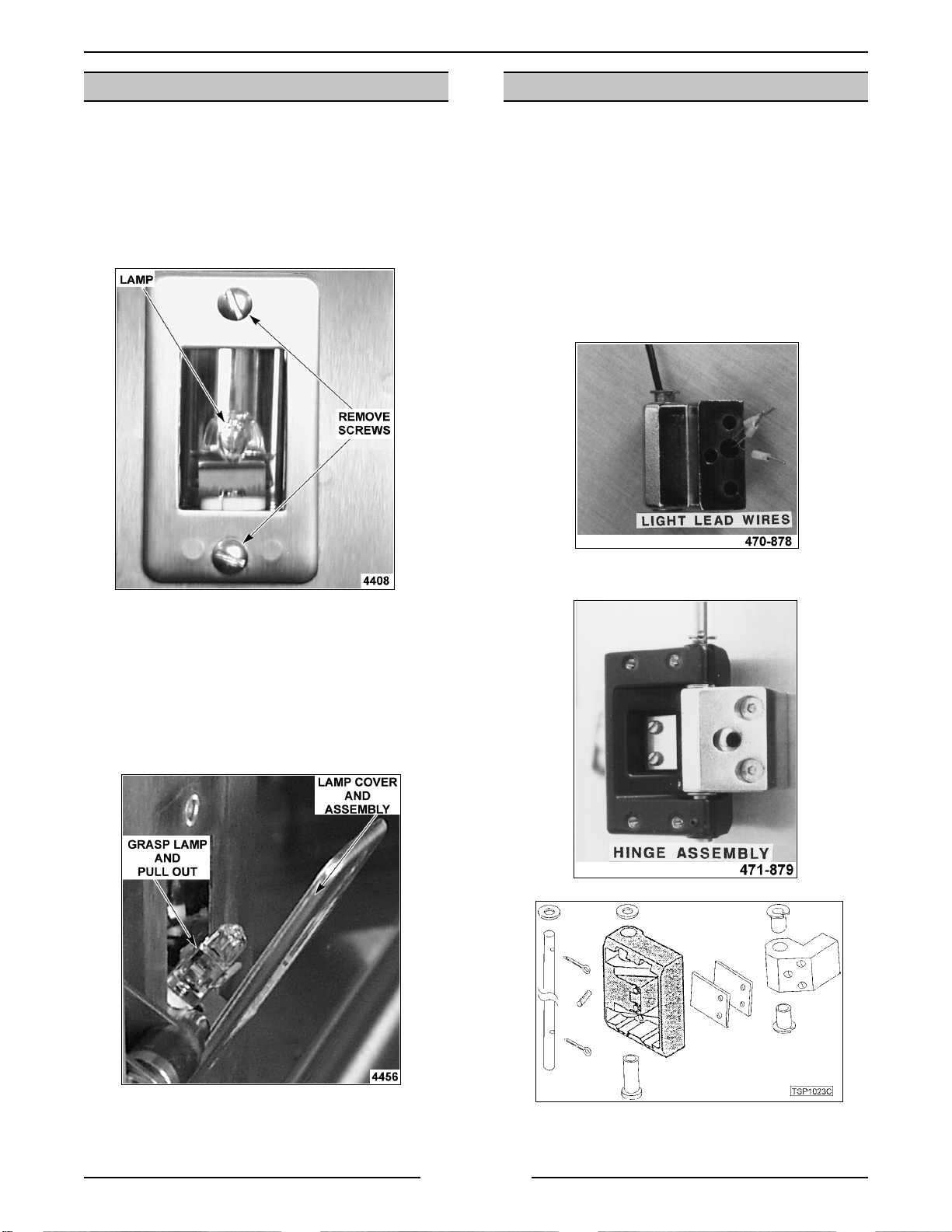

DOOR LAMP

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the screws holding the cover and

gasket.

DISCONNECT THE ELECTRICAL

OVEN DOOR HINGES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove and disassemble the door as outlined

under “OVEN DOOR”.

2. Remove the li ght lead wire from the hinge.

NOTE:

wires at the terminal end t o allow the terminals to be

fed through the hinge one at a time.

DISCONNECT THE ELECTRICAL

Strip 3 inches of the shielding away from the

2. Pull t he lamp and socket assembly out f r om the

door.

3. Hold the lamp assembly and grasp the bulb

using a cloth.

NOTE

: Do not touch t he Halogen lamp with bare

hands. If lamp is ex posed t o oil f r om the skin, the

life will be reduced. Ensure lamp is free from oil and

dirt before replacing.

3. Remove the cotter pins from the shaft and

remove the shaft from the hinges.

4. Pull up on light bulb to remove it from socket.

5. Reverse proc edur e to install .

4. Reverse proc edur e to install .

Page 19 of 68

Page 20

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

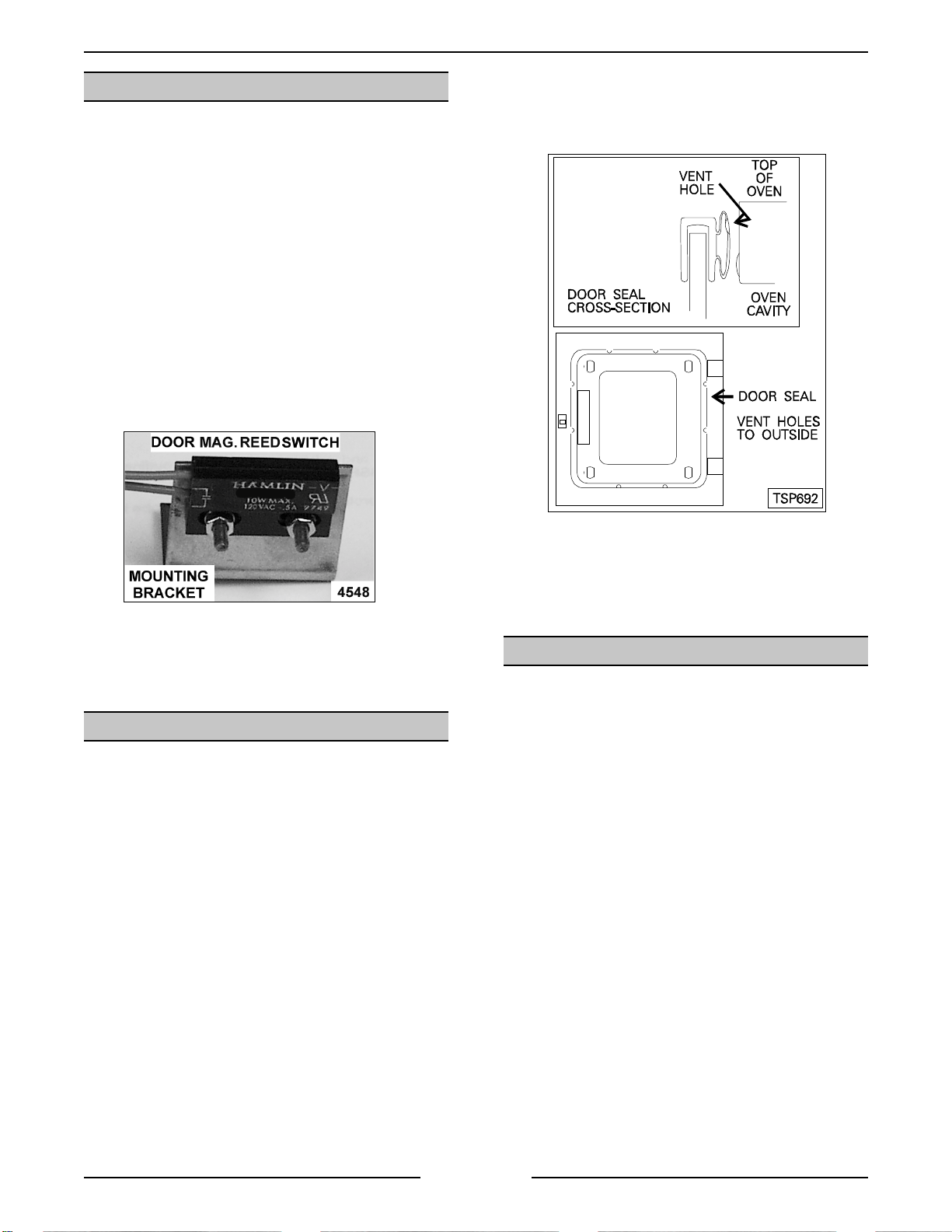

DOOR MAGNETIC REED SWITCH

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Remove the nuts that secure the door switch

mounti ng bracket to the bottom of the control

panel. On 20 levels, the switch is m ounted to

the underside of the channel f or the door

handle (no bracket required).

3. Disconnect the switc h lead wires.

4. Remove the switch f rom the oven.

DISCONNECT THE ELECTRICAL

5. Apply red silicone to the repl ac ement seal and

install the seal to the glass edge. The vent

holes must be i nstalled to the outside to all ow

the seal to contract when the door is closed.

6 AND 10 LEVELS

5. Reverse proc edur e to install and c hec k for

proper operati on.

DOOR SEAL

1. Turn the oven off.

2. Open the oven door.

3. Remove seal from the edge of the inside glass.

4. Clean the edge of the glass, rem ove the old

adhesive.

6. Adjust door closure, if nec essary, as outlined

under “OVEN DOOR AND DOOR LOCK

ADJUSTMENT” in “SERVICE PROCEDURES

AND ADJUSTMENTS”.

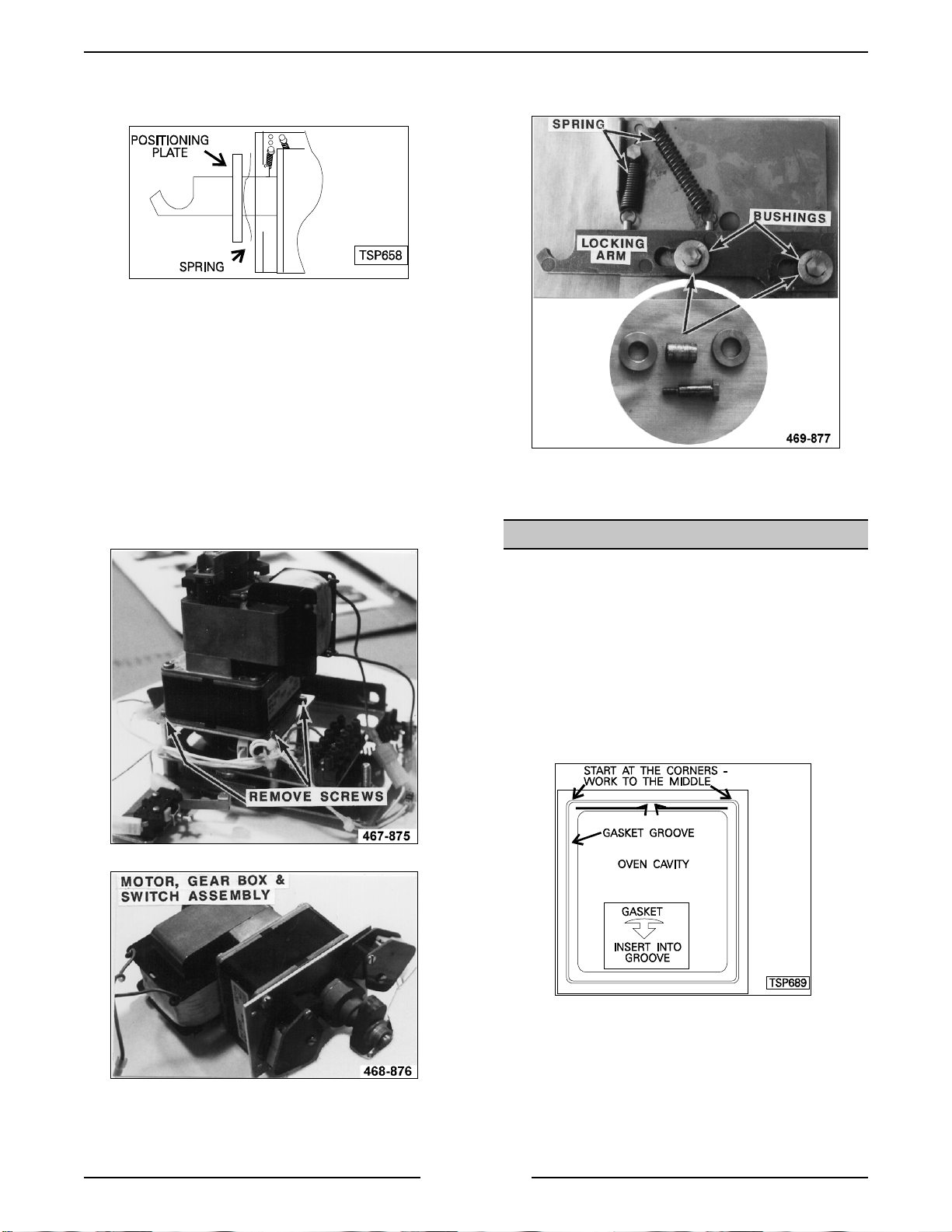

DOOR LOCKING MECHANISM

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Replacement

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect the lead wires to the motor and

switches.

3. Remove the nuts fr om the mounting studs and

remove the assembly from the oven.

DISCONNECT THE ELECTRICAL

Page 20 of 68

Page 21

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

4. Remove the spring and posit ioning plat e from

the locking arm.

5. Reverse proc edur e to install and adjust as

outlined under “O VEN DOOR ADJUSTMENT”

in “SERVICE PROCEDURES AND

ADJUSTMENTS”.

Disassembly

1. Remove the three screws that secure the motor

and switch assembly.

2. Remove the mot or , gear box and switch

assembly from the locking m ec hanism.

Remove the two bolts from the locking

mechanism. The springs, locking arm and

bushings can be removed.

4. The springs, loc k ing arm and bushings can be

removed.

5. Reverse proc edur e to install .

OVEN CAVITY SEAL

3. Remove the two bolts from the locking

mechanism.

1. Open the door.

2. Pull t he seal from the groove around the ov en

cavity.

3. Push the arrow head tip of the gasket int o the

groove. Install the four corners first.

4. Start at the corners and work to the m iddle of

each side, being c ar eful not to stretch the

replacement gasket.

5. Check the door for proper operation and adjust

if nec essary, as outlined under “OVEN DOOR

AND DOOR LOCK A DJ US TMENT” in

“SERVICE PROCEDURES AND

ADJUSTMENTS”.

Page 21 of 68

Page 22

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

POWER SUPPLY BOARD

AND TRANSFORMER

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect l ead wir e c onnec tions and ribbon

cable f r om the board.

DISCONNECT THE ELECTRICAL

CONTACTORS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the right side panel as outli ned under

“COVERS AND PANELS”.

2. Disconnect lead wi r es for the contactor being

replaced.

DISCONNECT THE ELECTRICAL

3. Loosen the two nuts securing the assembly to

the mounting bracket and lift the assembly off

the bracket.

4. Reverse proc edur e to install .

NOTE

: Ensure transf or mer tap wire i s i n the position

that corresponds to the machine data plate voltage.

Refer to the “power supply board and transformer

(1T) “ component on the wiring diagr am for pr oper

connection of the individual lead wires.

3. Remove the jumper bars from the contact or s.

4. Pull t he locking tab out at the contactor base to

release the catc h and r emov e c ontactor f r om

mounti ng bracket.

5. Reverse proc edur e to install .

Page 22 of 68

Page 23

ELECTRIC COMBI OVEN - REMOVAL AND REPLACEMENT OF PARTS

OVEN CAVITY DRAIN

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the oven cav ity door.

2. Lift up the ov en c avity drain grate to remove.

DISCONNECT THE ELECTRICAL

6. Remove the drain vent pi pe from the drain.

7. Disconnect the dr ain cool down water hose

from the drain ni pple extensi on.

8. Unscrew the drain line piping from the bottom

of the oven then remove the oven drain.

9. Reverse proc edur e to install .

3. Unscrew t-bar nut to release drain at the front.

4. Remove rear panel as outlined under

“COVERS AND PANELS”.

5. Disconnect the dr ain pump discharge hose

from the drain vent pipe.

Page 23 of 68

Page 24

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the rear panel as outlined under

“COVERS AND PANELS”.

2. Identify the type of convection fan motor ( s) on

the ov en before setti ng the motor values in

step 9 and 10.

3. Reverse proc edur e to install .

4. Re-connect power to the oven.

The configuration mode can be entered onl y when

the ov en is

mode can be done at any time by pressing the

key to sav e the confi guration settings and exit t he

confi gur ation mode.

To Perf orm:

1. To enter the configurat ion mode press the

TIME, TIME UP

simultaneously for 3 seconds. I n the tim e

display, C and F will be displayed. In the

temperat ure display, “Conf” will be displayed.

2. Press the

DOWN

indicat es t he temperature scale selected. The

control will automatically advance to the next

step, approximately three seconds after the

selection is made. To manually advance to the

next step, pr ess the

3. dSC is displayed in the time display and t he

number of clean cycles complet ed (deliming of

steam generator ) is displayed in t he

temperat ure display.

changed or modified

START/STOP

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

CONFIGURATION MODE -

PROGRAMABLE CONTROL

DISCONNECT THE ELECTRICAL

OFF

. Returning to the normal operating

TIME DOWN

and

TIME UP

key for Celsius. The blinking letter

key for Fahrenheit or

START/STOP

The number cannot be

. Press the

key to advance to the next step.

keys

key.

OFF

TIME

4. The EPROM r evisi on level is displayed in the

tim e display and “Conf” is displayed in the

temperat ure display. T o veri fy the EPROM is at

the current r evisi on level, ref er to the Technic al

Service Bulletins. Press the

to adv anc e to the next step.

5. HHH is displayed in the time display and the

total cook ing hours of the oven is di spl ay ed in

the temper ature display. P r ess the

key to increase number of hour s or t he

DOWN

the current number of hour s i s acceptable,

press

step.

NOTE

not changed withi n 3 seconds, t he c ontrol will

automatically advance to the next step wit hout

pressing the

6. bbb flashes and is di spl ay ed in the time

display, the frequency number is display ed in

the temper ature display and t he buz z er shoul d

be sounding. Press the

DOWN

continuous and 255 = very slow int er vals)

number. A good setting to start with is 050 or

any number that is prefer able to the customer.

If t he setting is accept able, press the

START/STOP

7. uuu is displayed in the time display and the

steam temperature setting is displayed i n the

temperat ure display. T he steam temper ature

setting is t he boiling point adjustm ent for

elevation and m ust

results. Press the

number or

number. Set the temper ature according to the

table below. P r ess the

advance to the next step.

key to decrease the number of hours. If

START/STOP

: If a c onfigurat ion parameter is selected and

START/STOP

keys to set the buzzer frequency (000 =

TEMP DOWN

START/STOP

TEMP UP

key to advance to the next

key.

TEMP UP

key to advance to the next step.

be set to achieve optimum

TEMP UP

key to decrease

START/STOP

or

key to increase

key

TEMP

TEMP

key to

Page 24 of 68

Page 25

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

: The temperature select ed in the table below

NOTE

will also be the highest starting point temperature

available, when the steam mode i s selected.

ELEVATION

(FT)

Sea level to 500 212

500 to 1000 211

1,000 to 2,000 209

2,000 to 3,000 207

3,000 to 4,000 205

4,000 to 5,000 204

5,000 to 6,000 202

6,000 to 7,000 200

7,000 to 8,000 198

8,000 to 9,000 196

9,000 to 10,000 195

Above 10,000 194

TEMPERATURE

(°F)

8. CCC is displayed in the time display and the

convec tion tem perature li mit is displayed in the

temperat ure display. Pr ess the

TEMP UP

key

to increase number (482°F to 518°F) and

TEMP DOWN

key to decrease num ber . Set the

temperat ure to read 518°F. Pre ss the

START/STOP

key to advance to the next step.

9. 1 - - is display ed in the time display and t he

minimum

value for the c onvection fan motor is

displayed i n the temperat ur e display. Press the

TEMP UP

DOWN

to Position 1

the v alue is correct , press the

key to increase number and

TEMP

key to decrease num ber . Set accordi ng

(minimum) in the table below. If

START/STOP

key to advance to the next step.

10. 2 - - is displayed in the time display and a

maximum

value for the c onvection fan motor is

displayed i n the temperat ur e display. Press the

TEMP UP

TEMP DOWN

according to Position 2

key to increase number and the

key to decrease num ber . Set

(max imum) in the table

below. If the value is correct, press the

START/STOP

key to advance to the next step.

CONVECTION FAN MOTOR

CONVECTION FAN

MOTOR TYPE

1 motor Leroy-Somer

(Hanning)

1 motor Brook-Crompton

2 motors Leroy-So mer

(Hanning)

2 motors Brook-Crompton 30 90

1 motor Leroy-Somer

(Hanning) and 1 motor

Brook-Crompton

: (*) Ove n s are shipped from the factory with th is

NOTE

motor and the oven control is configured

accordingly.

The values correspond to th e current limits only

and are not the actual current draw of the motor.

POSITION 1

(MINIMUM)

*

VALUE

POSITION 2

(MAXIMUM)

855

860

46 120

38 105

11. If all t he values have been entered corr ectly,

press the

key to sav e the confi guration

OFF

settings and exit the configuration mode. To

review or change a configuration value press

the

START/STOP

key to return to step 1.

DIAGNOSTIC TEST MODE -

PROGRAMABLE CONTROL

The test mode can be entered only when the oven is

The five t ests are r un in sequence (1 - 5) and

OFF.

are indicated by the position of the illuminated LED

in the bar graph of the com bi mode key.

The test are performed in a fixed sequence of:

1. ROM (automatical ly)

2. RAM (autom atically)

3. Displays and LED’s

4. Relays (relay on for max. of 2 seconds)

5. Keypad

To Perf orm:

1. To enter the t est mode press the

UP

and

TEMP DOWN

keys simul taneously for

3 seconds. The word “test” will be displayed in

the temper ature display.

TEMP, TEMP

2. If a RO M or RA M error is detect ed, a error

Page 25 of 68

code (01 = ROM and 02 = RAM) will be

displayed on the temperature display and will

repeat until a key is pushed to ex it this test. If

no errors are detected, the control advances to

the next test and runs it automatically.

Page 26

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

3. The DISPLAY and LE D test consists of flashing

all di splays and LED’s. The word “test” will flash

intermittent ly as the tem per ature display i s

tested. Verify all the DI SPLAYS and LED’s a re

flashing. This test will continue until a key is

pressed to advance to the next step.

4. The RELAY test consi st of selecting a

particular relay by its code number (01 to 11)

with the

TEMP UP

and

TEMP DOWN

keys.

The initial code displayed in the temperature

display i s 01 for relay K1. Press the

TEMP

key

to energize t he selected relay for a maxim um

of 2 seconds. Verify that each selected rel ay

(K1 to K10) is functi oning. See tabl e below. To

exit this test and proceed to the next, pr ess the

key.

OFF

CODE RELAY COMPONENT

01 K1 door mo tor

02 K2 cavity vent motor

03

*

04 K3 cooling fan(s) and door light only

05 K3, K4 water inje ction so lenoid (humidifier)

06 K5 drain pump

07 K3, K5 water fill solenoid

08

*

09

*

10

*

11

*

NOTE

engaged. No noticeable external component o p erates.

K6 contactor KM1 (ha lf power, full speed)

K7

K8

K10

K9

: Asterisk (*) indicates relay is checked but contactor not

contactor KM2 (half power, ha lf speed);

on 20 levels only, contactor KM3 and

drain cool do wn solenoid.

contactor KM3 and drain cool down

solenoid on 6 & 10 levels;

contactor KM5 on 20 levels only

(steam generator heating elements)

contactor KM7

(convection heating elements)

contactor KM6

(convection heating elements)

5. The keypad test consi st of pressing each key to

check its functionality. Initially, 02 is displayed

in the time display and “test” is displayed in the

temperat ure display. With each successful key

press, the number of the key i s di spl ay ed in

the time display. Each key is number ed,

starting wit h number 01 (ON) in the upper left

corner of the control and ends at 21

(humidifi er) on the lower right corner. See table

below. Verify that all keypad buttons are

functioning properly.

KEY NO. KEY NO.

ON 01 TEMP 12

OFF 02 TEMP DOWN 13

HOT AIR 03 TEMP UP 14

STEAM 04 DELTA T 15

COMBI 05 PROG 16

START/STOP 06 ENTER 17

PHASE 07 ENTER DOWN 18

TIME 08 ENTER UP 19

TIME DOWN 09 FAN SPEED 20

TIME UP 10 HUMIDIFIER 21

PROBE 11

6. To exi t the diagnosti c test mode, press and

hold the

key for approximately 3 seconds.

OFF

CONFIGURATION MODE -

MANUAL CONTROL S

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the rear panel as outlined under

“COVERS AND PANELS”.

2. Identify the type of convection fan motor ( s) on

the ov en before setti ng the motor values in

step 9 and 10.

3. Reverse proc edur e to install .

4. Re-connect power to the oven.

The configuration mode can be entered onl y when

the ov en is

mode can be done at any time by pressing the

START

exit the confi gur ation mode.

To Perf orm:

1. To enter the configurat ion mode press the

TIME

seconds. In the temperature display , “Conf” will

be displayed. P r ess the

to the next step.

2. C and F will be displayed in the time display.

Rotate the adj ustment knob counterclockwise

for Cel sius and clockwise for Fahrenheit. The

blinking letter indicates the temperature scale

selected. Ac c ept the selecti on by pr essing t he

TIME

DISCONNECT THE ELECTRICAL

. Returning to the normal operating

OFF

key to sav e the confi guration settings and

and

TEMP

keys simul taneously for 3

key to advance

TIME

key to advance to the next step.

Page 26 of 68

Page 27

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

3. dSCL is displayed in the time display and t he

number of clean cycles complet ed (deliming of

steam generator ) is displayed in t he

temperat ure display.

changed or modified

The number cannot be

. Press the

TIME

key to

advance to the next step.

4. The EPROM r evisi on level is displayed in the

tim e display and “Conf” is displayed in the

temperat ure display. T o veri fy the EPROM is at

the current r evisi on level, ref er to the latest

Technical Service Bulletins

. Press the

TIME

key to advance to the next step.

5. HHHH is displayed i n the tim e display and the

total cook ing hours of the oven is di spl ay ed in

the temper ature display. Rotate the adjustment

knob counterclockwise

hours and clockwise

to decrease number of

to increase number of

hours. If the current number of hours is

acceptable, press the

key to advance to

TIME

the next step.

6. bbbb flashes and is di spl ay ed in the

TIME

display, the frequency number is display ed in

the temper ature display and t he buz z er shoul d

be sounding. Rotate t he adjustment k nob

counterclockwise

and clockwise

to decrease buzzer frequency

to increase buzzer frequency

(000 = continuous and 255 = very slow

intervals) number. A good setti ng to start with is

050 or any number that is pref er able to the

customer. If the sett ing is acceptabl e, press the

key to advance to the next step.

TIME

7. uuuu is displayed in the time display and the

steam temperature setting is displayed i n the

temperat ure display. T he steam temper ature

setting is t he boiling point adjustm ent for

elevation and m ust

be set to achieve optimum

results. Rotat e the adjustment k nob

counterclockwise

to decrease and clock wise to

increase. Set the temperat ur e ac c or ding to the

table below. P r ess the

key to advance to

TIME

the next step.

: The steam temperatur e setting

NOTE

will also be

the initial cavit y set point tem per ature and the

maximum c avity temperature that can be set, when

the steam mode is selected.

ELEVATION

(FT)

Sea level to 500 212

500 to 1000 211

1,000 to 2,000 209

2,000 to 3,000 207

3,000 to 4,000 205

4,000 to 5,000 204

5,000 to 6,000 202

6,000 to 7,000 200

7,000 to 8,000 198

8,000 to 9,000 196

9,000 to 10,000 195

Above 10,000 194

TEMPERATURE

(°F)

8. CCCC is displayed i n the tim e display and the

convec tion tem perature li mit is displayed in the

temperat ure display. Rot ate the adjustm ent

knob counterclockwise

518°F) and cloc k wise

the temper ature to read 518°F. P r ess the

to decrease (482°F to

to increase number. Set

TIME

key to advance to the next step.

9. 1 - - is display ed in the time display and t he

minimum

value for the c onvection fan motor is

displayed i n the temperat ur e display. Rotat e

the adjustm ent knob counterclockwise

decrease and clockwise

Set according to Position 1

to increase number.

(minimum) in the

to

table below. If the value i s cor r ec t, press the

key to advance to the next step.

TIME

10. 2 - - is displayed in the time display and a

maximum

value for the c onvection fan motor is

displayed i n the temperat ur e display. Rotat e

the adjustm ent knob counterclockwise

decrease and clockwise

Set according to Position 2

to increase number.

(max imum) in the

to

table below. If the value i s cor r ec t, press the

key to advance to the next step.

TIME

Page 27 of 68

Page 28

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

CONVECTION FAN MOTOR

CONVECTION FAN

MOTOR TYPE

1 motor Leroy-Somer

(Hanning)

1 motor Brook-Crompton

2 motors Leroy-So mer

(Hanning)

2 motors Brook-Crompt on 30 90

1 motor Leroy-Somer

(Hanning) and 1 motor

Brook-Crompton

: (*) Ove n s are shipped from the factory with th is

NOTE

motor and the oven control is configured

accordingly.

The values correspond to th e current limits only

and are not the actual current draw of the motor.

POSITION 1

(MINIMUM)

*

VALUE

POSITION 2

(MAXIMUM)

855

860

46 120

38 105

11. If all t he values have been entered corr ectly,

press the

START

key to sav e the confi guration

settings and exit the configuration mode. To

review or change a configuration value press

the

key to return to step 1.

TIME

With each successful sel ec tion, the

corresponding num ber is displayed in t he

temperat ure display. F or the adjustment k nob,

an upper or lower dash line will be displayed

(depending on rotation). See t able below.

Verify that all knob positi ons and keypad

buttons are func tioning proper ly. When

satisfied, press and hold the

START

key for 4

seconds to advance to the next step.

SWITCH/ KEYPAD/KNOB POSITION NO./DASH

SELECTOR SWITCH OFF 0

SELECTOR SWITCH HOT AIR 1

SELECTOR SWITCH STEAM 2

SELECTOR SWITCH COMBI 3

SELECTOR SWITCH COOL DOWN 4

SELECTOR SWITCH DE-SCALE 5

KEYPAD BUTTON TIME 6

KEYPAD BUTTON PROBE 7*

KEYPAD BUTTON TEMP 8

LINE

DIAGNOSTIC TEST MODE -

MANUAL CONTROL S

The test mode can be entered only when the oven is

OFF.

The test are performed in a fixed sequence of:

1. Displays and LED’s

2. Selector swit c h, keypad and adjustm ent knob.

3. Relays (relay on for max. of 2 seconds).

To Perf orm:

1. To enter the t est mode press the

keys simul taneously for 4 seconds.

TEMP

START

2. The DISPLAY and LE D test consists of flashing

all di splays and LED’s while the buzzer sounds.

In the temperature displ ay , all the individual

display segments and the word “test” will flash

intermittent ly. Verify al l the displays and LED’s

are flashing. This test will continue until the

START

key is pressed and held f or 1 second t o

advance to the next step.

3. The word “test” is displayed in the temperature

display and 10 (start button keypad no.) is

displayed i n the “time” display. The KEYPAD

test consists of r otating the selec tor switch

clockwise

through each position, pressing each

button on the keypad and r otating the

adjustment knob clockwise

counterclockwise

to check the functionality of

then

each.

and

KEYPAD BUTTON DOOR 9

KEYPAD BUTTON START 10

KEYPAD BUTTON COMBI 12*

KEYPAD BUTTON VENT 13*

ADJUSTMENT KNOB ROTATE CW

ADJUSTMENT KNOB ROTATE CCW

: Asterisk (*) indicates not ava ilable on standard

NOTE

manua l controls.

“—“

4. The word “test” will still be displayed in the

temperat ur e display. The RE LA Y test consist of

selecting a par ticular r elay by its code number

(01 to 11) with t he adjustment knob and

pressing the

key to energize the relay

TEMP

for a maximum of 2 seconds. See table below.

Verify that each selec ted relay (K1 t o K 10) is

functioning. The status of the relay output (0 or

1) will be displayed in the left side of the

temperat ure display. When satisfied, press and

hold the

START

key for 1 second to advance

to the next step.

“—“

Page 28 of 68

Page 29

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

CODE RELAY COMPONENT TEST CONDITION

Door magnetic reed switch. Result will be displayed

01 K1 door motor

02 K2 cavity vent motor

03 K3, K6 contactor KM1 (half power, full speed)

04 K3 cooling fan(s) and door light only

05 K3, K4 water injection solenoid (humidifier) Visual - water injection into cavity.

06 K5 drain pump Water level sensors (water level in steam generator)

07 K3, K5 water fill solenoid Water level sensors (wa ter level in steam generator)

contactor KM2 (half power, ha lf speed);

08 K3, K7

09 K3, K8

10 K3, K10

11 K3, K9

on 20 levels only, contactor KM3 and

drain cool do wn solenoid.

contactor KM3 and drain cool down

solenoid on 6 & 10 leve ls; contactor

KM5 on 20 levels only.

(steam generator heating elements)

contactor KM7 (convection heating

elements on 10 & 20 levels)

contactor KM6

(convection heating elements)

automatically. Rotate the door handle to change the

condition. Press and hold the TEMP key to close the

door; release to open.

Cavity vent micro switch. Result will be displayed

automatically. Press and hold the TEMP key to

change condition.

Convection fan motor value - press and hold the

TEMP key for 30 sec. to test the fan motor

configuration settings. The test result will be

displayed .

Cavity Hi Limits and steam generator thermal

fuse(s). Press and h old the TEMP key for result.

0 = open;

1 = closed

0 = open;

1 = closed

0 = incorrect;

1 = correct.

0 = open;

1 = closed

0 = unsatisfied;

1 = satisfied

5. t1 is display ed in the time display and t he ac tual cavity t emperature i s di splayed in the temperature di spl ay .

Verify the probes are sensing tem per ature correctly. Rotate t he adjustment knob and select the probe

temperat ure to display (T1 = cavity probe (top on 20 levels); T2 = bottom cavit y pr obe ( 20 levels only); T3 =

cooking probe).

6. To exi t the diagnostic test mode, pr ess and hold t he

SERVICE ERROR LIGHTS

1. There are f our lights at the bottom of the

control. When l it, they tell the operator that t he

oven needs service related to the component

that the l ight(s) represent. Refer to

“TROUBLESHOOTING” for display error

codes.

START

key for approximately 3 seconds.

: If the steam generator thermal fuse(s) or the

NOTE

cavity high limits open, the steam gener ator heat

and the convection heat er ror light s will come on.

2. Turn the oven off and reset the oven control .

A. P r ogrammable control - pr ess the off key.

B. M anual controls - r otate the selector switc h

to the of f positi on.

3. Correct the pr oblem rel ated to the service error

light. See “TROUBLESHOOTING” section.

4. Turn the oven on and check operation.

A. P r ogrammable control - pr ess the on key,

select a heating mode and press start key

to begin.

The lights are, from left to right.

A. Water suppl y.

B. Convection heat.

C. Steam gener ator heat.

D. Cavity f an.

B. M anual controls - r otate the selector switc h

to one of t he three heating modes.

: On water supply err or s, monitor the oven for

NOTE

at least 5 m inutes to pass the “time out” period for

the steam generator fill.

Page 29 of 68

Page 30

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENTS

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

1. Measure the voltage at the heating element

terminals and verify it against t he data plate

voltage.

A. If voltage is incorrect, find the sourc e of

2. If volt age is correct, c hec k c ur r ent draw (amps)

through the heating element lead wires. If

current draw is correc t then heating element i s

ok.

A. If current draw is not correct then, replace

3. Check for proper operation.

MODEL VOLTAGE

VCE6H

VCE10H

VCE20F

VCE20H

NOTE

MODEL VOLTAGE

VCE6H

VCE10H

VCE20F

VCE20H

NOTE

THE FOLLOWI NG ST EPS REQUIRE

the problem.

See table below for p roper values.

heating element.

CONVECTION HEAT

KW PER

ELEMENT

208 9 15 14

240 9 13 19

480 9 11 26

208 6 10 22

240 6 8 29

480 6 7 38

Values in the table are nom i n al. Tolera nce is

:

+5/-10 %.

STEAM GENERATOR HEAT

KW PER

ELEMENT

208 8 13 16

240 8 11 22

480 8 10 29

Values in the table are nom i n al. Tolera nce is

:

+5/-10 %.

AMPS PER

ELEMENT

LEAD

(3 PH)

AMPS PER

ELEMENT

LEAD

(3 PH)

OHMS PER

ELEMENT

OHMS PER

ELEMENT

OVEN DOOR ADJUSTMENT

NOTE

: Follow the steps in the order outlined below

for proper door adjustment .

1. Turn the oven off.

2. Check the level of the oven from lef t to right

and front to back, in t he exact loc ation where

the ov en is to be positioned.

A. If the oven is not

necessary adjustment s before proceeding

to the next step.

B. If the oven is level, then proceed to step 3.

3. Loosen the hinge screws just enough to adjust

the door position but so the door stays when

not being m oved or supported.

4. Position the door square with the oven as

shown below.

5. Tighten t he hinge screws after adjusting.

WARNING:

DISCONNECT THE ELECTRICAL

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

6. Remove the right side panel and the contr ol

panel as outlined under ”COVERS AND

PANELS”.

7. Loosen the screws on the door roller (str iker)

just enough to adjust its position but stay s when

not being m oved.

level, make the

Page 30 of 68

Page 31

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

8. Position the door roller against the “striking”

edge of the locking arm but do not close t he

door.

A. Observe the posi tion of the door roll er to

the locking arm.

B. A djust the door rol ler so it m ates at the

“striki ng edge” ( bottom of the sloped edge)

of the locking arm. The exac t distance of

the “striking” edge to the bottom of the

roller is stated to be 1 mm (0.040 inches).

This position allows the locking arm to be

pushed down during closing, and after

closing the roller will be positioned in the

hook.

10. With t he door in the closed posit ion the roller

should be cradled in the locking arm hook.

11. Replace the control panel.

12. Close the door handle. The handl e is centered

in the cut- out of the control panel so the

magnet i n the handle will operate the m agnetic

reed switch.

1) If the door roller mates against the

locking arm as described, t hen

tighten t he door roller screws and

proceed to step 9.

2) If the rol ler does not mate against the

locking arm as described and there is

no more adjust ment in t he door r oller,

then loosen the bolts securing the

door motor assem bly and adjust the

locking arm position as described.

3) The door roller should now m ate

against the locking arm pr oper ly.

Tighten t he bolts securing the door

motor assembly and proceed to

step 9.

9. Push the door closed and observe the locking

arm. I t must not contact the bottom edge of t he

slot that t he locking arm travels in whil e the

door is closing.

NOTE:

adjustable if necessary. Remove t he br ac k et from

the bottom of the control panel. Loosen the hex nuts

securing the switch t o the bracket and position the

switch (left to ri ght) where desired. Tighten hex nuts

and replace brack et. Check switch for proper

operation.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE ADJUSTMENT. USE EXTREME CAUTION AT

ALL TIMES.

13. Turn t he oven on.

14. The door shoul d automati c ally pull shut and

15. The space between the t op inner edge of t he

The magnetic reed switch position is

THE FOLLOWI NG ST EPS REQUIRE

lock into position t o seal the oven opening.

door and the oven should be equal along its

length.

16. Thi s space can be adjusted by adding or

NOTE

motor assembly mounting bolts.

Page 31 of 68

removing shims from the door hinges or the

door locking mechanism.

: Ext r a shims are provided under the door

Page 32

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

A. If the space i s l arger at the hinge end,

remove shim( s) from behind the hinges or

from in fr ont of the door locking

mechanism.

B. If the space i s sm aller at t he hinge end,

add shim(s) behi nd the hinges or in front

of the door locking mechanism.

: If shi ms are removed f r om the top hi nge,

NOTE

also remove them from the top hinge.

17. If the space is equal, but the ov en does not

seal. Remove shims from the hinges and in

front of the door l oc king mechanism.

18. Once t he nec essary adjustments have been

made and the door is closing properl y , replace

the right side panel and turn the oven of f.

BUZZER ADJUSTMENT -

PROGRAMABLE CONTROL

To properly set the buzzer, both t he frequency and

volume

results. These adjustments are independent of each

other and requir e a c onfigurat ion mode change and

a manual adjustment of the tri m pot.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE ADJUSTMENT. USE EXTREME CAUTION AT

ALL TIMES.

1. Remove the right side panel as outli ned under

2. Place the control into configuration m ode as

must be adjusted to obtain the best audible

THE FOLLOWI NG ST EPS REQUIRE

“COVERS AND PANELS” in “REMOVAL AND

REPLACEMENT OF PARTS”.

outlined under “PROG RAMABLE CONTROL CONFIGURA TION MODE”.

4. To adjust the buz z er volume, turn t he buz z er

volume adjustment screw until the desired

volume is obtained.

5. Once the buzzer frequency and volume are set

to the desired level s, pr ess the

save the sett ing and exit the configuration

mode.

OFF

key to

BUZZER ADJUSTMENT -

MANUAL CONTROL S

To properly set the buzzer, both t he frequency and

volume

results. These adjustments are independent of each

other and requir e a c onfigurat ion mode change and

a manual adjustment of the tri m pot.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE ADJUSTMENT. USE EXTREME CAUTION AT

ALL TIMES.

must be adjusted to obtain the best audible

THE FOLLOWI NG ST EPS REQUIRE

A. Press the

through the configuration parameter s until

reaching the step for setti ng the buzzer

frequency.

B. To adjust the buzzer frequency, foll ow the

procedure as outlined in step 6 under

“PROGRAMABLE CONTROL CONFIGURA TION MODE”.

3. After the buzzer frequency is set to the desir ed

level, press the

through the configuration parameter s agai n,

until r eaching the step for setting the buz z er

frequency.

START/STOP

START/STOP

key to cycle

key to cycle

Page 32 of 68

1. Remove the right side panel as outli ned under

“COVERS AND PANELS” in “REMOVAL AND

REPLACEMENT OF PARTS”.

2. Place the control into configuration m ode as

outlined under “M A NUA L CONTROLS CONFIGURA TION MODE”.

A. Press the

confi gur ation param eters until reac hing

the step for setting the buzzer frequency.

B. To adjust the buzzer frequency, foll ow the

procedure as outlined in step 6 under

“MANUAL CONTRO LS CONFIGURA TION MODE”.

3. After the buzzer frequency is set to the desir ed

level, press the

confi gur ation param eters again, unti l reaching

the step for setting the buzzer frequency.

key to cycle through the

TIME

key to cycle through the

TIME

Page 33

ELECTRIC COMBI OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

4. To adjust the buzzer volume, turn the buzzer

volume adjustment screw until the desired

volume is obtained.

5. Once the buzzer frequency and volume are set

to the desired level s, pr ess the

save the sett ing and exit the configuration

mode.

START

key to

CLEAN CYCLE MODE - STEAM

GENERATOR DELIMING

WARNING:

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE OVEN. THE COOKING

COMPARTMENT CONTAINS LIVE STEAM. STAY

CLEAR WHEN OPENING DOOR.

Steam generator deliming should be done on a

scheduled basis. The frequency depends on the

quality of the loc al water supply and whether or not

a water treatment system is used. Even with the use

of a water tr eatment system , periodic deliming of

the steam generator is still required.

On combi ovens using a water t r eatment system ,

follow the instructions for that system to deli me the

steam generator . Only use the ty pe of chemical

recommended or described in the deliming

instructions for the system in use. If the Kleensteam

water treatment system is used, Scalekleen is the

recommended chemi c al.

If a water t reatment system is not