Vulcan Hart VCCG48 Manuel de service

VCCG36 Shown

SERVICE MANUAL

VCCG Series Heavy Duty Gas

Griddle

VCCG24

VCCG36

VCCG48

VCCG60

VCCG72

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45533 (1014)

VCCG Series Heavy Duty Gas Griddle

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

MODELS ............................................................................................... 3

INSTALLATION ........................................................................................ 3

OPERATION ........................................................................................... 3

SPECIFICATIONS ...................................................................................... 3

TOOLS ................................................................................................. 3

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 5

FRONT PANEL ......................................................................................... 5

BACK PANEL .......................................................................................... 5

CONTROL DEFLECTOR (HEAT SHIELD) ............................................................... 5

TEMPERATURE CONTROLLER ........................................................................ 6

RADIANT BURNER .................................................................................... 6

THERMOCOUPLE (RADIANT BURNER) ................................................................ 7

REMOVAL ......................................................................................... 7

INSTALLATION .................................................................................... 8

PILOT (RADIANT BURNER) ............................................................................ 8

IGNITION MODULE .................................................................................... 9

GAS VALVE ............................................................................................ 9

INFRARED BURNER .................................................................................. 10

THERMOCOUPLE (INFRARED BURNER) ............................................................. 11

REMOVAL ........................................................................................ 11

INSTALLATION ................................................................................... 11

IGNITOR (INFRARED BURNER) ...................................................................... 12

PILOT ORIFICE (INFRARED BURNER) ............................................................... 12

GRIDDLE PLATE ASSEMBLY ......................................................................... 13

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 14

TEMPERATURE CONTROLLER CALIBRATION ....................................................... 14

RADIANT BURNER - AIR SHUTTER ADJUSTMENT ................................................... 15

GAS MANIFOLD PRESSURE ADJUSTMENT .......................................................... 15

BURNER GAS ORIFICE CHECK ...................................................................... 16

THERMOCOUPLE TEST .............................................................................. 17

TEMPERATURE CONTROLLER TEST ................................................................ 17

IGNITION MODULE TEST ............................................................................. 18

RADIANT BURNER - PILOT FLAME ADJUSTMENT ................................................... 19

GAS VALVE TESTS ................................................................................... 19

INFRARED BURNER .................................................................................. 20

ADJUSTMENT .................................................................................... 20

FLAME APPEARANCE ............................................................................ 20

ELECTRICAL OPERATION ................................................................................ 21

COMPONENT FUNCTION ............................................................................ 21

SEQUENCE OF OPERATION ......................................................................... 21

GRIDDLE WIRING DIAGRAM ......................................................................... 22

TROUBLESHOOTING ..................................................................................... 23

TEMPERATURE CONTROLLER - LED DIAGNOSTICS AND OPERATING STATUS .................... 23

IGNITION MODULE - LED DIAGNOSTICS AND OPERATING STATUS ................................ 23

GENERAL ............................................................................................ 24

INFRARED BURNER .................................................................................. 26

RADIANT BURNER ................................................................................... 26

© VULCAN 2014

F45533 (1014) Page 2 of 26

VCCG Series Heavy Duty Gas Griddle - GENERAL

GENERAL

INTRODUCTION

This Service Manual covers specific service

information related to the models listed on the front

cover. Procedures in this manual will apply to all

VCCG Heavy Duty Gas Griddles unless otherwise

specified. Raising the griddle plate is not required for

servicing the griddle components. Griddle

components are serviced through the front and rear.

Pictures and illustrations can be of any model unless

the picture or illustration needs to be model specific.

The VCCG griddles are available with three different

cooking surface types:

• Steel (standard).

• Chrome (optional).

• Rapid Recovery™ Griddle Plate* (optional).

*The Rapid Recovery Griddle plate is a composite

material which is engineered to provide a high heat

transfer rate to the food. The top surface can be

scored or dented by careless use of a spatula or

scraper. The center of the plate is an aluminum core

with sheets of stainless steel laminated to the top and

bottom exterior surfaces.

MODELS

Vulcan

• VCCG24 - 24" x 24" (width x depth) griddle plate.

• VCCG36 - 36" x 24" (width x depth) griddle plate.

• VCCG48 - 48" x 24" (width x depth) griddle plate.

• VCCG60 - 60" x 24" (width x depth) griddle plate.

• VCCG72 - 72" x 24" (width x depth) griddle plate.

OPERATION

Detailed operation instructions are included in the

Installation & Operation Manual sent with each unit.

The manual is also available online at

www.vulcanequipment.com.

SPECIFICATIONS

Electrical

- 120VAC 50/60Hz 2 amp single phase.

- 6 foot corded plug with ground provided.

Gas Manifold Pressure:

- Natural Gas 4.0" W.C.

- Propane Gas 10.0" W.C.

Incoming Gas Pressure:

- 7" to 9" W.C. Natural Gas

- 11" to 12" W.C. Propane Gas.

- Incoming pressure should not exceed 14.0" W.C.

(0.5 PSI) for either gas type.

Burner Types

- Griddles with Infrared Burners have one 24,000 BTU/

HR burner for each 12" of griddle width.

- Griddles with Radiant Burners* have one 30,000

BTU/HR burner for each 12" of griddle width.

*Atmospheric type “U” shaped aluminized steel.

Controls

- One Solid State thermostat with thermocouple probe

for each 12" of griddle width.

INSTALLATION

Generally, installations are made by the dealer or

contracted by the dealer or owner. Detailed

installation instructions are included in Installation &

Operation Manual that is sent with each unit.

It should be noted that an improperly installed unit,

especially an unleveled unit can lead to premature

electrical component failures. A unit that is higher in

the front will cause the flue gases to vent improperly

and gather in the front near the electrical components.

Page 3 of 26 F45533 (1014)

- Temperature adjustment range 150°F to 550°F on all

griddle plate surface types except the Rapid Recovery

Griddle plate (150°F to 450°F).

- One Electronic Ignition module with pilot safety

system for each 12" of griddle width.

- One Dual Solenoid gas valve with internal regulator

for each 12" of griddle width.

TOOLS

Standard

• Standard set of hand tools.

• VOM with ability to measure micro amp current.

VCCG Series Heavy Duty Gas Griddle - GENERAL

• VOM with minimum of NFPA-70E CAT III 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt. Meter leads must also be rated at

CAT III 600V.

• Temperature tester (K type thermocouple

preferred) with surface probe.

• U-Tube or Digital Manometer.

• Thread sealant suitable for use with natural or

propane gas.

Special

• Torque wrench capable of measuring at least 25

in-lbs. for tightening thermocouple probe to

griddle plate. Bolt size 5/16"-18.

• Safekote 60™ or equivalent Heat Transfer and

Anti-Seize Compound rated for 600°F (purchase

locally). Apply to thermocouple probe.

F45533 (1014) Page 4 of 26

VCCG Series Heavy Duty Gas Griddle - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

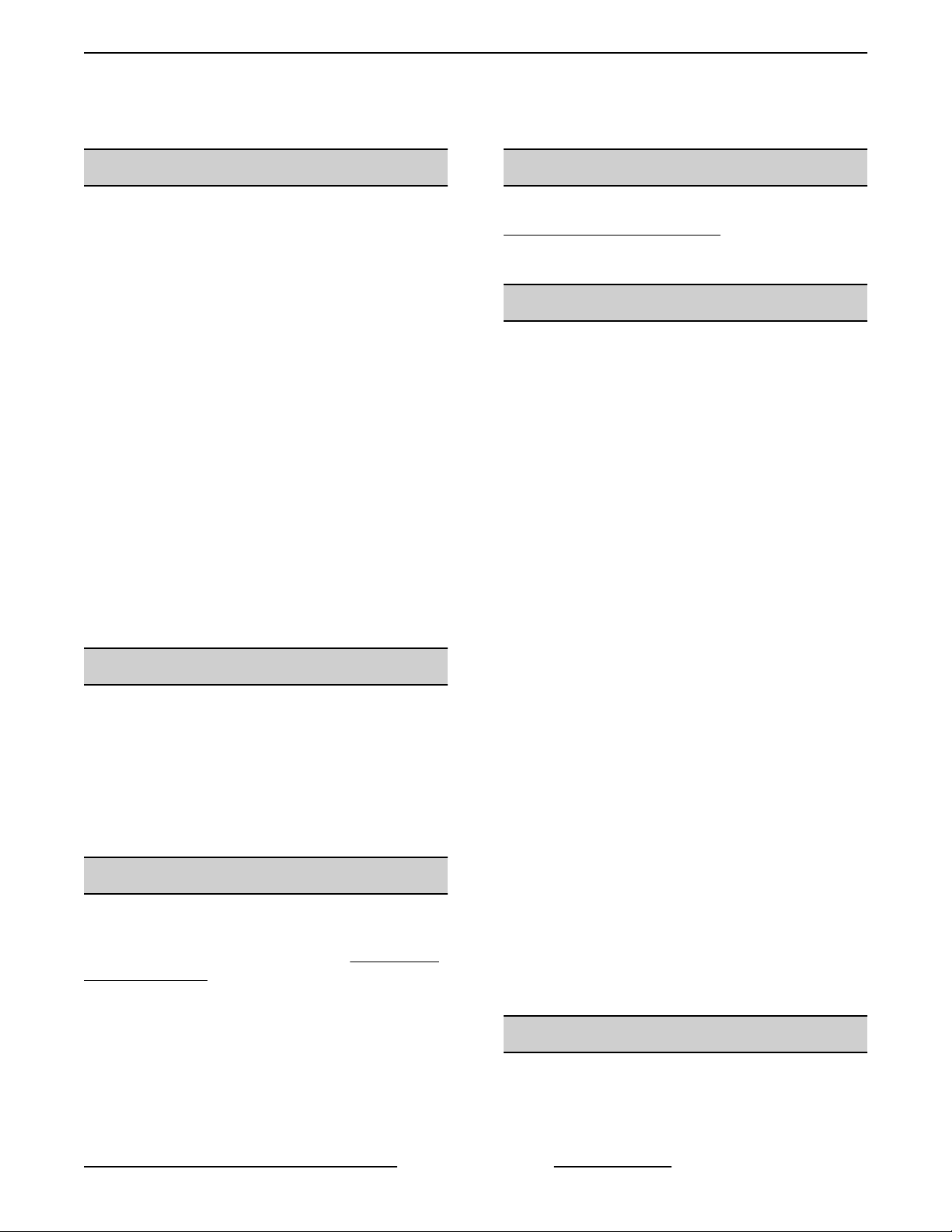

FRONT PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

The front panel holds the temperature controllers,

thermostat cycle lights and lighted power switch.

1. Remove four screws securing the front panel to

frame.

Fig. 1

2. Lay front panel face down in front of the unit while

servicing. Pull the drawer out to support the panel

as necessary.

NOTE: Griddles that are 60" and 72" wide have 2

grease drawers.

3. Reverse procedure to install.

BACK PANEL

1. Disconnect gas supply at griddle.

2. Remove all screws from rear of griddle securing

the back panel.

Fig. 2

3. Reverse procedure to install.

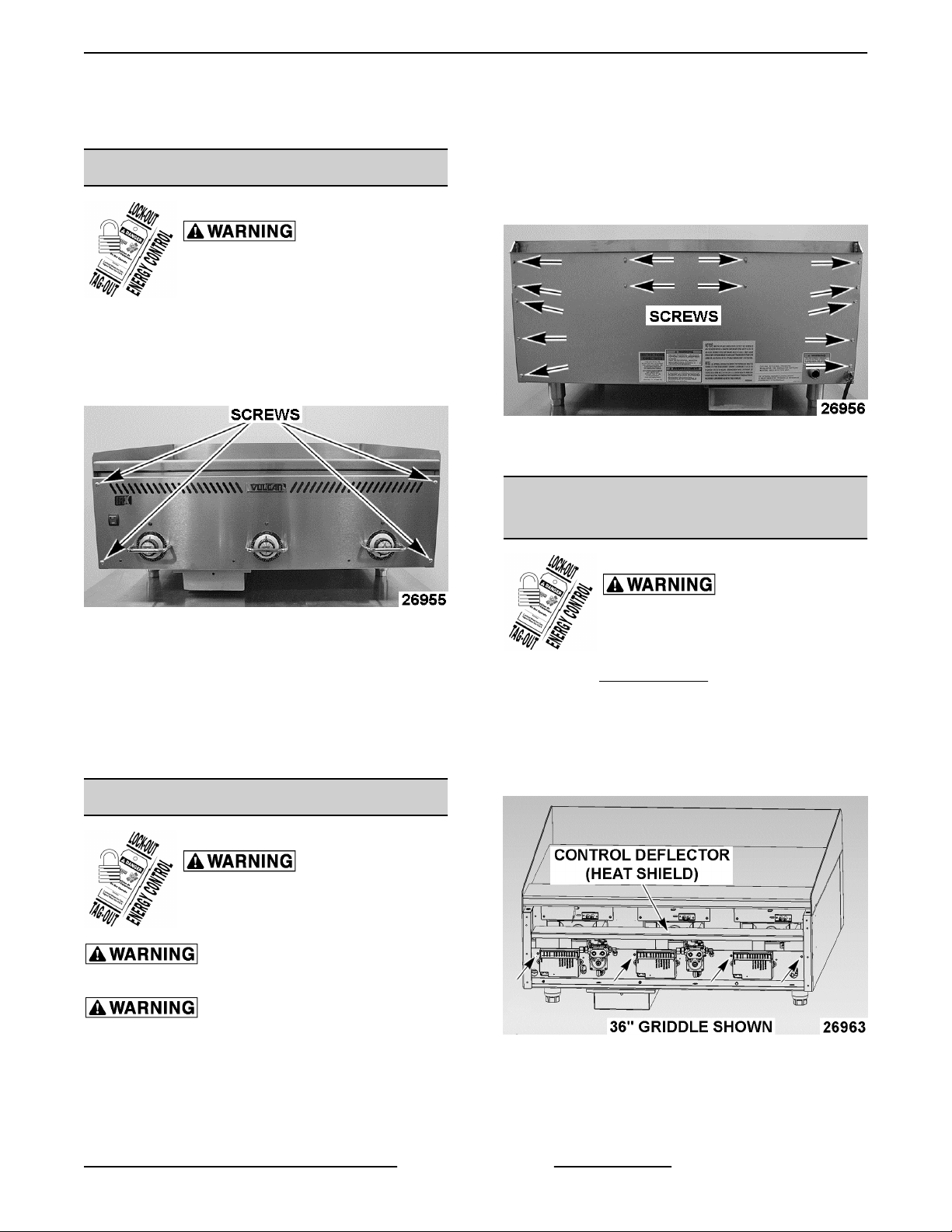

CONTROL DEFLECTOR (HEAT

SHIELD)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Remove control deflector (heat shield) from

griddle frame. The number of mounting screws

installed depends on griddle width. After screws

are removed, lift the control deflector and rotate

forward to remove from griddle.

FRONT PANEL.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

NOTE: Remove the back panel when servicing a

burner, temperature probe, pilot burner; or to remove

excessive grease build up from the flue area.

Page 5 of 26 F45533 (1014)

Fig. 3

3. Reverse procedure to install and check for proper

operation.

VCCG Series Heavy Duty Gas Griddle - REMOVAL AND REPLACEMENT OF PARTS

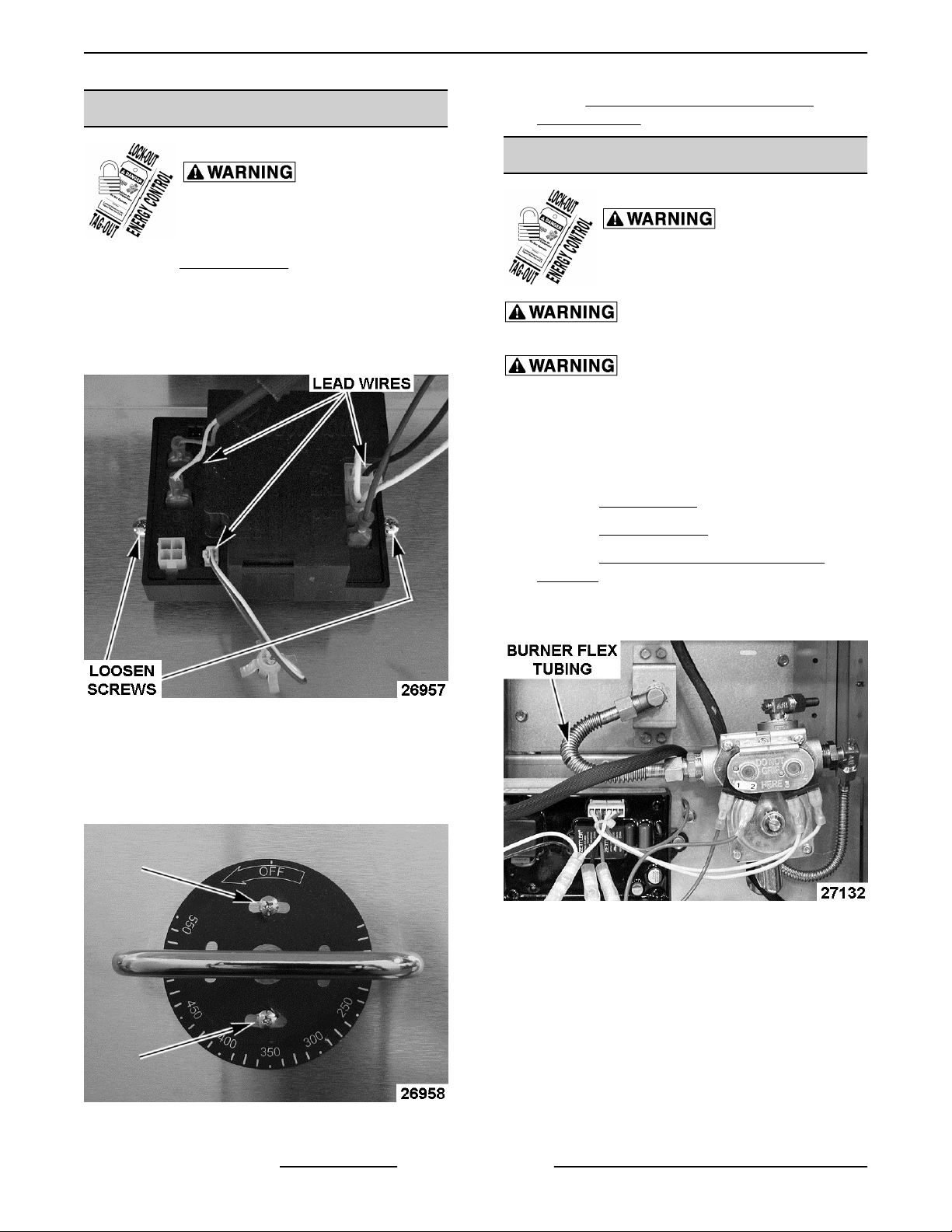

TEMPERATURE CONTROLLER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove FRONT PANEL.

2. Note wire connections then disconnect them

from temperature controller.

3. Loosen screws securing knob guard to front

panel to provide clearance for knob removal.

7. Check TEMPERATURE CONTROLLER

CALIBRATION.

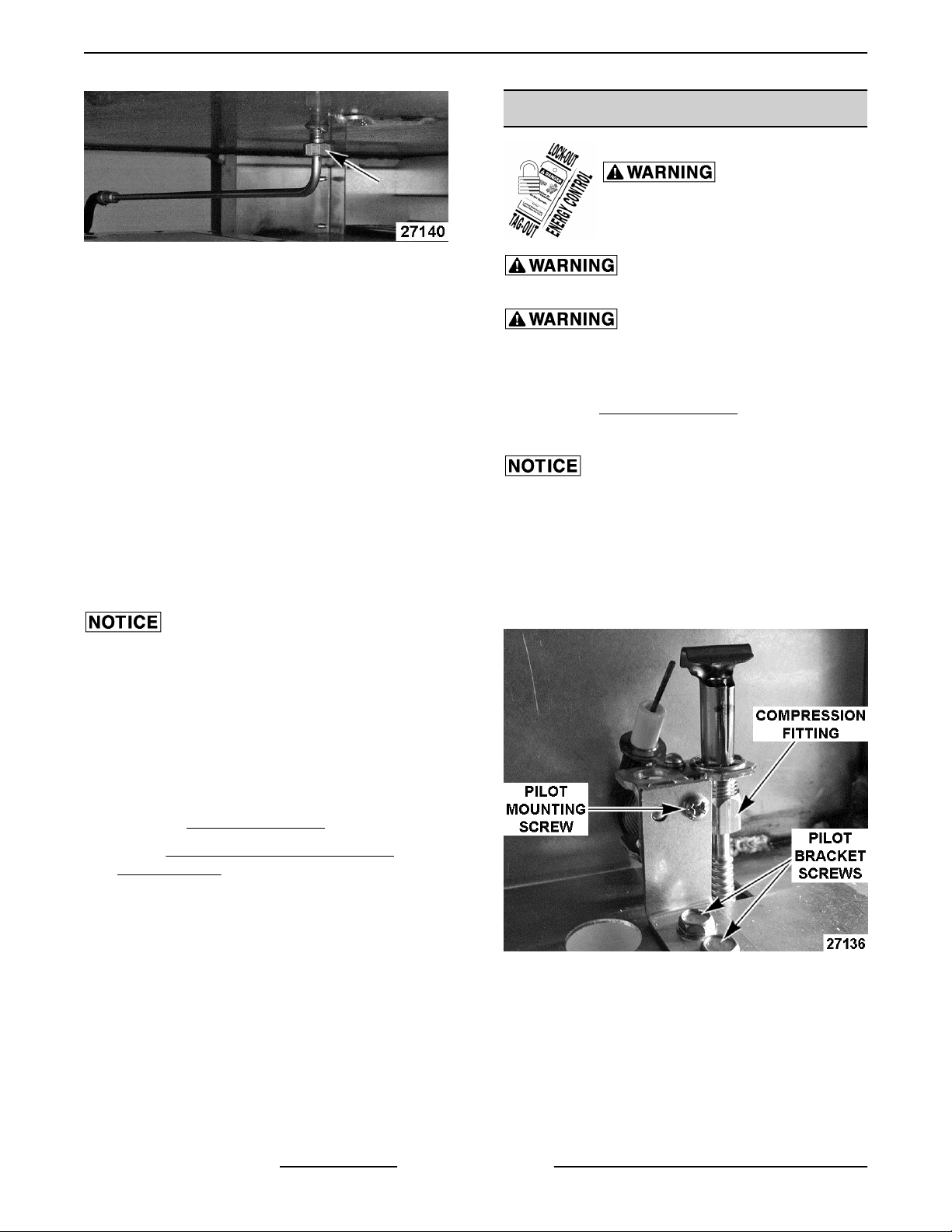

RADIANT BURNER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

NOTE: Radiant burner is removed through the front

of griddle.

1. Remove BACK PANEL.

2. Remove FRONT PANEL.

Fig. 4

4. Loosen set screw then remove knob from

temperature control shaft.

5. Remove screws securing temperature controller

to front panel.

3. Remove CONTROL DEFLECTOR (HEAT

SHIELD).

4. Remove burner flexible tubing from the burner

orifice elbow and gas valve fitting.

Fig. 6

5. Disconnect compression fitting from gas valve

inlet and slide gas valve off the tubing.

Fig. 5

6. Reverse procedure to install.

F45533 (1014) Page 6 of 26

VCCG Series Heavy Duty Gas Griddle - REMOVAL AND REPLACEMENT OF PARTS

Fig. 7

6. Note thermocouple connections then disconnect

from temperature controller.

7. Remove burner shield assembly and burner from

griddle (burner remains attached to the burner

shield assembly).

Fig. 9

9. Align mounting screw head on the burner air

shutter to the slot in heat shield assembly hole

and remove burner from heat shield.

10. Reverse procedure to install and check for proper

operation.

THERMOCOUPLE (RADIANT

BURNER)

Fig. 8

NOTE: When installing burner, ensure the locating

pin and mounting plate at the rear of burner are

properly inserted in the mounting slot. At the front of

griddle, ensure the thermocouple shield front

mounting tab is inserted in the burner shield slot to

support the thermocouple shield.

8. Remove orifice holder bracket from burner shield

assembly.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removal

1. Remove

to access thermocouple shield and

thermocouple.

2. Push thermocouple shield toward the front of

griddle to disengage the rear mounting tab on

thermocouple shield from the support bracket on

the bottom of griddle plate.

3. Loosen mounting nut and remove thermocouple

probe from bottom of griddle plate.

RADIANT BURNER (steps 1 through 8)

Fig. 10

Page 7 of 26 F45533 (1014)

VCCG Series Heavy Duty Gas Griddle - REMOVAL AND REPLACEMENT OF PARTS

PILOT (RADIANT BURNER)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fig. 11

4. Remove insulating sleeve from thermocouple

wires and retain for use on replacement

thermocouple.

Installation

1. Slide insulating sleeve over thermocouple wires.

2. Apply a thin coating of heat transfer and antiseize compound to the thermocouple probe tip

and mounting nut threads.

3. Route thermocouple probe through the front

opening in griddle frame and lay it on top of

burner mounting panel.

4. From rear of griddle, thread thermocouple probe

into the mounting hole in griddle plate and stop

when probe tip touches the plate. Torque the

mounting nut to a maximum of 25 in-lbs.

Do not over tighten or damage to the

thermocouple probe may occur. Due to the aluminum

plate core, it is also possible to create a raised area

over the probe if overtightened.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove RADIANT BURNER.

2. Disconnect compression fitting from pilot.

When disconnecting compression fitting

for the pilot, support bracket to prevent bending.

3. Remove pilot and mounting bracket from the

burner mounting panel.

4. Pull spark wire through the hole in control

mounting panel and remove pilot from griddle.

5. Remove pilot from pilot mounting bracket.

5. Insert rear mounting tab on thermocouple shield

into the support bracket on the bottom of griddle

plate.

6. Route thermocouple wires through the opening

in burner shield assembly.

7. Re-install RADIANT BURNER.

8. Check TEMPERATURE CONTROLLER

CALIBRATION.

Fig. 12

6. Reverse procedure to install.

NOTE: When installing, verify spark gap is 1/8".

F45533 (1014) Page 8 of 26

Loading...

Loading...