Page 1

INSTALLATION &

OPERATION MANUAL

VBP SERIES FOOD HOLDING AND

TRANSPORT CABINETS

MODELS

VBP4 ML-126352

VBP7 ML-126353

VBP13 ML-126355

VBP15 ML-126356

VBP40 ML-126357

VBP7

I

VBP13

VBP15

VBP77 ML-126354

VBP77

VBP8H

VBP12H

VBP15H

I

I

I

I

I

I

ML-126358

ML-126359

ML-126360

ML-126361

ML-126362

ML-126363

ML-126364

VBP7I

In U.S.A.:

VULCAN-HART COMPANY

P.O. BOX 696

LOUISVILLE, KY

40201-0696

TEL.: 502-778-2791

F31081B (399) PRINTED IN U.S.A.

HOBART FOOD EQUIPMENT GROUP CANADA

NORTH YORK, ONTARIO

In Canada:

190 RAILSIDE ROAD

M3A 1B1

TEL.: 1-800-444-4764

Page 2

TABLE OF CONTENTS

GENERAL............................................................................................................................................. 3

INSTALLATION.................................................................................................................................... 4

Unpacking ................................................................................................................................. 4

Location .................................................................................................................................... 4

Installation Codes and Standards ........................................................................................... 5

Electrical Connections ............................................................................................................. 5

Wiring Diagrams....................................................................................................................... 7

OPERATION ...................................................................................................................................... 10

Controls .................................................................................................................................. 10

Before First Use ..................................................................................................................... 10

Operating Cabinet .................................................................................................................. 11

Cleaning.................................................................................................................................. 12

MAINTENANCE ................................................................................................................................. 12

Service and Parts Information ............................................................................................... 12

© VULCAN-HART COMPANY, 1998

– 2 –

Page 3

Installation, Operation and Care of

MODEL VBP SERIES

FOOD HOLDING AND TRANSPORT CABINETS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Vulcan-Hart Holding and Transport Cabinets are produced with quality workmanship and material.

Proper installation, usage, and maintenance of your cabinet will result in many years of satisfactory

performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

The VBP series Holding and Transport Cabinets provide an efficient means of transporting and holding

bulk prepared foods at proper serving temperatures.

• VBP8HI, VBP12HI, and VBP15HI have an interior convected air system for even air circulation.

• VBP77 and VBP77I have individual controls for each of the two compartments. The operator is

able to hold two different products at two different temperatures in separate sections of the same

cabinet.

VBP commercial and institution series cabinets accommodate a variety of pan sizes by utilizing the

universal tray slides.

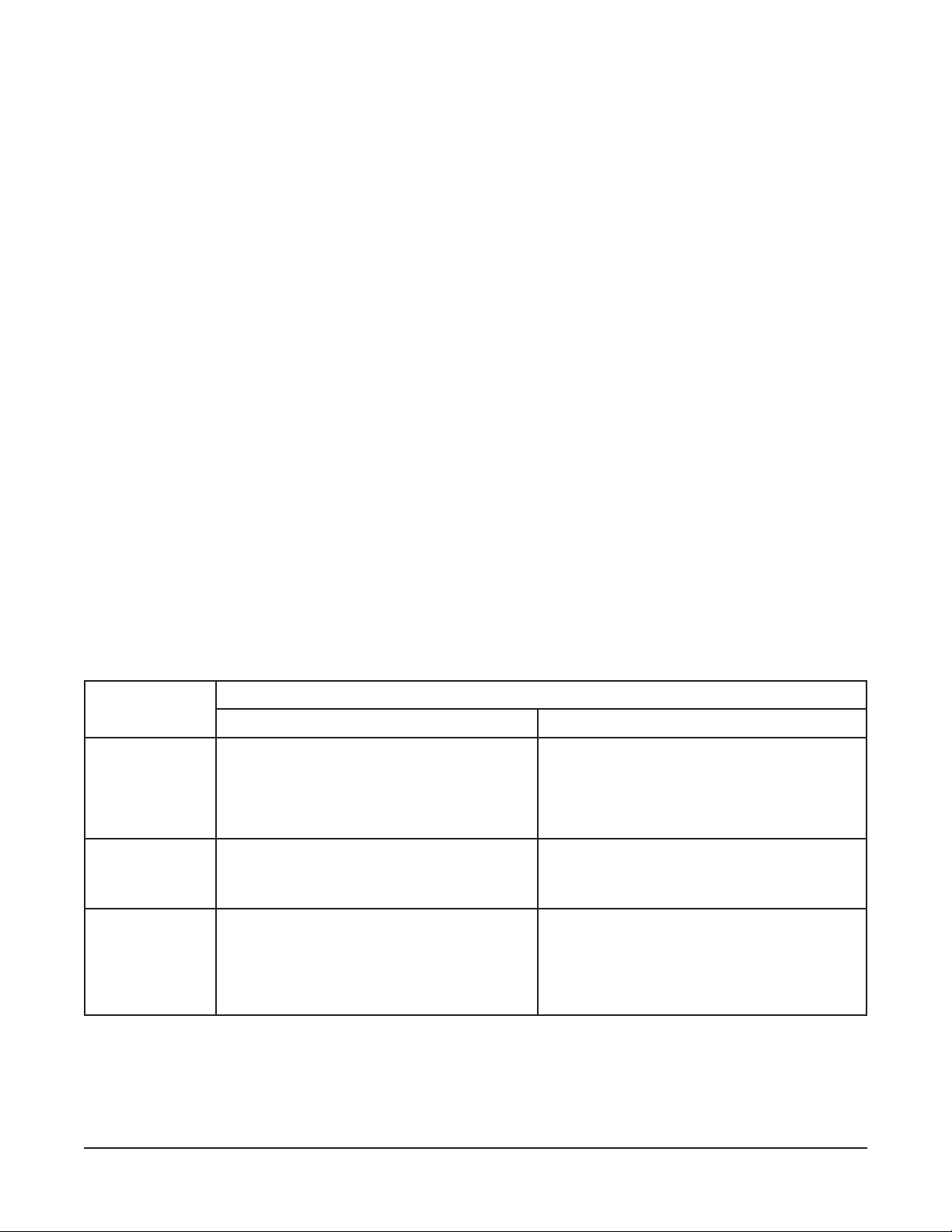

Model

Commercial Institution

VBP4, 7, 13, 15, 18x26" (457x660 mm) sheet 18x26" (457x660 mm) sheet

40, 7I, 13I, 15I 12x20" (305x508 mm) steam table 12x20" (305 x 508 mm) steam table

VBP8HI, 12HI, N/A 18x26" (457x660 mm) sheet

15HI 12x20" (305x508 mm) steam table

VBP77, 77I (7)18x26" (457x660 mm) sheet (7)18x26" (457x660 mm) sheet

(7)12x20x21⁄2" (305x508x64 mm) steam table (14)12x20x21⁄2" (305x508x64 mm) steam table

Combination of sheet and steam table Combination of sheet and steam table

VBP8HI, VBP12HI, VBP15HI have tray slides specifically designed to lock-in the covers of 12x20"

(305x508 mm) pans providing reduced spillage during transport cycle.

Pan Size

1/1 or 2/1 gastronorm pan

1/1 or 2/1 gastronorm pan

– 3 –

Page 4

INSTALLATION

Before installing, verify that the electrical service agrees with the specifications on the rating plate

located on the lower left corner. If the supply and equipment requirements do not agree, do not proceed

with the installation. Contact your dealer or Hobart Food Equipment Group Canada immediately.

UNPACKING

This cabinet was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage to the cabinet. If the cabinet is found to be damaged, save the packaging

material and contact the carrier within 7 days of delivery.

Carefully unpack cabinet and place in a work-accessible area as near to its final installed position as

possible.

1. Remove banding material holding the carton to the pallet.

2. Remove cardboard carton and plastic bag covering cabinet.

3. Carefully lift cabinet off carton bottom and place it on the floor, or table if it is a counter top cabinet.

4. Open cabinet door and remove box containing adjustable tray slides.

• If the cabinet is a VBP4, VBP7, VBP77, or VBP77I the box will also contain tray slide upright

side supports.

5. Remove cardboard element cover protector from cabinet bottom.

6. Remove adjustable tray slides from box.

7. If the cabinet is a VBP4, VBP7, VBP77, or VBP77I remove the tray slide supports and install them

in the cabinet.

a. Hook the openings in the flat flange of the support over two vertical carriage bolts on the

interior of the cabinet.

b. Make sure all flanges on the four supports face the door opening.

8. Install tray slides in the cabinet.

9. Make sure the hook on the end of the tray slide is up.

LOCATION

For efficient cabinet operation, choose a location that will provide easy loading and unloading without

interfering with the final assembly of food orders.

The installation location must allow adequate clearances for servicing and proper operation.

– 4 –

Page 5

INSTALLATION CODES AND STANDARDS

The cabinet must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. Canadian Electrical Code, CSA C22.1 (latest edition). Copies may be obtained from The

Canadian Standard Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: THIS APPLIANCE IS EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THIS PLUG MUST BE CONNECTED

INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT

THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

Refer to wiring diagrams in this manual (see pages 7-9).

All cabinets are equipped with an 8 ft. (2.4 m) cord and NEMA plug.

– 5 –

Page 6

Electrical Table

Model Voltage Amp Phase Hz NEMA Plug

VBP4

VBP7

VBP13

VBP15

VBP40

I

VBP7

VBP13I

VBP15I

VBP77

VBP77I

VBP8HI

VBP12HI

VBP15HI

110/120 10

208/240 5.4 6-15

110/120 10

208/240 5.4 6-15

110/120 10

208/240 5.4 6-15

110/120 10

208/240 5.4 6-15

110/120 16.7

208/240 9 6-15

110/120 10

208/240 5.4 6-15

110/120 10

208/240 5.4 6-15

110/120 10

208/240 5.4 6-15

110/120 20

208/240 10.9 6-15

110/120 20

208/240 10.9 6-15

110/120 16.7

208/240 9 6-15

110/120 16.7

208/240 9 6-15

110/120 16.7

208/240 9 6-15

160

160

160

160

160

160

160

160

160

160

160

160

160

5-15

5-15

5-15

5-15

5-20

5-15

5-15

5-15

5-30

5-30

5-20

5-20

5-20

– 6 –

Page 7

WIRING DIAGRAMS

– 7 –

VBP4, VBP7, VBP13, VBP15, VBP40, VBP7I, VBP13I, VBP15I

Page 8

VBP77, VBP77I

– 8 –

Page 9

VBP8HI, VBP12HI, VBP15HI

– 9 –

Page 10

OPERATION

WARNING: THE CABINET AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE CABINET.

CONTROLS

THERMOMETER

POWER INDICATOR LIGHT

HEAT INDICATOR LIGHT

FULL RANGE THERMOSTAT

Fig. 1

PL-41226-1

All Models (Fig.1)

POWER INDICATOR LIGHT – Lit when power is supplied to cabinet.

HEAT INDICATOR LIGHT – Lit when heat is supplied to cabinet.

FULL RANGE THERMOSTAT – Turn to desired temperature setting.

THERMOMETER – Indicates interior temperature of cabinet.

Models VBP8HI, VBP12HI, VBP15HI Only (Not Shown)

ON/OFF SWITCH – Interior circulating fans immediately start.

– Control/component compartment cooling fans start.

BEFORE FIRST USE

WARNING: UNPLUG ELECTRICAL POWER SUPPLY BEFORE CLEANING.

1. Clean cabinet thoroughly.

a. Use mild soap and water solution to clean cabinet.

b. Rinse thoroughly and wipe dry with a soft clean cloth.

c. Clean all accessories.

d. Rinse thoroughly and wipe dry.

2. Operate cabinet in highest temperature setting for a period of 30-45 minutes. (See Operating

Cabinet.)

– 10 –

Page 11

OPERATING CABINET

1. Connect electric power supply.

• Power indicator light is lit.

2. If cabinet is a VBP8HI, VBP12HI, or VBP15HI, press ON/OFF switch ON.

• Interior air circulating fans start.

• Control/component compartment cooling fans start.

3. Turn thermostat knob to desired setting.

• Heating elements begin heating.

• Heat indicator light is lit.

4. Thermometer will indicate the interior temperature of the cabinet.

5. Once desired temperature is reached, heating elements will cycle on and off.

• Heat light will cycle on and off with the heating elements.

6. Temperature in heated cabinet will fluctuate as the heating elements cycle on and off.

7. Monitor the food product to ensure proper temperatures.

Cabinet Temperatures

The greater the thermostat setting number, the higher the cabinet(s) temperature. The lower the

thermostat setting number, the lower the cabinet(s) temperature.

Approximate

Thermostat Setting Cabinet Temperature

1 110°F (43°C)

2 120°F (49°C)

3 130°F (54°C)

4 140°F (60°C)

5 150°F (66°C)

6 160°F (71°C)

7 170°F (77°C)

8 180°F (82°C)

9 190°F (88°C)

10 200°F (93°C)

– 11 –

Page 12

Shutdown

If cabinet is a VBP8HI, VBP12HI, or VBP15HI, press ON/OFF switch OFF.

Extended Shutdown

Unplug electrical power supply. Power indicator light will go off.

CLEANING

WARNING: UNPLUG ELECTRICAL POWER SUPPLY BEFORE CLEANING.

Clean cabinet interior with a mild soap and water whenever food spill occurs. Never use harsh

chemicals or abrasive pads to clean cabinet.

Daily

1. Allow cabinet to cool before cleaning.

2. Remove the tray slides and clean in a sink as you would any normal utensil.

3. Clean the interior of the cabinet with a mild soap and water.

4. Rinse and dry with a soft dry cloth.

5. Replace tray slides in cabinet.

MAINTENANCE

WARNING: THE CABINET AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE CABINET.

WARNING: UNPLUG ELECTRICAL POWER SUPPLY BEFORE SERVICING THE CABINET.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this cabinet, contact the Hobart Food Equipment

Group Office in your area or call 1-800-444-4764.

– 12 –

Loading...

Loading...